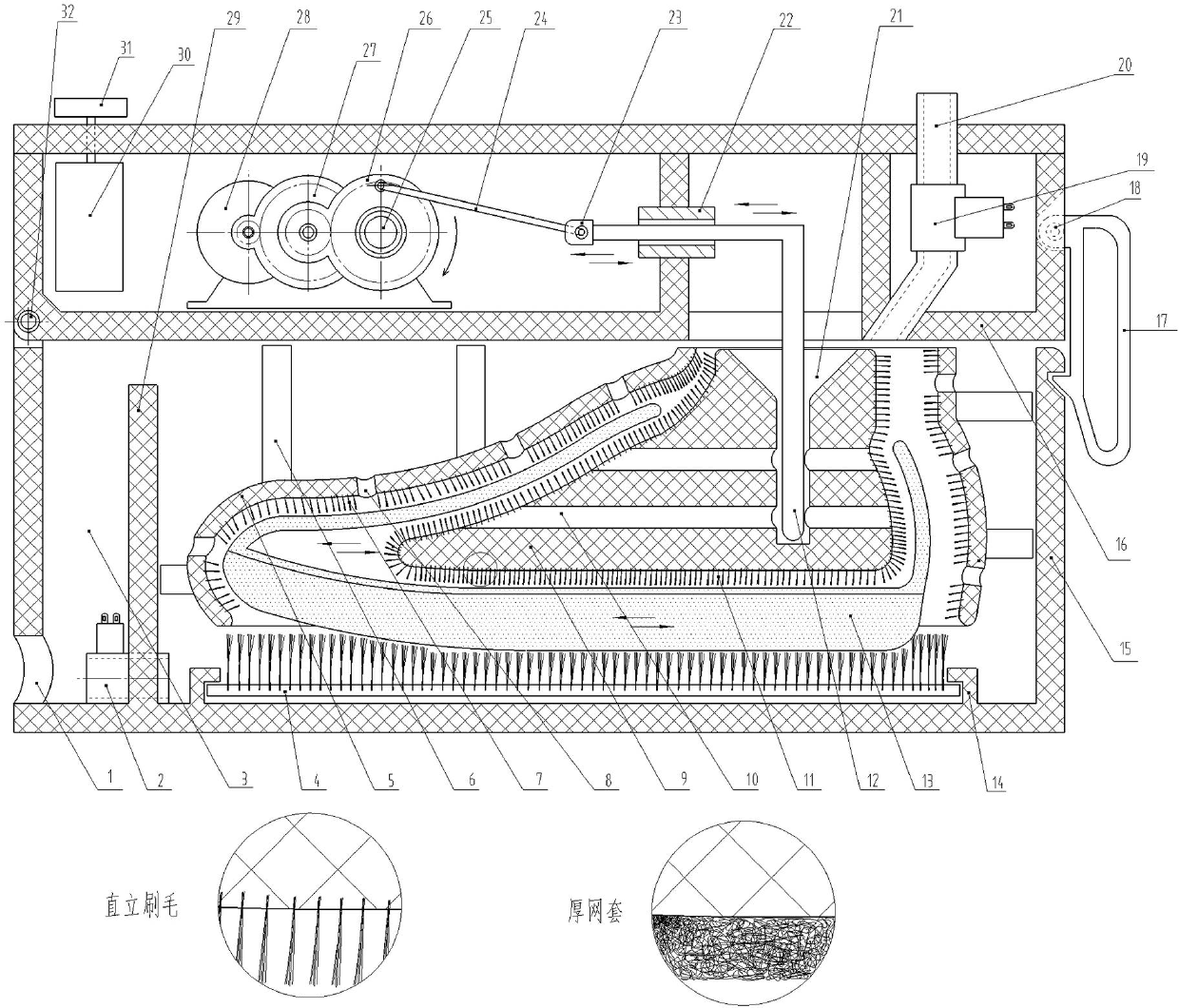

Profiling brush type shoe washing machine

A shoe washing machine and a brush-type technology, applied in the field of shoe washing machines, can solve the problems of small cleaning efficiency, inability to clean shoes thoroughly and effectively, and high production costs, and achieve low production costs, reduce household labor intensity, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

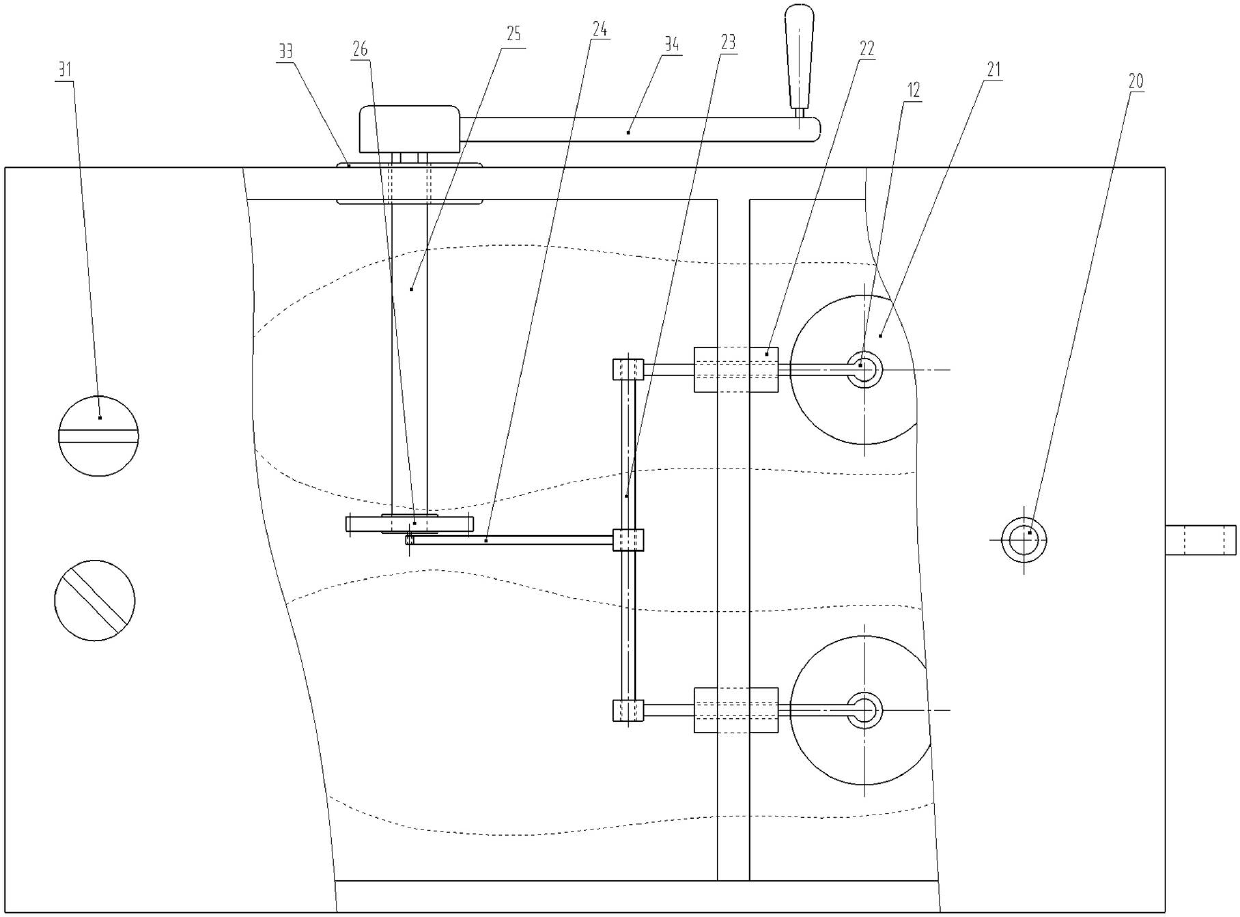

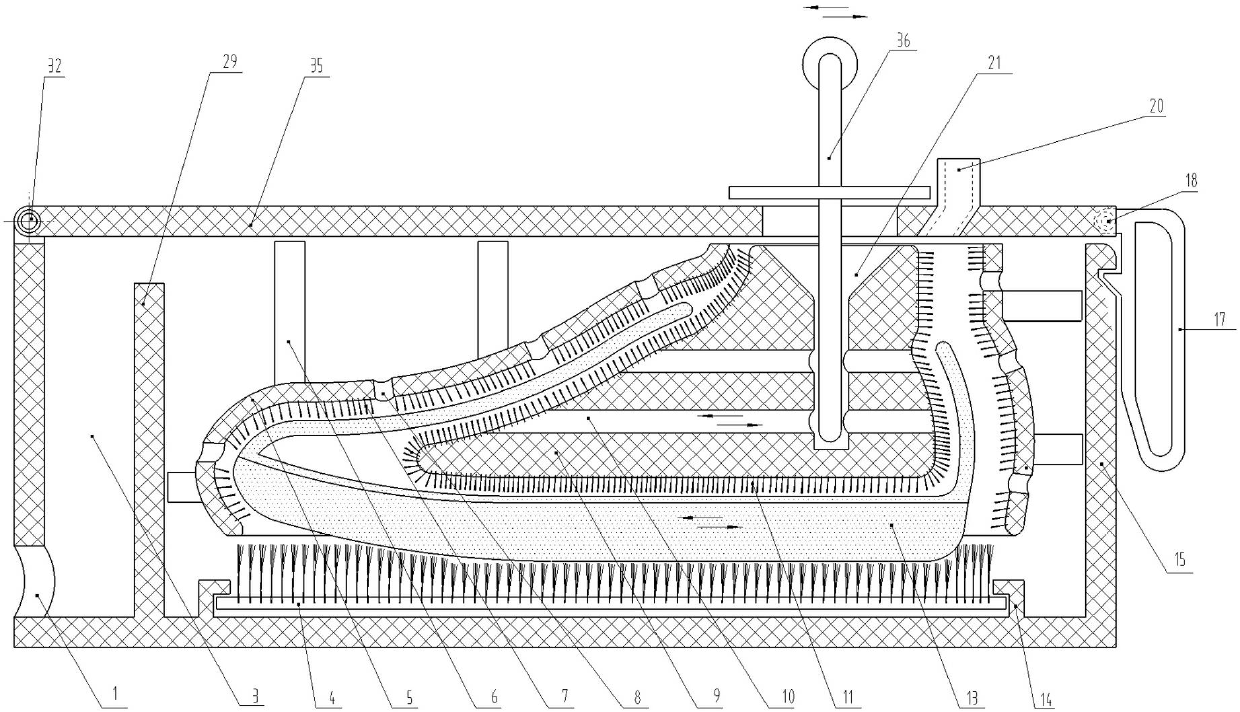

Embodiment 2

[0017] Embodiment 2 is a manual handle scheme, as shown in the accompanying drawings of the description image 3 , Instructions attached Figure 4 As shown, the outer surface of (9) inner profiling brush and the surface in contact with the inner wall of the shoe cover the bristle structure of (11) inner profiling brush, and 3-8 (10) are processed along the toe to heel direction of the inner profiling brush The through hole of the inner profiling brush, the end of the inner profiling brush located at the opening of the shoe is processed with (21) funnel-shaped hole, the inner profiling brush is put into the inside of the shoe (13), and its length is 2-5cm less than the inner length of the shoe to be washed (5) The outer profiling brush is set on the outer surface of the shoe, and the inner length is 2-5cm longer than the outer length of the shoe to be washed. (5) The inner wall of the outer profiling brush in contact with the outer surface of the shoe is covered with (7) The br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com