Patents

Literature

166results about How to "Save coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

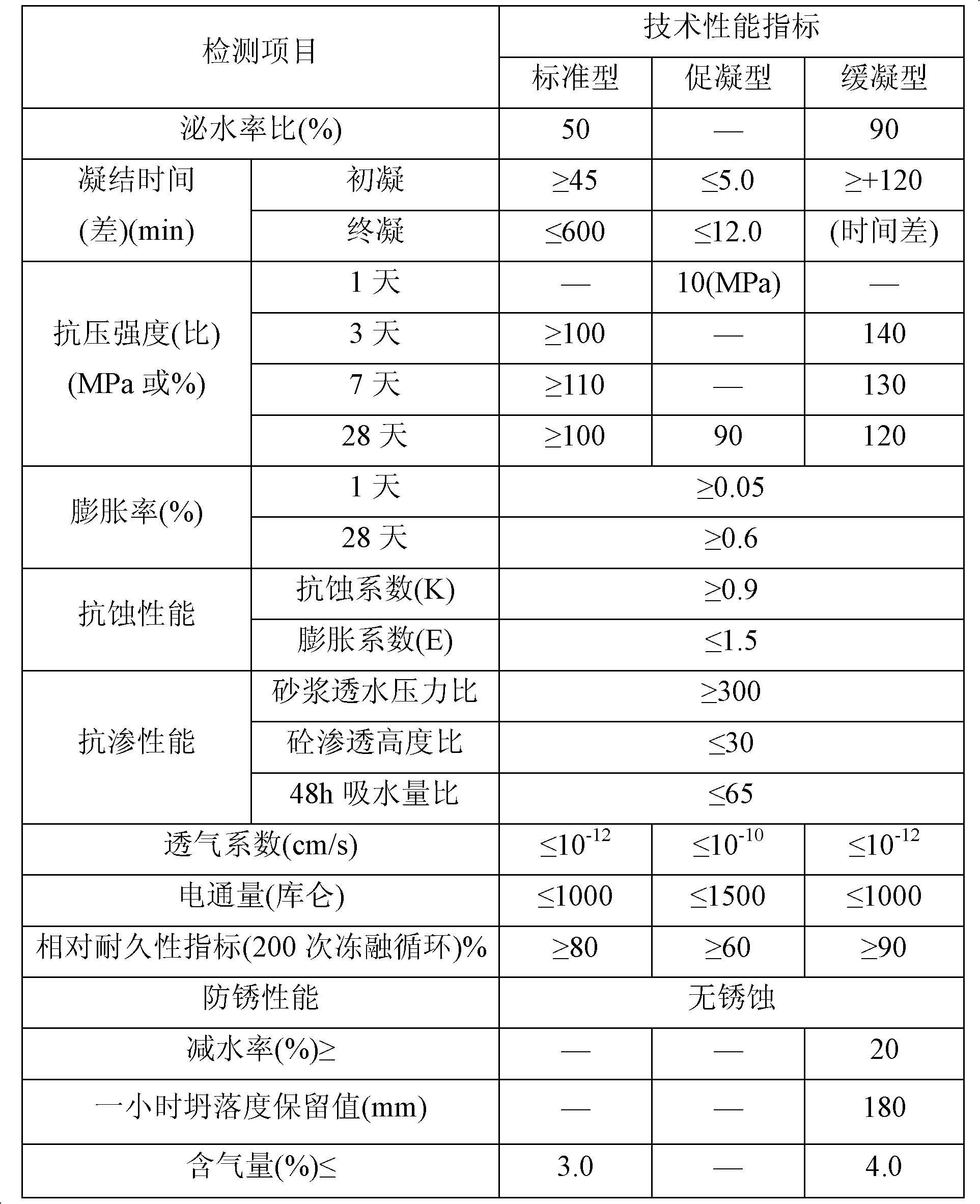

Anticorrosion expansion compacting agent composition and preparation method thereof

The invention relates to an anticorrosion expansion compacting agent composition and a preparation method thereof; the composition comprises the following components by weight: 15-35% of aluminium-containing compounds, 0-8% of zirconium-containing compounds, 2-10% of magnesium salts, 0-3% of titanium dioxide compounds, 0-6% of lithium salts, 2-6% of alkanolamine salts, 0-10% of super-plasticizers, 0-10% of solidification adjusting agents, 0-5% of acids, and the balance of carriers. The components are reacted in a reaction vessel at 80 DEG C+ / -5 DEG C for 3 hours, and then cooled to 45 DEG C+ / -5 DEG C; thermal insulation is performed for one hour; and anticorrosion expansion compacting agents of a standard type, a solidification-promoting type, or a pumping slow-solidifaction type are obtained according to the added solidification adjusting agents with different types and amounts.

Owner:苏琳

Environment protection coal-saving agent for cement vertical kiln

The invention provides an environmental-friendly coal-saving agent for a cement shaft kiln, comprising the following raw materials by weight portion: 3-7 portions of a coal combusting low-temperature modifying agent, 2-6 portions of a compound sulphur-fixing agent, 0.5-0.96 portion of a combusting inductive agent, 3-7 portions of a raising agent, 56-96 portions of a combusting poising agent, and 5-15 portions of a highly-efficient sulphur-fixing agent. The coal combusting low-temperature modifying agent can be potassium permanganate, potassium chlorate, potassium perchlorate, sodium chlorate, sodium nitrate and the like; the compound sulphur-fixing agent can be sodium carbonate, calcium oxide and the like; the raising agent can be waste liquor of paper mill containing Na or / and Ca sulphonate and the like; and the combusting poising agent can be a chemical waste reducing substance containing sodium chloride and the like. The method solves the problems of environmental pollution and resource waste in the prior art, uses compatibility of multiple chemical raw material of 6-10 percent and chemical waste to prepare the coal-saving agent with small dosage and fast effect to be added to the production of the cement shaft kiln in trace quantity, and has the advantages of resource conservation by using waste, coal conservation and consumption reduction, and reduction of dust and SO2 discharge and environmental pollution.

Owner:陶小勇

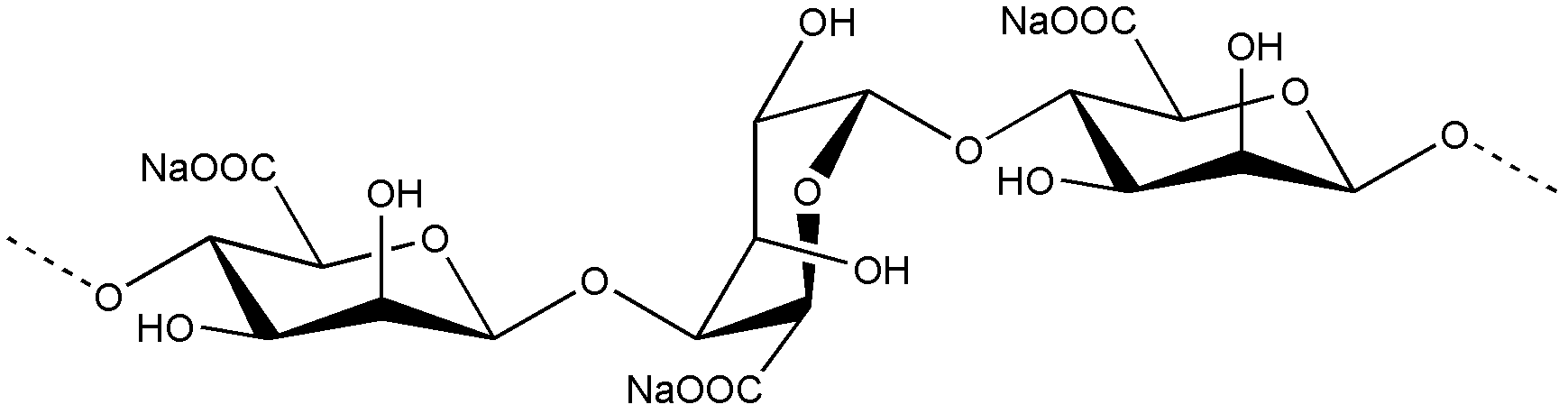

Enzymolysis-chemistry combined method for producing sodium alginate

ActiveCN102321191AThe production process is easy to controlChange the high energy consumption and high pollutionChemical industryCombined method

The invention relates to the field of seaweed chemical industry, and specifically provides an enzymolysis-chemistry combined method for producing sodium alginate. The method comprises steps of: mixing pretreated alga and compound enzyme at 45-60 DEG C and a pH of 4.5-6.5, reacting for 13-26 h, carrying out an enzymolysis, filtering and converting the filtrate to obtain sodium alginate; and addingalkali liquor in the precipitate after the enzymolysis, reacting for 2-4 h at 50-80 DEG C, calcifying a filtrate after filtering, and adding sodium carbonate into calcified precipitate to convert into sodium alginate. The method of the invention can fundamentally solve drawbacks of high energy consumption and high pollution of a traditional production technology. According to one ton of sodium alginate and iodine coproduct produced by the enzymolysis-chemistry combined method of the invention, fresh water for production is reduced by 38%, and coal is reduced by 23%, and soda acid waste water generated is reduced by 52% less; and the method can increase yield by 9-11% compared with a conventional chemical production technology.

Owner:SHANDONG JIEJING GROUP CORP

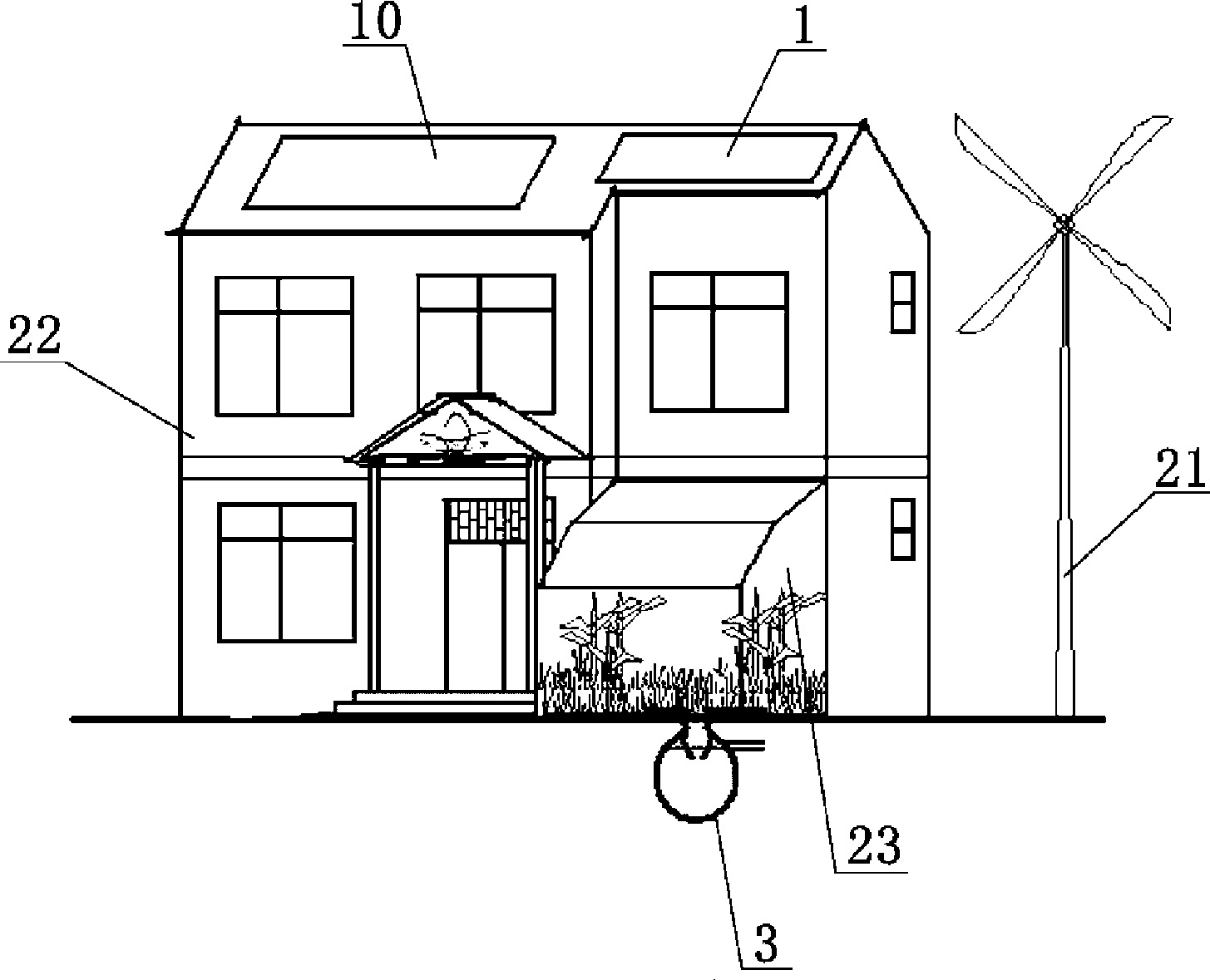

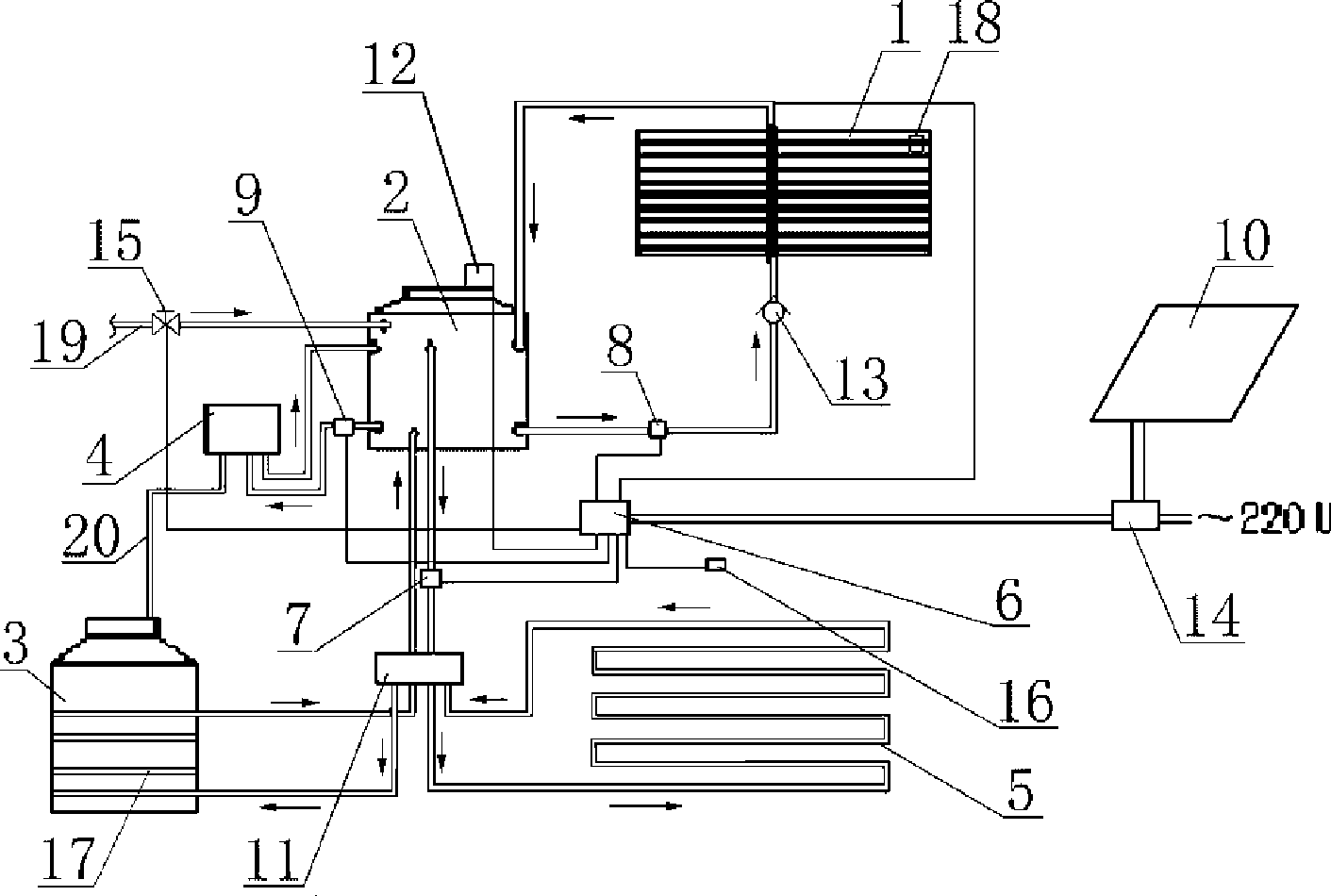

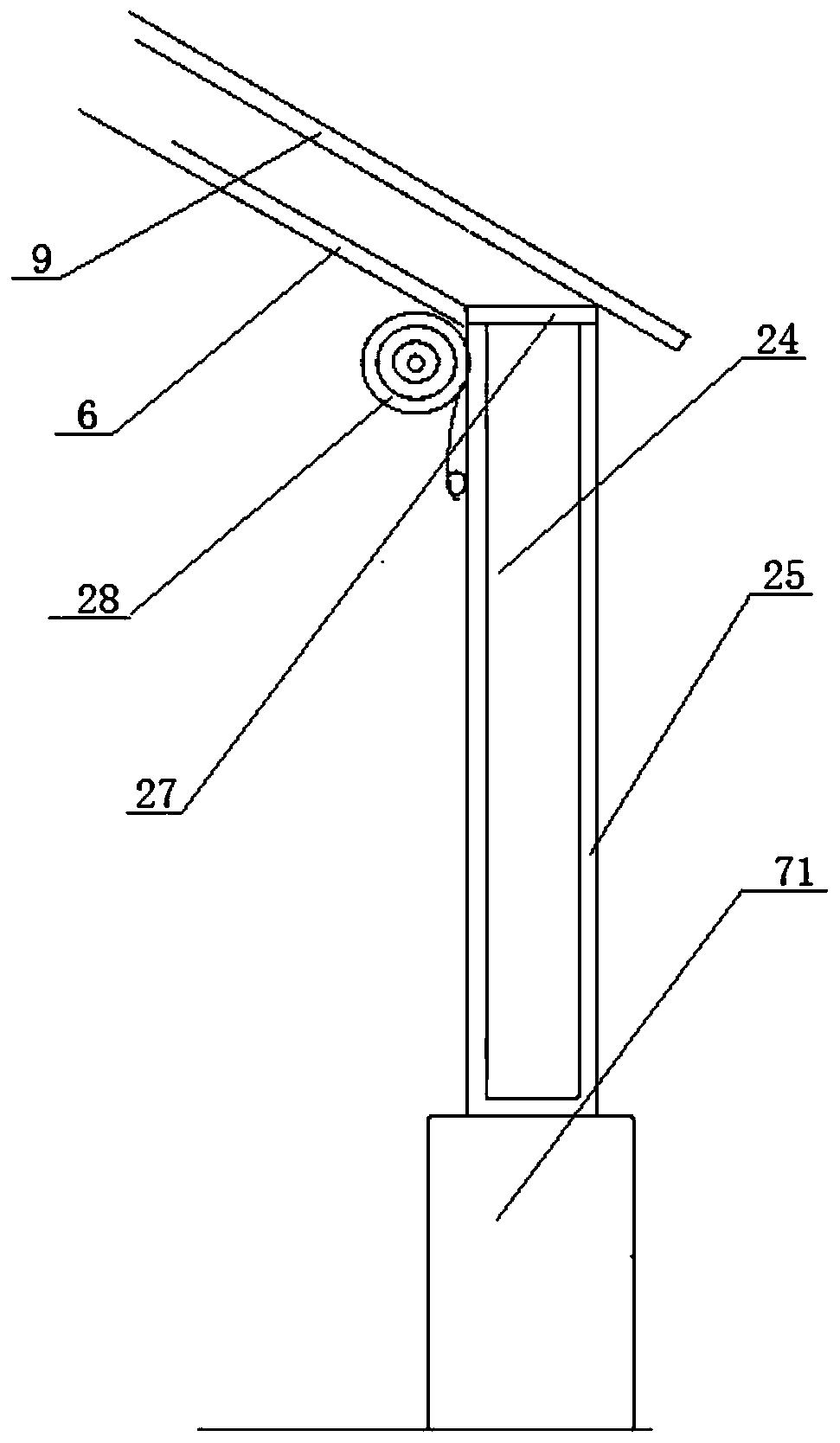

Green ecological zero energy consumption integration house

InactiveCN101457594AIncrease heatIncrease gas productionWallsSolar heat devicesLiving roomCollector device

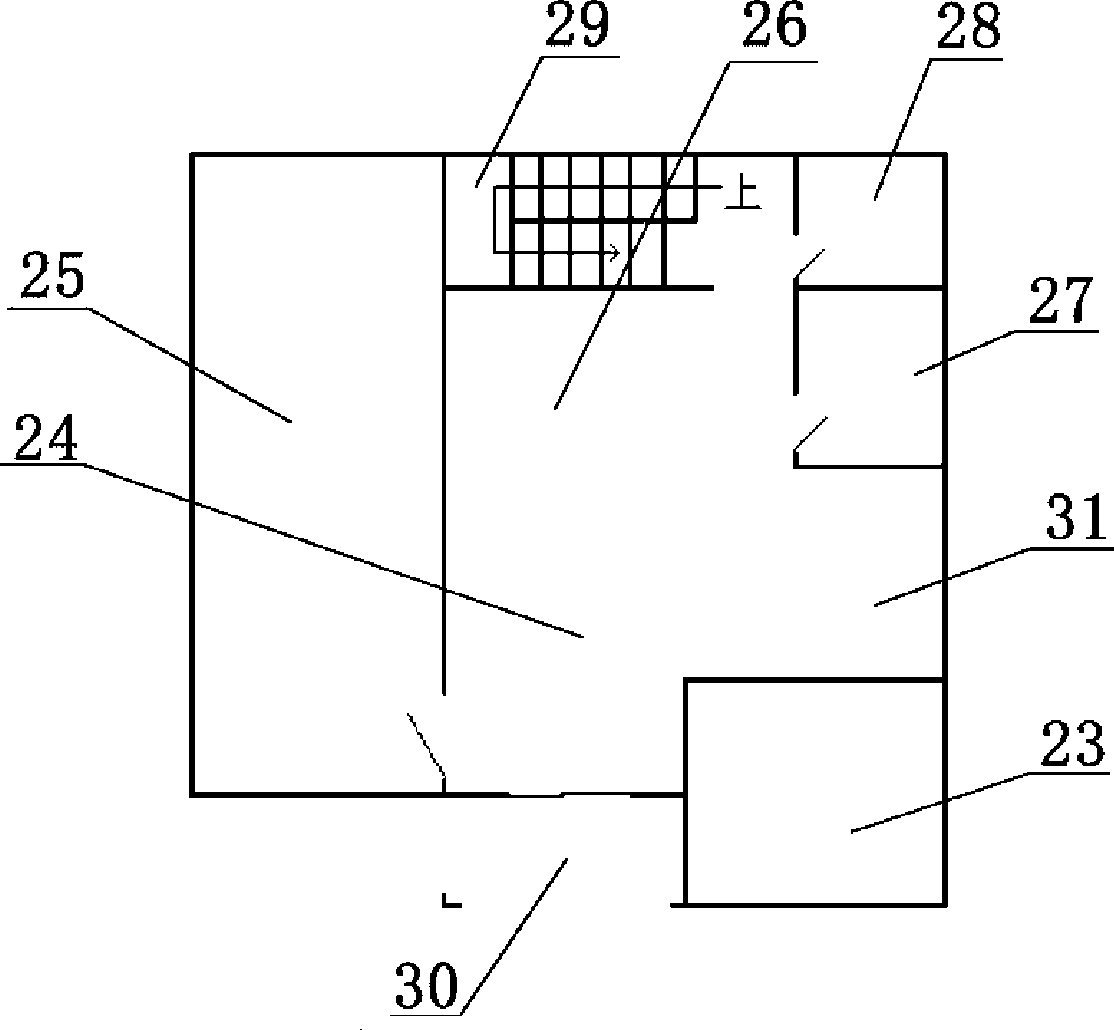

The invention relates to a green ecological zero energy integrated building, a first floor of the building is provided with a living room, a bedroom, a dinning room, a kitchen, a toilet; a second floor of the building is provided with a bedroom and a toilet; a heat supply system is arranged inside the room, the building is connected with a heliogreenhouse on the ground and is connected with a methane tank under the ground. A solar thermal collector arranged at the top of the building is communicated with a temperature-holder box arranged inside the rooms of the building by a circulating pipe of the first line, the temperature-holder box is communicated with a water heating pipe of a gas-fuel heater by the circulating pipe, a gas line of the gas-fuel heater is communicated with the methane tank by a methane pipe. A hot water outlet of the temperature-holder box is respectively communicated with a PE-RT pipe and a heating pipe of the methane tank which is buried near the methane tank. A water tank temperature sensor, a room temperature sensor and a collector temperature sensor are connected with an intelligent controller. With the solar energy, bioenergy and wind energy complementing each other, the building has the characteristics of comfort, environmental protection, energy saving and zero-pollution.

Owner:赵民忠

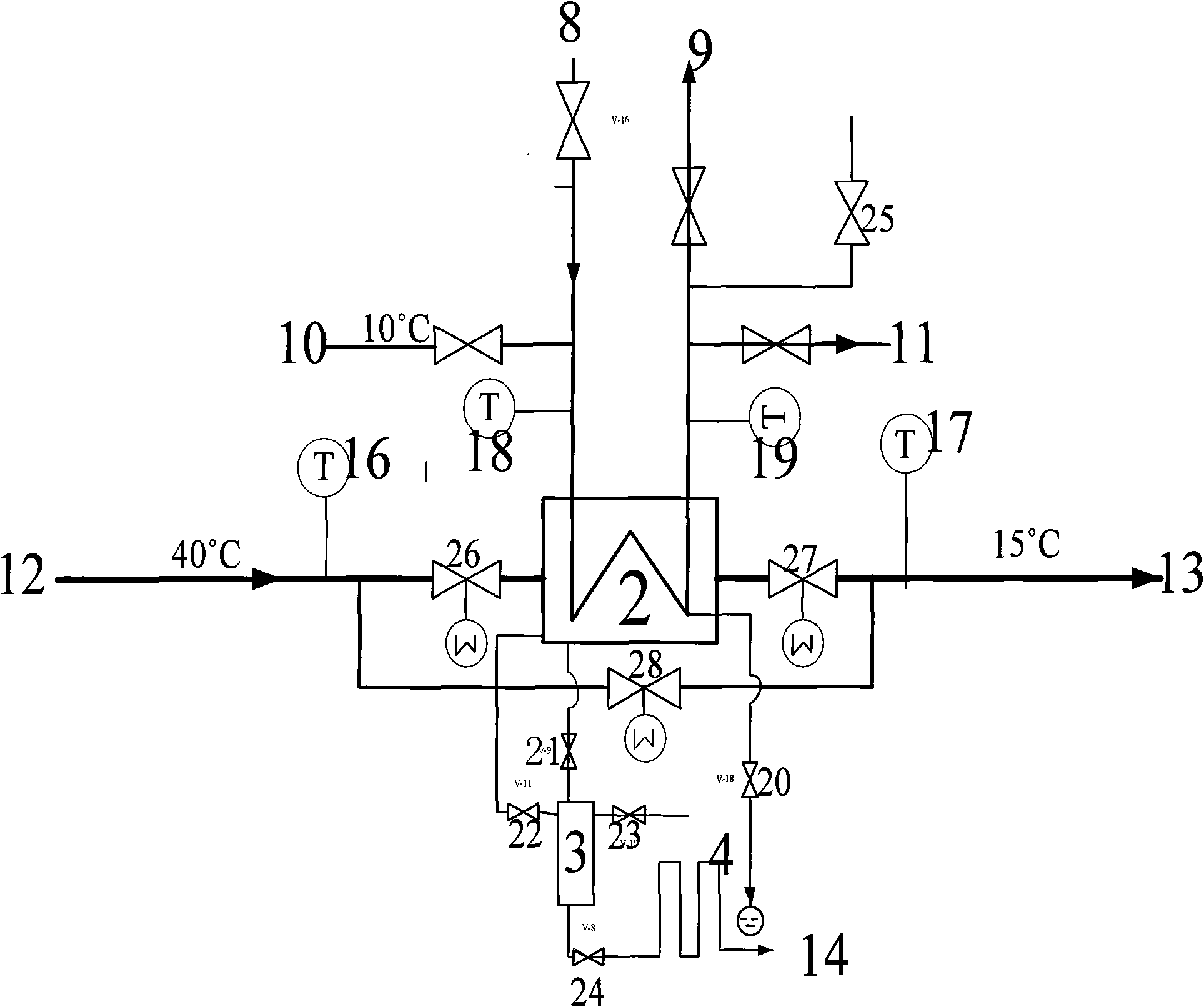

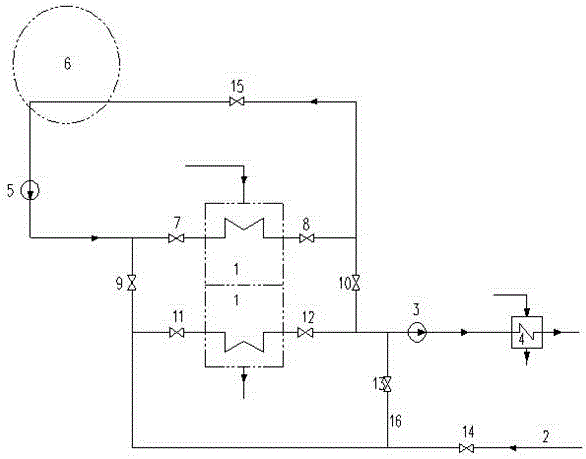

Method and system for comprehensive utilization of tail heat of boiler

InactiveCN103398369AImprove efficiencyReduce lossesLiquid degasificationCombustion processCold airAir preheater

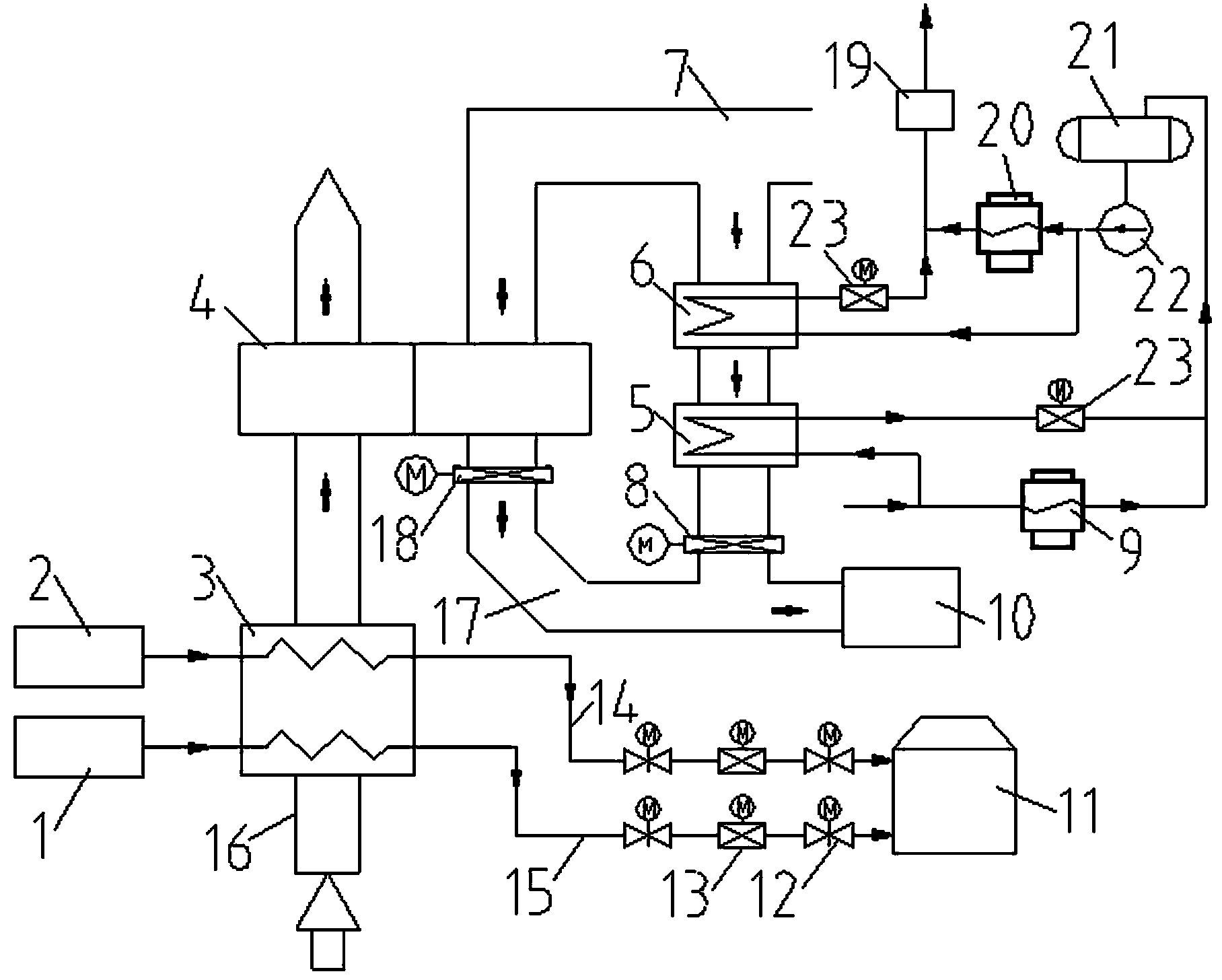

The invention relates to a method and system for comprehensive utilization of tail heat of a boiler. According to the method and system for comprehensive utilization of the tail heat of the boiler, low-level steam extraction is carried out by means of a turbine, in-boiler cold air in a boiler air inlet duct connected with the boiler is heated by extracted steam through a steam air heater, heated cold air in the steam air heater enters an air pre-heater through the boiler air inlet duct, heat exchange is carried out in the air pre-heater between part of smoke from a boiler economizer or a denitration device and the heated cold air, and the other part of smoke is used for heat exchange of part of supplied water through a water supply economizer. According to the method and system for comprehensive utilization of the tail heat of the boiler, the low-pressure steam is extracted to heat the cold air so that the heat of the steam is recovered to reduce cold source loss, part of the high-temperature smoke is saved at the same time, and the saved high-temperature smoke is used for heating part of the supplied water through an outlet flue of the economizer or an outlet flue the denitration device; high-level extraction steam of the turbine is saved due to the fact that the high-level smoke is used for heating part of the supplied water, the saved high-level extraction steam can continue to work in the turbine, and then the efficiency of the turbine is improved and fuel coal is saved.

Owner:吕克庆

High efficiency, environmental protection type coal-saving agent, and its prodn. art

An environment protection type coal saving agent is proportionally prepared from sulfur fixating agent, combustion promoter, oxidant, puffing agent, catalyst and water. Its advantages are high effect to decrease consumption of coal and increase thermal efficiency of boiler, and no secondary pollution.

Owner:田立军

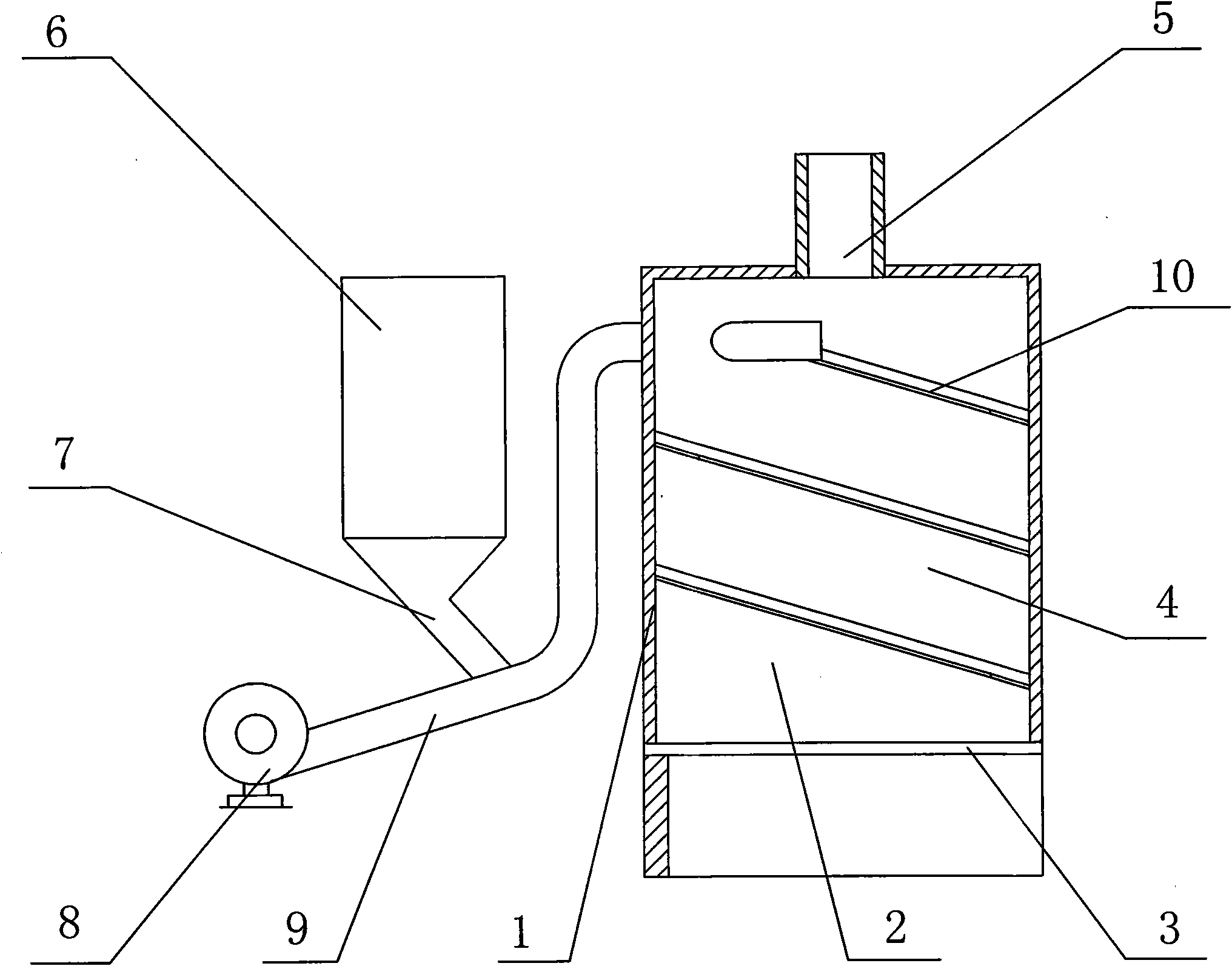

Straw fuel flying furnace

ActiveCN101818892ANot easy to pile upIncrease valueSolid fuel combustionIndirect carbon-dioxide mitigationHeat lossesHearth

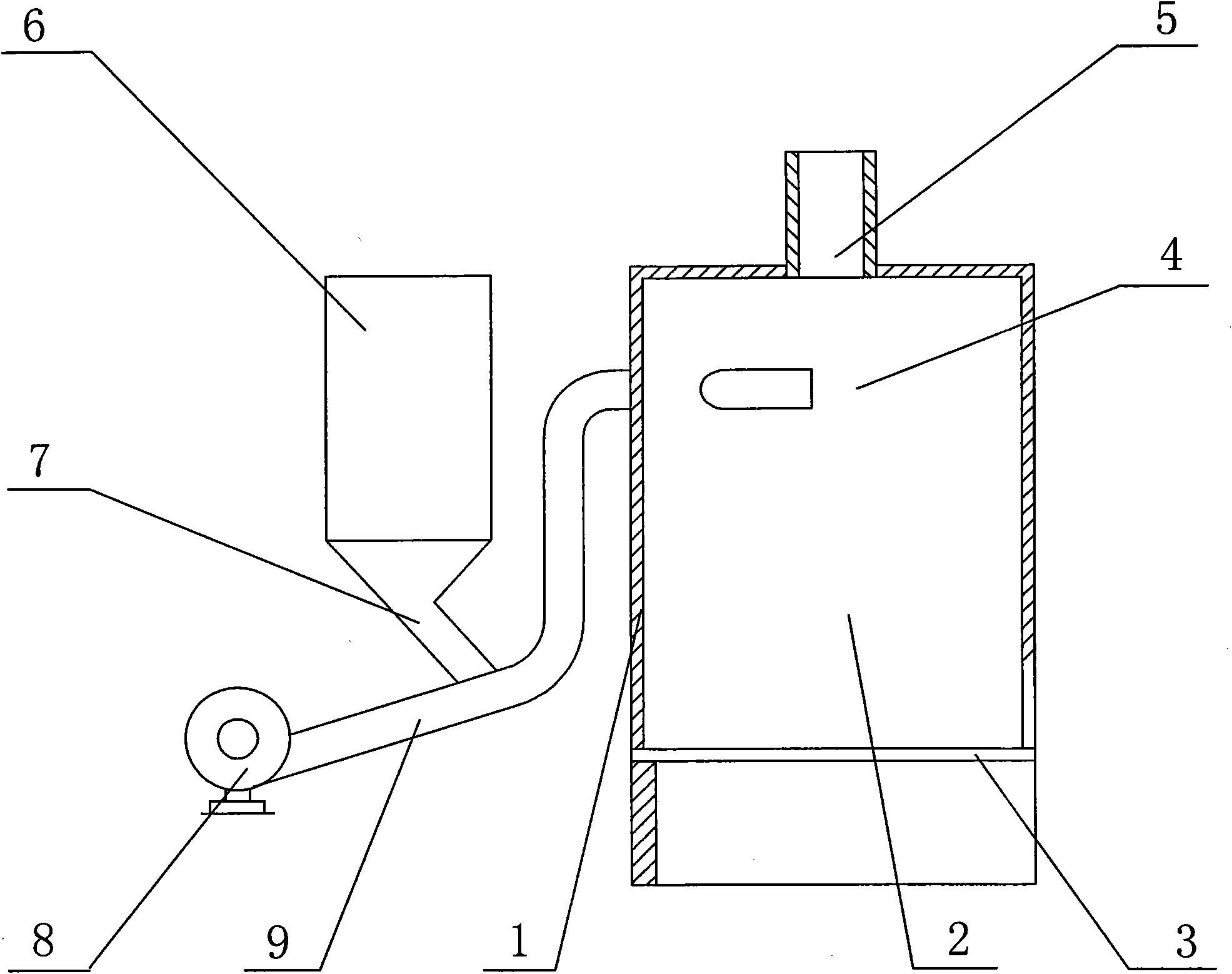

The invention relates to heat supply equipment, in particular to a straw fuel flying furnace which comprises a furnace body (1), a hearth (2), a fire grate (3) and a smoke exhaust pipe (5), wherein the furnace body (1) is externally connected with a fan (8), and an air supply pipe (9) of the fan (8) enters the hearth (2) from one side of the furnace body. The straw fuel flying furnace is characterized in that a fuel hopper (6) is arranged outside the furnace body (1), a blanking pipe (7) under the fuel hopper (6) is communicated with the air supply pipe (9) of the fan (8); and one end of the air supply pipe (9) entering the hearth (2) is provided with a cyclone guide curved surface (4). Fuel is combusted in rotatably flying after entering the hearth following wind, is not easy to accumulate, and is fully combusted. The fan blows the fuel by using hot air in the hearth to ensure that straws are heated in advance to be ignited. The furnace body and a flue are both provided with residual head recovery devices, thereby closing various channels of heat loss and remarkably improving the heat efficiency. The invention is suitable for being used as various heat exchange devices of a hot air furnace, a hot water furnace, an oil furnace and the like, replaces coal furnaces to carry out various heat supply operations, and has important implications on saving coal, protecting environment, fully utilizing crop plants, improving the straw value, and increasing the income of farmers.

Owner:张建臣

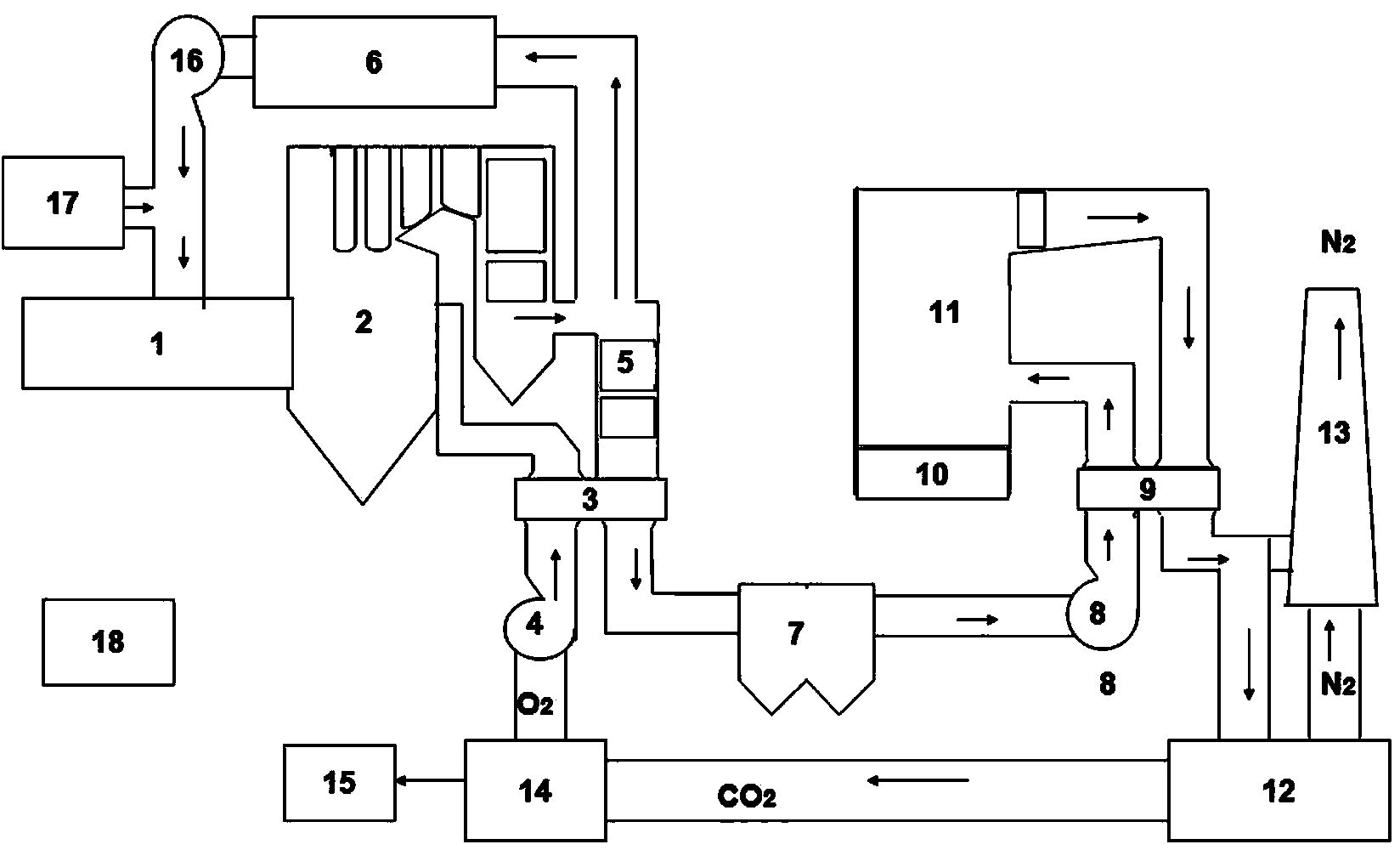

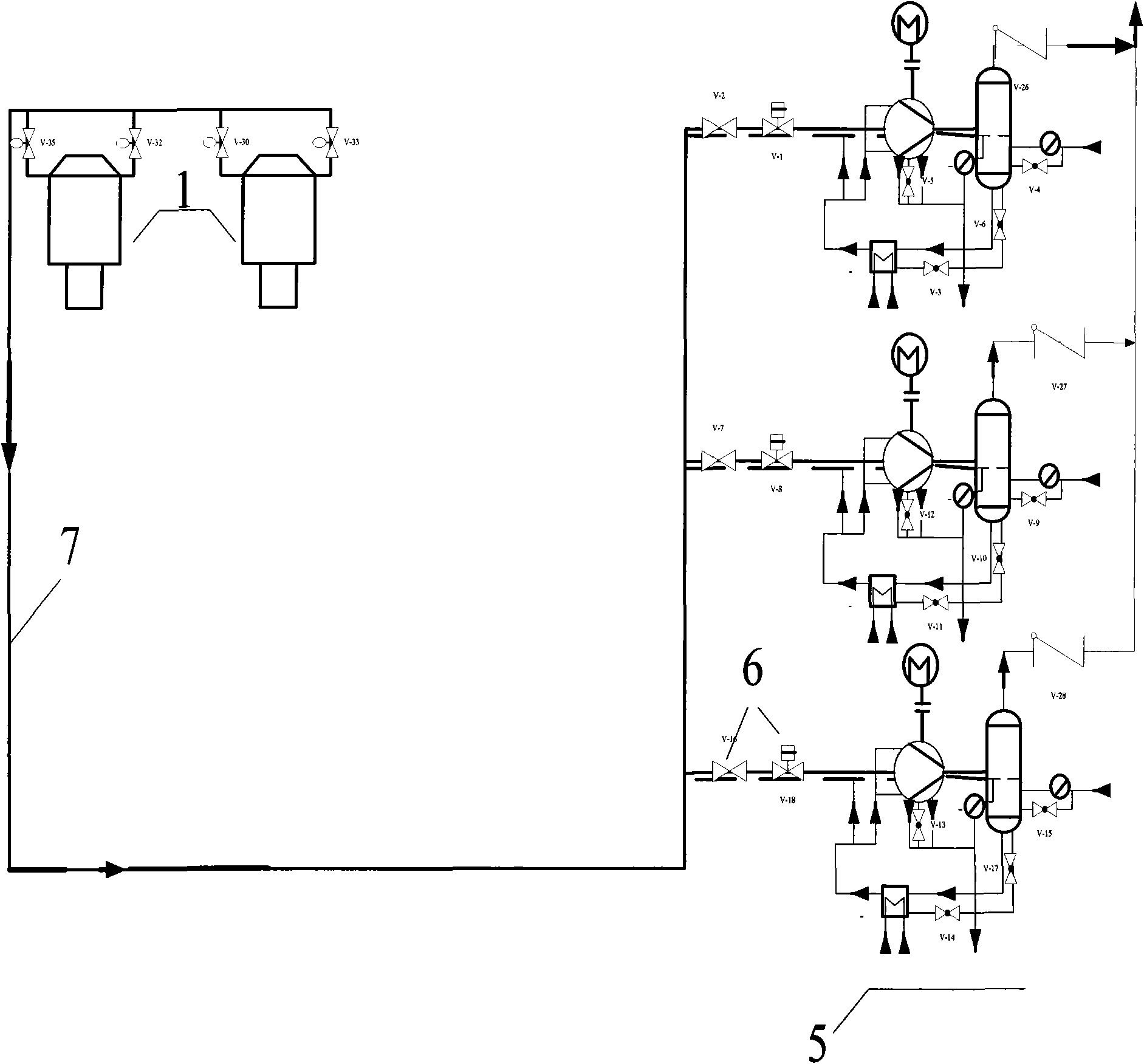

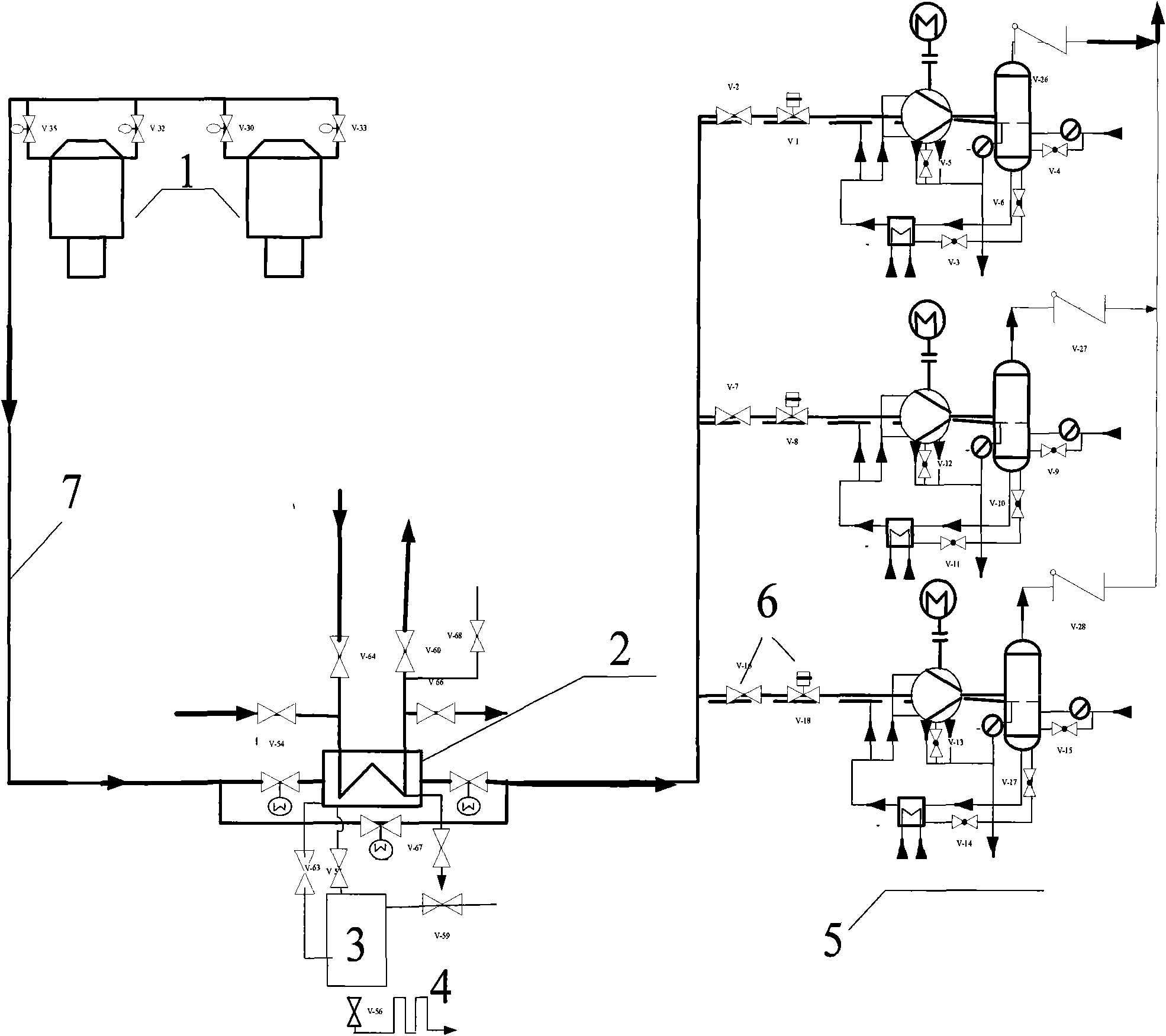

Power plant carbon and oxygen circulation utilization device and process of device

ActiveCN103453542ASmall volumeNet conversion increaseChemical industryGaseous fuelsCombustionProcess engineering

The invention relates to the field of energy saving and environment protection, and relates to the circulation utilization of CO2 (carbon dioxide) and O2 (oxygen gas), in particular to a power plant carbon and oxygen circulation utilization device and a process of the device. The power plant carbon and oxygen circulation utilization device comprises a coal conveyor (17), a CO2 back flow device (6), a plasma torch catalyst (1), an energy-saving boiler (2), a heat exchanger (3), a CO2 catching separator (12), a deaerator (14), a remote anti-explosion total control detection system (18) and a chimney (13). A carrier air coal conveying mode is adopted for conveying reaction raw materials into the plasma torch catalyst (1) to be catalyzed, the catalyzed reaction substances are conveyed into the energy-saving boiler (2) to realize the sufficient combustion with O2, and the generated CO2 is cyclically utilized after the deoxygenation. The device and the process have the advantages that firstly, the low-cost pure oxygen combustion is realized; secondly, the CO2 backflow catalysis and deoxygenation circulation utilization is realized; thirdly, the equipment investment is reduced, and 70 to 80 percent of the equipment volume of the boilers in links of dust removal, denitration, desulfuration and the like is reduced; fourthly, 45 to 70 percent of the coal consumption is saved; and fifthly, the pure conversion rate of heat energy is improved by more than one time.

Owner:浙江森井生物技术股份有限公司

Coal-burning boiler limestone dual-purpose desulfurizing method

InactiveCN1919420AIncrease costLow operation and maintenance costsDispersed particle separationEngineeringDual purpose

The invention discloses a fuel furnace limestone double-effective desulfurizing method in the environmental protective desulfurizing technological domain, which is characterized by the following: combining drying desulfurizing and wetting desulfurizing method into double-effective desulfurizing method, saving cost, discharging less sulfur dioxide than single operating course.

Owner:武建国

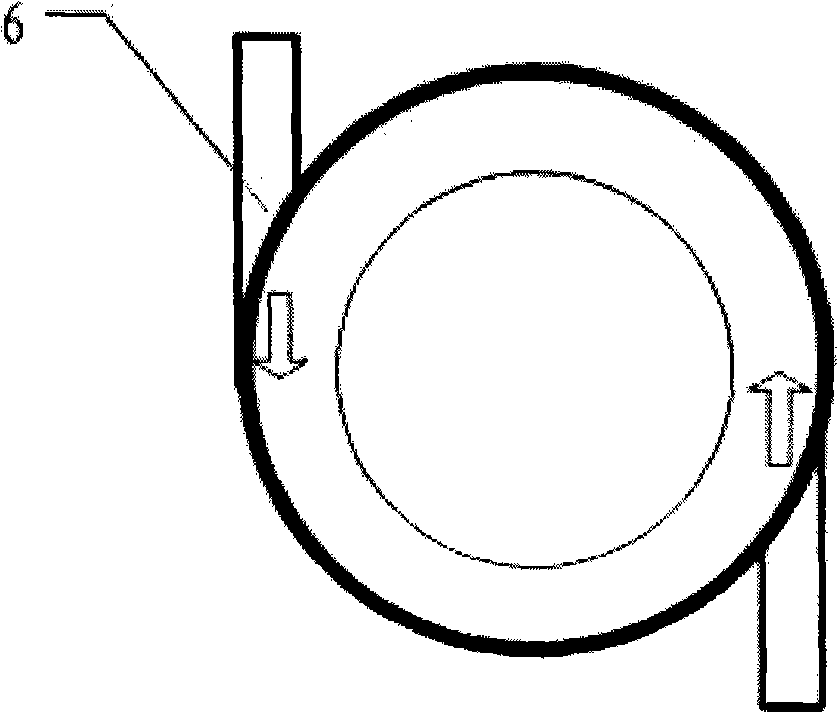

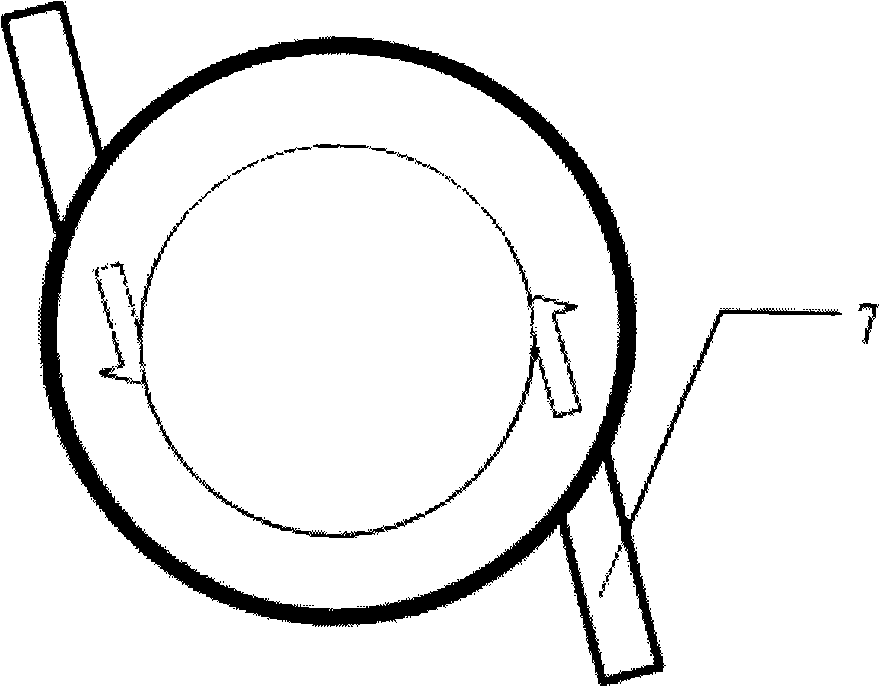

Modularized coal fines cleaning combustion apparatus

InactiveCN101290115AEasy to igniteEconomical co-firingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberButt joint

The invention discloses a modularized pulverized coal clean combustion device, relating to a combustion device for a boiler. The modularized pulverized coal clean combustion device comprises a cylindrical burning chamber arranged in the foreside of the boiler; the central part of the upper head face of the burning chamber is provided with a cyclone burner; the middle of the burning chamber is provided with a shrinking waist which divides the burning chamber into an upper burning chamber and a lower burning chamber, wherein the upper burning chamber is connected with a primary wind pulverized coal inlet with direct current incision; the upper and the lower burning chambers are connected with a secondary wind spout with direct current incision; the central part of the bottom of the lower burning chamber is provided with a mouth; a detritus tank is arranged on the corresponding position of the mouth; the tail of the lower burning chamber is connected with the boiler through a burnout chamber. The modularized pulverized coal clean combustion device can be directly in modularized butt joint with a pressed body of the prior boiler, is suitable for burning various pulverized coals, improves thermal efficiency, replaces the prior coal blocks or fuel gas as fuel and has good environment-friendly effect.

Owner:赵凯

Method for preparing clinker brick

InactiveCN1915895AReduce weightSave coalCeramic materials productionClaywaresSlagPulverized fuel ash

This invention relates to a method for preparing sintered bricks. The method comprises: (1) selecting 115-145 parts of incompletely burned fly ashes, 2365-2375 parts of clay and 1000-1500 parts of water; (2) pulverizing incompletely burned fly ashes to less than 5 mm; (3) mixing the above raw materials; (4) molding in a brick maker, and making into green bodies; (5) drying and torrefying to obtain the final products. The method effectively uses incompletely burned fly ashes from electricity plant waste fly ashes, waste residues, furnace ashes, furnace rewsidues, flue ashes, etc., thus can save coal, reduce pollution and reduce the weight of sintered bricks. The sintered bricks have better quality than conventional clay bricks.

Owner:杨金华

Method for enhancing vacuum of steam condenser

The invention discloses a method for enhancing vacuum of a steam condenser. A cooler is arranged on a pipeline between the steam condenser and a vacuum pump, a condensate water recovery and storage tank is installed at the gas side of the cooler, and the water storage tank is connected with a hot well of the steam condenser through a water seal. Only when temperature of the outlet of the cooler is kept at about 15 DEG C, the steam condenser vacuum can approach ultimate vacuum of the vacuum pump. In summer, if the installed cooler is put into operation, the steam condenser vacuum is enhanced to the ultimate vacuum of the vacuum pump with increase of about 2 kpa, therefore, by calculating according to that the steam condenser vacuum is enhanced by 1kpa, the coal consumption is lowered by 1.97g / kwh, and a machine set of 600 MW annually generates power for 300 days on average, the invention can save coals for 17020.8 t every year; and if the price of the coal is 500 yuan / t, the invention can save the generation cost for 8510400 yuan every year, thereby having remarkable economic benefit.

Owner:曾华

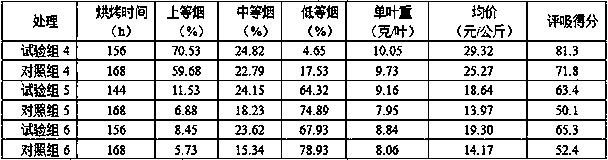

Roasting method of carthamus tinctorius mammoth gold variety based on fresh tobacco leaf quality

The invention discloses a roasting method of a carthamus tinctorius mammoth gold variety based on fresh tobacco leaf quality. According to the method, for fresh tobacco leaves with different quality indicators, roasting is conducted targetedly by controlling the optimization combination of temperature, humidity and roasting time, the purpose is to ensure that the roasting quality of each kind of tobacco leaf is higher, the problem of difficult roasting of special tobacco leaves in tobacco leaf production is solved on one hand, on the other hand the roasting time of tobacco leaves with superiorquality can be shortened on the basis of ensuring roasting quality to reduce the roasting cost, and the emotion of fearing of difficulties of basic-level tobacco production purchasing staff and tobacco growers planting the carthamus tinctorius mammoth gold variety is overcome.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

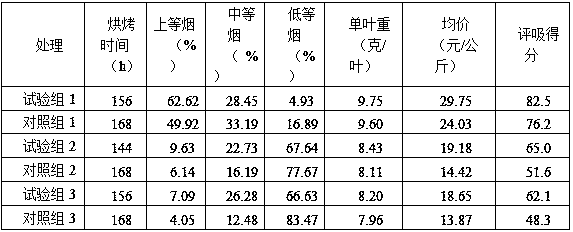

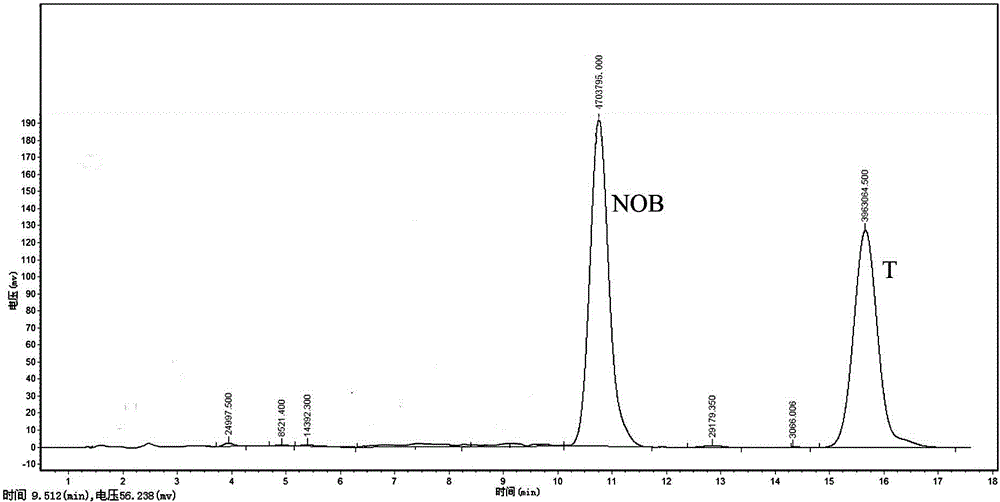

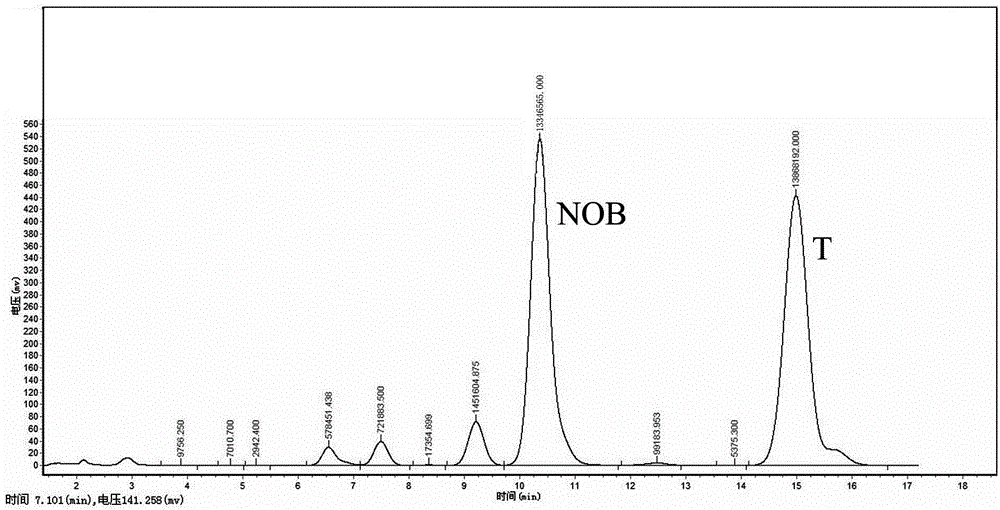

Technology for jointly extracting synephrine, hesperidin and PMFs (polymethoxy latednavones) from fructus aurantii immaturus

ActiveCN104098634AHigh yieldIncrease contentSugar derivativesOrganic compound preparationAlcoholWater methanol

The invention relates to a technology for jointly extracting synephrine, hesperidin and PMFs (polymethoxy latednavones) from fructus aurantii immaturus. The technology comprises the following steps: a, smashing fructus aurantii immaturus, and subpackaging equal quantity of the smashed fructus aurantii immaturus in a percolation tank I and a percolation tank II respectively; adding a dilute acid solution in the percolation tank I, soaking, stirring and percolating; adding effluent liquid into the percolation tank II, soaking, stirring and percolating; mixing the leachate, performing vacuum concentration, adsorbing synephrine by a resin column, desorbing and collecting a desorption solution by using weak aqua ammonia, and performing vacuum drying to obtain dried synephrine; b, washing fructus aurantii immaturus dregs to be neutral with clear water, soaking with a dilute strong base solution, stirring, percolating, performing vacuum concentration, adding absolute methanol or absolute ethyl alcohol, performing still standing, filtering, performing vacuum concentration on the filtrate, and recycling alcohol to obtain a mother solution; c, adsorbing PMFs from the mother solution through the resin column and a chromatographic column, enabling methyl alcohol or ethyl alcohol to pass through the columns for desorbing under static pressure, collecting the stripping liquid, performing vacuum concentration, and recycling an eluent to obtain PMFs; acidizing the effluent liquid passing through resin, standing, and performing devitrification to obtain dried hesperidin.

Owner:SICHUAN XINHUAKANG BIO TECH

Softener for station boiler sediment incrustation and two-stage incrustation-removing method

InactiveCN101274803ANot corrosiveDoes not affect normal operationScale removal and water softeningEthylenediamineLow voltage

The invention provides a softener of the scale that is difficult to be removed from a boiler used in a power station and a two-step washing scale removing method. The softener consists of the raw materials as follows based on the mass ratio: 0.5 to 7 percent of sodium ethylenediamine tetramethylene phosphonate, 0.6 to 8 percent of sodium polyacrylate, 10 to 40 percent of Na3PO4 question mark 12H2O, 8 to 35 percent of NaOH, 15 to 65 percent of Na2CO3, 2 to 10 percent of sodium humate and 0.5 to 5 percent of disodium ethylenediamine tetraacetate. The two-step scale removing method comprises the steps as follows: the softener for removing the scale is added during the operation of the boiler till the pH value is 10 to 12, the pH value of the water in the boiler is kept for 5 to 7 days under normal waste discharging situation to lead the scale of the boiler to fall off after being softened and dissolved; a corrosion inhibiting hydrochloride cleaning agent bought from market is used for cleaning at normal temperature according to a technique of Chemical Cleaning Rules of Boilers, thereby greatly shortening operation time with good cleaning effect. The scale cleaning time can be shortened to 2 to 3 days from the original 8 to 10 days. The softener for removing the scale has the advantages of innocuity, no harm and no corrosion, and can completely soften and dissolve the scale that is difficult to be removed. The problem that difficult scale of boilers of medium and low voltage power stations can not be cleaned in the prior art. The softener is also applicable to industrial boilers.

Owner:杨兴富

Easy-to-kindling and high efficiency honeycomb coal briquet

This invention relates to a high-efficiency energy-saving ignition honecyomb briquette which is burnt by striking a fire on top. It is made up by mixing raw coal, yellow earth, charcoal, sodium chloride, calcium oxide and parafin, with this invented igntion honeycomb briquette, only a stick of matches is needed only for kindling other ordinary honeycomb briquettes.

Owner:徐加清 +2

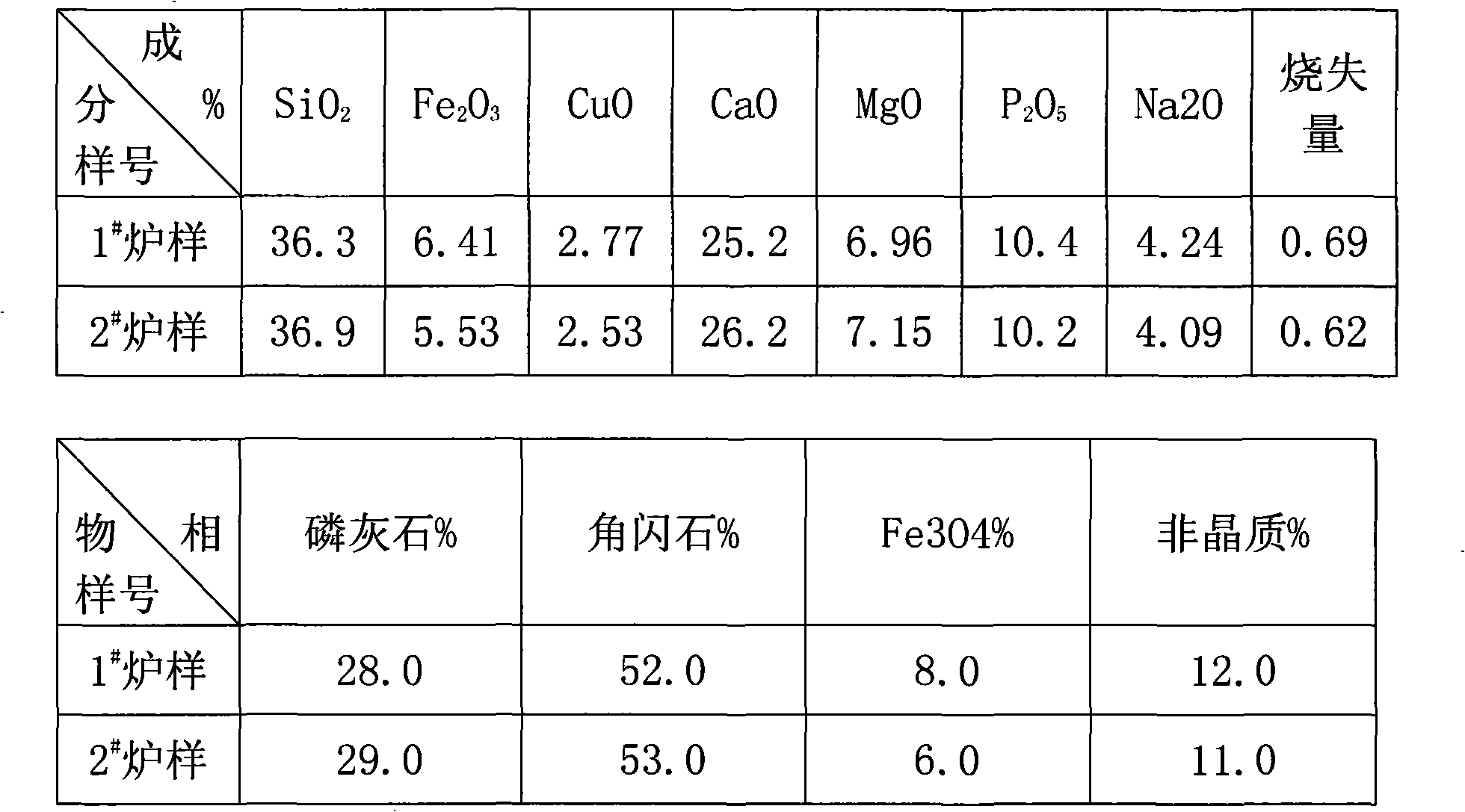

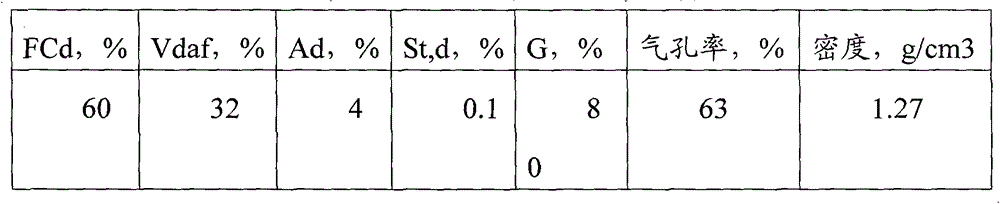

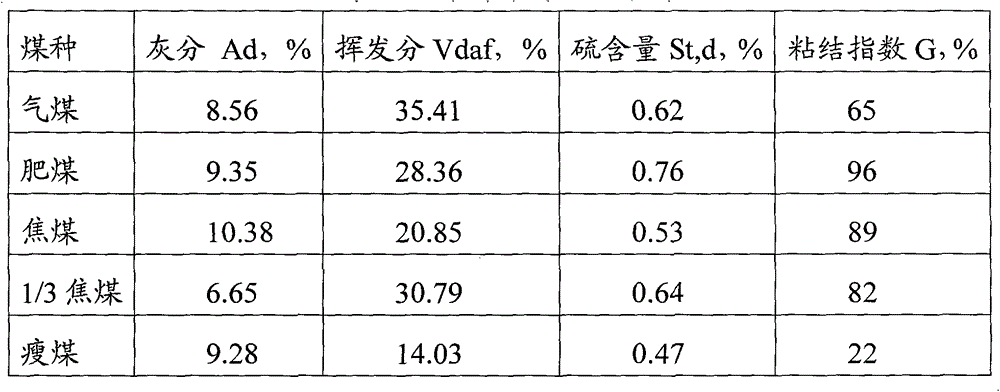

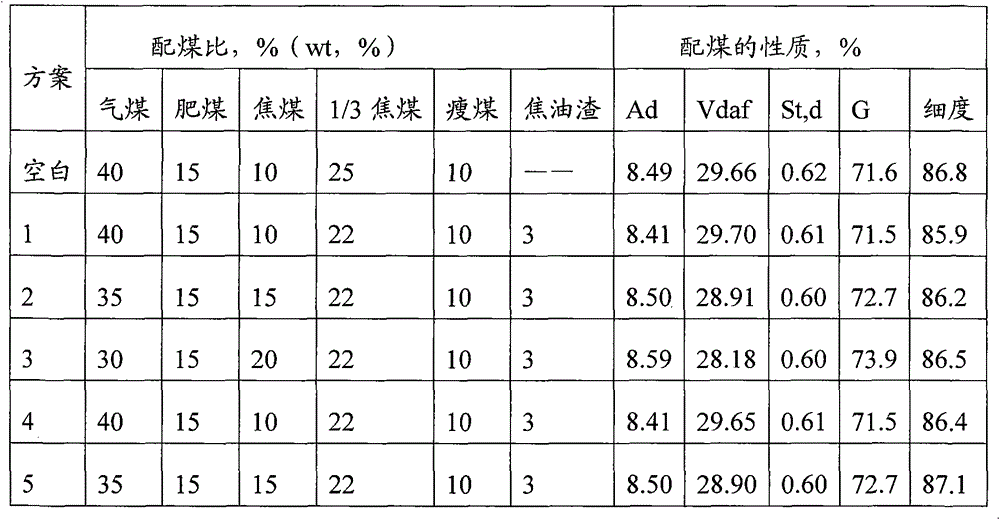

Method for coking tar residue in coal blending manner

The invention relates to a method for coking tar residue in a coal blending manner. According to the technical scheme, the method comprises the steps of selecting a coal blending ratio, carrying out the coking experiment for blending the tar residue by utilizing a 20kg small coke oven and analyzing the quality of coke. The raw material consists of gas coal, fat coal, coking coal, 1 / 3 coke coal, lean coal and tar residue, wherein the gas coal accounts for 35 to 40 percent by mass, the fat coal accounts for 15 percent by weight, the coking coal accounts for 10 to 20 percent by weight, the 1 / 3 coke coal accounts for 19 to 25 percent by weight, the lean coal accounts for 10 percent by weight, the tar residue accounts for 3 to 6 percent by weight, and the tar residue is firstly independently crushed and then blended with the raw material to be coked. The method is used for coking the coal, so that not only is the environmental pollution problem caused by the tar of a coking plant be solved, but also the coal source is saved, the secondary utilization of the energy is realized; and moreover, by adding the tar residue, the lump coke rate of the coke can be obviously increased, and a novel way for reducing the cost and improving the efficiency can be provided for the coking plant.

Owner:田秀文

Method for resource utilization of water-containing sludge

InactiveCN103396019AAchieve harmless treatmentMeet application requirementsCement productionProduction lineSludge

The invention discloses a method for resource utilization of water-containing sludge. At a section from a raw material shed or a raw material warehouse to a raw material vertical milling area in a dry-method cement production line, water-containing sludge is mixed into raw material or put in a vertical mill, so as to adjust the comprehensive water content and the material plasticity of raw materials and the vertically milled material of the raw material to 3wt% to 15wt%; and the sludge-containing raw material powder which is prepared from the vertically milled raw material is fed into a cement kiln system so as to be calcined into cement clinker. According to the method, based on such natural characteristics of water-containing sludge as high water content, the flocculence structure, the plasticviscosity, water content and plasticity required by the vertically milled material can be provided, the application requirements of the raw material vertical mill are met, the purpose of resource utilization of the water-containing sludge is reached, the method is simple, feasible, practical and low in investment, the harmless treatment of water-containing sludge is realized, the investment in technical transformation of the method is small, the utilization amount of the sludge is large, and good benefits and optimal economy are achieved.

Owner:尹无忌

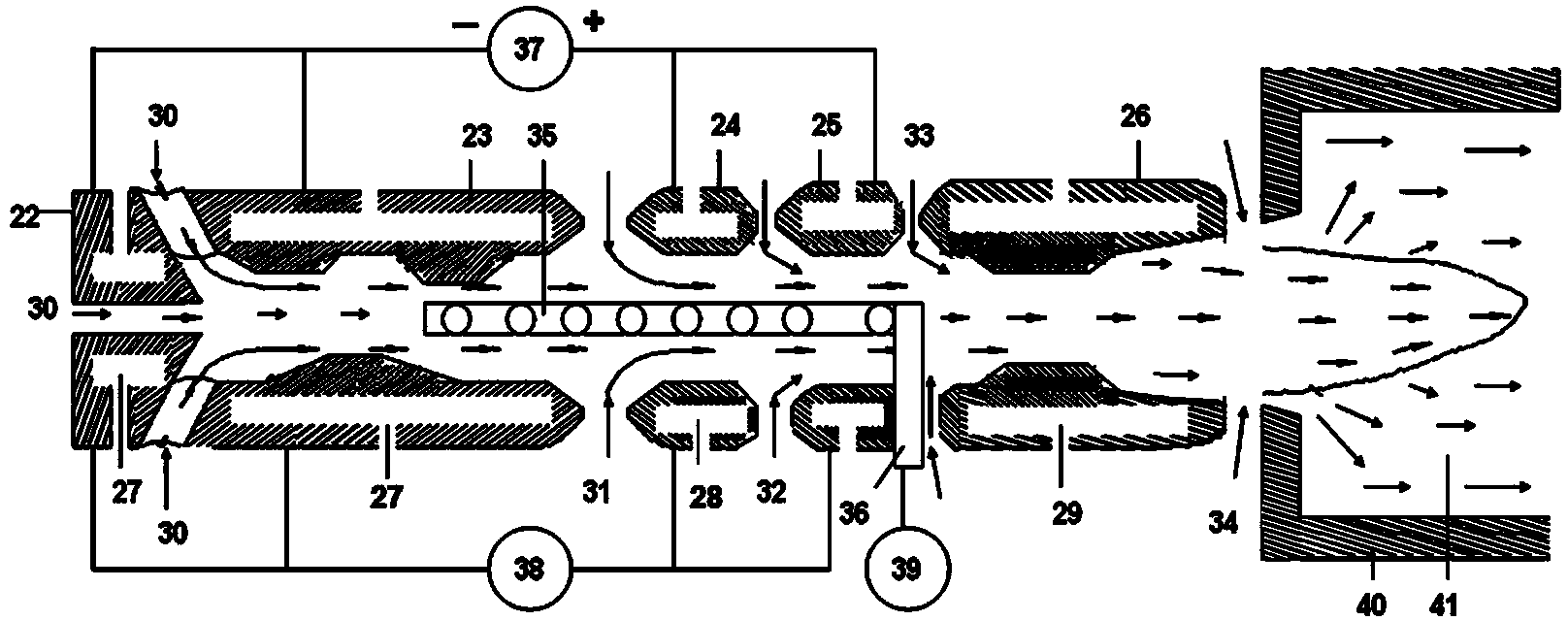

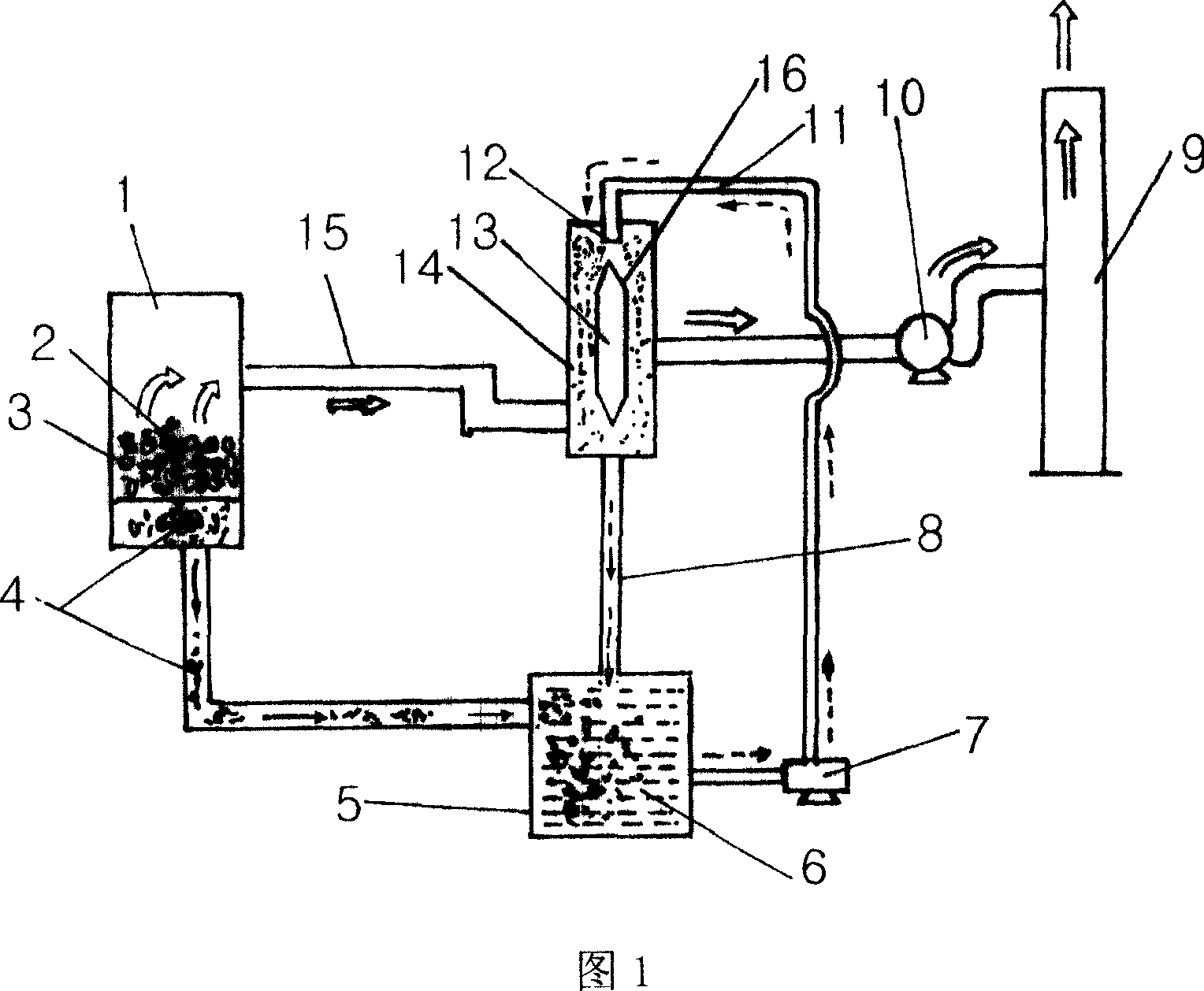

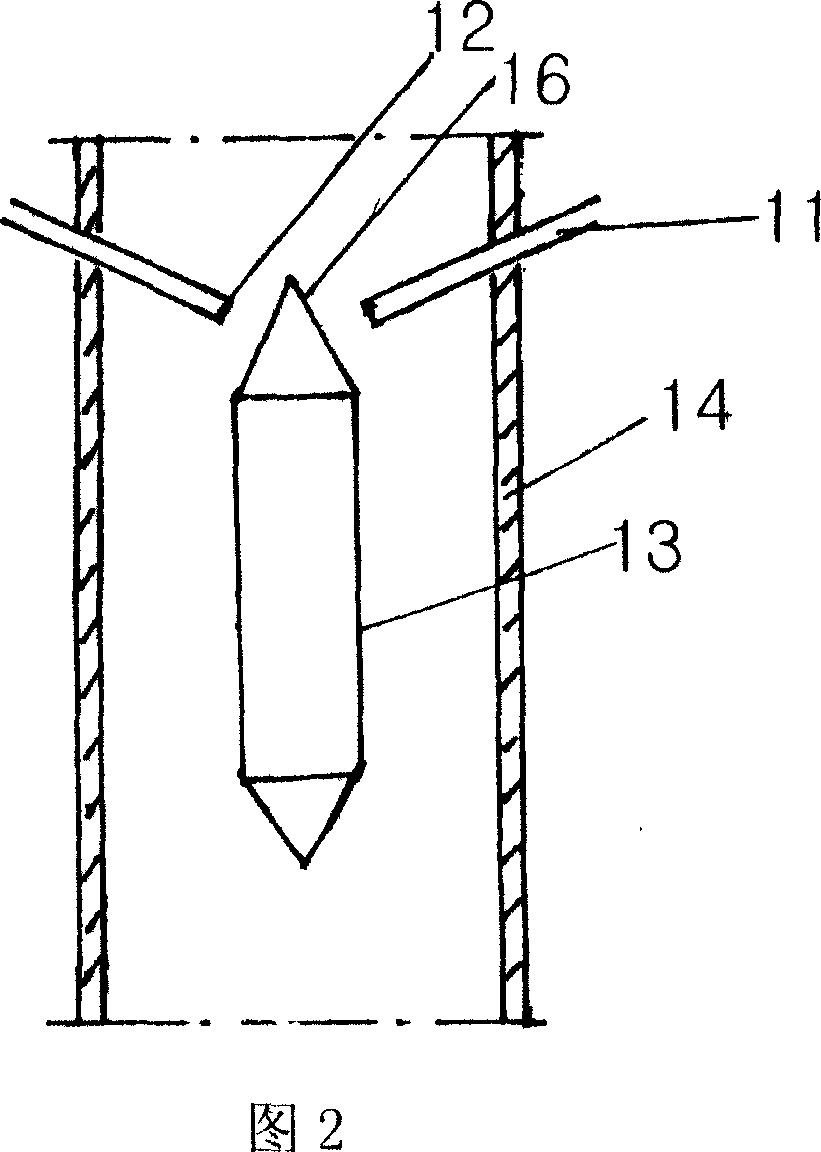

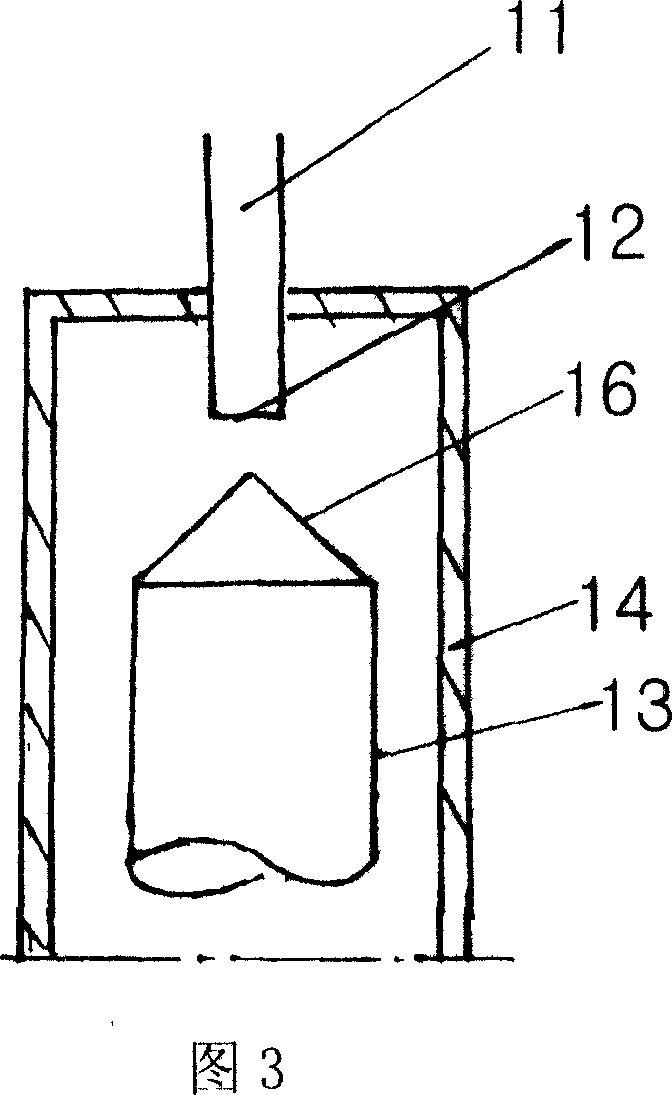

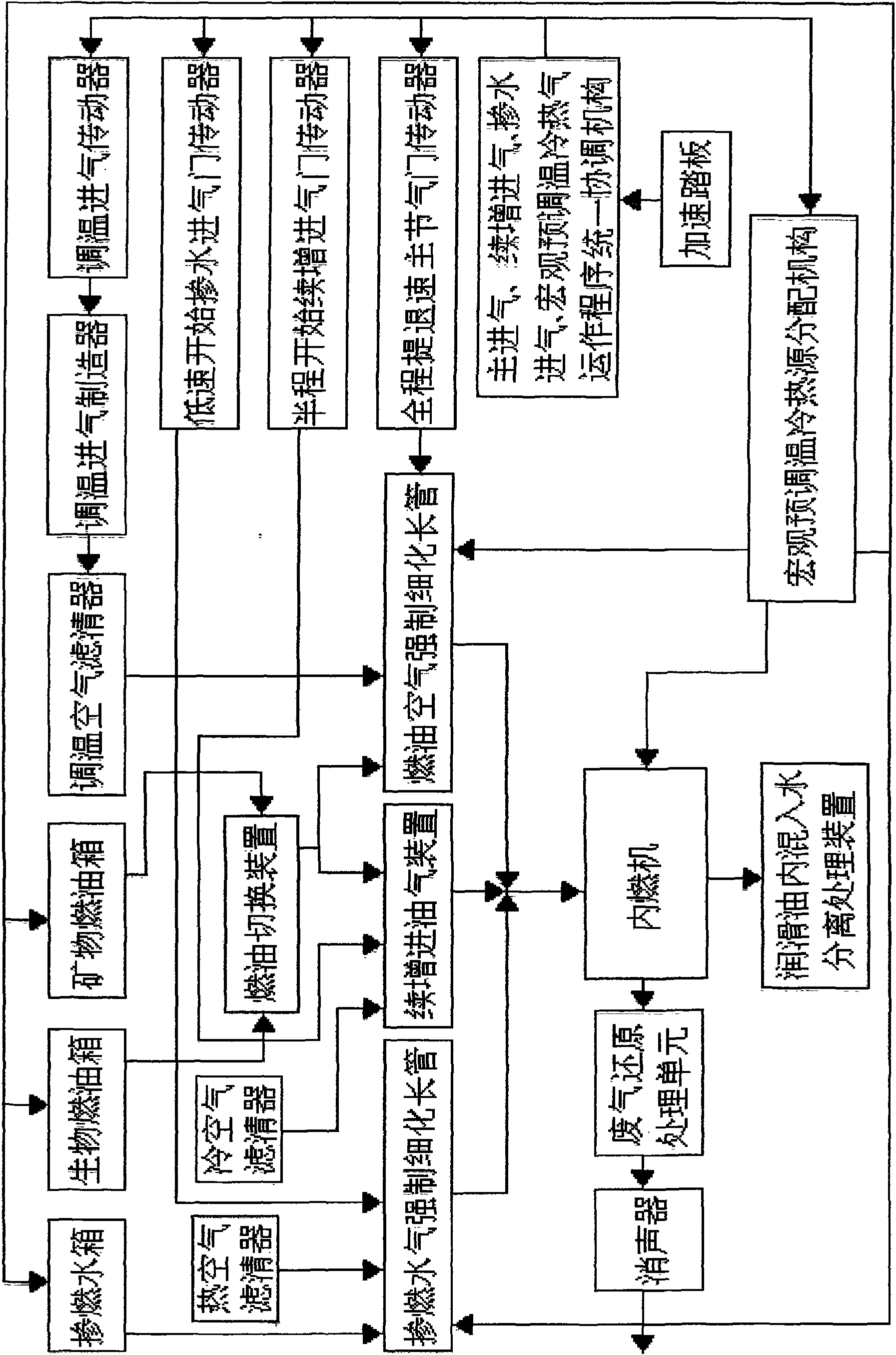

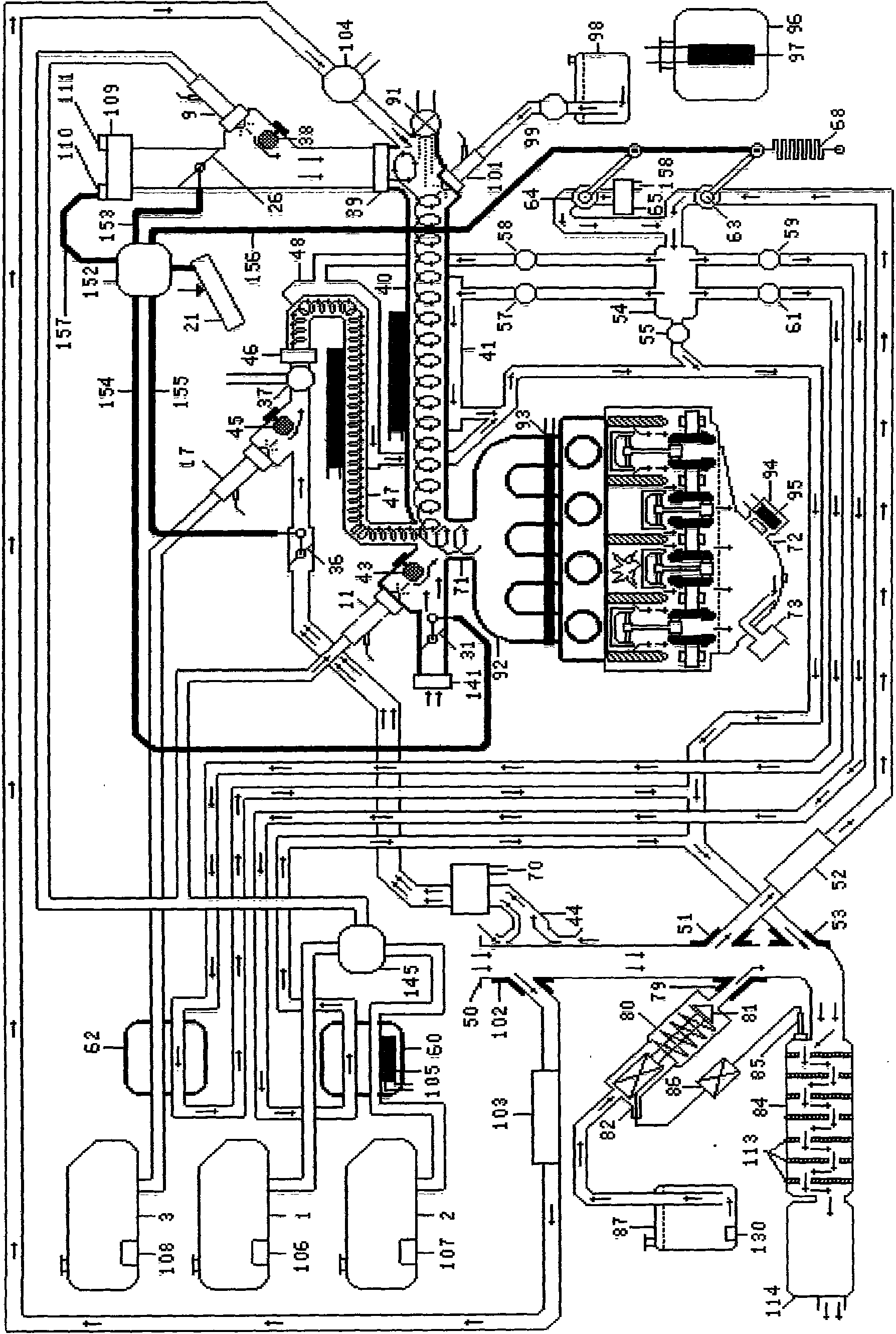

Engine energy-saving and emission-reducing system coordinated by heat pipe and cold pipe and working method thereof

InactiveCN101644208AReduced discharge resistanceEasy dischargeNon-fuel substance addition to fuelInternal combustion piston enginesCombustionExternal combustion engine

The invention relates to an engine energy-saving and emission-reducing system coordinated by a heat pipe and a cold pipe, which comprises an energy-saving and emission-reducing system of an internal combustion engine and the energy-saving and emission-reducing system of an external combustion engine, wherein, the energy-saving and emission-reducing system of the internal combustion engine comprises the internal combustion engine, a temperature-conditioning mineral fuel tank and a thick long swirling flow thin unit; and the energy-saving and emission-reducing system of the external combustion engine comprises the external combustion engine, a temperature-conditioning blending water tank and a water gas forced thinned long pipe. The working method comprises the working method of the energy-saving and emission-reducing system of the internal combustion machine and he working method of the energy-saving and emission-reducing system of the external combustion machine. The system has the advantages that the principle is simple and easy to develop and most of parts can directly select the existing standard parts for being used after simple transformation of the parts; the aggregate role of various technologies can sufficiently thin mixed gas, greatly reduce working temperature, improve the key technology which can greatly improve the geometric compression ratio and lead an oil-saving index to be about 50%; and the various technologies can be comprehensively applied for obtaining the energy-saving and emission-reducing ultra-high index, and the single technology therein can be independently used for obtaining the medium energy-saving and emission-reducing index with a small amount of investment.

Owner:段洪池 +3

Boiler chromium-based decoking and coal saving agent composition and preparation method thereof

The invention relates to a coal additive for coal-fried boilers in industries such as electricity generation, thermoelectricity, petroleum, chemical industry, metallurgy and the like and particularly relates to a boiler chromium-based decoking and coal saving agent composition, which is prepared from the following components in parts by weight: 65-80 parts of chromium oxide, 12-20 parts of copper sulfate, 8-13 parts of cerium oxide, 8-13 parts of vanadium pentoxide, 10-16 parts of manganese dioxide, 12-18 parts of potassium permanganate, 6-11 parts of potassium chlorate, 15-22 parts of zinc oxide, 10-15 parts of potassium molybdate, 8-13 parts of cobalt carbonate, 9-15 parts of barium carbonate, 30-40 parts of sodium carbonate, 6-10 parts of ferric trichloride, 40-55 parts of active white attapulgite clay and 0.1-0.3 part of a penetrant JFC. By using the boiler chromium-based decoking and coal saving agent composition, the problems of boiler coking and dust deposition, which are not solved for a long time, of the coal-fried boilers, are solved, the coal saving rate is larger than 4%, the problem that boiler parts are corroded by acidic substances is solved, the service life of a boiler is prolonged, and the atmospheric environment pollution is reduced. The boiler chromium-based decoking and coal saving agent composition is also suitable for deslagging of the coal-fried boilers.

Owner:LANZHOU XINXING NEUTRAL CLEANING TECH

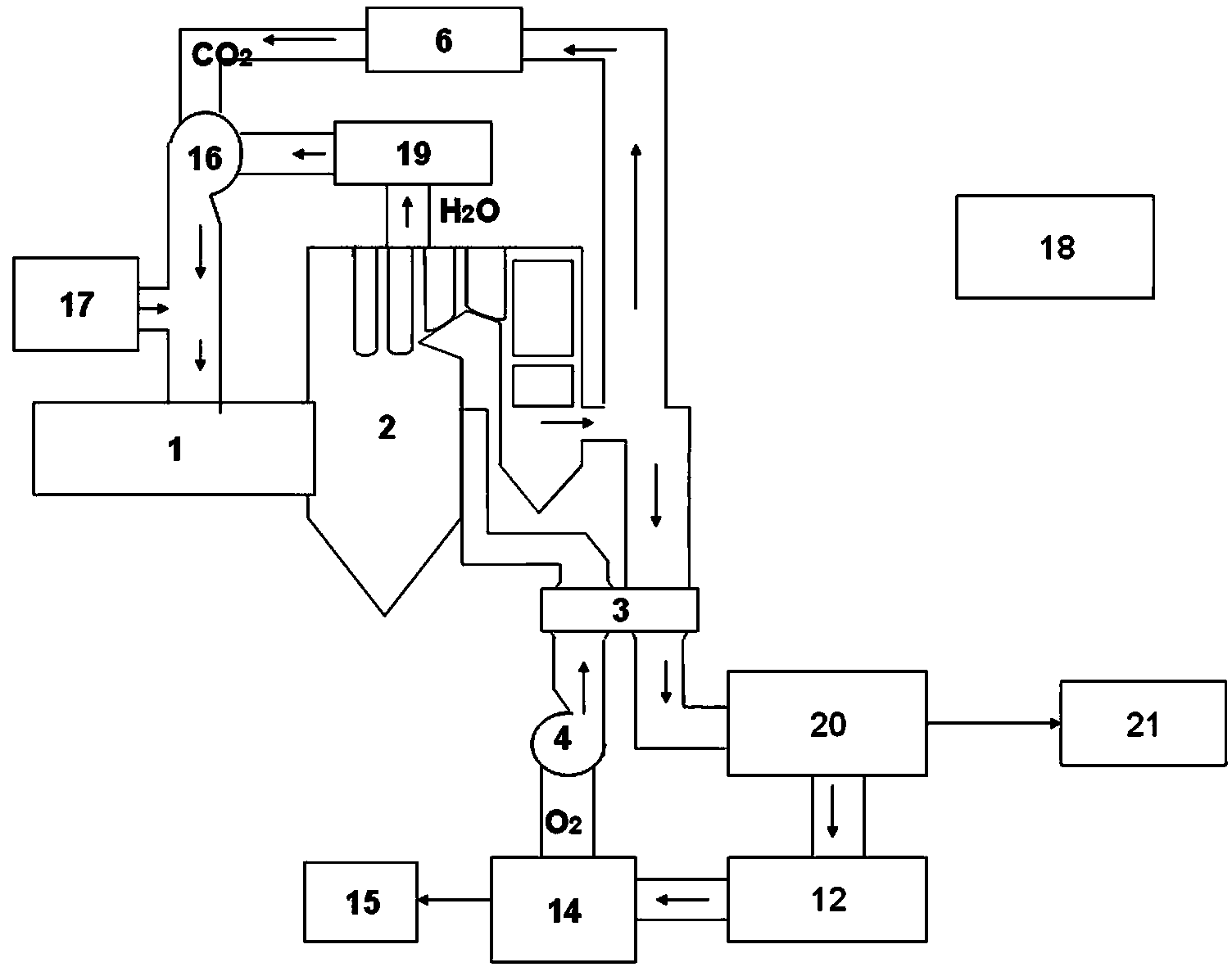

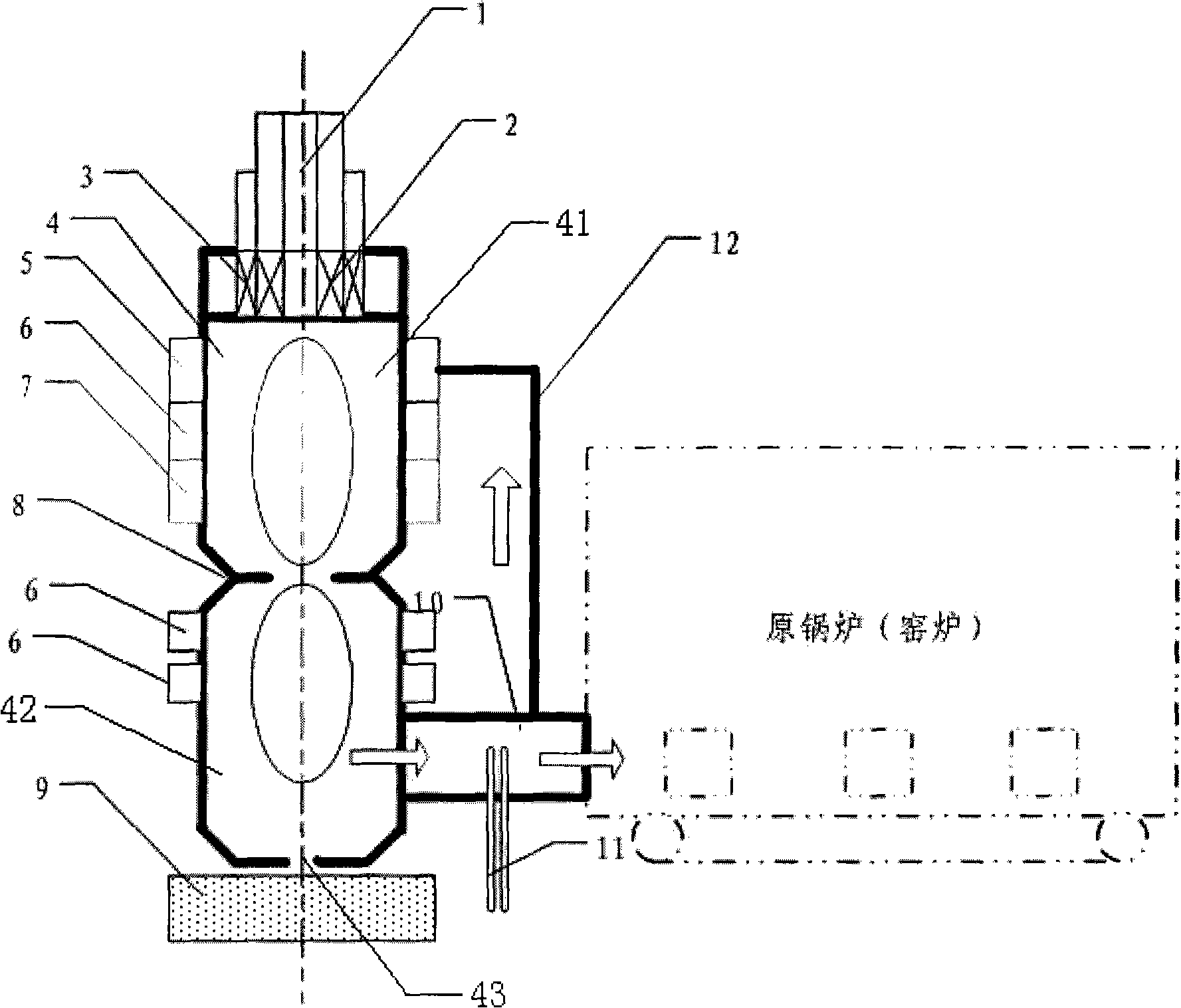

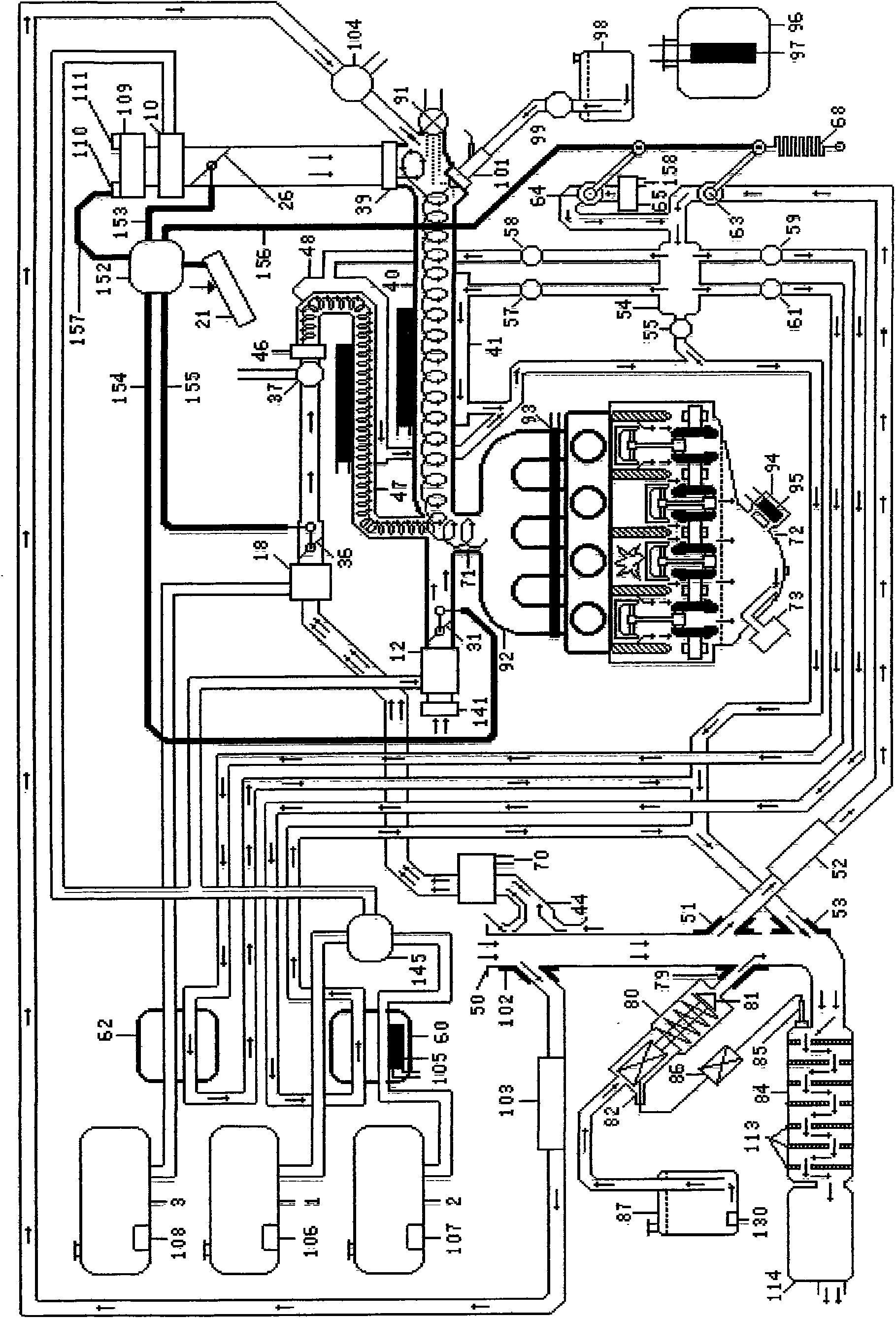

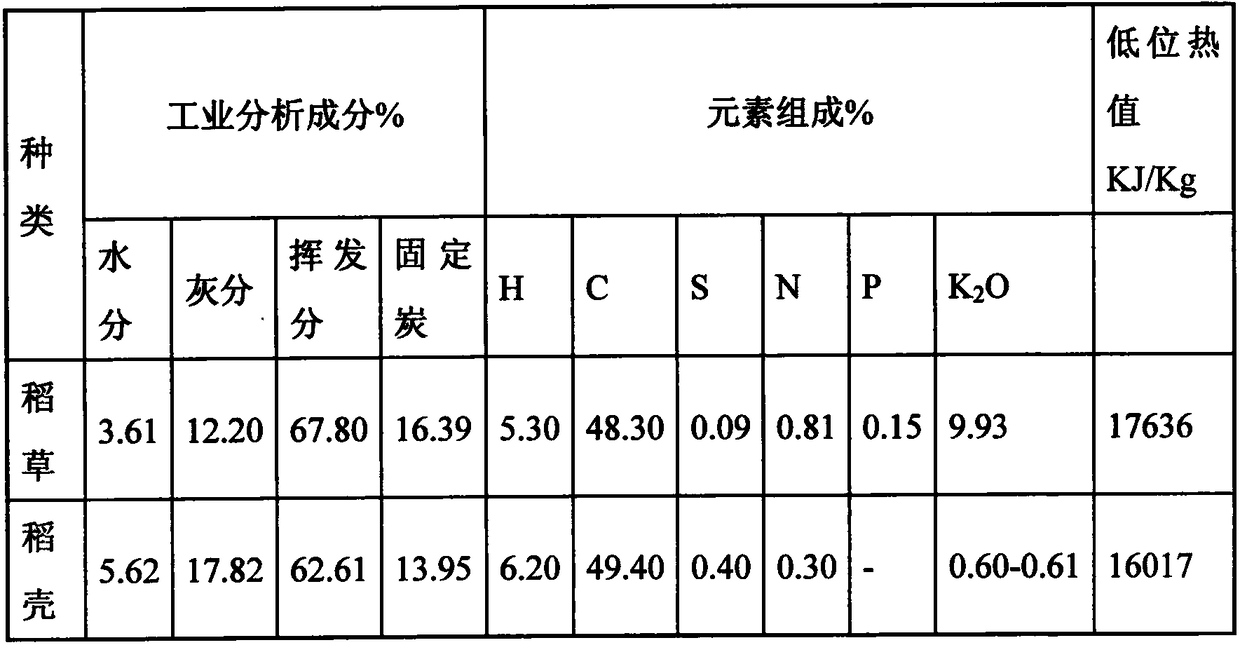

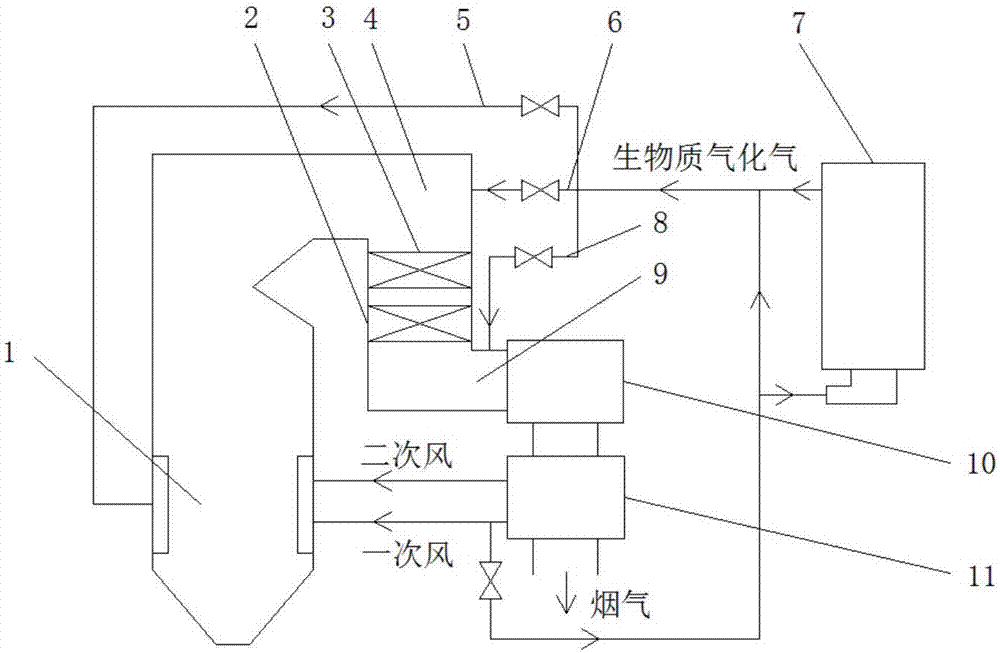

Power generation system and power generation method for biomass gasification coupled coal-fired boiler

PendingCN108456556ASave coalReduce NOx emissionsEnergy inputGasification processes detailsEconomizerBoiler feedwater

The invention provides a power generation system for a biomass gasification coupled coal-fired boiler. The power generation system comprises a biomass storage conveying unit, a biomass circulating fluidized bed gasification unit, a biomass high-temperature fuel gas waste heat recovering unit, a crude gas metering air supply unit and a matched combustion unit, wherein the biomass storage conveyingunit is used for finishing and storing collected biomass raw materials, as well as cutting, breaking and discharging the biomass raw materials; the biomass circulating fluidized bed gasification unitis used for gasifying cut and broken biomass particles into crude gas; the biomass high-temperature fuel gas waste heat recovering unit is used for adopting boiler feed water from a high-temperature economizer of a coal-fired boiler as a cooling medium and cooling the crude gas; the crude gas metering air supply unit and the matched combustion unit are used for feeding the cooled crude gas into the coal-fired boiler for combusting in a metering manner. The invention also provides a power generation method for the biomass gasification coupled coal-fired boiler. By coupling biomass gasification,waste heat recovery and combustion, the power generation system and the power generation method disclosed by the invention have the advantages that indirect power generation of biomass is realized, the biomass is efficiently utilized while fire coal is saved, NOx emission of the coal-fired boiler is reduced and a broad application prospect is realized.

Owner:SHANGHAI BOILER WORKS

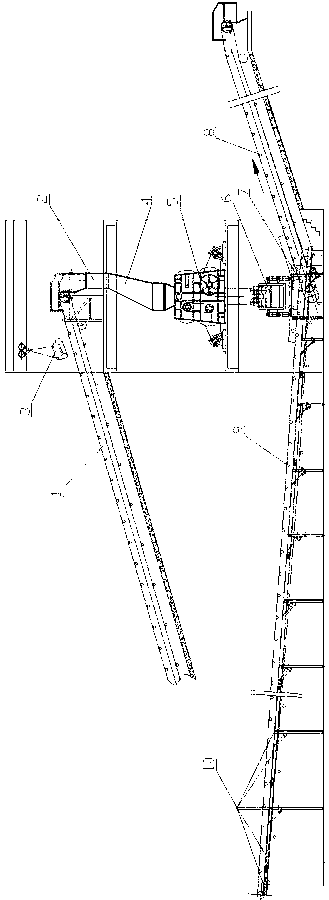

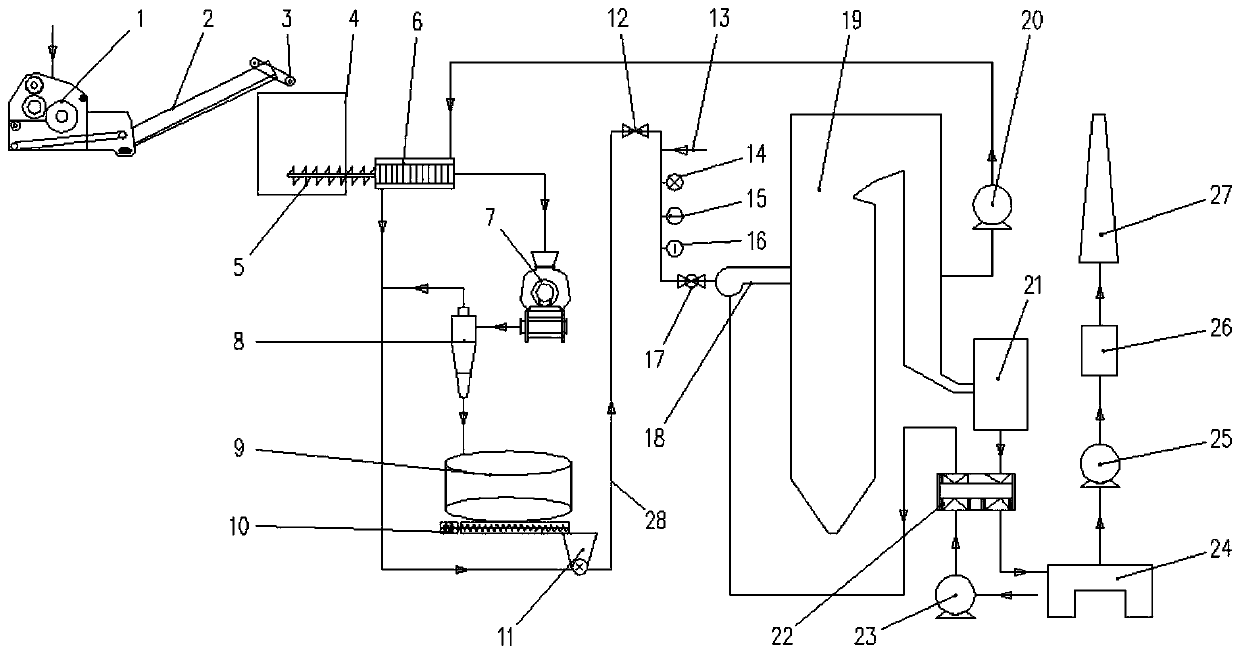

Smashing, screening and circulating coal feeding system

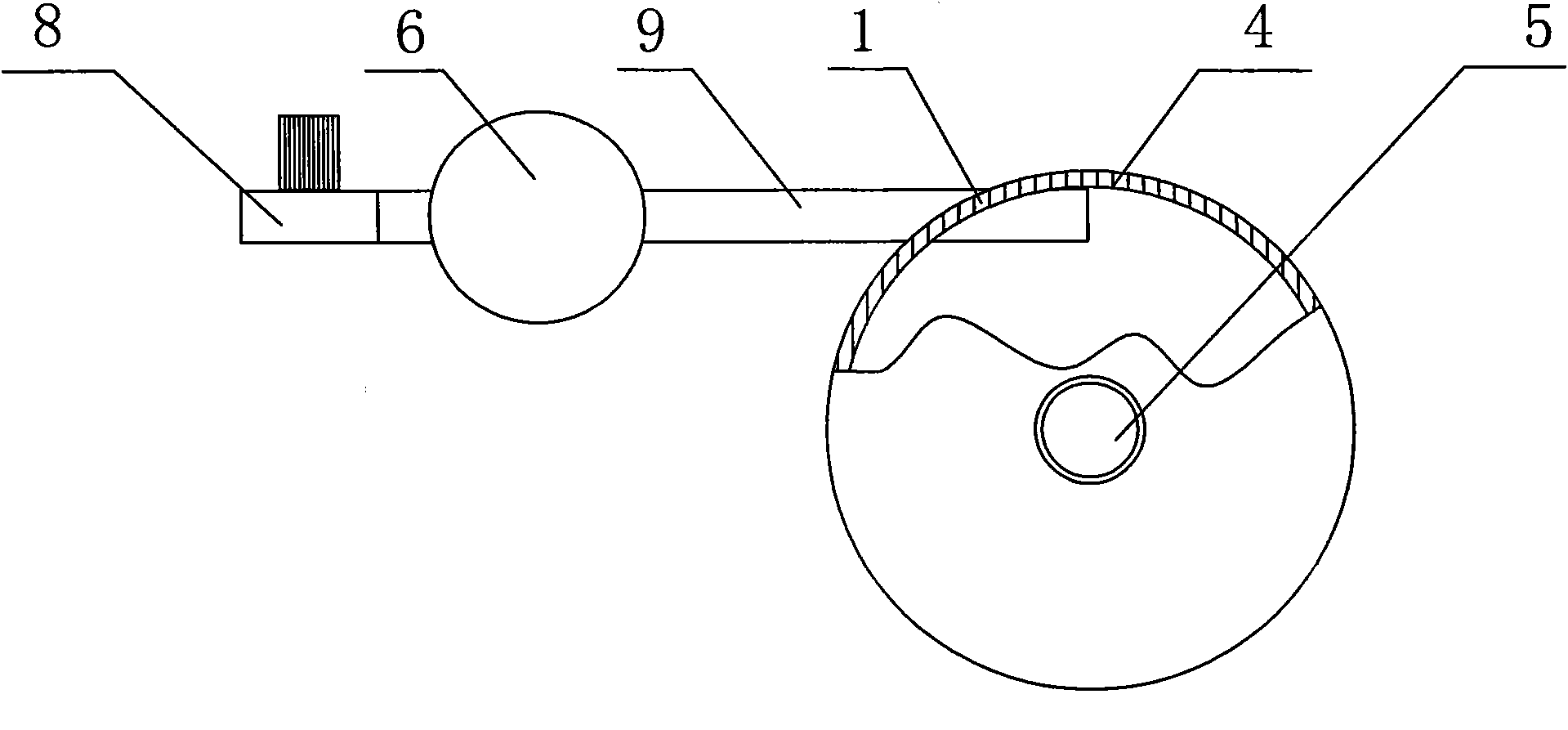

InactiveCN103292341AReduce insecuritySolve the problem of easy wear and tearLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationCoal briquetteThermodynamics

The invention relates to a smashing, screening and circulating coal feeding system which comprises a mixed coal bunker, a coal feeding material nozzle, an iron separator, a smasher and a number one coal feeding belt conveyor. The lower portion of the number one coal feeding belt conveyor is connected with the mixed coal bunker, the coal feeding material nozzle is positioned at the bottom of the mixed coal bunker, the lower portion of the coal feeding material nozzle is connected with the smasher, and materials after being processed are conveyed to a boiler by the belt conveyor. The smashing, screening and circulating coal feeding system is characterized in that a vibratory screening machine is additionally arranged at an outlet of the smasher, a material separating nozzle is arranged on the lower portion of the vibratory screening machine and connected with a number two below-screen belt conveyor, coal briquette with qualified granularity is conveyed to the boiler by the number two below-screen belt conveyor, materials on a screen of the vibratory screening machine are conveyed to a number three above-screen belt conveyor, and a hanging rack is arranged on the end portion of the number three above-screen belt conveyor. By the smashing, screening and circulating coal feeding system, resource waste caused by incomplete burning of large-sized coal is effectively reduced, burning efficiency of the coal briquette is improved, production cost of the boiler is reduced, and the problems of difficulty in raw coal separating and high load of the coal smasher are solved. The smashing, screening and circulating coal feeding system is suitable for closed cycle processes like smashing, screening, separating and the like of bulky materials.

Owner:TAIYUAN IRON & STEEL GROUP

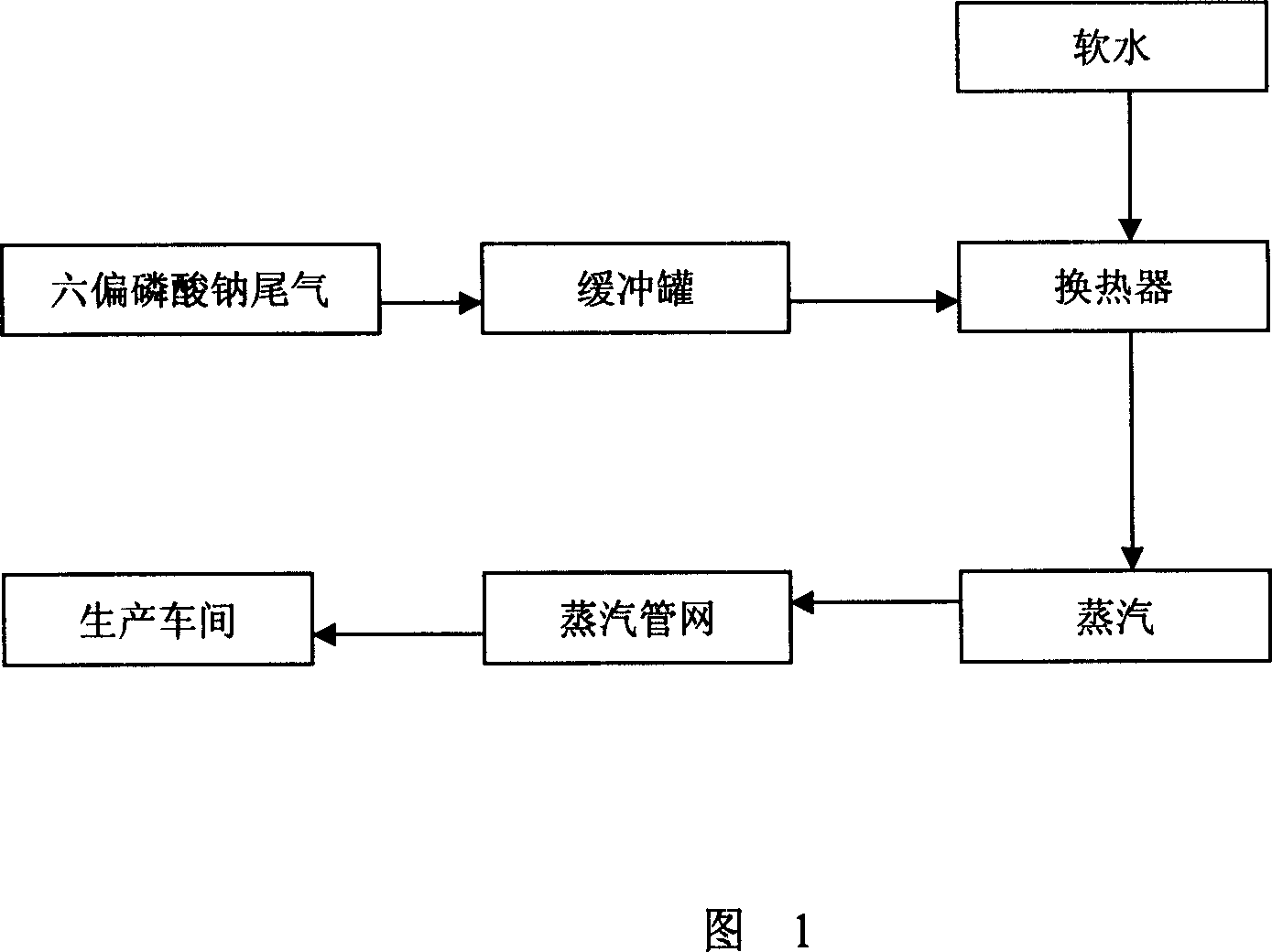

Method for recovering and reutilizing exhaust waste heat of producing hexa poly sodium metal-phosphate

InactiveCN1987198AReduce the temperatureSave coalEnergy inputPhosphorus compoundsPhosphateBuffer tank

A method for reclaiming the afterheat (at 350 deg.C) of the tail gas generated by preparing sodium hexametaphosphate features that an afterheat steam drum composed of buffer tank, heat exchanger and heat conductive tube is installed onto tail gas pipeline to heat the water (at 20 deg.C) and generate steam for reusing it.

Owner:HUBEI XINGFA CHEM GRP CO LTD

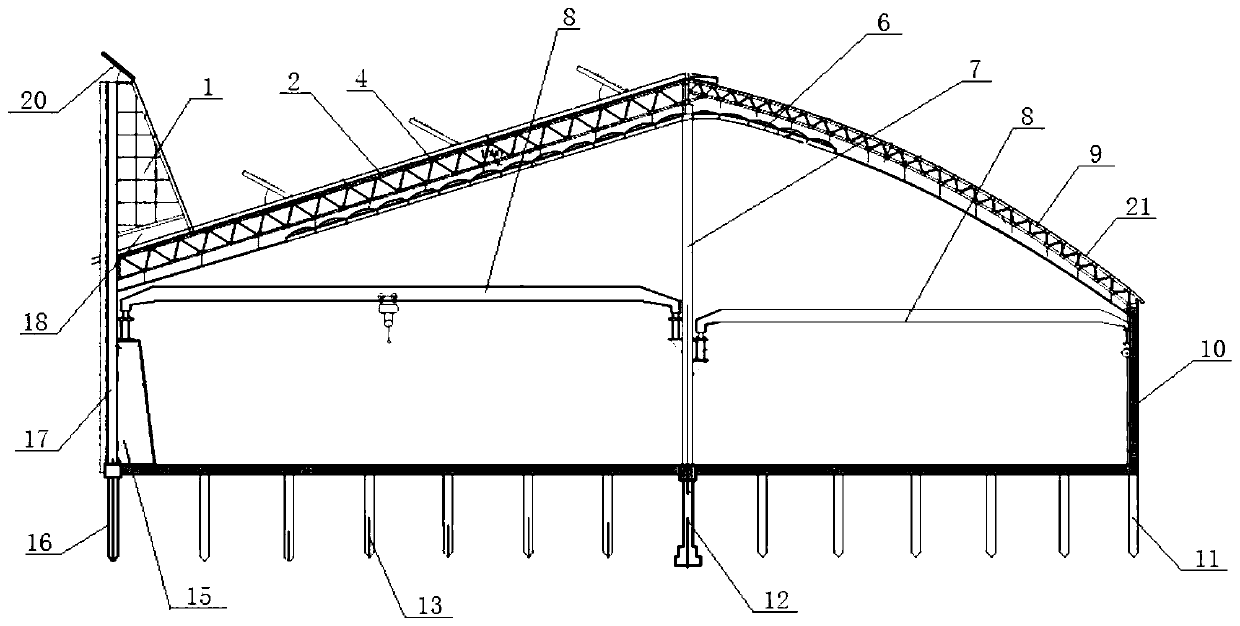

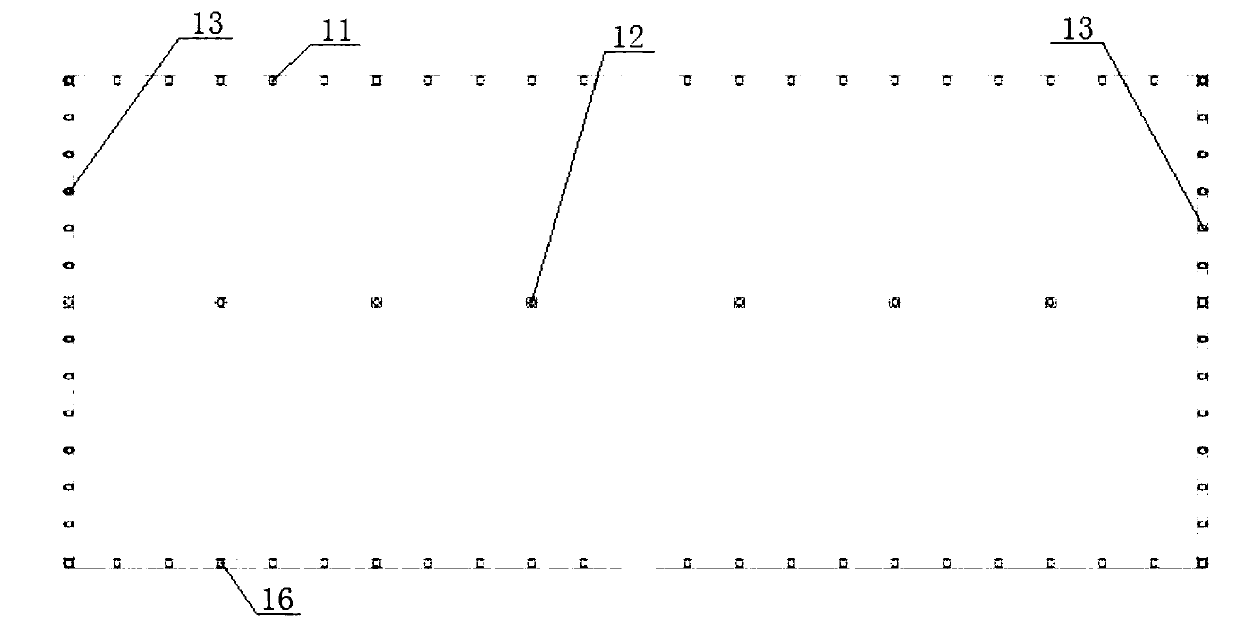

Energy-saving, environmental protection and ecological triune industrial plant stadium and key joint design method and construction method thereof

ActiveCN110185292AGood effect of capturing light energyAvoid Morning Cream EffectsSolar heating energyDucting arrangementsEngineeringRidge

The invention relates to an energy-saving, environmental protection and ecological triune industrial plant stadium and a key joint design method and a construction method thereof. The energy-saving, environmental protection and ecological triune industrial plant stadium is characterized by comprising a foundation, the lower end of the foundation extends into the ground, a front wall, a gable and arear wall are fixedly connected to the upper part of the foundation, a center pillar is arranged on and fixedly connected with the top surface of a fourth pile foundation of the foundation, a front roof is arranged on and fixedly connected with the top surface of the front wall, the gable and a ridge, a rear roof is arranged on and fixedly connected with the middle parts of the ridge, the gable and the rear wall; key joints include orientation positions and the height of the ridge of a lighting roof; the construction method comprises the steps that the foundation is built, then the gable, therear wall, the front wall, the rear roof and the front roof are built sequentially, and an energy cabin, an insulation layer, a heat storage wall, an energy storage and heat storage system, an air circulation system and a wind and light power generation system are installed in sequence.

Owner:吉林市东北生态农业发展有限责任公司

Direct high back pressure heat supply system of indirect air cooling unit

InactiveCN105910454ASolve the problem that the electrical load is limited by the thermal loadEnsure safetySteam/vapor condensersCooling towerNuclear engineering

The invention relates to the technical field of unit heat supply, in particular to a direct high back pressure heat supply system of an indirect air cooling unit. The direct high back pressure heat supply system comprises a condenser and is characterized in that recycled water pipelines in the condenser are uniformly divided into two separate parts: on one side, a water inlet pipe communicates with a heat supply network water return pipe, and a water outlet pipe communicates with a heat supply network water heater by virtue of a heat supply network circulating pump; on the other side, the water inlet pipe communicates with an indirect cooling tower through a frequency conversion circulating water pump, and the water outlet pipe communicates with the water inlet pipe of the indirect cooling tower. The direct high back pressure heat supply system is small in investment and simple in structure, takes effect quickly, and can realize operation under pure condensing and back pressure modes; in addition, in case that the heat supply network is abnormal, the unit can switch over two operational modes without halt to ensure operating safety of the unit.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

Method for preparing mixed fuel by cooperatively treating organic matter-containing hazardous waste in cement plant

InactiveCN111808649AGood for clean burningSimple processSolid fuelsAlternative fuelsComponents of crude oil

The invention discloses a method for preparing mixed fuel by cooperatively treating organic matter-containing hazardous waste in a cement plant. The method comprises the following steps: (1) carryingout modification treatment; (2) preparing mixed fuel powder; and (3) spraying into a kiln for combustion. The method is simple in process and low in investment, material components of hazardous wasteare modified, volatile peculiar smells are eliminated, pollutants such as heavy metal are stabilized, the pollutants such as peculiar smells generated in the drying and grinding process are eliminatedthrough the natural adsorption performance of pulverized coal, and secondary pollution is avoided in the treatment process; organic matter-containing hazardous waste is modified to serve as a combustion promoting component (namely a combustion improver) and alternative fuel of cement plant fire coal, mixed powder is ground into mixed fuel powder, clean combustion of the organic matter-containinghazardous waste and clean combustion of kiln-entering pulverized coal are facilitated, the fire coal can be effectively saved, environmental protection is facilitated, and sustainable development of green, low-carbon and circular economy is facilitated.

Owner:长沙紫宸科技开发有限公司

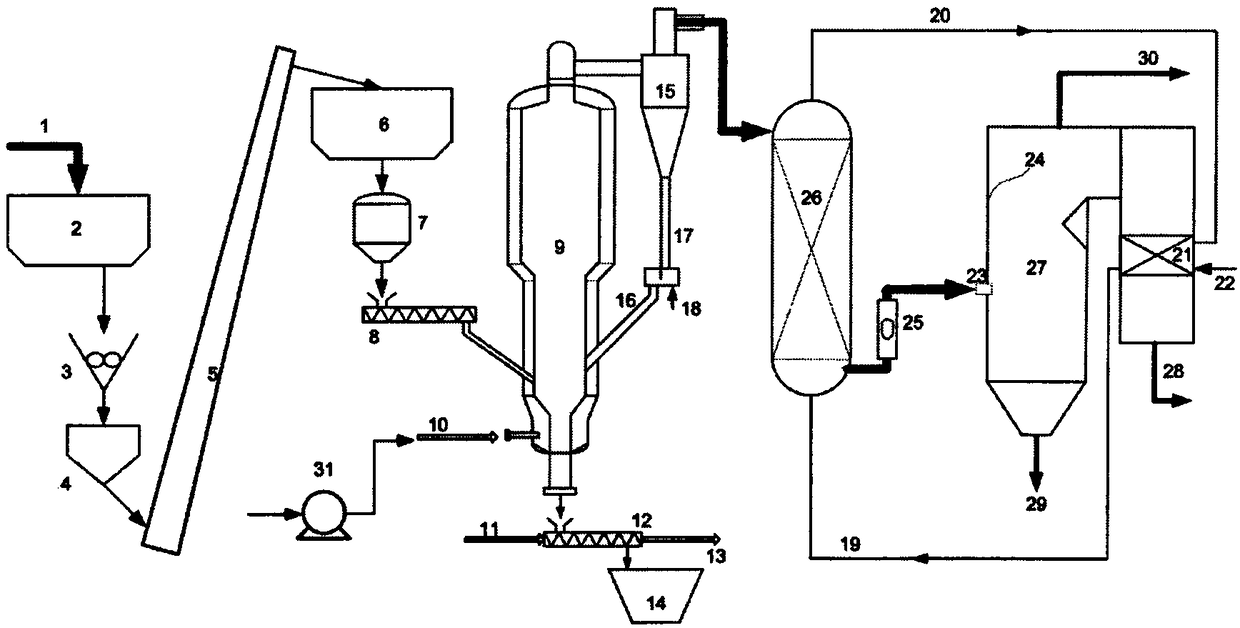

Coupled superfine biomass and coal-fired power generation system and method with flue gas drying and power feeding functions

PendingCN109797006AIncrease profitImprove combustion efficiencyDrying gas arrangementsSolid fuel combustionEngineeringBiomass fuels

The invention belongs to the technical field of coupled biomass and coal-fired power generation, relates to a coupled superfine biomass and coal-fired power generation system and method with flue gasdrying and power feeding functions, and is intended to solve the safety problems that, for instance, the coupled biomass gasification and coal-fired power generation technique has complex gasifier structure, high operation control difficulty, high input cost and valve blockage due to coke separation. The system herein comprises a biomass particle preparation system, a biomass particle conveyer system and a biomass particle combustion and flue gas purification system; superfine biomass fuel prepared by the biomass particle preparation system is conveyed into a coal-fired boiler via the biomassparticle conveyer system; part of the flue gas from the coal-fired boiler is delivered to the biomass particle preparation system for delivery and drying of the superfine biomass fuel, and the other part of the flue gas is used for heating air required by combustion of the fuel; the flue gas is discharged before passing through the flue gas purification system. The system and method herein are significant to the enhancement of enterprise economic benefit and surviving capacity.

Owner:HARBIN BOILER

Sintering flue gas denitrifying agent and preparation method thereof

InactiveCN106178862AEasy to lockSave coalGas treatmentDispersed particle separationPyrolusiteFlue gas

The invention provides a sintering flue gas denitrifying agent and a preparation method thereof. The sintering flue gas denitrifying agent is prepared from the following raw materials in percentage by weight: 10-20 percent of sludge, 5-10 percent of pulverized fuel ash, 0.5-1 percent of ammonium salt, 0.5-1 percent of lanthanum nitrate, 0.02-0.1 percent of phosphorus oxide, 15-30 percent of pyrolusite powder and the balance of water. The preparation method comprises the following steps: weighing the sludge, pulverized fuel ash, ammonium salt, lanthanum nitrate, phosphorus oxide, pyrolusite powder and water according to proportion; and mixing and stirring to form a pasty material. The denitrifying agent is high in denitrification efficiency and long in operation time.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

Method for producing silicate clinker by replacing silicon-aluminum raw material ingredients with modified coal gangue

InactiveCN111704375ASolve the pollution problemReduce consumptionCement productionClinker (cement)Materials science

The invention discloses a method for producing silicate clinker by replacing silicon-aluminum raw material ingredients with modified coal gangue. The method comprises the following steps of: (1) modifying coal gangue; (2) preparing raw material powder from the modified coal gangue instead of a silicon-aluminum raw material, and carrying out pre-decomposition; and (3) adjusting the use amount of tailings, oxidizing and calcining. According to the invention, the problem that the working condition stability of the kiln system is influenced by serious crusting and sticking of the kiln system due to the characteristics of the raw coal gangue can be solved, so that large-scale consumption of the coal gangue by cement enterprises is facilitated, and the problem of environmental pollution caused by coal gangue accumulation is solved.

Owner:长沙紫宸科技开发有限公司

Power station boiler system and method for increasing tail fume temperature of power station boiler by integrating supplemental combustion for biomass gasification

InactiveCN107255269AIncrease smoke temperatureSafe and stable operationGas treatmentDispersed particle separationPower stationCombustion

The invention discloses a power station boiler system and a method for increasing the tail fume temperature of a power station boiler by integrating supplemental combustion for biomass gasification. According to the method, one or more fixed bed biomass gasifiers are additionally arranged, the gasifiers maintain the rated loads to continuously and stably operate, and hot primary air of the boiler is used as a gasification agent to promote the gasification efficiency of the gasifiers and increase the heat value of gasified gas; when the boiler operates with the low load, the biomass gasified gas is delivered into a flue behind a coal economizer or a steering fume chamber in front of the coal economizer, and the fume temperature at an outlet of the coal economizer is increased through supplemental combustion of the biomass gasified gas, so that a selective catalytic reduction fume denitration system operates safely and stably; supplemental-combustion gas is reduced correspondingly along with increasing of the loads, and the reduced gasification gas for supplemental combustion is delivered into the upper portion of a hearth so as to be combusted, and when the boiler operates with the full load, all the biomass gasified gas is delivered into the upper portion of the hearth so as to be combusted; and supplemental-combustion temperature increasing of the tail fume of the power station boiler is finally achieved through biomass resources, and meanwhile, the biomass resources can be further efficiently used for power generation.

Owner:GUODIAN SCI & TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com