High-rise building hydraulic discharging platform device and working method thereof

A technology for unloading platforms and high-rise buildings, applied in the processing of building materials, construction, building structure, etc., can solve problems such as hidden safety hazards, troublesome lifting and difficult to push the loading rack, and achieve the effect of reducing unloading resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

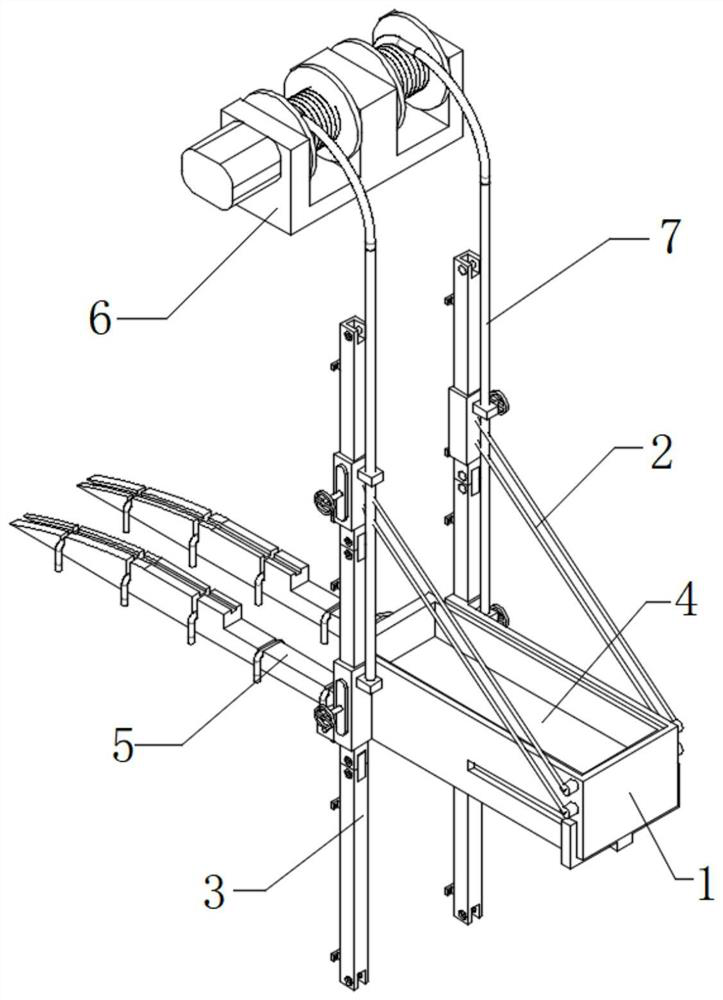

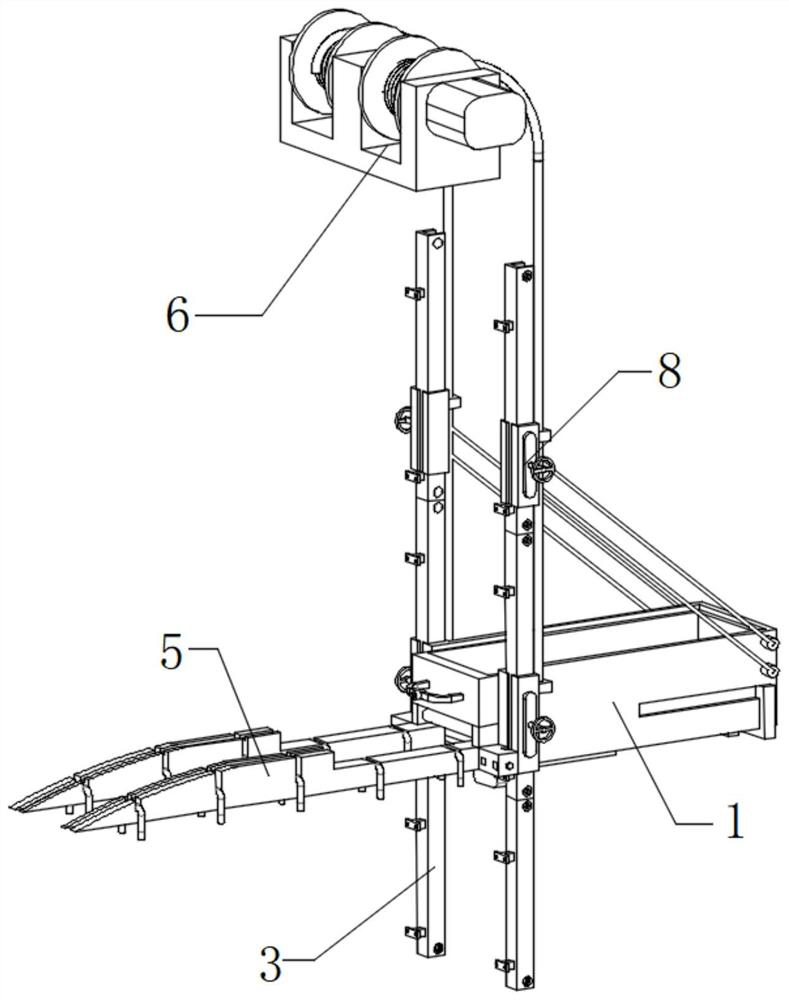

[0052] like Figure 1-8 Shown is a high-rise building hydraulic unloading platform device and its working method, comprising a unloading platform main body 1 and a slidable storage hopper 4 arranged inside the unloading platform main body 1;

[0053] The unloading platform main body 1, one end of the unloading platform main body 1 is fixedly installed with the unloading slide rail 5, the two sides of the unloading platform main body 1 are provided with spliced slide rails 3 for height lifting, and the other end of the unloading platform main body 1 is provided A cable-stayed cable 2 is fixedly installed, and a sliding sleeve 8 is fixedly connected to the outer surface of the unloading platform main body 1 and the end of the cable-stayed 2 , and the sliding sleeve 8 is fixedly installed on the outer surface of the spliced slide rail 3 . , the top of the spliced slide rail 3 is provided with a wire reel 6, and the inside of the wire reel 6 is wound with a lifting wire 7, a...

Embodiment 2

[0058] like Figure 1-8 Shown is a high-rise building hydraulic unloading platform device and its working method, comprising a unloading platform main body 1 and a slidable storage hopper 4 arranged inside the unloading platform main body 1;

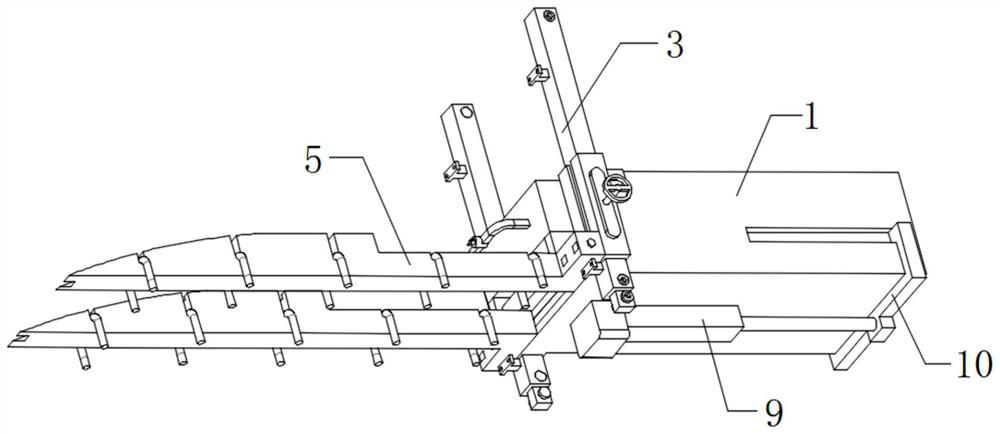

[0059] Storage hopper 4, the bottom of the storage hopper 4 is provided with a sliding support frame 11, the lower surface of the unloading platform main body 1 is provided with a hydraulic telescopic rod 9, the output end of the hydraulic telescopic rod 9 is fixedly connected with the sliding support frame 11, and the sliding support frame 11 A rotating flap 14 is rotatably connected to the inner top of the rotating flap 14, and a rotating strut 18 is hinged on the lower surface of the end of the rotating flap 14. The other end of the rotating strut 18 is internally rotatably connected with a sliding shaft 16, and the two ends of the sliding shaft 16 slide respectively. Connected to both sides of the inner wall of the main body 1 of the...

Embodiment 3

[0063] like Figure 1-8 Shown is a high-rise building hydraulic unloading platform device and its working method, comprising a unloading platform main body 1 and a slidable storage hopper 4 arranged inside the unloading platform main body 1;

[0064] The pulley is rollingly connected to the upper surface of the rotating flap 14, the slideway 25 is the same height as the sliding support frame 11, the outer surface of the storage hopper 4 is fixedly connected with a discharge handle 26, and the middle of the discharge handle 26 is fixedly welded with a fixed sleeve 27 , a pull rod 28 is movably inserted inside the fixed sleeve 27, and a T-shaped clamping rod 29 is movably inserted on both sides of the lower surface of the storage hopper 4. The sliding support frame 11 is movably clamped, the storage hopper 4 is provided with a spring 31 in the internal measurement, the spring 31 is in contact with the top of the T-shaped clamping rod 29, the top of the T-shaped clamping rod 29 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com