Patents

Literature

834results about How to "Reduce maintenance rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

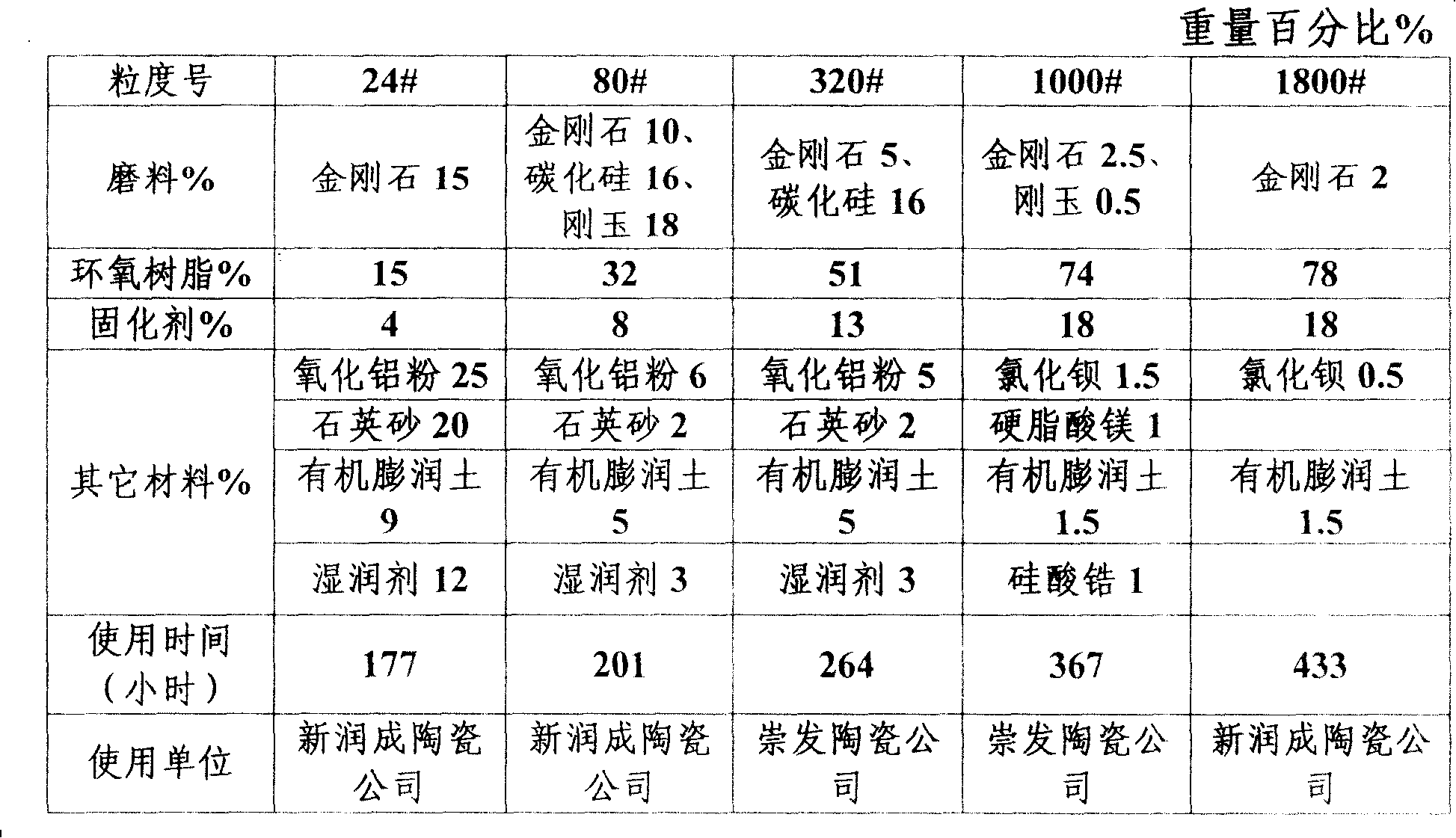

Abrasive tool of epoxy resin combined with compounded abrasive

Disclosed is an abrasive tool made of epoxy resin-bonded compound abrasive material, which comprises epoxy resin, abrasive material and curing agent. The weight percentages are as follow: the epoxy resin is 15 to 78 percent, the abrasive material is 2 to 44 percent and the curing agent is 4 to 18 percent. Wherein, the abrasive material comprises one of diamond, silicon carbide or corundum or the combination of more than one material. The curing agent comprises one of 4.4`-methylenedianil, solid diaminodiphenyl methane or liquid modified diaminodiphenyl methane or the combination of more than one material. The component of the abrasive tool also comprises the other auxiliary material, which comprises one of alumina, barium chloride, sodium chloride, quartz sand, organobentonite, wetting agent, zirconium silicate, calcium carbonate, graphite powder, garnet, magnesium sulfate, phenolic resin, zinc stearate and magnesium stearate, or the combination of more than one material. The product can be made into any shape the same with the present product, which can be applied in various grinding and polishing equipment with wide application scope.

Owner:广东奔朗新材料股份有限公司

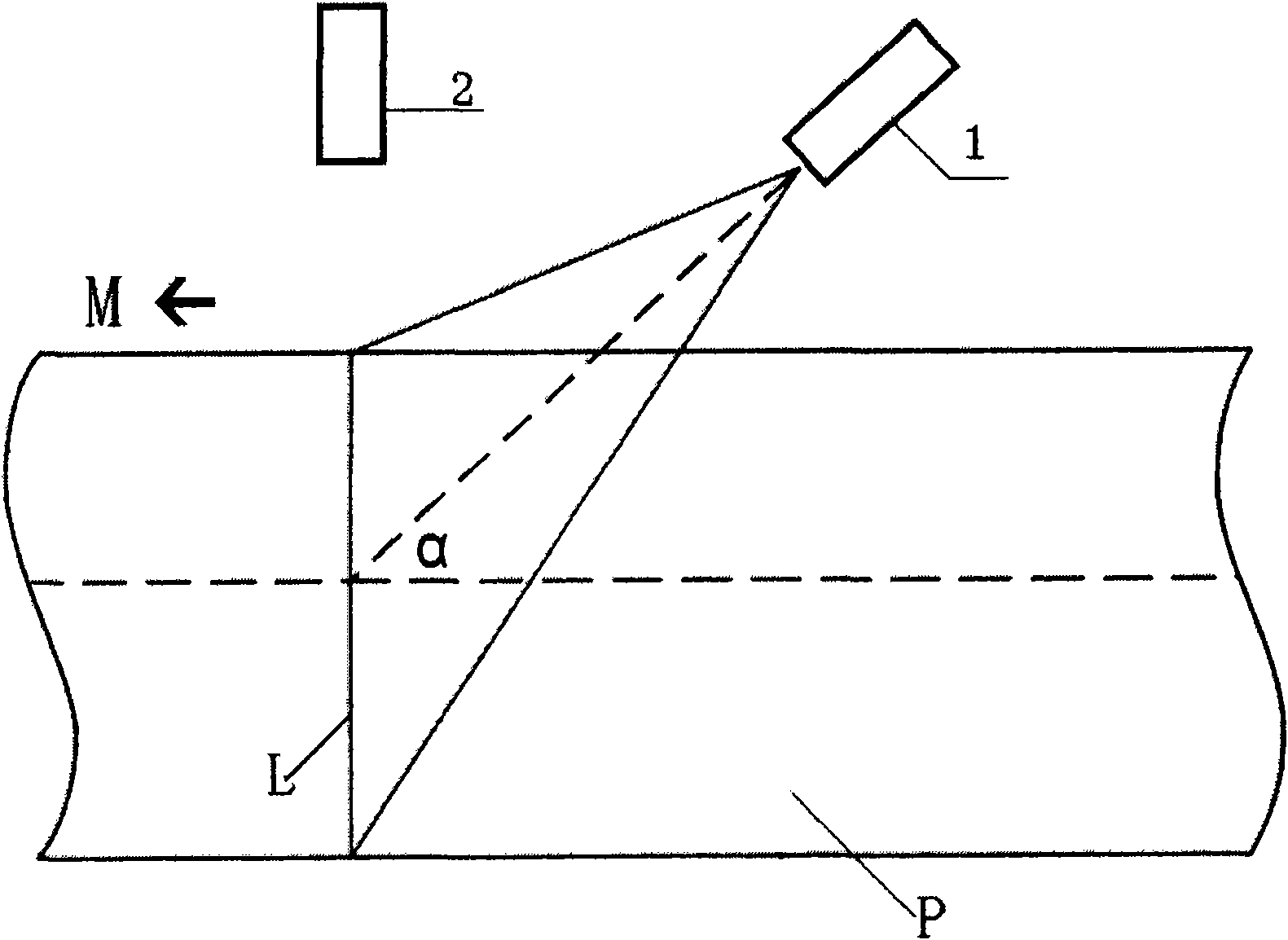

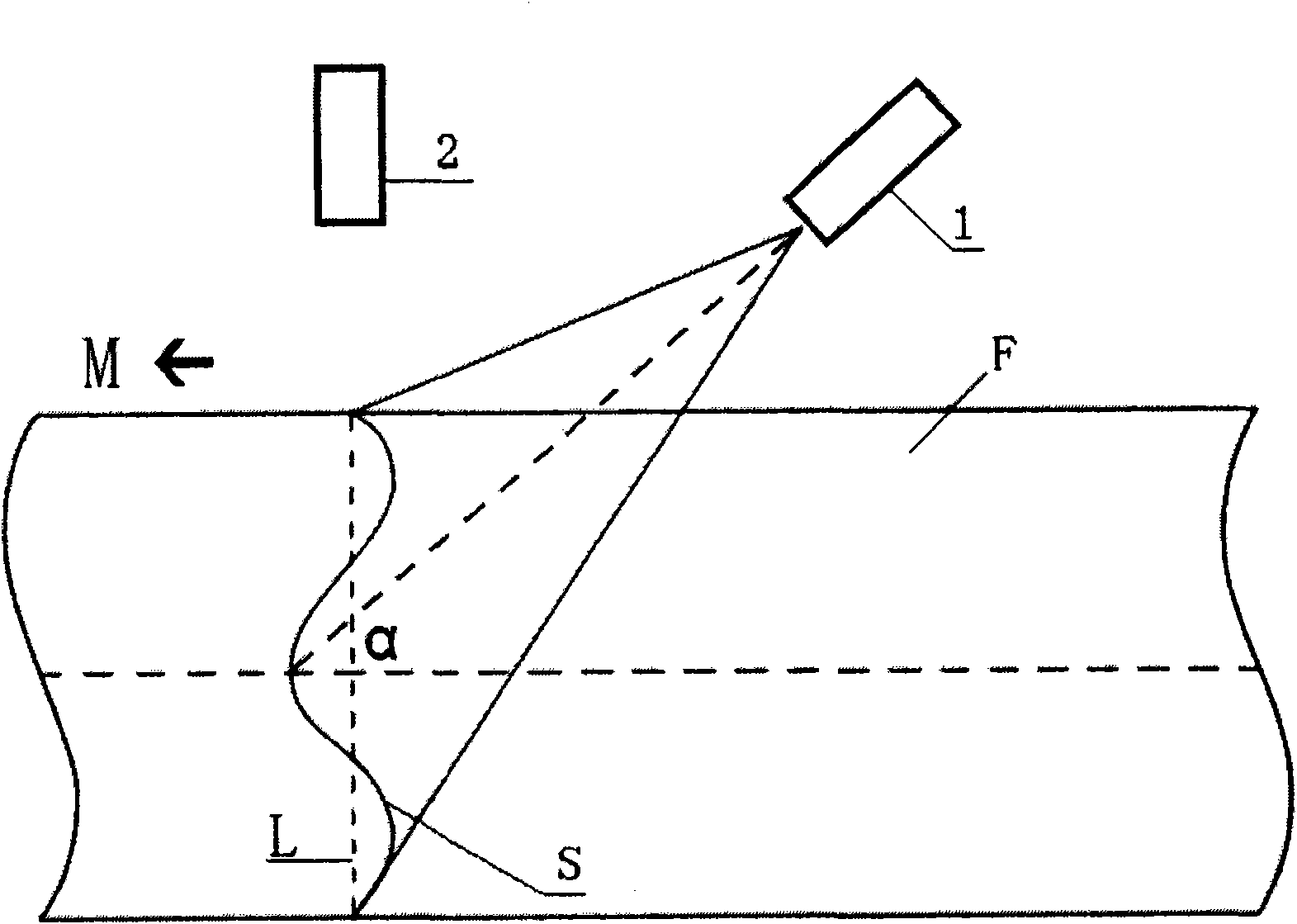

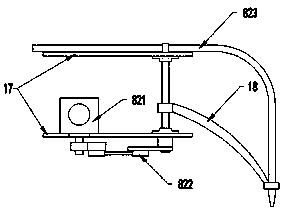

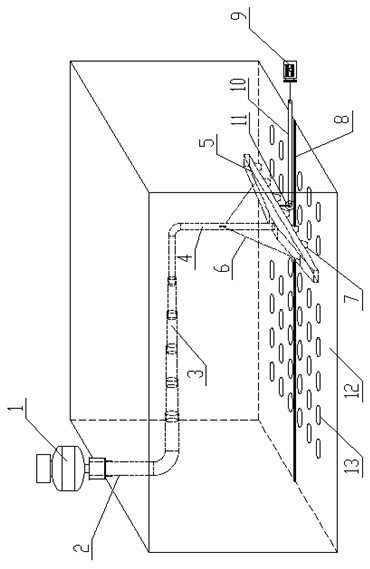

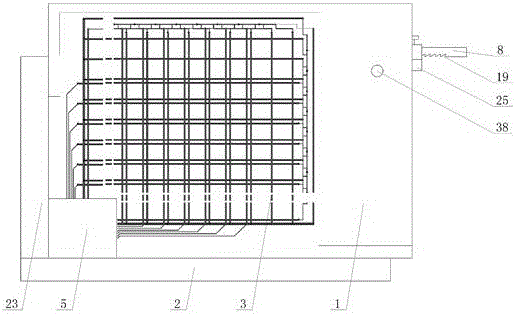

Method and system for laser detection of shape of charge level

InactiveCN101576376AThe detection method of material surface is simpleHigh precisionUsing optical meansLaser detectionLaser beams

The invention provides a method and a system for laser detection of the shape of charge level. The method comprises the following steps: exerting a laser beam on the charge level to be detected from the upper part of the charge level to be detected, and making the plane limited by the laser beam parallel to the transverse direction (width direction) of the charge level to be detected and angulated at an included angle alpha with the longitudinal direction (movement direction or length direction) of the charge level to be detected; shooting a picture on an intersection line of the laser beam and the charge level directly from the upper part of an intersected position of the laser beam and a reference charge level; and acquiring the shape of the charge level according to the shot image of the intersection line. The method for detecting the charge level is simple and has high precision. Moreover, the system for detecting the charge level does not need to directly contact the charge level, so that the maintenance rate of the system is greatly reduced.

Owner:SHENVANG PAJONIIR TEK CORP BEJDZHING +1

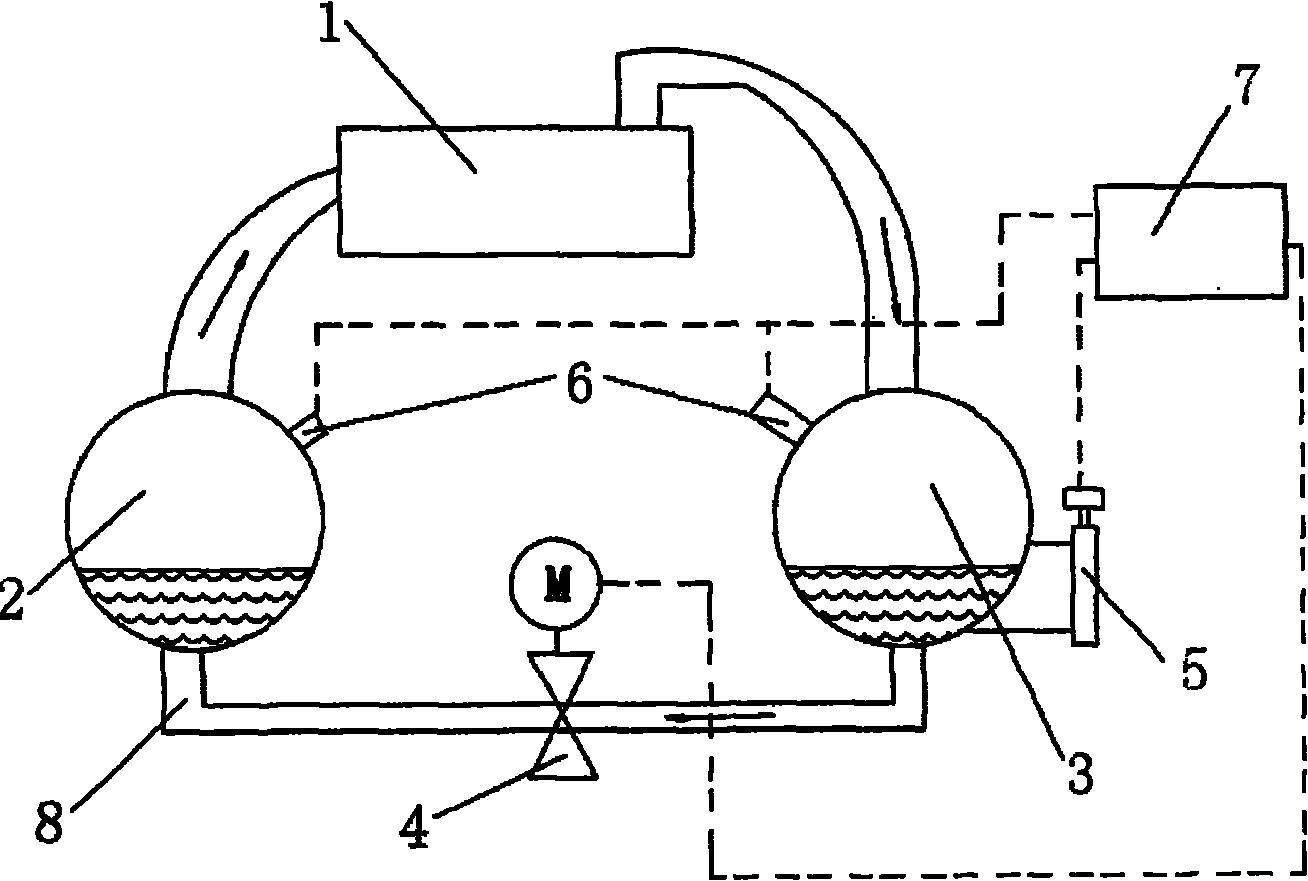

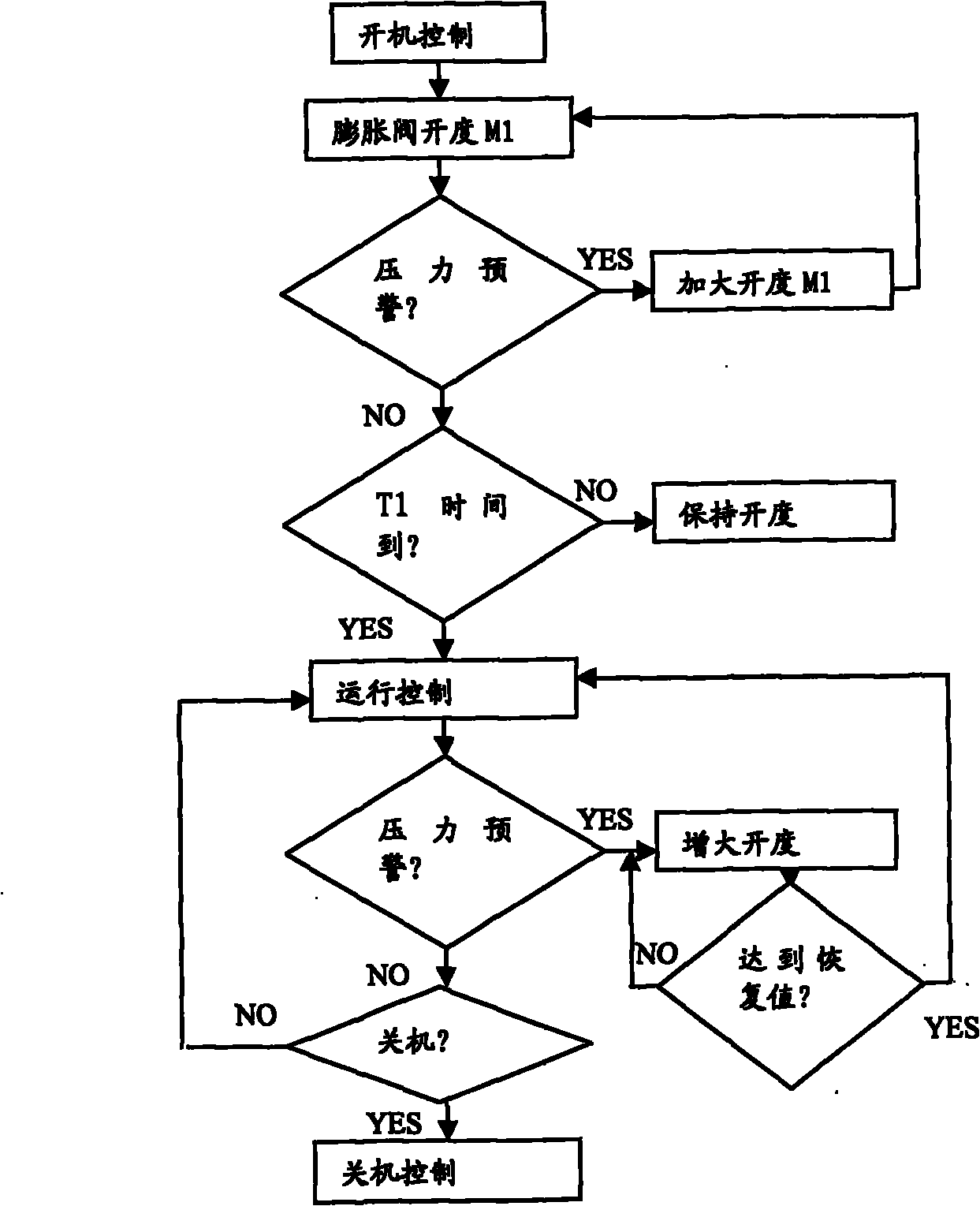

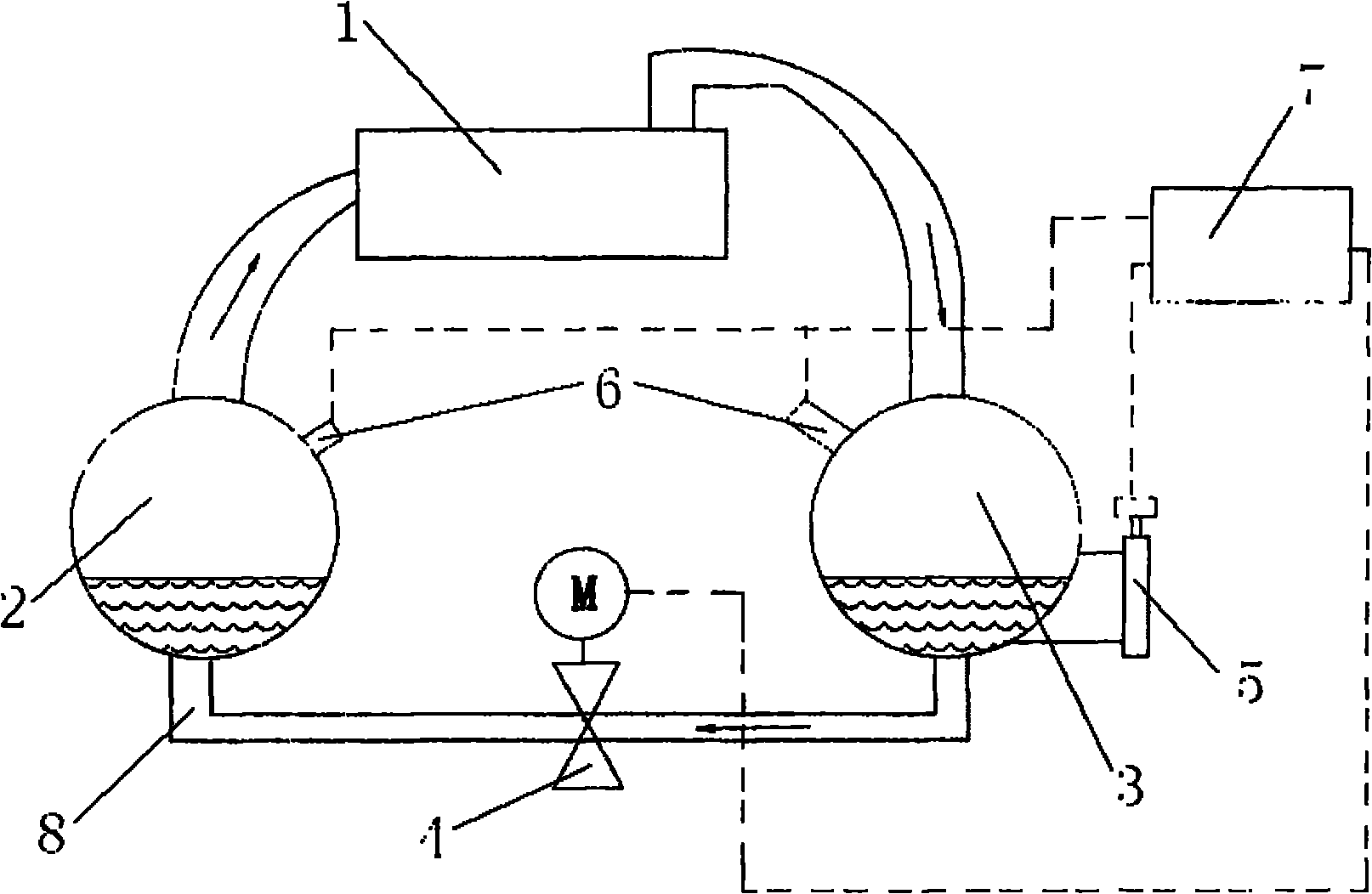

Central air conditioner and method for controlling flow of refrigerant therein

ActiveCN102032731AEliminate liquid hammer defectsReduce maintenance rateSpace heating and ventilation safety systemsSpace heating and ventilation control systemsControl flowControl theory

The invention provides a central air conditioner and a method for controlling the flow of a refrigerant therein. The central air conditioner comprises an evaporator, a condenser, an electronic expansion valve, a liquid level meter and a controller, wherein the electronic expansion valve is connected to a refrigerant pipeline between the evaporator and the condenser; the liquid level meter is connected with the evaporator or the condenser; the controller is used for controlling the opening of the electronic expansion valve and is provided with an input port and an output port; the input port of the controller is connected with a signal sending end of the liquid level meter; and the output port of the controller is connected with a signal receiving end of the electronic expansion valve. Themethod comprises the following steps of: at the operation stage of the central air conditioner, sending a real-time refrigerant liquid level L1 of the evaporator or the condenser detected by the liquid level meter to the controller; and comparing L1 with a first target liquid level L and adjusting the opening of the electronic expansion valve according to a comparison result to ensure that L1 approaches L and is finally equal to L by using the controller. The liquid impact of a pressing machine can be avoided, and the control accuracy of the flow of the refrigerant is improved.

Owner:HAIER GRP CORP +1

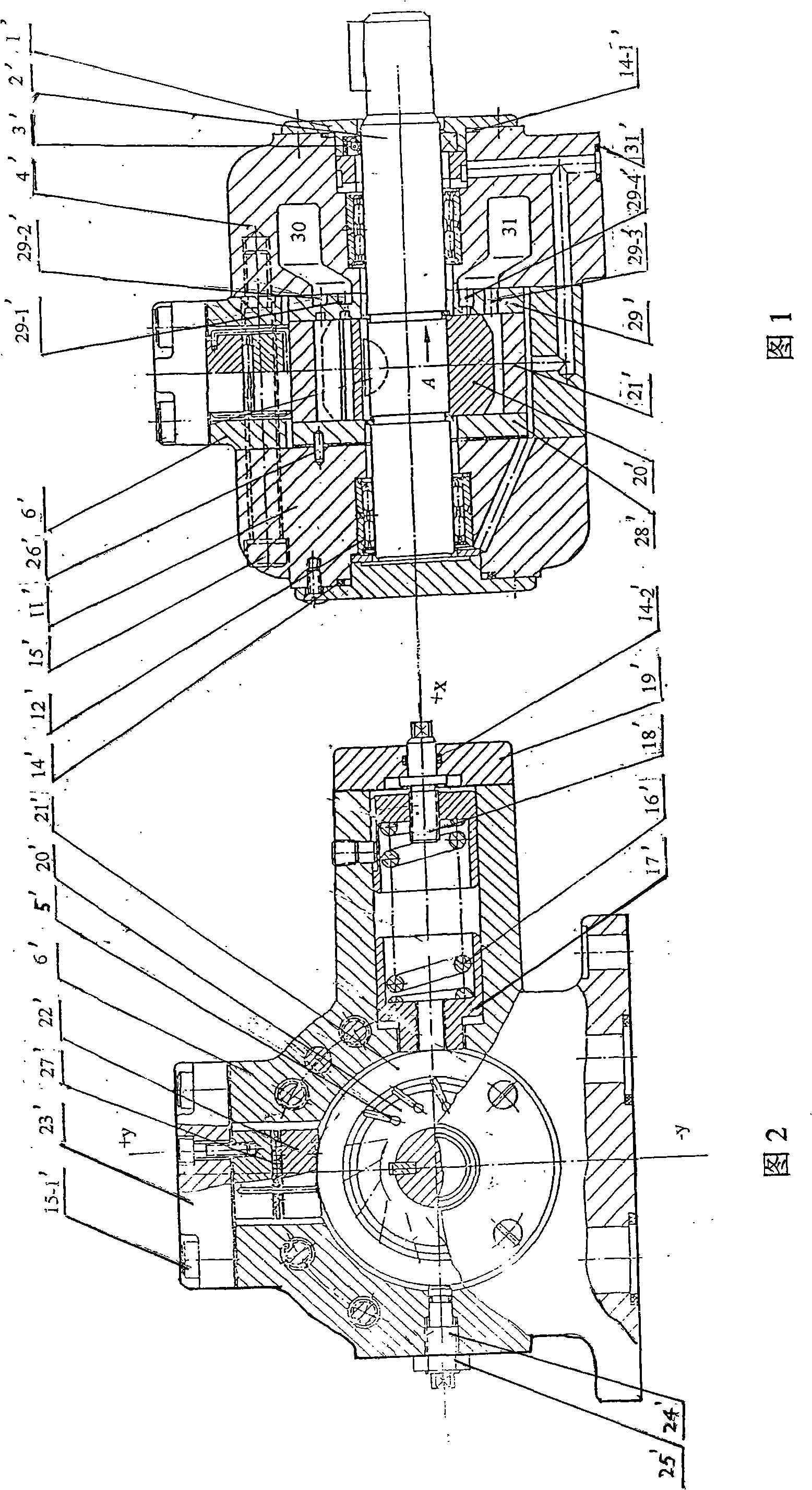

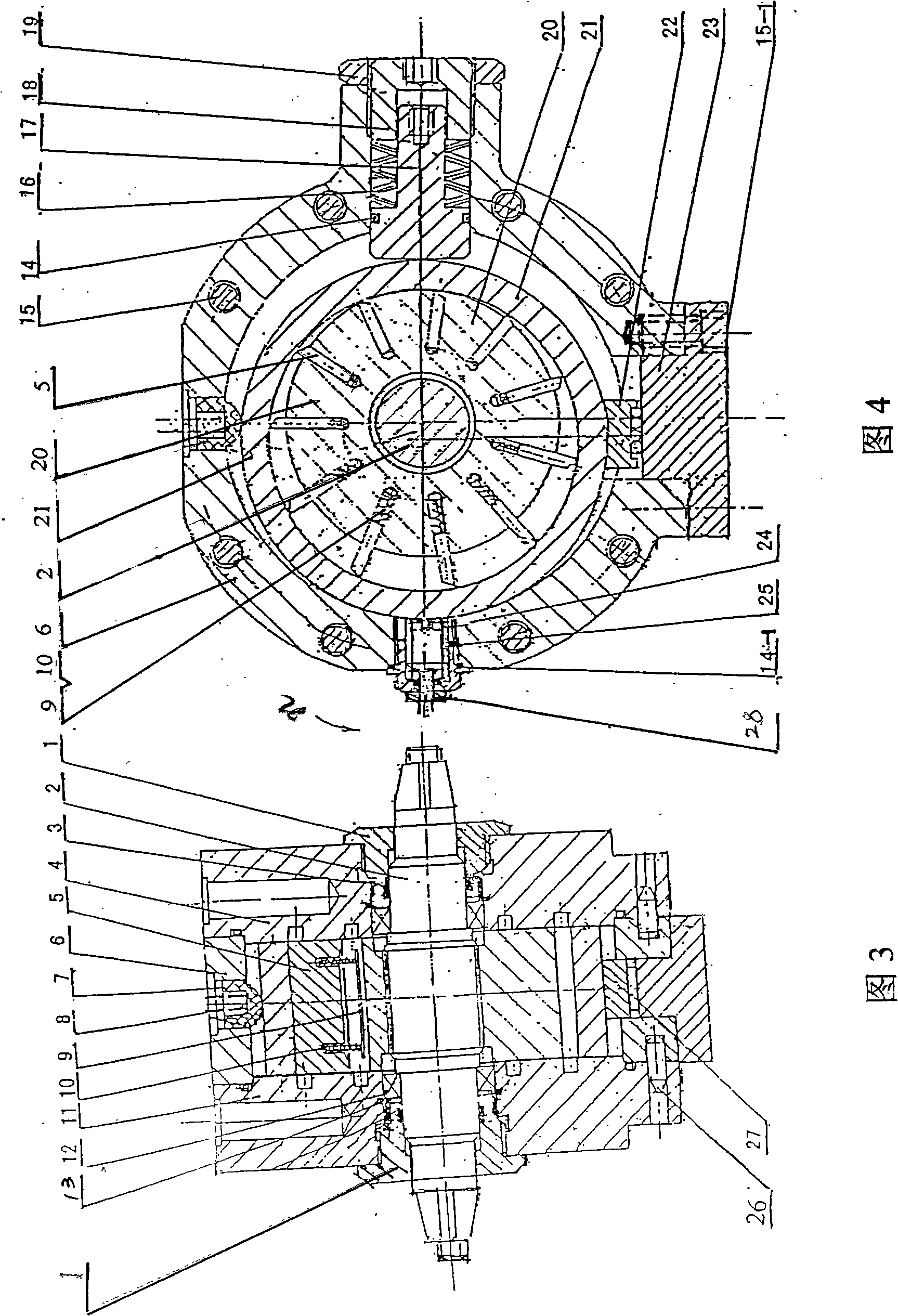

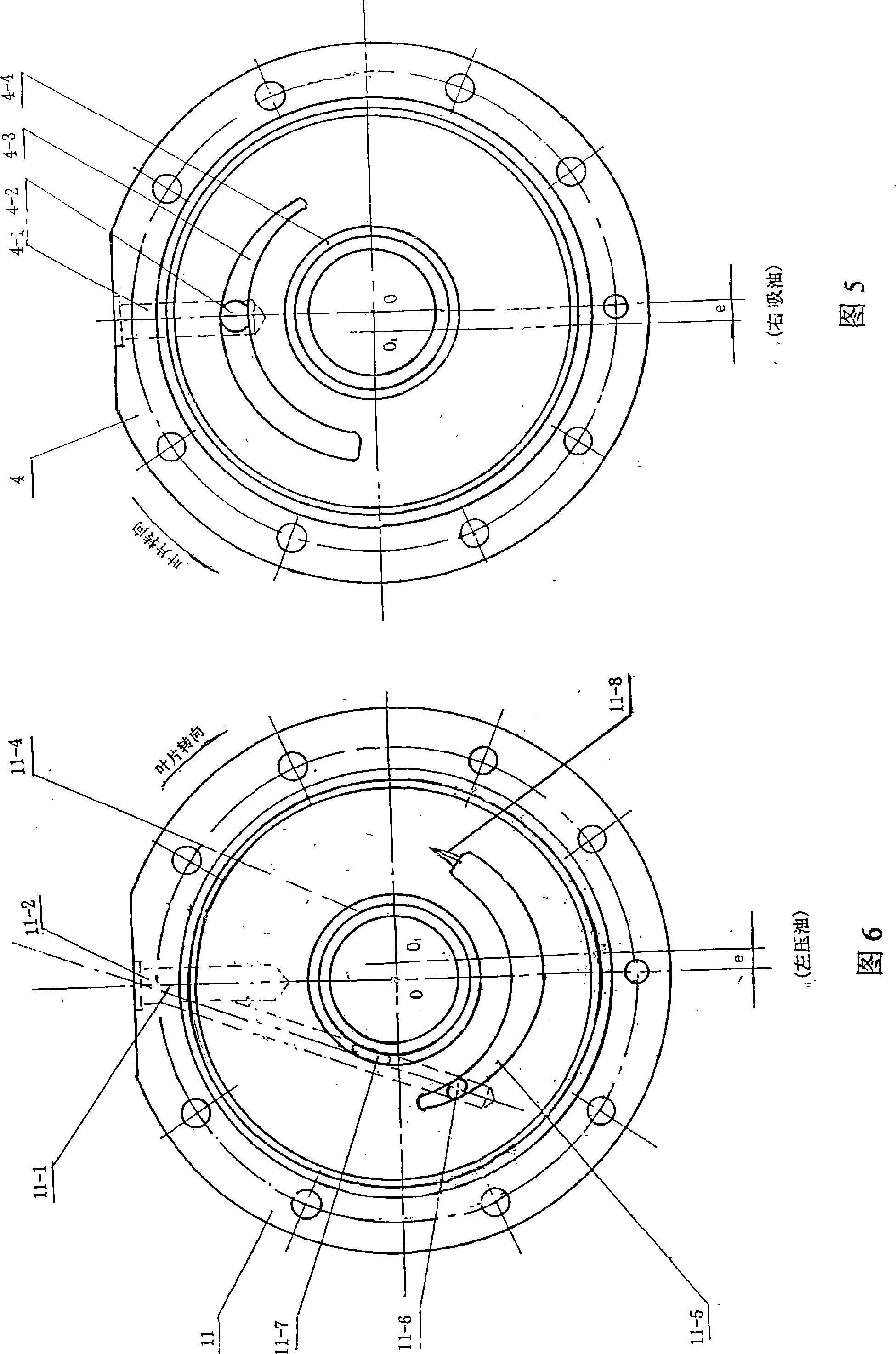

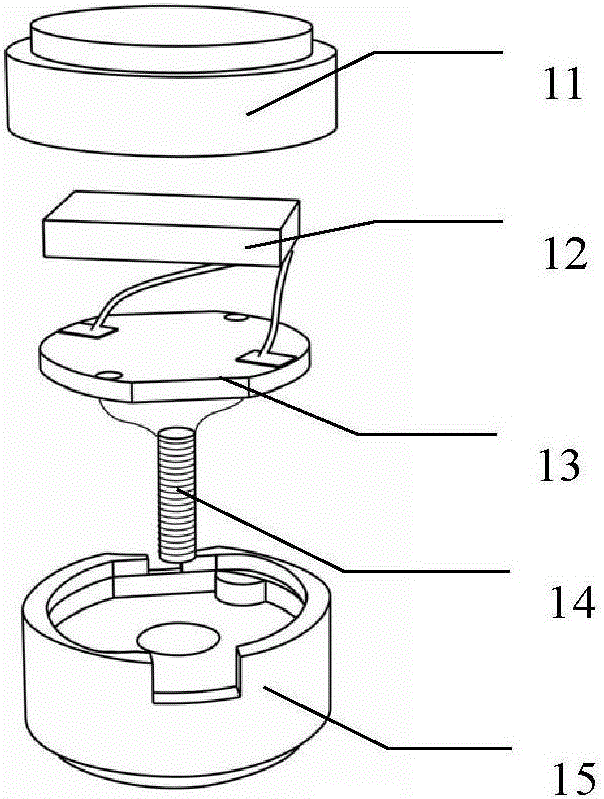

Low speed heavy pressure vane pump for hydraulic bicycle

InactiveCN101290008AReduce weightReduce volumeRotary piston pumpsNon-mechanical gearing transmissionStatorSelf weight

The invention discloses a low-speed high-pressure vane pump for hydraulic bicycles. The invention comprises an end cover, a principal axis, a framework oil seal, a right casing, a blade, a middle casing, a left casing, a bearing, an O-shaped sealing ring, a bolt, a pressure-limiting spring, a spring seat, a regulating nut, a side end cover, a rotor, a stator, a slide block, a cover plate, a flow adjusting screw, a sealing ring, a lock nut and a needle roller. The invention is characterized in that: a vane groove is arranged in the rotor, a vane spring and a vane bracket are arranged in the vane groove, the vane bracket is positioned by the vane spring, the blade is arranged in the vane groove of the rotor, one end of the blade presses the vane spring, while the other end clings to the inner surface of the stator. The low-speed high-pressure vane pump for the hydraulic bicycles has the advantages of reasonable structure, light self-weight, small bulk, high efficiency, low cost, labor conservation and rapidness, which is adopted to be matched with all wheel diameters of bicycles and has the function of pressure servo variation.

Owner:邵锐勋 +1

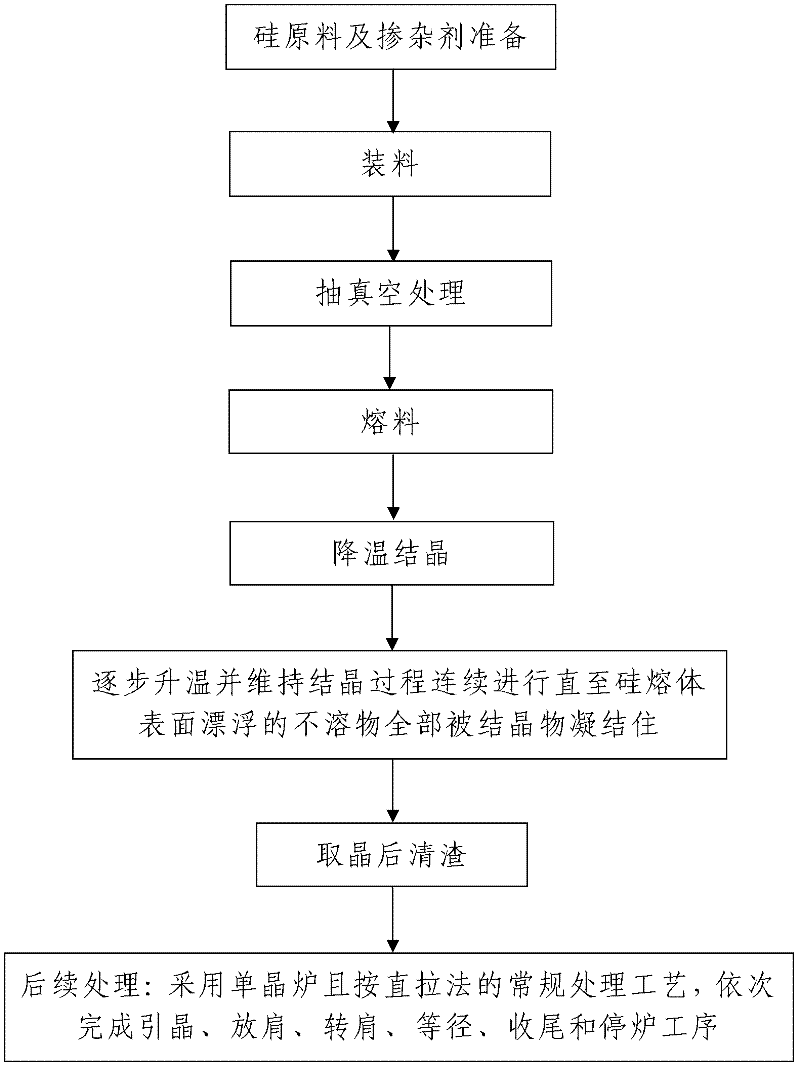

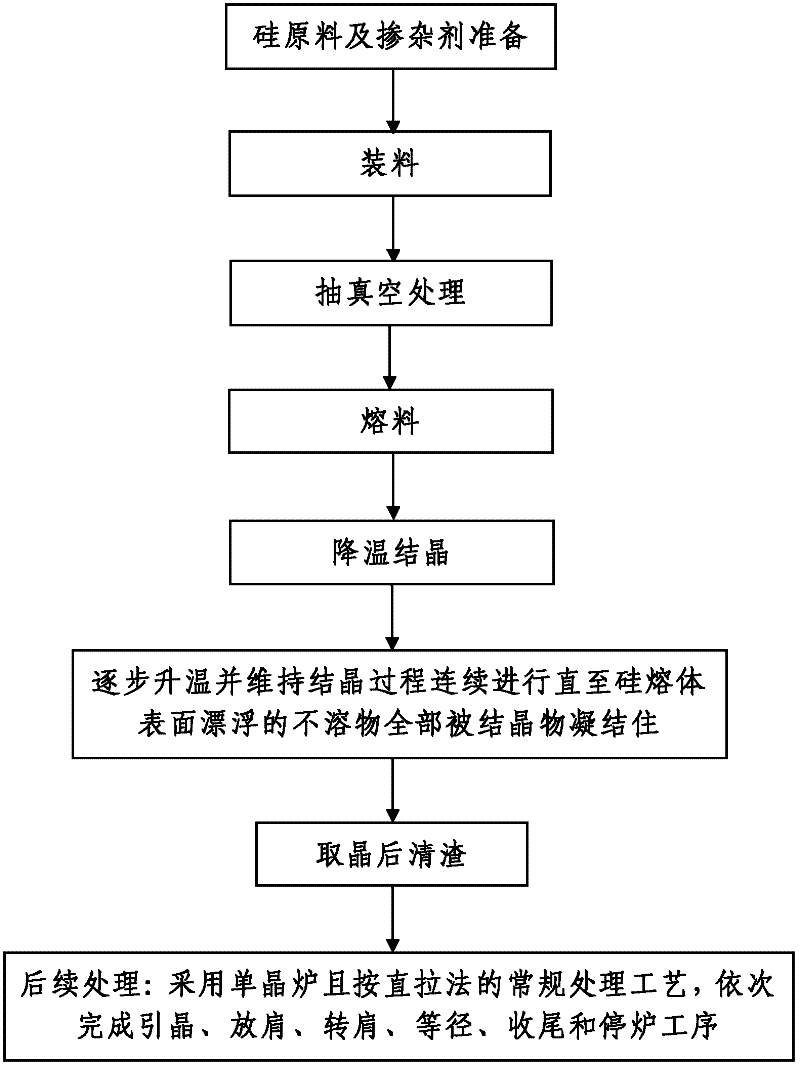

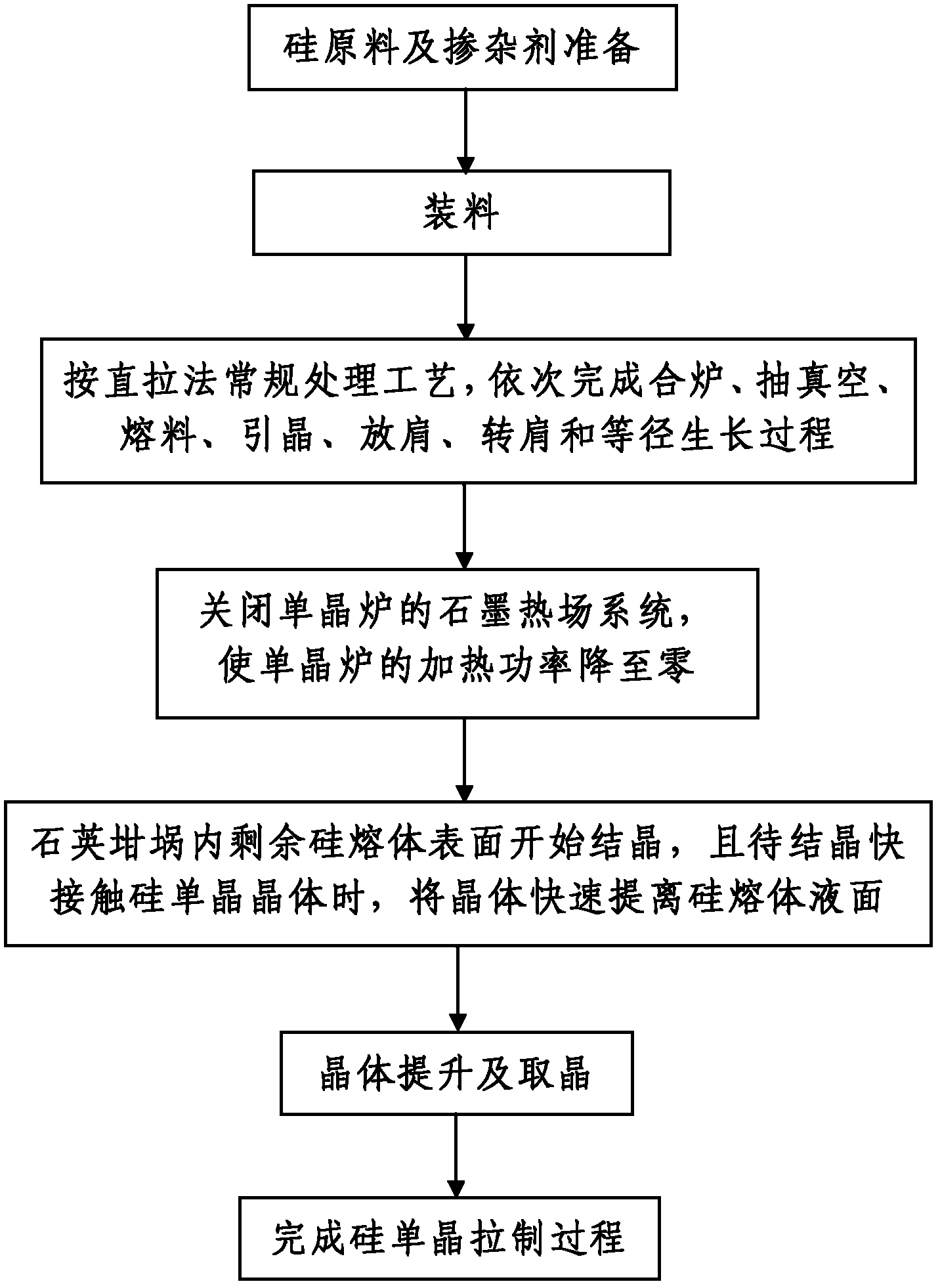

Process for producing Czochralski silicon single crystal

InactiveCN102242397AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltDopantSlag

The invention discloses a process for producing a Czochralski silicon single crystal, which comprises the following steps of: 1, preparing a silicon raw material and a doping agent; 2, charging; 3, vacuumizing; 4, melting; 5, extracting slag, namely 501, performing cooling crystallization, 502, gradually heating, and keeping the crystallization process continuously performed until insoluble substances floating on the surface of a silicon melt are completely condensed by the crystal, and 503, taking the crystal out, and removing the slag; and 6, performing subsequent treatment, namely finishing crystal leading, shoulder expanding, shoulder rotating, diameter equalizing, ending and blowing down processes in turn by using a single crystal furnace according to the conventional treatment process of a Czochralski method to obtain the finished silicon single crystal formed by pulling. The process is reasonable in design, simple in steps, convenient to implement, easy to master and good in using effect, can effectively ensure the quality of the produced silicon single crystal, and can solve the practical problems that slag removing time is difficult to master, the slag extracting effect is poor, the produced silicon single crystal has low purity, and the like.

Owner:XIAN HUAJING ELECTRONICS TECH

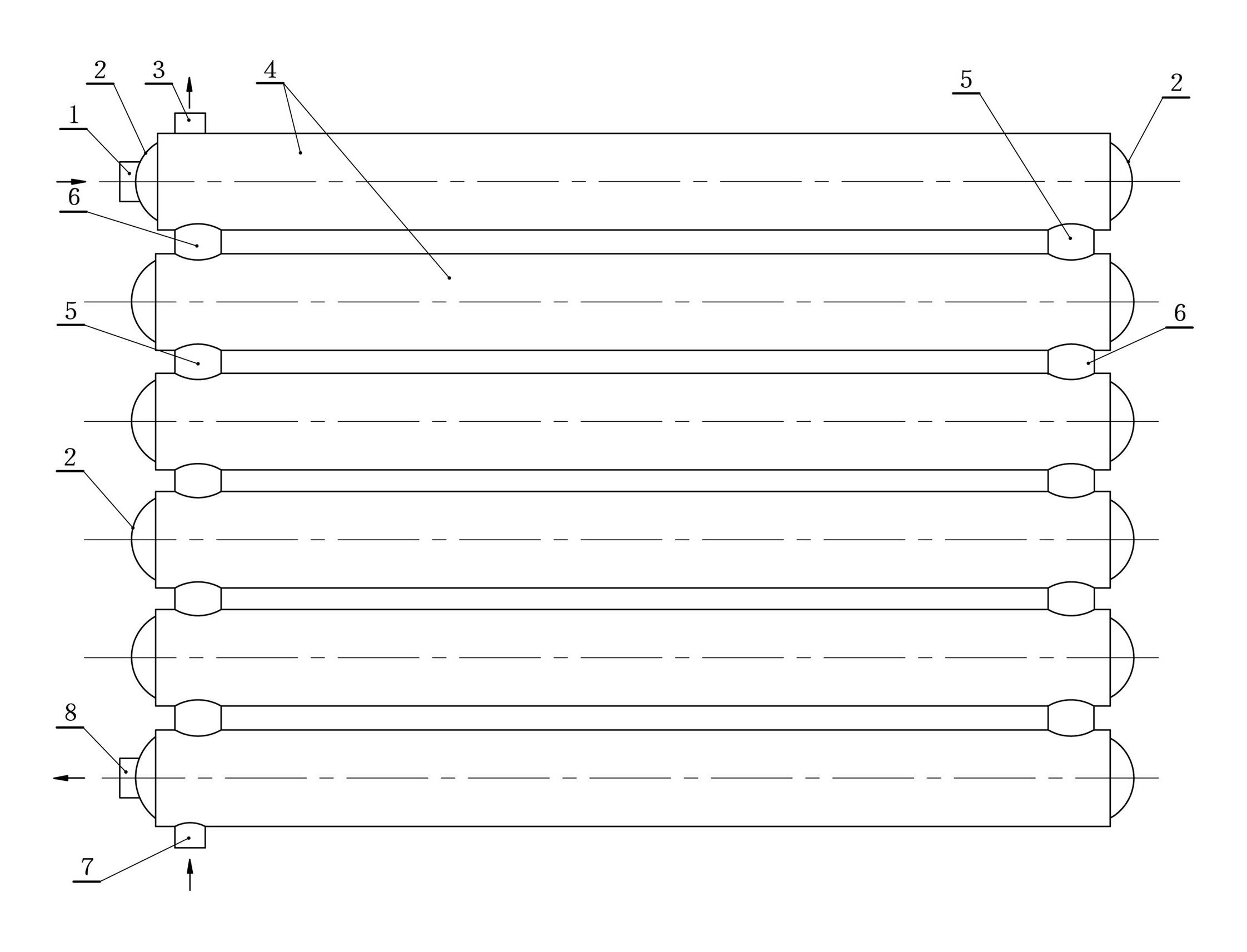

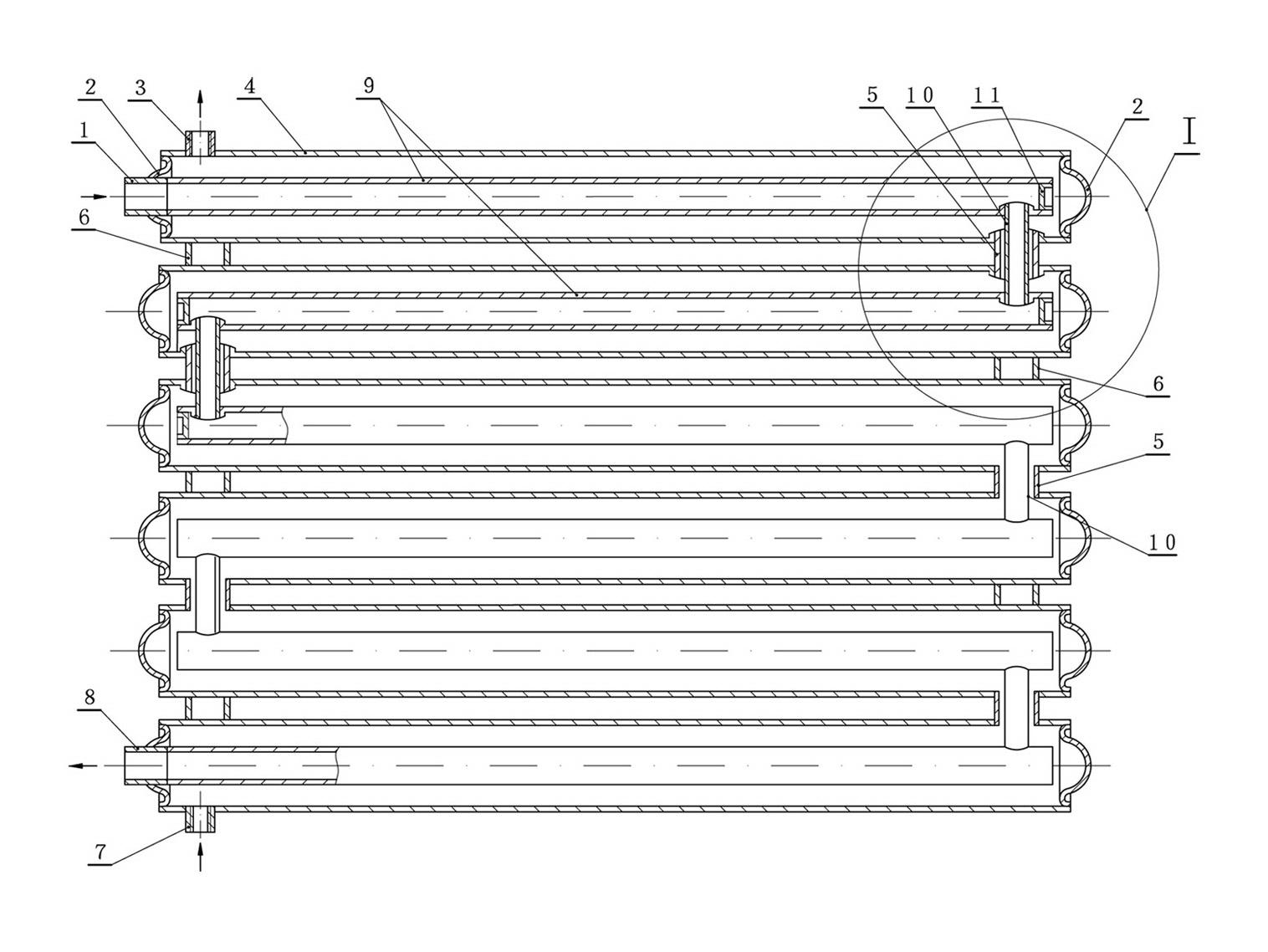

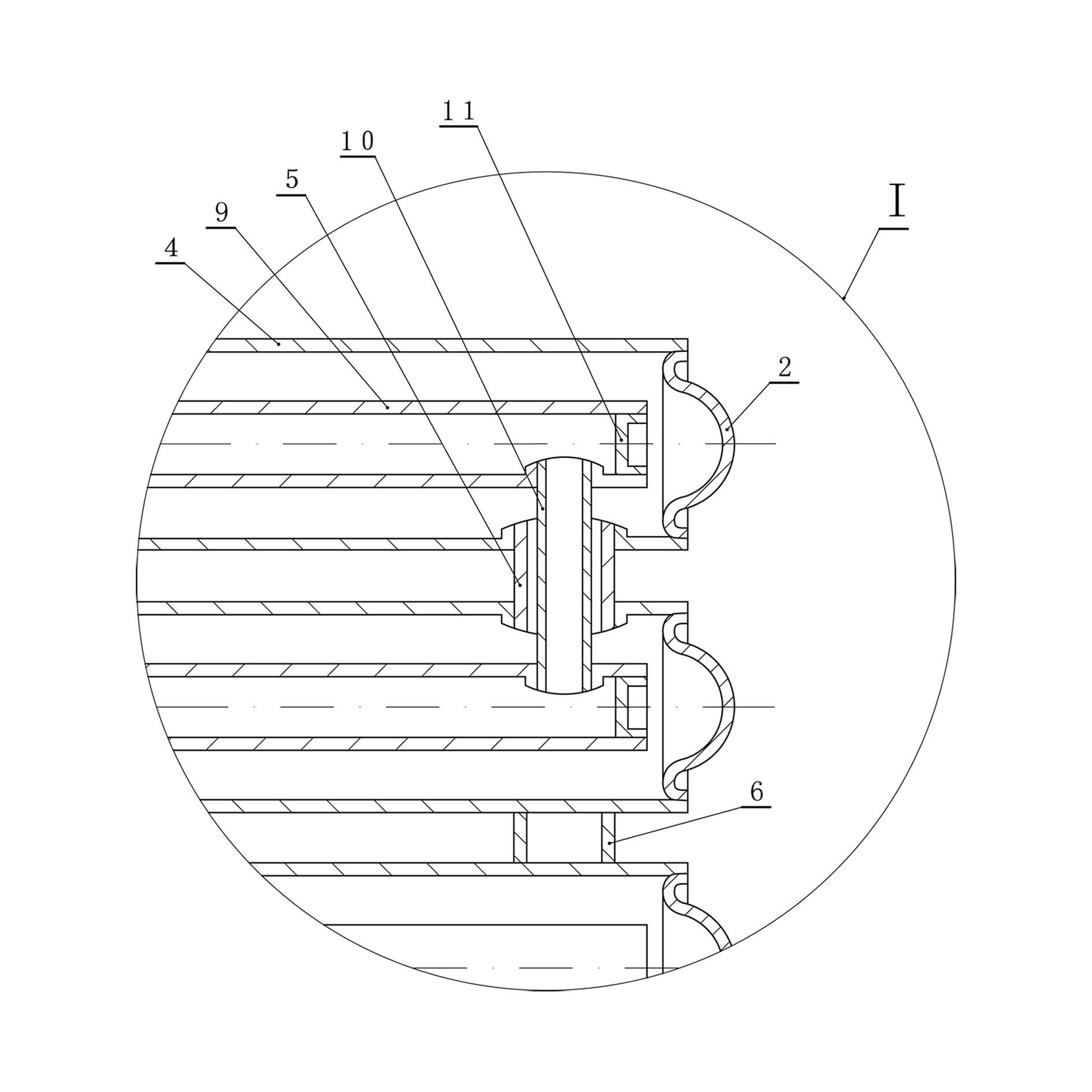

Pipe communication splice welding pressure-bearing type heat exchanger

InactiveCN102322754AIncrease heat transfer areaSolve the welding seam leakage rate is too highHeat exhanger sealing arrangementHeat exchanger casingsWater leakagePlate heat exchanger

The invention relates to a pipe communication splice welding pressure-bearing type heat exchanger, which comprises tap water heat absorption pipes. Heat supply pipes are arranged in the tap water heat absorption pipes. The tap water heat absorption pipes are communicated through tap water communication pipes. The heat supply pipes are communicated through heat supply pipe communication pipes. The seal heads of the tap water heat absorption pipes are outwardly flanged and embedded in the ports of the tap water heat absorption pipes. The flanges of the seal heads of the tap water heat absorption pipes and the port edges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. The walls of the tap water heat absorption pipes are punched and inwardly flanged. The tap water communication pipes are inserted in the punches of the tap water heat absorption pipes. The port edges of the tap water communication pipes and the punched inward flanges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. Heat supply pipe blocking plates are embedded in the ports of the heat supply pipes. The heat supply pipe blocking plates are outwardly flanged. The outward flanges of the heat supply pipe blocking plates and the port edges of the tap water heat absorption pipes are in splice alignment edge-kneading welding connection. According to the pipe communication splice welding pressure-bearing type heat exchanger disclosed by the invention, two technical defects of higher water leakage ratio of the welding line and incapability of continuously producing hot water of the original patent product can be solved; and the heat exchanger has the advantages of no leakage and continuous hot water production.

Owner:张伟

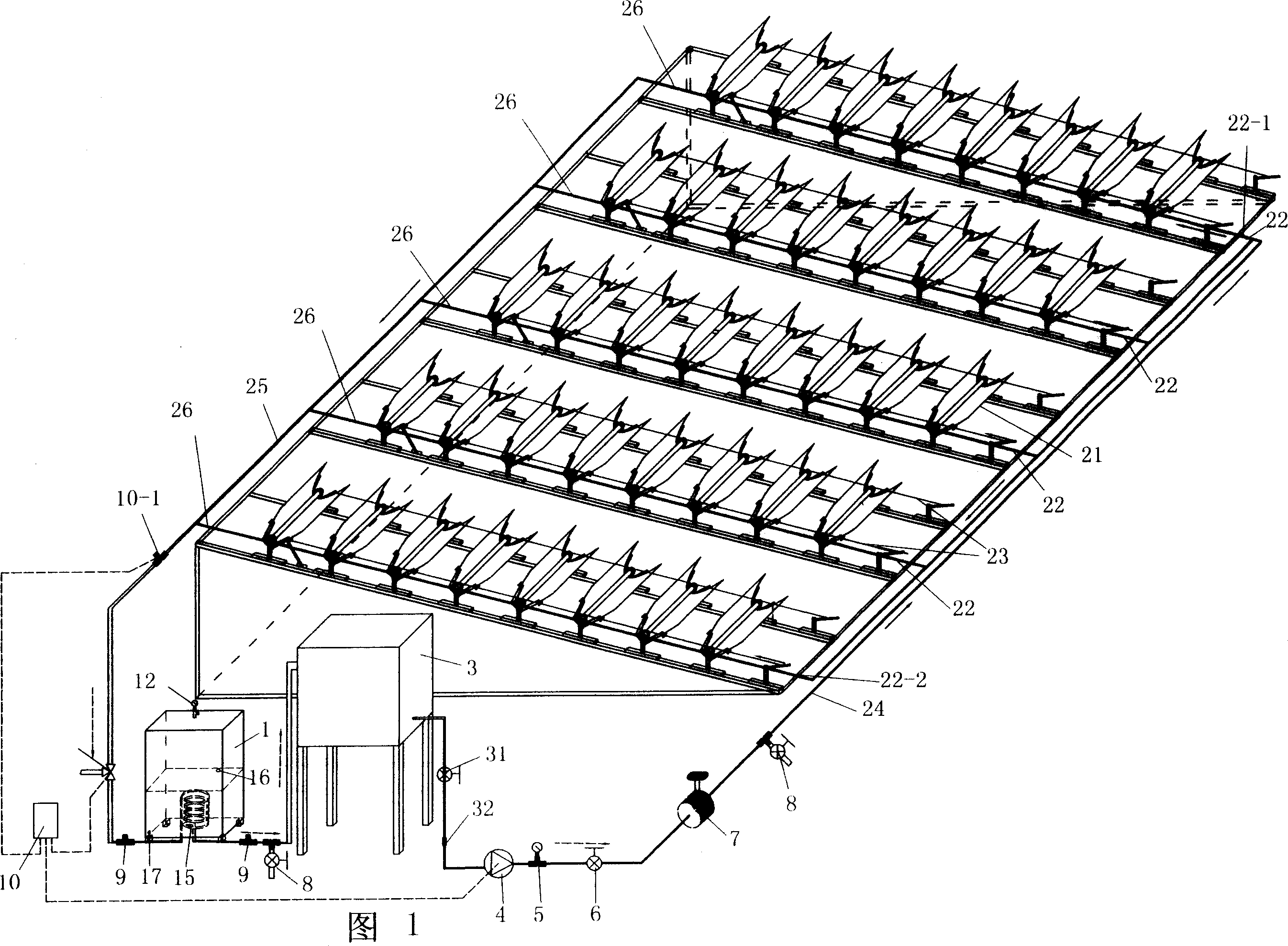

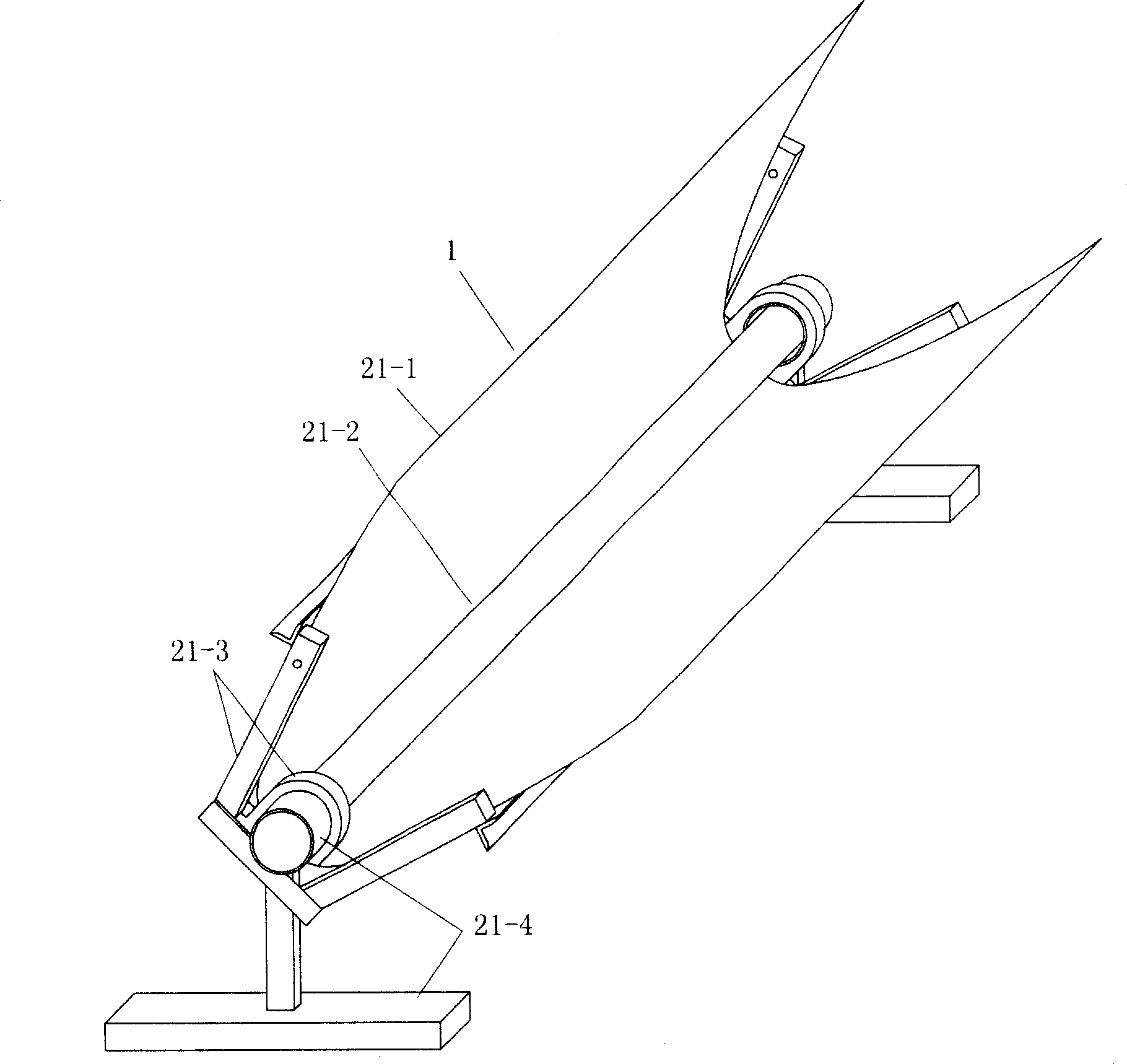

Composite parabolic light focusing type solar rice cooker

InactiveCN1749672ANot easy to damageEasy to useSolar heating energySolar heat devicesPlate heat exchangerCollector device

The composite parabolic light focusing solar rice cooker includes pressure rice cooker and square heat collector array comprising composite parabolic light focusing units. The pressure rice cooker has housing, rice utensil frame, water tank, water pipeline and heat exchanger. The heat exchanger has its two ends extending beyond the housing and connected to the medium input pipe and output pipe of the square heat collector array to form the medium flow loop, in which there are medium storage and circulating pump. The present invention performs heat exchange between heat medium inside the loop and water around the heat exchanger to evaporate water and the heat medium may be scale-proof and cold-proof medium for convenient use. The composite parabolic light focusing units have antiageing light condensers and long period high heat collecting efficiency.

Owner:TRINA SOLAR CO LTD

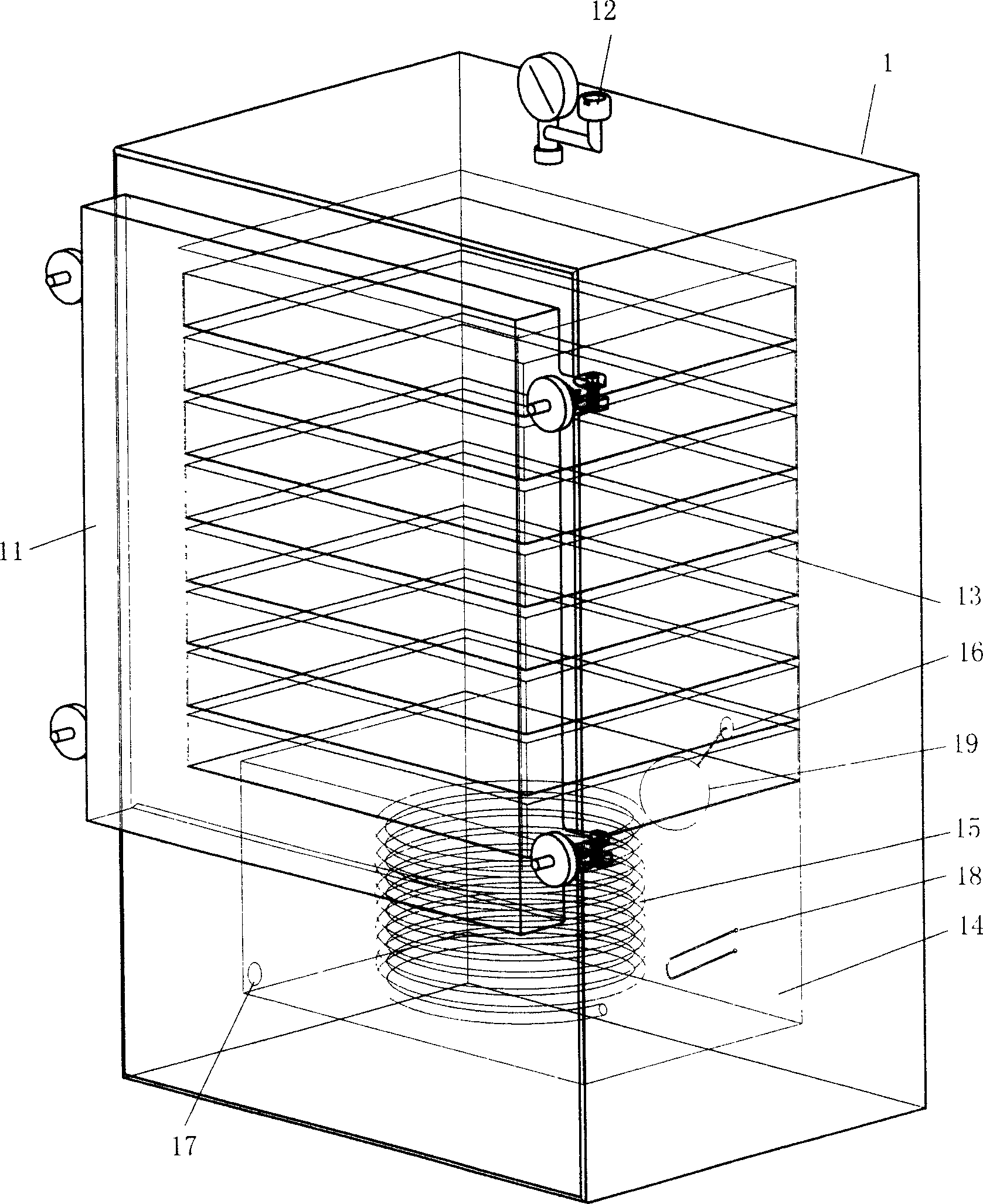

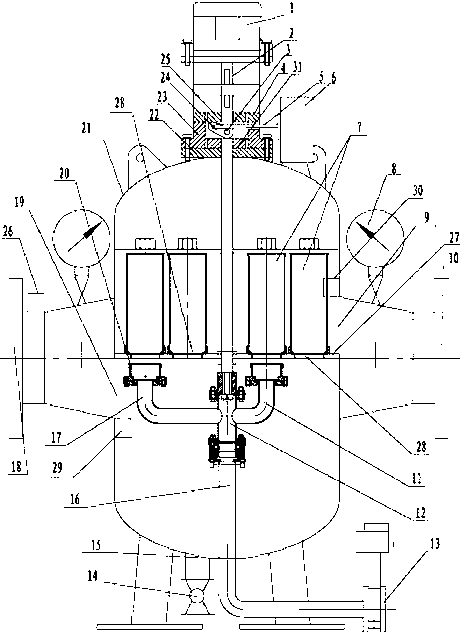

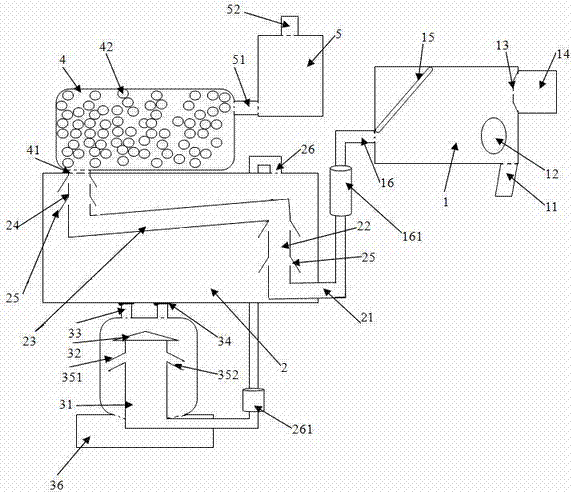

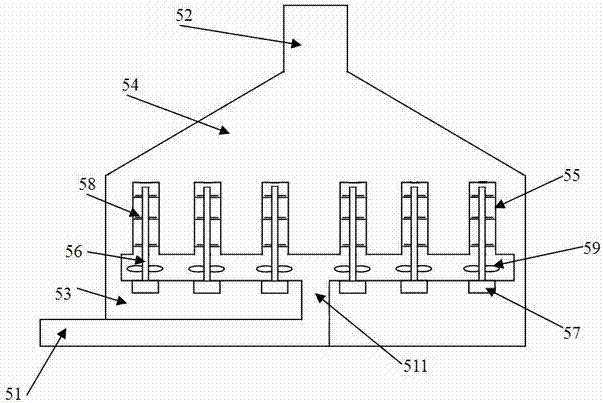

Multi-filter cylinder automatic backwashing filter apparatus

InactiveCN102794044AReduce backwash frequencyMaximum backwash frequencyStationary filtering element filtersElectric machineControl system

The invention discloses a multi-filter cylinder automatic backwashing filter apparatus. A housing is divided into an upper chamber and a lower chamber by a separation plate. The separation plate is provided with filter cylinders in the manner of one, two, or multiple concentric circles. The sidewall of the housing under the separation plate is provided with a sewage inlet, and the sidewall of the housing above the separation plate is provided with a pure water outlet. A motor of a backwashing mechanism drives a main shaft to rotate. A lifting mechanism drives the main shaft to go up and down. A multi-way connection seat connects the main shaft, rotating arms and a waste pipe together. The main shaft drives the rotating arms to lift and rotate. The waste pipe is fixed. Suction nozzles fixed on the upper end port of the rotating arms can be in sealed connection with water inlets on the separation plate. The end part of the waste pipe is connected with an electric drain valve or a pneumatic drain valve. A control system controls the actions of the motor, the lifting mechanism and the electric drain valve or the pneumatic drain valve. The filter apparatus has the advantages of small size, large amount of water filtration, high production efficiency, good filtration effect of filtered water, good backwashing effect, low frequency of backwashing, long-life apparatus, low maintenance rate, and saving backwash water.

Owner:HEBEI AGRICULTURAL UNIV. +1

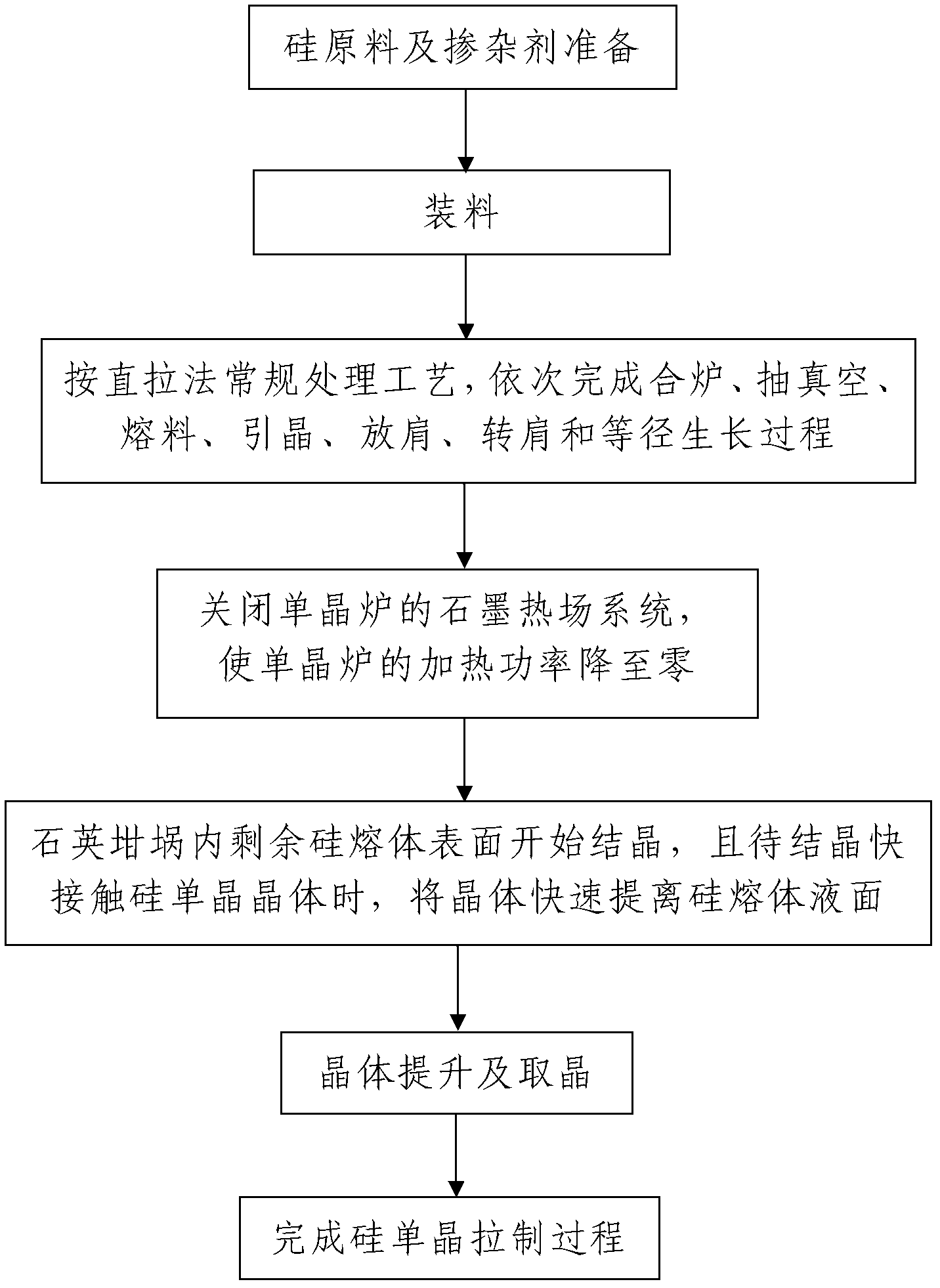

Method to raise production efficiency of czochralski silicon mono-crystal

InactiveCN102220634AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltVacuum pumpingDopant

The invention discloses a method to raise production efficiency of czochralski silicon mono-crystal. The method comprises the following steps: 1. preparation of silicon raw material and a doping agent; 2. charging; 3. processing in a mono-crystal furnace: completing processes of furnace mixing, vacuum-pumping, stock melting, seeding, diameter controlling, casting speed increase and equal diametergrowth, according to a routine processing technology of a czochralski method; 4. post processing: first, a graphite thermal field system of the mono-crystal furnace is closed to lower thermal power of the mono-crystal furnace to zero; then residual silicon melt surface in a quartz crucible begins to crystallize, and when the crystals are about to contact silicon mono-crystals, the mono-crystals are lifted from the silicon melt liquid surface rapidly; last, crystal lifting and crystal collection are carried out to obtain silicon mono-crystal finished product. The invention has the advantages of reasonable design, simple method steps, convenient realization, easy grasp, good usage effect. An ending process of crystal drawing is omitted to increase production efficiency, so as to solve the problem that czochralski silicon mono-crystal production efficiency is restricted by a demanded ending process in the silicon mono-crystal production process.

Owner:XIAN HUAJING ELECTRONICS TECH

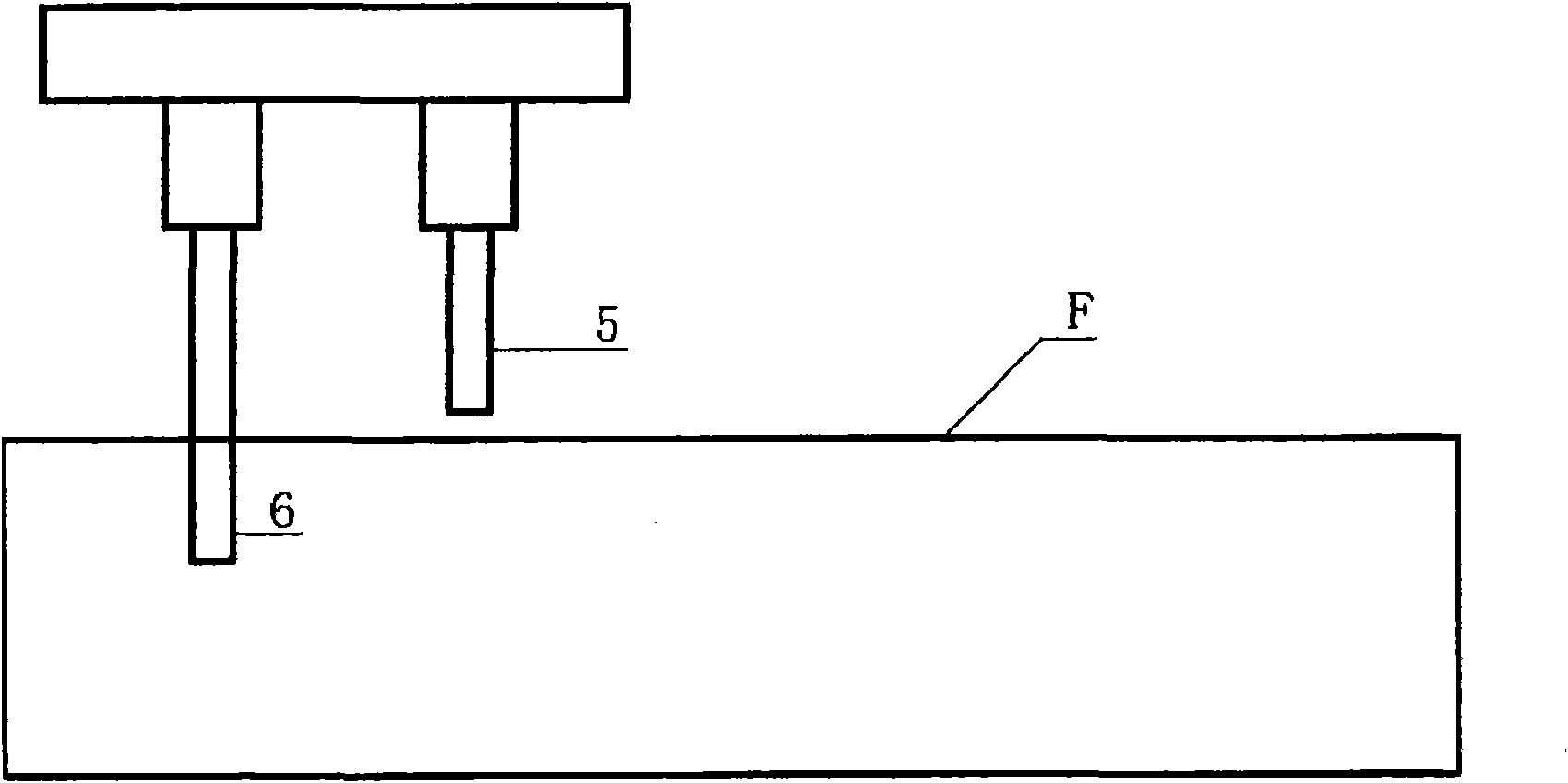

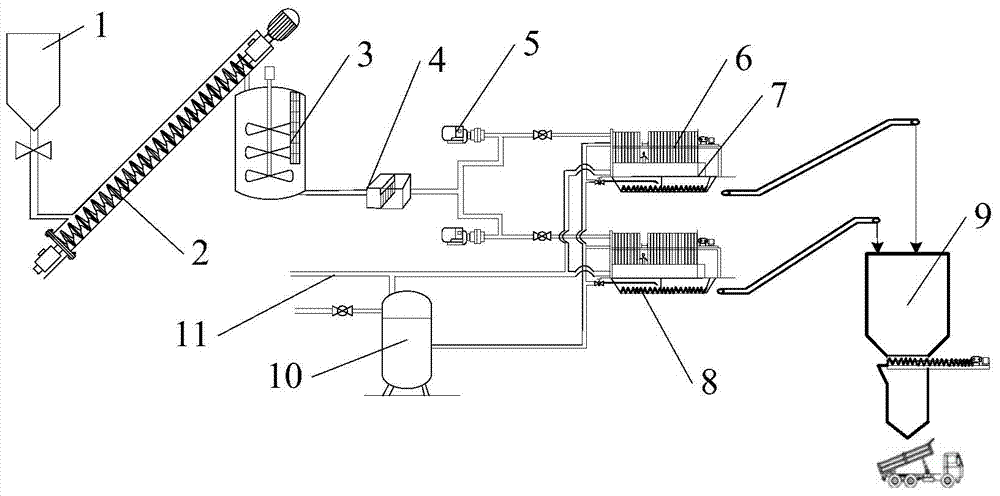

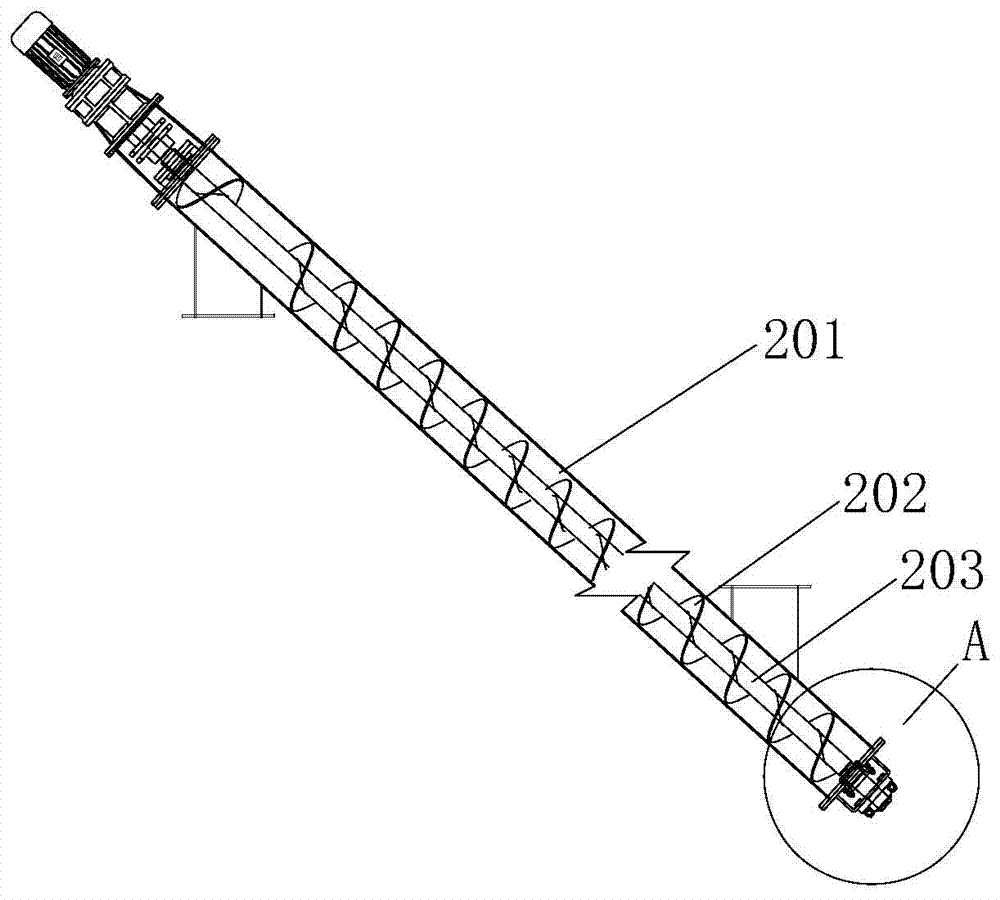

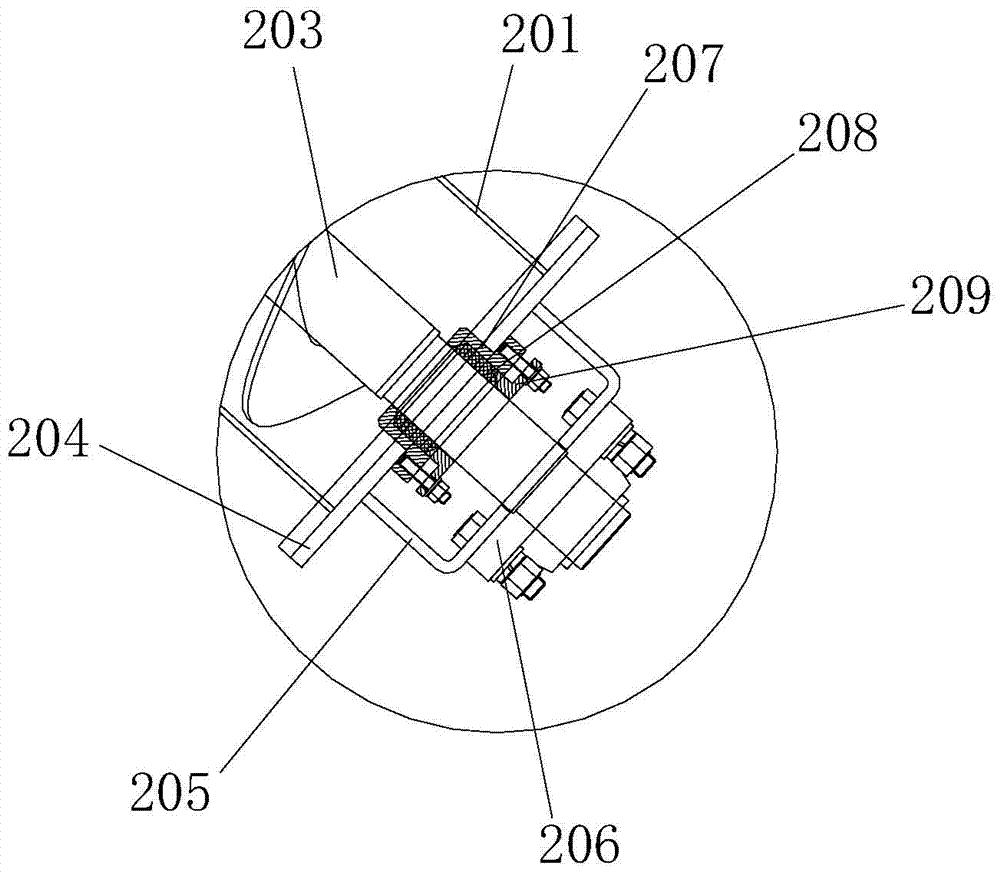

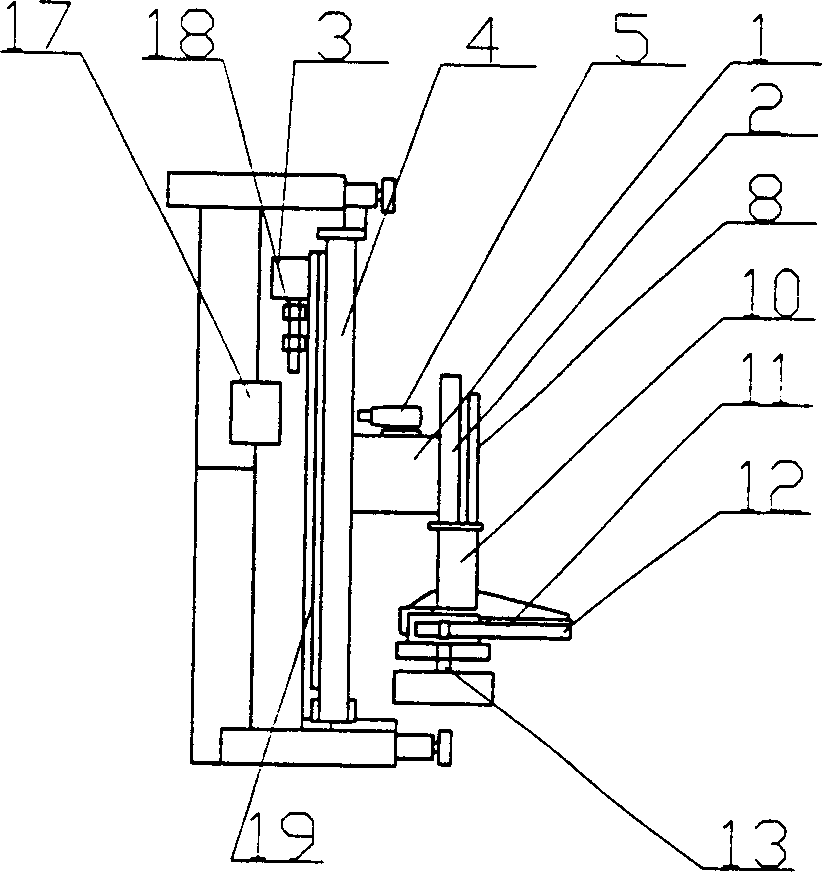

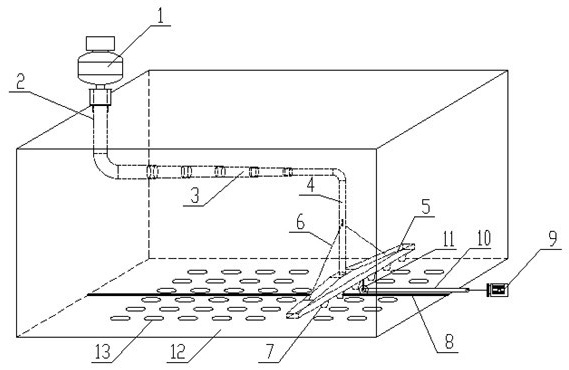

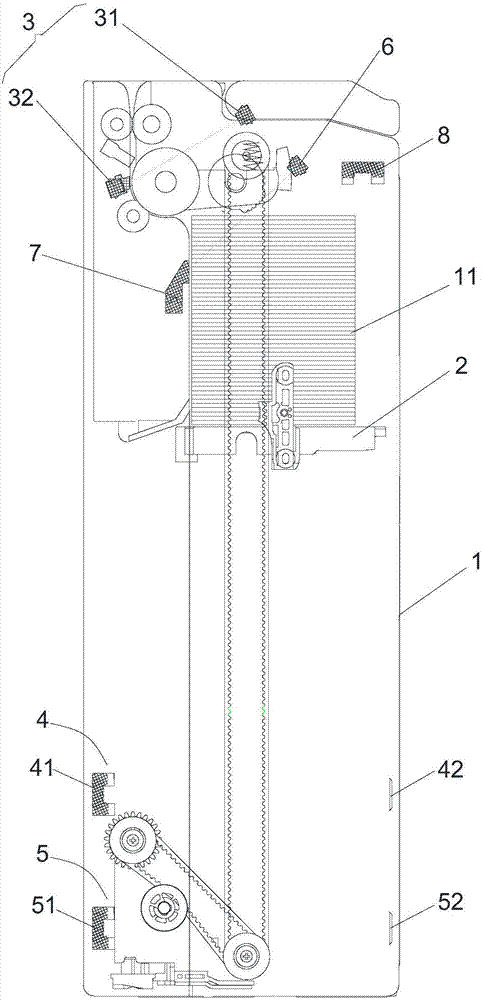

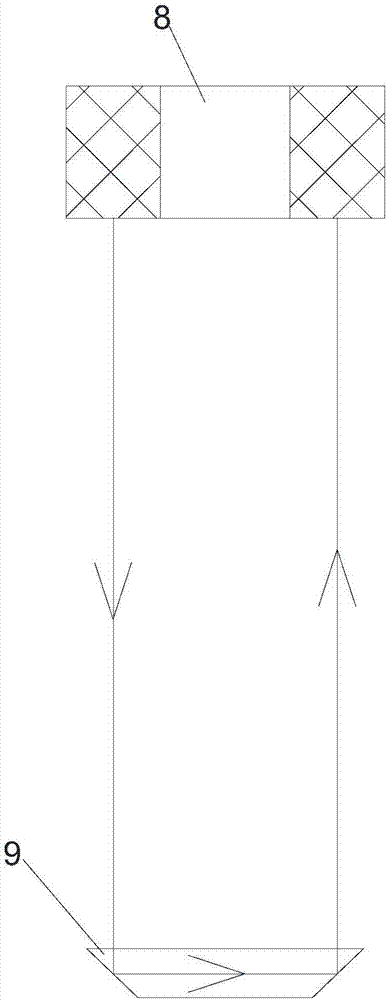

Method and system for deep dehydration of sludge

ActiveCN103693841AFacilitate deep dehydrationHigh economic valueSludge treatment by de-watering/drying/thickeningSludgeFilter press

The invention relates to a method and a system for deep dehydration of sludge. The method comprises the following steps: S1, adding sludge and a modifier to a sludge conditioning tank; S2, fully stirring the sludge and the modifier in the sludge conditioning tank, so that the sludge is subjected to flocculating modification; S3, carrying out second-level filtering on the sludge flowing out from the sludge conditioning tank, and then conveying to a high-pressure diaphragm plate-and-frame filter press to carry out filter pressing through a high-pressure pump, extruding the moisture in the sludge and forming a mud cake; S4, conveying the mud cake to a mud cake discharge bin to store through screw conveying equipment. The system comprises a modifier storage bin (1), a modifier conveyer (2), a sludge conditioning tank (3), a second-level filtering device (4), a high-pressure pump (5), a high-pressure diaphragm plate-and-frame filter press (6), screw conveying equipment (8) and a mud cake discharge bin (9). The method and the system are high in automatic degree, the sludge treatment efficiency is improved, the sludge is conveyed in the sealed equipment, and secondary pollution to the environment is not generated.

Owner:华新环境工程有限公司 +1

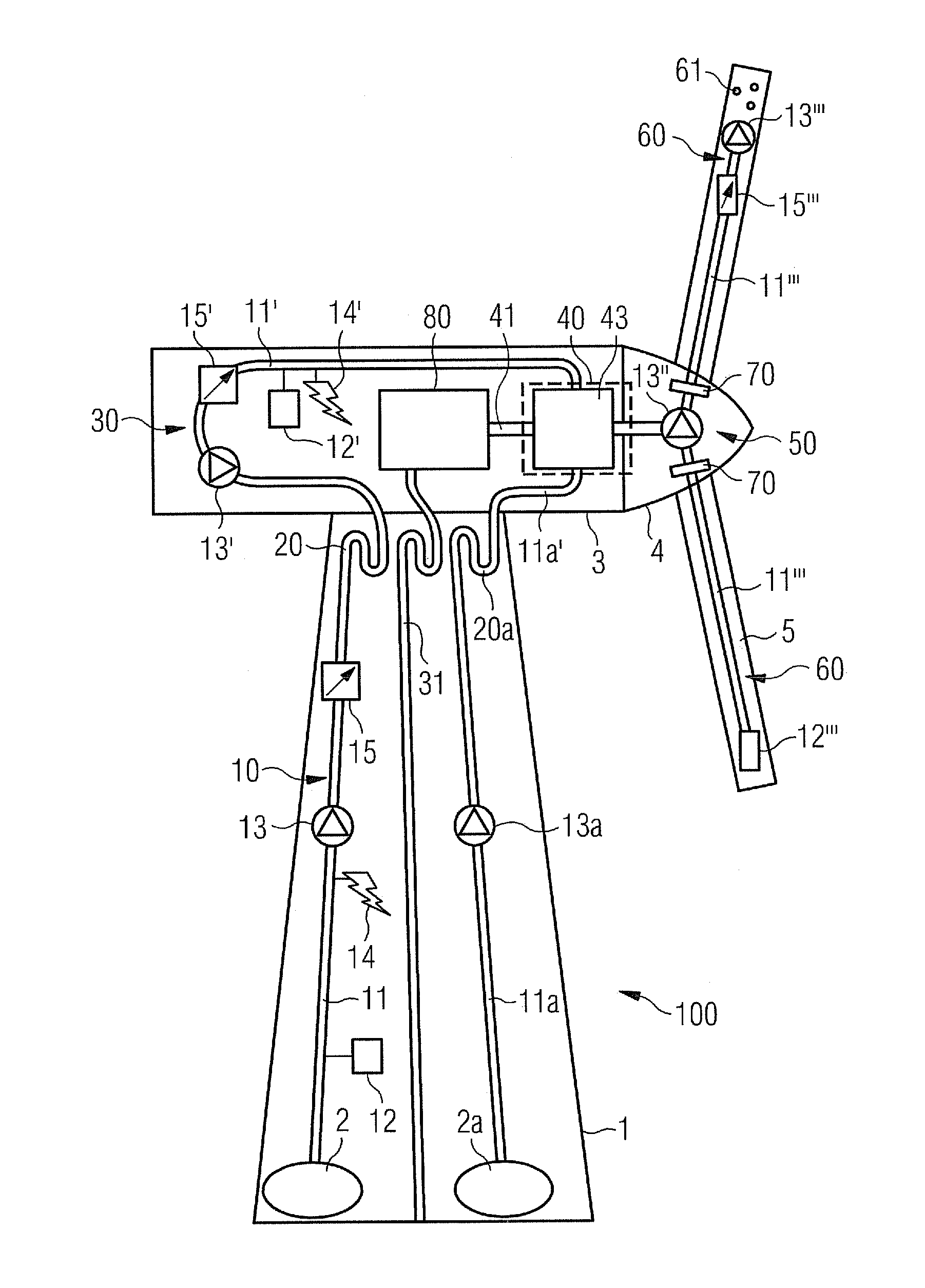

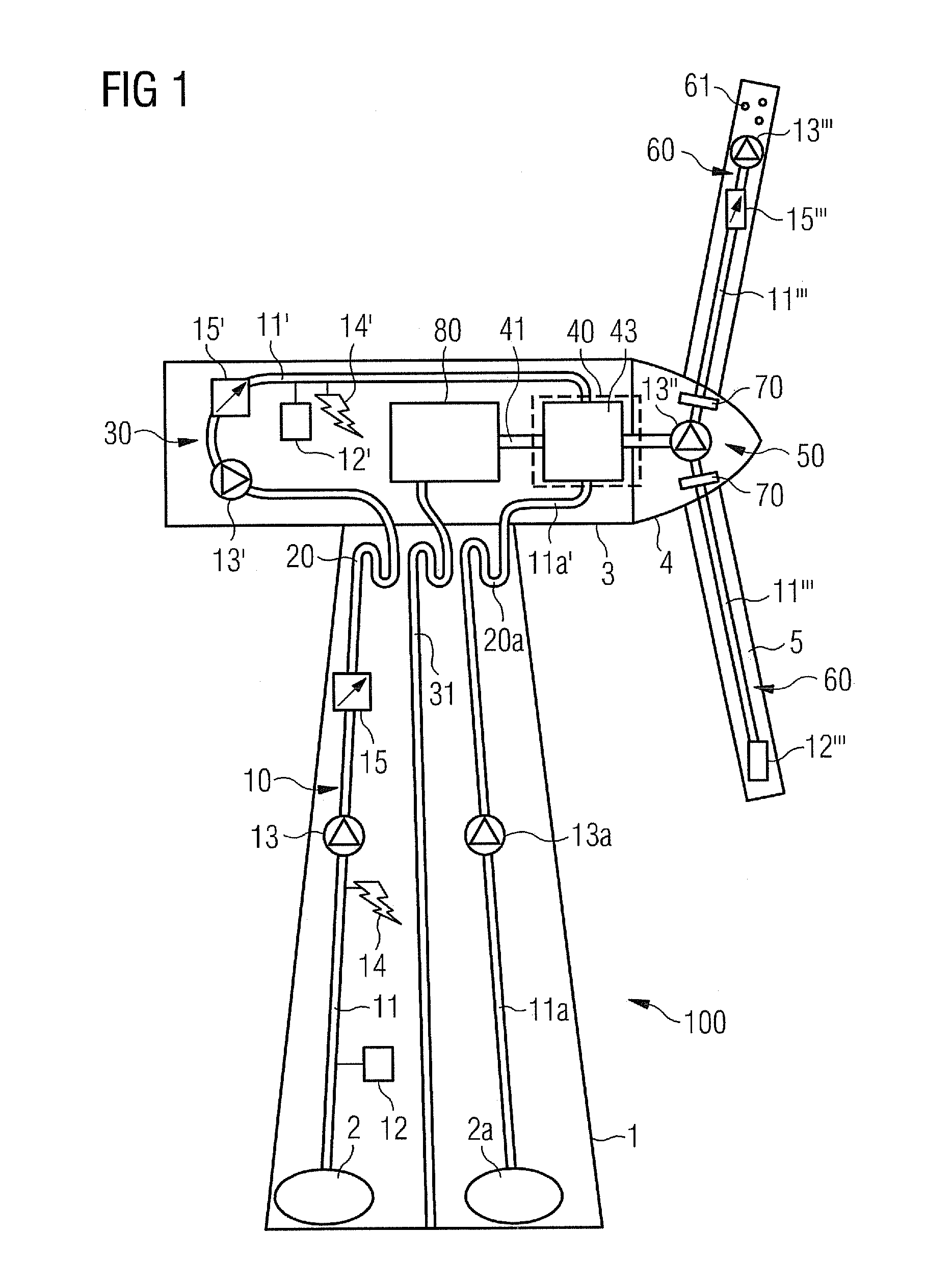

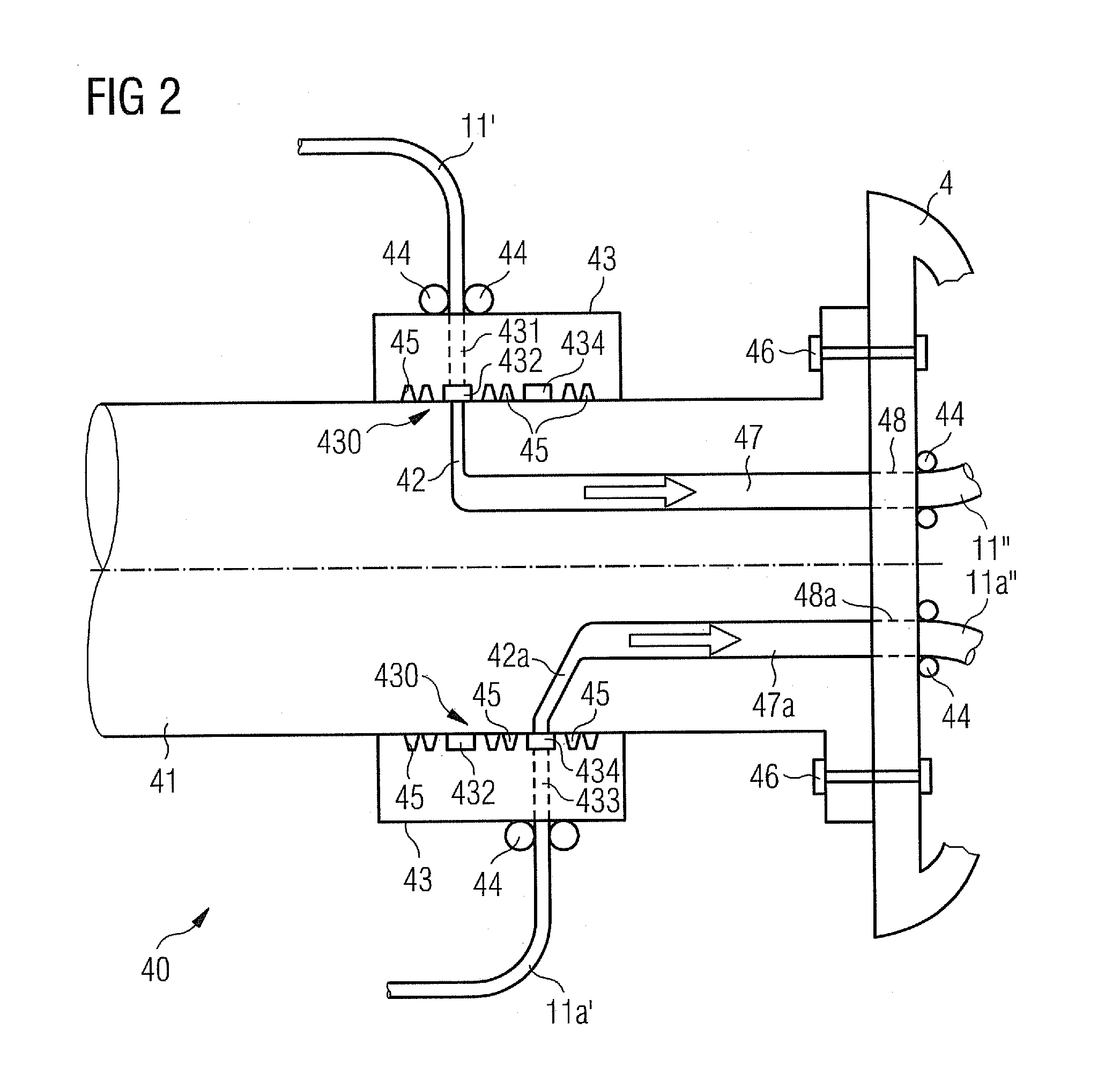

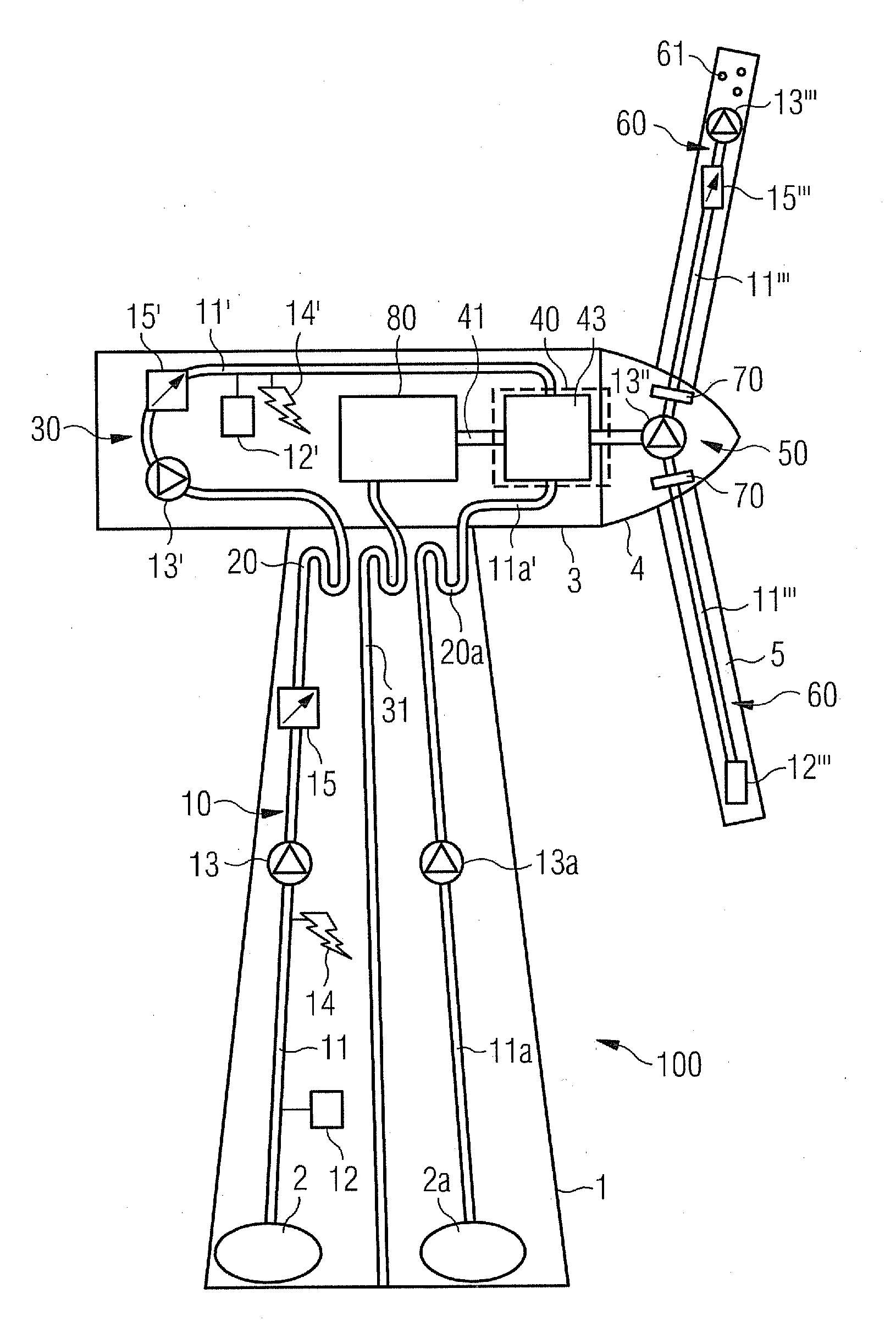

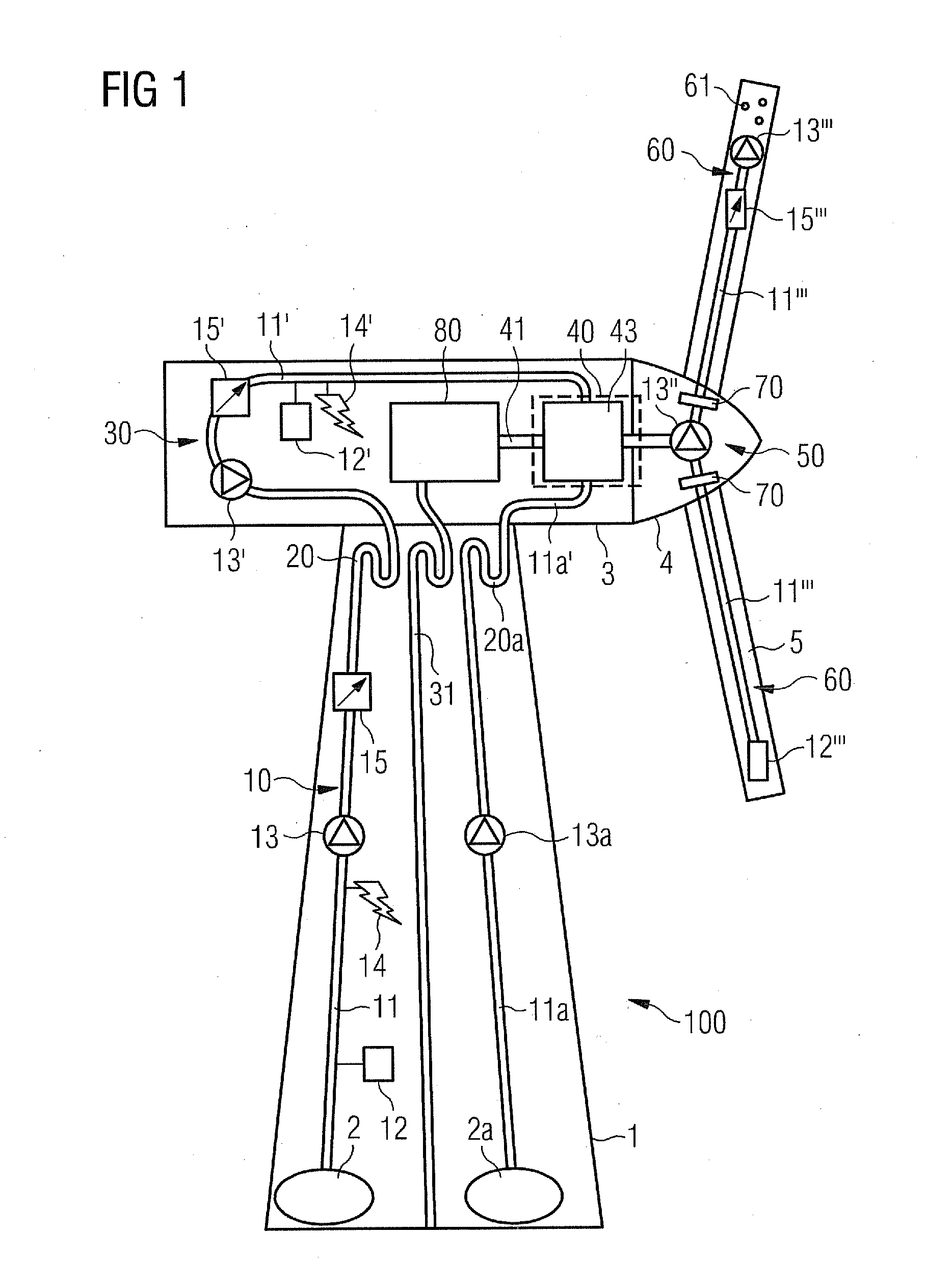

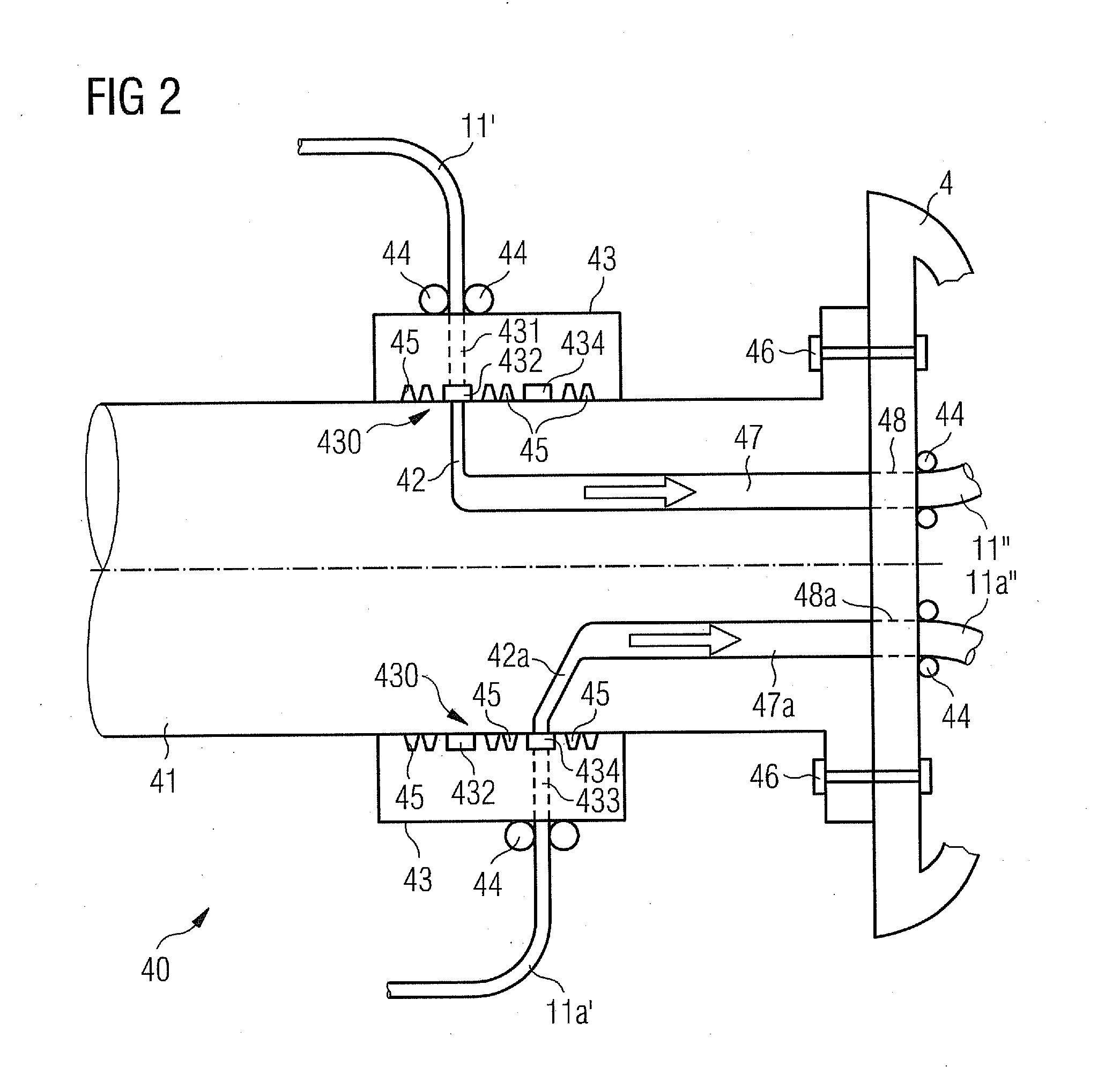

Wind turbine with liquid medium distribution system

A wind turbine with a tower, a nacelle, a main shaft, a hub and blades is provided. The wind turbine also includes a liquid medium distribution system for transport of liquid medium in the wind turbine. The liquid medium distribution system has a first distribution sub-system located in the tower, a second distribution sub-system located in the nacelle, a third distribution sub-system located in the hub, a tower-nacelle-interface connecting the first distribution sub-system to the second distribution sub-system, and a nacelle-hub-interface connecting the second distribution sub-system to the third distribution sub-system. Further, a method of transporting liquid medium in a wind turbine is provided.

Owner:SIEMENS AG

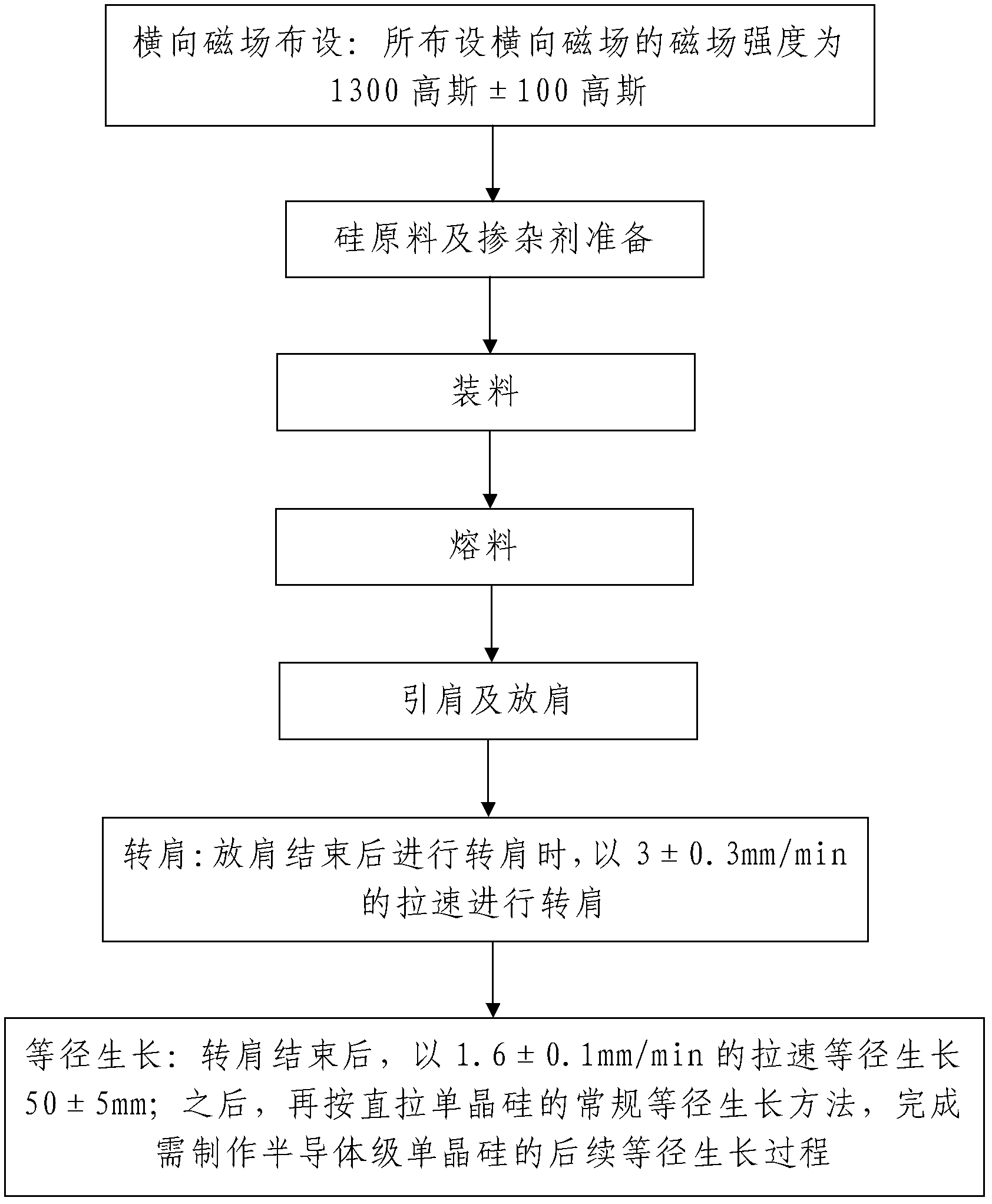

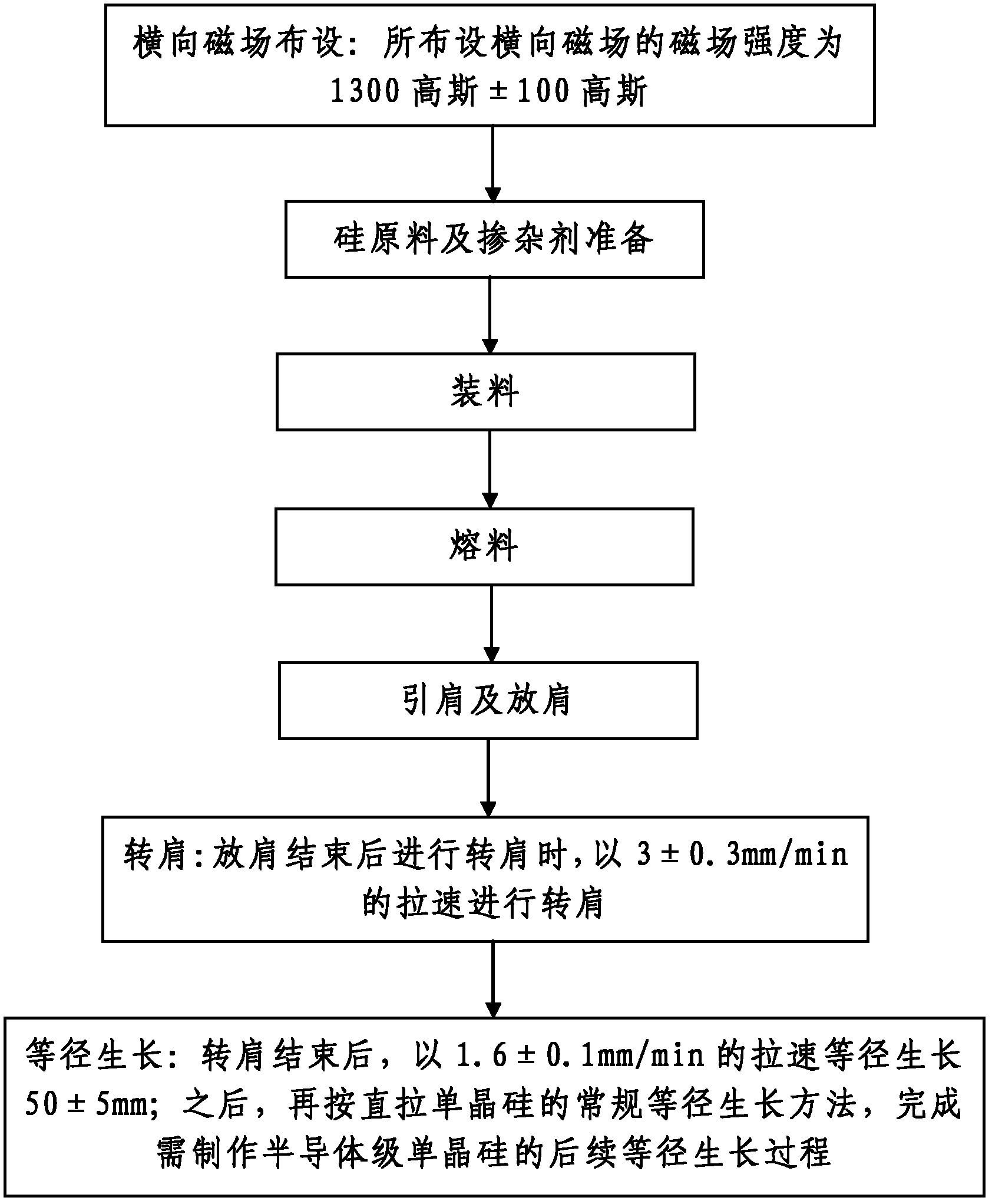

Production technology of semiconductor grade silicon single crystal

InactiveCN102220633AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltTransverse magnetic fieldSingle crystal

The invention discloses a production technology of semiconductor grade silicon single crystal, comprising the following steps: 1, arranging a transverse magnetic field: the magnetic field intensity of the transverse magnetic field is 1300 + / - 100 gausses; 2, preparing silicon material and doping agent; 3, charging; 4, melting material; 5, introducing shoulder and expanding shoulder; 6, rotating shoulder: after the step of expanding shoulder, the step of rotating shoulder is carried out with a casting speed of 3 + / - 0.3 mm / min; and 7, growing at the same diameter: after the step of rotating shoulder, the material grows up to 50 + / - 5 mm with a casting speed of 1.6 + / - 0.1 mm / min; then, a conventional method of growing at the same diameter for direct pulling silicon single crystal is used to complete the subsequent process of growing at the same diameter of the semiconductor grade silicon single crystal. The method has the advantages of reasonable design, simple steps, easiness in realization, easiness in mastering and good using effect, and is capable of effectively guaranteeing the quality of the produced semiconductor grade silicon single crystal. The produced semiconductor grade silicon single crystal has high uniformity of cross-section electric resistivity and no micro-defects such as swirl.

Owner:XIAN HUAJING ELECTRONICS TECH

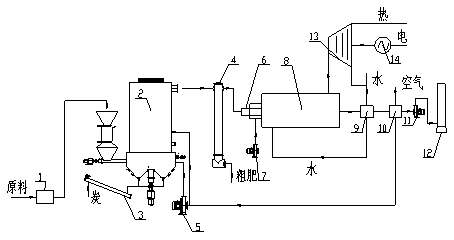

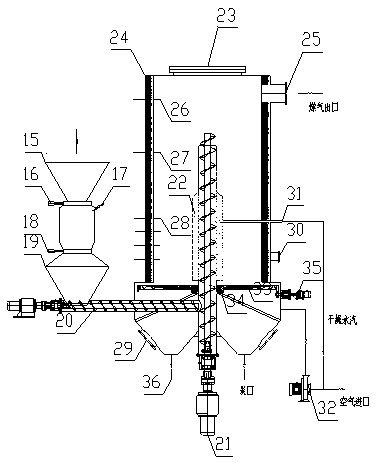

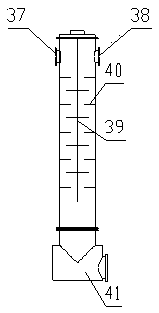

Process method for cogenerating electricity, charcoal, heat and fertilizer through gasified gas supply of biomass

ActiveCN105368496AWide adaptabilityHigh thermal efficiencyEnergy inputGasification processes detailsFertilizerCogeneration

The invention relates to a process method for cogenerating electricity, charcoal, heat and a fertilizer through gasified gas supply of biomass. The process method is characterized by carrying out gasifying by a self-drying and spouting multi-cogeneration gasifier so as to prepare hot combustible gas as fuel of a boiler, and enabling steam generated by the boiler to propel a steam turbine to generate electricity, thereby obtaining four products, i.e., electricity, charcoal, heat and a crude fertilizer simultaneously. The process method comprises the process steps: carrying out biomass pretreatment (collecting and chipping); gasifying the biomass in the multi-cogeneration gasifier; collecting the crude fertilizer; supplying the hot combustible gas, obtained after gasifying, to a gas-fired boiler through a combustor; cooling and collecting biomass charcoal; and enabling the steam generated by the boiler to propel the steam turbine for electricity generation and heat supplying. The process method has the advantages that three kinds of residues of agriculture and forestry are adopted as a raw material, so that environmental protection and the resource-converting utilization of the three kinds of residues of agriculture and forestry are facilitated; and the process is stable in operation, high in hot-combustible-gas combustion heat efficiency, diverse in product and good in economic benefit and is applicable to large-scale application.

Owner:NANJING FORESTRY UNIV

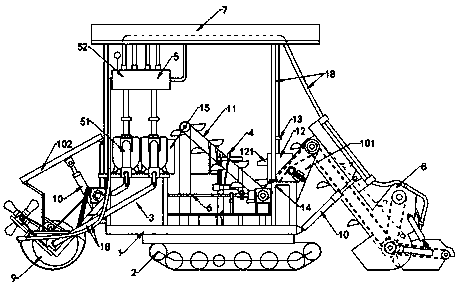

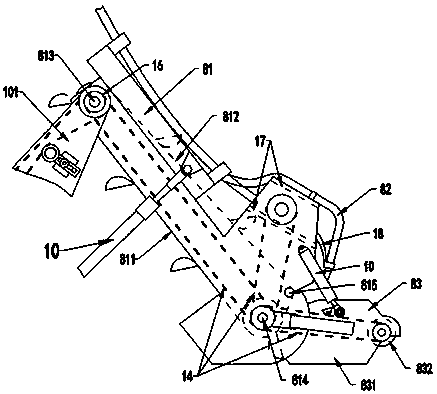

Improved water chestnut harvester

InactiveCN108260399AIntegrity guaranteedEasy to useDigger harvestersMoving filtering element filtersHydraulic cylinderWater Chestnuts

The invention provides an improved water chestnut harvester. The improved water chestnut harvester is characterized in that a collecting mechanism (8) controlled and lifted by a hydraulic cylinder (10) and a filtering water intake device (9) are arranged at two ends of a rack (1); a conveying mechanism (11) is arranged in the middle of the rack (1), a water tank (12) is arranged between the conveying mechanism (11) and the collecting mechanism (8), and a discharge port (121) is formed in the water tank (12); an engine controls operation of a transmission device (6) through a reduction gearbox,the transmission device (6) drives the collection mechanism (8), the conveying mechanism (11) and the filtering water intake device (9) to work, and the engine drives a water pump (51) to work; the engine drives the collecting mechanism (8) to collect water chestnuts, the collected water chestnuts with mud are sent to the water tank (12) for high pressure washing, the washed water chestnuts are output from the discharge port (121) and poured into a collecting basket (15) by the conveying mechanism (11). The collected water chestnuts are good in integrity, and the process of cleaning again inthe later stage is omitted.

Owner:马锁才

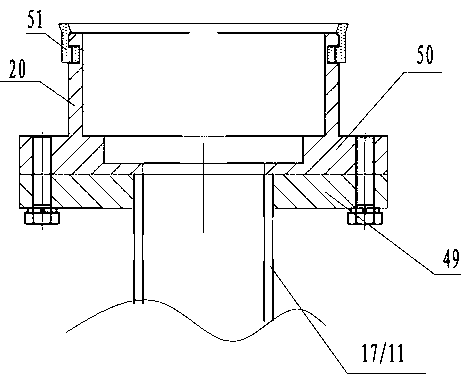

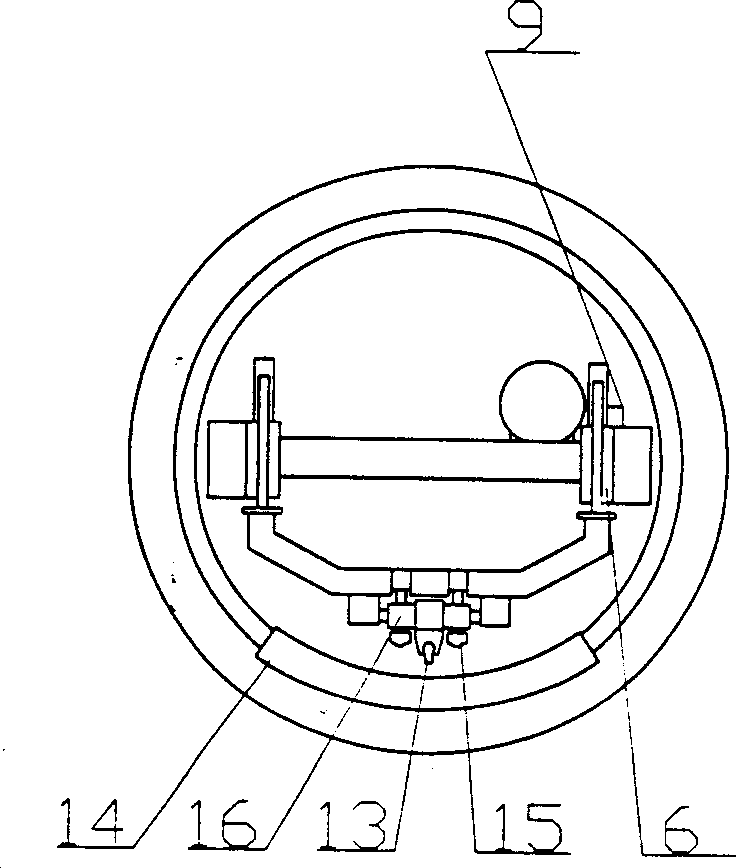

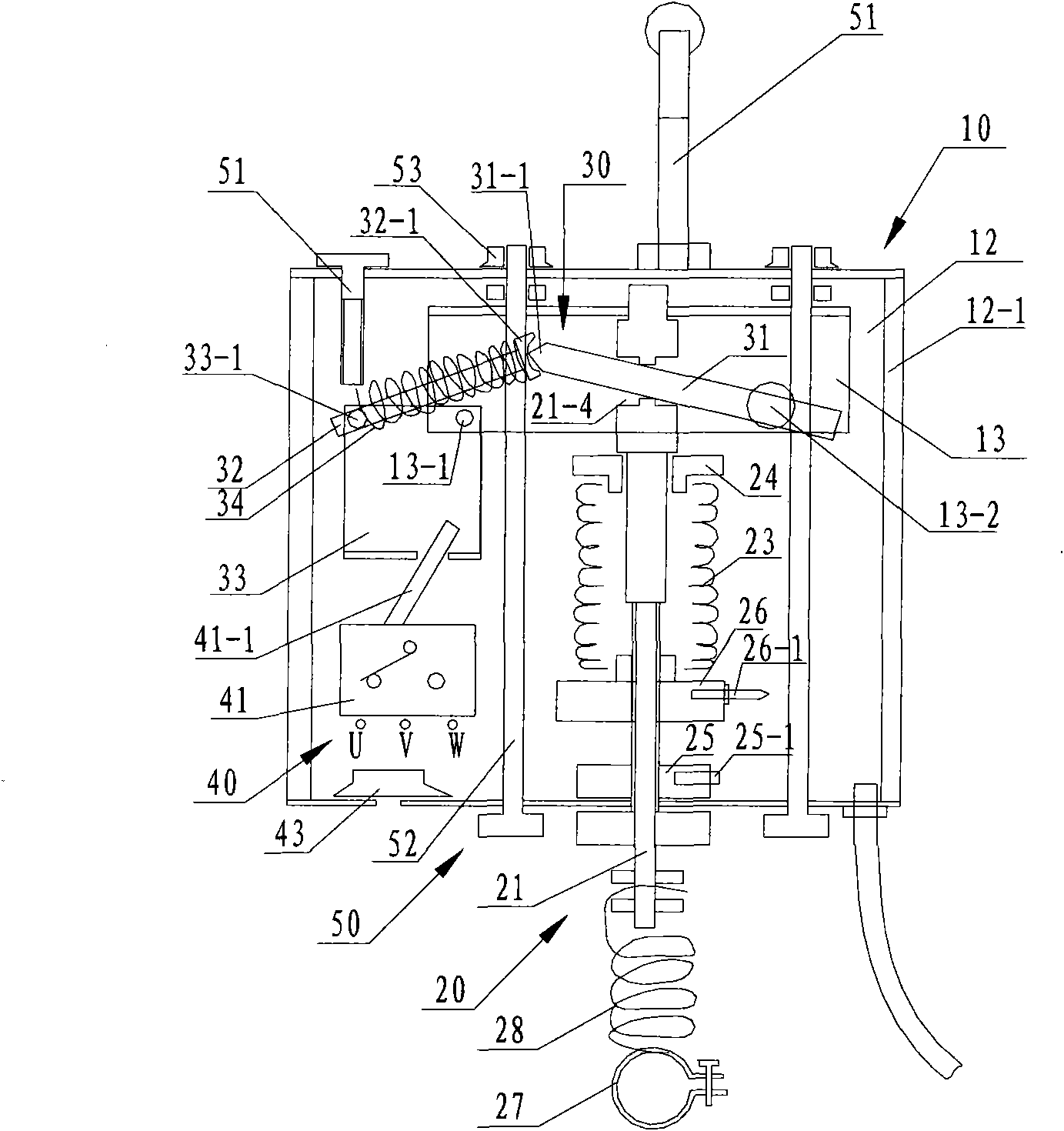

Lining assembling machine having pressure type total leak-proof fuel cell

InactiveCN1448616AEnsure safetySimple structureUnderground chambersTunnel liningPipe wrenchFuel cells

The lining and assembling machine with pressurized sealed oil tank belongs to tunnel engineering constructing machinery. The connecting mode includes setting the cantilever beam and the oil tank cantilever beam in the same side of the disk, driving the disk with the rotating driver, setting the electric control assembly on the top of the oil tank steel structure, setting the hydraulic pump set on the top of the oil tank cantilever beam, setting the pressurized sealed oil tank inside the steel structure of the oil tank steel structure, welding the guide barrel on one side of the cantilever beam, fixing the elevating oil cylinder onto the outside of the guide barrel, setting the elevating beam below the elevating oil cylinder, screwing the translating mechanism in the lower part of the elevating beam, setting the translating oil cylinder in the middle of the translating mechanism, and setting two pipe wrench beside the translating oil cylinder. The present invention has simple structure and high construction speed.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

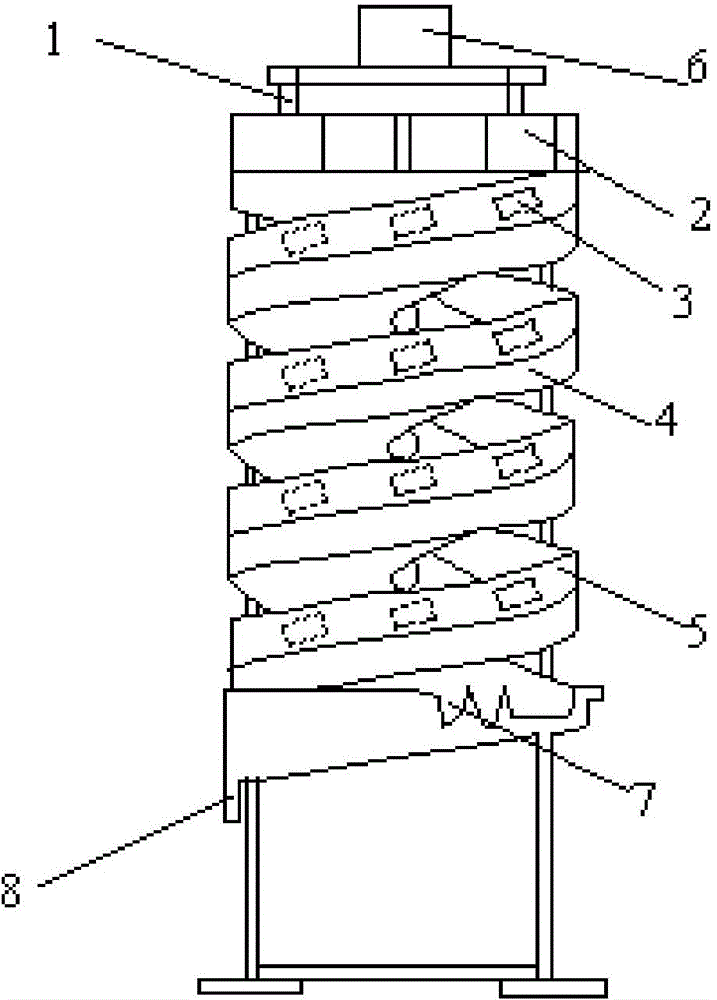

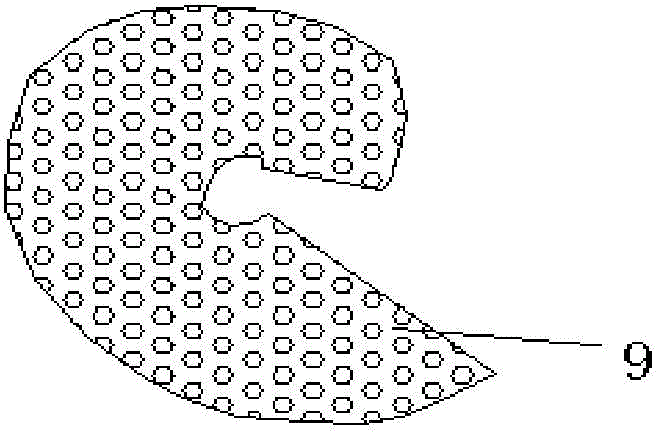

Complex force field spiral chute for ore dressing

The present invention discloses a complex force field spiral chute for ore dressing, and fine particles can be effectively prevented from entering into a tailing zone. The spiral chute comprises a channel steel support, an ore-feeding device, magnetic poles, a pulsating pressure water tank, a spiral blade, an ore dividing bucket, an ore intercepting bucket and an ore receiving bucket. The permanent magnetic fixed magnetic poles are installed at an external portion of a spiral blade of an existing spiral chute, so that magnetic fine particles in magnetic mineral can be forced by an inward-radial magnetic retentive force to enter into a concentrate zone under the function of an applied magnetic field. The pulsating water tank is installed at the bottom of a spiral surface, ore particles are prevented from rubbing with the spiral surface, so that the ore particles can be well layered and separated conveniently, and equipment abrasion can be eliminated conveniently. Concentrate grades can be improved, concentration ratio can be increased, mineral recovery rates can be improved, an existing spiral ore dressing technology can be simplified, and equipment maintenance rates and equipment power consumption can be reduced.

Owner:UNIV OF SCI & TECH LIAONING

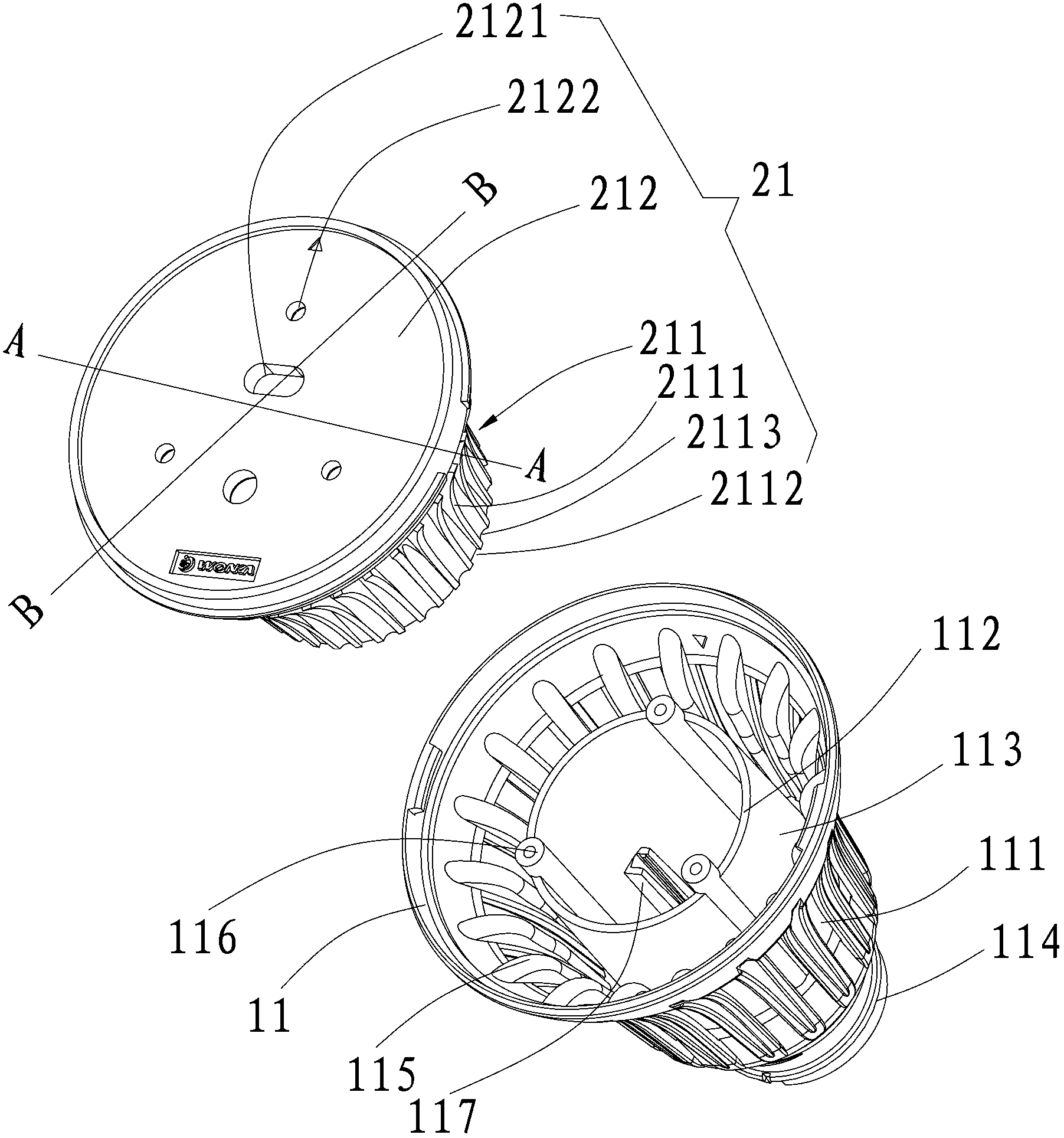

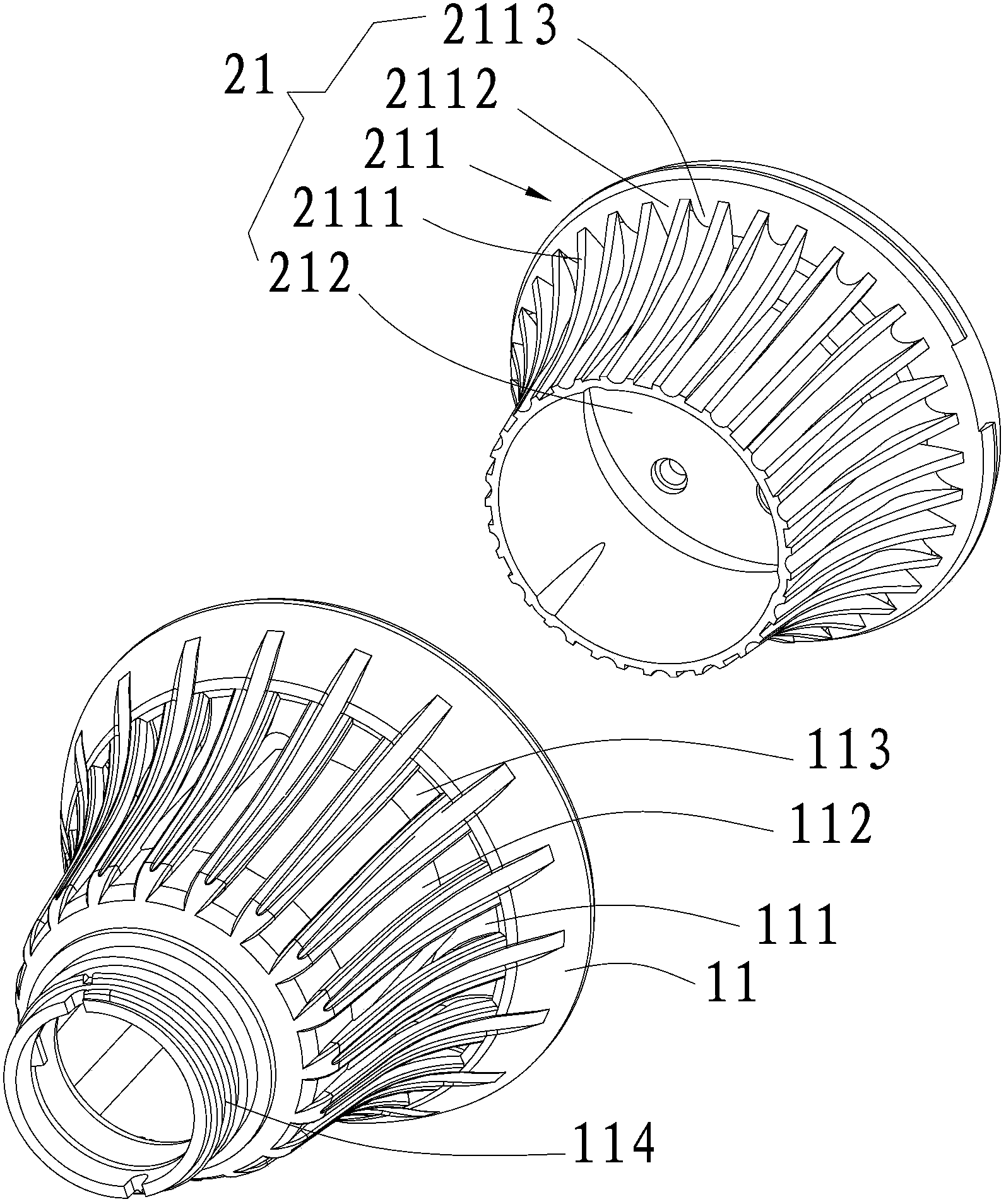

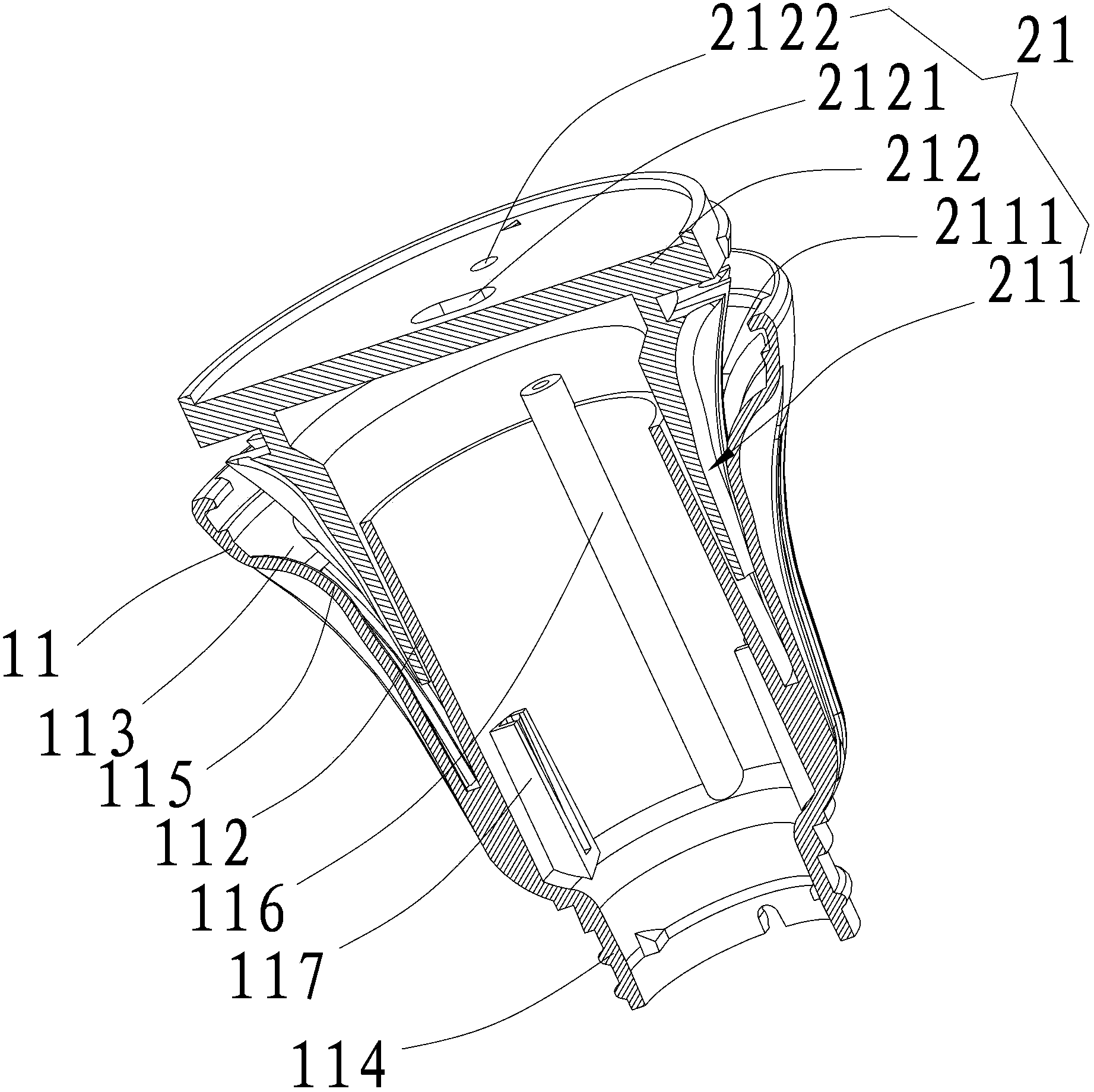

Lamp body and light-emitting diode (LED) bulb

ActiveCN103453335AReduce maintenance rateGuaranteed cooling effectPlanar light sourcesPoint-like light sourceScaldingEngineering

The invention provides a lamp body. The lamp body is used for supporting a light-emitting diode (LED) module. The lamp body comprises a plastic casing and a radiator installed in the plastic casing so as to absorb heat generated by the LED module, and heat dissipation holes for dissipating head absorbed by the radiator are arranged outside the plastic casing. The lamp body enables heat emitted by a lamp to be dissipated through the radiator, heat exchange is performed with the outside through the heat dissipation holes positioned on the plastic casing, the temperature of the casing is not high while heat dissipation is guaranteed, and people do not feel hot when touching the casing. The invention further provides an LED bulb where the lamp body is applied. The skin is not scalded when people touch the casing in the process of replacement, trial and maintenance and the like, the problem that the bulb is dropped and broken due to scalding is solved, and the maintenance rate of the bulb can be effectively reduced.

Owner:SHENZHEN WANJIA LIGHTING

Blowing device with large air rate in a movable and positioning way

InactiveCN102600682AReduce in quantityEasy to cleanDispersed particle filtrationEngineeringSurface dust

The invention belongs to the technical field of environment-friendly equipment, and relates to a pulse dust cleaning device of a fixed pulse bag type dust remover and dust removing equipment using the pulse dust cleaning device. The pulse dust cleaning device is a pulse blowing device matched with the bag type dust remover. The pulse blowing device comprises a blowing device body; a large air storage bag is connected with a blowing branch pipe in the body through an intake-tube; and a pattern plate arranged at the bottom of the body is provided with a plurality of filter bag holes; and the pulse blowing device is characterized in that the blowing branch pipe can be positioned and moved on the pattern plate arranged at the bottom of the body. According to the invention, after the structure of the device and the dust cleaning method are adopted, the blowing in a movable and positioning way can be realized, the quantity of the blowing pipes and the pulse valves can be reduced, the cost of investment is low, the overhaul rate is low; and the pulse blowing device is large in air rate for dust cleaning, thereby being easy to clean surface dust on the filter bag.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

Environment-friendly smoke denitrification and desulfurization equipment

ActiveCN107875825AImprove purification efficiencyImprove purification effectGas treatmentDispersed particle filtrationNitrogen removalWater vapor

The invention relates to environment-friendly smoke denitrification and desulfurization equipment which comprises an oxidizing chamber, a nitrogen removal chamber, a sewage treatment chamber, a desulfurization chamber and a bag-type dust collector. Due to the respective arrangement of the nitrogen removal chamber and the desulfurization chamber, the efficiency of removing nitric oxides and sulfuroxides in smoke is improved, residual water vapor in the nitrogen removal chamber serves as a raw material in the desulfurization chamber to use, heat is recycled, the heat is also recovered while performing smoke purification, and environment-friendly smoke treatment is really realized.

Owner:ZHEJIANG ZHIYUAN ENVIRONMENTAL TECH CO LTD

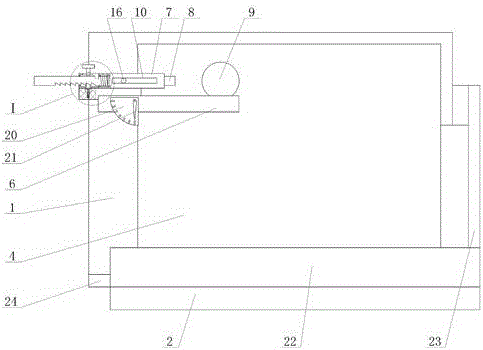

Electromagnetic positioning device

ActiveCN105845000AReduce experimental errorReduce maintenance rateEducational modelsFree fallingLinear motion

The invention provides an electromagnetic positioning device, which comprises an induction positioning plate. The outer boundary of a side of the induction positioning plate is equipped with a fixing plate. A support base is mounted on the fixed plate on the front of the induction positioning plate. The lower portion of the support base is equipped with a track on which a projectile is disposed. A slide rod is mounted on the support base. A first spring is mounted on the slide rod. One end of the slide rod in the length direction is located at one side of the projectile, while the other end of the slide rod is located at the outer side of the fixing plate. The back of the induction positioning plate is provided with horizontally and vertically arranged coil array circuits. A USB interface is disposed in the induction positioning plate and is connected with a computer through a line. The projectile has an upper shell and a lower shell, and forms a cavity once being closed. A battery is mounted in the cavity and is connected with a circuit board via a wire. The circuit board is connected with a magnetic core coil via the wire. The invention can display the horizontal projectile motion as the resultant motion of the uniform linear motion in a horizontal direction and the free-fall motion in a vertical direction via the computer, and has the advantages of easy operation, low maintenance rate and long service life.

Owner:SHANDONG YUANDA LLONGWILL EDUCATIONAL SCI & TECH LTD

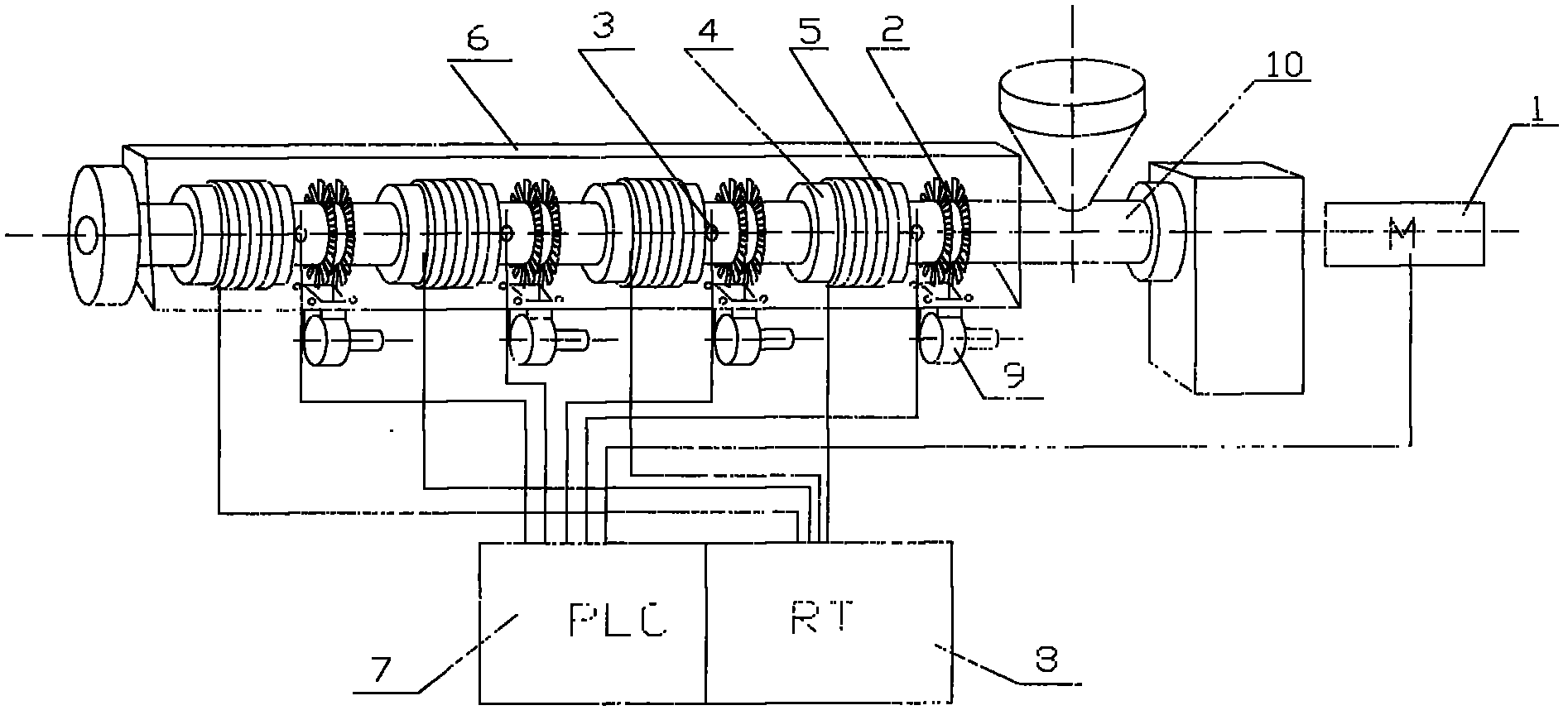

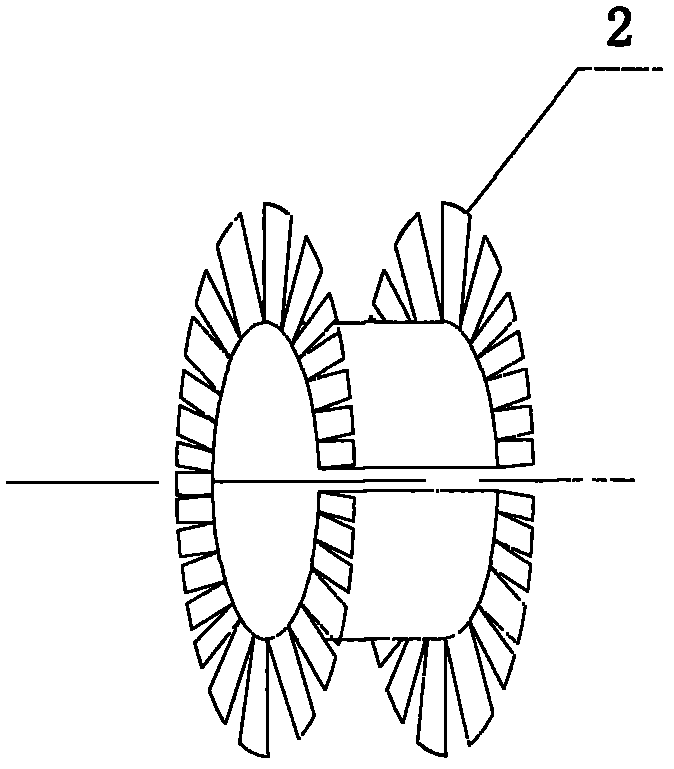

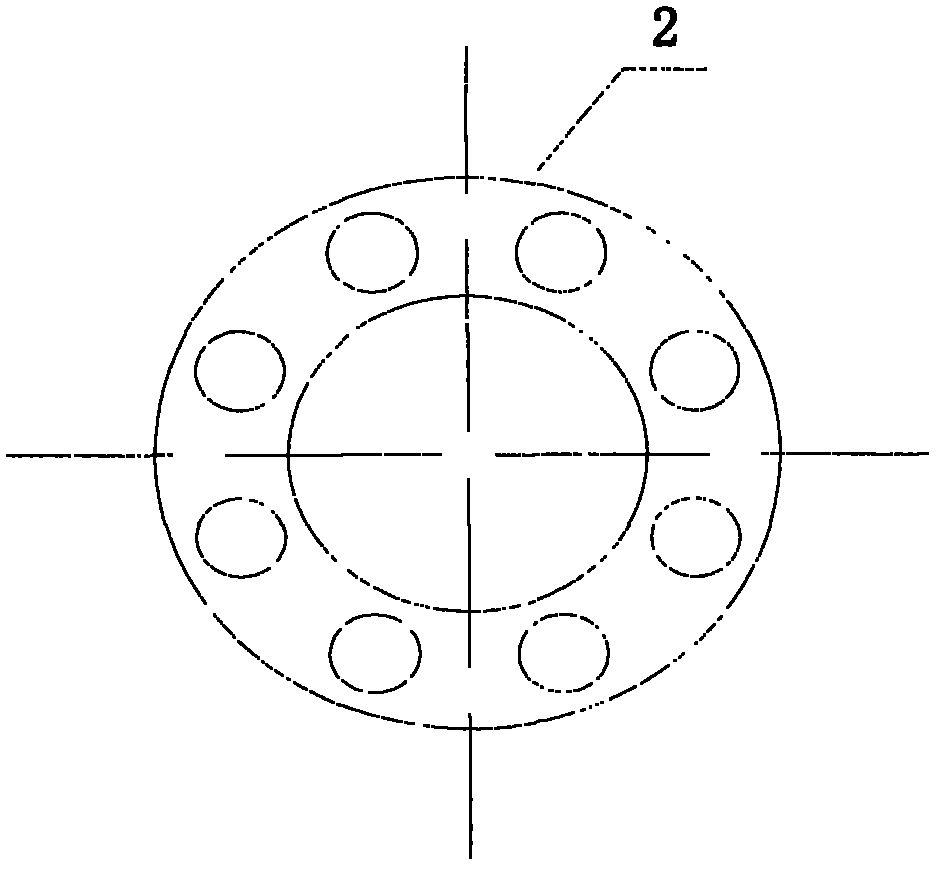

Air-cooled electromagnetic heating device for plastic extrusion equipment

InactiveCN102133795AHigh power saving rateExtended service lifeInduction heating apparatusStatus testThermal insulation

The invention relates to an air-cooled electromagnetic heating device for plastic extrusion equipment. The device comprises a thermal insulation layer, an electromagnetic induction coil and a temperature measuring element, wherein the thermal insulation layer is sectionally wound around a charging barrel, the electromagnetic induction coil is wound around the thermal insulation layer, and the temperature measuring element is exposed on the charging barrel; in addition, the air-cooled electromagnetic heating device also comprises a cooling system and a controller, wherein the cooling system is used for cooling the charging barrel, one end of the controller is connected with a screw motor status test element and the temperature measuring element, and the other end of the controller is connected with the thermal insulation layer and the cooling system. Detection signals of the screw motor status test element and the temperature measuring element are fed back to the controller so as to control the operations of the cooling system and the electromagnetic induction coil. The air-cooled electromagnetic heating device disclosed by the invention has the advantages that the precise control on temperature and the maximum utilization of shearing heats in plastic processing are realized; and compared with traditional resistance heating, more than 90% of power is saved; and compared with the existing electromagnetic heating device, and 50% of power is saved.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

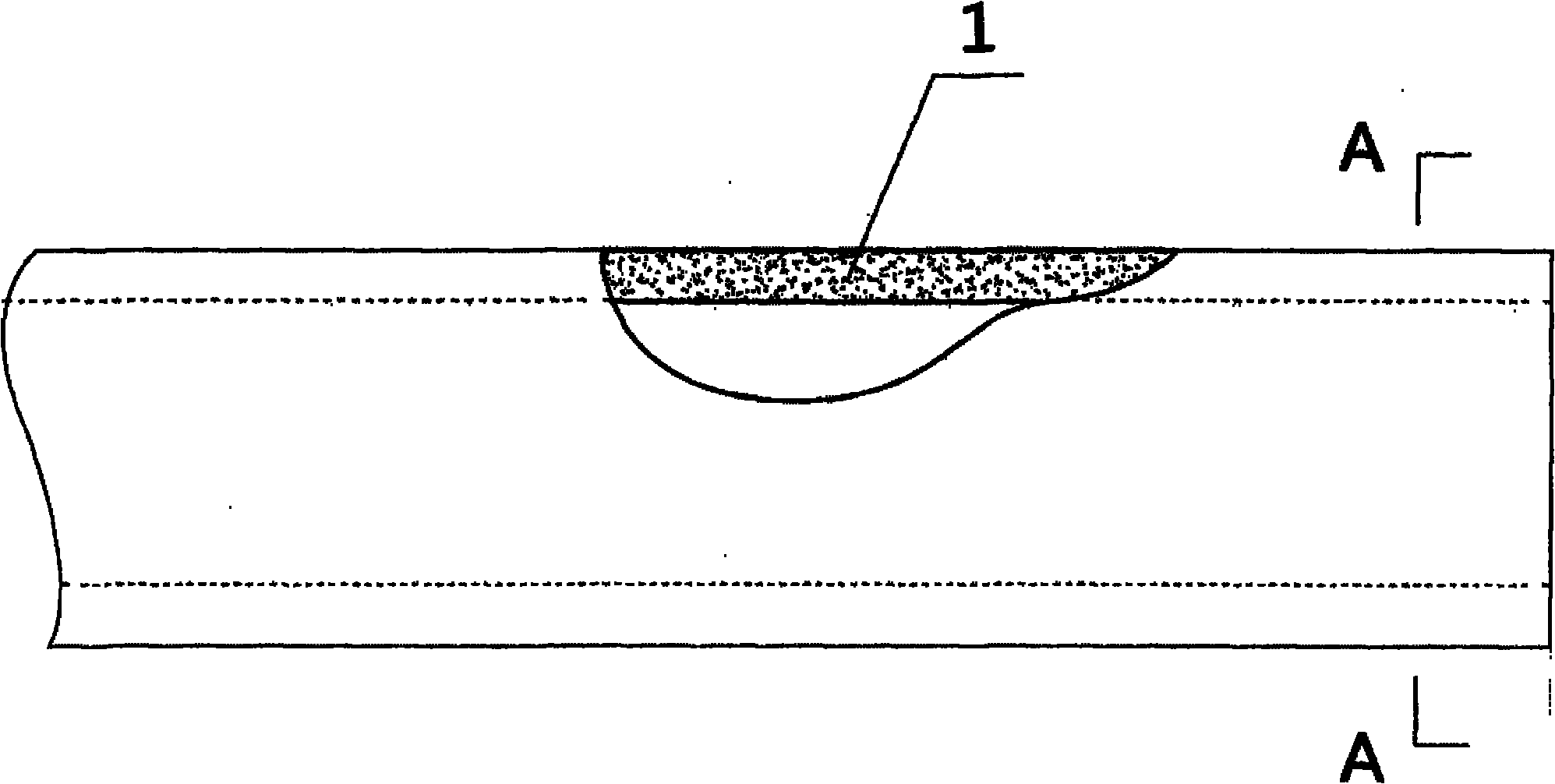

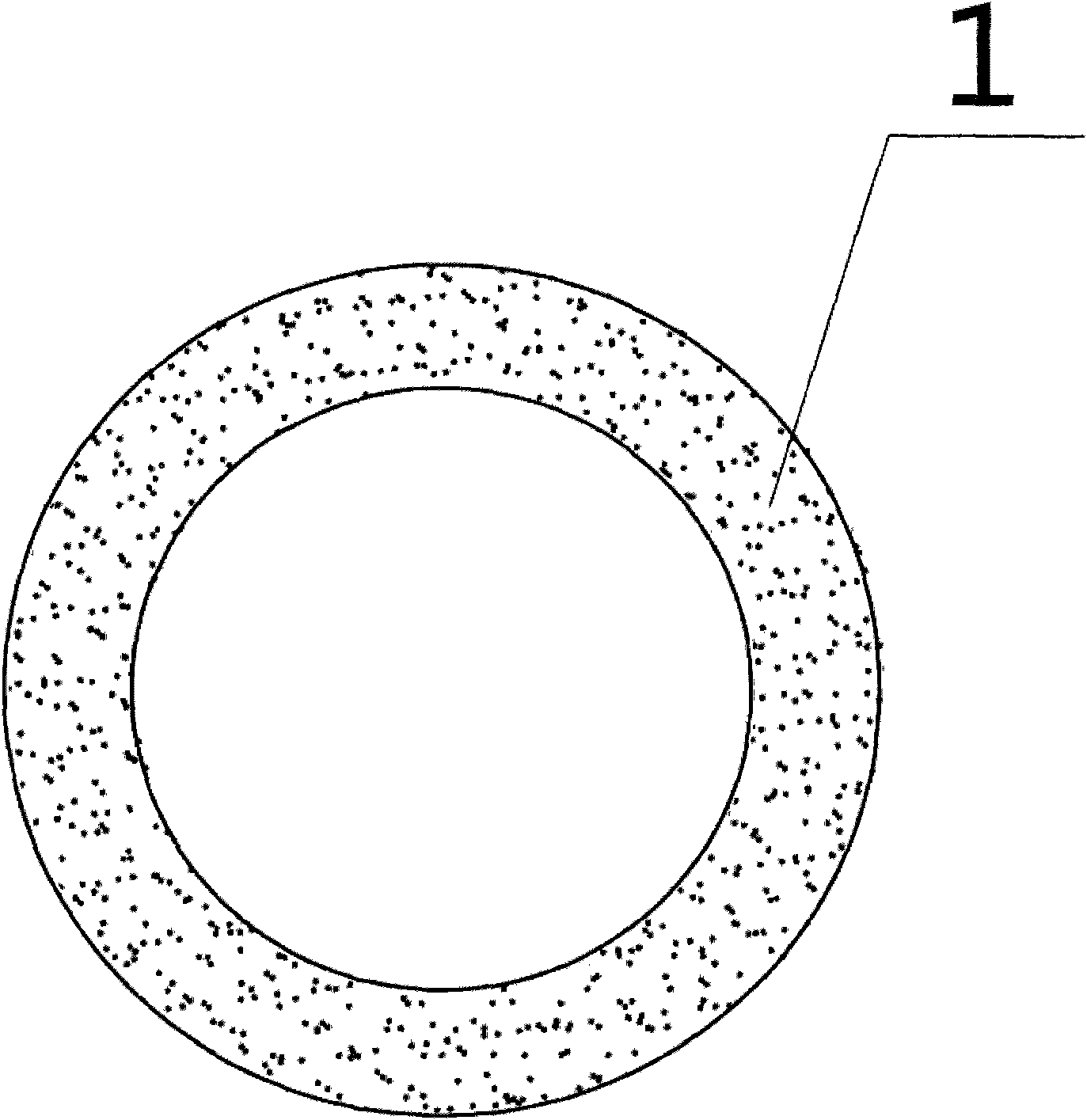

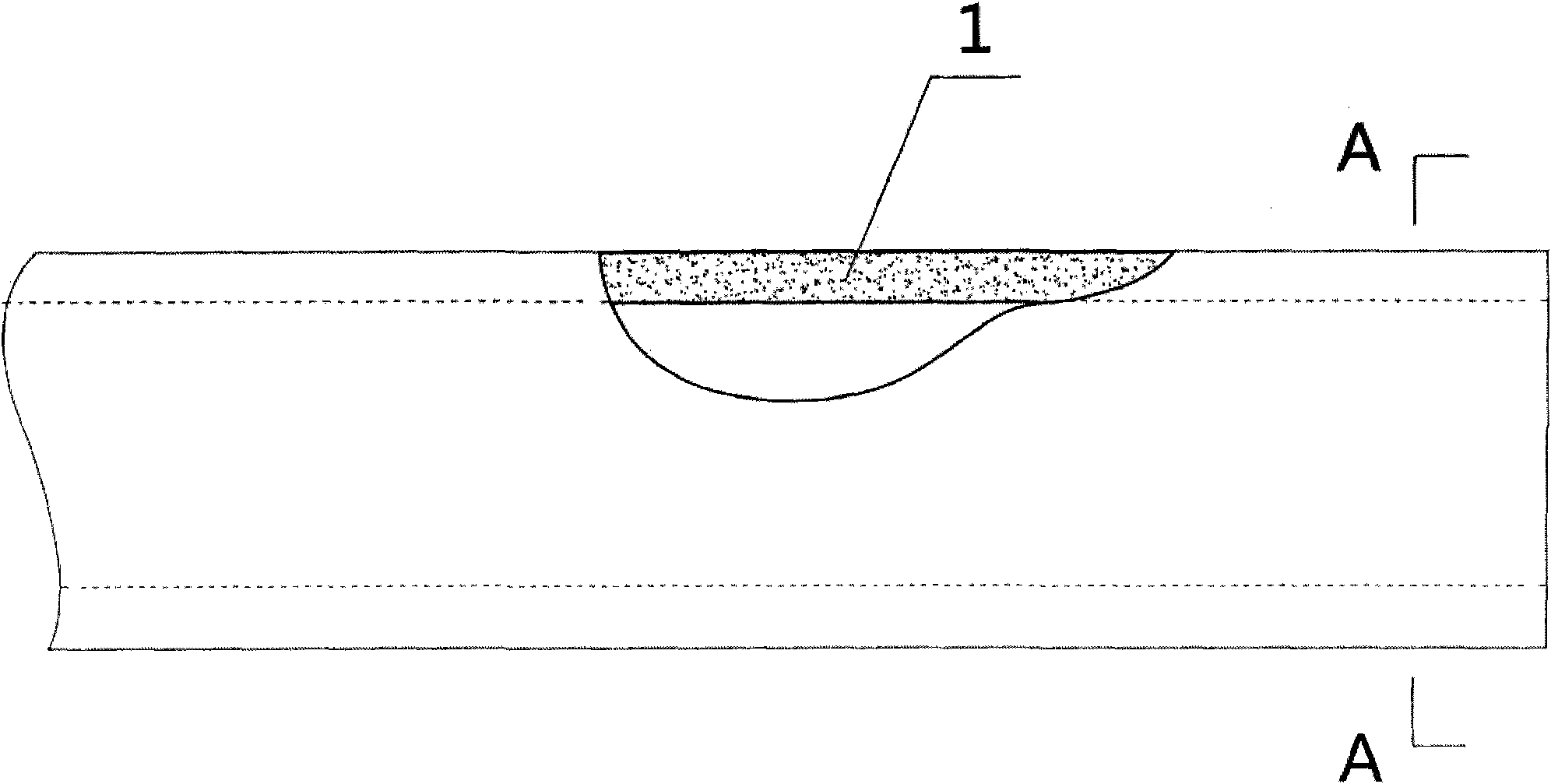

Micro infiltrating irrigation pipeline and preparation method thereof

ActiveCN102500478AAggregate structureWill not damage the aggregate structureClimate change adaptationWatering devicesEconomic benefitsEngineering

The invention relates to a micro infiltrating irrigation pipeline for water-saving irrigation, which is in a pipe-shaped structure, and is characterized in that a pipe body is made of waste tyres and polyethylene in high-temperature injection molding, a large quantity of capillary micropores in different shapes and uncertain directions are distributed in a pipe wall, and water is uniformly permeated from inside to outside. Compared with the irrigation pipeline, the micro infiltrating irrigation pipeline has the advantages of good quality, saving, economic property, production increase, income increase being over 50%, and remarkable economic benefit. By using the product of the invention, the fertilizer-free planting can be realized under a certain environment, water can be saved over 90% compared with spray irrigation, the irrigation efficiency is high, the growth of crops can be prompted, the soil agglomerate phenomenon can be reduced, and the soil improvement is facilitated.

Owner:项锋

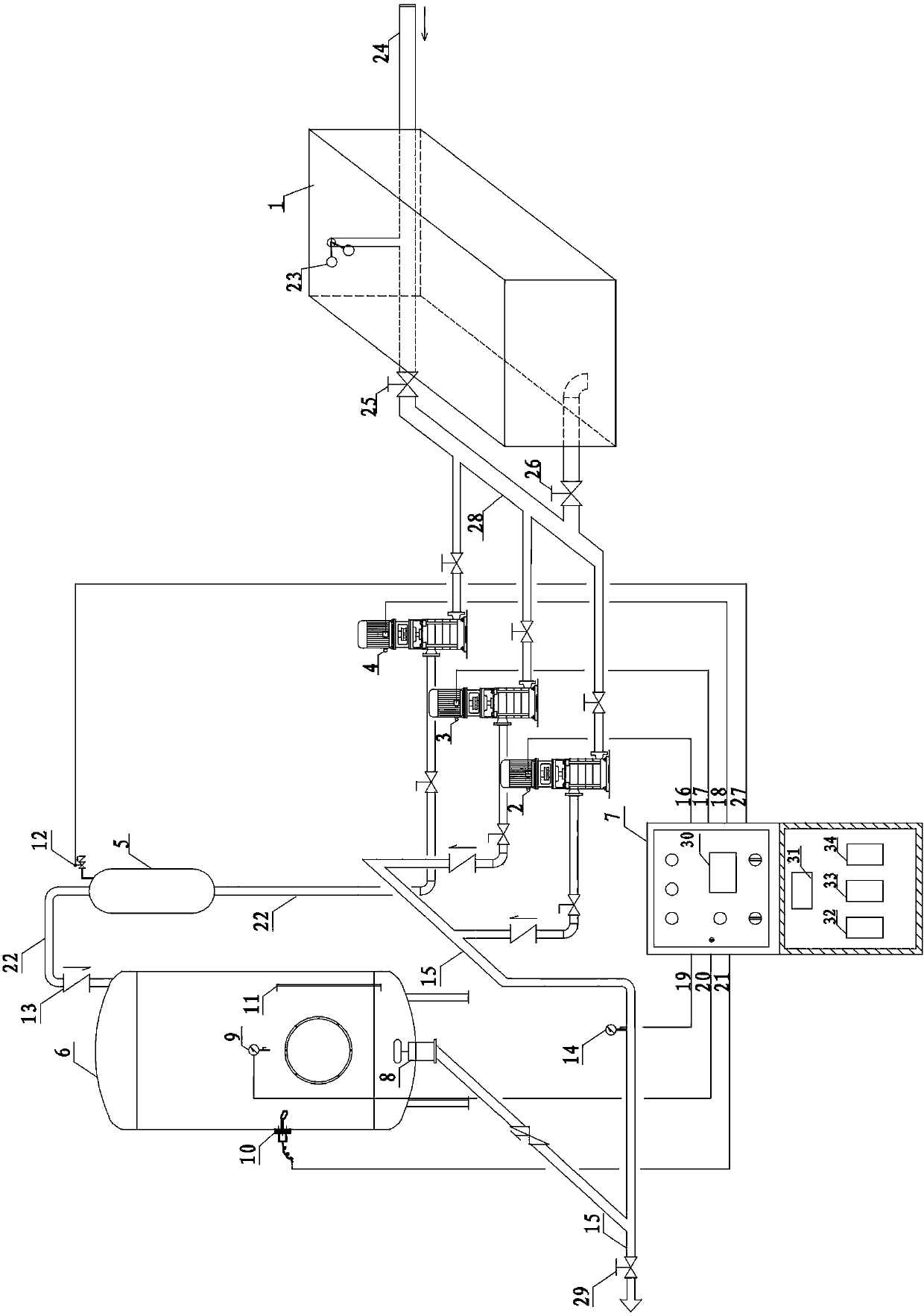

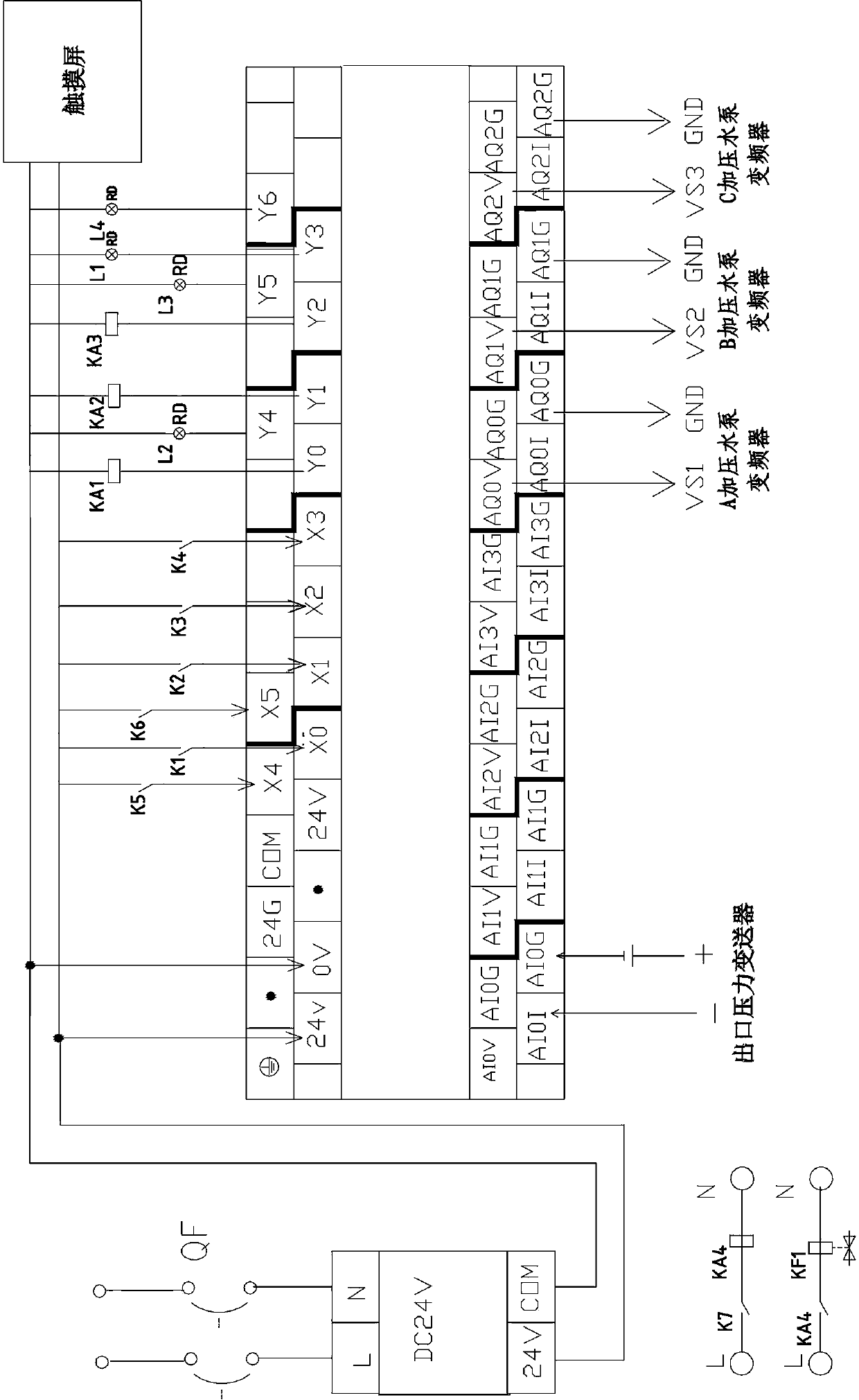

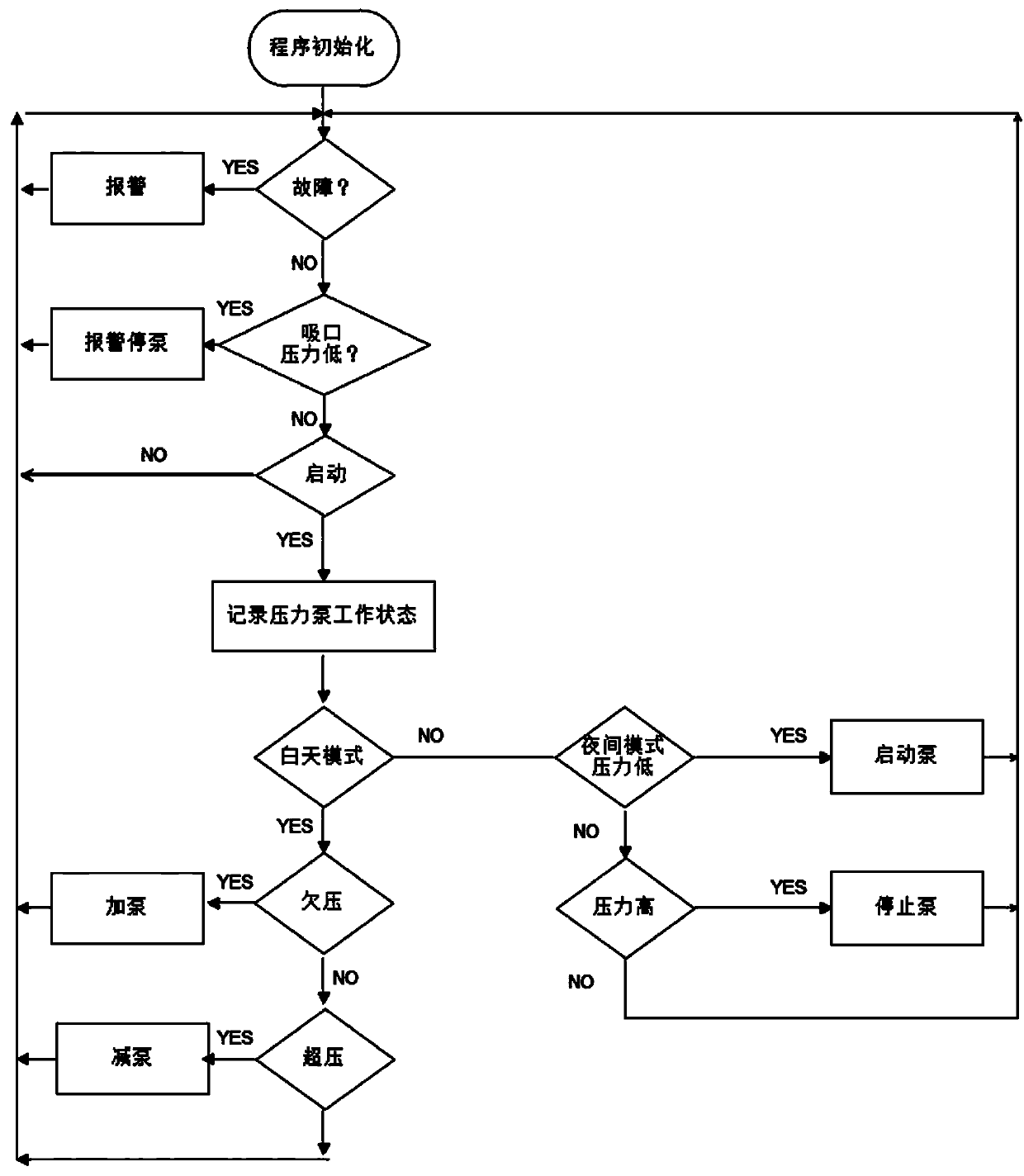

Device for utilizing PLC to intelligently control plurality of frequency converters to perform pressure regulating water supply

ActiveCN104005454AAvoid burnsAvoid secondary pollutionService pipe systemsWater mainsFrequency changerConverters

Provided is a device for utilizing a PLC to intelligently control a plurality of frequency converters to perform pressure regulating water supply. A traditional microcomputer water supply control mode is broken through, each pressurized water pump is controlled through one independent frequency converter to run, the damage to the whole device caused by the frequency converter damage is effectively avoided, and burnout of the frequency converters caused by reverse power transmission caused by suction adhesion of a contactor is also avoided. An air pressure water tank is arranged, the air pressure ratio in the water tank is controlled strictly, gas is supplemented when lacked, the regulating water quantity is increased, running time and starting times of the water pumps are shortened when the water utilization quantity is small, and the effects of energy saving and power saving are achieved obviously. Noise caused by gas and water pump air blockage caused by the fact that compressed gas in the tank enters a pipe network during the power outage and water supply stopping period of the device can be effectively avoided through the arrangement of air stopping valves in the tank. Reactive loss caused by high floatation of the water utilization quantity and frequent starting of a high-power water pump can be avoided by adopting a plurality of small-power water pumps to replace the high-power water pump. Secondary pollution to living water is avoided due to the arrangement of a buffering tank, the constant air pressure ratio in the air pressure water tank is controlled, and the regulating water quantity in the water tank is guaranteed.

Owner:DANDONG CHUANYU FIRE FIGHTING ENG

Banknote box, automatic teller machine and method for detecting state of banknote box

PendingCN107093262AJudging the actual locationAccurate state judgment resultCoin/currency accepting devicesEngineeringStructural engineering

Owner:SHENZHEN YIHUA COMP +2

Wind turbine with liquid medium distribution system

A wind turbine with a tower, a nacelle, a main shaft, a hub and blades is provided. The wind turbine also includes a liquid medium distribution system for transport of liquid medium in the wind turbine. The liquid medium distribution system has a first distribution sub-system located in the tower, a second distribution sub-system located in the nacelle, a third distribution sub-system located in the hub, a tower-nacelle-interface connecting the first distribution sub-system to the second distribution sub-system, and a nacelle-hub-interface connecting the second distribution sub-system to the third distribution sub-system. Further, a method of transporting liquid medium in a wind turbine is provided.

Owner:SIEMENS AG

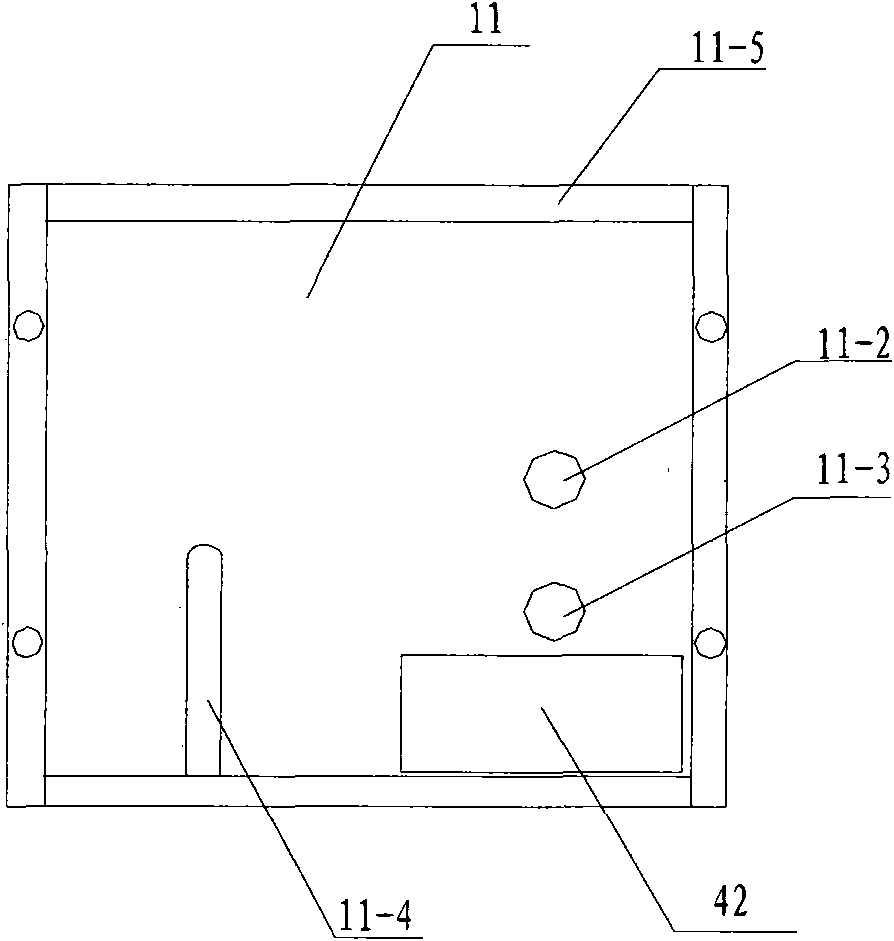

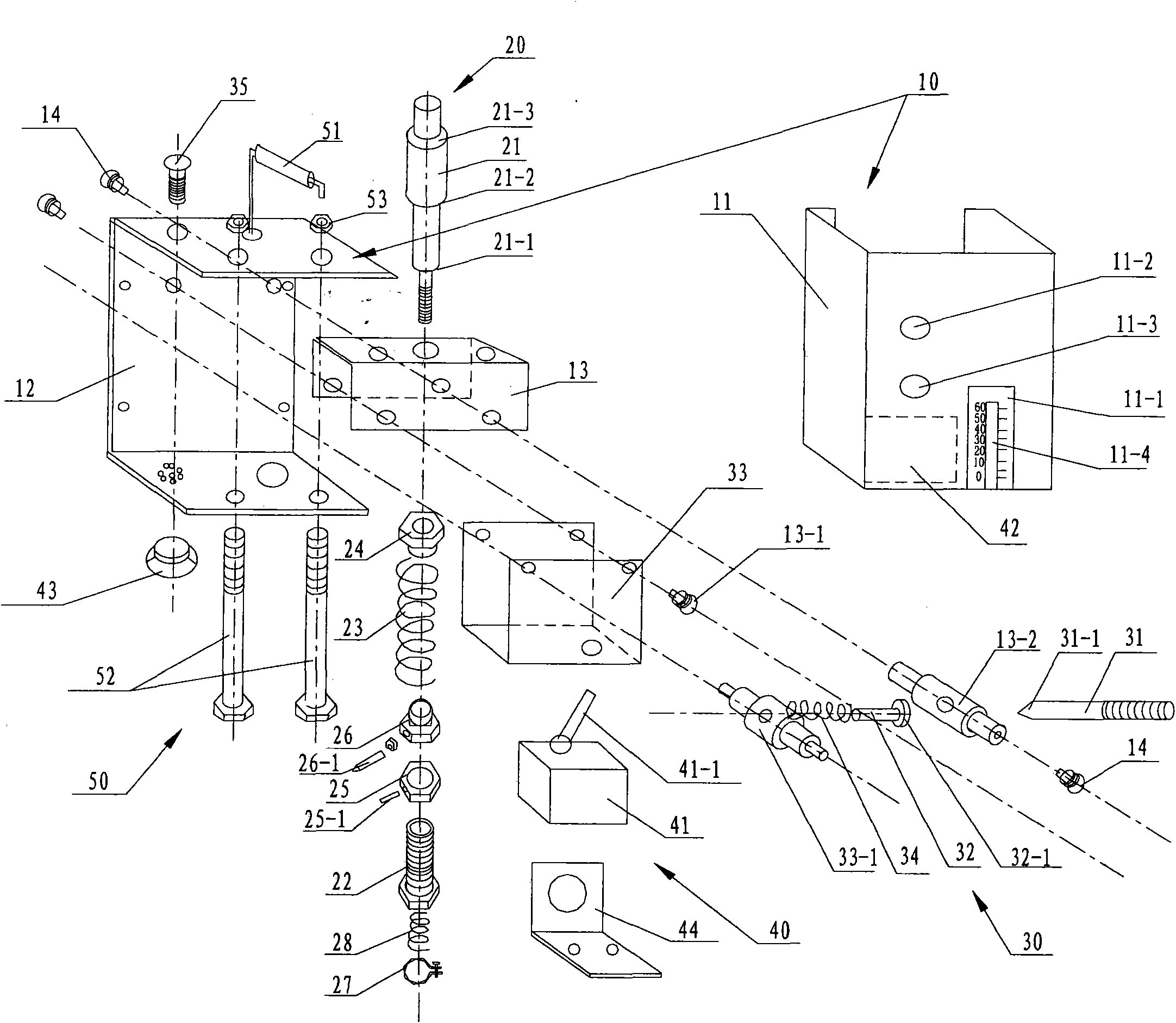

Tensile force alarm device

The invention provides a tensile force alarm device, which can solve the problems of cost increment and easy occurrence of potential safety hazard caused by easy breakage of cables of construction machines existing in the prior art. The tensile force alarm device is arranged on the construction machine, effectively prevents the cables from being broken, reduces cable damage rate and mechanical maintenance rate, and prolongs the service life of the cables. The invention adopts the technical following scheme that: the tensile force alarm device comprises a shell part, a pull rod part, a deflector rod part, an alarm part and a fixing part, wherein the shell part comprises cover plates and a base which are hermetically connected; the pull rod part comprises a pull rod capable of moving up and down according to external tensile force; the deflector rod part comprises a deflector rod, a compression rod and a rotary support, and the deflector rod receives the tensile force of the pull rod to drive the compression rod and the rotary support to swing; the alarm part comprises a toggle switch, an alarm circuit module and a loudspeaker which are electrically connected, and the toggle switch receives motive power of the rotary support to change state; and the fixing part comprises a drag hook and at least one lengthened screw, and the lengthened screw passes through the base.

Owner:许宾

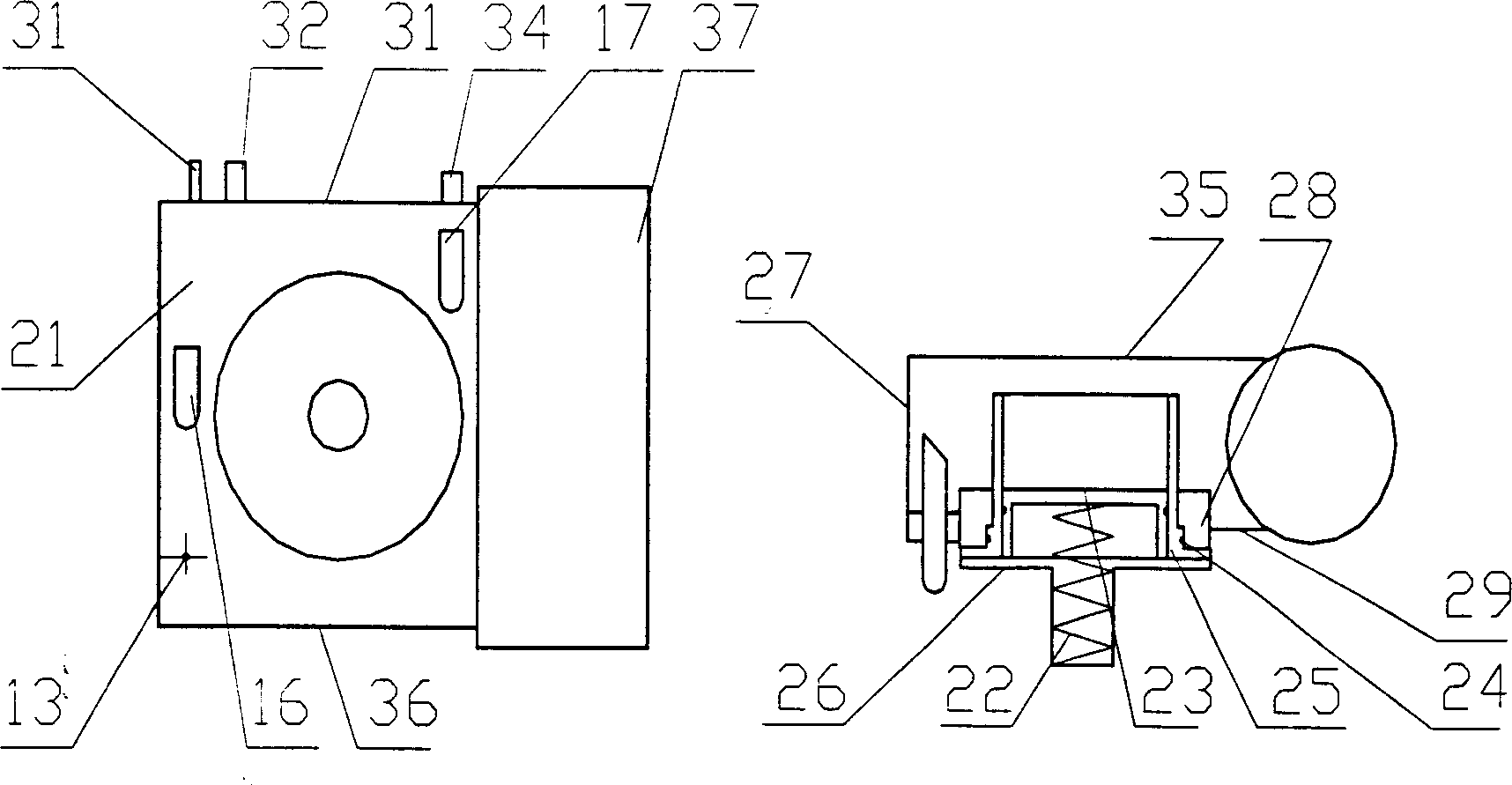

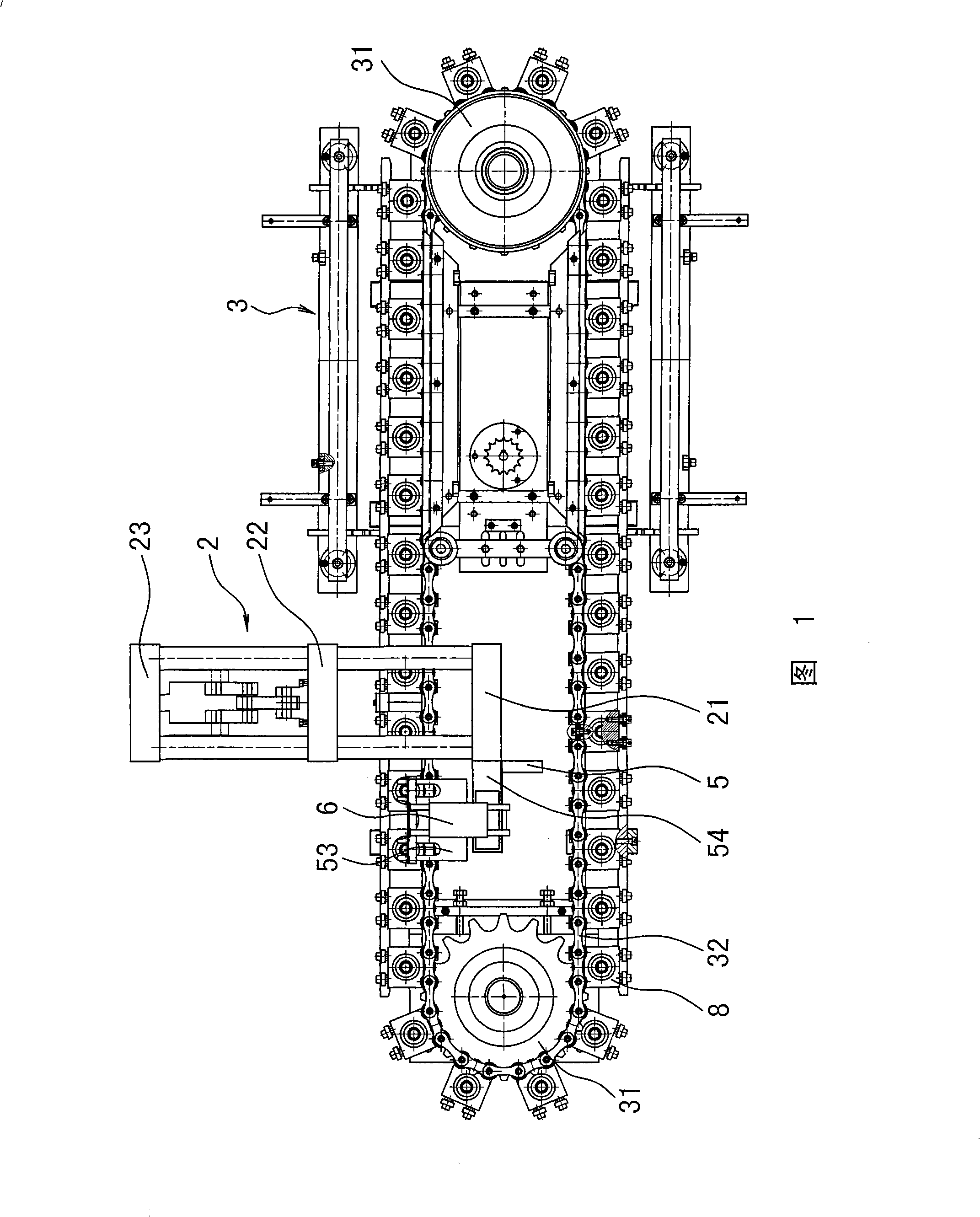

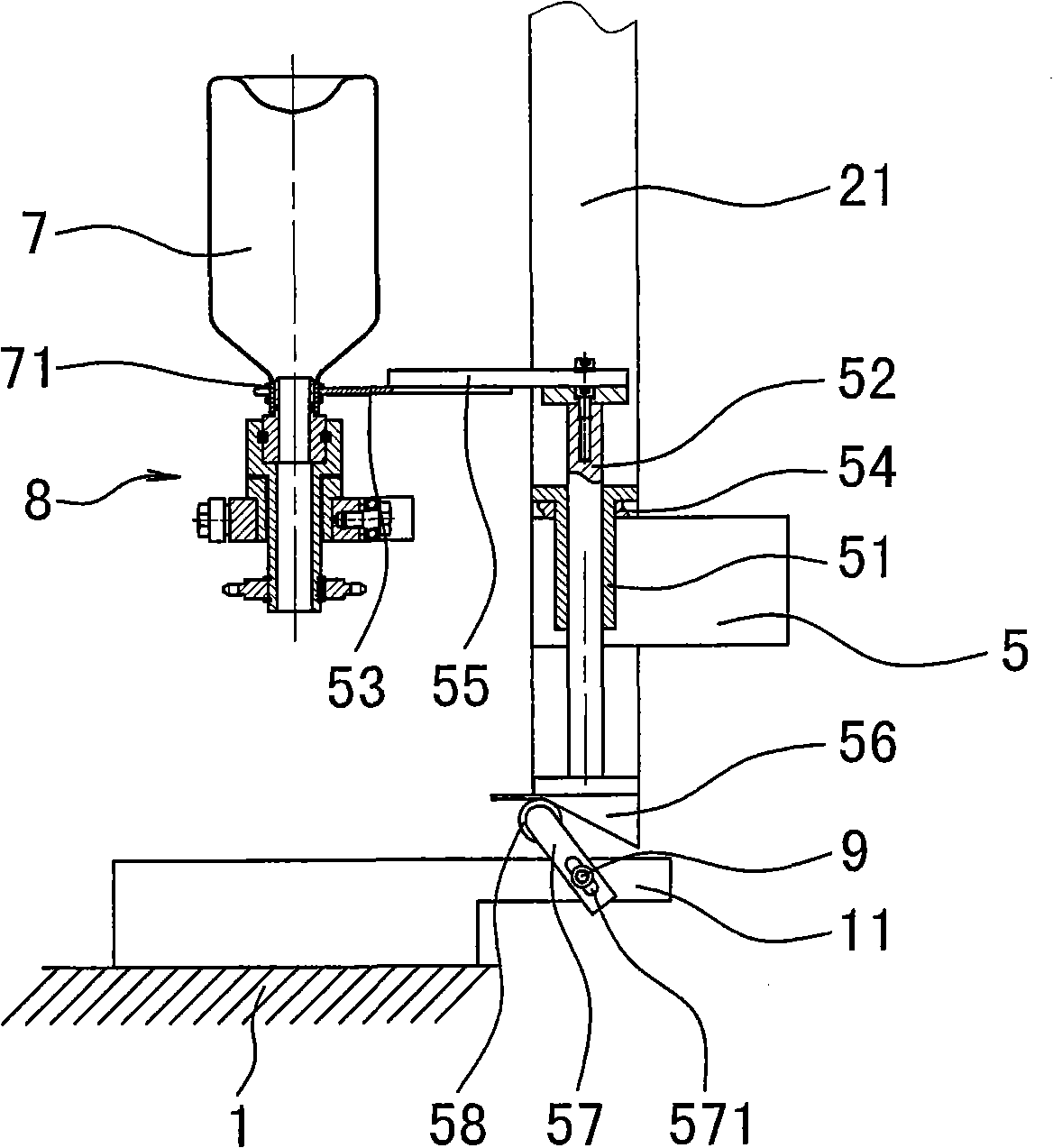

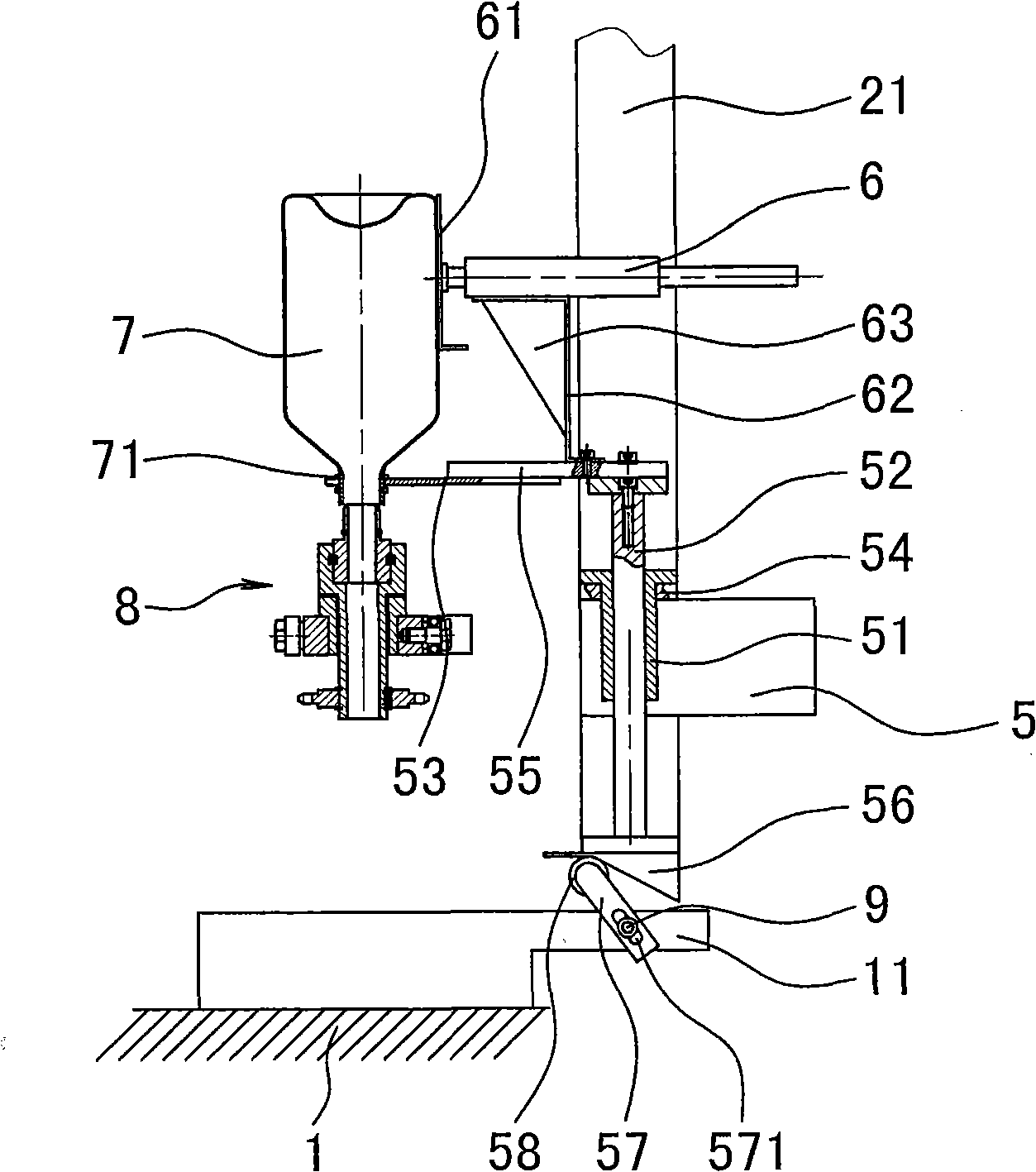

Automatic bottle removing mechanism of plastics hollow container stretching-blowing device

The invention relates to an automatic bottle dropping mechanism of a plastic hollow container blowing and stretching machine, which comprises a machine frame. The machine frame is provided with a blowing and stretching system and a bottle pipe heating system; and the blowing and stretching system comprises a front template, a middle template, a rear template, a mould opening and closing mechanism and a blowing and stretching mechanism, wherein the mould opening and closing mechanism drives the templates to move; and the bottle pipe heating system comprises a transporting mechanism consisting of a chain wheel, a chain and power, and a heating device consisting of a bracket and a lighting tube. The mechanism is characterized in that a fixing plate is arranged on the side of the front template and connected with a supporting plate; a straight line guide rail is arranged in the supporting plate; a guide rod moving up and down is arranged in the straight line guide rail; the lower part of the guide rod contacts a lifting jacking block or a cam on the machine frame; a bottle dropping fork is arranged on the upper part of the guide rod; the opening part of the bottle dropping fork is matched with a convex ring of a plastic container; and a transverse bottle pushing device is arranged on the top of the guide rod. The bottle dropping fork arranged on the guide rod is directly driven by the self opening and closing movement of the front template to realize dropping the bottle without time difference. The mechanism does not need additional power, such as a cylinder and the like and has the advantages of simple structure and cost conservation.

Owner:浙江东方州强塑模实业有限公司

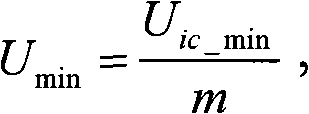

Device and method for intelligently supplying power to node based on wireless sensor network

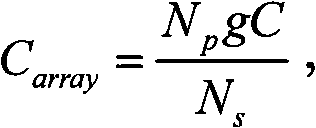

InactiveCN101951033AImprove supply efficiencyEfficient use ofElectrical storage systemEnergy efficient ICTCapacitanceHigh energy

The invention relates to a device and a method for intelligently supplying power to a node based on a wireless sensor network, which belongs to the technical field of low-energy consumption power supply of the node of the wireless sensor network, and aims to solve the problem that the energy supplies and management of the node are inconvenient because the distribution of the node in the field wireless sensor network is wide and the layout environment thereof is complicated. In the technical scheme of the invention, a MCU microprocessor selects the power supply mode of supplying power directly by a solar battery or releasing energy by a super capacitor by collecting external voltages and through internal comparison and judgment so as to intelligently control charging and power supply circuits, and control the node to enter different working modes according to the energy state so as to improve the efficiency of energy utilization. The device and the method of the invention can solve the intrinsic power supply problem of the nodes of the wireless sensor network, and extend the lifecycle of the whole wireless sensor network.

Owner:CHINA AGRI UNIV

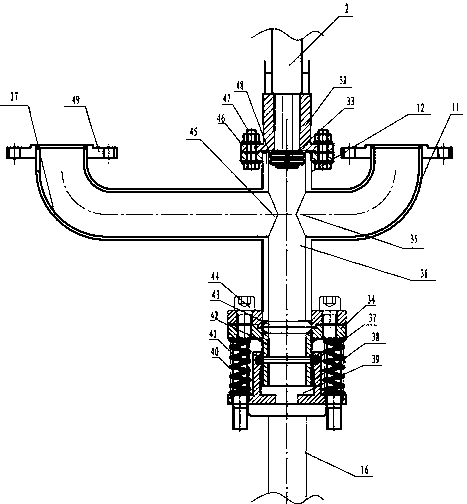

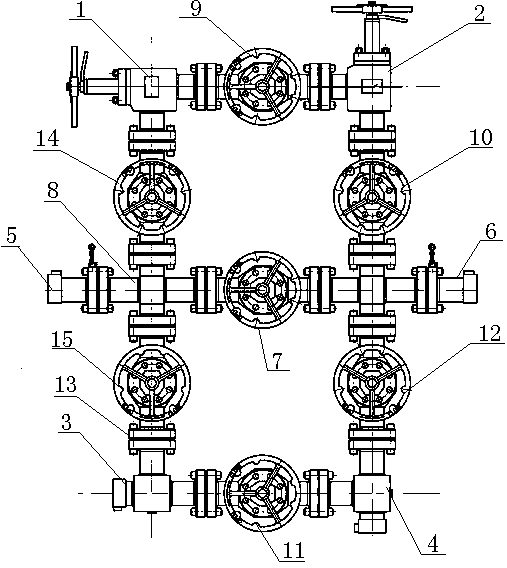

Hierarchical-depressurizing oil nozzle manifold

InactiveCN103758481AReduce maintenance rateExtended service lifeSealing/packingHigh pressurePressure reduction

The invention relates to the field of oil / gas field blowout work depressurizing and provides a hierarchical-depressurizing oil nozzle manifold which comprises a manifold pipeline, a first adjustable oil nozzle connected with the manifold pipeline through a first flat-plate gate valve, a first fixed oil nozzle connected with the manifold pipeline through a second flat-plate gate valve, a second adjustable oil nozzle and a second fixed oil nozzle. The first adjustable oil nozzle and the first fixed oil nozzle are disposed on two sides of the manifold pipeline respectively, and the second adjustable oil nozzle and the second fixed oil nozzle are disposed on the two sides of the manifold pipeline respectively. By the hierarchical-depressurizing oil nozzle manifold, after multistage depressurizing and multiple pressure adjusting of high-pressure fluid during incoming, connection pressure reduction of a pipeline manifold and other parts is prolonged, or part replacement and maintenance probability is reduced, so that production efficiency is improved; due to preferable processing and careful material selection, technical effect of depressurizing of the manifold is better, and the advantages include but are not limited to that service lives of the above parts are prolonged, depressurizing effect is improved, and performance-cost ratio is high.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

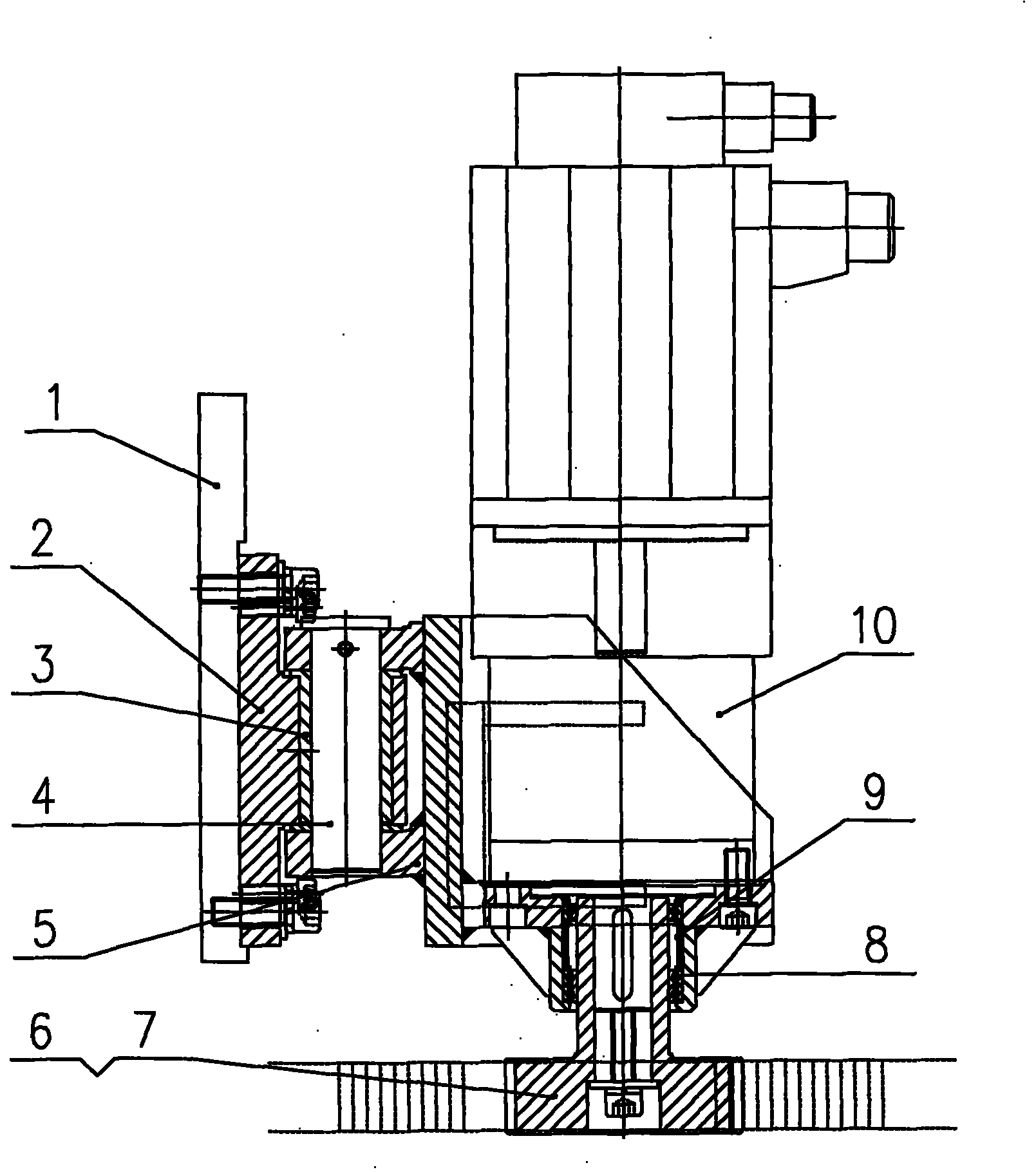

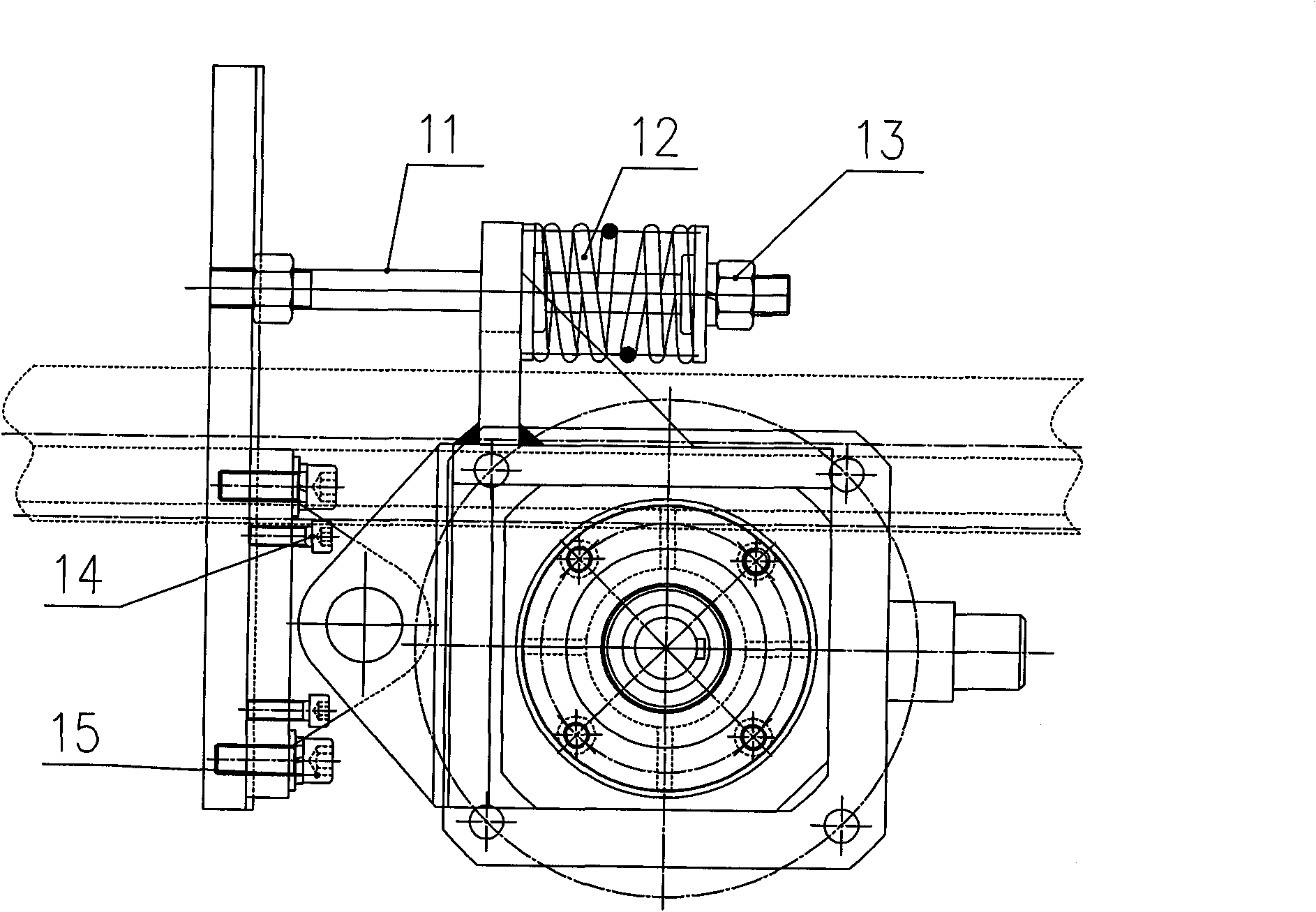

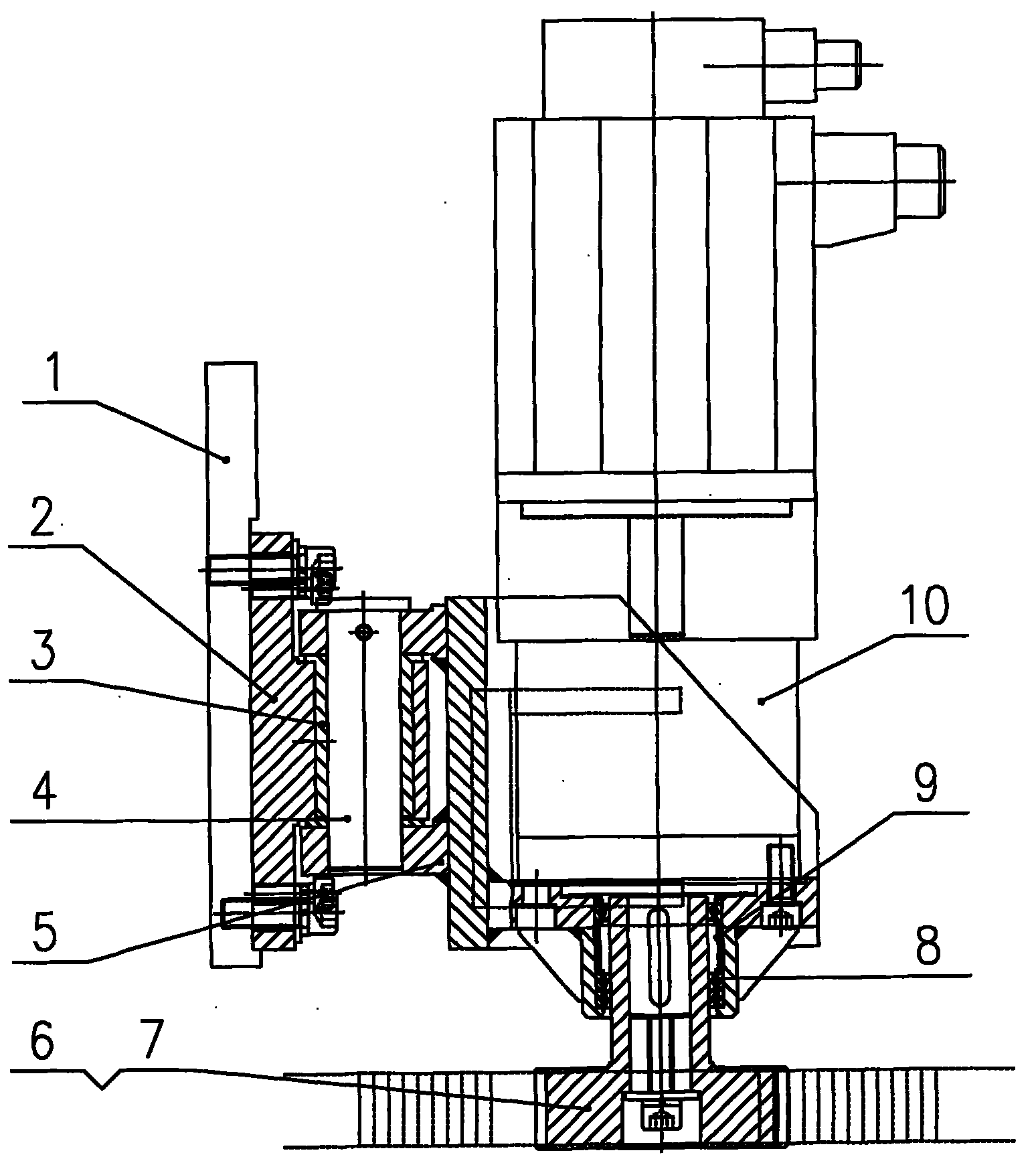

Transmission gap adjusting mechanism of gantry numerical control cutting machine

ActiveCN101920417ASimple structureEasy to adjustWelding/cutting auxillary devicesPortable liftingNumerical controlReduction drive

The invention relates to a transmission gap adjusting mechanism of a gantry numerical control cutting machine, which is mainly as follows: bearings are mounted in a mounting seat, a spacing sleeve is used for positioning between the bearings, the spacing sleeve compresses outer rings of the bearings, a speed reducer is fixed on the mounting seat, a gear is connected with an output shaft of the speed reducer, a fixed seat is arranged in a copper sleeve, the mounting seat is connected with the fixed seat by a rotating shaft, the fixed seat is mounted on a frame by a first bolt and a second bolt, a screw rod is screwed in the frame, a spring is arranged in the screw rod, a nut is screwed in and compresses the gear, and the gear is meshed with a rack. The first bolt is used for regulating the verticality between the gear and the rack. The transmission gap adjusting mechanism of the numerical control cutting machine has simple structure, convenient regulation and large assembly space, and can facilitate the processing of the frame, improve the rigidity of the frame, reduce the phenomenon of fracture of the expensive output shaft of a reduction gearbox, reduce the maintenance ratio of replacing the reduction gearbox, further reduce the manufacturing cost and improve the product quality.

Owner:WUXI HUALIAN SCI & TECH GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com