Patents

Literature

39results about How to "Reduced discharge resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

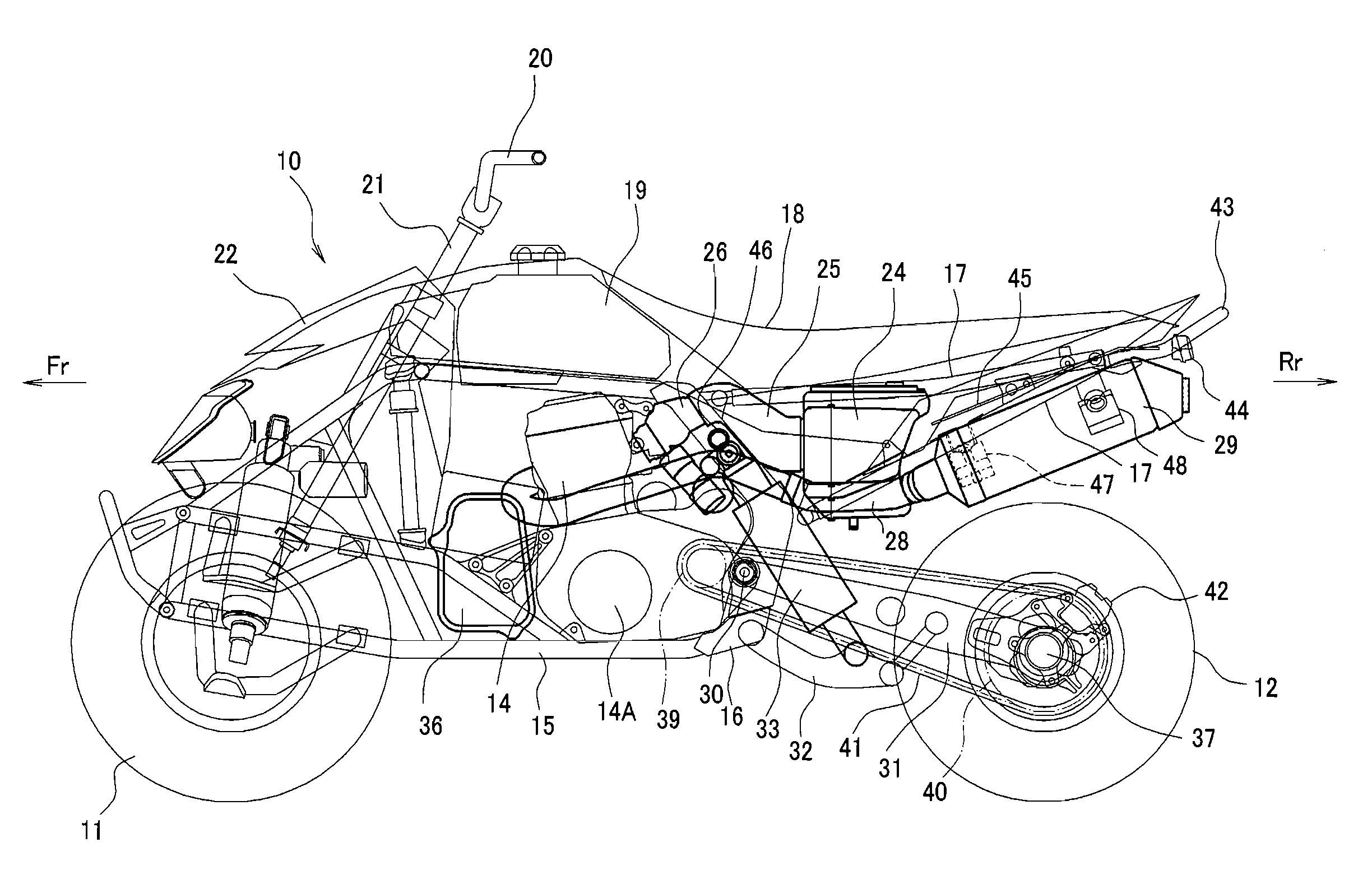

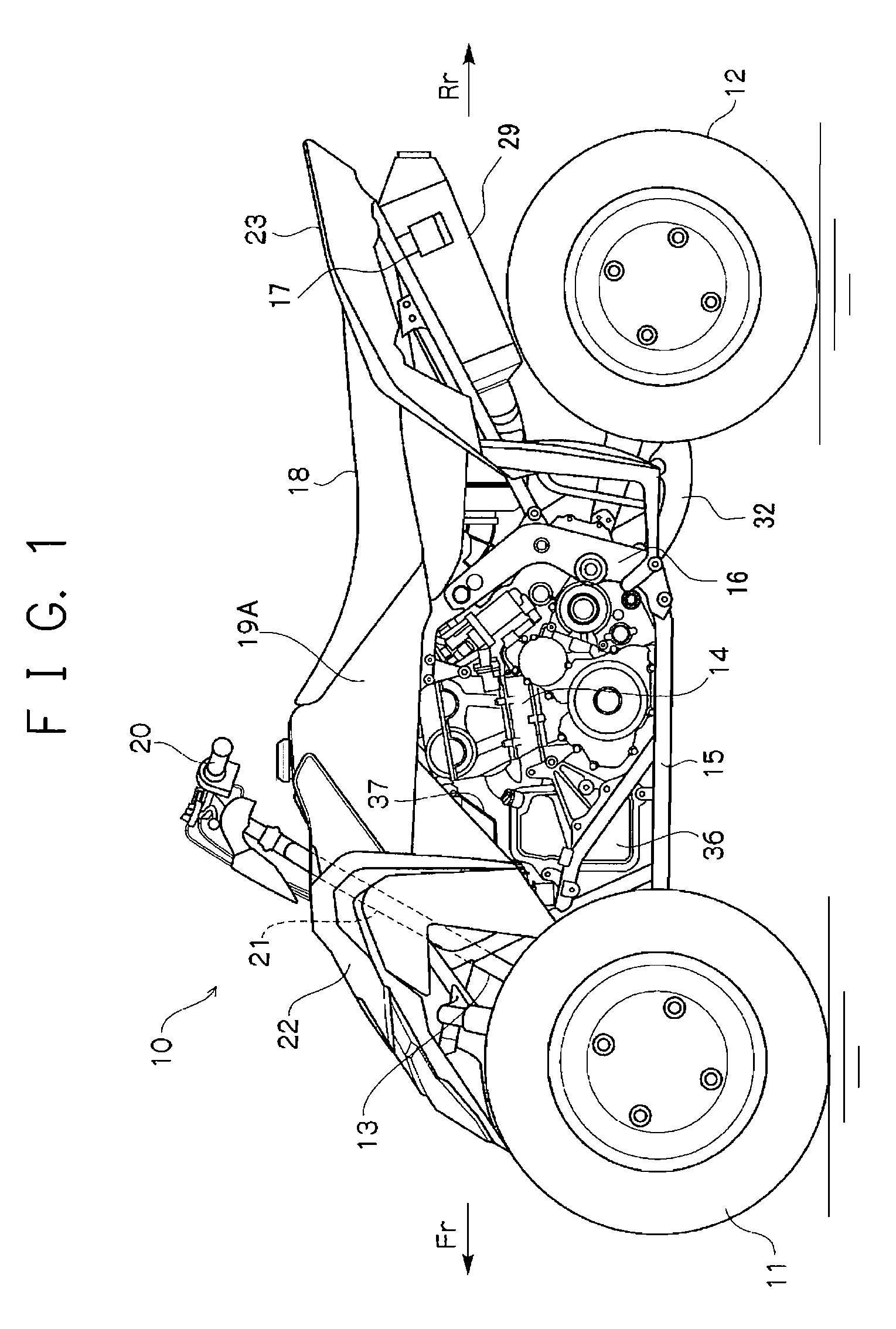

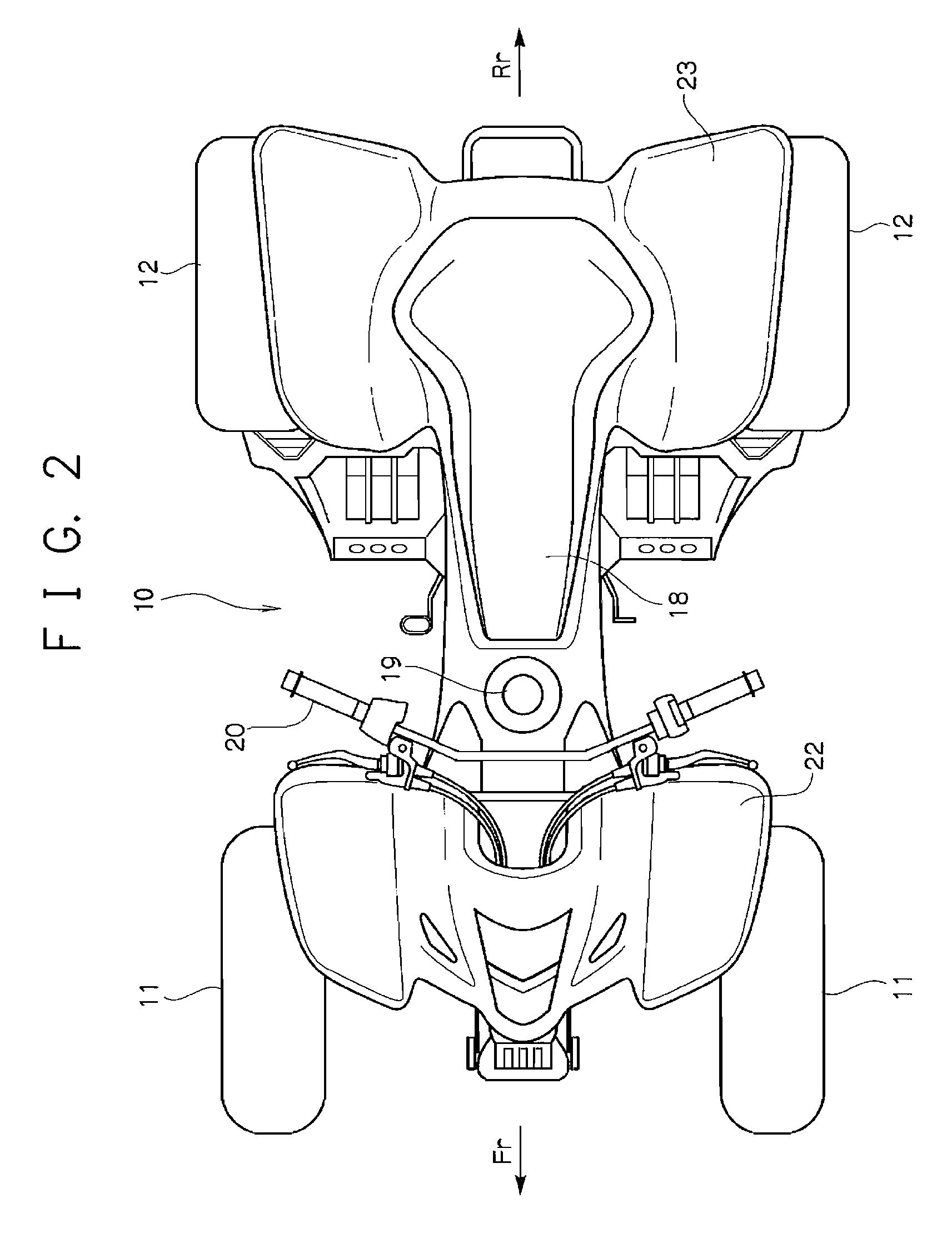

All terrain vehicle

ActiveUS8047324B2Easy to operateIncrease capacityElectric propulsion mountingGas pressure propulsion mountingElectric power transmissionOperational stability

Aiming at providing a straddle-type all terrain vehicle effectively improved in the operational stability of vehicle and engine performance, power transmissions transmitting driving force of a power unit to a rear axle shaft, and braking devices exerting braking force to rear wheels are provided respectively at both side of an end of a rear swing arm in the vehicle width direction, and an exhaust silencer is disposed in a space between the power transmissions and the braking devices, below a seat.

Owner:SUZUKI MOTOR CORP

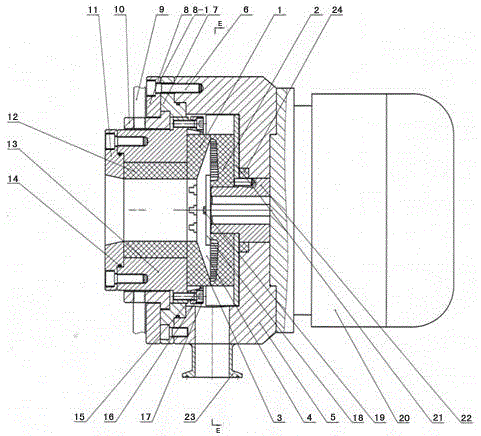

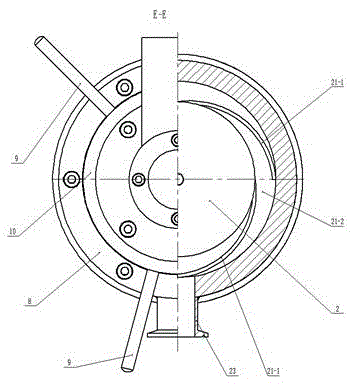

Ceramic pipe grinder for food grinding processing

A ceramic pipe grinder for food grinding processing solves the problems that in the prior art, the idle grinding area is large, the material discharge resistance is large, the grinding efficiency is low, the processing capacity is small, the processing effect is poor, the wear-resisting property of grinding discs is poor, the service life is short, and the application range is narrow. The ceramic pipe grinder is characterized in that a movable grinding disc and a semi-open type vane wheel are installed at the shaft end of a motor shaft extending into a shell, a fixed grinding disc is installed in a fixed grinding disc installation clip clutch, the joint surfaces of the fixed grinding disc and the movable grinding disc inwards form an internally-concave cone-shaped grinding cavity, a fixed grinding disc adjusting seat is connected with an adjusting nut in a threaded mode, the internally-concave conical surface of the fixed grinding disc is provided with symmetrical step-shaped oblique teeth, and the internally-concave plane of the movable grinding disc is provided with material guide grooves and trapezoid teeth. The ceramic pipe grinder for food grinding processing has the advantages that the fixed grinding disc and the movable grinding disc have the synergistic action of extruding, smashing, shearing and grinding on foodstuffs, the wear-resisting property is good, the manufacturing cost is low, the service life is long, the whole machine production efficiency is high, the production capacity is large, and the requirements for ultra-fine processing, dry material slurrying and industrialized continuous production can be met.

Owner:LIAONING YINGGUAN HIGH TECH CERAMIC CO LTD

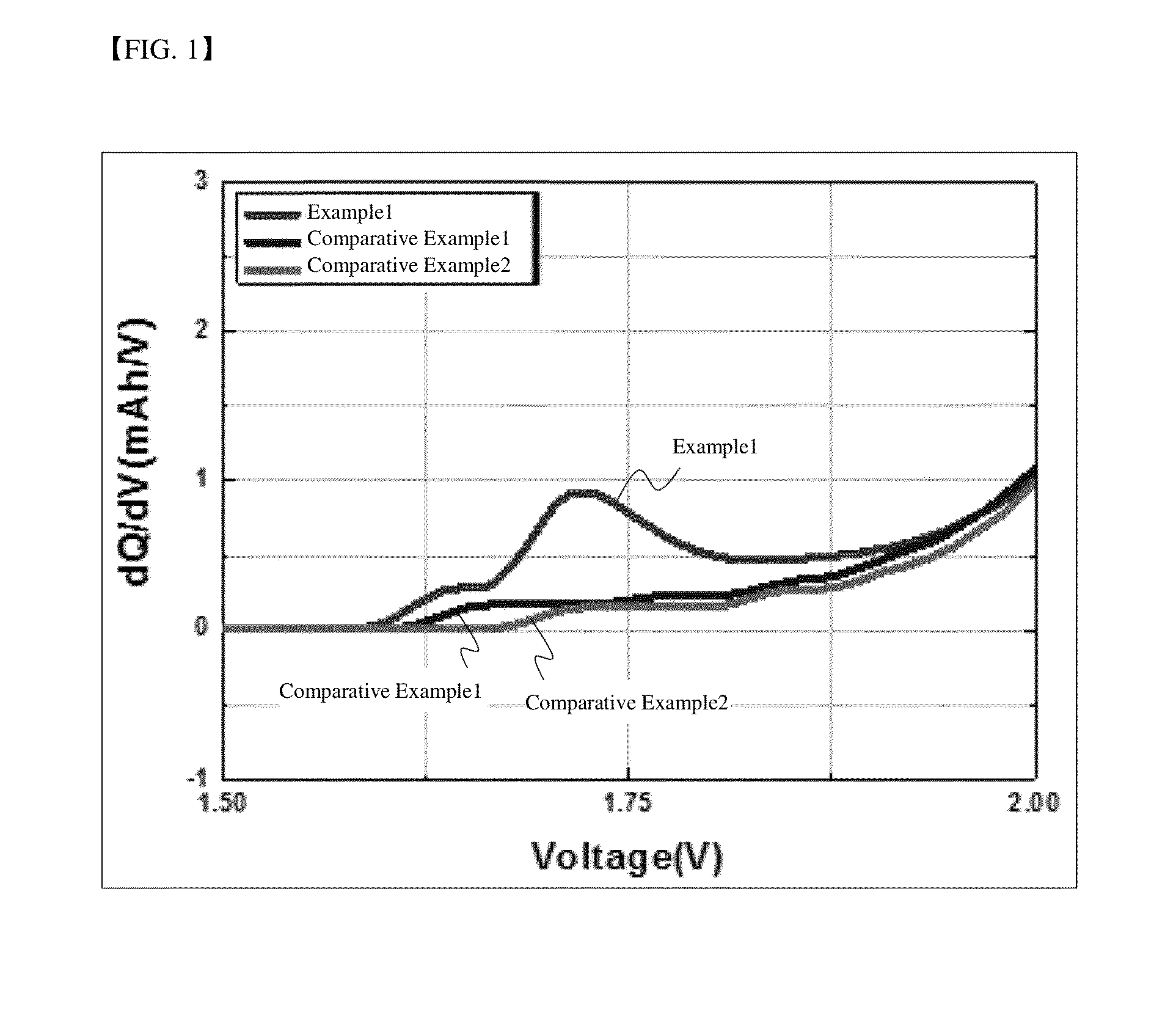

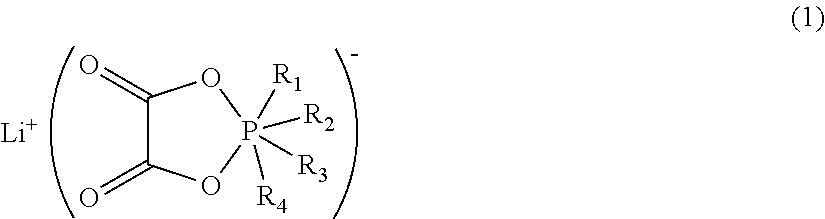

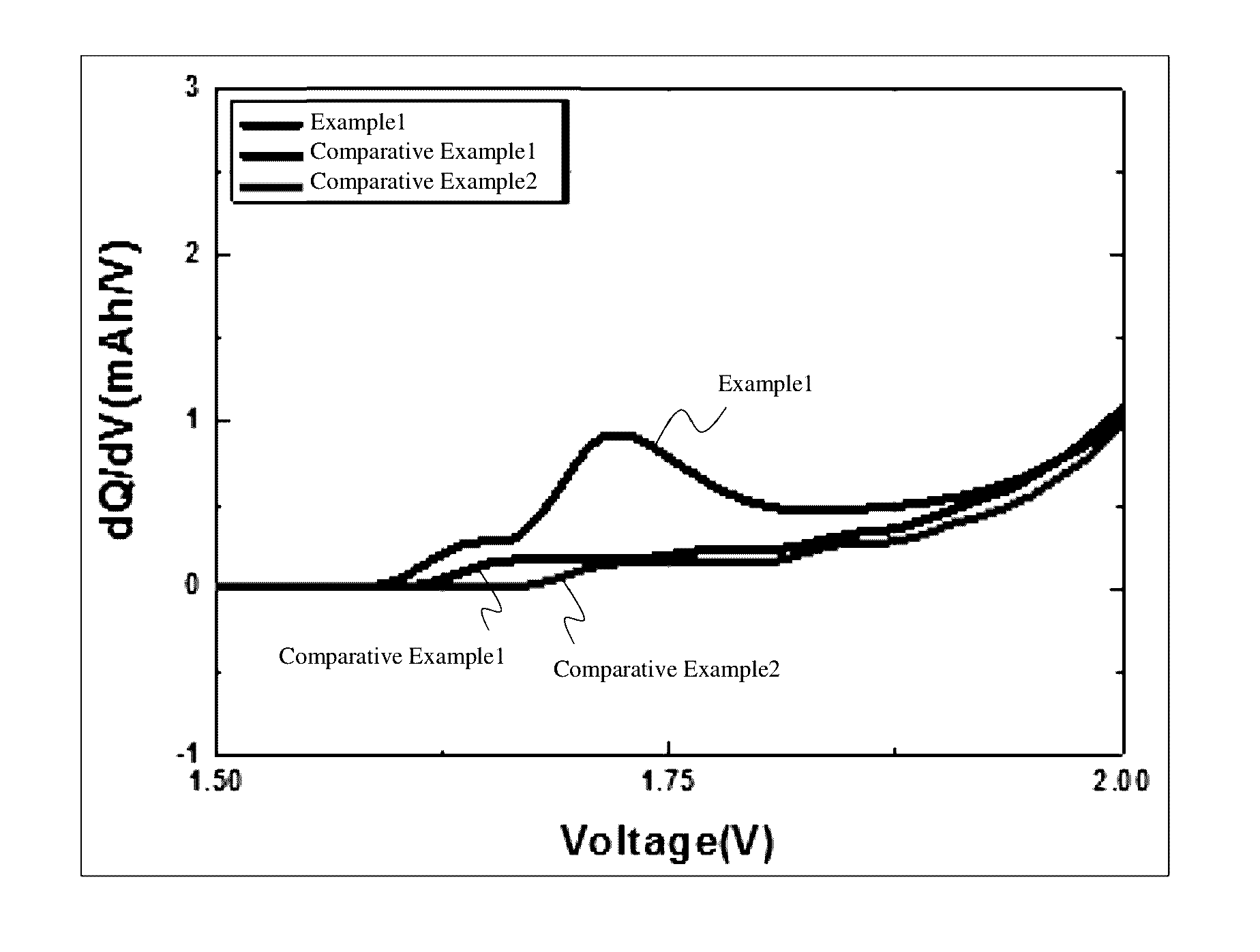

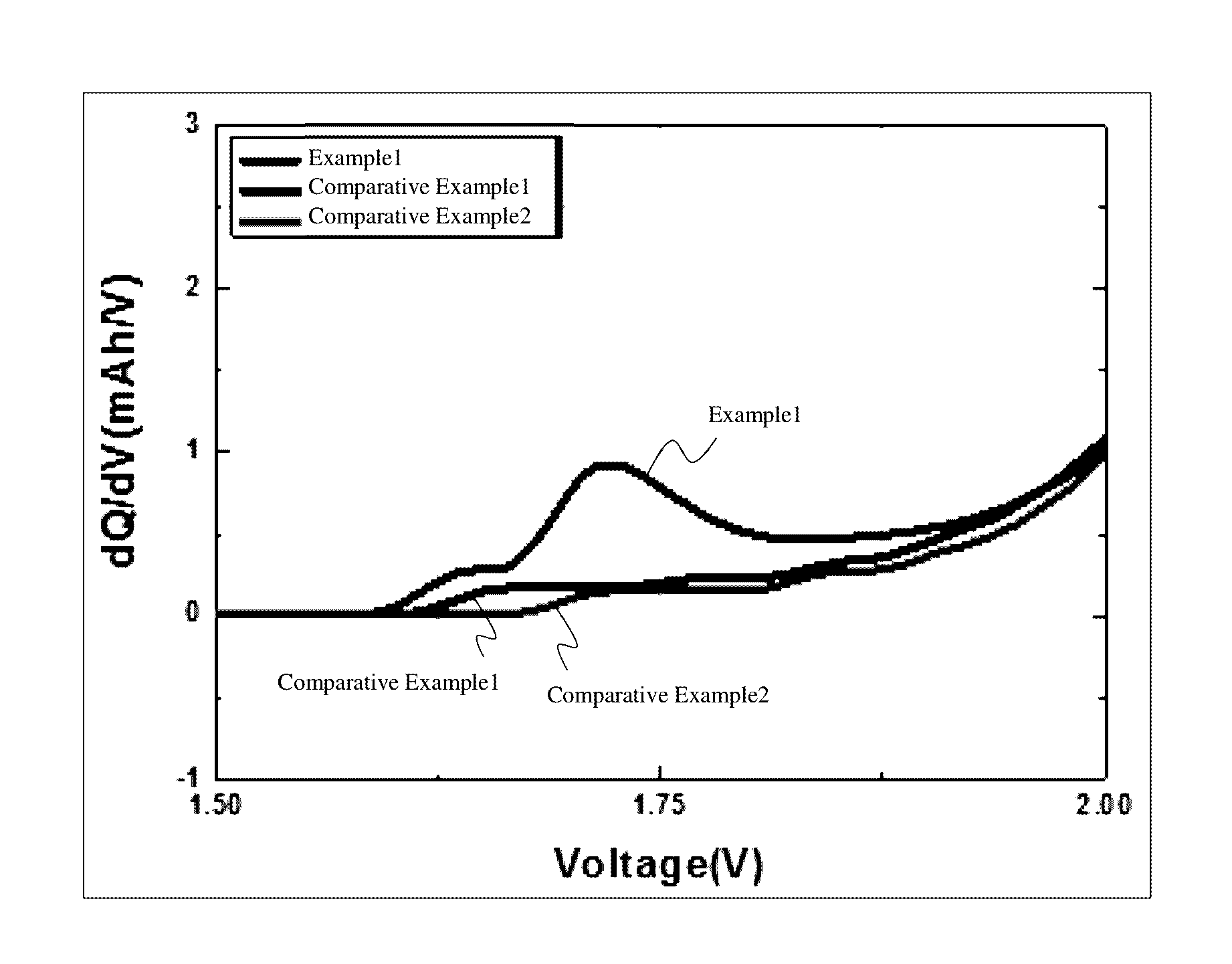

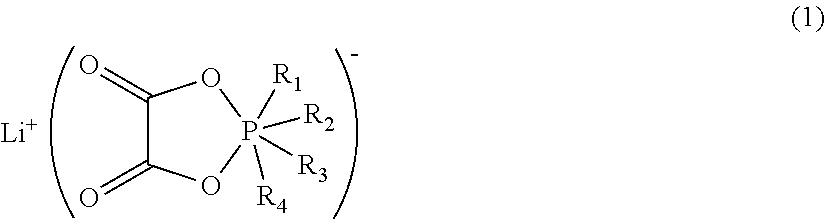

Lithium secondary battery having improved lifespan characteristics

ActiveUS20150086880A1Improve conductivityImprove adhesionCell electrodesOrganic electrolyte cellsSulfonateTitanium oxide

Disclosed is a lithium secondary battery having improved lifespan characteristics. More particularly, a lithium secondary battery comprising a cathode, an anode, a separator interposed between the cathode and anode, and an electrolyte, wherein the anode comprises lithium titanium oxide (LTO) as an anode active material, the electrolyte comprises a lithium salt; a non-aqueous-based solvent; and (a) a phosphate compound which can prevent gas generation during high-temperature storage, (b) a sulfonate compound which can reduce discharge resistance by forming a low-resistance SEI layer, or a mixture of the compound (a) and the compound (b), is disclosed.

Owner:LG ENERGY SOLUTION LTD

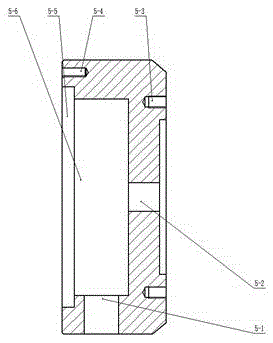

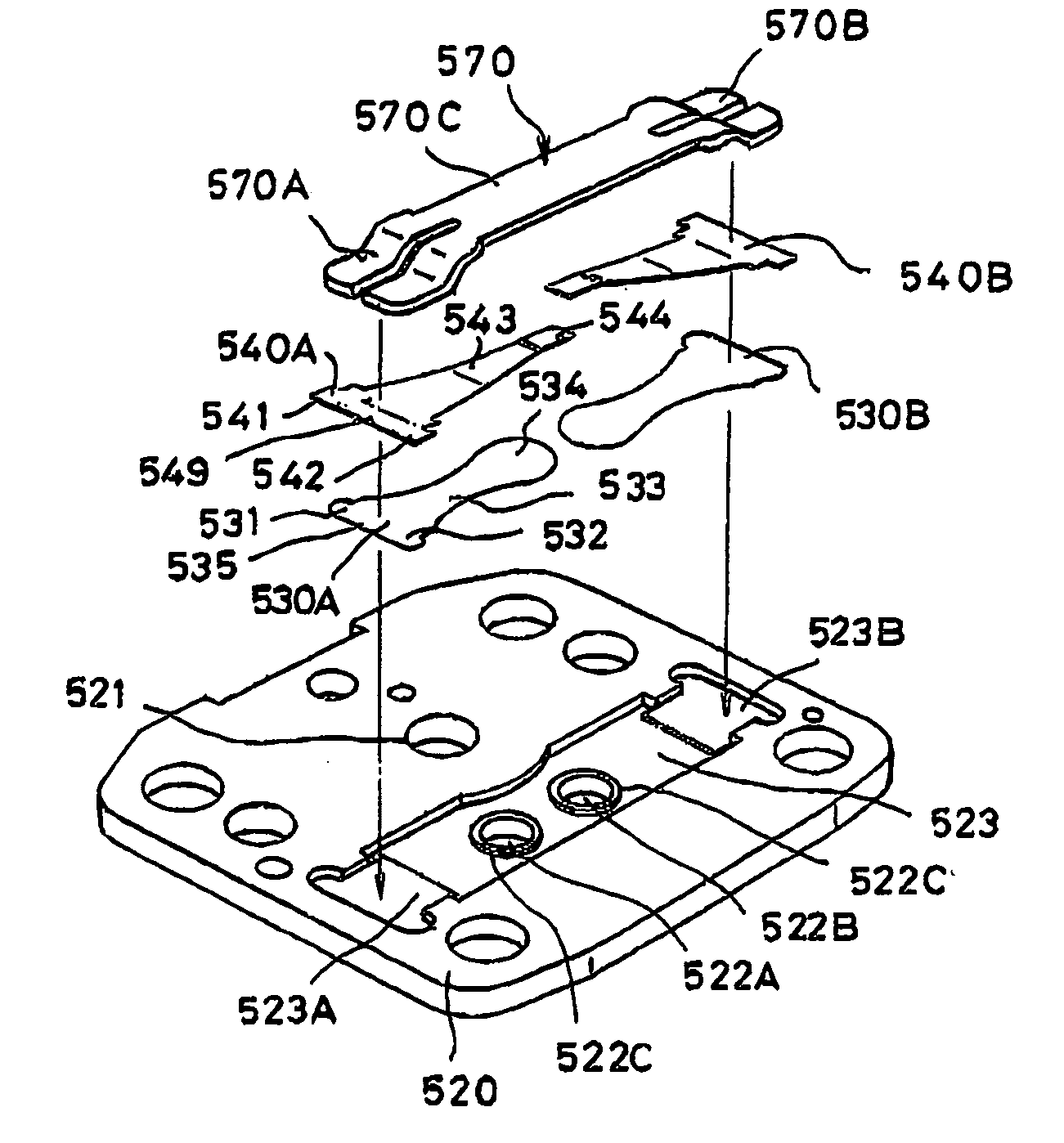

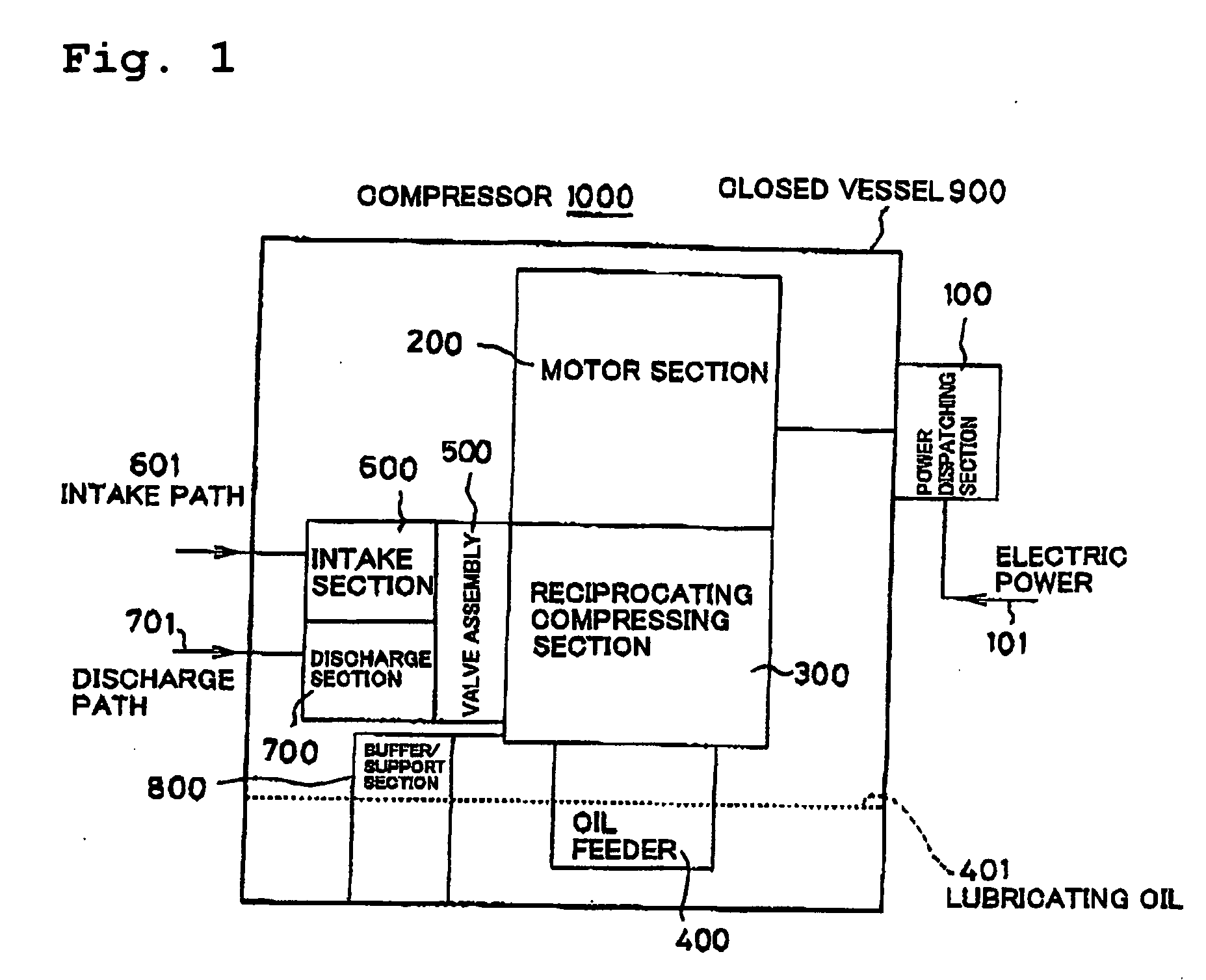

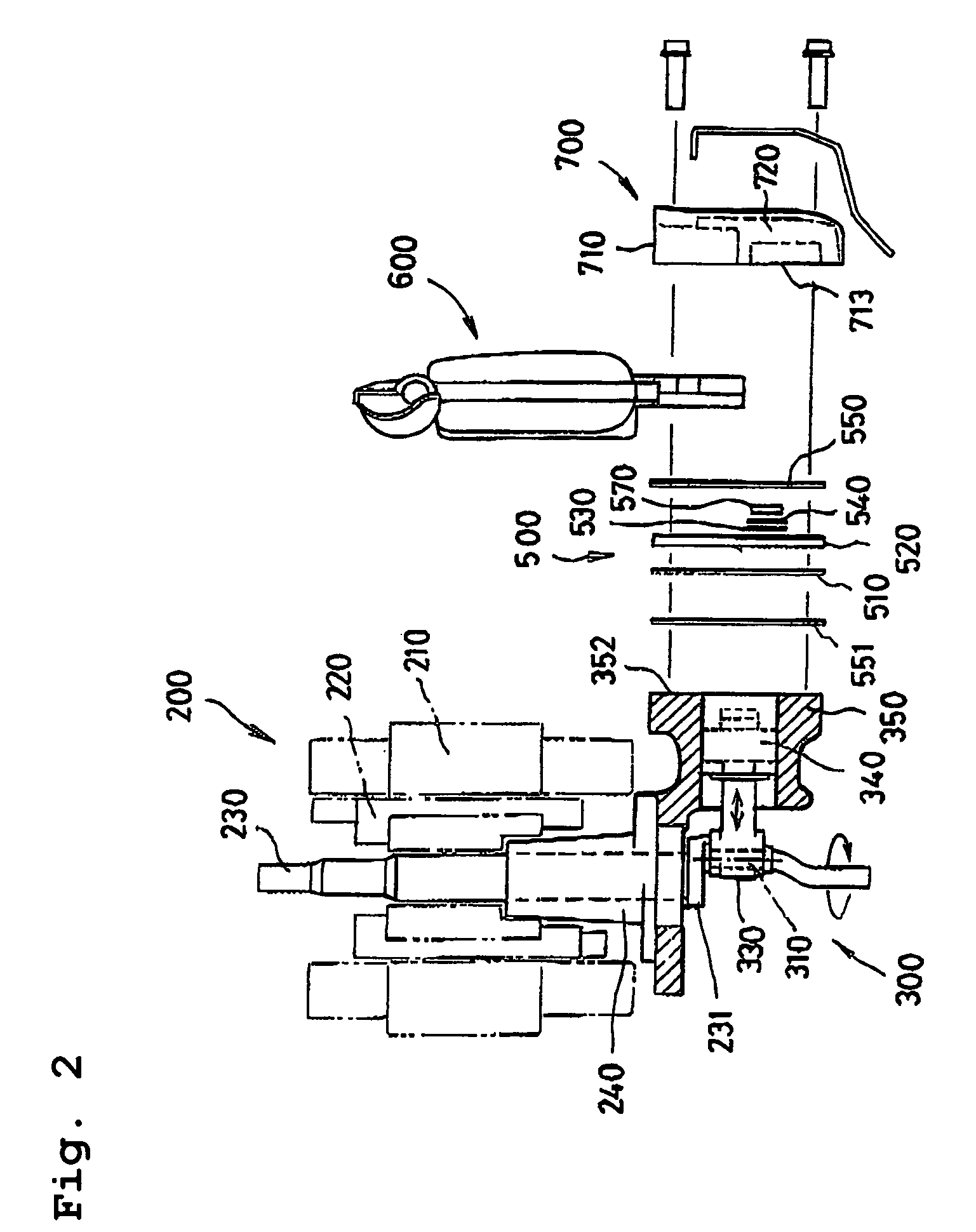

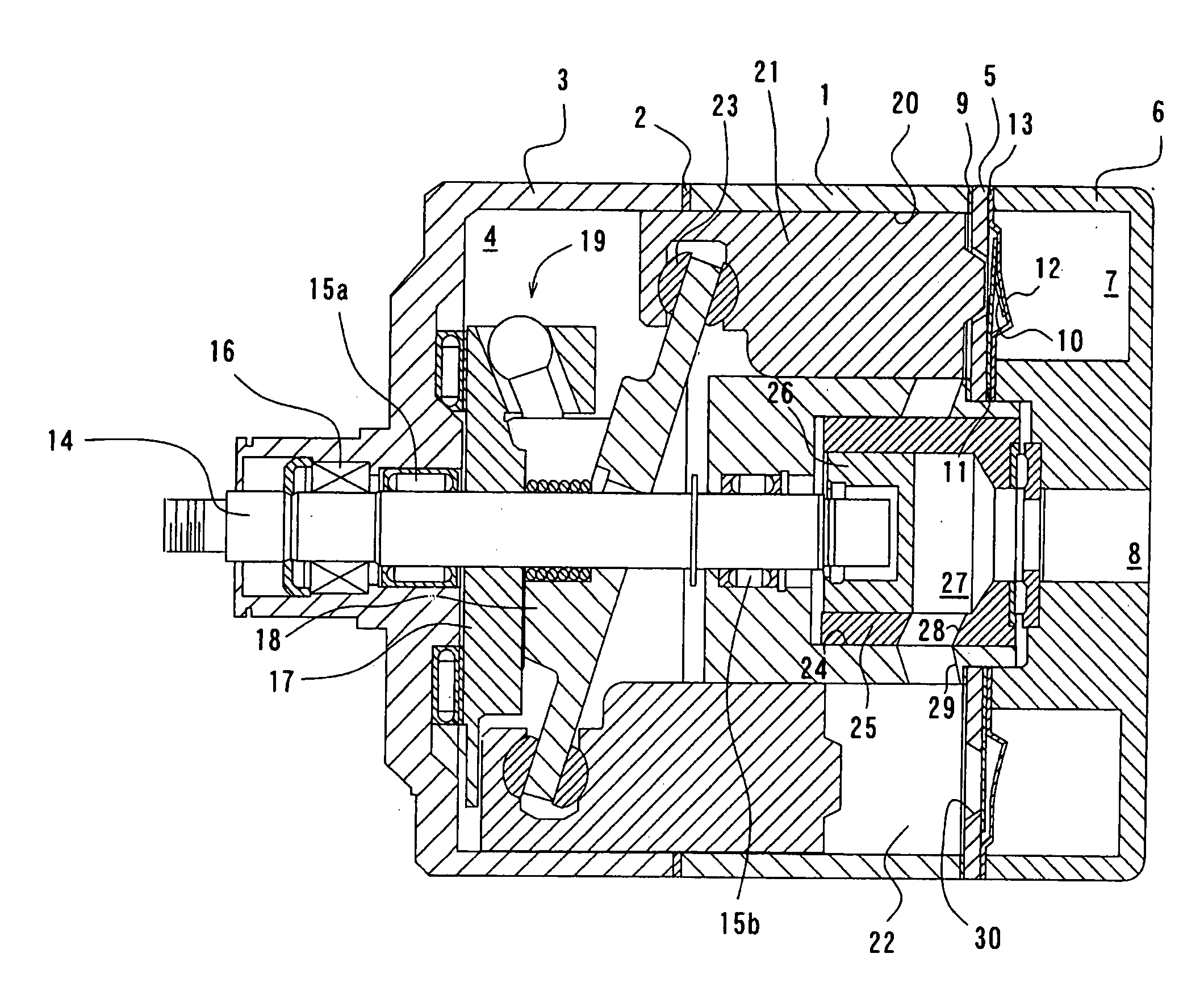

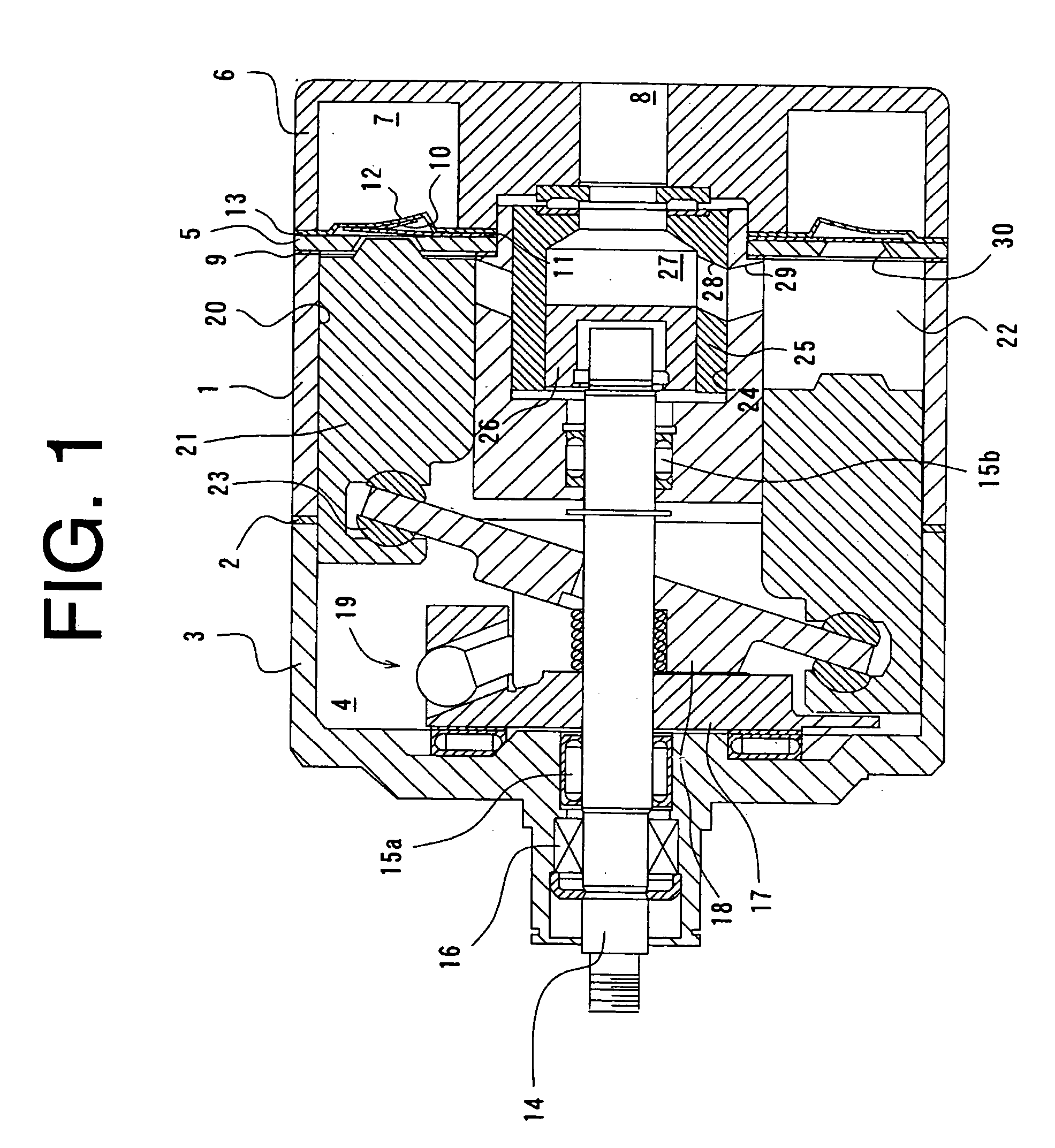

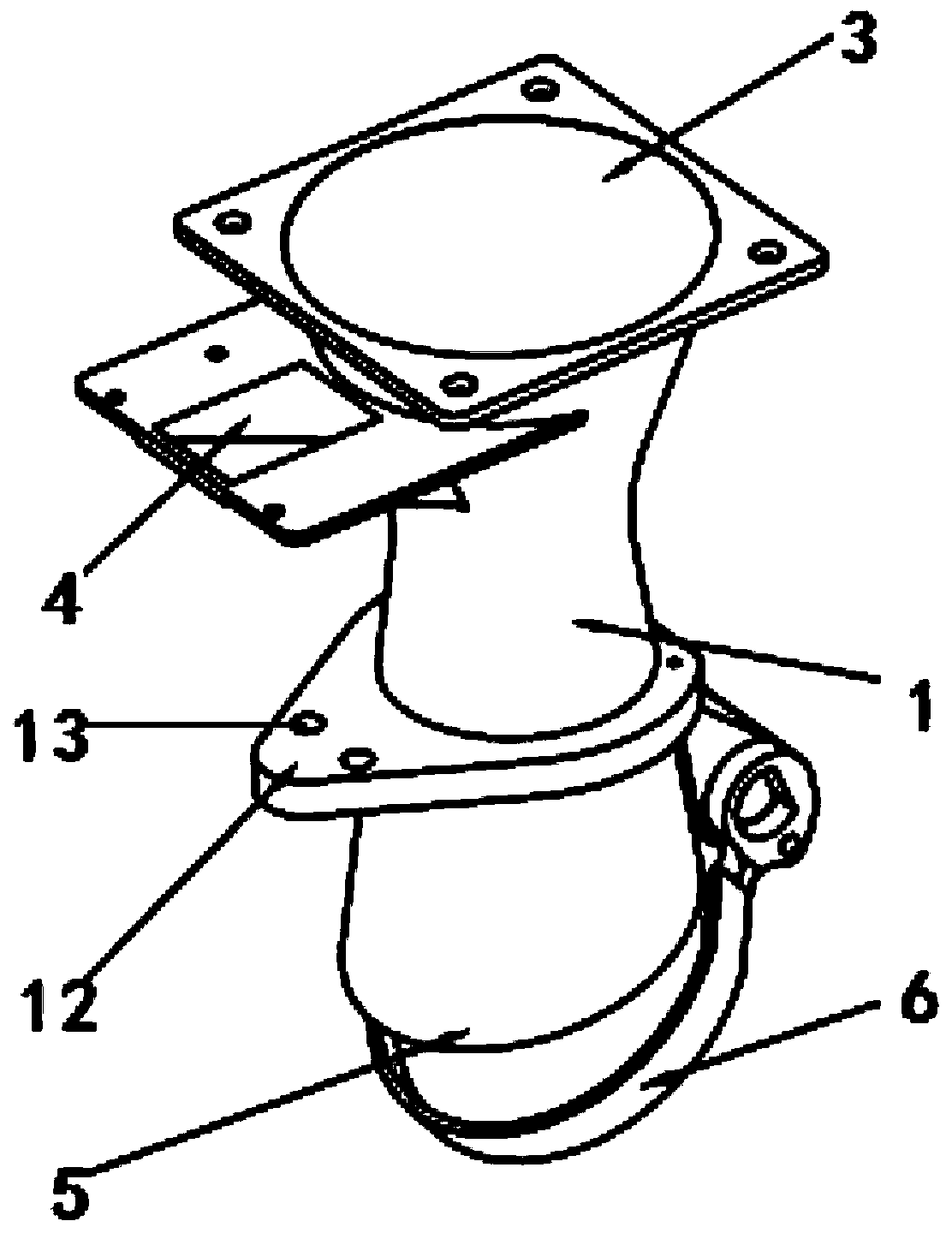

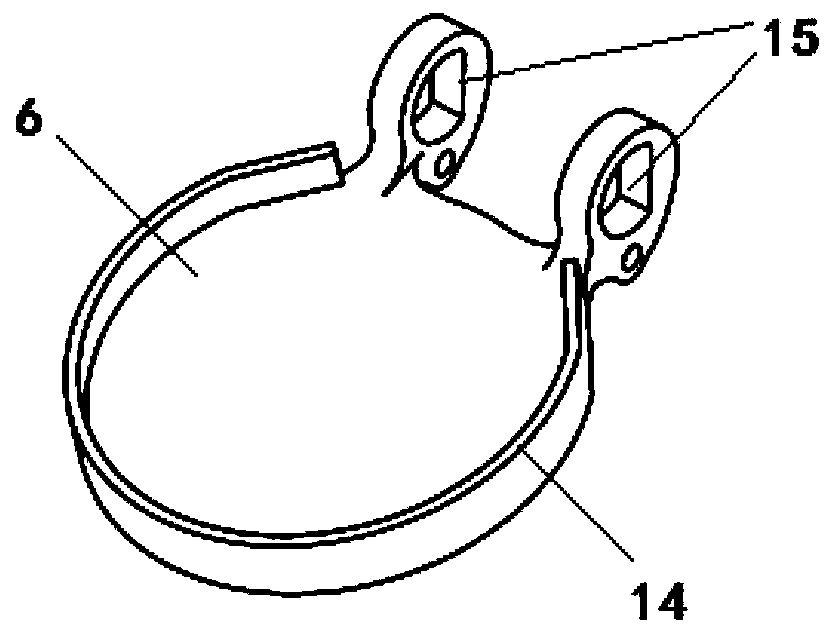

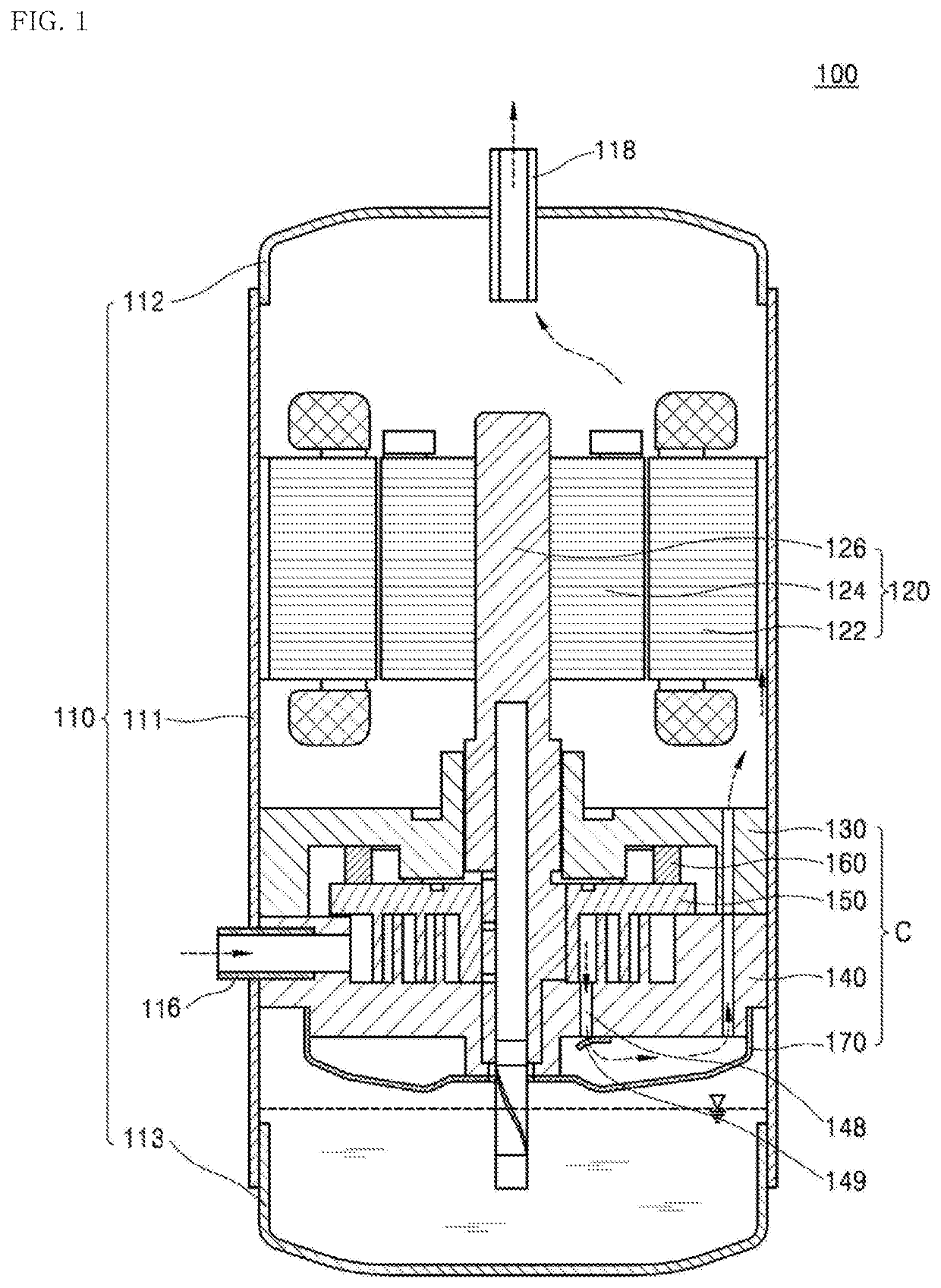

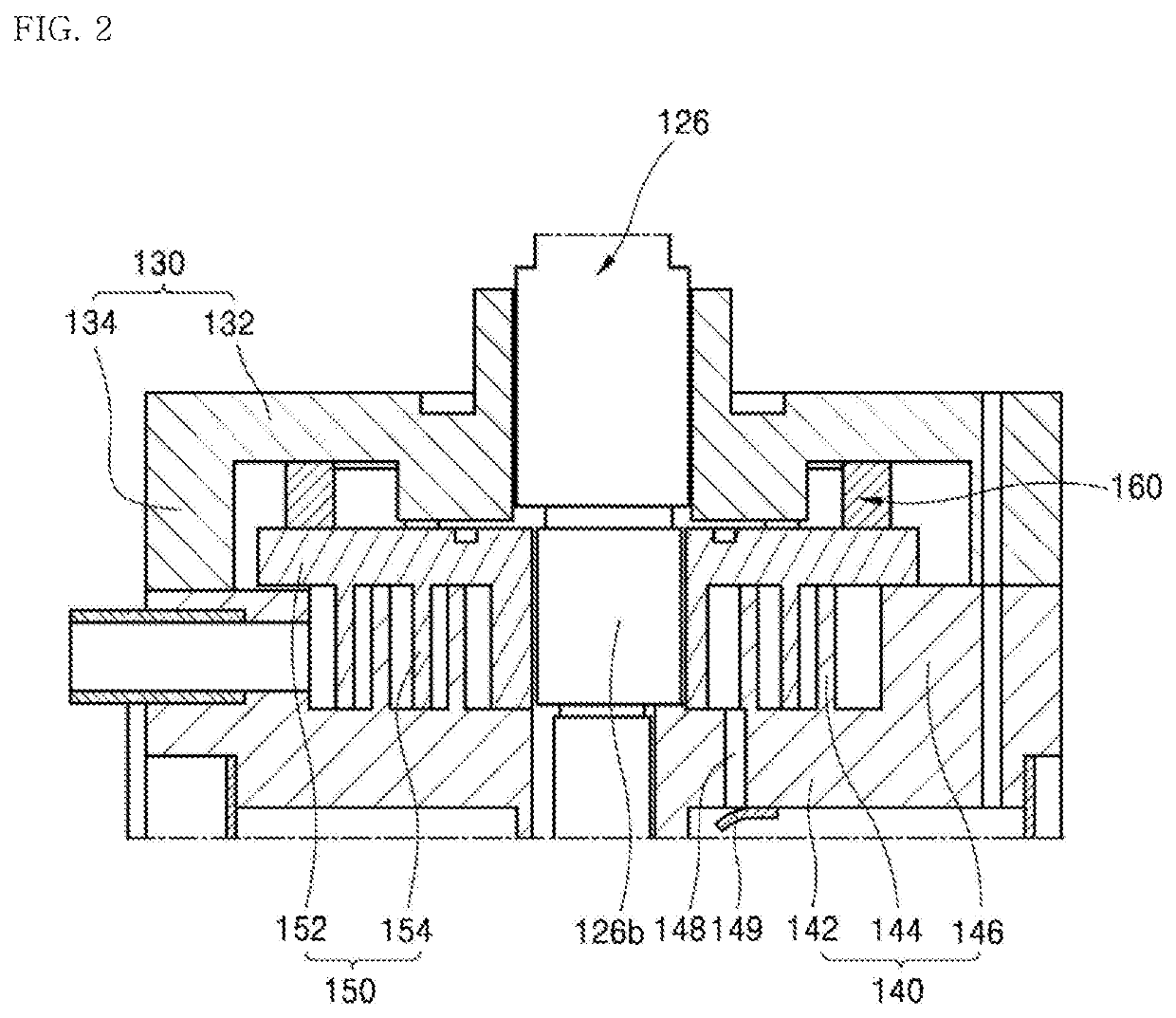

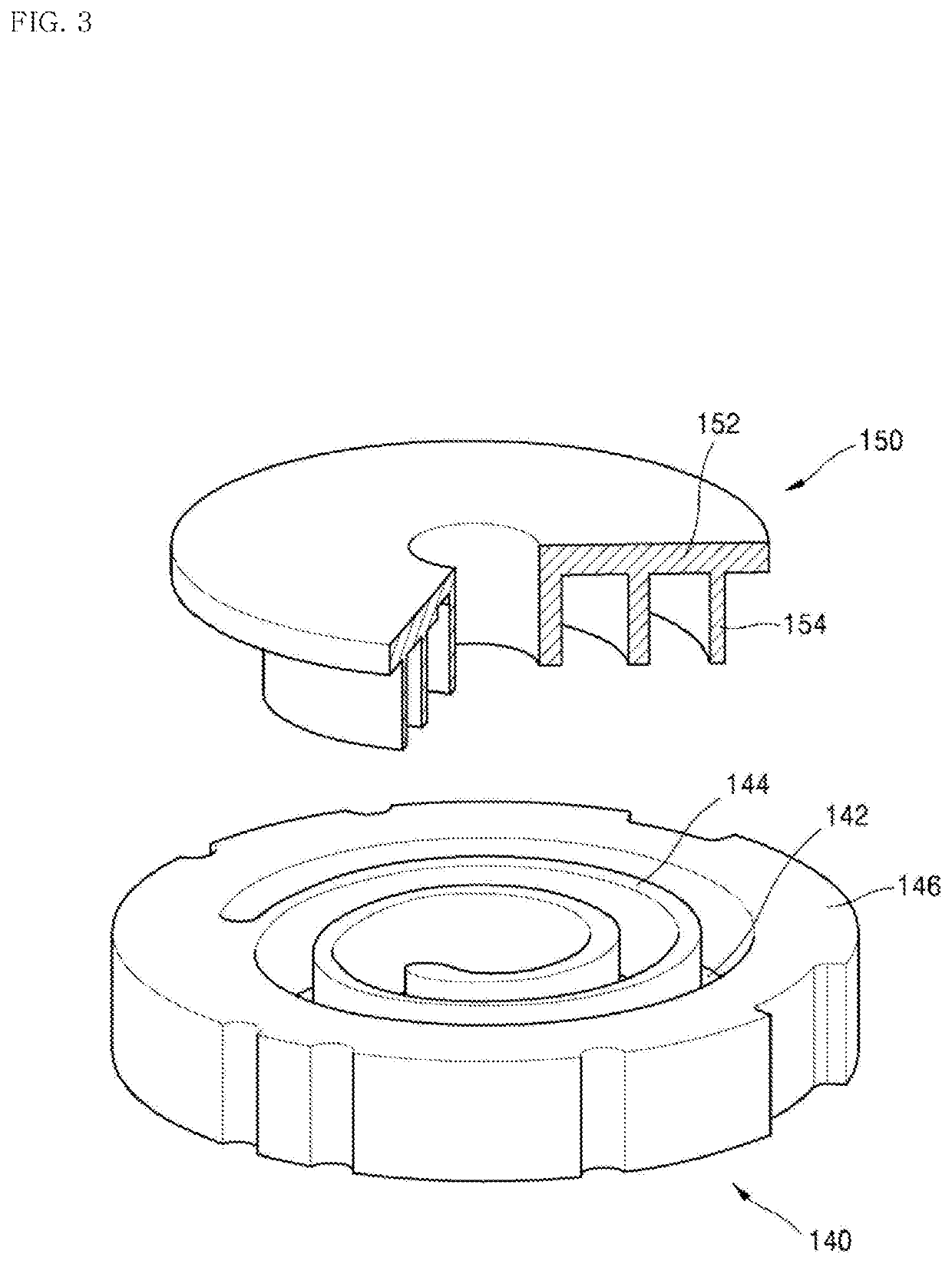

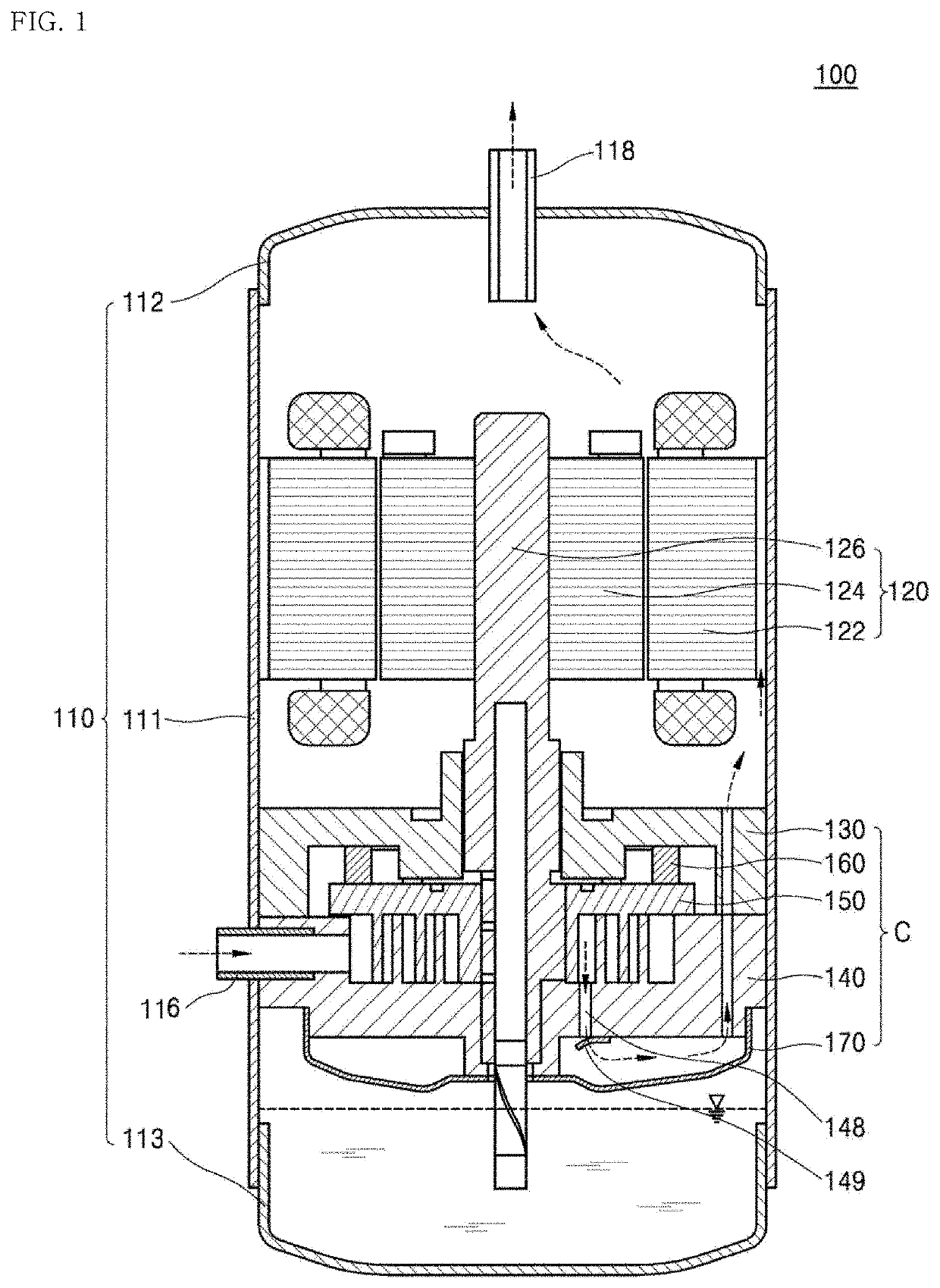

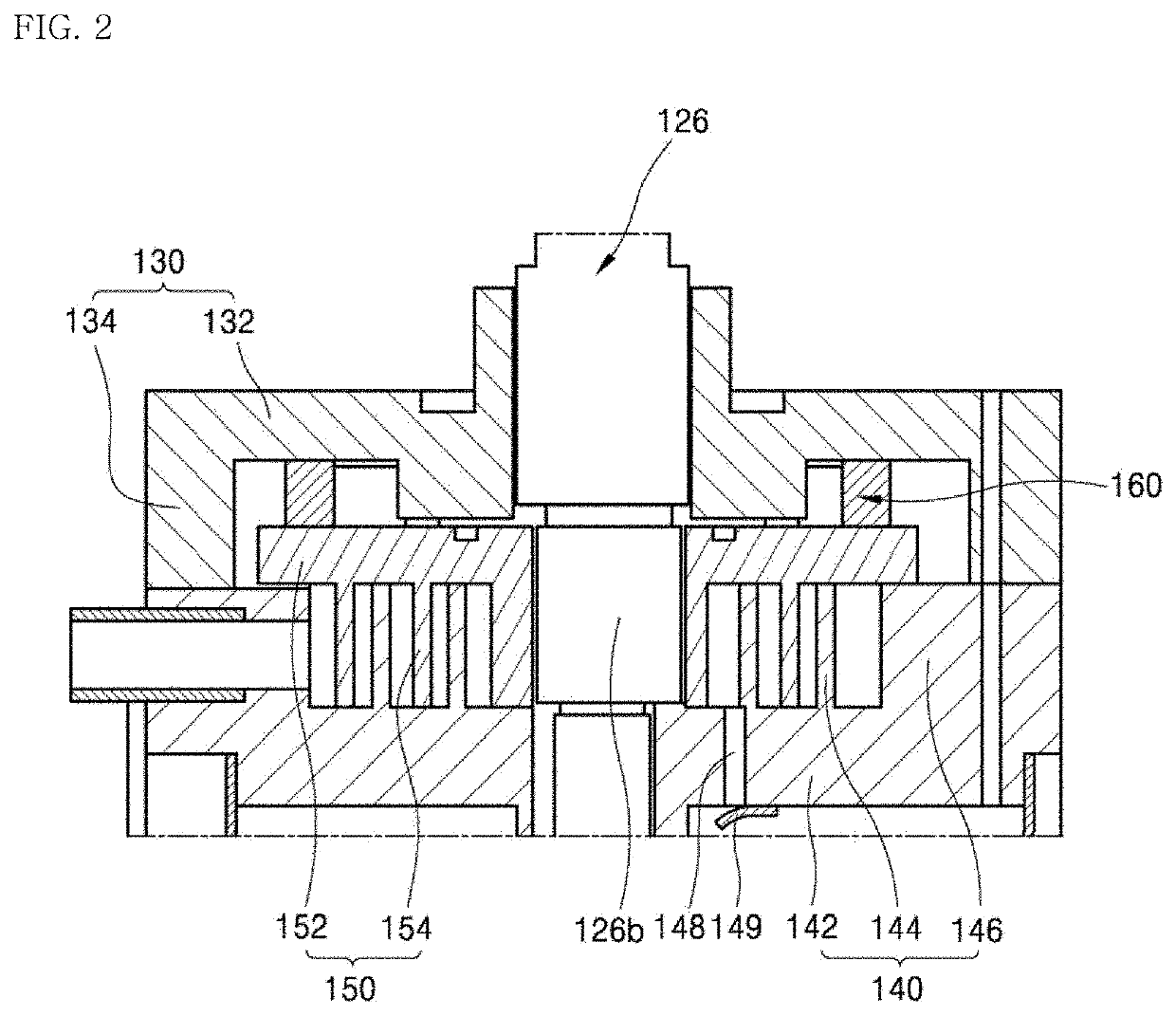

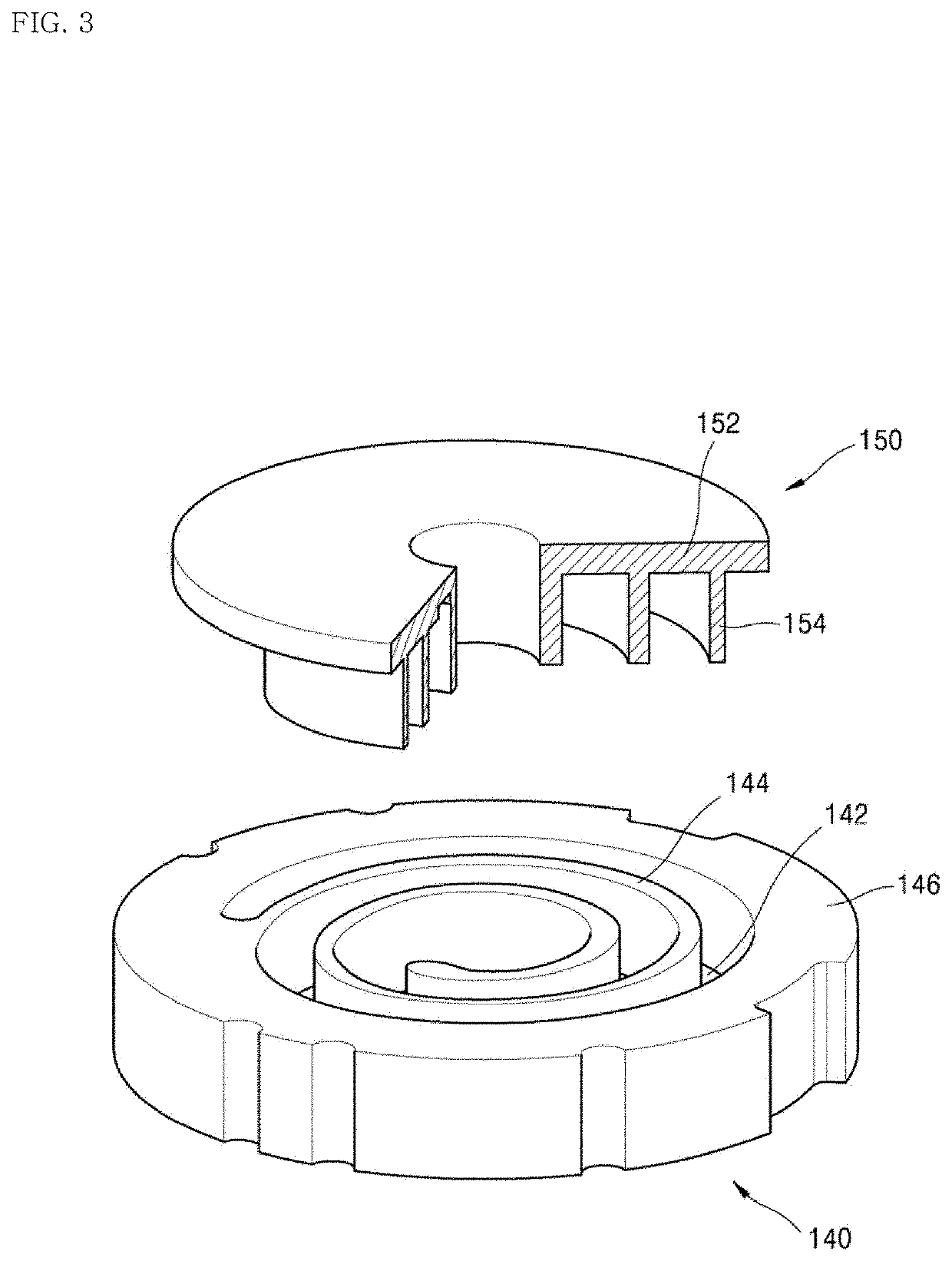

Reciprocating compressor

InactiveUS20070231167A1Reduced discharge resistanceImprove compression efficiencyPositive displacement pump componentsPositive-displacement liquid enginesEngineeringReed valve

A reciprocating compressor is disclosed which has a valve construction using plural discharge ports, plural reed valves and plural valve backers to lower the discharge resistance and improve the compression efficiency. The reciprocating compressor (1000) has within a closed vessel (900) a reciprocating compressing section (300) for compressing a required fluid, the reciprocating compressing section (300) comprising a discharge unit for discharging the fluid and a valve assembly (500) for opening and closing the discharge unit, with a plurality of discharge ports (522A, 522B) being formed in the valve assembly, the valve assembly (500) comprising valve members (560), the valve members (560) comprising reed valves (530A, 530B) disposed correspondingly to the discharge ports (522A, 522B) and valve backers (540A, 540B) disposed respectively on back sides of the reed valves, a valve seat (520) having a recess for receiving the valve members therein, and valve members fixing means for urging end sides of the valve members to fix the valve members elastically to fixing portions (523A, 523B) of the recess.

Owner:SANYO ELECTRIC CO LTD

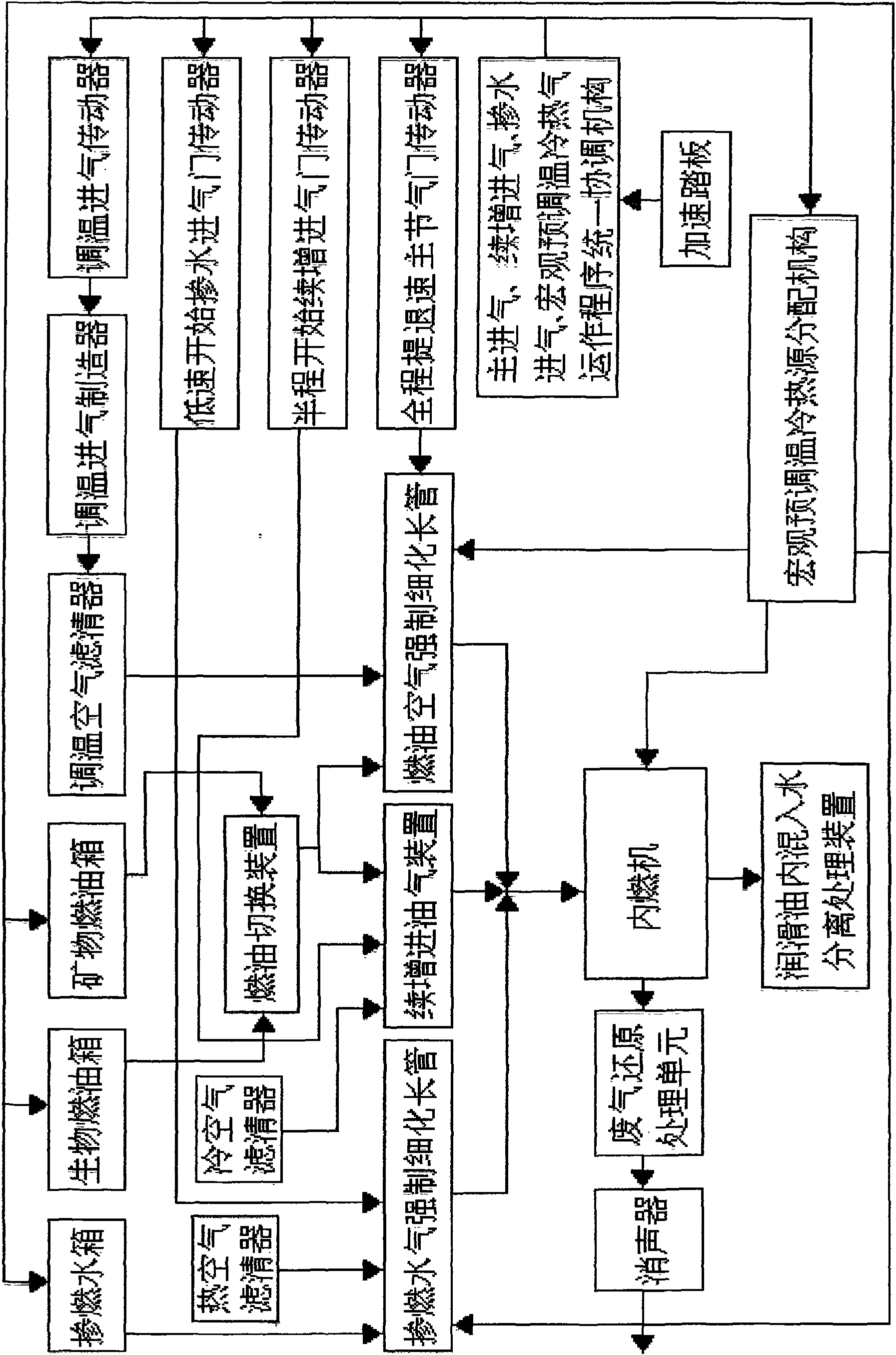

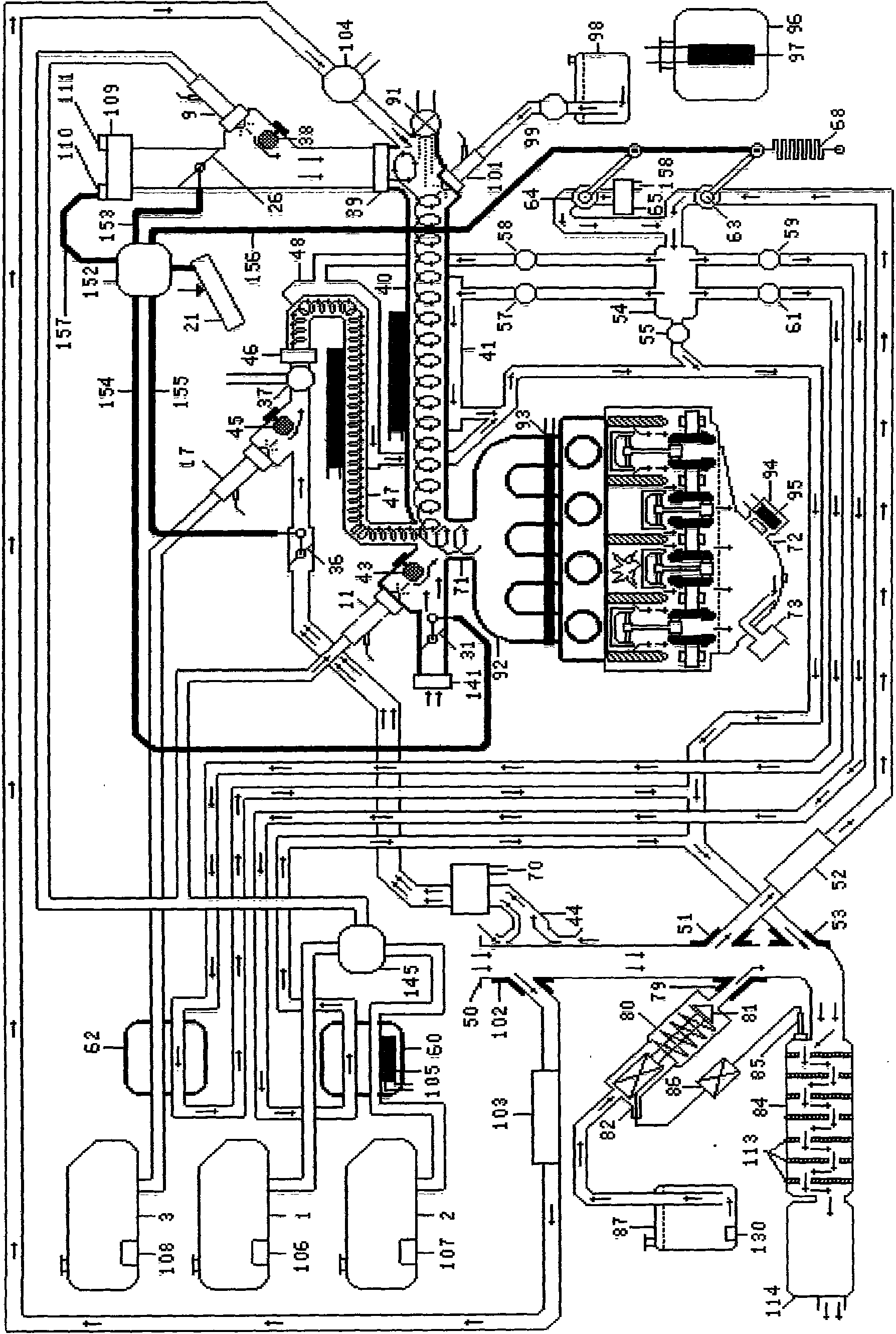

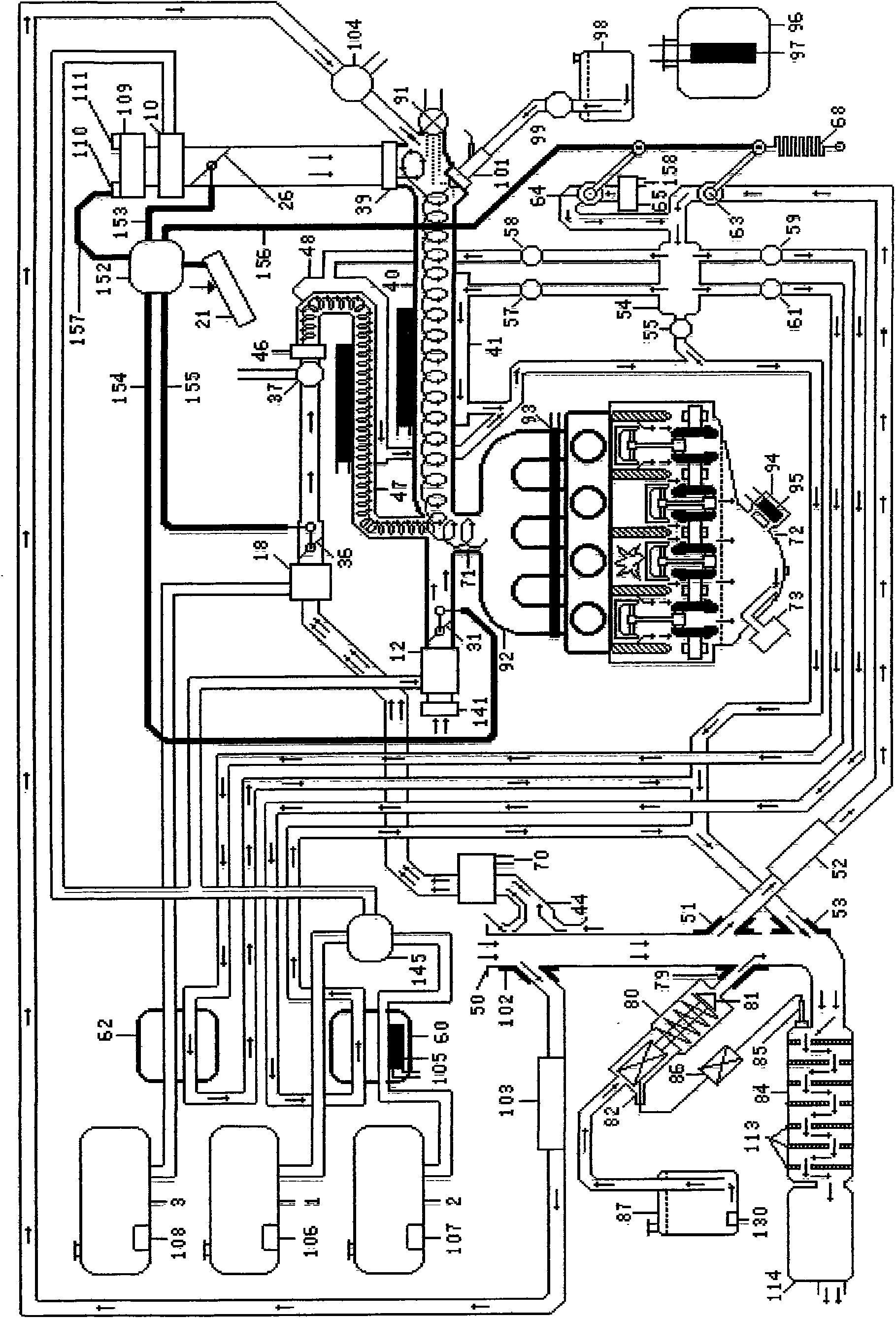

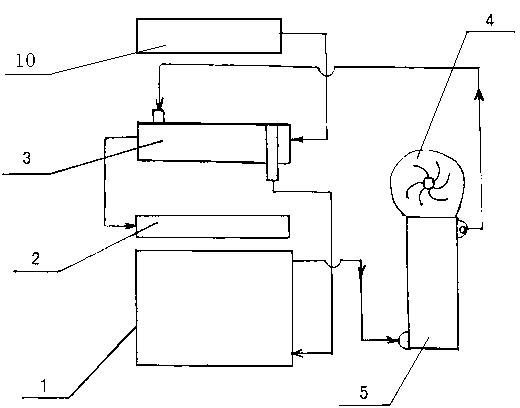

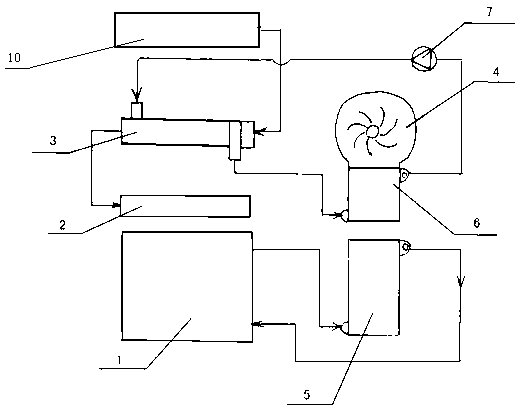

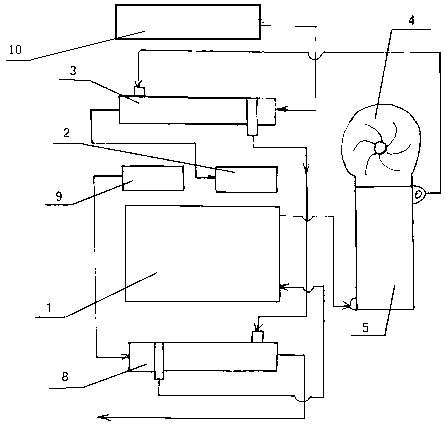

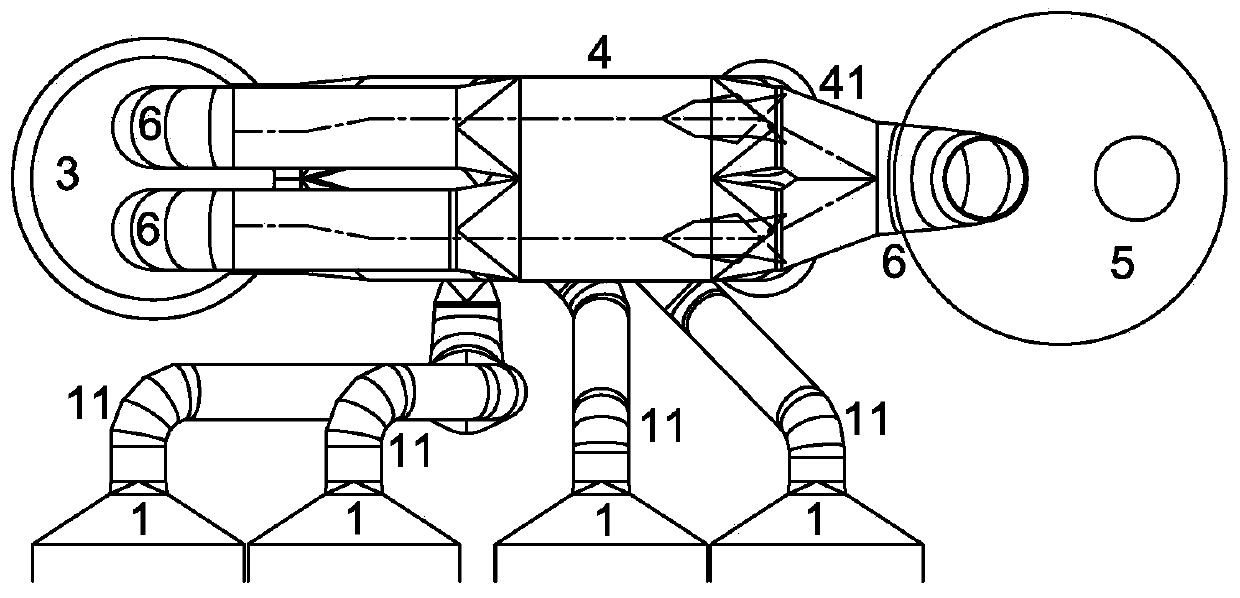

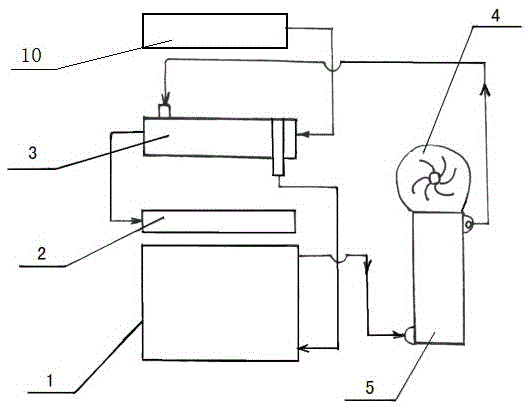

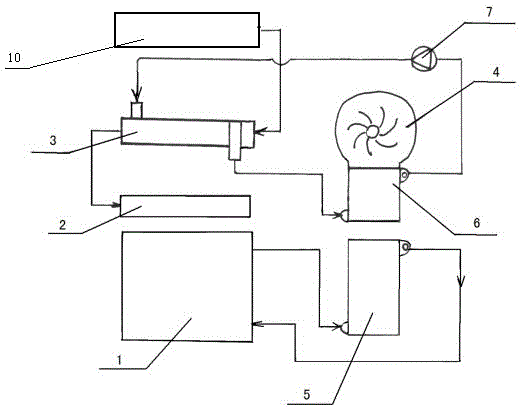

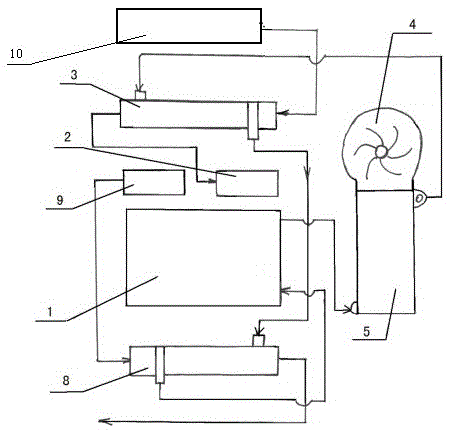

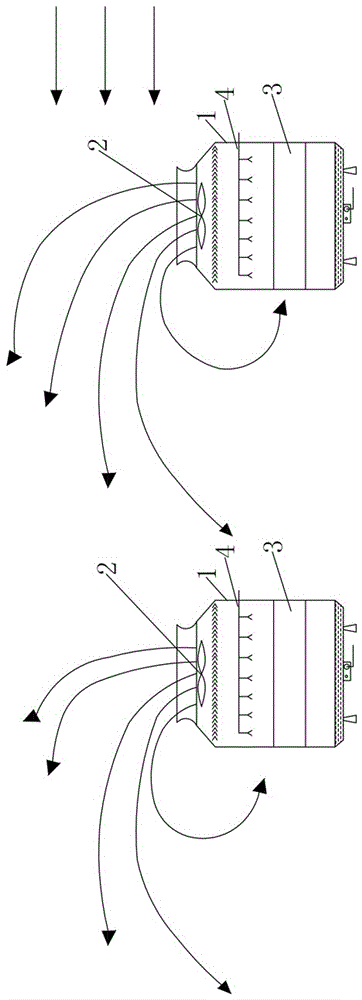

Engine energy-saving and emission-reducing system coordinated by heat pipe and cold pipe and working method thereof

InactiveCN101644208AReduced discharge resistanceEasy dischargeNon-fuel substance addition to fuelInternal combustion piston enginesCombustionExternal combustion engine

The invention relates to an engine energy-saving and emission-reducing system coordinated by a heat pipe and a cold pipe, which comprises an energy-saving and emission-reducing system of an internal combustion engine and the energy-saving and emission-reducing system of an external combustion engine, wherein, the energy-saving and emission-reducing system of the internal combustion engine comprises the internal combustion engine, a temperature-conditioning mineral fuel tank and a thick long swirling flow thin unit; and the energy-saving and emission-reducing system of the external combustion engine comprises the external combustion engine, a temperature-conditioning blending water tank and a water gas forced thinned long pipe. The working method comprises the working method of the energy-saving and emission-reducing system of the internal combustion machine and he working method of the energy-saving and emission-reducing system of the external combustion machine. The system has the advantages that the principle is simple and easy to develop and most of parts can directly select the existing standard parts for being used after simple transformation of the parts; the aggregate role of various technologies can sufficiently thin mixed gas, greatly reduce working temperature, improve the key technology which can greatly improve the geometric compression ratio and lead an oil-saving index to be about 50%; and the various technologies can be comprehensively applied for obtaining the energy-saving and emission-reducing ultra-high index, and the single technology therein can be independently used for obtaining the medium energy-saving and emission-reducing index with a small amount of investment.

Owner:段洪池 +3

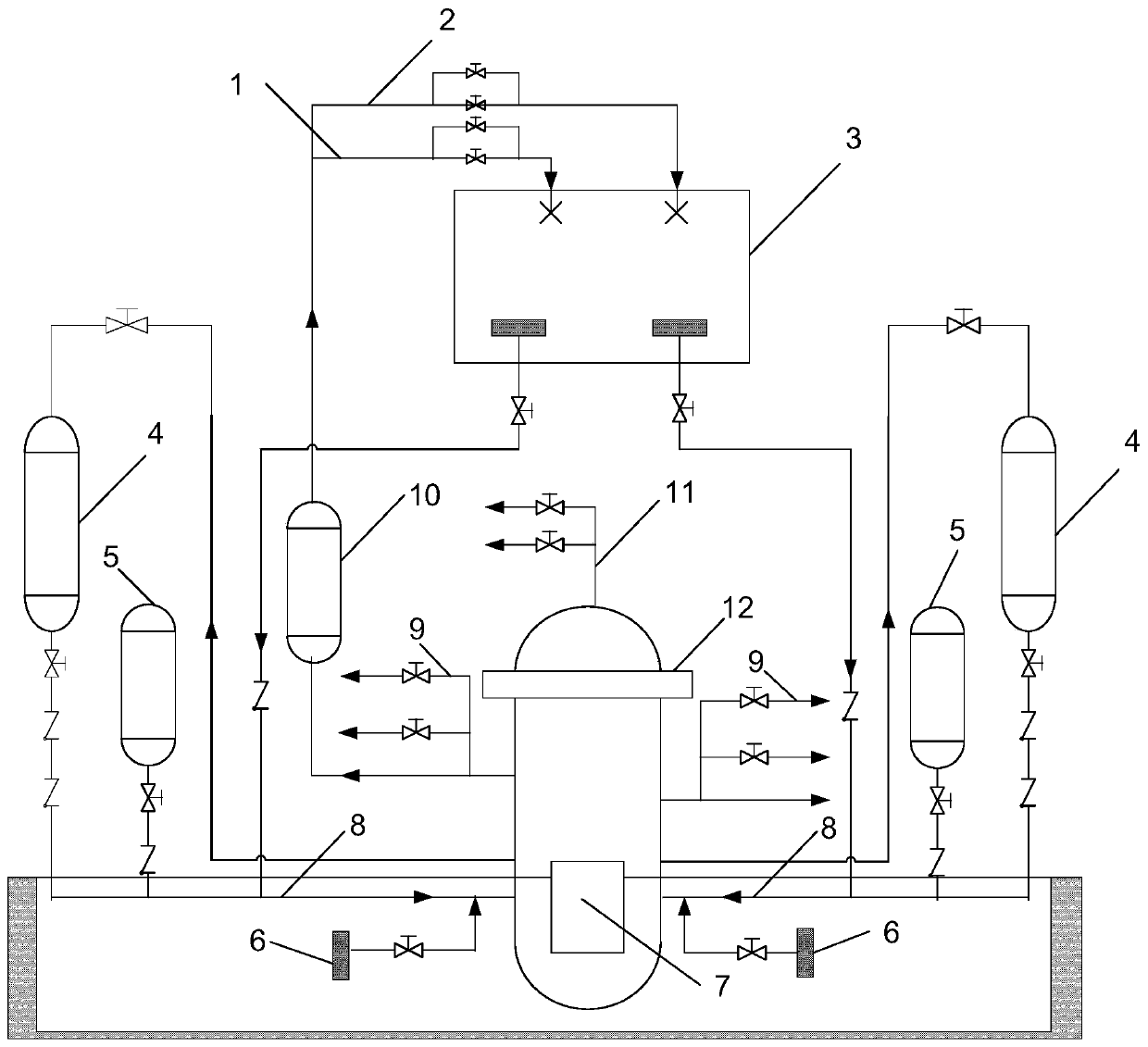

Long-term cooling system for loss-of-coolant accident during isolation failure of modular small reactor containment

InactiveCN109887624ARelieve stressAvoid interruptionNuclear energy generationEmergency protection arrangementsWater storage tankNuclear engineering

The invention discloses a long-term cooling system for a loss-of-coolant accident during the isolation failure of a modular small reactor containment. The cooling system comprises a primary cooling loop, a secondary cooling loop and a tertiary cooling loop, the primary cooling loop is a loop formed between a reactor core water supply tank and a pressure container, boron-containing water in the reactor core water supply tank enters the pressure container through a pressure container direct-injection pipeline and is supplied to the reactor core, the boron-containing water in the pressure container returns into the reactor core water supply tank through a pipeline, the secondary cooling loop is a loop formed between a built-in refueling water storage tank and the pressure container, the boron-containing water in the built-in refueling water storage tank enters the pressure container through the pressure container direct-injection pipeline, and is supplied to the reactor core, steam generated by the reactor core returns into the built-in refueling water storage tank through an automatic pressure relief system, and the tertiary cooling loop is a natural circulation loop formed between aground pit and the reactor core. The problem that existing cooling systems cannot achieve long-term cooling of the reactor core after the loss-of-coolant accident during isolation failure of the containment is solved in the invention.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for preparing ceramic fiber diaphragm for thermal batteries based on 3D printing technology

InactiveCN110190233AExtend your lifeImprove high temperature stabilityCell component detailsFiberPorosity

The invention discloses a method for preparing a ceramic fiber diaphragm for thermal batteries based on the 3D printing technology. The method is characterized in that the method of printing the ceramic fiber diaphragm through direct writing can control printing precision by controlling a diameter of an extrusion head, porosity is precisely controlled by a solidification ratio of the slurry so that the porosity required for ion migration is achieved while the electrolyte is loaded as much as possible, discharge resistance is reduced, and the output voltage is stable. The method is advantaged in that 3D printing is utilized to make the ceramic fiber diaphragm, thickness of the diaphragm can be controlled to meet use requirements of various thermal batteries, the modified ceramic fiber diaphragm produced by the method has excellent high temperature stability and high corrosion resistance, the life of the thermal battery can be extended by 5-10 years, the replacement frequency is reduced,and a lot of manpower and financial expenses are saved.

Owner:XI AN JIAOTONG UNIV

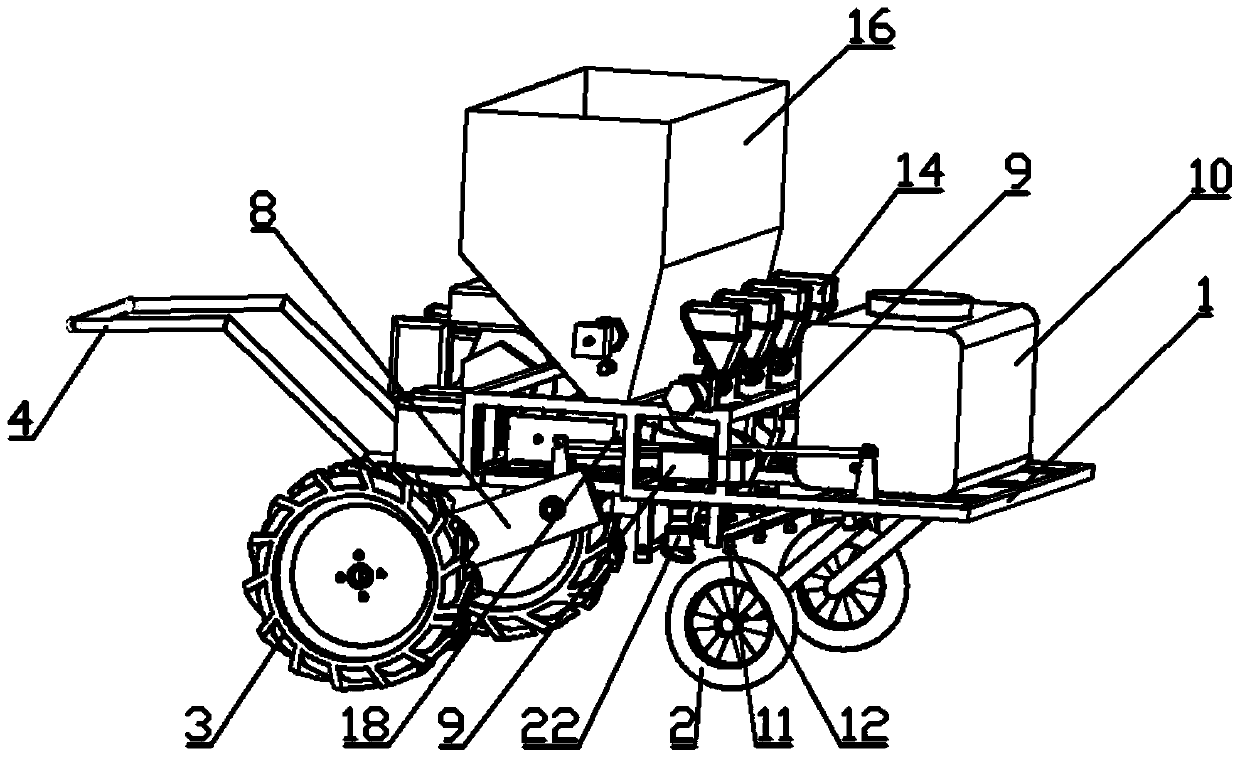

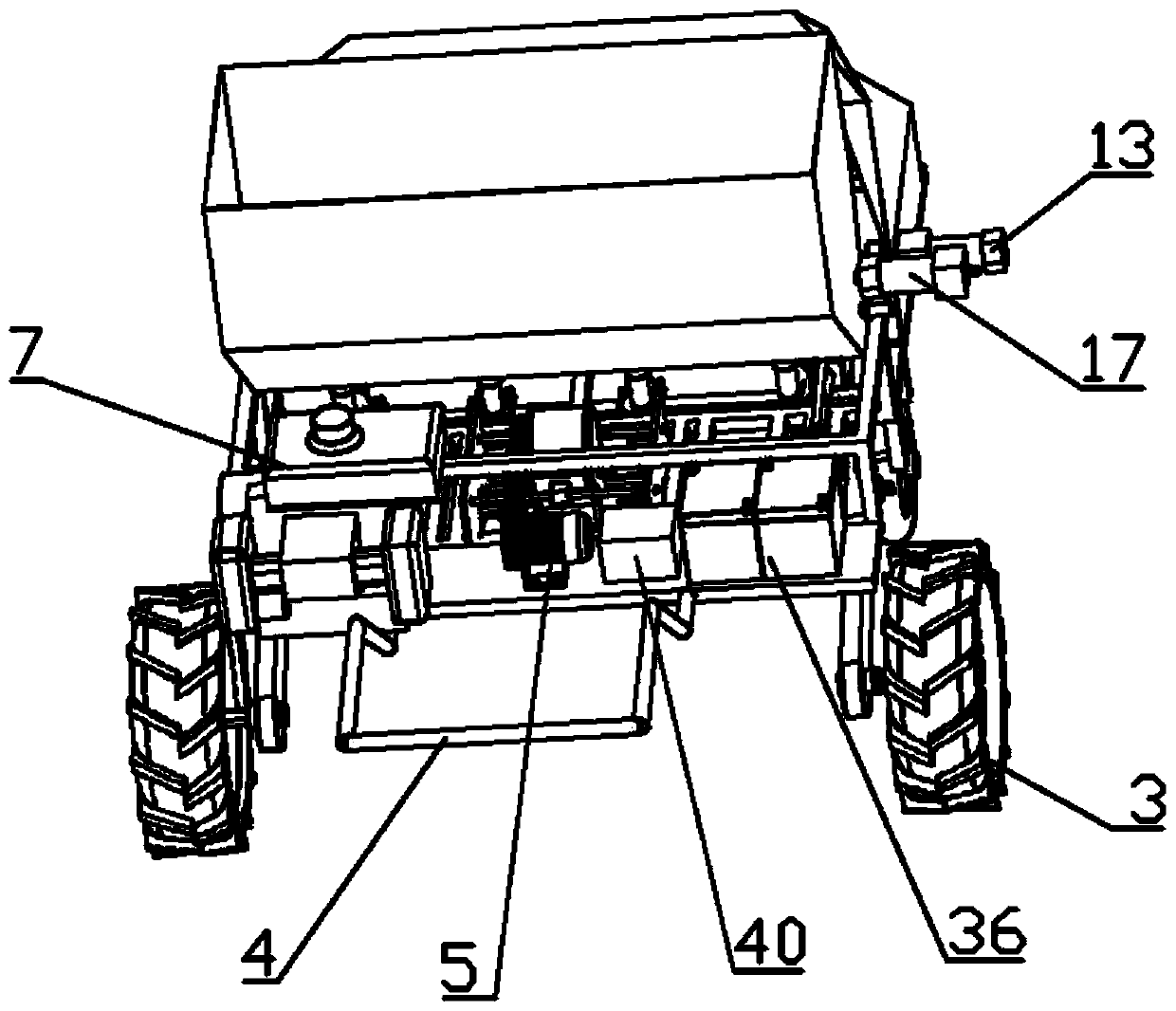

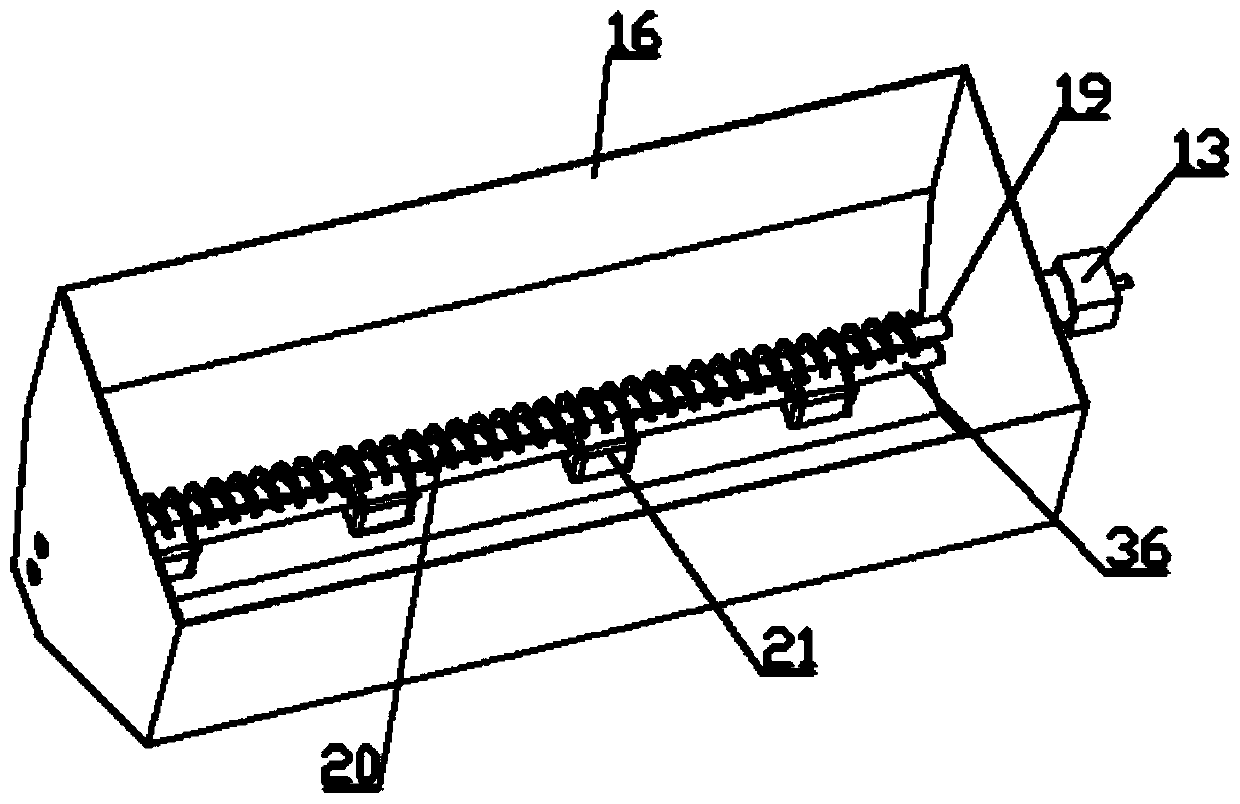

Water-fertilizer-seed integrated automatic seeder and seeding method thereof

ActiveCN110741779AImprove germination rateImprove the utilization rate of seed fertilizerWatering devicesCultivating equipmentsSeederAgricultural engineering

The invention relates to a water-fertilizer-seed integrated automatic seeder and a seeding method thereof, and belongs to the technical field of agricultural machinery. The water-fertilizer-seed integrated automatic seeder comprises a travelling device, a water spraying device, a seed discharging device, a fertilizer discharging device, a seed and fertilizer mixing device and an automatic seedingcontrol system. The travelling device comprises a bottom plate, front wheels and rear wheels. The bottom plate is provided with a motor, a battery, a range-extending power generator and a chain box. The water spraying device comprises a water tank, a water pump and spray nozzles. The seed discharging device comprises a seed discharging motor, seed dischargers and a seed guide tube. The fertilizerdischarging device comprises a fertilizer tank, a fertilizer discharging motor, a fertilizer stirring mechanism, a fertilizer discharging mechanism and a fertilizer guide tube. The seed and fertilizermixing device comprises seed and fertilizer cups and a fertilizer retaining cover. The automatic seeding control system comprises a PLC controller, an encoder and a counting sensor. Through precise control of seed discharge, fertilizer discharge, fertilizer drop, water spray, seed quantity and traveling distance, the linkage logic of components is clear, the seed discharge amount, fertilizer discharge amount and hole spacing are precise, the seed germination rate and seeding efficiency are high, and the adaptability is high.

Owner:SOUTHWEST UNIVERSITY

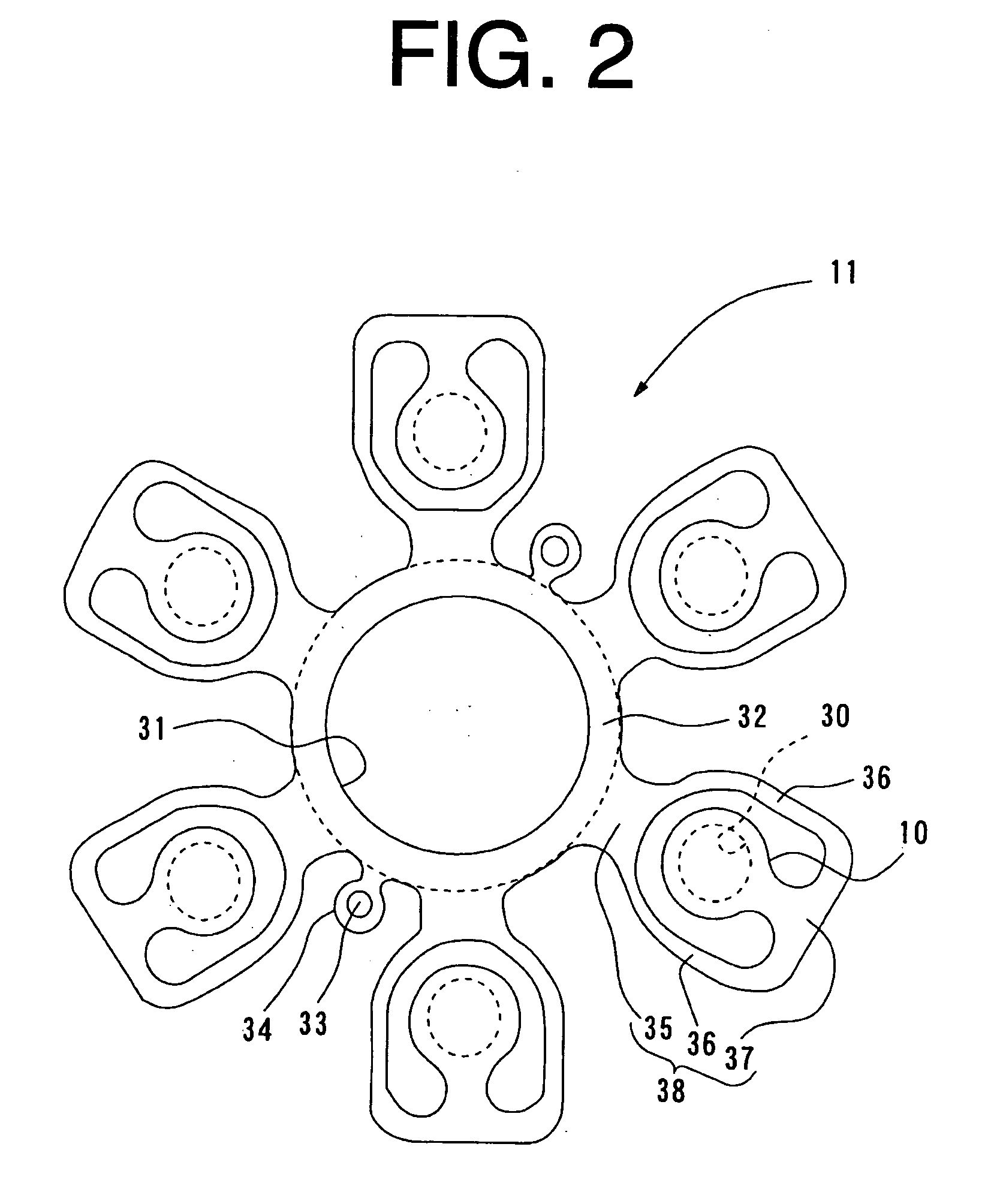

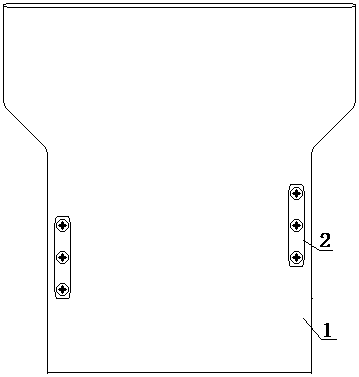

Discharge valve mechanism in compressor

InactiveUS20050031477A1Reduced discharge resistanceEasy to compressPositive displacement pump componentsFlexible member pumpsEngineeringCantilever

A discharge valve mechanism in a compressor for compressing refrigerant gas includes a valve plate and a discharge valve plate. The valve plate forms a discharge port into which the compressed refrigerant gas is discharged. The discharge valve plate is located between the valve plate and a rear housing and includes a support portion, a connecting portion and a discharge valve. The support portion is sandwiched between the valve plate and the end surface of the rear housing. The connecting portion is bendably cantilevered from the support portion. The connecting portion extends to an opposite side of the discharge port so as to bypass the discharge port from the support portion. The connecting portion has a free end portion. The discharge valve extends from the free end portion to the discharge port toward the support portion for opening and closing the discharge port.

Owner:TOYOTA IND CORP

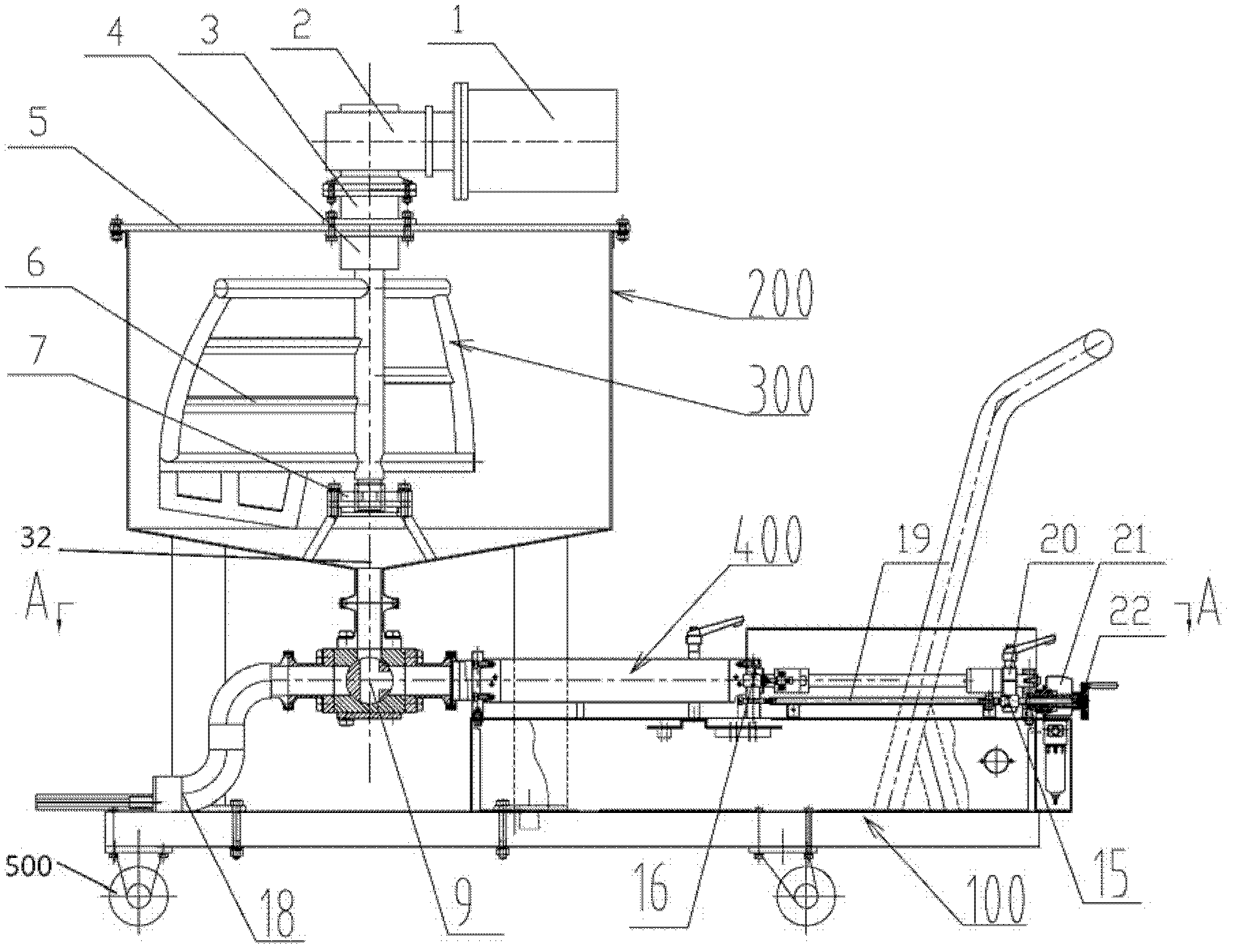

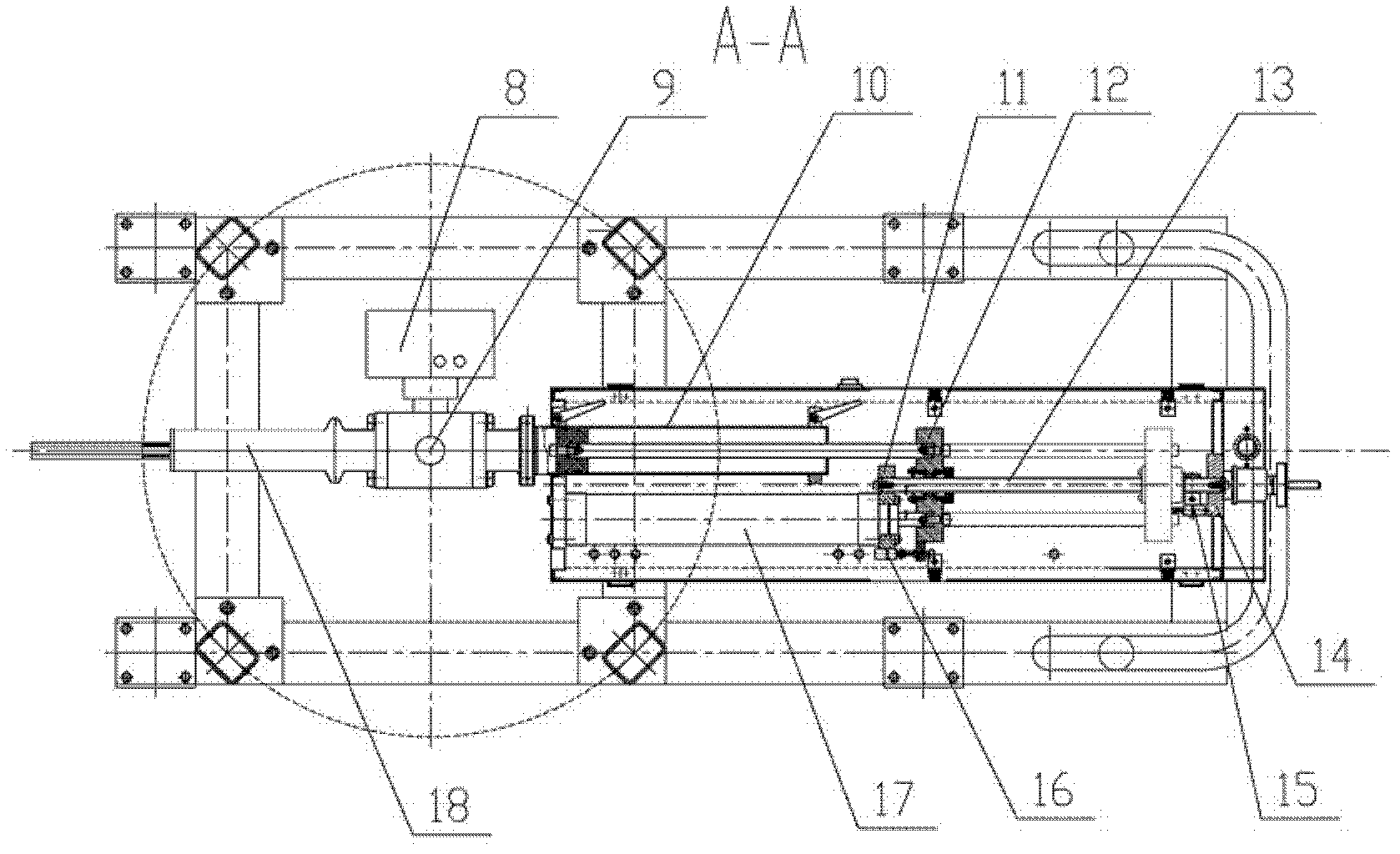

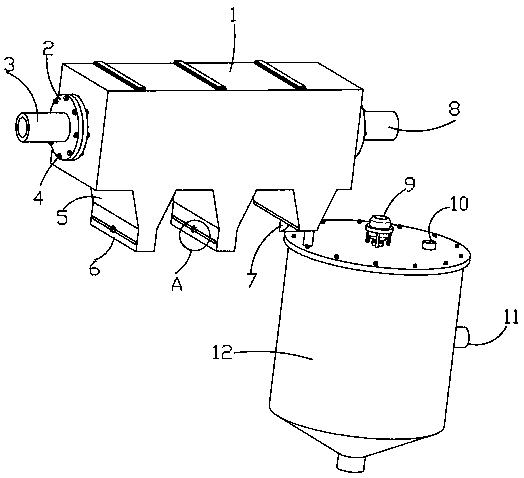

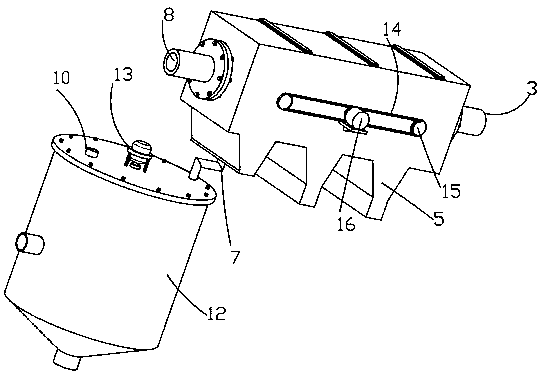

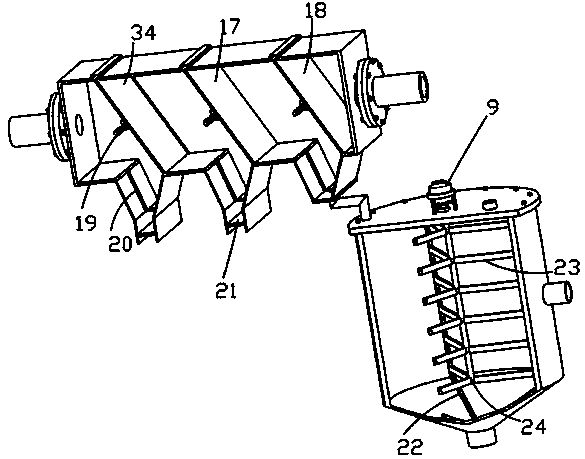

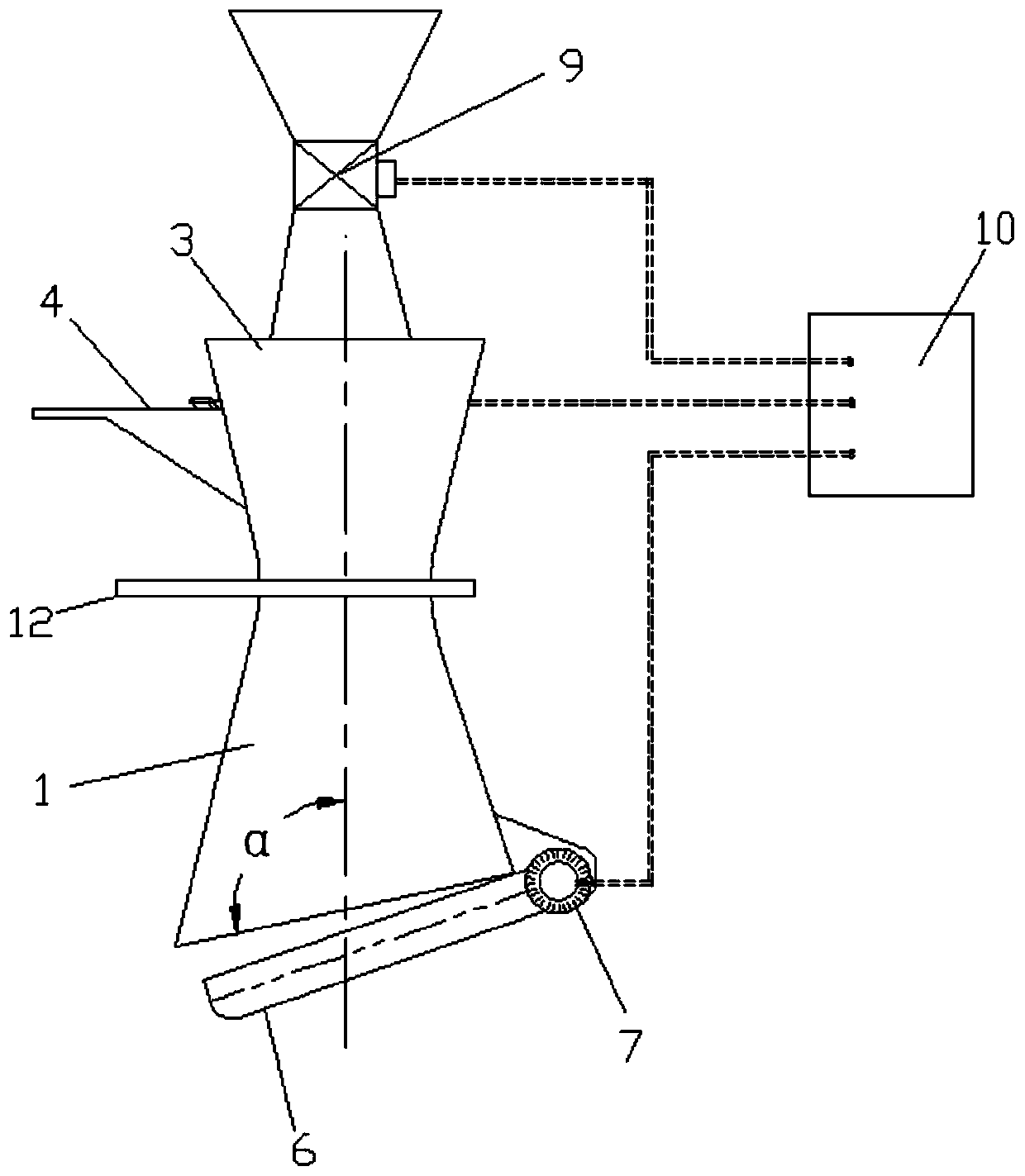

Crammer for ducks and geese

InactiveCN102599076AQuick and even suctionImprove efficiencyAvicultureEngineeringMechanical engineering

The invention discloses a crammer for ducks and geese, which comprises a barrel, a feeding device and a pneumatic control loop. The pneumatic control loop connected with the feeding device is used for driving and controlling the feeding device to suck and squeeze material. The feeding device is disposed below the barrel. A suction end of the feeding device is communicated with a discharge hole reserved on the lower wall of the barrel. A stirring device is disposed in the barrel and vertically and axially fixed in the barrel. The stirring device is used for mixing and discharging feeding fodder in the barrel. The stirring device disposed in the barrel is enabled to quickly and evenly suck the material, cavitation of the material around the discharge hole can be avoided under the stirring action of the stirring device, and accordingly sucking efficiency is improved. An air cylinder and a swing cylinder are coordinate to achieve feeding, and the crammer is high in structural tightness and high in discharging precision.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY +1

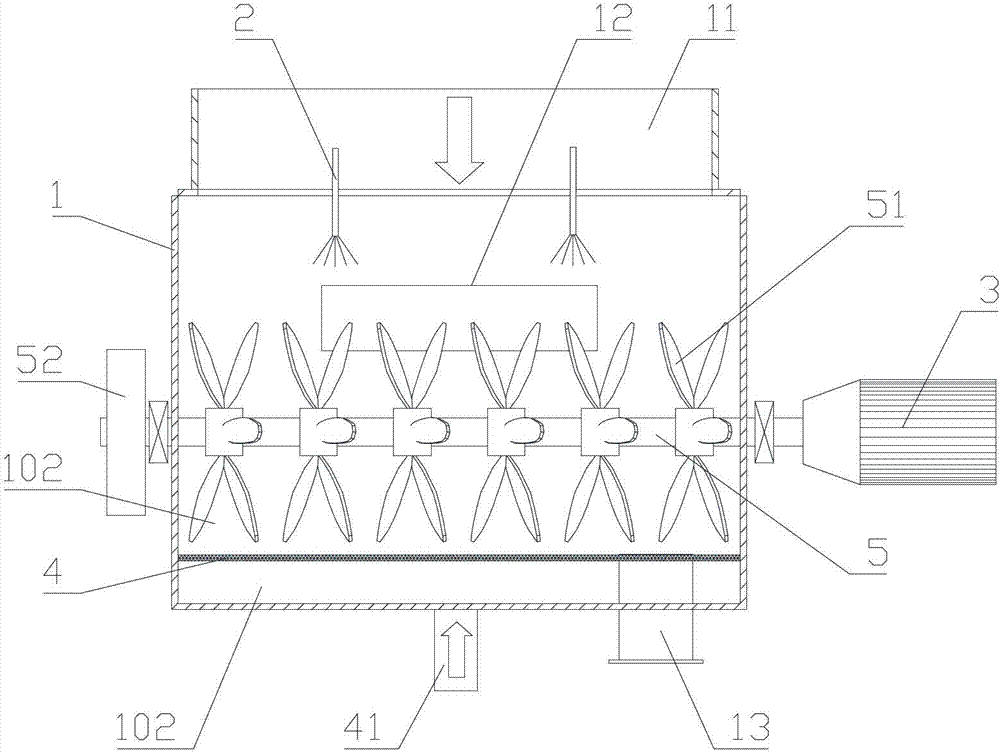

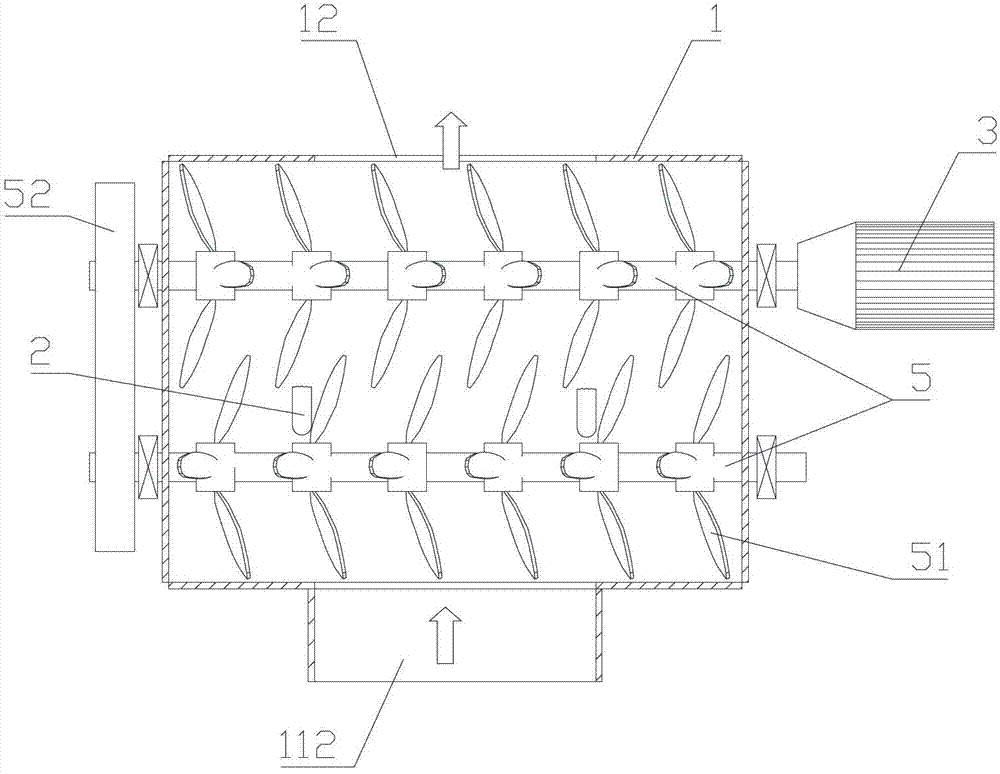

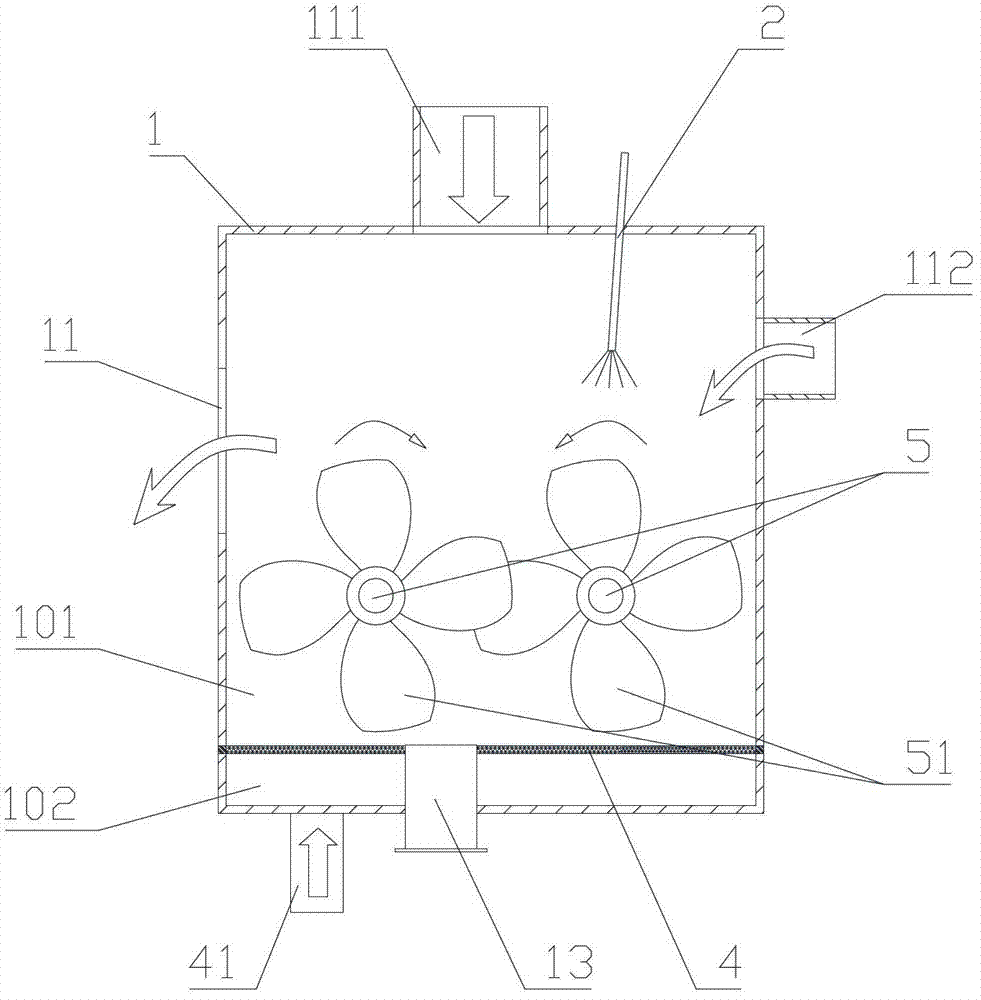

Double-shaft powder stirring humidifying device

InactiveCN103111216AHumidifying Mixing FastReduced discharge resistanceTransportation and packagingMixing methodsPowder mixtureFlue gas

The invention discloses a double-shaft powder stirring humidifying device which is flue gas treatment equipment capable of evenly mixing and humidifying the powder to prepare various humidified powder mixtures. The device comprises a stirring bin, wherein a stirring mechanism is arranged in the stirring bin; a water spraying device is arranged at the upper part of the top wall or the side wall of the stirring bin; a powder inlet and a powder outlet are formed in the stirring bin; the stirring mechanism is driven by a driving device; a fluidifying device is arranged at the lower part of the stirring bin; and the stirring mechanism is arranged above the fluidifying device. The device disclosed by the invention is especially suitable for a half-dry flue gas treatment system.

Owner:HAIYUAN ENVIRONMENTAL SCI & TECH

Scaling prevention and removal device for mine gas drainage equipment

InactiveCN111411918AEasy to filterReduce solubilityWaste water treatment from quariesDispersed particle filtrationElectric machineryStructural engineering

The invention relates to a scaling prevention and removal device for mine gas drainage equipment in the technical field of the mine gas drainage equipment. The device includes a processing box. The processing box, an air inlet pipe and an air outlet pipe are provided with flanges; the flanges are equipped with first bolts; mounting holes are installed on the processing box; cover caps are disposedon the processing box; the processing box is provided with inclined plates; a first filter plate, a second filter plate and a waterproof and breathable membrane are disposed between the inclined plates; the processing box is equipped with a cleaning structure; the processing box is provided with hoppers on the first filter plate, the second filter plate and the waterproof and breathable membrane;the hoppers are equipped with material unloading sleeve pipes, the material unloading sleeve pipes are provided with horizontal holes, and the material unloading sleeve pipes are provided with baffleplates; fixation structures are disposed on the baffle plates; the material unloading sleeve pipe on the right end is provided with a flow guiding pipe, and the flow guiding pipe is connected with asedimentation tank; the sedimentation tank is provided with an overflow pipe; the sedimentation tank is provided with a cover plate; a mounting frame and a drug adding pipe are disposed on the cover plate; a drive motor is installed in the mounting frame; the drive motor is provided with a rotation shaft; and the rotation shaft is provided with cross bars, and L-shaped scrapping plates are disposed on the cross bars. A drainage system of the device can operate normally, internal space of the equipment is guaranteed, discharge resistance is reduced, internal friction is reduced, and the efficiency of drainage equipment is improved.

Owner:崔广永

Seed-fertilizer mixed sowing device

ActiveCN110663319AWon't clogEasy to receiveDibble seedersSeed depositing seeder partsAgricultural scienceControl system

The invention belongs to the technical field of agricultural machinery and relates to a seed-fertilizer mixed sowing device. The seed-fertilizer mixed sowing device comprises a cup body, a dischargingregulator and a mixing control system. The cup body is internally provided with a mixing passage with a mixing passage, the upper end of the mixing passage with a small middle and two large ends is provided with an organic fertilizer inlet and a seed inlet, and the lower end of the mixing passage is provided with a seed-fertilizer discharging port. The discharging regulator comprises a retainingcover and an opening-closing motor, the retaining cover is rotationally arranged at the seed-fertilizer discharging port, and the opening-closing motor is used for rotating driving of the retaining cover. The mixing control system comprises a counting sensor, an on-off electromagnet and a PLC controller, the counting sensor is arranged at the seed inlet, the on-off electromagnet is arranged at theorganic fertilizer inlet, and the PLC controller is in electrical communication with the counting sensor and the on-off electromagnet. The seed-fertilizer mixed sowing device has advantages that automatic mixing and hole application of the organic fertilizer and crop seeds can be realized, and high automation degree, uniformity and reliability in mixing, fine operation, no waste, high adaptability and high seed survival rate are realized.

Owner:SOUTHWEST UNIVERSITY

Lithium secondary battery having improved lifespan characteristics

ActiveUS9472830B2Reduced discharge resistanceImprove conductivityCell electrodesLi-accumulatorsSulfonateElectrical battery

Disclosed is a lithium secondary battery having improved lifespan characteristics. More particularly, a lithium secondary battery comprising a cathode, an anode, a separator interposed between the cathode and anode, and an electrolyte, wherein the anode comprises lithium titanium oxide (LTO) as an anode active material, the electrolyte comprises a lithium salt; a non-aqueous-based solvent; and (a) a phosphate compound which can prevent gas generation during high-temperature storage, (b) a sulfonate compound which can reduce discharge resistance by forming a low-resistance SEI layer, or a mixture of the compound (a) and the compound (b), is disclosed.

Owner:LG ENERGY SOLUTION LTD

Device and method for improving work efficiency of engine and reducing emission of harmful gas

InactiveCN103133124AIncrease air densityEmission reductionInternal combustion piston enginesExhaust apparatusIntercoolerEngineering

Disclosed are a device and a method for improving the work efficiency of an engine and reducing emission of harmful gas. The device comprises a vortex supercharger, the engine, a gas inlet manifold, an inter-cooler, a radiating fan and a radiating water tank II; the inter-cooler is a counter-current heat exchange type cooler, the counter-current heat exchange type cooler comprises fin structures and micro-channel or mini-channel structures which are alternately arranged, an outlet of a fin side of the counter-current heat exchange type cooler is connected with the gas inlet manifold by a pipeline, and an inlet of the fin side of the counter-current heat exchange type cooler is connected with the vortex supercharger by a pipeline; and the engine is respectively connected with a coolant inlet of the radiating water tank II and a coolant outlet of the inter-cooler by pipelines, and a coolant outlet of the radiating water tank II is connected with a coolant inlet of the inter-cooler by a pipeline. The invention further provides the method for improving the work efficiency of the engine and reducing the emission of the harmful gas. The device and the method have the advantages that the work efficiency of the engine can be improved by 10% at least, and the emission of the harmful gas NOX can be reduced by 24% at least.

Owner:HUNAN AGRICULTURAL UNIV +1

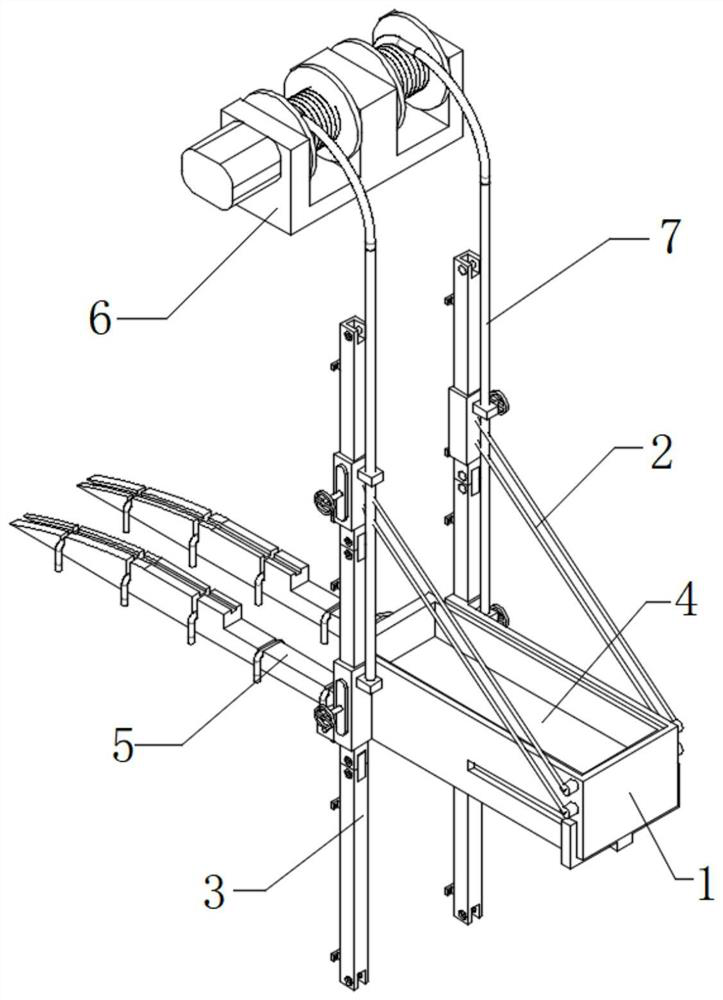

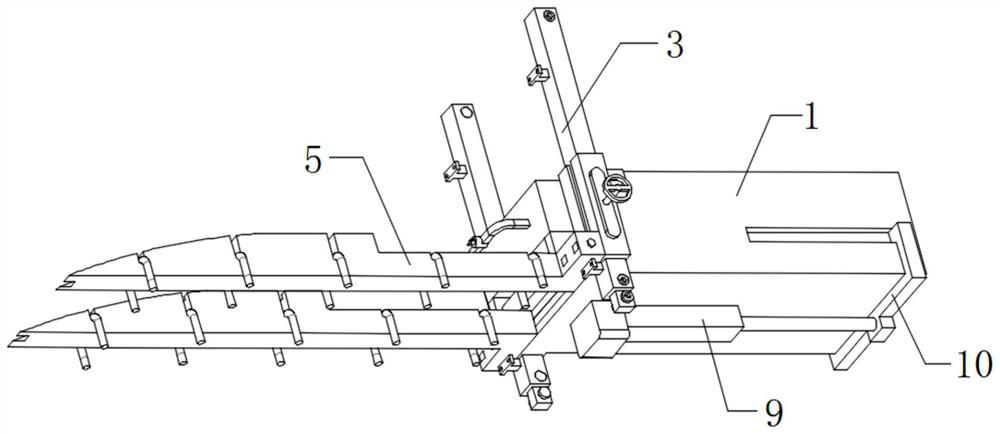

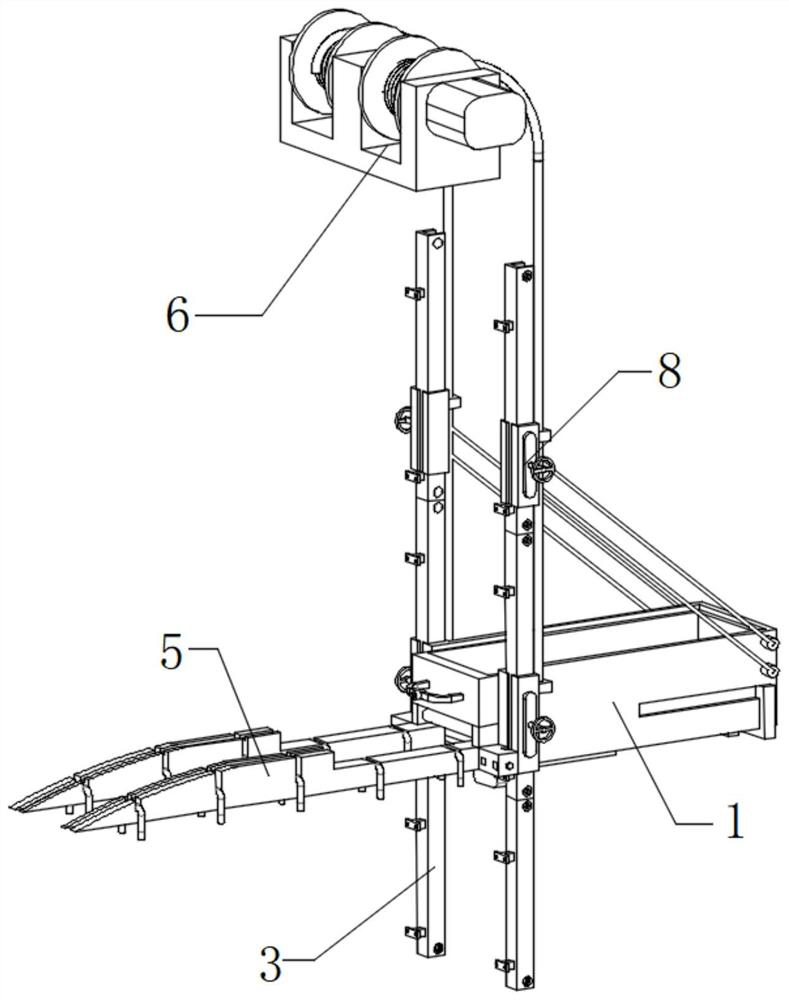

High-rise building hydraulic discharging platform device and working method thereof

PendingCN114837435AReduced discharge resistanceIncrease heightBuilding material handlingArchitectural engineeringHydraulic pressure

The invention discloses a high-rise building hydraulic discharging platform device and a working method thereof, and relates to the field of building construction discharging. According to the high-rise building hydraulic discharging platform device and the working method thereof, a storage hopper is arranged in a discharging platform main body, a sliding supporting frame is arranged at the bottom of the storage hopper, a hydraulic telescopic rod for driving the sliding supporting frame is arranged on the lower surface of the discharging platform main body, and a rotating turning plate is rotationally connected to the inner top of the sliding supporting frame; a rotary supporting rod is movably hinged to the lower surface of the end of the rotary turning plate and slidably connected to the inner wall of the discharging platform body through a sliding shaft. According to the high-rise building hydraulic discharging platform device and the working method thereof, by starting the hydraulic telescopic rod, the connecting frame slides towards the interior of a floor, meanwhile, the tail end of the rotating turning plate is tilted upwards, the storage hopper slides into the sliding way from the rotating turning plate, and therefore discharging resistance is reduced, and meanwhile the high-rise building hydraulic discharging platform device is safer.

Owner:别金全

Scroll compressor having enhanced discharge structure

ActiveUS20190360490A1Enhanced discharge structureReduced discharge resistanceRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsRefrigerantElectrical and Electronics engineering

A scroll compressor is disclosed, which comprises an auxiliary discharge path capable of sufficiently making sure of a discharge area at an initial discharge stage. The compressor comprises a fixed scroll including a fixed end plate portion and a fixed wrap, and an orbiting scroll including an orbiting end plate portion and an orbiting wrap, wherein a discharge hole is formed in the fixed end plate portion, and an auxiliary discharge path for connecting a side of the orbiting wrap with a bottom surface of the orbiting wrap is provided to be communicated with the discharge hole, whereby a compressed refrigerant may be discharged through the auxiliary discharge path.

Owner:LG ELECTRONICS INC

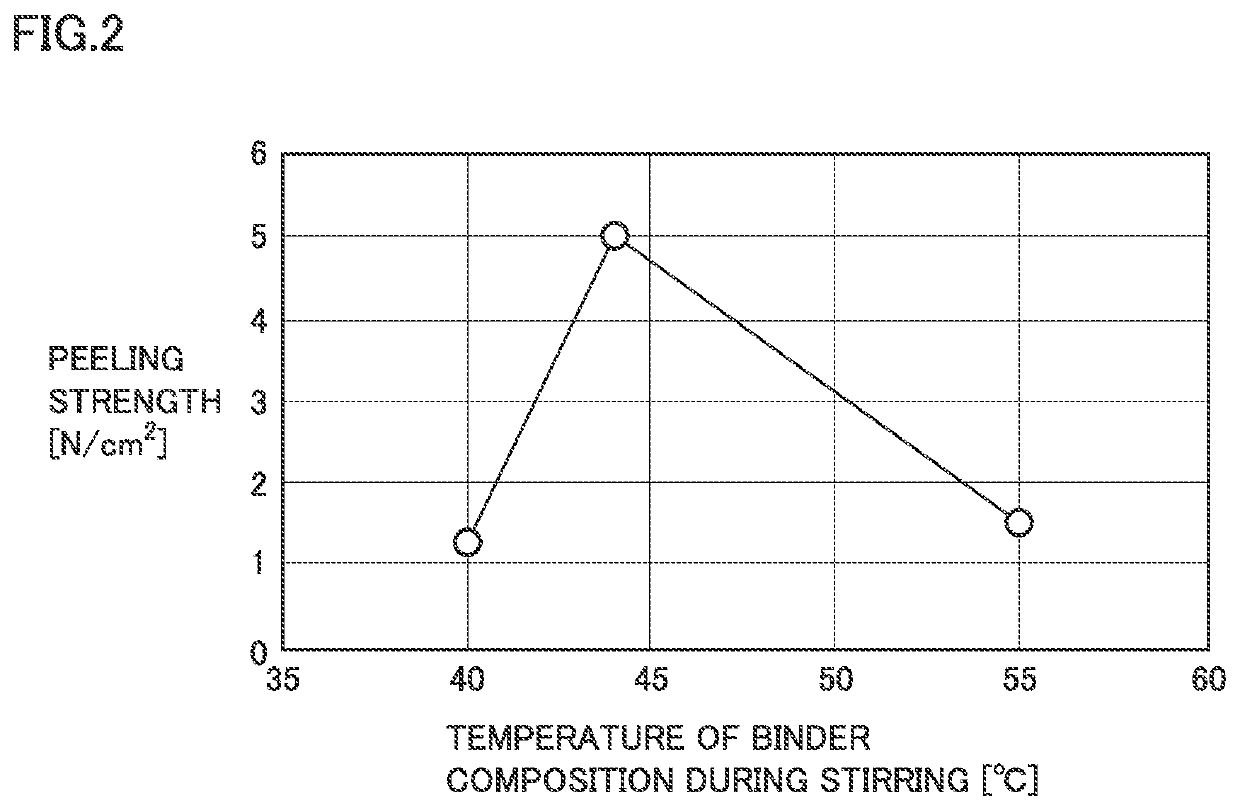

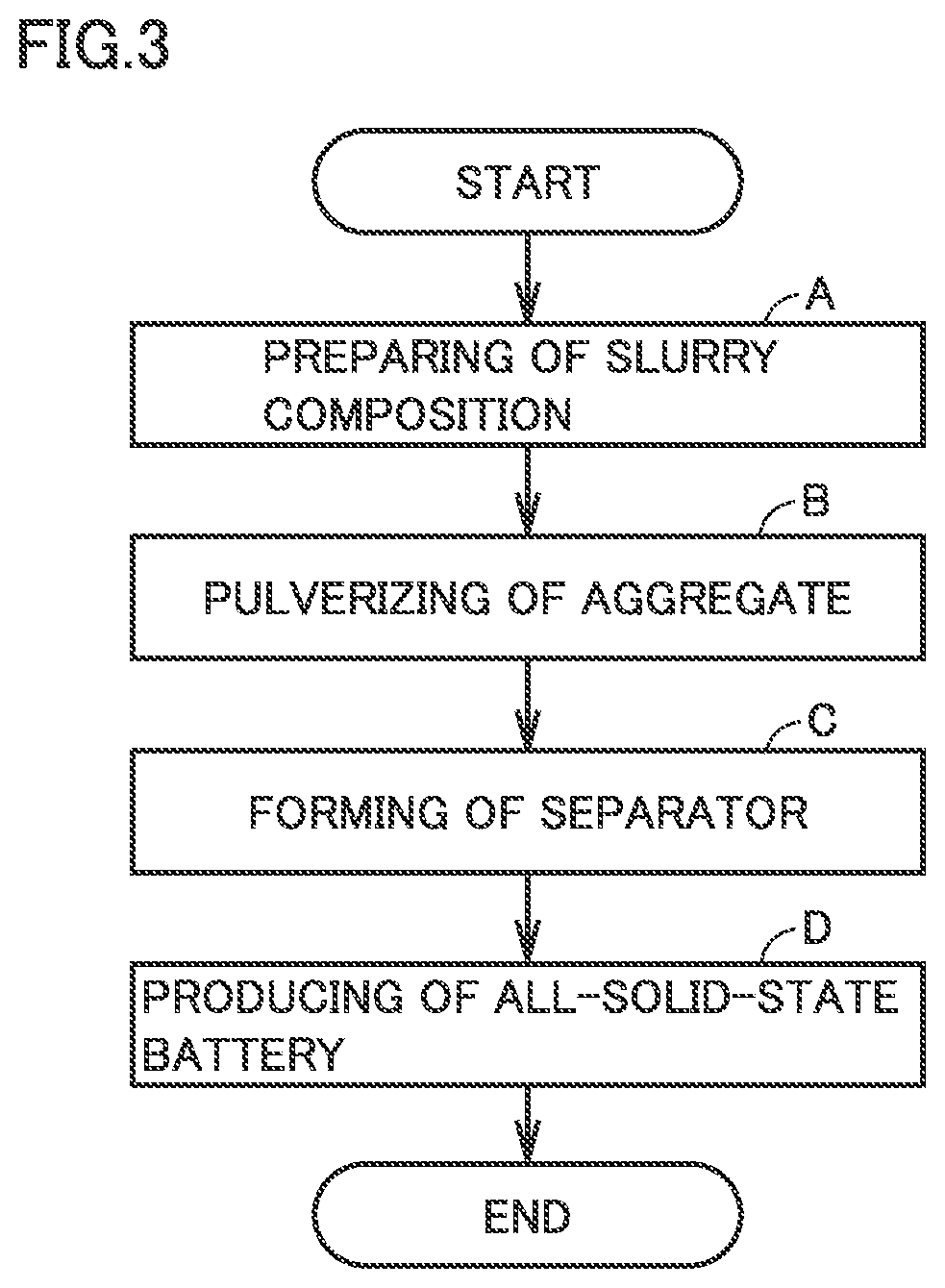

Binder composition, method of producing binder composition, and method of producing all-solid-state battery

PendingUS20210380791A1Increase temperatureImprove bindingSolid electrolytesFinal product manufactureAll solid stateDifluoride

A binder composition includes a dispersion medium and a group of binder particles. The group of binder particles is dispersed in the dispersion medium. The group of binder particles include a polymer material. The polymer material includes a constitutional unit originated from vinylidene difluoride. The group of binder particles has a number-based particle size distribution. The particle size distribution satisfies the following conditions: “0.19≤X≤0.26”, “0.69≤Y≤0.76”, and “0≤Z≤0.05”. Here, “X” represents a frequency of particles each having a particle size of less than or equal to 40 μm. “Y” indicates a frequency of particles each having a particle size of more than 40 μm and less than or equal to 110 μm. “Z” indicates a frequency of particles each having a particle size of more than 110 μm and less than or equal to 250 μm.

Owner:TOYOTA JIDOSHA KK +1

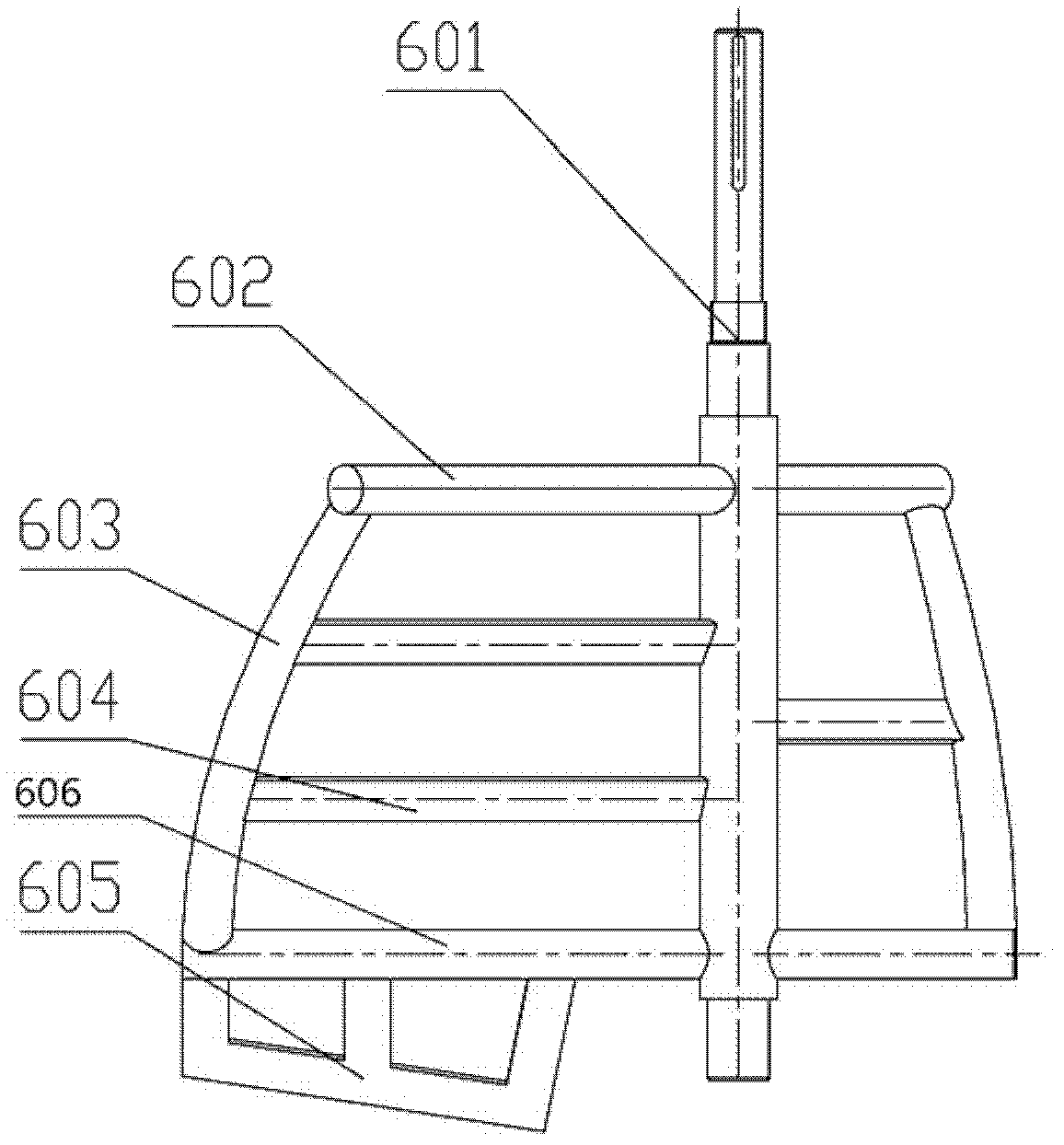

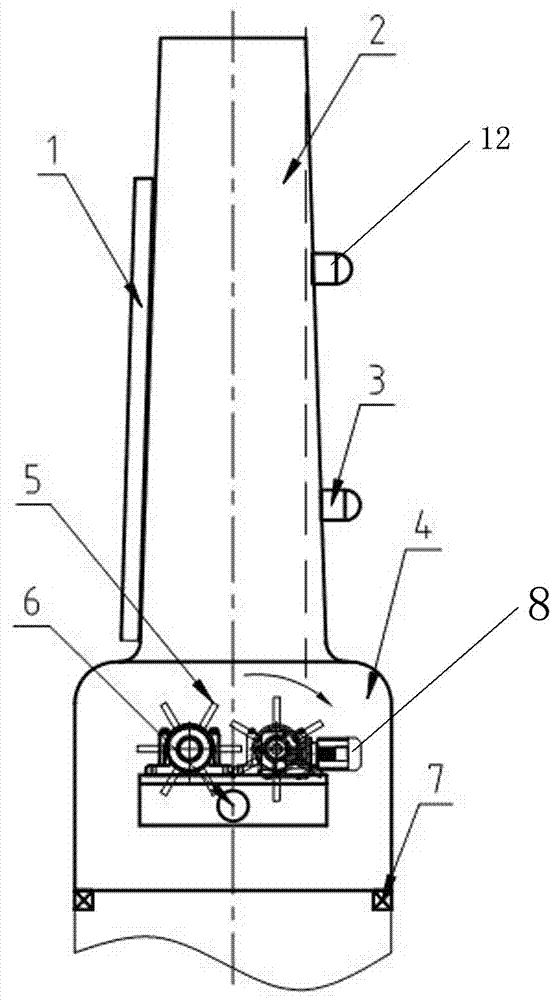

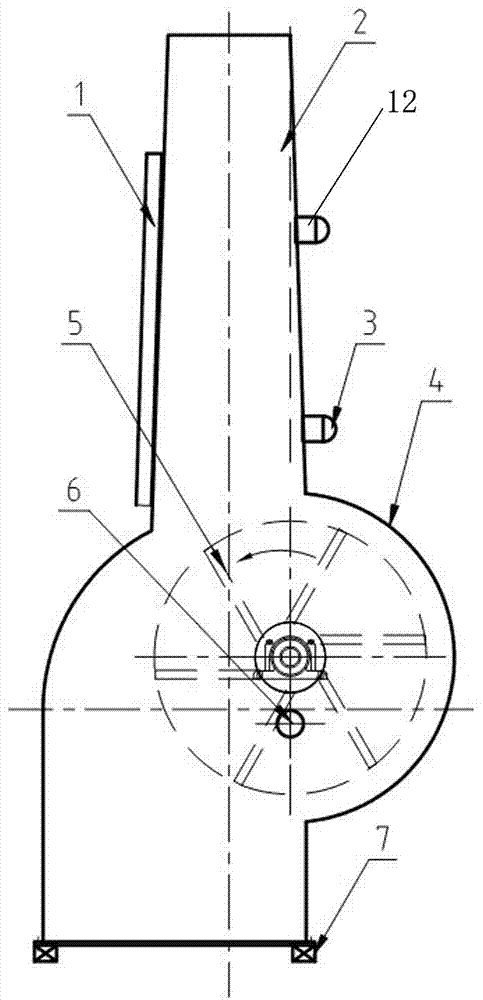

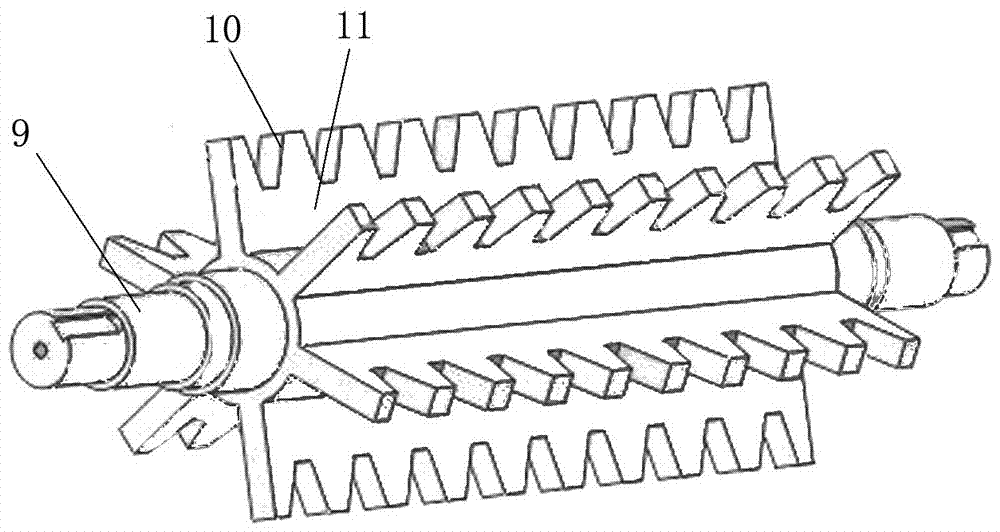

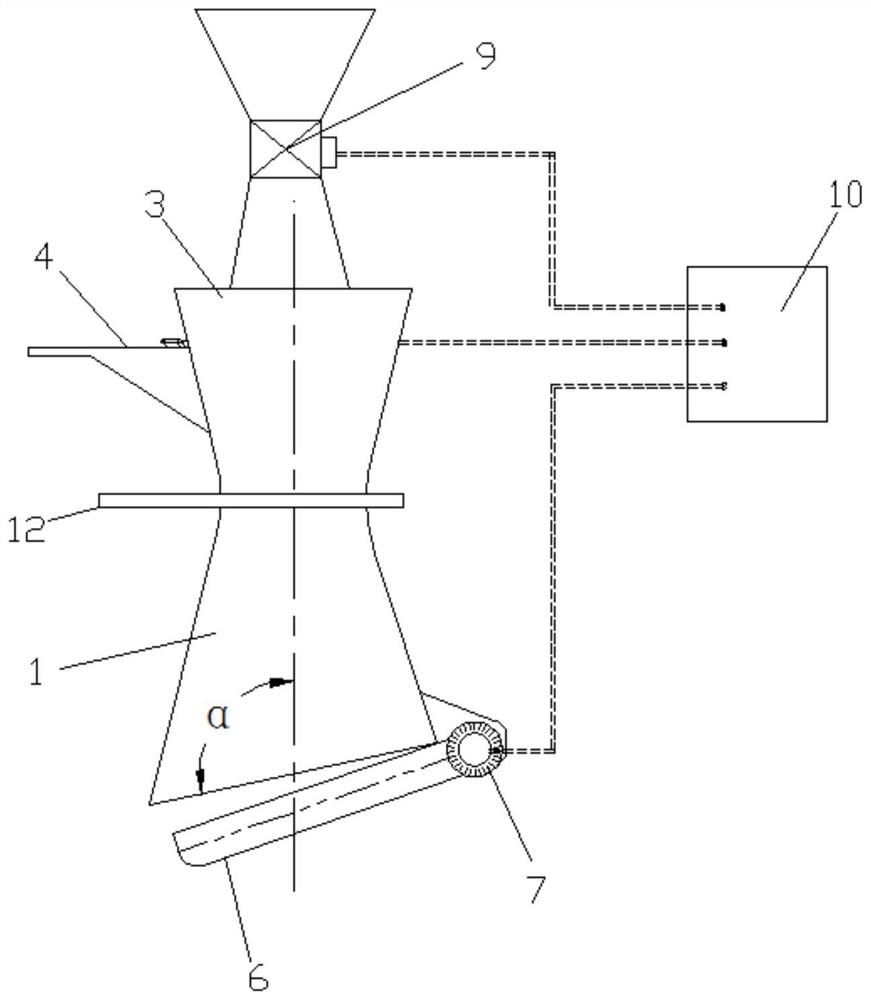

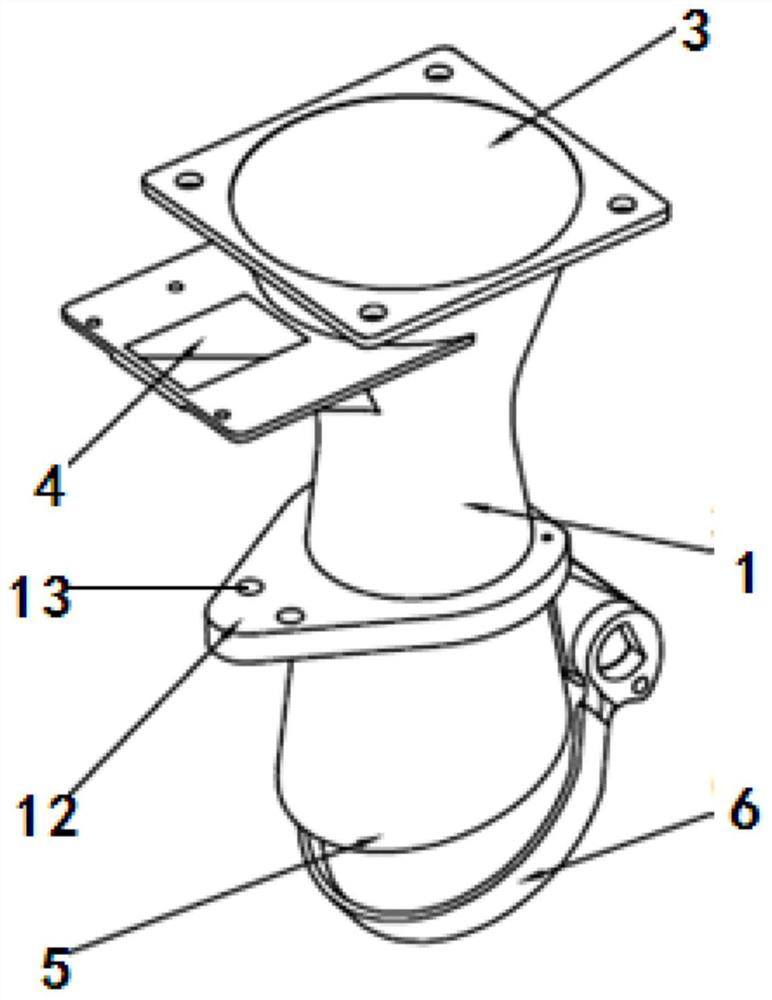

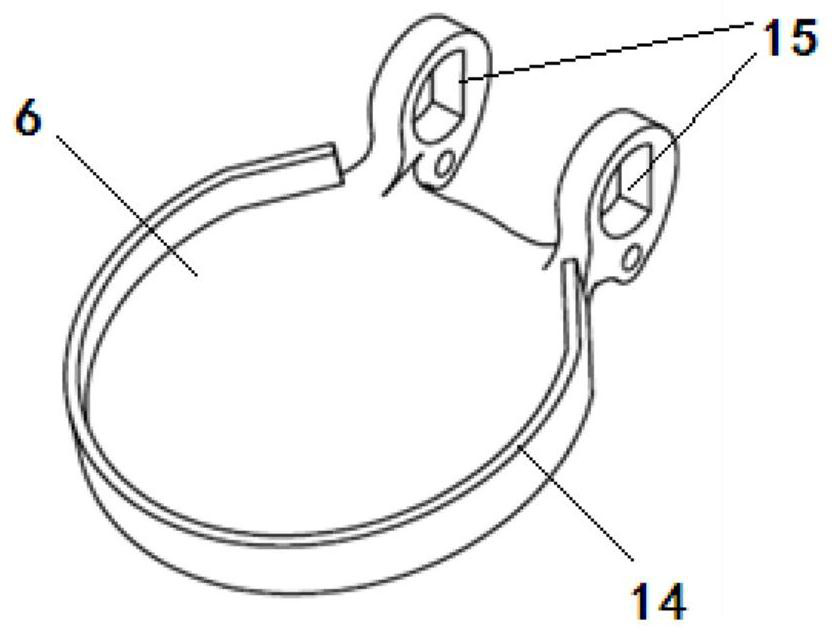

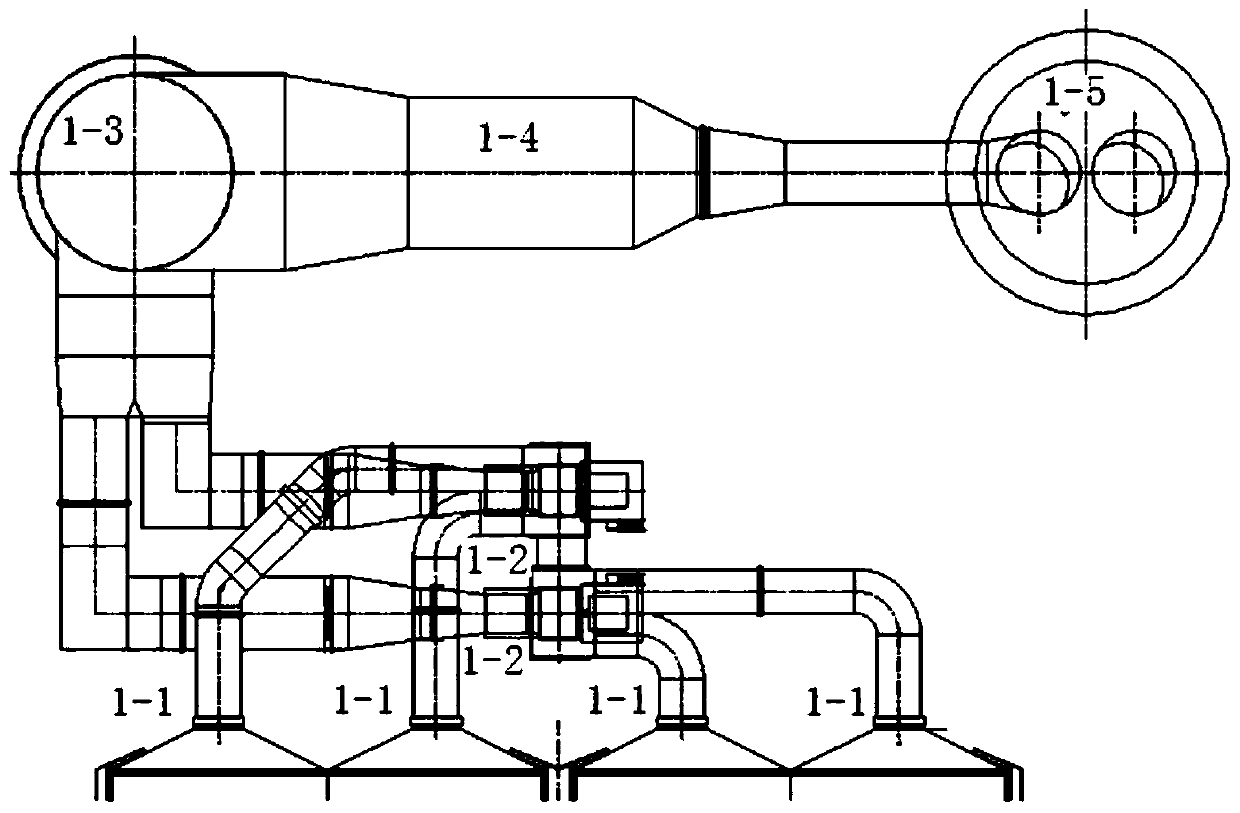

Novel intelligent wind locking device for vertical mill

PendingCN107442260AReduce discharge resistanceIncrease outputGrain treatmentsAutomatic controlReceiver

The invention discloses a novel intelligent wind locking device for a vertical mill. The novel intelligent wind locking device comprises a wind locking body, an electric control mechanism and a hopper arranged at the upper part of the wind locking body, wherein stirring rollers are arranged in the wind locking body and driven by a variable frequency motor; the variable frequency motor is controlled by the electric control mechanism; a high-order level gage, a low-order level gage and a level gage receiver are arranged on the outer wall of the hopper; the level gage receiver acquires information from both the high-order level gage and the low-order level gage through corresponding settings; the electric control mechanism receives the information of the level gage receiver; and the discharging speed is changed through changing the speed of the variable frequency motor, so that the level in the hopper is always kept at a certain height, and wind blockage is formed during feeding through a feed opening. Compared with the prior art, the novel intelligent wind locking device is simple in structure and reasonable in design, can realize automatic control through the electric control mechanism, reduces air intake as much as possible while guaranteeing the normal feeding quantity of the vertical mill, and achieves wind locking and blocking functions.

Owner:孟周强

Seed fertilizer mixing planting device

ActiveCN110663319BWon't clogEasy to receiveDibble seedersSeed depositing seeder partsAgricultural scienceSolenoid valve

The invention relates to a seed fertilizer mixing planting device, belonging to the technical field of agricultural machinery, comprising a cup body, a blanking regulator and a mixing control system. The cup body is provided with two large and middle small mixing passages, and an organic mixing passage is arranged at the upper end of the mixing passage. Fertilizer inlet and seed inlet, the lower end of the mixing channel is provided with a seed fertilizer drop opening, and the feeding regulator includes a material retaining cover that can be rotatably arranged at the seed fertilizer drop opening and an opening and closing motor that rotates and drives the material retaining cover , the mixing control system includes a counting sensor arranged at the seed inlet, a switching solenoid valve arranged at the organic fertilizer inlet, and a PLC controller electrically connected to the counting sensor and the switching solenoid valve. The invention can realize automatic mixed hole application of organic fertilizer and crop seeds, and has high automation degree, uniform and reliable mixing, fine operation without waste, strong adaptability and high seed survival rate.

Owner:SOUTHWEST UNIV

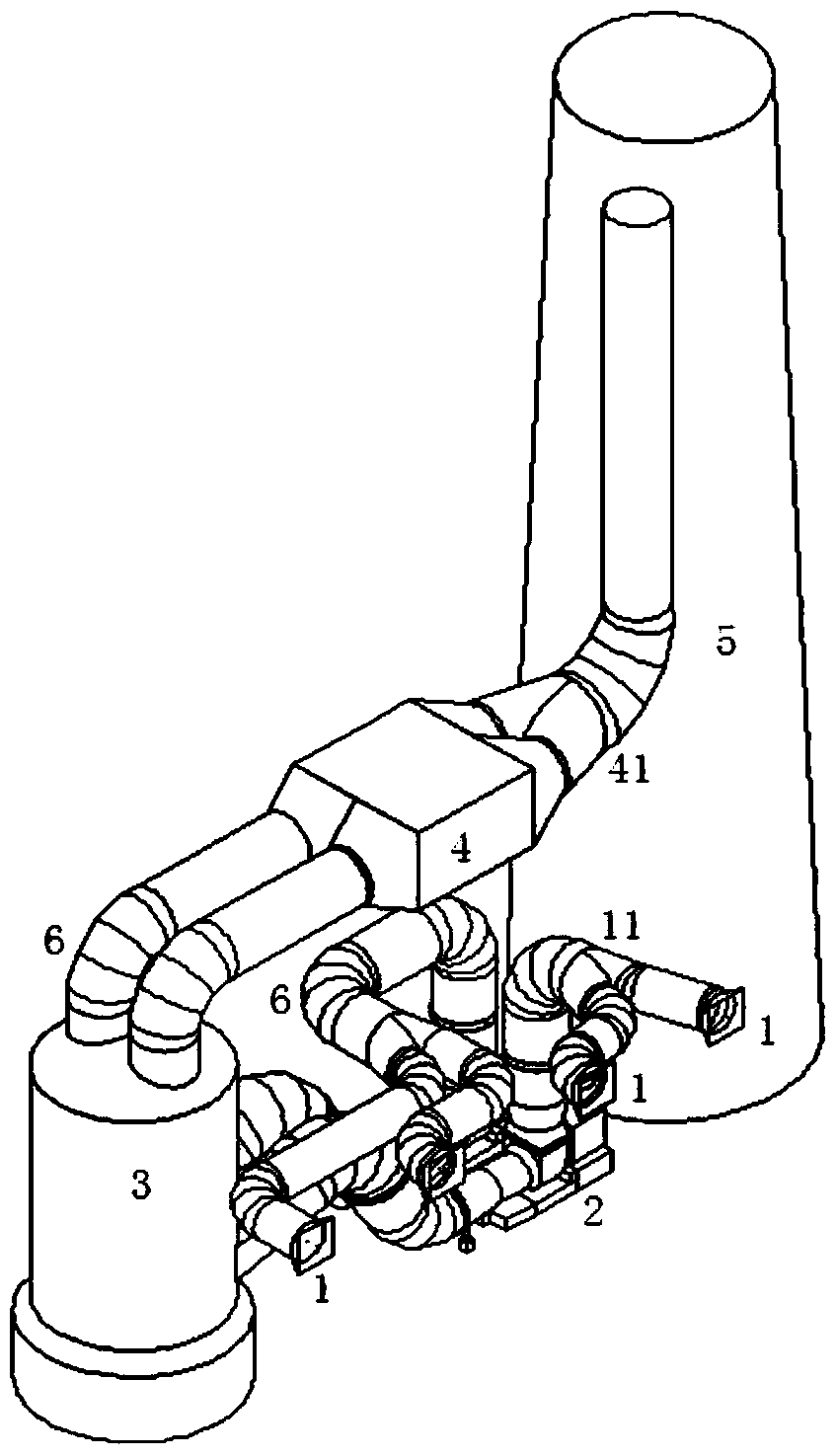

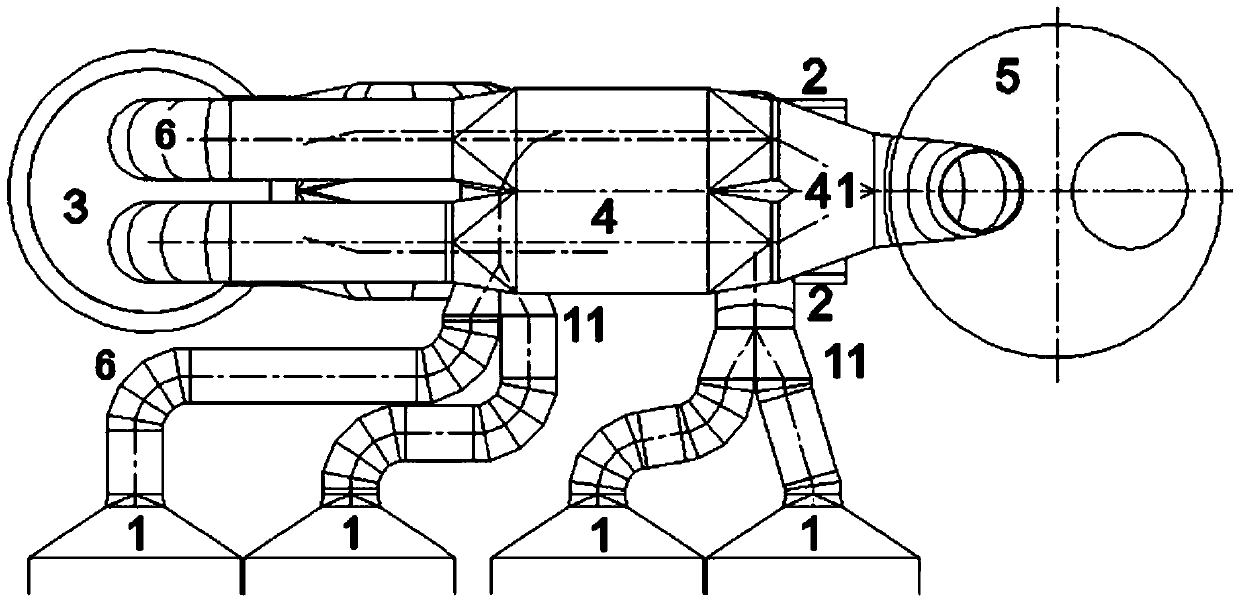

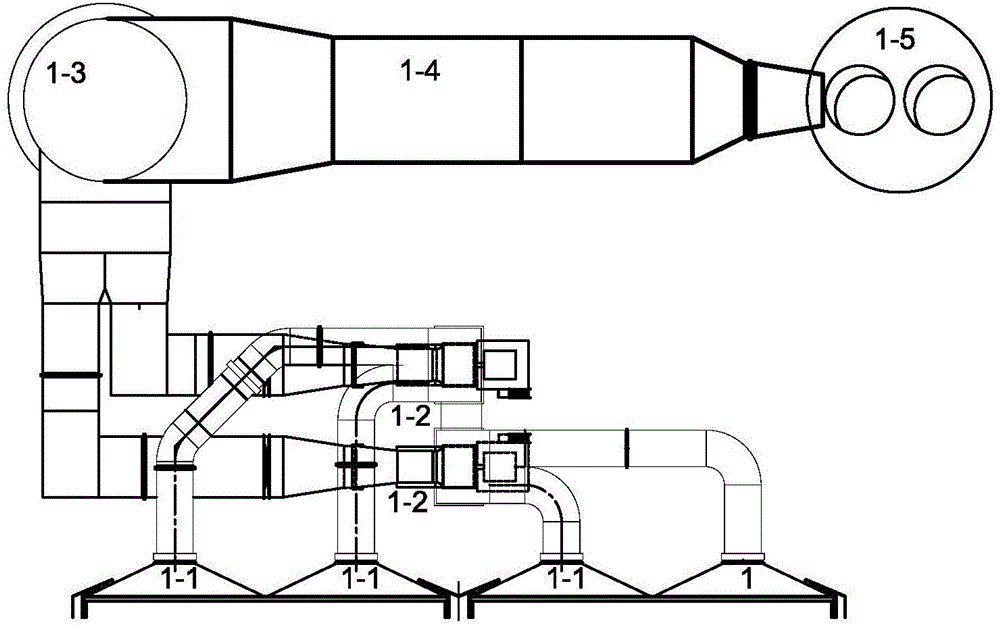

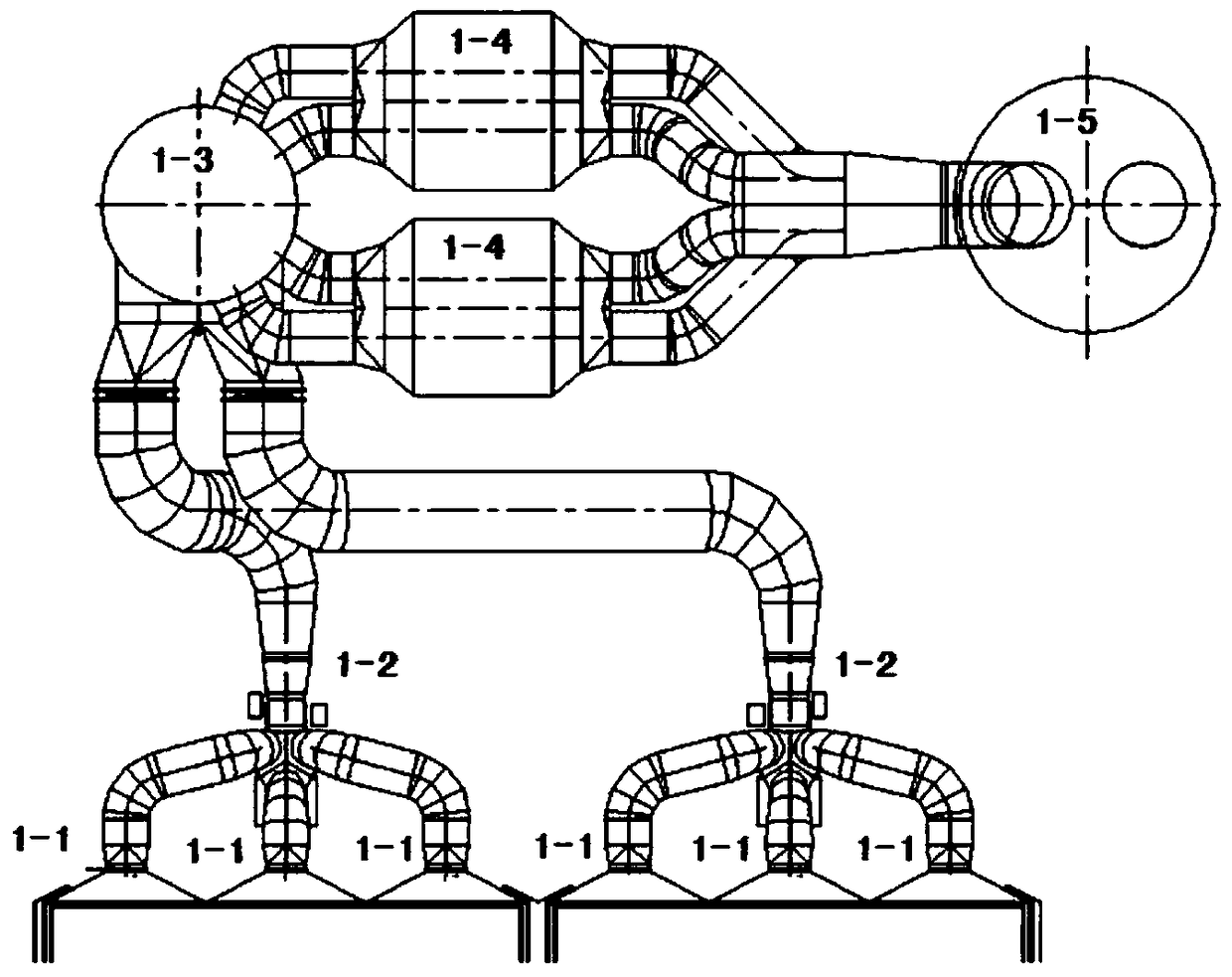

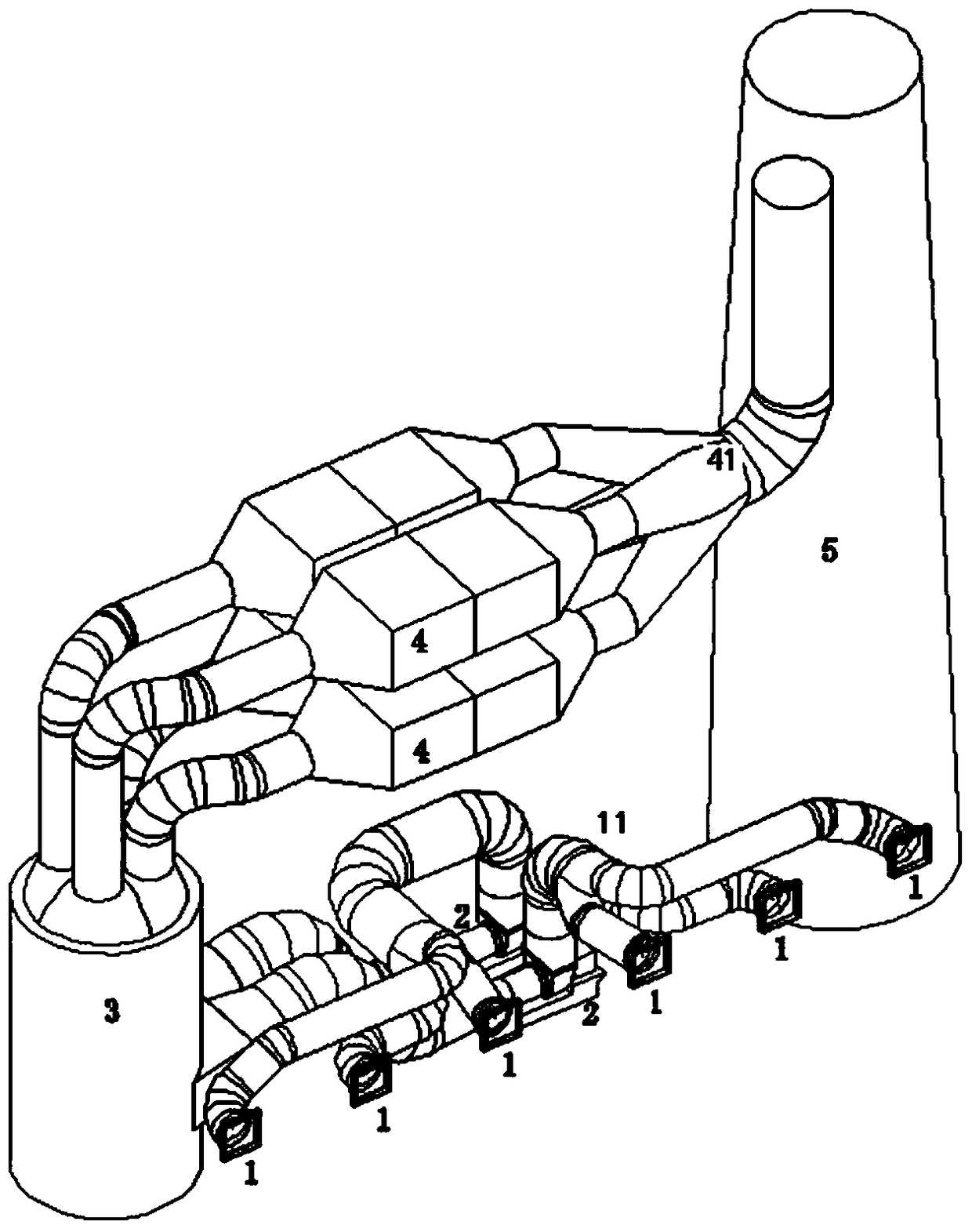

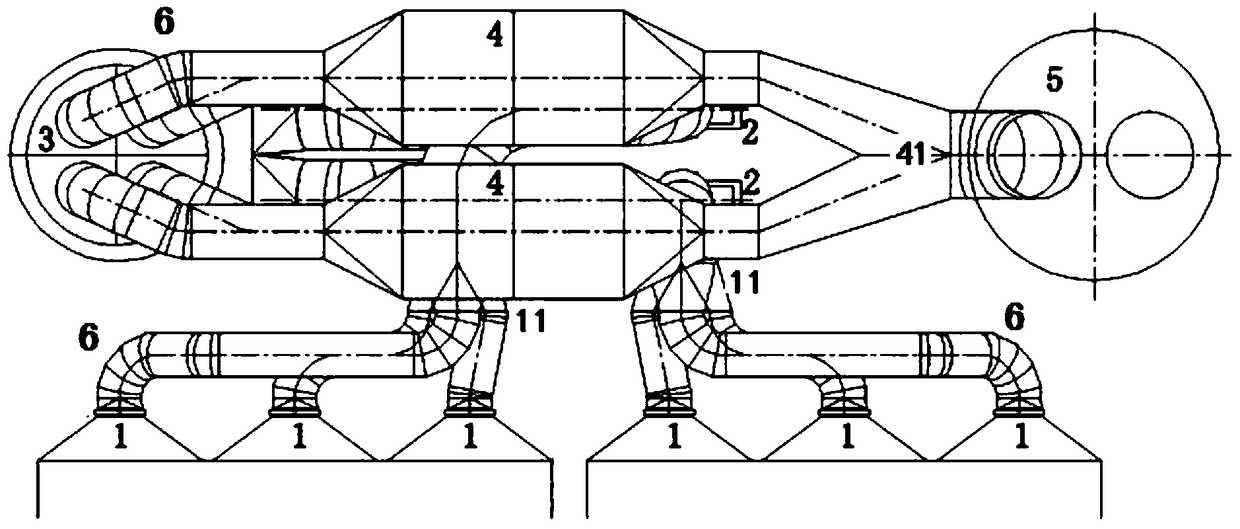

Combined layout structure of four-outlet dust collector and double-row induced draft fan for rear flue air system in power plant

ActiveCN104791821BReduce the amount of materialSmall pressure lossDraught inductionAbsorption columnFlue gas

The present invention relates to the joint layout structure of four outlets of dust collectors and double-row induced draft fans for power plants, including four outlets of dust collectors, induced draft fan structure, desulfurization absorption tower, wet electrostatic precipitator and chimney, and the induced draft fan structure consists of two One set of induced draft fans constitutes a double-row induced draft fan structure, and the outlets of every two dust collectors are connected to the air inlet of one induced draft fan; the air outlets of the two induced draft fans are connected to one air inlet of the desulfurization absorption tower, and the air outlet of the desulfurization absorption tower passes through The wet electrostatic precipitator is connected to the air inlet of the chimney; the desulfurization absorption tower is a vertical structure, the air inlet of the desulfurization absorption tower is set at the lower part of the side wall, and the air outlet is set at the top; the induced draft fan structure and the outlets of the four dust collectors are set in the desulfurization absorption tower Between the chimney and the chimney, the structure of the induced draft fan is located below the outlets of the four dust collectors, the wet electrostatic precipitator is located above the outlets of the four dust collectors, the structure of the wet electrostatic precipitator is located directly above the induced draft fan, and the outlets of the dust collectors are arranged horizontally , the air inlet of the induced draft fan structure is arranged vertically, and the air outlet is arranged horizontally. The invention has low cost, less land occupation and good operation effect.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

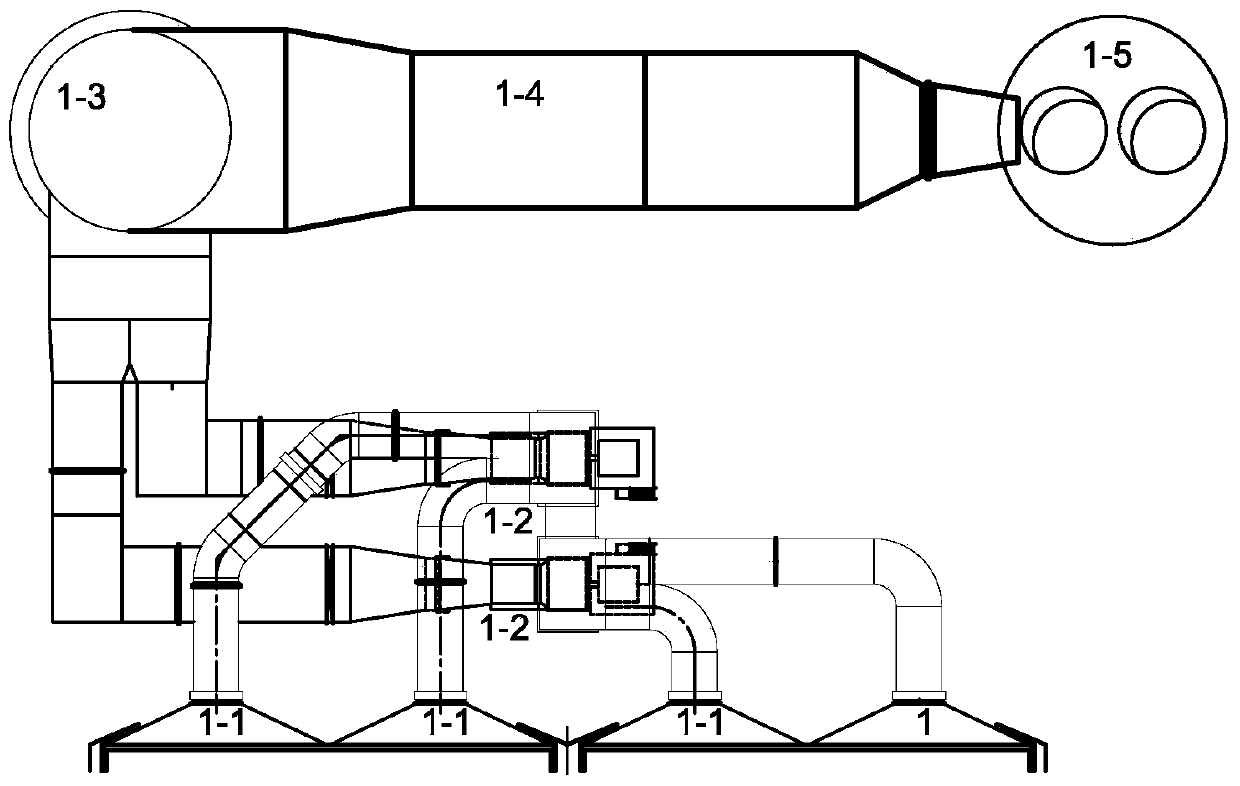

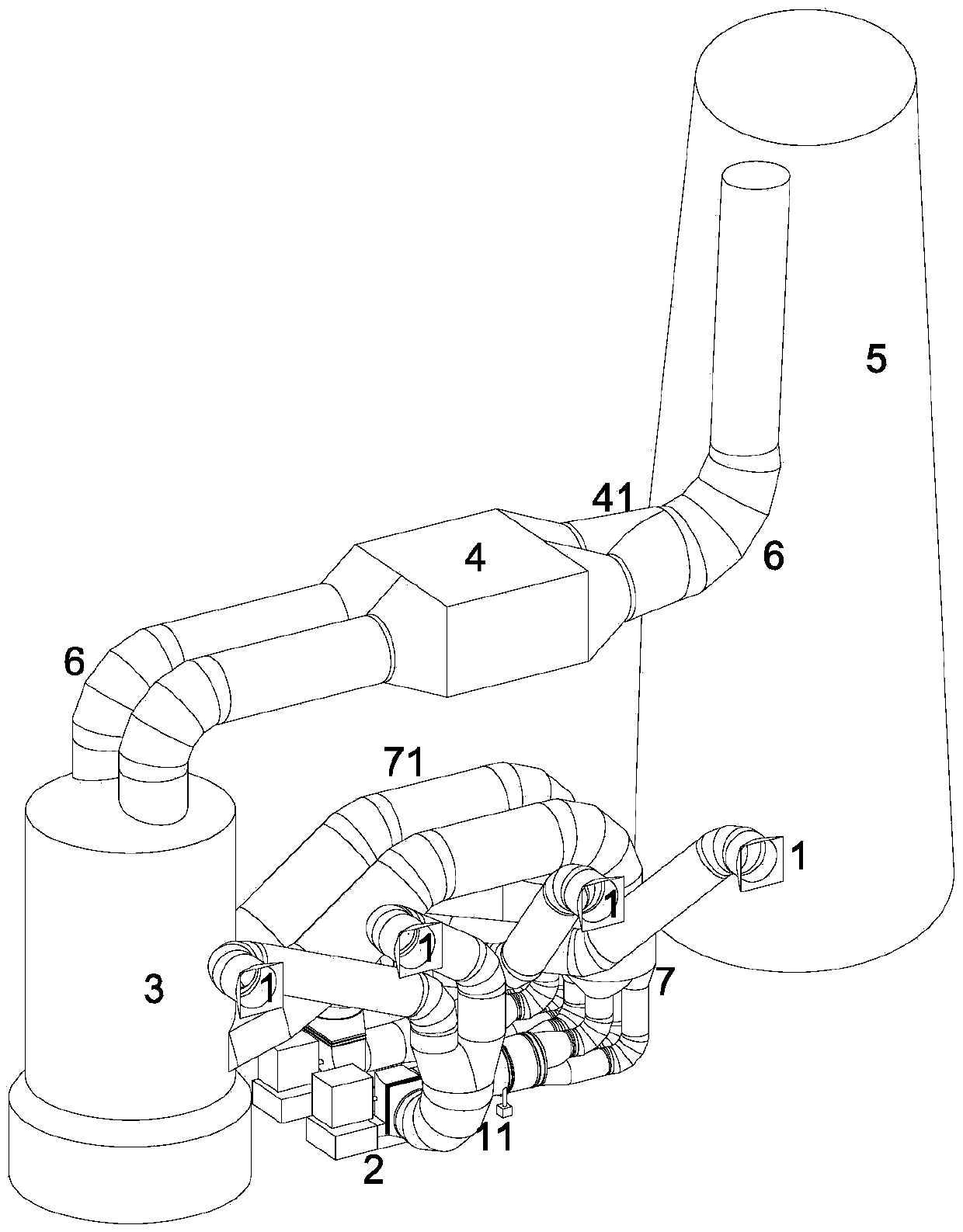

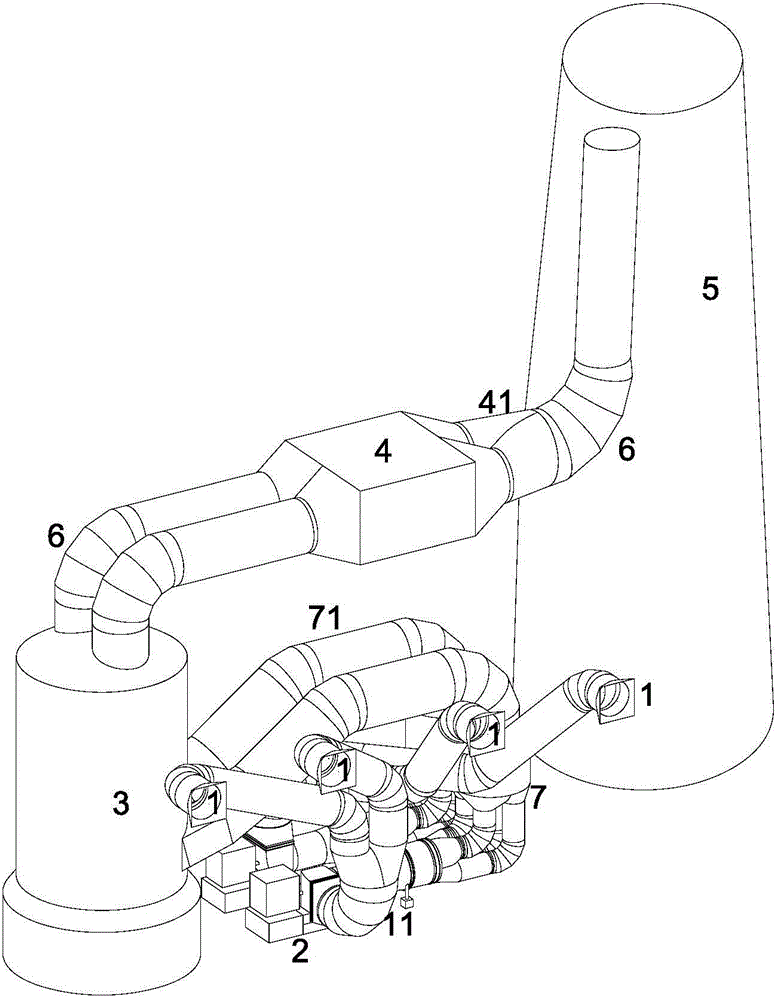

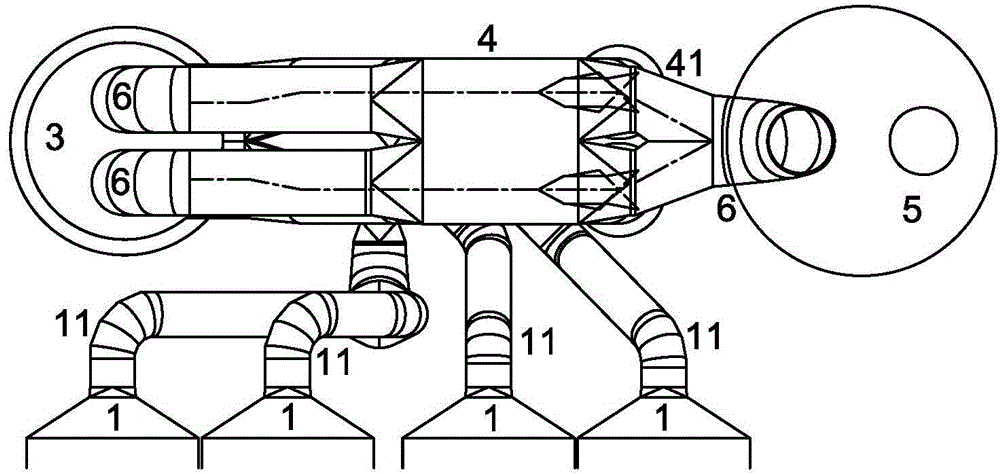

Combined layout structure of four-outlet double-row rear flue air system with flue gas waste heat recovery device

ActiveCN104896491BSave materialUniform flow fieldCombustion technology mitigationDraught inductionWind systemSmall footprint

The invention relates to a four-outlet biserial rear smoke wind system combined layout structure with a flue gas waste heat recovery device. The four-outlet biserial rear smoke wind system combined layout structure comprises four dust catcher outlets, a draught fan structure, a desulfurizing absorption tower, a wet type Electrostatic precipitator structure and a chimney; the draught fan structure is a biserial draught fan structure composed of two draught fans, an air inlet of each draught fan is communicated with the two corresponding dust catcher outlets, and the two draught fans are connected with an air inlet of the desulfurizing absorption tower through the flue gas waste heat recovery device; the wet type Electrostatic precipitator structure is made of a wet type Electrostatic precipitator, two air outlets of the desulfurizing absorption tower are connected with two air inlets of the wet type Electrostatic precipitator, and two air outlets of the wet type Electrostatic precipitator are connected with an air inlet of the chimney through a collecting pipe; and the draught fan structure, the flue gas waste heat recovery device and the four dust catcher outlets are disposed between the desulfurizing absorption tower and the chimney, the draught fan structure and the flue gas waste heat recovery device are located below the four dust catcher outlets, and the wet type Electrostatic precipitator structure is located over the four dust catcher outlets. The four-outlet biserial rear smoke wind system combined layout structure has the advantages of the less occupied area, initial investment cost reduction and the like, and also has the effects of efficient operation, energy conservation and the like.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

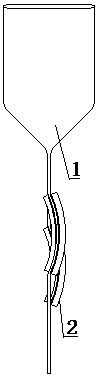

Deodorization plugging and discharging device for kitchen and bathroom

PendingCN108517924AWide openReduced discharge resistanceWater closetsSewerage structuresPunchingToilet

The invention relates to a deodorization plugging and discharging device for a kitchen and a bathroom, which aims to solve the problems of large opening amplitude and large discharge resistance in theprior art. The device includes a flexible hose with its upper port end sealed and connected to a sewer port or a sewer pipeline of the fitting appliance and communicated to the sewer pipeline or a septic tank or a lavatory pit in suspension mode. When molded, the flexible hose is presented as a flat pipe section at the middle and the lower parts or below the upper port; The flat pipe section is bent and flattened for plugging under normal conditions by using a syntropy vertical bending reinforcement way with a high edge and a low edge which are diagonal relative to the transverse direction and are relatively overlapped on the transverse parts. The flat pipe section is passively opened during punching and discharging, and is automatically recovered to the original state after punching anddischarging. The sewer port or the sewer pipeline which is hermetically connected with the upper port of the flexible hose is a toilet; or a floor drain; or a rinsing tank; or a wash basin; or a lavatory pit; or a sewer port or a sewer pipeline of a sewer pipe. The device has the advantages of large opening amplitude, small discharge resistance and easy plugging recovery.

Owner:广西康巴科技有限公司

Four-outlet biserial rear smoke wind system combined layout structure with flue gas waste heat recovery device

ActiveCN104896491ASave materialUniform flow fieldCombustion technology mitigationDraught inductionWind systemSmall footprint

The invention relates to a four-outlet biserial rear smoke wind system combined layout structure with a flue gas waste heat recovery device. The four-outlet biserial rear smoke wind system combined layout structure comprises four dust catcher outlets, a draught fan structure, a desulfurizing absorption tower, a wet type Electrostatic precipitator structure and a chimney; the draught fan structure is a biserial draught fan structure composed of two draught fans, an air inlet of each draught fan is communicated with the two corresponding dust catcher outlets, and the two draught fans are connected with an air inlet of the desulfurizing absorption tower through the flue gas waste heat recovery device; the wet type Electrostatic precipitator structure is made of a wet type Electrostatic precipitator, two air outlets of the desulfurizing absorption tower are connected with two air inlets of the wet type Electrostatic precipitator, and two air outlets of the wet type Electrostatic precipitator are connected with an air inlet of the chimney through a collecting pipe; and the draught fan structure, the flue gas waste heat recovery device and the four dust catcher outlets are disposed between the desulfurizing absorption tower and the chimney, the draught fan structure and the flue gas waste heat recovery device are located below the four dust catcher outlets, and the wet type Electrostatic precipitator structure is located over the four dust catcher outlets. The four-outlet biserial rear smoke wind system combined layout structure has the advantages of the less occupied area, initial investment cost reduction and the like, and also has the effects of efficient operation, energy conservation and the like.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Outdoor high-temperature smoke gas protective cover

The invention discloses an outdoor high-temperature smoke gas protective cover. The outdoor high-temperature smoke gas protective cover comprises a first transition cover and a second transition cover which are distributed symmetrically up and down. An upper cover piece is fixed to the top of the first transition cover. A lower cover piece is fixed to the bottom of the second transition cover. A conical dust sliding hopper is mounted in the first transition cover. An inverted-cone-shaped dust collection hopper is mounted in the second transition cover. A dust exhaust pipe is mounted at the bottom of the dust collection hopper. One end of the dust exhaust pipe communicates with the interior of the dust collection hopper, and the other end of the dust exhaust pipe obliquely penetrates through the lower cover piece downwards to communicate with the outside. Through the lower cover piece, the second transition cover, the first transition cover and the upper cover piece which are sequentially distributed along the axis, the exhaust resistance of high temperature smoke gas can be effectively reduced, and the burnout phenomenon is avoided; and rainwater and dust entering the protective cover can be rapidly drained to the outside, economic losses of equipment where the rainwater and dust flow into are avoided, the influence of direction on exhaust is reduced, and the protective cover is suitable for various regions and has the good using effect and popularization value.

Owner:HEFEI CALSIION ELECTRIC POWER SYST

Method to improve engine operating efficiency and reduce harmful gas emissions

InactiveCN103133124BImprove work efficiencyEmission reductionInternal combustion piston enginesExhaust apparatusEngine efficiencyEngineering

Disclosed are a device and a method for improving the work efficiency of an engine and reducing emission of harmful gas. The device comprises a vortex supercharger, the engine, a gas inlet manifold, an inter-cooler, a radiating fan and a radiating water tank II; the inter-cooler is a counter-current heat exchange type cooler, the counter-current heat exchange type cooler comprises fin structures and micro-channel or mini-channel structures which are alternately arranged, an outlet of a fin side of the counter-current heat exchange type cooler is connected with the gas inlet manifold by a pipeline, and an inlet of the fin side of the counter-current heat exchange type cooler is connected with the vortex supercharger by a pipeline; and the engine is respectively connected with a coolant inlet of the radiating water tank II and a coolant outlet of the inter-cooler by pipelines, and a coolant outlet of the radiating water tank II is connected with a coolant inlet of the inter-cooler by a pipeline. The invention further provides the method for improving the work efficiency of the engine and reducing the emission of the harmful gas. The device and the method have the advantages that the work efficiency of the engine can be improved by 10% at least, and the emission of the harmful gas NOX can be reduced by 24% at least.

Owner:HUNAN AGRICULTURAL UNIV +1

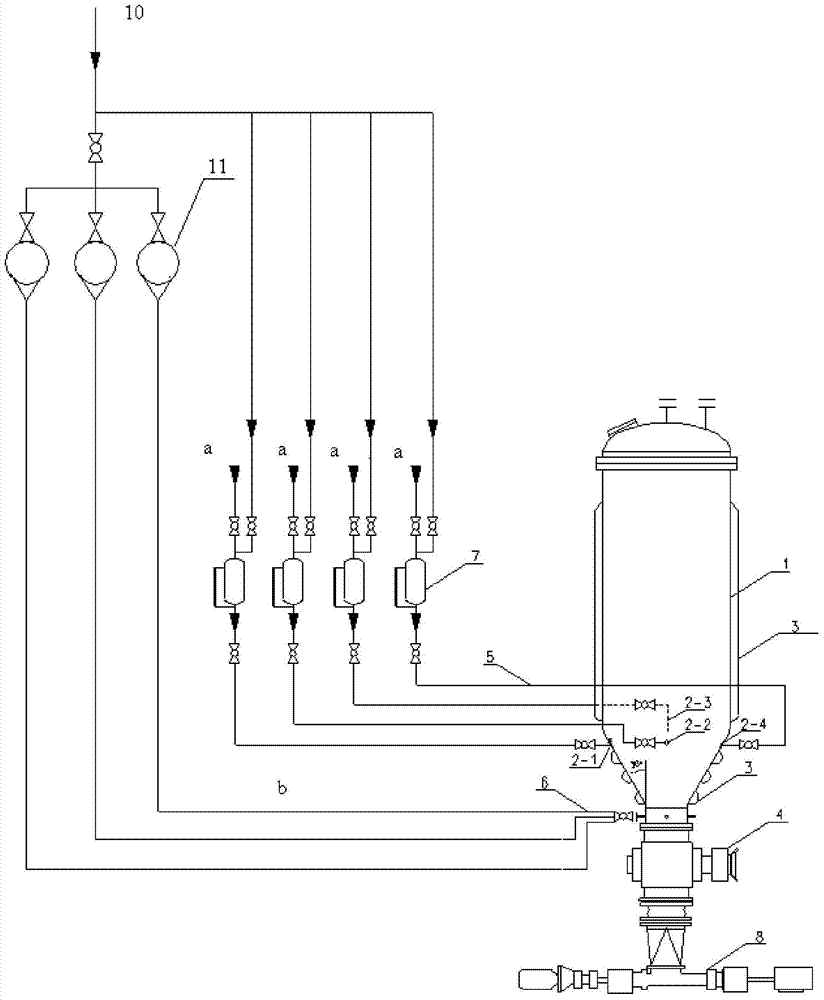

A kind of polymerization reactor component and its using method

Owner:CHINA PETROLEUM & CHEM CORP +1

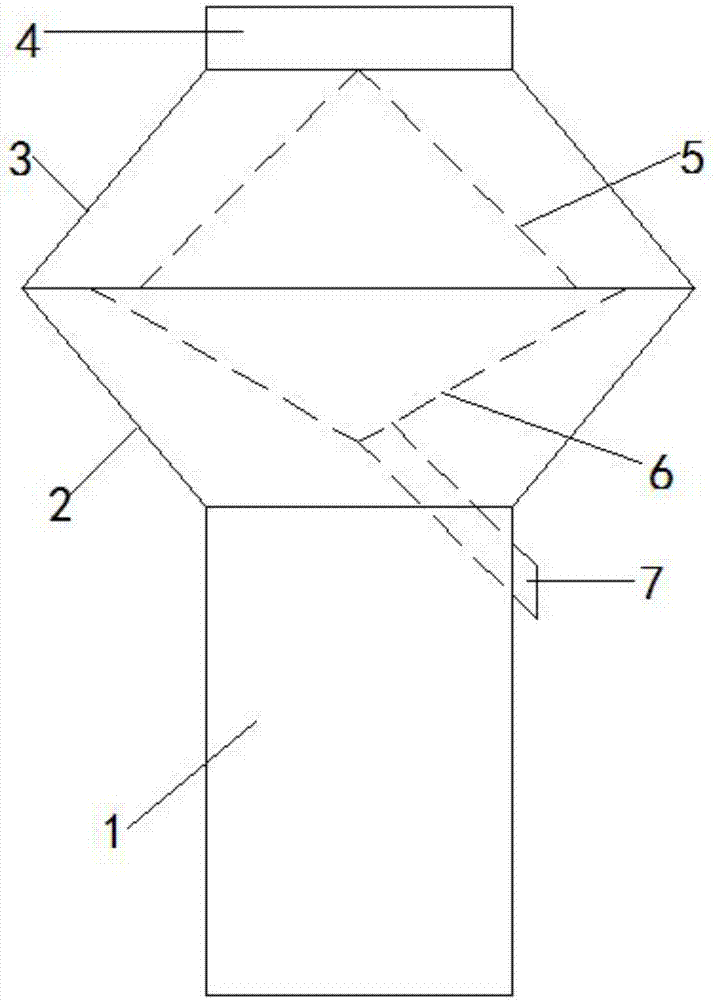

Combined layout structure of the rear flue air system with six outlets of dust collectors in power plants

The invention relates to a rear air-flue gas system combined arrangement structure with six dust remover outlets for a power plant. The rear air-flue gas system combined arrangement structure comprises the six dust remover outlets, an induced draft fan structure, a desulfurization absorbing tower, a wet electrical dust remover structure and a chimney, wherein the induced draft fan structure is a double-column induced draft fan structure composed of two induced draft fans, every three dust remover outlets are connected with an air inlet of one induced draft fan, and air outlets of the two induced draft fans are connected with an air inlet of the desulfurization absorbing tower; the wet electrical dust remover structure is composed of four wet electrical dust removers; the desulfurization absorbing tower is provided with one air inlet and four air outlets; the induced draft fan structure and the six dust remover outlets are formed between the desulfurization absorbing tower and the chimney, the induced draft fan structure is located below the six dust remover outlets, the wet electrical dust remover structure is located above the six dust remover outlets and just over the induced draft fans, the six dust remover outlets are horizontally formed, the air inlets of the induced draft fan structure are vertically formed, and the air outlets of the induced draft fan structure are horizontally formed. The rear air-flue gas system combined arrangement structure disclosed by the invention is low in cost, occupies small space, and is good in running effect.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Scroll compressor having enhanced discharge structure

PendingUS20220364564A1Enhanced discharge structureReduced discharge resistanceRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRefrigerant

Owner:LG ELECTRONICS INC

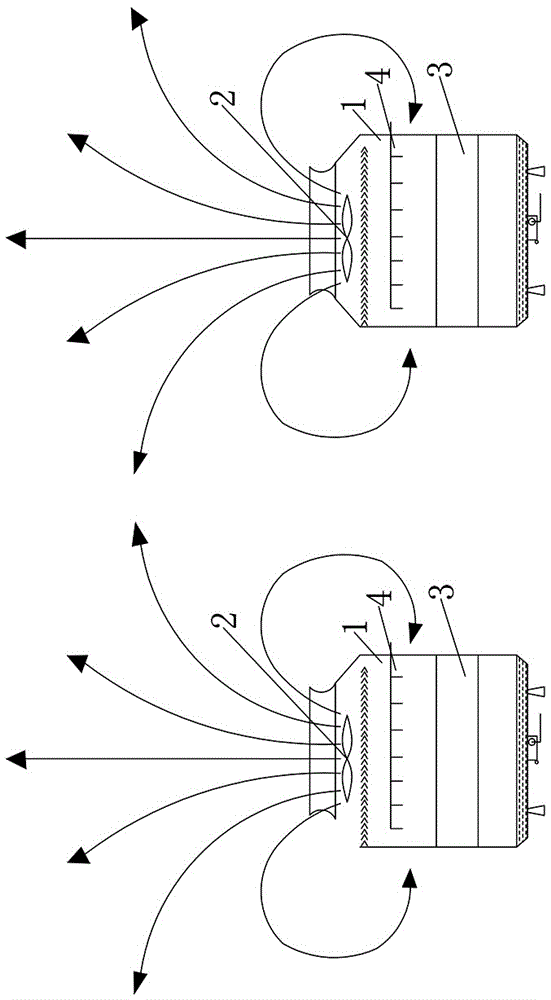

Air-conditioning and cooling tower group that can reduce the back-mixing rate of hot and humid air

ActiveCN104329957BReduced discharge resistanceReduce refluxTrickle coolersCooling towerAir conditioning

The invention discloses an air conditioner cooling tower group capable of reducing the damp and hot air back-mixing ratio. The air conditioner cooling tower group includes a plurality of cooling towers. The top of each cooling tower is provided with a wind tunnel. The plurality of the cooling towers are arranged in the environmental wind flowing direction and are arranged in more than two rows. Heights of the wind tunnels are gradually reduced in the environmental wind flowing direction. By means of the air conditioner cooling tower group capable of reducing damp and hot air back-mixing ratio, the ventilating resistance can be reduced and damp and hot air discharged from the cooling towers can be discharged to upper air easily.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com