Patents

Literature

69 results about "Pipe Tobacco" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

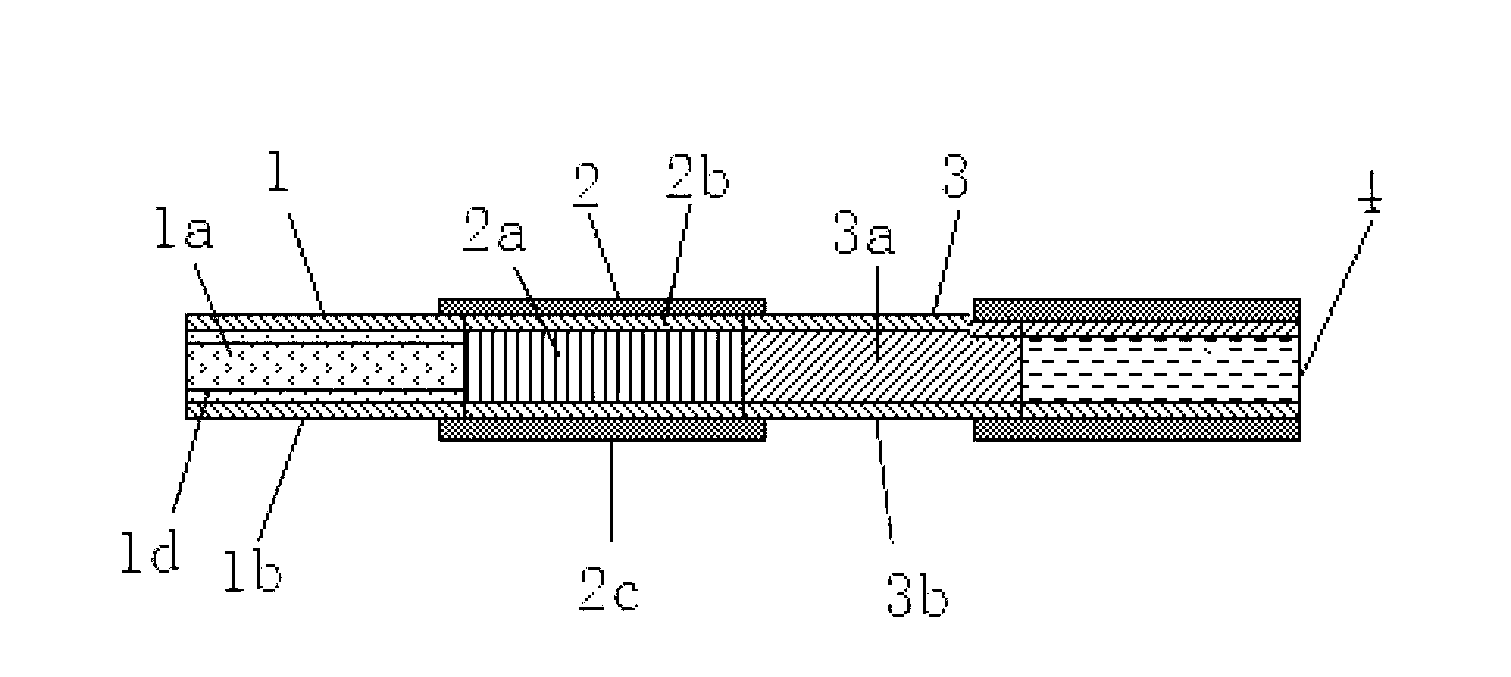

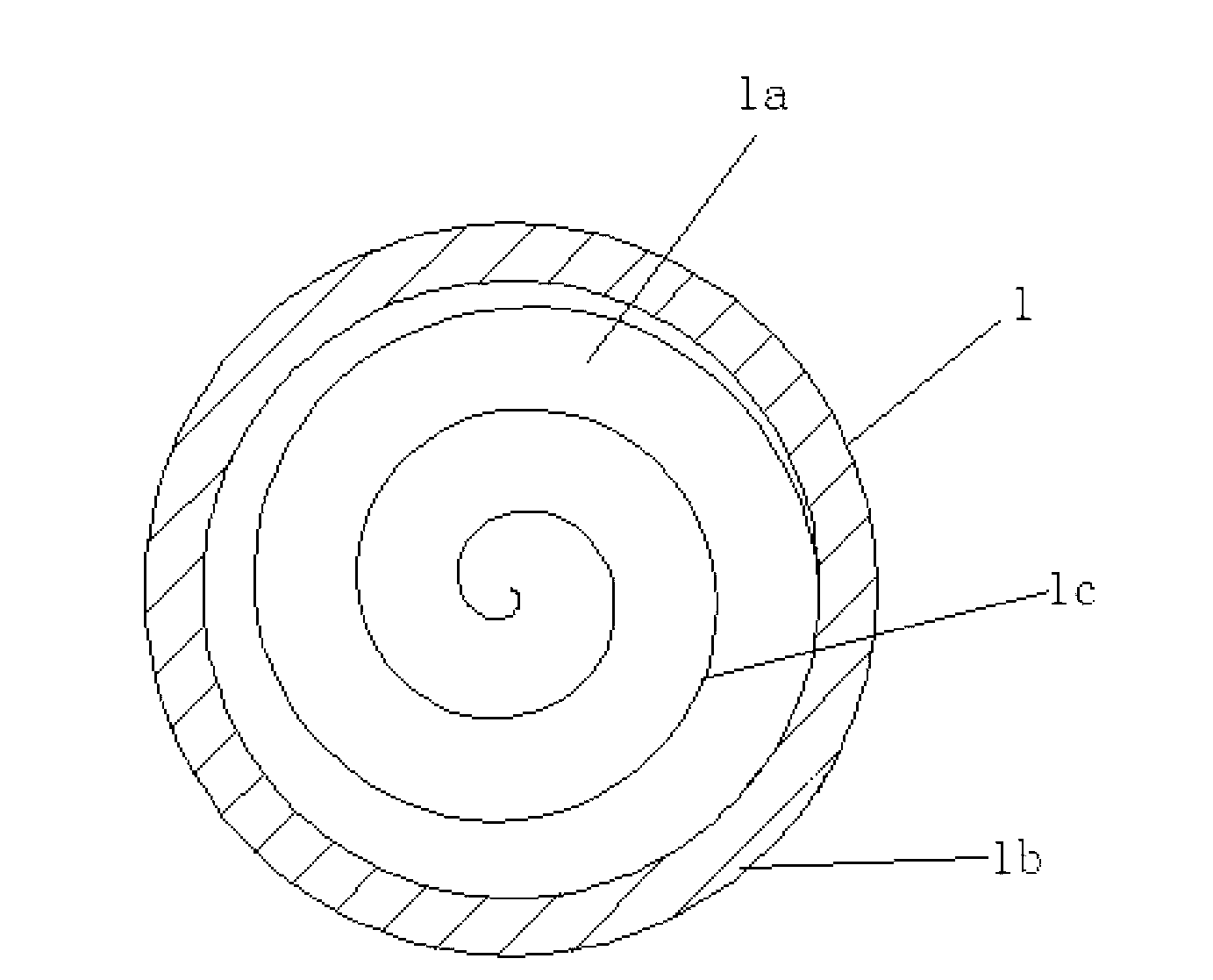

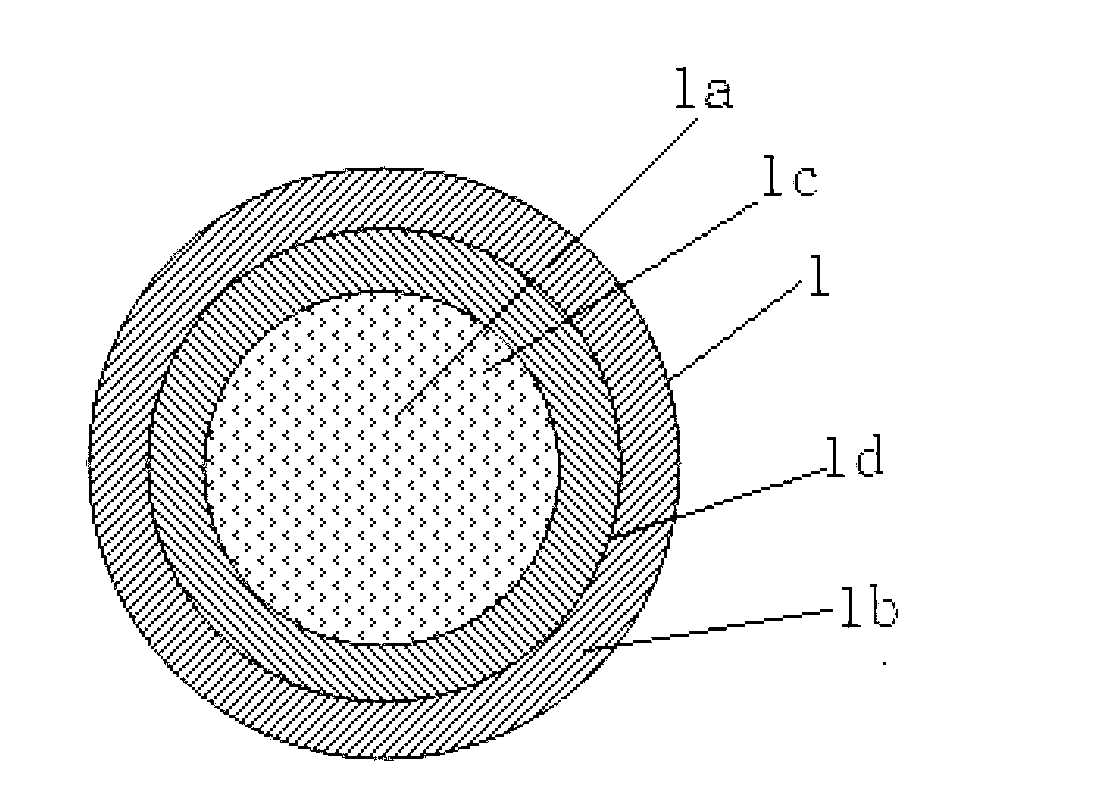

Novel carbon heating electronic cigarette

InactiveCN103271447AImprove the problem of insufficient smoke aromaReduce releaseTobacco devicesPipe TobaccoTar

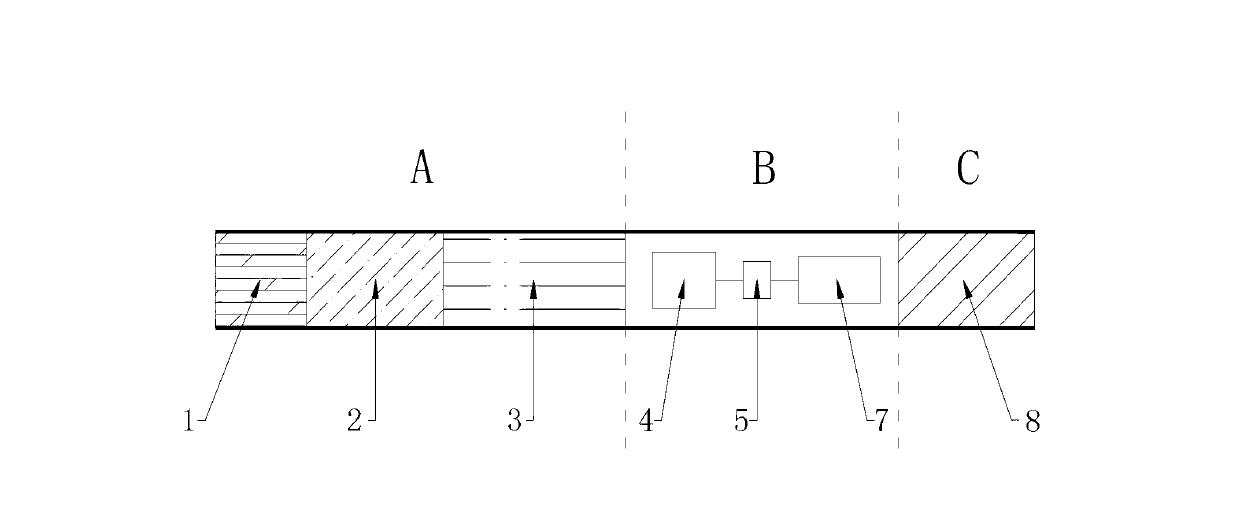

The invention discloses a novel carbon heating electronic cigarette which is formed by a carbon heating area, an electronic atomization area and a cigarette holder in sequence. The carbon heating area, the electronic atomization area and the cigarette holder are separated one another through breathable partition plates. The carbon heating area is formed by a carbolic matter heat source, an aerosol forming part and a fragrance forming part in sequence. The electronic atomization area is formed by connecting a power supply, an atomizer and a liquid storage cavity electrically. The cigarette holder is a conventional cellulore filter stick. When the novel carbon heating electronic cigarette is sucked, the carbolic matter heat source heats aerosol forming matters and pipe tobacco to form aerosol, sucked airflow triggers a pneumatic inductive switch to be opened, the atomizer works, tobacco liquid in the liquid storage cavity is atomized to form smog, and the smog and the aerosol are sucked into a mouth. The novel carbon heating electronic cigarette integrates advantages of carbon heating type cigarettes and advantages of electronic cigarettes, is novel in appearance and easy to manufacture, does not generate sidestream gas, can meet requirements for cigarette fragrance and nicotine of a consumer, and is low in the content of tar and harmful ingredients.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

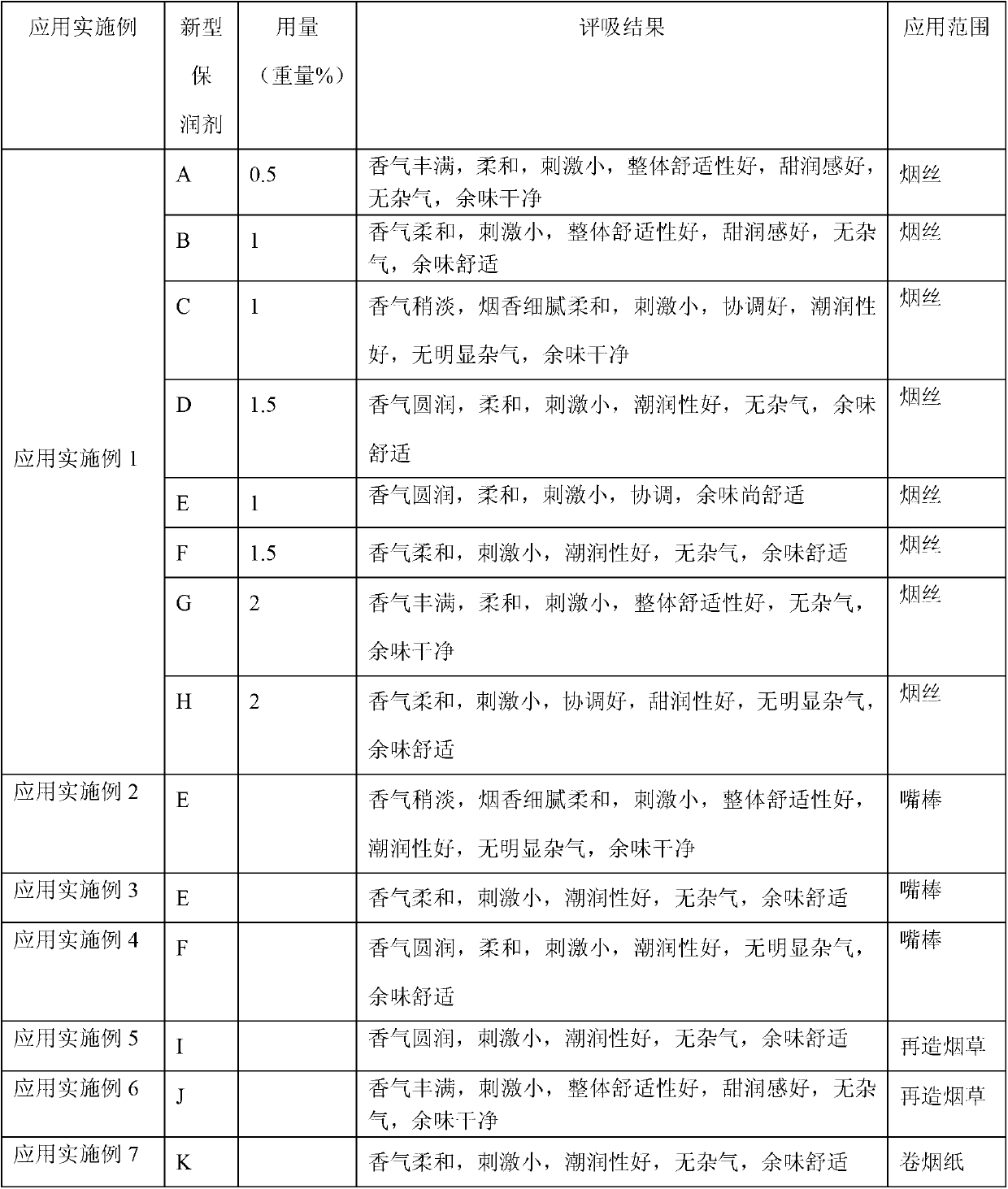

Tobacco moistening agent and application thereof

InactiveCN103099310ARaw materials are non-toxic and harmlessSufficient sourceTobacco treatmentBiotechnologyPolyol

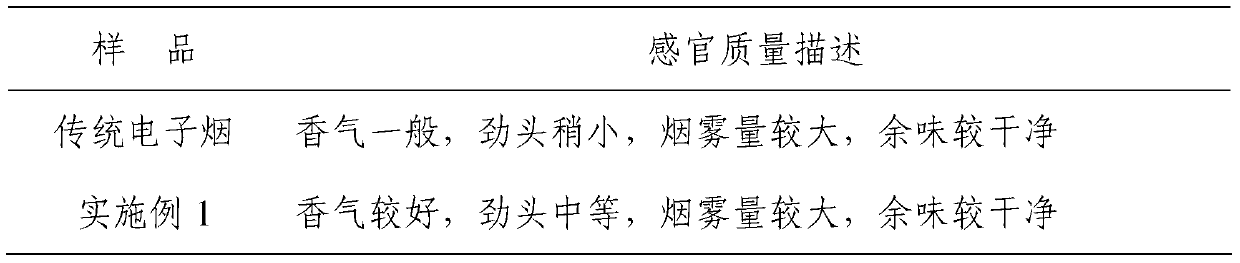

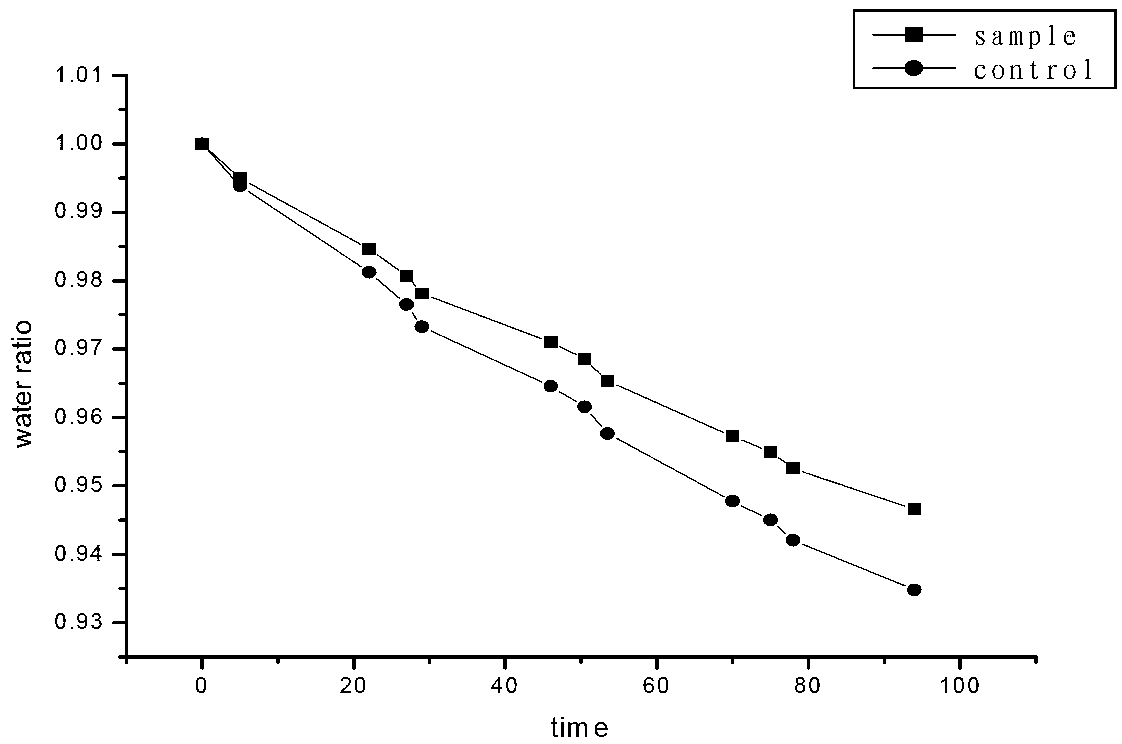

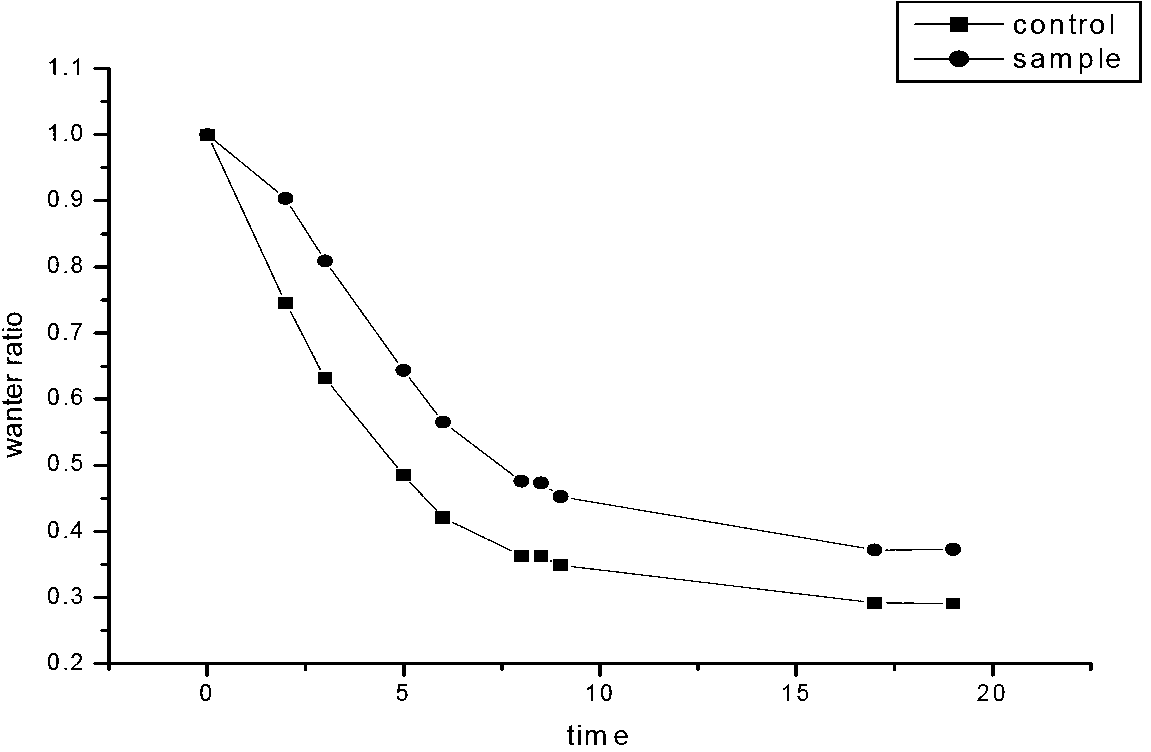

The invention discloses a tobacco moistening agent and application thereof. After alkali metal salt, sea algae extracts, natural moisturizing factors, amino acid and polyhydric alcohols are evenly mixed under a heating condition, a required tobacco moistening agent is obtained. The tobacco moistening agent can be applied to pipe tobacco, paper-making mode reconstruction tobacco, cigarette paper, a cigarette holder and other tobacco products. Taking the pipe tobacco as a sample, if the weight of 0.5-2% of the pipe tobacco is added, the pipe tobacco has the function of obviously keeping moisture of the pipe tobacco, enables cigarette to keep original style, increases smoke wetness, reduces stimulation, and obviously improves comfort of a throat. Raw materials of products are non-toxic and harmless, sufficient in source, simple in technological process, convenient to manufacture, low in cost, and simple in adding technology, does not change existing cigarette production technology, is beneficial to improving core competitiveness of an enterprise, and brings substantial benefits for the enterprise.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

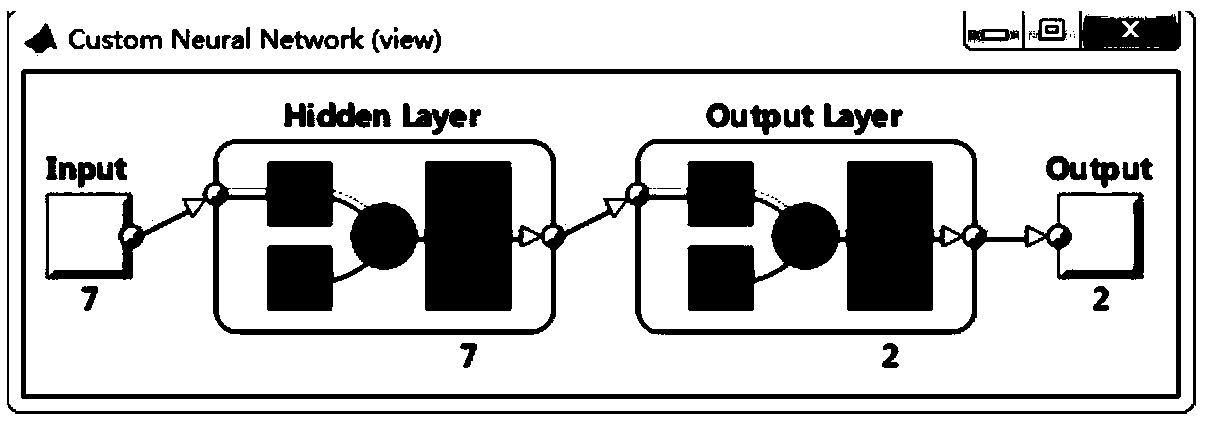

Tobacco leaf conditioning water addition prediction method, storage medium and terminal equipment

ActiveCN109674080APrediction is simplePrediction is accurateTobacco preparationTerminal equipmentPipe Tobacco

The invention provides a tobacco leaf conditioning water addition prediction method, a storage medium and terminal equipment. The method comprises the steps of acquiring the production time of tobaccoleaves, the training demand, the moisture content after feeding, the moisture content before pipe tobacco drying, the wall temperature of a pipe tobacco drying oven, the workshop temperature and theworkshop humidity parameter, and carrying out standardization and normalization on the acquired data; constructing a BP neural network by taking the parameters as input signals and a conditioning procedure water addition and outlet moisture as outputs, and determining the iterations, learning rate and target value of the neural network, so as to obtain a tobacco leaf conditioning water addition prediction model; and training the tobacco leaf conditioning water addition prediction model by taking part of processed data as training data while a preset requirement is met, and predicting the collected data by virtue of the trained tobacco leaf conditioning water addition prediction model, so as to obtain a prediction result.

Owner:CHINA TOBACCO SHANDONG IND

Tea cigarette and its manufacturing method

InactiveCN101011188AIn line with smoking habitsEasy to cutTobacco preparationTobacco treatmentMicrowavePipe Tobacco

The invention relates to a method for producing tea cigarette, which uses the tea pipe tobacco as the pipe tobacco. And the production comprises that 1, selecting the fresh teas, removing foreign tea, tea steam and drying; 2, putting the dried tea into cutter to be cut into pipes; 3, putting the tea into full-automatic microwave dewatering drying machine to dewater and dry; 4, naturally cooling the dried tea, and screening the tea powder via the screen whose mesh is 1X1mm, to obtain the tea pipe tobacco; 5, putting the pipe tobacco, cigarette paper and filter tip into full-automatic cigarette machine to obtain the final product. The invention can smell tea taste and obtain the nourishment of tea.

Owner:曾祥福

Dry distillation cigarette

The invention discloses a dry distillation cigarette, comprising a heat source section, a dry distillation section, a filling section and a chewing bar section, wherein the heat source section, the dry distillation section, the filling section and the chewing bar section are orderly connected; the heat source section comprises a carbon heat source and cigarette paper coated at the outer layer of the carbon heat source; and a hole penetrating along the axial direction is formed inside the carbon heat source. The carbon heat source disclosed by the invention is not coated by a glass fiber. Thus, the damage generated when the glass fiber is inhaled by a human body is reduced; and the heat source section has a good air flow channel, so that the flammability of the carbon heat source and the atomizing effect of a pipe tobacco are better.

Owner:HUBEI CHINA TOBACCO IND +1

A compound addictive for lowering CO content in cigarette smoke and application thereof

InactiveCN1951240AReduce carbon monoxideImproving and improving the taste qualityTobacco treatmentPipe TobaccoAlkali metal

The invention relates to a composite additive which can reduce the carbon monoxide content of smoke gas, and relative application. Wherein, said composite additive comprises that tobacco extract, alkali metal salt, transition metal hydroxide, or metal hydroxide; the composite additive can be used in variable tobaccos as flue-cured tobacco, suncured tobacco leaf, oriental tobacco leaf, expansion pipe tobacco, etc. The inventive composite additive can be used in tobacco to reduce carbon monoxide content 1.5-3.0mg / n of smoke gas and reduce the tar content.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

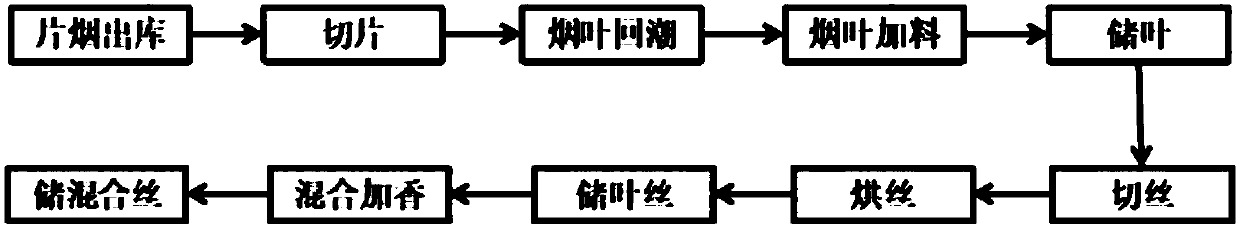

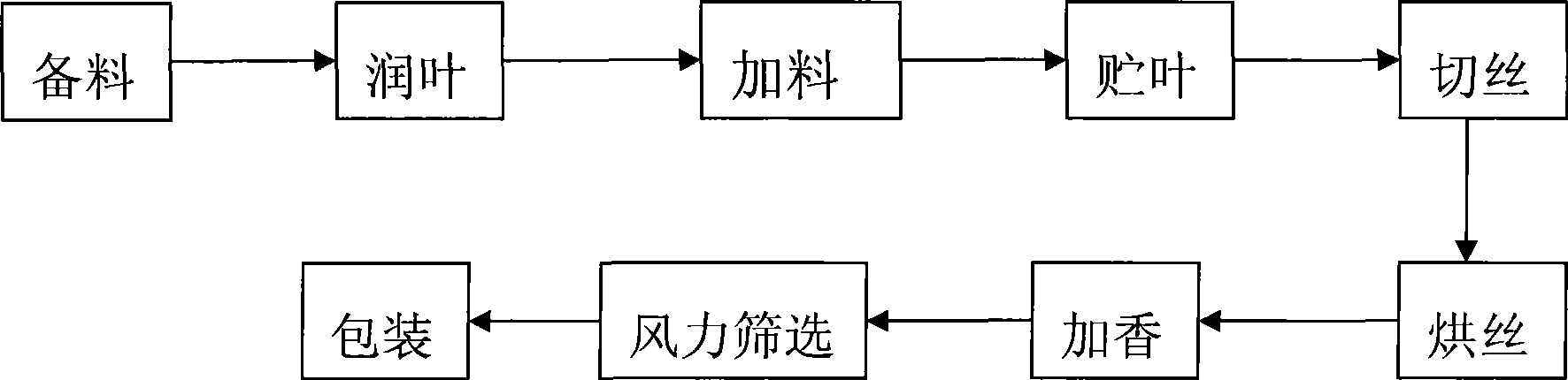

Industrialization production method of pipe tobacco

InactiveCN101396167AUniform widthImprove purityTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

The invention discloses an industrialized method for producing pipe tobacco, and pertains to the technical field of tobacco making. The method comprises the following sequential procedures: (1) conditioning procedure: the moisture is 17-19%, and the temperature is 50-60 DEG C; (2) charging procedure: the feed liquid accounts for 3.5% of the gross weight of the tobacco, the moisture accounts for 20-22%, and the temperature is 55-65 DEG C; (3) storing procedure: storing for 2-4 hours; (4) cutting procedure: the cut width is 0.18-0.22mm; (5) drying procedure: conditioning is carried out at the high temperature of 75-85 DEG C; and drying is carried out at the temperature not more than 60 DEG C, and the moisture is 12-13%; (6) perfuming procedure; the perfuming proportion is 0.6%; and (7) air screening procedure: the air rate is 2-6m<3> / s. The method is simple and easily operable, and the daily average output is dozens of times of the daily average output of the manual operation; compared with the pipe tobacco produced manually, the pipe tobacco produced by the method is better.

Owner:WUHAN TOBACCO GROUP

Method of nicotine biological degradation

InactiveCN1800361AIncrease added valueSolving Industrial Usability ProblemsBacteriaTobacco treatmentBiotechnologyOchrobactrum intermedium

The invention relates to a method of biology degradation nicotine which uses (Ochrobactrum intermedium) DN2 as bacteria seed and uses the nicotine zymosis enzyme of the Ochrobactrum intermedium DN2 or Ochrobactrum intermedium DN2 to effect on the flue-cured tobacco leaf, pipe tobacco, industrial or agricultural tobacco leftover bits and pieces and tobacco residues and the extracting liquid of the above materials to do degradation to part of or all of the nicotine.

Owner:NANJING AGRICULTURAL UNIVERSITY

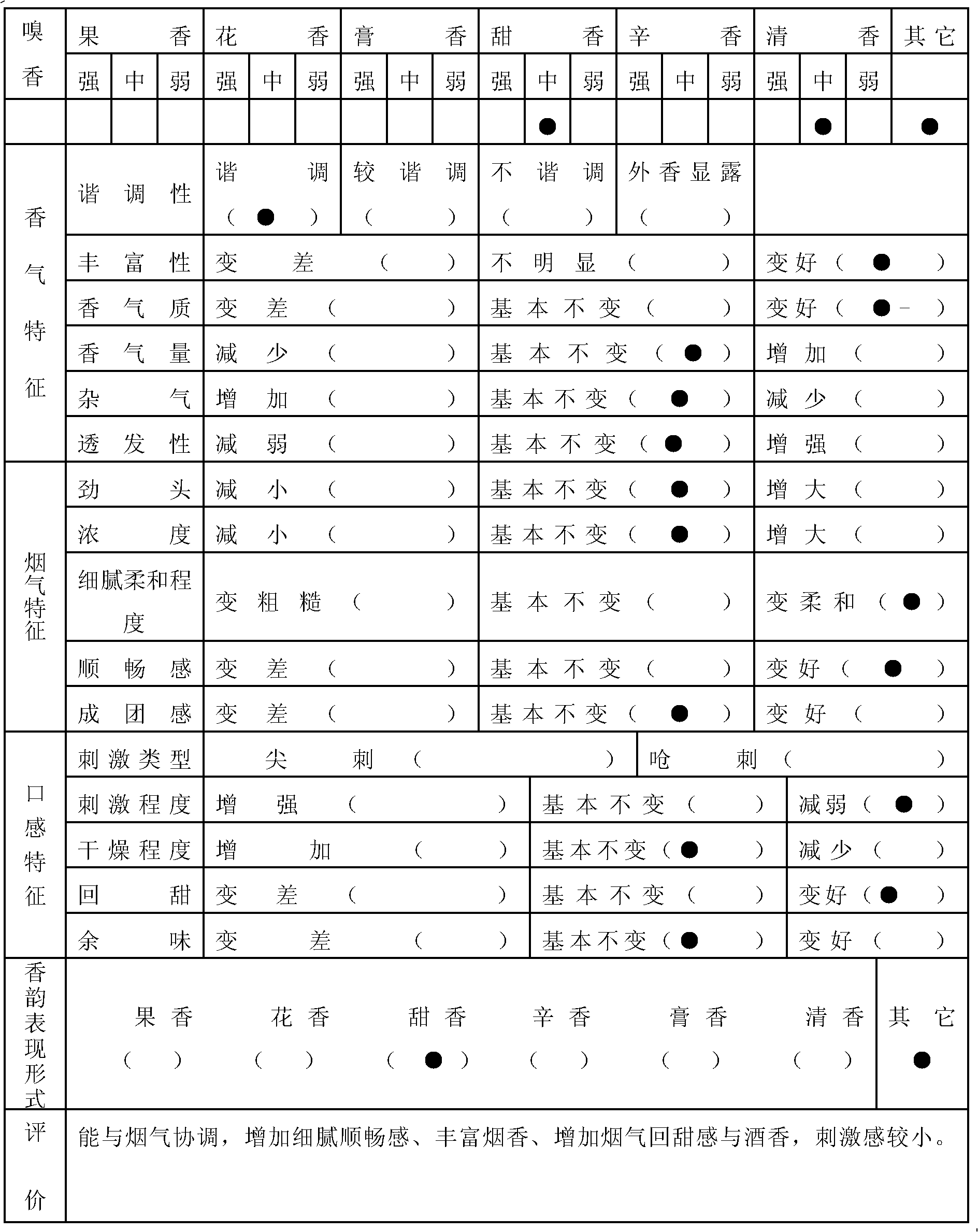

Perfume material of heating incombustible cigarette perfume producing section of pipe tobacco style and its preparation method

InactiveCN108142978AHigh purityFlavor improvement of heat-not-burn cigarettesTobacco preparationTobacco treatmentFlavorPipe Tobacco

The invention discloses a perfume material of heating incombustible cigarette perfume producing section of a pipe tobacco style and its preparation method, and relates to the technical field of the heating incombustible cigarette. The perfume material comprises a base perfume module, a perfume increasing module, a concentration module, a taste module, a strength module and a flavor module, whereinthe base perfume module is selected from one or more of fried smoke, perfume smoke and smoke stem; the perfume increasing module is nature perfume material; the concentration module comprises dried smoke leaves; the taste module is selected from one or more plant with homology of medicine and food; the strength module is selected from burley tobacco and / or dried tobacco; the flavor module is selected from one or more of coffee, coco and Maillard reactant. The finally prepared perfume material has very obvious effect in improving the flavor of the heating incombustible cigarette, and is suitable for adding to the heating incombustible cigarette of the pipe tobacco style. The preparation method of the perfume material of the heating incombustible cigarette perfume producing section of the pipe tobacco style is simple and easy to practice, and high in raw material utilization rate.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD

Tobacco production system

InactiveUS20130048000A1High leaf to stalk ratioTobacco preparationTobacco treatmentPipe TobaccoEngineering

A tobacco production system is provided for producing useable tobacco material having chemical and physical properties acceptable to tobacco industry stakeholders, by growing tobacco entirely in a directly seeded system, under an intensive biomass growing system, mechanically harvesting above-ground portions of the plant a plurality of times during the growing season, curing tobacco leaves and stalks together, and processing the cured tobacco material to obtain cured leaf material suitable for use in tobacco products including, but not limited to, cigarettes, cigars, snus, snuff, chewing tobacco, pipe tobacco, reconstituted tobacco material, and other manufactured tobacco products.

Owner:UNIVERSAL LEAF TOBACCO

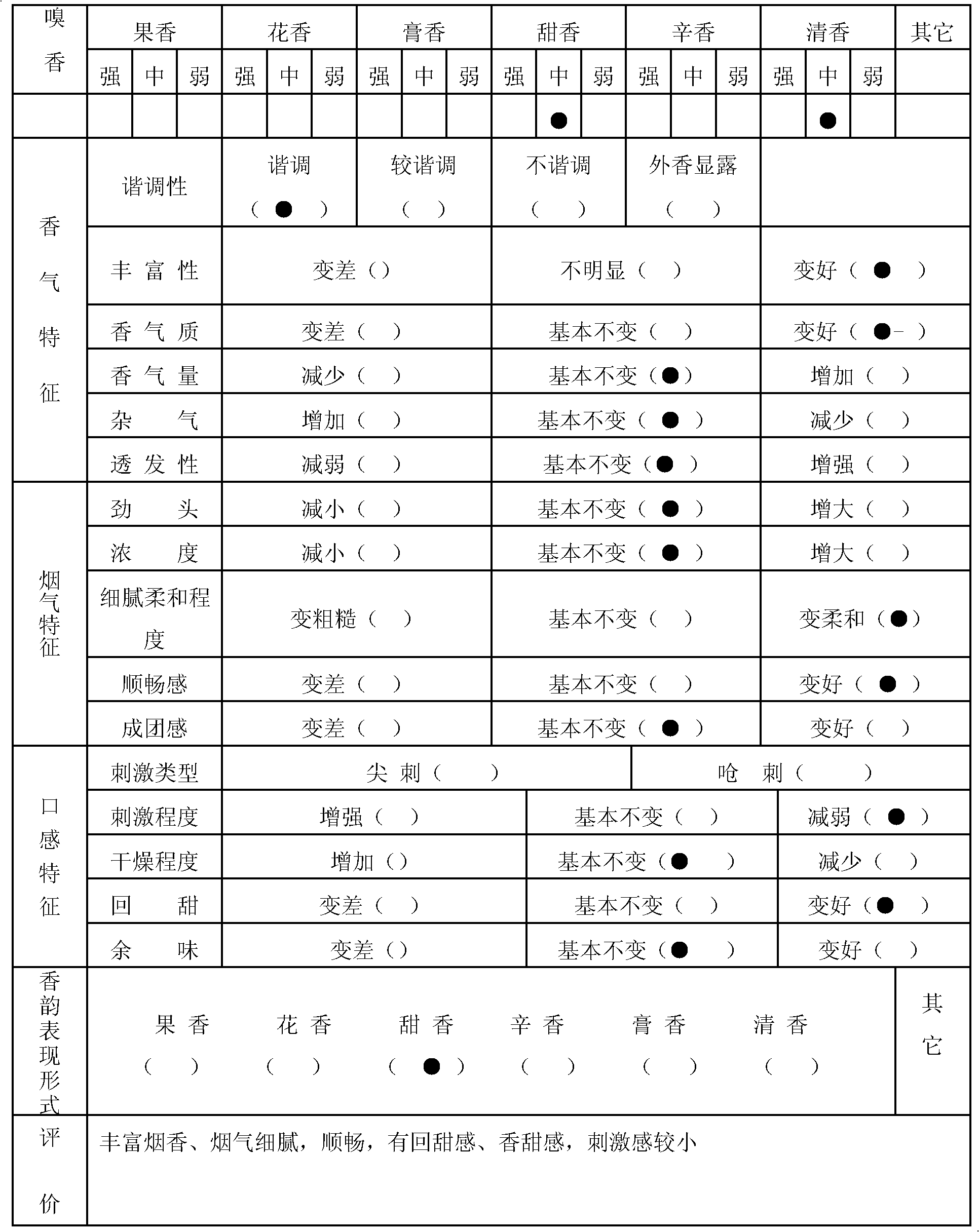

Cutch extracts preparation method for tobacco and application thereof

InactiveCN102978002AImprove comfortImprove retouching effectTobacco treatmentEssential-oils/perfumesChemistryPipe Tobacco

The invention discloses a cutch extracts preparation method for tobacco and application thereof. The method includes taking one part of raw materials of cutch, adding ethanol with weight of 10-20 times and volume fraction of 30%-95% or lactic acid water solution with volume fraction of 0.1%-1%, soaking for 1-2 hours, heating and returning flow and extracting 2-4 times in a normal pressure, extracting for 1-4 hours each time, filtering after cooling, and keeping filter solution of 2-4 times respectively. Cutch extracts for the tobacco are required after the raw materials of the cutch is reduced in pressure and concentrated to 2-4 times of weight of the cutch raw materials under 55-65 DEG C. Cutch extract solution is evenly sprayed in blank pipe tobacco according to additive amount of pipe tobacco dry weight of 0.01-0.1%, the pipe tobacco is dried to moisture content of 12-16% on the condition of 55-65 DEG C, and a cigarette can be manufactured. Natural aroma which is contained in extracts obtained is coordinated with tobacco and has good decoration function on smoke state after added into tobacco leaves, so that the aroma is rich, and the smoke is soft, fine and smooth.

Owner:HUBEI CHINA TOBACCO IND +1

Tobacco production system

A tobacco production system is provided for producing useable tobacco material having chemical and physical properties acceptable to tobacco industry stakeholders, by growing tobacco entirely in a directly seeded system, under an intensive biomass growing system, mechanically harvesting above-ground portions of the plant a plurality of times during the growing season, curing tobacco leaves and stalks together, and processing the cured tobacco material to obtain cured leaf material suitable for use in tobacco products including, but not limited to, cigarettes, cigars, snus, snuff, chewing tobacco, pipe tobacco, reconstituted tobacco material, and other manufactured tobacco products.

Owner:UNIVERSAL LEAF TOBACCO

Tobacco substitution chrysanthemum health cigarette

InactiveCN101011184AGood for healthWith fragranceTobacco treatmentPharmaceutical delivery mechanismDiseaseFlavor

The invention relates to a chrysanthemum health-care cigarette which can replace the tobacco. The invention uses natural chrysanthemum as main material. And it comprises 1-100 mass percentages of chrysanthemum and 0-99 mass percentages of pipe tobacco and the essence. The invention can hold the effective components of chrysanthemum and improve the health of user, while it can reduce or eliminate the nicotine and obtain the functions as chrysanthemum, detoxication, or the like.

Owner:高国强

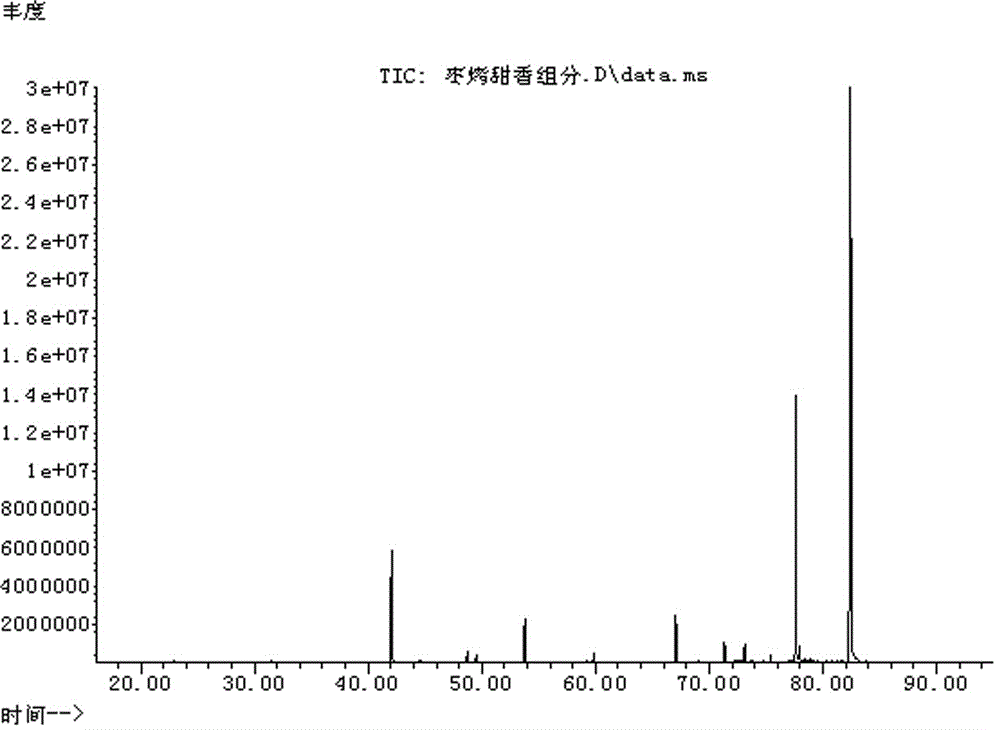

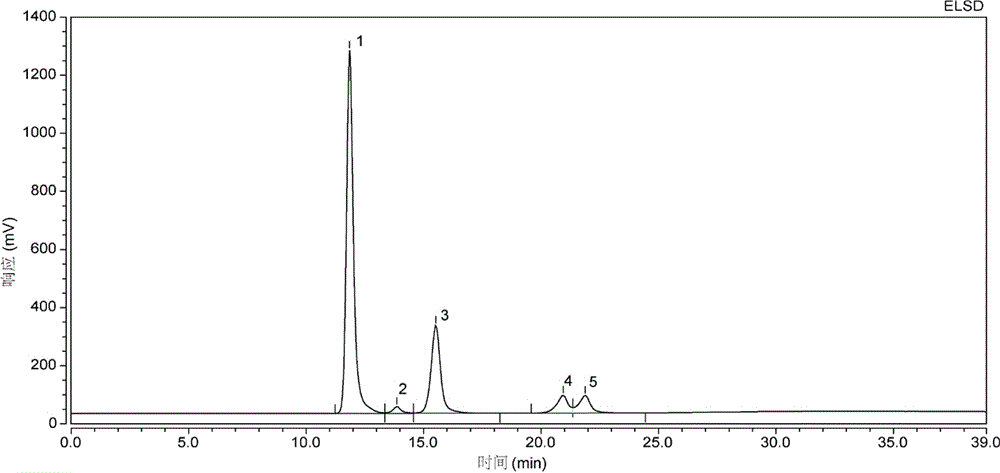

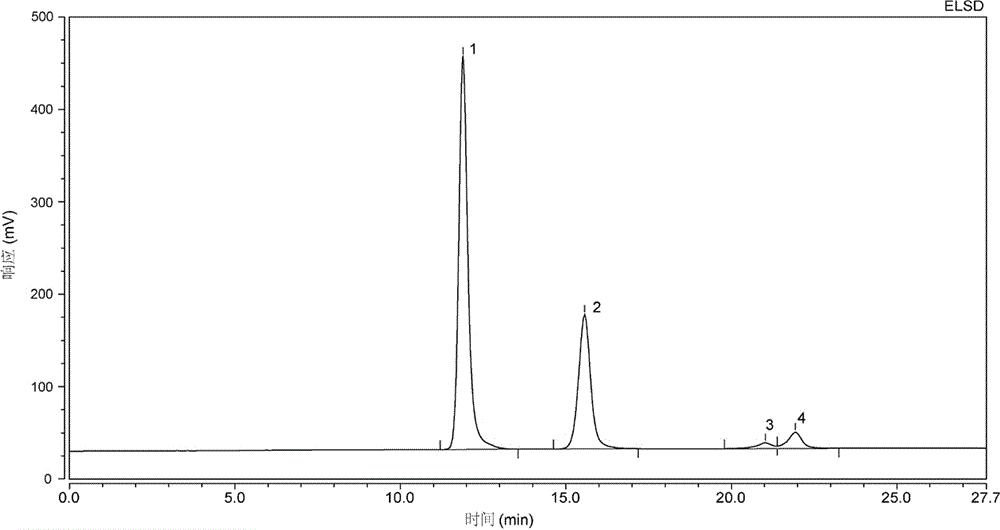

Method for preparing roasted fragrant and sweet components of red dates and application of roasted fragrant and sweet components of red dates to pipe tobacco

ActiveCN105831792AAroma harmonyComfortable tasteTobacco preparationEssential-oils/perfumesBiotechnologyFuran

The invention belongs to the technical field of tobacco spice, and particularly relates to a method for preparing roasted fragrant and sweet components of red dates. The method comprises the steps that a, the red dates are washed, decored and dried; b, ethanol extraction is carried out; c, membrane separation is carried out to remove macromolecular matter; d, the materials pass through a macroporous adsorption resin chromatographic column to separate and acquire effective ingredients. The roasted fragrant and sweet components of the red dates contain rich monosaccharide, disaccharide and multiple roasted fragrance and sweet ingredients (furan, furanone, pyrone, cyclopentenone and other compounds), after the roasted fragrant and sweet components of the red dates are applied to the cut pipe tobacco, joyful roasted fragrant and sweet smells can be given to the pipe tobacco, the remaining taste is sweet and comfortable, and the pipe tobacco meets the favor of tobacco product consumers in China better. According to the preparation process of the roasted fragrant and sweet components of the red dates, ingredients having side effects on smoking of the pipe tobacco in red date crude extract can be effectively removed, two kinds of effective ingredients are separated and enriched, and the optimal application effect is achieved through effective blending of flavorists. The preparation process is simple and easy to operate, the production process is economical and environmentally friendly, and the method is suitable for being applied to large-scale industrial production.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

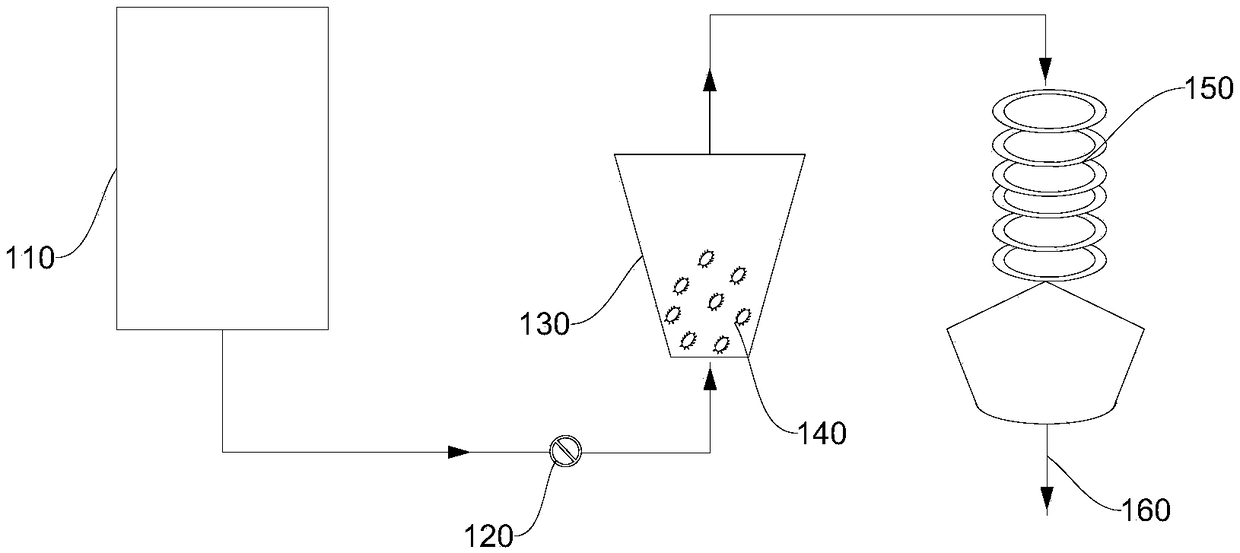

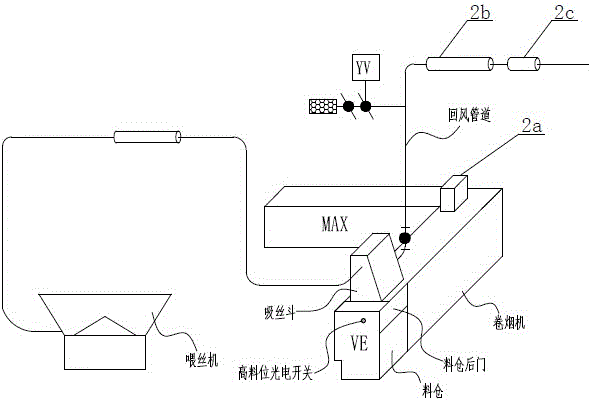

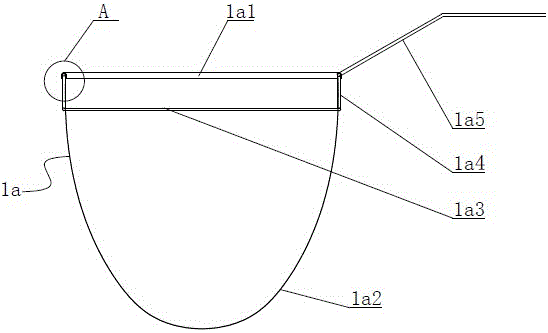

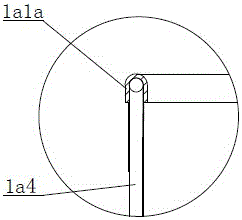

Sampling test method for whole cut rate and broken cut rate of cut tobacco obtained after air conveying and sampling device

ActiveCN106370546AAvoid spillingGuaranteed Sampling IntegrityMaterial weighingPipe TobaccoEngineering

The invention provides sampling test methods for the whole cut rate and the broken cut rate of cut tobacco obtained after air conveying and a sampling device and relates to the technical field of sampling test of the whole cut rate and the broken cut rate of the cut tobacco. The sampling device for testing the whole cut rate and the broken cut rate of the cut tobacco obtained after air conveying comprises a cigarette making machine cut tobacco sampling device and an air return pipe tobacco powder metering device. The cigarette making machine cut tobacco sampling device comprises an opaque shielding part inserted into a cigarette making machine material bin to shield a high-material photoelectric switch, and a sampling bag used for stretching into the cigarette making machine material bin to collect the cut tobacco. The air return pipe tobacco powder metering device comprises a controller, a powder concentration meter and an air speed flow meter, wherein the powder concentration meter and the air speed flow meter are installed on an air return pipeline. The sampling test method for the whole cut rate of the cut tobacco obtained after air conveying and the sampling test method for the broken cut rate of the cut tobacco obtained after air conveying are both achieved based on the sampling device, the sampling test methods for the whole cut rate and the broken cut rate of the cut tobacco obtained after air conveying both include the steps of cut tobacco sampling, air return pipe tobacco powder metering data reading and recording, and calculating of the whole cut rate of the cut tobacco obtained after air conveying.

Owner:HUNAN HESANLI TECH ENG CO LTD

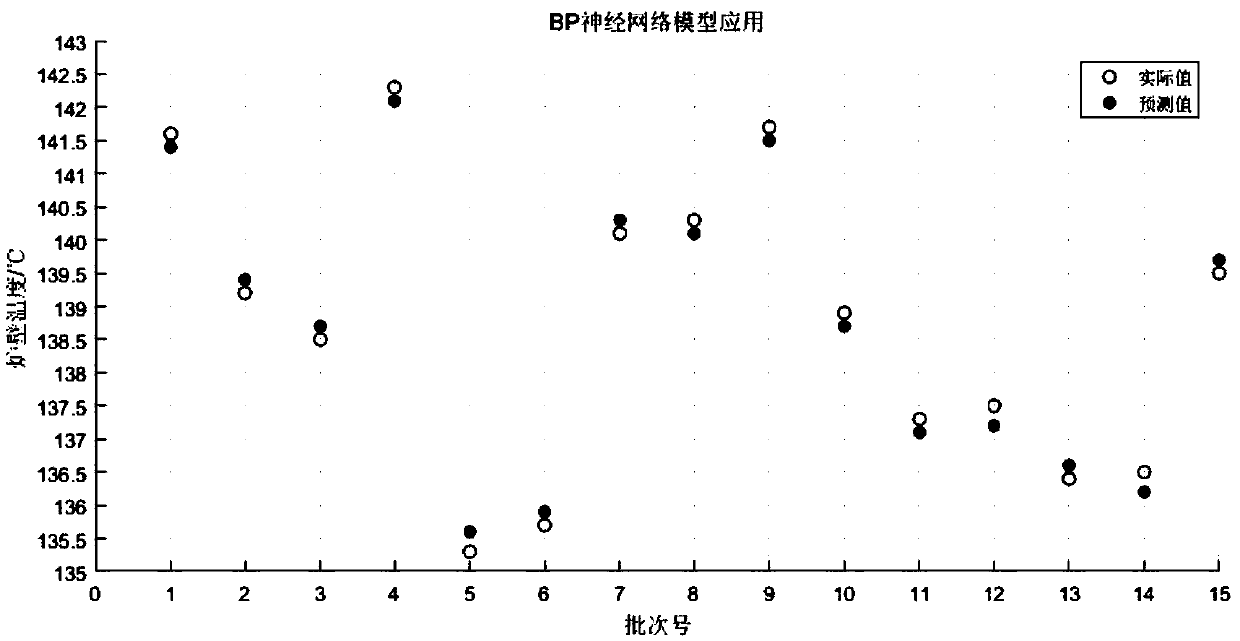

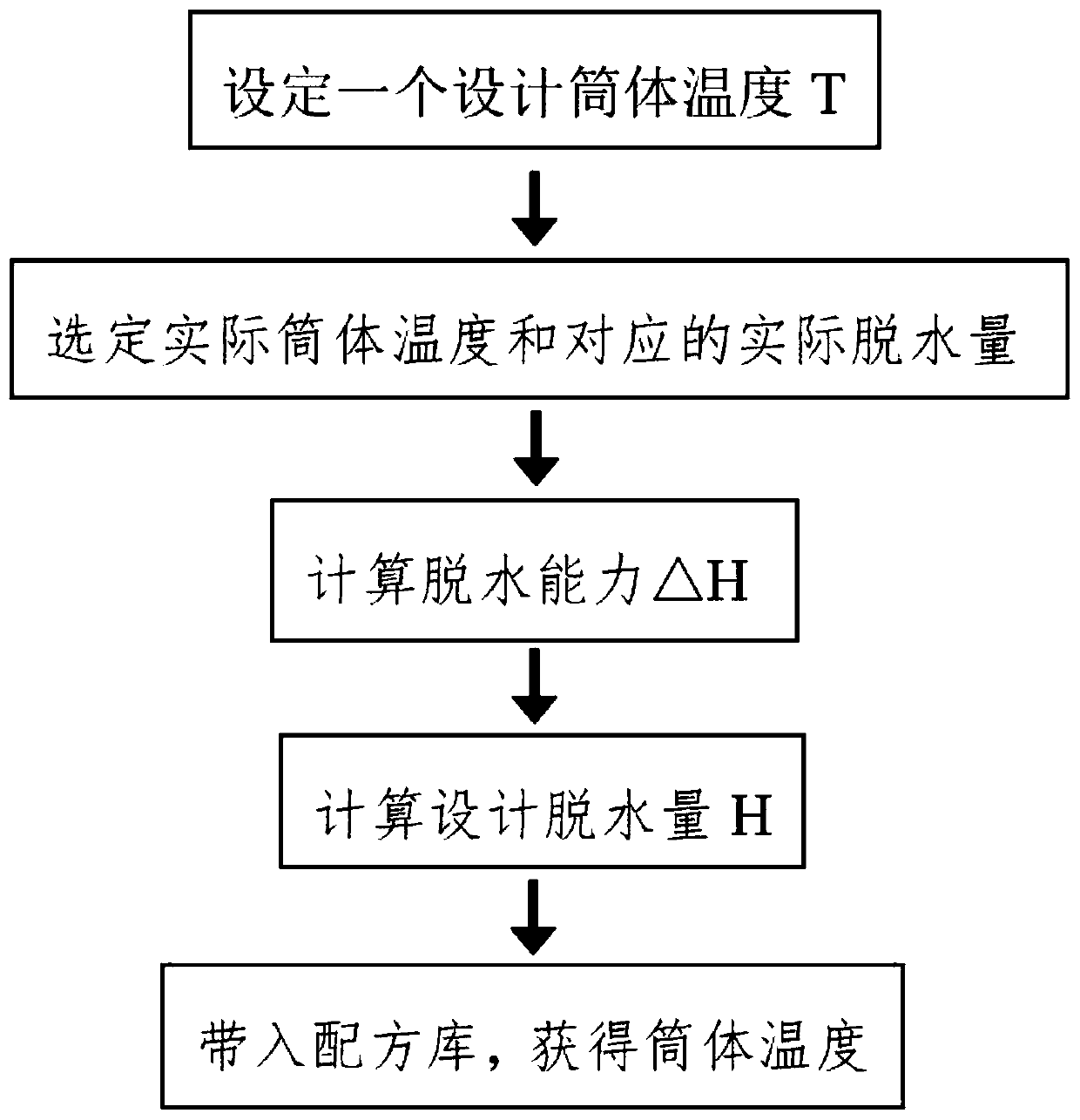

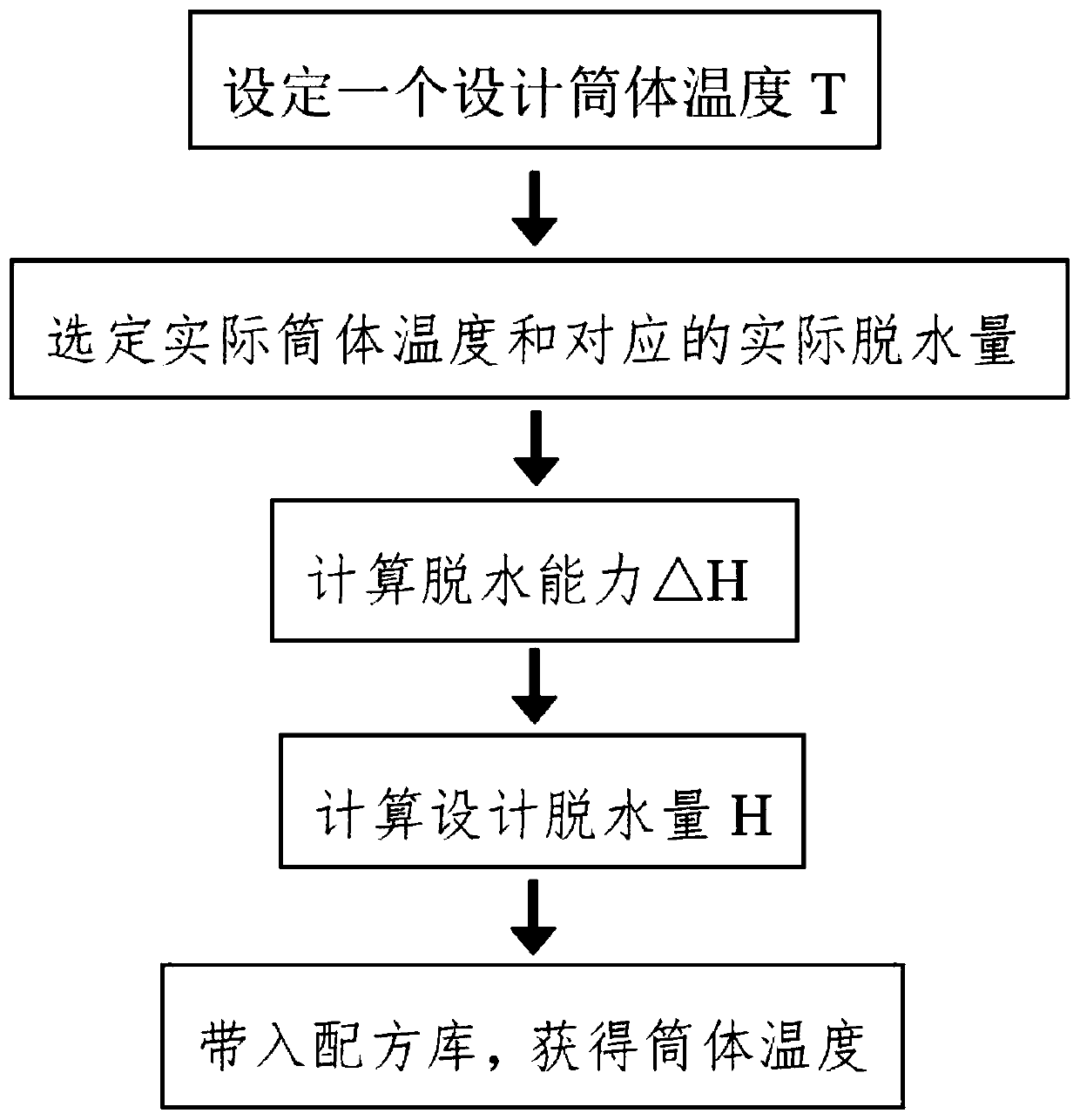

Method for obtaining cylinder body temperature by calculating dewatering amount of KLD-2 cut-tobacco drier

ActiveCN110013044AAccurate amount of dehydrationImprove accuracyTobacco preparationPipe TobaccoEngineering

The invention discloses a method for obtaining the cylinder body temperature by calculating the dewatering amount of a KLD-2 cut-tobacco drier. Firstly the designed cylinder body temperature needed for production is designed, in a historical trend chart, two groups of actual cylinder temperatures and the corresponding actual dewatering mount are selected, the dewatering capacity of per degree cylinder body temperature on pipe tobacco and the designed dewatering mount corresponding to the designed cylinder body temperature are calculated, the designed dewatering mount value obtained by calculating is input into the KLD-2cut-tobacco drier recipe library parameters, and the designed cylinder body temperature required for production is obtained. The method is not affected by environmental airpressure, the steam source quality and the accuracy of an on-line moisture meter, the problem of partial dry or partial wet of a stub bar due to improper setting is avoided, the dewatering amount corresponding to different cylinder body temperatures of the KLD-2 cut-tobacco drier can be accurately calculated, the amount of inlet water according to brand requirements can be backstepped, the accuracy of process design of the process cylinder body temperature of the KLD-2 cut-tobacco drier can be improved, and the method is suitable for the KLD-2 cut-tobacco drier with any production capacity.

Owner:CHINA TOBACCO GUIZHOU IND

Preparation method and application of milk sweet flavor essence

PendingCN109161439AKeep aroma componentsSimple and fast operationTobacco preparationTobacco treatmentActivated carbonOrganic solvent

The invention discloses a preparation method and application of milk sweet flavor essence. The preparation method comprises the following steps: after introducing gas into a fresh milk product, concentrating the product onto active carbon or silica gel particles to obtain adsorbed particles with a milk sweet flavor, then washing and soaking the adsorbed particles with an organic solvent, and carrying out concentration to obtain the milk sweet flavor essence. According to the method, no heating and other pretreatment are performed on natural fresh milk, the purely natural flavoring compositionof the essence is maintained, and the method is simple and convenient to operate and high in practicability. The milk sweet flavor essence prepared by the invention can be widely applied to the aspects of pipe tobacco flavoring, filter stick tow flavoring, filter tip adhesive, lap adhesive flavoring and the like, the essence can endow cigarette with unique natural milk sweet fragrance, and harmonize the cigarette fragrance, so that the smoke is mellow and full, rich and soft, and the taste is improved.

Owner:INNER MONGOLIA KUNMING CIGARETTE CO LTD

Use of extracts of grape seeds as free group eliminating agent for tobacoo products and the concerned tobacco products

An application of the grape seed's extract as the cleanser for removing the free groups from the tobacco products, which are generated during smoking, is disclosed. Said grape seed's extract can be proportionally mixed with tobacco shreds. Said tobacco products may be cigarette, cigar and pipe tobacco.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Preparation method of cigarette slice added with activated carbon

The invention relates to a preparation method of a cigarette slice added with activated carbon. The cigarette slice which comprises 5-10% of activated-carbon tobacco sheet is sliced in into a filament. The length of the filament is 1-3mm. The filament is added into cigarette cut tobacco in the proportion of 2-5% and the cigarette cut tobacco is stirred in a speed of 100-200r / min. After the pipe tobacco of the cigarette is mixed evenly, the pipe tobacco is scrolled and packed. The preparation method has the advantages of reducing oil tar of the cigarette by 16.76% and reducing nicotine by 32.04% due to the fact that each cigarette comprises 13.62%mg of tar content by adoption of 13.72%mg of the oil tar in one cigarette.

Owner:SUZHOU GULI BIOTECH

Early identifying method of pistachio male trees and pistachio female trees

InactiveCN102147400ASimple methodStart fastAnalysis using chemical indicatorsInsect diseaseAfter treatment

The invention relates to a chemical detecting method, in particular to an early identifying method of male pistachios and female pistachios. The early identifying method comprises the steps of: (1) collecting clean and non-insect-disease fresh leaves, respectively weighing 0.5 gram of clean male plant leaves without main veins and 0.5 gram of clean female plant leaves without main veins, shearing the leaves into the shape of pipe tobacco by adopting the leaf shearing method, putting the shorn leaves into a clean 50-milliliter triangular flask, adding a cresol red solution with the concentration of 0.1, 0.2 or 0.3 percent, putting the triangular flask into a constant-temperature box at the temperature of 28 DEG C, preserving the temperature for 12 to 72 hours, observing the change of color, and comparing with distilled water; and (2) judging the yellow red leaves after treatment as female plant leaves and the glaucous leaves as the male plant leaves so as to judge the female pistachio seeds and the male pistachio seeds. The early identifying method of male pistachios and female pistachios is rapid and effective, and is easy to operate and master.

Owner:李洁

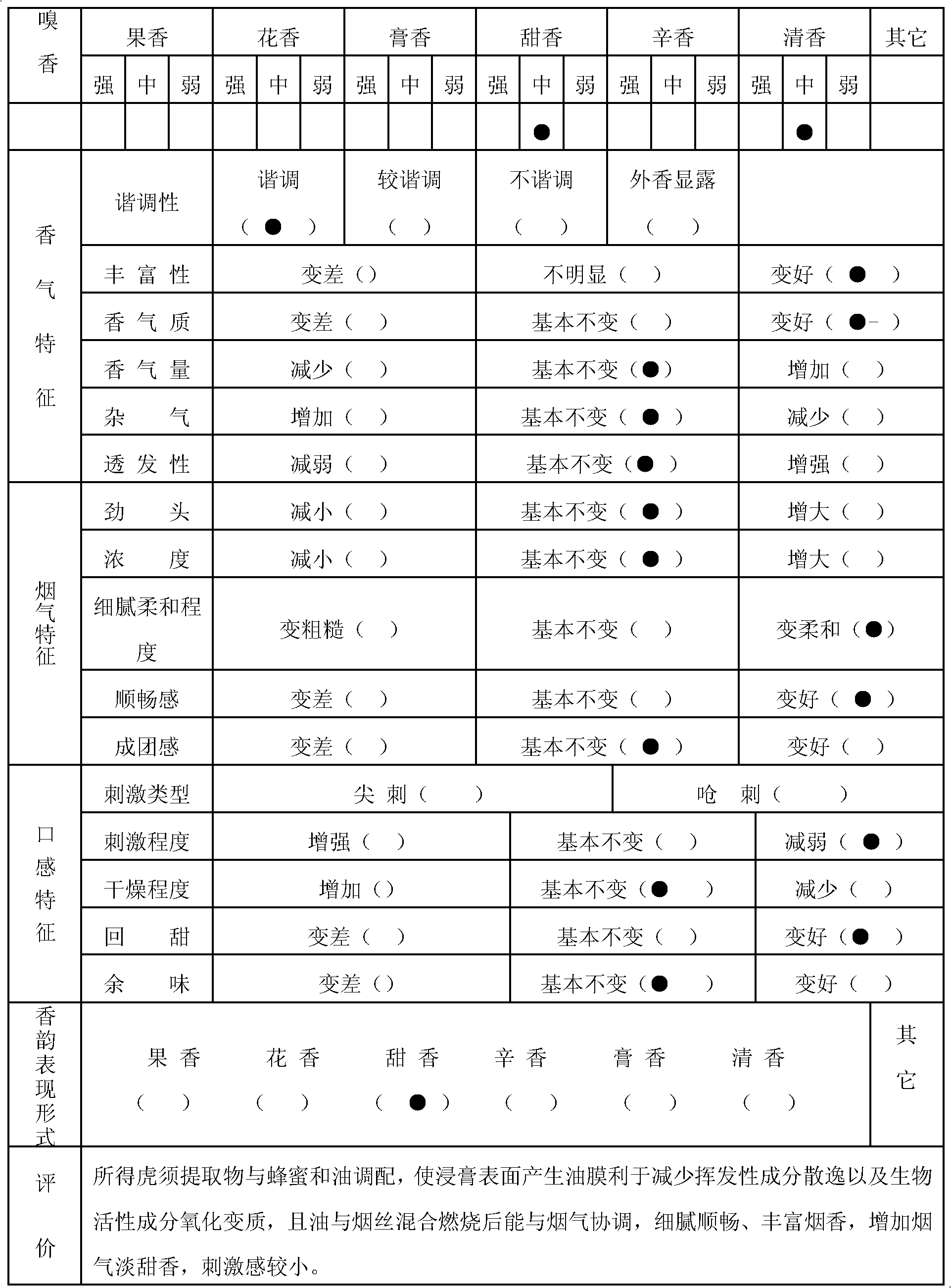

Shisha paste containing extractive from natural plant Tacca chantrieri Andre and preparation method thereof

Owner:HUBEI CHINA TOBACCO IND

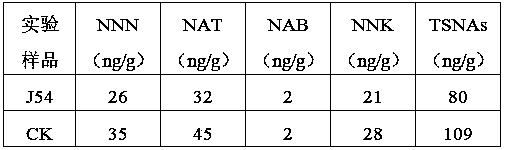

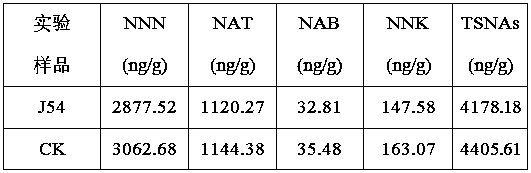

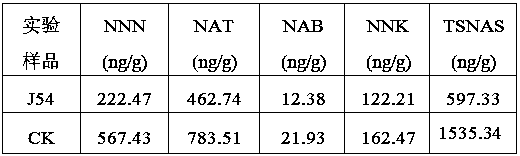

Bacillus altitudinis J54 and application thereof

ActiveCN110713957AIncrease production capacityConducive to popularization and applicationTobacco preparationTobacco treatmentBiotechnologyNicotiana tabacum

The invention discloses Bacillus altitudinis J54 and application thereof. The Bacillus altitudinis is Bacillus altitudinis J54, is preserved in the China Center for Type Culture Collection, and has apreservation number of CCTCC No. M2019667. Separation is performed on tobacco leaves, and then screening and purification are performed so as to obtain the Bacillus altitudinis J54; through processesof fermentation, inoculation and degradation, nitrosamine (TSNAs) specific in tobaccos can be degraded effectively in the process of tobacco leaf processing or pipe tobacco preparation, and the degradation rate can reach 5.2-46.6%, so that the quality of the tobacco leaves is improved; and the bacterial strain has good resistance to stress, easy acquisition, convenient use and broad market application prospects.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

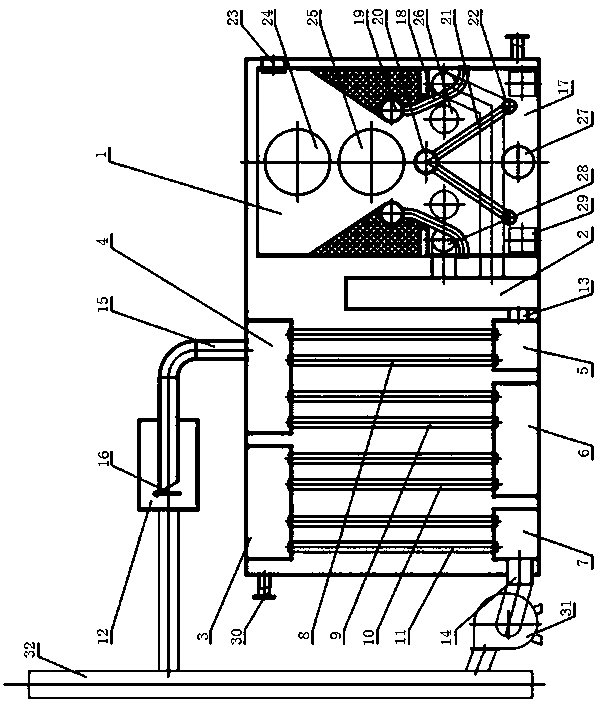

Cleaned briquette environment-friendly boiler

InactiveCN107842846AGuaranteed to burnSolve the emission problemSolid fuel combustionWater heatersCombustion chamberFlue gas

The invention discloses a clean type coal environment-friendly boiler, which relates to the technical field of boilers. The coal storage chamber is set on the upper part of the combustion chamber, the combustion chamber is connected to the dust-reducing chamber through pipes, the dust-reducing chamber is connected to the first lower smoke box through the flue gas channel, and the first lower smoke box is connected to the second upper smoke chamber through the first return smoke pipe. The second upper smoke box is connected with the second lower smoke box through the second return smoke pipe, the second lower smoke box is connected with the first upper smoke box through the third return smoke pipe, and the first upper smoke box is connected with the fourth return smoke The pipe is connected with the third lower smoke box, the third lower smoke box is provided with a smoke outlet, and the auxiliary smoke port provided on the second upper smoke box is connected with the baffle in the flue gas converter through the pipe. The invention ensures continuous combustion after the boiler is shut down, completely solves the problem of smoke when the boiler is shut down, is energy-saving and environment-friendly, has strong practicability, is easy to popularize and use, and can also use bituminous coal and biomass fuels in addition to burning briquettes.

Owner:黄骅市鑫通环保科技有限公司

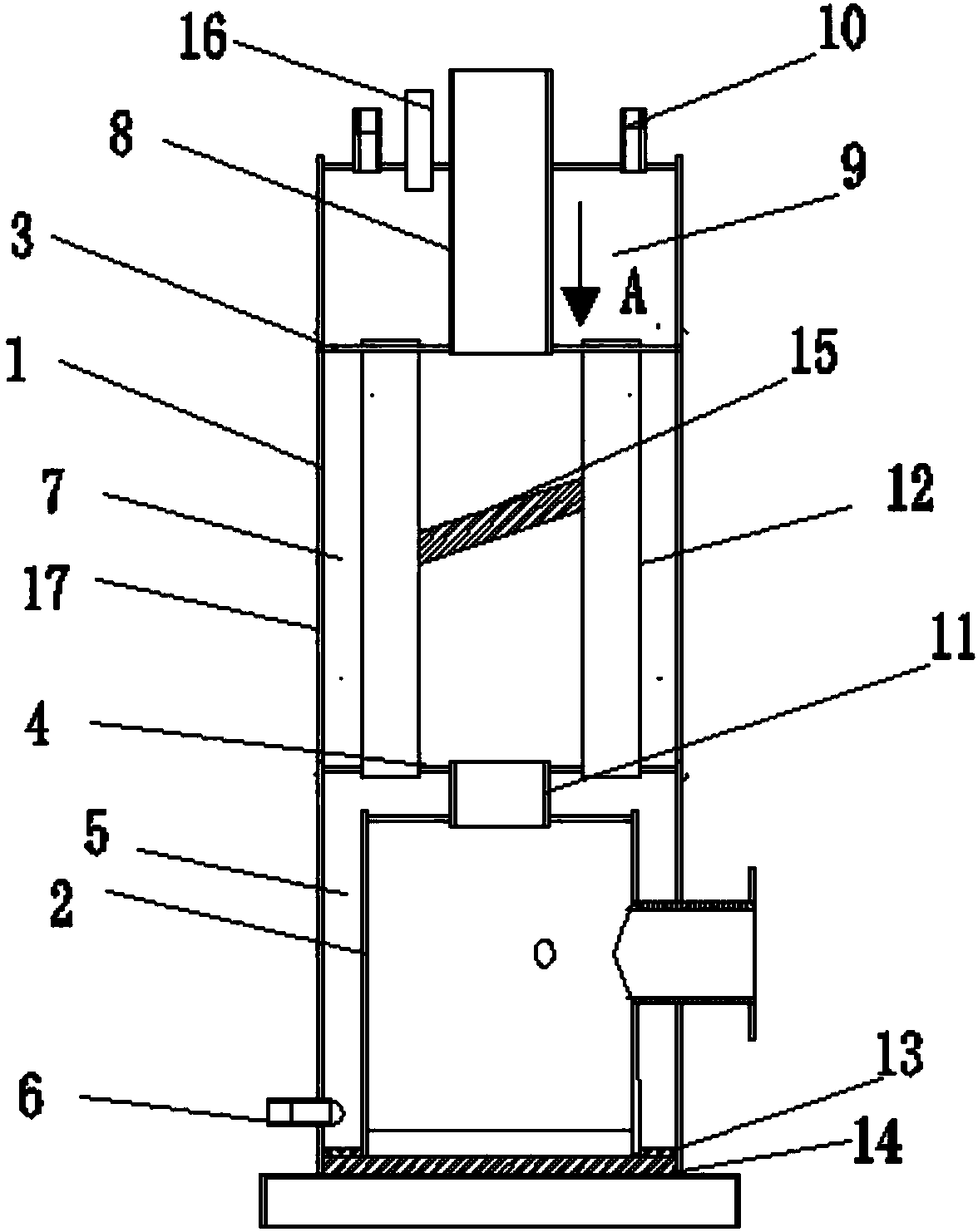

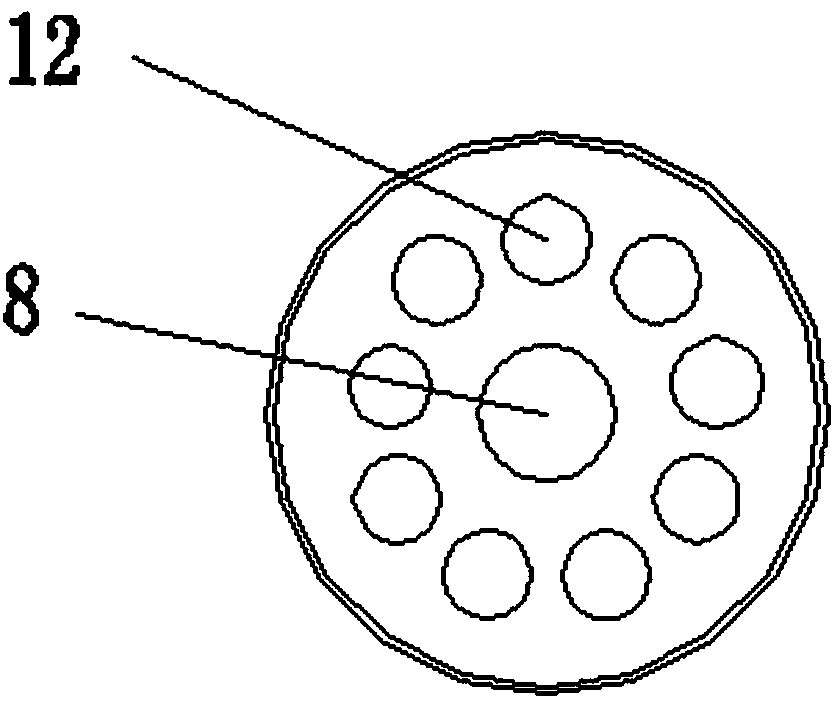

Efficient steam generator

InactiveCN107869710AImprove heat transfer efficiencyRealize heat exchangeSteam generation using hot heat carriersCombustionPipe Tobacco

The invention discloses a high-efficiency steam generator, which relates to the technical field of fuel equipment, and comprises a cylinder and a furnace. A water storage cavity is formed at the bottom, and a water inlet pipe is connected to the outside of the water storage cavity. The tube plate and the upper part of the cylinder form a steam chamber, the steam chamber is provided with an air outlet, and the furnace is provided with a return pipe above the furnace, the return pipe communicates with the return chamber, and there are multiple water pipes connected between the upper tube plate and the lower tube plate , the water pipes are surrounded by a circle, and the invention solves the technical problems of insufficient fuel combustion and low heat exchange efficiency in the prior art.

Owner:JIANGSU ANXIN BOILER

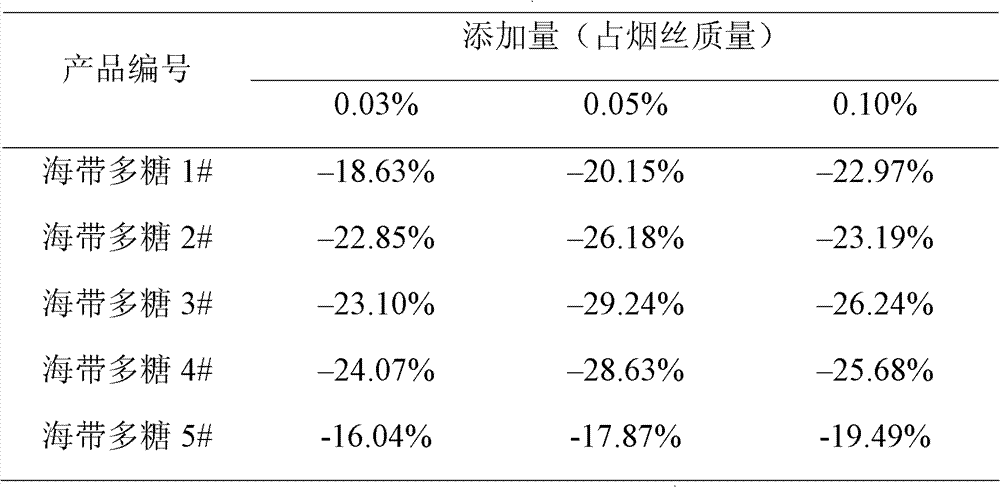

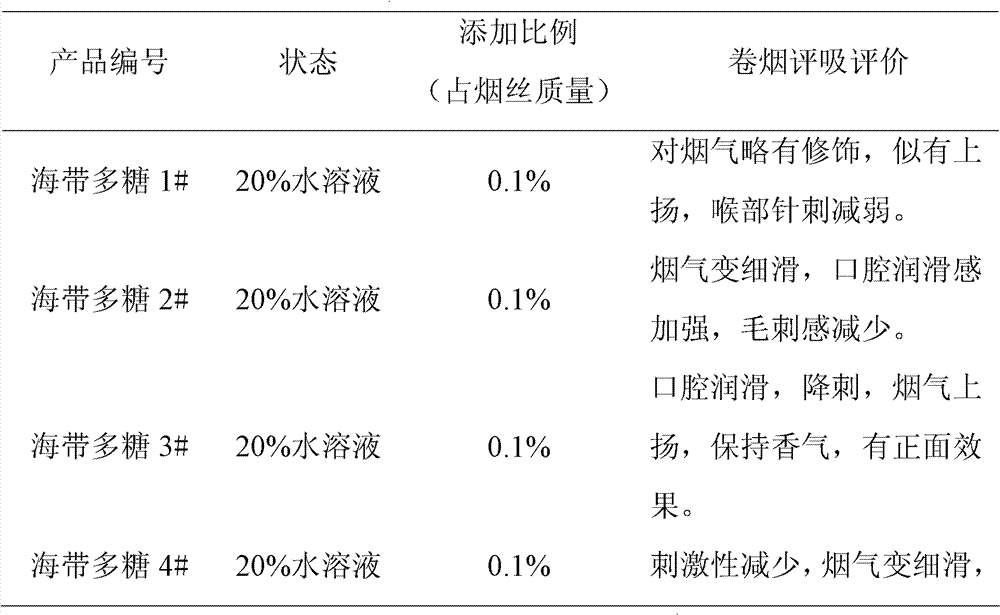

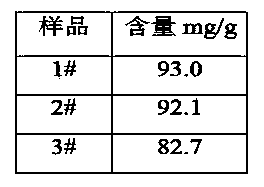

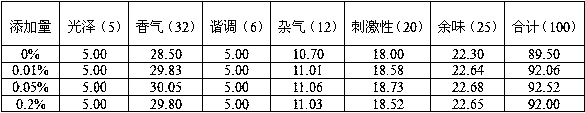

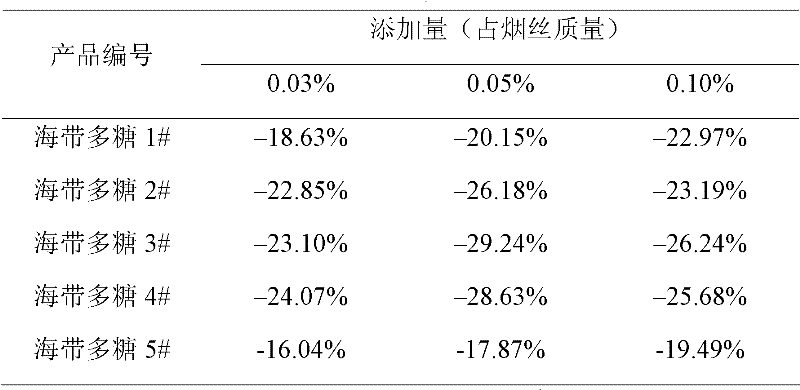

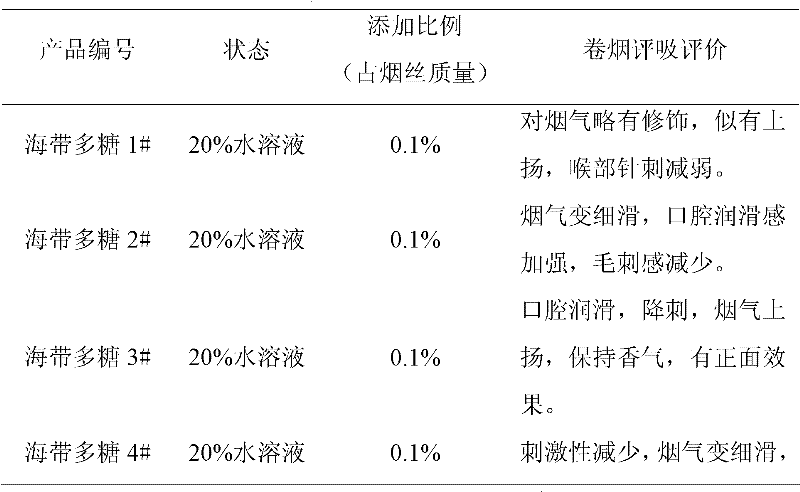

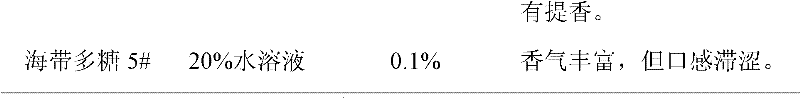

Laminarin as well as extraction method and application thereof

ActiveCN102367283BReduce free radical contentLess irritatingTobacco treatmentTobacco smoke filtersBiotechnologyLaminaria japonica

The invention discloses a laminarin. The laminarin is extracted and obtained by the following method: smashing kelp and then adding water, and extracting for 2-5 hours at the temperature of 105-125 DEG C; filtering to obtain extract, and concentrating the extract so as to obtain a concentrated liquid in which the content of solid substances is 35-45%; adding ethanol in the concentrated liquid forevenly mixing, and then standing for 4-12 hours at the temperature of 0-4 DEG C, and filtering so as to obtain polysaccharide precipitate; and carrying out freeze drying to obtain the laminarin. The laminarin the mass of which is 0.01-1.0% of pipe tobaccos is prepared into a solution, and then the laminarin solution is added in the pipe tobaccos or a filter tip through a spraying mode, thereby effectively reducing the content of free radical in main steam smoke of cigarette and also improving the smoking quality of cigarette, wherein the content of the free radical is reduced by more than 18%. The laminarin has the functions of reducing stimulation effect on nasal cavity, throat and the like, leading smoke to be smooth, leading mouth feel to be soft and maintaining aroma, and has no any side effects. The laminarin has no fishy smell, high extraction efficiency and low cost, and is easy to obtain.

Owner:CHINA TOBACCO GUANGDONG IND

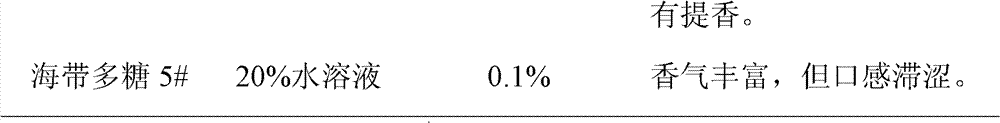

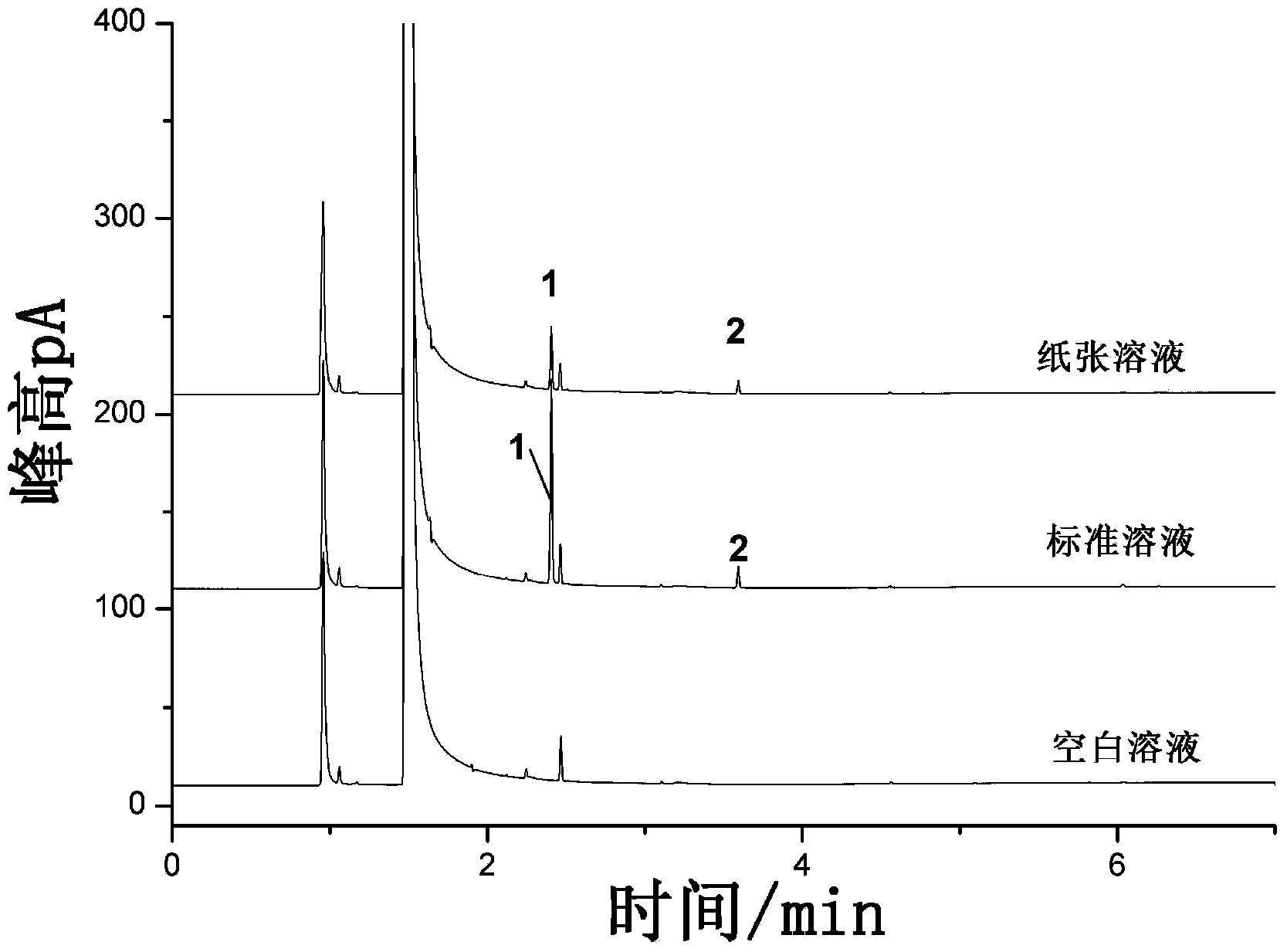

Method for measuring content of piperitol in tobacco paper through headspace gas chromatography

ActiveCN103969387AEasy to handleReduce volatile lossComponent separationRetention timeConcentration ratio

The invention discloses a method for measuring the content of piperitol in tobacco paper through headspace gas chromatography. The method comprises the following steps: (1), preparing an internal standard solution, a standard stock solution and a standard work solution; (2), carrying out sample pretreatment: after a cigarette sample is peeled out of a pipe tobacco and an acetate filter tip, a paper sample is directly weighted and placed into a 20 mL headspace bottle, the internal standard solution is added and sample feeding is performed after sealing to a gland; (3), sample measuring: an Agilent headspace gaschromatograph is adopted; (4), carrying out qualitative diagnosis and quantification: standard substance retention time and single standard sample introduction qualitative diagnosis are used for chromatograms of a blank solution, a standard solution and a paper solution; an internal standard method is adopted for quantification, the area ratio y and the concentration ratio x of piperitol and an internal standard peak are used for drawing working curves, so as to obtain corresponding retention time, linear equation, detection limit and determination limit. According to the method, headspace sample introduction is adopted, and the sample pretreatment is simple and easy for automation. The method has the advantages of simplicity, accuracy, automation, wide application range and the like.

Owner:CHINA TOBACCO ZHEJIANG IND

Nelumbo nucifera Gaertn essence, preparation method thereof and application of Nelumbo nucifera Gaertn essence in cigarettes

InactiveCN108192733AWidely distributedDoes not increase production costsTobacco preparationTobacco treatmentFlavorReflux extraction

The invention discloses a preparation method of Nelumbo nucifera Gaertn essence. The preparation method comprises the steps of: performing crushing and mashing on Nelumbo nucifera Gaertn, performing filtration and concentration under reduced pressure, adding a sugar source and an amine source into concentrated liquor, performing a reaction at 100-180 DEG C for 1-5 hours, then adding 3-10 volume times of an organic solvent, and performing heating reflux extraction at 45-80 DEG C for 1-4 hours; and performing primary molecular distillation and secondary molecular distillation on the extracted liquor under certain conditions so as to obtain a distilled light phase which is the Nelumbo nucifera Gaertn essence. The preparation method has the advantages of a simple preparation process and low cost, and after the obtained Nelumbo nucifera Gaertn essence is evenly sprayed onto pipe tobacco through a cigarette flavoring process, flavor of baked sweet or coked sweet of the cigarettes can be highlighted, so that the smoking quality and sensory comfort of the cigarettes are improved; therefore, the preparation method is worthy of promotion for application throughout the industry.

Owner:CHINA TOBACCO HENAN IND

Laminarin as well as extraction method and application thereof

ActiveCN102367283AReduce free radical contentLess irritatingTobacco treatmentTobacco smoke filtersNasal cavityThroat

The invention discloses a laminarin. The laminarin is extracted and obtained by the following method: smashing kelp and then adding water, and extracting for 2-5 hours at the temperature of 105-125 DEG C; filtering to obtain extract, and concentrating the extract so as to obtain a concentrated liquid in which the content of solid substances is 35-45%; adding ethanol in the concentrated liquid forevenly mixing, and then standing for 4-12 hours at the temperature of 0-4 DEG C, and filtering so as to obtain polysaccharide precipitate; and carrying out freeze drying to obtain the laminarin. The laminarin the mass of which is 0.01-1.0% of pipe tobaccos is prepared into a solution, and then the laminarin solution is added in the pipe tobaccos or a filter tip through a spraying mode, thereby effectively reducing the content of free radical in main steam smoke of cigarette and also improving the smoking quality of cigarette, wherein the content of the free radical is reduced by more than 18%. The laminarin has the functions of reducing stimulation effect on nasal cavity, throat and the like, leading smoke to be smooth, leading mouth feel to be soft and maintaining aroma, and has no any side effects. The laminarin has no fishy smell, high extraction efficiency and low cost, and is easy to obtain.

Owner:CHINA TOBACCO GUANGDONG IND

Health-care cigarette

InactiveCN104544551AThe taste of smoke is mellowNot addictiveTobacco treatmentTobacco devicesCodonopsis pilosulaPipe Tobacco

The invention relates to a preparation method of a health-care cigarette. The preparation method comprises the following steps of respectively adopting the following components in parts by weight: 10-20 ginseng, 2-10 flowers carthami, 1-8 Astragalus membranaceus, and 2-20 Codonopsis pilosula; respectively extracting for three times with water; combining the extracting solution to obtain total extracting solution; cooling the total extracting solution to room temperature; soaking pipe tobacco into the total extraction solution for 2-48 hours; taking out the pipe tobacco; putting the pipe tobacco outside to dry by airing, or putting the pipe tobacco in a drying box to dry; then preparing the health-care cigarette according to a conventional cigarette preparation process. The health-care cigarette prepared by the invention can be helpful to strengthen tendons and bones, soothe the nerves and beautify, is pure in taste, has aroma of traditional Chinese medicines, is not easy to addict, and is suitable to be used for a long time.

Owner:GUANGZHOU KANGLINNAI BIOLOGICAL SCI & TECH CO LTD

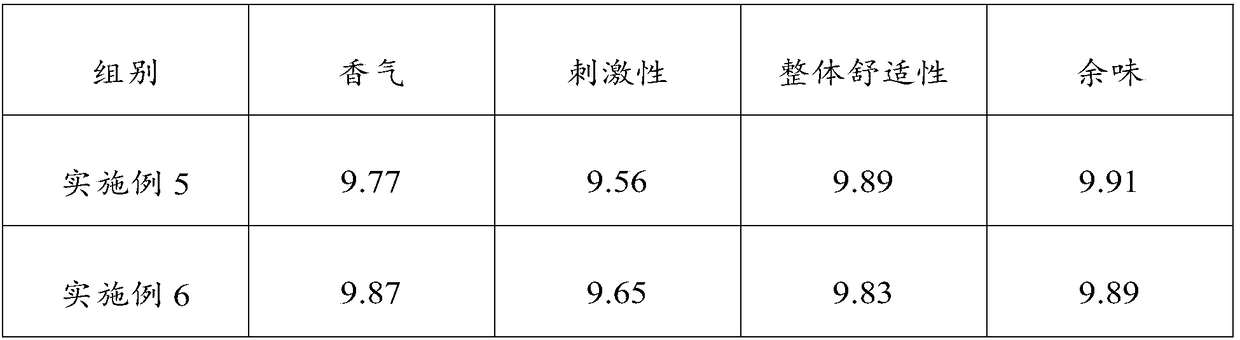

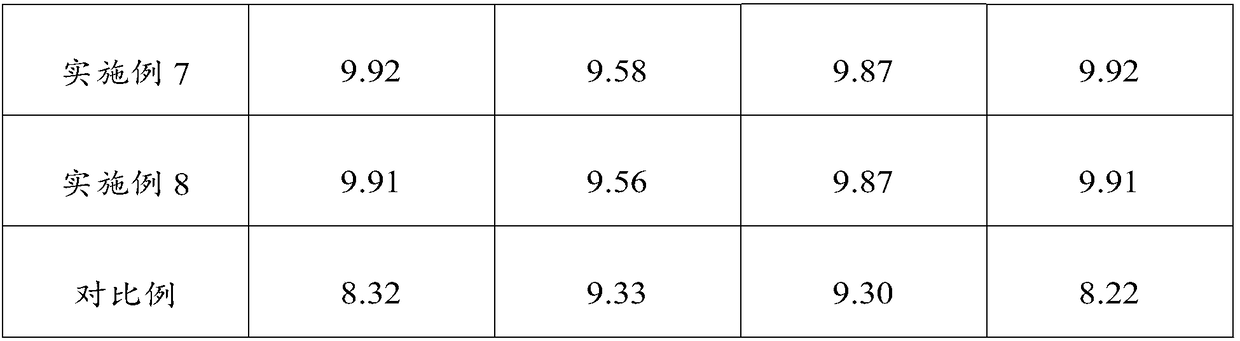

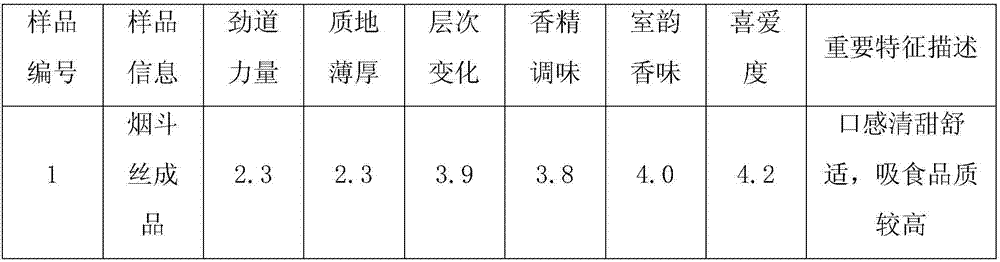

Chinese style pipe tobacco preparation process method

ActiveCN107467709ARich fragranceMeet consumer demandTobacco preparationTobacco treatmentFlavorAlcohol

The invention discloses a Chinese style pipe tobacco preparation process method. The method comprises the steps of A, preparing black pipe tobacco, wherein the mixture of the black pipe tobacco is prepared form 75 % of tobacco stems, 10 % of Burley tobacco leaves, 6 % of aromatic tobacco leaves, 9 % of sun-cured tobacco leaves, and feed liquid A is added to the mixture of the black pipe tobacco; B, preparing flue-cured pipe tobacco, wherein the mixture of the flue-cured pipe tobacco is prepared from 10 % of aromatic tobacco leaves, 10 % of Burley tobacco leaves, 10 % of sun-cured tobacco leaves and 65 % of flue-cured tobacco leaves, and a feed solution B is added to the mixture of the flue-cured pipe tobacco; C, preparing a mixed pipe tobacco mixture, wherein the mixed pipe tobacco mixture is prepared from 40 % of the black pipe tobacco which is prepared in the step A and 60 % of the flue-cured pipe tobacco which is prepared in the step B, and a feed solution C is added into the mixed pipe tobacco mixture. The pipe tobacco which is produced by the method has the advantages of being rich, pure and mild in aroma, moderate in concentration and vigour, sweet and comfortable in taste and the like, and meanwhile the production efficiency of the pipe tobacco is improved, and the production cost of the pipe tobacco is reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com