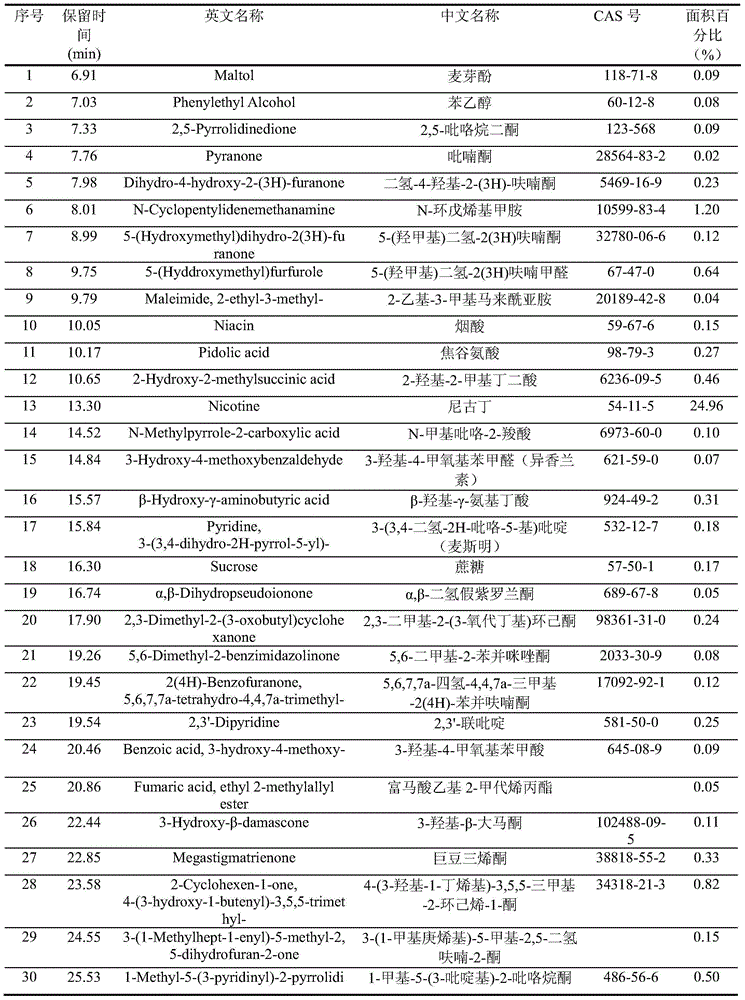

Patents

Literature

31 results about "Snus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

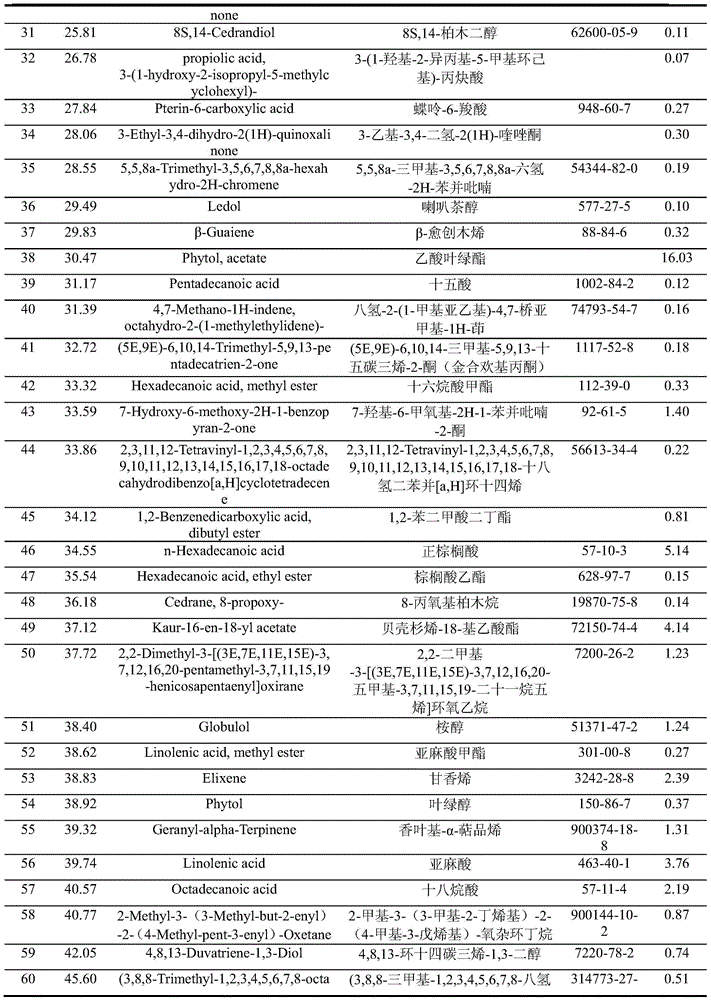

Snus (/snuːs/ SNOOSS, Swedish: [¹snʉːs] ) is a moist powder smokeless tobacco product originating from a variant of dry snuff in early 18th-century Sweden. It is placed in upper lip for extended periods. Snus is not fermented. Although used similarly to American dipping tobacco, snus does not typically result in the need for spitting and, unlike naswar, snus is steam-pasteurized.

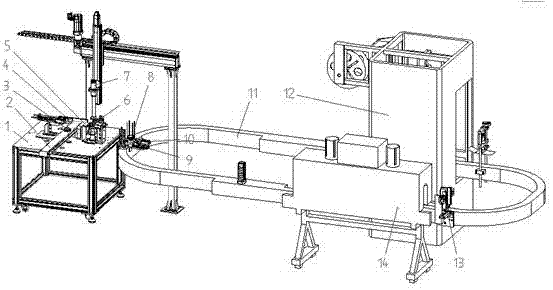

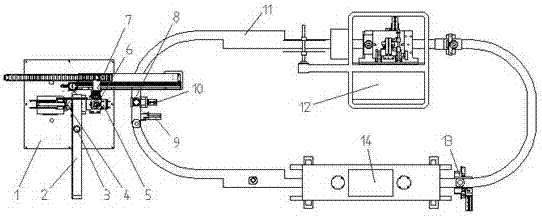

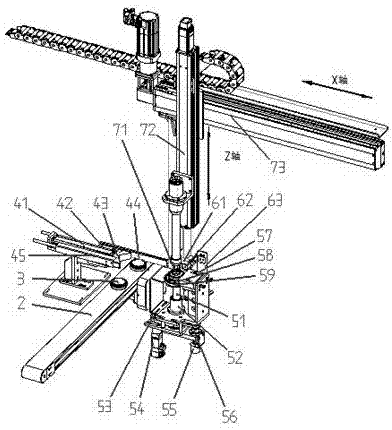

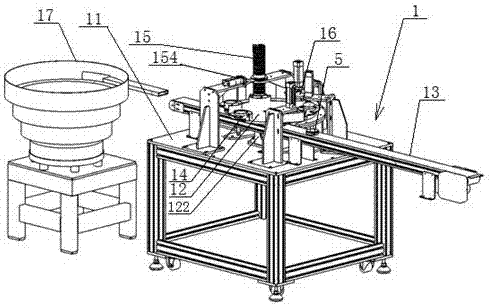

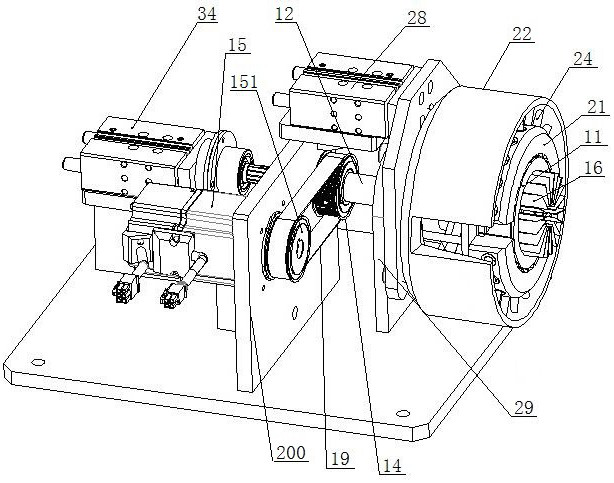

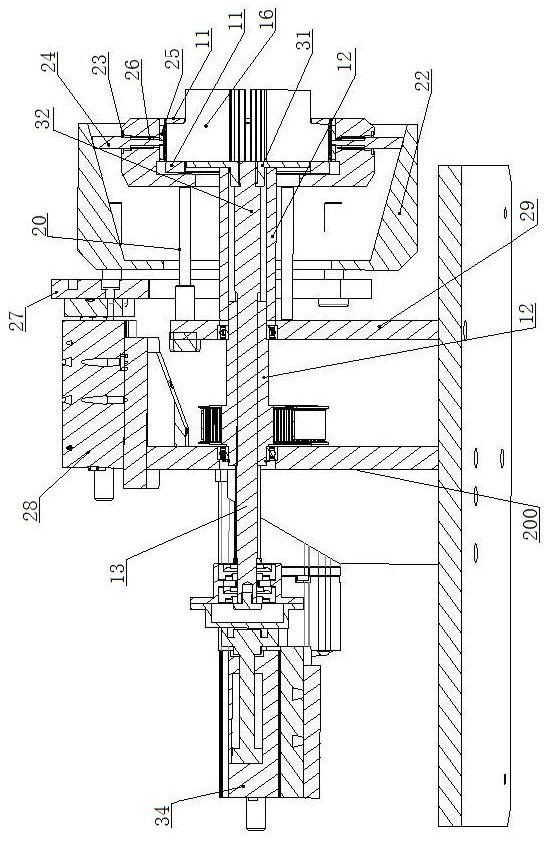

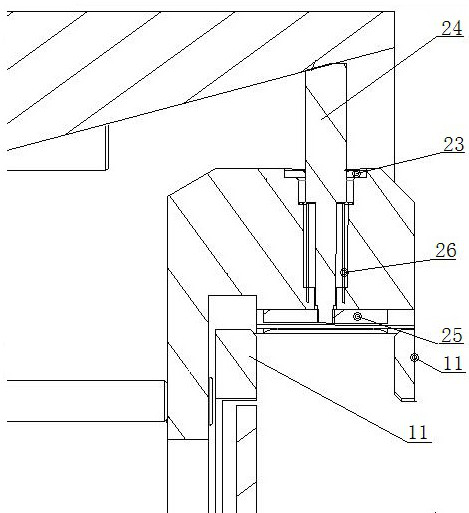

Snus barrel packaging device

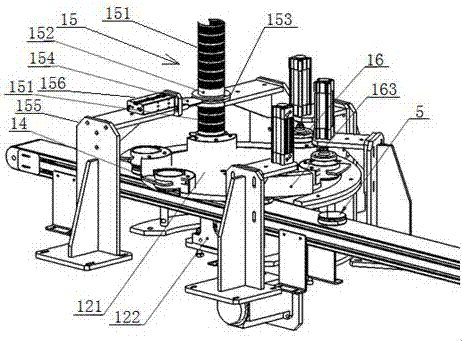

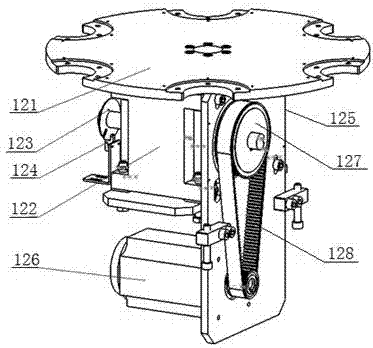

PendingCN108001762ARealize automatic material sortingHigh degree of automationWrappers shrinkagePackaging automatic controlCircular discRectangular coordinates

The invention belongs to the field of snus packaging, and particularly relates to a snus barrel packaging device. The snus barrel packaging device comprises a visual inspection platform and a label sleeve packaging line, the platform is provided with a visual inspection rotary table, a visual inspection device and a pushing air cylinder assembly, the visual inspection rotary table is provided witha negative pressure adsorption disc and a hollow rotating shaft, a rectangular coordinate mechanical arm is arranged between the platform and the label sleeve packaging line, the label sleeve packaging line comprises a label sleeve machine, a thermal contraction furnace and a circulation conveying line, and the annular conveying line is provided with a barrel transferring die. According to the snus barrel packaging device, the rectangular coordinate mechanical arm is matched with the visual inspection rotary table, and therefore arrangement and stacking of box-packed snus in the same direction can be achieved; and through a transferring die and the conveying line, automatic circulated label sleeve and thermal contraction barrel packaging of multiple stacked snus (the number of the snus boxes is generally ten, hereinafter referred to as barrels) are achieved, the barrel stacking is ordered and attractive, and the barrel packaging external packing quality is improved.

Owner:ETABONG QINGDAO TOBACCO MACHINERY

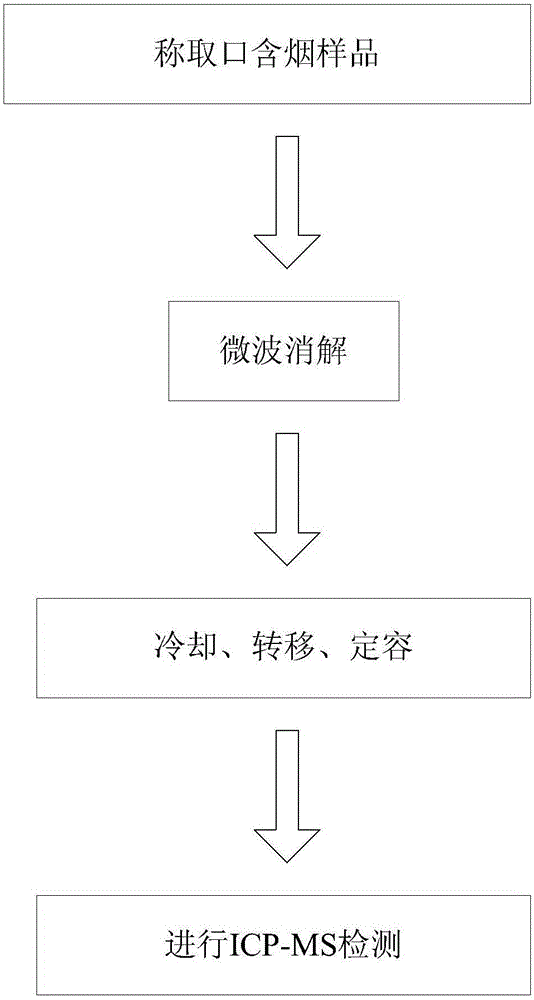

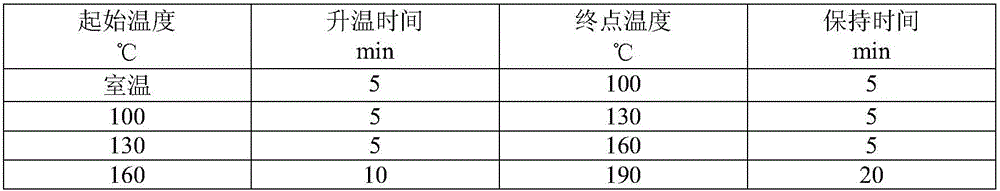

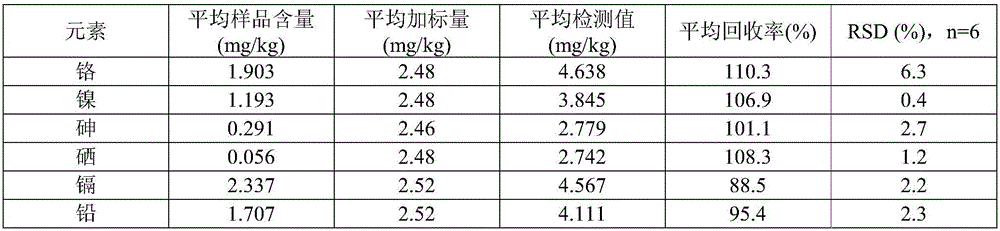

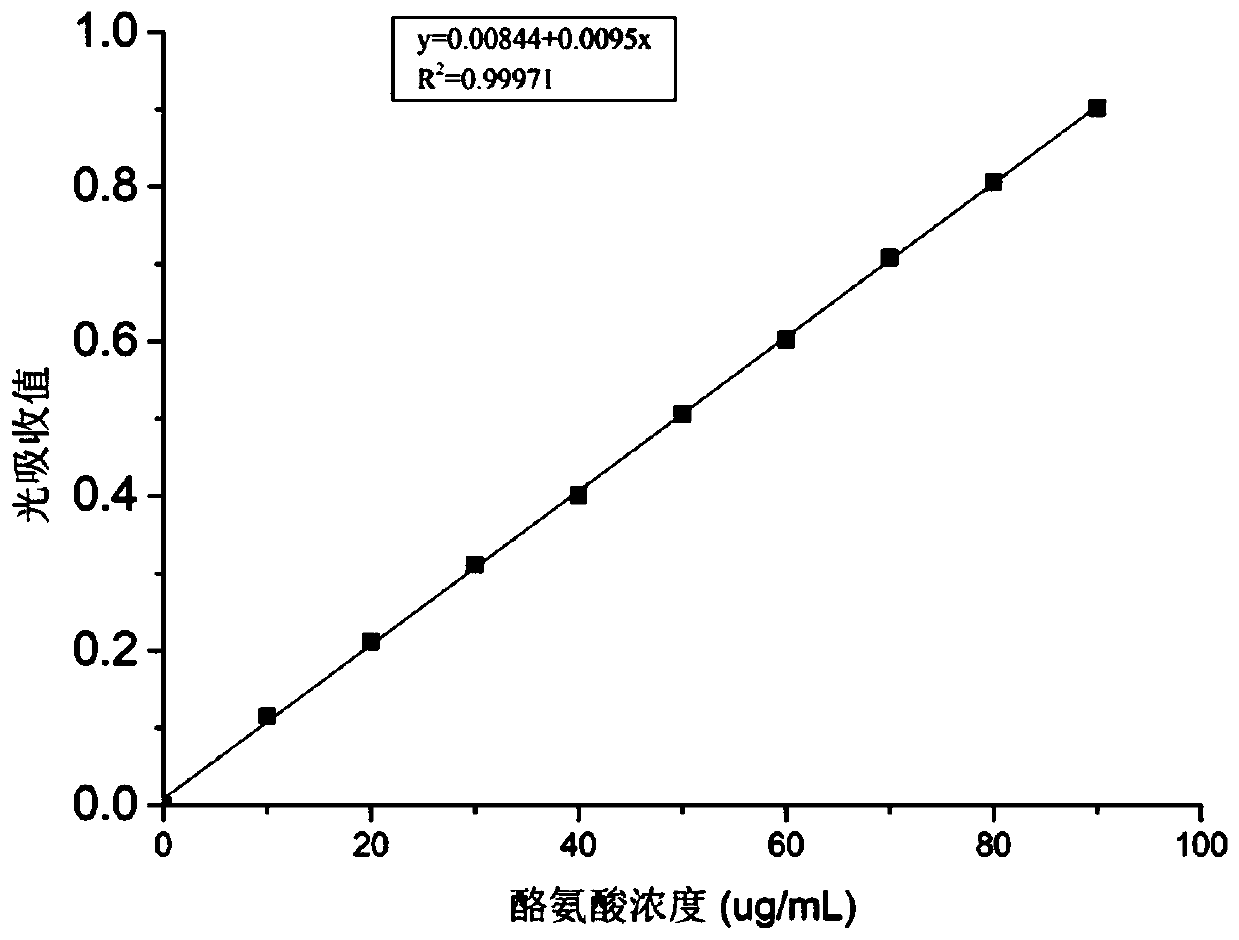

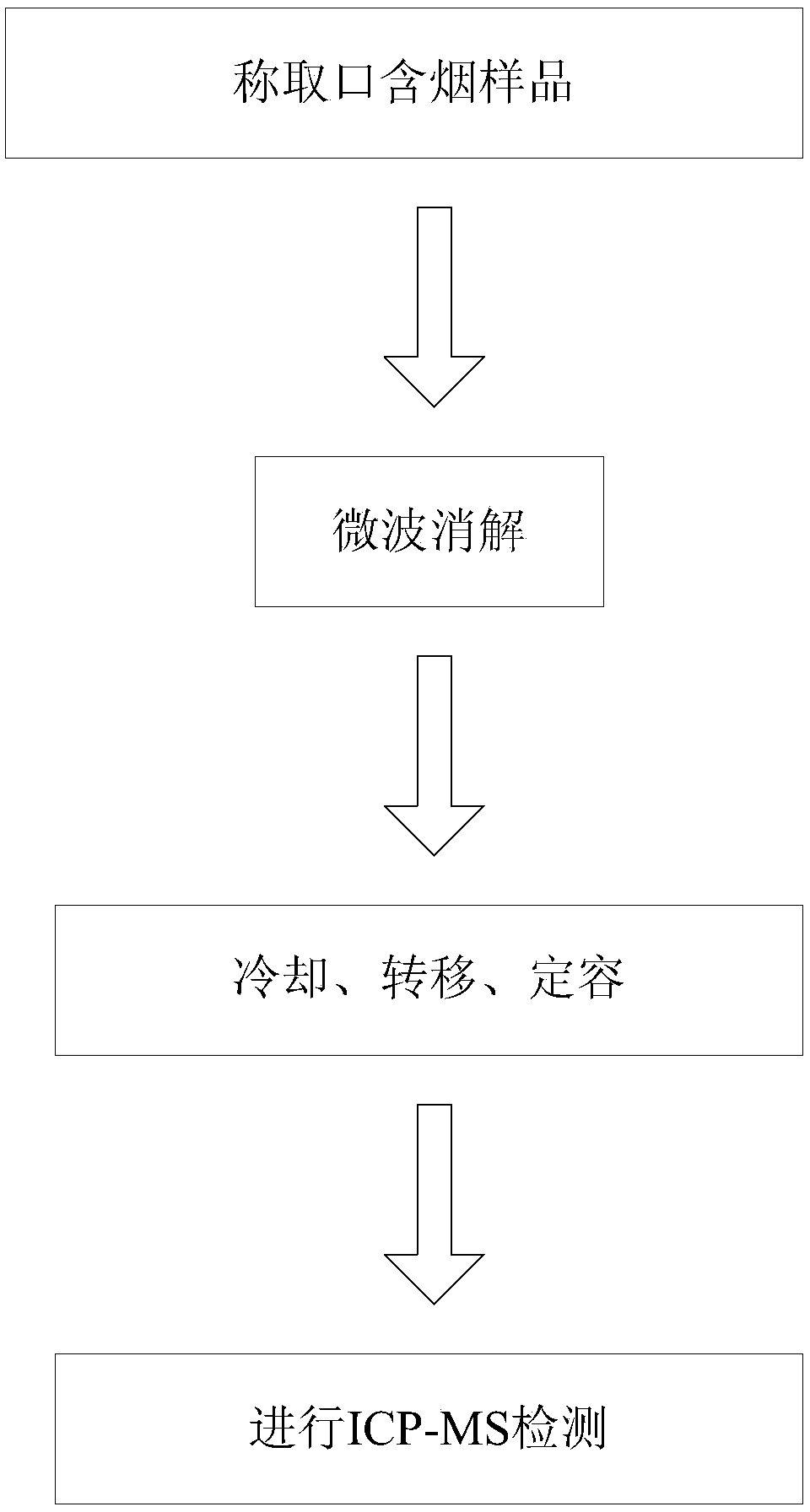

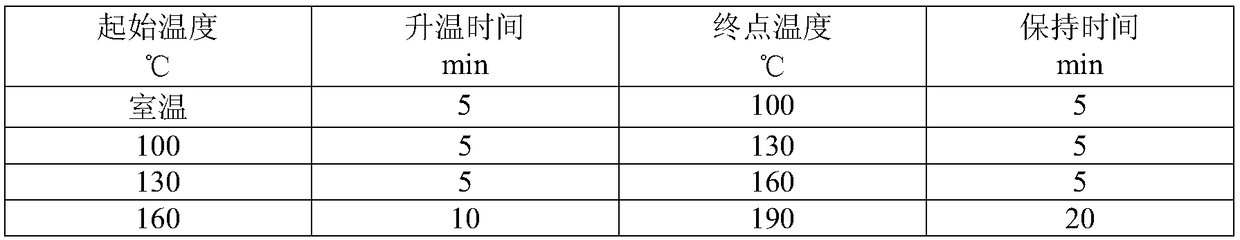

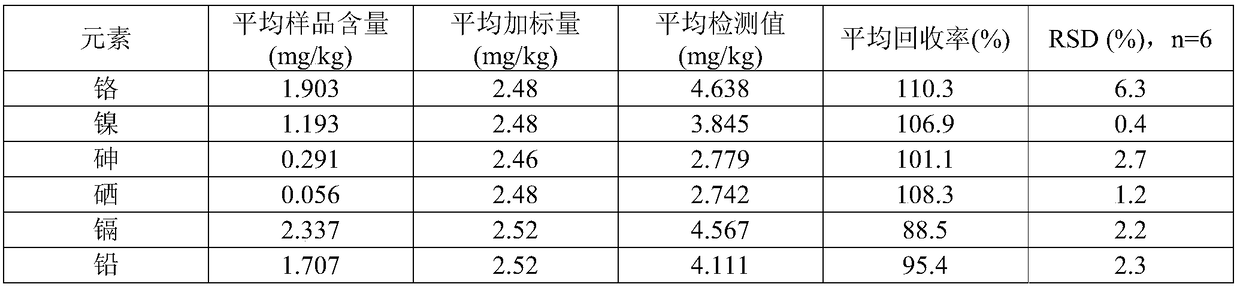

Determination method of chromium elements, nickel elements, arsenic elements, selenium elements, cadmium elements and lead elements in Snus

ActiveCN105784828AEffective Quantitative Assay ControlPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumInductively coupled plasma

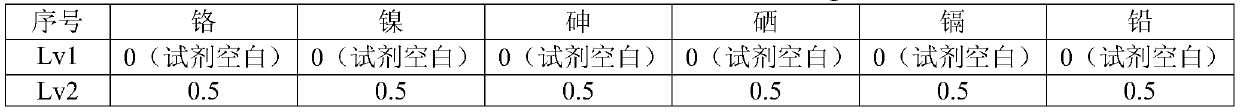

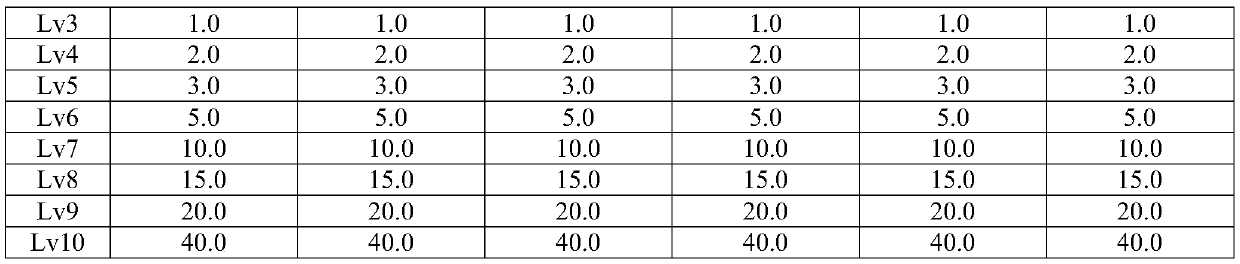

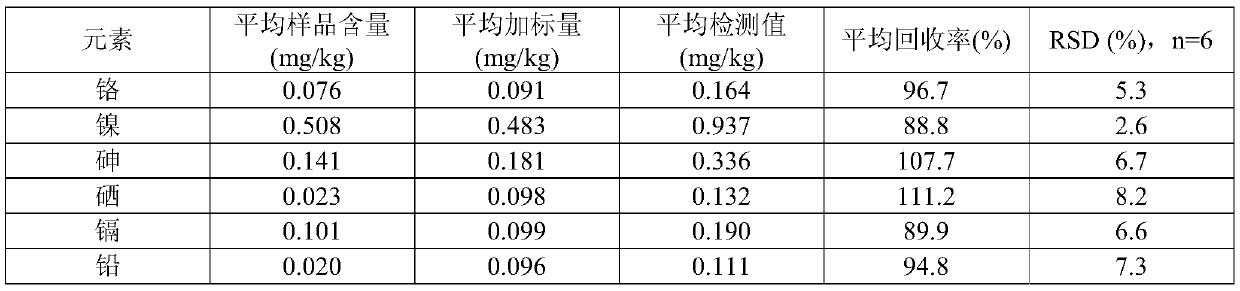

The invention provides a determination method of chromium elements, nickel elements, arsenic elements, selenium elements, cadmium elements and lead elements in Snus. The determination method comprises the following steps: (1) performing sample pretreatment: weighing Snus samples, performing resolution by a microwave resolution method, then performing cooling and transferring, and setting a volume so as to obtain a sample solution; (2) preparing a standard liquid: preparing an internal standard solution of germanium <72>, indium <115> and bismuth <209>, and a standard solution of chromium elements, nickel elements, arsenic elements, selenium elements, cadmium elements and lead elements; (3) separately performing detection on the sample solution, the standard solution and the internal standard solution with an inductively coupled plasma mass spectrometer, and performing quantitation with an internal standard synchronous standard curve method so as to obtain the content of the chromium elements, the content of the nickel elements, the content of the arsenic elements, the content of the selenium elements, the content of the cadmium elements and the content of the lead elements in the sample solution. According to the determination method of the chromium elements, the nickel elements, the arsenic elements, the selenium elements, the cadmium elements and the lead elements in the Snus, provided by the invention, correlation coefficients, the recovery rate and the repeatability are good, and effective quantitative determination and control of relevant technical staff in tobacco trade on the content of six kinds of heavy metal elements in the Snus are facilitated.

Owner:SHANGHAI TOBACCO GRP CO LTD

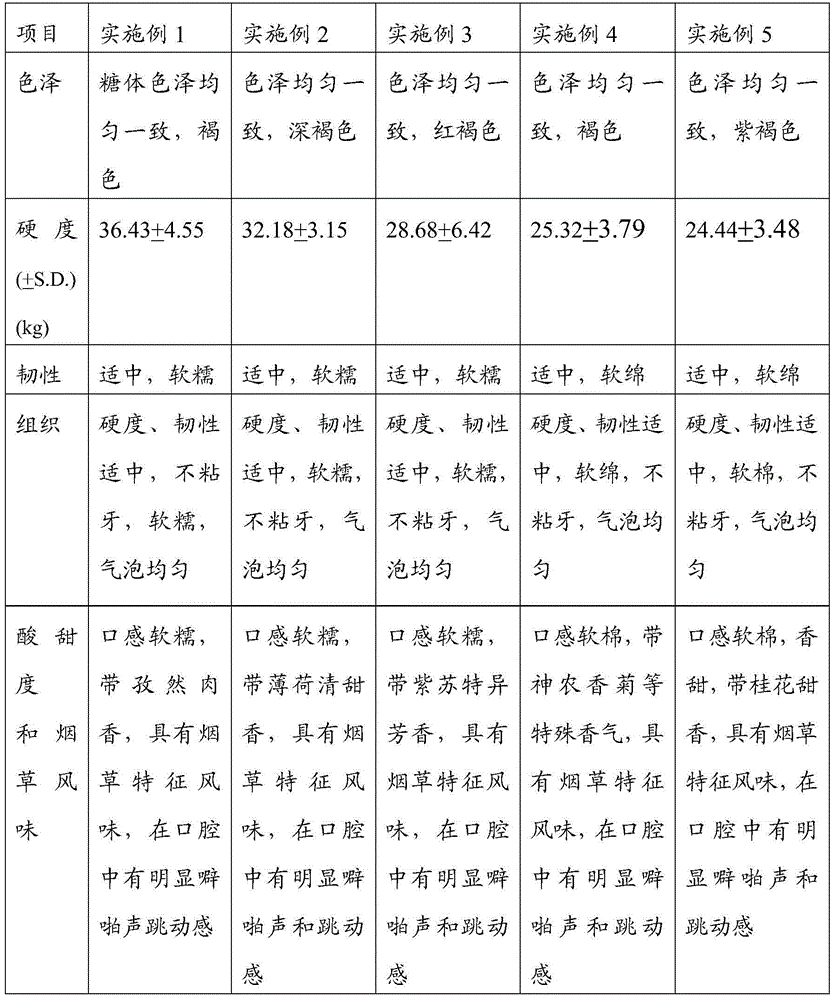

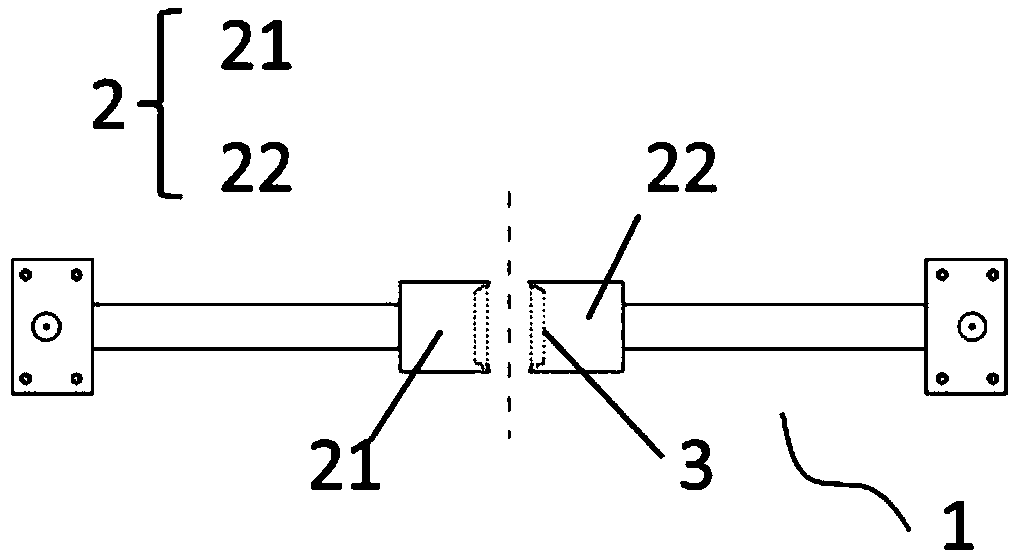

Soft snus and preparation method thereof

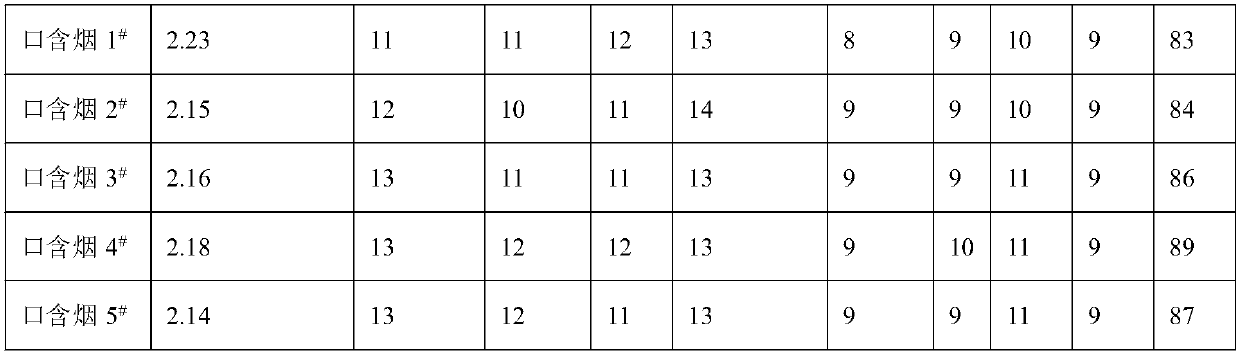

The invention discloses a soft snus and a preparation method thereof, the raw materials of the soft snus, calculated according to parts by weight ratio, are composed of: 5 to 20 parts of tobacco powder, 10 to 40 parts of sugar, 10 to 30 parts of corn starch or defatted soybean powder, 20 to 40 parts of binding agent, 0.5 to 3 parts of corrigent, 1 to 5 parts of spice and 10 to 20 parts of water. Put the sugar and the tobacco powder into hot water, stir uniformly, and heat the mixture to 60 to 150 DEG C; until the melted material is cooled to 60 DEG C, add the binding agent, natural perfume and the corrigent into the mixture, mix and stir uniformly; obtain the melted material, then add the corn starch or the defatted soybean powder, mix and stir uniformly; obtain the soft snus with different shapes. The snus disclosed by the invention contains many tiny and uniform carbon dioxide bubbles, when the snus is contained in the mouth, with the surface of the sugar dissolving gradually, the small bubbles therein breaks one by one, give out light sound of cracking, generate a tiny bursting (cracking) effect, and give people a unique sense and a novel sense.

Owner:HUBEI CHINA TOBACCO IND

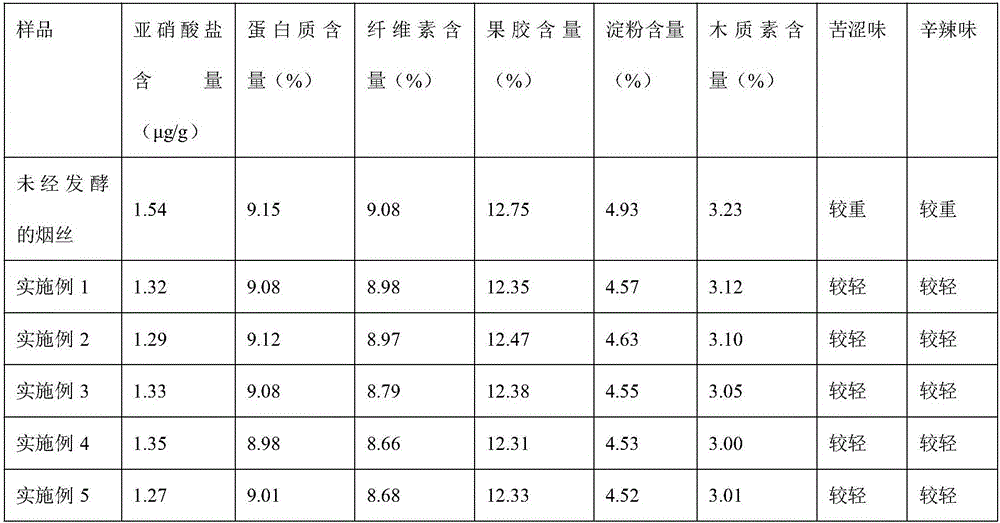

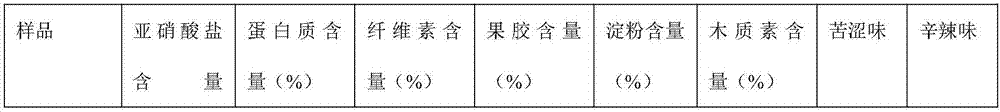

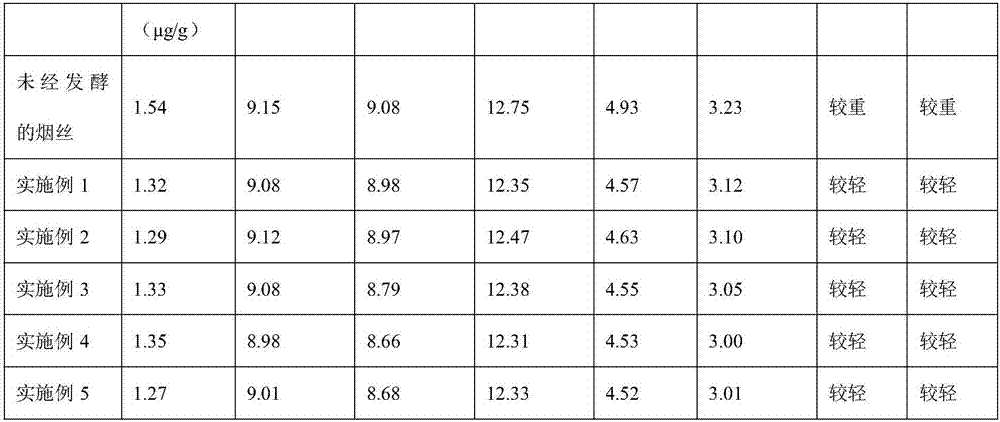

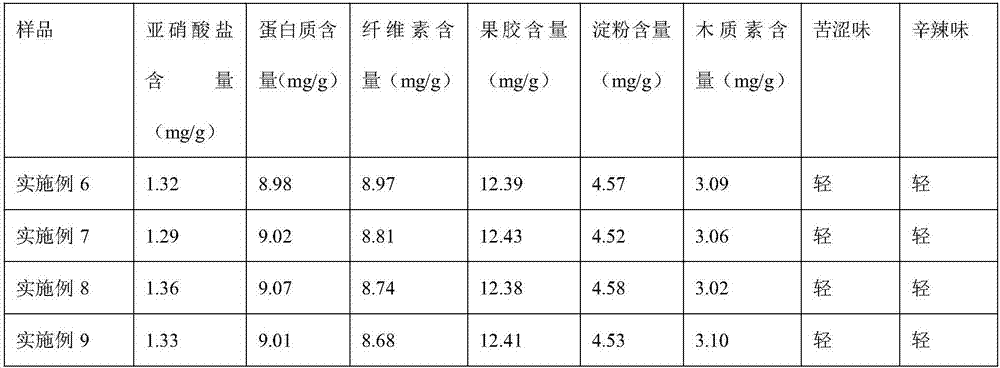

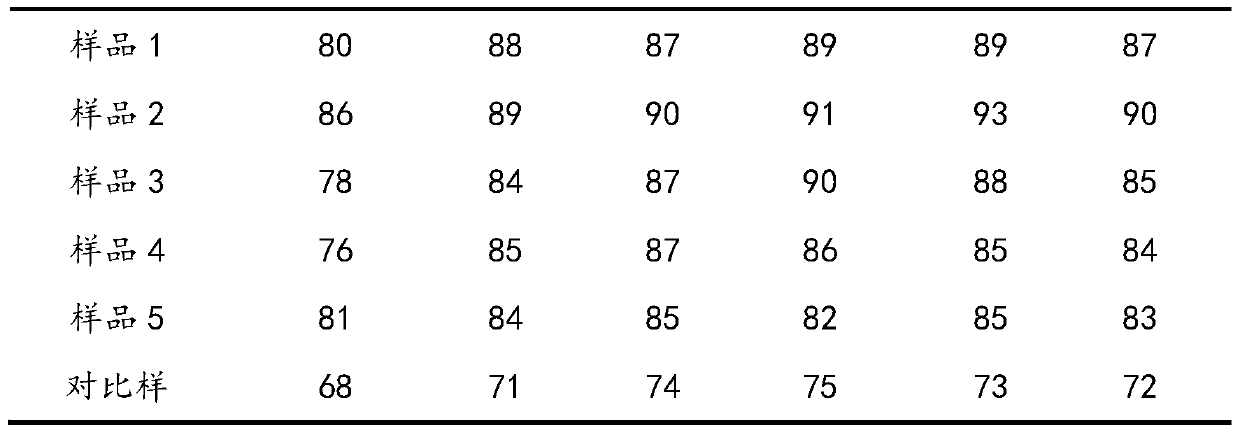

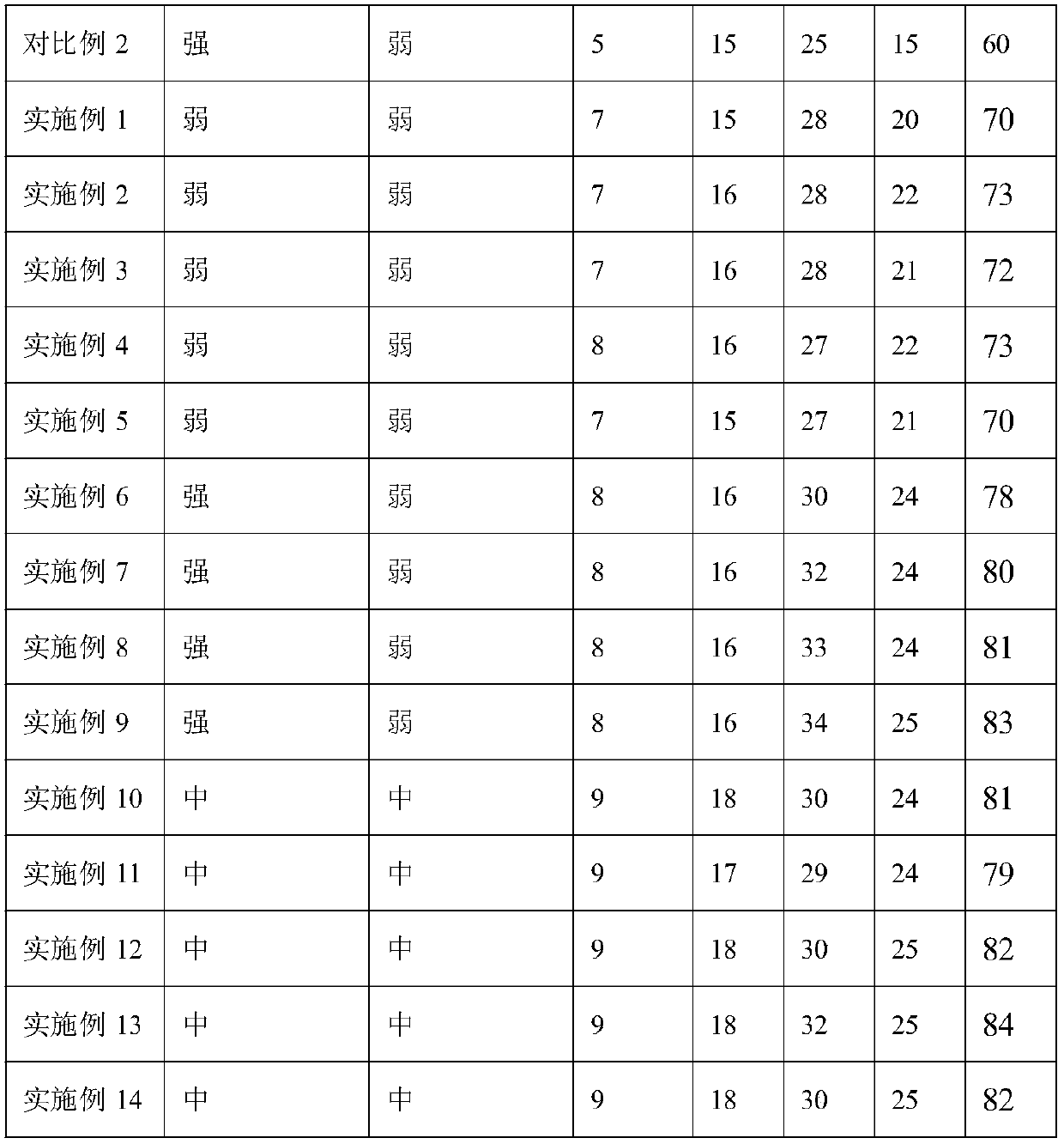

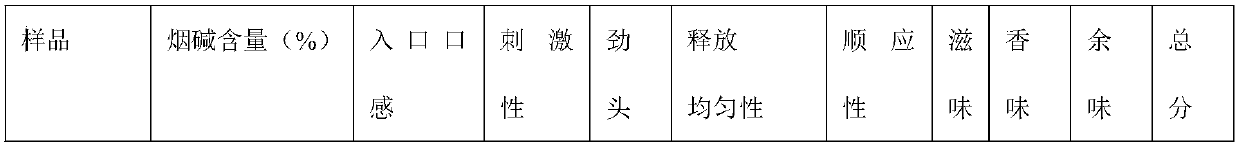

Method for preparing cigarette tobacco suitable for snus and application of cigarette tobacco

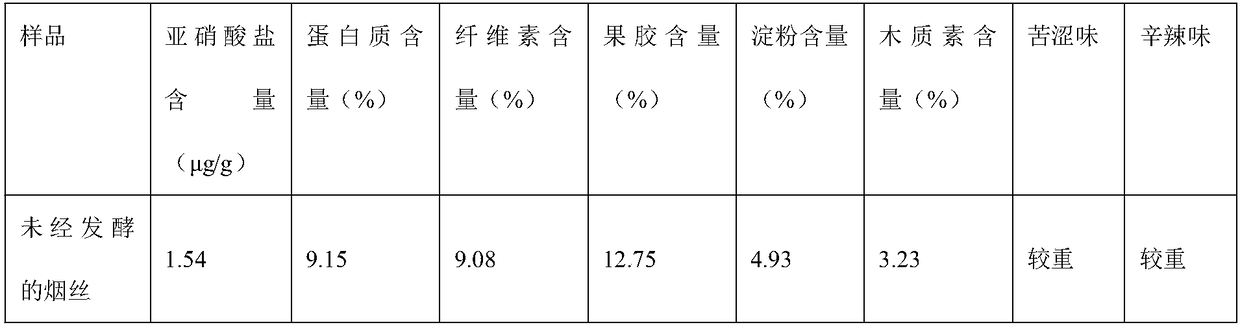

ActiveCN105831799AEfficient removalEffective bitternessTobacco treatmentMacromolecular SubstancesBiology

The invention discloses a method for preparing cigarette tobacco suitable for snus and application of cigarette tobacco. Part of large-molecular matter in tobacco is degraded through scientific and reasonable microorganism fermentation by means of a tobacco leaf composition of a reasonable formula, bitterness and spicy taste of cigarette tobacco are effectively reduced, and the cigarette tobacco has the soft and coordinative sensory characteristics. The tobacco leaves are processed in a targeted mode through the scientific fermentation technology, taste comfort of raw materials of snus is improved, fragrance is rich and mellow, green miscellaneous gas and irritation of the raw materials are successfully reduced, and the use quantity of flavoring agents and other additives is effectively reduced.

Owner:CHINA TOBACCO GUANGDONG IND

Snus preparation method

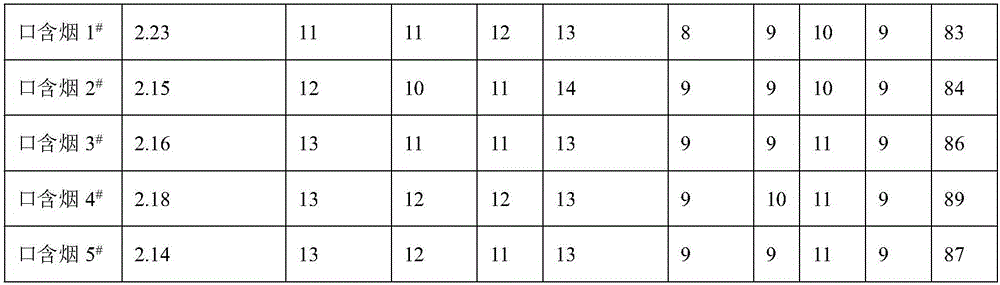

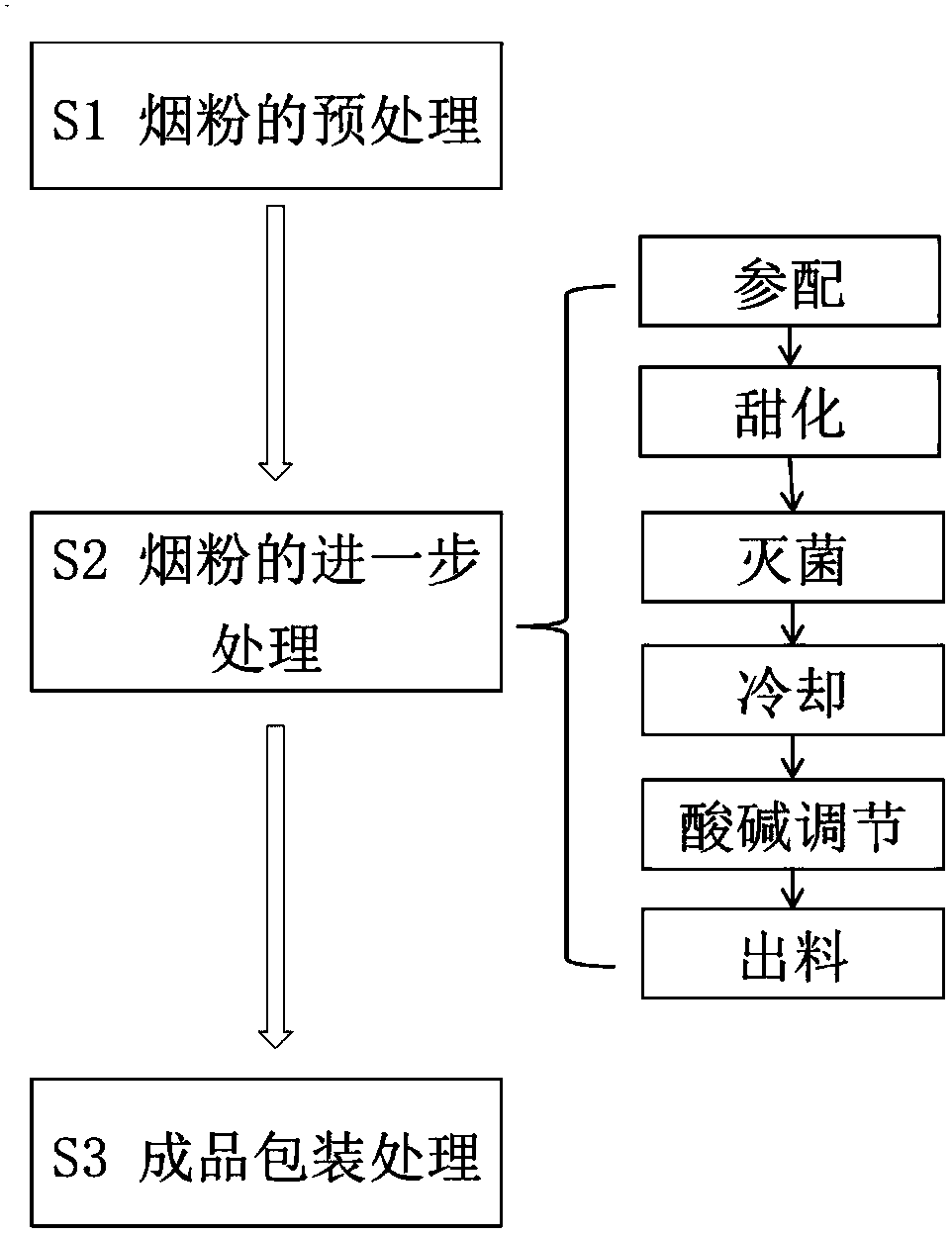

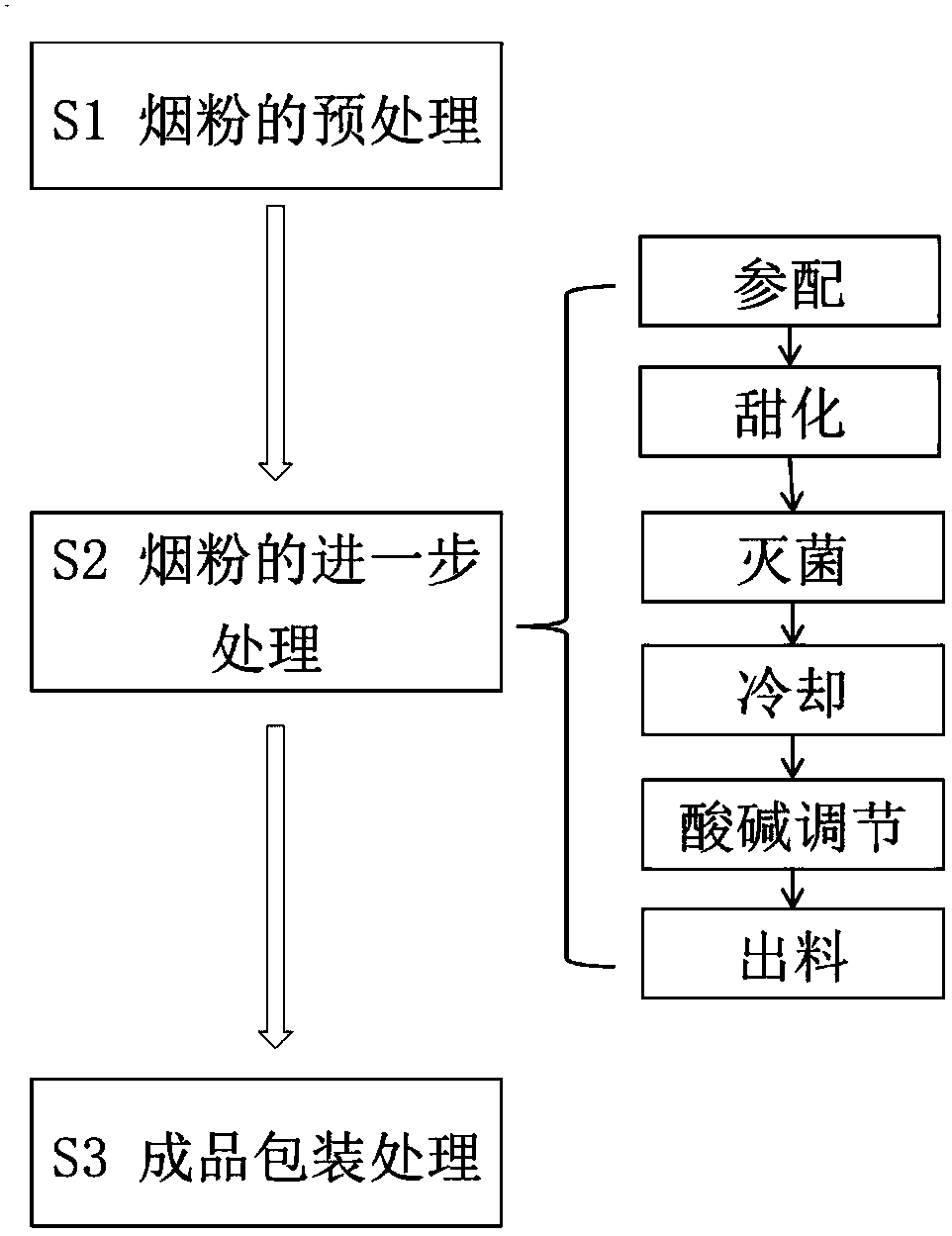

The invention discloses a snus preparation method. The method comprises the following steps of S1, preprocessing tobacco powder; S2, further processing tobacco powder, wherein preparation is performed, automatic sampling is performed according to a certain ratio, sweetening is performed, high-boiling-point feed liquid is added for performing sweetening treatment, sterilizing is performed, steam isadopted for performing high-temperature sterilizing treatment, cooling is performed, acid-base regulation is performed, a pH regulating solution is added for regulating pH of materials, and discharging is performed; S3, performing finished product packaging treatment. Compared with the prior art, the method has the advantages that a finished product is high in quality, convenient to carry, capable of meeting the requirements of different users, high in automatic degree, capable of meeting the batched production requirement, and the like.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD

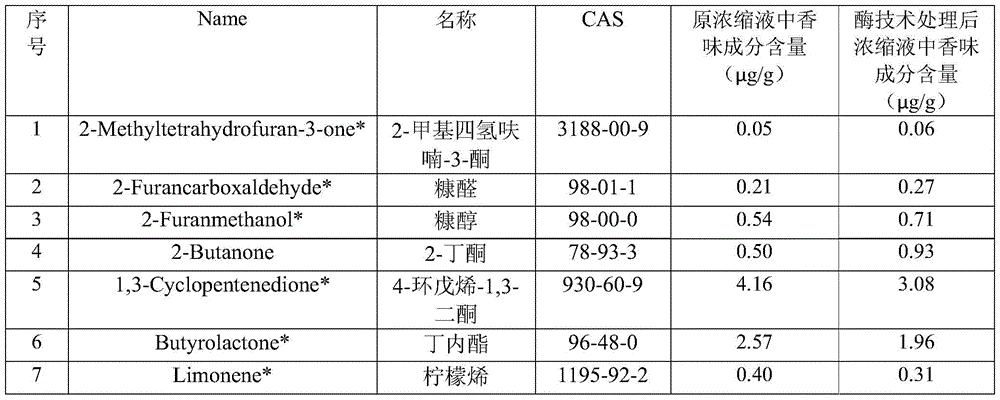

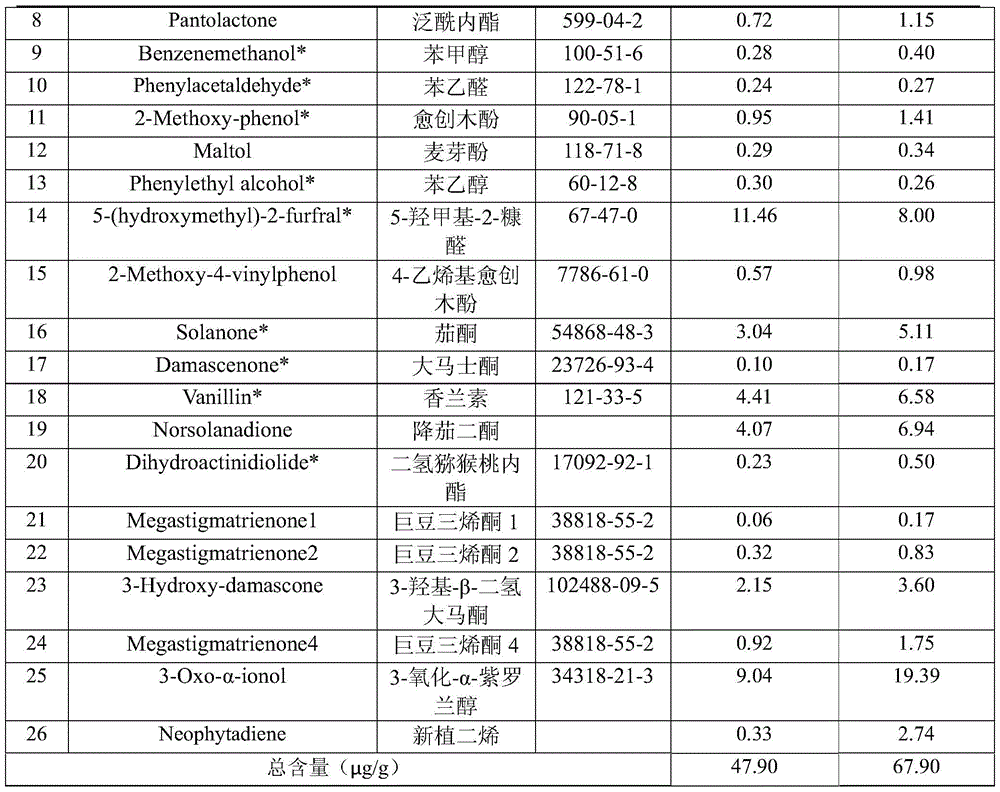

Method for applying tobacco flavor extracted from tobacco branches to snus

The invention discloses a method for applying tobacco flavor extracted from tobacco branches to suns. The method includes pretreating different types of tobaccos, drying tobacco branches of flue-cured tobacco under a low temperature of 40-60 degrees, air drying tobacco branches of burley tobacco and cigars in a ventilating room, sterilizing pretreated dried tobacco branches through UV light, grinding the sterilized tobacco branches into 10-80 meshes, adding crushed samples into a supercritical fluid extraction kettle, adding entrainer having a concentration of 60%-100%, carrying out carbon dioxide supercritical fluid extraction carbon dioxide under an extraction temperature of 40-65 degrees and extraction pressure of 200-350bars, adding extract product of the tobacco branches in snus at a mass proportion of 0.1%-0.3%. The method applies tobacco flavor extracted from tobacco branches through supercritical fluid technology to suns, which solves the problem of insufficiency of raw materials, ensures the safety of snus, minimizes environmental pollution and prevents resources waste.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Comprehensive processing method for bagged Pu'er tea snus

ActiveCN107549865AImprove taste comfortGood sense of satisfactionTobacco preparationTobacco treatmentFlavorCold storage

The invention discloses a comprehensive processing method for bagged Pu'er tea snus, and belongs to the technical field of tea processing. The method includes the following steps of even mixing of fresh tea leaves and ground tea leaves, fixation, first rolling, piling, drying, steam treatment, acid-base regulation, cold storage alcoholization and split charging to obtain the bagged Pu'er tea snus.By means of the comprehensive processing method for the bagged Pu'er tea snus, the obtained bagged Pu'er tea snus has a rich mixed flavor of natural Pu'er tea and tobacco, the taste comfort, satisfaction and excitation are greatly improved, and then the flavor quality and healthcare effect of the product are greatly improved.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

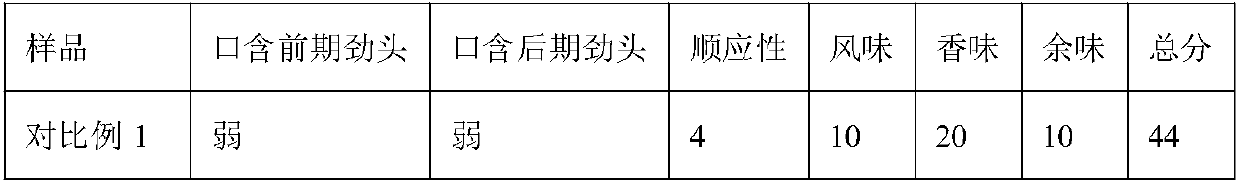

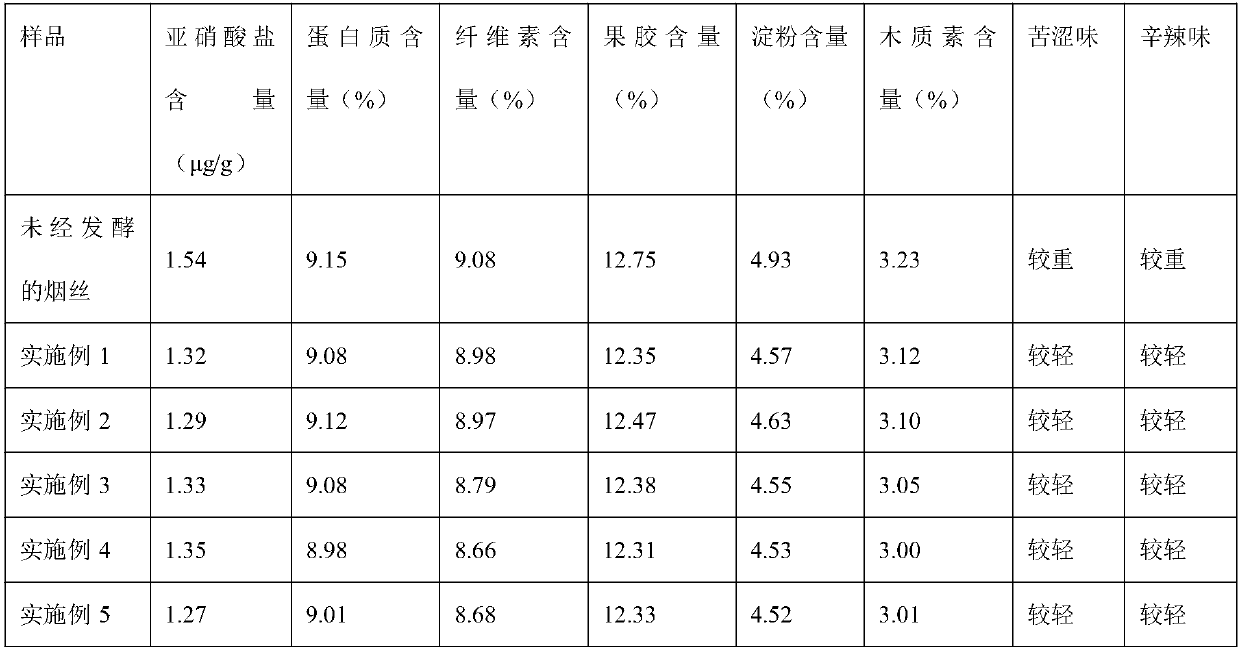

fermented snus

The invention discloses a fermented buccal tobacco. The buccal tobacco is prepared from the following components by mass percent: 50%-80% of tobacco shred particle, 10%-30% of water, 1%-5% of flavoring agent, 1%-5% of sweetening agent, and 1%-10% of odorant. The tobacco leaf group is fermented through microorganism to obtain the tobacco shred particle, the tobacco shred particle is reasonably seasoned so as to improve the mouthfeel comfort of the buccal tobacco raw material, the flavor quality is abundant and thick, the green miscellaneous gas and irritation of the raw material are successfully eliminated, the quality of the tobacco leaf is effectively improved, and the high-quality buccal tobacco is obtained in the combination with the reason and safe seasoning treatment.

Owner:CHINA TOBACCO GUANGDONG IND

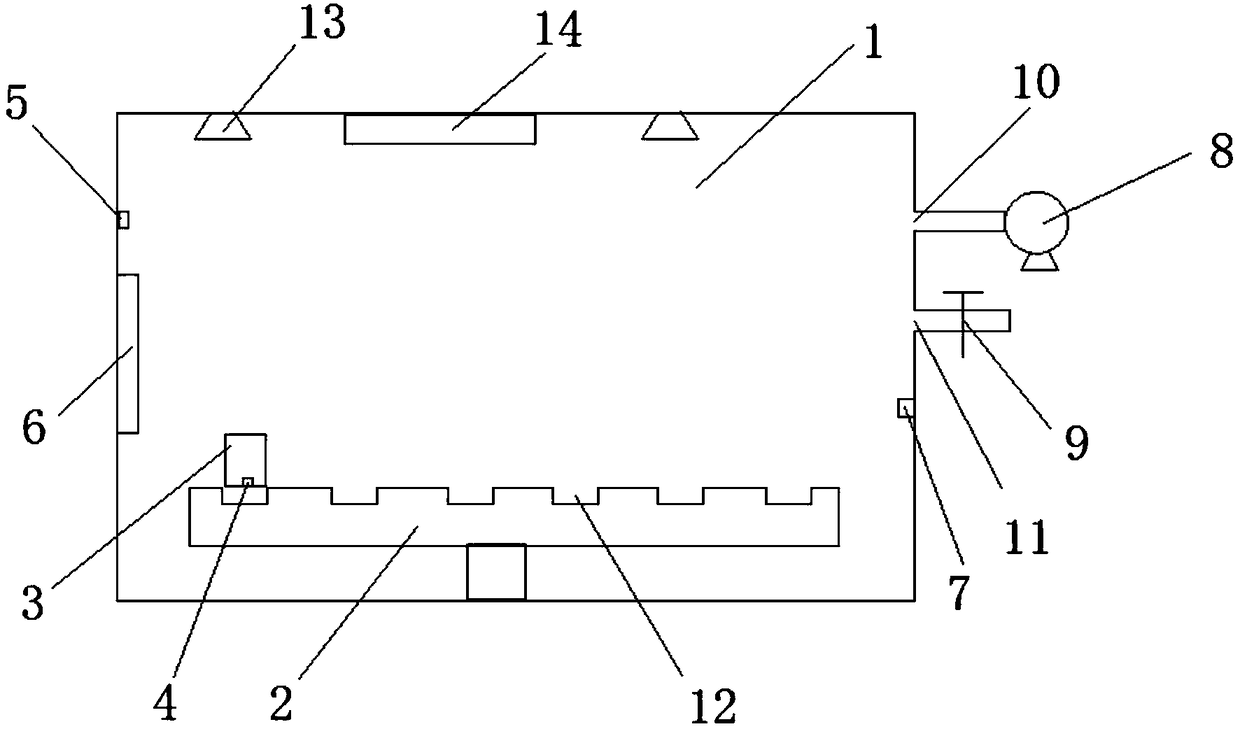

Packaging system for snus

PendingCN107985693ARealize automatic buckleAchieve cullingPackaging automatic controlPackaging foodstuffsEngineeringMechanical engineering

The invention provides a packaging system for snus and belongs to the field of snus packaging equipment. The packaging system comprises a feeding-into-box device, a cover buckling device and a weighing, removing and caching device which are connected in sequence; the packaging system further comprises a feeding-into-box work platform, a feeding-into-box turntable assembly, a first conveyor, a cover buckling work platform, a cover buckling turntable, a second conveyor, a support platform and a third conveyor, wherein small snus boxes can sequentially pass through the first conveyor, the secondconveyor and the third conveyor to finish feeding-into-box, cover buckling, weighing, removing and caching. The packaging system has the beneficial effects as follows: small snus bags are accurately fed into the boxes by the feeding-into-box device, and multi-station positioning of the small boxes is realized; by means of the cover buckling device, automatic buckling of box covers and the small boxes is realized, and unqualified products are removed; by means of the weighing, removing and caching device, accurate detection, screening and transportation of the small box and box cover combinations are realized. With the adoption of the whole system, automatic feeding-into-box, cover buckling, detection and screening of the small snus bags are realized.

Owner:ETABONG QINGDAO TOBACCO MACHINERY

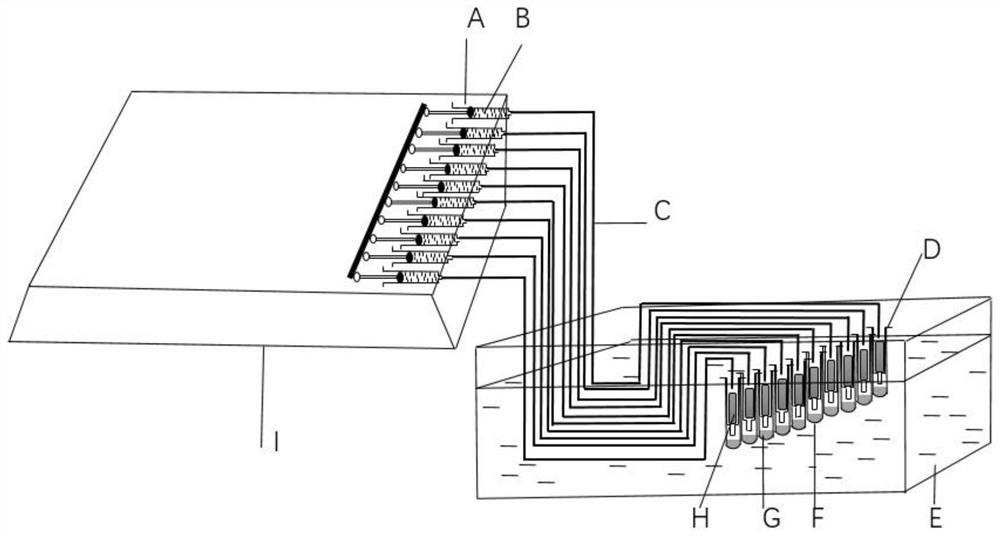

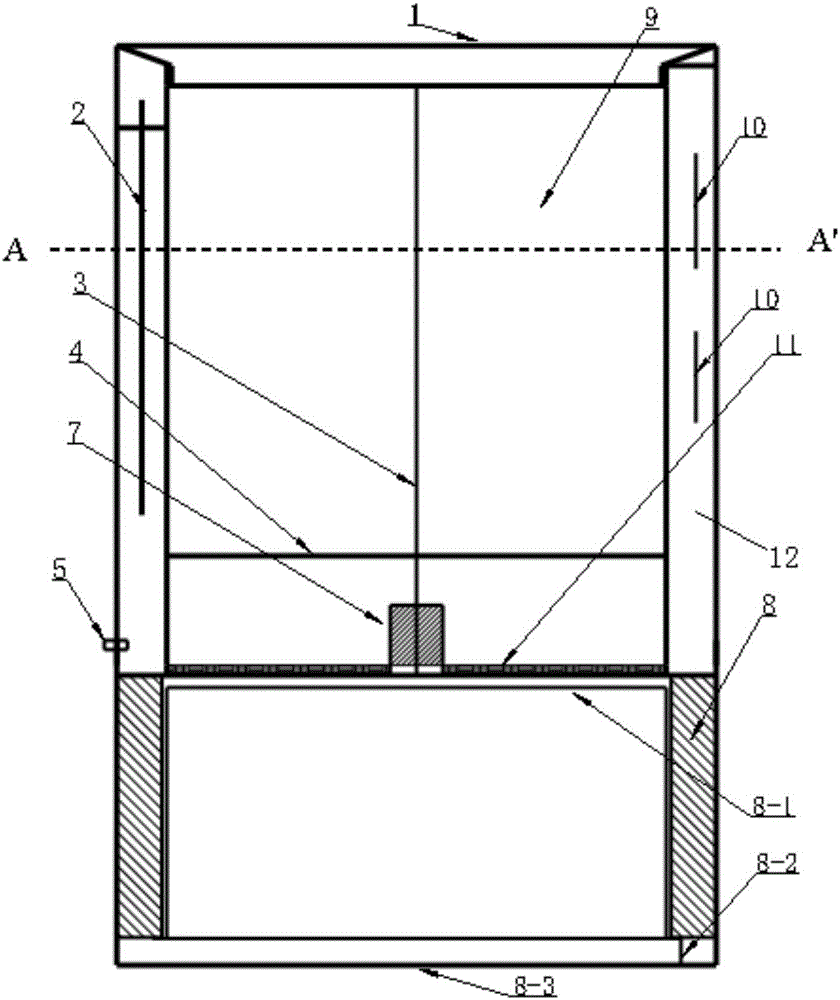

Bacterial culture apparatus and method for testing antibacterial performance of snus

PendingCN108485953AImprove test efficiencyReduce manual labor intensityBioreactor/fermenter combinationsBiological substance pretreatmentsTest efficiencyTemperature control

The invention relates to a bacterial culture apparatus and a method for testing the antibacterial performance of snus. The apparatus comprises a plurality of independent box bodies, wherein a turntable is arranged in each box body, the turntable is provided with a plurality of fixed grooves for placing culture dishes, a temperature control unit and a gas exchanging unit are arranged in the box body, a rotator is arranged in the culture dish, and the bacterial culture apparatus is also provided with a controller which is connected with the temperature control unit and the gas exchanging unit inthe box body; and the to-be-tested snus and bacteria are cultured in the box body, so that the antibacterial performance of the snus can be determined. Compared with the prior art, the antibacterialperformance of the snus of the same batch can be tested by virtue of the apparatus of the invention, and the test efficiency is high; moreover, the temperature control unit and the gas exchanging unitare automatically controlled by virtue of the controller, so that the labor intensity is small; and meanwhile, the antibacterial performance of the snus can be quantitatively and qualitatively tested, and a test result is more complete.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD +1

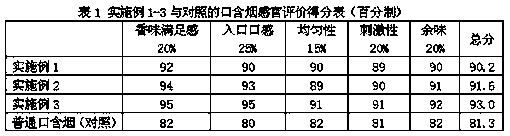

Fermented snus with slow-release function and preparation method thereof and snus

The invention discloses a fermentation type mouth-holding cigarette with a slow release function and a preparation method thereof. The mouth-holding cigarette is prepared from 50-80% of mixed cut tobacco granules, 10-30% of water, 1-5% of corrigent, 1-5% of sweetening agent and 1-10% of flavoring agent. The mixed cut tobacco granules is the mixture of cut tobacco granules and micro capsule granules, and the mixed mass ratio of the cut tobacco granules to the micro capsule granules is 2:1-4:1. Micro capsule packaging is scientifically adopted, the defects that according to an existing product, the nicotine release speed is too high, strength is too large in the early mouth-holding stage and is too small in the later mouth-holding stage, and cigarette flavor is rapidly weakened in the whole mouth-holding process are overcome, the nicotine dissolving-out resistance in the initial mouth-holding stage is increased, and the uniform-speed nicotine dissolving-out time is prolonged on the premise of not changing the total nicotine release amount, so that it is ensured that stable strength and cigarette flavor can be kept within a long time in the mouth-holding process; in addition, no alkali salt is added.

Owner:CHINA TOBACCO GUANGDONG IND

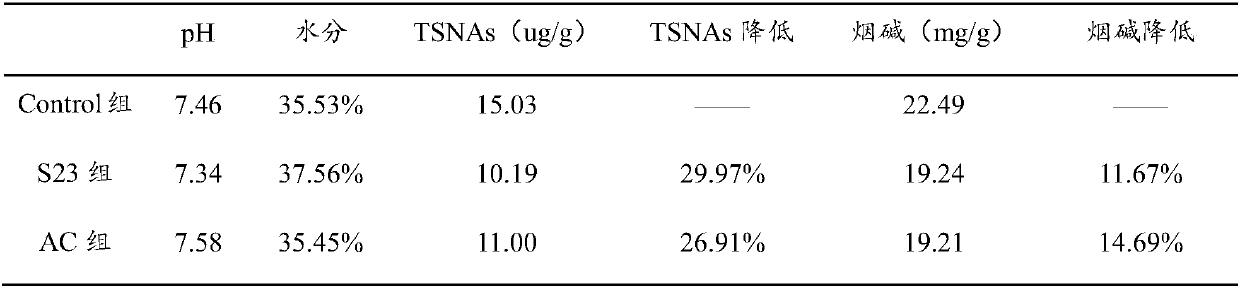

Method for adsorbing tobacco-specific nitrosamines in tobacco power of snus

InactiveCN110313631AIncrease the adsorption ratioUniform adhesionTobacco treatmentSocial benefitsTobacco-specific nitrosamines

The invention discloses a method for adsorbing tobacco-specific nitrosamines in tobacco power of snus. The method comprises the following steps that S1, the particle size of an adsorbing material foradsorbing the tobacco-specific nitrosamines (TSNA) is ground to 300-500 meshes for standby application; S2, an appropriate amount of water is added outside the tobacco power so that the moisture content of the tobacco power can be 30-50% to exhibit a wet state, and the treated tobacco power is sealed; S3, the adsorbing material is added to the treated tobacco power in the step S2 and evenly mixed,the sample is sealed and left for a period of time, so that the adsorbing material gradually adsorbs the TSNA in the tobacco power; and S4, after the adsorption is completed, the sample is dried in the air or dried by baking. Compared with the prior art, the method utilizes the wettability of the surface of the tobacco power to promote the high spread-dispersion of adsorbing particles, so that the TSNA in the tobacco power escapes outward, the adsorption performance of the adsorbing material on the TSNA is improved, energy and time are saved, environmental pollution is reduced, cost is reduced, and economic and social benefits are significant.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD +1

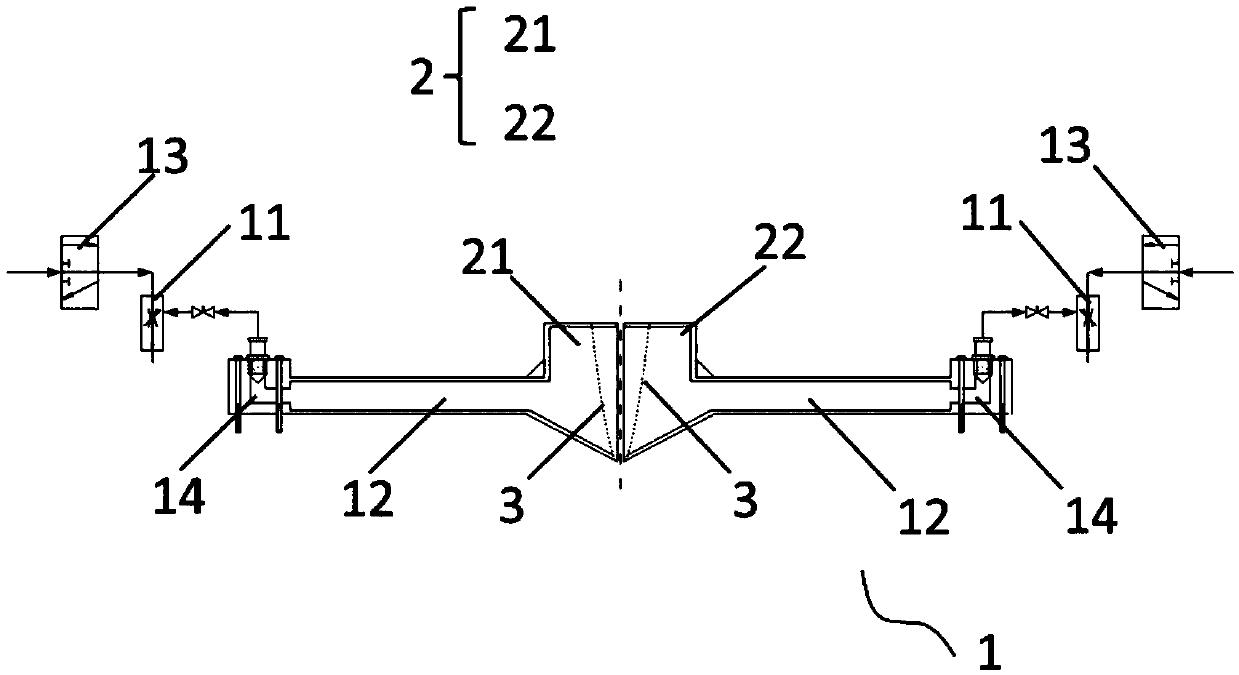

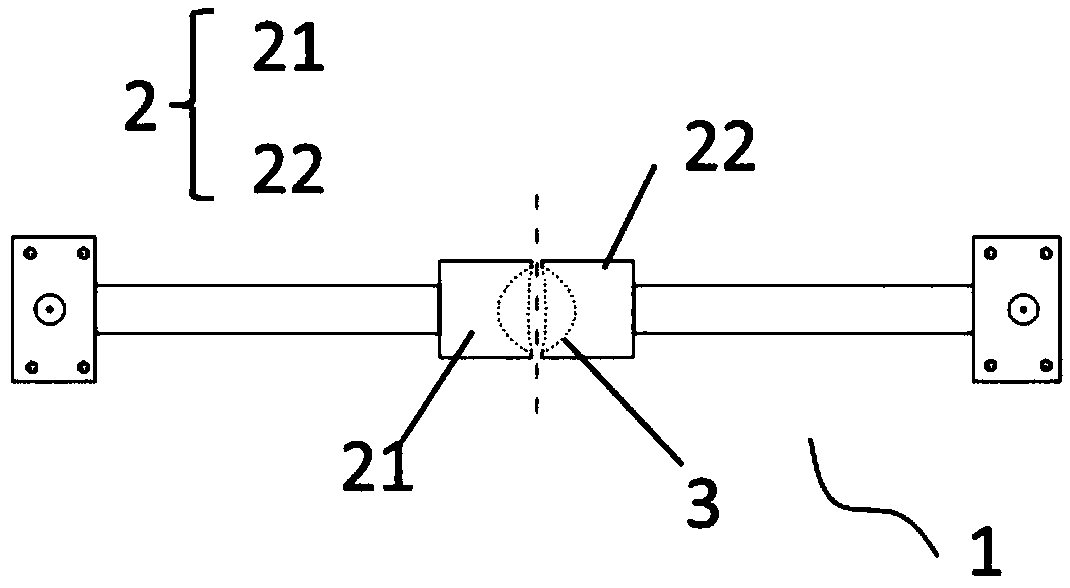

Simulated oral device and method of use for studying release of snus components

ActiveCN109406725BAccurate supplyUniform and quantitative supplyMaterial analysisArtificial salivasCatheter

The invention discloses a simulated oral cavity device for studying the release law of snus components and its use method, which includes an automatic injection pump, a plurality of syringes, a syringe jacket, a test tube and a constant temperature water bath, and the plurality of syringes are arranged on the automatic injection pump. The artificial saliva is inhaled into the syringe and connected to the syringe jacket through the catheter, the mouth smoke is placed in the syringe jacket, the syringe jacket is placed in the test tube in the constant temperature water bath and there is a gap with the bottom of the test tube; the bottom of the syringe jacket Leave an opening. The device and its use method can simultaneously collect the eluate of different or the same types of snus samples through multiple channels. After connecting multiple syringes to the automatic syringe pump, and then connecting a catheter to each syringe, it can be realized. Multiple snus samples were supplied with artificial saliva accurately, uniformly and quantitatively at the same time, and the eluate of different time periods was collected at any time.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

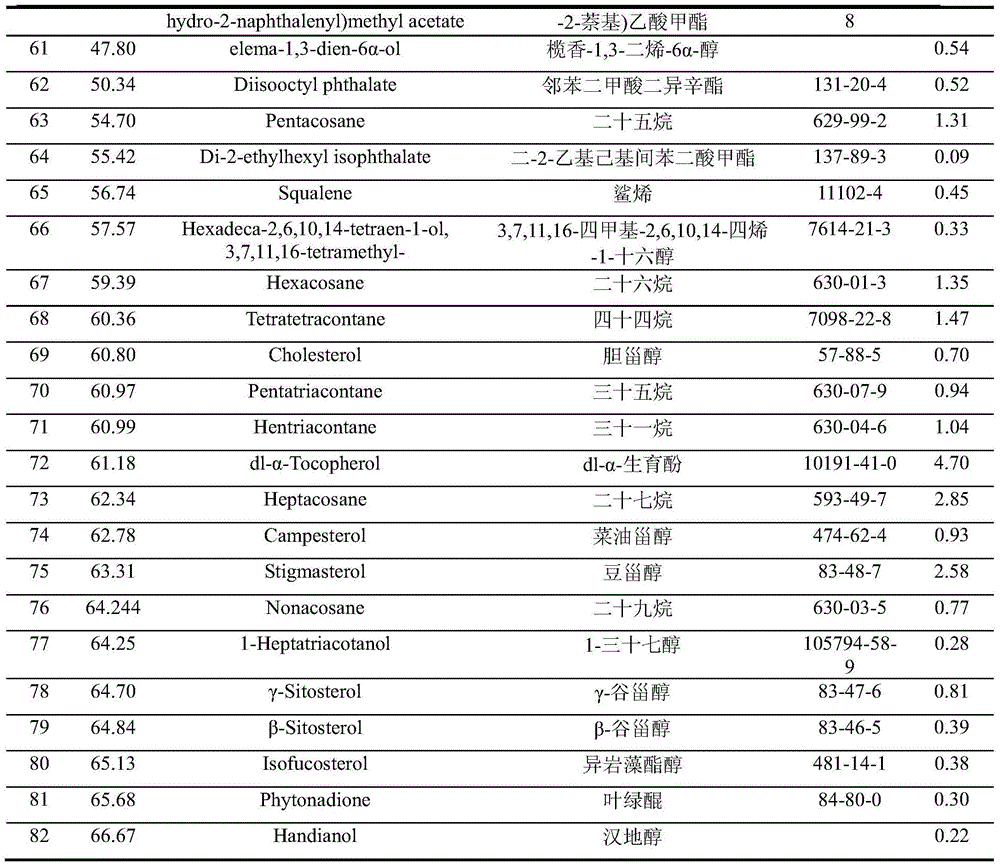

Device for packaging snus, system for packaging snus and packaging method

PendingCN111409906APrevent leakageRegular shapeWrapper twisting/gatheringSuccessive articlesEngineeringMechanical engineering

The invention provides a device for packaging snus, a system for packaging the snus and a method using the system to package the snus. The device for packaging the snus is used for wrapping and clamping a snus packaging bag when the snus packaging bag is filled with raw materials. The device for packaging the snus comprises a wrapping cavity capable of forming the negative pressure and used for wrapping and clamping the snus packaging bag. The wrapping cavity comprises a wrapping face. The wrapping face is in contact with the interior of the wrapping cavity and wraps the end face of the snus packaging bag. The wrapping face is sunken relative to the interior of the wrapping cavity and is a breathable surface. According to the device for packaging the snus, the end clamping phenomenon whenthe snus is packaged at present is solved, the leakage of the cigarette material is avoided, and the appearance of the snus packaging bag is regular and consistent.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD +1

A comprehensive processing method of bagged Pu'er tea snus

ActiveCN107549865BImprove taste comfortGood sense of satisfactionTobacco preparationTobacco treatmentFlavorCold storage

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Tobacco leaf particle suitable for preparing snus and application thereof

The invention discloses tobacco leaf particles suitable for preparing buccal cigarettes and application of the tobacco leaf particles. According to the tobacco leaf particles, tobacco leaves are shredded, carbon dioxide expansion treatment is carried out, then fermentation treatment is carried out, screening is carried out after micro smashing, and the permeable part is taken. The bitterness and spicy taste of the tobacco leaves are removed through pertinent scientific treatment, the fragrance is rich and mellow, the tobacco leaf particles and auxiliary materials are scientifically matched, reasonable and safe seasoning treatment is carried out, and a new buccall cigarette material is obtained. The taste is richer, the flavor is coordinative and high in quality, the buccal cigarettes can be gradually molten in the mouth in the eating process, no particle feeling or rough feeling is generated in the oral cavity, and the buccal cigarettes do not need to be abandoned after being eaten.

Owner:CHINA TOBACCO GUANGDONG IND

Easy-feeding snus container

The invention discloses an easy-feeding snus container comprising a container body; a first cavity and a second cavity are arranged at an interval in the horizontal direction in the container body; the first cavity is matched with a lifting unit; the lifting unit drives snus product in the first cavity to rise up for a user to take or for storage; the second cavity is matched with the lower portion of the first cavity; a storage portion is arranged in the second cavity so as to store snus residual after usage; the first cavity used for containing snus of the snus container is provided with the lifting unit; the lifting unit can drive the snus in the first cavity to rise up, thus allowing the user to more conveniently enjoy the snus; the snus container comprises the first and second cavities arranged at interval; the storage portion is arranged in the second cavity so as to well store the snus residual, thus preventing environment pollution.

Owner:CHINA TOBACCO SHANDONG IND

A device for snuffing cigarettes into a box

ActiveCN106829004BSolve time-consuming and laborious problemsReduce labor intensityProcess efficiency improvementIndividual articlesStructural engineeringStorage ring

Owner:ETABONG QINGDAO TOBACCO MACHINERY

Preparation method of bibacterial preparation for producing multiple enzymes and application of bibacterial preparation

InactiveCN109797117AImprove qualityImprove food valueBacteriaTobacco treatmentAmylaseProteinase activity

disclosed is a bibacterial preparation for producing multiple enzymes. The bibacterial preparation is prepared from bacillus amyloliquefaciens GUHP-86 and bacillus amyloliquefaciens GZU03. The preparation method includes 1), preparation and sterilization of a seed solution; 2), preparation of single preparations; 3), preparation of the bibacterial preparation for producing the multiple enzymes. In the method, tobacco leaves are put in a sealed bag, two single preparations are sucked up respectively on the tobacco leaves, the total volume of the bibacterial preparation for producing the multiple enzymes is controlled, a sugar and salt solution is applied to the tobacco leaves with even mixing, the tobacco leaves are put in an incubator for cultivation with regular ventilation every day, and the sugar and salt solution is refilled when the humidity drops. The bibacterial preparation has the advantages that nattokinase, protease and amylase activities can be improved during tobacco fermentation, quality of the tobacco leaves is improved, the edible value of snus is greatly improved, and the fermentation process can be strengthened; the method is suitable for improving the quality ofthe snus.

Owner:GUIZHOU UNIV

Method for extracting tobacco flavor from fireworks and applying it to snus

The invention discloses a method for applying tobacco flavor extracted from tobacco flowers to suns. The method includes pre-treating different types of tobaccos, drying tobacco flowers of flue-cured tobacco under a low temperature of 40-60 degrees, air drying tobacco flowers of burley tobaccos and cigars in a ventilating room, sterilizing pretreated dried tobacco flowers through UV light, grinding the sterilized tobacco flowers into 10-80 meshes, dissolving the grinded samples by adding distilled water with a mass ratio of sample to distilled water between 1:4-1:8, stirring and extracting under a temperature of 60-90 DEG C for 0.5-1.5 hours, filtering extract, reducing pressure and compensating under a temperature of 40-70 DEG C to increase the weight to two times the weight of raw materials, adding one or more of protease, pectase and cellulase in the concentrate, stirring for enzymolysis for one to two hours under a temperature of 40-60 DEG C and pH value of 4.0-6.0, inactivating, freeze-drying under ultralow temperature, and then adding tobacco flower extract product into snus. The method solves the problem of insufficiency of raw materials, minimizes environmental pollution, and reduces resource waste.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

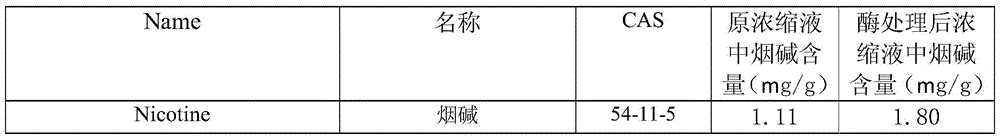

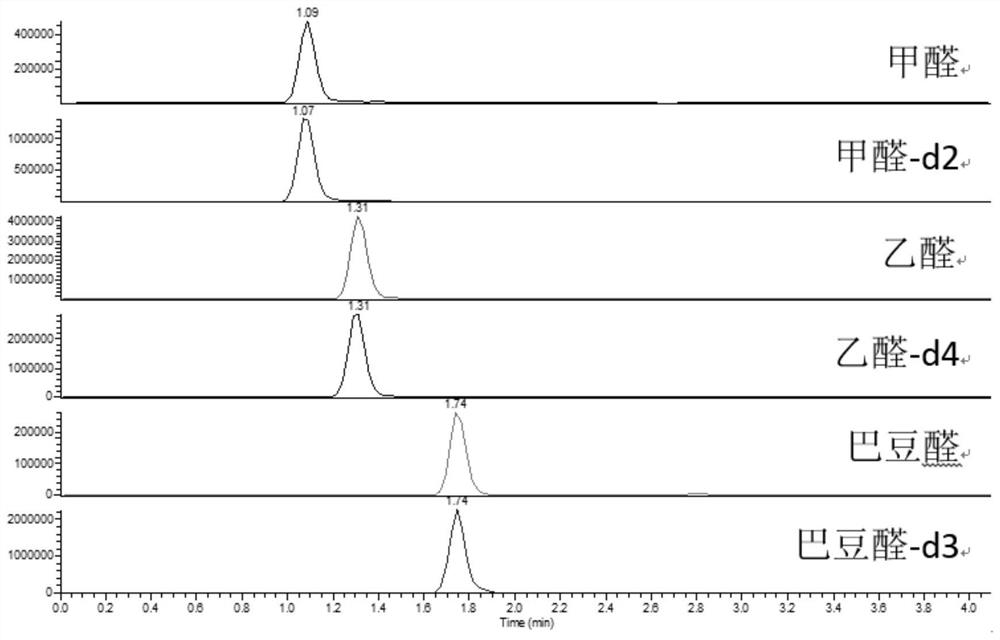

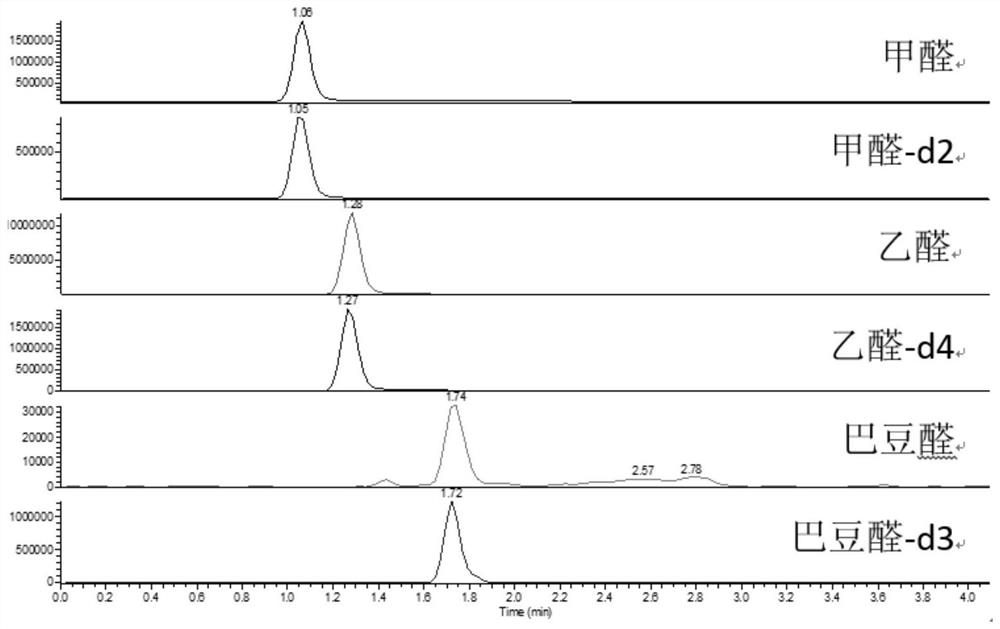

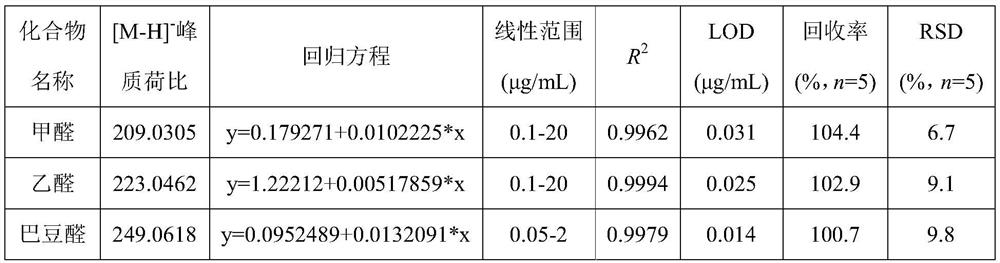

A processing method for snus samples and a detection method for aldehydes in snus

The invention relates to a method for treating buccal tobacco sample and a method for detecting aldehyde substances of buccal tobacco, and belongs to the technical field of smoke-free tobacco productchromatographic analysis and detection. The method for treating the buccal tobacco sample comprises the following steps: adding an acidity pH regulator, a derivatization reagent and an extracting agent into the buccal tobacco sample sequentially and mixing uniformly, leaving to stand and layering, and taking the upper layer of organic phase as a to-be-detected sample, wherein the volume of the extracting agent corresponding to 1 g of buccal tobacco is 8 to 15 ml. According to the method for treating the buccal tobacco sample, leaching of the aldehyde substances of the buccal tobacco can be accelerated, the reaction time of the aldehyde substances and the derivatization reagent of the buccal tobacco is shortened, the product after reaction is extracted to enter the organic phase, the analysis and detection time is further shortened, the loss of the aldehyde substances in the analysis and detection process is reduced and the accurate degree of analysis and detection is increased.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for enhancing tobacco cut stem fermentation process

InactiveCN109907359ASpeed up the fermentation processImprove finenessTobacco treatmentBacteriaBiotechnologyNicotiana tabacum

The invention discloses a method for enhancing a tobacco cut stem fermentation process. A bacillus amyloliquefaciens GZU03 preparation is used for processing tobacco cut stems in the fermentation process, and is prepared from bacillus amyloliquefaciens GZU03. The bacillus amyloliquefaciens GZU03 is preserved in CCTCC (China Center for Type Culture Collection) on November 9, 2018 and the preservation number is CCTCC M 2018762. The method for enhancing the tobacco cut stem fermentation process, disclosed by the invention, has the beneficial effects that the bacillus amyloliquefaciens GZU03 preparation can enhance the tobacco cut stem fermentation process, and has the effects of increasing cigarette aroma, softening smoke, increasing exquisiteness, reducing irritation, obviously improving smoke quality and improving the practical safety of snus. Meanwhile, the invention further discloses a method for improving the activity of protease and amylase in the tobacco cut stem fermentation process.

Owner:CHINA TOBACCO YUNNAN IND

A method for the determination of chromium, nickel, arsenic, selenium, cadmium and lead in snus

ActiveCN105784828BEffective Quantitative Assay ControlPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumInductively coupled plasma

Owner:SHANGHAI TOBACCO GRP CO LTD

Tobacco stem particles suitable for preparing snus and its application

ActiveCN105831797BImprove taste comfortEliminate irritationTobacco preparationTobacco treatmentBiotechnologyFermentation

The invention discloses tobacco stem particles suitable for preparing mouth holding cigarettes and application thereof. The tobacco stem particles are obtained through the steps that tobacco stems are shredded after microwave puffing, the stem shreds are micro-smashed after fermentation treatment, and screening is conducted. The tobacco stem particles can be well applied to preparing the mouth holding cigarettes, the utilization efficiency of tobacco raw materials is improved, the bitterness and pungent taste of the tobacco stems are removed through scientific treatment, and fragrance matter is rich and mellow. The tobacco stems are scientifically matched with tobacco leaf particles and auxiliary materials, in combination with reasonable and safe seasoning treatment, the new mouth holding materials are obtained, the taste is richer, the special flavor is coordinated, quality is high, the mouth holding cigarettes are gradually kept in the mouth and melted during eating, no granular feeling or roughness is generated in the oral cavity, and the cigarettes do not need to be abandoned after being eaten.

Owner:CHINA TOBACCO GUANGDONG IND

A kind of snus and its preparation method

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD

Snus essence, and preparation method and application thereof

ActiveCN110331043AConvenient careComfortable and rich flavor profileTobacco preparationTobacco treatmentSweetnessLinalool

The invention discloses a snus essence, and a preparation method and an application thereof. 100 parts of the snus essence essence comprise, by weight, 25-35 parts of bamboo leaf flavones extract, 10-20 parts of a fruit Maillard reactant, 10-20 parts of Malania oleifera extract, 0.35-0.85 part of limette oil, 0.05-0.10 part of carvone, 0.10-0.15 part of linalool, 0.02-0.06 part of butyl isovalerate, 0.30-0.60 part of vanillin, and the balance of propylene glycol. The snus essence of the invention improves the sweetness and tobacco breath of the snus, improves the mouth-feel comfort of the snus, has rich and mellow flavor, and successfully eliminates the irritation and bitterness of raw materials.

Owner:云南天宏香精有限公司

Preparation method and application of shredded tobacco suitable for snus

ActiveCN105831799BLess irritatingReduce conversionTobacco treatmentBiotechnologyMacromolecular Substances

Owner:CHINA TOBACCO GUANGDONG IND

Snus using a large proportion of tobacco material and its preparation method

The invention discloses a buccal cigarette adopting a big proportion of tobacco materials and a preparation method for the buccal cigarettes. The buccal cigarette is prepared from the following components in percent by mass: 80-95% of tobacco raw materials, 1-5% of a filler, 0.5-5% of a flavoring agent, 1-10% of an adhesive and 0.1-1% of essence, wherein the tobacco raw materials are formed by mixing tobacco leaf particles and tobacco stem particles in percent by mass being (60-80%): (40-20%); and the tobacco leaf particles and the tobacco stem particles are separately obtained by screening and getting penetration parts after carrying out fermentation treatment and micro-grinding. According to the buccal cigarette, the big proportion of tobacco raw materials are greatly used in the preparation of the buccal cigarette, so that the use ratio of the tobacco raw materials is guaranteed to be as high as 95%; moreover, the tobacco raw materials comprise a great proportion of tobacco stems, so that the utilization rate of the tobacco raw materials in the buccal cigarette is increased, technical support is provided for cigarette localization of the buccal cigarette, the bitter taste and the biting taste of the tobacco raw materials are scientifically treated, and the smell is rich and thick; while eating, the buccal cigarette is gradually melted while no granular sensation and roughness exist in an oral cavity, so that the buccal cigarette does not need to be spit and discarded after being consumed.

Owner:CHINA TOBACCO GUANGDONG IND

A method for measuring the release of heavy metal elements in snus

Owner:SHANGHAI TOBACCO GRP CO LTD

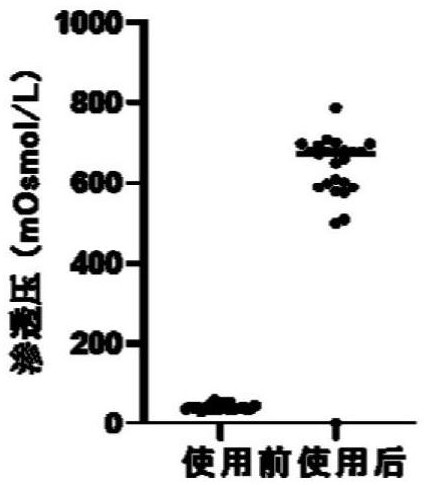

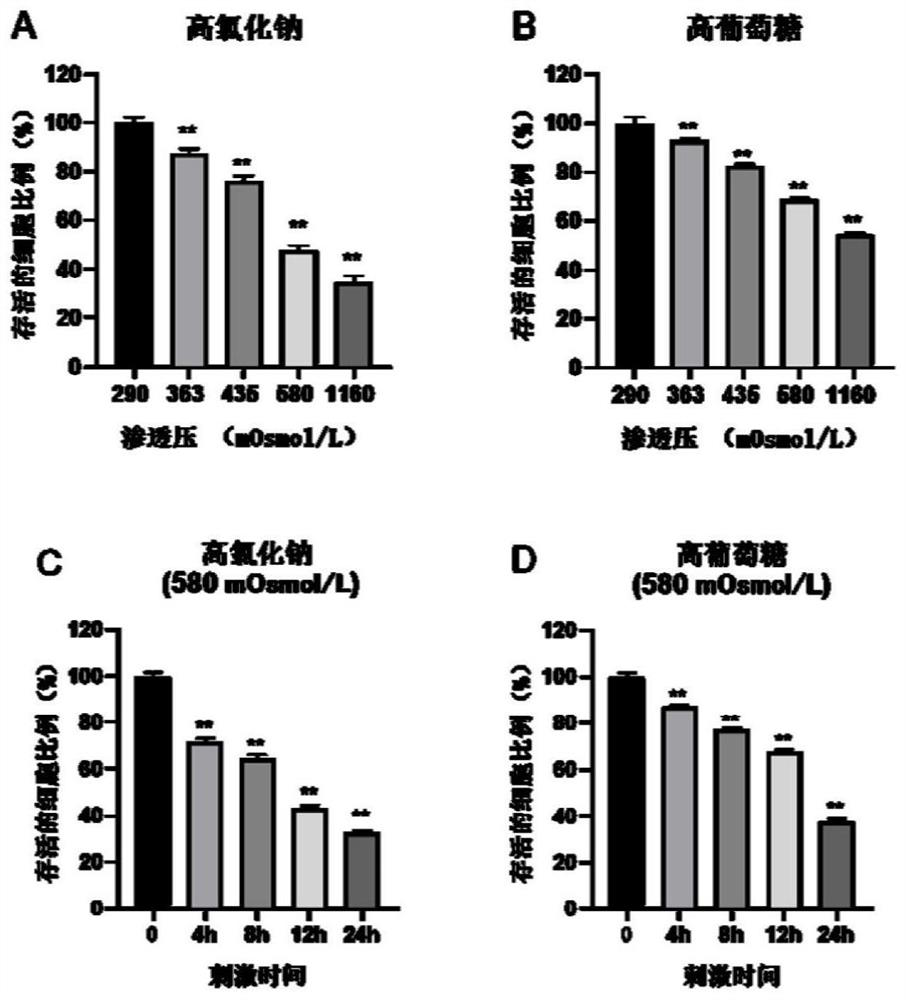

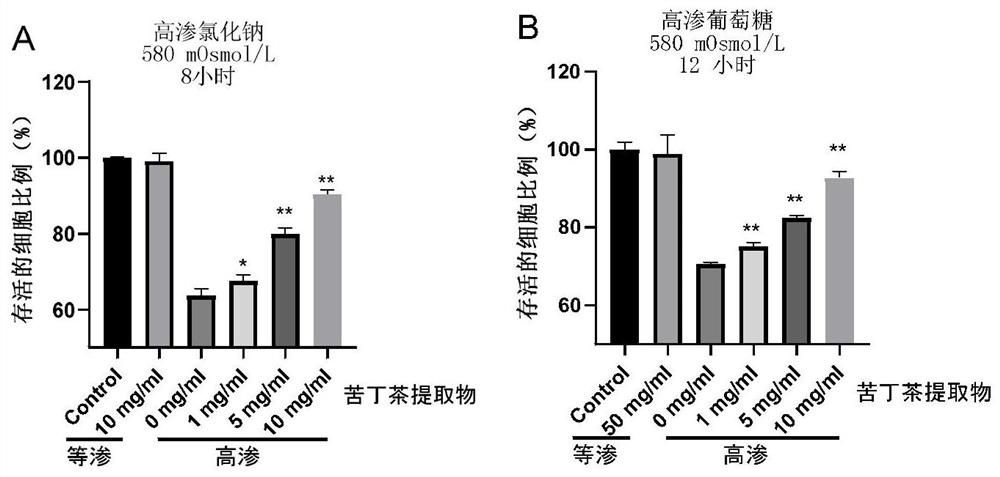

A bagged snus capable of reducing health risks of oral epithelium and preparation method thereof

ActiveCN111264899BCause deathReduce Oral RiskTobacco preparationTobacco treatmentBiotechnologyOral epithelium

The invention relates to a bagged snus capable of reducing the health risk of oral epithelium and a preparation method thereof, belonging to the technical field of smokeless tobacco products. Take Kudingcha and pulverize it, shake and extract it with ultrapure water for several times, combine the extracts, centrifuge at 4°C, take the supernatant, freeze-dry the supernatant and save it for later use to obtain Kudingcha extract; The diameter is 50~100 mesh, and the moisture content is controlled at 8~12%, to obtain tobacco leaf powder; the water added to the tobacco leaf powder obtained in step (2) is then heat-treated, and then the flavoring agent, 1~ 6 parts of acid-base regulator, flavoring agent, kudingcha extract, cooling agent and antioxidant are mixed until uniform, refrigerated, sterilized and packaged to obtain snus in bags that can reduce the health risk of oral epithelium. The preparation method of the invention is simple and reliable, and the prepared snus bag can effectively reduce the risk of the oral cavity, and can greatly improve the death of oral epithelial cells caused by the hypertonic environment produced by the snus bag in the prior art.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com