Blowing device with large air rate in a movable and positioning way

A technology of blowing device and mobile positioning, which is applied in the fields of dust removal equipment, pulse bag dust removal equipment, and pulse dust cleaning device, can solve the problems of aggravating the operation burden of pulse bag dust collector, large investment, and high steel consumption. The effect of reducing the number of blowing pipes and pulse valves, large cleaning gas volume and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

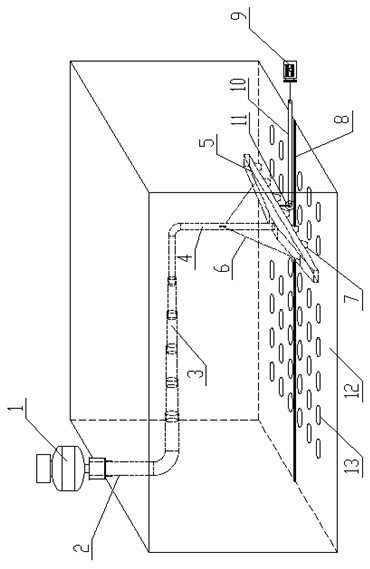

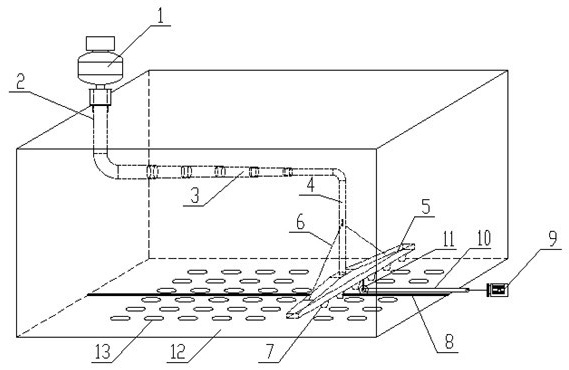

[0013] Embodiment: In this embodiment, the mobile positioning large-volume injection device is a pulse injection equipment matched with a bag filter, and its structure is as follows: figure 1 As shown, it mainly includes the main body of the injection device, the large air storage bag (1) is connected to the injection branch pipe (5) in the main body through the air intake pipe (2), and there are several filter bag holes on the flower plate (12) at the bottom of the main body (13), its main feature is that the injection branch pipe (5) can be positioned and moved on the flower plate (12) at the bottom of the body.

[0014] Specifically, the injection branch pipe (5) in this embodiment realizes positioning and movement through the following structure: the air intake pipe (2) is connected to the injection branch pipe (5) through the metal telescopic sleeve (3), and the metal telescopic sleeve (3) ) to telescopically move the injection branch pipe (5); the roller (11) under the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com