Cleaning fluid for cleaning plasma etching residue

A technology of etching residue and cleaning liquid, which is applied in the field of cleaning liquid, can solve the problems of poor cleaning effect, high corrosion of the substrate, small operating window, etc., and achieve good corrosion inhibition, excellent low temperature resistance, and strong chelation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

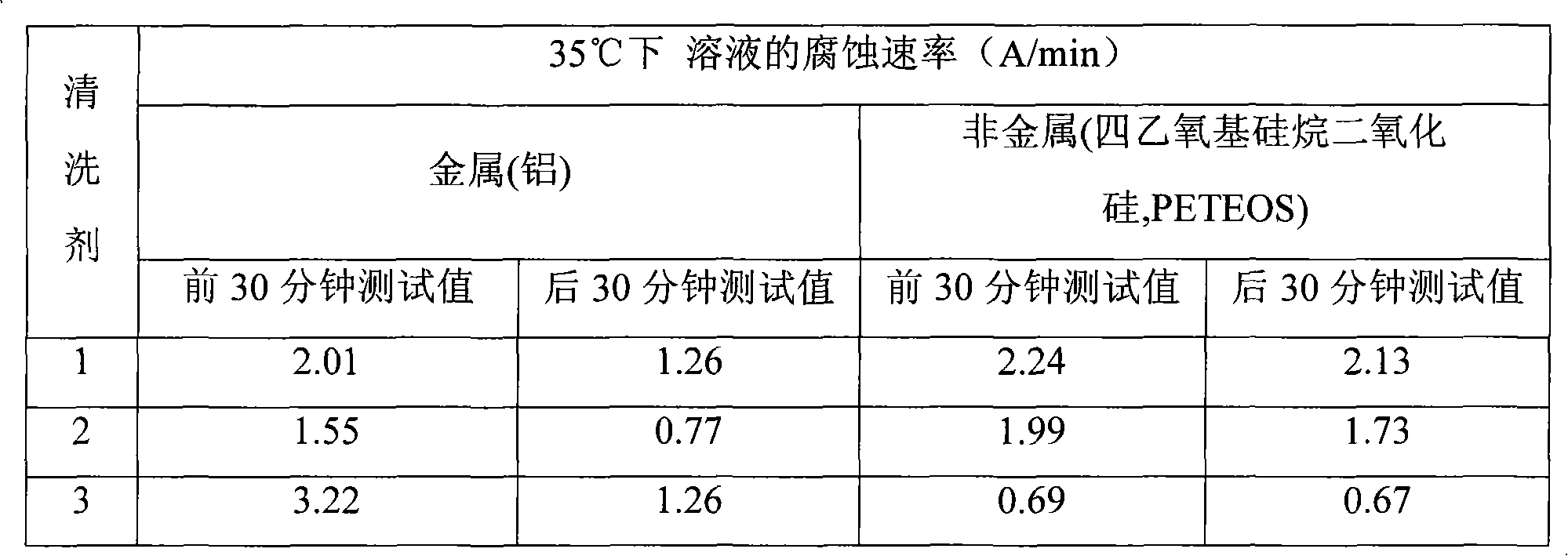

Embodiment 1

[0025] 15 wt% citric acid / ammonium citrate buffered aqueous solution, 0.0001 wt% hydroxyl-containing polyethyl ether (molecular weight 1000), 5 wt% ethylene glycol, 2 wt% ammonium fluoride and 77.9999 wt% sulfolane.

[0026] In the citric acid / ammonium citrate buffer solution, the content of citric acid and ammonium citrate is 5wt% by mass, and the content ratio of citric acid and ammonium citrate is 10:1.

Embodiment 2

[0028] 56wt% citric acid / tetramethylammonium citrate buffered aqueous solution, 1wt% polyvinyl alcohol homopolymer (molecular weight 2000), 1wt% glycerol, 1wt% hydrogen fluoride, 1wt% 2-phosphonic acid butane-1,2,4 - tricarboxylic acid and 40 wt% dimethylsulfoxide.

[0029] In the citric acid / tetramethylammonium citrate buffer solution, the content of citric acid and tetramethylammonium citrate is 60wt% by mass, and the content ratio of citric acid and tetramethylammonium citrate is 1:1.

Embodiment 3

[0031]15wt% citric acid / tetraethylammonium citrate buffered aqueous solution, 1wt% polyvinyl alcohol copolymer (molecular weight, 3000), 1wt% pentaerythritol, 2wt% tetramethylammonium fluoride, 1wt% aminotrimethylene phosphonic acid and 80wt% N - Methylpyrrolidone (NMP).

[0032] In the citric acid / tetraethylammonium citrate buffer solution, the content of citric acid and tetraethylammonium citrate is 10 wt%, and the content ratio of citric acid and tetraethylammonium citrate is 1:30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com