Patents

Literature

626 results about "Surface dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

Nano mirror spray coating

InactiveCN1944710AExtended use timeImprove adsorption capacityLiquid/solution decomposition chemical coatingPotassium borohydrideSpray coating

The nanometer mirror spraying process includes the following steps: 1. eliminating surface dust; 2. spraying primer; 3. sensitizing and activating treatment; 4. spraying solution A comprising silver nitrate solution, ammonia water solution and sodium hydroxide solution and solution B comprising sodium borohydride, potassium borohydride or p-methylaminophenol sulfate solution in the volume ratio of 1 to 1-1.7 to produce reduction; 5. shaping and developing; 6. blowing to dry; and 7. drying. The present invention has the advantages of diversified products, high corrosion resistance, suitability to mass production, high hardness, low cost, etc.

Owner:方宏亮

Admixture for minimizing the presence of surface dust on cement and concrete structures

An admixture for minimizing or preventing dust on surfaces of cured cement and concrete structures comprises a shrinkage reducing additive in combination with a fatty alcohol. Cementitious compositions containing the admixture, and methods for reducing dusting on cement structures, are also described.

Owner:WR GRACE & CO CONN

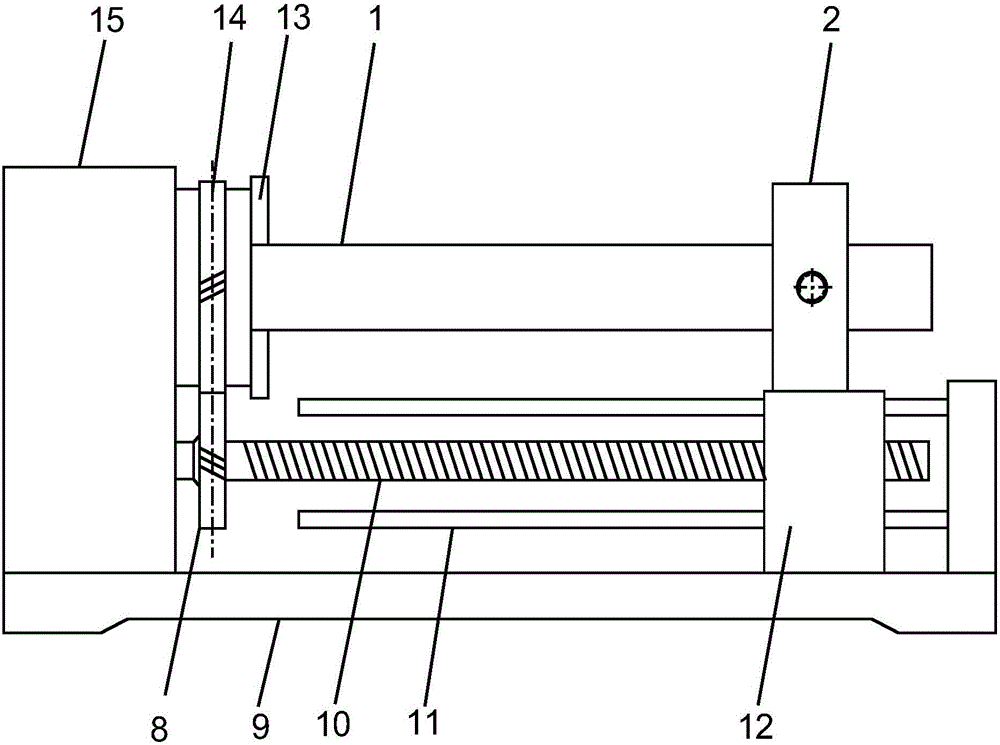

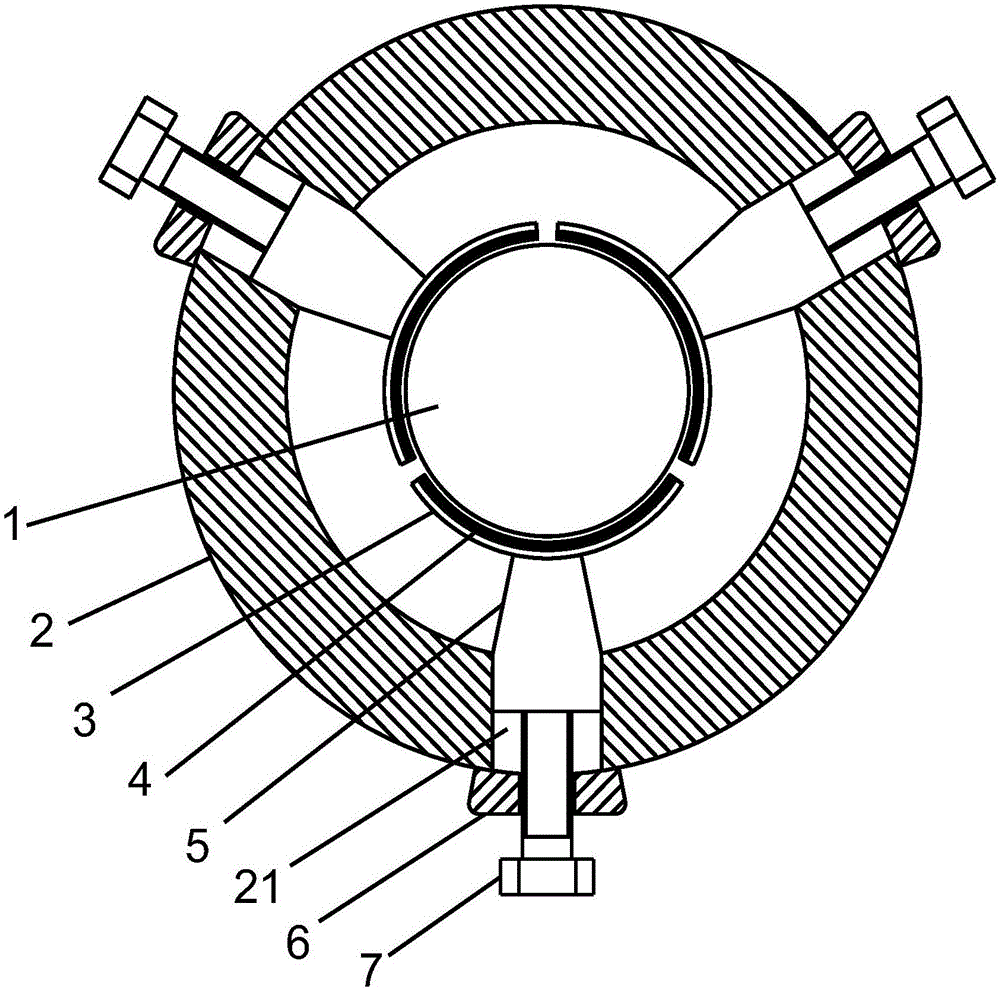

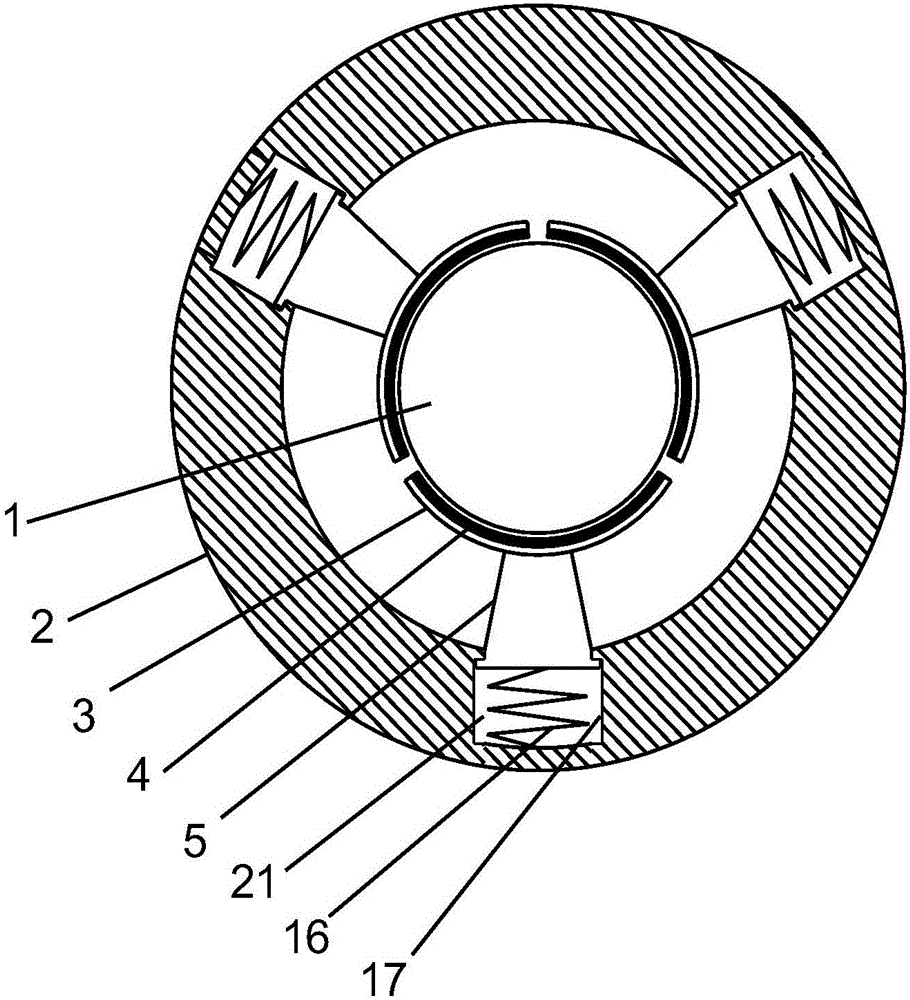

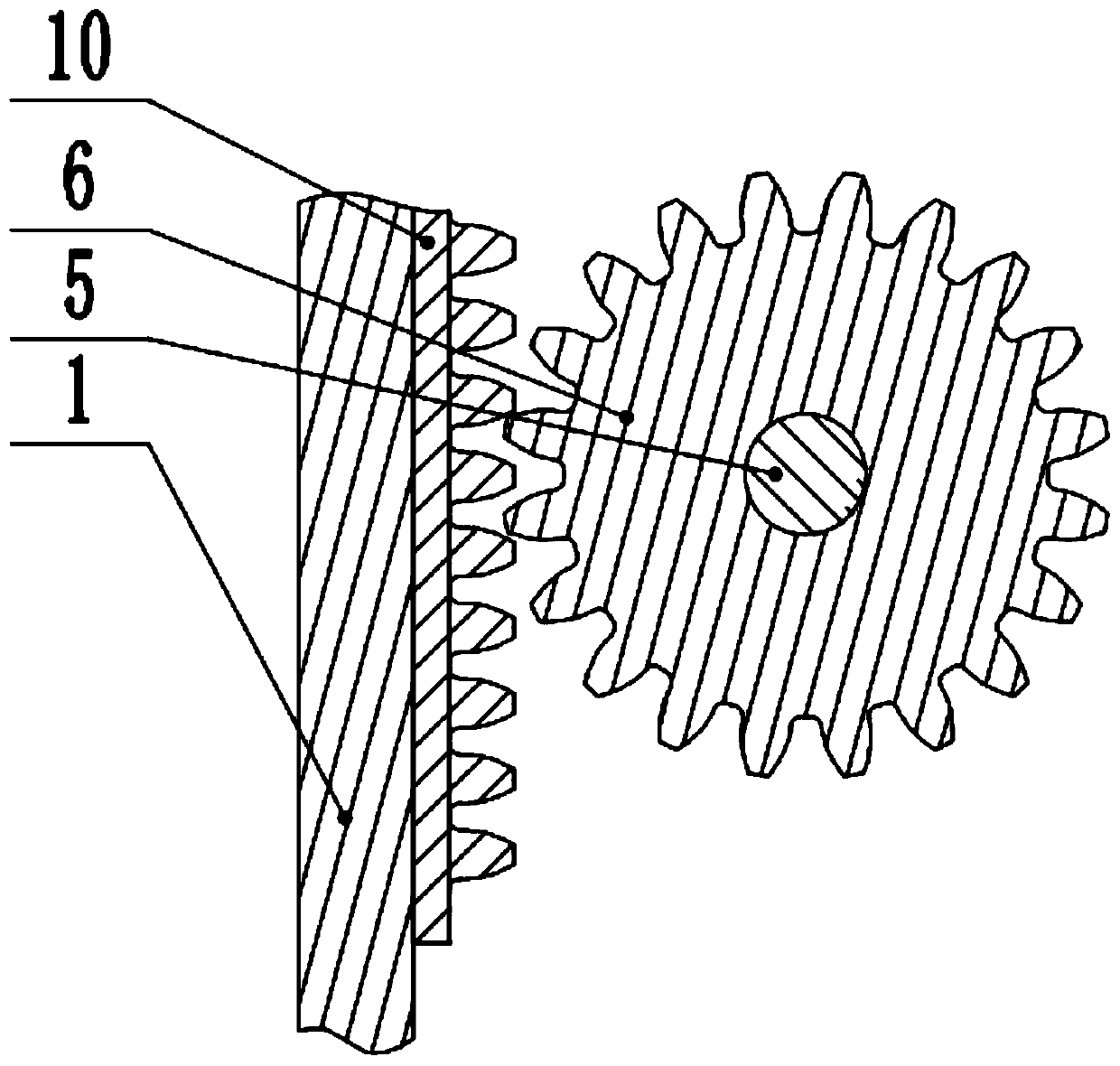

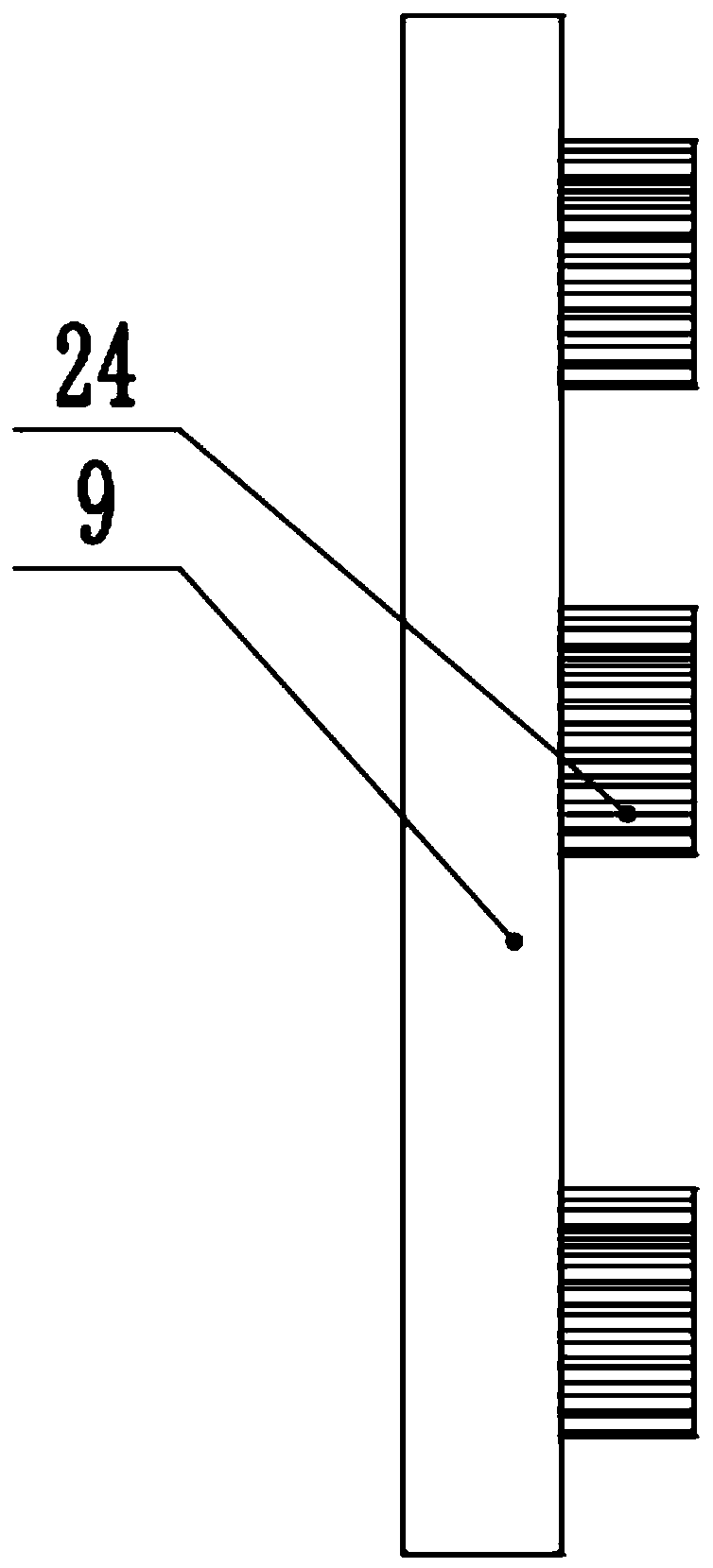

Oil drill rod circumferential surface rust removing device

ActiveCN106363510AQuick installationAdjustable pressureGrinding carriagesRevolution surface grinding machinesScrew threadPetroleum

The invention discloses an oil drill rod circumferential surface dust removing device which comprises a machine frame, a power box, a three-jaw chuck and an annular plate. Holding plates are arranged in the annular plate. The holding plates are three arc plates which are formed after the whole annular plate is equally divided into three parts. The inner surface of each holding plate is provided with polishing abrasive paper. The middle of the outer surface of each holding plate is connected with a sliding block in a welded mode. The annular plates are provided with three equally-divided cylindrical holes. The sliding blocks are arranged in the cylindrical holes. Bosses are fixedly arranged outside the cylindrical holes. First thread holes are formed in the bosses. Bolts are arranged in the first thread holes. The annular plates are fixed to a sliding base in a welded mode. The sliding base is arranged on the machine frame and can move on the machine frame in parallel. The sliding base is provided with a second thread hole. A screw rod is arranged in the second thread hole. A screw rod is arranged in the second thread hole. A gear is connected to the left end of the screw rod. The outer circumference of the three-jaw chuck is provided with an annular rack. The rack is engaged with the gear. According to the oil drill rod circumferential surface dust removing device, the polishing strength can be adjusted, it is ensured that dust on the surface of a drill rod is thoroughly removed, and the efficiency is higher.

Owner:江苏省德诚测控设备有限公司 +1

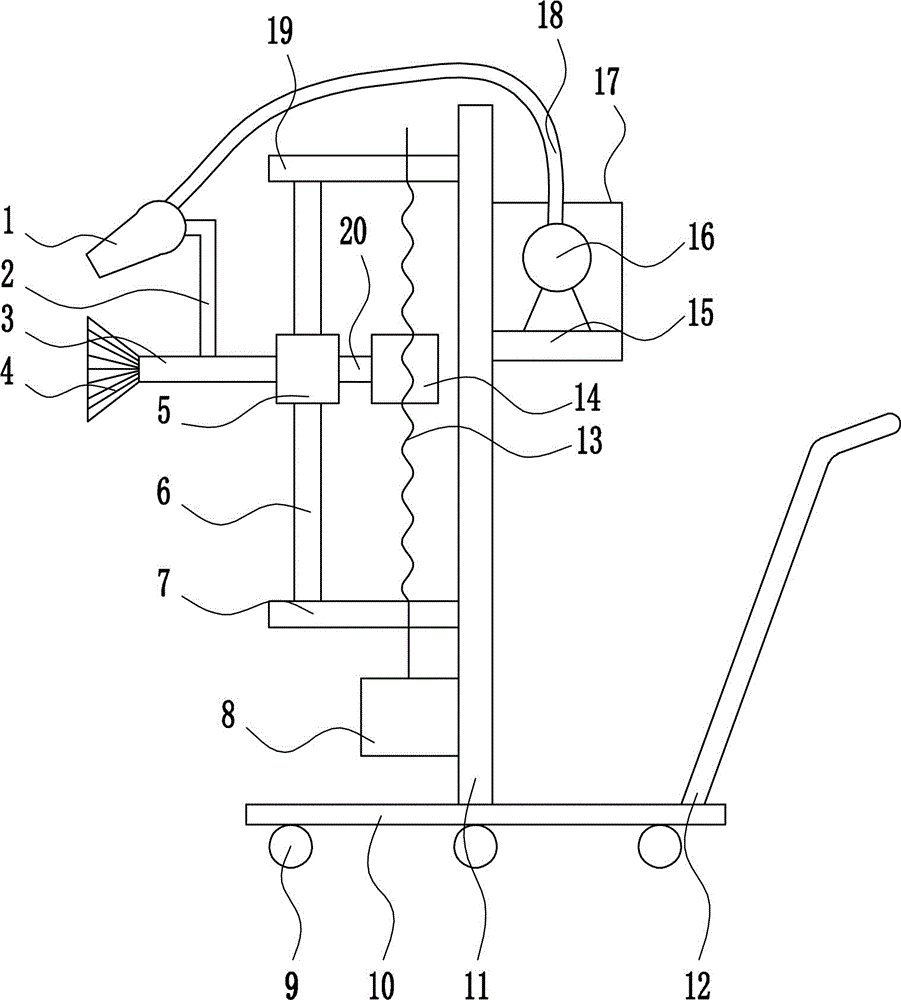

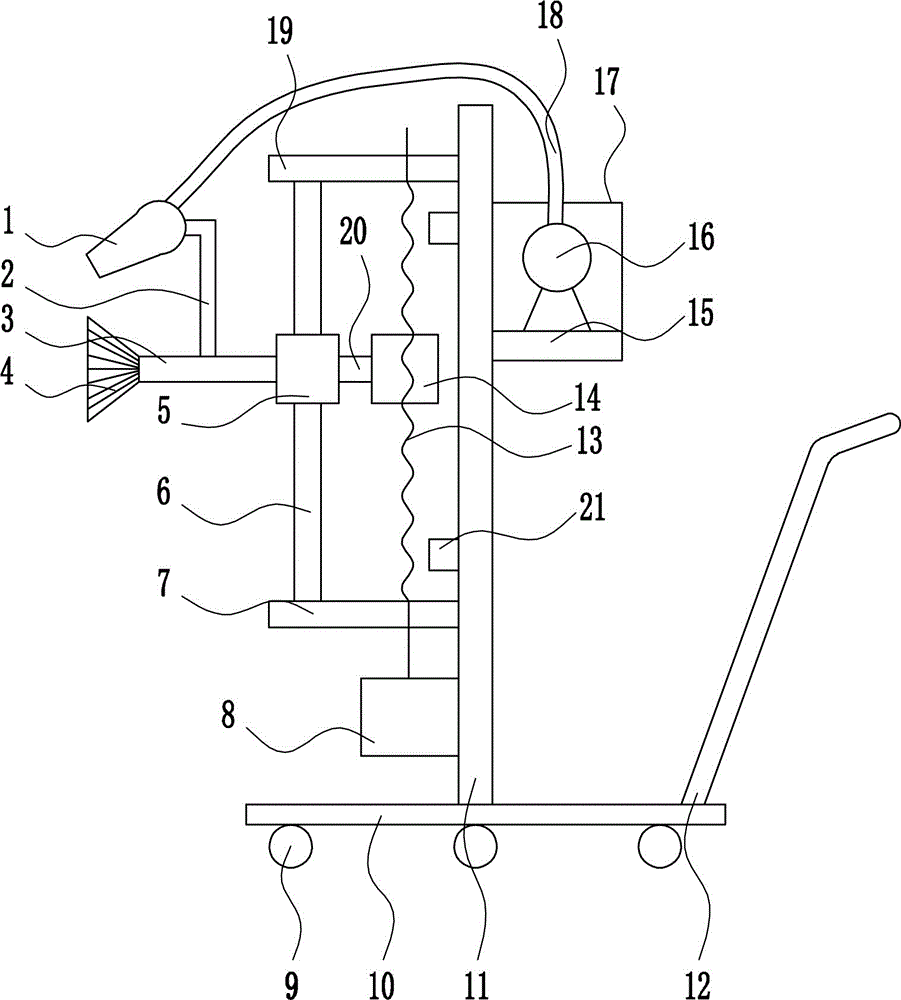

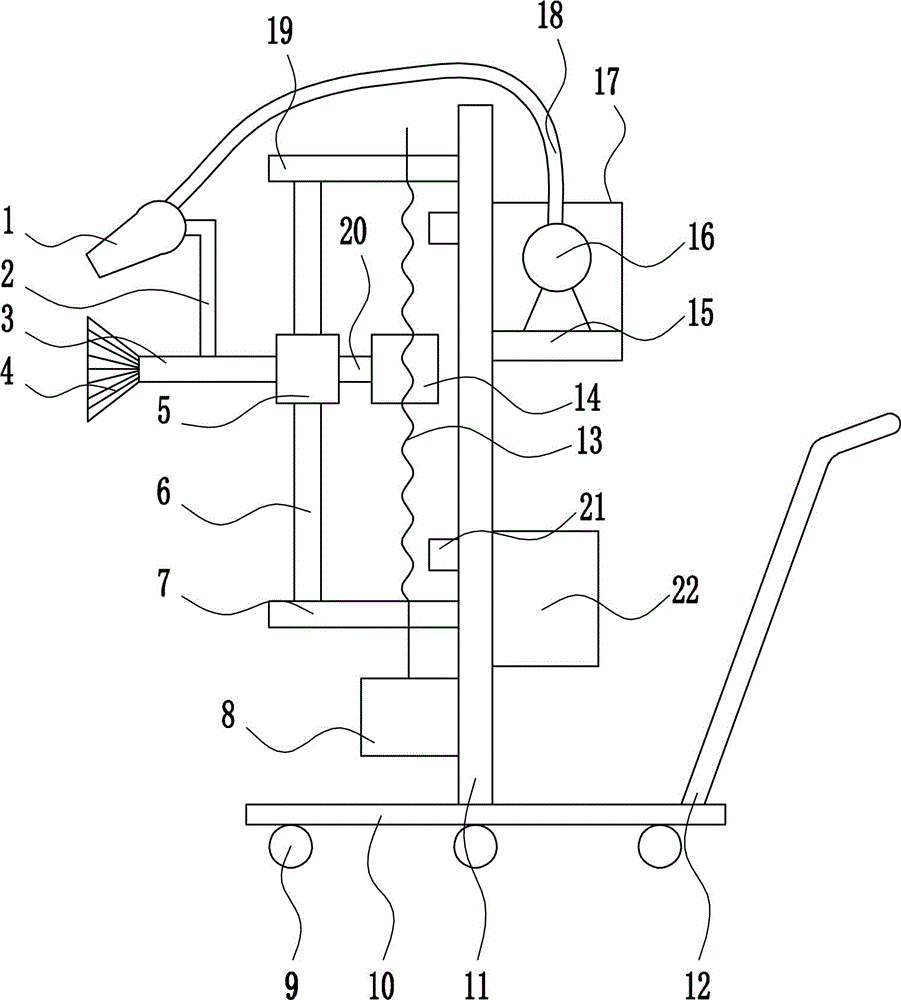

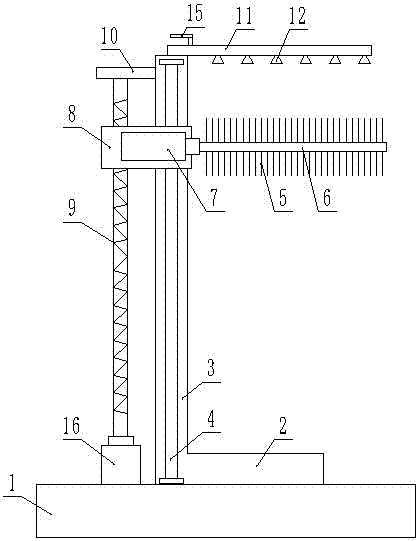

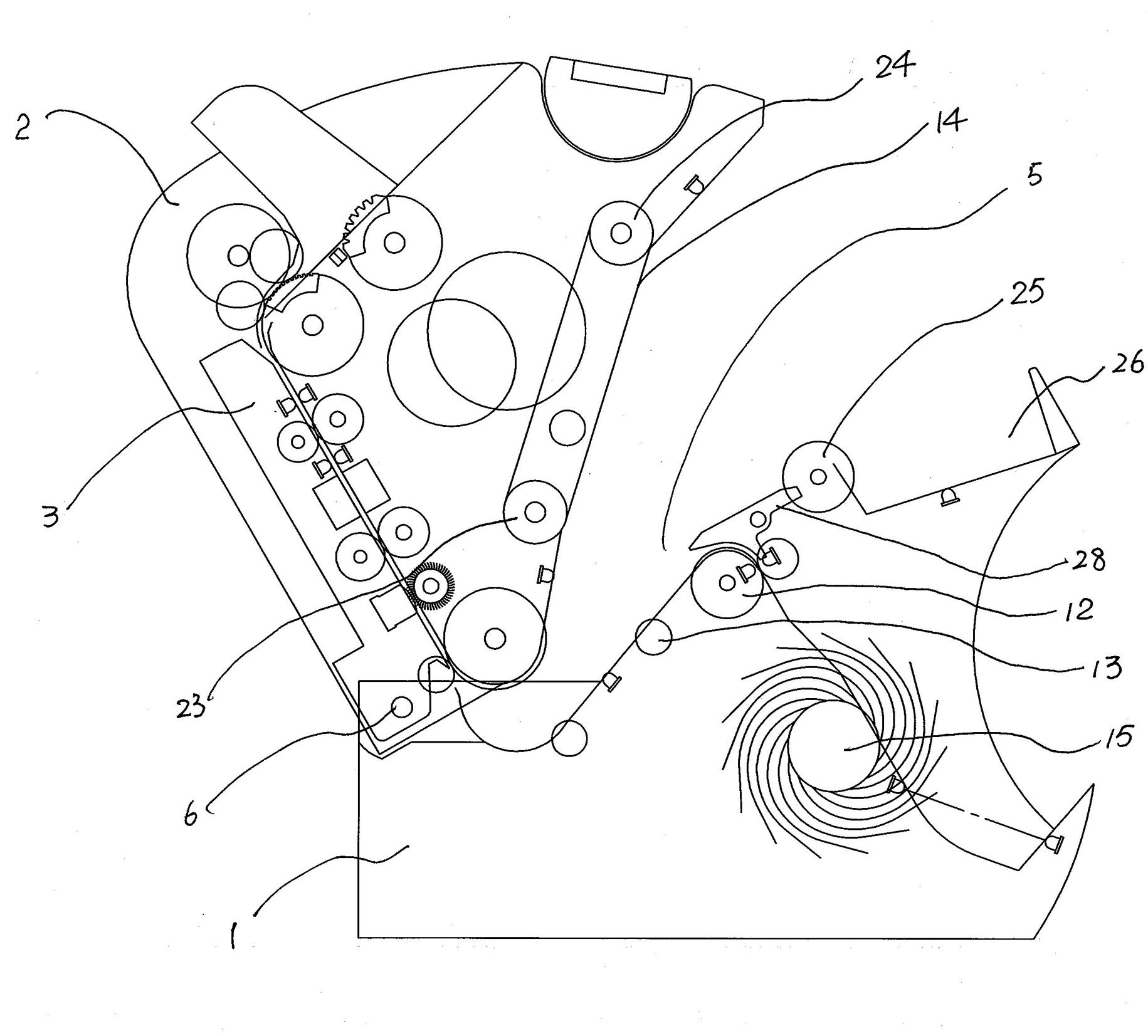

Surface dust removing device for internet display screen

InactiveCN106362968AFully removeImprove work efficiencyCleaning using toolsCleaning using gasesThe InternetEngineering

The invention relates to a dust removing device, in particular to a surface dust removing device for an internet display screen and aims at achieving the technical purpose of providing the surface dust removing device for the internet display screen, wherein the surface dust removing device is high in dust removing speed, good in dust removing effect and capable of saving time and labor in the dust removing process. To achieve the above technical purpose, the surface dust removing device for the internet display screen is provided and comprises a sprayer, a support, a supporting rod, a brush, a guiding sleeve, a guiding column, a second bearing block, a rotation motor, wheels, a bottom plate, a fixing plate, a push handle, a lead screw, a nut and the like. The bottom of the bottom plate is connected with the wheels through fixing rods, the wheels can freely rotate, and the fixing plate is welded to the center of the top of the bottom plate. The surface dust removing device achieves the effects that the dust removing speed is high, the dust removing effect is good, and time and labor are saved in the dust removing process. Through the up-down reciprocating movement of the brush and the sprayer, the dust on the surface of the internet display screen is sufficiently removed.

Owner:麻城英太利济智能物联网科技有限公司

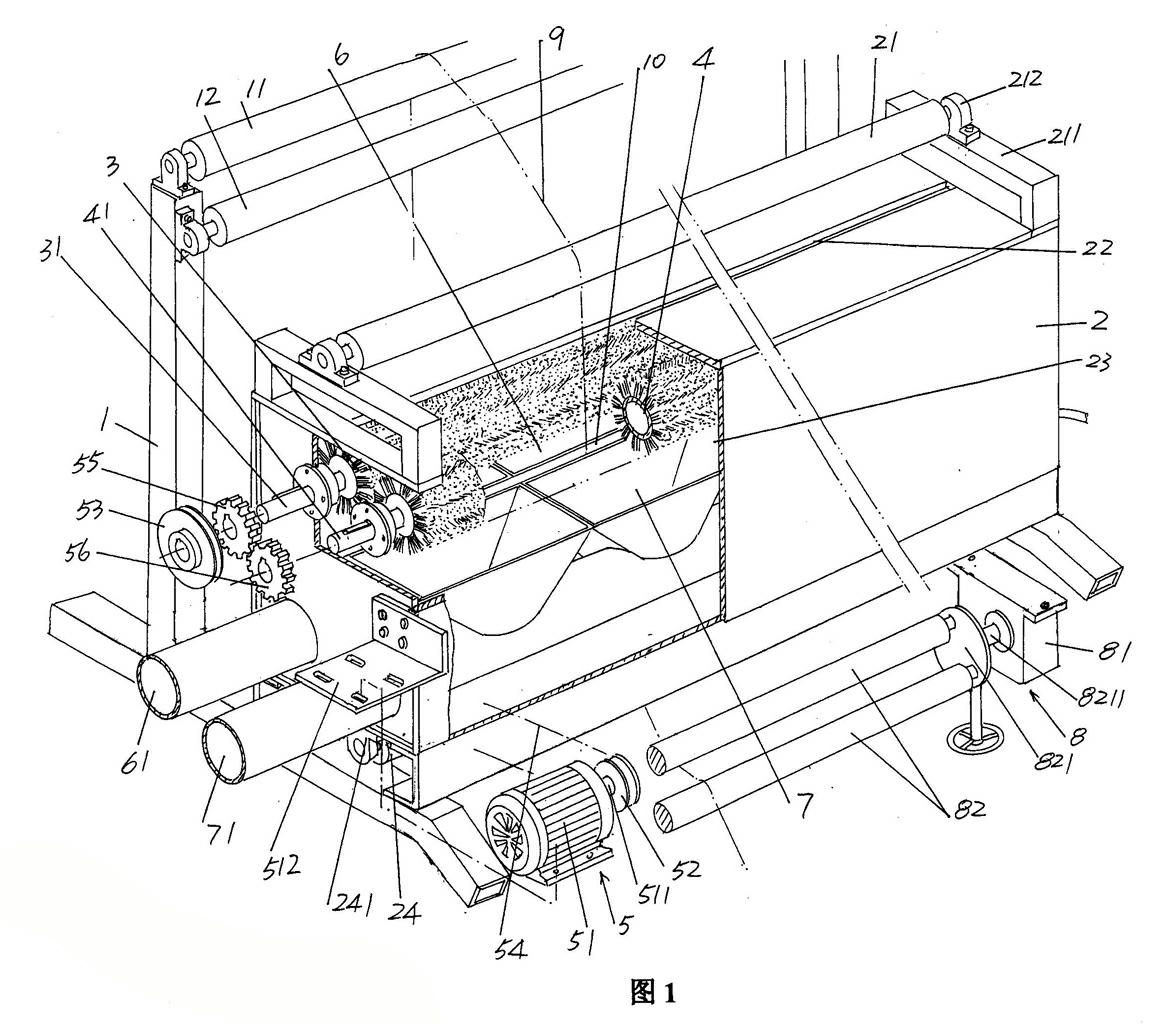

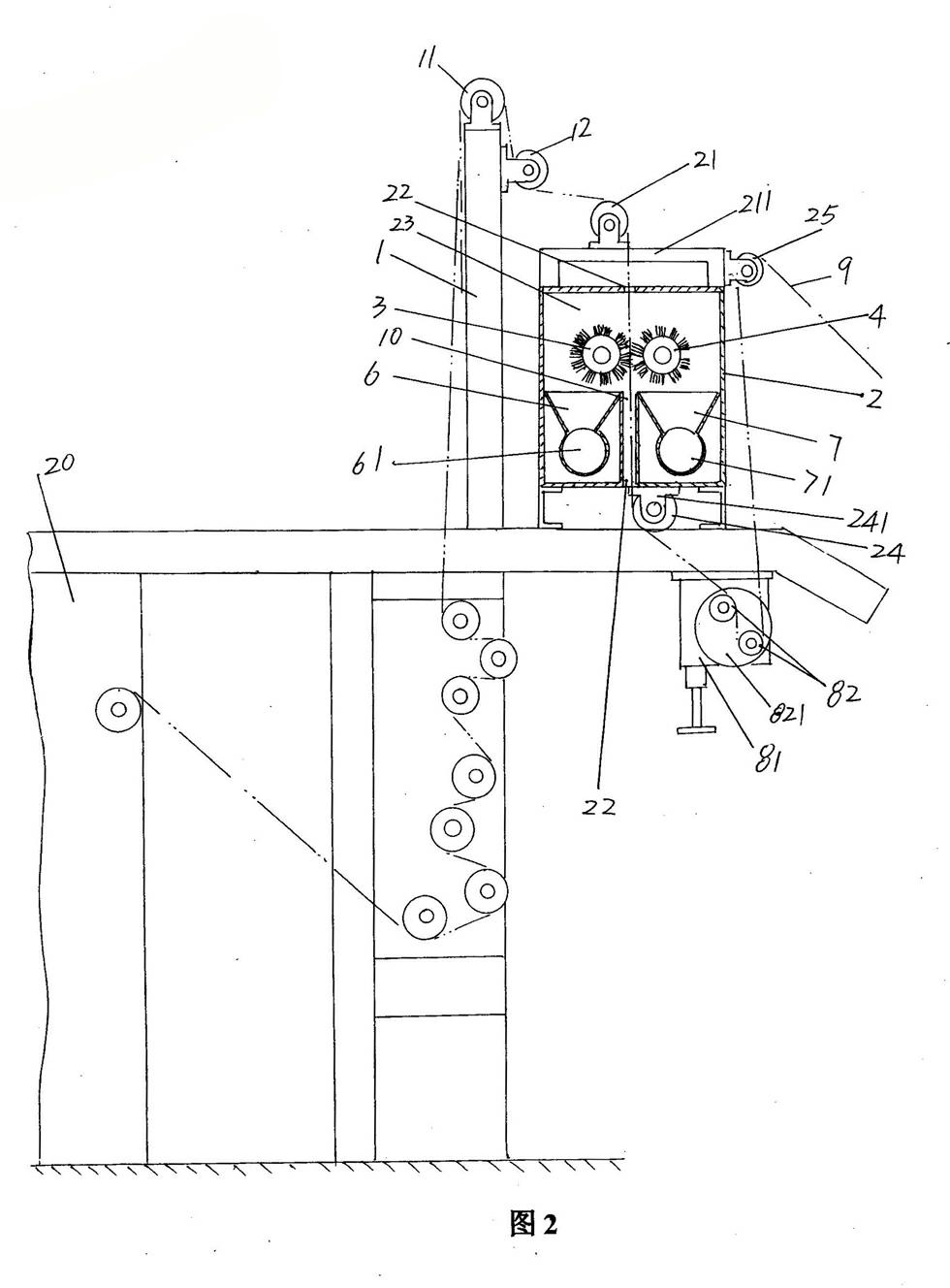

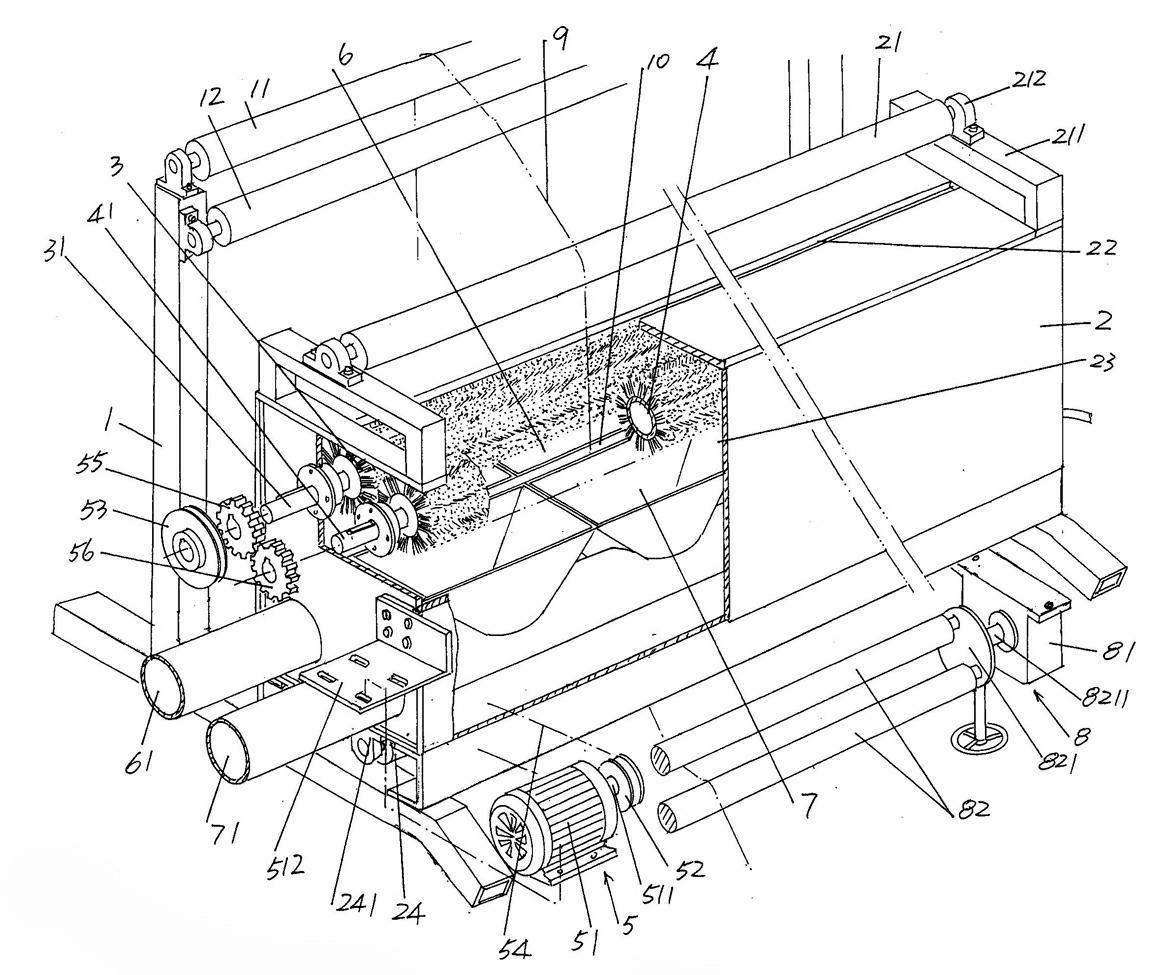

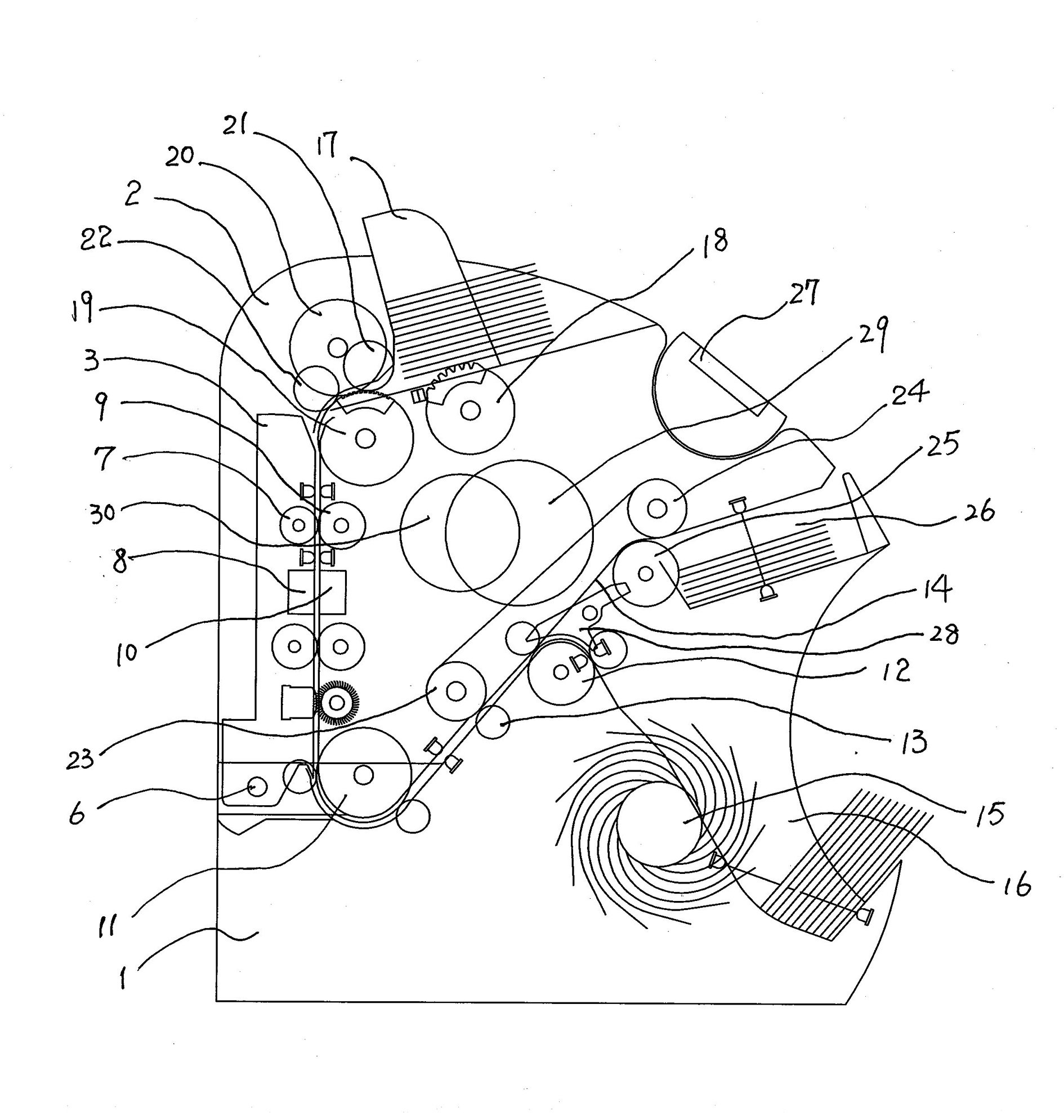

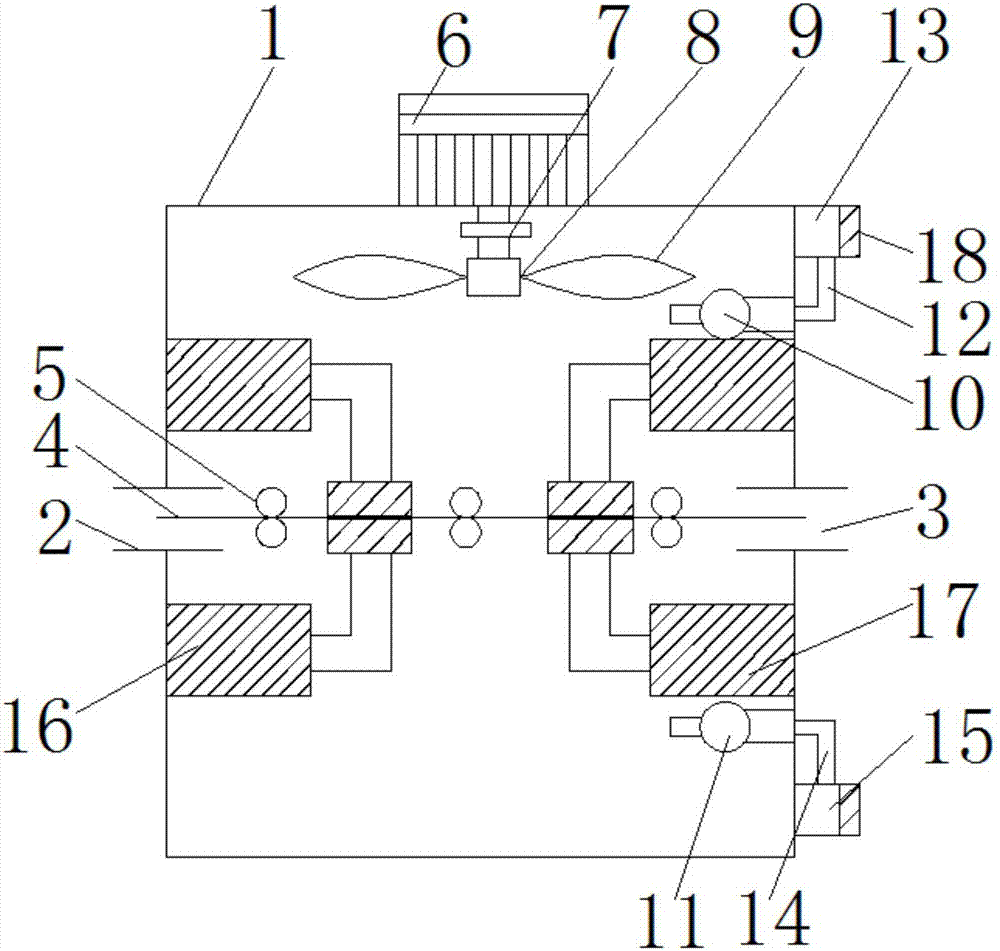

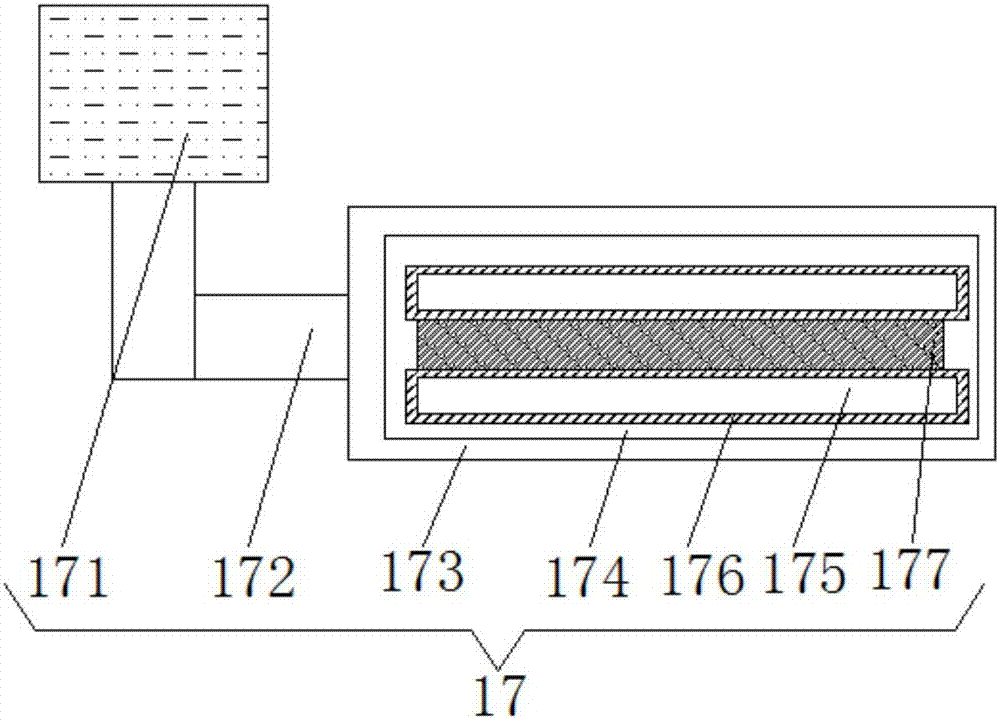

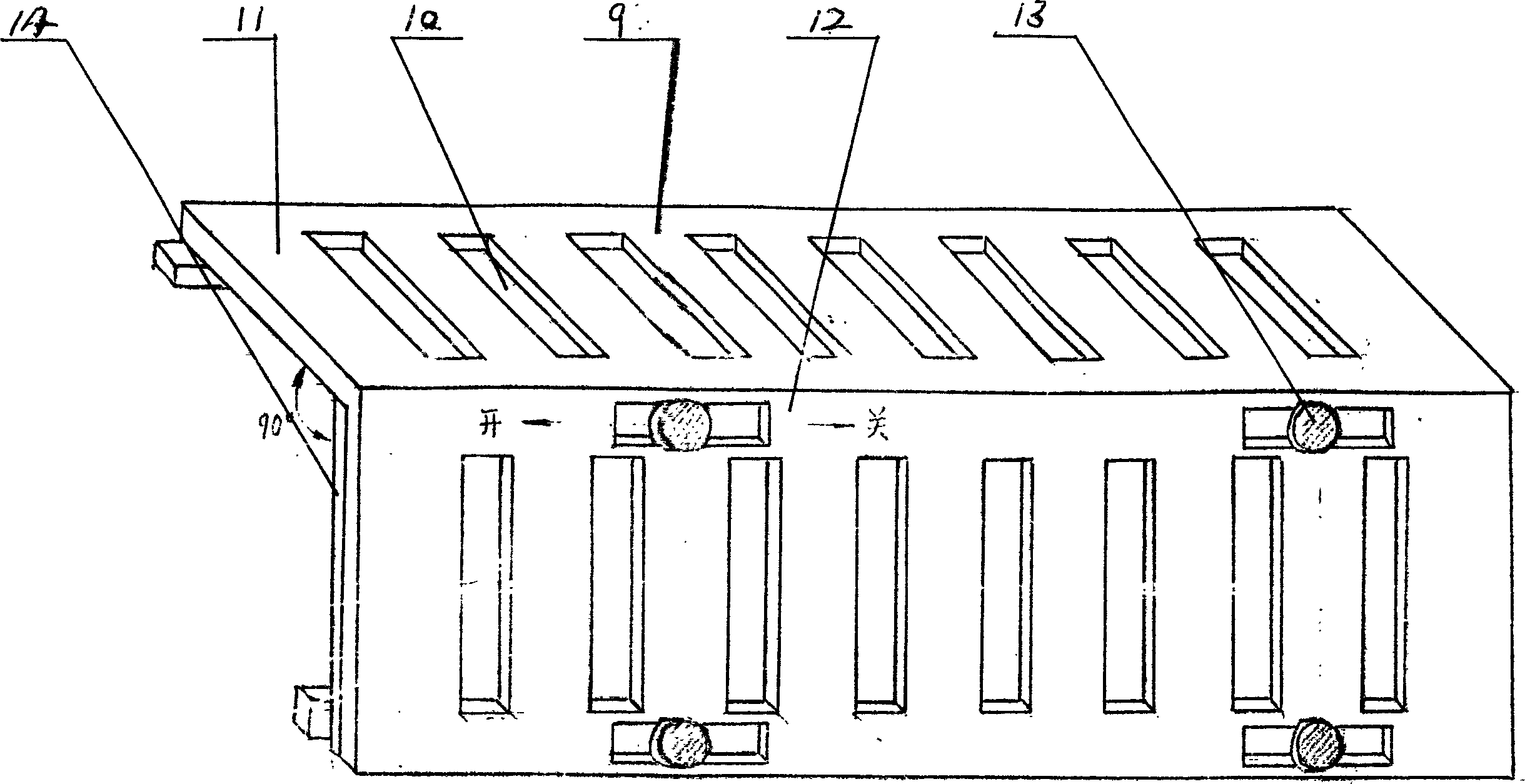

Fabric surface dust removal device

InactiveCN102319682AGuaranteed dust removal performanceSmooth entryDirt cleaningFlexible article cleaningDust controlStructural engineering

The invention relates to a fabric surface dust removal device, which belongs to the technical field of fabric dust removal facilities and comprises a machine frame, a box body of a dust removal box, a first hair brush roller, a second hair brush roller, a motive power transmission mechanism, a first dust collection bucket and a second dust collection bucket, wherein a first cloth guide roller and a second cloth guide roller are arranged on the top of the machine frame, the top of the box body of the dust removal box is provided with a dust removal fabric guide-out roller, the bottom of the box body of the dust removal box is provided with a fabric guide-in roller, in addition, a cloth guide groove is formed in the center of the box body of the dust removal box, the first hair brush roller and the second hair brush roller are arranged in a box body cavity of the box body of the dust removal box, the same ends of a first hair brush roller shaft of the first hair brush roller and a second hair brush roller shaft of the second hair brush roller extend to a position outside the box body cavity and are connected with the motive power transmission mechanism, the motive power transmission mechanism is fixed on the box body of the dust removal box, a first dust suction pipe is connected onto the first dust collection bucket, a second dust suction pipe is connected onto the second dust suction bucket, and both the first dust suction pipe and the second dust suction pipe are connected with a negative pressure dust removal mechanism. The fabric surface dust removal device has the advantages that the dust removal effects on both sides of the fabric can be ensured without generating the secondary pollution of dust, and the fabric can smoothly enter the subsequent work procedures in a stable state.

Owner:常熟华懋纺织有限公司

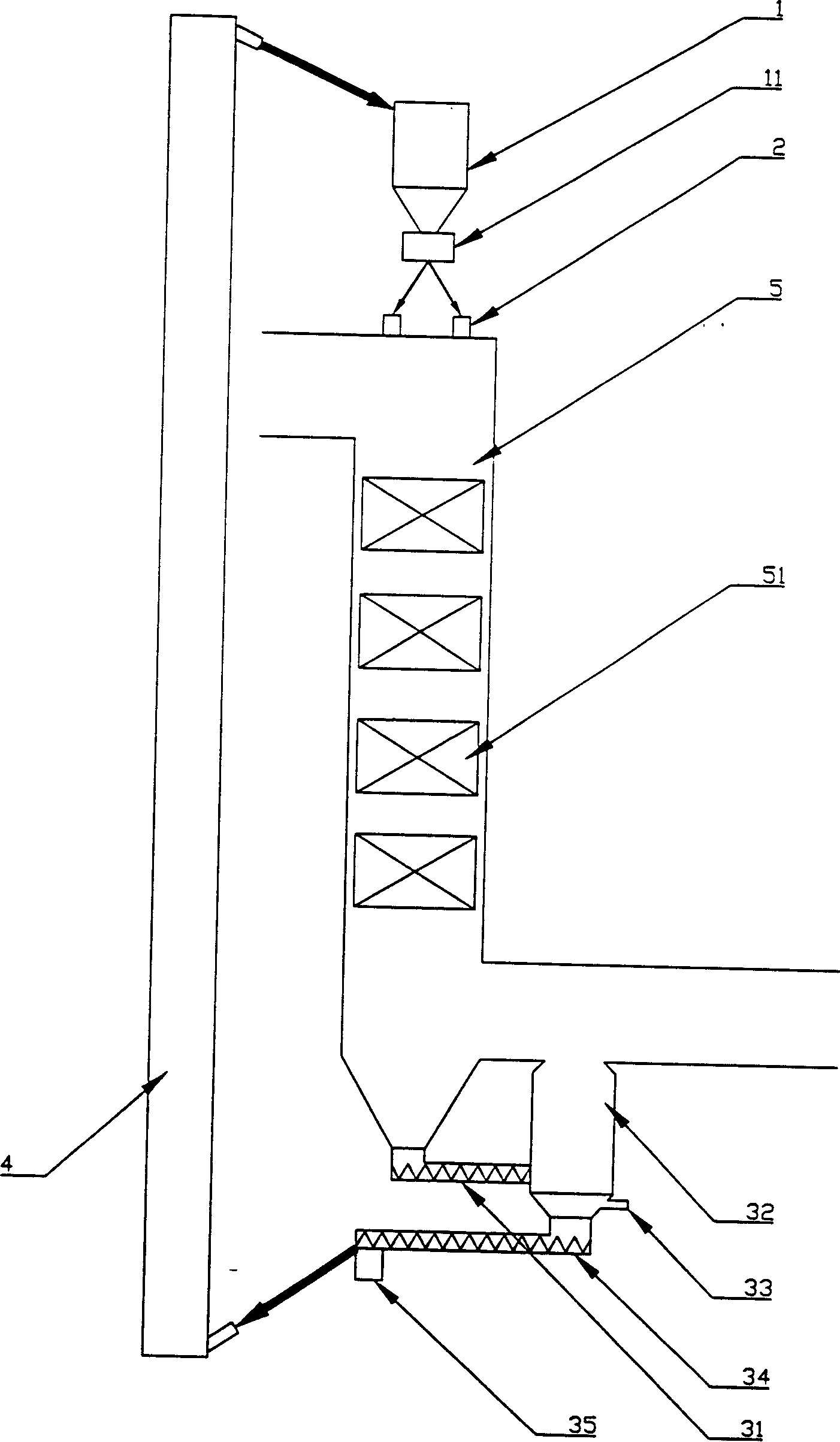

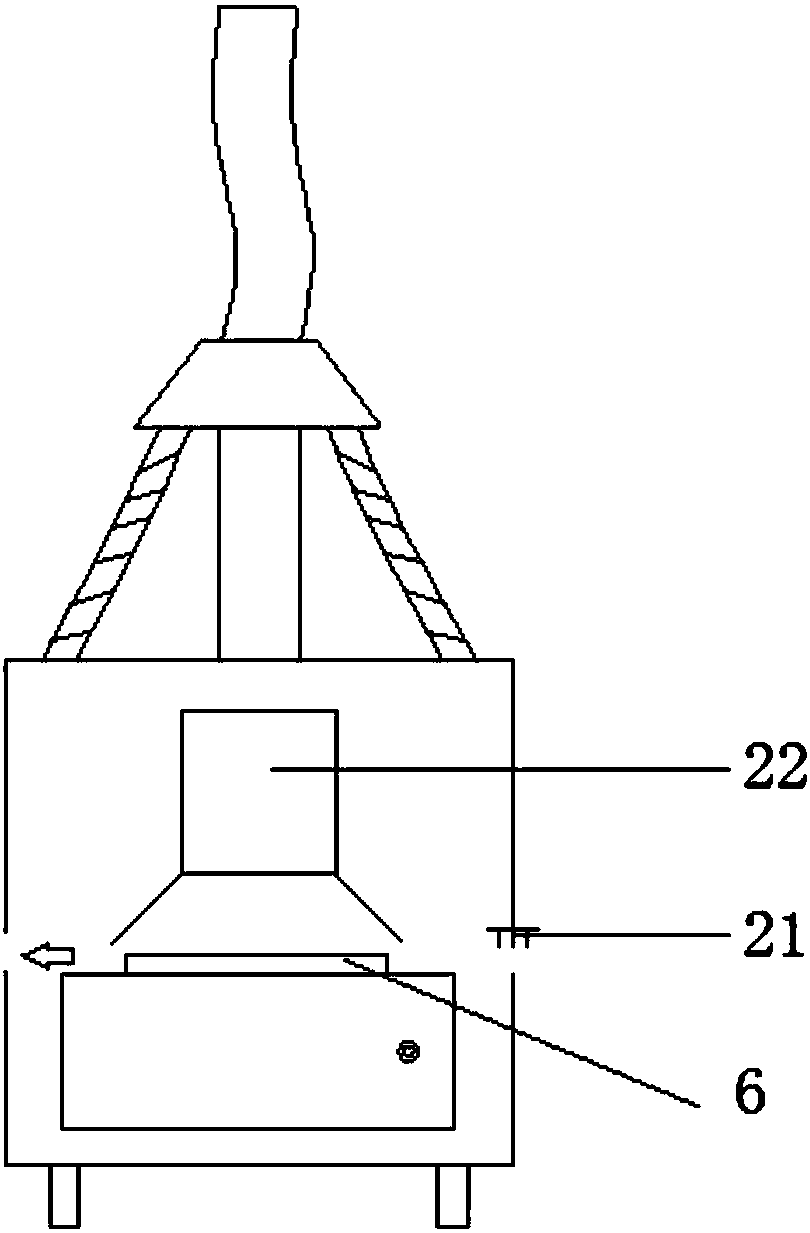

Method and apparatus for removing viscous ash deposit in boiler

InactiveCN1789814AEfficient removal of sticky dustSticky Soot RemovalSolid removalFluidized bedSurface dust

This invention relates to one method and device to remove adhesive dust in oven, wherein the method comprises the following steps: Joining the particles from oven tail smoke channel or remaining oven top along with smoke to tube beam to take off its surface dust; depositing the dust and particles one the smoke channel bottom to enter flow bed filtering device; the air outside smoke channel entering flow chamber to flow the particle and dust from flow chamber top to smoke channel back section; the particle are sent to the feed back device through the flow chamber bottom discharge screw through gas force transmission system or lift machine to send to materials bin; if the particle and dust are severely stuck, then from bin screw to re-fill particle from the side exhaust system by the bin.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Electroplating or chemical-plating pretreatment method of aluminum alloy and application of electroplating or chemical-plating pretreatment method

ActiveCN105274545AImprove bindingUniform removalLiquid/solution decomposition chemical coatingChemical platingPretreatment method

The invention provides an electroplating or chemical-plating pretreatment method of aluminum alloy and a copper plating method of aluminum alloy. The pretreatment method which comprises the steps of chemical sand treatment, surface dust removal, primary zinc immersion, secondary zinc immersion and nickel preplating is adopted, a proper solution formula and proper technological parameters are selected, the binding force of a plating layer obtained later is increased, and it is ensured that the plating layer of copper or other metal is qualified after 280 DEG C welding. The pretreatment method is stable and suitable for cyaniding copper plating treatment of aluminum alloy materials and other kinds of electroplating and chemical-plating pretreatment of the aluminum alloy materials. A thermal shock experiment result shows that aluminum alloy parts can bear high temperature of 280 DEG C for 3 min without bubbling or peeling or falling off after being plated with copper through the method, and the pretreatment method can be applied to electroplating and chemical-plating processes of a large number of parts.

Owner:天津航空机电有限公司

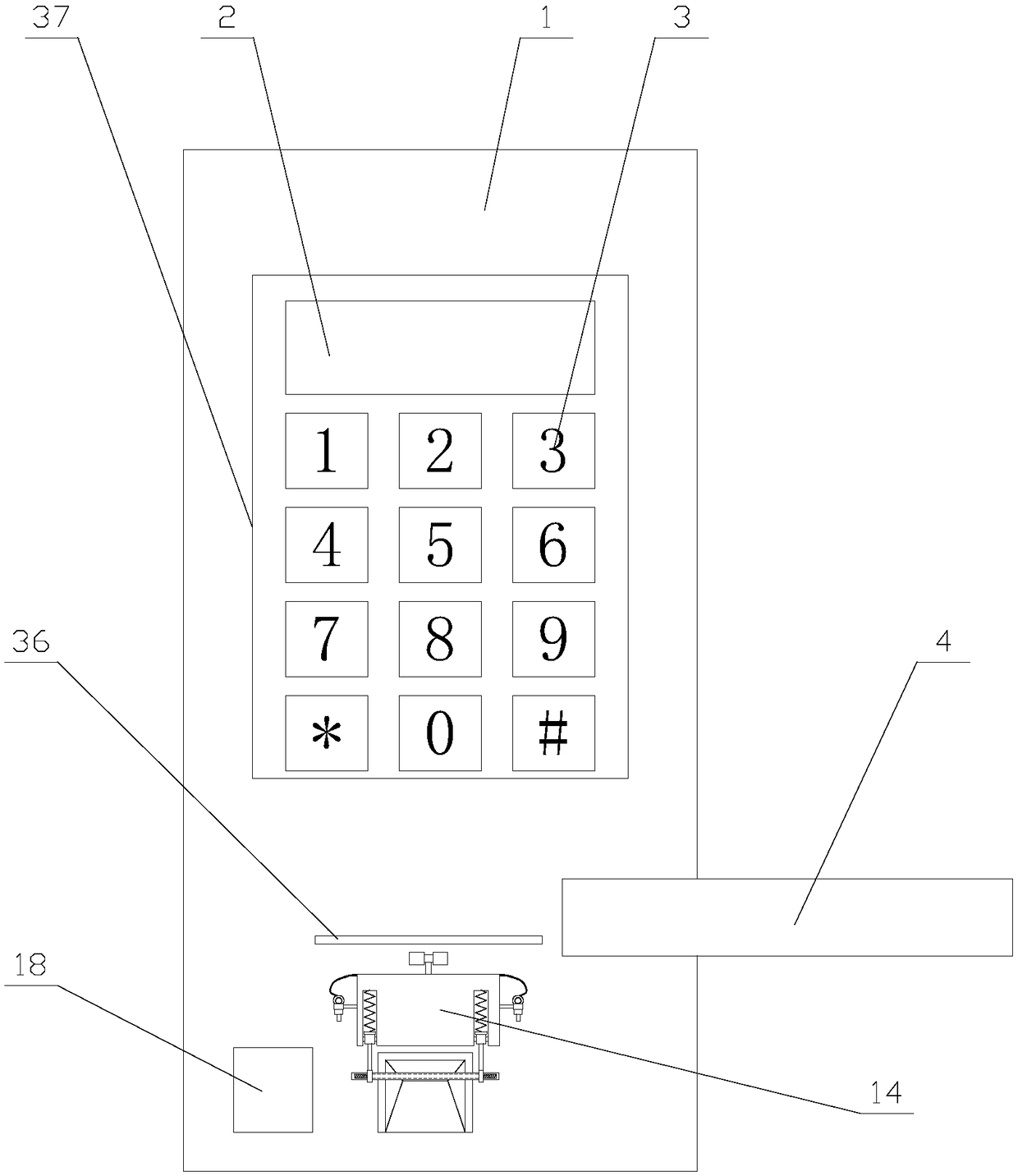

Conveniently mountable and demountable fingerprint lock with automatic cleaning function

ActiveCN108979341AWith automatic cleaning functionEasy to cleanHousehold cleanersElectric permutation locksEngineeringSurface dust

The invention relates to a conveniently mountable and demountable fingerprint lock with an automatic cleaning function. The fingerprint lock comprises a body which is provided with a handle and a fingerprint acquisition device, and the fingerprint acquisition device comprises a pressing mechanism, a connection mechanism and an acquisition mechanism. The acquisition mechanism comprises a recess anda cleaning component, and the cleaning component comprises a cleaning panel, a hinge unit, a cleaning unit, two connection units and two fixing units. The conveniently mountable and demountable fingerprint lock with the automatic cleaning function has advantages that the pressure mechanism drives a fingerprint window in the acquisition mechanism to move outside the recess to make it convenient for fingerprint acquisition, a roller in the cleaning component is abutted against the surface of the fingerprint window in movement to remove surface dust and residual fingerprints, and accordingly safety and reliability in use are improvement; after use, automatic resetting of a pressing panel is realized through first springs, then a retractable frame drives the fingerprint window to move into the recess, and accordingly surface dust of the fingerprint window is prevented, and practicality of the fingerprint lock is improved.

Owner:DONGGUAN REEWORLD SECURITY PRODUCTS LTD

Internet of things based electronic communication cabinet

InactiveCN109862748AImprove cooling effectTo achieve the purpose of dust removalCleaning using toolsCleaning using gasesElectronic communicationEngineering

The invention relates to the technical field of internet of things electronic communication, and discloses an internet of things based electronic communication cabinet. The cabinet includes a frame; the left and right sides at the lower part of the frame are provided with slide grooves; the slide grooves slidingly connected to slide blocks; the left and right sides at the internal of the frame areprovided with dustproof meshes; the inner wall of the frame is fixedly connected to object placing separating plates; communication equipment is placed on the object placing separating plates; the left and right sides on the top of the frame are fixedly connected to guiding columns; the guiding columns are slidingly connected to a crossbeam; and the left and right ends of the crossbeam are fixedly connected to connecting rods. Through the arrangement of a rack and pinion mechanism consisting of gears and racks, fans and dedusting frames can be driven to rotate through the mechanism, so that the purpose of performing heat dissipation and dedusting on the internal of the cabinet can be realized; the device is simple in operation; through the arrangement of a self-cleaning device, heat dissipation can be performed on the internal of the frame, and surface dust can be removed as well, so that heat dissipation effects can be enhanced; and the cabinet is reasonable in design and suitable for popularization and usage.

Owner:JINGCHU UNIV OF TECH

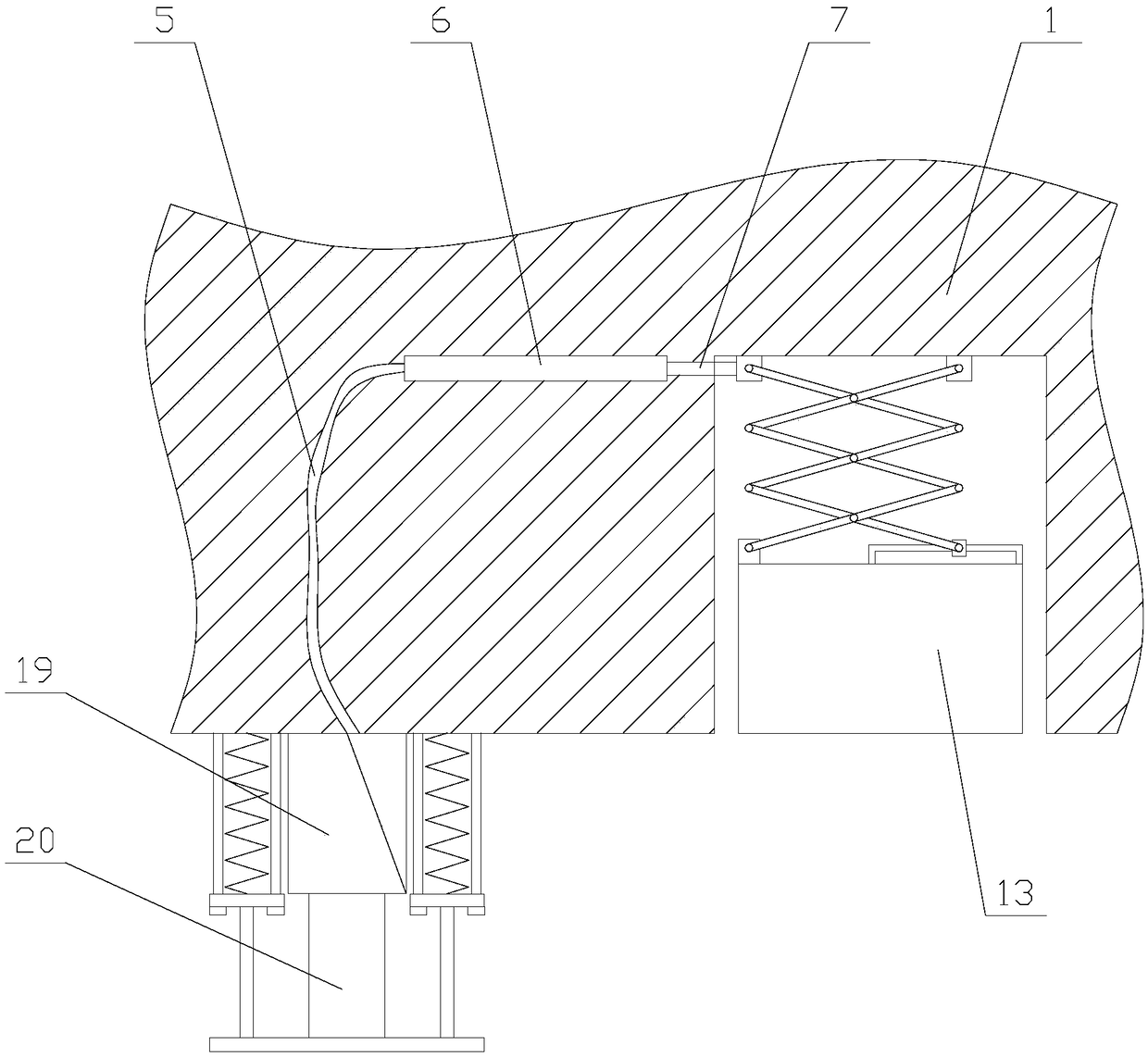

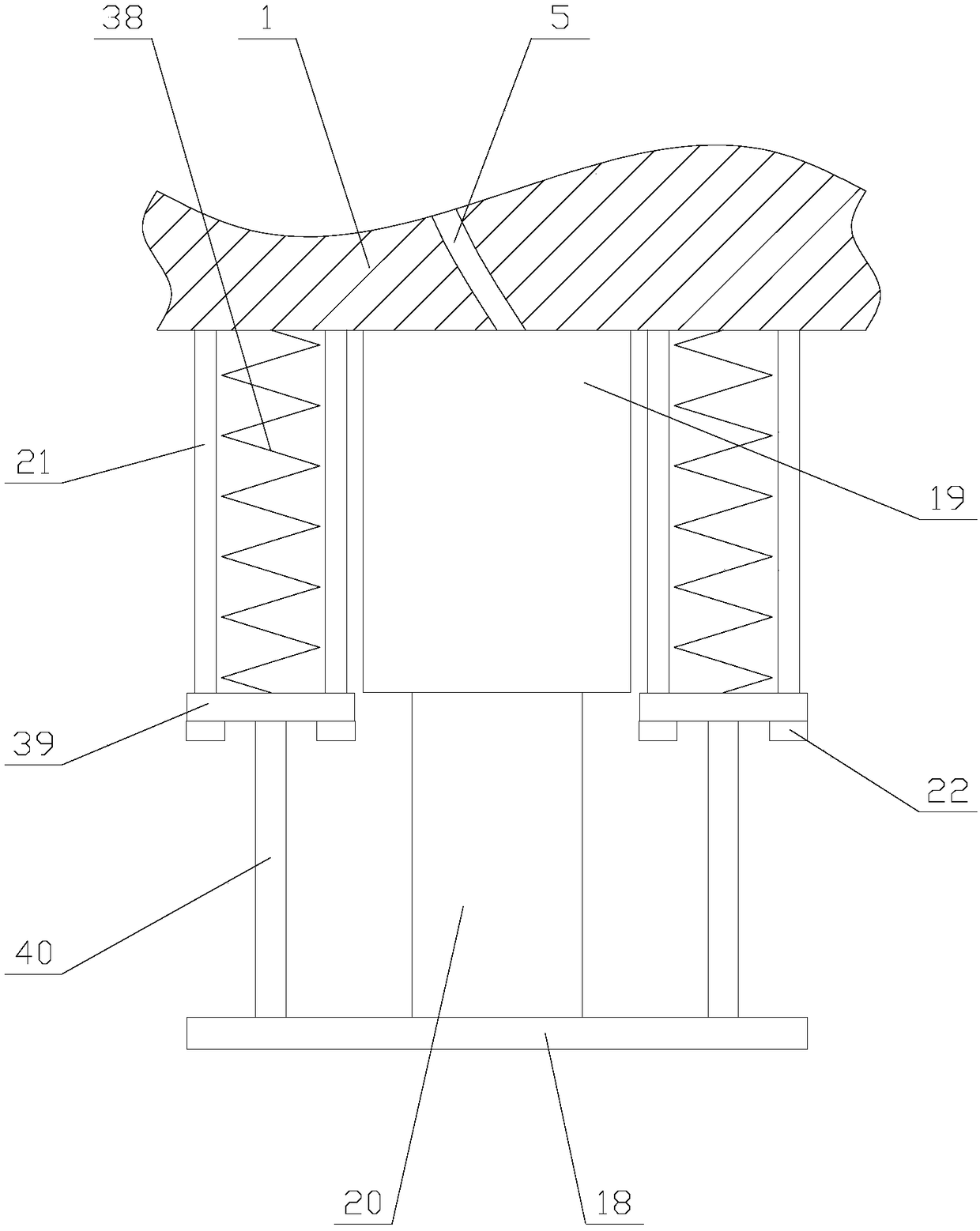

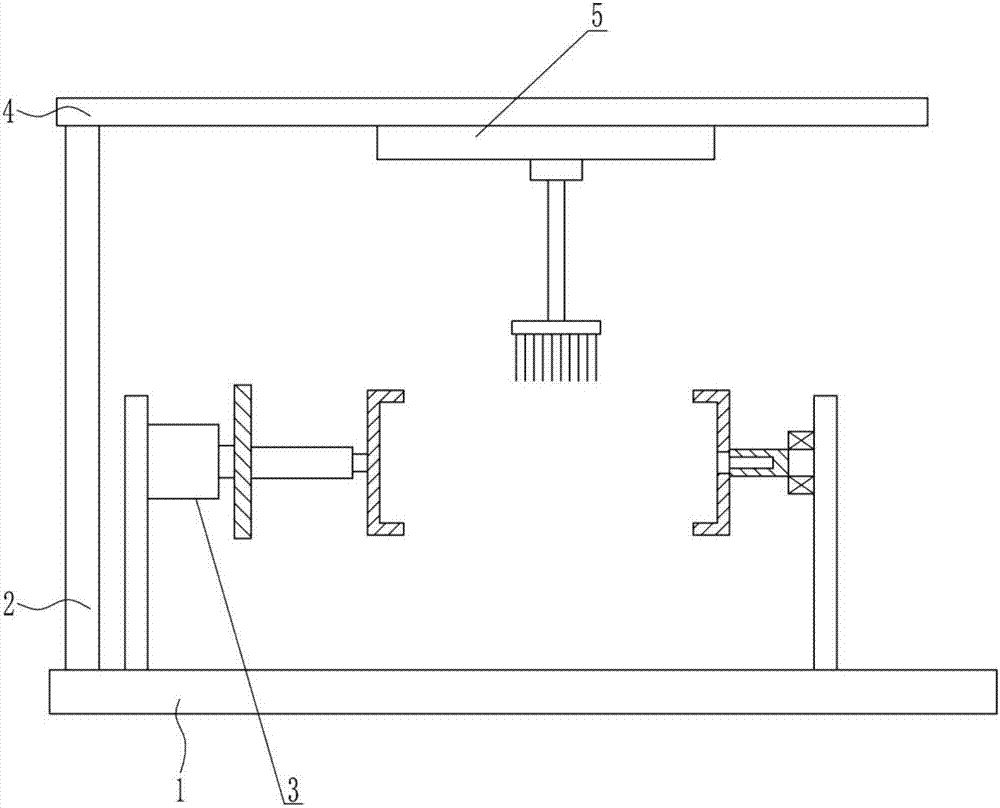

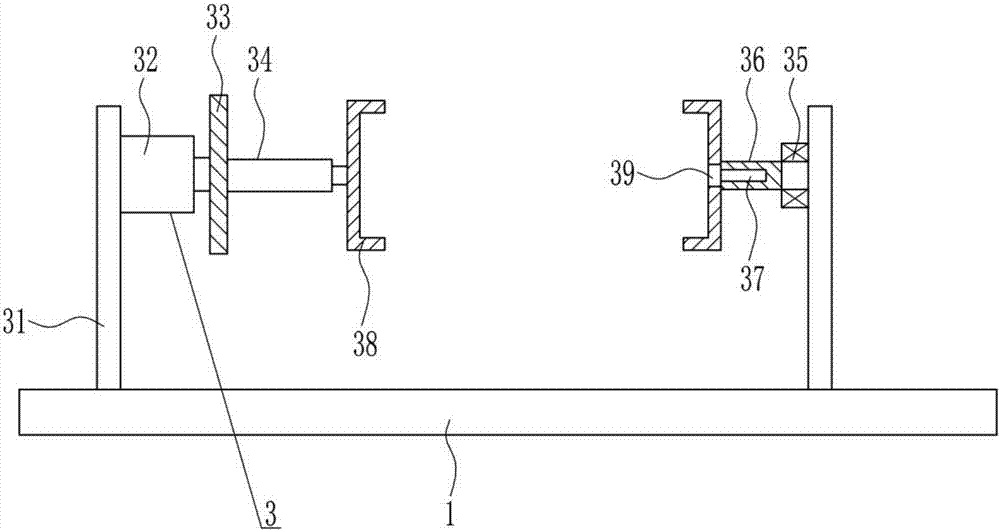

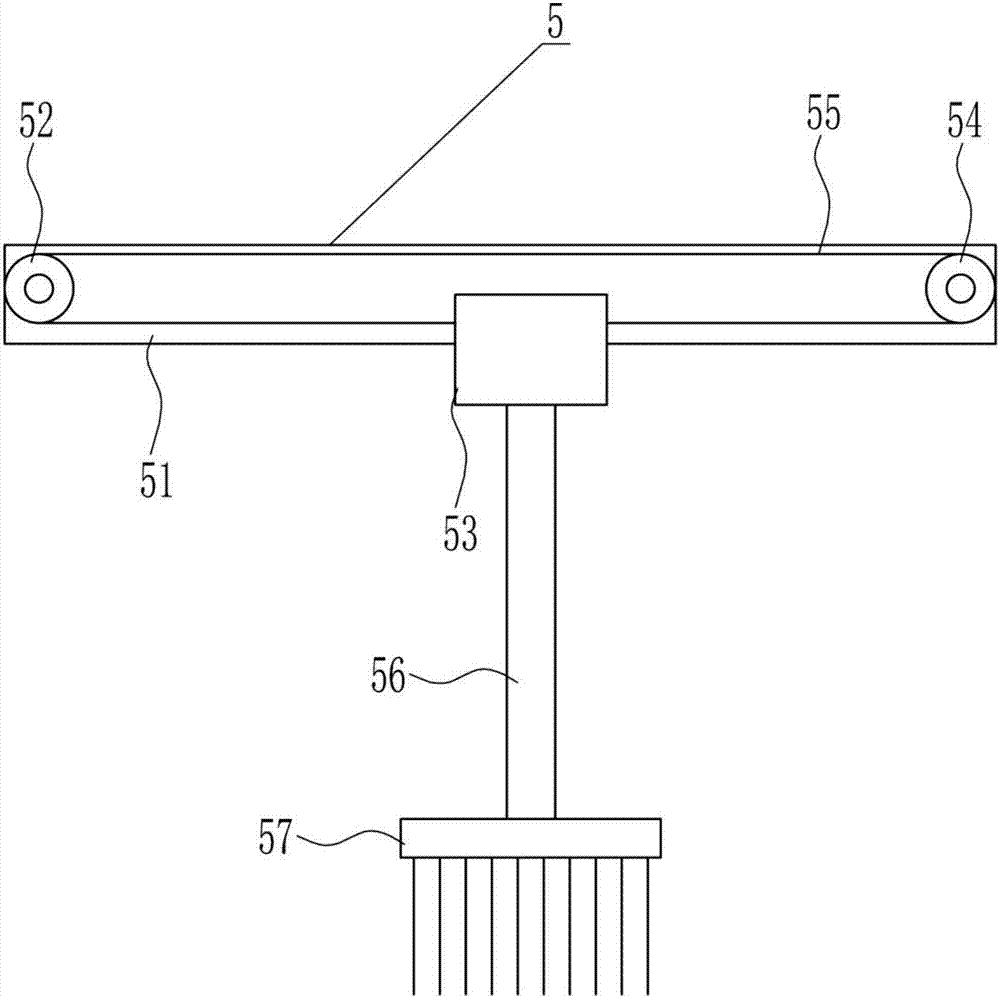

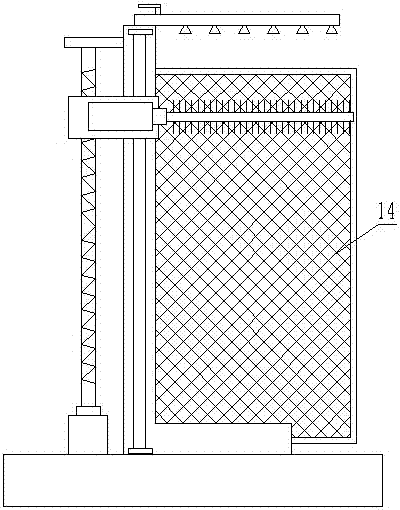

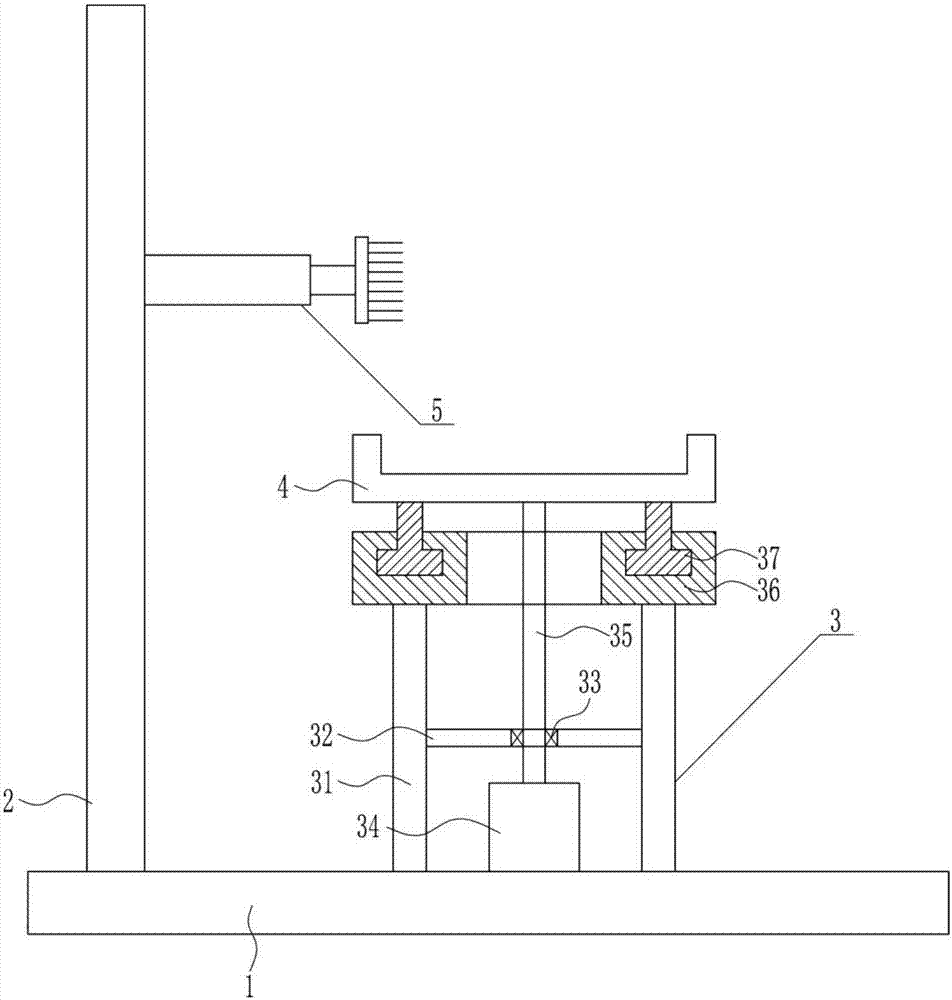

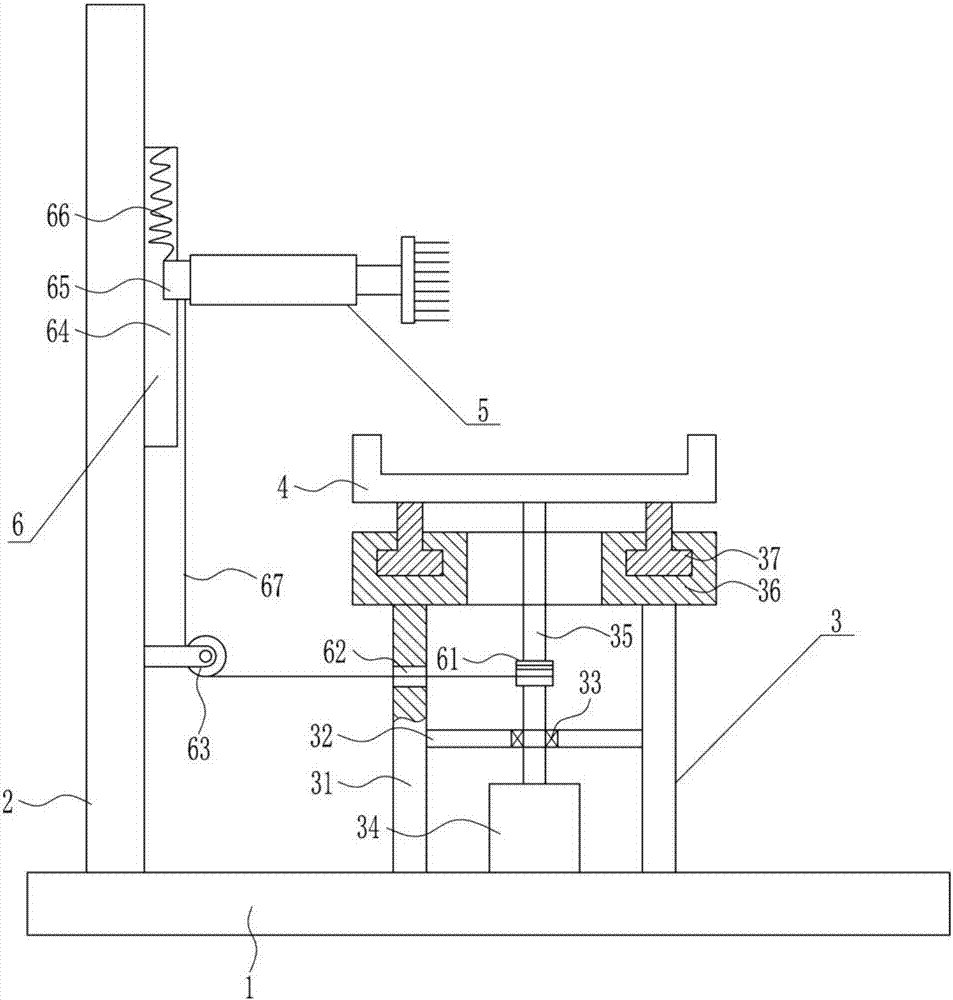

Motor surface dust comprehensive sweeping equipment for motor maintenance

InactiveCN107262407ANot easy to damageNo manual manipulationUsing liquid separation agentCleaning using toolsPhysical healthSurface dust

The invention relates to motor maintenance equipment, in particular to motor surface dust comprehensive sweeping equipment for motor maintenance. The technical effects that the motor surface dust comprehensive sweeping equipment for motor maintenance is capable of saving manpower and time and low in labor intensity, dust is not liable to be inhaled by workers, and the motor surface dust comprehensive sweeping equipment does not influence physical health are achieved. In order to achieve the technical effects, the provided motor surface dust comprehensive sweeping equipment for motor maintenance comprises a bottom plate and the like. A support is vertically mounted on the left side of the bottom plate in a bolt connection mode. A rotary fixing device is arranged in the position, on the right side of the support, of the top of the bottom plate. Dust on the surface of a motor can be cleaned up rapidly, and the effects that manpower and time are saved, the labor intensity is low, dust is not liable to be inhaled by workers, and the motor surface dust comprehensive sweeping equipment does not influence physical health are achieved.

Owner:闫梦蝶

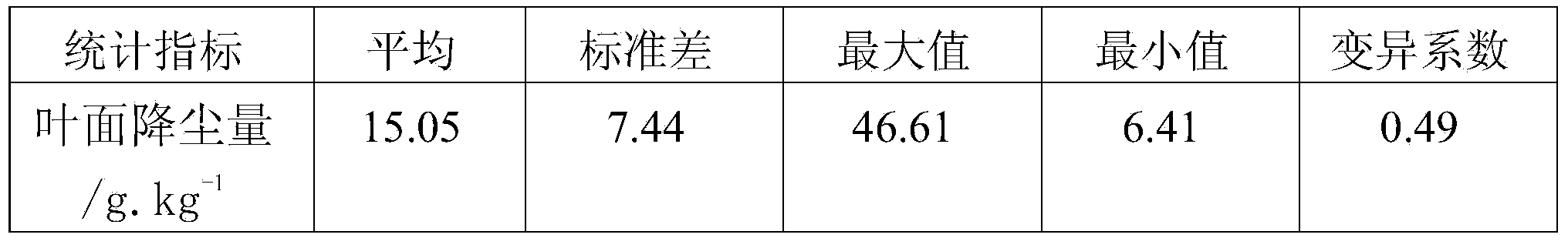

Leaf surface dust fall quantity testing method based on hyperspectral technique

InactiveCN103411846AImprove efficiencyEasy to operateWeighing by removing componentSpectral bandsCoefficient of determination

The invention relates to a leaf surface dust fall quantity testing method based on a hyperspectral technique. The method comprises the following steps: firstly, collecting healthy leaves with different leaf surface dust fall quantities, quickly testing spectral information of a single leaf, putting the leaf subjected to the spectral information testing into a room, acquiring leaf surface dust fall quantity data of the leaf by virtue of a leaf area instrument and an electronic scale, and determining a sensitive spectral band subjected to leaf surface dust fall by analyzing the correlation between hyperspectral information and the leaf surface dust fall quantity data; and carrying out modeling by virtue of the data of the sensitive spectral band subjected to the leaf surface dust fall, selecting a model with a minimal root-mean-square error and maximal errors between a determination coefficient and a predicted root-mean-square error and between a sample standard deviation and the predicted root-mean-square error, and predicting the leaf surface dust fall quantity of the model only by virtue of the hyperspectral information of the leaf. Compared with a traditional determination method, the leaf surface dust fall quantity testing method has the beneficial effects of reducing the tedious experimental steps of indoor leaf area testing, cleaning, weighing and the like, being simple, convenient and rapid, and meanwhile, providing references for monitoring of the sand storm strength and environment quality of a dust fall region by virtue of astronautic hyperspectral remote sensing.

Owner:TARIM UNIV

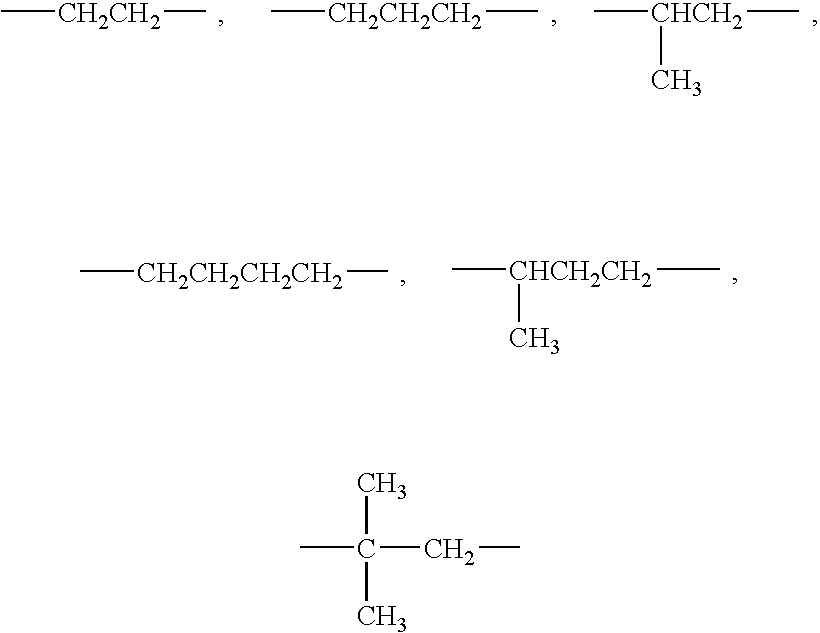

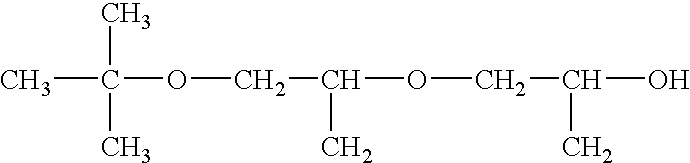

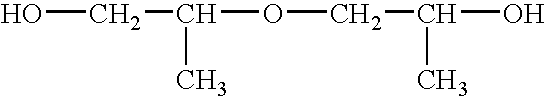

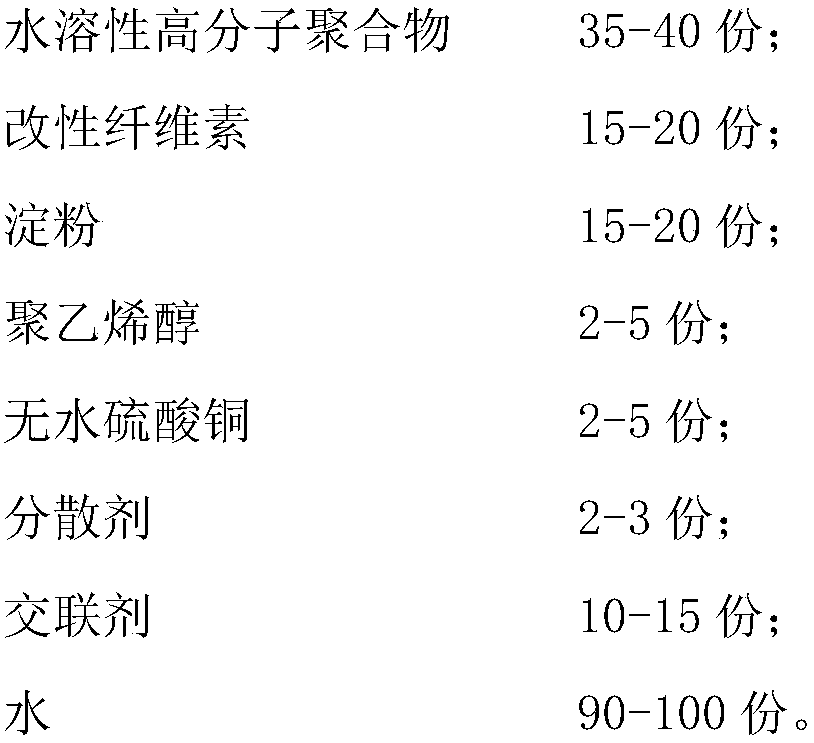

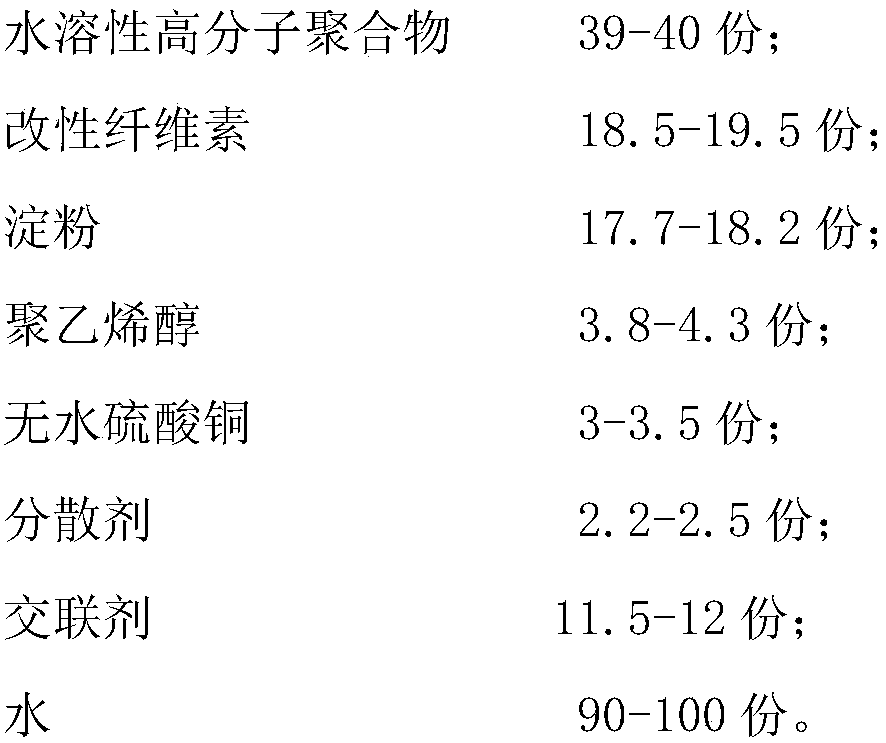

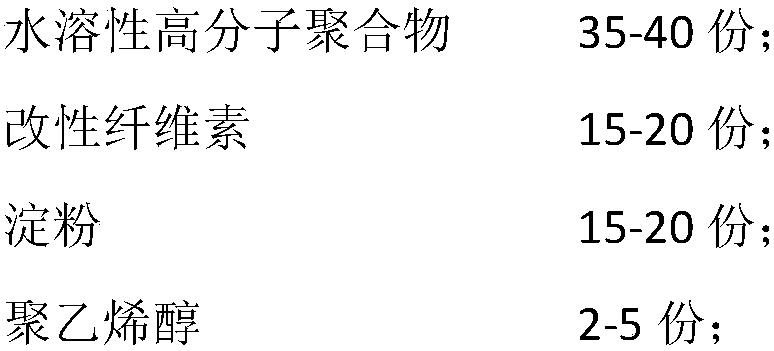

Natural environment-friendly surface dust suppression curing agent and preparation method thereof

ActiveCN107828381AEffective immobilizationEffective reunionOther chemical processesEnvironmental resistanceDust particles

The invention provides a natural environment-friendly surface dust suppression curing agent and a preparation method thereof. The curing agent is characterized by being prepared from the following components in parts by weight: 35-40 parts of a water-soluble polymer, 15-20 parts of modified cellulose, 15-20 parts of starch, 2-5 parts of polyvinyl alcohol, 2-5 parts of anhydrous copper sulfate, 2-3parts of a dispersant, 10-15 part of a crosslinking agent and 90-100 parts of water. The obtained product is rapidly dissolved and can be uniformly sprayed to the surface of dust, so that dust particles can be fixed and agglomerate very effectively in a short time. The curing agent is corrosion-free to vehicles and railway tracks, soluble in water and waterproof; a waterproof shell cannot be dissolved in water once formed. A curing layer with high elasticity can still be formed under the unfrozen condition and has certain strength and toughness, and people can walk on the curing layer withoutbreaking the curing layer due to existence of elasticity.

Owner:周长胜

Method for preparing sea cucumber

InactiveCN101181081AShorten hair processing timeUniform structureFood preparationHygienic qualityHigh pressure

The invention discloses a fermented preparation method of sea cucumber, comprising the following steps: the sea cucumber is cleaned to remove the surface dust, salt, visceral remains, calcareous infarct on the month of the sea cucumber; the sea cucumber is soaked in water for 12-24h to desalt; the sea cucumber is put into a pressure cooker of 0.05-0.15MPa to be boiled with high pressure for 15-35min and then be put into water of -4-4 DEG C to be fermented for 20-24h. The method can shorten the boiling and preparation time of the sea cucumber in traditional method and overcomes the shortages that the preparation method of sea cucumber is long in the current technology and the nutrition loss is big. The water-risen sea cucumber processed by the method of the invention has the advantages of little nutrition loss, plump shape, large rehydration multiple, good sanitary quality, etc.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

High-viscosity antirust concrete demoulding agent and preparation method of same

InactiveCN106590893AGood release effectImprove performanceCeramic shaping apparatusLubricant compositionPollutionWaste material

A high-viscosity antirust concrete demoulding agent and a preparation method thereof. The concrete demoulding agent includes, by weight, 10-40% of industrial waste oil, 20-89% of water, 0.1-5% of a surfactant, 0.1-5% of an emulsifier, 0.1-5% of an antirust agent, and 0.1-5% of a defoamer. The ratio of the surfactant to the emulsifier is 5-1. The concrete releasing agent being high in viscosity, on one hand, achieves recovery of waste materials, and on the other hand, solves environment pollution due to the industrial waste oil. By adding trace amount of the surfactant, the emulsifier and the antirust agent to the industrial waste oil, the components are stirred at room temperature by adding water, thereby producing the concrete demoulding agent which is good in demoulding effect, has stable performance, is zero-pollution and is low in cost. The concrete demoulding agent employs simple production process and equipment and has low production cost and good demoulding effect. A steel mould member has smooth surface and has no surface dust and residual concrete, is convenient to clean and has no rust.

Owner:QUJING NORMAL UNIV

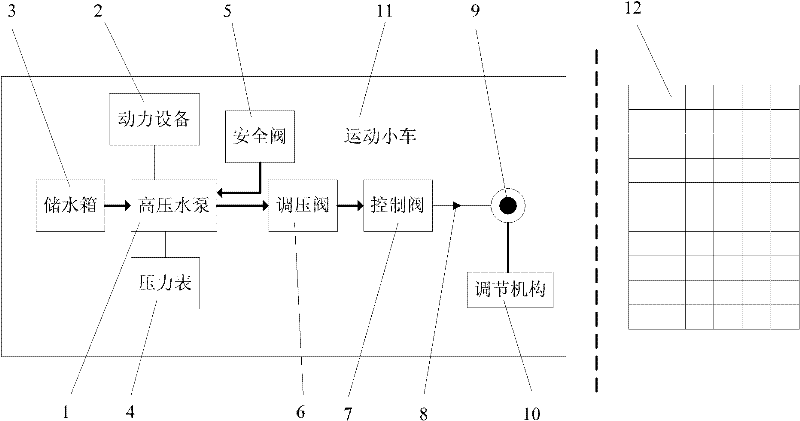

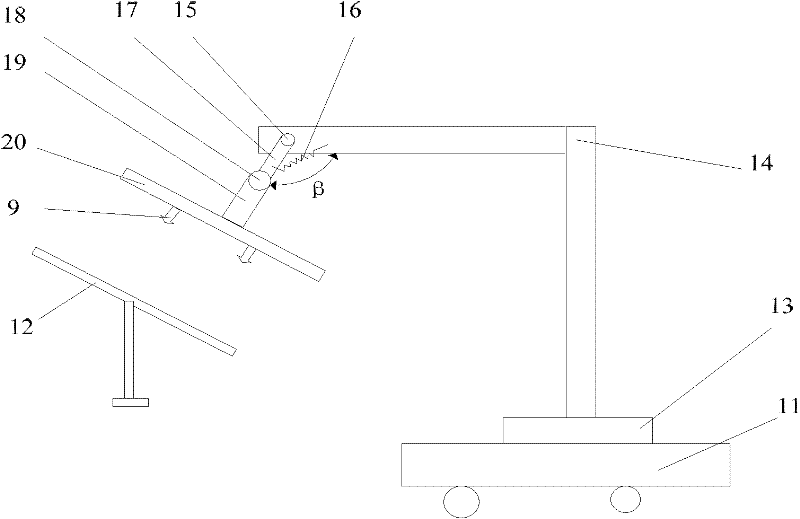

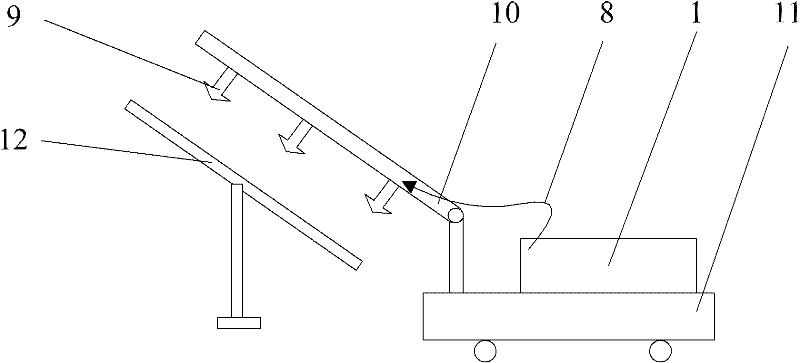

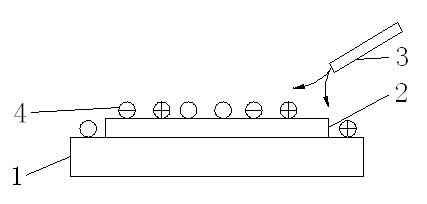

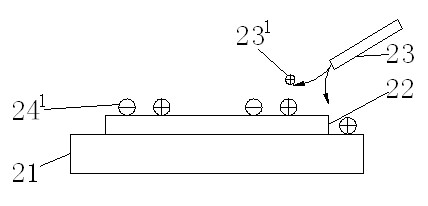

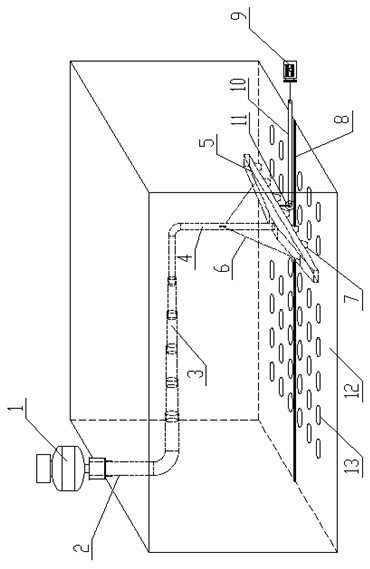

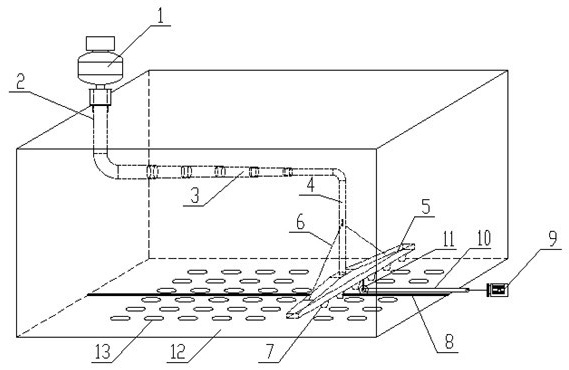

Solar panel array surface dust removal system and method

ActiveCN102441541ANo pollutionImprove protectionCleaning using liquidsWater savingHigh pressure water

A solar panel array surface dust removal system and a method belong to the technical field of solar photovoltaic power generation. The solar panel array surface dust removal system comprises a high-pressure water generating device, a delivery pipe, an adjusting mechanism, at least one jetting device and a moving trolley, high-pressure water generated by the high-pressure water generating device forms a high-pressure water flow jetting plane via the jetting devices, two comprehensive actions of impacting and shearing are produced for dust covered on surfaces of solar panel arrays, and accordingly the dust of the surfaces of the solar panel arrays is removed. The main steps of the method comprise that basic dust removal parameters are determined, parameters of the jetting devices are selected, overall arrangement of the jetting devices is determined according to the sizes of the solar panel arrays, and a cleaning operation path is planned. The solar panel array surface dust removal system and the method are simple to be realized, are applicable to installation of most of solar panel arrays, save water, do not damage surfaces of solar panels, do not pollute environments, not only can realize a large-range high-efficient dust removal, but also have an auxiliary summer cooling function and a winter snow removal function.

Owner:北京动力协合科技有限公司

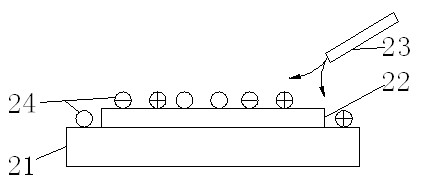

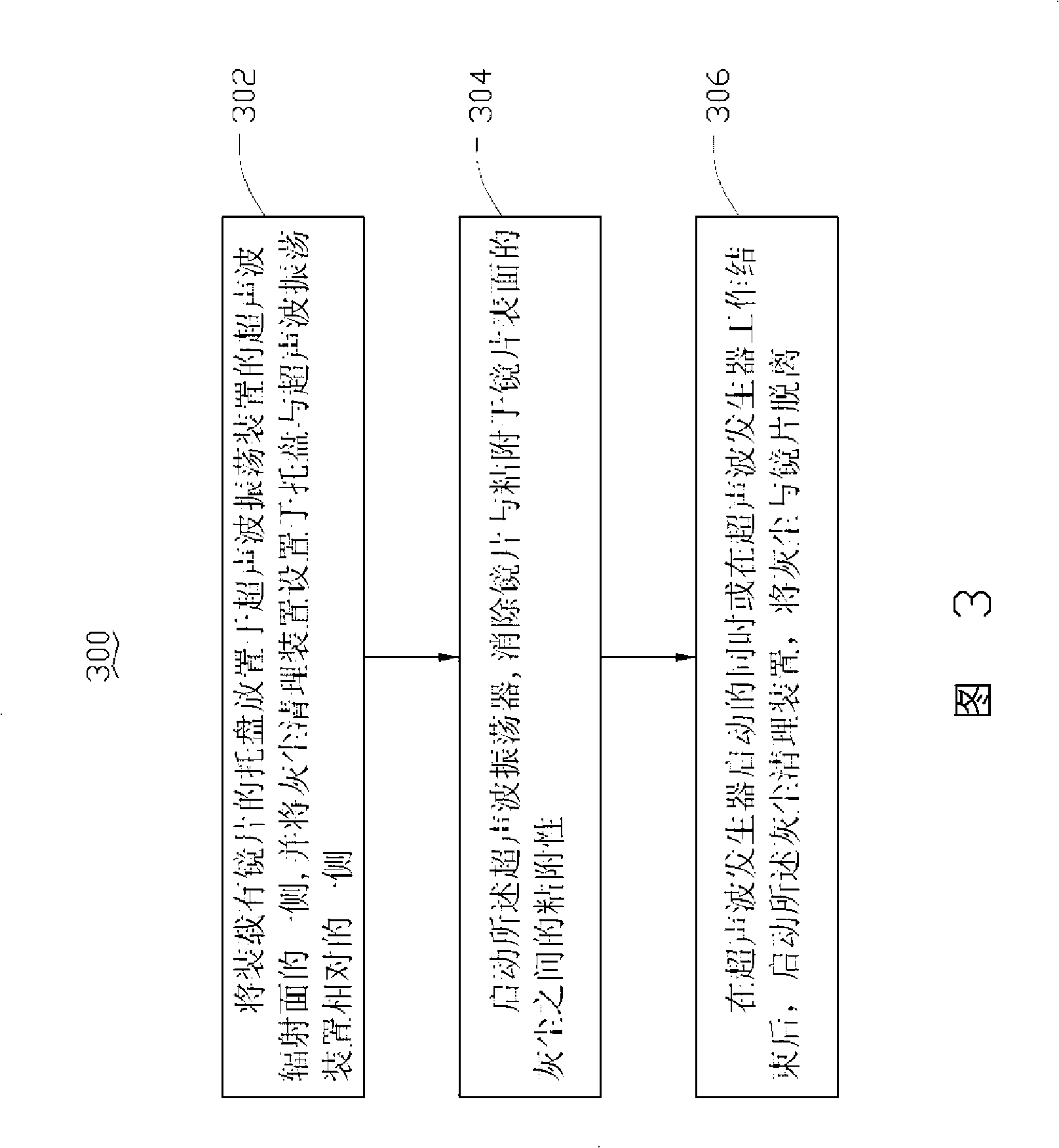

Method for removing surface dust of mask plate

InactiveCN102426412AImprove dust removal efficiencyReduce the risk of damaging the reticleOriginals for photomechanical treatmentCleaning using gasesEngineeringSurface dust

The invention relates to a method for removing dust, especially relates to a method for removing surface dust of a mask plate. According to the invention, under the premise that the air blowing pressure is not raised, the method for removing the surface dust of the mask plate can eliminate the adsorption capacity of the dust through blowing ionic wind to neutralize the electrical property of the charged dust, thereby the dedusting efficiency can be raised, the charged dust can be removed, the risk of destroy on the mask plate is reduced, and the technology is simple and easy to operate.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

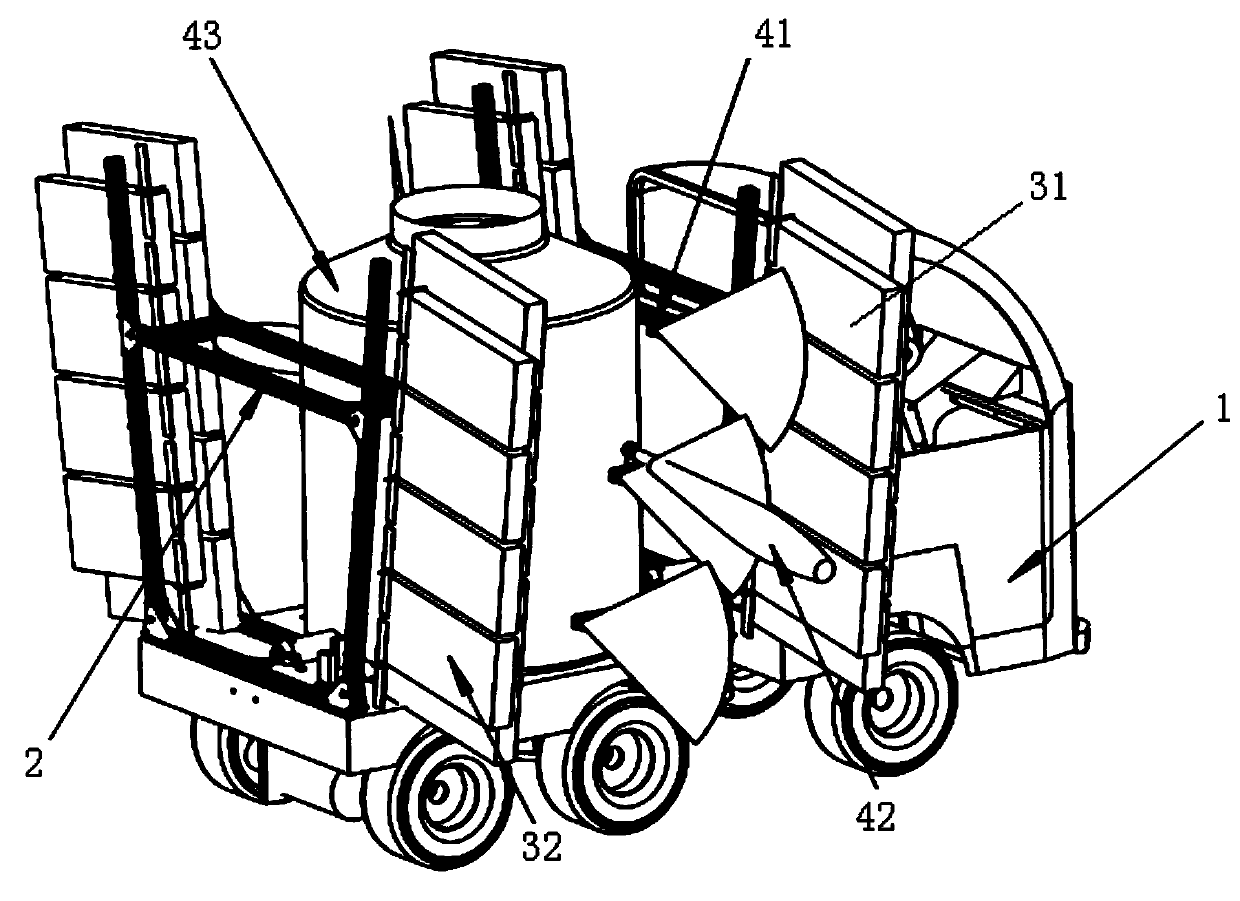

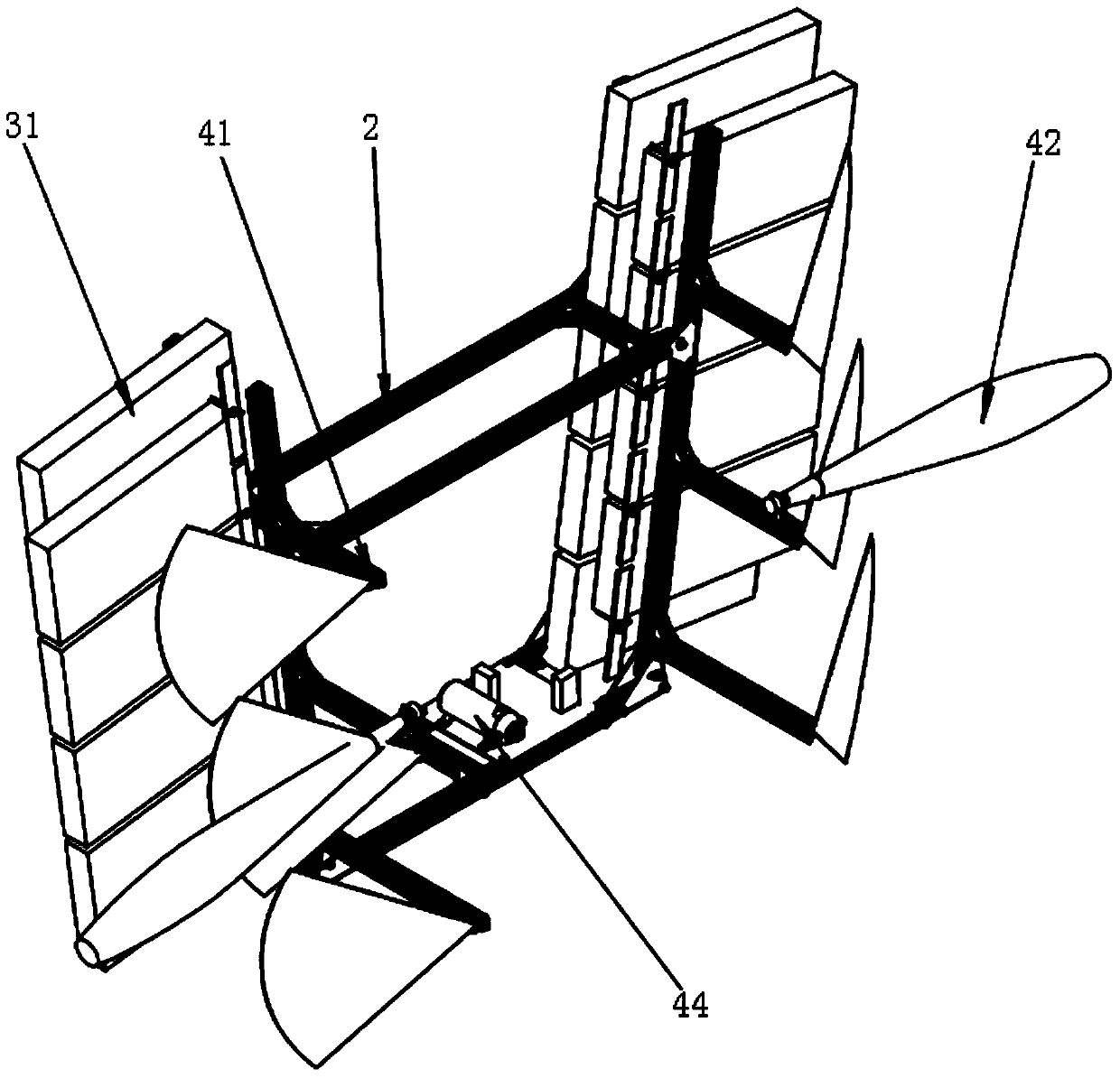

Heliostat cleaner

ActiveCN103721959AImprove cleaning efficiencyConserve waterCleaning using toolsCleaning using liquidsHeliostatSurface dust

The invention provides a heliostat cleaner comprising a cleaning platform, a cleaning mechanism frame, a cleaning mechanism, at least two sponge members, a plurality of nozzles, and a spray controller. The cleaning mechanism is used for cleaning a heliostat. The sponge members are used for cleaning the surface of the heliostat and both arranged on the cleaning mechanism. The nozzles are used for spraying water to the surface of the heliostat and disposed on the cleaning mechanism frame. The nozzles are arranged between the sponge members. The spray controller is used for controlling the nozzles to spray water. One sponge member is used to wipe the surface of the heliostat to be cleaned, for the first time to remove surface dust on the surface of the heliostat; after the spray controller controls the nozzles to spray water, the other sponge member is used to wipe the residual water and dust on the surface of the heliostat to be cleaned, for the second time. Compared to the prior art, the heliostat cleaner has the advantages that the heliostat is cleaned twice with the sponge, the features of light weight and ease of deformation in the sponge ensure that the sponge can fully contact with the surface of the heliostat, the heliostat is suitable for use in dry, dusty environments such as deserts and plateaus, less water is used, and cleaning effect is better.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

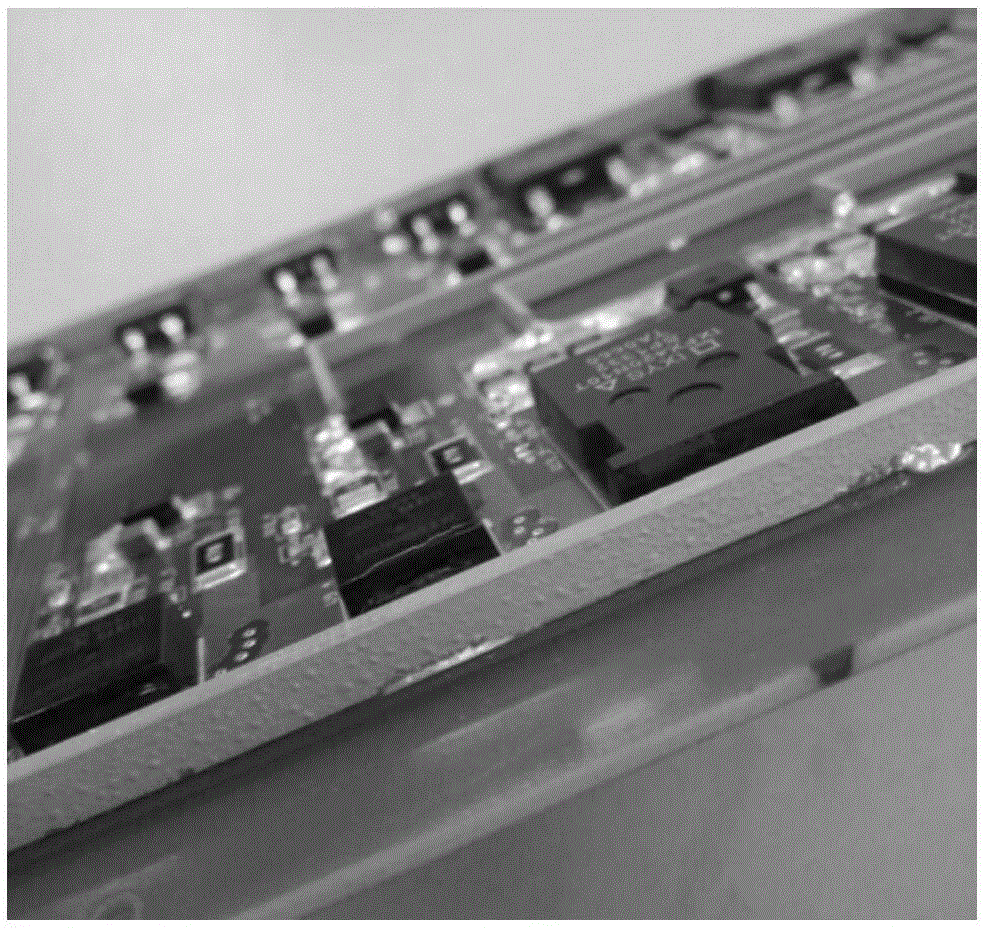

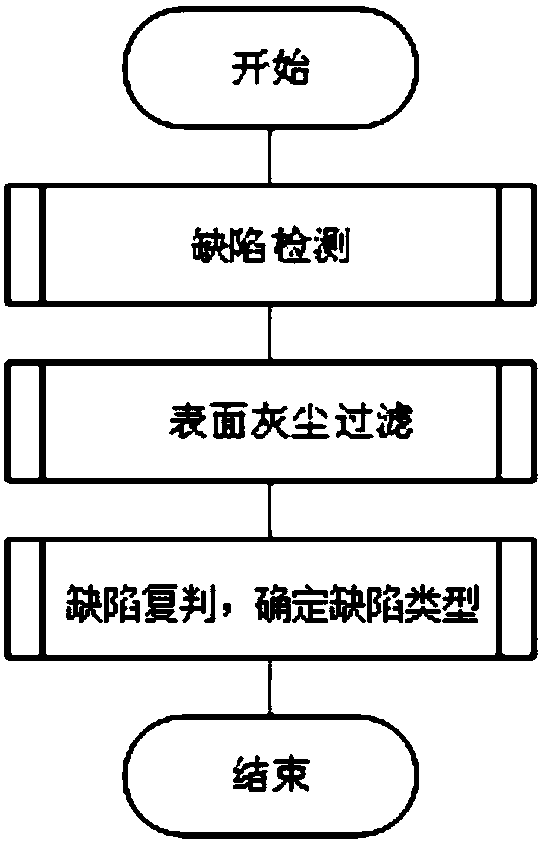

Method and device for classifying defects of L0 pictures in AOI detection

InactiveCN107677679AAccurate classificationImprove performanceOptically investigating flaws/contaminationNon-linear opticsForeign matterFiltration

The invention discloses a method and device for classifying defects of L0 pictures in AOI detection. The method comprises the steps that defect detection is conducted on L0 pictures of a panel to determine all brightness defects; surface dust filtration is conducted on the detected brightness defects; the brightness defects are switched to a detection picture one by one for re-judgment, light transmission at the defect positions of the panel proves foreign matter brightness defects, light non-transmission proves bright point type defects, and the detection picture is a picture only displayingbacklight and having no voltage signal. Foreign matter brightness and bright points can be accurately classified by adding one detection picture to re-judge defects, the method is simple and effective, the practicability is strong, the performance of an AOI detection system is effectively improved, and the method has the advantages of being easy to achieve, low in cost and good in practicability.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

Screen window surface dust quick cleaning device and its using method

The invention relates to a screen window surface dust quick cleaning device and its using method. The cleaning device includes a base, a mounting frame fixedly connected on the upper surface of the base, a spraying mechanism located above the mounting frame, and a screen window surface dust cleaning mechanism; the cleaning mechanism includes a first driving motor, a sweeping roller and a driving mechanism used for driving the first driving motor to do up-and-down reciprocating motion, the sweeping roller is fixedly connected with an output shaft of the first driving motor, and a brush is arranged on the sweeping roller; the driving mechanism includes a second driving motor, a reciprocating screw rod, a guide rod and a sliding block, and the first driving motor is fixedly connected with the sliding block. Compared with the prior art, through the cooperation of the cleaning mechanism and the spraying mechanism, dust on the screen window surface can be quickly cleaned, the cleaning efficiency is high, the dust is cleaned thoroughly, no dust is left, and by replacing manual cleaning with machine cleaning, the labor intensity is reduced.

Owner:侯林格

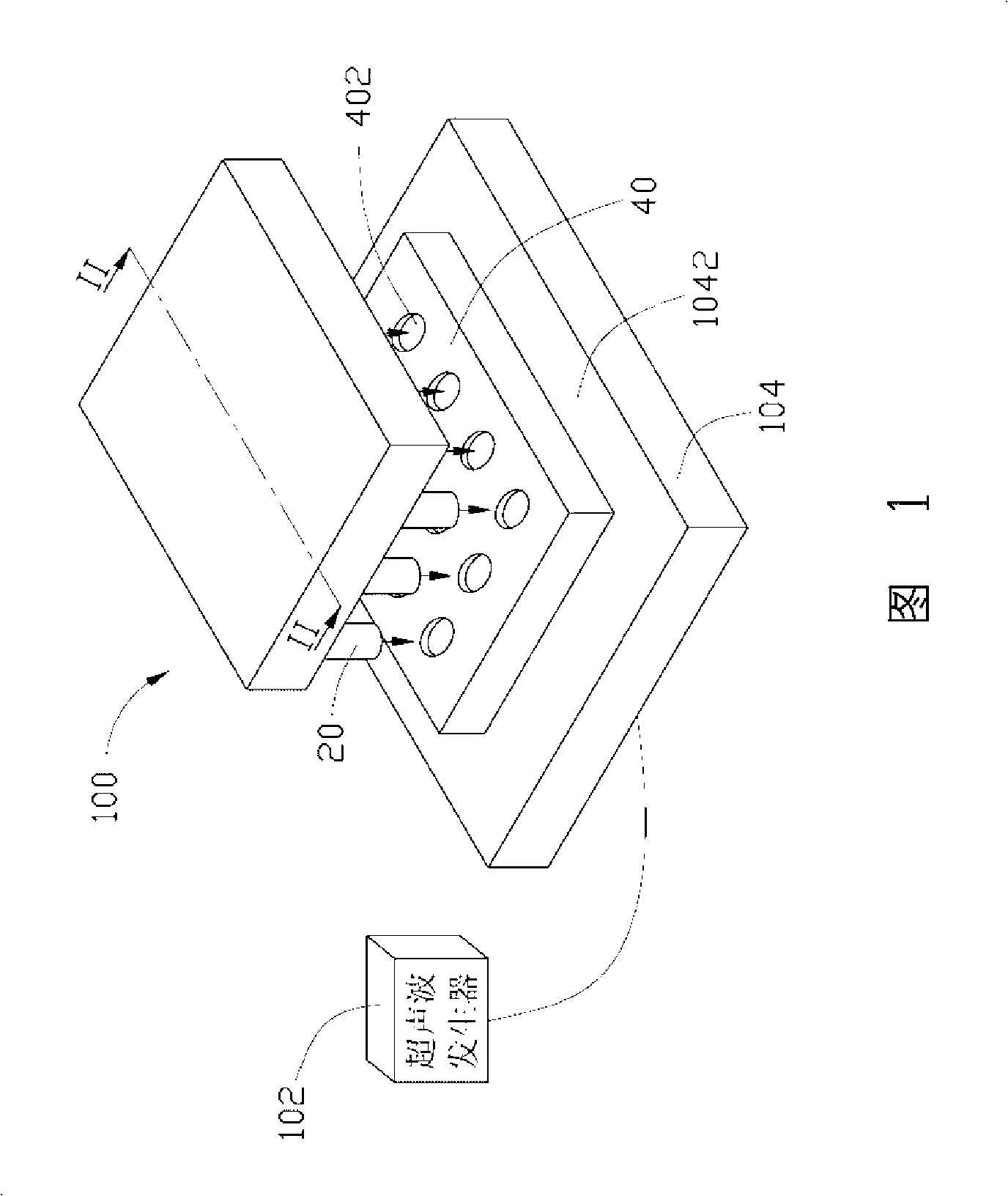

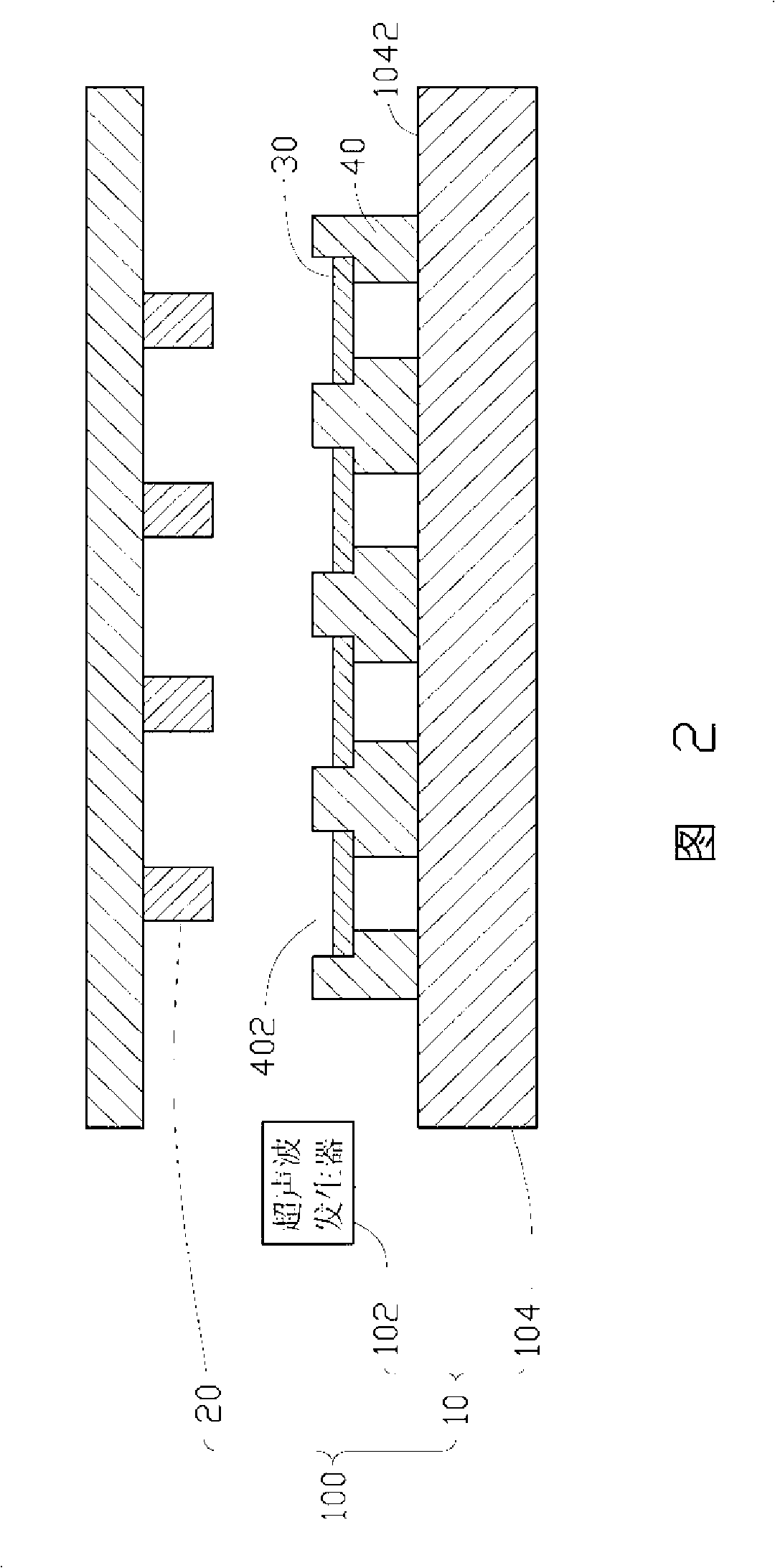

Optical lens surface dust cleaning apparatus and dust collection method

InactiveCN101274326AAvoid secondary pollutionClean up thoroughlyHollow article cleaningFlexible article cleaningOptoelectronicsCollection methods

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

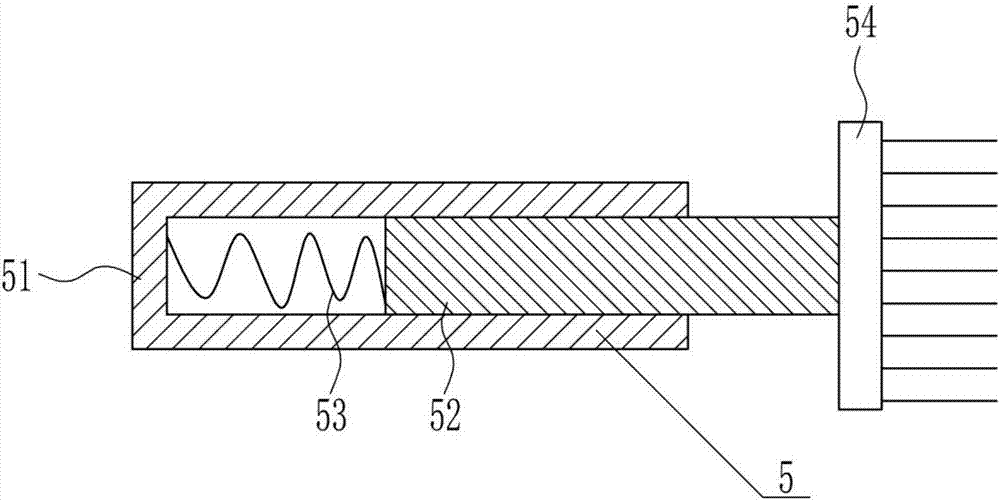

Rapid-opening mechanism of paper money channel for financial machine

InactiveCN102034301AEasy to removeUndisturbedCoin/currency accepting devicesStructural engineeringSurface dust

The invention relates to a rapid-opening mechanism of a paper money channel for a financial machine, comprising a fixing seat, a movable frame and a rear cover, wherein a money receiving impeller and a money receiving inlet are arranged in the fixing seat, a money setting part is arranged in the movable frame, the rear cover is hinged on the movable frame, and the movable frame is hinged on the fixing seat. A paper money dragging and checking channel is formed between mutual-hinged opposite surfaces of the rear cover and the movable frame, a paper money transmitting channel communicated with the paper money dragging and checking channel is formed between mutual-hinged opposite surfaces of the movable frame and the fixing seat, and the paper money dragging and checking channel is arranged vertically. The rapid-opening mechanism overcomes disadvantages in the prior art that a paper money channel of a common financial checking machine has insufficient opening scope and a sensor is easilydisturbed. Through the design of the rapid-opening mechanism, blocked paper money can be taken out conveniently, and meanwhile, the surface dust sweeping and the fault removing of various sensitive sensors and the maintenance of equipment can be properly convenient. The rapid-opening mechanism greatly improves the precision of signal detection, and has the advantages of compact structure and strong reliability.

Owner:SHANGHAI DINGYI FINANCIAL EQUIP

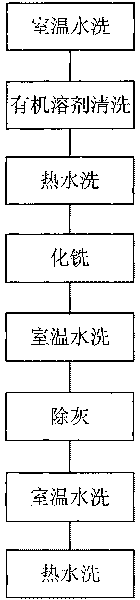

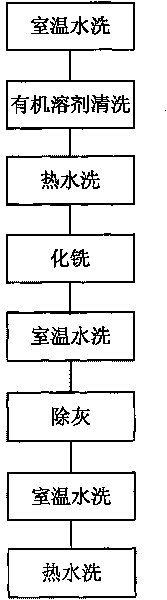

Chemical milling method for titanium alloy blades

ActiveCN101709471AMeet the precision requirementsMeet the design drawing requirementsOrganic solventRoom temperature

The invention provides a chemical milling method for titanium alloy blades. The method is implemented according to the following steps: (1) washing a titanium alloy blade subjected to finish forging with water in order to remove surface dust, adopting organic solvent to remove surface oil stain and then removing the organic solvent; (2) immersing the titanium alloy blade after the organic solvent is removed in chemical milling solution for 3 to 15 minutes; (3) cleaning the obtained product with room-temperature water to remove residual acid solution on the surface and then immersing the obtained product in dust-removing solution for 3 to 15minutes; and (4) removing the residual acid solution on the surface of the titanium alloy blade after dust removal. The method can effectively control the rate of corroding the surface of the blade by preparing the chemical milling solution so as to allow titanium alloy blades to meet precision requirements. The whole chemical milling process is simple in method and easy to control, and can meet design requirements without machining blade discs, blade backs, inner edges and surfaces of the titanium alloy blades.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

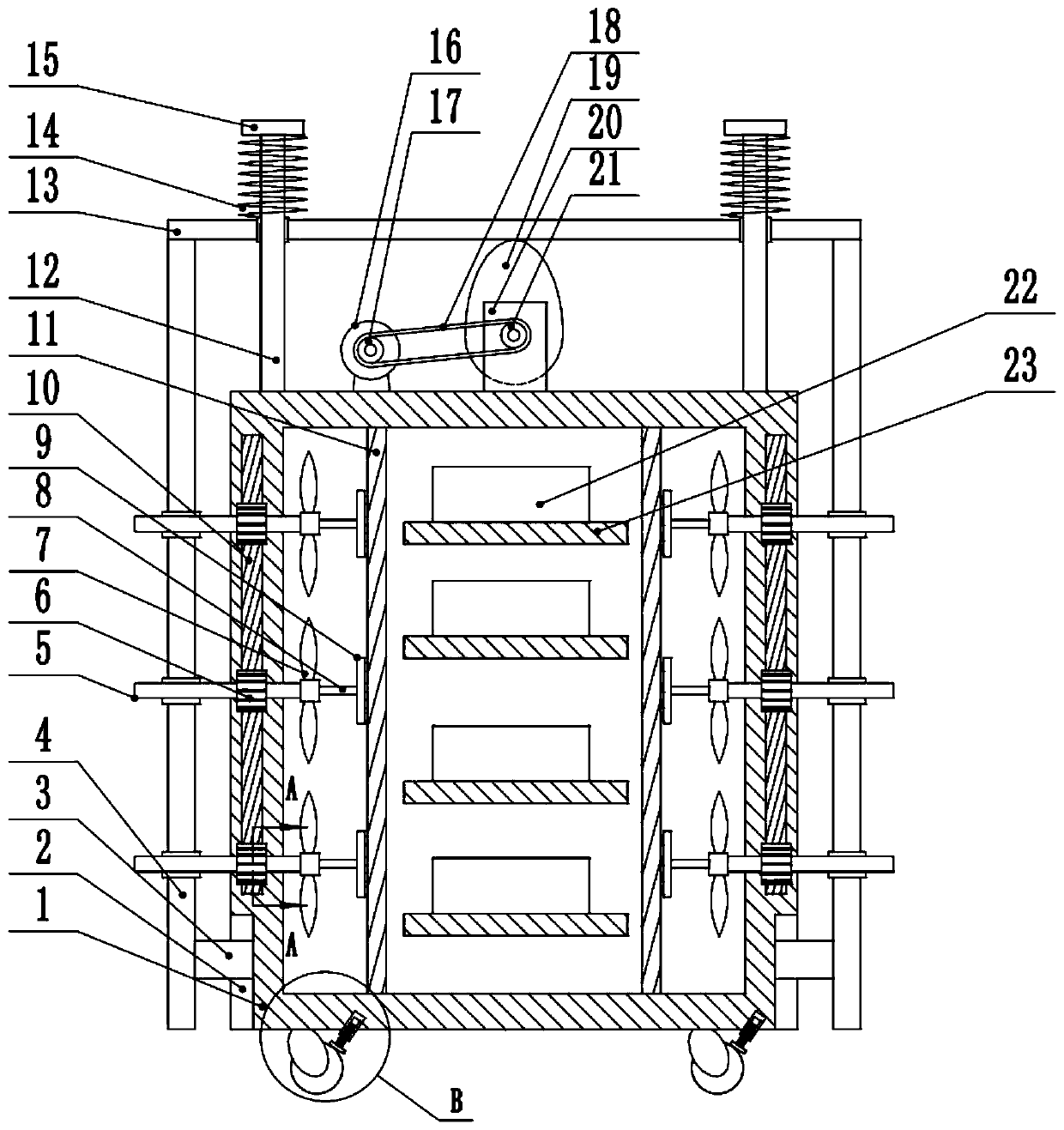

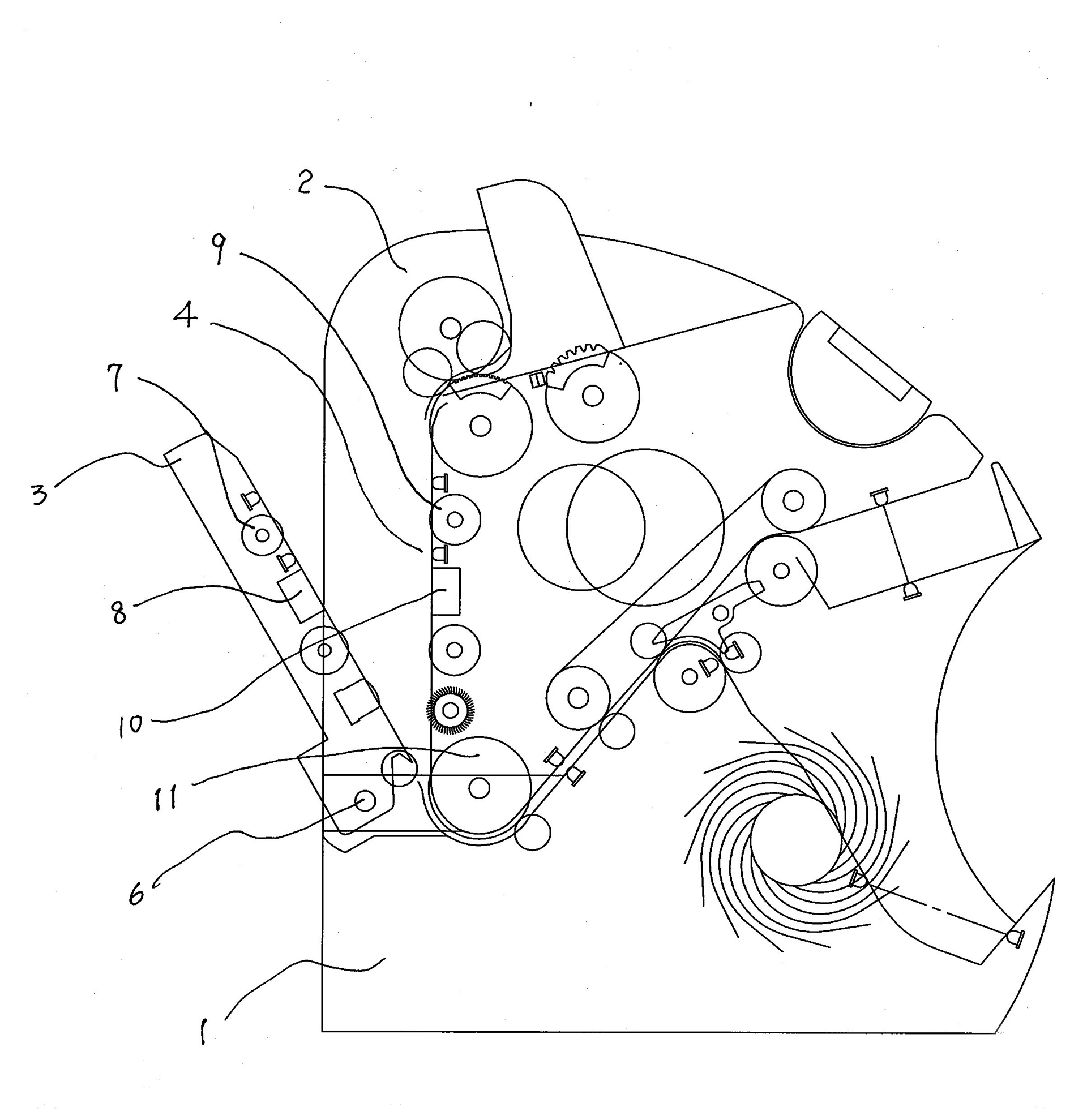

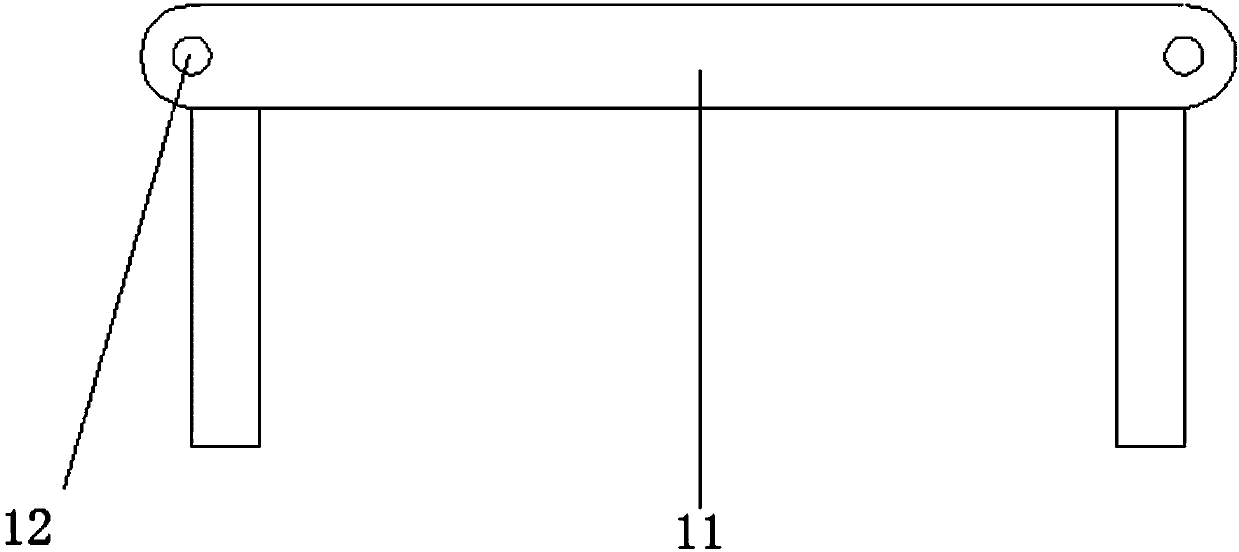

Wool and cashmere product surface dust-removal and pill-removal machine

InactiveCN107044045ABlow up effectivelyEfficient collectionMechanical cleaningPressure cleaningCouplingEngineering

The invention relates to the technical field of wool sweater processing, and discloses a machine for removing dust and balls from the surface of wool and cashmere products. The inside of the feed port is provided with a sweater fabric, rollers are provided on both sides of the sweater fabric, a motor is provided on the top of the body, and the output shaft of the motor passes through a coupling A rotating shaft passing through the body is rotatably connected, and a connecting block is fixedly connected to the bottom of the rotating shaft, and fan blades are symmetrically arranged on both sides of the connecting block. The wool and cashmere product surface dust removal machine can effectively blow up the dust on the woolen sweater fabric, prevent the dust from sticking to the woolen sweater fabric, reduce people's burden, increase people's work efficiency, and can effectively clean the woolen sweater. The hair balls on the sweater fabric are cleaned, so that people do not need to clean the sweater fabric twice.

Owner:浙江托姿时装有限公司

Measuring method for dust fall quantity of plant canopy leaf surface

InactiveCN103411847APracticalSimplify the measurement stepsWeighing by removing componentMeasuring instrumentDistilled water

The invention relates to a measuring method for the dust fall quantity of a plant canopy leaf surface. The measuring method comprises the following steps: (1) selecting a well-grown plant, and picking 15-20 leaves from the upper, middle and lower parts of a plant canopy; (2) placing the healthy leaves picked from each plant in numbered envelopes, taking the envelopes to a lab, shearing the petioles of the leaves, and drying the leaves without the petioles in a drying box under the temperature being 105 DEG C; (3) weighing the leaves in the step (2) to obtain W1; (4) soaking the leaves after the weighing in the step (3) in distilled water for 20-30 minutes, so as to enable falling dust on the front surface of the leaves to be cleaned, after washing of the leaves by the distilled water, drying the washed leaves till the weight is constant, and weighing for the second time to obtain W2; (5) wetting the leaves in the step (4), and measuring the total leaf area S of each plant by a leaf area measuring instrument, wherein a computational formula of the dust fall quantity is as follows: FDC (g.m<-2>)=(W1-W2) / S*10000. The method is simple, easy to operate, and can be used for providing new indexes for air quality monitoring; by using the method, the breakthrough and the progress of research on influence of leaf surface dust fall on the plant can be realized.

Owner:TARIM UNIV

Blowing device with large air rate in a movable and positioning way

InactiveCN102600682AReduce in quantityEasy to cleanDispersed particle filtrationEngineeringSurface dust

The invention belongs to the technical field of environment-friendly equipment, and relates to a pulse dust cleaning device of a fixed pulse bag type dust remover and dust removing equipment using the pulse dust cleaning device. The pulse dust cleaning device is a pulse blowing device matched with the bag type dust remover. The pulse blowing device comprises a blowing device body; a large air storage bag is connected with a blowing branch pipe in the body through an intake-tube; and a pattern plate arranged at the bottom of the body is provided with a plurality of filter bag holes; and the pulse blowing device is characterized in that the blowing branch pipe can be positioned and moved on the pattern plate arranged at the bottom of the body. According to the invention, after the structure of the device and the dust cleaning method are adopted, the blowing in a movable and positioning way can be realized, the quantity of the blowing pipes and the pulse valves can be reduced, the cost of investment is low, the overhaul rate is low; and the pulse blowing device is large in air rate for dust cleaning, thereby being easy to clean surface dust on the filter bag.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

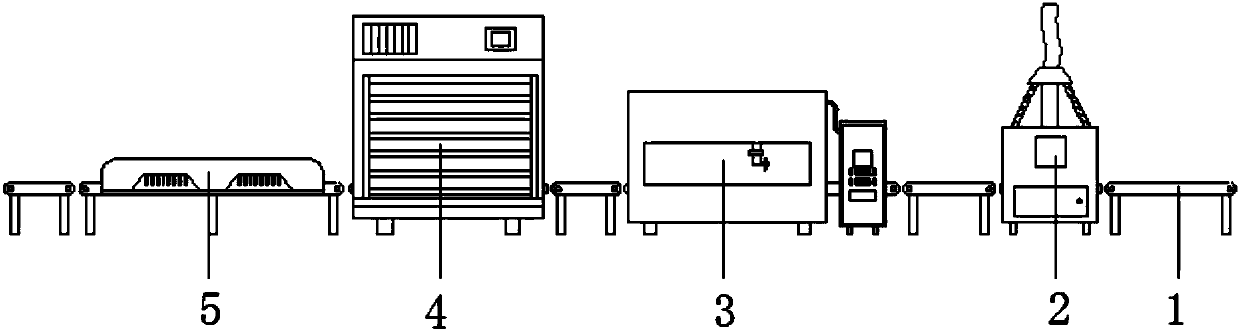

Full-automatic paint spraying production line for furniture plates

PendingCN109967297AReduce labor costsContinuous production cyclePretreated surfacesCoatingsProduction lineQuality control

The invention relates to a full-automatic paint spraying production line for furniture plates. The full-automatic paint spraying production line comprises a dust removal device, a paint spraying device, a primary drying device and a secondary drying device which are sequentially connected, wherein the production line is provided with a belt conveying mechanism used for conveying the furniture plates, the belt conveying mechanism penetrates through the whole assembly line, surface dust of the furniture plates is removed through the dust removal device, the furniture plates are sprayed with paint through the paint spraying device, are solidified and dried through a primary drying device, and are further solidified and dried through a secondary drying device, and the whole paint spraying process is completed in a full-automatic mode. Compared with the prior art, the full-automatic paint spraying process does not need to participate in the paint spraying process, the labor cost is saved, the production rhythm is continuous and compact, the production efficiency is high, the product quality control is strict, and the paint spraying quality is effectively guaranteed; the paint spraying device only sprays the paint on the upper area of the plates, so that the paint waste is reduced; and a multi-layer three-dimensional structure is adopted by the drying device, so that the occupied area is small, the continuous production is realized, and the production rhythm is fast.

Owner:AURORA CHINA

Rehydration method for sea cucumber

The invention discloses a rehydration method for sea cucumber, which comprises the following steps: placing dry sea cucumber into clear water and washing surface dust and salinity; placing sea cucumber in clean water, heating to 30-60 DEG C. by micro wave, keeping the temperature for 20-90 min, and cooling naturally; cleaning the sea cucumber internal organ and impurity, placing sea cucumber into purified water, heating to 60-95 DEG C. by microwave, and keeping the temperature for 20-40 min, cooling naturally, heating to 60-95 DEG C again, keeping the temperature for 10-30 min; finally placing sea cucumber into purified water after cooling, placing in an enclosed container for vacuum-pumping, keeping the degree of vacuum at 0.02-0.09 MP, placing the sea cucumber into -4-4 DEG C. for rehydration about 6-10 hours, and obtaining the finished product, and the invention has the advantages of short time, low temperature, less nutrition loss, large rehydration multiple, plump and complete shape and glistened color.

Owner:DALIAN XIAOQIN FOOD

W-type city roadway

This invention can improve the design for city road. It's features are: Between the motor-vehicle-road and non-motor-vehicle-road install a bare ground zone, its surface is lower than the city road, so the section of city road is as W shape, it provide for the dust, mud and surface dust a way-out, so the zone of bare ground can be planted some trees and flowers along the road.

Owner:HENAN WUJIAN CONSTR GRP +1

Comprehensive cleaning device of battery surface dust for daily maintenance of computer power supply

InactiveCN107377447AImprove dust removal effectStable positionCleaning using toolsPhysical healthEngineering

The invention relates to a cleaning device of battery surface dust, in particular to a comprehensive cleaning device of battery surface dust for daily maintenance of a computer power supply. The technical problem to be solved herein is to provide a comprehensive cleaning device of battery surface dust for daily maintenance of a computer power supply, the device being simple to operate, requiring low labor intensity, having good cleaning effect, never affecting physical health of an operator, and having high working efficiency. In order to solve the technical problem above, the invention provides such a comprehensive cleaning device of battery surface dust for daily maintenance of a computer power supply; the comprehensive cleaning device comprises a bottom plate and the like; a support is vertically mounted at the left end of the top of the bottom plate by means of bolt connection, a rotating device is arranged at the top of the bottom plate on the right of the support, and a holding frame is connected to a rotating part of the rotating device. The comprehensive cleaning device is simple to operate, requires low labor intensity, has good cleaning effect, never affects physical health of an operator, and has high working efficiency.

Owner:邵林芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com