Softener for station boiler sediment incrustation and two-stage incrustation-removing method

A power plant boiler and softener technology, which is applied in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as long cleaning time and affecting power generation production, and achieve real and effective results. Considerable economic value and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

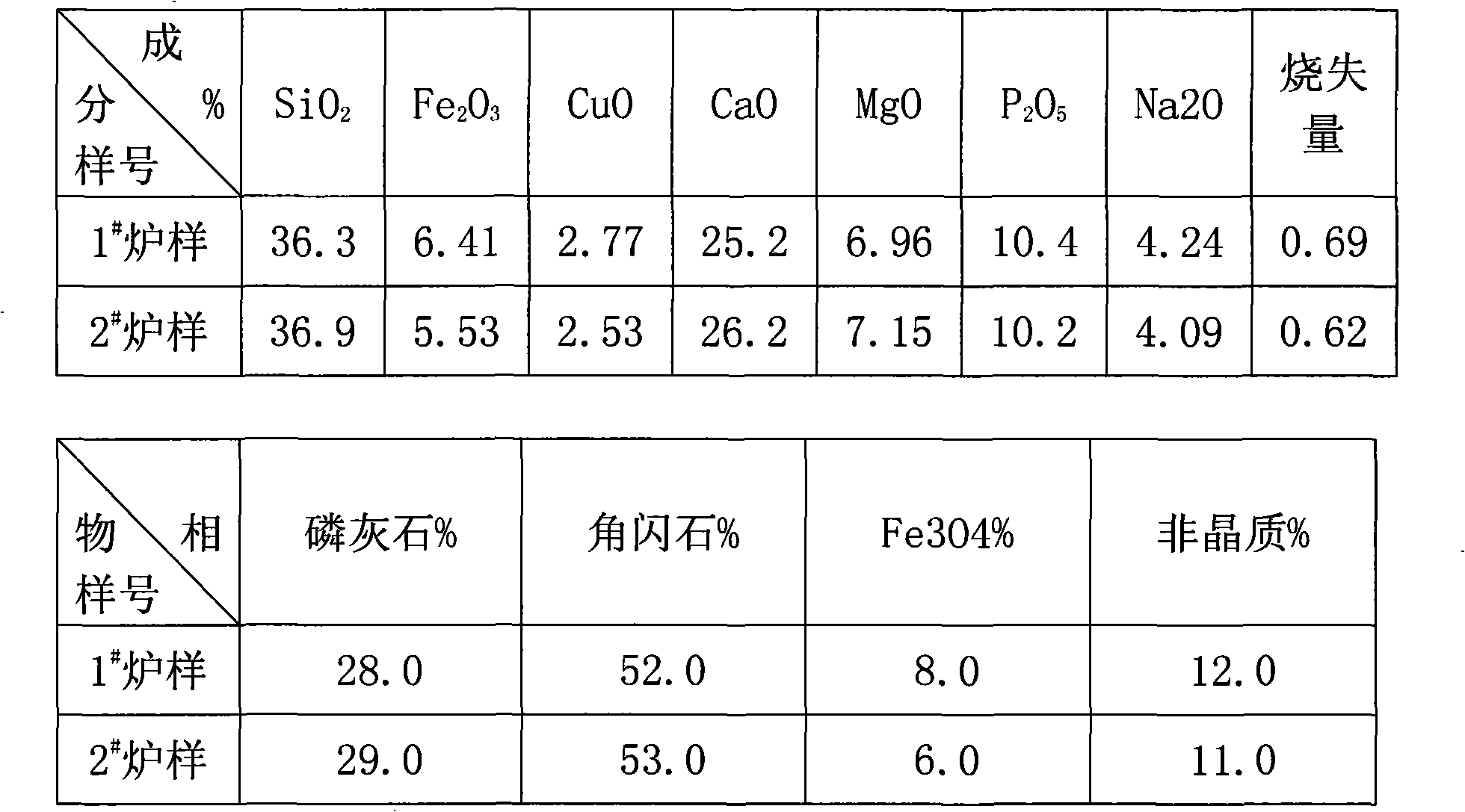

[0029] A large-scale joint venture in Guangzhou, two B&WB35 / 3.8-M power generation boilers, one was put into operation in 1995 and the other was put into operation in 1997. It has never been cleaned since it was put into operation, and gray-black scale with a thickness of 1 to 3 mm is formed on the heating surface. , the scale is mixed with black organic matter, which is very hard and adheres tightly. The results of scale analysis are shown in Table 1.

[0030] Table 1 Analysis and detection results of scale samples

[0031]

[0032] From the analysis results of the scale samples, it can be seen that the scale formed by the two power plant boilers contains SiO 2 It is more than 36%, converted into silicate, its amount is more than 50%, which is a typical silicate difficult scale, and most of the scale has formed hornblende crystals, which are very hard and difficult to remove.

[0033] Then can effectively remove with technical method of the present invention, its way is: ...

Embodiment 2

[0044] A HG212-75 / 3.8 power generation boiler in a power plant of an iron and steel company in Kunming has not been cleaned since it was put into production. Difficult scale with a thickness of 1.5 to 3 mm has formed on the heating surface. After cleaning with the present invention, the effect is very good. The inspection and acceptance by the boiler inspection department shows that the quality is superior to the standard requirements of the "Boiler Chemical Cleaning Rules", and is well received by users (see user report, acceptance report).

[0045] The specific method is:

[0046]The first step is to add the following descaling and softening agent in the mass ratio to pH=12±0.3 during the operation of the boiler, and maintain the pH value so that the boiler water can run for 5 to 7 days under normal blowdown conditions, and then stop the boiler, and the original scale has disappeared. Transformation, partly eluted:

[0047] Sodium ethylenediamine tetramethylene phosphonate ...

Embodiment 3

[0056] Feed according to the following formula:

[0057] Sodium ethylenediamine tetramethylene phosphonate 5kg

[0058] Sodium polyacrylate 3kg

[0059] Na 3 PO 4 12H 2 O 40kg

[0060] NaOH 15kg

[0061] Na 2 CO 3 29kg

[0062] Sodium humate 5kg

[0063] Disodium edetate 3kg

[0064] After the above raw materials are fully mixed, the descaling and softening agent product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com