A kind of polymerization reactor component and its using method

A technology for a polymerization reaction kettle and an assembly is applied in the field of the reaction kettle assembly and its control process, which can solve the problems of high labor intensity for operators in manual cleaning, large pressure difference between the upper and lower rubber blocks, affecting production efficiency, etc. The effect of reducing design pressure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

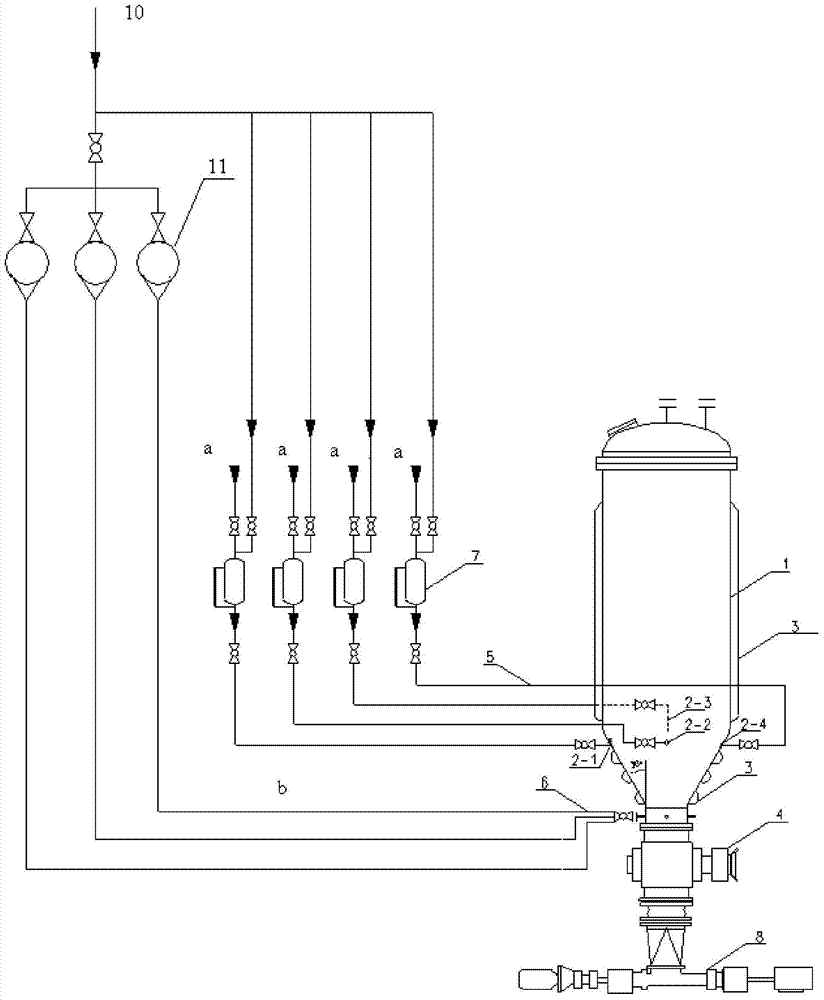

Embodiment 1

[0037] A polymerization reactor assembly and a method of use for a reaction that uses or contains acrylamide as a raw material, wherein the polymerization reactor assembly includes a kettle body 1, a gas blowing port and a gas blowing line 6, and the gas blowing port and the gas blowing line 6 Connect the gas source 10 (four groups in total), the bottom of the kettle body 1 is provided with a discharge port and connected to the granulation device, and the kettle body 1 is provided with lubricating liquid inlets 2-1, 2-2, 2-3 , 2-4, can be used for passing into lubricating liquid and purge gas, each lubricating liquid feeding port 2-1, 2-2, 2-3, 2-4 connects lubricating liquid and adds pipeline 5 to transport lubricating liquid. Each lubricating liquid adding pipeline 5 is provided with a lubricating liquid metering tank 7 , and each lubricating liquid metering tank 7 is connected to the air source 10 .

[0038] The top of the kettle body 1 is provided with a feed inlet, the bo...

Embodiment 2

[0054] The difference between embodiment 2 and the polymerization reactor assembly of embodiment 1 is:

[0055] The diameter of the straight section of kettle body 1 is φ1800mm, the length of the straight section is 3150mm, and the length of the cone section is 1300mm. Other features of the polymerization reactor assembly of Example 2 are the same as those of Example 1.

[0056] The usage method of this embodiment is as follows:

[0057] 1) Through the feeding port set on the top of the kettle body 1, add the reaction raw materials to carry out the polymerization reaction according to the requirements of the reaction process. During the polymerization reaction, use the gas blowing port and the gas blowing pipeline 6 to feed nitrogen gas to stir and mix the reaction raw materials in the kettle body 1 , after the end of the polymerization reaction, a whole block of polymer glue is formed in the kettle body 1, and the discharging operation is started;

[0058] 2) Open the disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com