Method for recovering and reutilizing exhaust waste heat of producing hexa poly sodium metal-phosphate

A technology of sodium hexametaphosphate and waste heat recovery, which is applied in steam generation methods using heat carriers, chemical instruments and methods, phosphorus compounds, etc., can solve problems such as regional environmental pollution, waste of heat energy, and corrosion of tail gas transportation equipment, and achieve The effects of protecting the environment, saving coal, and realizing the development of circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

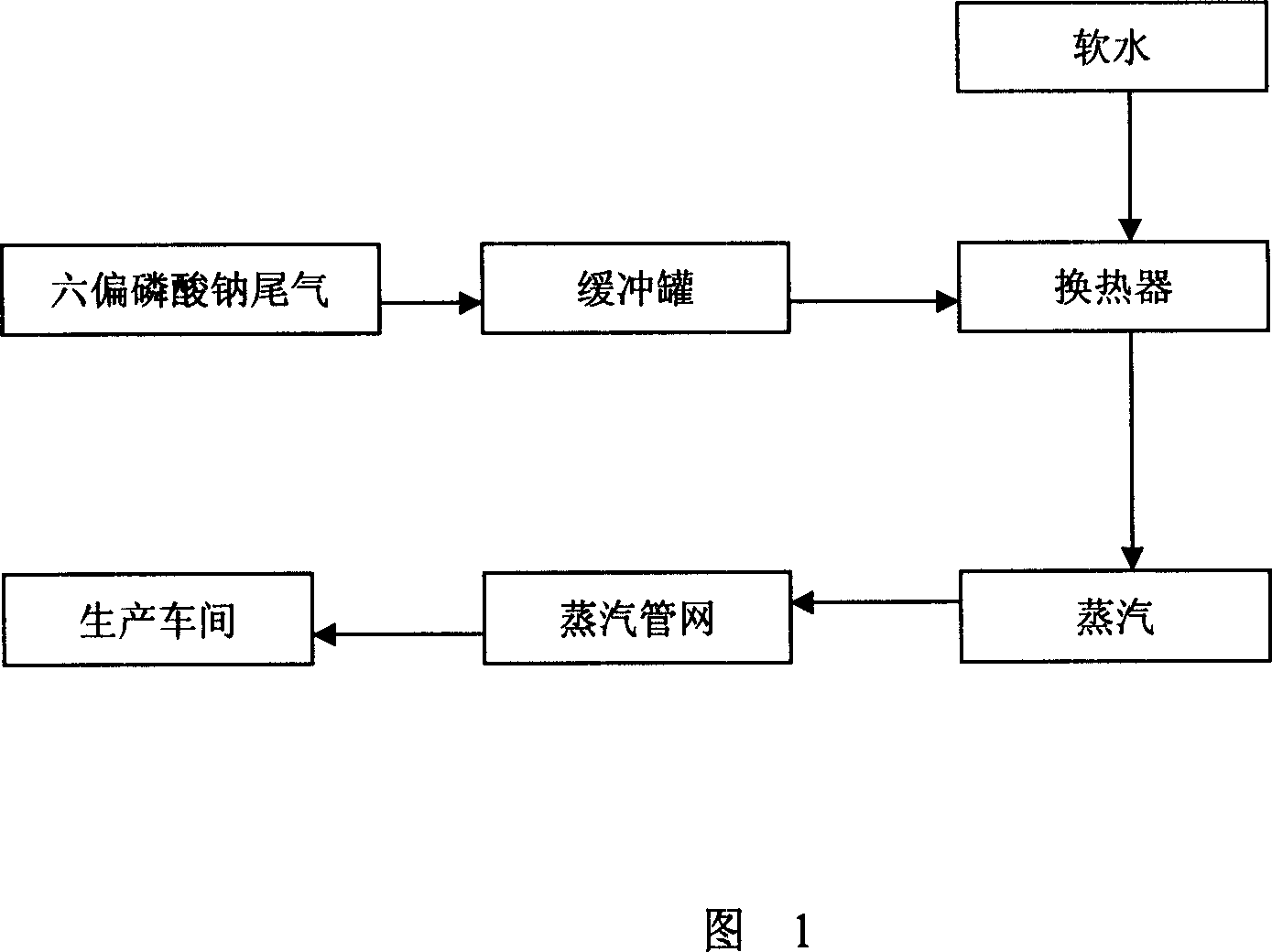

[0009] As shown in Figure 1, a method for recovering waste heat from tail gas produced by sodium hexametaphosphate is to install a waste heat drum on the tail gas pipeline produced by sodium hexametaphosphate, and the waste heat drum is composed of a buffer tank, a heat exchanger Composed of heat pipes, the tail gas with a temperature of 350°C generated during production is transferred to the heat exchanger through the heat pipes in the heat exchanger in the waste heat drum, and the water with a temperature of 20°C is heated to generate water vapor, which produces The steam passes through the steam flow meter and enters the steam pipe network of the factory area, where it is used as heating gas.

[0010] The high-temperature gas from the fusion furnace enters the tail gas flue under the action of the induced draft fan, and then enters the buffer tank. The flue gas from the buffer tank enters the heat exchanger and contacts the heat pipe. The heat of the high-temperature gas pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com