Patents

Literature

84results about How to "Reduce carbon monoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

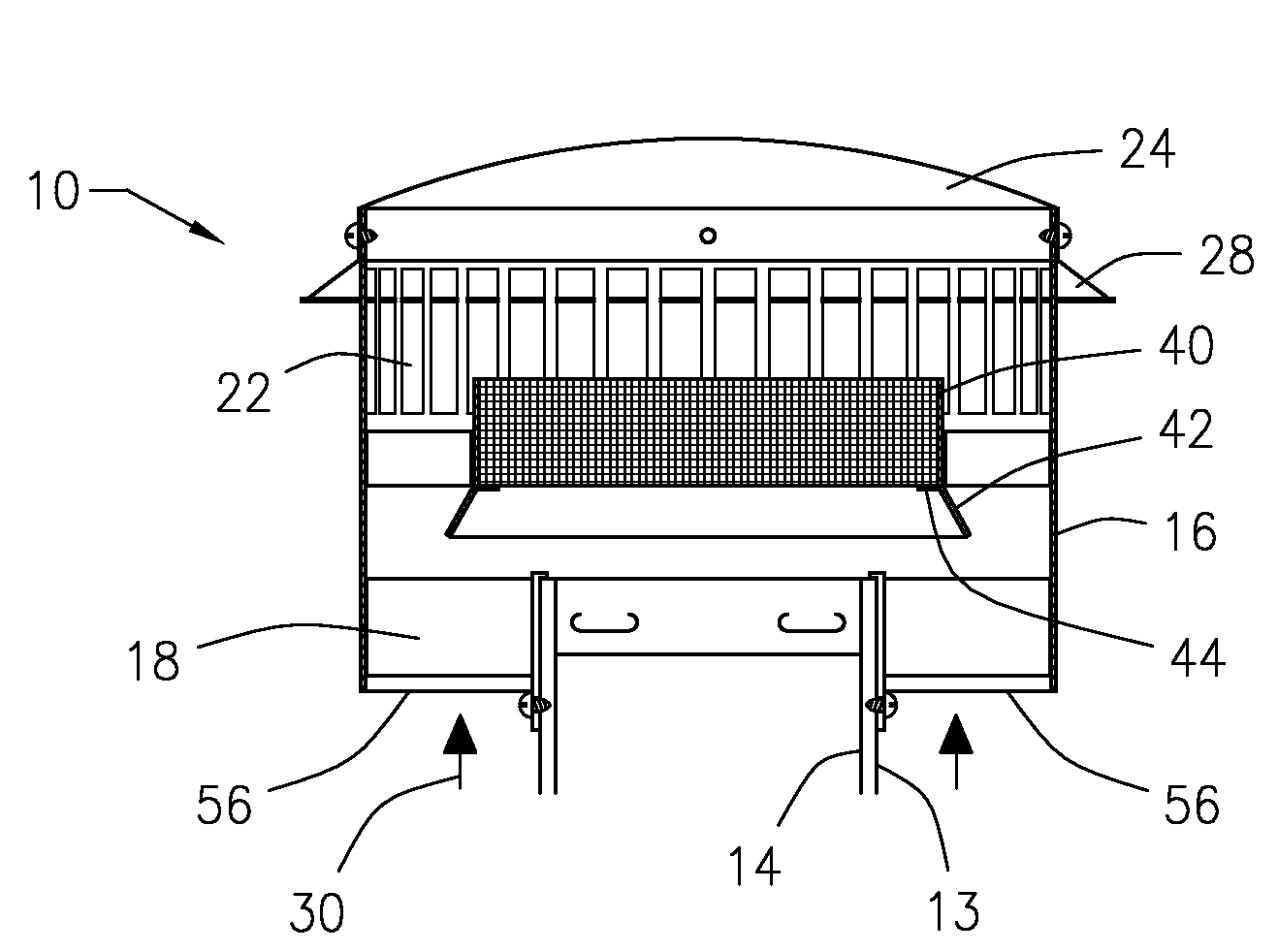

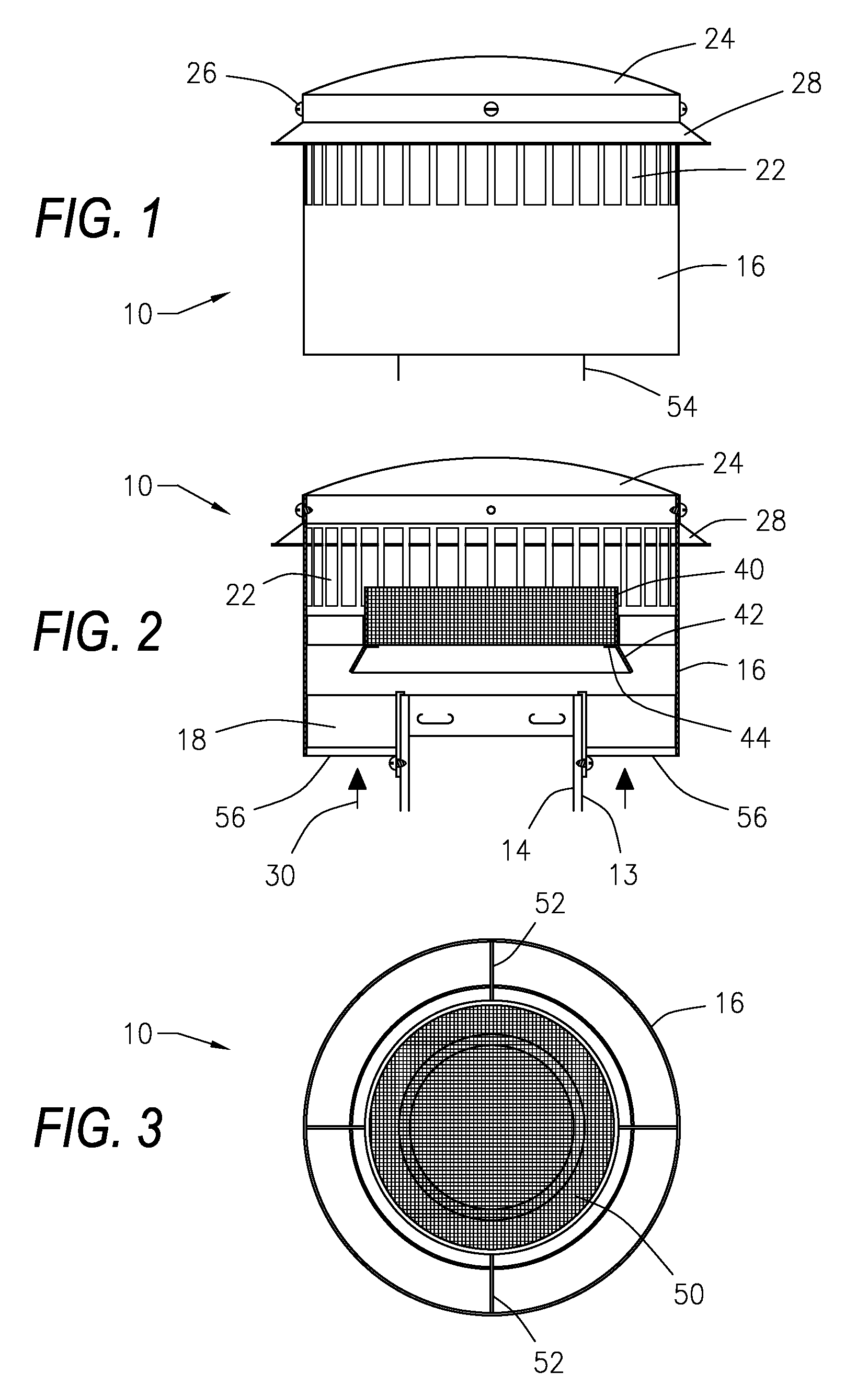

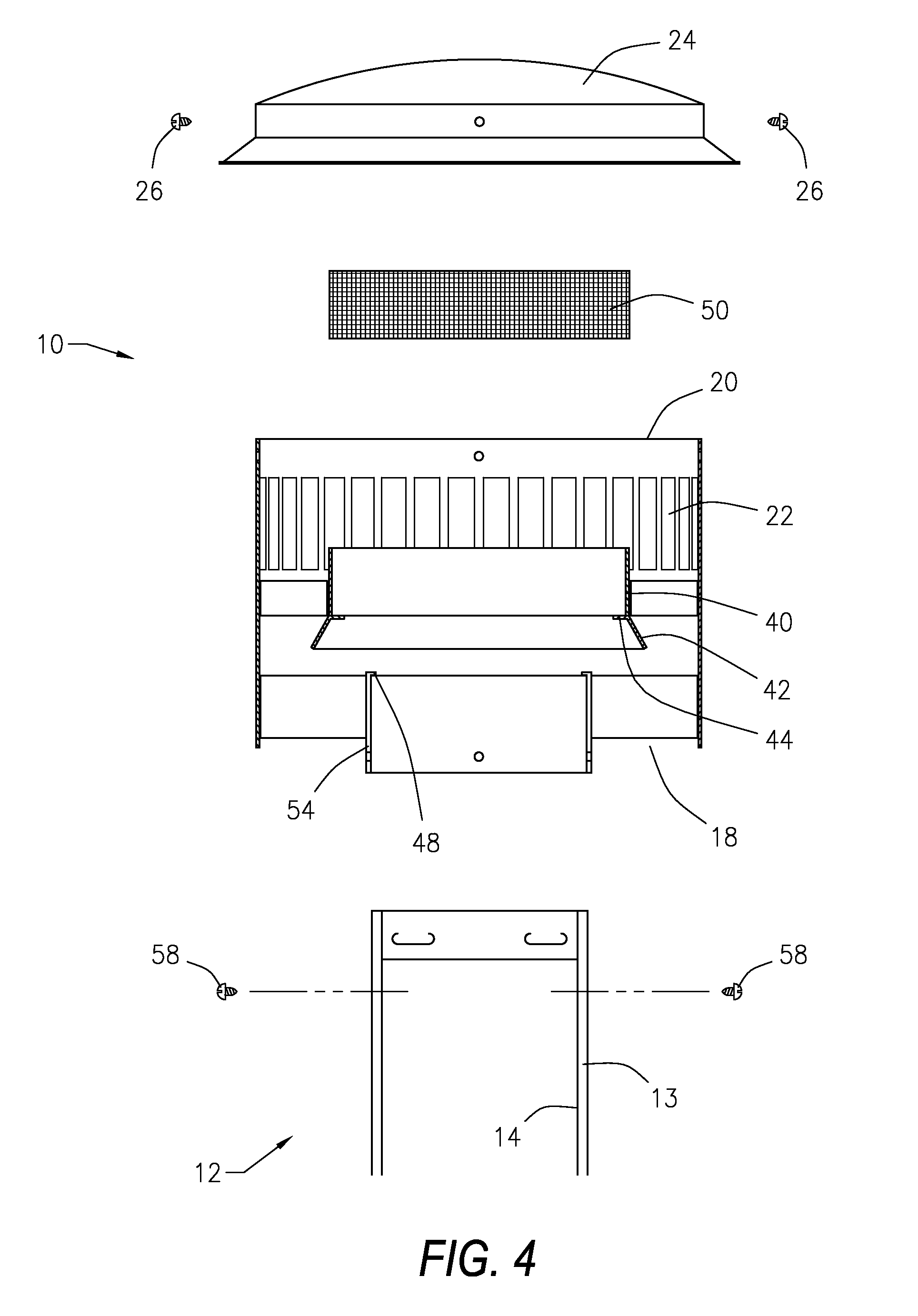

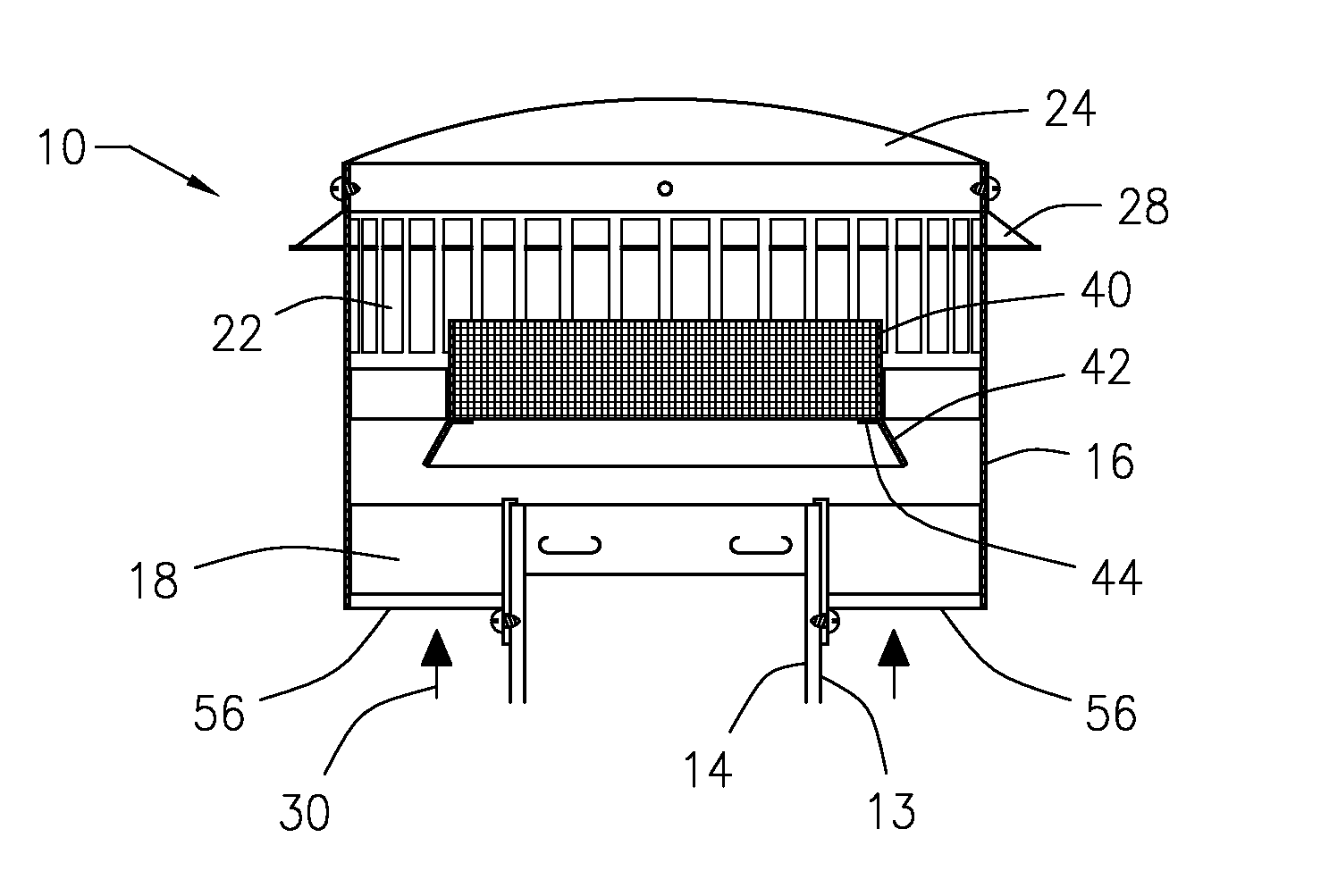

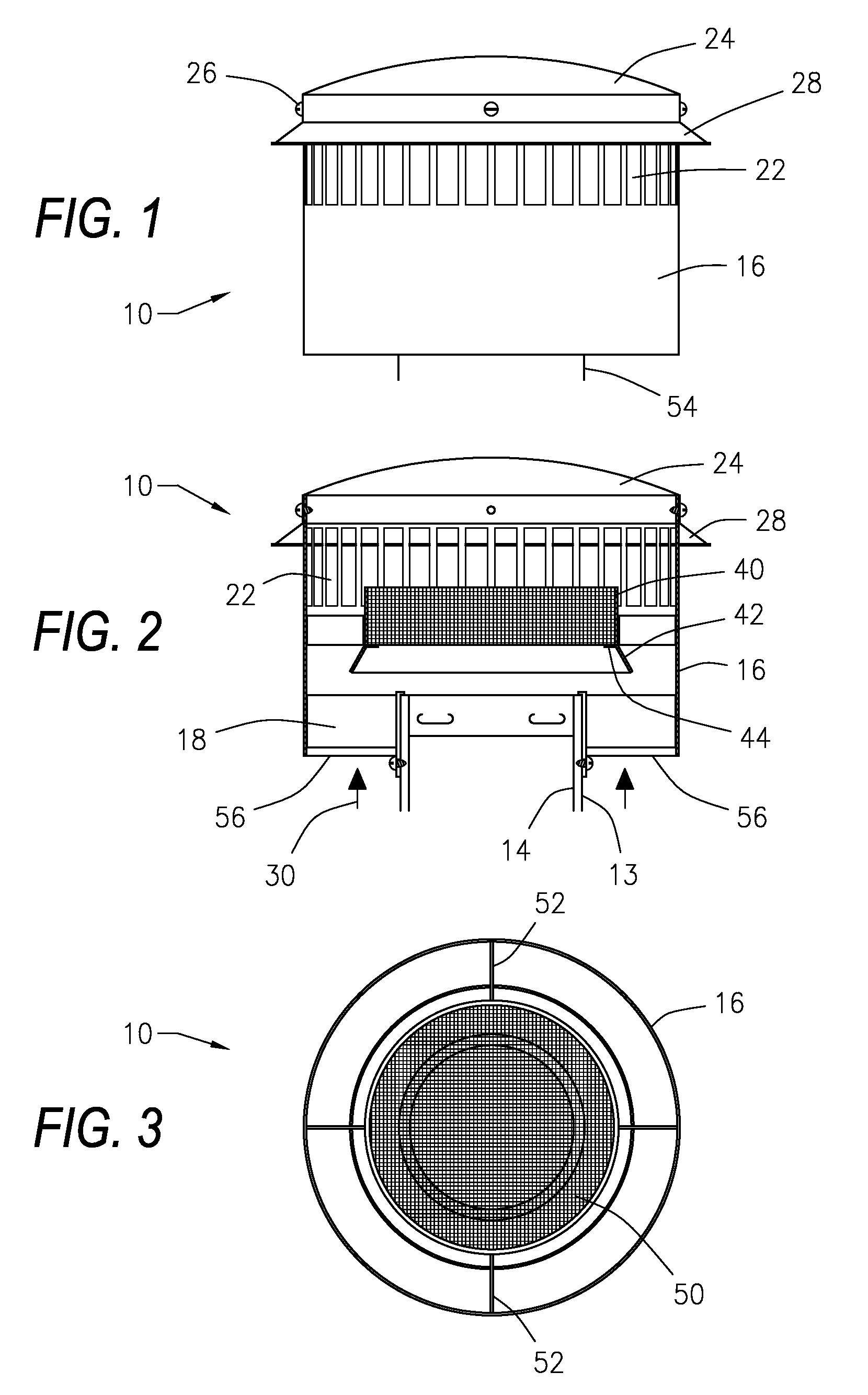

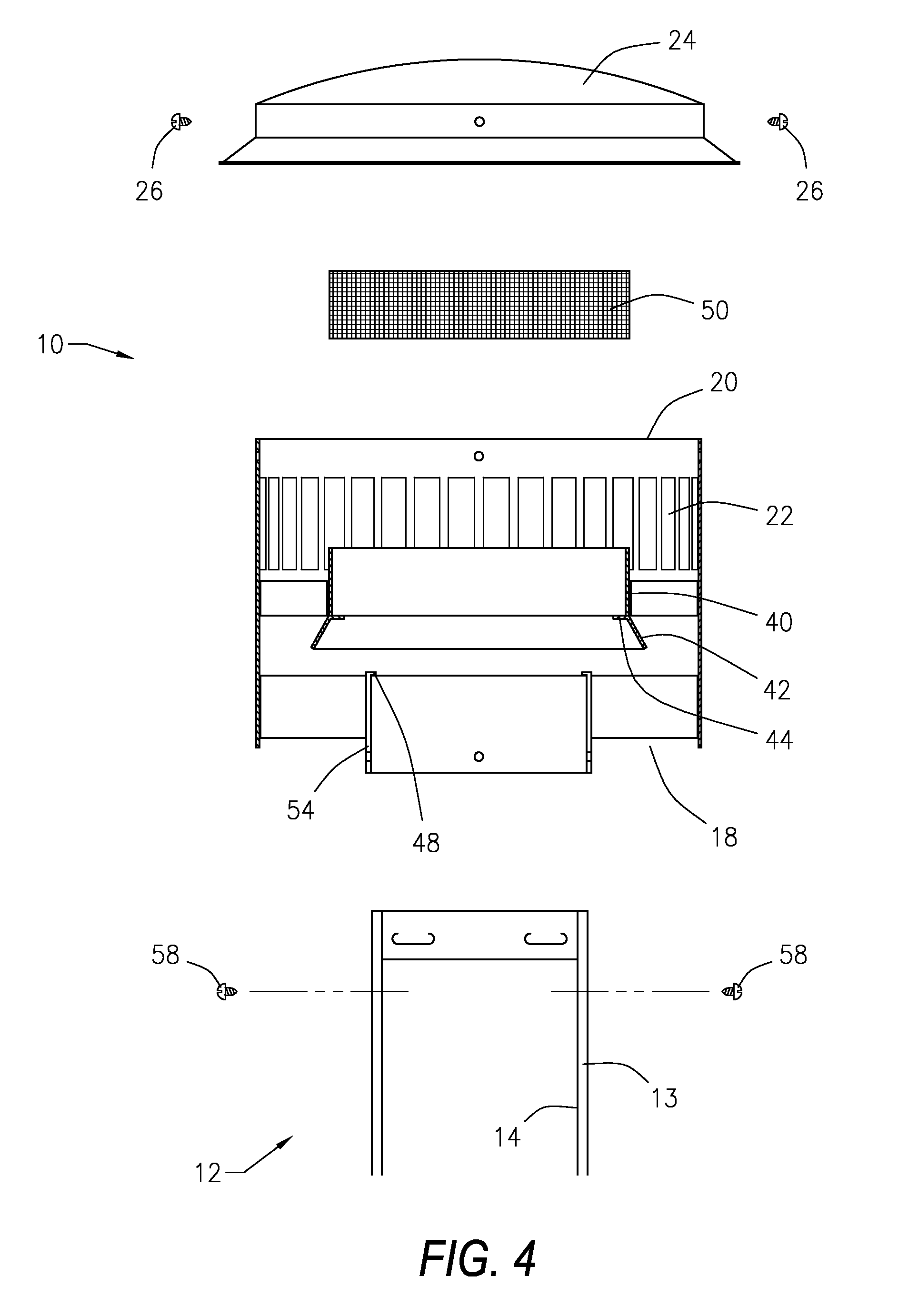

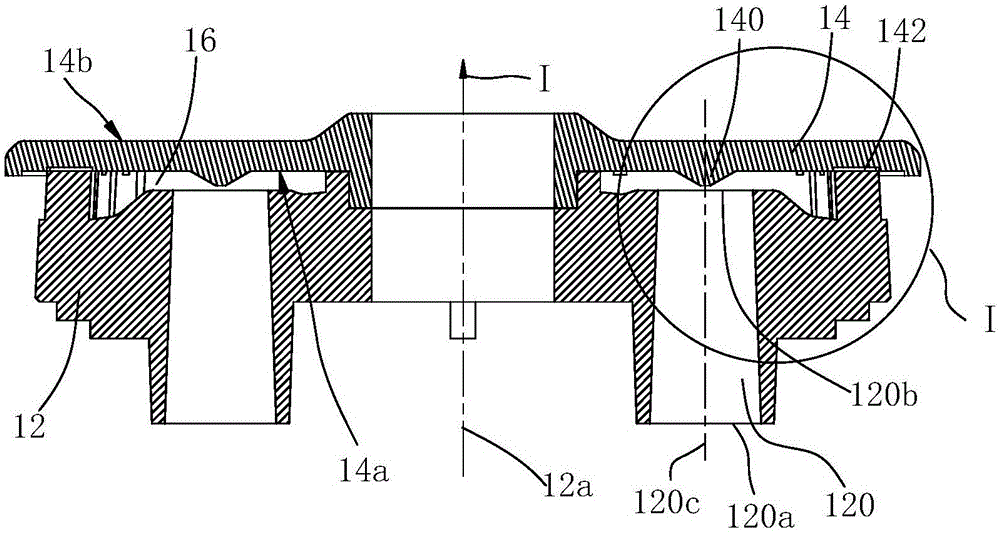

Exhaust flue cap and filter device for a gas fired appliance

ActiveUS20090088060A1Reduce carbon monoxideSmall diameterDispersed particle separationIncinerator apparatusEngineeringMechanical engineering

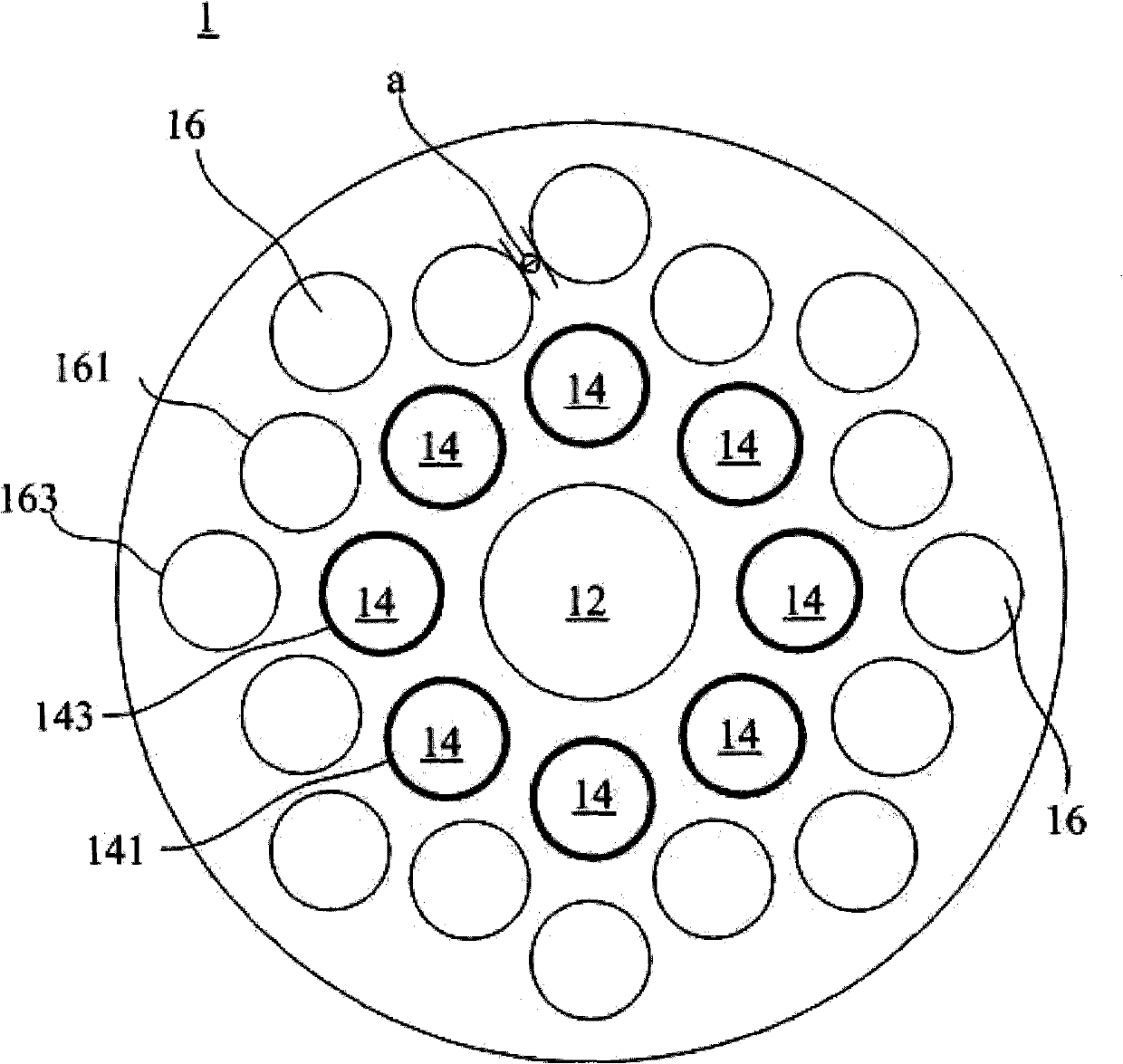

An exhaust flue cap and filter device for a gas fired appliance in communication with an exhaust flue opening having an outer pipe and a coaxial liner. The device includes a tubular cap with an open lower end, an opposed open upper end, and a plurality of ventilation holes wherein the cap is receivable over the flue opening. A removable top is attached to and closes the open upper end of the tubular cap. A filter tray having a smaller diameter than the tubular cap includes a ledge extending radially inward from the tray. A removable catalytic converter filter insert within the tubular cap is supported on the ledge.

Owner:ARNOLD JOHN G JR

A compound addictive for lowering CO content in cigarette smoke and application thereof

InactiveCN1951240AReduce carbon monoxideImproving and improving the taste qualityTobacco treatmentPipe TobaccoAlkali metal

The invention relates to a composite additive which can reduce the carbon monoxide content of smoke gas, and relative application. Wherein, said composite additive comprises that tobacco extract, alkali metal salt, transition metal hydroxide, or metal hydroxide; the composite additive can be used in variable tobaccos as flue-cured tobacco, suncured tobacco leaf, oriental tobacco leaf, expansion pipe tobacco, etc. The inventive composite additive can be used in tobacco to reduce carbon monoxide content 1.5-3.0mg / n of smoke gas and reduce the tar content.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Functional cigarette paper and preparation method

InactiveCN102242527AReduce exposureWon't breakPaper/cardboardPhysical paper treatmentAlcoholCombustion

The invention provides functional cigarette paper and a preparation method. The functional cigarette paper comprises common cigarette paper prepared by using a paper making process, and the surface of the common cigarette paper is sprayed or dip-coated with a molecular capsulation material layer capable of reducing the contents of harmful substance, such as carbon monoxide, nitrosamine and the like in cigarette smoke. The preparation method comprises following steps of: finishing making of cigarette paper on a paper making machine, introducing a spraying device at the back of a combustion adjusting agent feed point of the paper making machine, preparing a molecular capsulation material into a molecular capsulation adsorbent solution, uniformly spraying the solution on the cigarette paper, and drying by a drying tank; or after finishing the making of the cigarette paper, preparing the molecular capsulation material into a molecular capsulation adsorbent alcohol solution, and uniformly dip-coating the solution to the cigarette paper on a coating machine, and then drying through a low-temperature drying cylinder until the alcohol fully volatilizes; and the addition amount of the molecular capsulation absorbing agent accounts for 1-20% of the mass percentage of the weight of the cigarette paper. The preparation method has the characteristics of simple molecular capsulation process, convenience for addition of the absorbing agent, and capability of reducing the content of harmful substances, such as carbon monoxide, nitrosamine and the like, in the cigarette smoke.

Owner:MINFENG SPECIAL PAPER

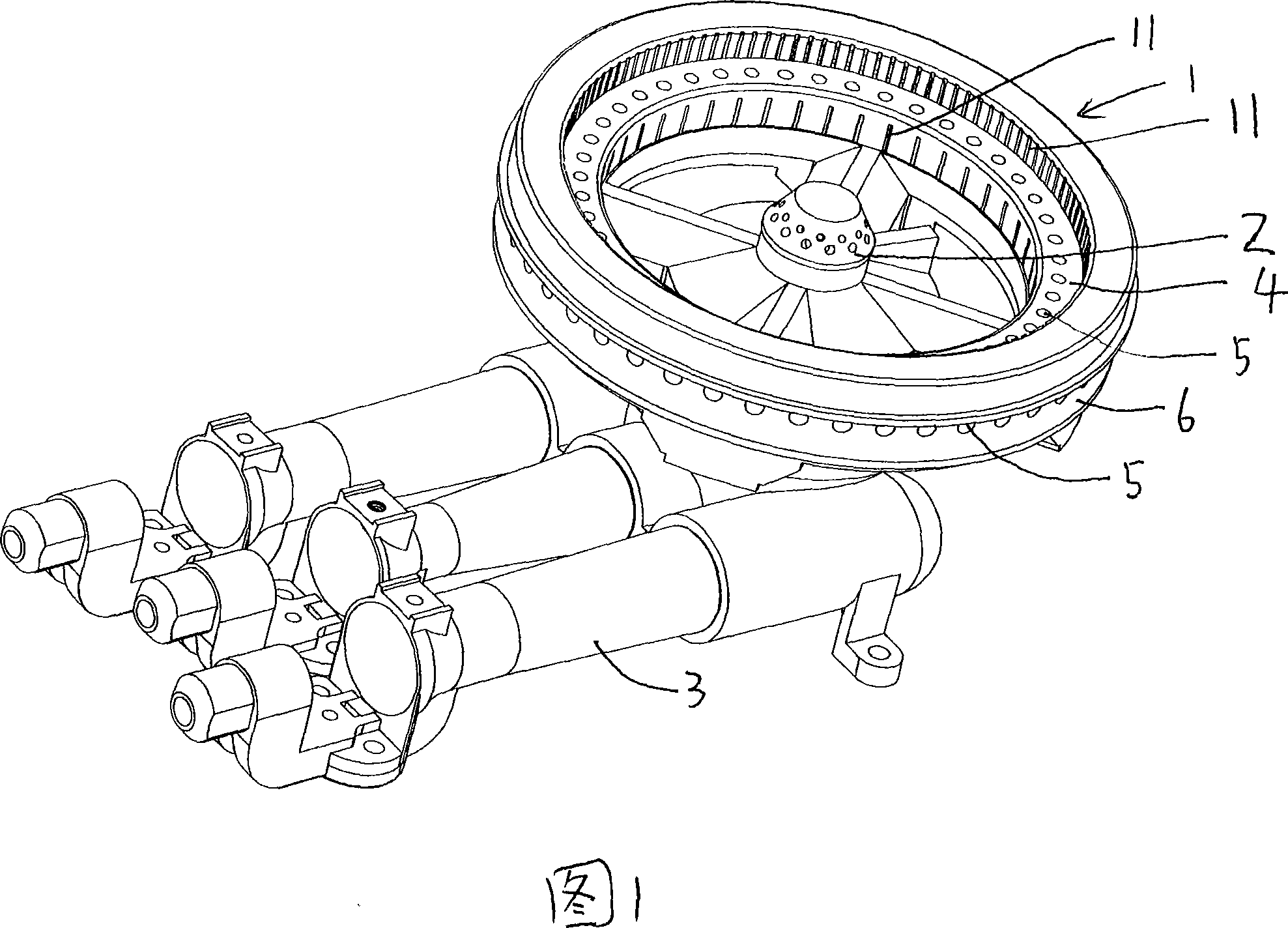

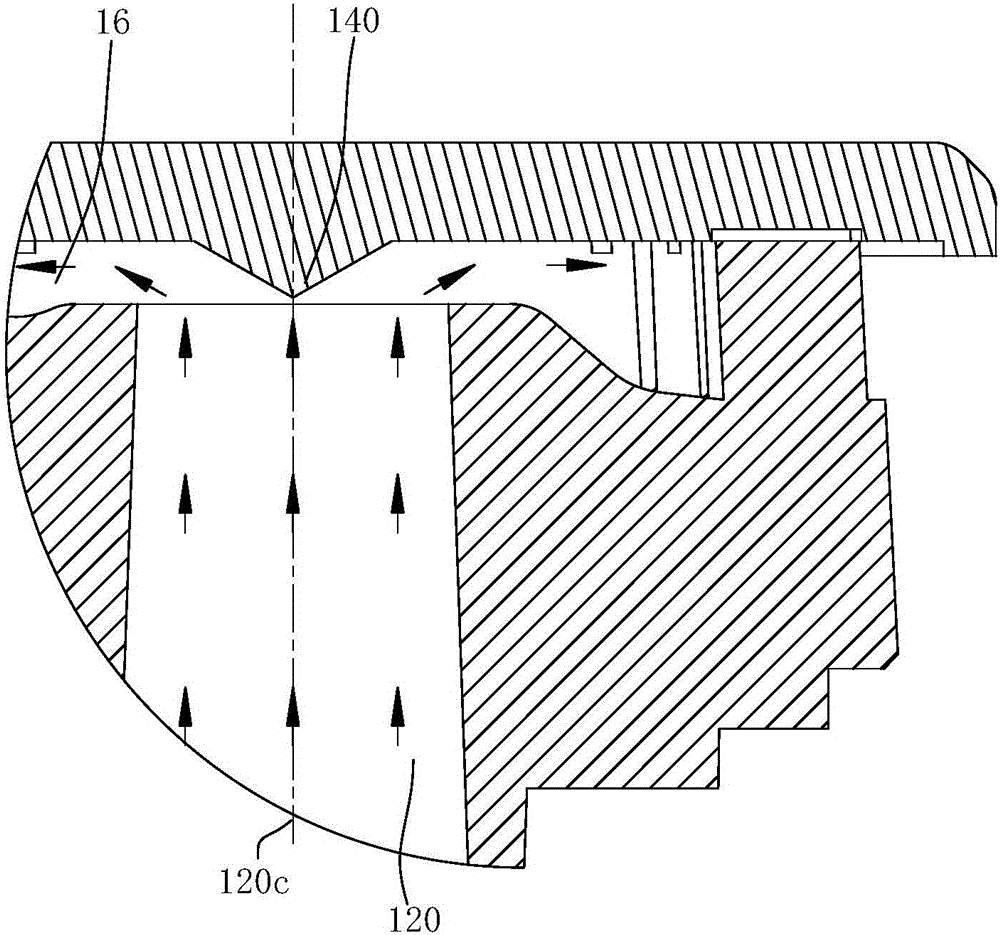

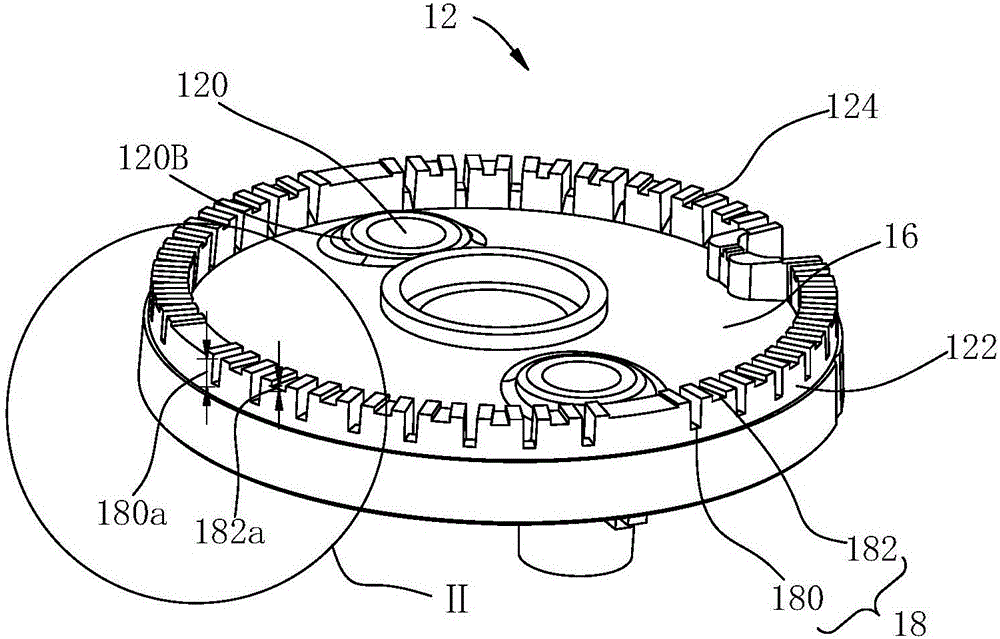

Gas kitchen ranges burner

InactiveCN101162088ASecondary air supplementHigh thermal efficiencyGaseous fuel burnerHeating efficiencyFlue gas

The invention discloses a gas range burner, comprising a fire cover and a induction tunnel, wherein the fire cover comprises an outer ring fire cover and an inner ring fire cover, the inner side of the outer ring fire cover is provided with at lest two rows of outer ring fire holes which are an upper row of fire holes and a lower row of fire holes, the upper row of fire holes and the lower row of fire holes are spaced and direct toward the fire cover center; the inner side of the outer ring fire cover is also provided with at least three induction tunnels among which one induction tunnel is communicated with the inner ring fire holes on the inner ring fire cover, the other induction tunnels are communicated with the outer ring fire holes; secondary air inlets are arranged between the upper row of fire holes and the lower row of fire holes. The invention has the advantages of sufficient supply of the primary air and the secondary air, high heating efficiency and low flue gas emission; by the experimental determination, the load of the invention is 3.6KW which is higher than 3.5KW, the carbon monoxide content in the emitting fuel gas is 280PPM which is far lower than 500PPM.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

Additive for reducing the content of coke tar and whitedamp in the cigarette smoke and method of use thereof

An additive capable of reducing tar and carbon monoxide contained in cigarette is provided, as well as the application method of the additive, which contains inorfil loaded with metal-salt. The accretion provided by the present invention prepared and added conveniently with low cost is suitable for requirement of industrialized production, capable of well decreasing the tar and carbon monoxide contained in cigarette smoke and greatly reducing the harm to the smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Catalyst capable of reducing carbon monoxide content in cigarette smoke, preparation method and application of same

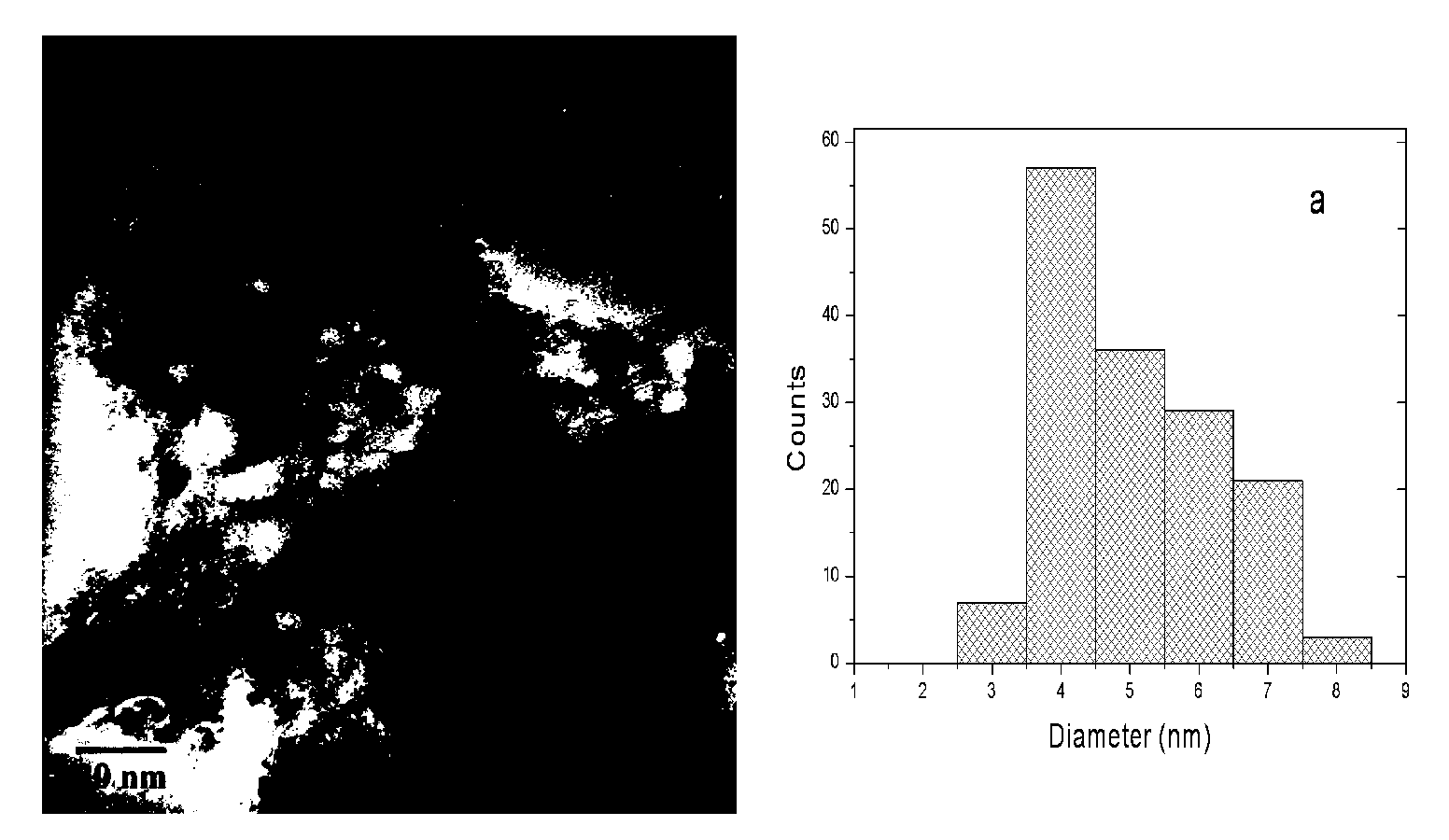

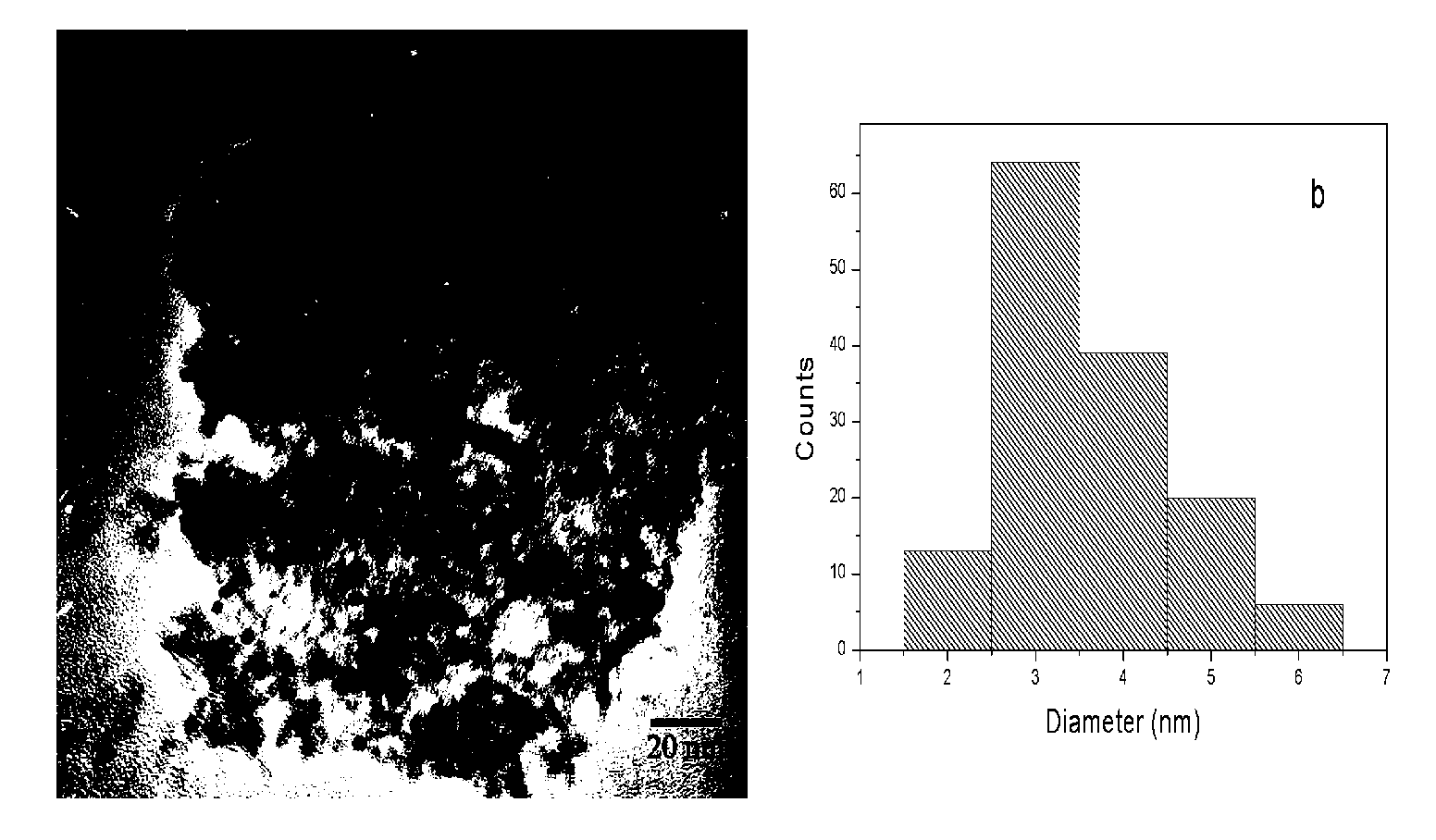

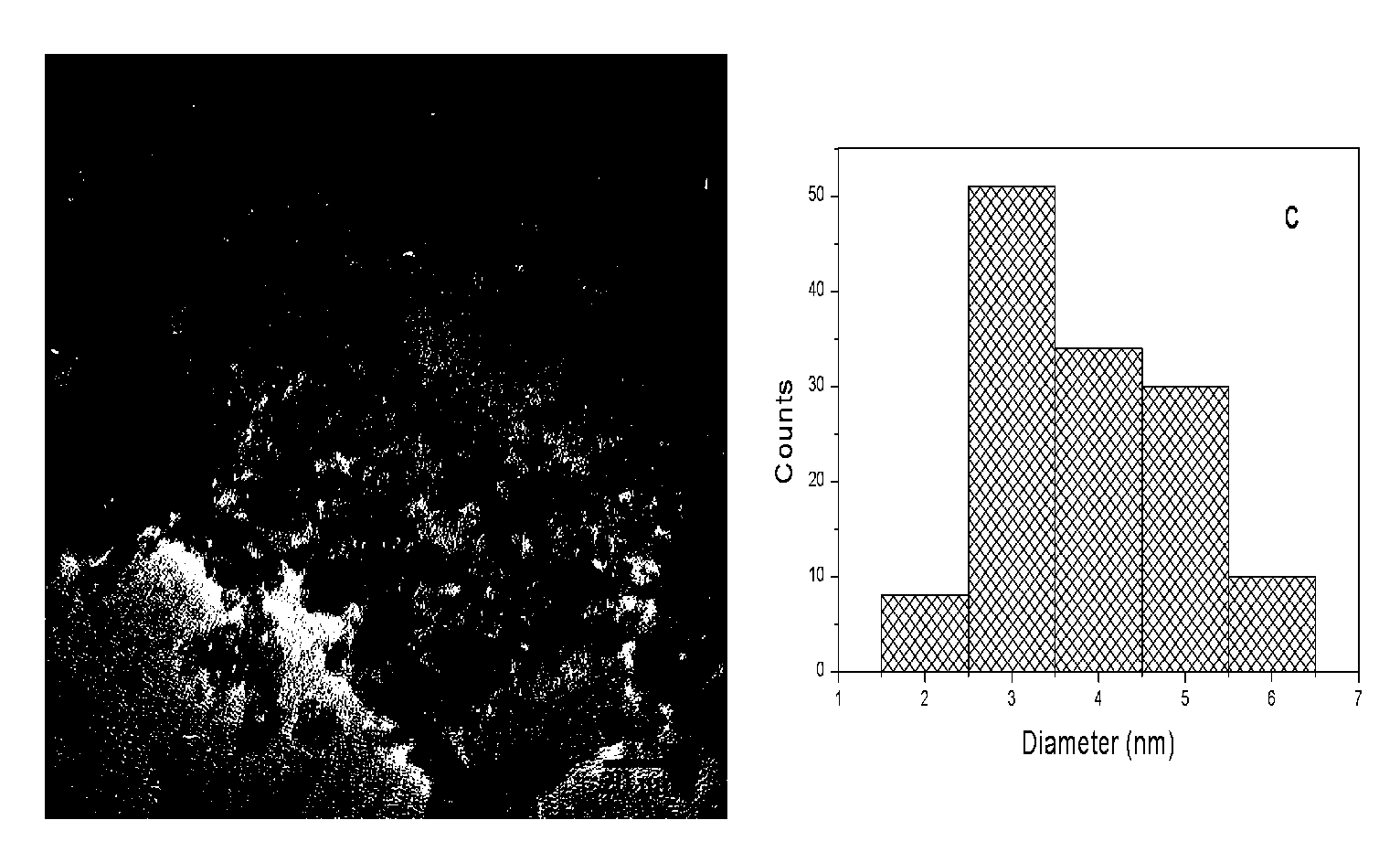

ActiveCN101611927AReduce metal contentReduce carbon monoxideTobacco treatmentTobacco smoke filtersIon exchangeCarbon monoxide

The invention belongs to the field of harm and tar reduction of cigarettes, and relates to a catalyst capable of reducing carbon monoxide content in cigarette smoke at normal temperature, and a preparation method and the application of the same. The method comprises the following steps that: directing agents with different structures are synthesized into mesoporous alumina with a high specific surface and a plurality of surface basic sites as a carrier of the catalyst, and nanometer metal catalytic active components are highly dispersed on the surface of the carrier by adopting different methods, such as a homogeneous deposition-precipitation method, a deposition-precipitation method, an ion exchange method and the like to prepare a mesoporous metal alumina catalyst. The specific surface of the catalyst is 100 to 400 m<2> / g; a pore size is 2.0 to 10.0 nm; the surface basicity of the mesoporous metal alumina catalyst is 0.01 to 0.08 mmol / g; pH of a surface isoelectric point (an IEP value) is 8 to 10; and the catalytic active components are nanometer metal. The catalyst of the invention can oxidate carbon monoxide to carbon dioxide completely at normal temperature and can selectively reduce the carbon monoxide content in the cigarette smoke by 10 to 30 percent when the catalyst is added to a filter candle of the cigarette.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Methanol-diesel and preparation thereof

InactiveCN101381632AImprove performanceExtended shelf lifeBiofuelsLiquid carbonaceous fuelsLiquid fuelPower performance

The invention relates to liquid fuel oil, in particular to methanol diesel oil and a method for preparing the same. The methanol diesel oil comprises the following components in weight percentage: 40 to 80 percent of diesel oil, 5 to 20 percent of methanol and 1 to 10 percent of additive. The formula with unique auxiliary materials and the additive is introduced to the fuel, thereby effectively solving the problem that the methanol and the diesel oil are hard to mutually dissolve and completely replacing the commercial diesel oil to be used in various environments; moreover, the methanol diesel oil also has the advantages of low cost and good burning property, starting property and power performance; in particular, carbon monoxide and the smoke intensity in the tail gas emission are obviously reduced, so that the methanol diesel oil is a perfect fuel.

Owner:山西华顿实业有限公司

Technique for recycling purge gas of device used for synthesizing methyl alcohol by utilizing synthesis gas

The invention relates to a technique for synthesizing methyl alcohol by utilizing synthesis gas in the field of chemical industry and in particular relates to a technique for recycling purge gas of device used for synthesizing methyl alcohol by utilizing synthesis gas. The technique comprises the following steps of: carrying out a water vapour transformation reaction on the purge gas of the methyl alcohol synthesizing device, wherein carbon oxide in the purge gas is converted into carbon dioxide and hydrogen, and methyl alcohol in the purge gas is reformed and decomposed into carbon dioxide and hydrogen; carrying out pressure swing adsorption separation purification on the purge gas after the transformation reaction, so as to obtain hydrogen with higher purity; and returning the hydrogen after pressure swing adsorption purification to a methyl alcohol synthesis process, so as to achieve higher feed gas utilization rate. According to the technique for recycling the purge gas of the device used for synthesizing methyl alcohol by utilizing the synthesis gas, content of hydrogen in the purge gas is increased, and discharge of carbon monoxide effective gas is also reduced; direct discharge of methyl alcohol is eliminated, and recycling of the methyl alcohol in the purge gas is realized; and the total consumption of the synthesis gas in methyl alcohol synthesis front processes such as low temperature transformation reaction and pressure swing adsorption decarbonisation is reduced, and direct discharge of carbon dioxide and methyl alcohol synthesis cost are reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for refining biologic diesel oil, phospholipid and glycerin by using leftovers of vegetable oil

InactiveCN1958728AShort reaction timeImprove conversion rateOrganic chemistryChemical industryVegetable oilBiodiesel

This invention discloses a method for producing biodiesel oil, phospholipid and glycerol from waste plant oil. The method comprises: (1) extracting the raw material to separate phospholipid, neutral oil and soap; (2) performing interesterification on neutral oil to obtain biodiesel oil and glycerol; (3) acidifying and esterifying the soap to obtain biodiesel oil. The method has such advantages as short reaction time, simple process, high conversion rate of biodiesel oil, low energy consumption, easy recovery of the products, and no pollution. The produced biodiesel oil can satisfy the international DIN V 51.606 standard and China 2# diesel oil standard. The method utilizes waste plant oil to produce biodiesel oil, thus largely reduces the cost and is suitable for mass production.

Owner:HUAZHONG UNIV OF SCI & TECH

Hydrogen generator and application thereof

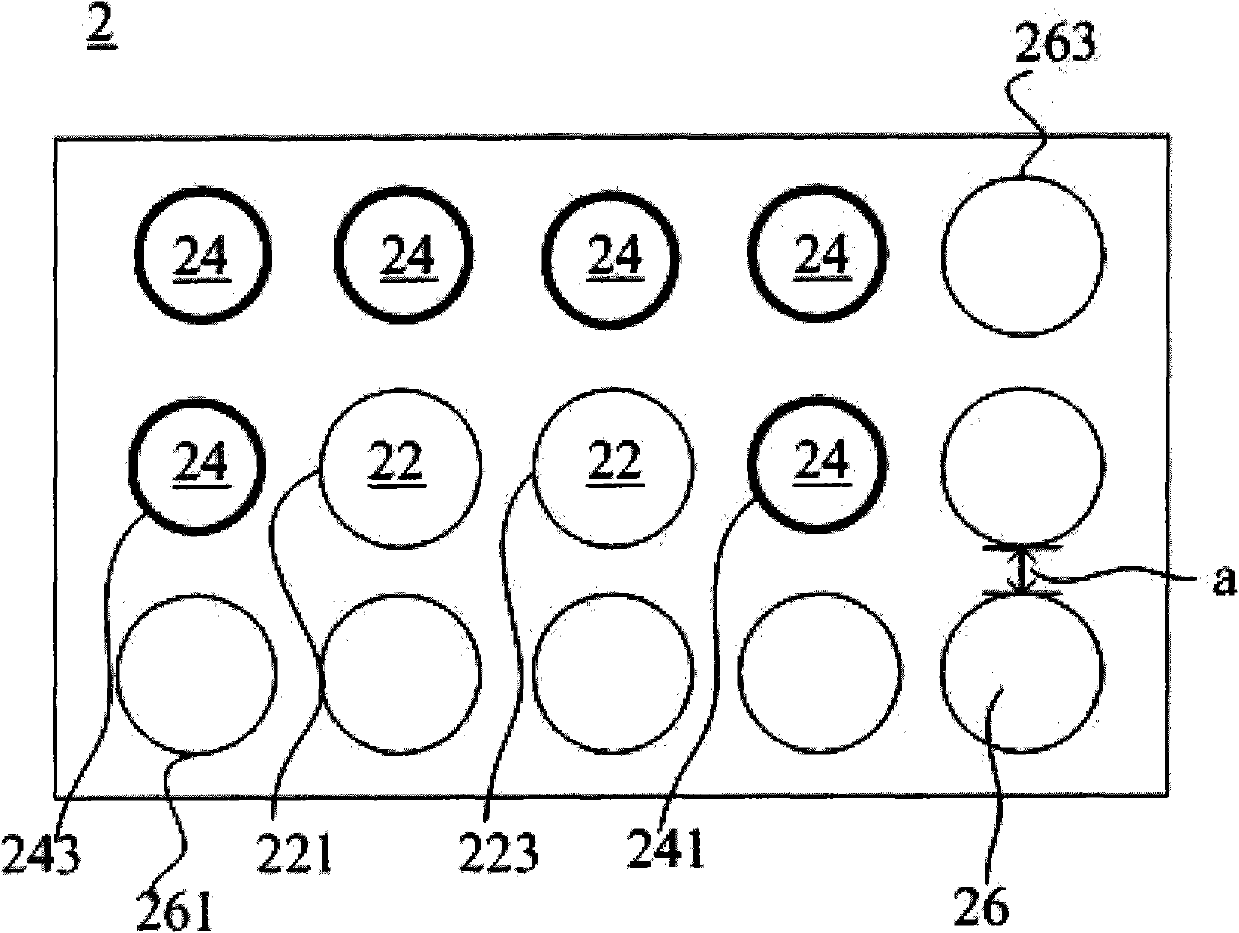

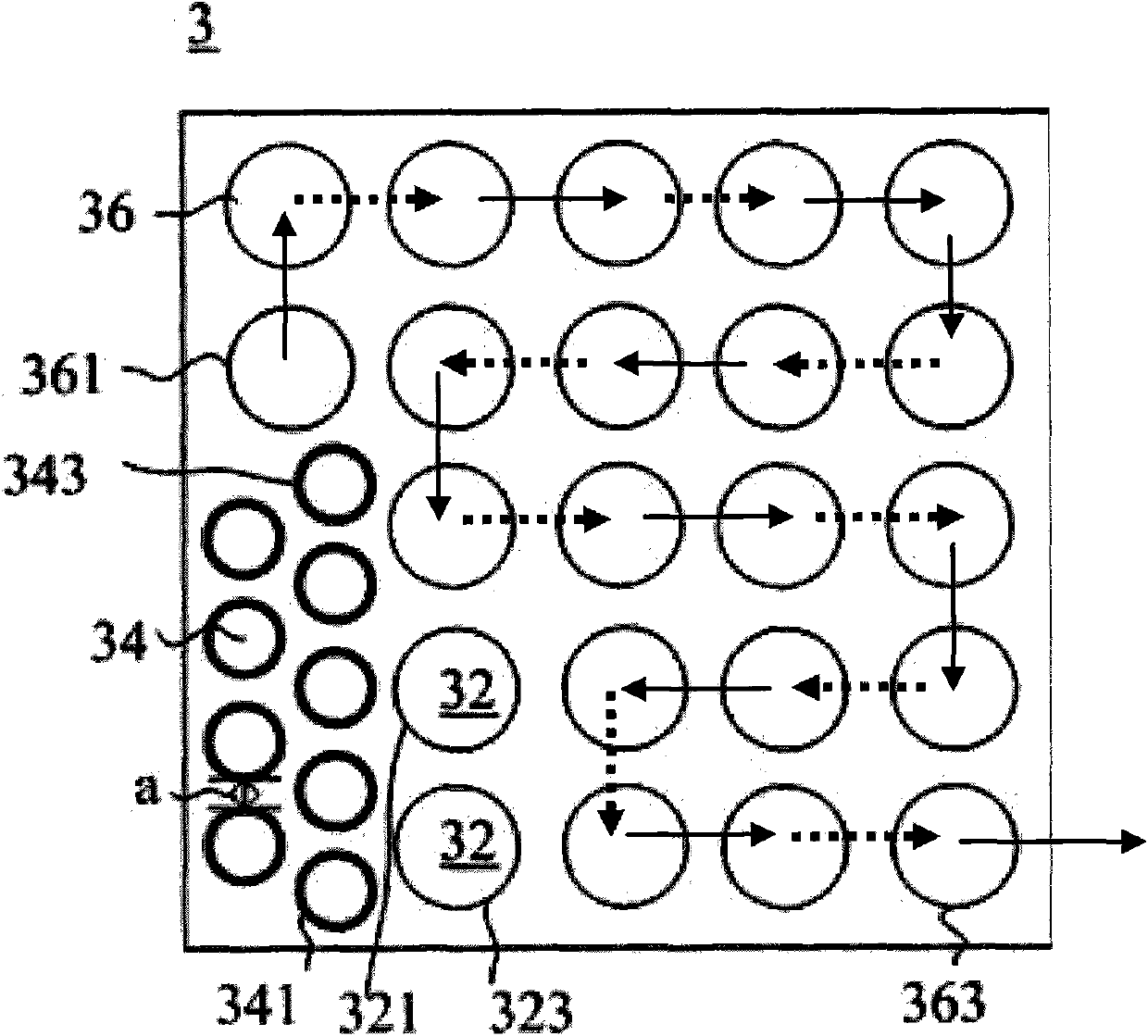

ActiveCN102020245AGood heat transfer performanceUniform temperature distributionHydrogenHeat-exchange elementsChemistryHeating energy

The invention relates to a hydrogen generator and application thereof. The hydrogen generator is formed by a first medium comprising a recombination zone, an oxidation zone and a preheating zone, wherein the recombination zone is used for accommodating a recombination accelerant so as to carry out the steam recombination reaction of a hydrogen-producing raw material to generate hydrogen; the oxidation zone is used for carrying out heat release oxidation reaction so as to provide a heat source, and a first oxidation accelerant exists in the oxidation zone; the heat source provided by the oxidation zone supplies heat energy to the preheating zone and the recombination zone so as to firstly preheat the hydrogen-producing raw material in the preheating zone and subsequently carry out the steam recombination reaction in the recombination zone; first media exist among the recombination zone, the oxidation zone and the preheating zone at the intervals of the shortest distance of at least 0.5mm; and the coefficient (K) of heat conduction of the first media is at least 60W / m-K. The carbon monoxide content of a hydrogen-contained gas mixture prepared by the hydrogen generator is quite low, therefore, the gas mixture can be directly applied to common fuel.

Owner:GREEN HYDROTEC

Environmental protection energy saving methanol gasoline

An environment-protection and energy-saving methanol gasoline is prepared from methanol (60-70 wt.%), crude gasoline (25-38) and special composite additive (2-7) while can improve the solubility, anticorrosion nature, and burning performance. Its advantages are high stability, full combustion, high power, and saving oil by 15-20%.

Owner:蓝鸿泽 +1

Gas kitchen ranges burner

The invention discloses a gas range burner, comprising a fire cover and a induction tunnel, wherein the fire cover comprises an outer ring fire cover and an inner ring fire cover, the inner side of the outer ring fire cover is provided with at lest two rows of outer ring fire holes which are an upper row of fire holes and a lower row of fire holes, the upper row of fire holes and the lower row offire holes are spaced and direct toward the fire cover center; the inner side of the outer ring fire cover is also provided with at least three induction tunnels among which one induction tunnel is communicated with the inner ring fire holes on the inner ring fire cover, the other induction tunnels are communicated with the outer ring fire holes; secondary air inlets are arranged between the upper row of fire holes and the lower row of fire holes. The invention has the advantages of sufficient supply of the primary air and the secondary air, high heating efficiency and low flue gas emission; by the experimental determination, the load of the invention is 3.6KW which is higher than 3.5KW, the carbon monoxide content in the emitting fuel gas is 280PPM which is far lower than 500PPM.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

Catalyst for reducing the content of CO in cigarette smoke and preparation and application thereof

ActiveCN101804356ASimple production processGood storage stabilityPhysical/chemical process catalystsTobacco smoke filtersComposite filterCarbon dioxide

The invention relates to a catalyst for the oxidation of CO under normal temperature, in particular to a catalyst for reducing the content of CO in cigarette smoke and the preparation and the application thereof. The catalyst for reducing the content of CO in cigarette smoke comprises the following components in mass percentage: 0.5 to 3% of PdCl, 5 to 15% of CuCl2, and 65 to 95% of active carbon carrier. The catalyst of the invention has simple production technology, good storage stability and lower production cost. A catalyst suitable for the use in cigarette is provided by using the catalysis method, wherein the carbon monoxide is oxidized to carbon dioxide. The invention provides a catalyst suitable for the use in cigarette, and the produced composite filter tip can reduce the content of carbon monoxide in the main smoke stream of cigarette by 5 to 25%.

Owner:CHINA TOBACCO ZHEJIANG IND

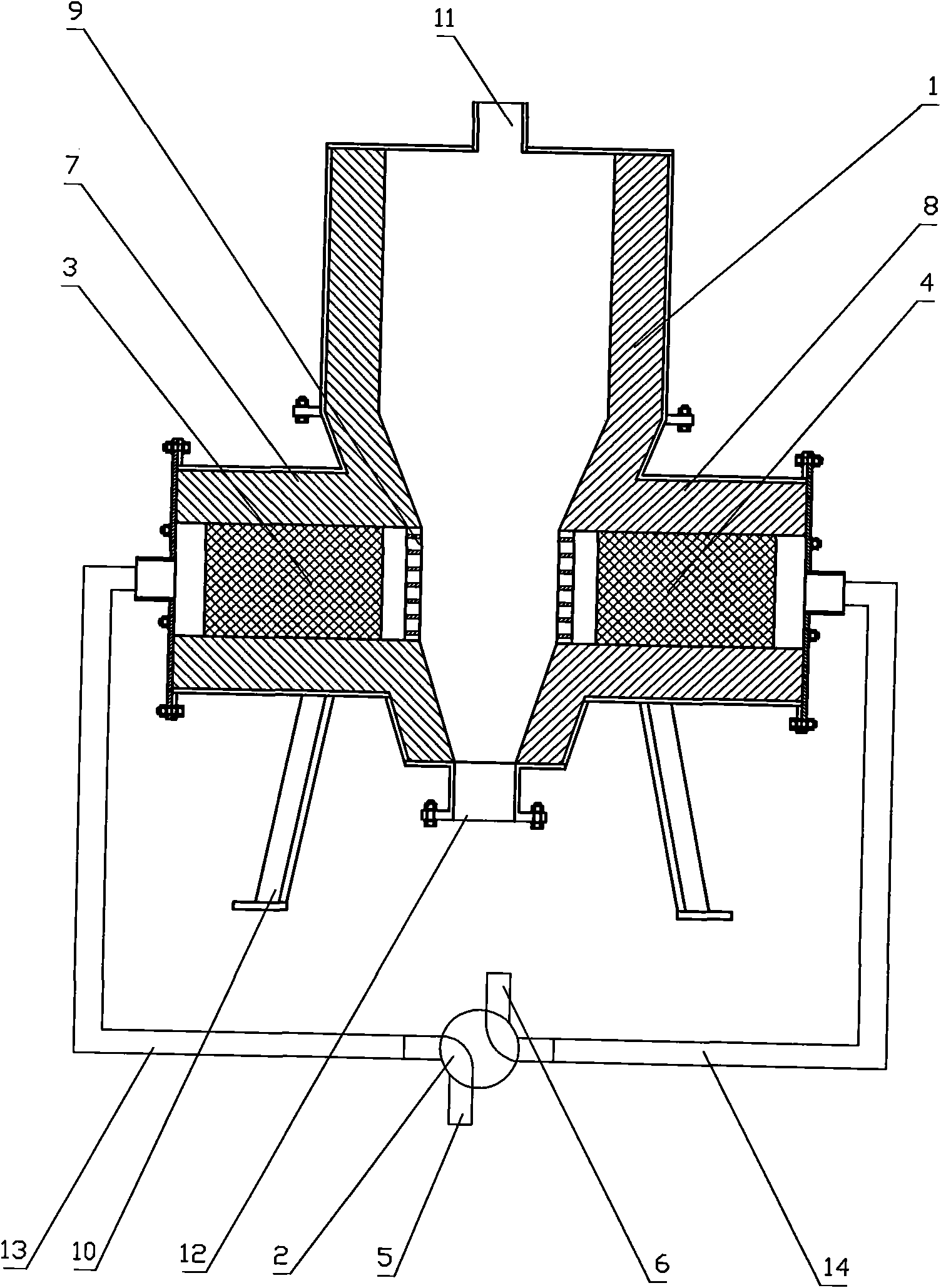

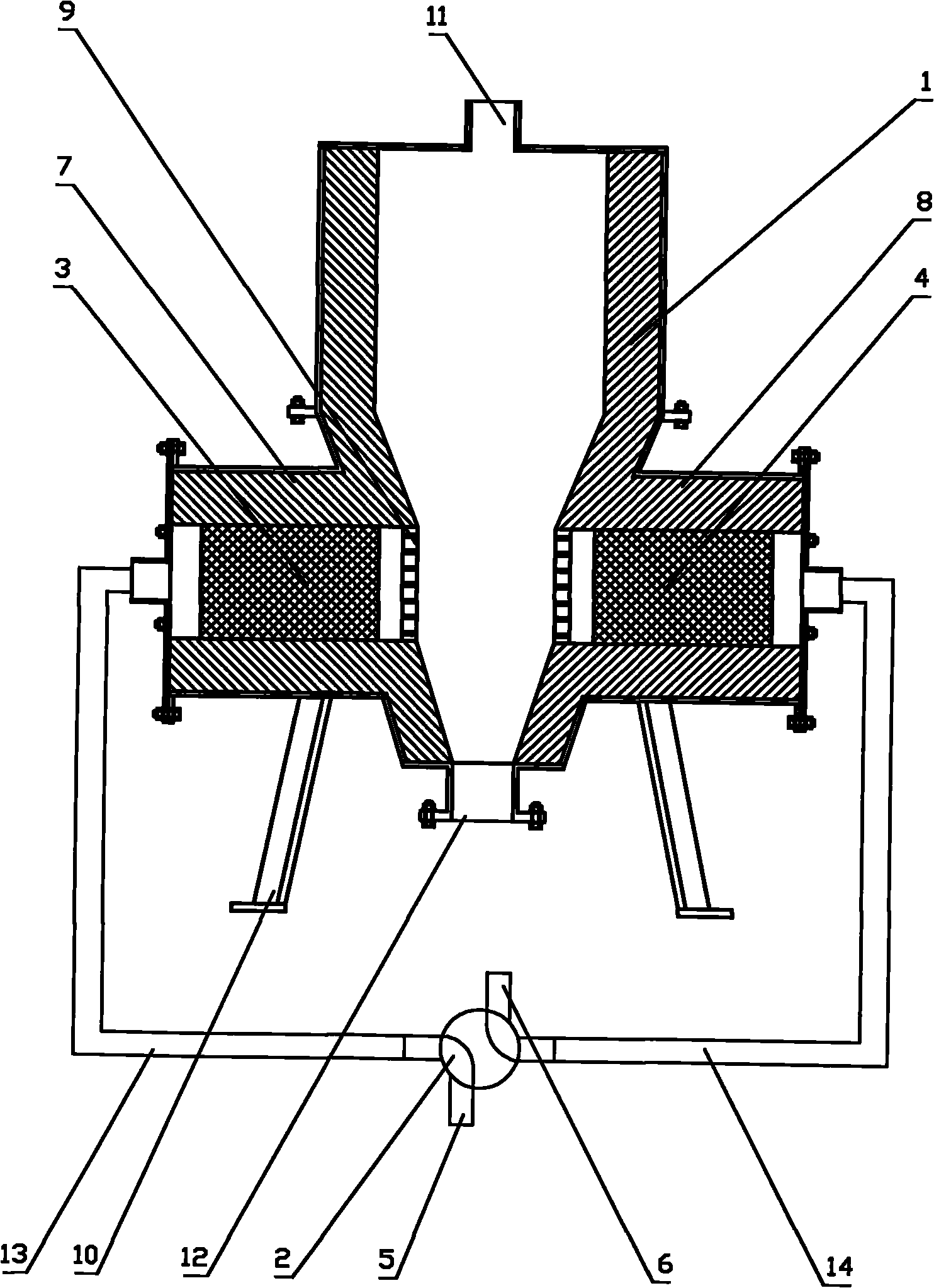

High-temperature solid fuel gasification device

InactiveCN101880550AIncrease temperatureAchieve recyclingEnergy inputCombustible gas productionHoneycombTar

The invention discloses a high-temperature solid fuel gasification device which comprises a hearth body, a four-way changeover valve and a left honeycomb ceramic and a right honeycomb ceramic oppositely arranged at the lower part of the hearth body, wherein one end of the four-way changeover valve is a gasification agent inlet end, one end is a produced gas outlet end, one end of the rest two ends is communicated with the left honeycomb ceramic, and the other end is communicated with the right honeycomb ceramic; and a nickel-based catalyst layer is coated in honeycomb holes of the left honeycomb ceramic and the right honeycomb ceramic. The honeycomb ceramic can stay in two states; when one honeycomb ceramic is heated, the other one is a heating gasification agent. The states of the two honeycomb ceramics are switched through the four-way changeover valve, the waste heat of a produced gas can be recycled smoothly, the gasification agent is heated to increase the temperature of a gasification area in the blast hearth, and the tar content is efficiently reduced. Meanwhile, the retention period of the produced gas can be prolonged, and tar cracking is promoted. The tar in the produced gas can be catalytically cracked by the nickel-based catalyst in the honeycomb ceramics.

Owner:CHONGQING UNIV

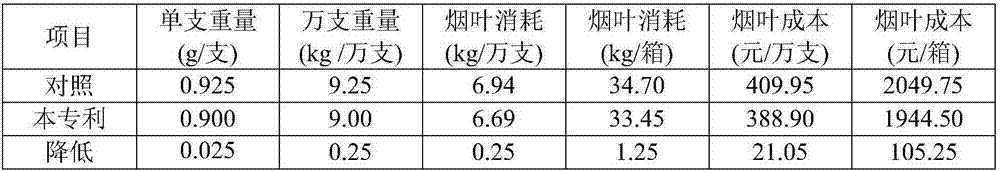

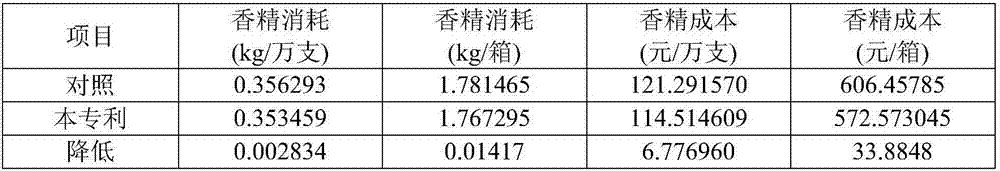

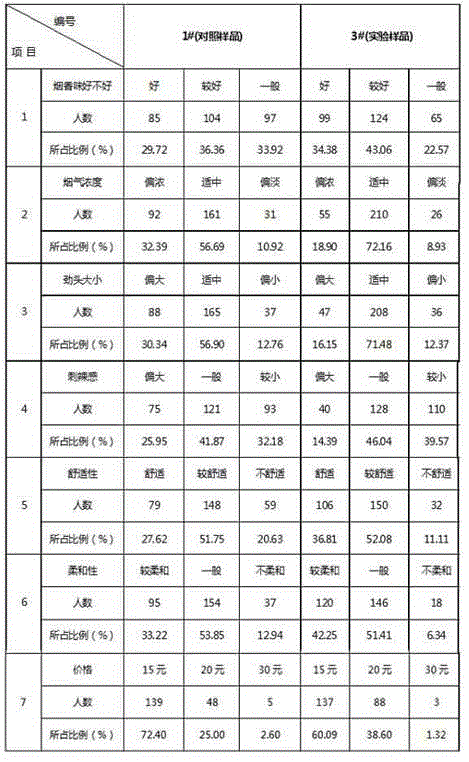

Cigarette formula grouped designing and processing method

The invention discloses a cigarette formula grouped designing and processing method. The cigarette formula grouped designing and processing method comprises the following steps: (1) screening raw materials of an auxiliary formula; (2) carrying out composition design of the auxiliary formula; (3) carrying out feed liquid design of the auxiliary formula; (4) processing tobacco shreds; (5) designingthe ratios of cut tobaccos; and (6) carrying out comparison and verification. In the method, two formulae are adopted, one is the auxiliary formula, the other one is a basic formula, the auxiliary formula adopts the air flow type drying process, and the basic formula adopts the tube-plate type drying process. The cigarette formula grouped designing and processing method has the beneficial effectsthat 1, the flexibility in adjusting the raw materials of the formulae is strong, the raw materials of the formulae can be adjusted by combining with the suitable processing technologies of the raw materials, thus the pertinence and effects of grouped processing are improved, and the improvement for the formulae of the product is facilitated; 2, the features of different processing technologies can be fully exerted, thus the utilization ratio of the raw materials is improved, the consumption of the raw materials is reduced, and the cost of the formulae is reduced; and 3, the tar content of theproduct and the content of carbon monoxide of smoke can be reduced.

Owner:SHANGHAI TOBACCO GRP CO LTD

Exhaust flue cap and filter device for a gas fired appliance

ActiveUS8083574B2Reduce carbon monoxideSmall diameterDispersed particle separationIncinerator apparatusMechanical engineeringFlue

Owner:ARNOLD JOHN G JR

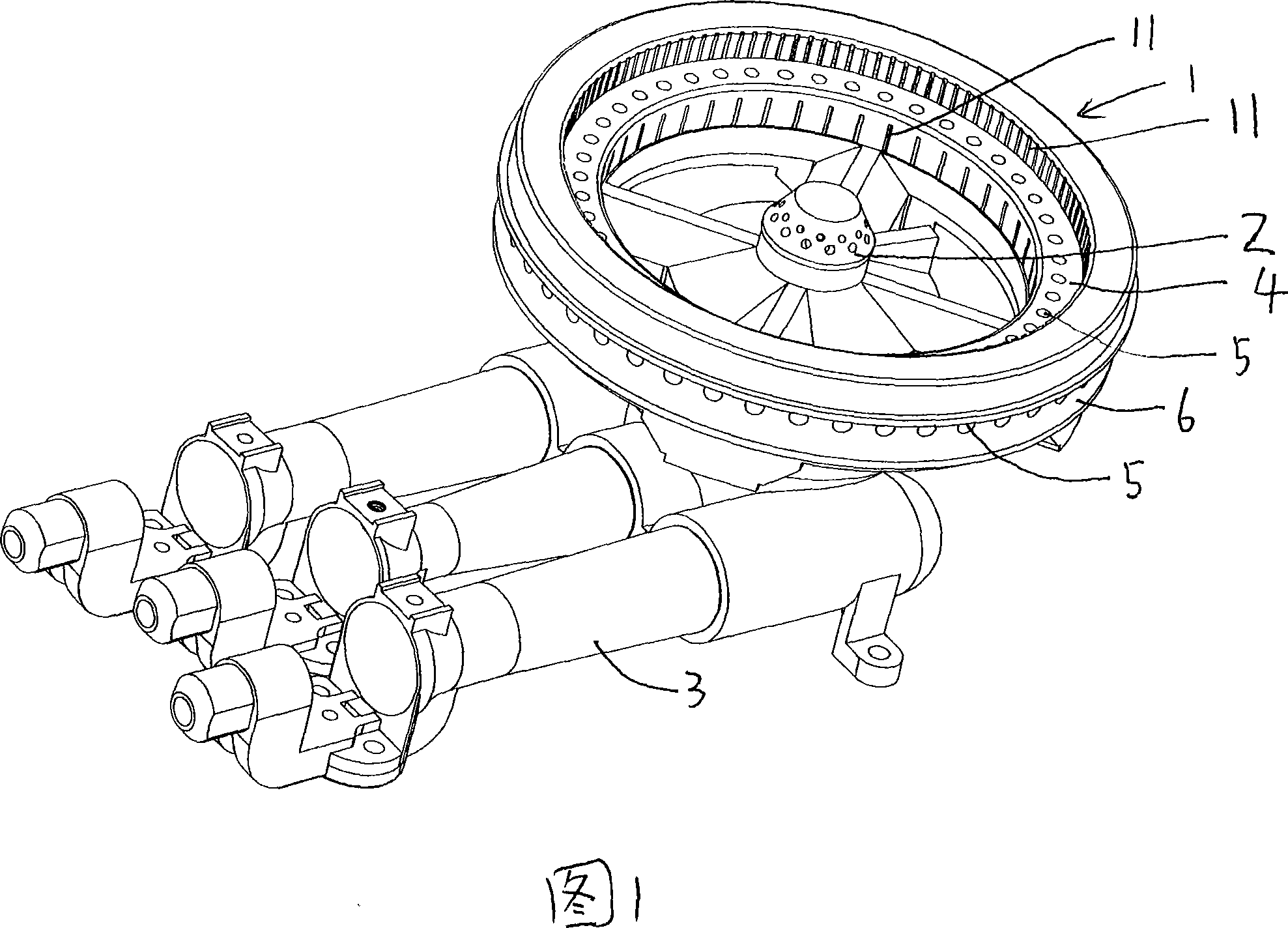

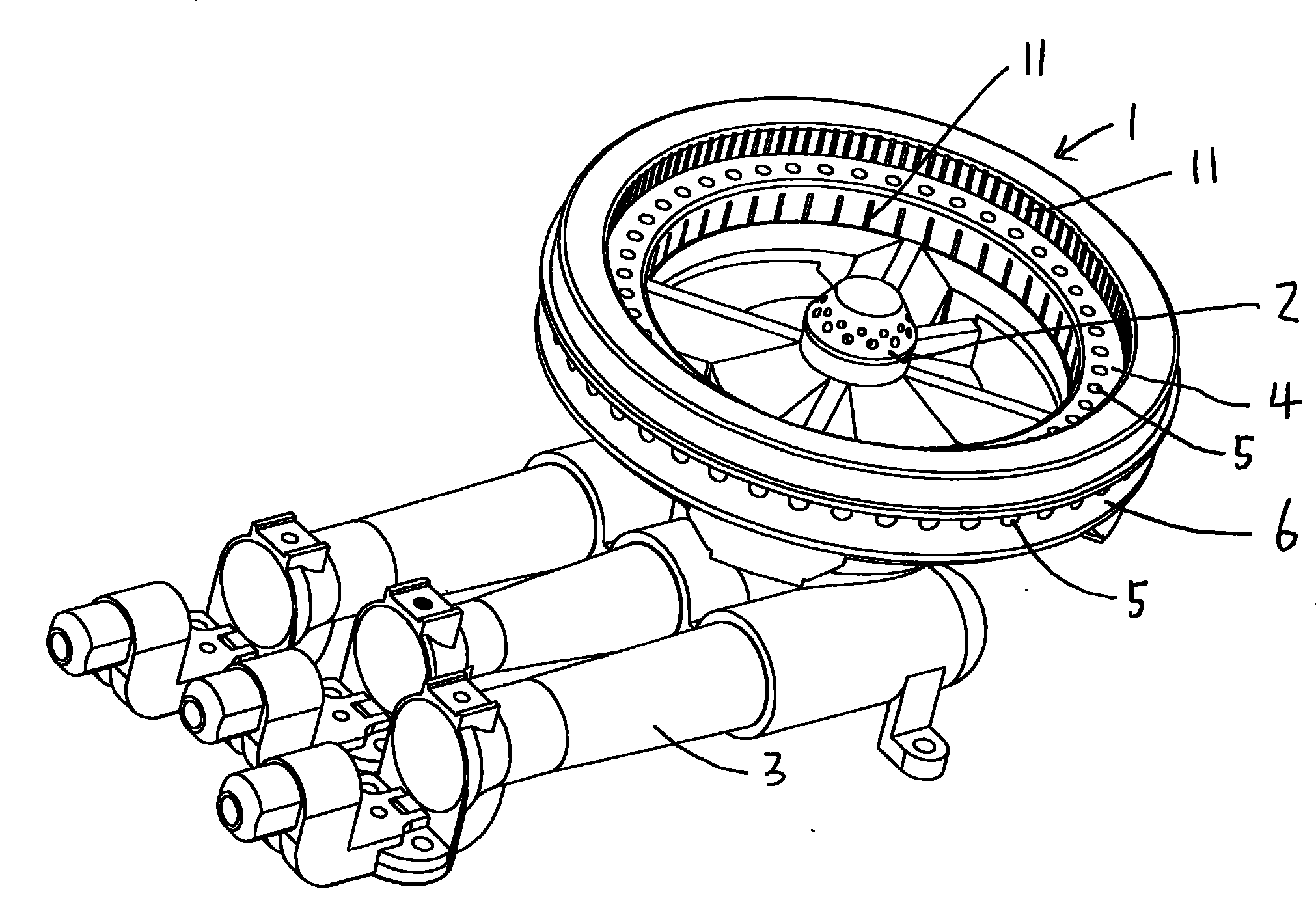

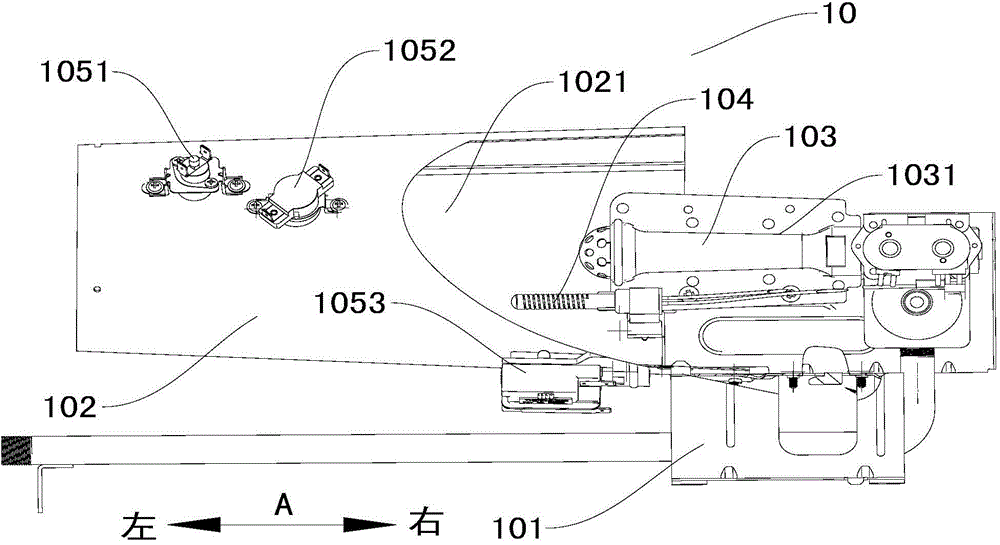

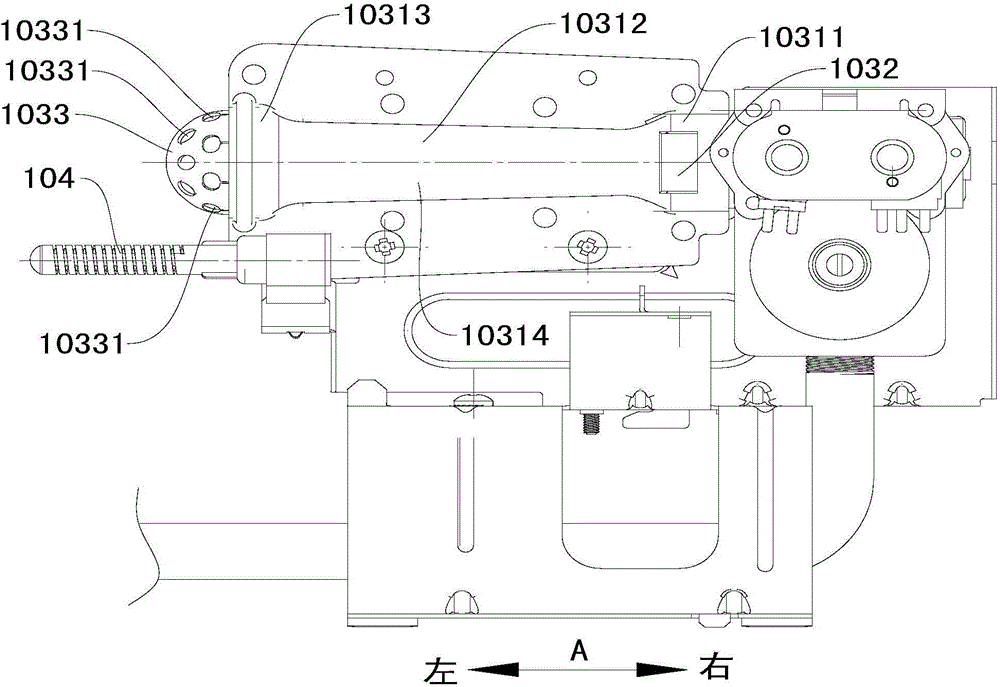

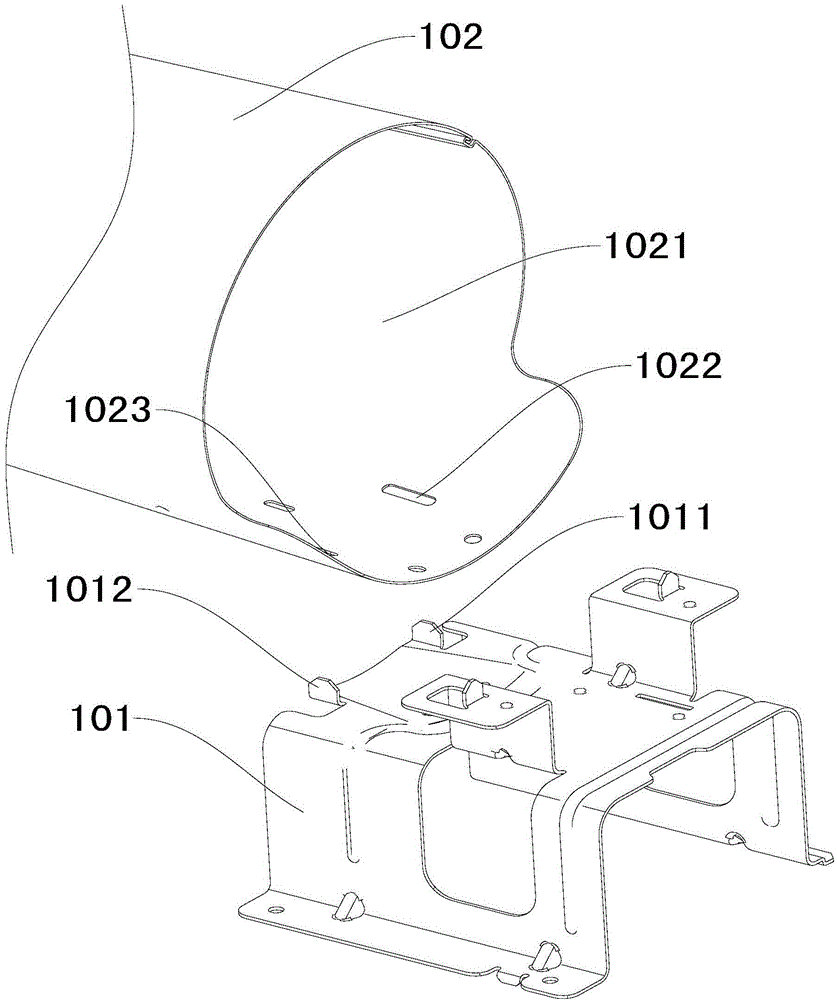

Gas heating system for gas clothes dryer and gas clothes dryer with gas heating system

InactiveCN105780430AImprove combustion efficiencyReduce carbon monoxideTextiles and paperLaundry driersExhaust gasAutomotive engineering

The invention discloses a gas heating system for a gas clothes dryer.The gas heating system comprises a support, a combustion cylinder, a combustor and an ignition needle, wherein the combustion cylinder is arranged on the support and internally provided with a combustion chamber, at least part of the combustor extends into the combustion chamber from the inlet of the combustion chamber, at least part of the ignition needle extends into the combustion chamber from the inlet of the combustion chamber, the central axis of the ignition needle is parallel to the central axis of the combustor, and the distance between the ignition needle and the combustor is larger than or equal to 5 mm and smaller than or equal to 13 mm.The gas heating system has the advantages that combustion efficiency is high, the content of carbon oxide in tail gas is low, and ignition success rate is high.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

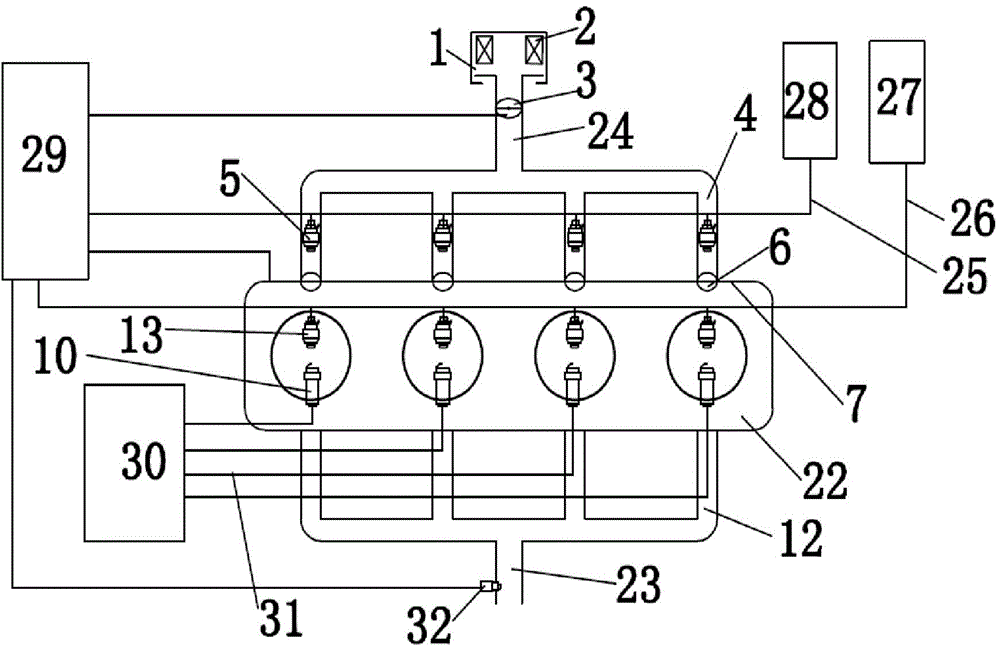

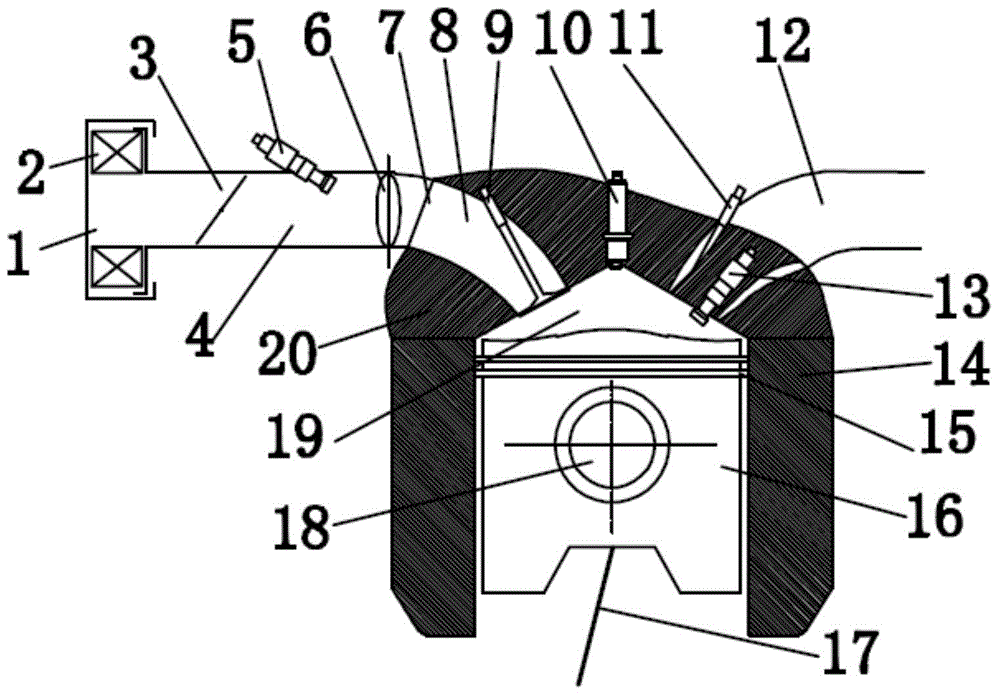

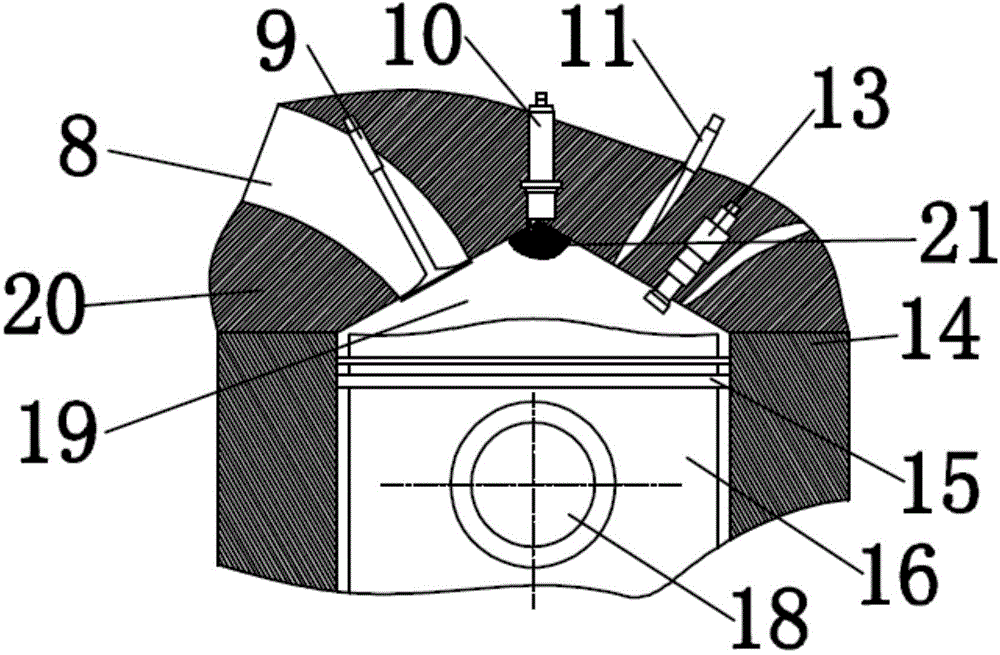

In-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and control method

InactiveCN104948296ASatisfy lean burn requirementsChange the disadvantage of lack of powerElectrical controlInternal combustion piston enginesInlet channelCombustion

The invention relates to an in-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and a control method, aims to solve the problems that combustion is unstable in an ultra-lean-combustion mode of a gas fuel spark ignition type internal combustion engine, the oil consumption is high and emission is heavy under the work conditions of cold start and small load and the like and develops a spark ignition type in-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and a control method of the internal combustion engine. The internal combustion engine adopts an internal combustion engine technology combining in-cylinder direct injection and gas inlet channel injection based on double gas fuel, the internal combustion engine is provided with a gas flow control device which cooperates with a piston roof in a special shape, and accordingly, good mixed gas layering is realized. According to the special combustion characteristic of gas fuel, ultra-lean mixed gas in higher compression ratio can be adopted; gas flow movement of the mixed gas entering a cylinder is controlled, meanwhile, gas inflow is increased, ultra-lean combustion of the mixed gas in the cylinder is realized, the heat transfer loss is reduced, the heat efficiency is improved, and oil consumption and pollutants are reduced.

Owner:JILIN UNIV

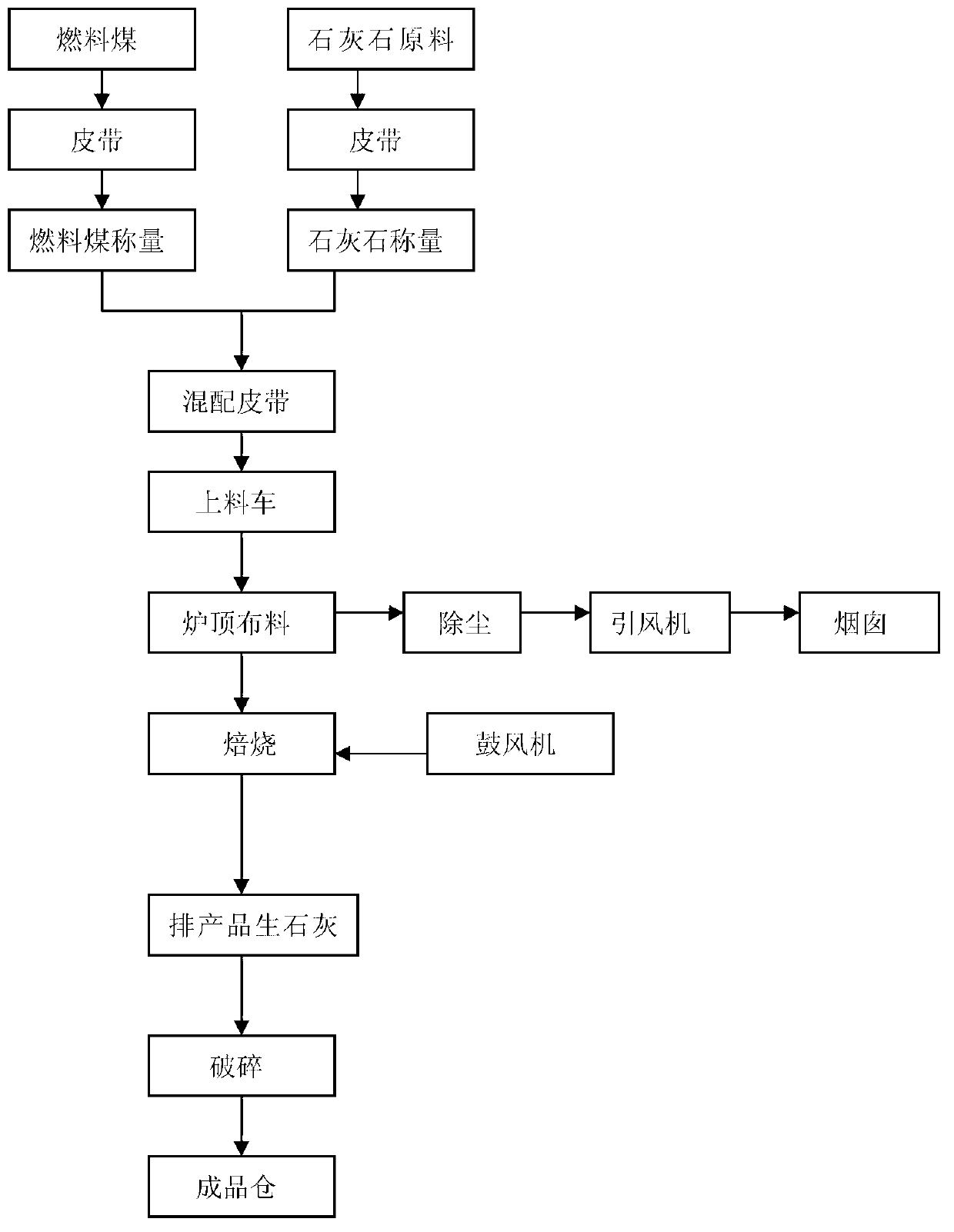

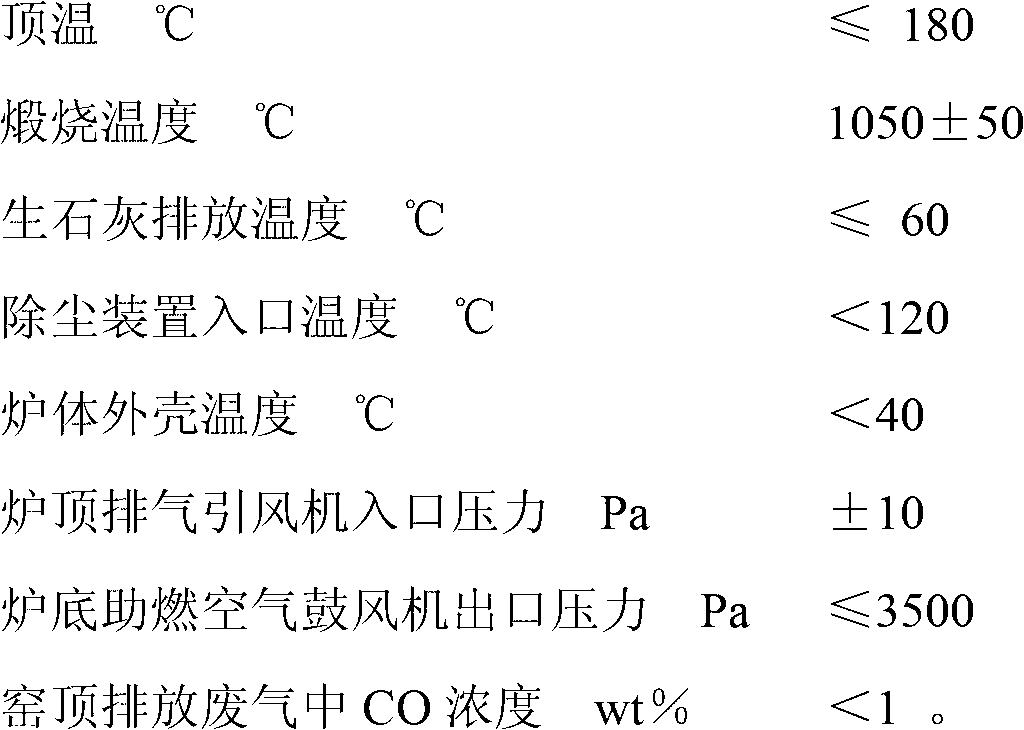

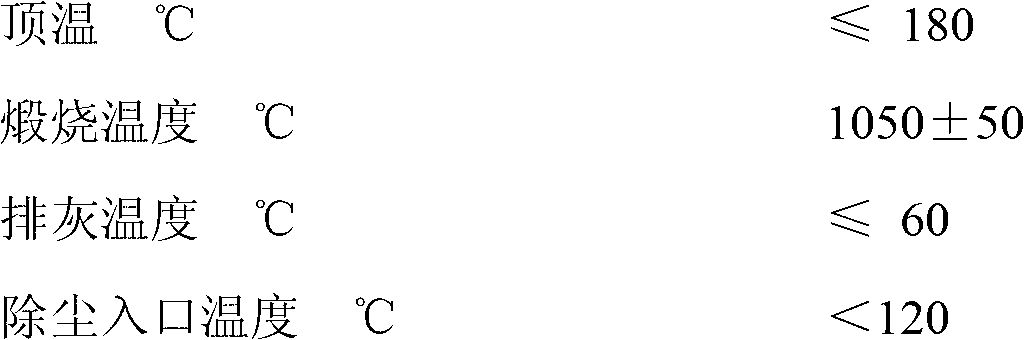

Method for preparing quicklime by continuously calcining limestone in shaft kiln

InactiveCN102815876AImprove thermal efficiencyReduce consumptionLime productionThermal energyCombustion

The invention relates to a method for preparing quicklime by continuously calcining limestone in a shaft kiln, belonging to a method for preparing quicklime by calcining limestone in a shaft kiln. The method is provided with a computer centralized control system, and implements the following steps according to a preset program: (1) while automatically controlling gas flow and pressure of kiln bottom combustion-supporting blast air and kiln top exhaust induced air, continuously calcining; (2) automatically discharging qualified calcining product quicklime in a periodical and discontinuous way; and (3) evenly mixing the raw material limestone and fuel coal according to a preset ratio, and automatically supplementing synchronous with the discharged product in a periodical and discontinuous way. The method provided by the invention has the advantages of high raw material coal heat efficiency, low consumption, stable operating conditions and low production cost. The heat efficiency of the fuel coal is greater than or equal to 80%. The heat utilization ratio is enhanced by more than 20% as compared with the prior art. The quality indexes the product quicklime are as follows: CaO>=94%, MgO<=3%, SiO2<=2%, and discretionary reduction<=10%. The consumption of the raw material coal is lowered, i.e. every ton of product quicklime consumes 115-120kg of fuel coal.

Owner:张金永

Biomass clean gasoline

InactiveCN102161917ARatio increaseReduced blending ratioLiquid carbonaceous fuelsEngineeringMethanol

The invention discloses biomass clean gasoline and a preparation method thereof. The biomass clean gasoline is characterized by consisting of biological methanol, national standard gasoline or crude gasoline and auxiliaries (heat value synergist, combustion-supporting smoke-removing agent, stabilizer and the like). The preparation method of the biomass clean gasoline is performed at room temperature and normal pressure and has simple operation process is simple; raw material source is wide and cannot be exhausted, cost is low, the engine and other parts of the existing automobile do not need to be modified or updated, igniting property is good, starting is easy, the emission of tail gas reaches national standard and Europe standard III, the content of carbon monoxide is reduced by 98%, the content of a hydrocarbon compound is reduced by 30-40.5%, and the mark number can reach 90-120 standard.

Owner:雷菊花

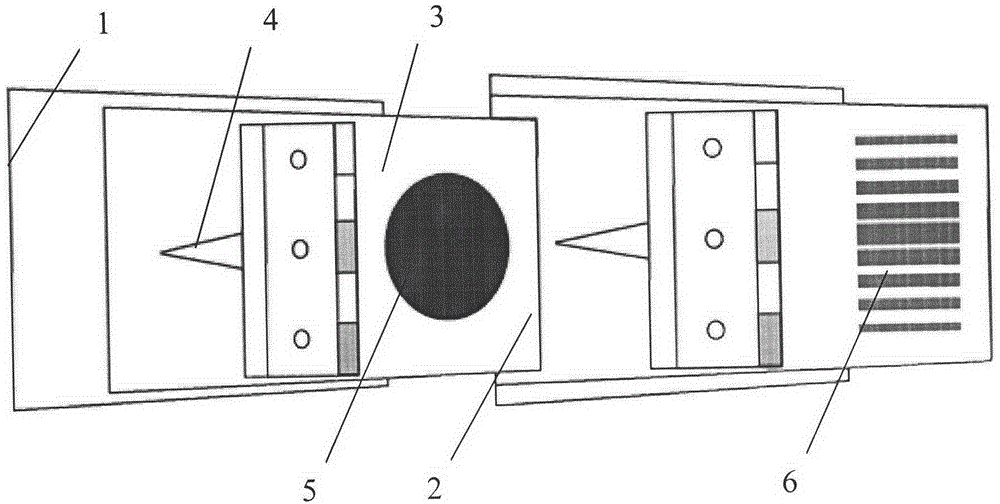

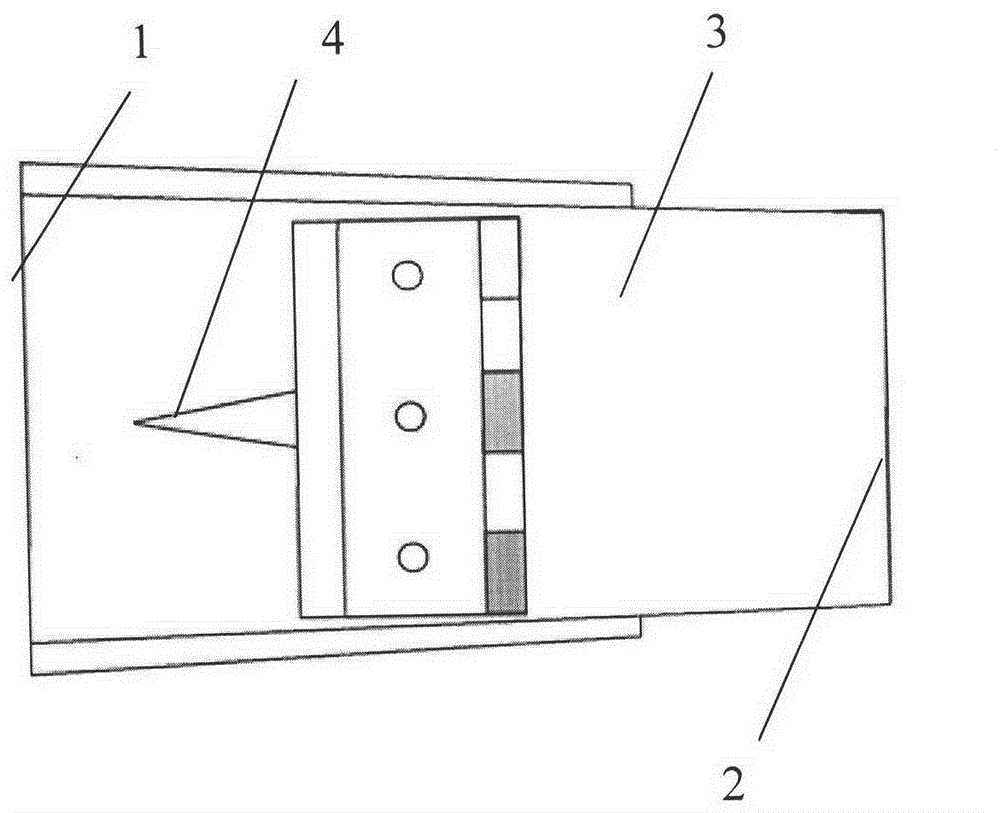

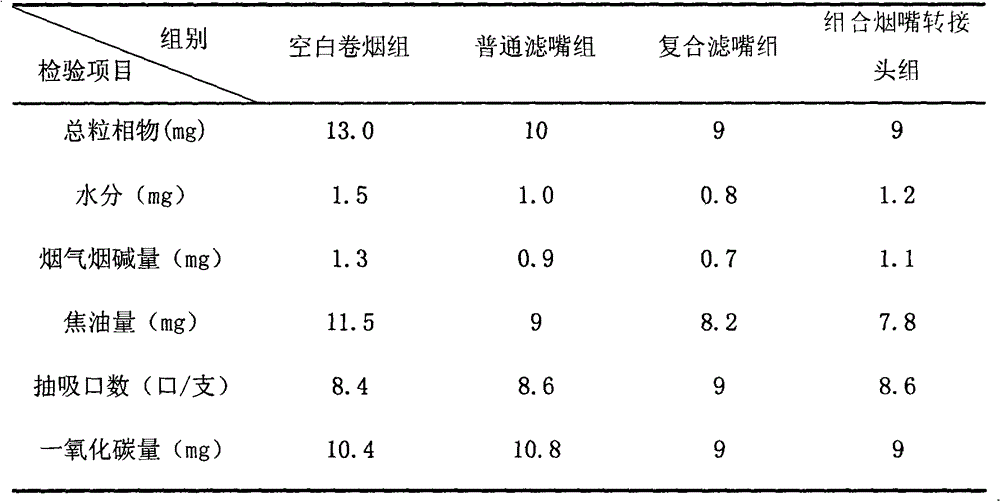

Combined cigarette holder adapter

ActiveCN102907762ARich aroma and smoking comfortProtect your healthTobacco pipesEngineeringTobacco pipe

A combined cigarette holder adapter comprises two or more than two adapter units; an opening I and an opening II are formed at two ends of each adapter unit respectively; an accomodating cavity is arranged at the middle of each adapter unit; and the adapter units can be connected with or separated from one another. According to the invention, the adapter units with different functions can be used in a combined or separated manner, so that not only can harmful components of cigarettes be reduced systematically and specifically in a segmental manner, but also cigarettes can be perfumed segmentally according to personal taste and smoking habits, and the indigenous perfume and smoking comfort degree of the cigarettes can be enriched. The combined cigarette holder adapter provided by the invention has very strong compatibility, can be used with other cigarette holders, mouthpieces or tobacco pipes, can be conveniently used in a combined or separated manner, greatly improves comfort and safety of cigarettes, and increases personalized taste of cigarettes.

Owner:陈东

Combustor and fuel gas stove

ActiveCN106090920AHinder outflowImprove combustion efficiencyDomestic stoves or rangesGaseous fuel burnerInlet channelCombustor

The invention discloses a combustor and a fuel gas stove. The combustor comprises a fire distributor and a fire cover. The fire distributor is provided with a gas inlet channel. The fire cover is arranged on the fire distributor. A flow guide convex face is formed on the fire cover and faces towards the gas inlet channel. In the combustor, due to the fact that the flow guide convex face is arranged above the gas inlet channel, when fuel gas flows to the flow guide convex face from the gas inlet channel, fuel gas is rapidly guided to the periphery of the flow guide convex face under the effect of the flow guide convex face, the reaction of the fire cover on gas flow is reduced, the problem that fuel gas flows to the fire cover and then backflows into the gas inlet channel to prevent fuel gas from flowing out of the gas inlet channel is avoided, and therefore the fuel gas pressure loss can be reduced. In this way, the practical heat load of the combustor is approximate to the designed heat load to the largest degree, combustion efficiency of fuel gas is improved, and the content of carbon monoxide produced during combustion of fuel gas is reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

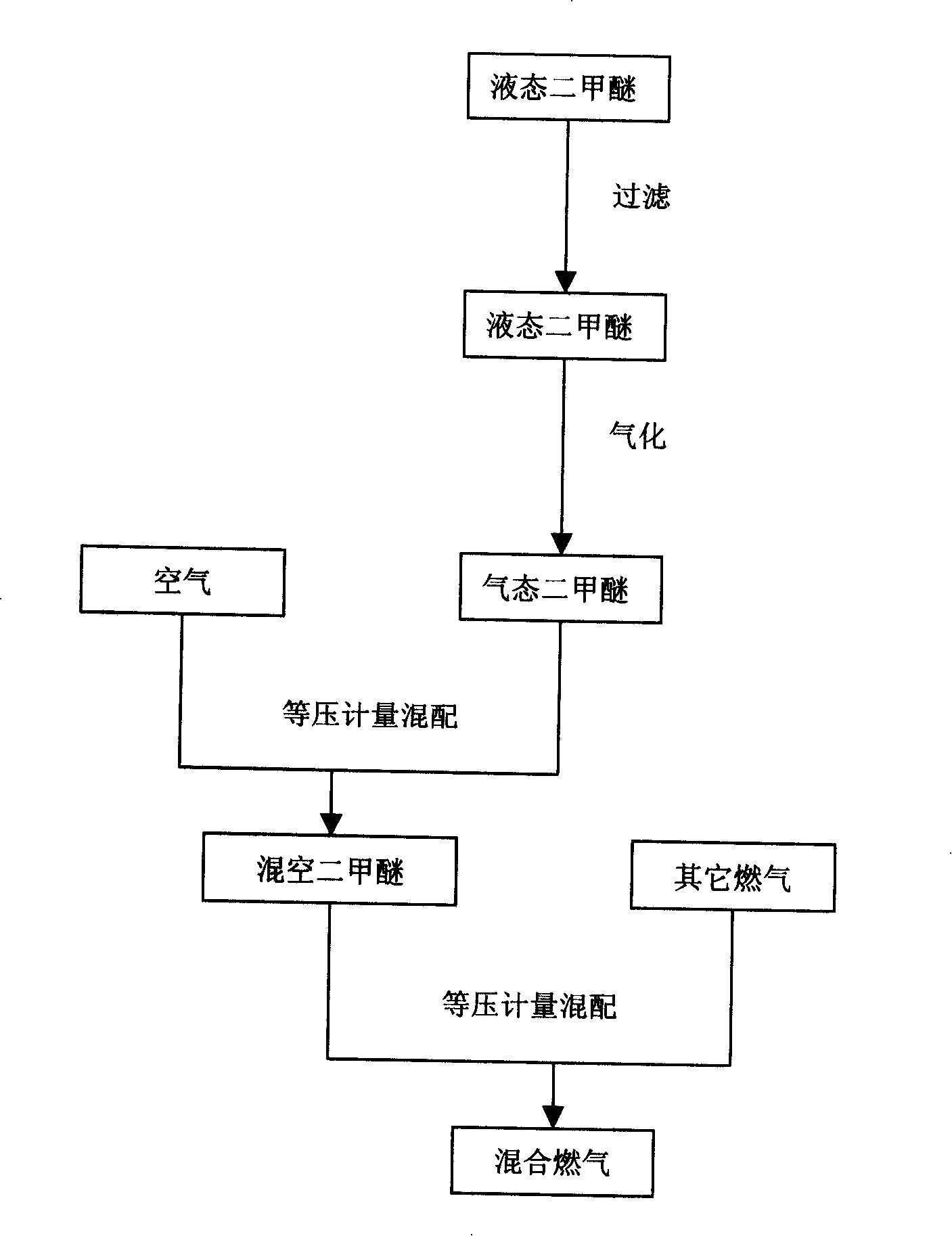

Mixed flue gas blendedwith air and dimethyl ether and preparation method thereof

A mixture gas mixed with air-mixed dimethyl ether is prepared by mixing 10 to 40%vol air-mixed dimethyl ether with 60 to 90%vol other gases, wherein the air-mixed dimethyl ether is prepared by mixing 50 to 70%vol dimethyl ether with 30 to 50%vol air. The preparation method of the mixture gas comprises the following steps of: filtering the liquid dimethyl ether to remove impurities, feeding the filtered liquid dimethyl ether into a thermal-compensation vaporizer for vaporization, mixing the vaporized dimethyl ether with air at equal pressure to obtain air-mixed dimethyl ethyl, and mixing the air-mixed dimethyl ethyl with other gases at equal pressure to obtain the mixture gas. By mixing the air-mixed dimethyl ethyl, the mixture gas of the invention has effectively improved heat value and supply amount, which provides an effective path for relieving the current energy crisis condition.

Owner:SHANGHAI LIANXIANG REAL ESTATE

Preparation method of papermaking-process reconstituted tobaccos capable of reducing content of CO in mainstream smoke

ActiveCN104013096AStrong adaptability of production processReduce carbon monoxideTobacco preparationAlcoholPapermaking

The invention relates to a preparation method of papermaking-process reconstituted tobaccos capable of reducing the content of CO in mainstream smoke. The CO release amount of papermaking-process reconstituted tobacco products produced at home and abroad is relatively high and basically the same as that of pure tobacco shreds, and even is greatly higher than that of the tobacco shreds. The preparation method comprises the following steps: soaking lalang grass rhizome in cold water, boiling, filtering to obtain a crude extract of lalang grass rhizome, soaking the crude extract in the cold water, and continuously repeating the step for three times to obtain a final crude extract of lalang grass rhizome; processing the final crude extract of lalang grass rhizome obtained in the step 1 by adopting an alcohol-water method to obtain a fine extract of lalang grass rhizome; mixing the fine extract of lalang grass rhizome, a tobacco flavoring module and tobacco raw material concentrated liquid according to a ratio of 2 : 1 : 12 to obtain coating liquid, and coating a papermaking substrate with the coating liquid to prepare the functional papermaking-process reconstituted tobaccos. The content of CO in the mainstream smoke of a cigarette containing the functional papermaking-process reconstituted tobaccos can be reduced to 1.0mg / cigarette.

Owner:CHINA TOBACCO SHAANXI IND

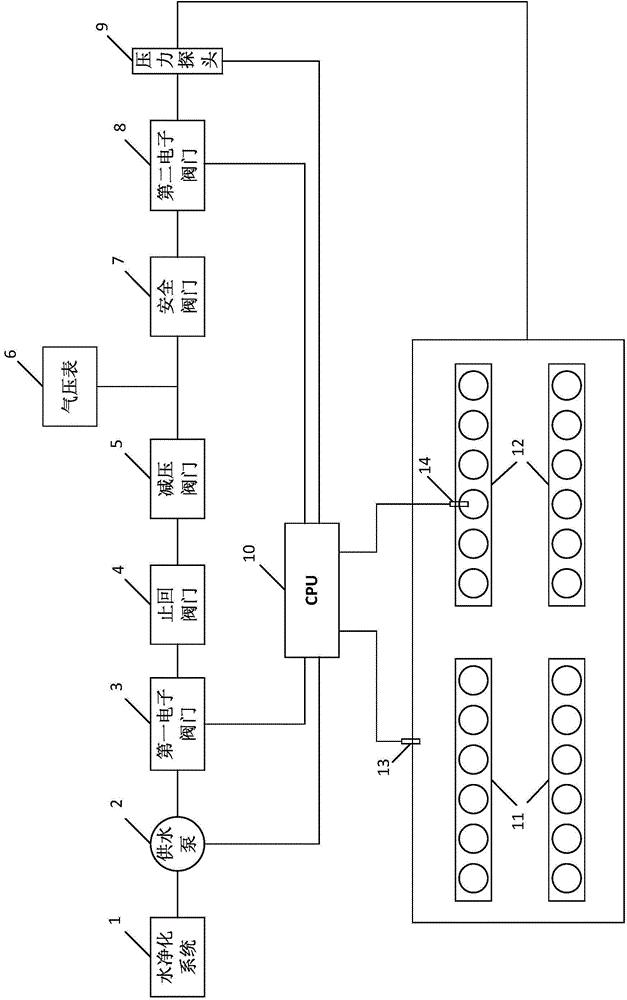

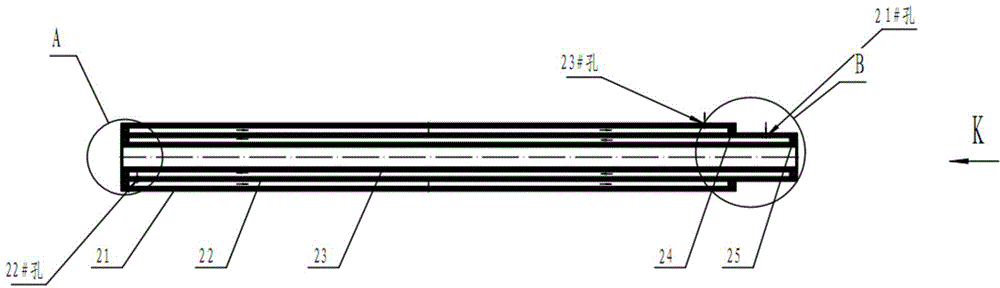

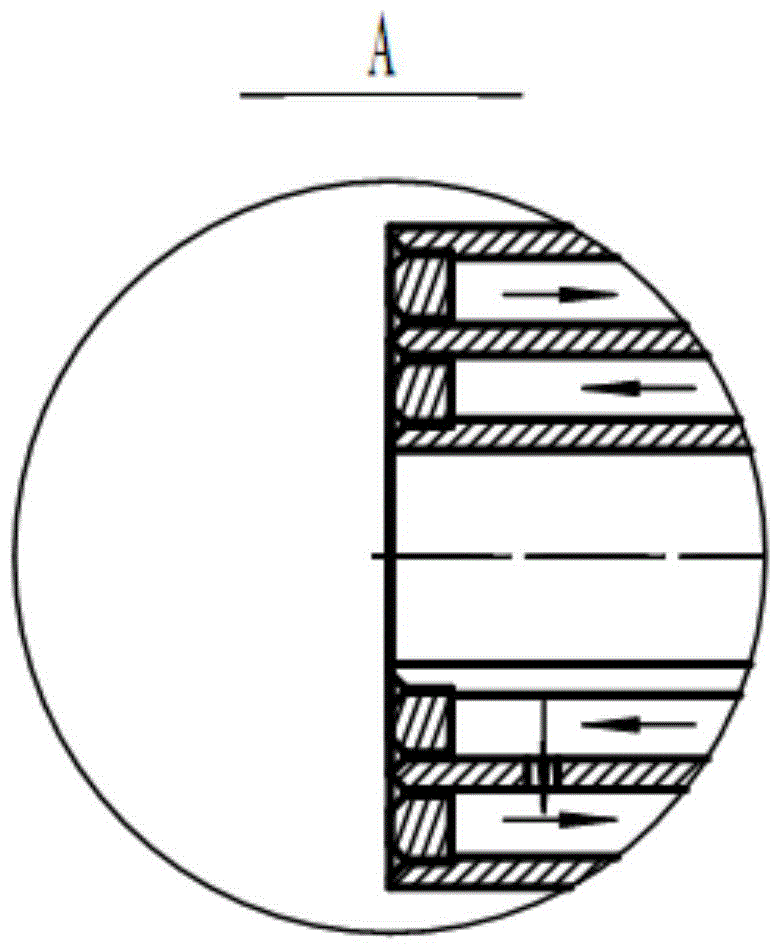

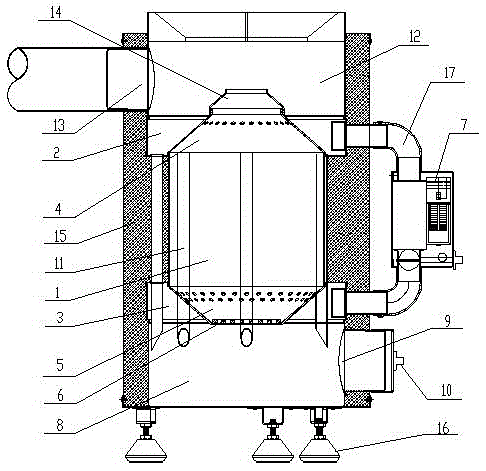

Energy-efficient environment-friendly boiler equipment and energy-saving treatment method

ActiveCN104315495ANo need to change the subjectNo need to change the structureBoiler controlSteam boilersCombustion chamberChemical reaction

The invention provides energy-efficient environment-friendly boiler equipment. A water purification system, a water supply pump, a first electronic valve, a check valve, a pressure reduction valve, a safety valve, a second electronic valve, a water supply pipeline pressure probe and a boiler are arranged on a water supply pipeline. A control system controls the first electronic valve and the second electronic valve to open and close fittingly, the water supply pipeline pressure probe provides real-time pressure data to the control system, and the control system controls starting, stopping and rotation speed of the water supply pump. An evaporator and a superheater are arranged in the boiler; the evaporator makes use of air heat of a combustion chamber to generate water vapor by heating liquid water and supplies the water vapor to the superheater; the superheater makes use of flame heat of the combustion chamber of the boiler to generate oxyhydrogen plasmas and superheated water vapor by subjecting the water vapor to superheating retreatment, and the generated oxyhydrogen plasmas and superheated water vapor are jetted to a coal layer in the boiler through a jet pipe and then chemically react with coal to generate carbon monoxide and hydrogen so as to form efficient and clean gaseous combustion in the combustion chamber.

Owner:徐泽蛟

Fuel additive

InactiveCN101955820AFacilitate the combustion reactionBurn completelyLiquid carbonaceous fuelsFuel additivesExhaust gasButanol

The invention relates to a fuel additive which comprises the following components of ethanol, tertiary butanol, benzoic acid, distilled water, molybdenyl dialkyl dithiophosphate, copper diisooctyl dithiophosphate and benzotriazole fatty amine. After the fuel additive is mixed with internal combustion engine fuel in an internal combustion engine, the fuel can react rapidly and can combust completely in combustion, the content of carbon oxide in exhaust tail gas is greatly reduced, the abrasion between cylinders and pistons is reduced, and fuel is saved.

Owner:北京奈特通达科技发展有限责任公司

Method for preparing far infrared ceramic honeycomb type anti-high temperature energy saving furnace plate

The present invention discloses the preparation process of far infrared ceramic honeycomb type heat resisting energy saving furnace plate and belongs to the field of environment friendly energy saving product technology. The materials comprising silica 58-78wt%, alumina 16.9-25.5wt%, potassium oxide 1-5wt%, zirconium oxide 1-3 wt%, titania 0.1-0.5 wt%, sodium oxide 1-3wt% and calcium oxide 2-5wt% are produced into the far infrared ceramic honeycomb type heat resisting energy saving furnace plate through mixing, high temperature sintering and cooling. The present invention can convert peripheral far infrared heat energy into useful energy, and this can reduce the consumption of coal gas and natural gas greatly.

Owner:寇莉祯 +1

Upper combustion and balanced oxygen supply type biomass particle cooking furnace

InactiveCN105650685ABurn fullyFierce fireDomestic stoves or rangesLighting and heating apparatusCarbon oxideEngineering

The invention discloses an upper combustion and balanced oxygen supply type biomass particle cooking furnace. The upper combustion and balanced oxygen supply type biomass particle cooking furnace comprises a combustion hearth containing cavity arranged inside the furnace wall; a secondary air inlet sleeve containing cavity is arranged at the upper end of the combustion hearth containing cavity in a communicating mode; a primary air inlet sleeve containing cavity is arranged at the lower end of the combustion hearth containing cavity in a communicating mode; a combustion hearth with an upper opening and a lower opening is arranged inside the combustion hearth containing cavity; a secondary air inlet sleeve with an upper opening and a lower opening is arranged inside the secondary air inlet sleeve containing cavity; air inlet holes are evenly formed in the secondary air inlet sleeve in the circumferential direction; a primary air inlet sleeve with an upper opening and a lower opening is arranged inside the primary air inlet sleeve containing cavity; multiple circles of streamline air inlet holes are formed in the primary air inlet sleeve in the circumferential direction; the lower opening of the primary air inlet sleeve is closed by a fire grate; and a draught fan communicates with the secondary air inlet sleeve containing cavity and the primary air inlet sleeve containing cavity through air flues correspondingly. Biomass particles are combusted sufficiently, fire is strong, the combustion time is long, the content of carbon oxide in exhausted smoke gas is low, and energy conservation and environmental protection of combustion of biomass particle fuel are achieved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Environmental protection energy saving methanol gasoline

InactiveCN1167773CGood storage stabilityReduce the presence of hazardous substancesLiquid carbonaceous fuelsSolubilityCombustion

An environment-protection and energy-saving methanol gasoline is prepared from methanol (60-70 wt.%), crude gasoline (25-38) and special composite additive (2-7) while can improve the solubility, anticorrosion nature, and burning performance. Its advantages are high stability, full combustion, high power, and saving oil by 15-20%.

Owner:蓝鸿泽 +1

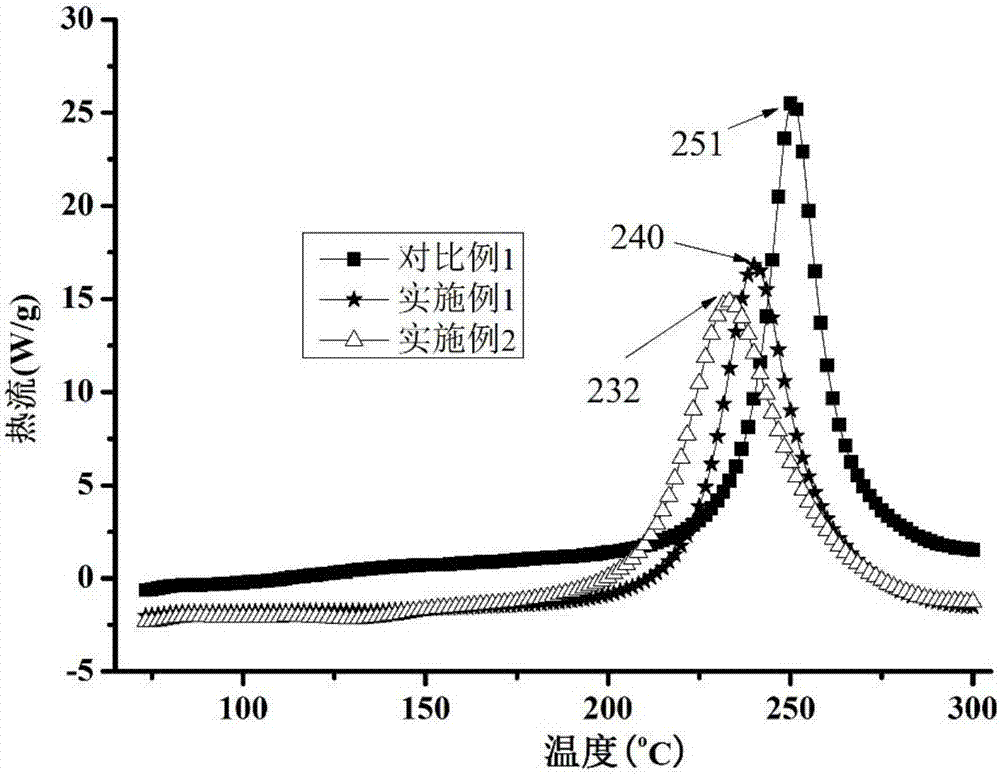

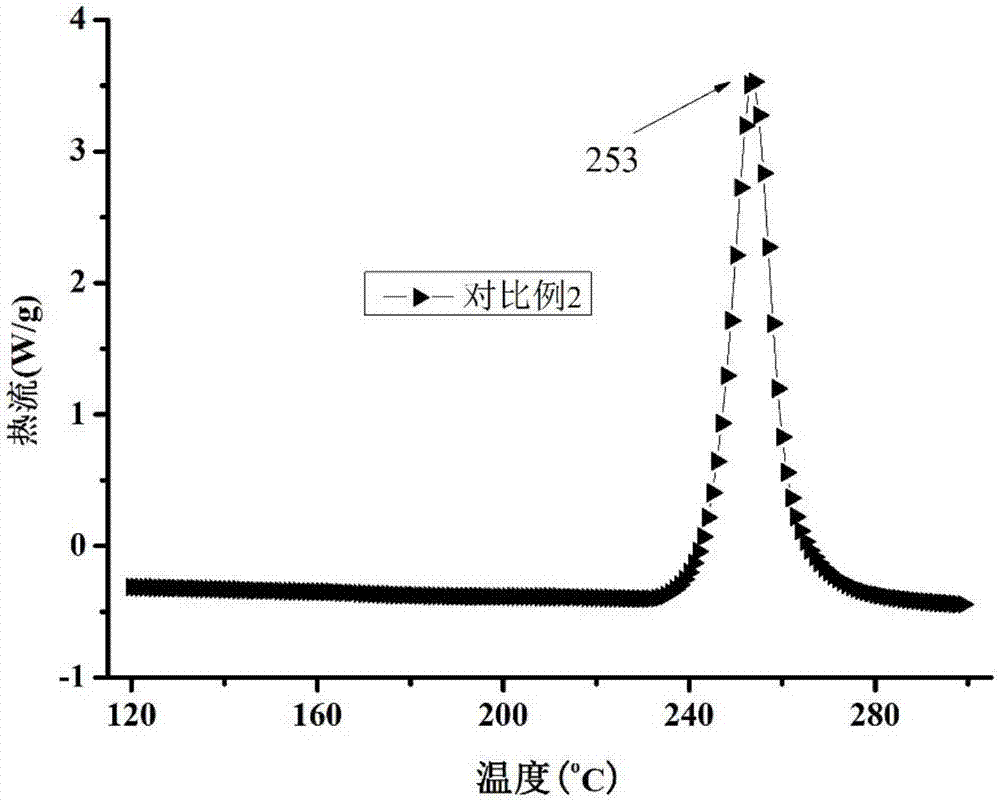

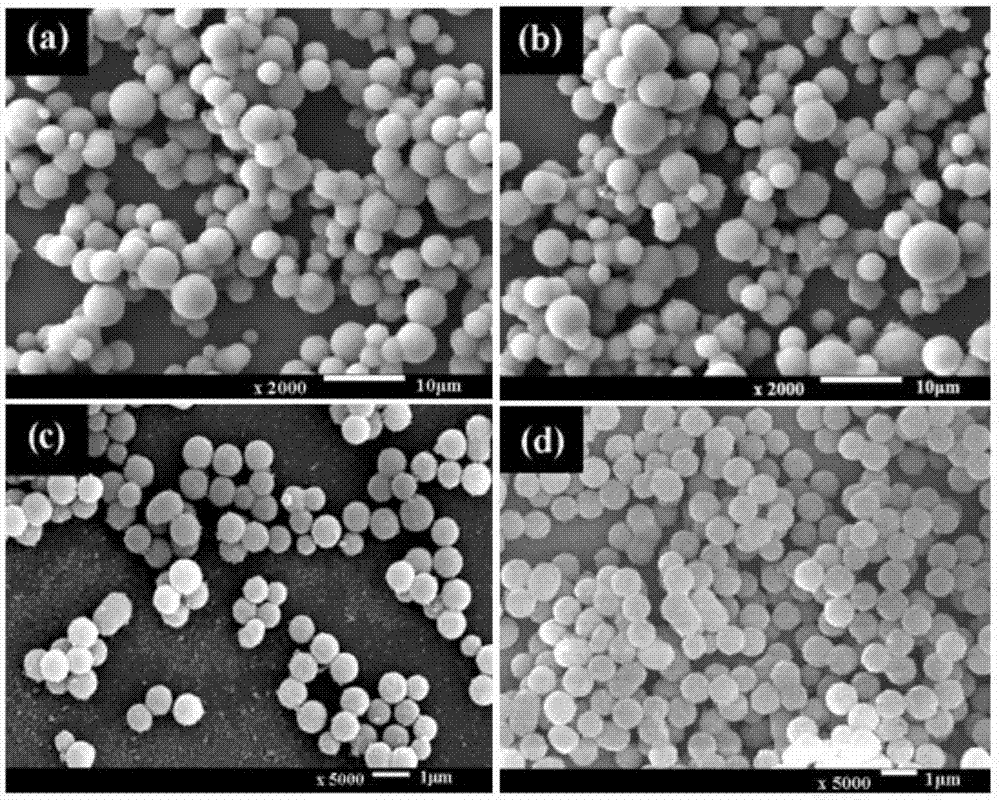

Multifunctional benzoxazine composite material and preparation method thereof

ActiveCN107474208AReduce the ring-opening polymerization temperatureReduce consumption costAlcoholPolyphosphazene

The invention discloses a multifunctional benzoxazine composite material. The multifunctional benzoxazine composite material is prepared from benzoxazine monomers through an open-loop curing reaction under the catalytic action of sulfonated crosslinking structured polyphosphazene microspheres. A preparation method comprises steps as follows: S1, the sulfonated crosslinking structured polyphosphazene microspheres are prepared; S2, the benzoxazine monomers are dissolved in solvents, the sulfonated crosslinking structured polyphosphazene microspheres are added, and a mixture is subjected to ultrasonic dispersion; S3, acetone and alcohol as the solvents are removed through evaporation, and air in the mixture is removed; S4, the mixture of the benzoxazine monomers and the sulfonated crosslinking structured polyphosphazene microspheres is poured into a glass mold while being still hot; S5, the glass mold is cured for 2-3 h at the temperature of 150-180 DEG C, cured for 1-3 h at the temperature of 190-200 DEG C and cooled, and the multifunctional benzoxazine composite material is obtained. The open-loop curing temperature of the benzoxazine monomers in the preparation process of the composite material is reduced, and the composite material integrates remarkable flame retardance and good fracture toughness property, thereby being widely applied to the field with higher requirements for overall performance of the materials.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com