Low speed heavy pressure vane pump for hydraulic bicycle

A bicycle and vane pump technology, which is applied to vehicle gearboxes, pumps, pump components, etc., can solve problems such as inconvenient operation, strict technical requirements, and power mismatch, and achieve easy installation and disassembly, simple process and materials, and starting performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

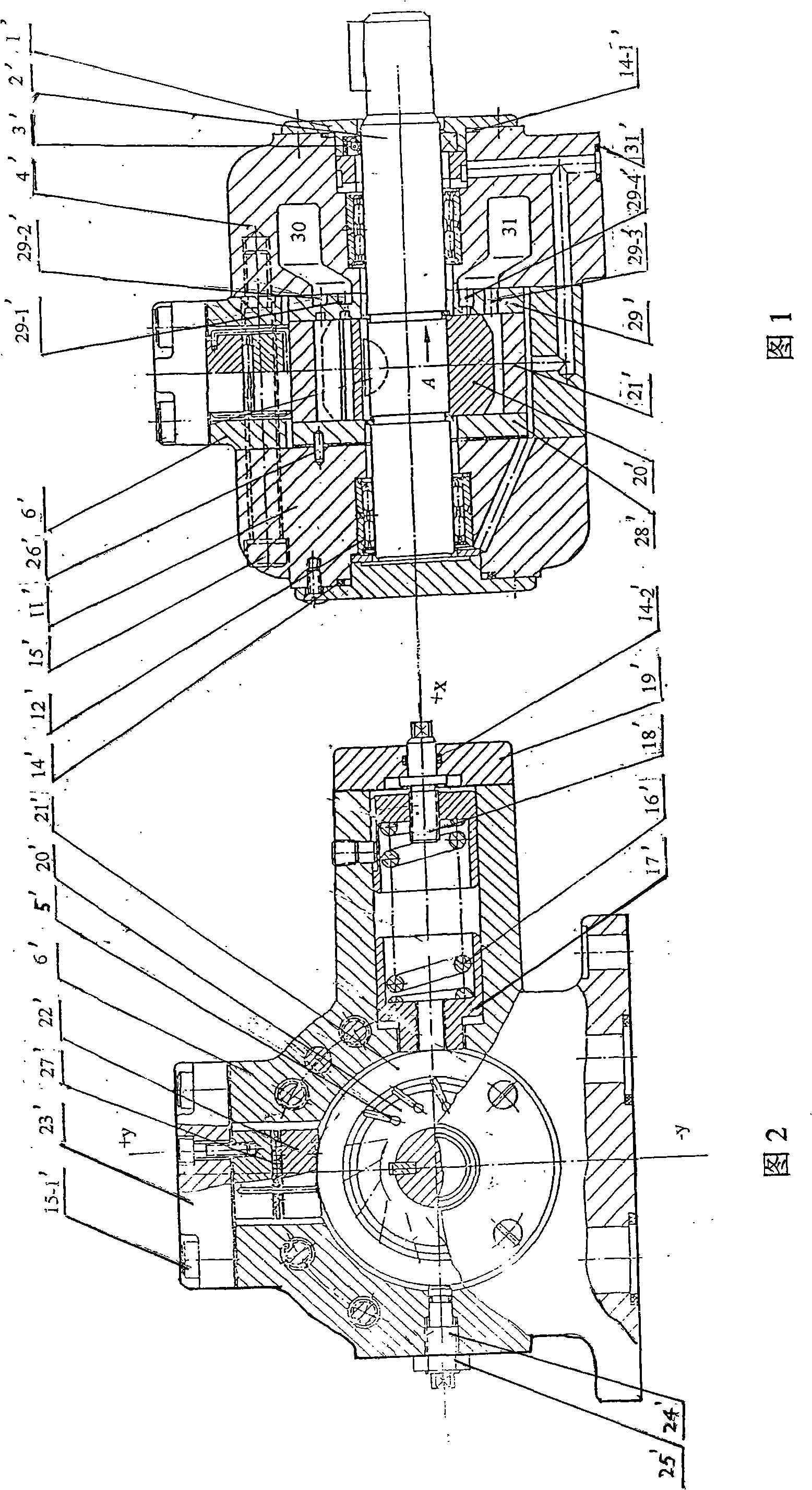

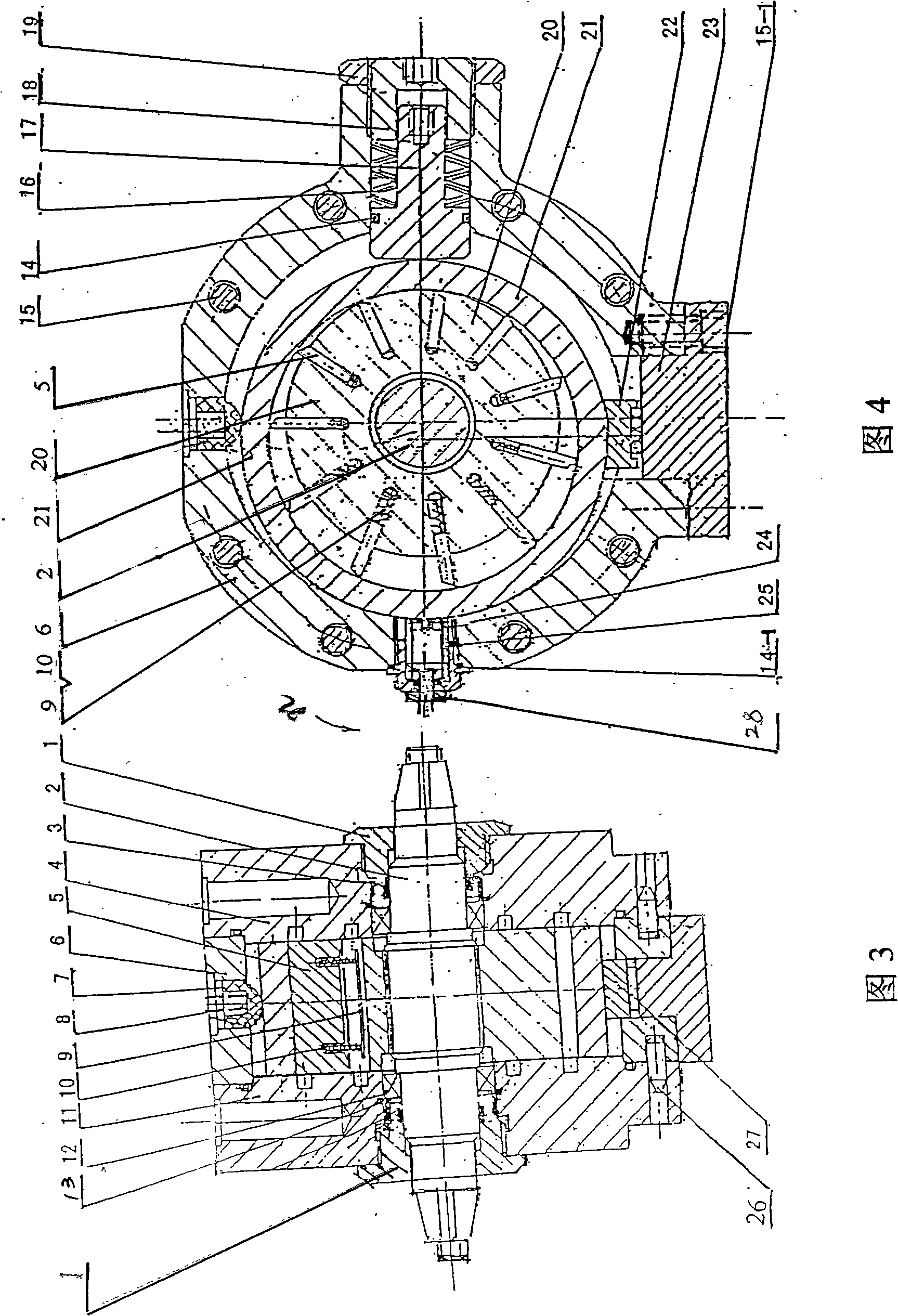

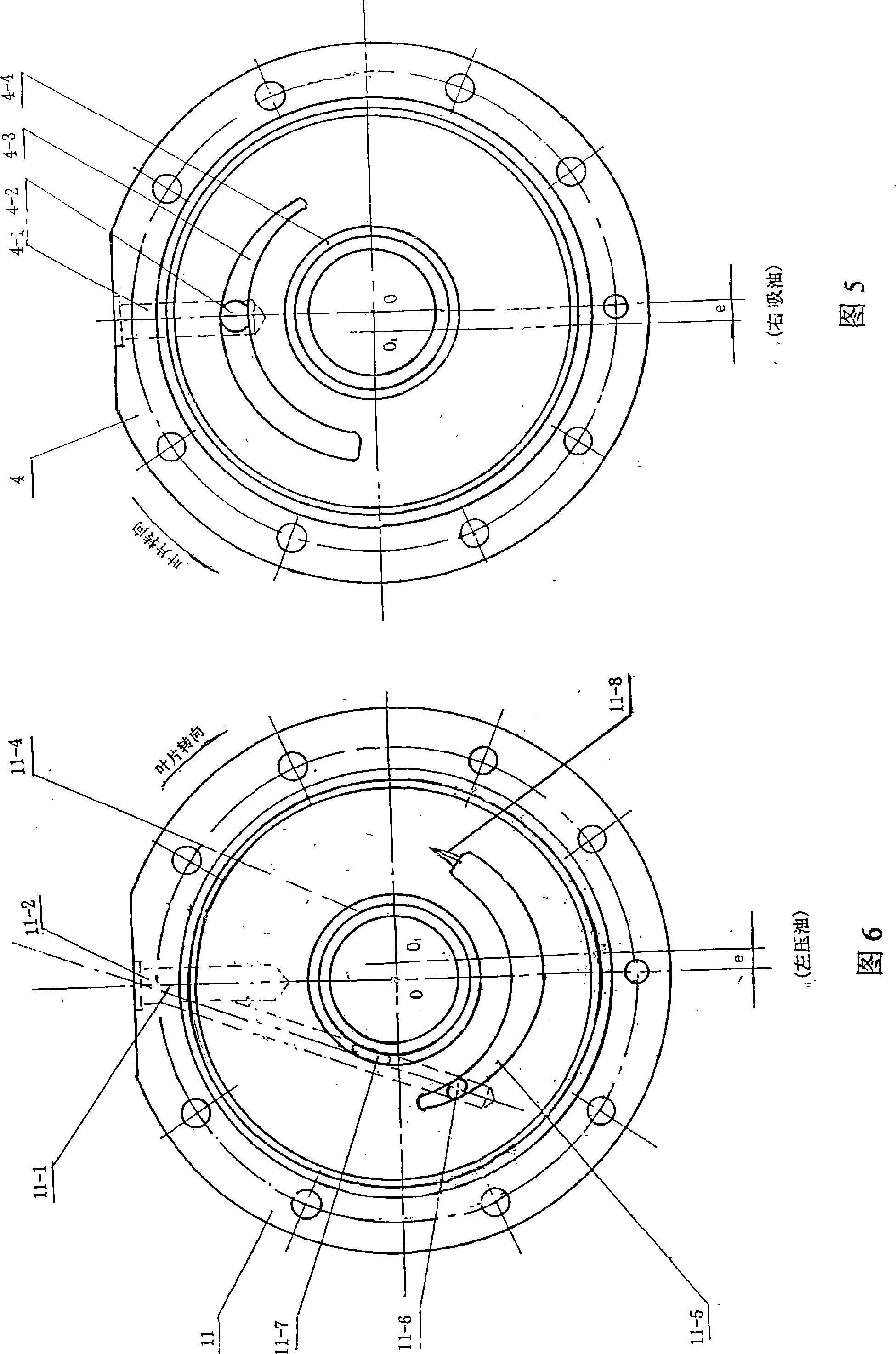

[0044] The present invention will be described in further detail below in conjunction with accompanying drawing (embodiment):

[0045] Referring to Figures 3 to 9, the present invention includes an end cover 1, a main shaft 2, a skeleton seal 3, a right housing 4, blades 5, a middle housing 6, a positioning guide sleeve 7, a positioning spring 8, a blade bracket 9, and a blade spring 10 , left housing 11, bearing 1 2, collar 1 3, "O" type sealing ring 14, 14-1, screw 15, pressure limiting spring 16, spring seat 17, adjusting nut 18, lock nut 19, rotor 20, Stator 21, slider 22, cover plate 23, flow adjustment screw 24, sealing ring 25, positioning pin 26, needle roller 27, lock nut 28, etc. The present invention is a "three-piece" structure, which is composed of three pieces, namely the left casing 11, the right casing 4 and the middle casing 6. The rotor 20, the stator 21, the pressure limiting spring 16, the adjustment nut 18, the lock nut 19, the flow adjustment screw 24, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com