Patents

Literature

523results about "Draught induction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable-volume exhaust system

ActiveUS10029289B2Reduce energy consumptionReduce flow ratePump componentsSpace heating and ventilation safety systemsControl systemShock absorber

Owner:GREENHECK FAN

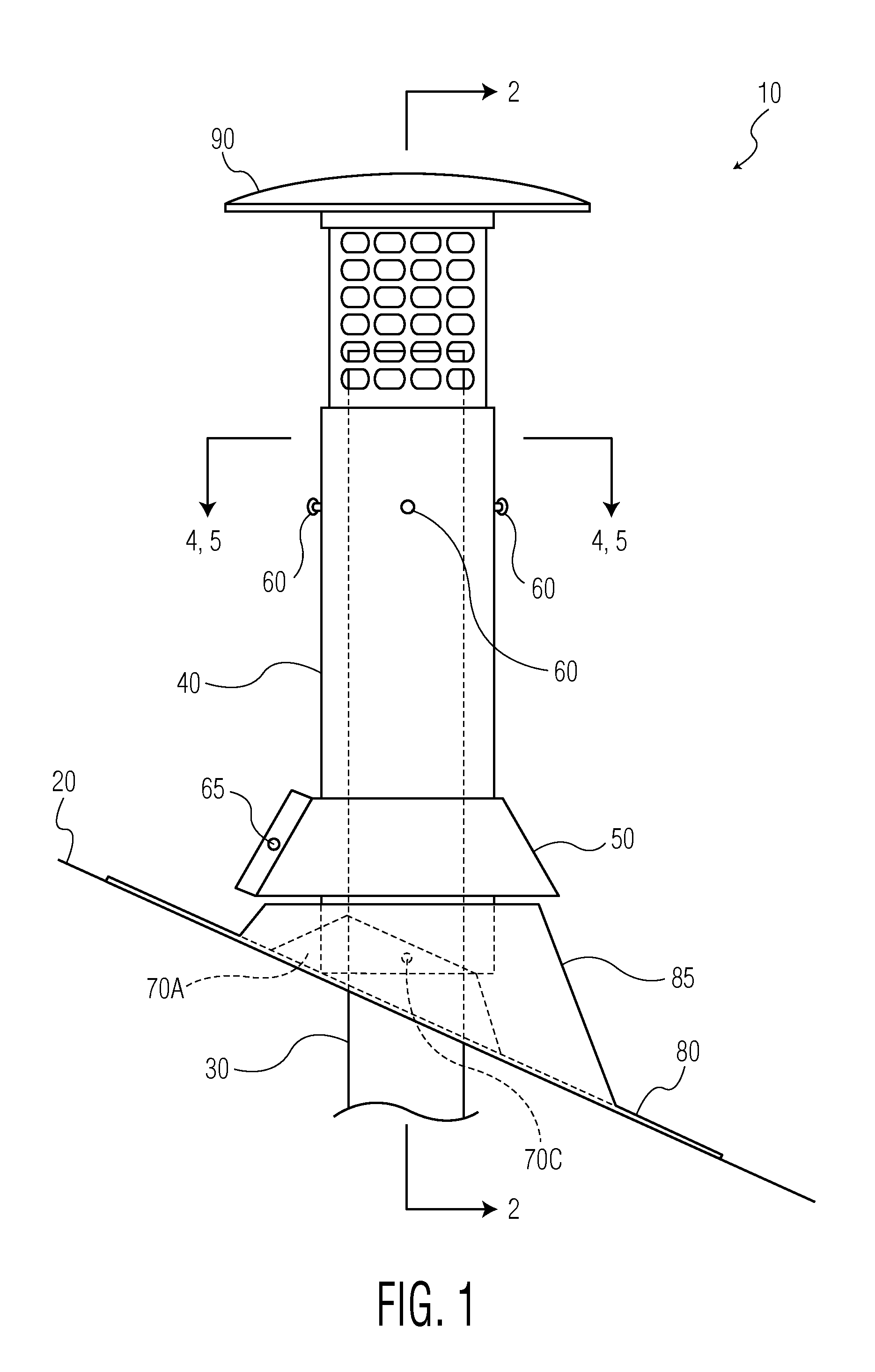

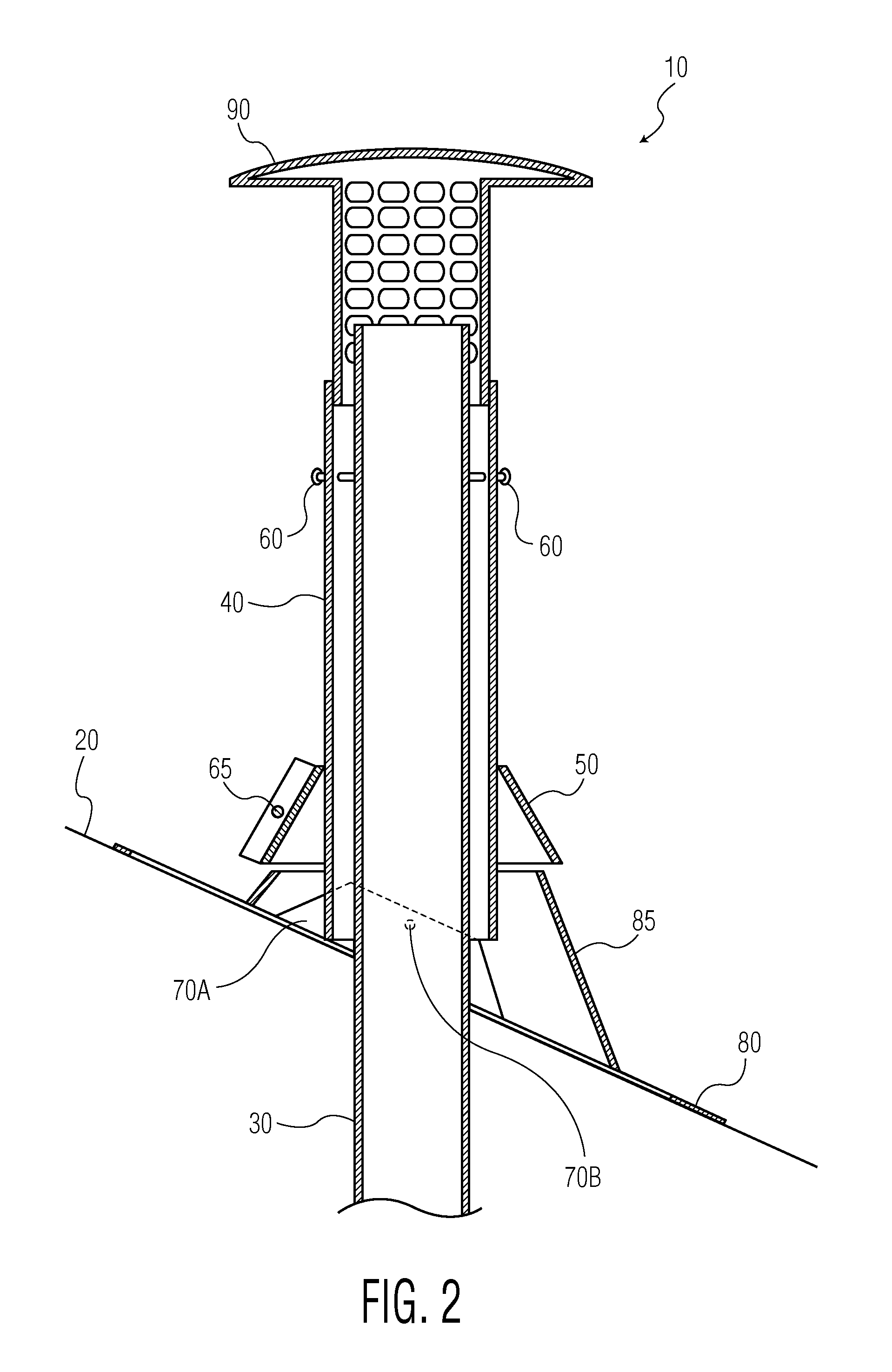

Universal chimney pipe cover

A covering system that covers an end pipe of a chimney system. A portion of the end pipe protrudes from the roof of a house or building where the chimney system is located. The system comprises of at least two base supports that sit on the roof. A channel spanning around the end pipe of the chimney system that protrudes from the roof. The base supports are attached at the base of the channel. The base has a protruding section whose dimensions are larger than the channel. A collar covering having a first and a second opening. The collar covers the protruding section of the base by its first opening and receives the channel at its second opening. A crown top base that slides inside of the channel from the top.

Owner:TOP HAT CHIMNEY SYST

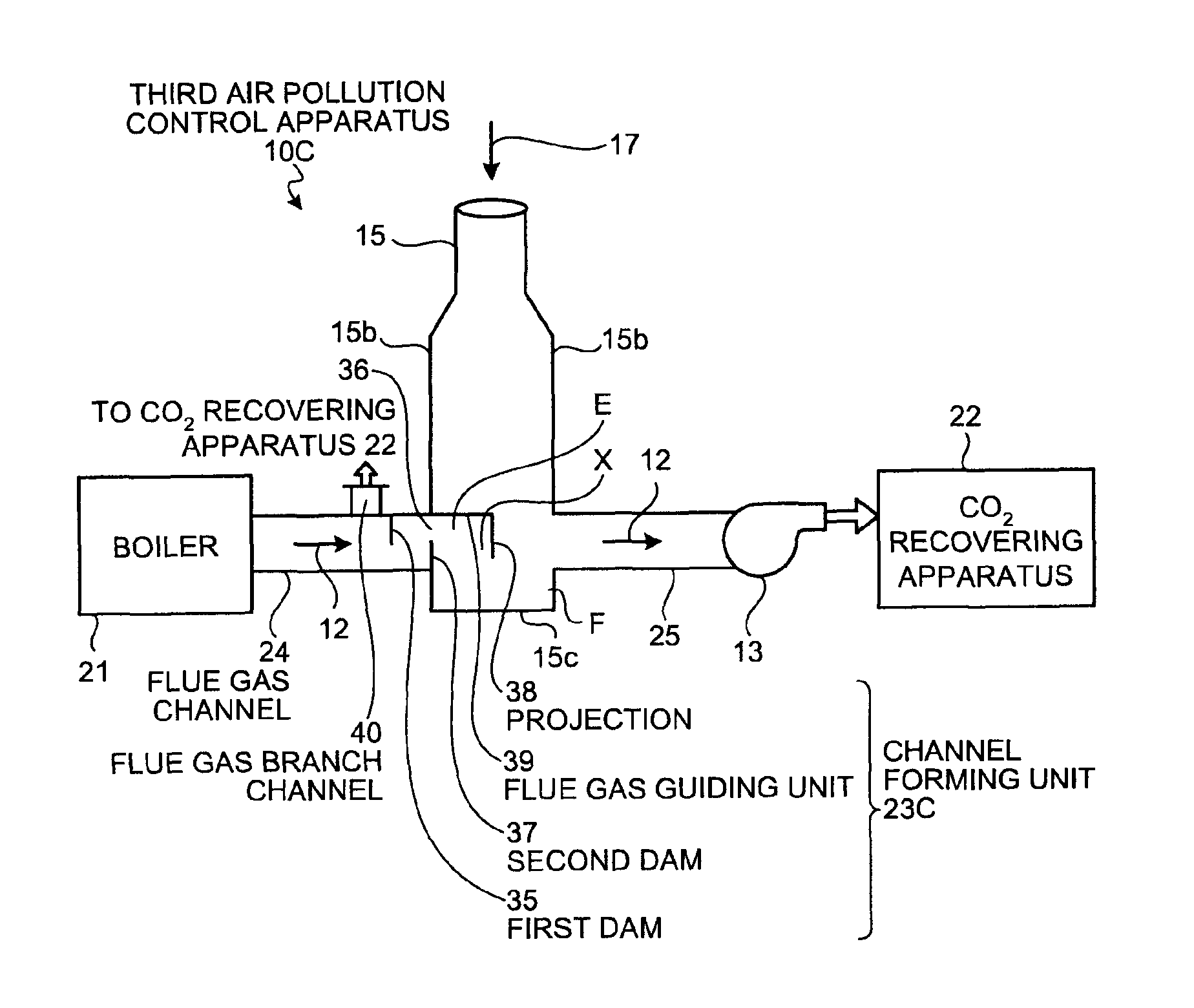

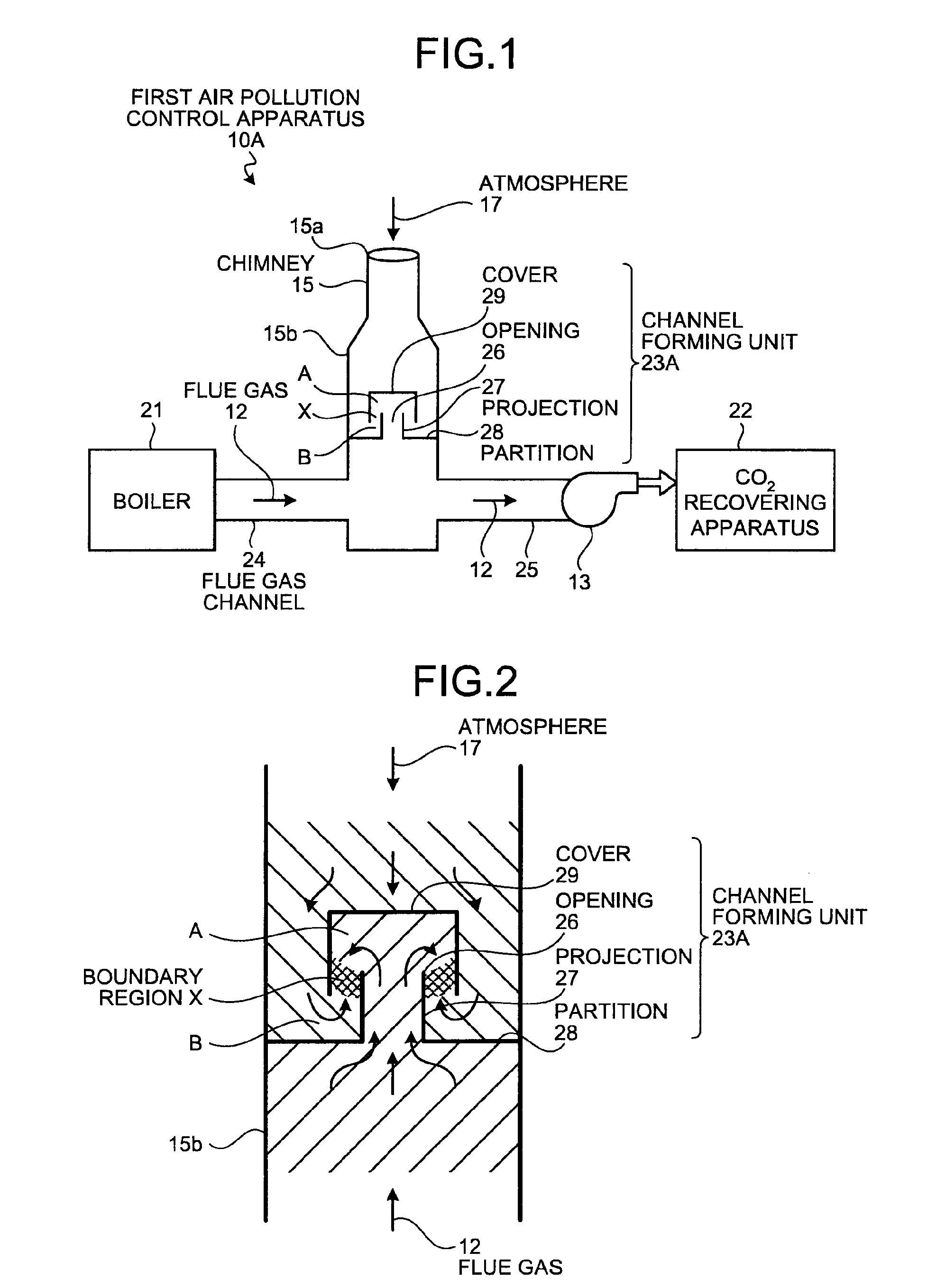

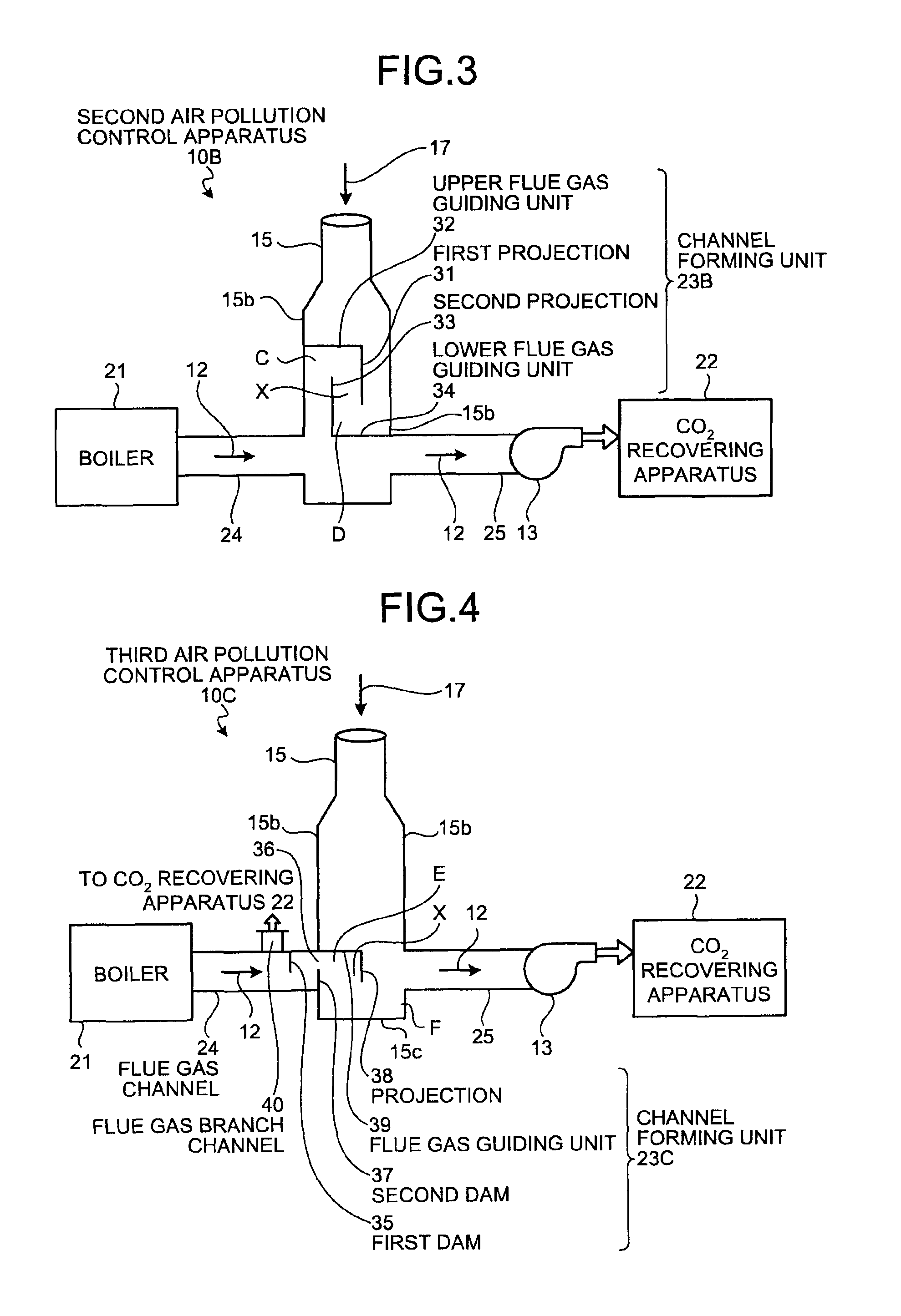

Air pollution control apparatus and air pollution control method

An air pollution control apparatus according to an embodiment of the present invention includes: a stack that discharges flue gas discharged from a boiler outside; a blower that is provided downstream of the stack and draws in the flue gas; and a CO2 recovering apparatus that recovers CO2 in the flue gas drawn in by the blower. The stack includes a controlling unit that suppresses release of the flue gas outside from the stack and suppresses inflow of atmosphere to the stack, and the controlling unit is a channel forming unit that forms a serpentine channel through which the flue gas and the atmosphere in the stack flow.

Owner:MITSUBISHI HEAVY IND ENG LTD

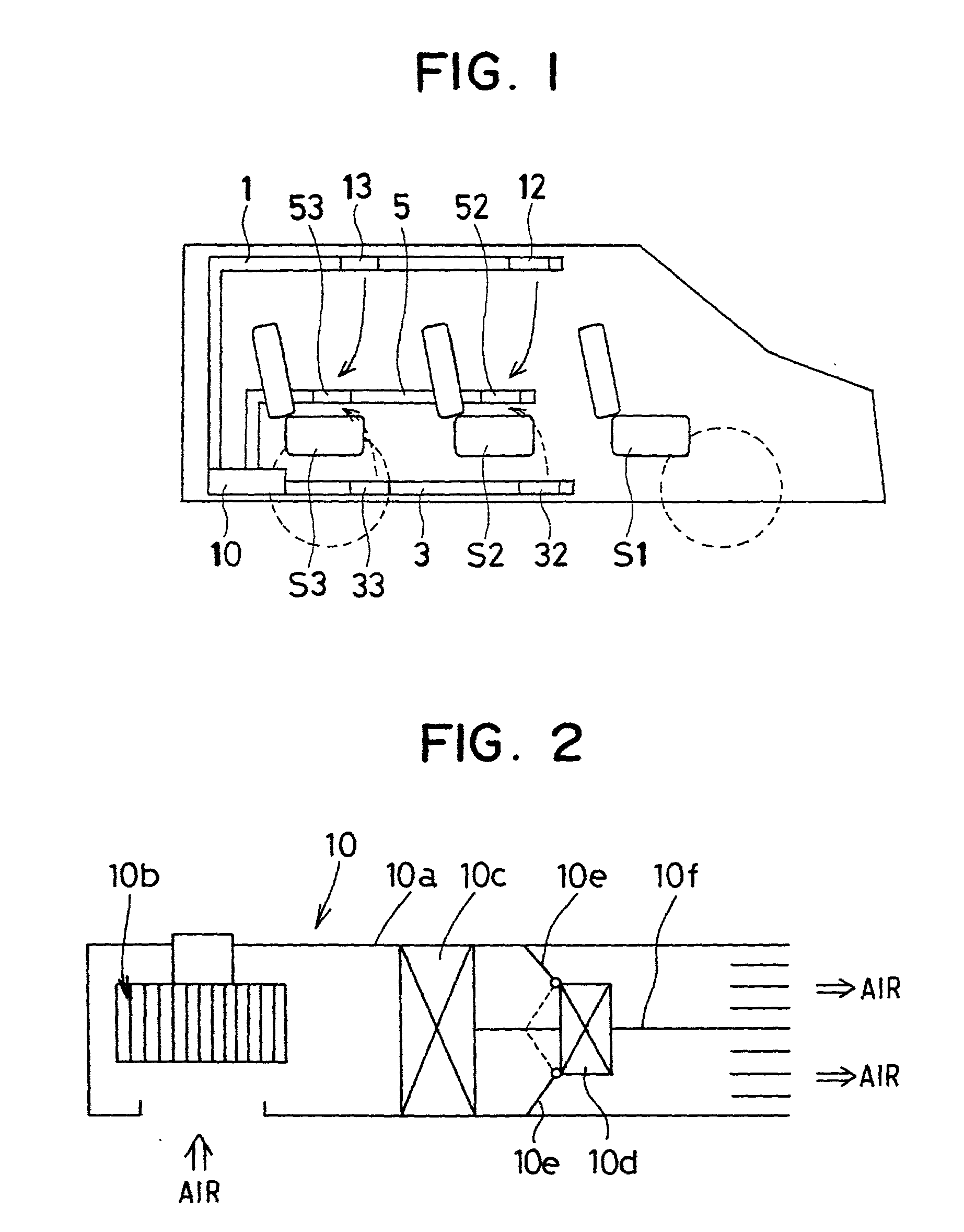

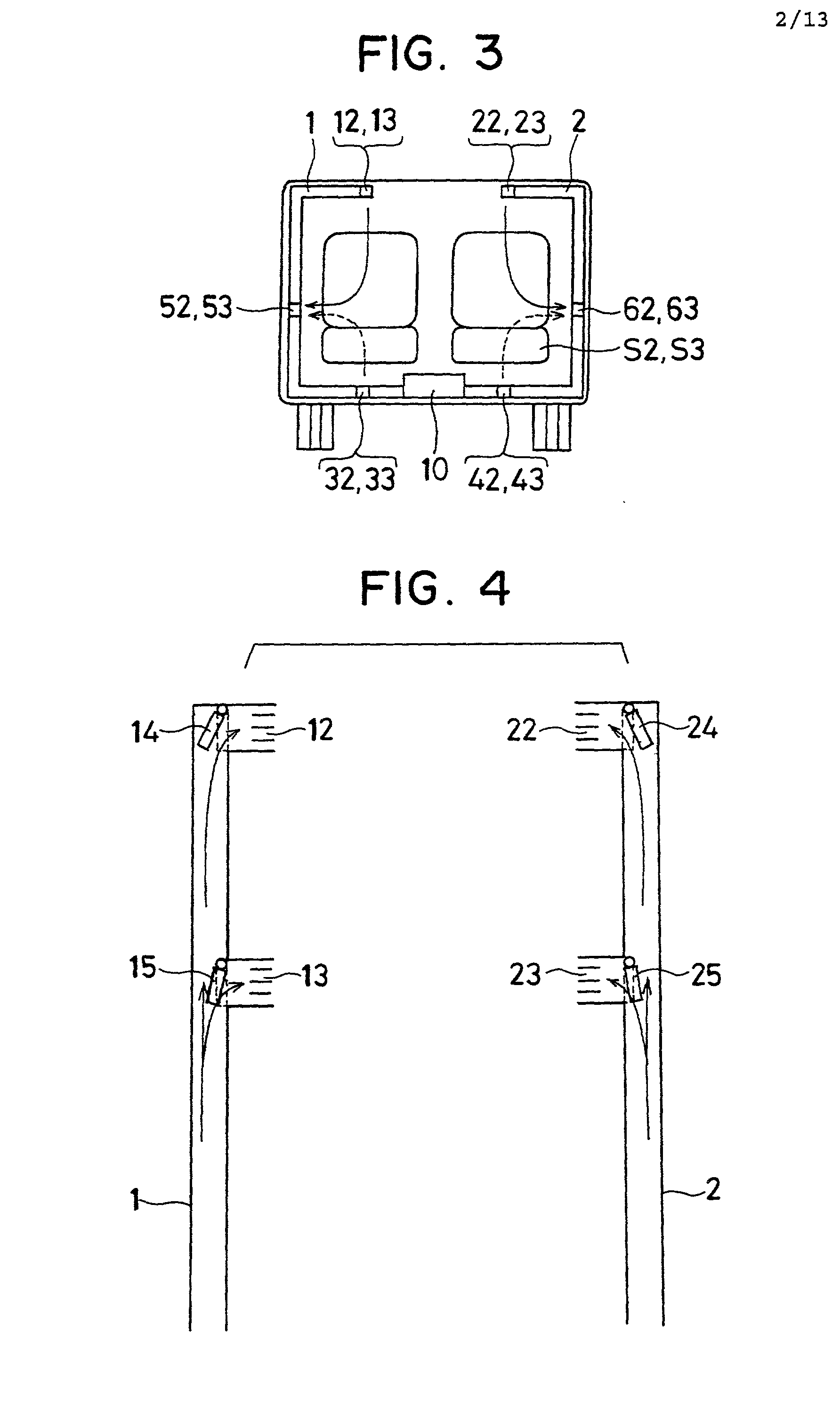

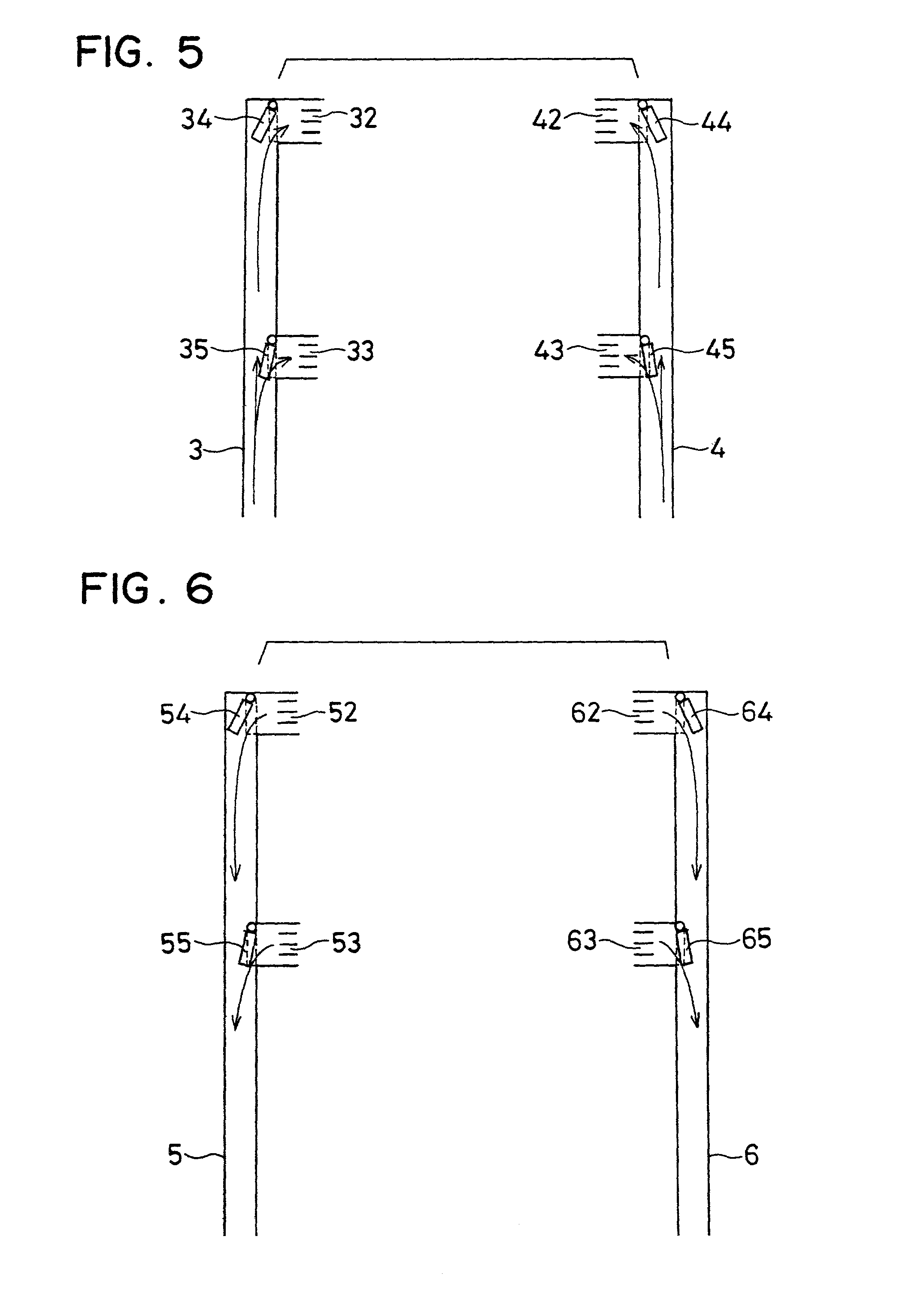

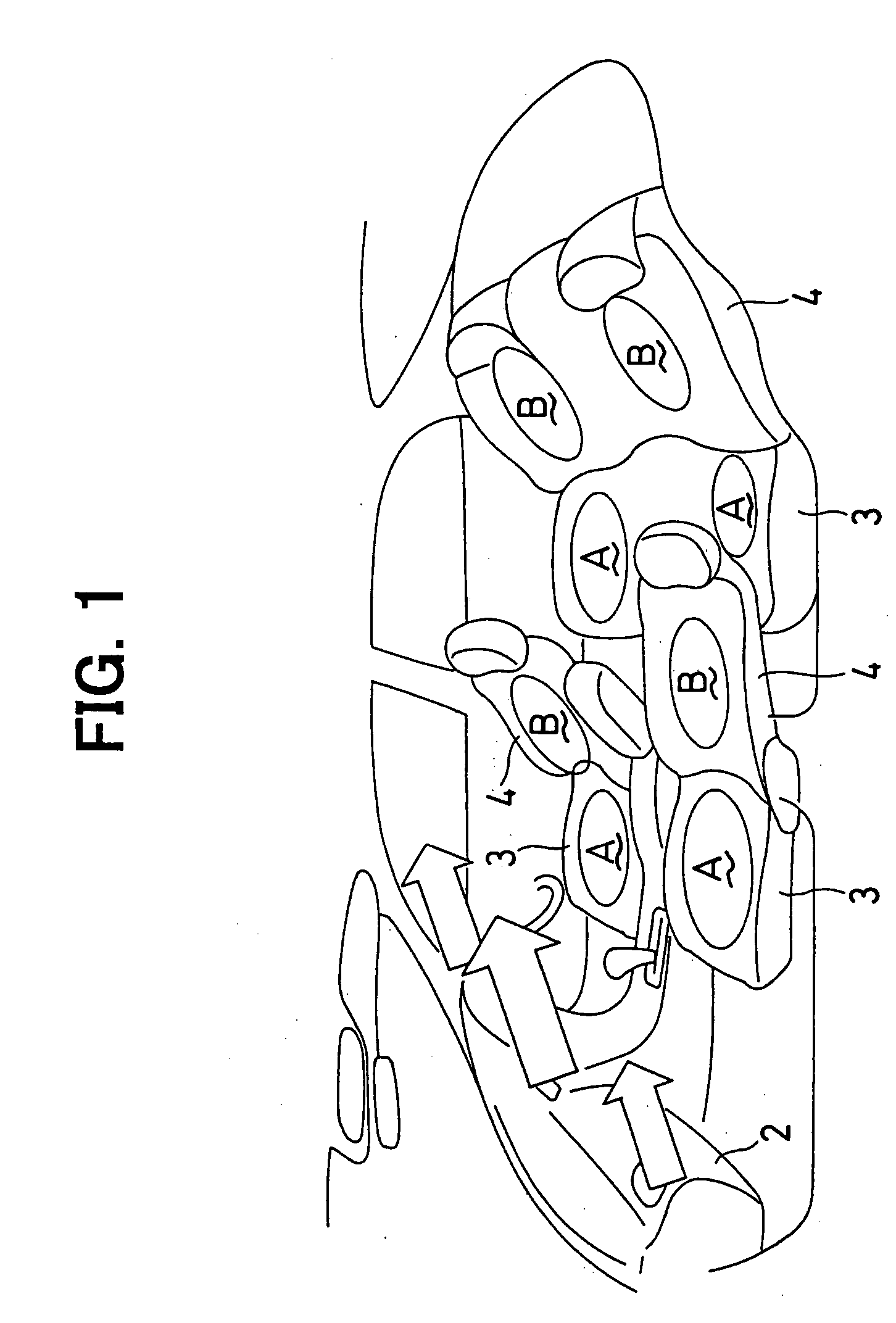

Vehicle air conditioner having air suction port for each seat

InactiveUS20010029162A1Improve controlEfficient executionAir-treating devicesSeat heating/ventillating devicesCold airEngineering

In a vehicle air conditioner, each of cool air outlets is provided at an upper side of each seat at second and third seat lines from a most front seat so that cool air from an air conditioning unit is blown from the cool air outlets toward upper sides of the seats, respectively, and each of warm air outlets is provided at a lower side of each seat at the second and third seat lines so that warm air from the air conditioning unit is blown from the warm air outlets toward lower sides of the seats, respectively. In addition, each of suction ports is provided for each corresponding seat at the second and third seat lines so that air inside a passenger compartment is sucked from the suction ports to be returned to the air conditioning unit.

Owner:DENSO CORP

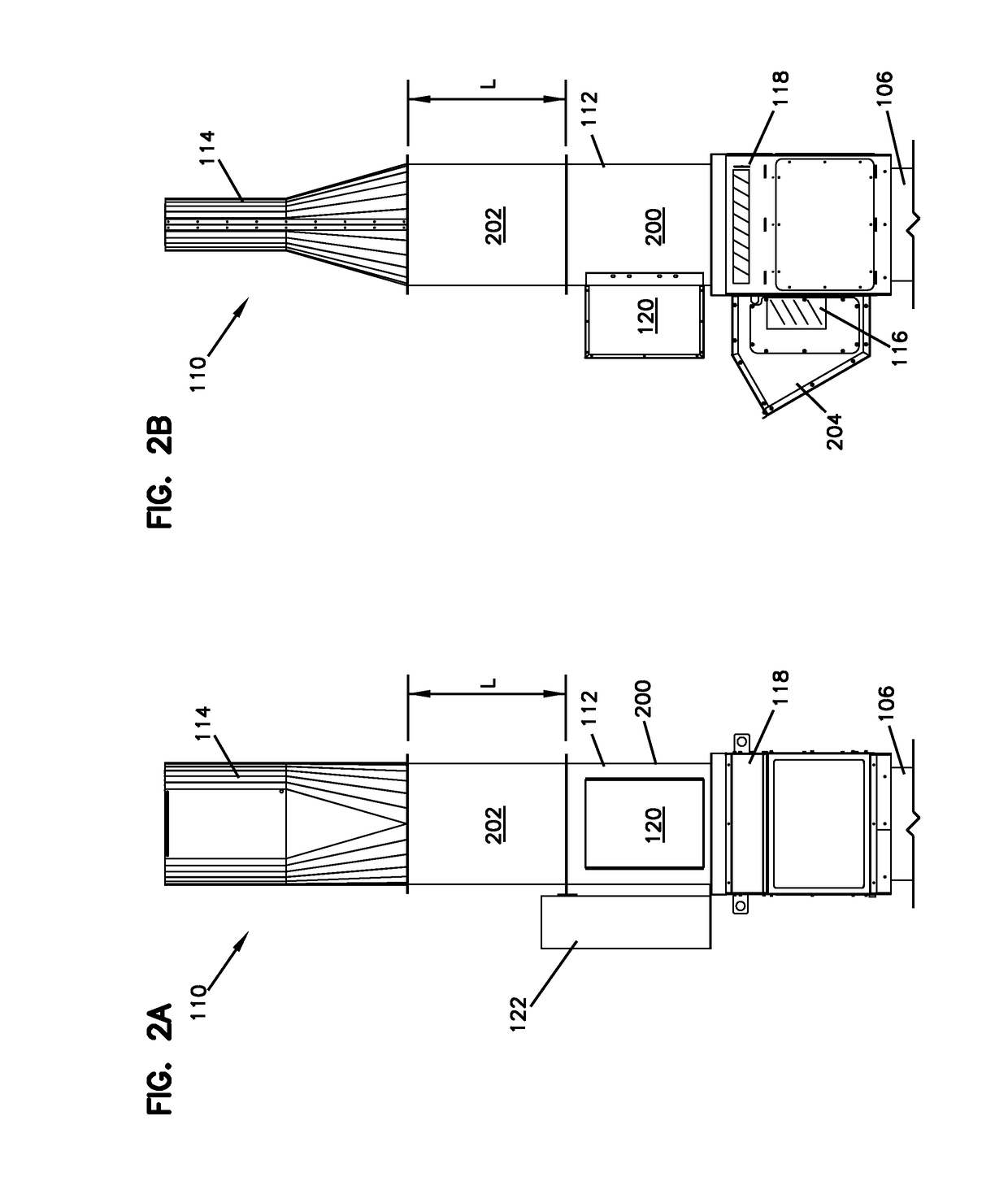

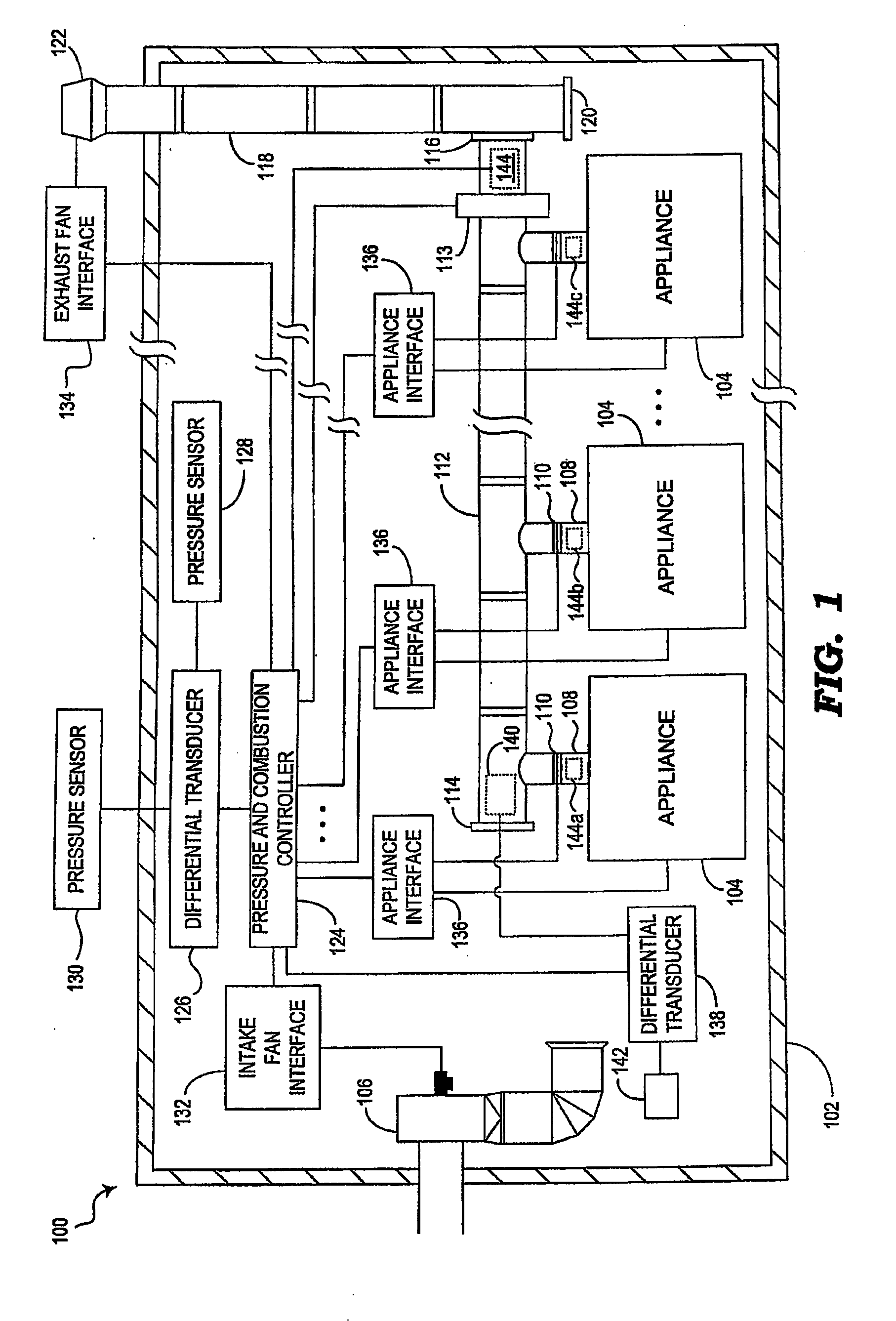

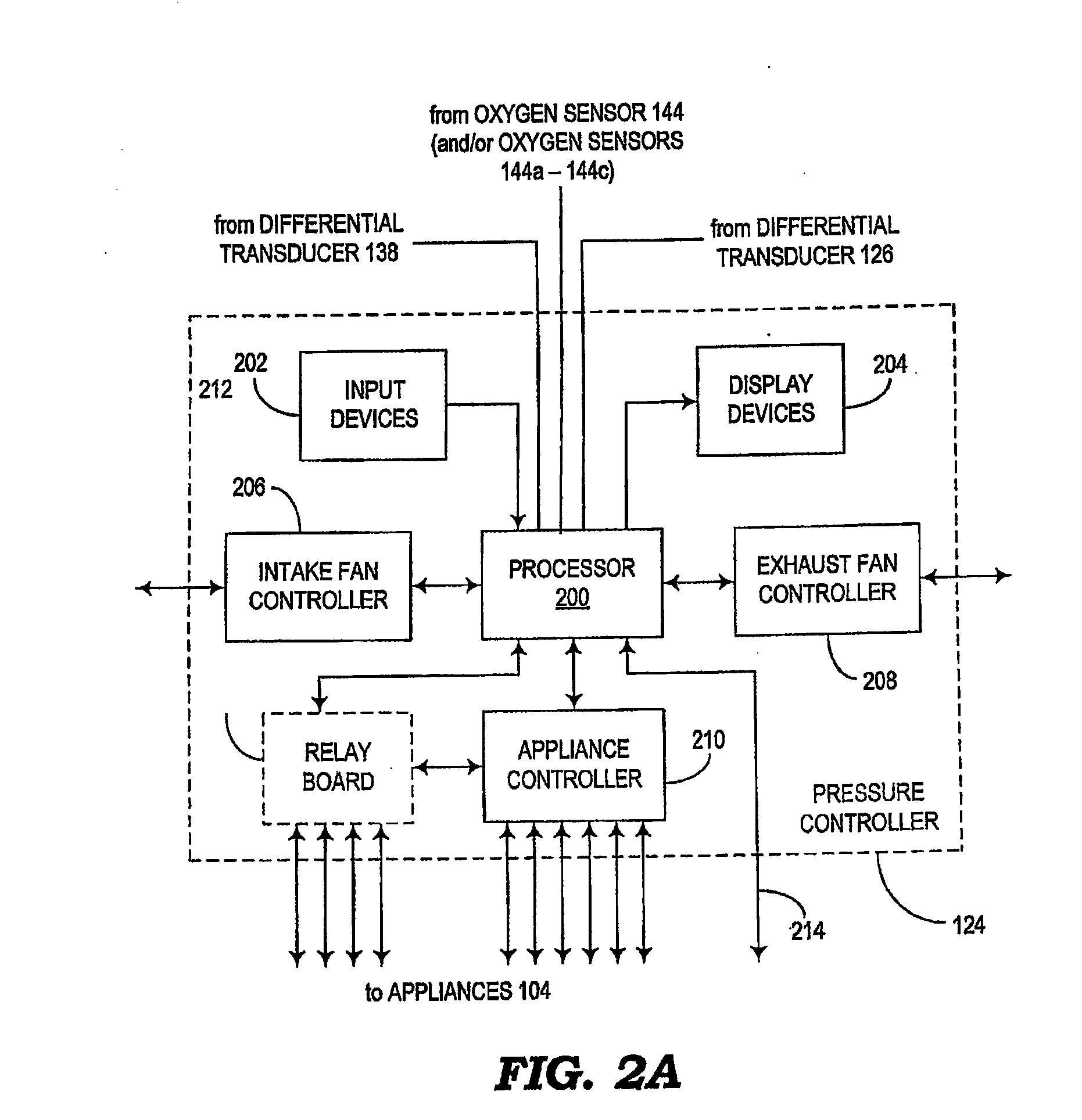

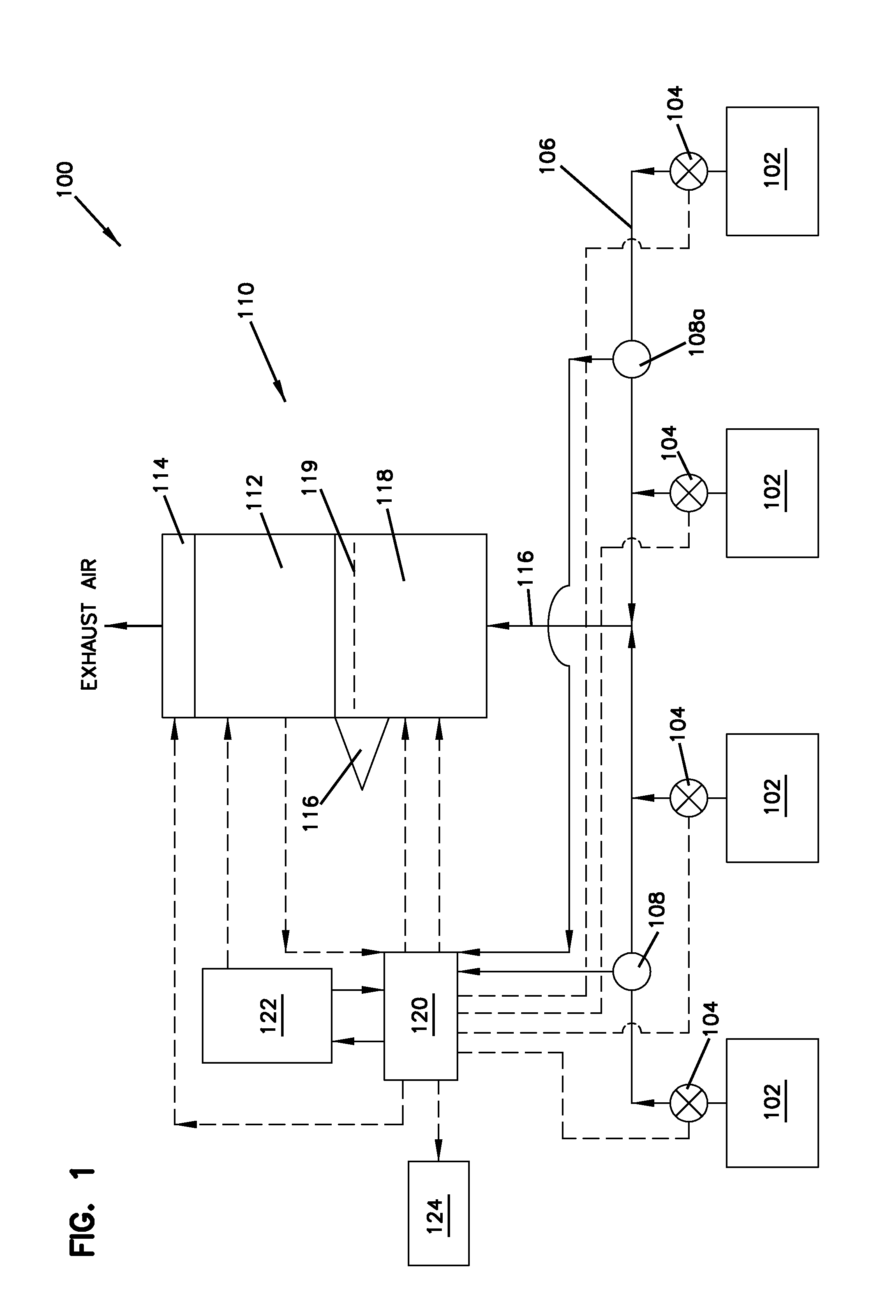

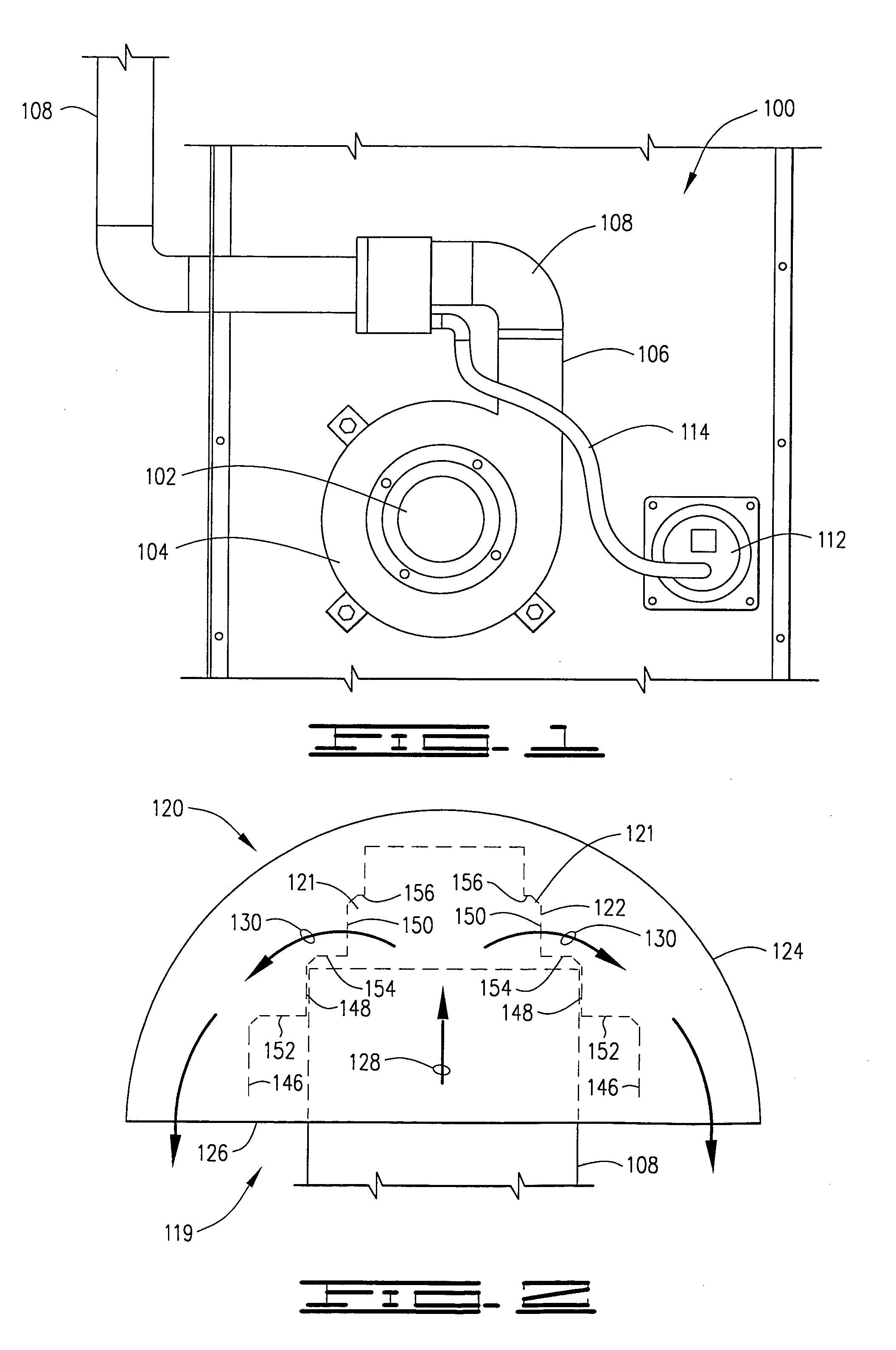

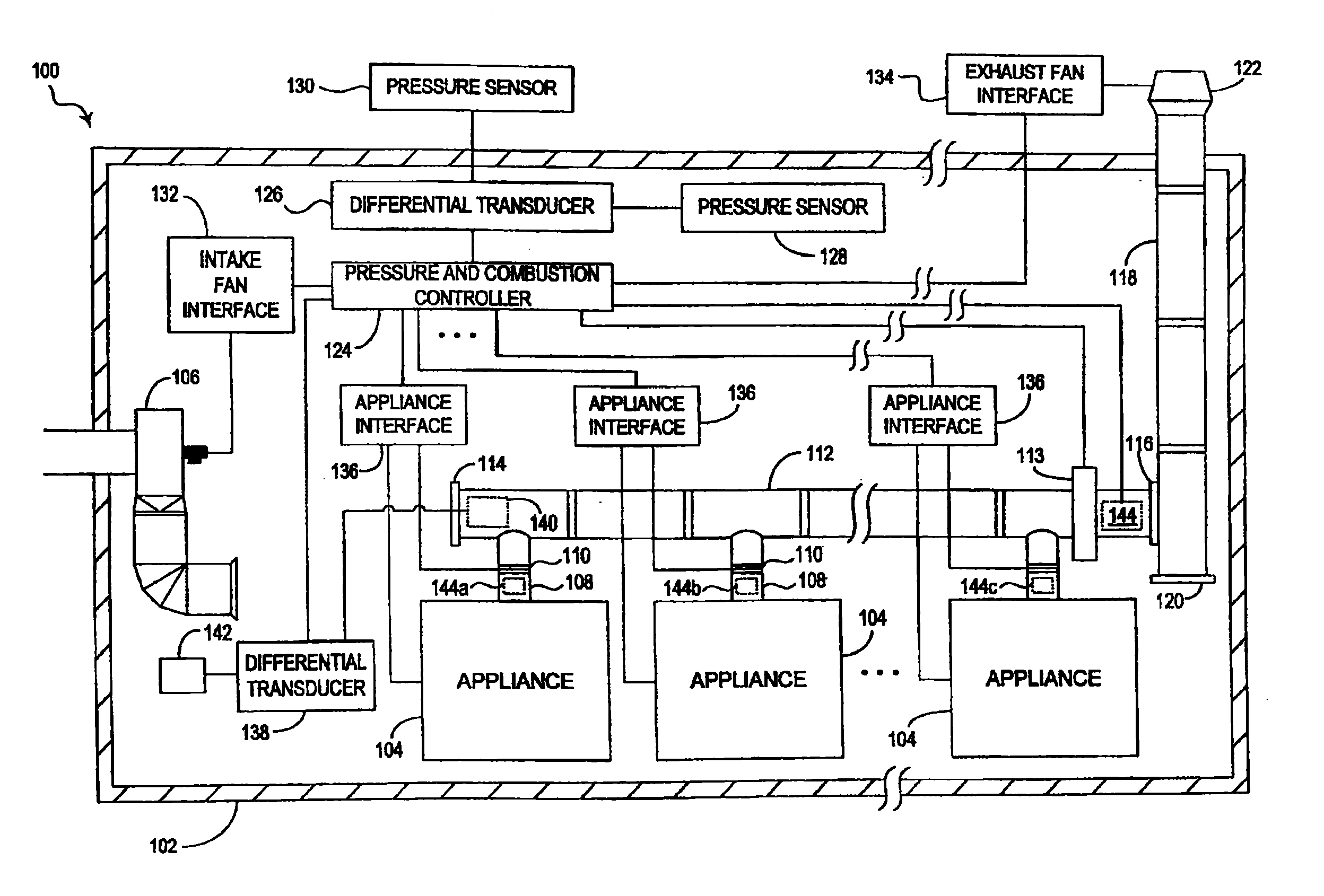

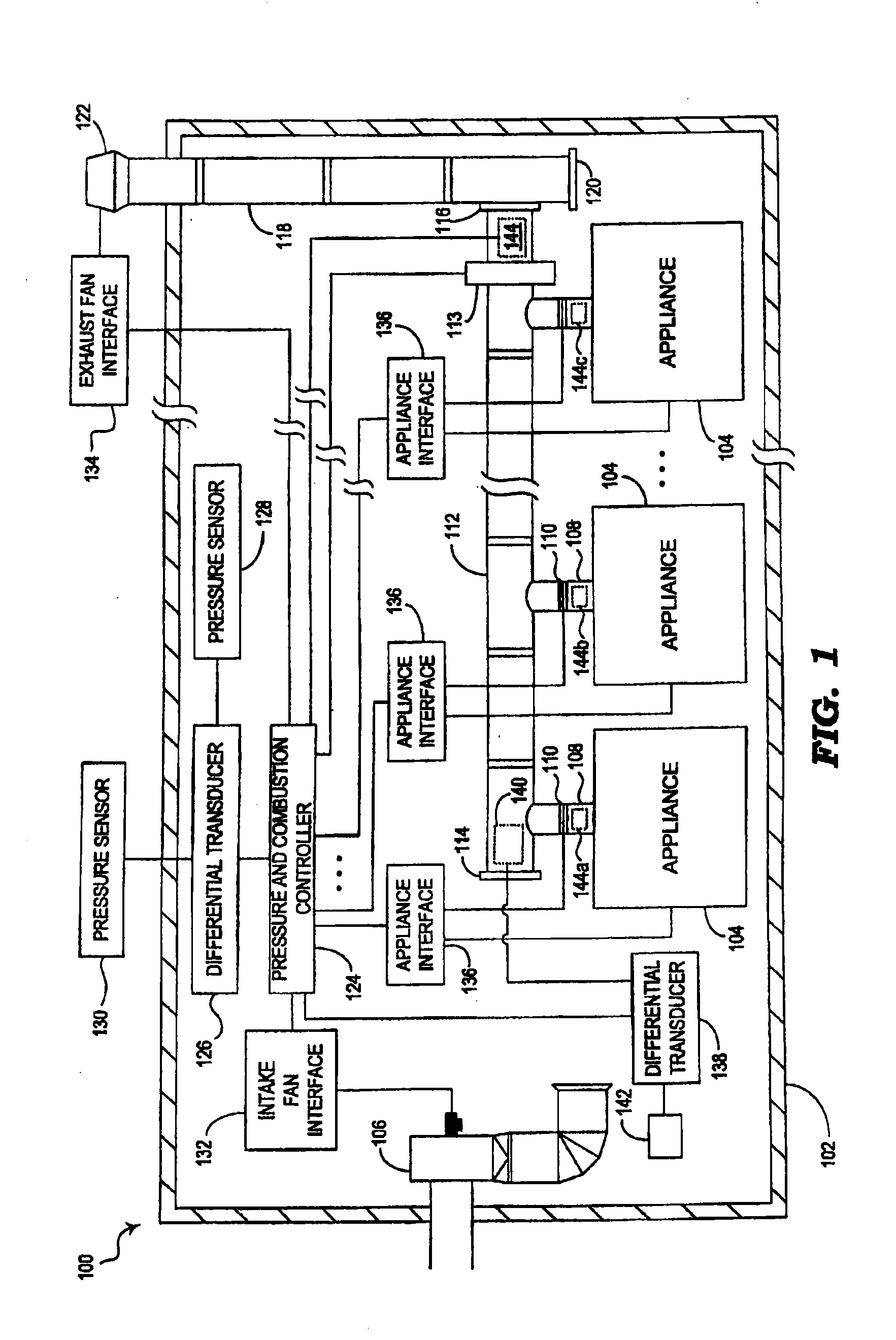

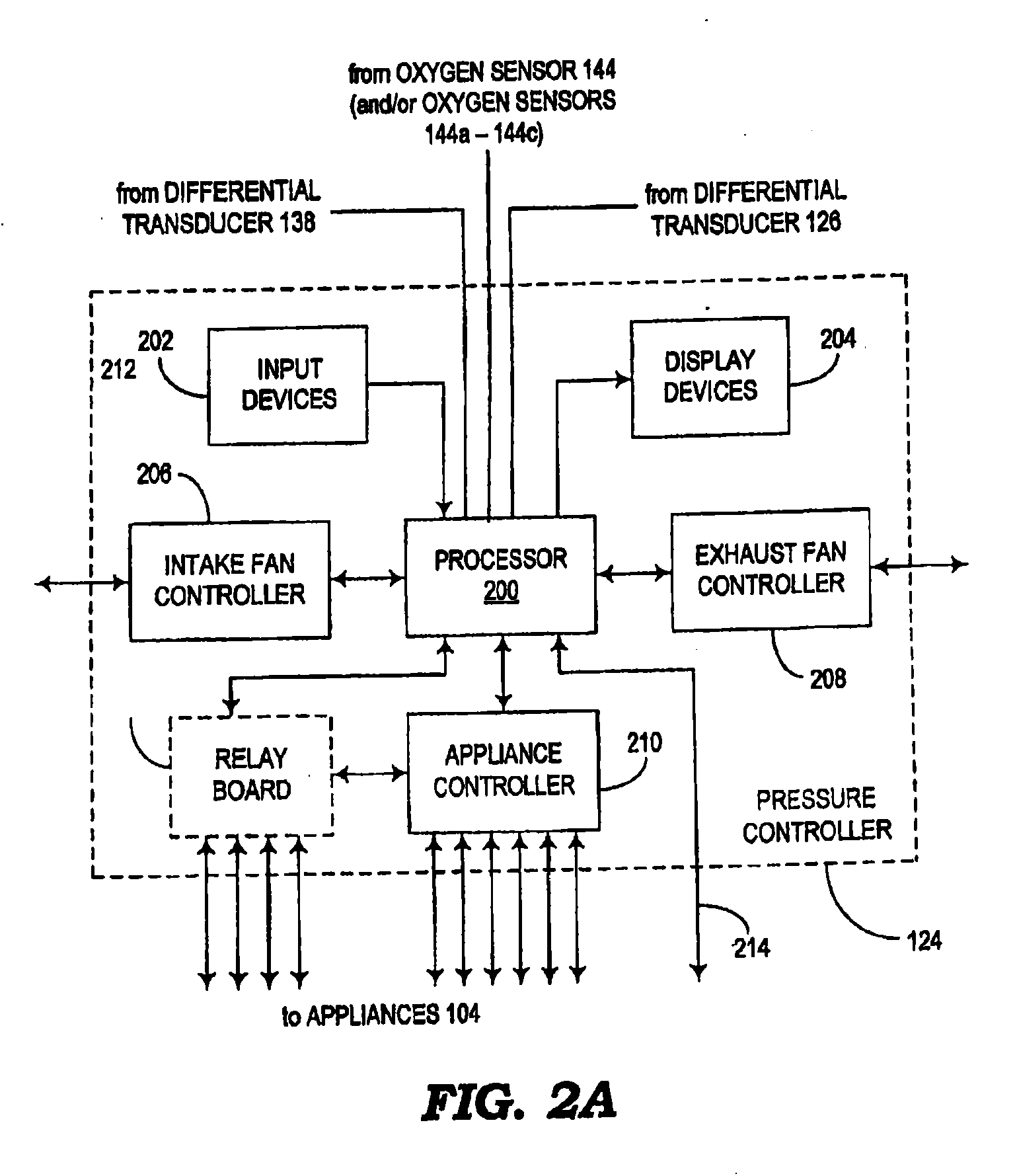

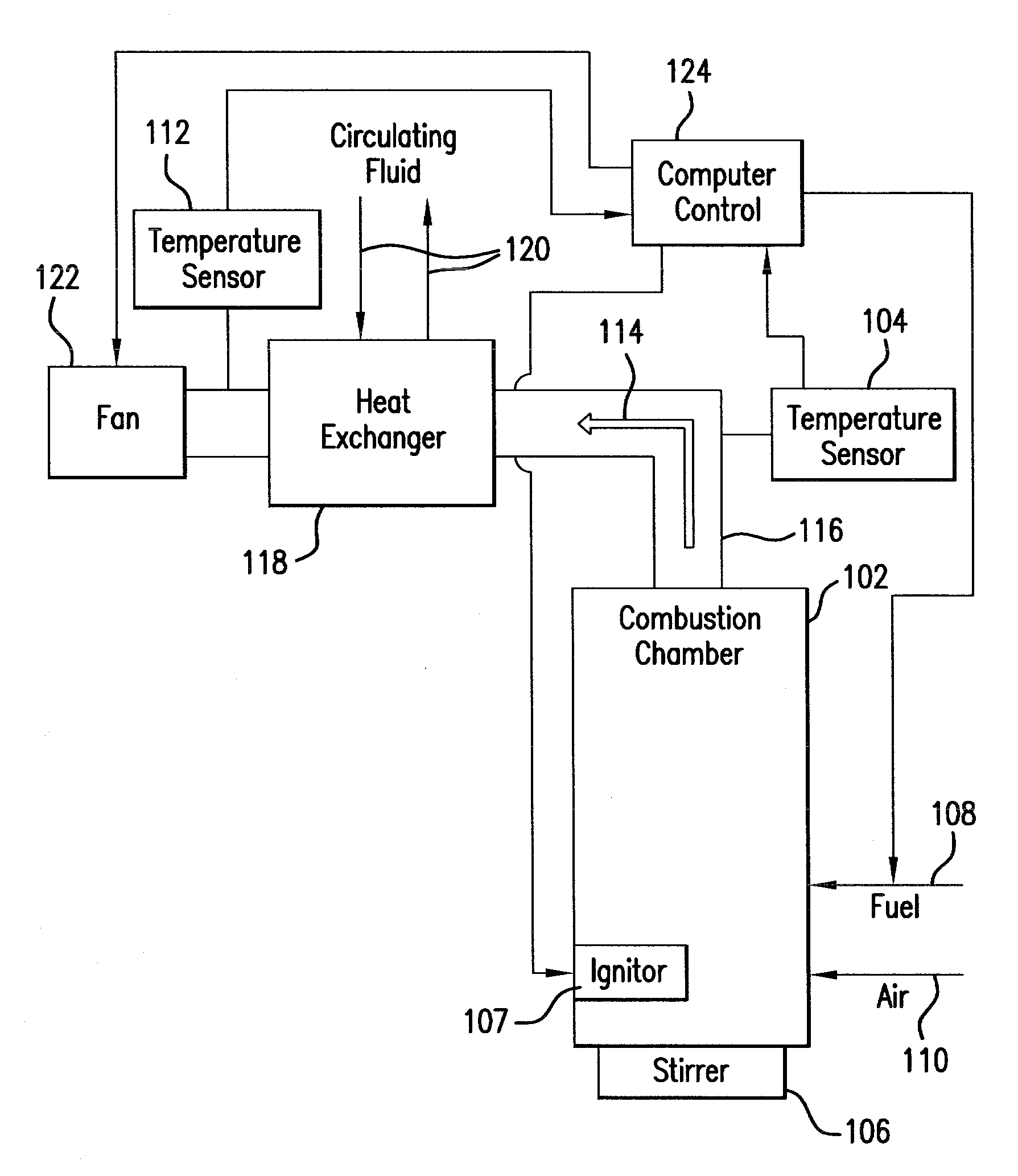

Fan Assemblies, Mechanical Draft Systems and Methods

InactiveUS20090215375A1Facilitate independentFacilitate locally controlled ignitionDomestic stoves or rangesLiquid heating fuelDirect combustionControl theory

Fan assemblies, mechanical draft systems and methods are provided. In this regard, a representative mechanical draft system for use with multiple appliances includes: a chimney operative to direct combustion products from multiple appliances; a chimney fan operative to draw combustion products from the chimney; and a controller operative to adjust an operating speed of the chimney fan such that, responsive to a change in pressure in the chimney, the controller adjusts the operating speed of the chimney fan to maintain a desired pressure in the chimney.

Owner:GREENVEX

Vent hood and flashing assembly for metal roof

A vent hood and flashing assembly for use on a metal roof. A vent hood overlies and is joined to flashing. A cover and a screen overlie an upper end portion of the flashing to exclude rain, snow and pests. The flashing includes a resilient, flexible, water-repellant, flexible flange that extends outward from, and is attached to, a lower end portion of the flashing and a flexible, ring seal that overlies an upper surface of the flange. The assembly can be placed over a projection through an opening in a metal roof such that the cover and screen overlie an upper end of the projection and with the flashing surrounding the projection, and the flange can be bent to sealingly conform to the roof surface and secured thereto by fasteners.

Owner:RICH DANIEL L

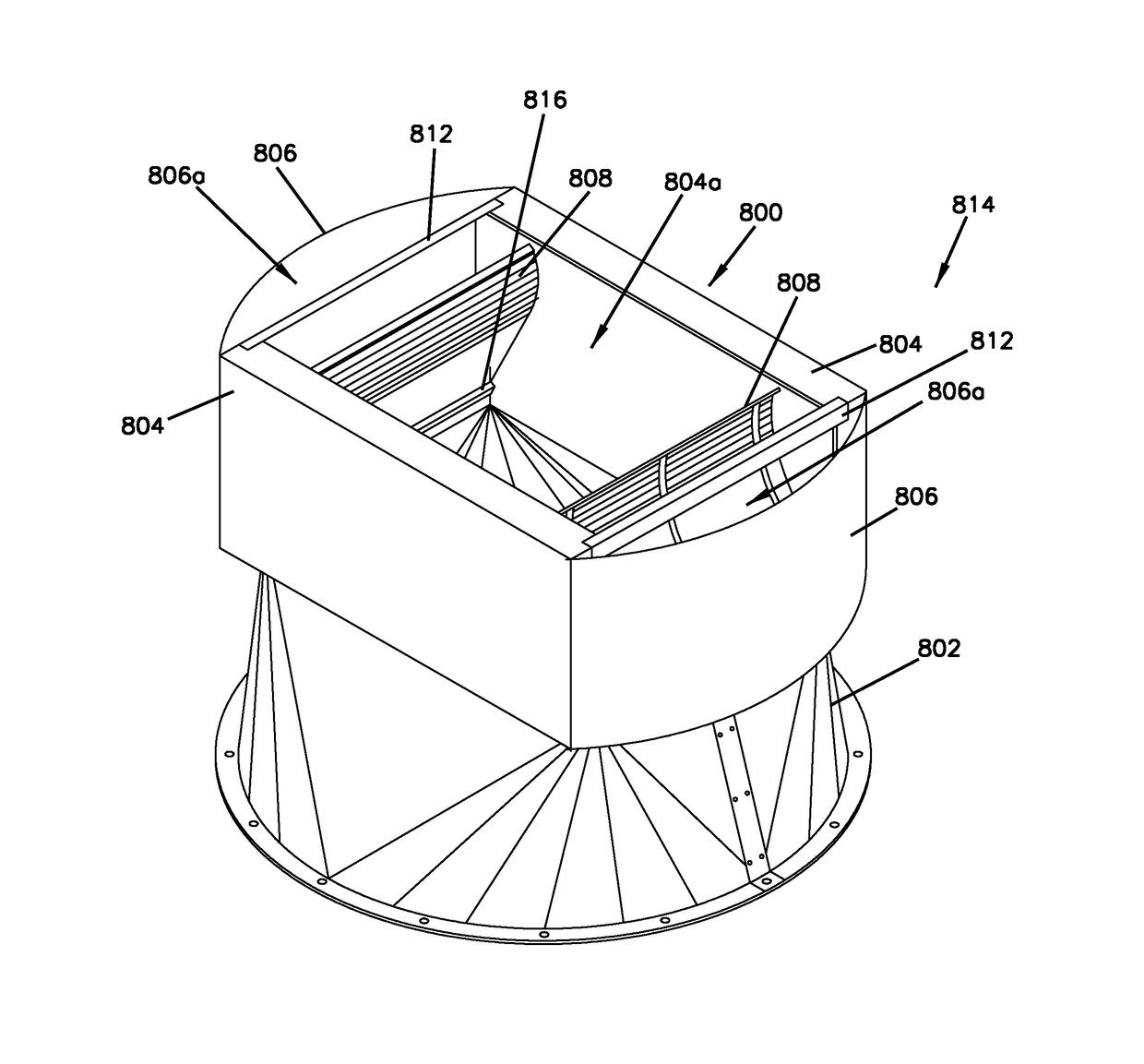

System and process for collecting effluents from an electrolytic cell

InactiveUS20090159434A1Increase ratingsStrict controlCellsMachining electric circuitsStreamflowElectrolytic cell

The invention provides a system and a process for collecting effluents produced by an electrolytic cell intended for the production of aluminium and for drawing said effluents away from the cell in a flow of gas. The system comprising a hooding to confine the effluents, at least one outlet channel to collect said flow of gas and suction means to draw said flow of gas away from the cell. The hooding includes removable hoods and, optionally, at least one door to get access to the inside of the hooding. The system further comprises at least one pipe for blowing pressurized air within the outlet channel so as to increase the rate of said flow of gas. Pressurized air supply is activated at a specified pressure Po so as to obtain a specified flow rate Ro.

Owner:ALUMINUM PECHINEY

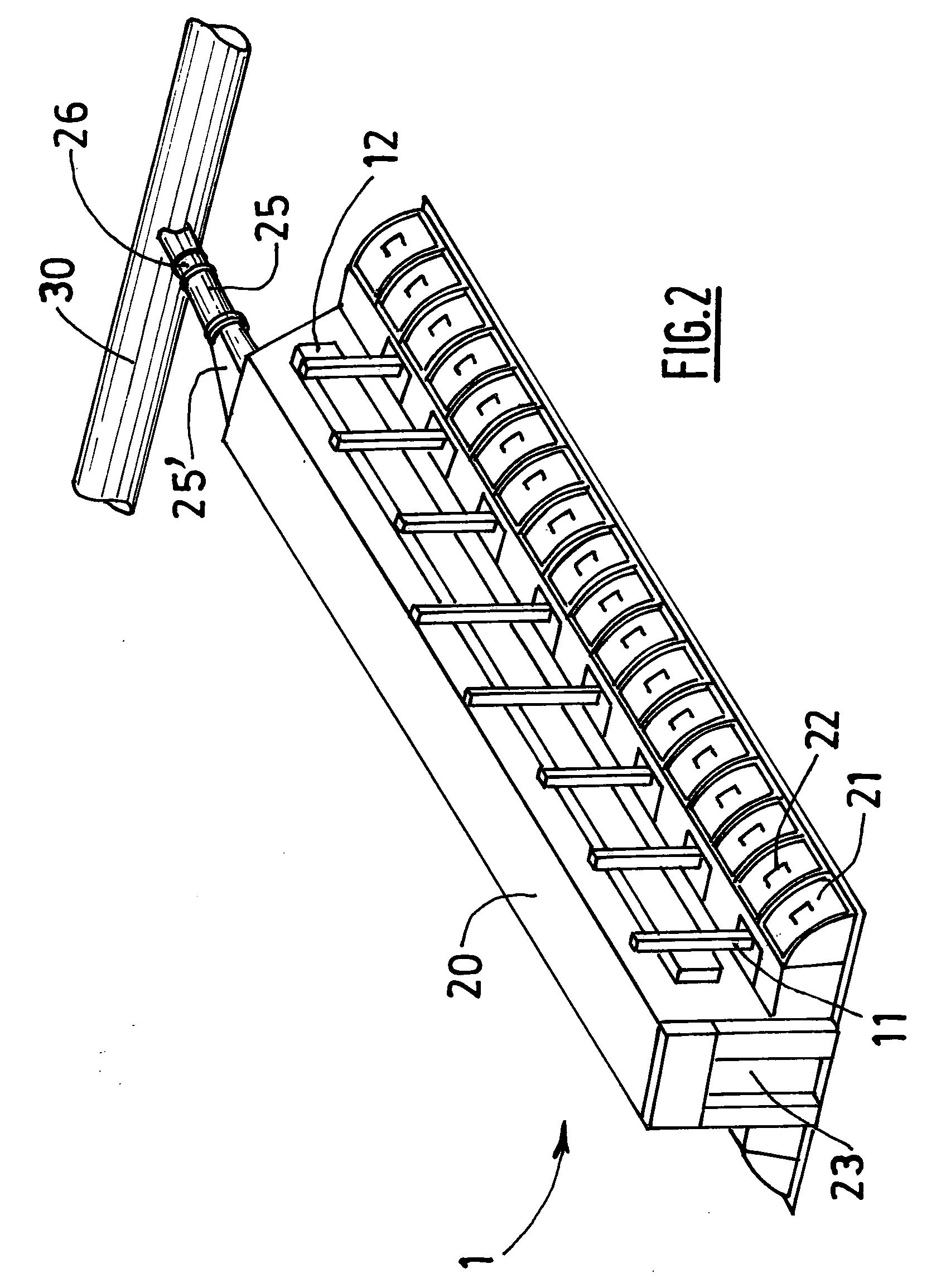

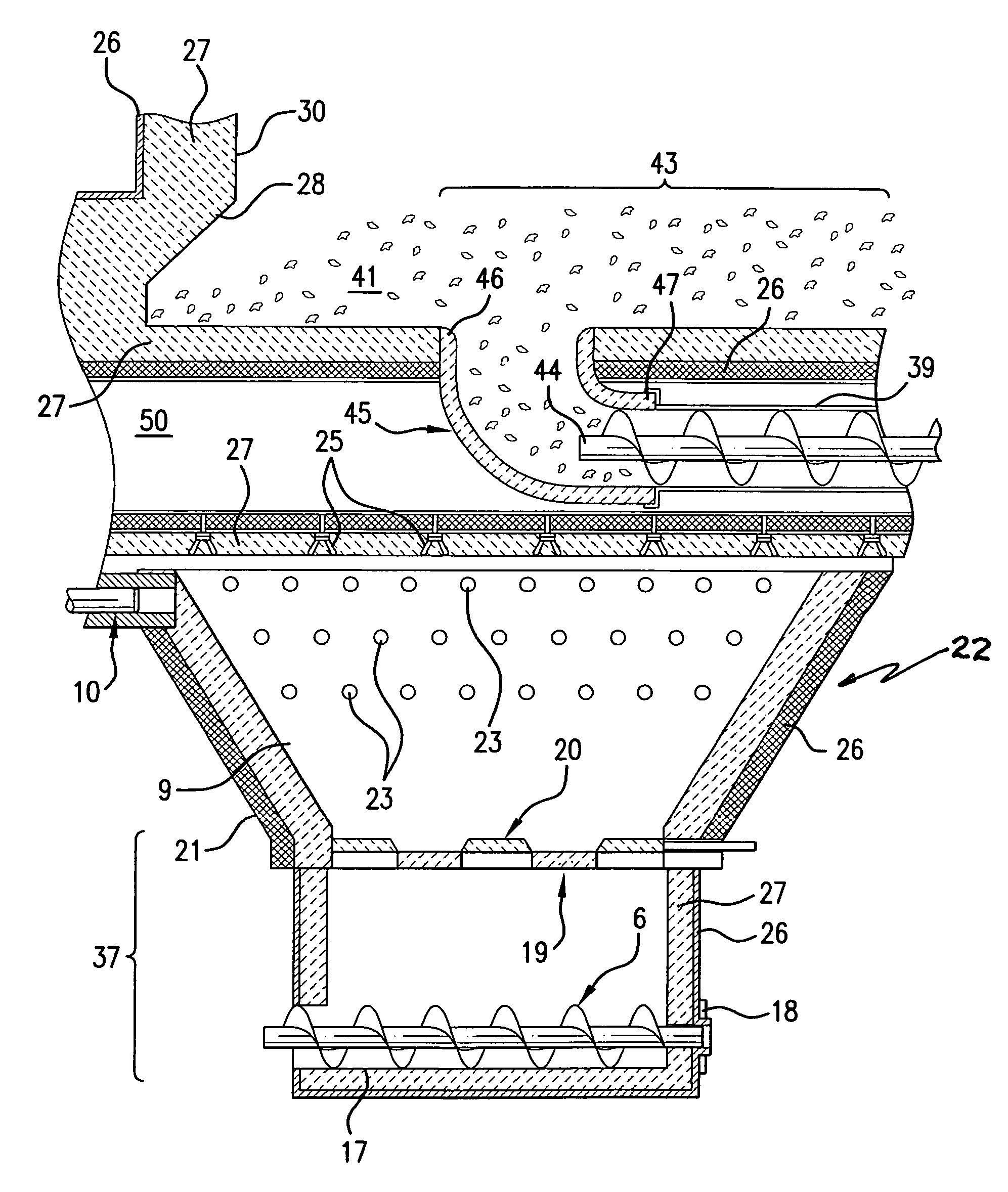

Gasifier and gasifier system for pyrolizing organic materials

InactiveUS7976593B2Lower buildCost of operationMuffle furnacesGasifier mechanical detailsMechanical engineeringEngineering

A gasifier and gasifier system based on the gasifier, which contains as a major component, a novel feed system for feeding organic materials into the burn pile of the gasifier. The gasifier feed system is a horizontal auger driven feed system that feeds directly through a ceramic elbow into the furnace without having to auger the feed through significant vertical elevations.

Owner:HEAT TRANSFER INT

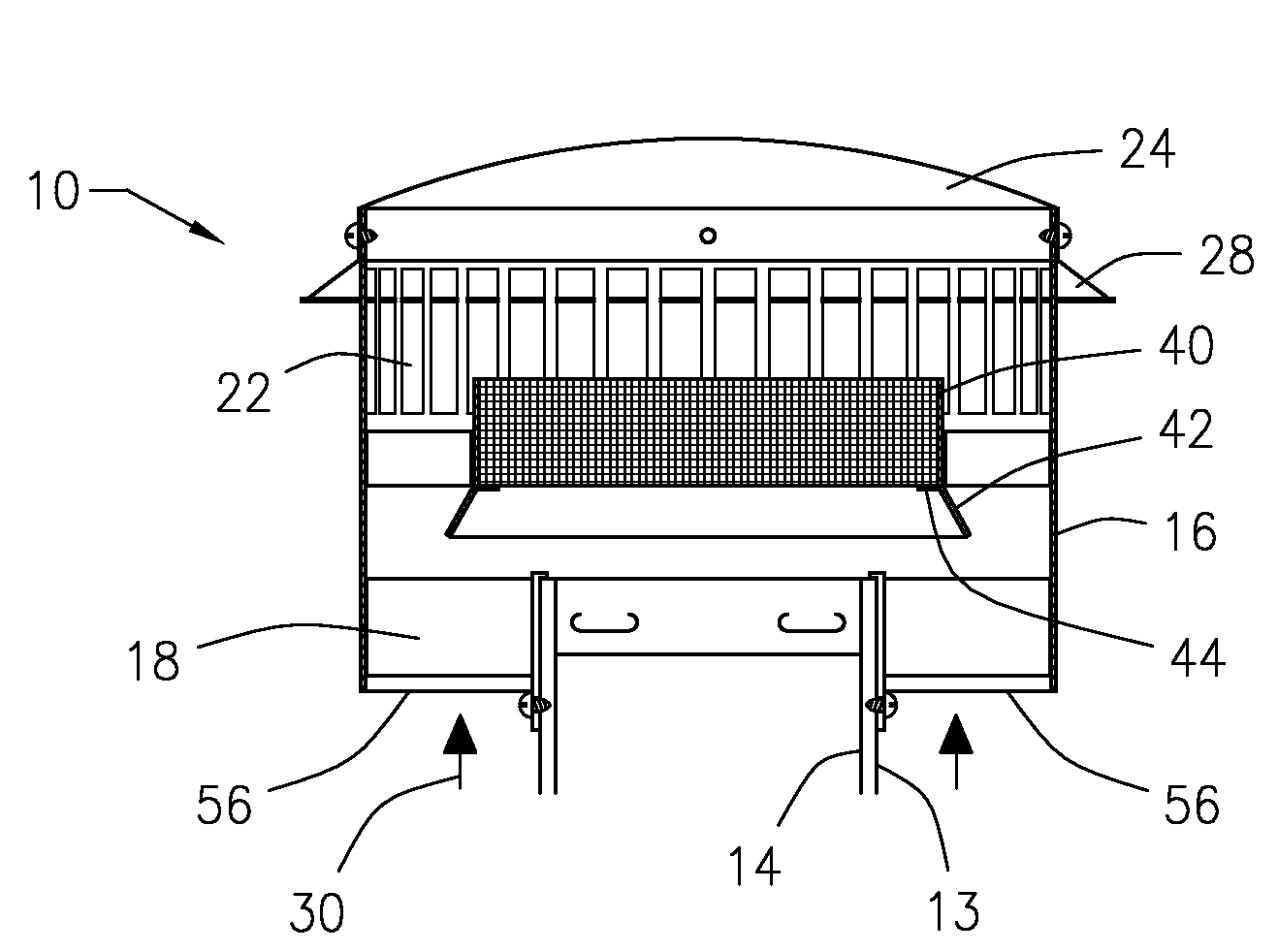

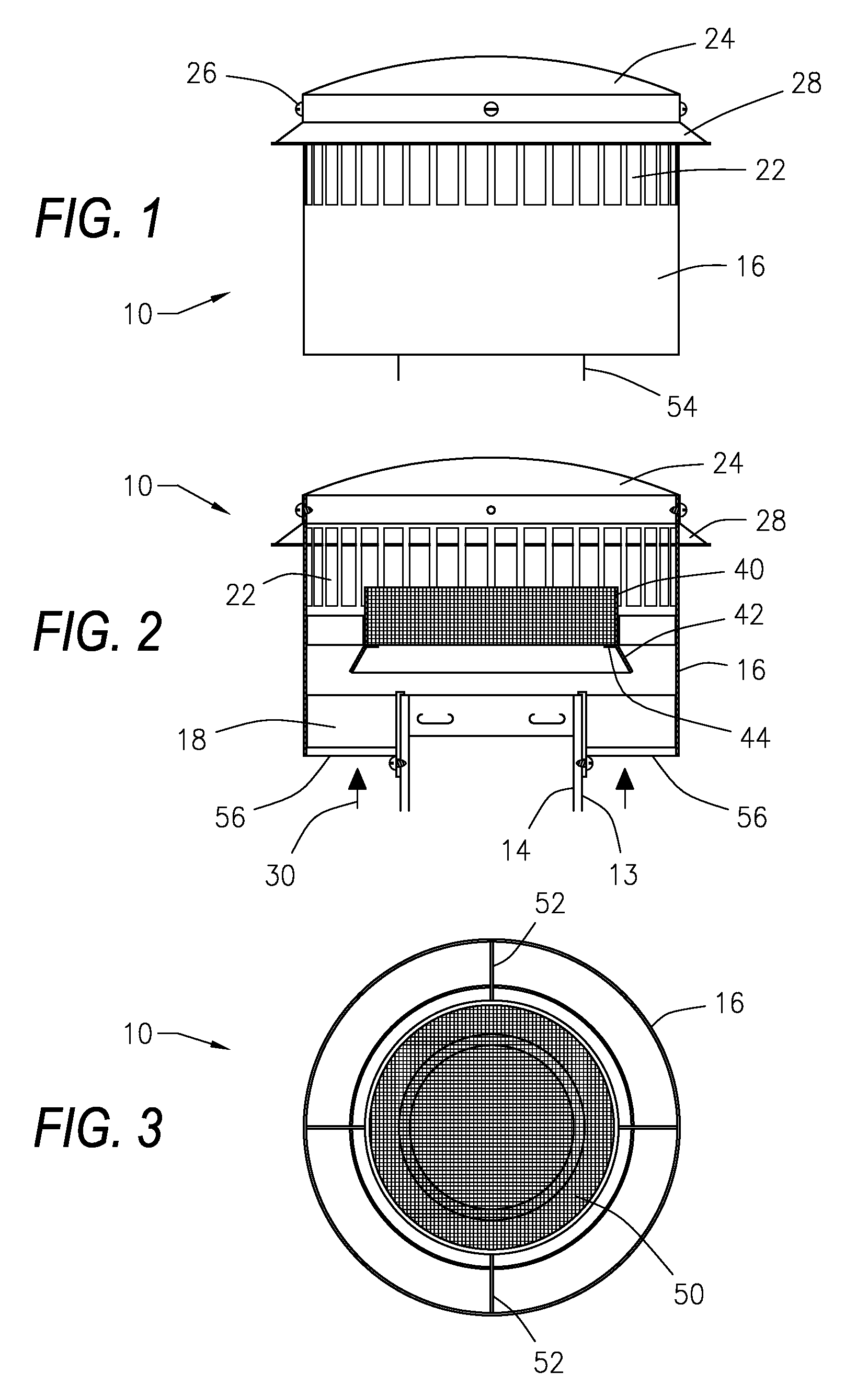

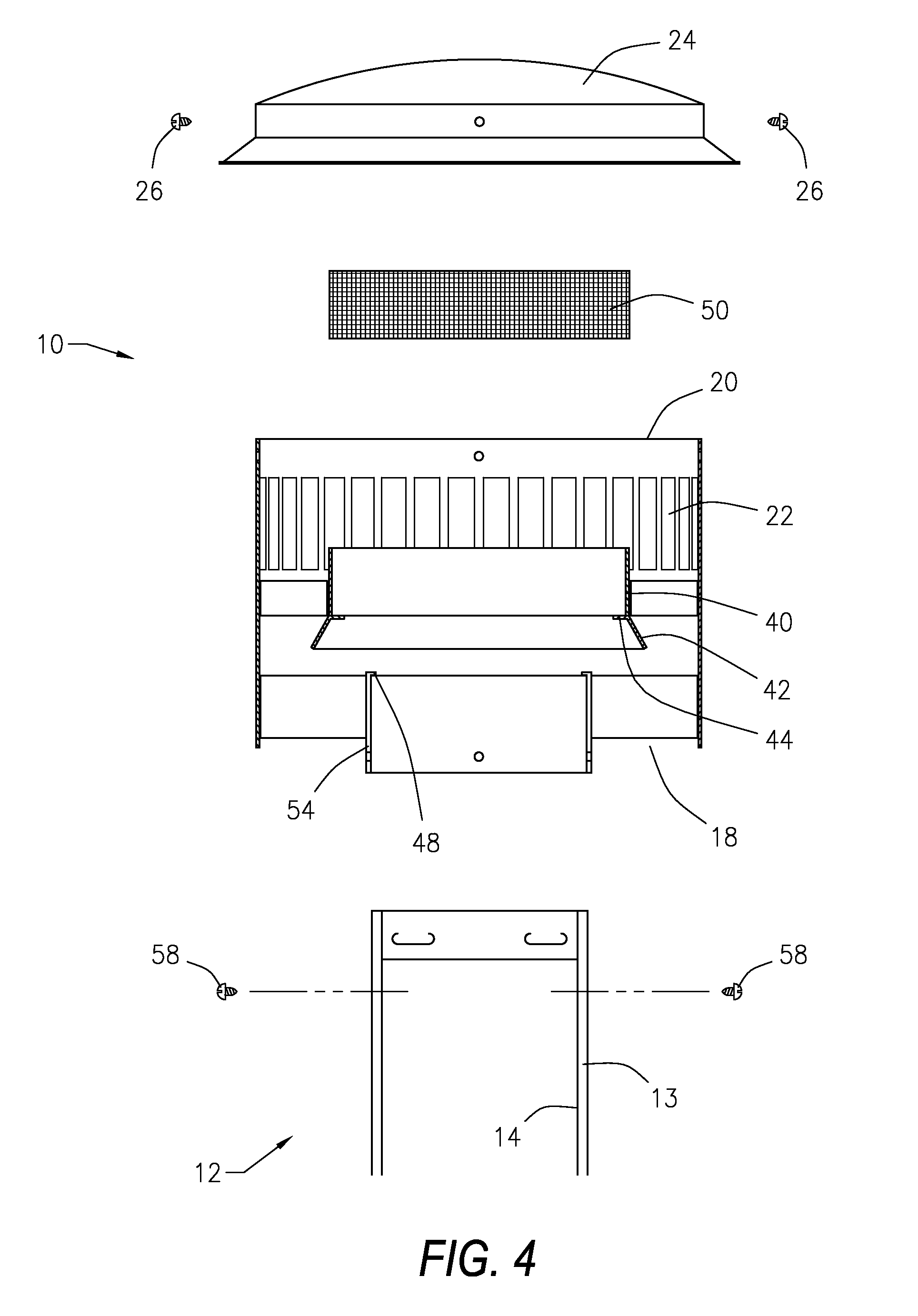

Exhaust fan assembly

ActiveUS20050170767A1Improve efficiencyEasy accessAir supply regulationDirt cleaningEngineeringContaminated air

Owner:GREENHECK FAN

Outlets for a pyrolytic waste treatment system

The inventive subject matter is directed toward a pyrolytic waste treatment system comprising an outlet adapted to channel a composition out of a pyrolysis chamber. A mechanism is used for cleaning the outlet during operation of the pyrolytic system.

Owner:APS IP HLDG

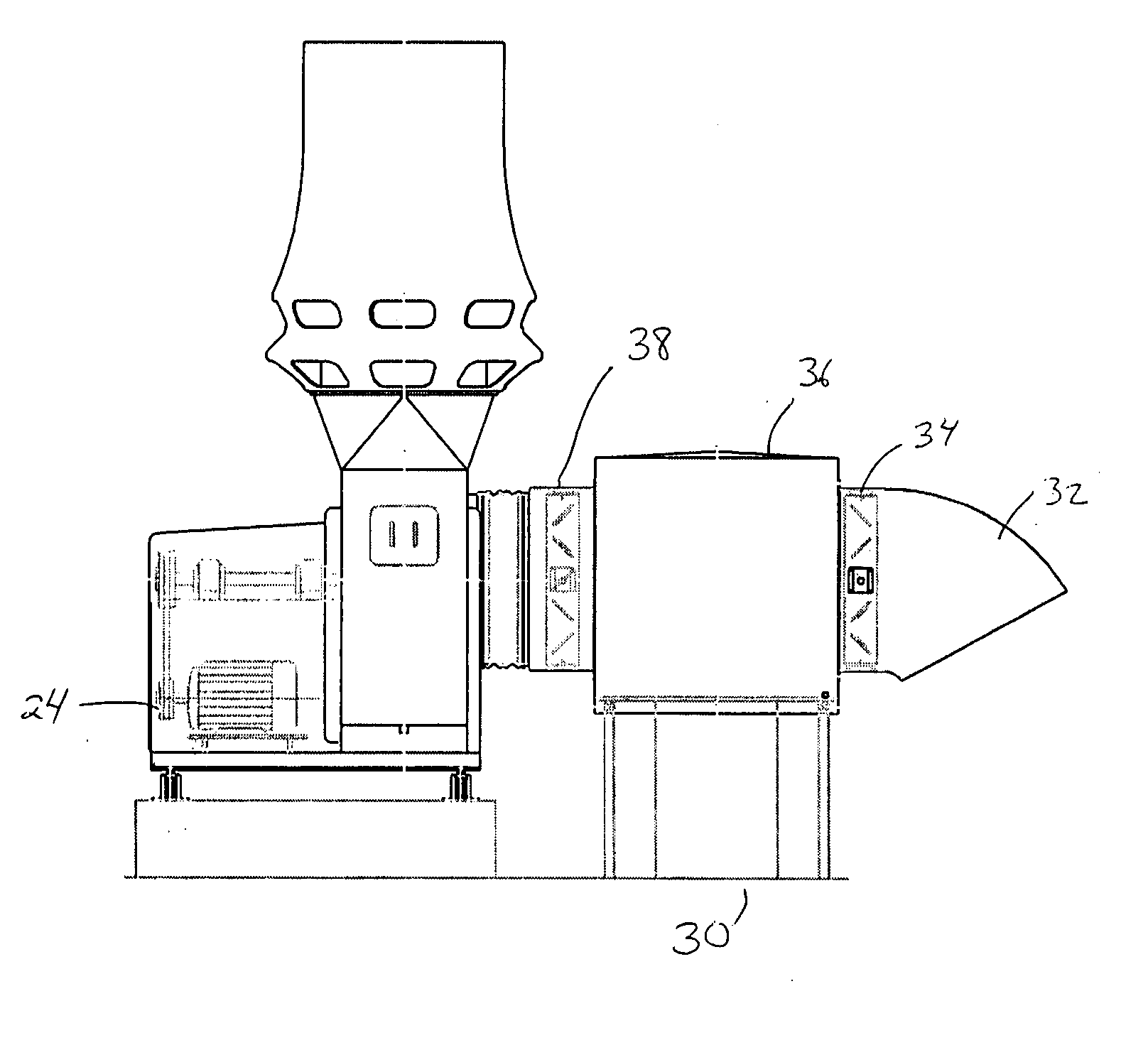

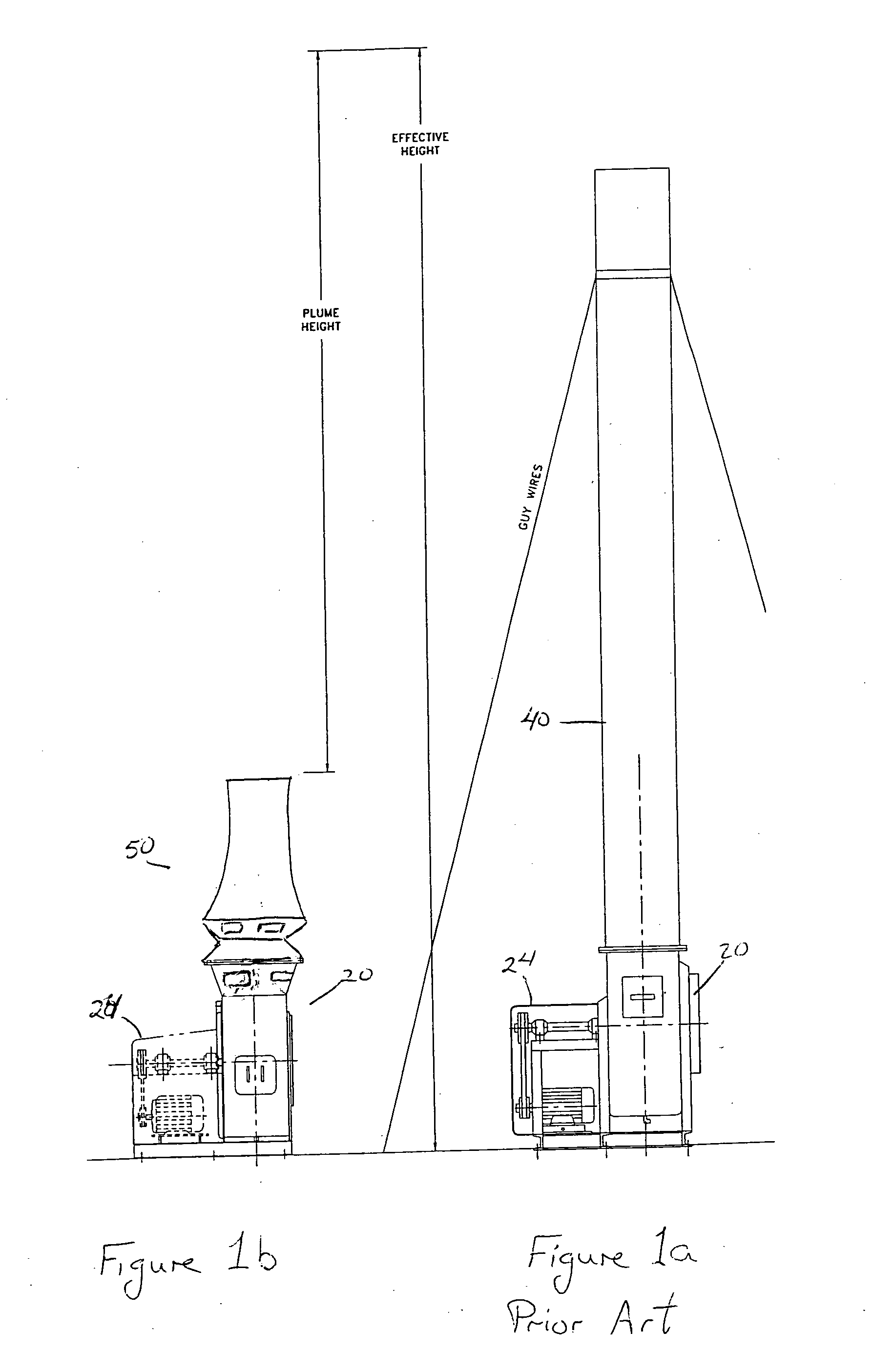

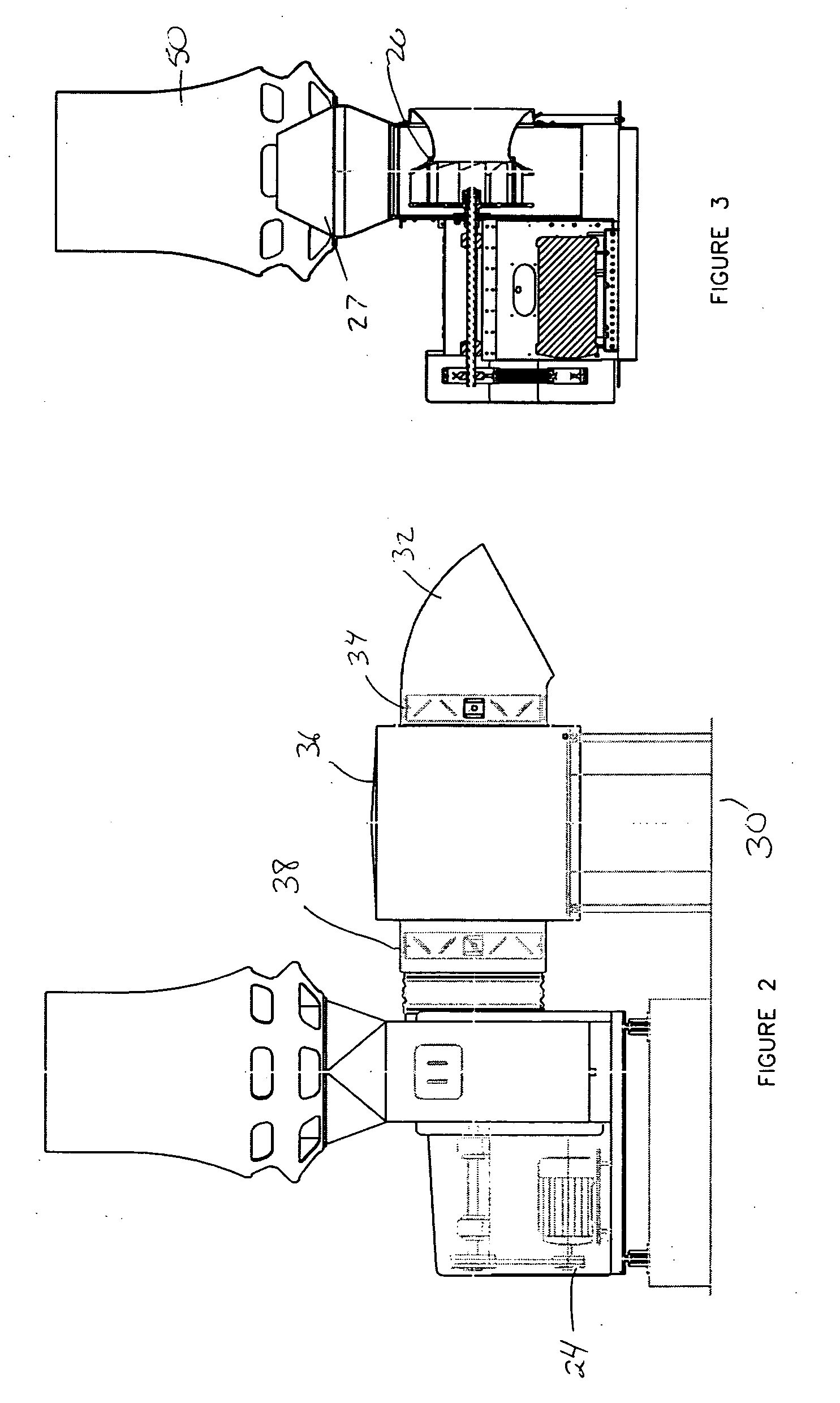

High velocity and high dilution exhaust system

ActiveUS20060019592A1Prevent buildupEliminating costly corrosionAir supply regulationPump componentsEffective heightEngineering

The high velocity and high dilution exhaust system uses a centrifugal fan provided with a tapered nozzle. The nozzle compresses the airstream exiting the fan to increase back pressure and velocity. The air flow from the fan enters a stack having a venturi further increasing the velocity and decreasing the pressure. The decrease in pressure causes a suction, allowing the introduction of ambient air to mix with and dilute the output of the fan. The total discharge from the exhaust stack has a high velocity resulting in a plume height. and effective height of the exhaust before dispersion occurs.

Owner:KUPFERBERG MINEL +1

Waterproofing and humidity control system

InactiveUS6904723B1Reduce leakageLower Level RequirementsBuilding repairsProtective foundationBasementControl system

A waterproofing and humidity control system is provided for a building which includes drain members located in trenches provided in ground beneath and adjacent the basement of the building. A suction and fan and motor assembly is located within a housing positioned within the building. Conduits communicate with the drain members and the motor and fan housing. An exhaust vent is located in the wall of the building spaced from the motor housing and has an air inlet and outlet. A separate conduit or duct communicates with and connects the inlet of the vent with an outlet of the motor and fan housing. The duct may extend between joints in the wall of the building. An adapter conduit is used with the system and is positioned between the motor and fan housing and the duct. The adapter conduit has portions which are offset from each other to allow the fan housing to be positioned in front of a finished basement wall.

Owner:EVERDRY MARKETING & MANAGEMENT

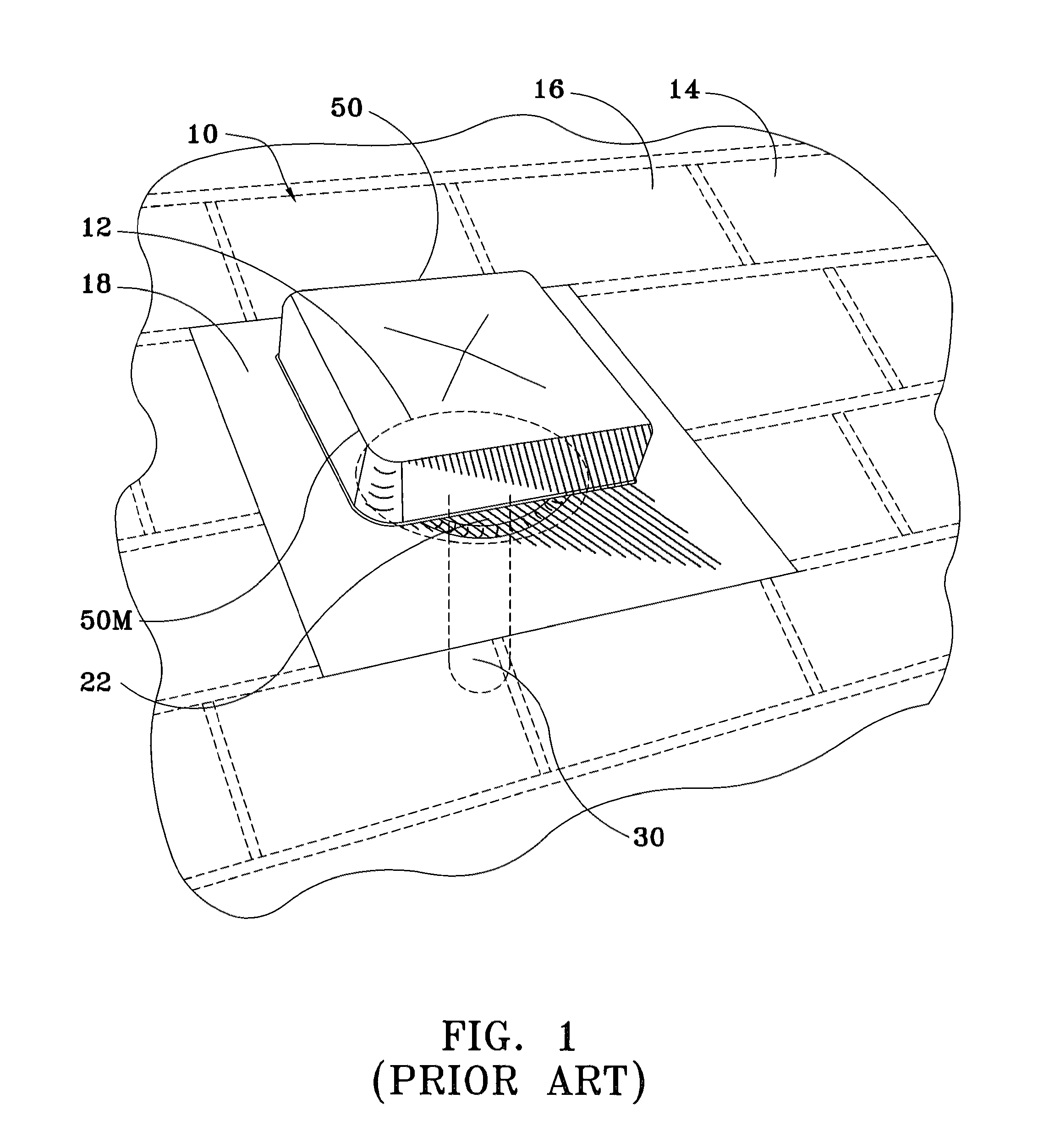

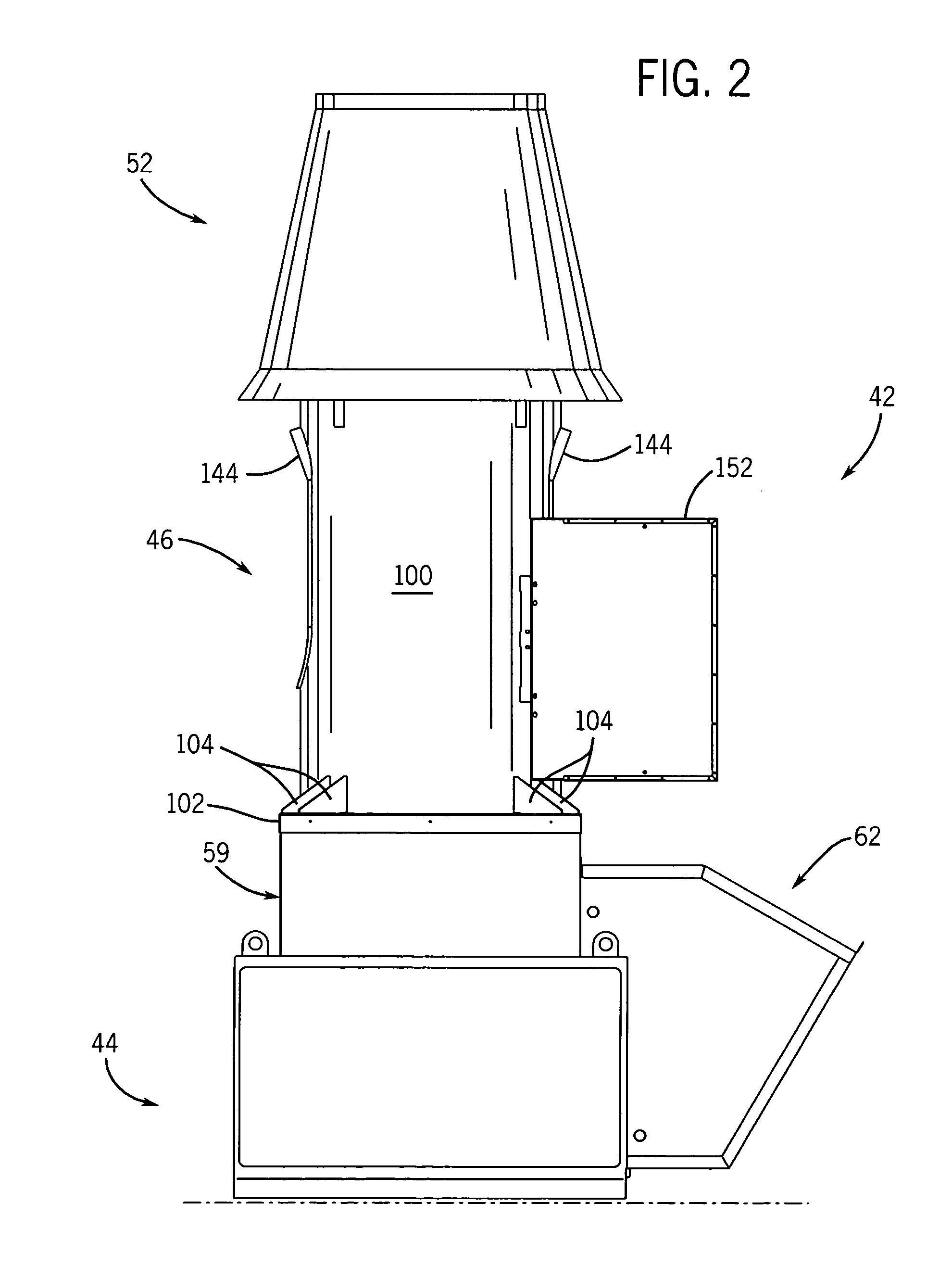

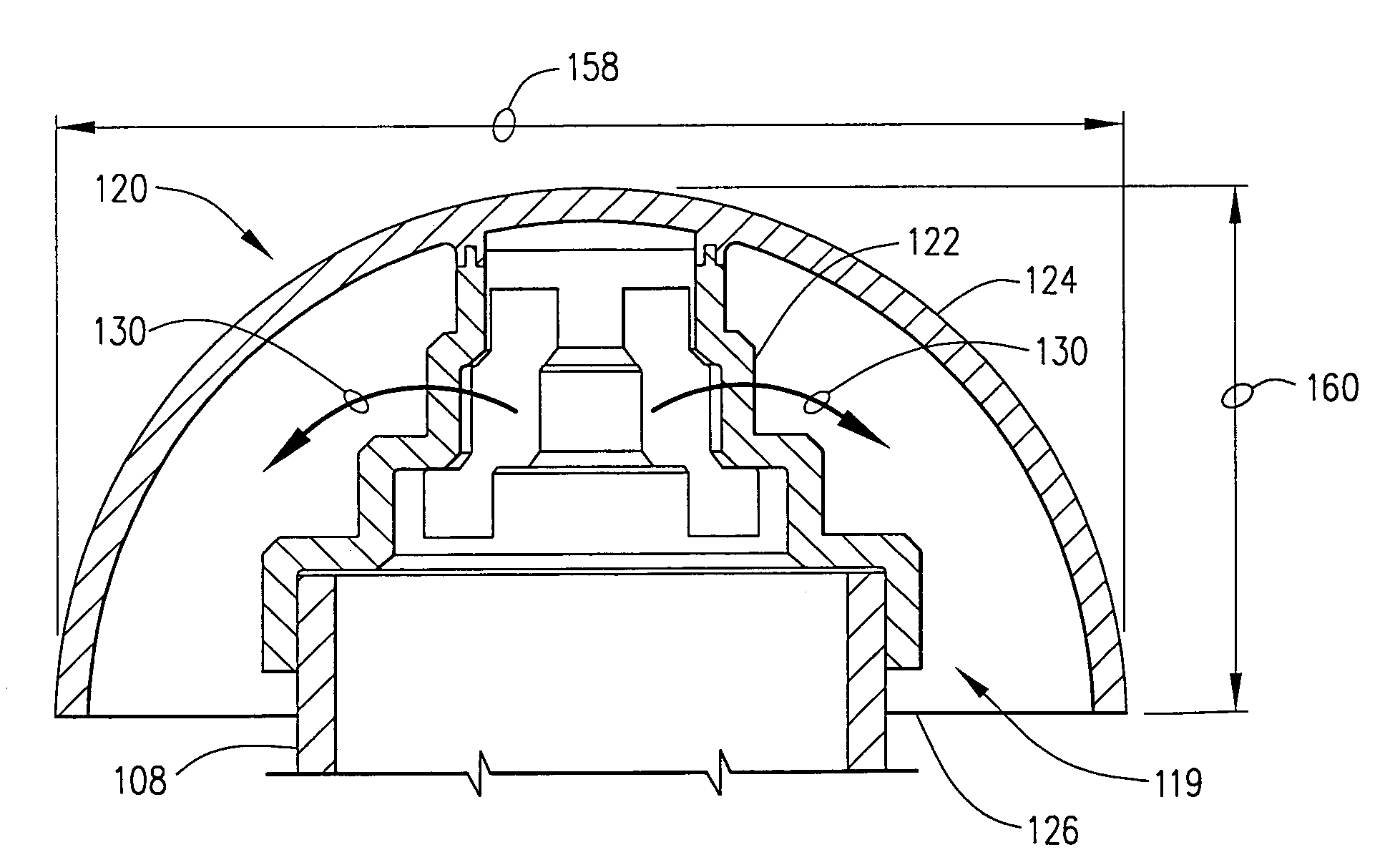

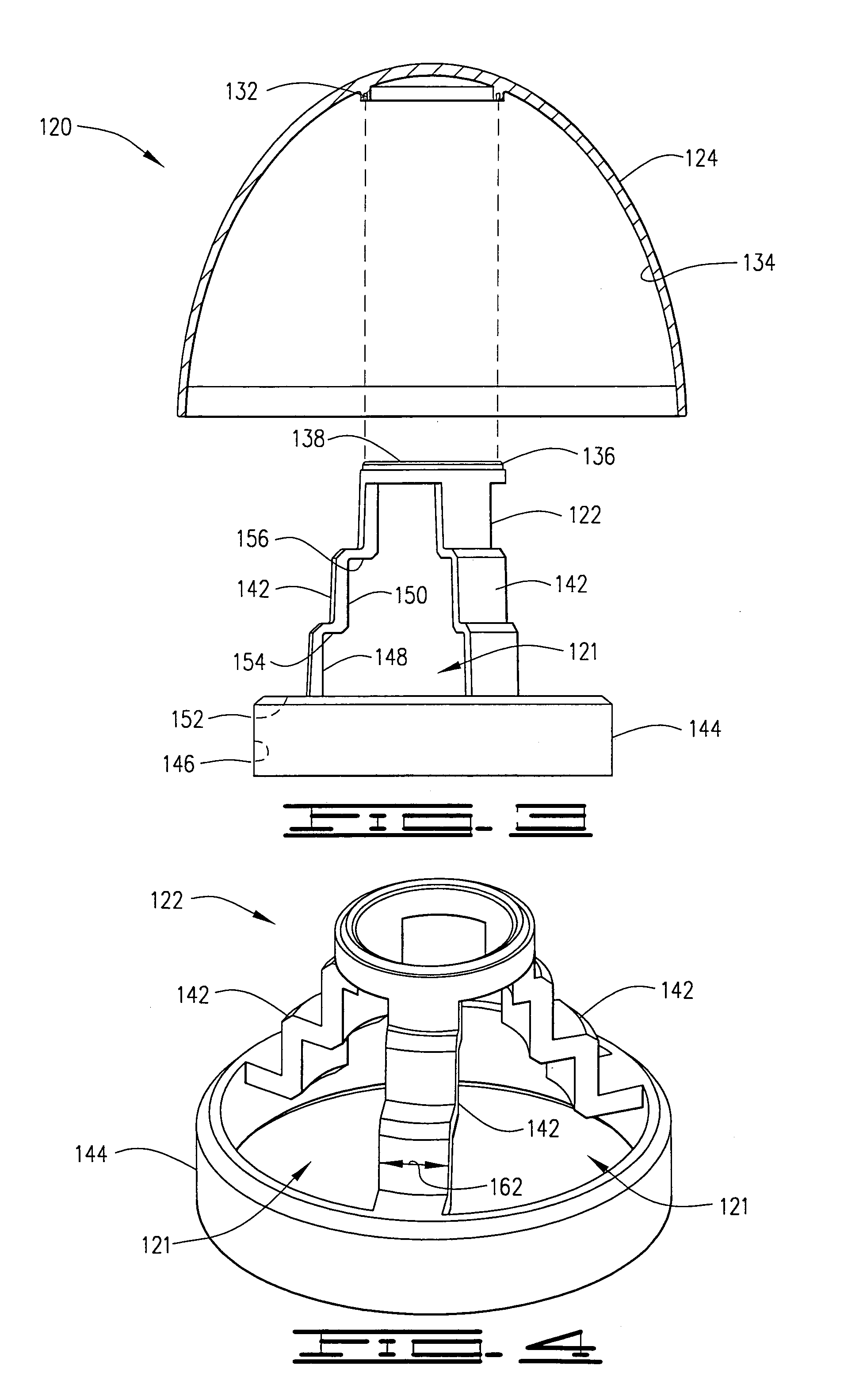

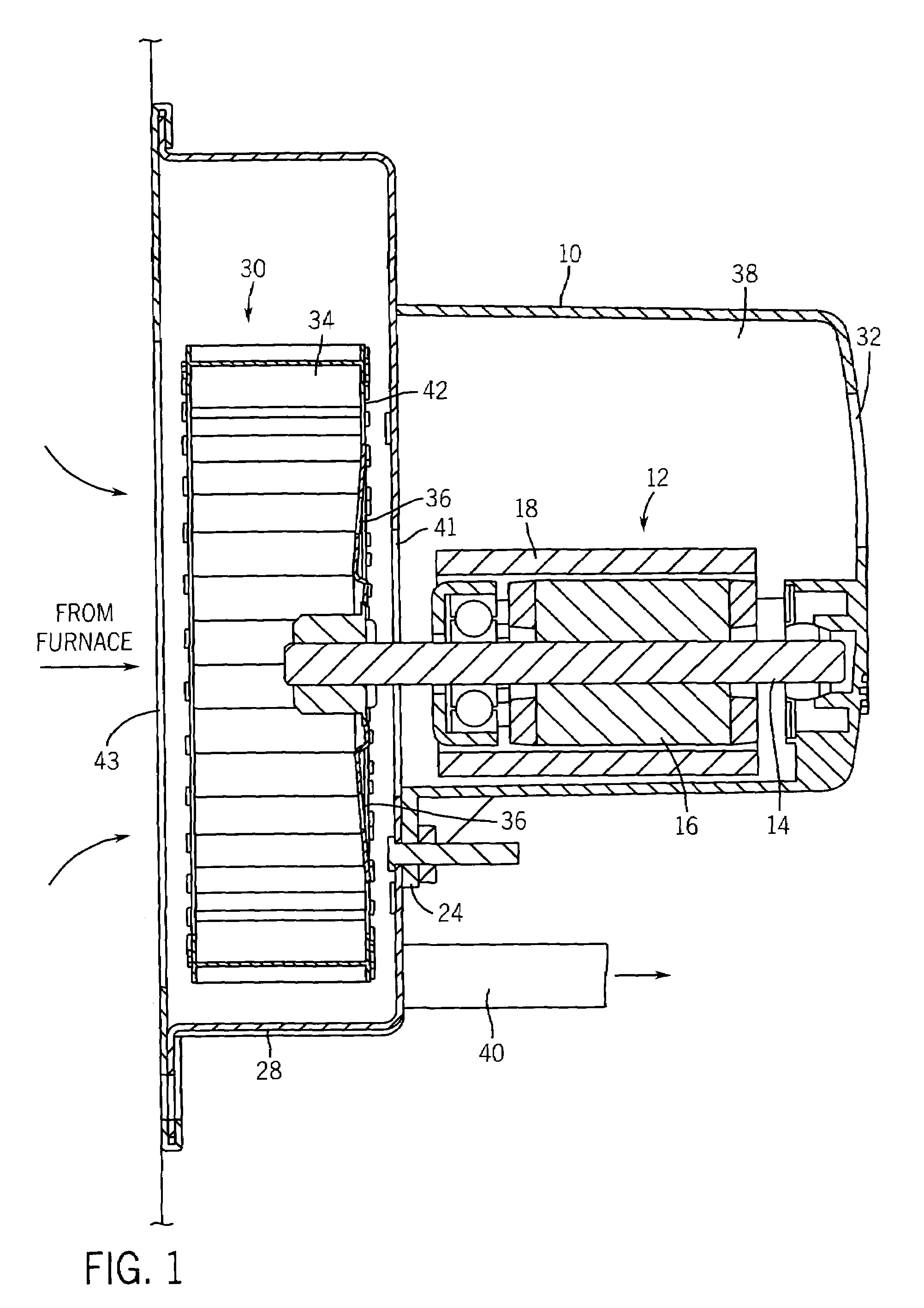

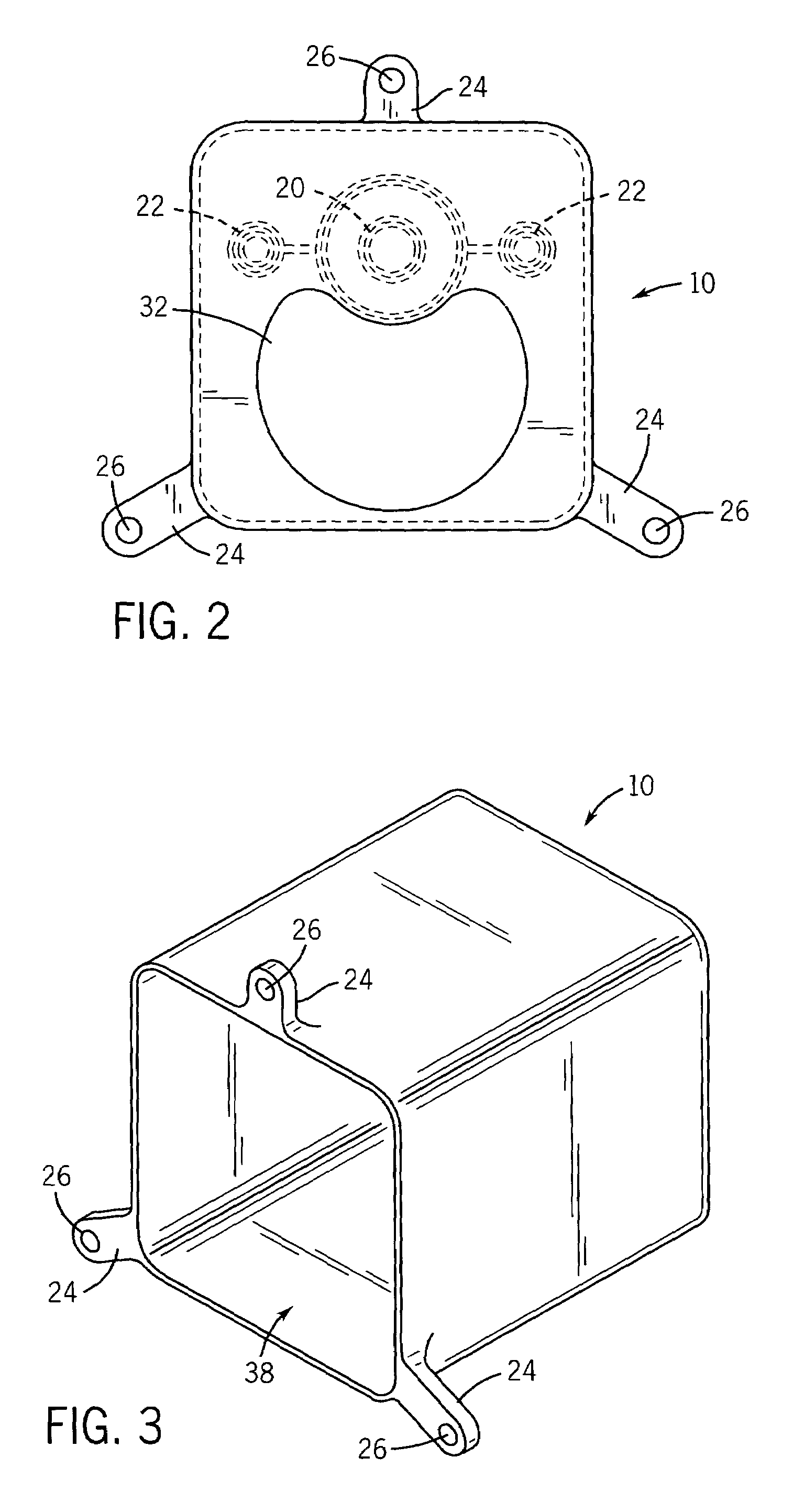

Exhaust fan assembly

An exhaust fan assembly is provided for expelling contaminated air from a building. The assembly includes fan housing connected to the building via a duct. The fan housing contains a fan the draws air from the building through the duct. An extension is mounted to the outlet end of the fan housing, and has a cylindrical upper end connected to a nozzle. A windband is connected to the upper end of the nozzle, and provides an air entrainment path that allows ambient air to mix with the exhaust air prior to exiting through an exhaust fan assembly outlet.

Owner:GREENHECK FAN

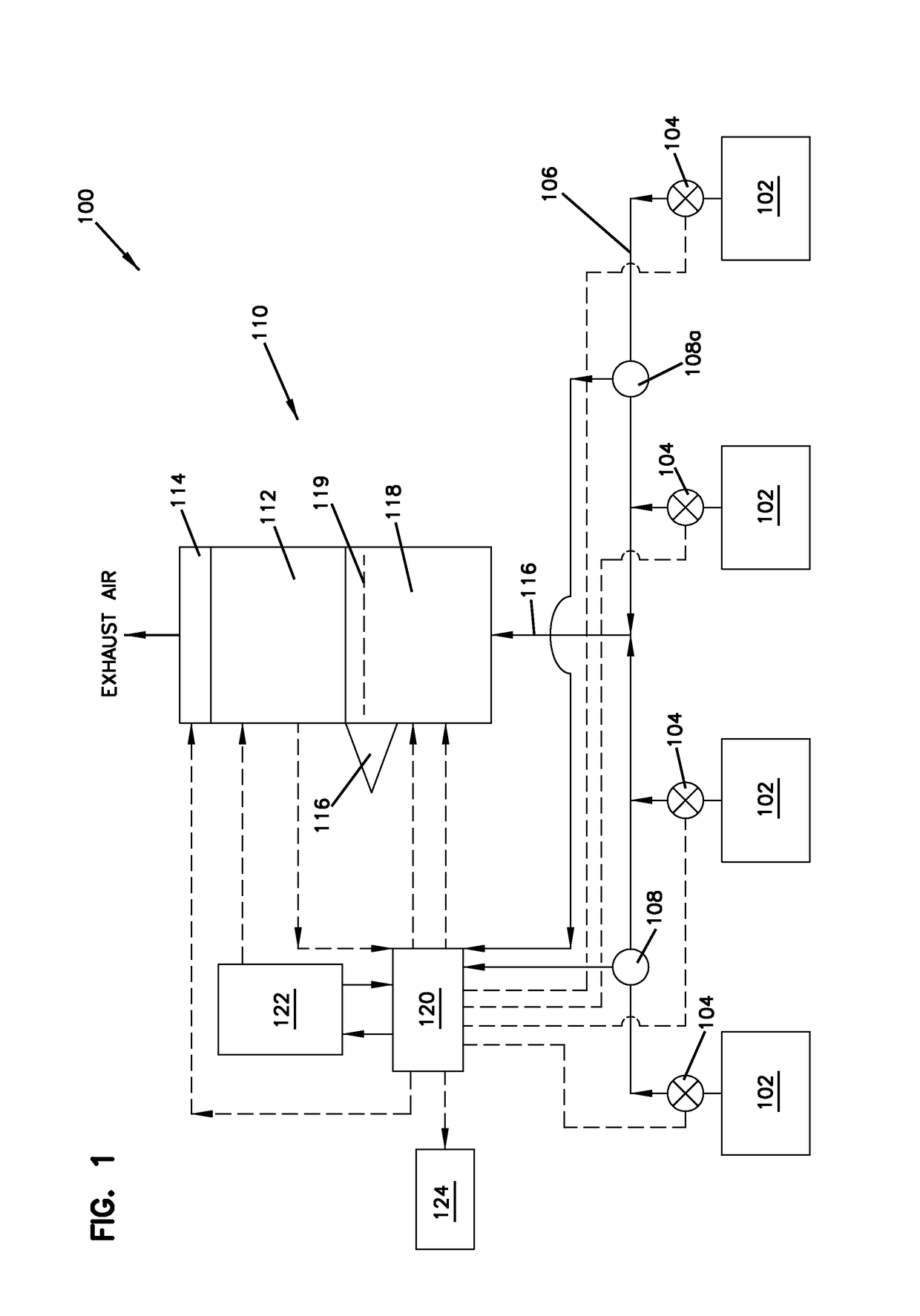

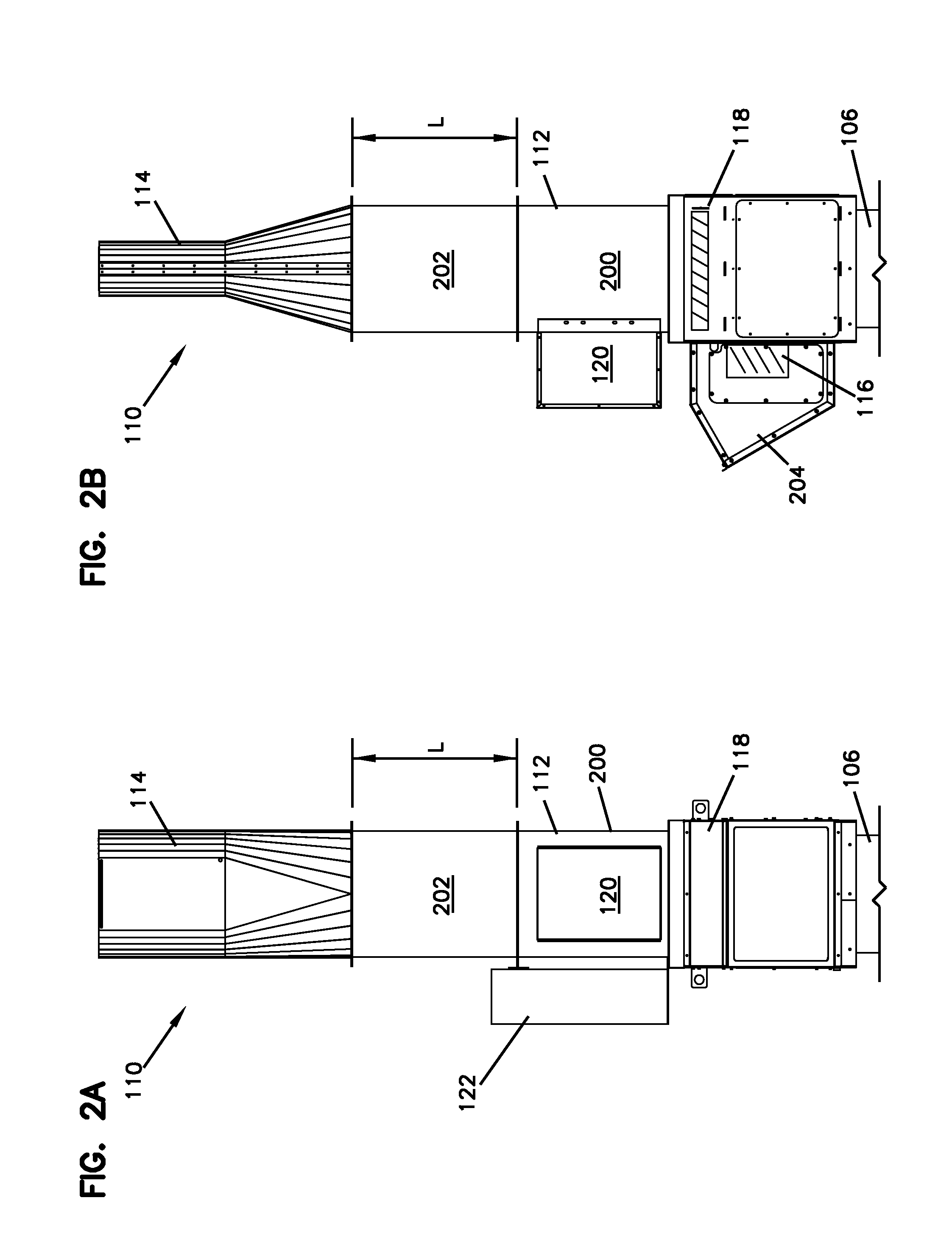

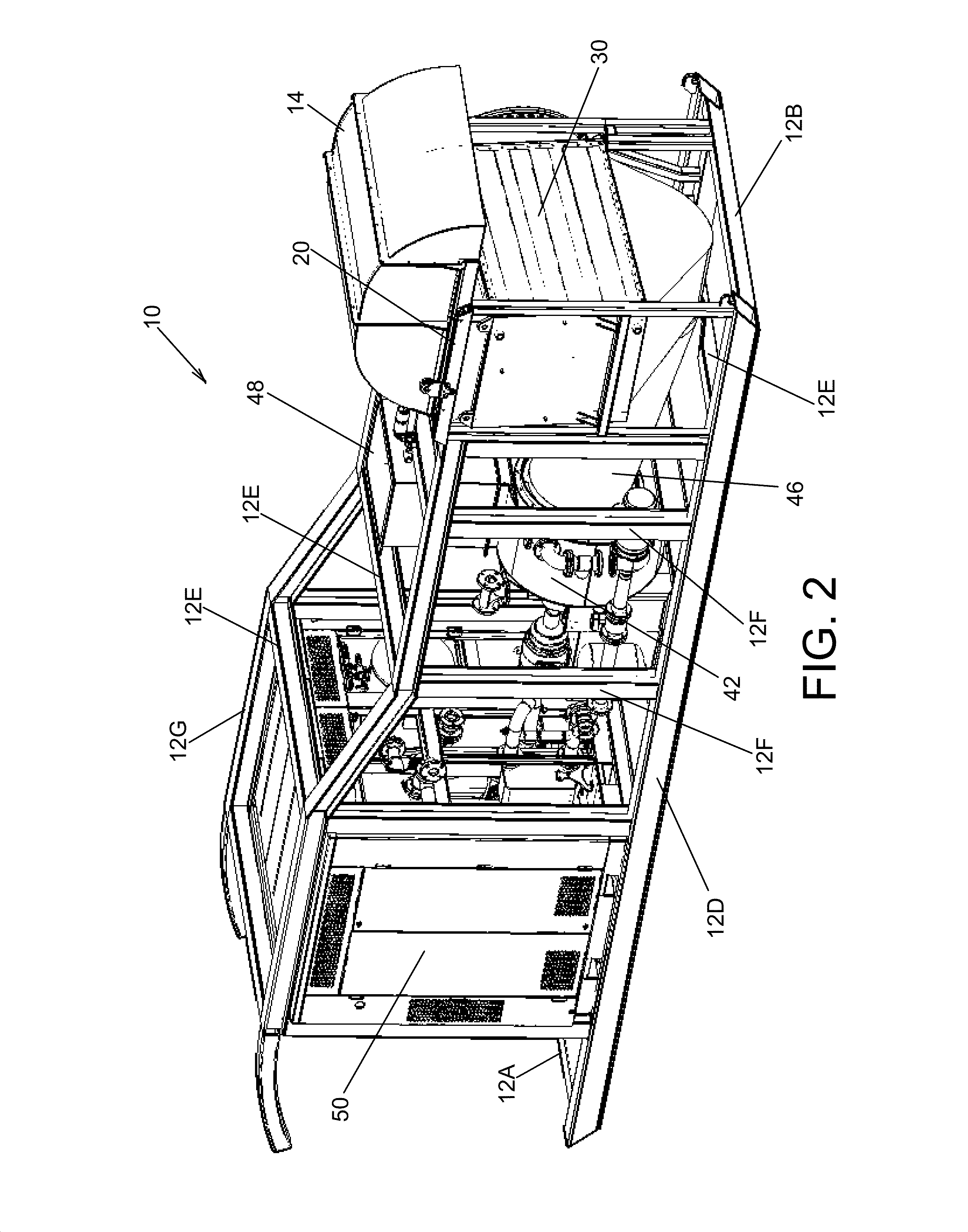

Variable-volume exhaust system

ActiveUS20120322358A1Reduce energy consumptionReduce flow ratePump componentsSpace heating and ventilation safety systemsControl systemShock absorber

An exhaust system for exhausting air from a space includes a variable-volume exhaust air moving system having at least one fan having an inlet and an outlet. A duct is connected to the inlet and an outlet nozzle defining a variable cross-sectional outlet area is fluidly connected to the outlet. A selectively operable bypass damper is fluidly connected to the inlet. A sensor is located in the exhaust system for detecting at least one of a pressure condition and a flow condition therein. A control system controls the at least one fan, the outlet nozzle, and the bypass damper, based on a signal sent from the sensor.

Owner:GREENHECK FAN

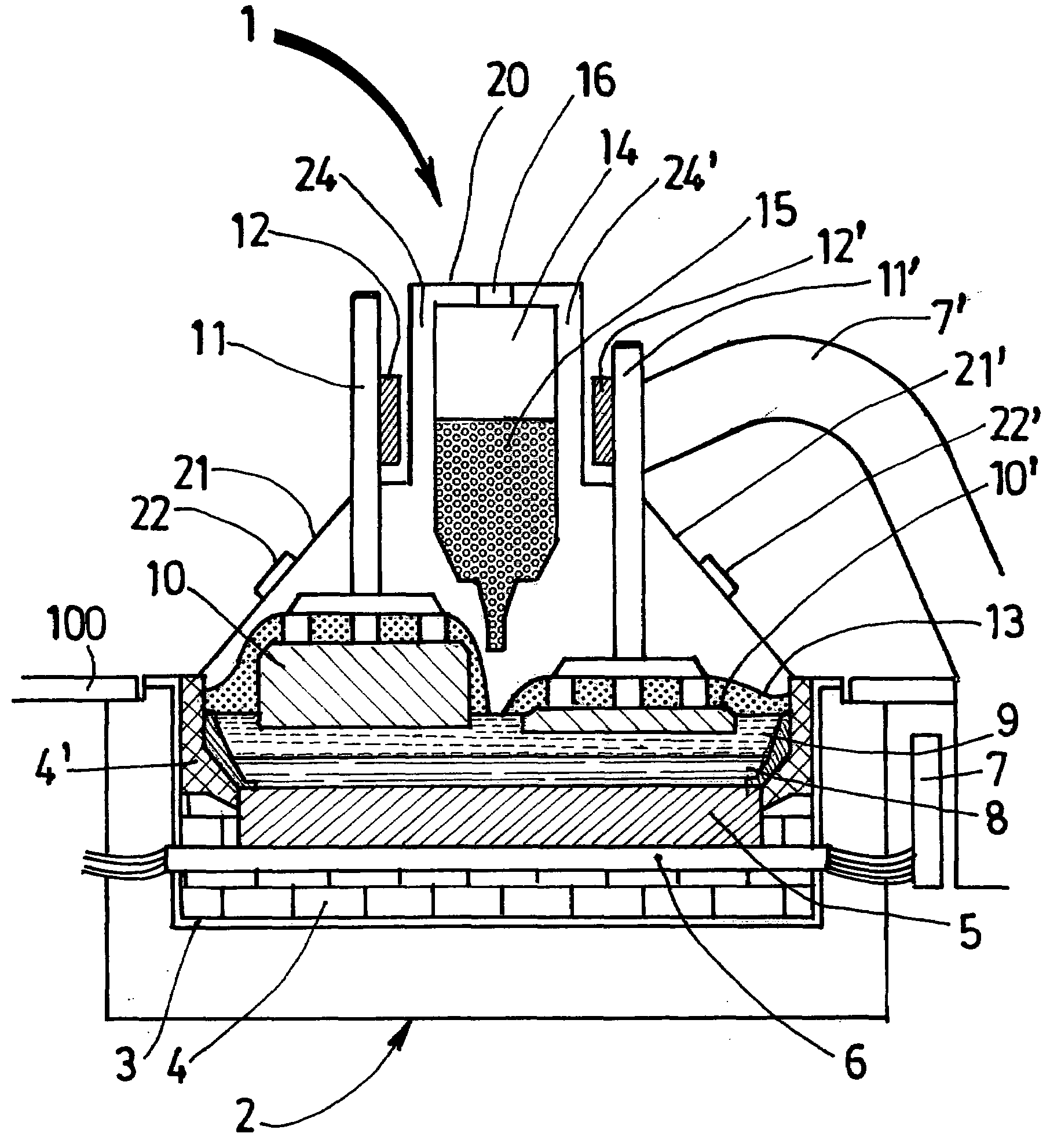

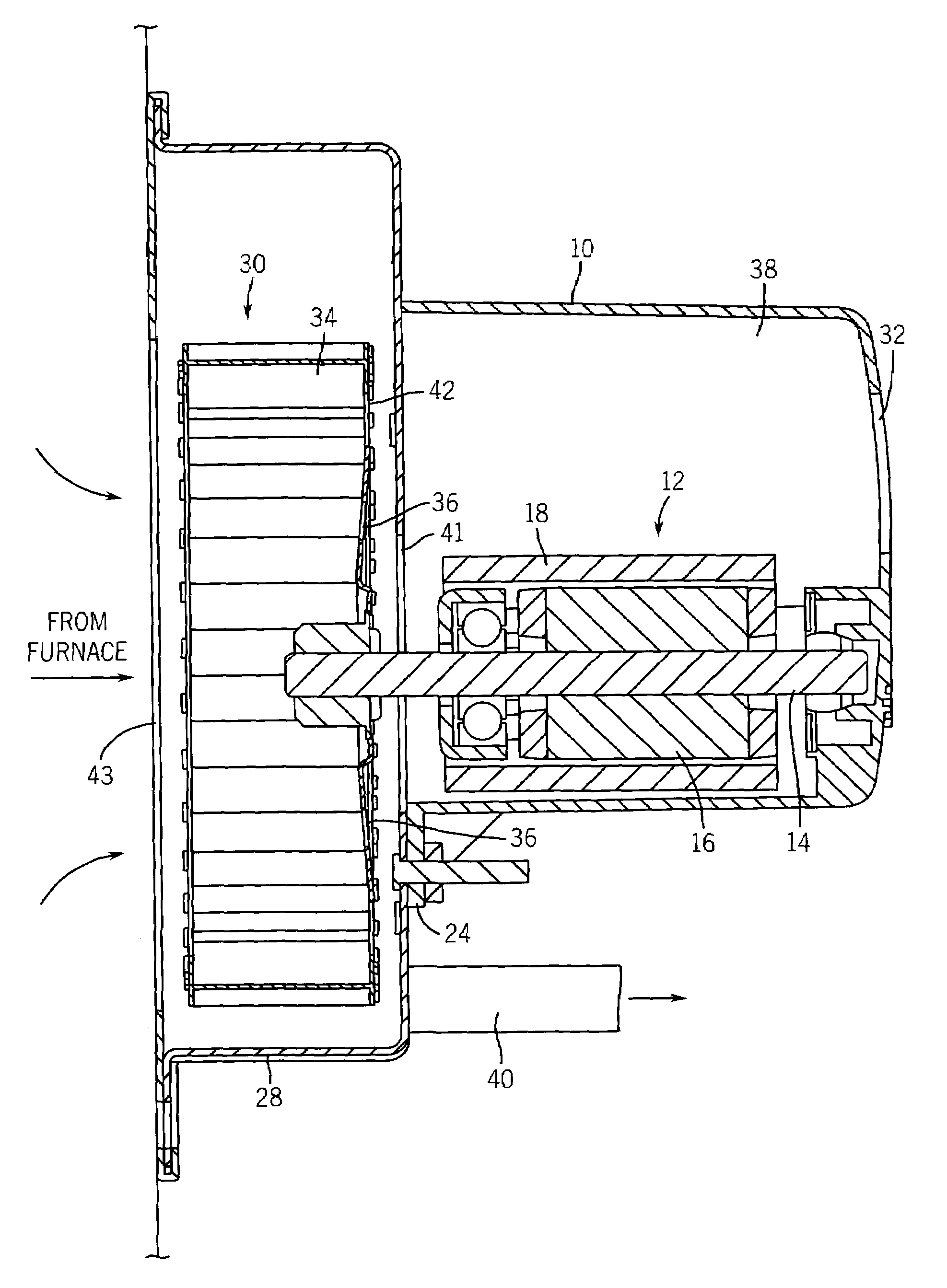

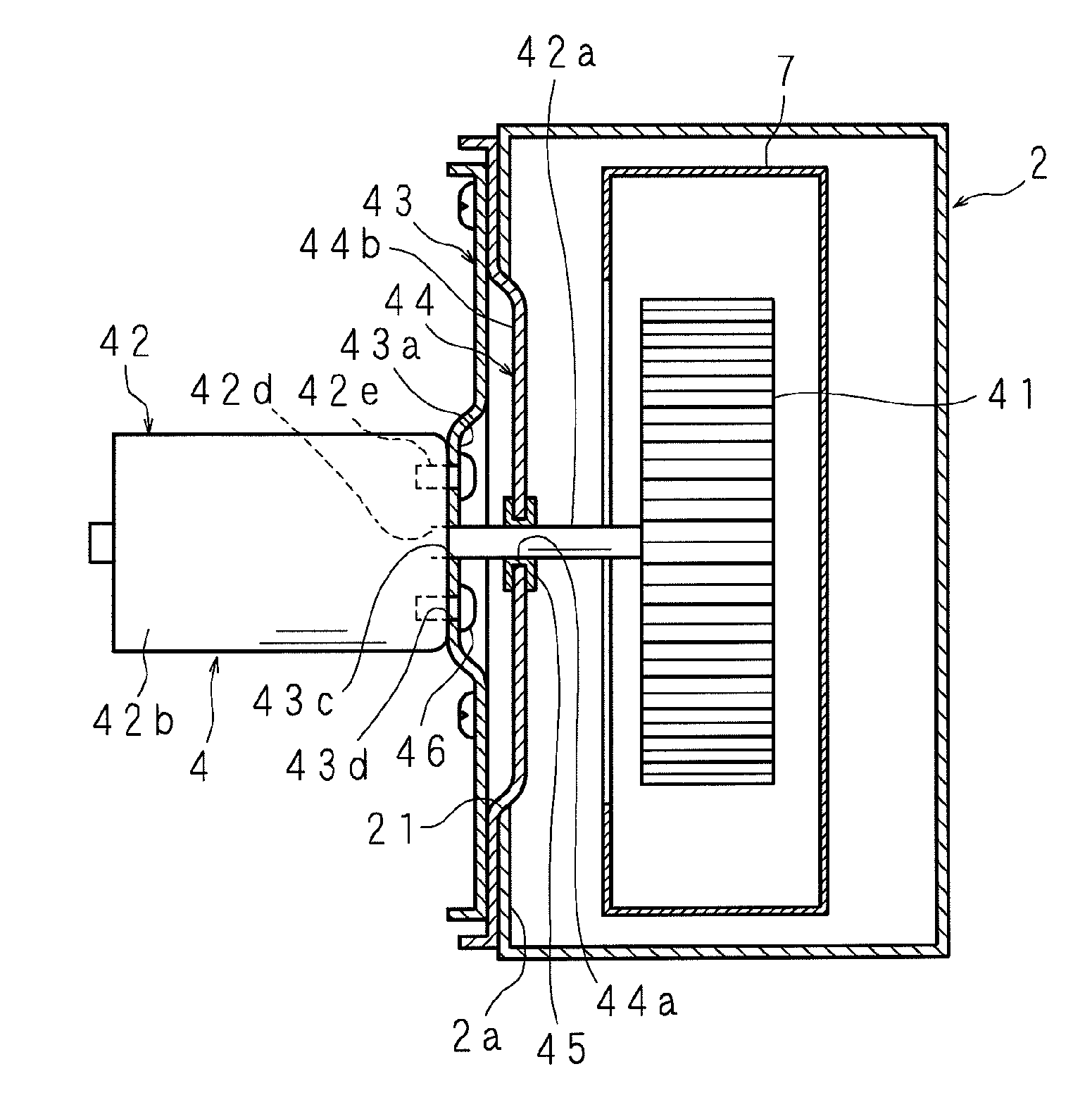

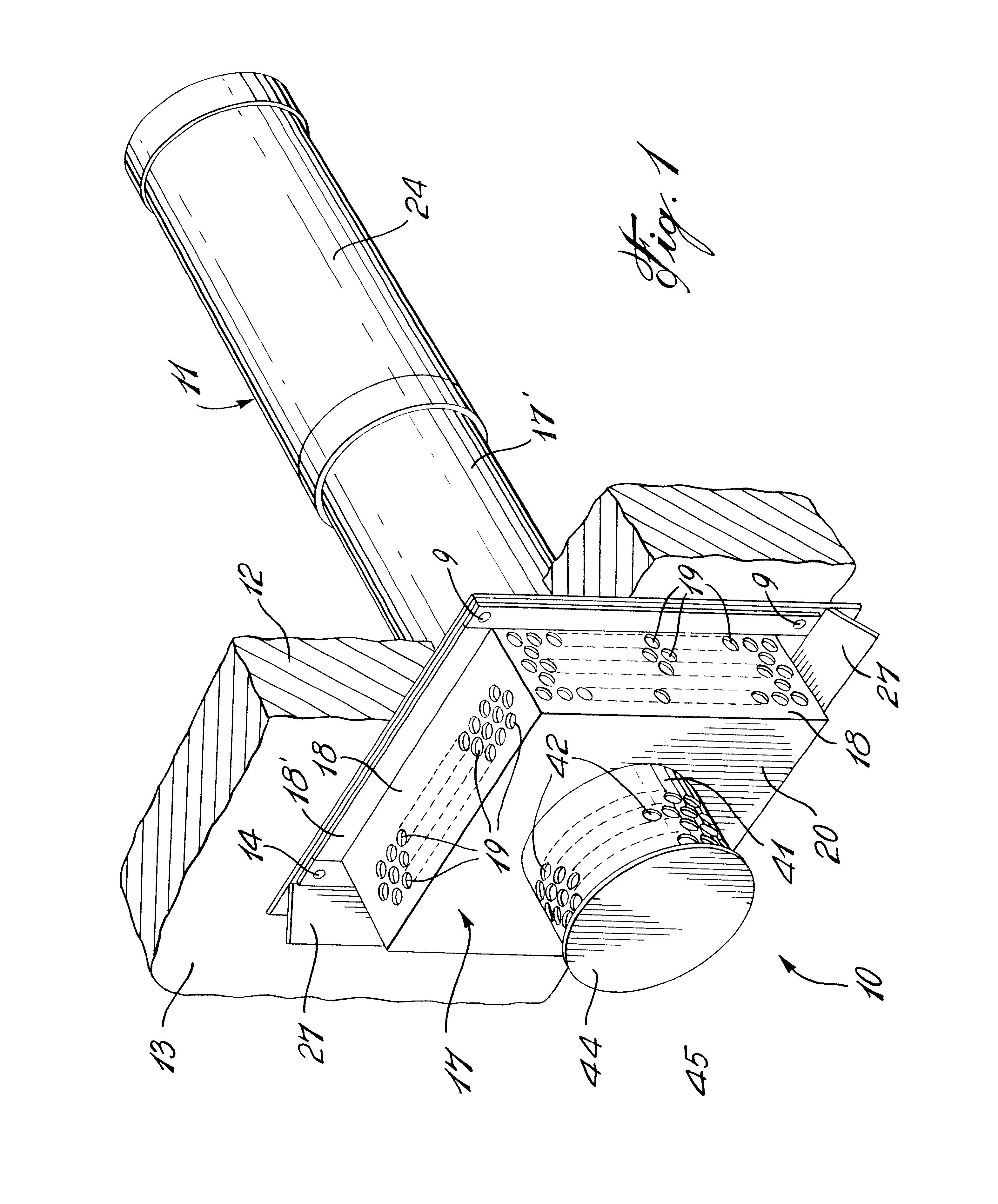

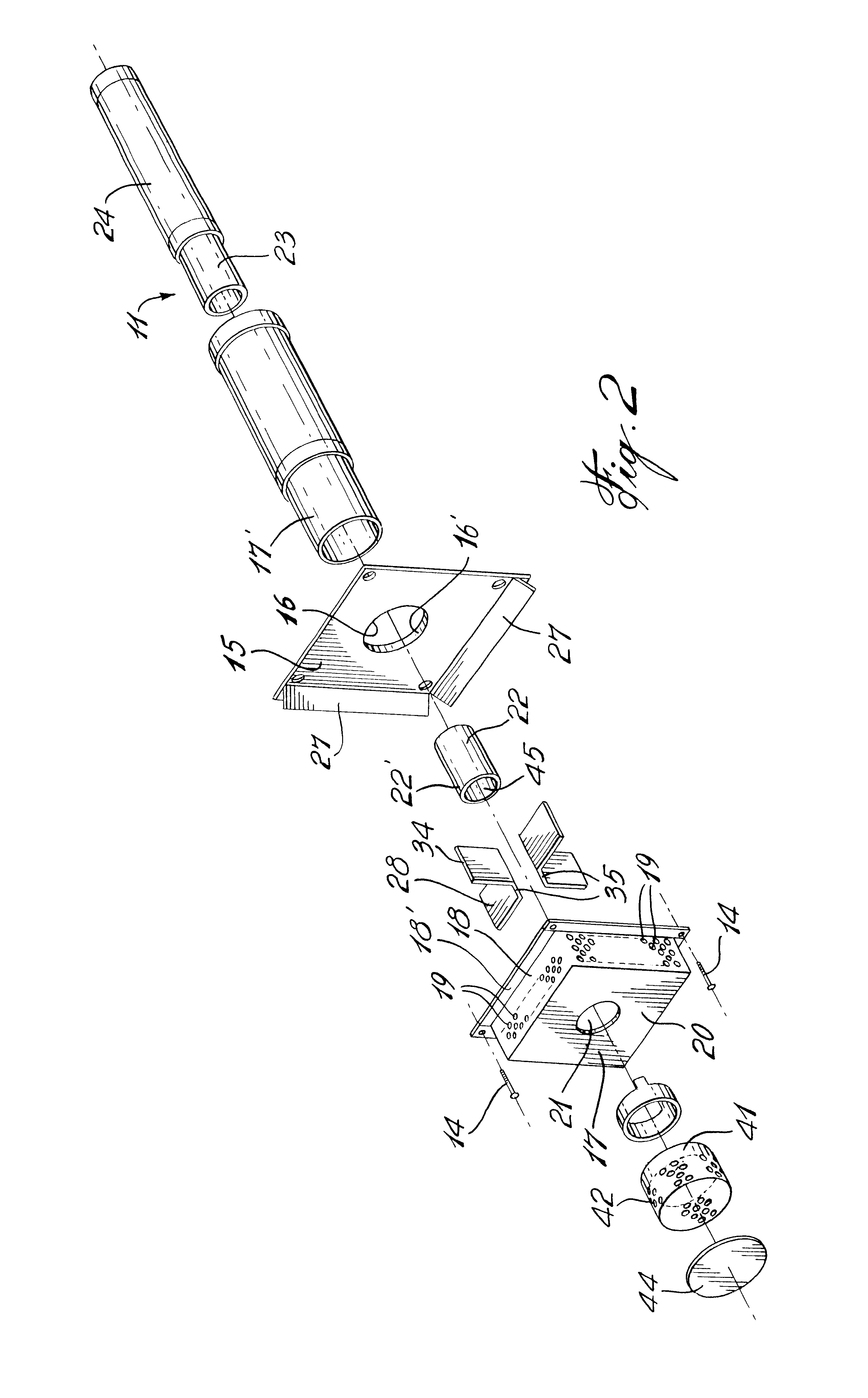

Method and apparatus for providing dilution air to a blower motor

A blower is disclosed which has a housing that provides a means for drawing dilution air into a combined motor and impeller housing. The dilution air is drawn into a first chamber which houses the blower motor and is then drawn into the impeller chamber where the dilution air mixes with hot exhaust gases from a hot water heater to which the blower is attached. Apertures on a back plate of the impeller provide fluid communication between the motor chamber and the impeller chamber. The housing has walls which extend beyond a housing cover to form a skirt so that the attachment of the blower to a water heater top results in a third chamber being formed within which the water heat flue is situated.The combination of the skirt section, the housing cover and the top of the hot water heater comprise the third chamber which has at least one slot provided therein for drawing dilution air into the third chamber where the dilution air is mixed with the exhaust gases exiting the water heater flue. The mixed air and exhaust gas is drawn into the second chamber by the operating impeller where the mixture is further mixed with the dilution air drawn from the motor chamber into the housing. The mixed gases are then channeled out an outlet port formed in the blower housing.The invention eliminates the need for fans dedicated to cool the blower motor while providing the means for more effectively reducing the temperatures of the exhaust gases which exit the blower.

Owner:RBC MFG COPORATION

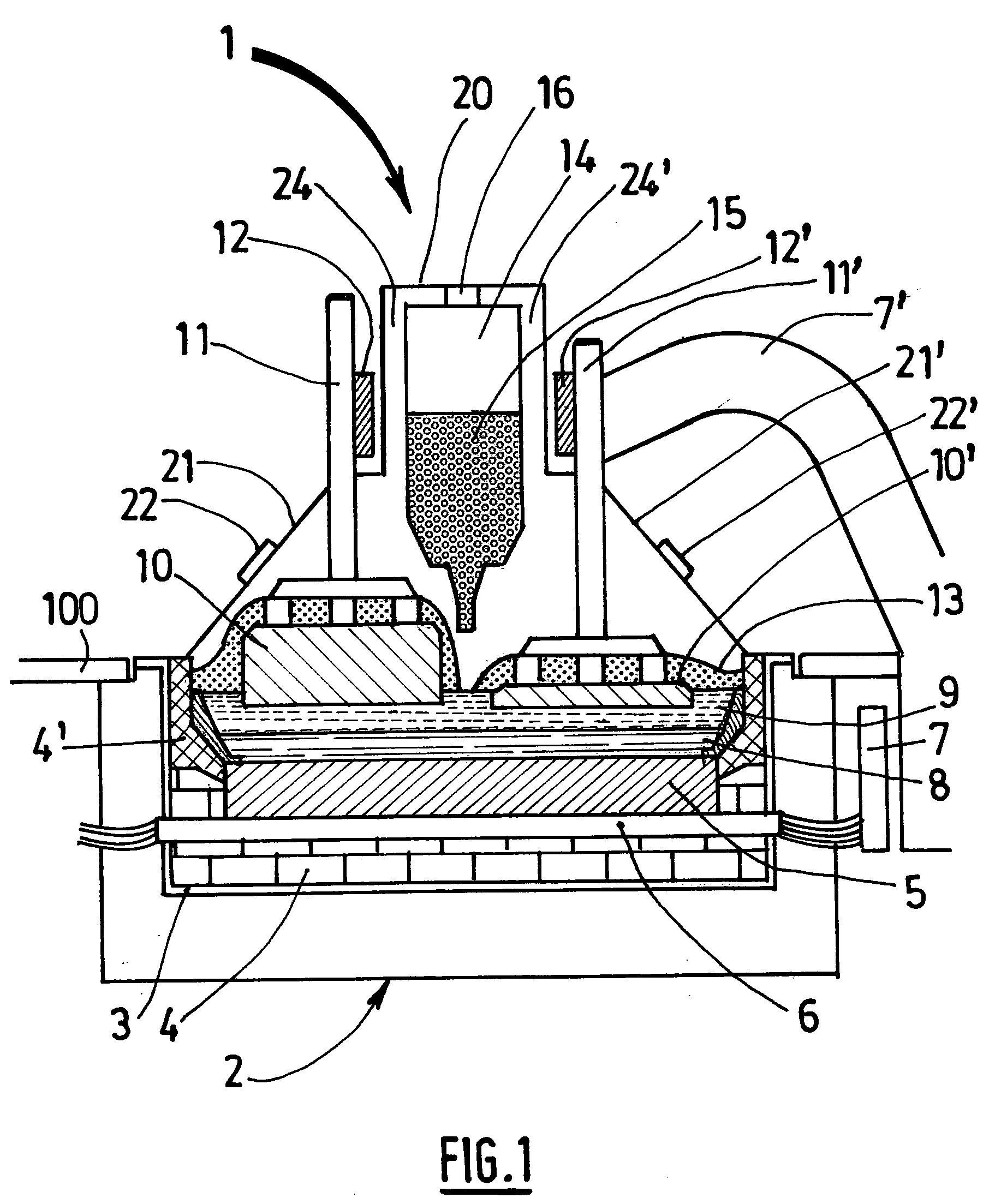

Apparatus for and method of operating a furnace blower to evaporate condensate within an exhaust flue

InactiveUS20020014233A1Reduce noiseCooler vestibulePump componentsAir heatersMotor speedExhaust valve

A blower for a furnace is provided where the blower has an impeller that is configured to create a primary air flow of combustion air into the blower housing and a secondary air flow of cooling air through the blower motor. The primary air flow of combustion air into the furnace generates hot exhaust gases for a heat exchanger in the furnace. The secondary air flow cools the blower motor. The secondary air flow is mixed with the hot exhaust gases in the blower housing and cools the exhaust gases before being discharged from the blower housing. A control operates the blower for a time period after each combustion cycle to introduce ambient air into the exhaust flue and chimney to ensure the evaporation of any condensate forming from the products of combustion contained in the exhaust. The blower may be a variable or multi-speed motor so that a different motor speed may be used for combustion than for the run time after combustion.

Owner:JAKEL

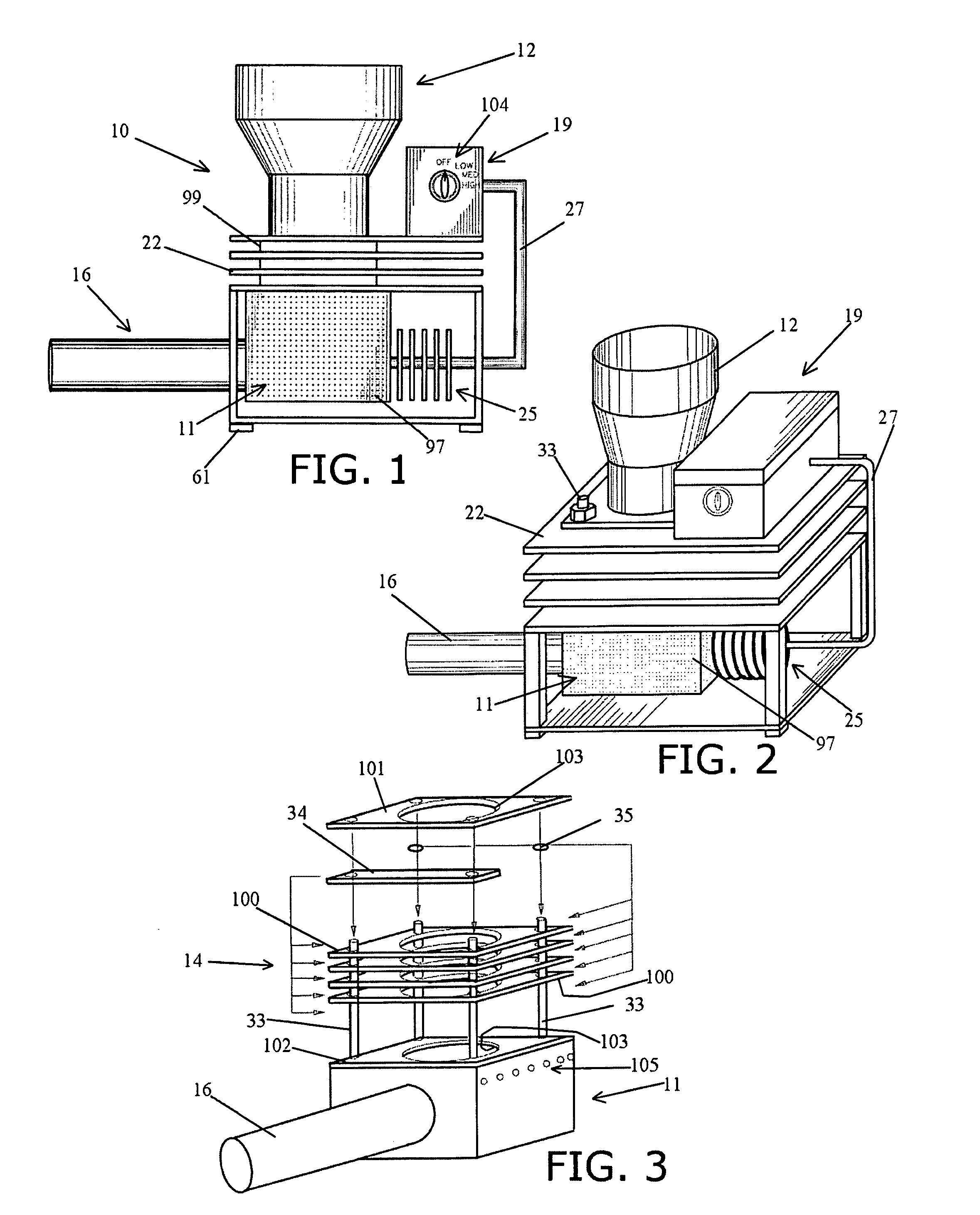

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

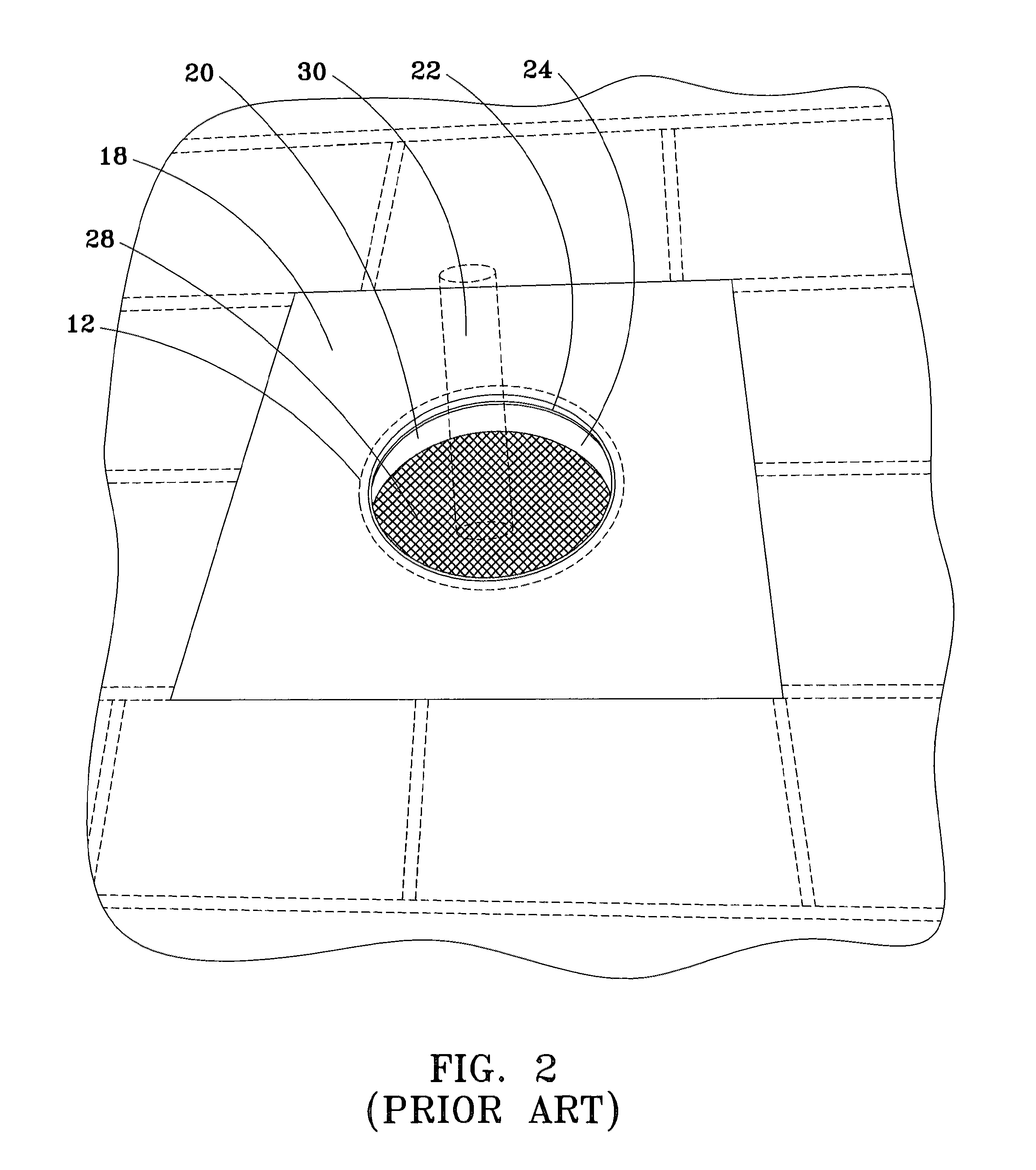

Exhaust fan assembly

ActiveUS7682231B2Constant flow of airImprove efficiencyAir supply regulationDirt cleaningOperating energyContaminated air

An exhaust fan assembly is provided for expelling contaminated air from a building. The assembly includes a plenum, a fan assembly attached to the plenum, and a windband mounted on top of the fan assembly. The fan assembly is constructed of cylindrical outer and inner walls which define a bearing chamber and surrounding annular space. A fan driven by a shaft extending downward from the bearing chamber draws exhaust air from the plenum and blows it up through the annular space to a nozzle at the top of the fan assembly.

Owner:GREENHECK FAN

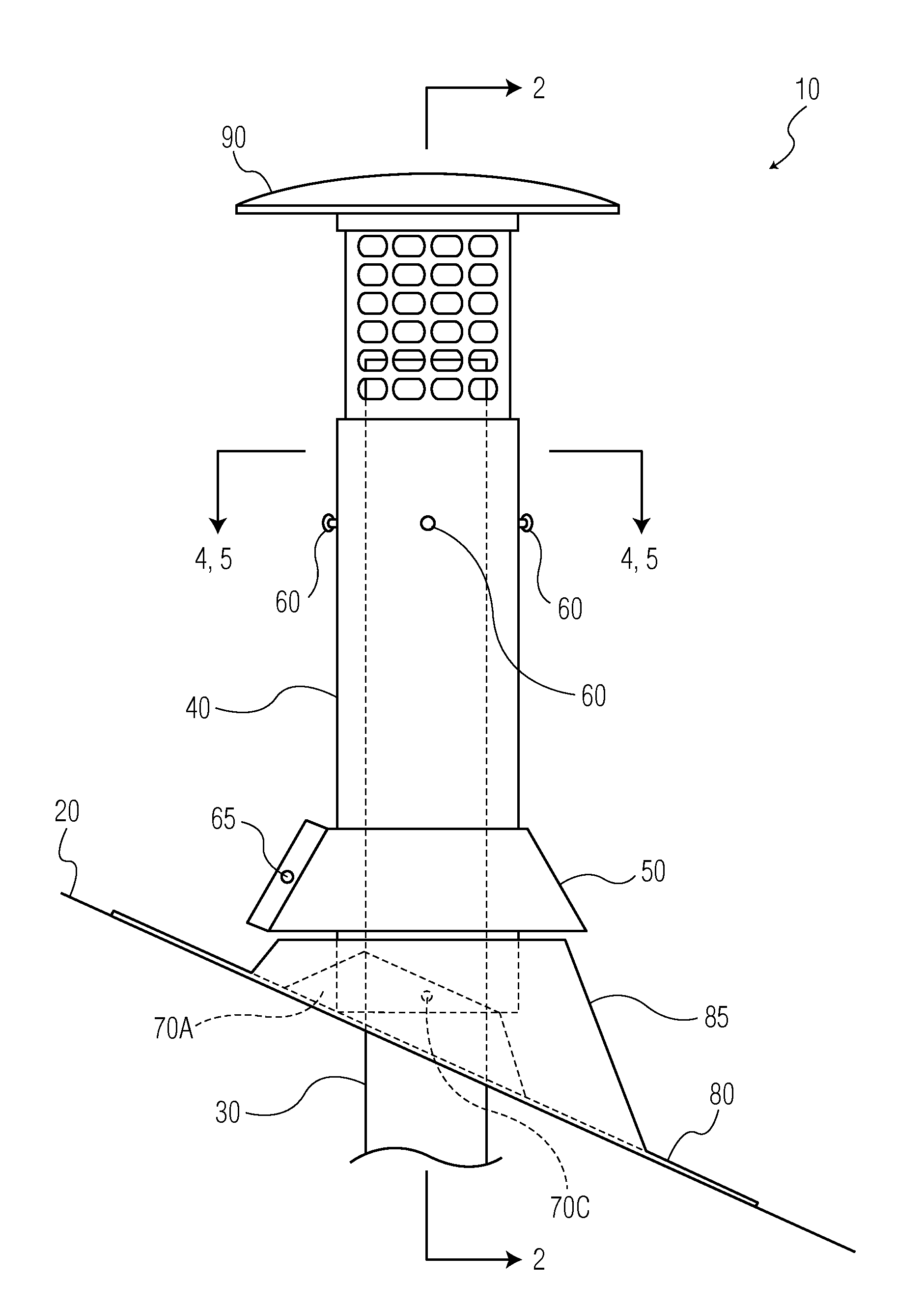

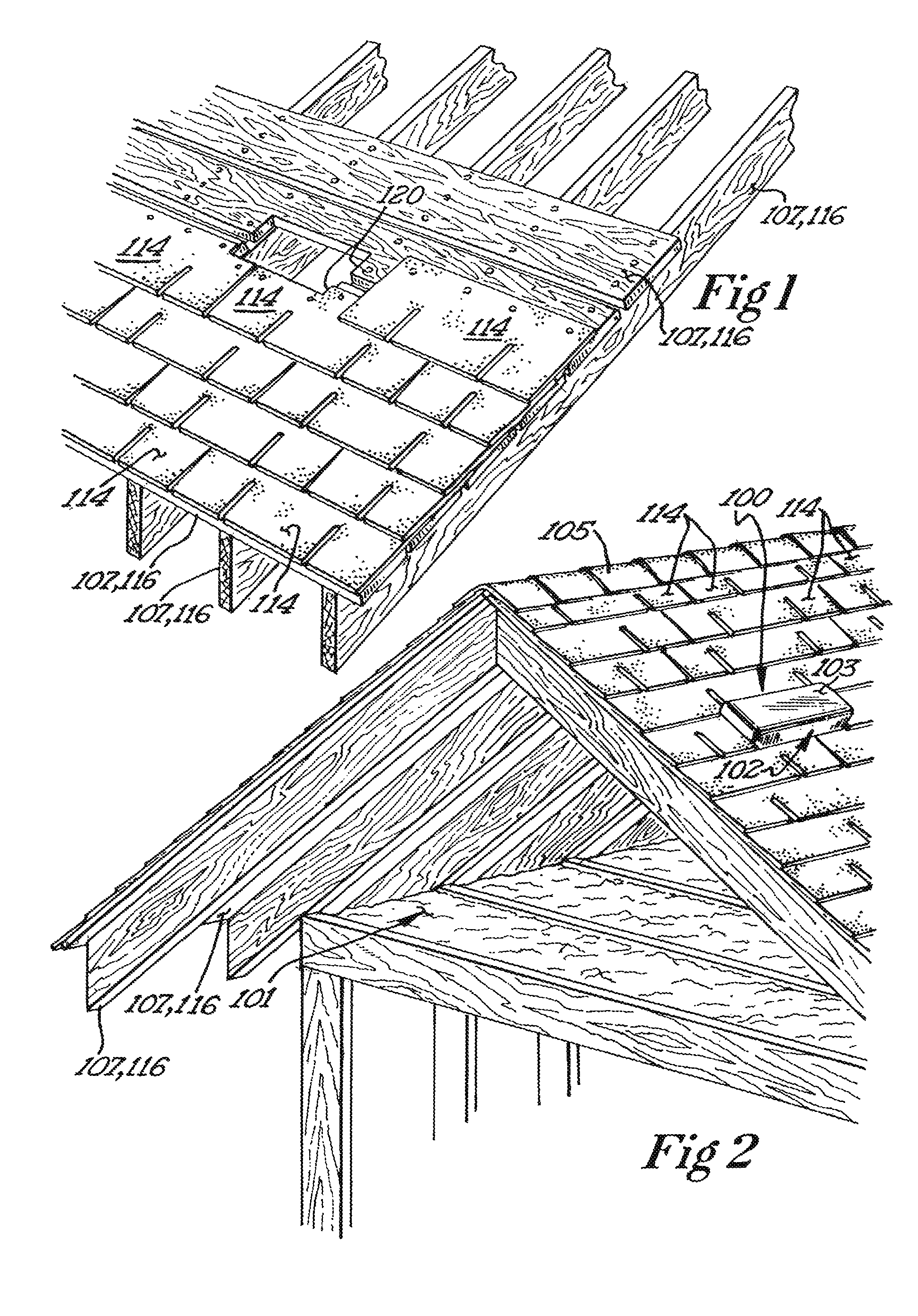

Roof vent base plate and installation methods

InactiveUS7882670B2Avoid property damageQuick installationBuilding roofsHeating and ventilation casings/coversAir exchangeEngineering

A roof ventilation apparatus for a sloped roof having a cap and base plate is provided. The cap has a top surface and a bottom surface. The bottom surface has a flange that defines an opening to a cavity formed between the top and bottom cap surface. The cavity provides a path for air exchange from a roof opening through an air passage formed between the flange and cap top. The base plate has a collar or curb surrounding an aperture that fits inside the cap bottom cavity. The base plate preferably is shaped such that when installed on the sloped roof the cap entirely covers the base plate. Preferably, the base plate includes a collar and an angled edge configured to channel moisture that seeps within the vent cap.

Owner:WEST G LEONARD

Flue cap

Owner:K & M PLASTICS

Method for cooling a motor in a blower assembly for a furnance

InactiveUS6951241B1Shorten the lengthReduce noiseDomestic stoves or rangesPump componentsImpellerEngineering

A method of cooling the bearings of a motor in a motor housing for a furnace assembly is disclosed comprising an aperture in the motor housing whereby air is brought into the motor housing and drawn around the motor via an impeller into the impeller housing thereby eliminating the need of a separately attached fan to cool the motor or motor bearings. The impeller pulls the air from the motor housing into the impeller housing or blower via an inlet port in the impeller housing and apertures in the back plate of the impeller and out an exhaust port situated in the impeller housing.

Owner:REGAL BELOIT AMERICA

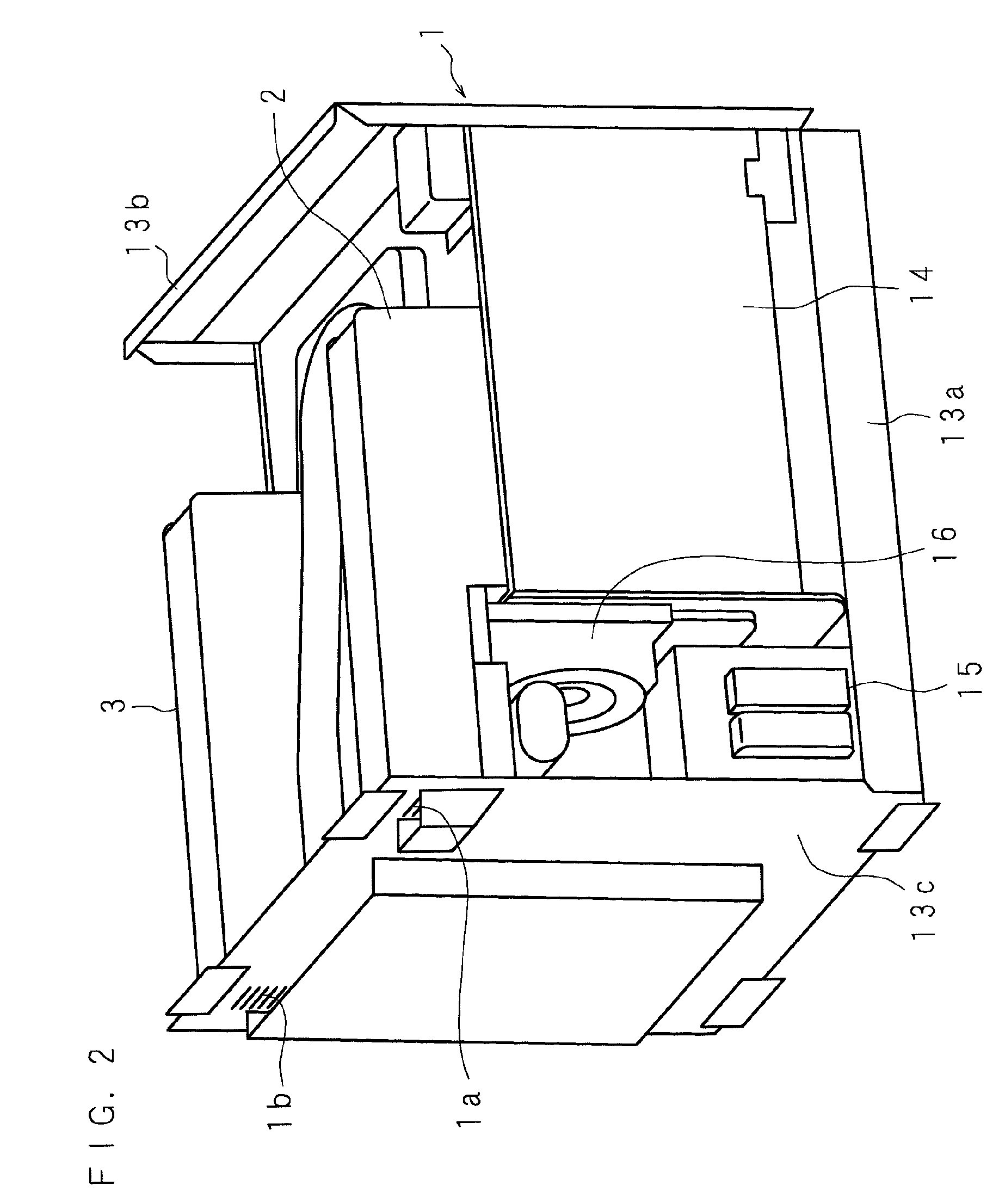

Cooking device

InactiveUS7992552B2Increased durabilityDomestic stoves or rangesCooking fumes removalImpellerElectric motor

Owner:SHARP KK

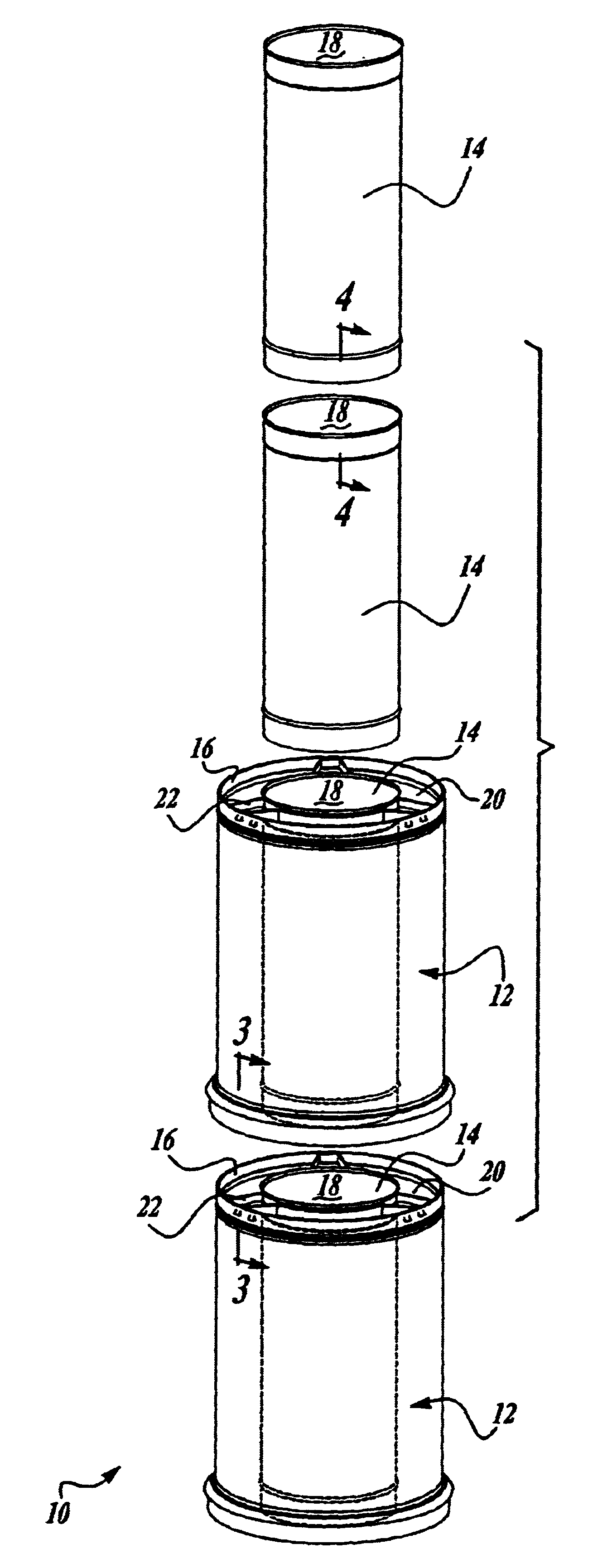

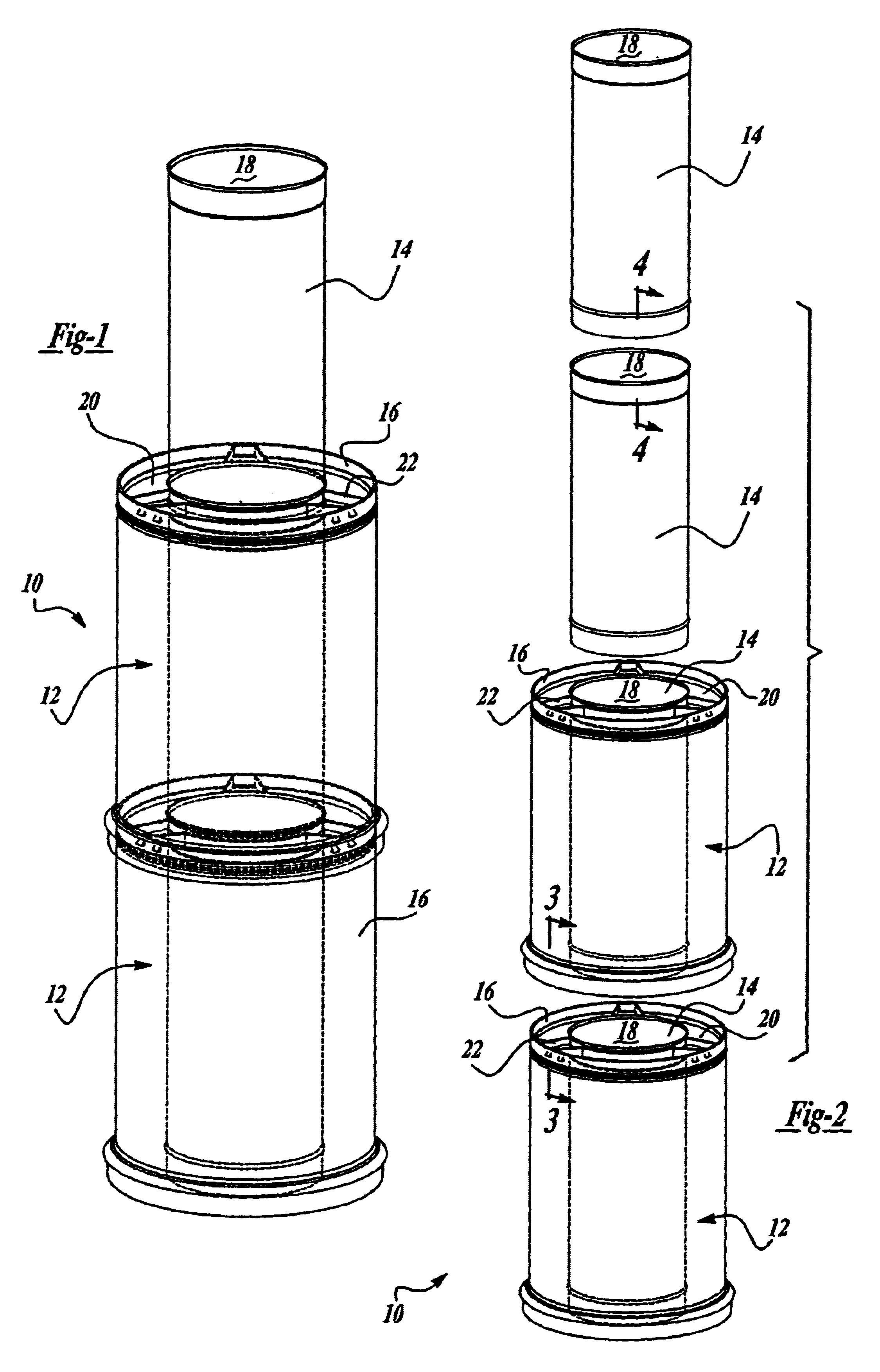

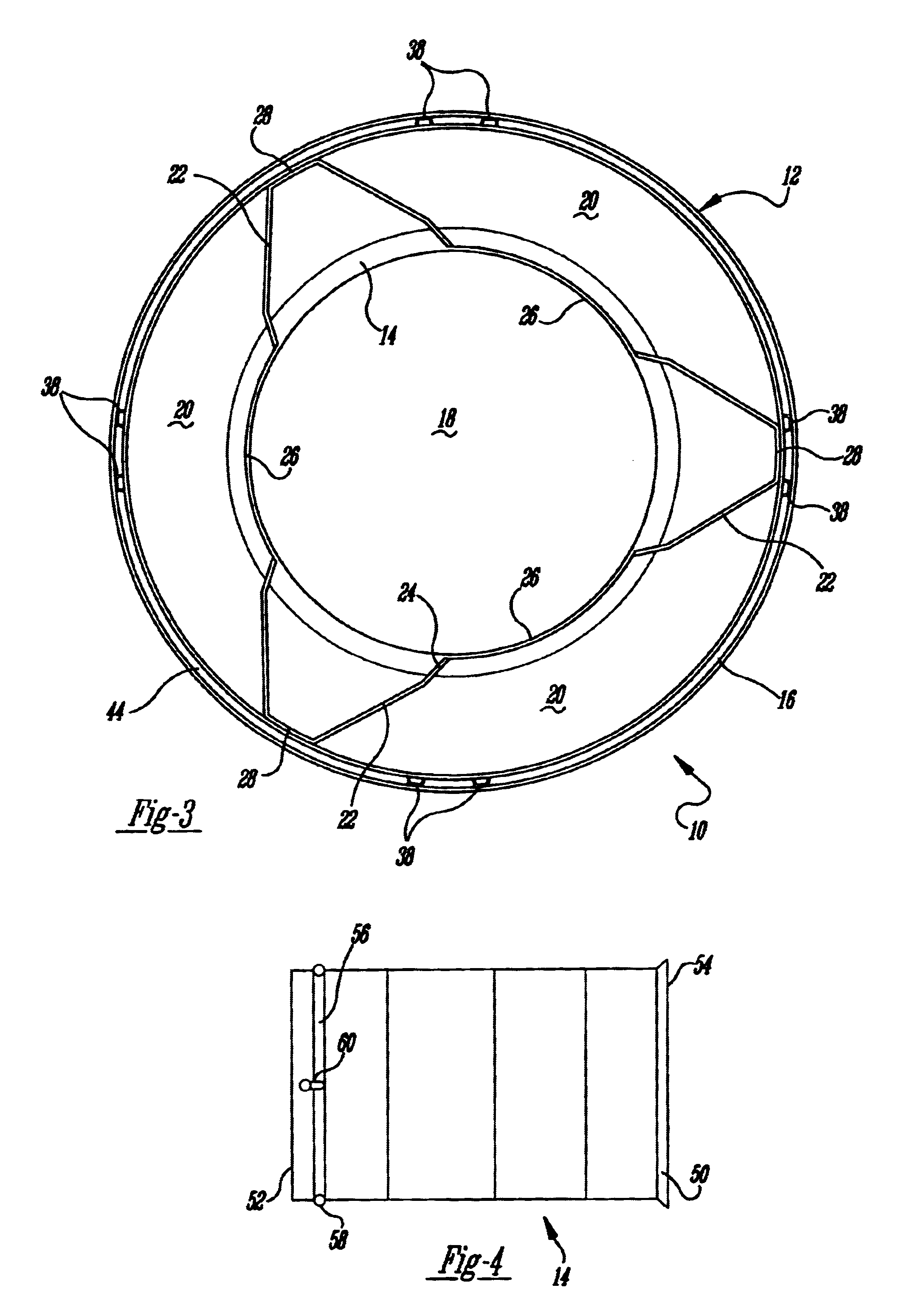

Direct venting vent pipe

InactiveUS6634352B2Facilitate run of unrestricted lengthEfficient combustionPipe supportsDomestic stoves or rangesDirect combustionDouble wall

A venting system for a direct vent fireplace or other direct vent appliance to direct combustion gases to an exterior area. The direct venting vent pipe facilitates unrestricted lengths of pipe installations. The vent pipe has a double wall construction forming an interior axial passageway and a coaxial outer passageway. The double walls are spaced apart by an insert to maintain coaxial spacing. Sections of the vent pipe are lockingly connected to prevent separation and ensure sealing connection between the pipe sections. Elastic seal members are utilized between the matingly connected sections and a mechanical lock assembly prevents separation.

Owner:CARDINAL IP HLDG LLC

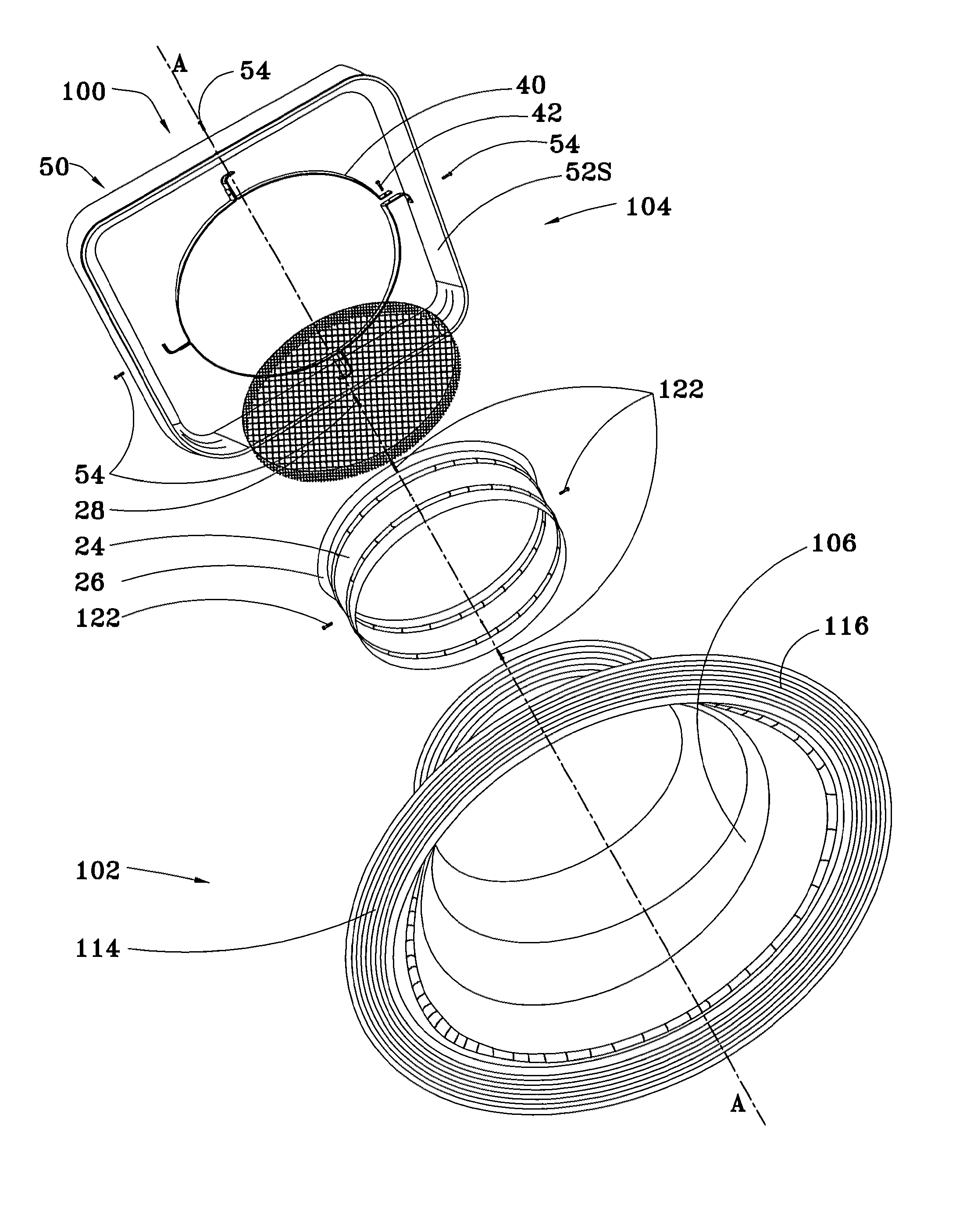

Exhaust flue cap and filter device for a gas fired appliance

ActiveUS20090088060A1Reduce carbon monoxideSmall diameterDispersed particle separationIncinerator apparatusEngineeringMechanical engineering

An exhaust flue cap and filter device for a gas fired appliance in communication with an exhaust flue opening having an outer pipe and a coaxial liner. The device includes a tubular cap with an open lower end, an opposed open upper end, and a plurality of ventilation holes wherein the cap is receivable over the flue opening. A removable top is attached to and closes the open upper end of the tubular cap. A filter tray having a smaller diameter than the tubular cap includes a ledge extending radially inward from the tray. A removable catalytic converter filter insert within the tubular cap is supported on the ledge.

Owner:ARNOLD JOHN G JR

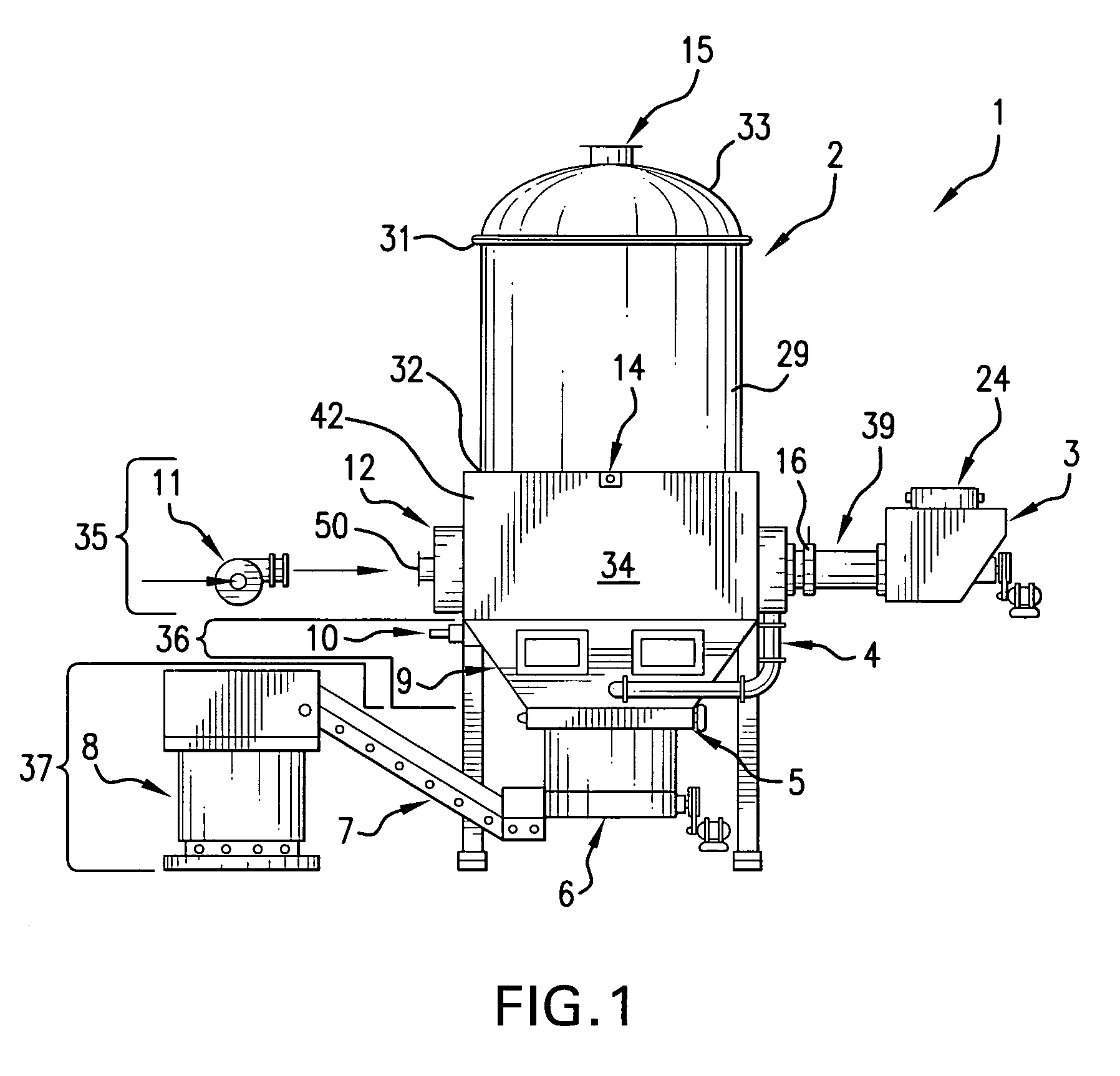

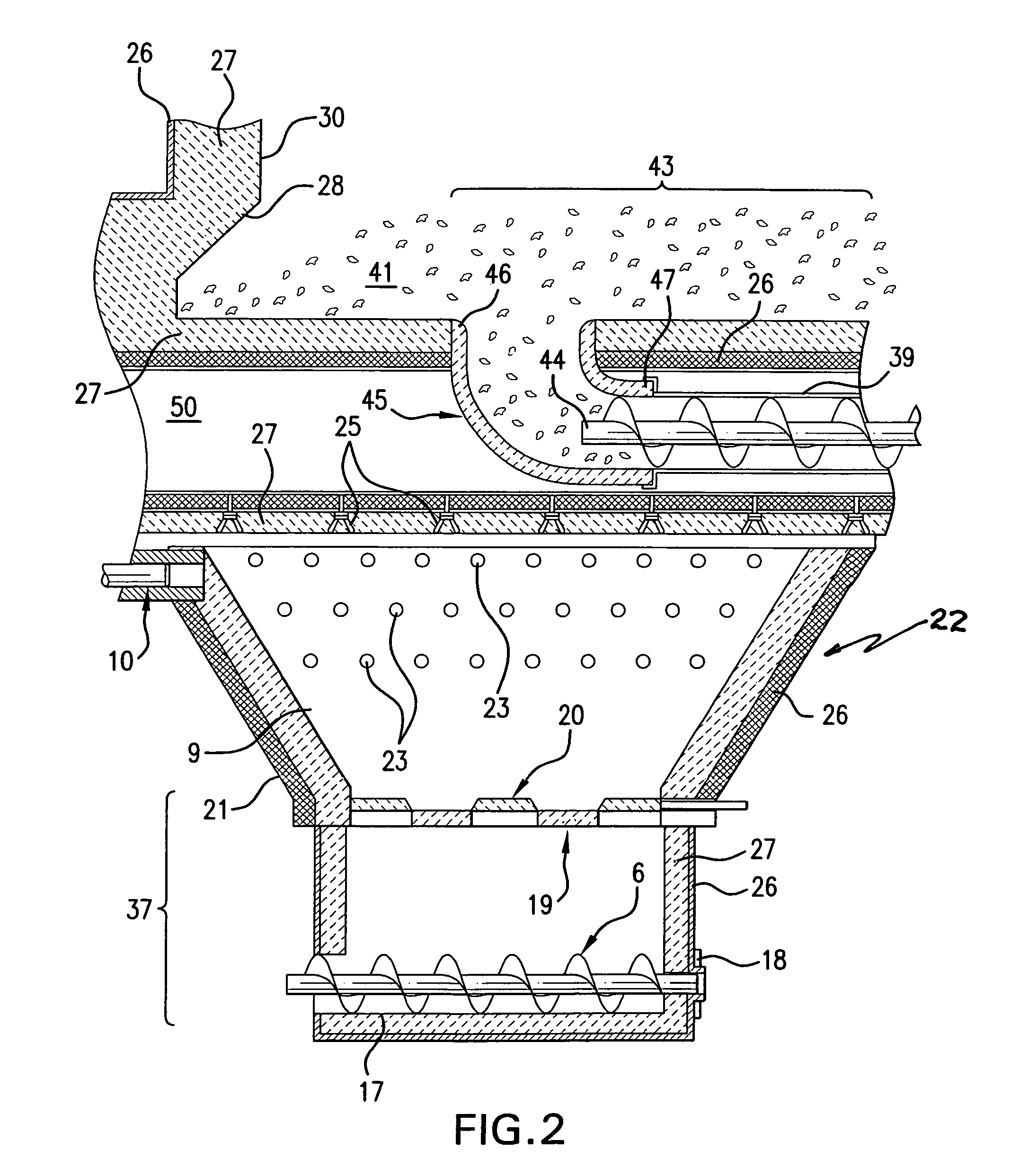

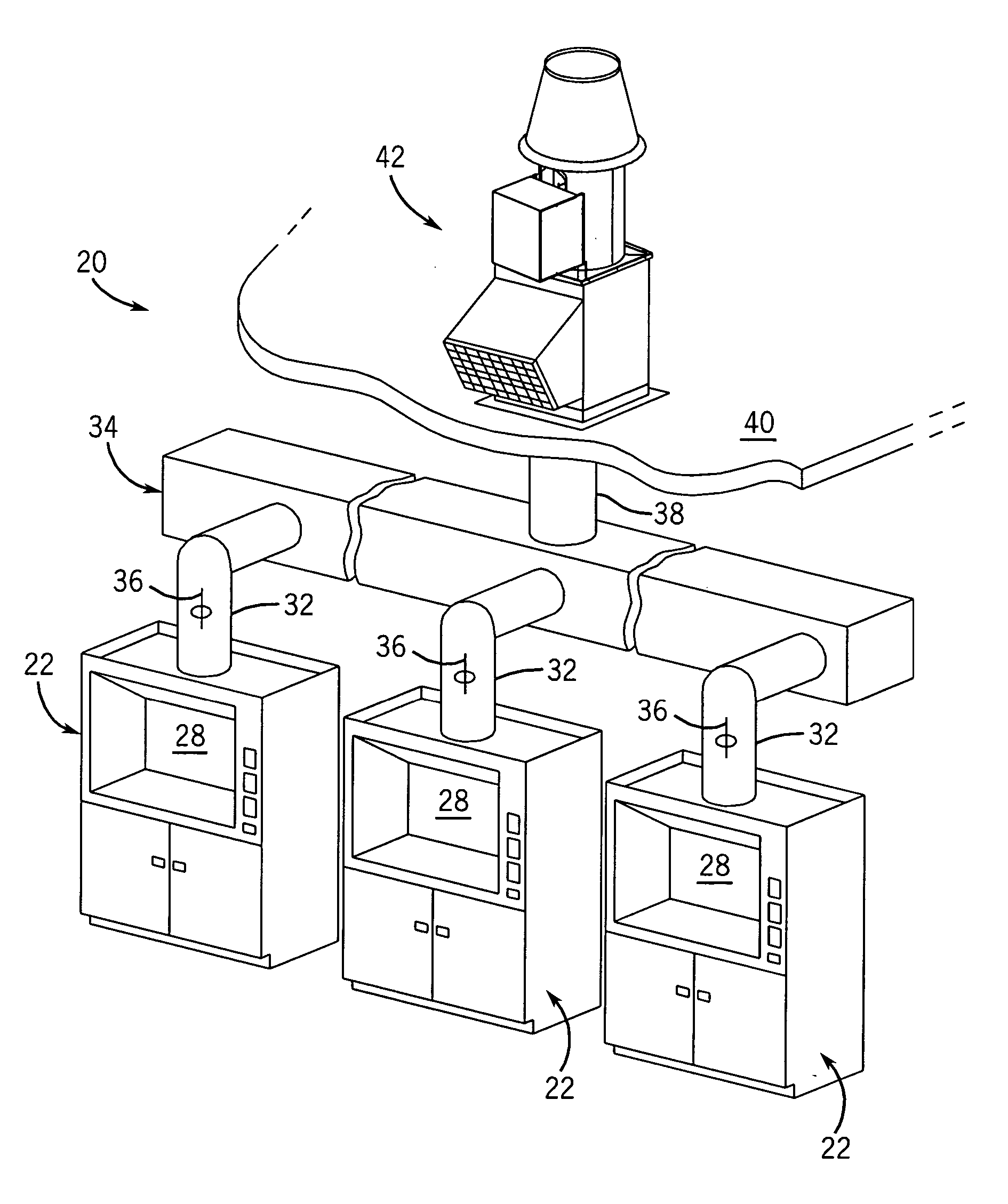

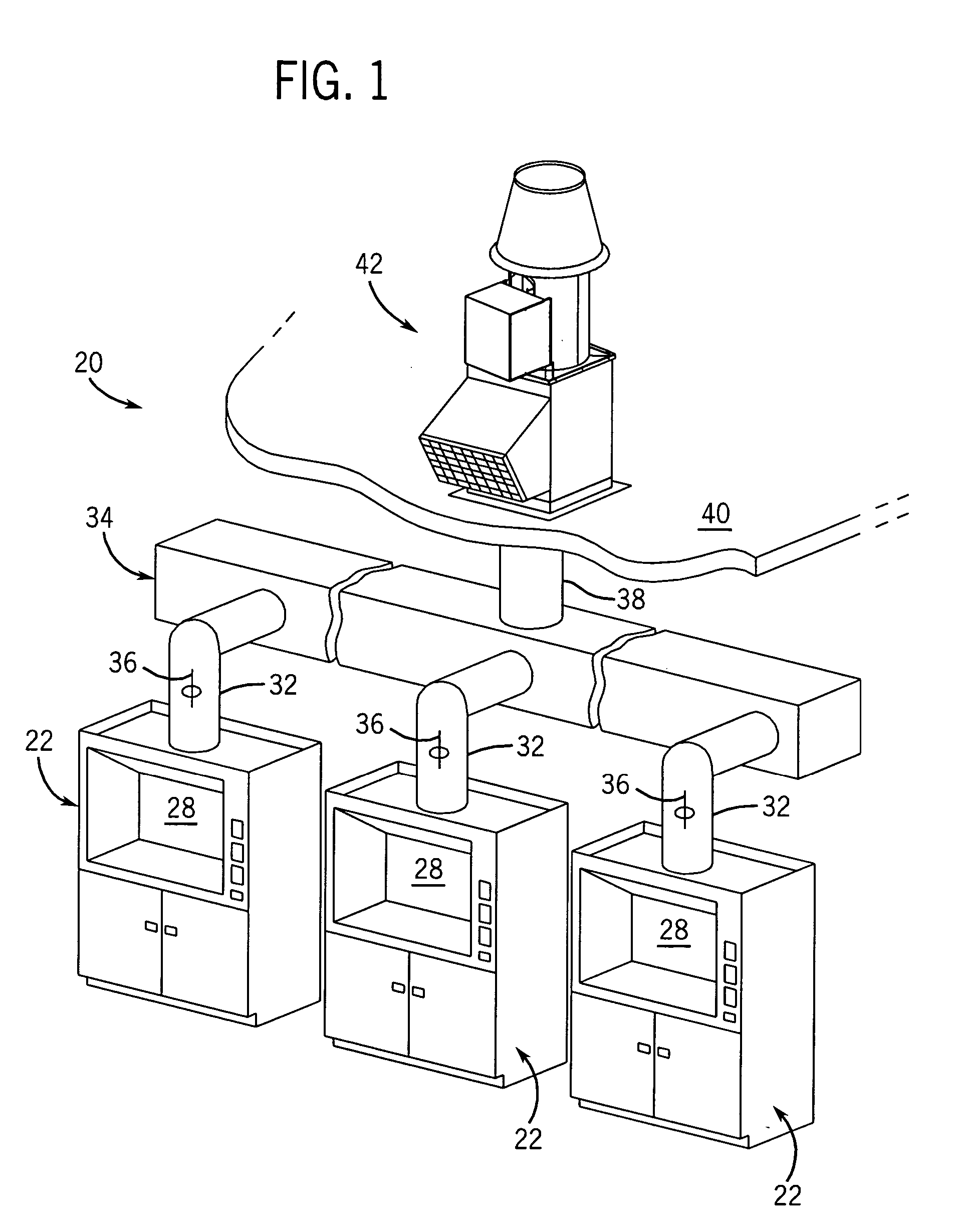

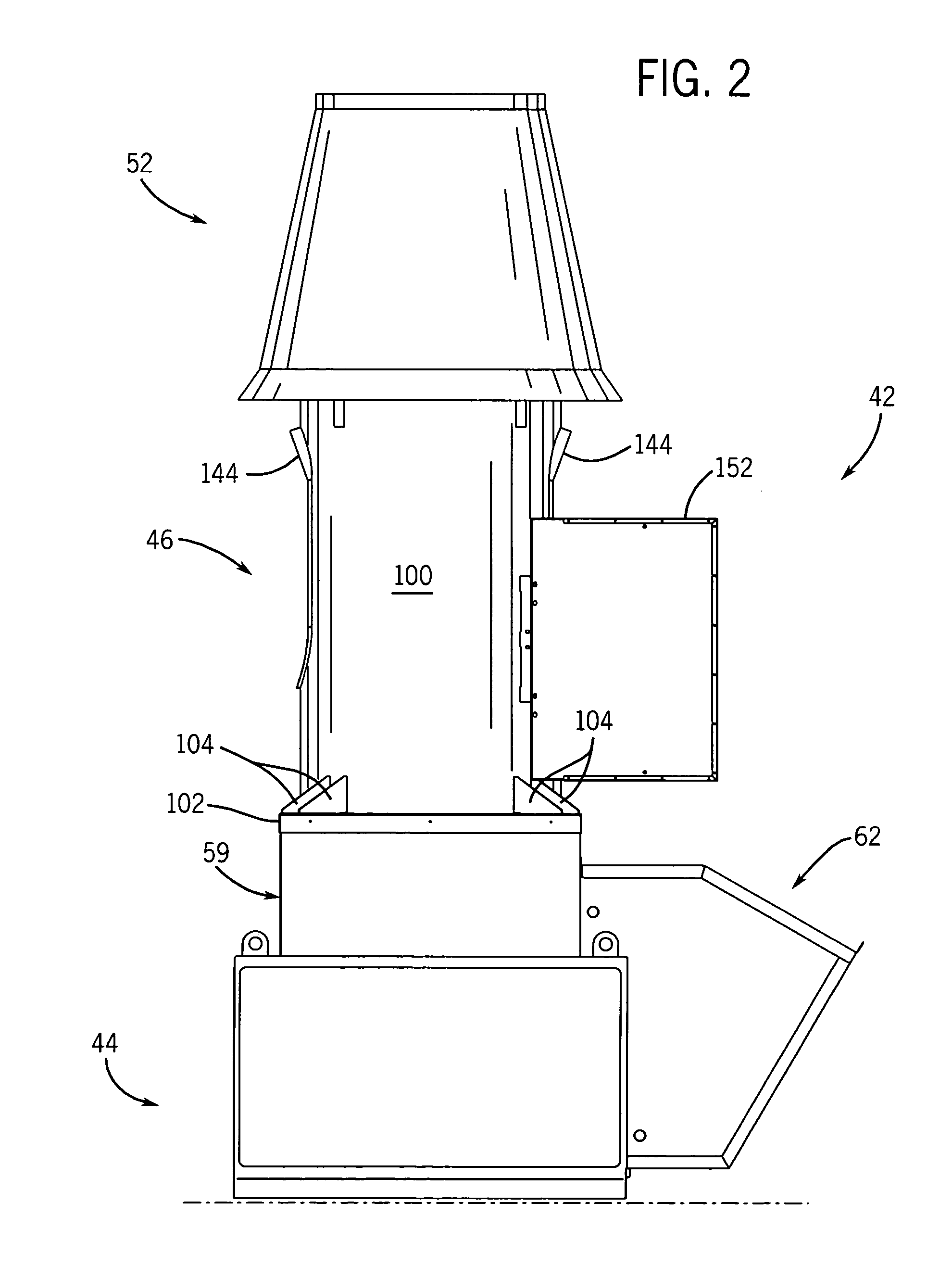

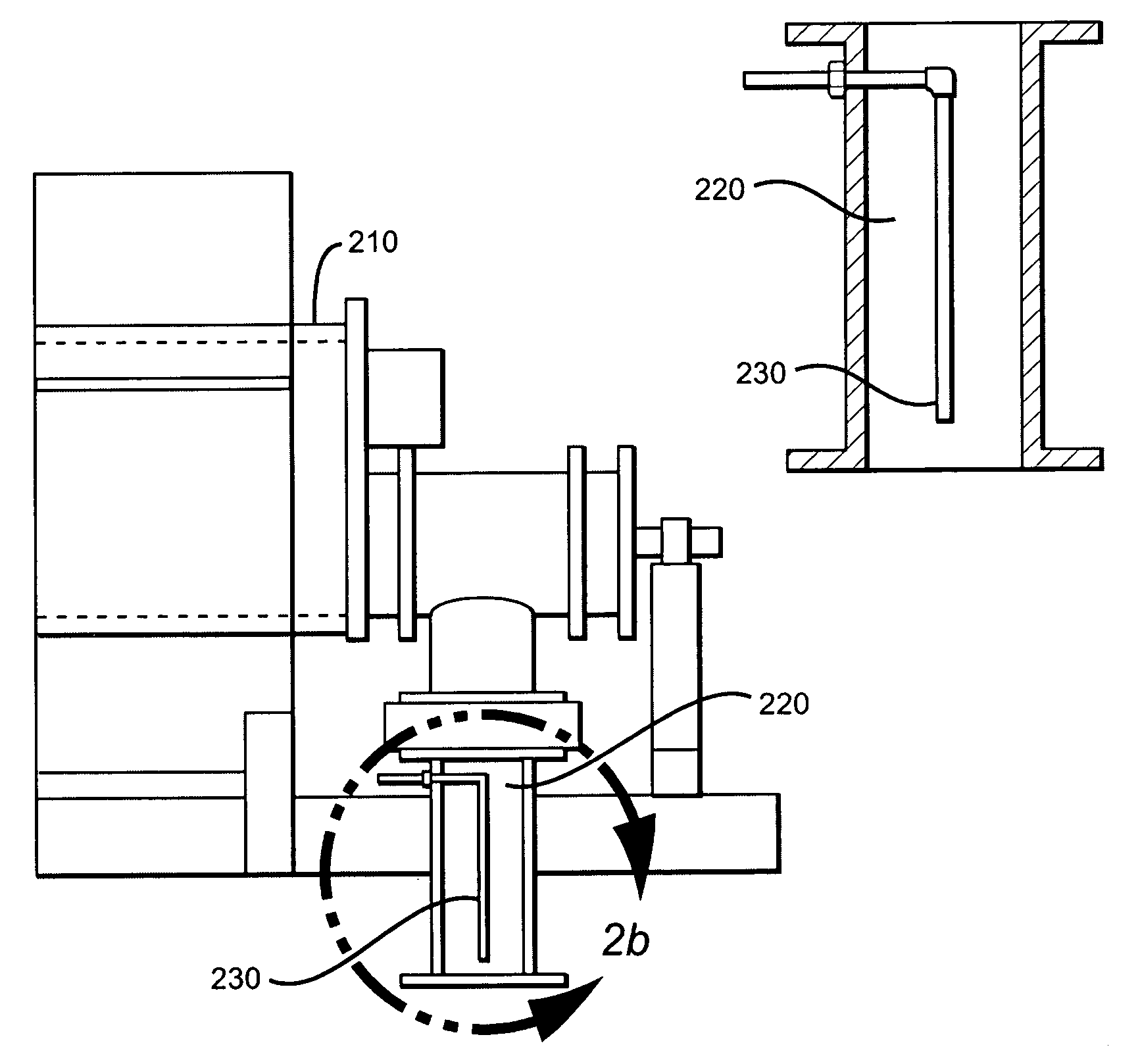

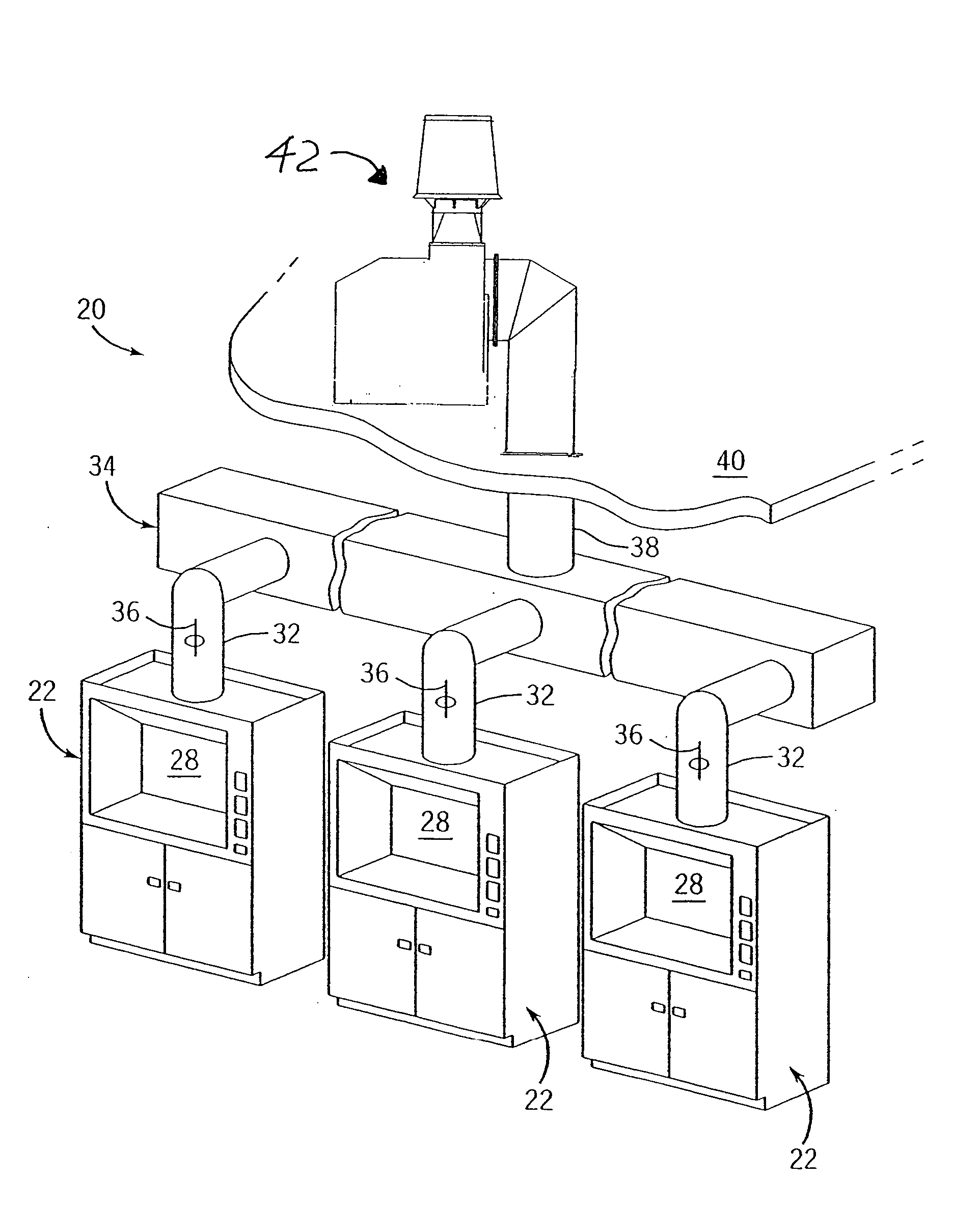

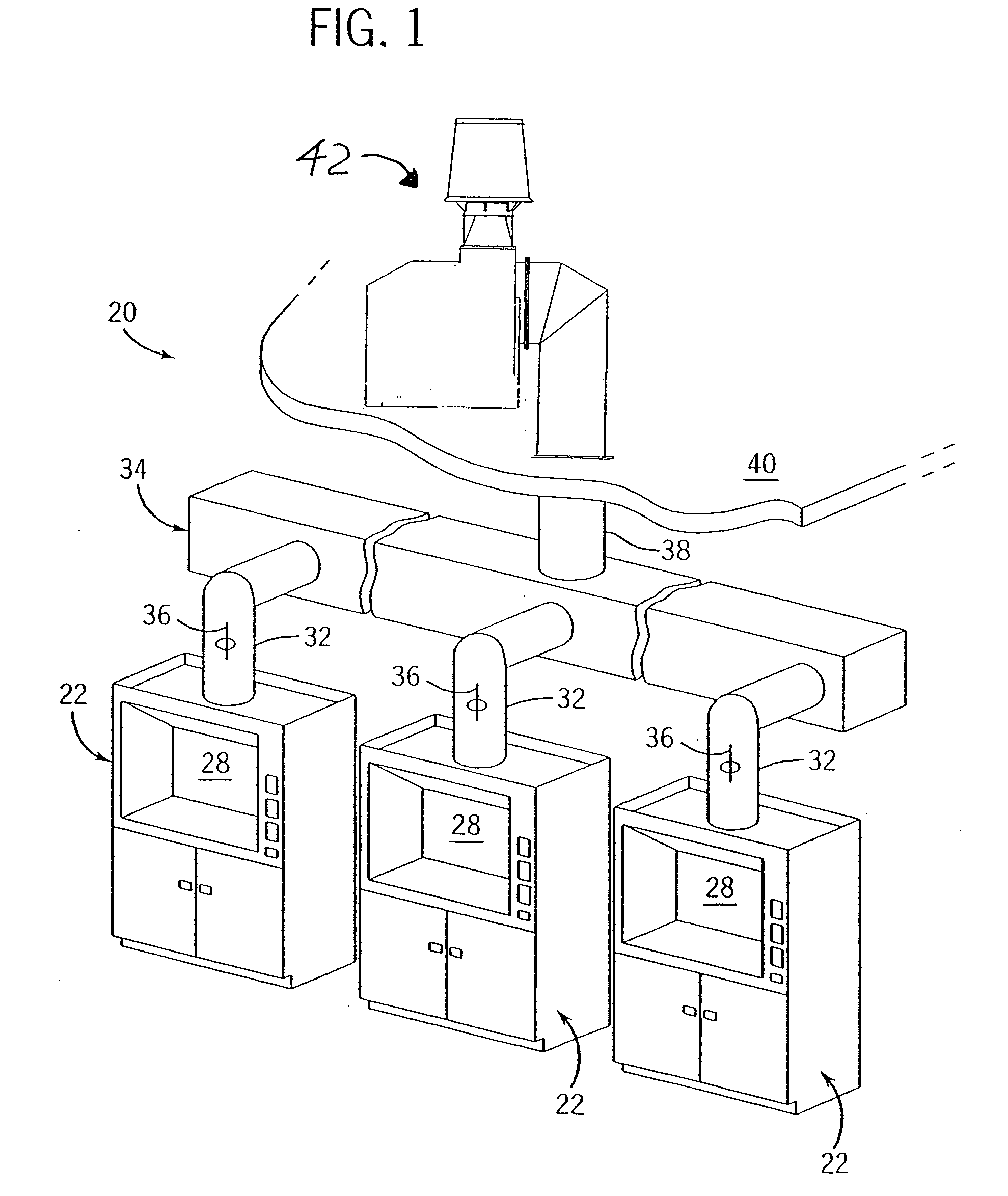

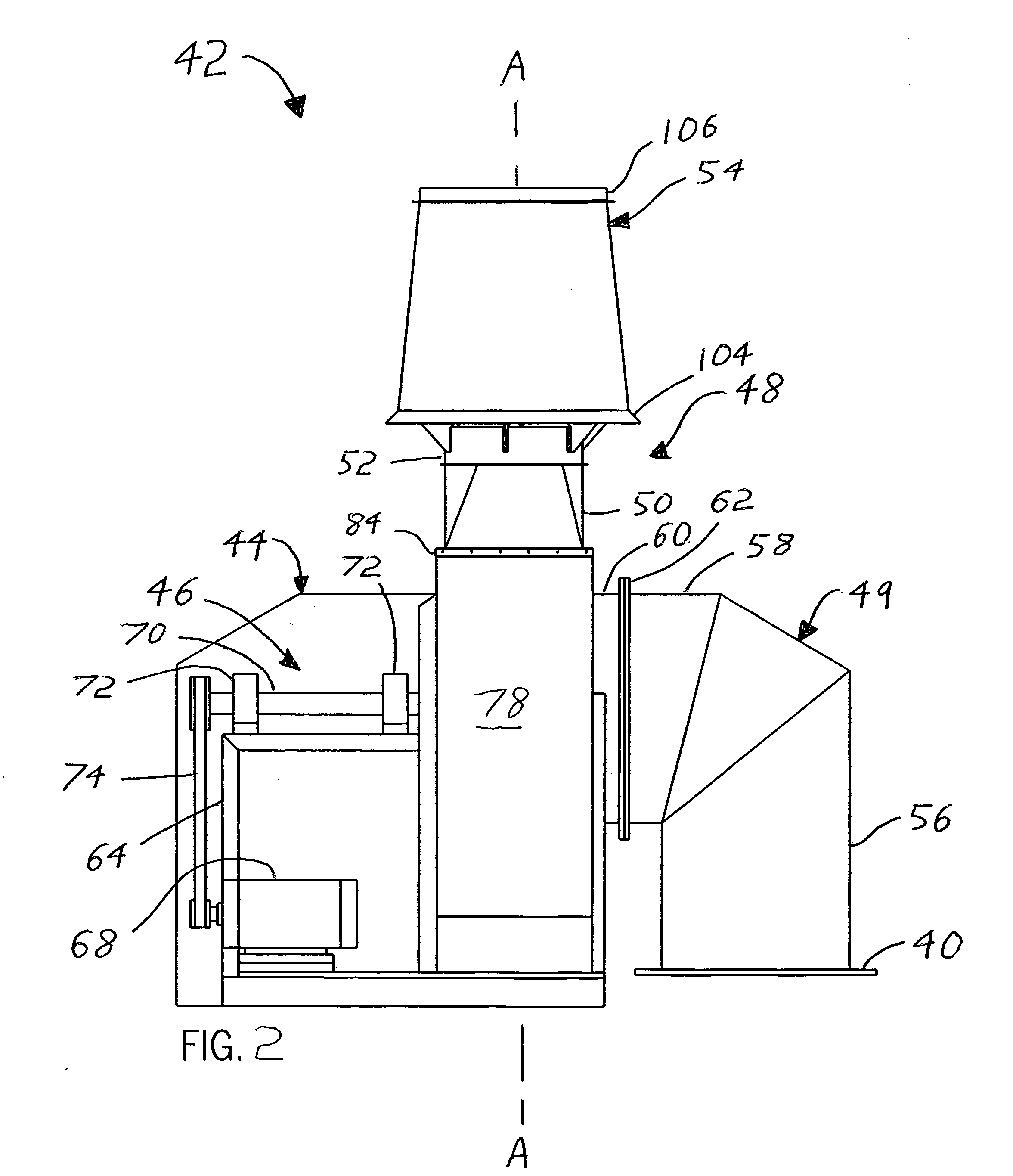

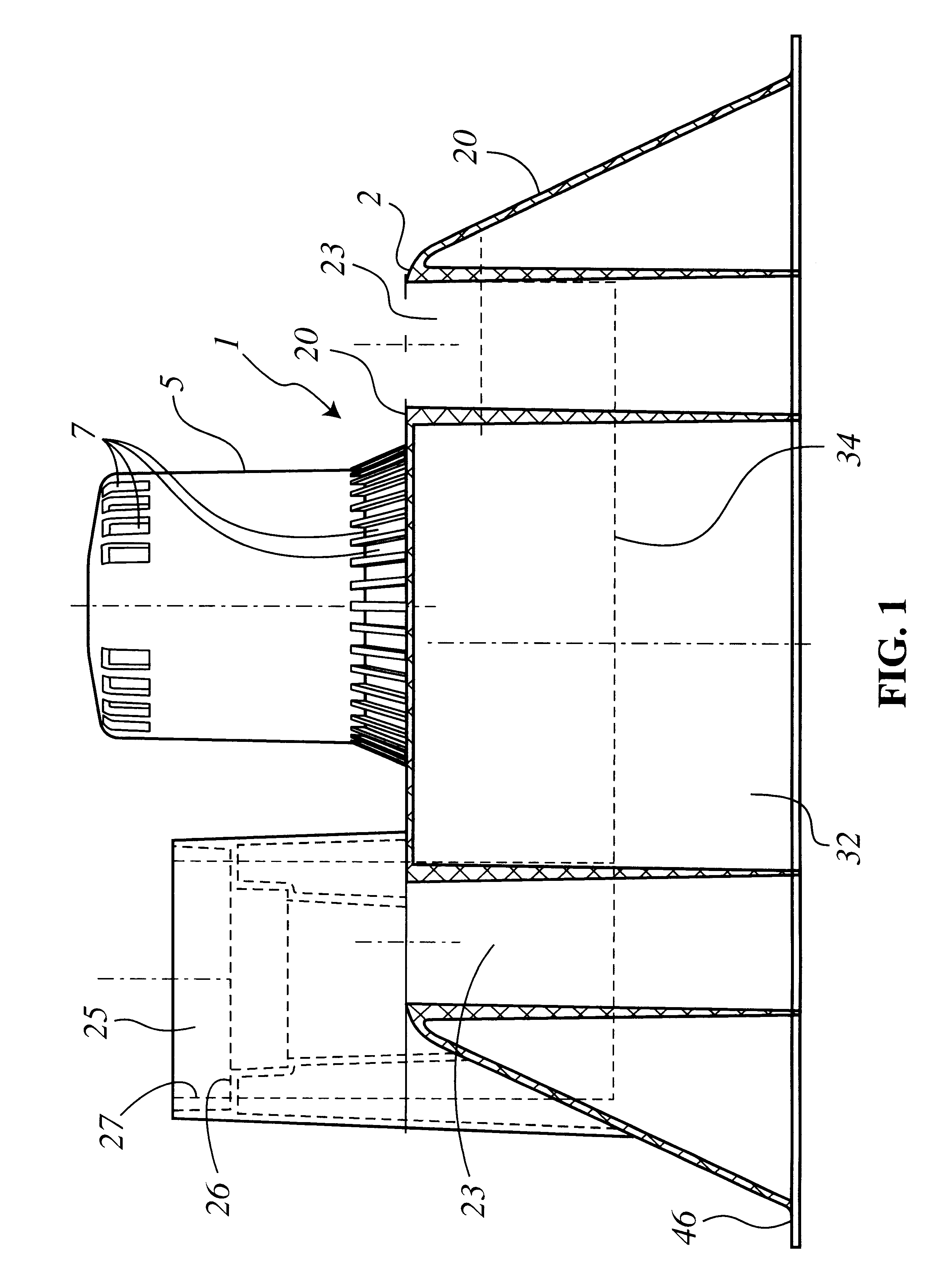

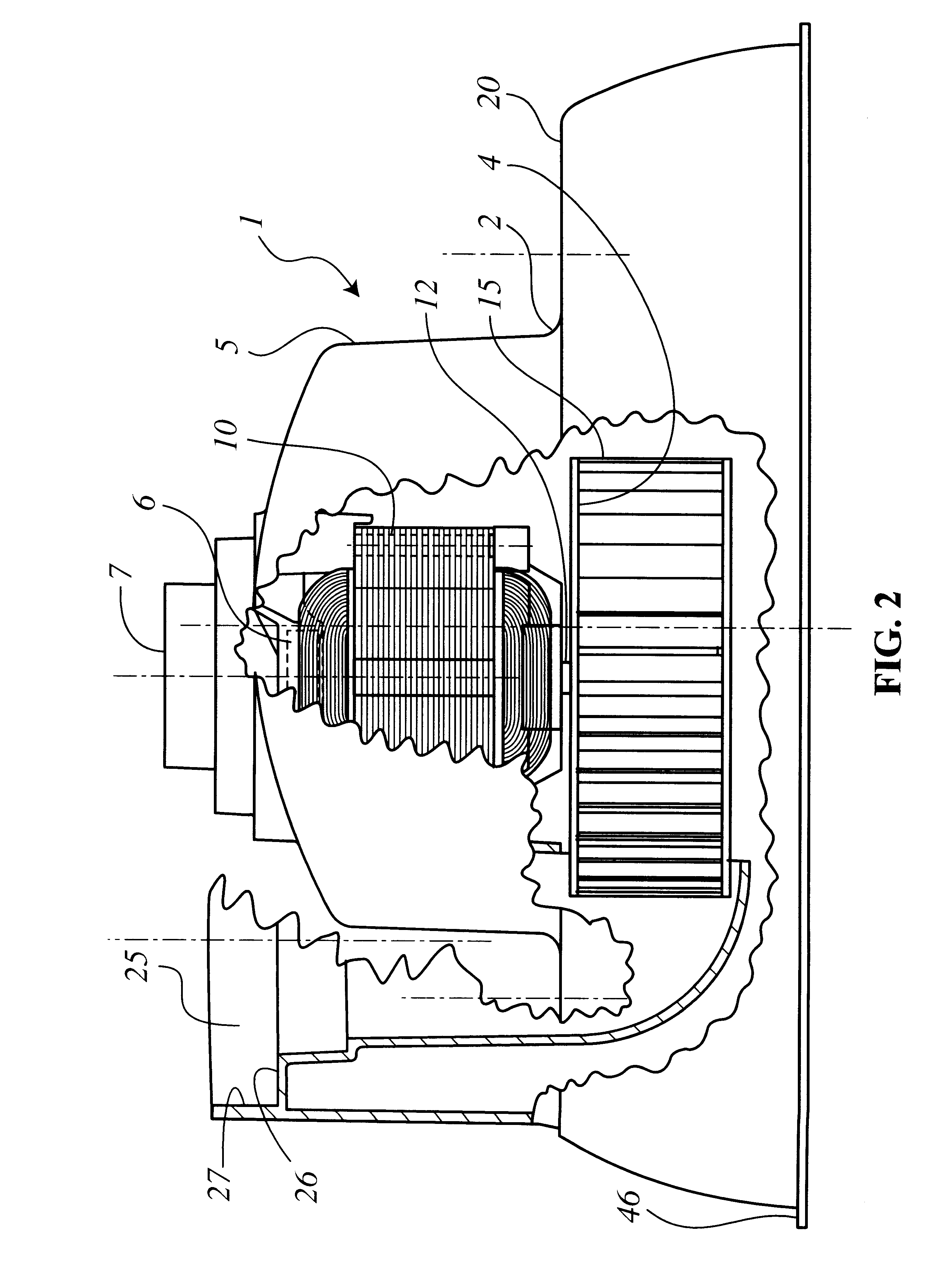

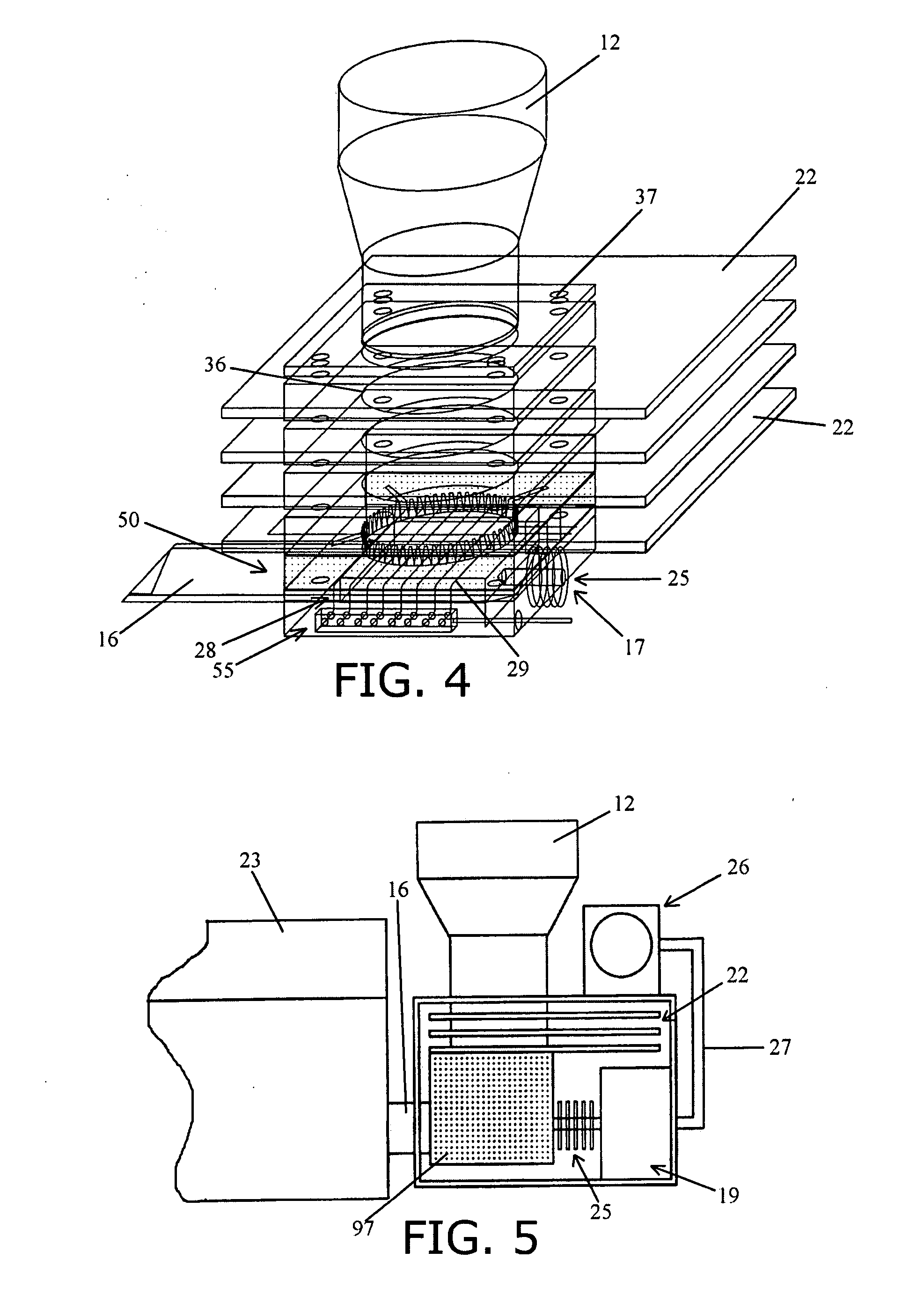

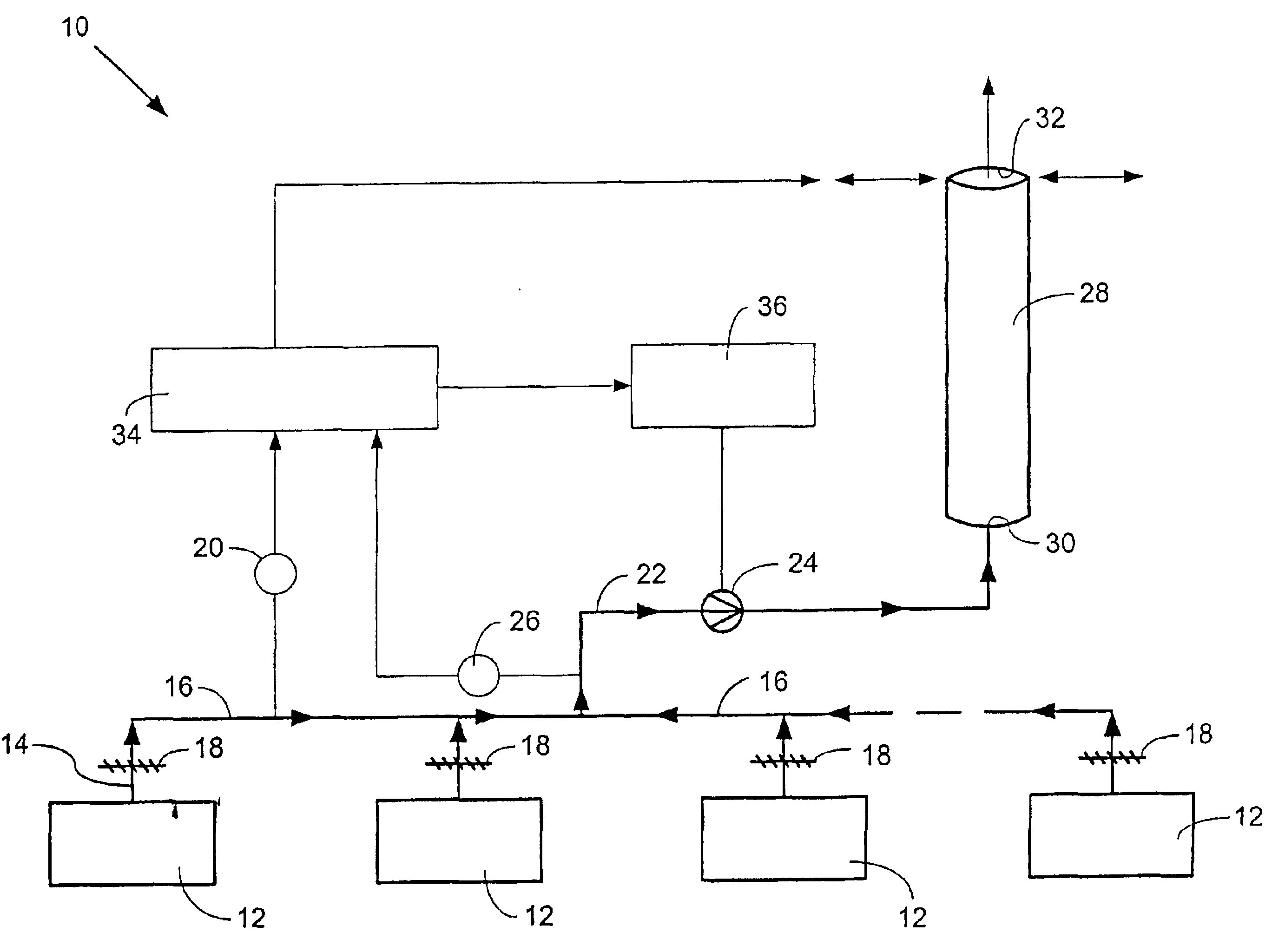

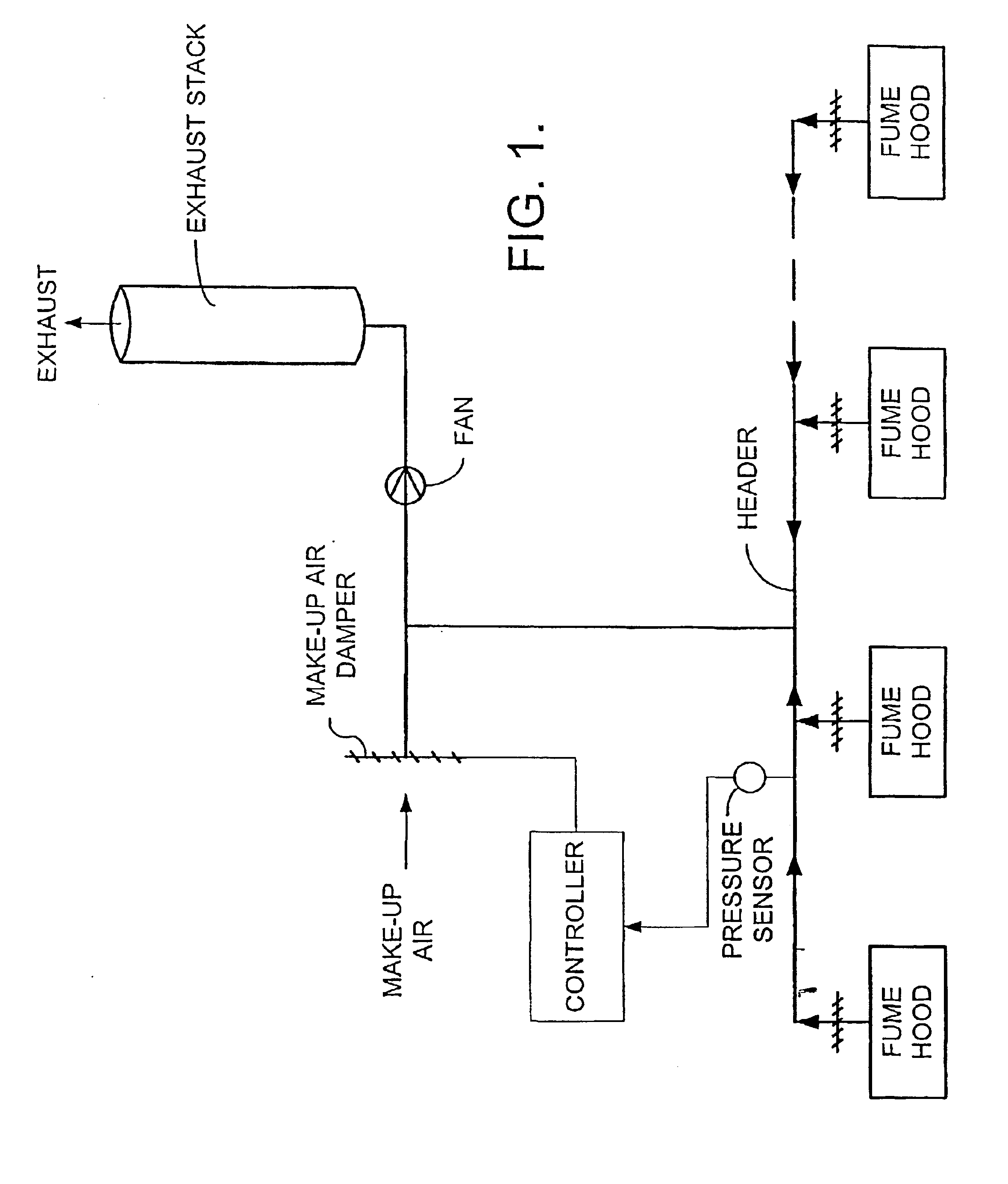

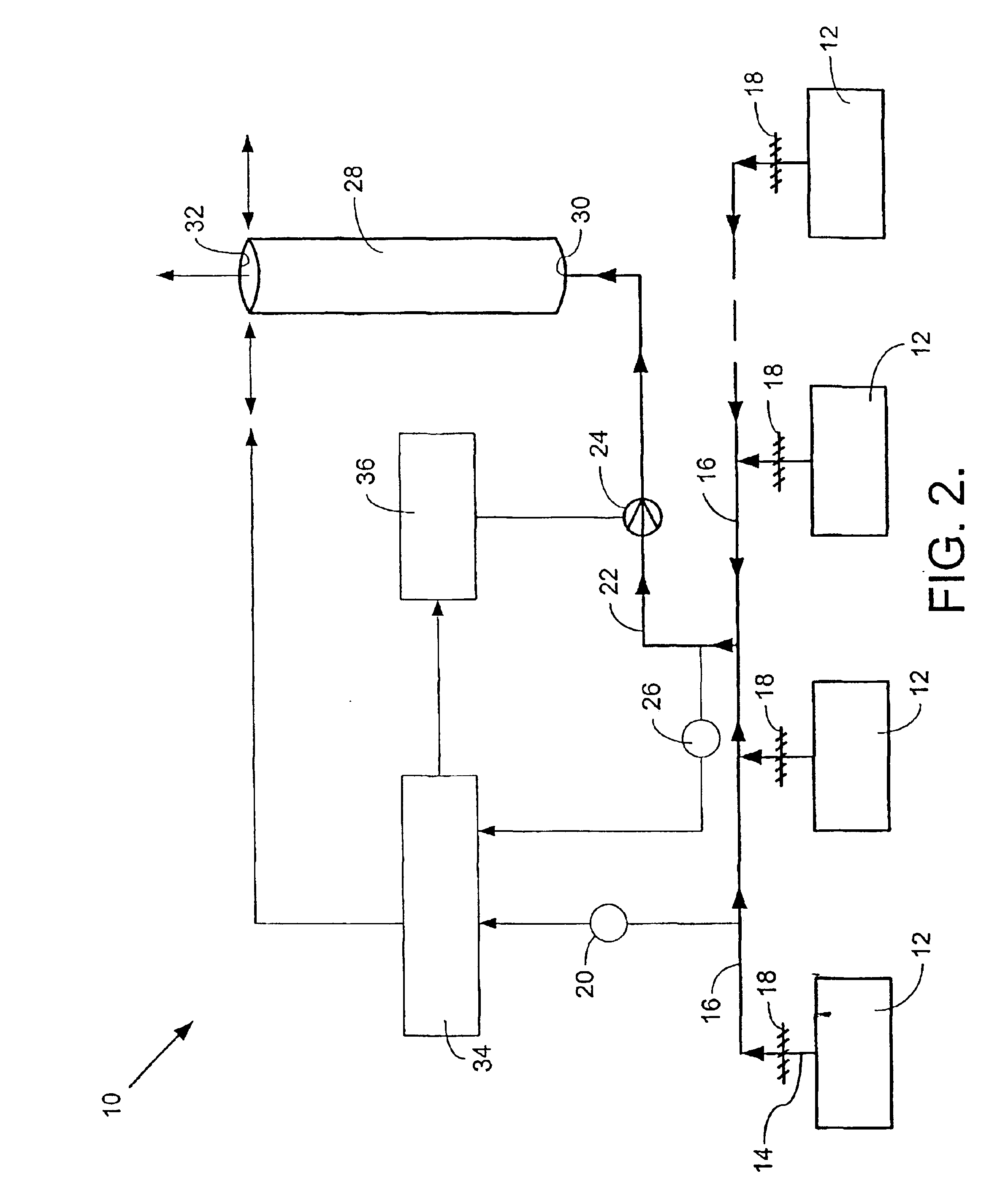

Fume hood exhaust stack system

InactiveUS6890252B2Constant momentumConstant velocityDomestic stoves or rangesSpace heating and ventilation safety systemsMomentumAtmospheric air

A fume hood exhaust stack system (10) and method utilize a variable speed fan (24) and an exhaust stack (28) having an adjustable cross-sectional area. Toxic exhaust from one or more fume hoods (12) is conveyed through a header (16) to the fan. The fan forces the exhaust through the exhaust stack, and the exhaust is then discharged into the atmosphere at a sufficient velocity and momentum to ensure that the exhaust reaches an environmentally sound altitude. A variable speed drive (36), programmable controller (34), flow signals (26), and static pressure and total pressure signals (20) are utilized to modulate the speed of the fan and the area of the exhaust stack to maintain the desired fan inlet pressure and exhaust velocity.

Owner:LIU MINGSHENG

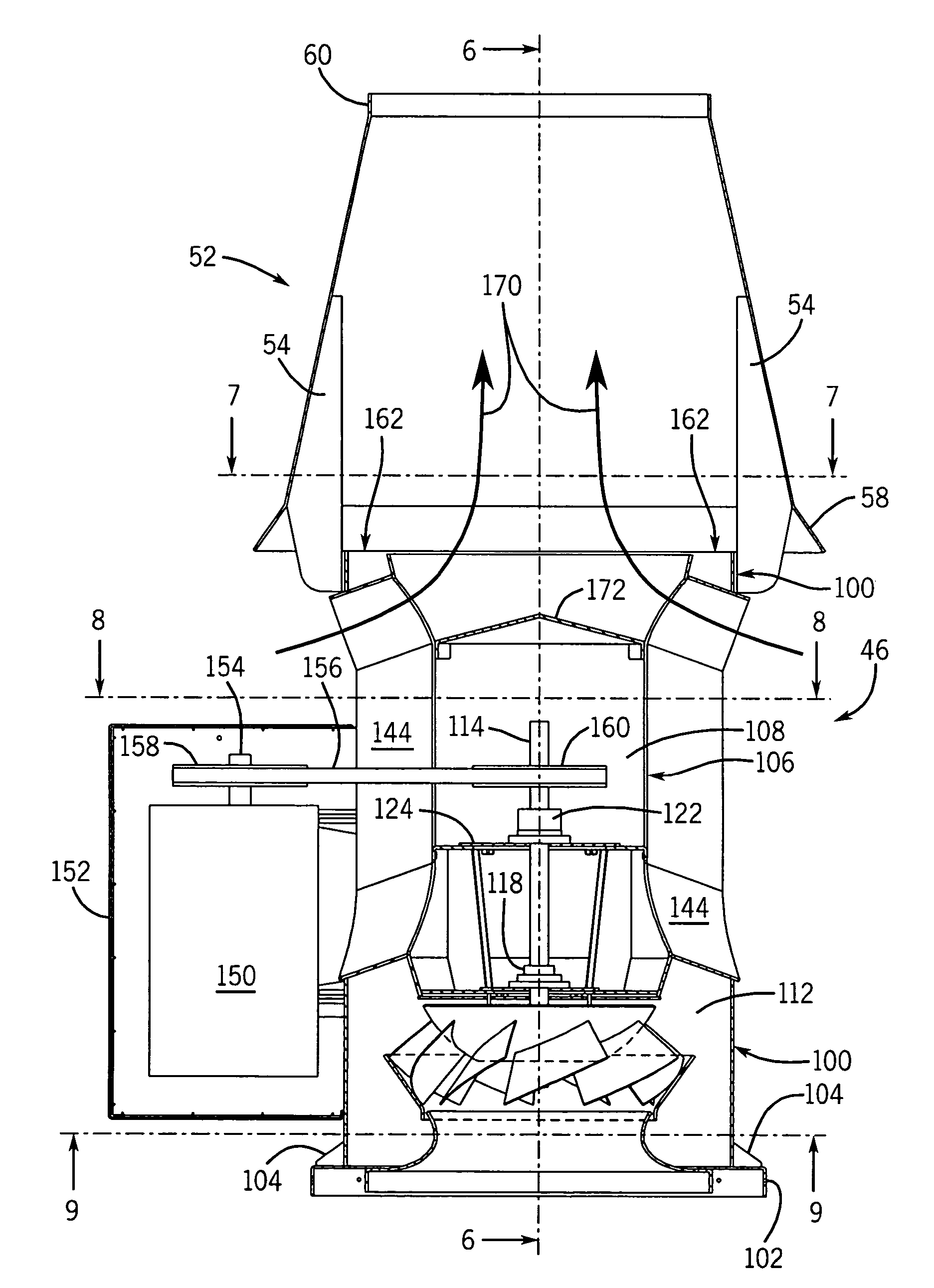

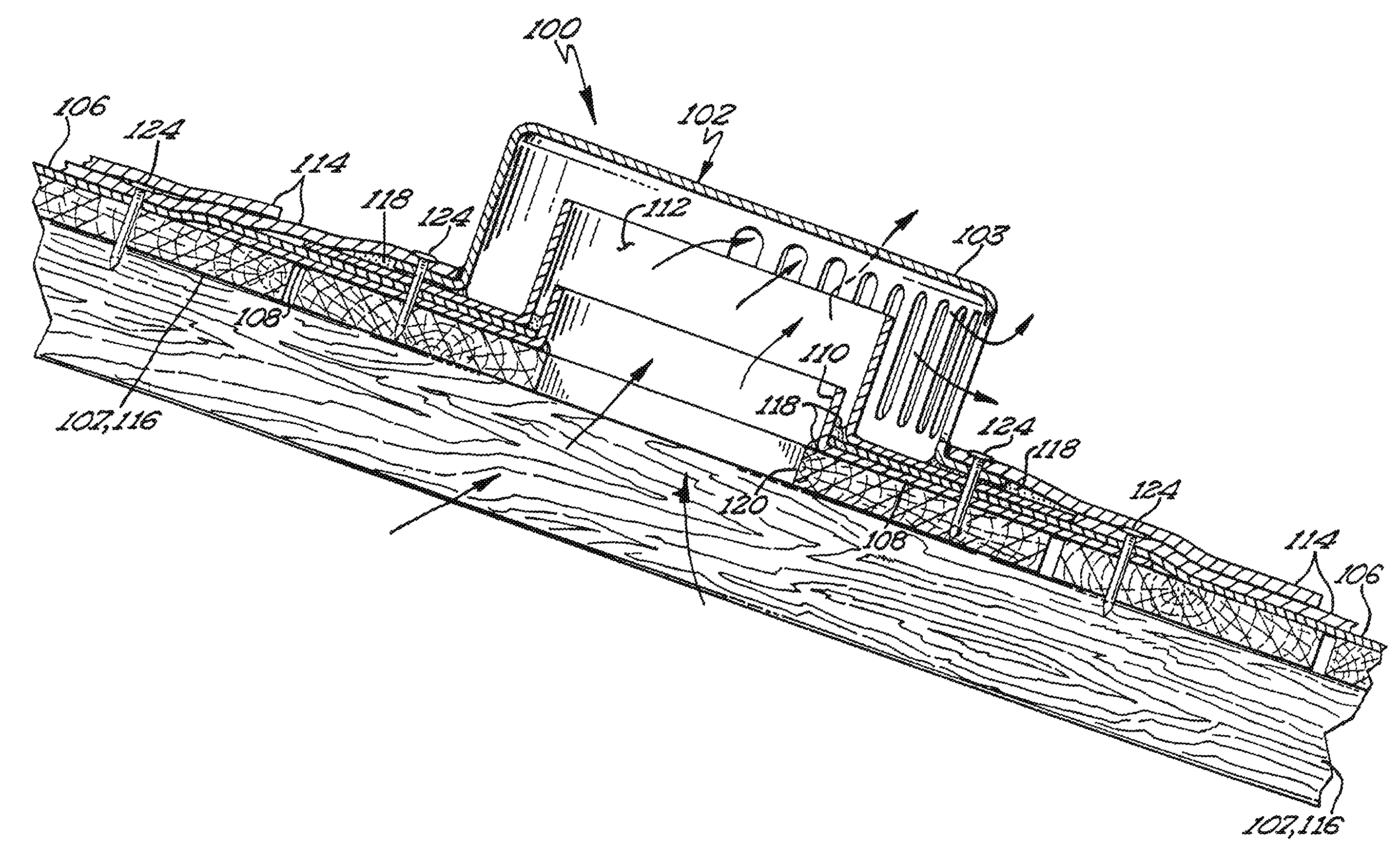

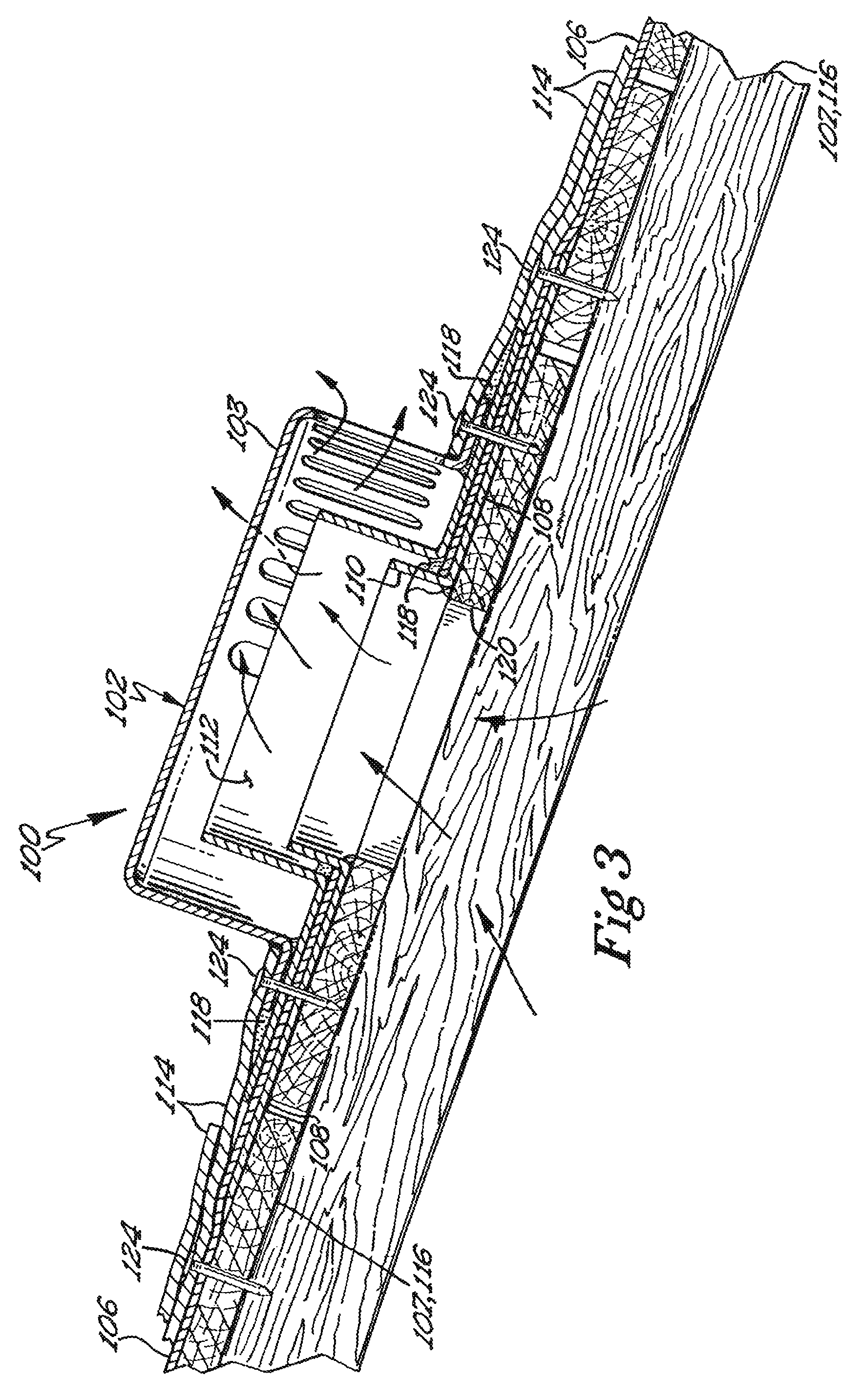

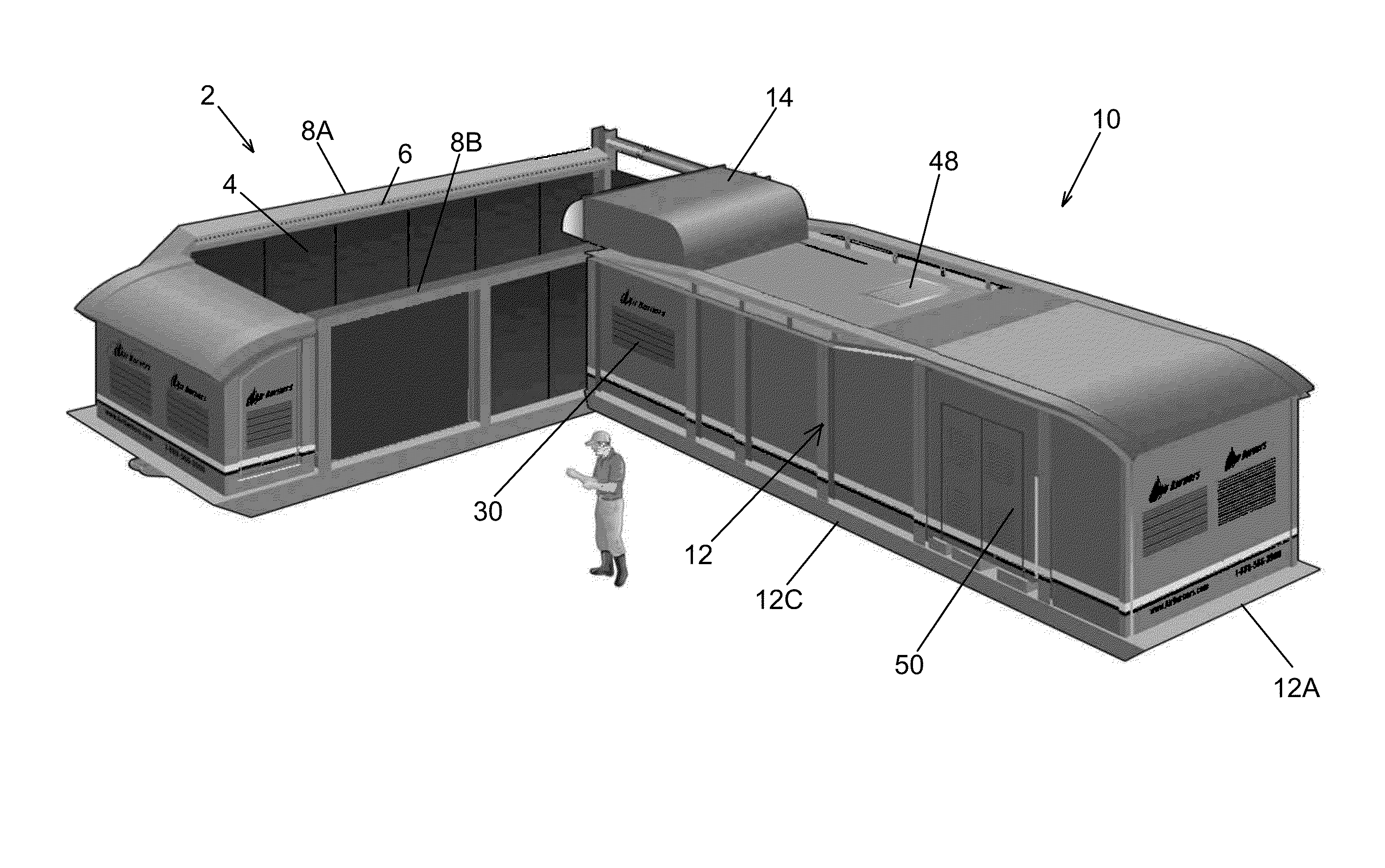

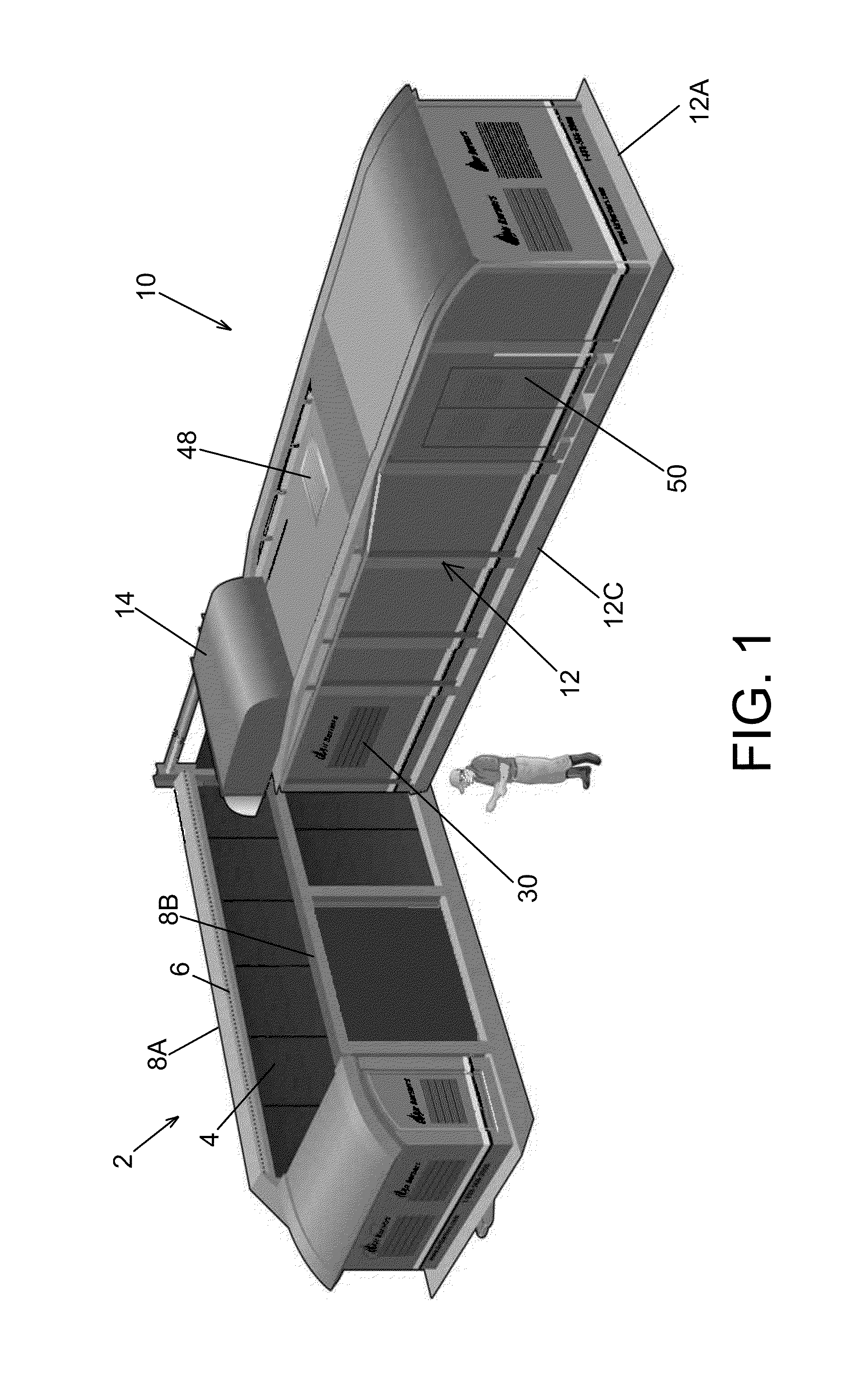

Heat capturing module and power generating system incorporating the module

ActiveUS20160130985A1Prevent heat transferSpace heating and ventilation safety systemsSpace heating and ventilation control systemsOrganic Rankine cycleEngineering

A heat capturing module for obtaining useful energy from waste heat includes an extendable hood directing hot gas through a heat exchange assembly having a plurality of heat pipes. A closed flow loop directs a heat transfer medium through the heat exchange assembly to heat the heat transfer medium, and directs the heated medium for use by an application. In one embodiment, the closed flow loop directs the heat transfer medium through an organic Rankine cycle unit where heat is converted to electrical power. An exhaust system having a variable-speed induction fan induces flow of the hot gas through the heat exchange assembly. The speed of the induction fan may be controlled to maintain a setpoint temperature of the heat transfer medium. The hood may be extended and retracted based on a measured temperature of gas at an intake region of the hood. The module is transportable by truck trailer.

Owner:AIR BURNERS

Termination unit for a coaxial flue pipe

A termination unit for a through-the-wall horizontal vent of a gas combustion device having a combustion chamber and a burner, is described. The termination unit comprises a wall mounting plate which is secured to a vertical wall outer surface and about an outer sleeve of a coaxial flue pipe. A fresh air chamber is secured to the wall mounting plate. An exhaust end of an exhaust flue pipe extends through the wall mounting plate and the fresh air chamber to exit through an outer wall of the chamber. Air intake ports are provided in an outer peripheral wall of the chamber to supply fresh air to a coaxial passage between the exhaust flue pipe and the outer sleeve to feed the combustion chamber. An air baffle is provided in the chamber about the exhaust end of the flue pipe and extends through the chamber. Wind deflector flanges are disposed in spaced relationship about the air intake ports of the chamber.

Owner:MICLAU S R I

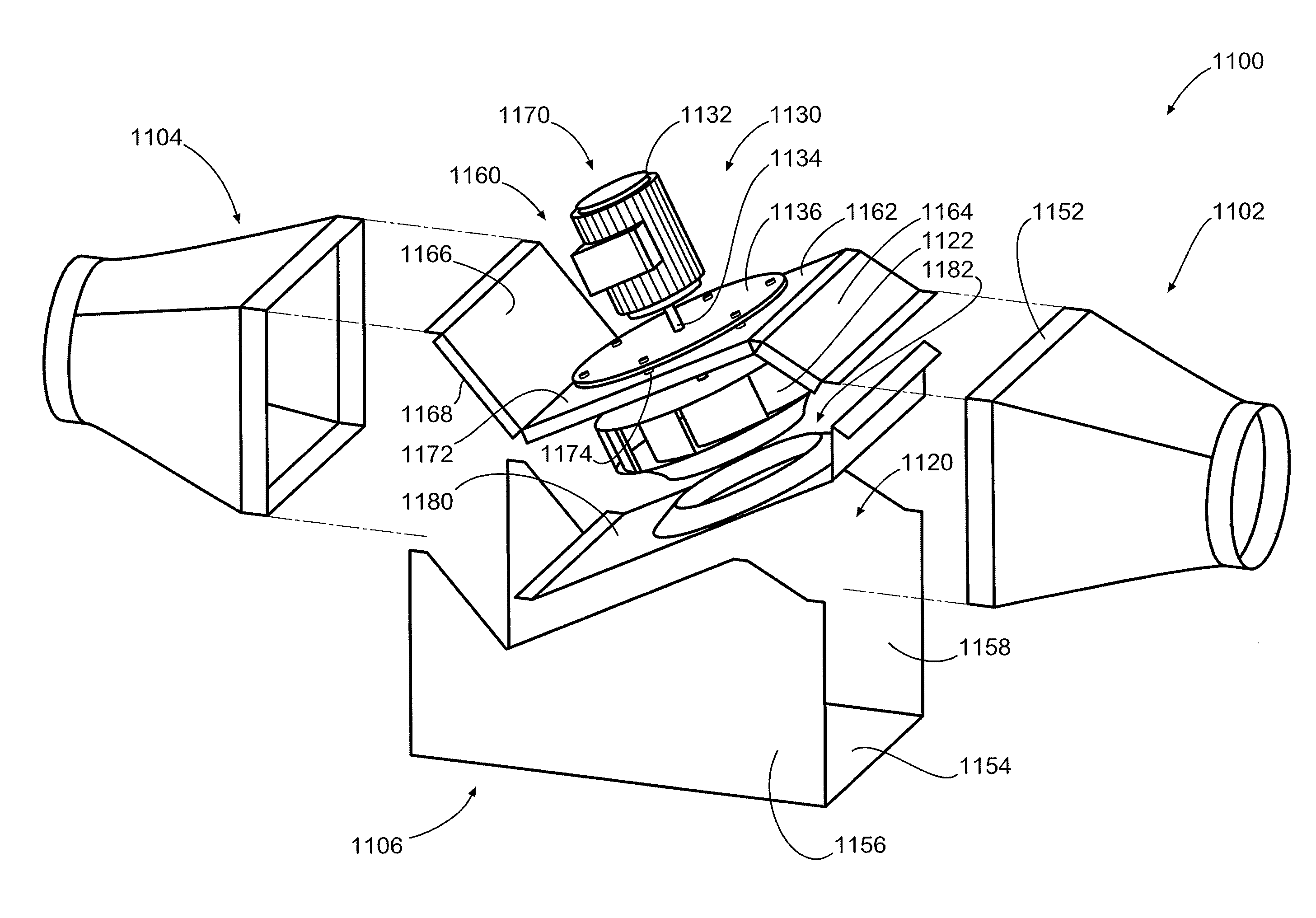

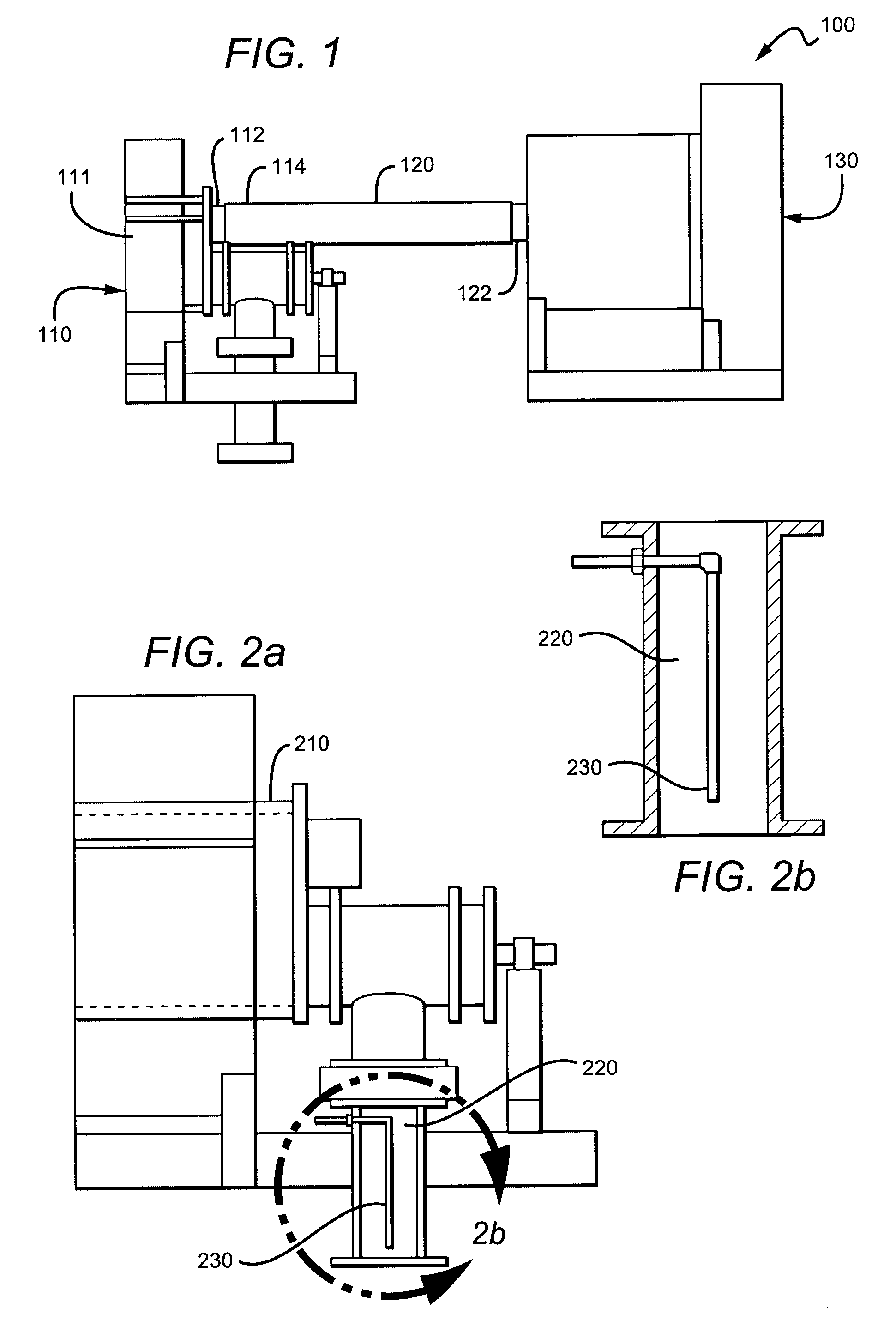

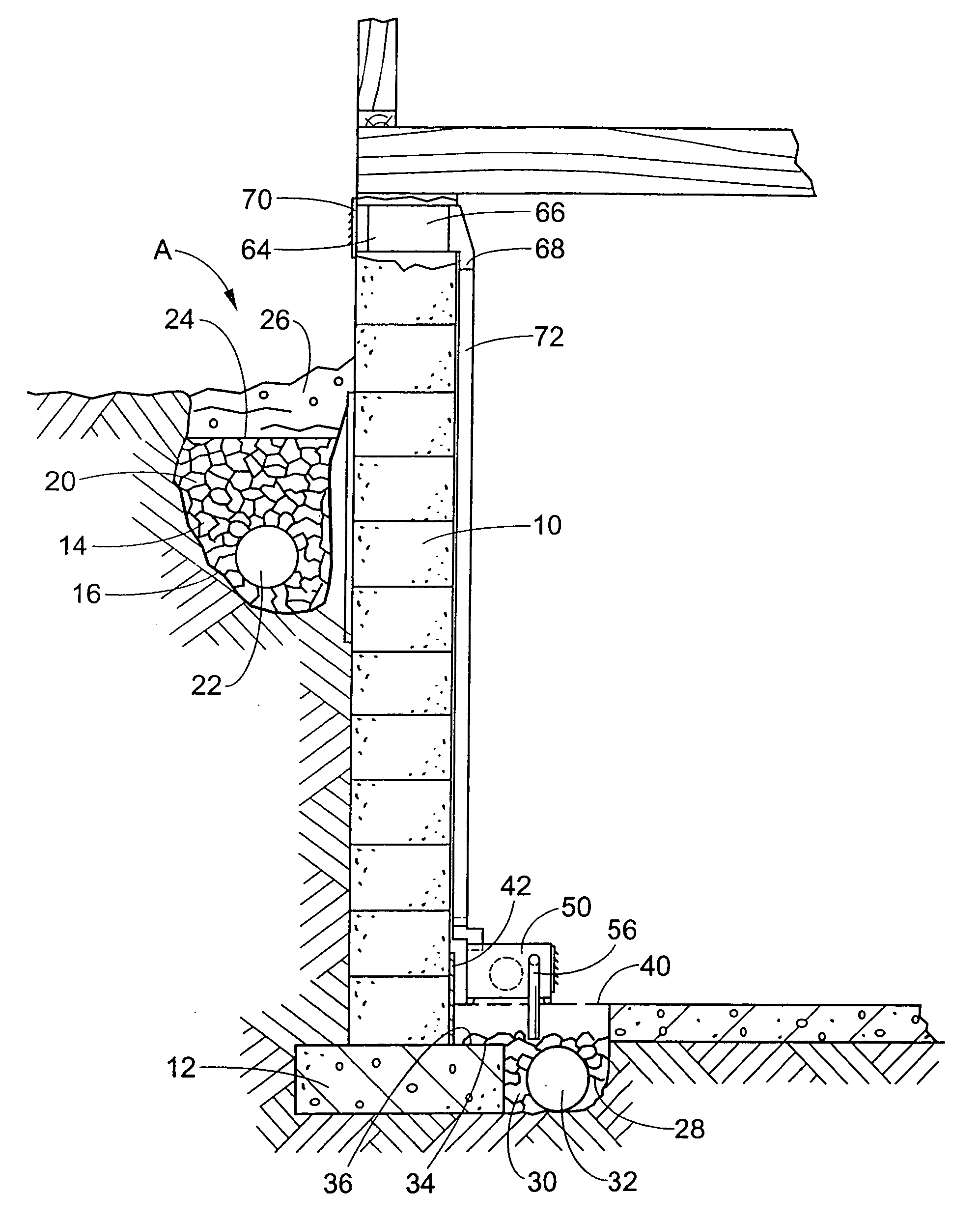

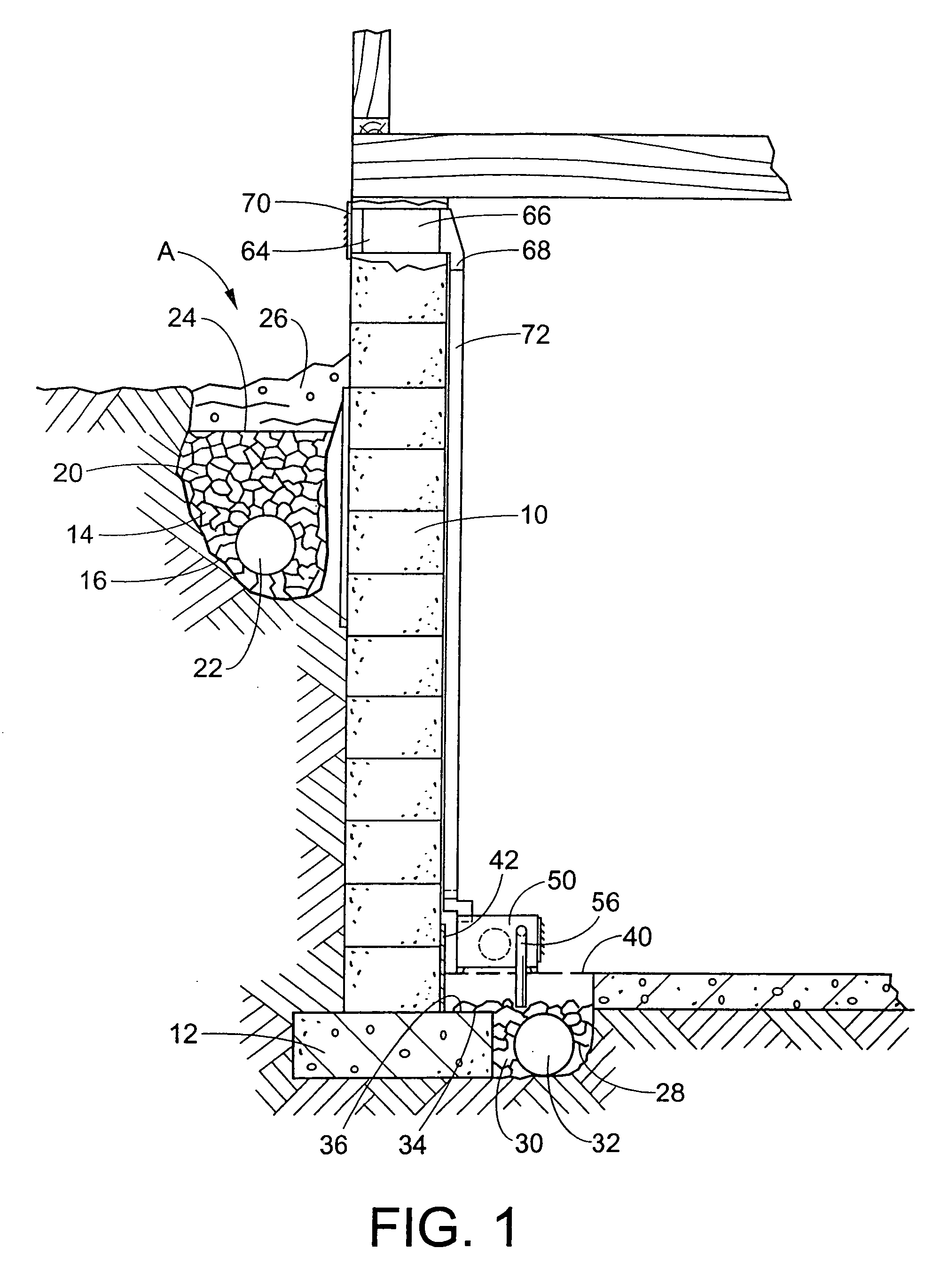

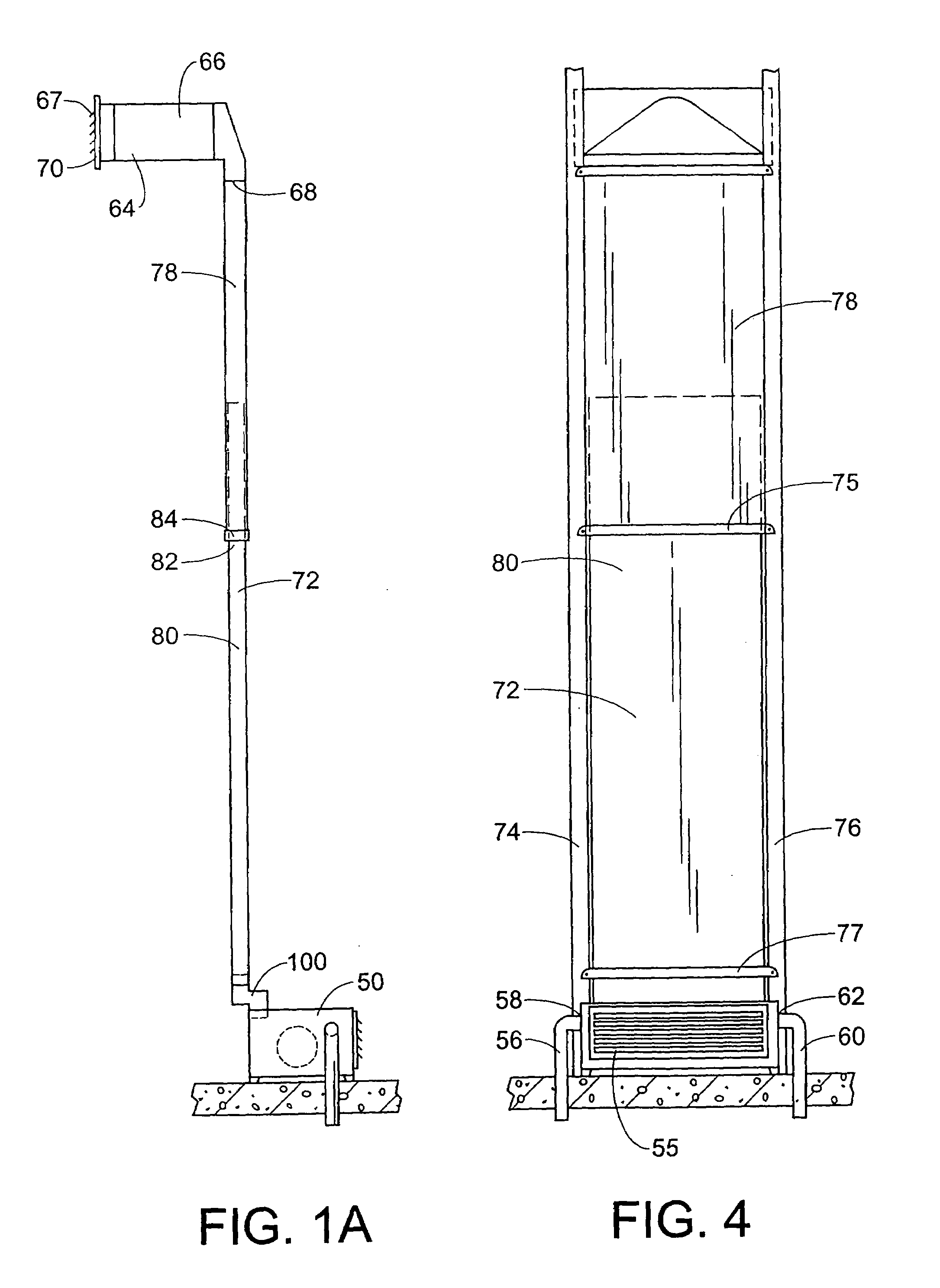

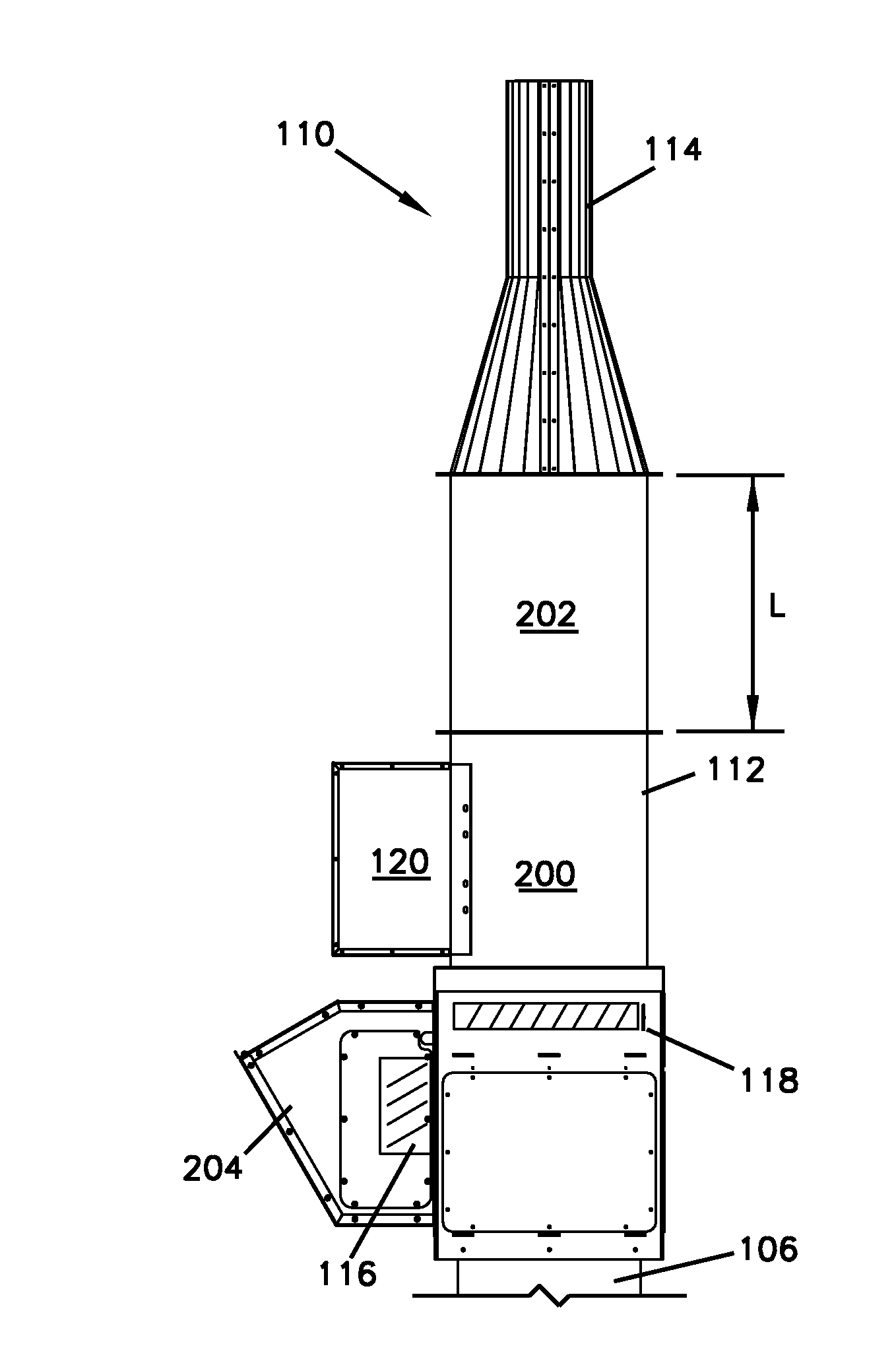

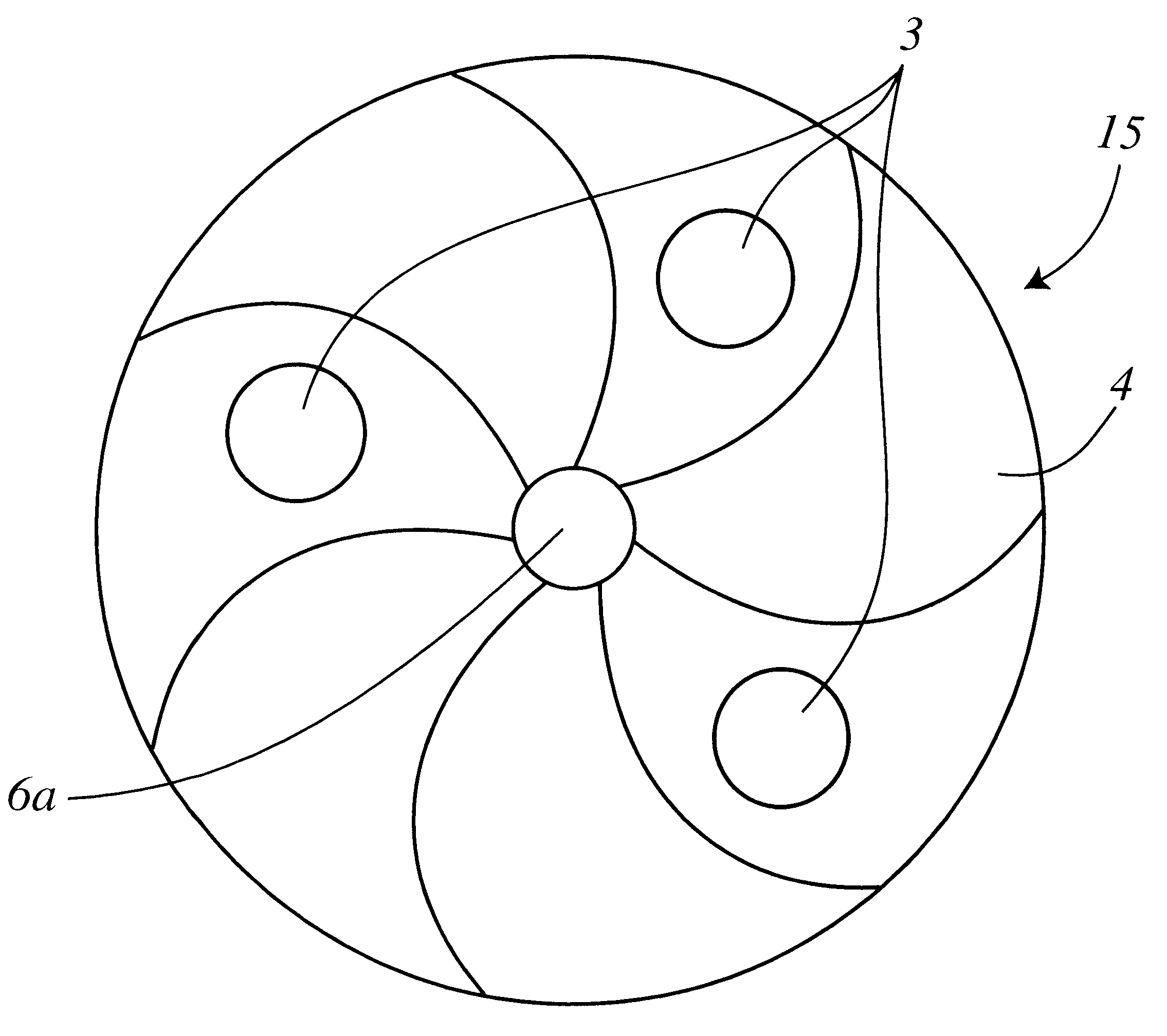

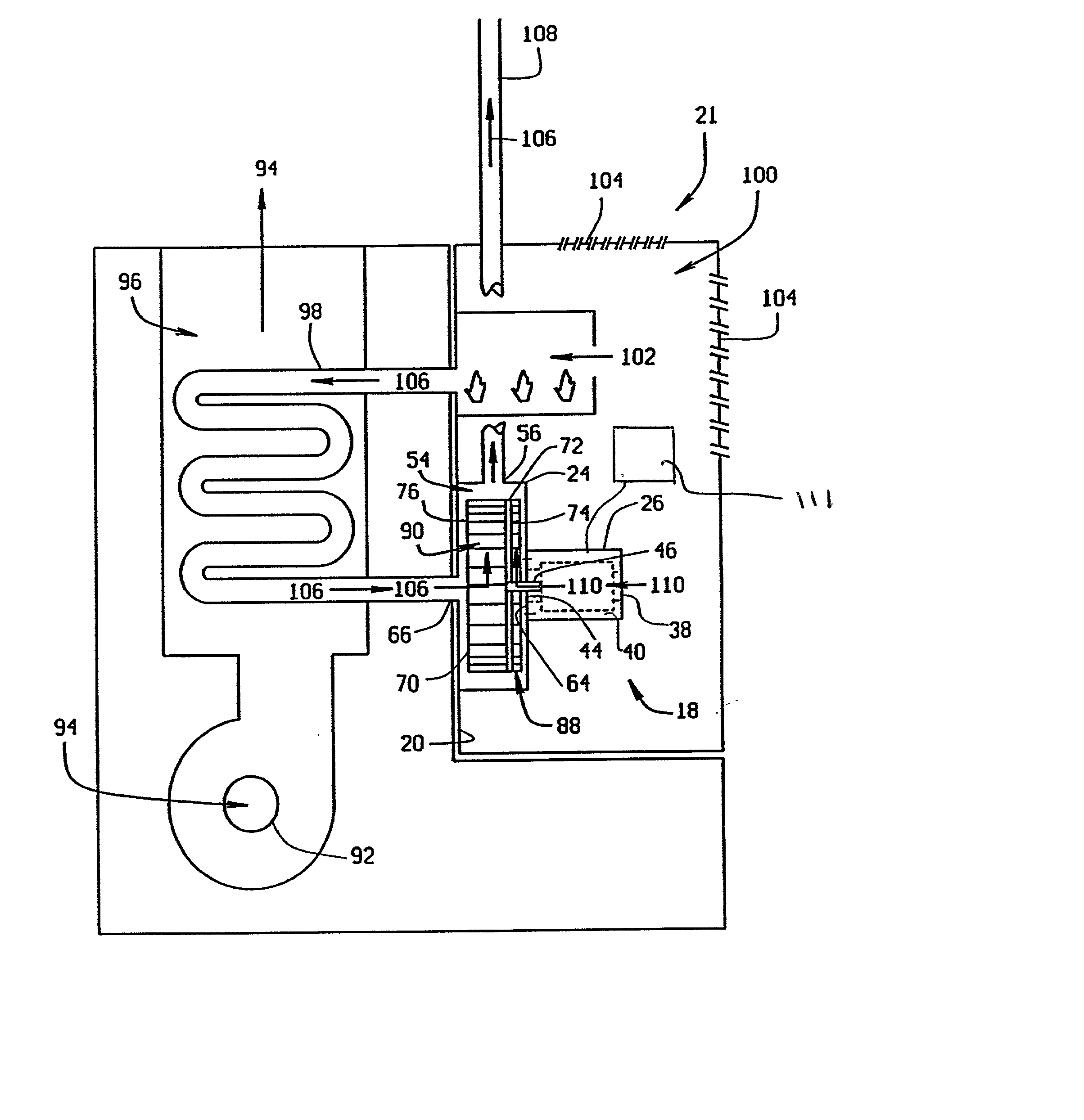

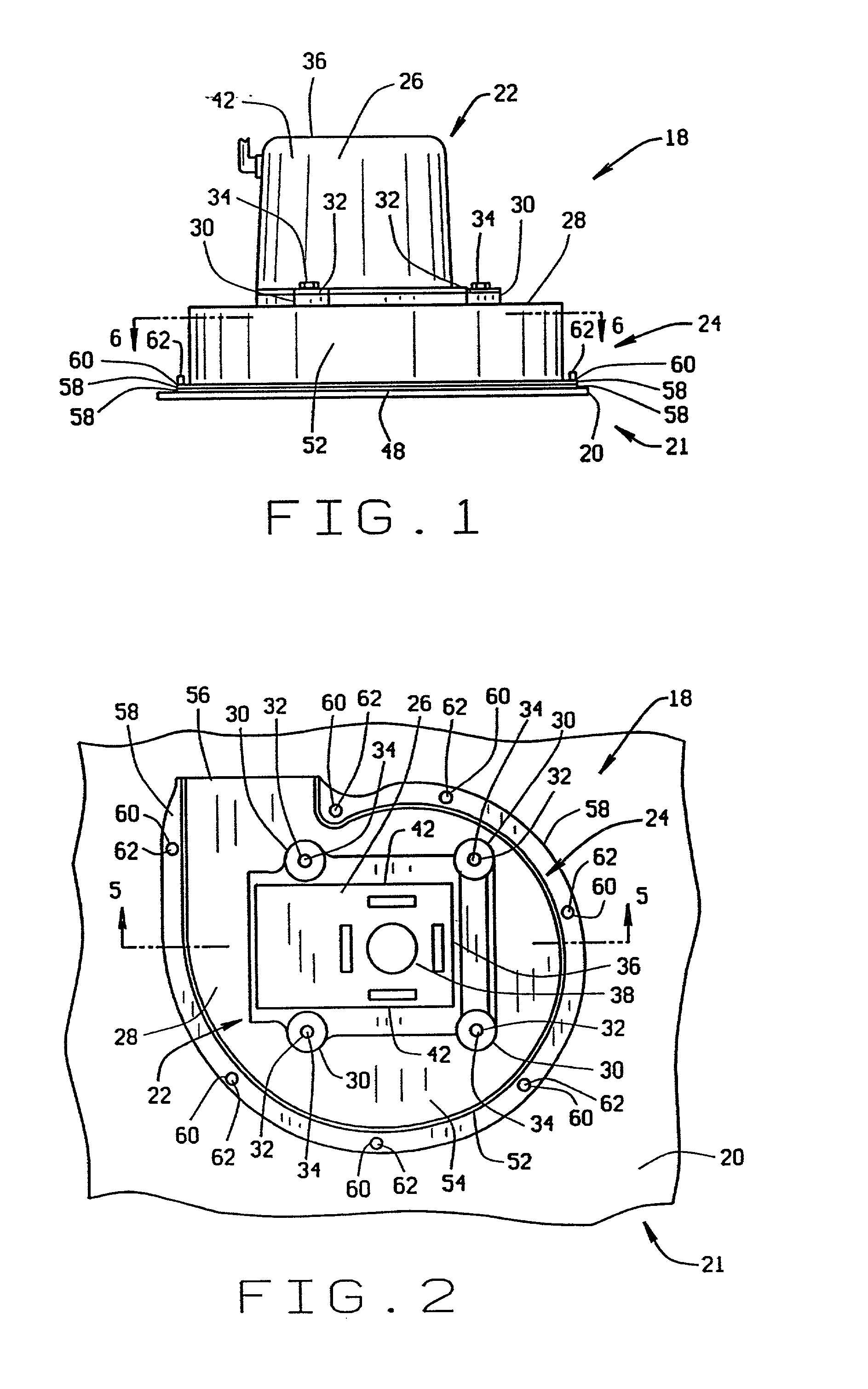

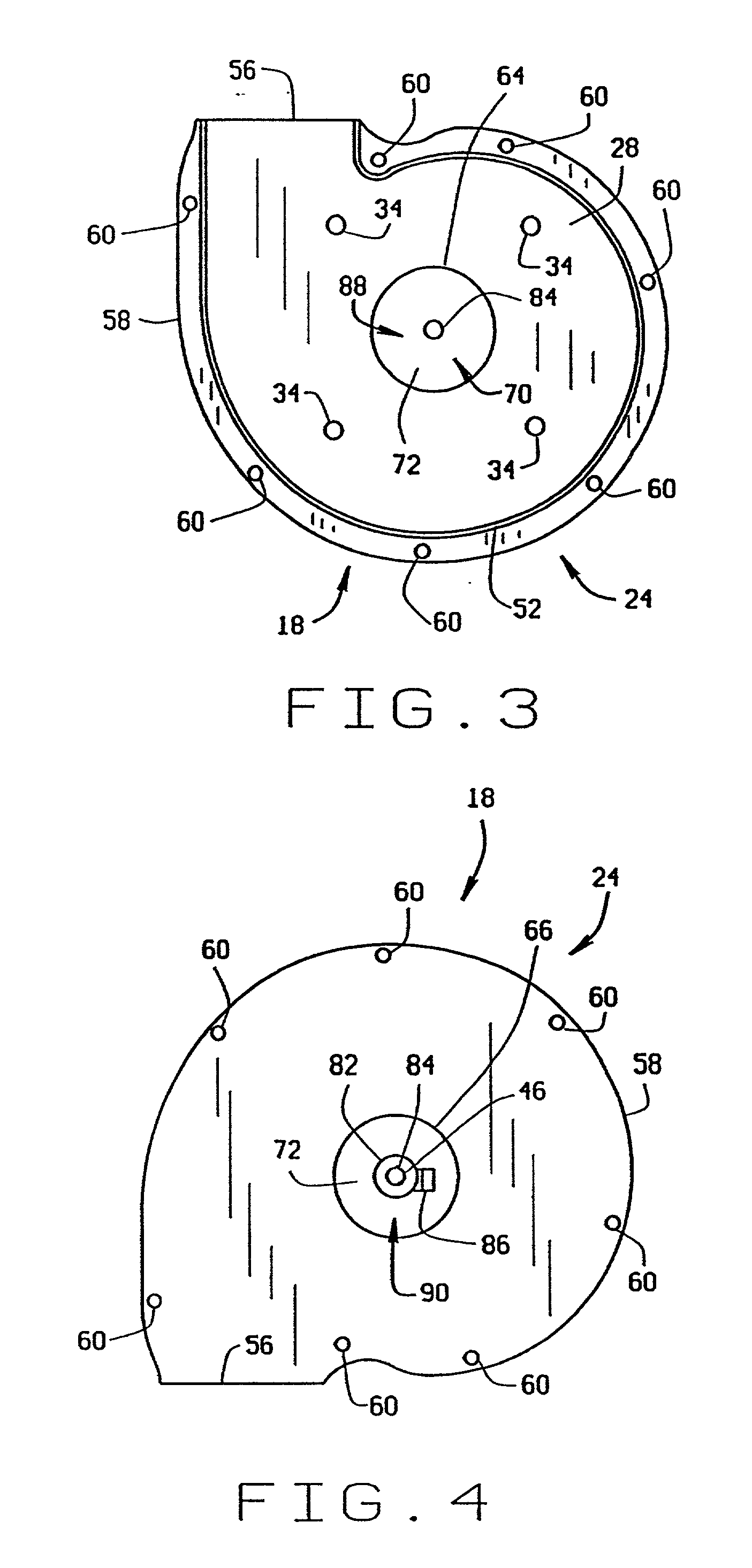

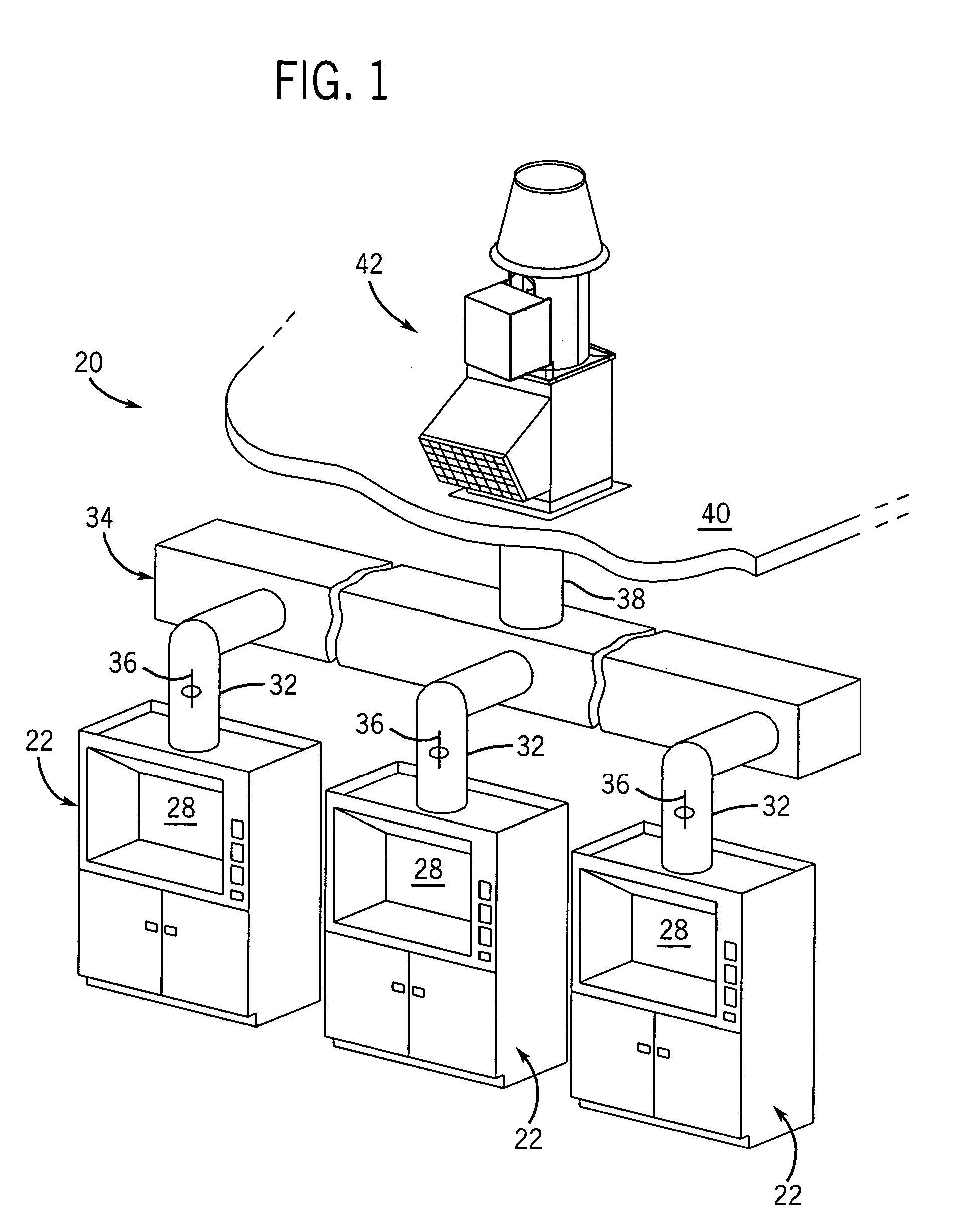

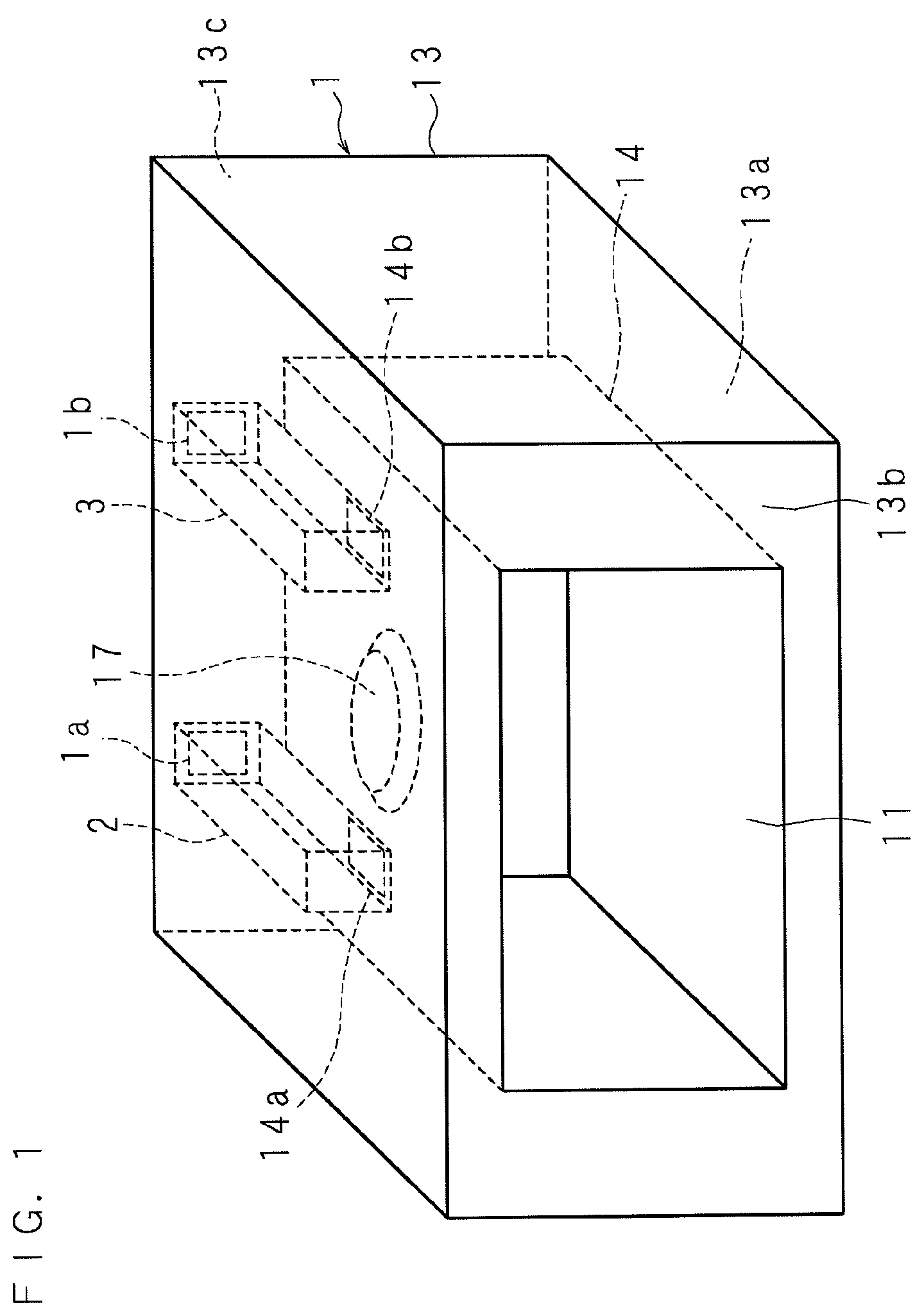

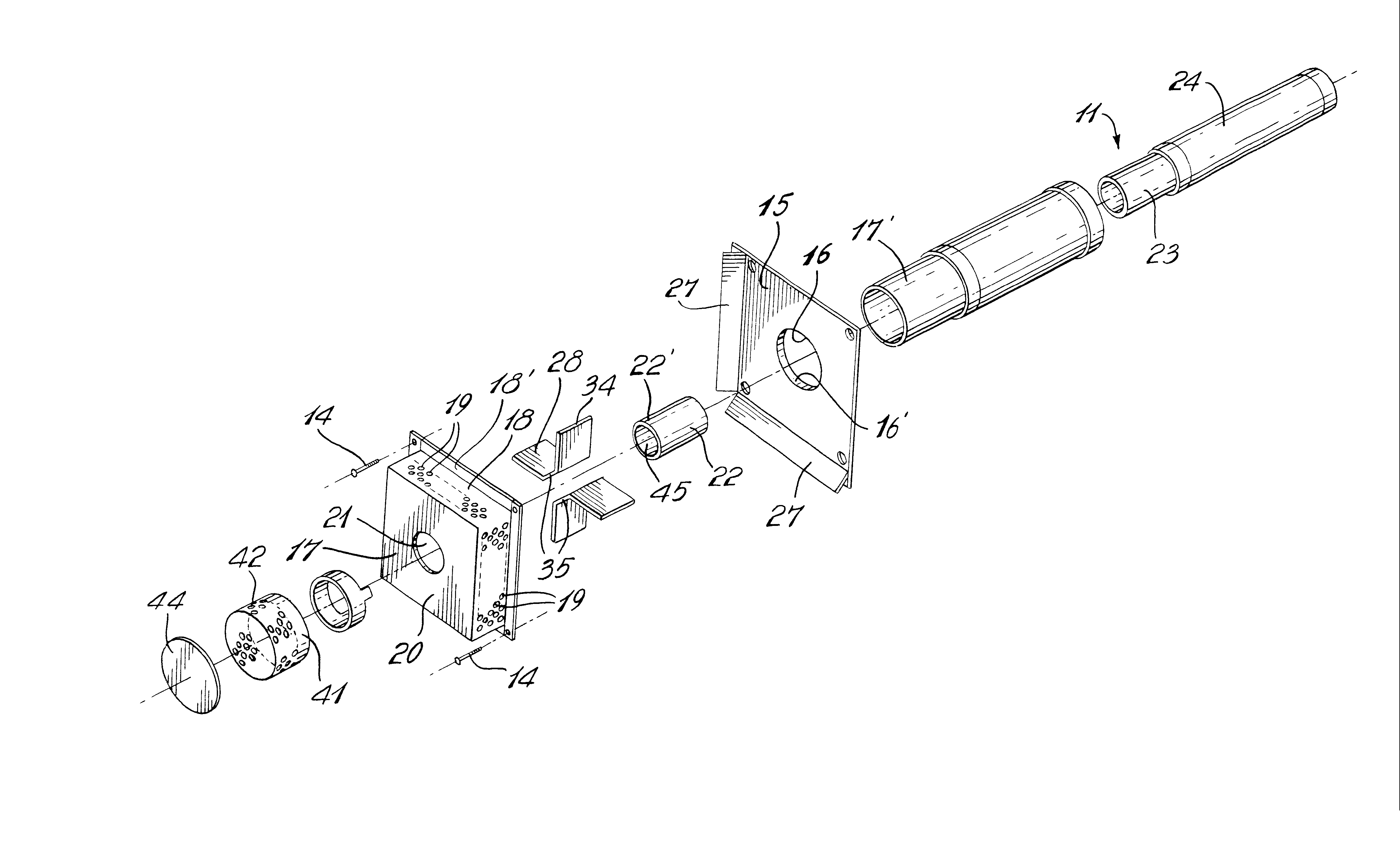

Mechanical draft systems

A representative mechanical draft system for drawing exhaust gasses from a chimney includes: an exhaust fan assembly having: a housing defining a chamber and having opposing openings, the opposing openings having a centerline extending therebetween, a first of the openings being operative to intake a flow of gasses, a second of the openings being operative to exhaust the flow of gasses from the chamber; and a centrifugal fan having a motor and an impeller, the motor being mounted external to the housing, the impeller being positioned within the chamber, a rotational axis of the impeller being inclined with respect to the centerline extending between the openings of the housing.

Owner:ENERVEX

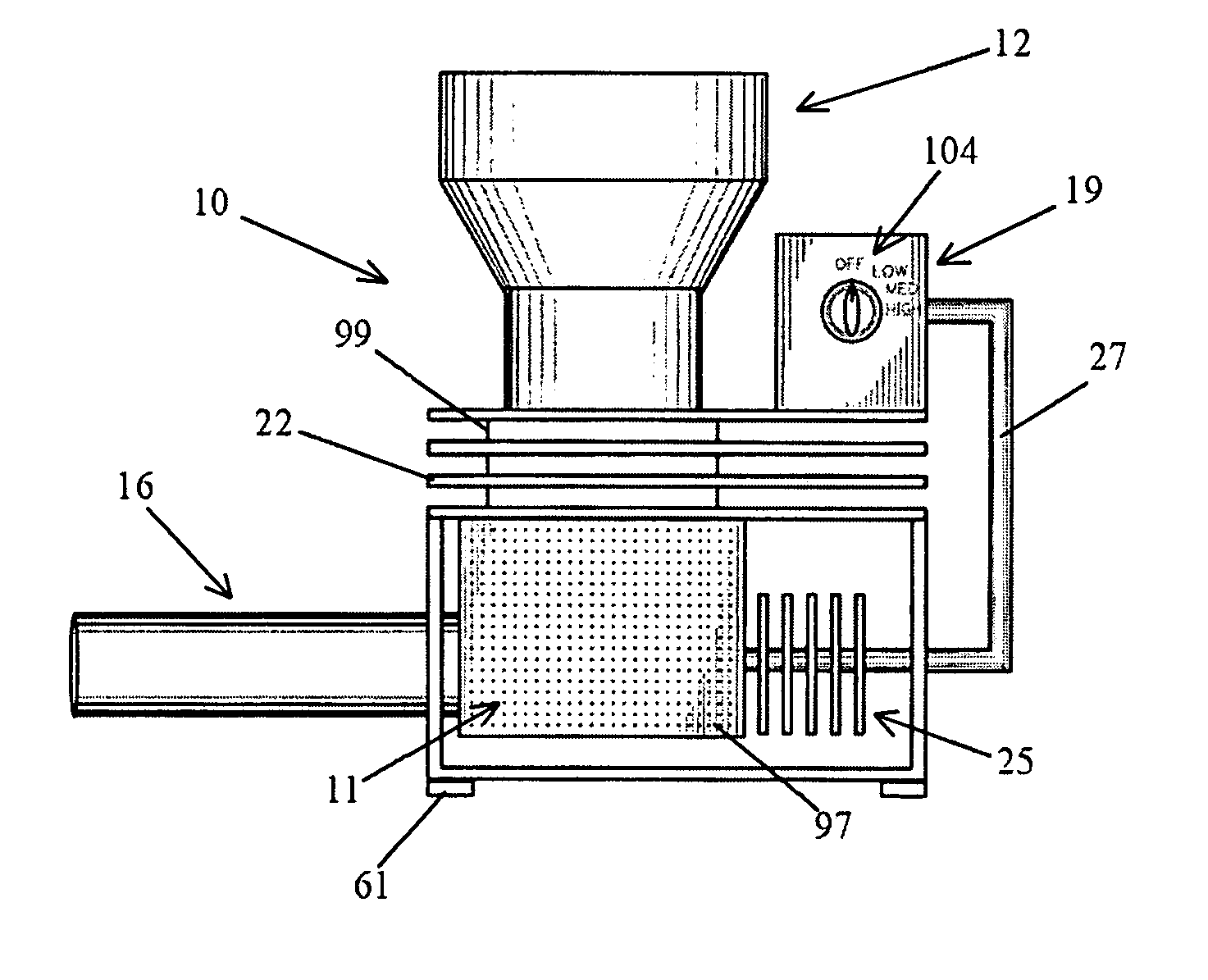

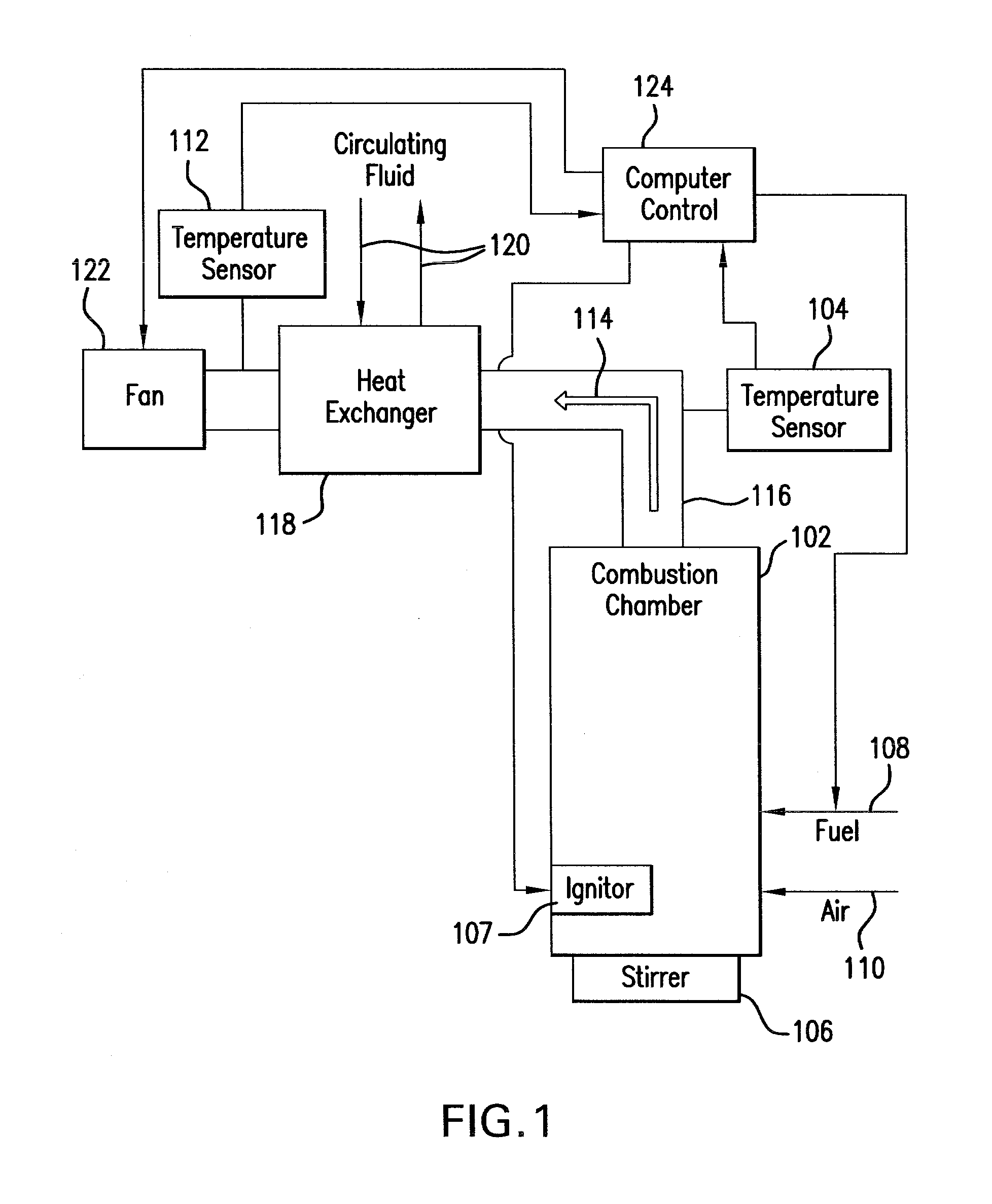

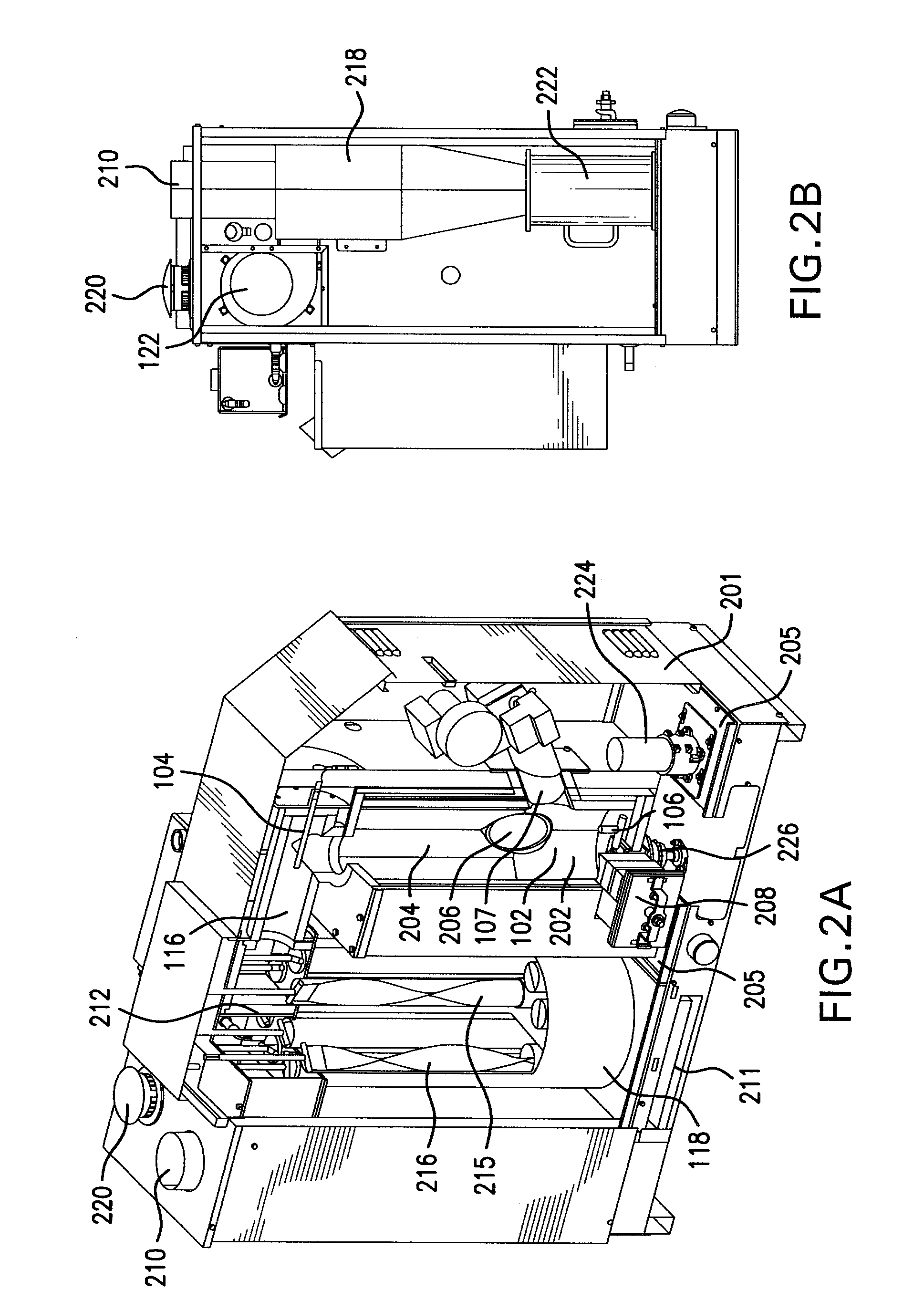

Non-catalytic biomass fuel burner and method

The present invention relates to a non-catalytic biomass burner that may be used to burn a variety of fuel types at high efficiencies. The burner may include a cylindrical combustion chamber with an auxiliary igniter to heat the fuel in the combustion chamber until desirable combustion temperatures are reached. Fuel may be added to the chamber via a fuel feed assembly, and the rate of fuel addition to the chamber by the fuel feed assembly may be controlled by a computer. A fan located on the distal side of a flue pipe from the chamber may also be provided that pulls air into the chamber through one or more air inlets that are designed to encourage cyclonic air and exhaust flow in the chamber. Methods are further provided for controlling the manner of operation of the burner by a computer that may be instructed by a computer program code.

Owner:LASKOWSKI SCOTT +3

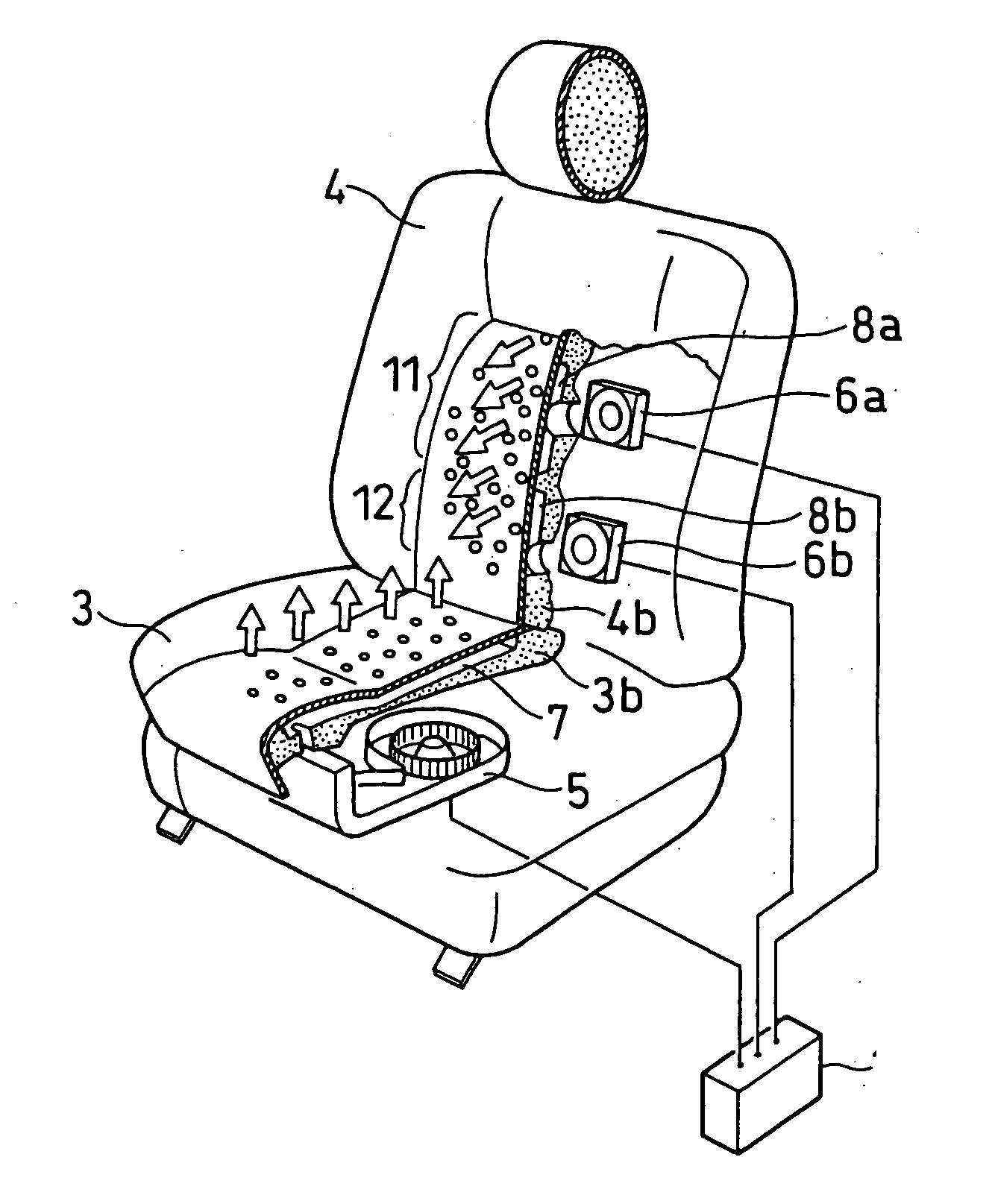

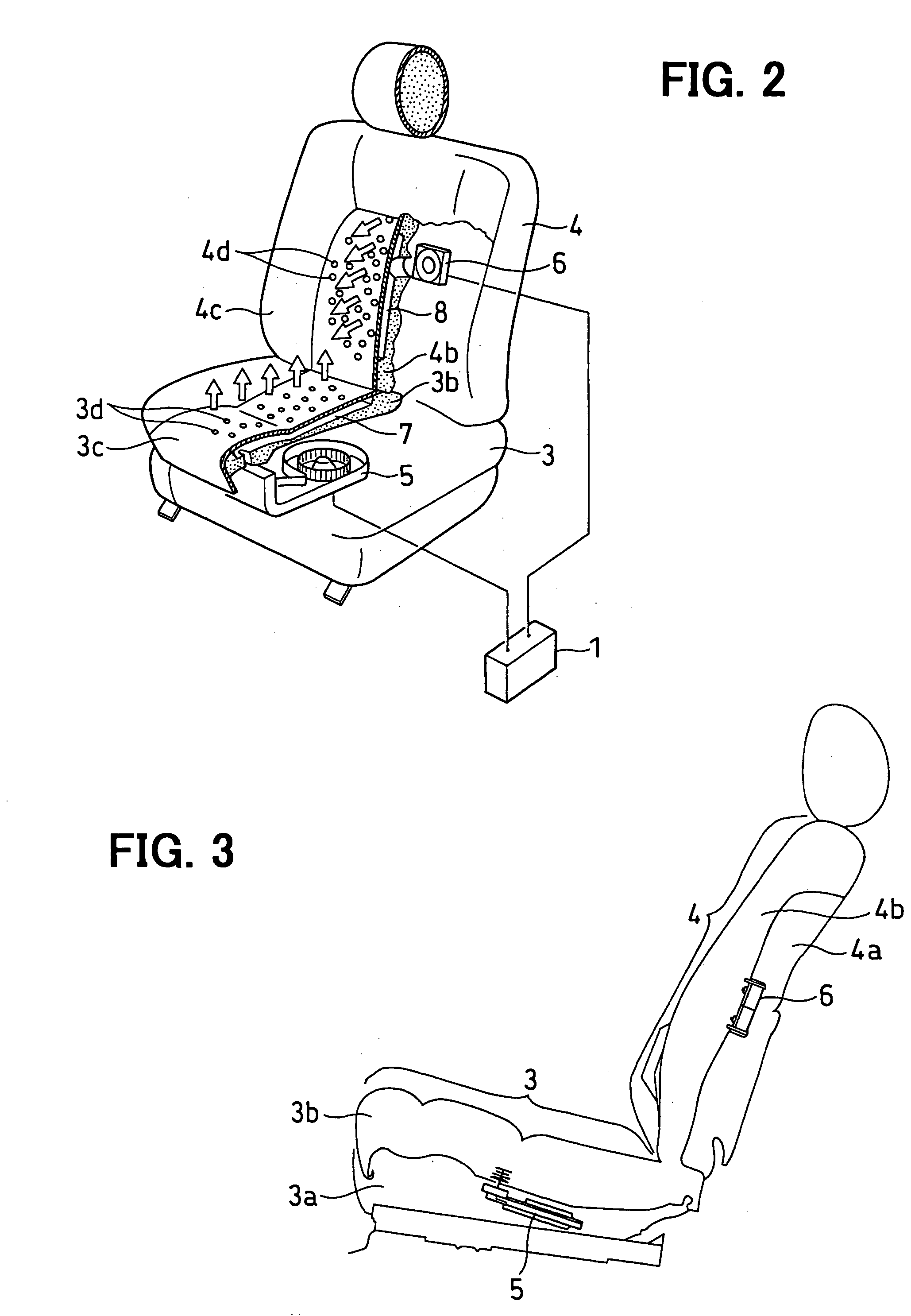

Vehicle air conditioner with seat air conditioning unit

ActiveUS20040139754A1Solve large capacityComfortable seat coolingAir-treating devicesSeat heating/ventillating devicesAir conditioningCooling capacity

In a seat air conditioning unit for a vehicle seat constructed with a seat cushion and a seat back, when a seat air conditioning operation is performed in a cooling operation of a passenger compartment, a cooling capacity of cool air blown from the seat back is set smaller than a cooling capacity of cool air blown from these at cushion while a passenger sits on the vehicle seat. Further, the cooling capacity of cool air blown from a lower portion of the seat back can be set smaller than the cooling capacity of an upper portion of the seat back. Accordingly, even when the cooling operation is continued for a long time while the seat air conditioning operation is performed, the waist portion of the passenger can be prevented from being excessively cooled.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com