Method for preparing cigarette tobacco suitable for snus and application of cigarette tobacco

A technology for snus and shredded tobacco, which is applied in the field of preparation to achieve the effects of reducing nitrogen-containing substances, reducing consumption, and improving taste comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

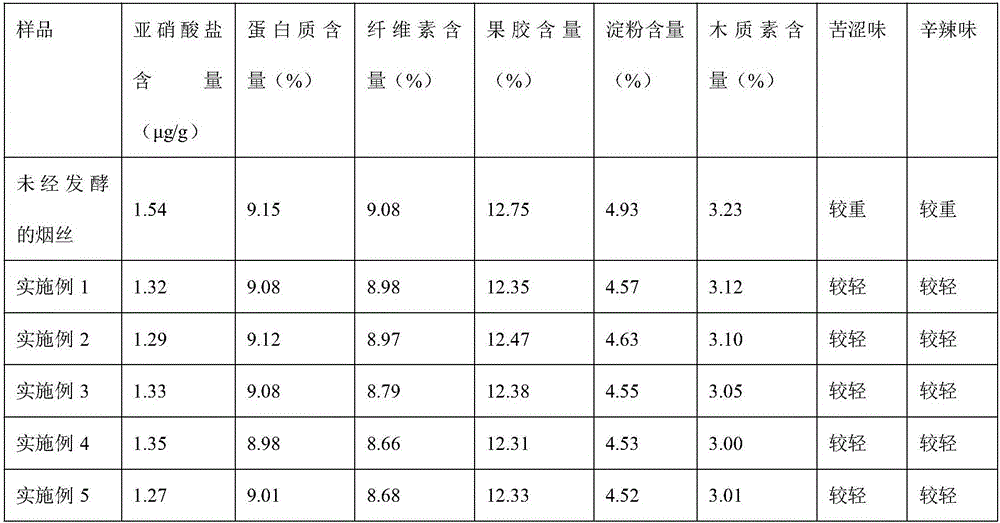

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing shredded tobacco suitable for snus, comprising the following steps:

[0035] S1. Prepare the tobacco leaf formula group: prepare the tobacco leaf group according to the mass ratio of flue-cured tobacco: burley tobacco at 2:4;

[0036] S2. Tobacco leaf treatment: wash the tobacco leaves with water, remove surface dust, shake dry slightly, remove excess water, and shred;

[0037] S3. Fermentation of shredded tobacco: prepare the inoculum, and ferment after inoculation according to the inoculation amount of 1g inoculum / 100g shredded tobacco. The fermentation conditions are: keep the temperature at 45°C during the fermentation process, and the fermentation time is 15 days; the scientific fermentation process not only obtains Good snus flavor with reduced nitrite content.

[0038] The composition of the inoculum is fructose syrup: protein peptide: bacterial strain: distilled water mass ratio=50g: 5g: 0.1g: 250g; the bacterial ...

Embodiment 2

[0042] This embodiment provides a method for preparing shredded tobacco suitable for snus, comprising the following steps:

[0043] S1. Prepare the tobacco leaf formula group: prepare the tobacco leaf group according to the mass ratio of flue-cured tobacco: burley tobacco: air-dried tobacco at 1:1:1;

[0044] S2. Tobacco leaf treatment: wash the tobacco leaves with water, remove surface dust, shake dry slightly, remove excess water, and shred;

[0045]S3. Fermentation of shredded tobacco: prepare the inoculum, and ferment after inoculation according to the inoculation amount of 1g inoculum / 100g shredded tobacco. The fermentation conditions are: keep the temperature at 45°C during the fermentation process, and the fermentation time is 15 days; the scientific fermentation process not only obtains Good snus flavor with reduced nitrite content.

[0046] The composition of the inoculum is fructose syrup: protein peptide: bacterial strain: distilled water mass ratio=50g: 5g: 0.1g: ...

Embodiment 3

[0049] This embodiment provides a method for preparing shredded tobacco suitable for snus, comprising the following steps:

[0050] S1. Prepare the tobacco leaf formula group: prepare the tobacco leaf group according to the mass ratio of flue-cured tobacco: burley tobacco: air-dried tobacco at 1:1:1;

[0051] S2. Tobacco leaf treatment: wash the tobacco leaves with water, remove surface dust, shake dry slightly, remove excess water, and shred;

[0052] S3. Fermentation of shredded tobacco: prepare the inoculum, and ferment after inoculation according to the inoculation amount of 10g inoculum / 100g shredded tobacco. The fermentation conditions are as follows: the fermentation process keeps the controlled temperature at 35°C, and the fermentation time is 20 days; the scientific fermentation process not only obtains Good snus flavor with reduced nitrite content.

[0053] The composition of the inoculum is fructose syrup: protein peptide: strain: mass ratio of distilled water=100g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com