Lining assembling machine having pressure type total leak-proof fuel cell

A fully-sealed, pressure-type technology, applied in shaft lining, tunnel lining, shaft equipment, etc., can solve problems such as hoses being hung on other components or being pulled off, inconvenient maintenance time, and unsafe operation by workers , to achieve the effect of improving operating conditions and safety, shortening assembly time and reducing maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

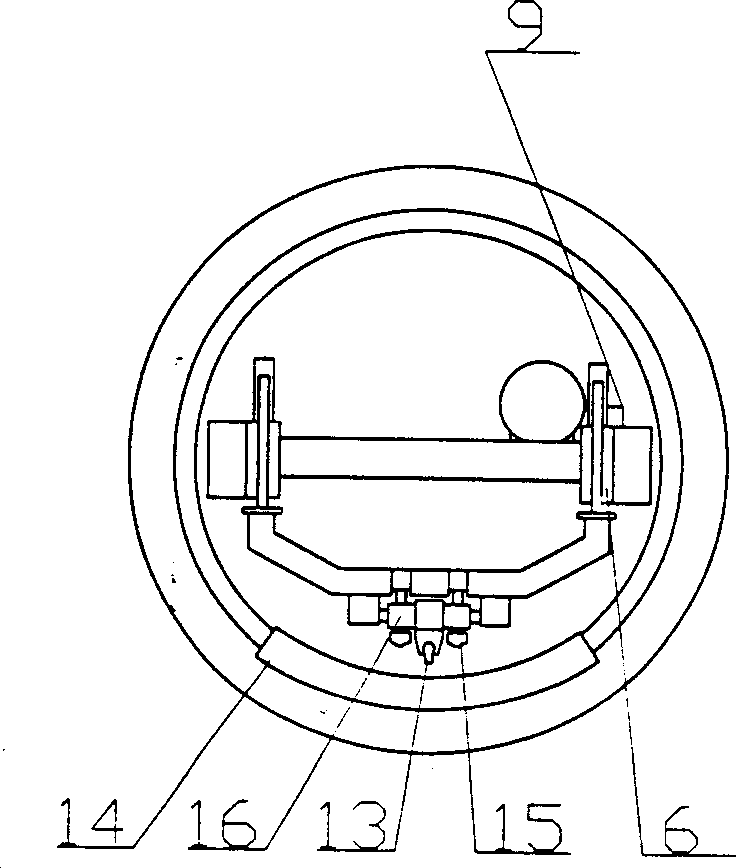

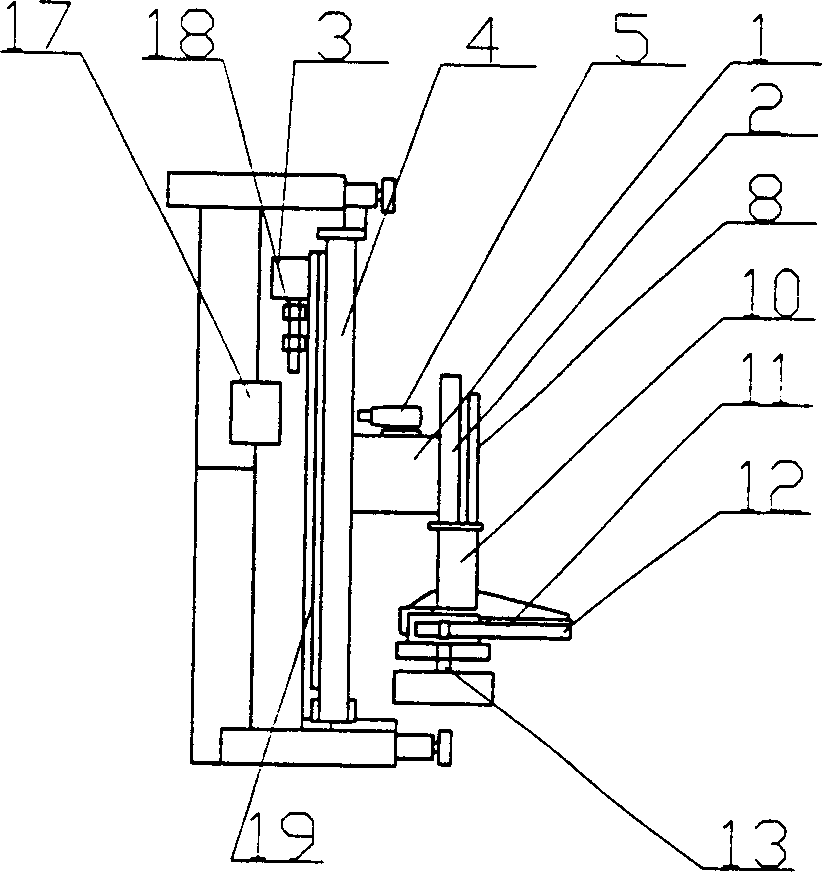

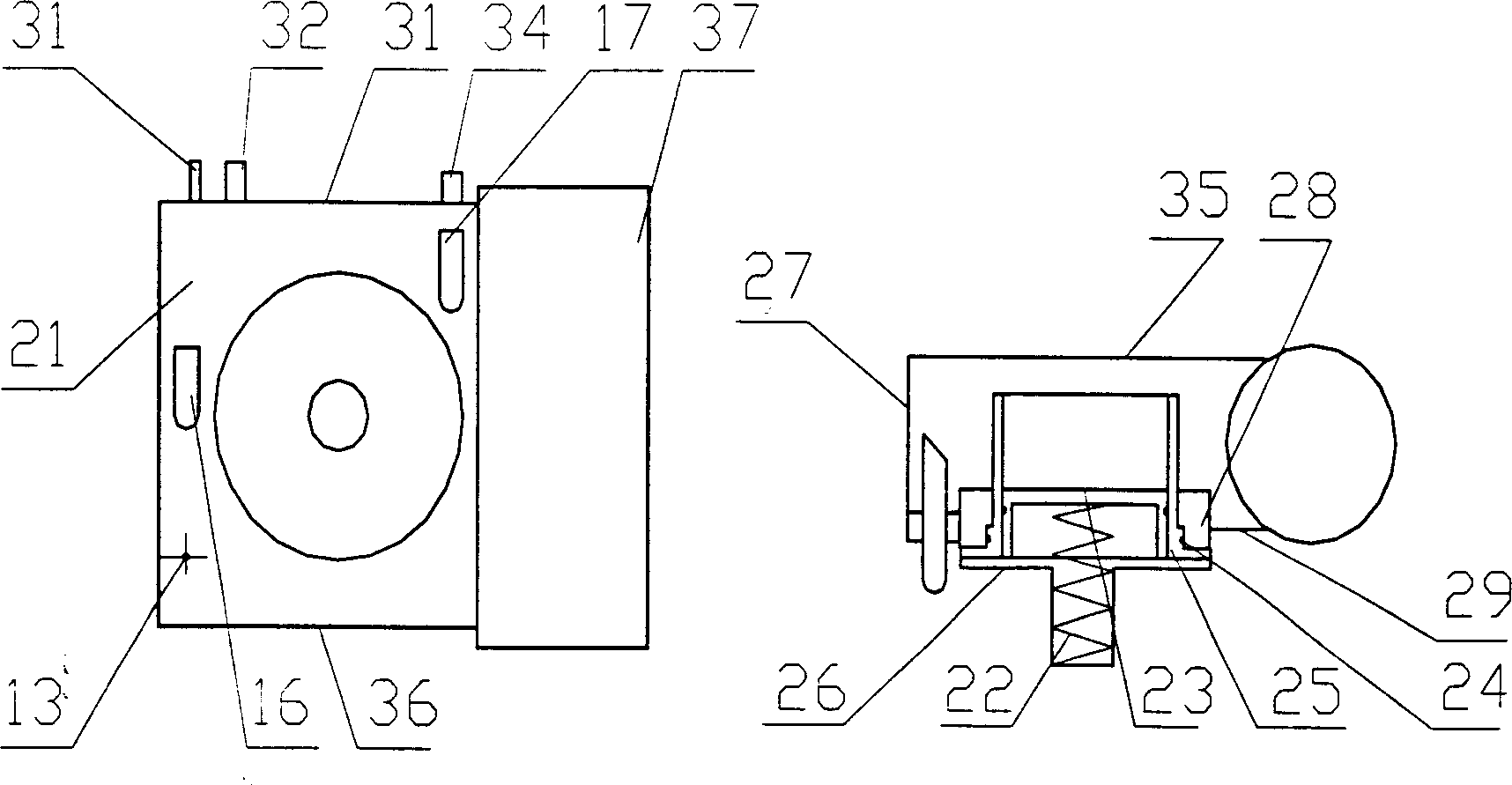

[0017] Such as figure 1 , figure 2 and image 3 , Figure 4 As shown, the present invention includes: the cantilever beam of the fuel tank is the pressure type fully sealed fuel tank 1, the guide cylinder 2, the rotary drive device 3, the disc body 4, the hydraulic pump group 5, the cantilever beam 6, the cable reel 7, the lifting cylinder 8, the electrical Control component 9, lifting beam 10, translation cylinder 11, translation mechanism 12, suspension ring 13, support cylinder 15, segment clamp 16, cable guide frame 18, cable trough frame 19, the connection method is: cantilever beam 6 and fuel tank cantilever beam 1 On the same side of the disc body 4, the disc body 4 is rotated by the rotary drive device 3, the electric control component 9 is arranged on the steel structure top beam of the cantilever beam 6, the hydraulic pump group 5 is arranged on the top of the cantilever beam 1 of the fuel tank, and the cantilever of the fuel tank The inner space of the steel str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com