System and process for collecting effluents from an electrolytic cell

an electrolysis cell and effluent technology, applied in the direction of combustion process, dirt cleaning, combustion treatment, etc., can solve the problems of reducing the collection efficiency of the extraction system, complex system, and involving mechanical means, and significantly increasing the investment cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

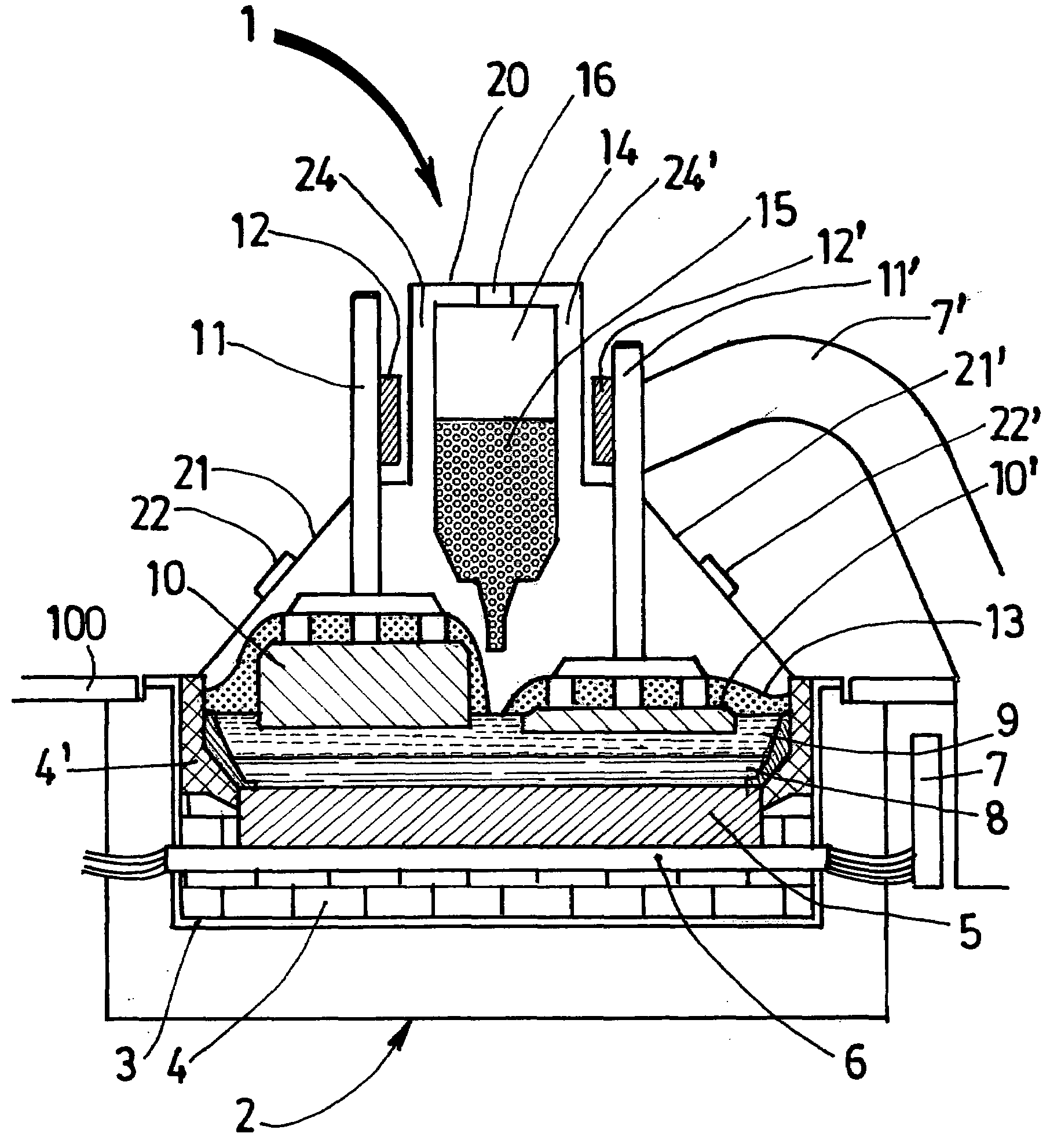

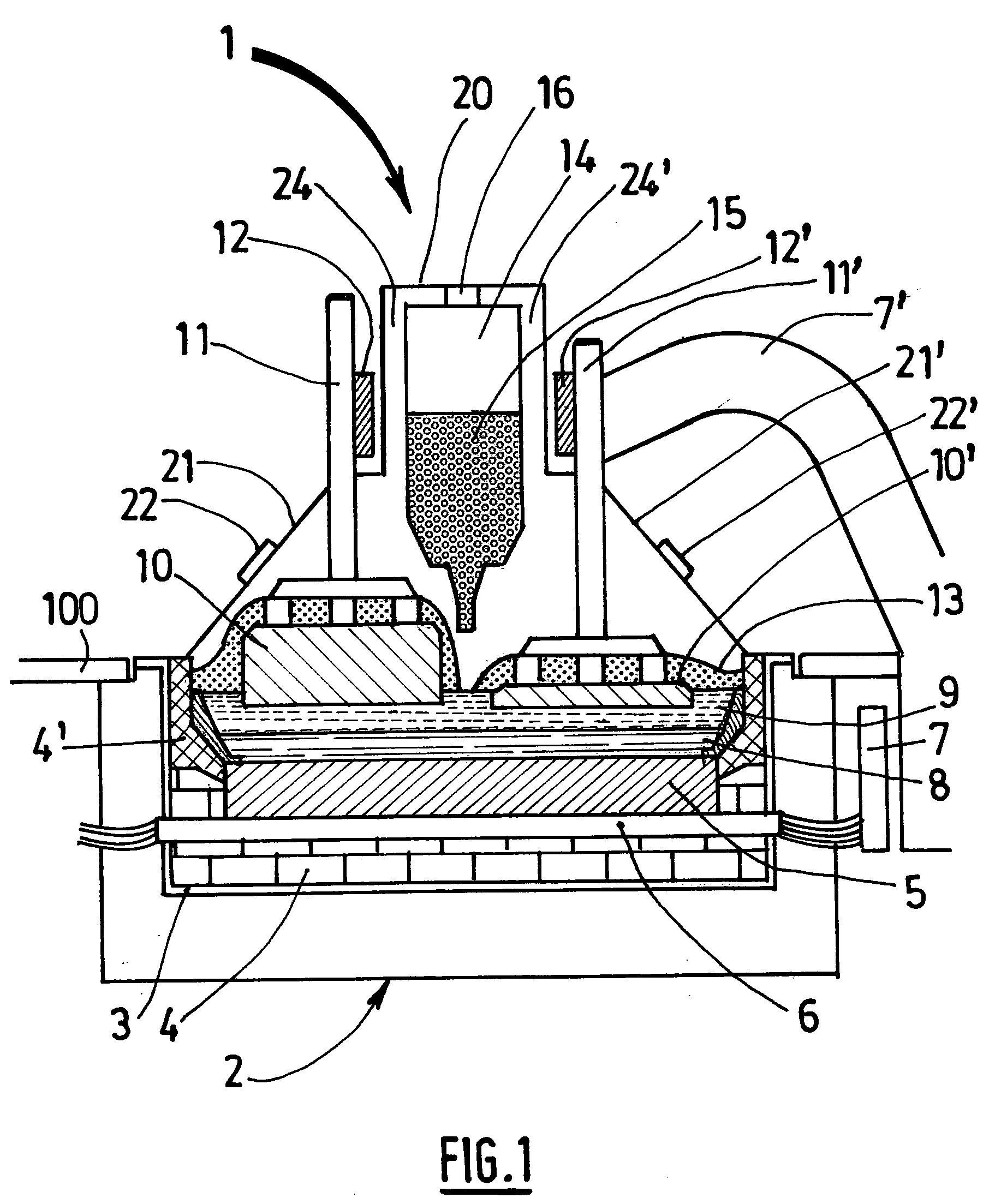

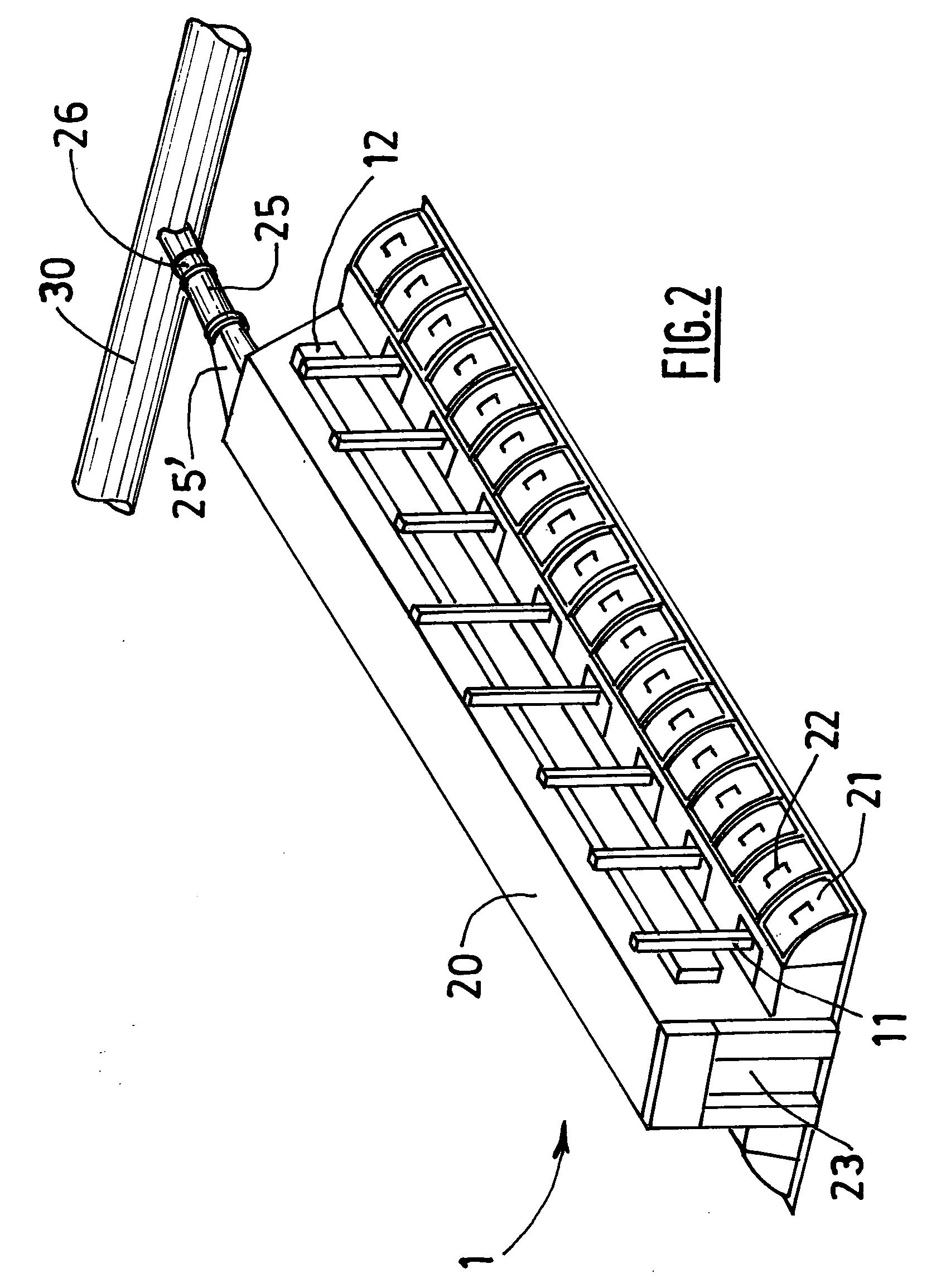

[0010]An object of the invention is a system for collecting effluents produced by an electrolytic cell intended for the production of aluminium and for drawing said effluents away from the cell in a flow of gas, said system comprising a hooding to confine the effluents, at least one outlet channel to collect said flow of gas and suction means to draw said flow of gas away from the cell through said at least one outlet channel, said hooding including removable hoods and, optionally, at least one door, to get access to the inside of the hooding, wherein said system further comprises at least one pipe comprising:[0011]a first end that is directly or indirectly connected to a pressurized air supply and[0012]a second end that is located inside said at least one outlet channel, includes at least one aperture and is oriented so that pressurized air can be projected through said aperture in a manner that increases the rate of said flow of gas within said at least one outlet channel.

[0013]An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com