Patents

Literature

73results about How to "Reduce backwash frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

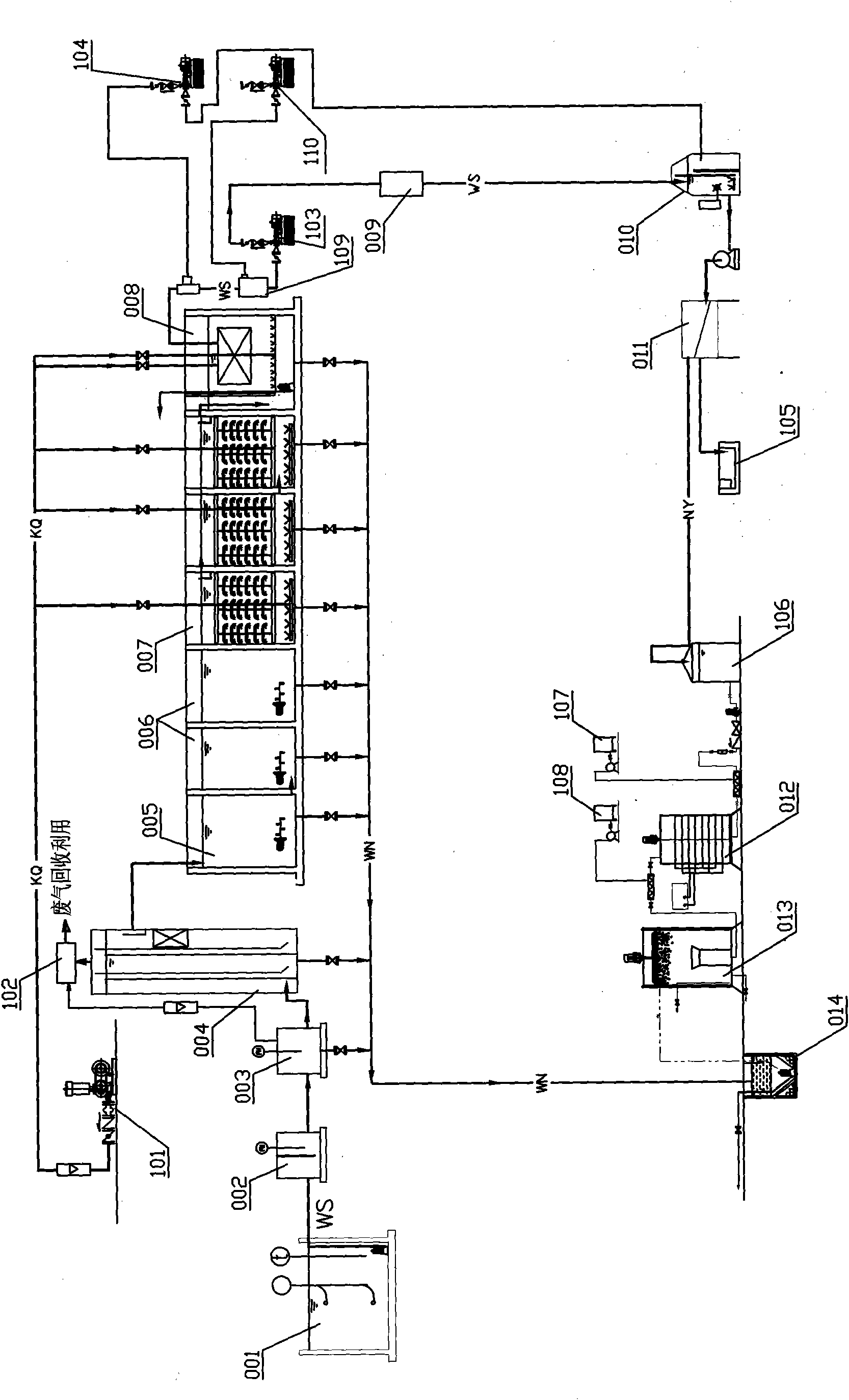

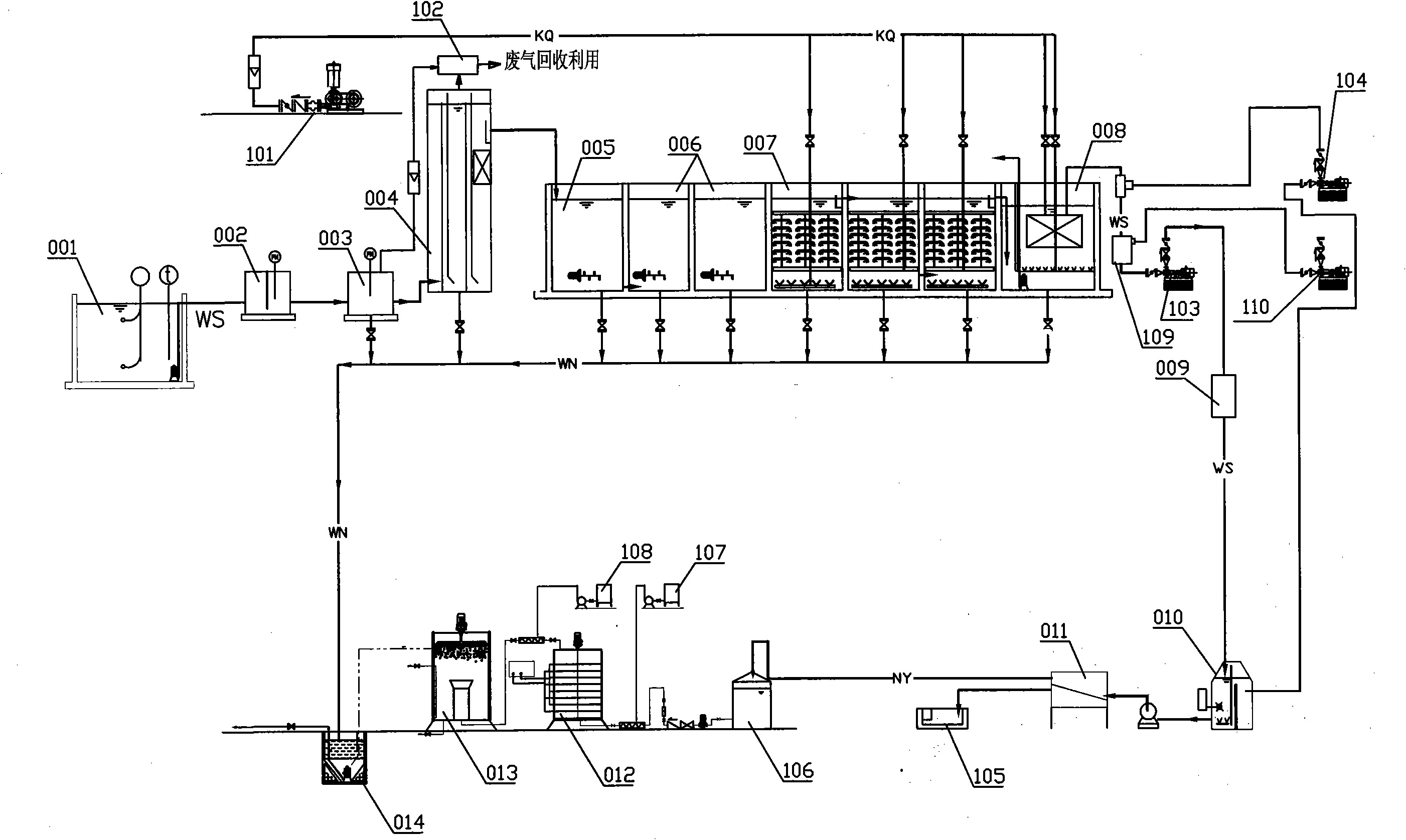

Ultrasonic combined waste water treatment process and system of refuse leachate

InactiveCN102139990ASimple processCompact structureWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentEmission standardCatalytic oxidation

The invention relates to an ultrasonic combined waste water treatment process of refuse leachate, relating to the technical field of waste water treatment and recycling of resources and environmental protection. The ultrasonic combined waste water treatment process of the refuse leachate comprises the following steps of: enabling waste water to enter a regulating pond; treating colloids, amphoteric substances and heavy metals in a coagulation sedimentation pond; eliminating ammonia nitrogen in an ultrasonic catalytic oxidation pond; sequentially sedimentating through biological treatment in an ABR (Acrylate Butadience Rubber) baffle plate anaerobic pond, a hydrolytic pond, a facultative pond and an aerobic pond; filtering in a CMBR (Chatter Membrane Bioreactor); eliminating waste gases and stench in a carbon filter pond; disinfecting in a contact disinfection pond; and filtering in an RO (Reverse Osmosis) membrane reverse osmosis system so as to obtain water meeting the requirements for emission standards. The invention also provides a treatment system for the ultrasonic combined waste water treatment process. The ultrasonic combined waste water treatment process and system can obtain the outflow water with stable quality by treating the refuse leachate; the treatment system has the advantages of small size and occupying area, high efficiency, low energy consumption and easy realization for mechanical-electrical integration control and management; and in addition, the invention is beneficial to the protection of the original landscapes of a construction party by adopting a non-buried type structure and also reduces the influence of the operation of the treatment system on an office area.

Owner:深圳市万山红环保实业有限公司

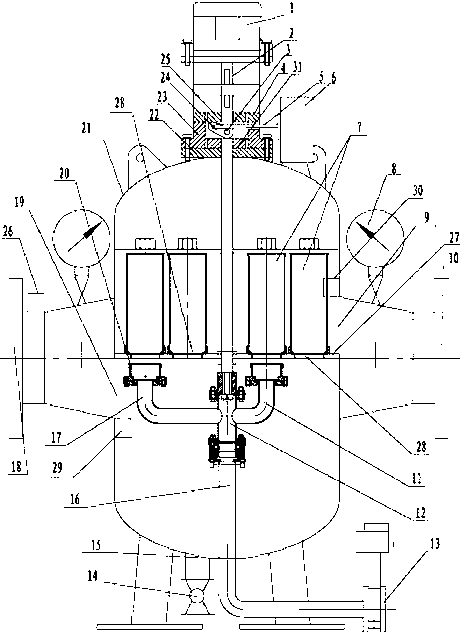

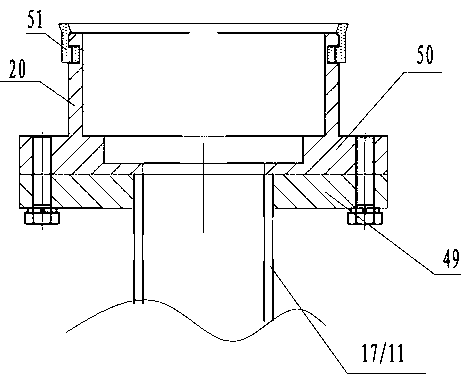

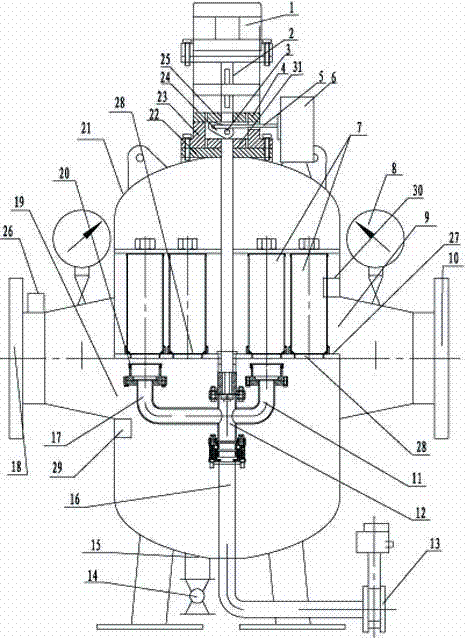

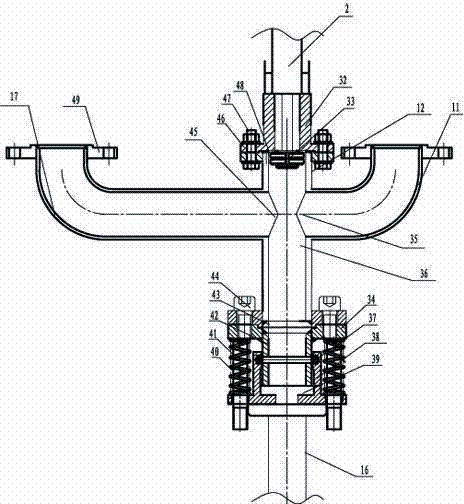

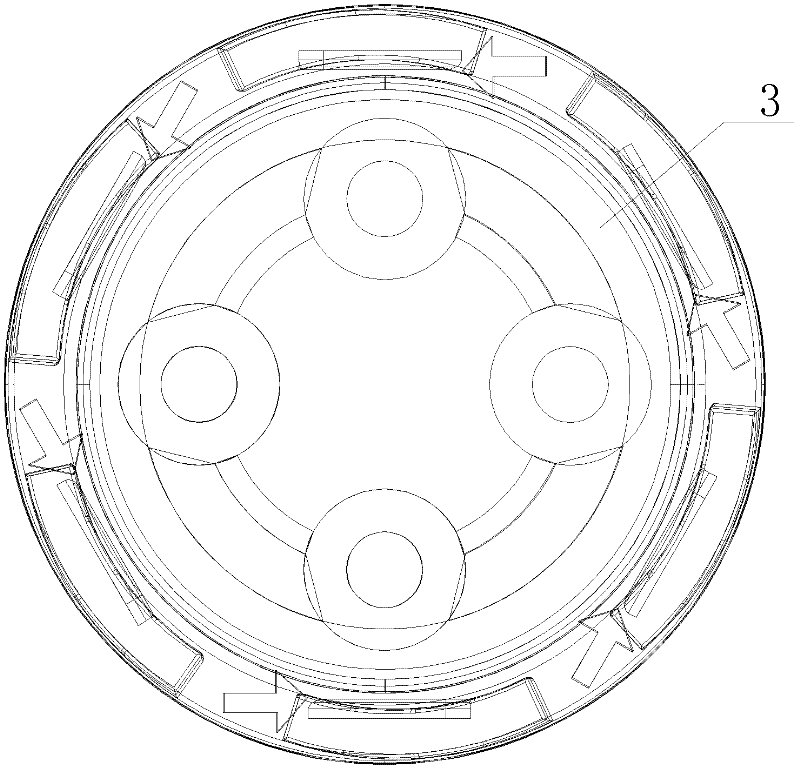

Multi-filter cylinder automatic backwashing filter apparatus

InactiveCN102794044AReduce backwash frequencyMaximum backwash frequencyStationary filtering element filtersElectric machineControl system

The invention discloses a multi-filter cylinder automatic backwashing filter apparatus. A housing is divided into an upper chamber and a lower chamber by a separation plate. The separation plate is provided with filter cylinders in the manner of one, two, or multiple concentric circles. The sidewall of the housing under the separation plate is provided with a sewage inlet, and the sidewall of the housing above the separation plate is provided with a pure water outlet. A motor of a backwashing mechanism drives a main shaft to rotate. A lifting mechanism drives the main shaft to go up and down. A multi-way connection seat connects the main shaft, rotating arms and a waste pipe together. The main shaft drives the rotating arms to lift and rotate. The waste pipe is fixed. Suction nozzles fixed on the upper end port of the rotating arms can be in sealed connection with water inlets on the separation plate. The end part of the waste pipe is connected with an electric drain valve or a pneumatic drain valve. A control system controls the actions of the motor, the lifting mechanism and the electric drain valve or the pneumatic drain valve. The filter apparatus has the advantages of small size, large amount of water filtration, high production efficiency, good filtration effect of filtered water, good backwashing effect, low frequency of backwashing, long-life apparatus, low maintenance rate, and saving backwash water.

Owner:HEBEI AGRICULTURAL UNIV. +1

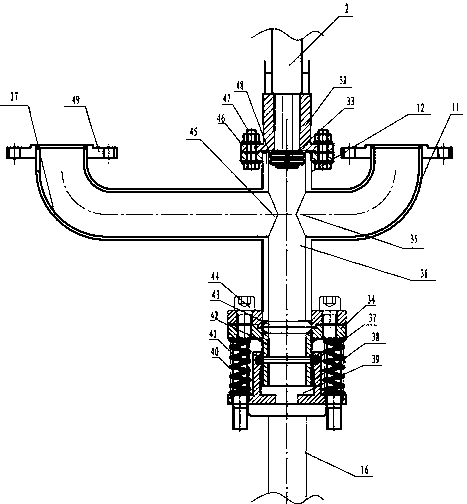

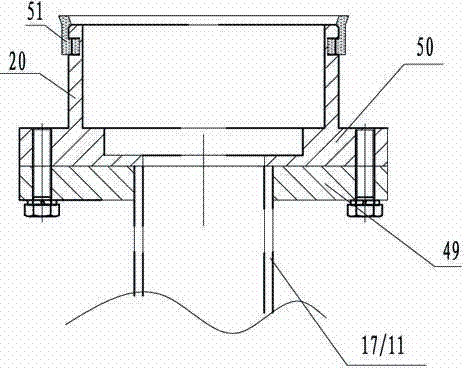

Automatic backwashing system in filtering device with multi filter drums

InactiveCN102784504AImprove filtration efficiencyClean thoroughlyMembrane filtersStationary filtering element filtersMotor driveControl system

The invention discloses an automatic backwashing system in a filtering device with multi filter drums. The automatic backwashing system is characterized in that: a motor drives a main shaft to rotate; a lifting system drives a rotating shaft to ascend and descend; a multi-way connecting base connects the main shaft, a rotary arm and a drainage pipe together; the main shaft drives the rotary arm to ascend and descend and rotate; the drainage pipe stays still; a suction nozzle, which can be connected with a water inlet on a separating plate in a sealing way, is fixed at an upper port of the rotary arm; an end of the drainage pipe is connected with an electric drainage valve or a pneumatic drainage valve; and a control system controls action of the motor, the lifting mechanism and the electric drainage valve or the pneumatic drainage valve. By using the filtering device disclosed by the invention, when one filter drum backwashes, other filter drums keep on filtering, therefore, water yield is not influenced at all; since backwashing water flow is high in magnitude, filter screens of the filter drums can be washed more cleanly and more thoroughly, therefore, the backwashing effect is good, the backwashing frequency is low, and the backwashing water can be saved; during rotation of the automatic backwashing system, the suction nozzle and the separating plate are separated, thus relative friction between the suction nozzle and the separating plate can be avoided, and the service life of the suction nozzle can be prolonged; and in addition, all components are connected mutually with high reliability and good sealing performance.

Owner:河北北洋水处理设备有限公司 +1

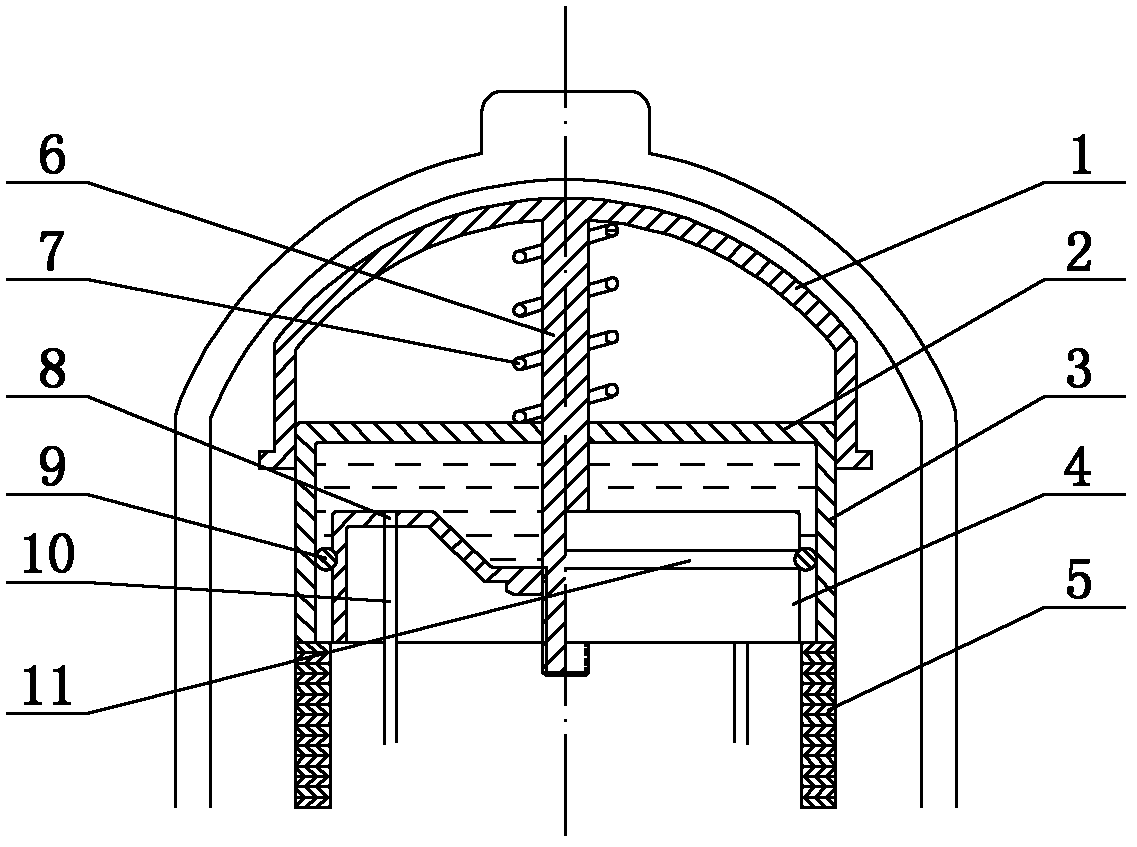

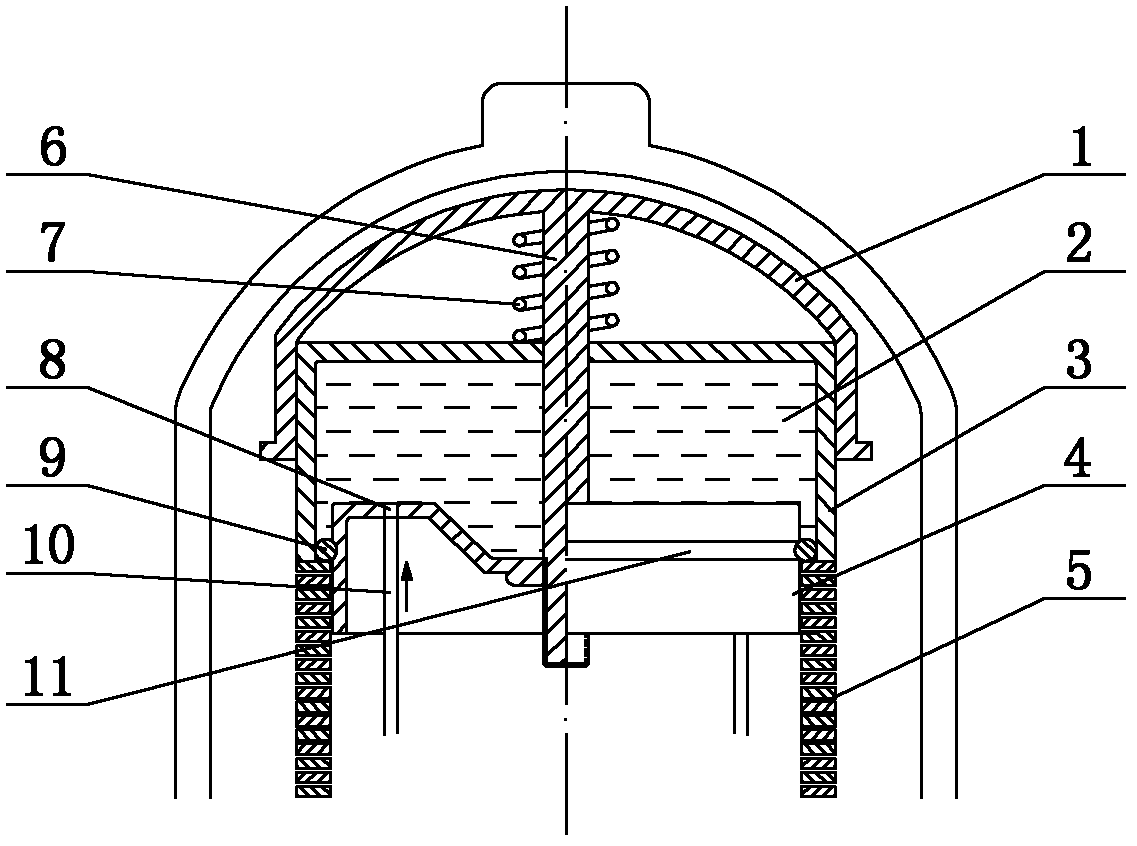

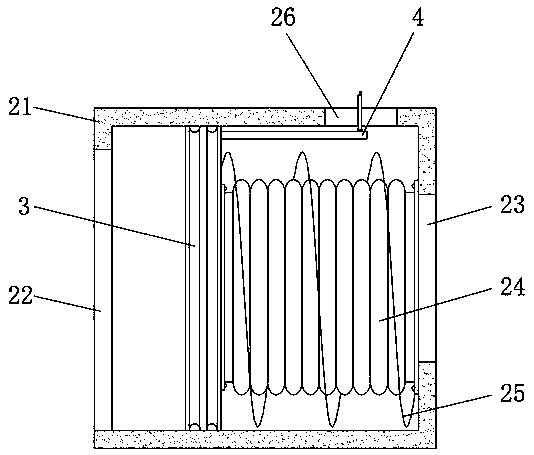

Laminated filter unit

InactiveCN102430281AGuaranteed filtration accuracyGuaranteed Filtration QualityFiltration circuitsStationary filtering element filtersWater flowEngineering

The invention relates to a laminated filter unit, which belongs to a component of a laminated filter. The filter unit comprises a shell, wherein the shell is provided with an inlet and an outlet; a piston, a piston sleeve and a piston seat are arranged in the shell; the side wall of the piston sleeve is arranged on a lamination assembly; the lower part of the lamination assembly is provided with centrifugal flow guide blades; and a check valve is arranged between the centrifugal flow guide blades and the outlet. Impurities in liquid get away from the lamination assembly and move upwards by centrifugal force produced by the liquid rotating at a high speed and are finally centralized at the top end of the laminated filter unit, so that the back wash frequency of a product is greatly reduced. In a back wash state, after a high-pressure clean water flow is gathered to a flow guide pipe in a reverse direction, the water flow enters a piston chamber through a piston hole at the top end of the flow guide pipe, and the piston sleeve overcomes outward movement of the spring pressure on the top so as to release the pressure applied to the lamination assembly; and by now, the lamination assembly is loose, and the cleaning water flow can extremely easily pass through each lamination to clean impurities inside and outside a laminated filter tank.

Owner:乌鲁木齐瑞拓环保设备制造有限公司

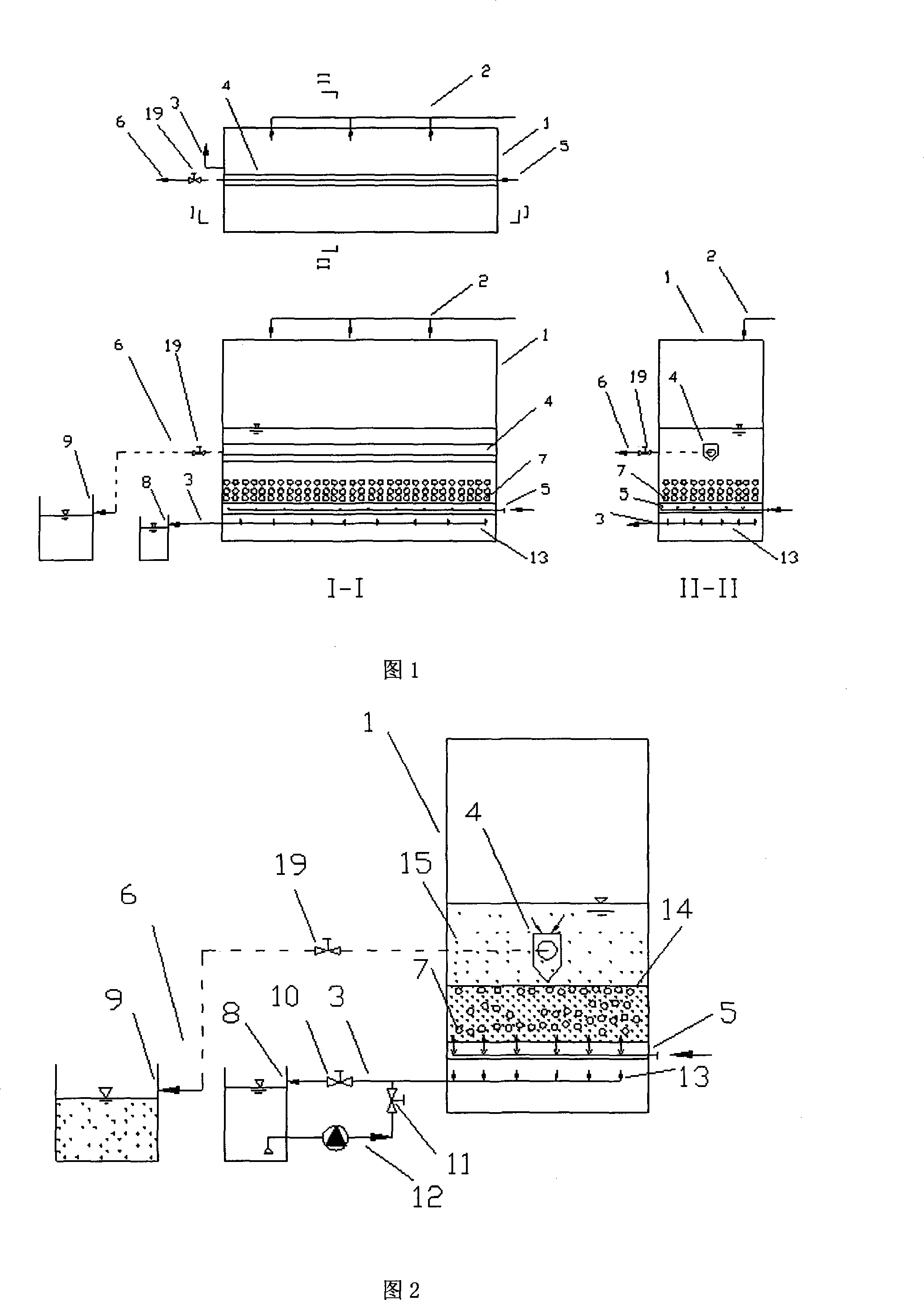

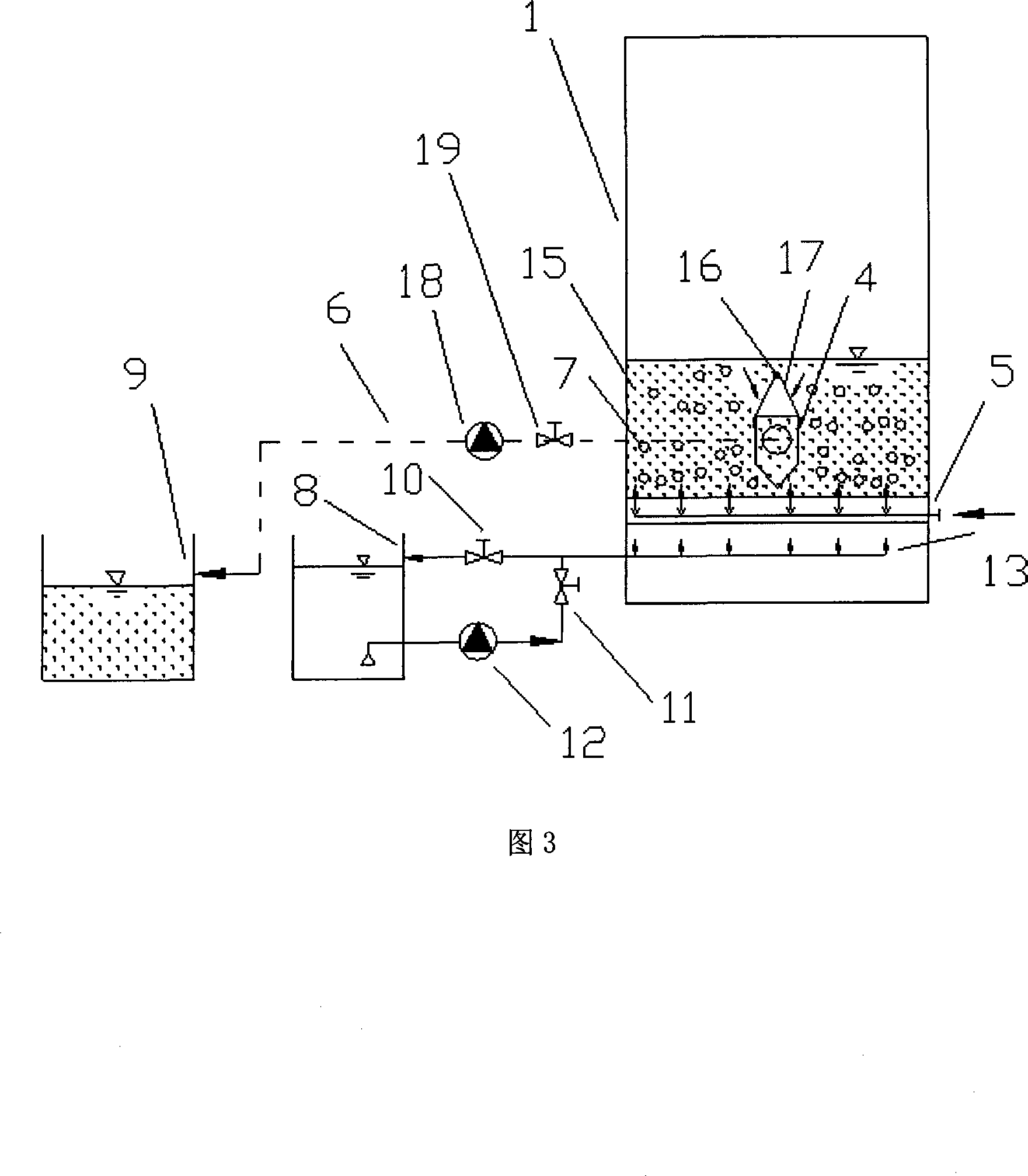

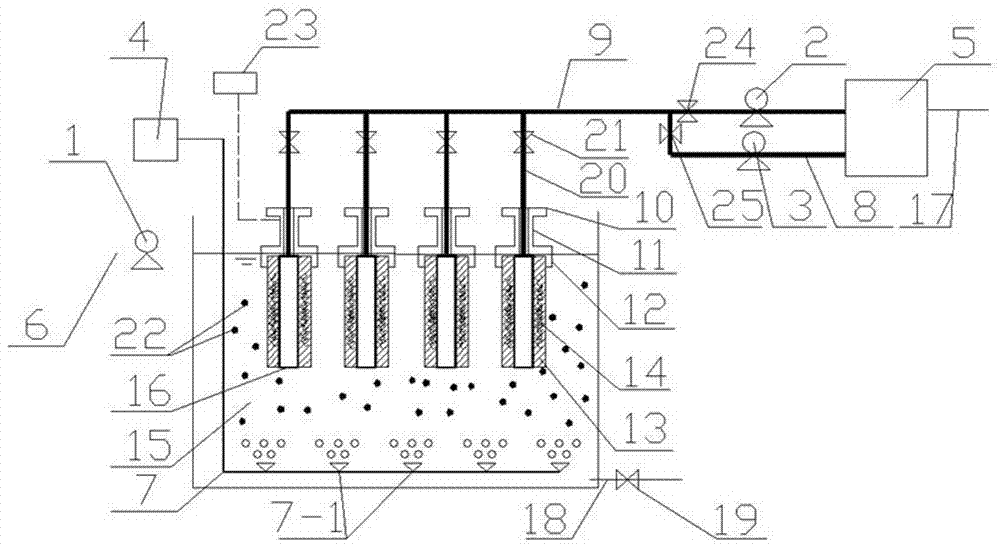

Improved structure for gas and water mix backwash of aerating biological filter

InactiveCN101172699AAchieve separationNo reduction in flow areaSustainable biological treatmentBiological water/sewage treatmentBiological filterMaterial consumption

The invention relates to an improved gas-water mixed backwash structure of an aeration biological filter chamber. The clear water in a clear water pool (8) is pumped out by a pressurizing water pump (12) and is led to the bottom of a chamber body (1) through a water distributing pipe net (13), then the clear water passes through a filter material (7) from bottom to top so as to take filter residue (15); then the water enters into a backwash water collecting groove (4) through a sieve (17); the sewage flows to a sewage pool (9) through a water drainage pipeline (6); the upward side of the backwash water collecting groove (4) is provided with a through length supporting lever (16); the sieve (17) encases the backwash water collecting groove (4) and the supporting lever (16) so as to ensure that the filter bed restores the function of filtering and purifying the sewage, prolongs the backwash period and reduces the backwash frequency, as well as ensure that the sewage purifying system canbe better and normally operated; the sieve has simple mounting and dismounting, less material consumption and convenient maintenance.

Owner:DONGHUA UNIV

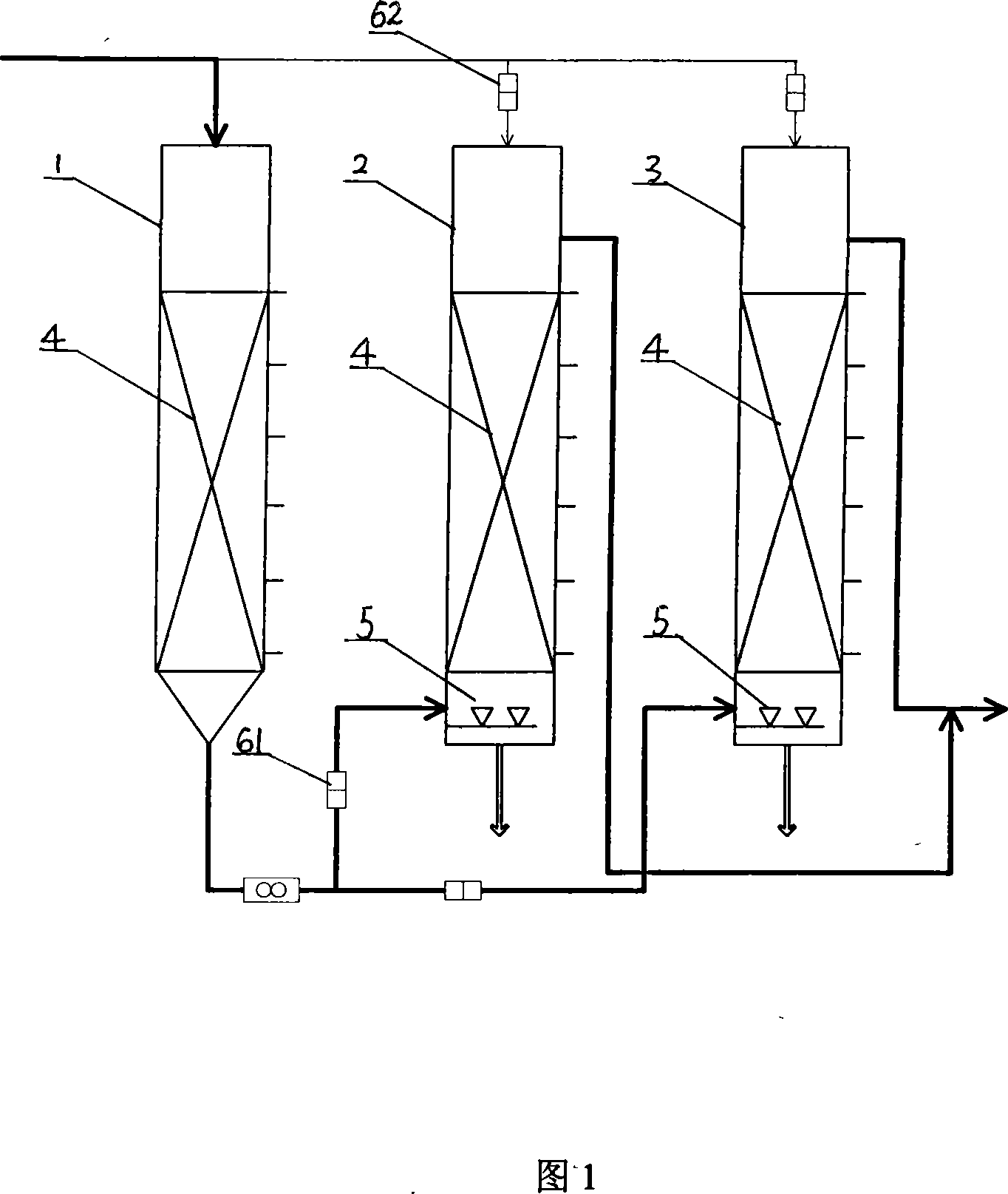

Intermittent aerating biological filter seprobia dephosphorization technique

InactiveCN101172736AAdaptableGuaranteed uptimeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWork periodPhosphor

The invention relates to a dephosphorization technique for sewage organisms in an intermittent air-exposition biologic filtering pond, with the adoption of a sewage treatment system orderly consisting of a fixed bed anaerobic biologic filtering pond and an intermittent air-exposition biologic filtering pond. The intermittent air-exposition biologic filtering pond discharges an anaerobic reaction liquid rich in phosphor, namely, the anaerobic liquid rich in phosphor, when the anaerobic phase comes to an end, and the water is taken in continuously during the aerobic phase. Two intermittent air-exposition biologic ponds are aligned, and two filtering ponds are crossed for work. Each intermittent air-exposition biologic pond circularly works according to the time limit of the arranged intermittent air exposition period, and the whole system achieves the continuous water intake and outtake. The technique has simple and convenient operation and lowoperational cost, and can effectively eliminate the phosphor in the sewage. Compared with the prior dephosphorization technique, the invention adopts the method of the discharge of the anaerobic liquid rich in phosphor rather than the aerobic biologic cells rich in phosphor to remove the phosphor in the intermittent air-exposition biologic filtering pond. The dephosphorization property of the reactor does not depend on the anti-washing, the work period of the reactor is effectively prolonged, and the energy consumption during the anti-washing of the filtering pond is reduced.

Owner:CHONGQING UNIV

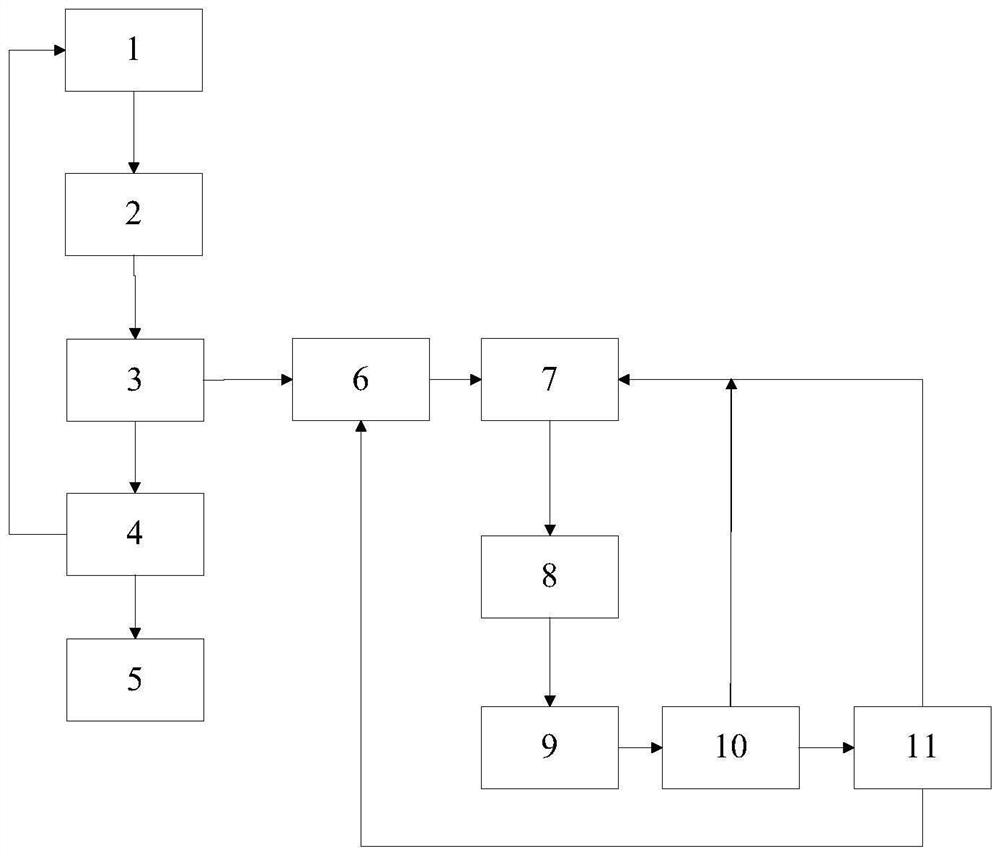

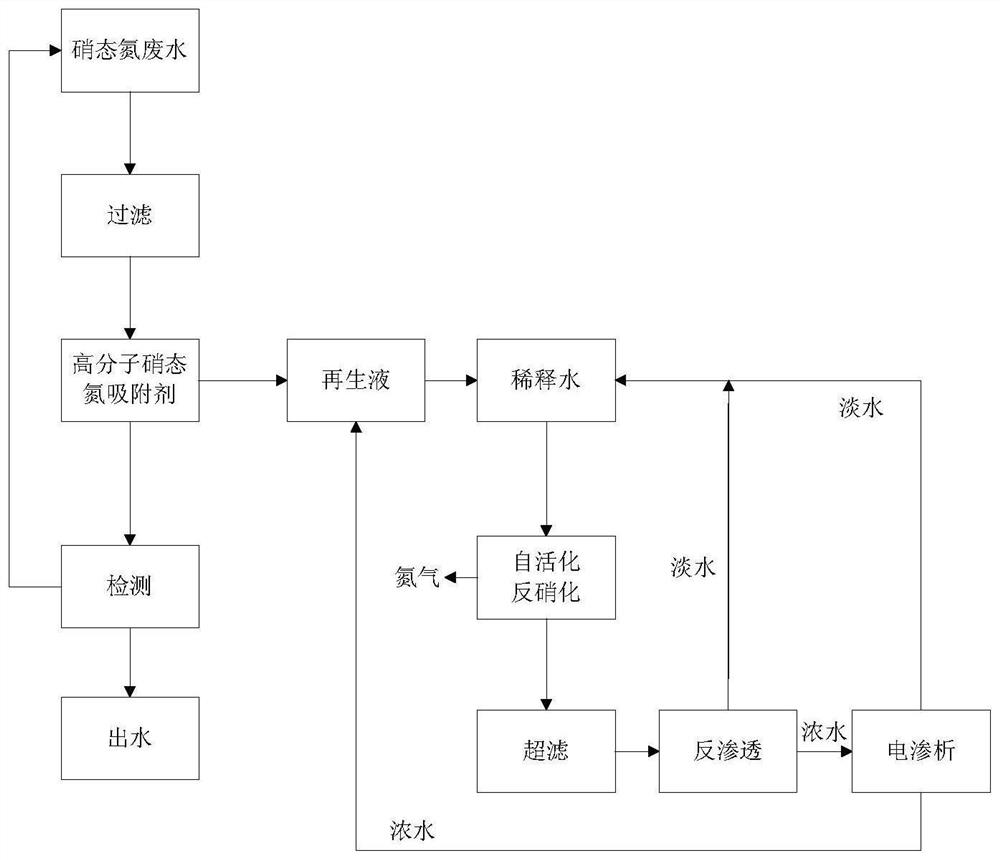

Process method and device for advanced treatment of nitrate nitrogen in water

PendingCN112266050AStrong impact resistanceIncrease frictionSpecific water treatment objectivesWater contaminantsSorbentReverse osmosis

The invention discloses a process method and device for advanced treatment of nitrate nitrogen in water, and belongs to the field of nitrate nitrogen wastewater treatment processes. Nitrate nitrogen wastewater is absorbed through a macromolecular nitrate nitrogen adsorbent to obtain nitrate-removed effluent, and the nitrate-removed effluent is discharged after the nitrate-removed effluent is detected to reach the standard; when the effluent does not reach the standard, a sodium chloride solution with the mass percentage concentration of 35% is added into the macromolecular nitrate nitrogen adsorbent for regeneration, a self-activity denitrification process is conducted after obtained regenerated waste liquid is diluted, and the effluent obtained after the self-activity denitrification process is sequentially subjected to ultrafiltration, reverse osmosis and electrodialysis concentration to serve as fresh regenerated liquid; and both the reverse osmosis fresh water and the electrodialysis fresh water are used as diluents of regenerated waste liquid. The process is high in automation degree, easy to manage, small in equipment investment and low in operation cost. According to the method, the macromolecular nitrate nitrogen adsorbent is adopted to adsorb nitrate nitrogen in the water, the regenerated waste liquid is filtered out through self-activity denitrification, and the method has the advantages that no waste liquid or waste gas is discharged, and the process cleanliness is high.

Owner:艾西姆(辽宁)环境技术有限公司

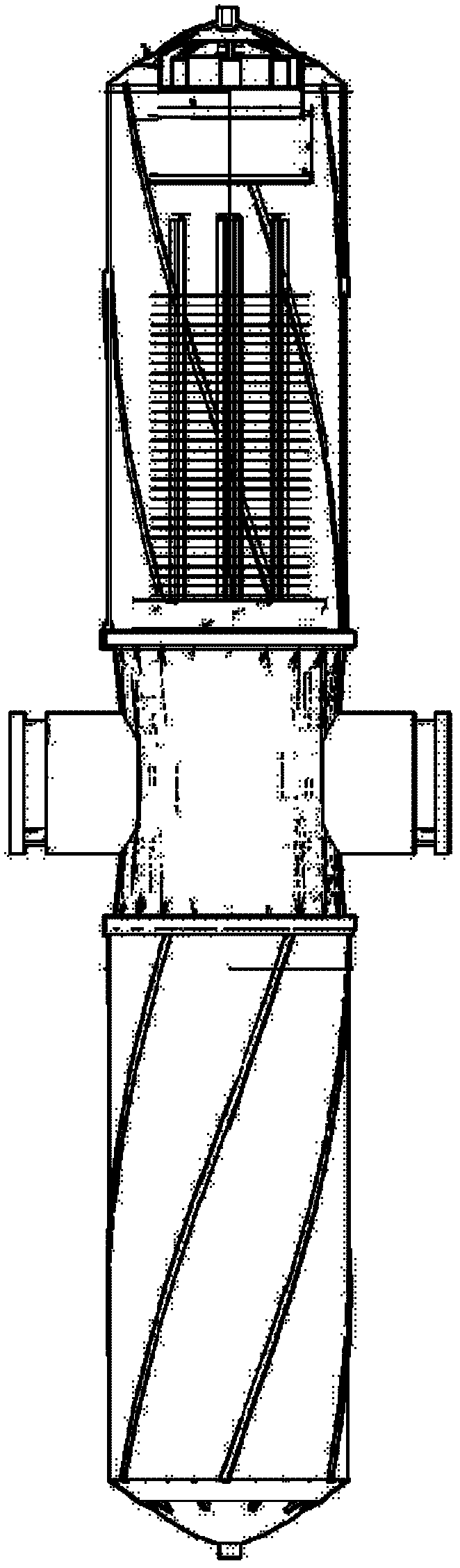

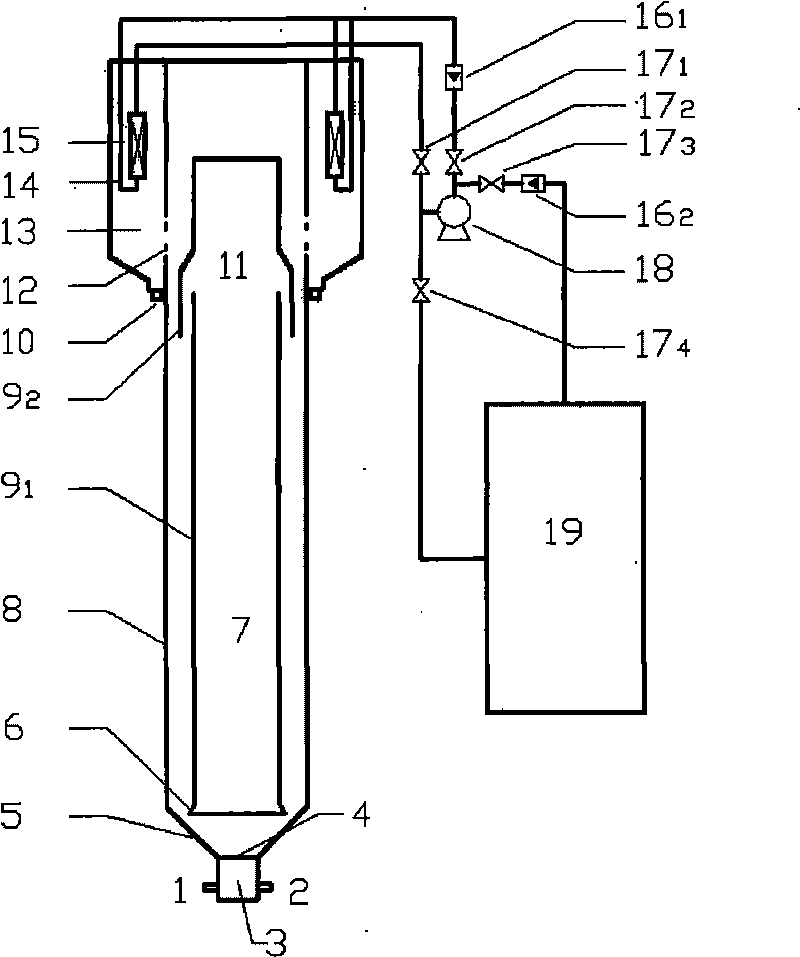

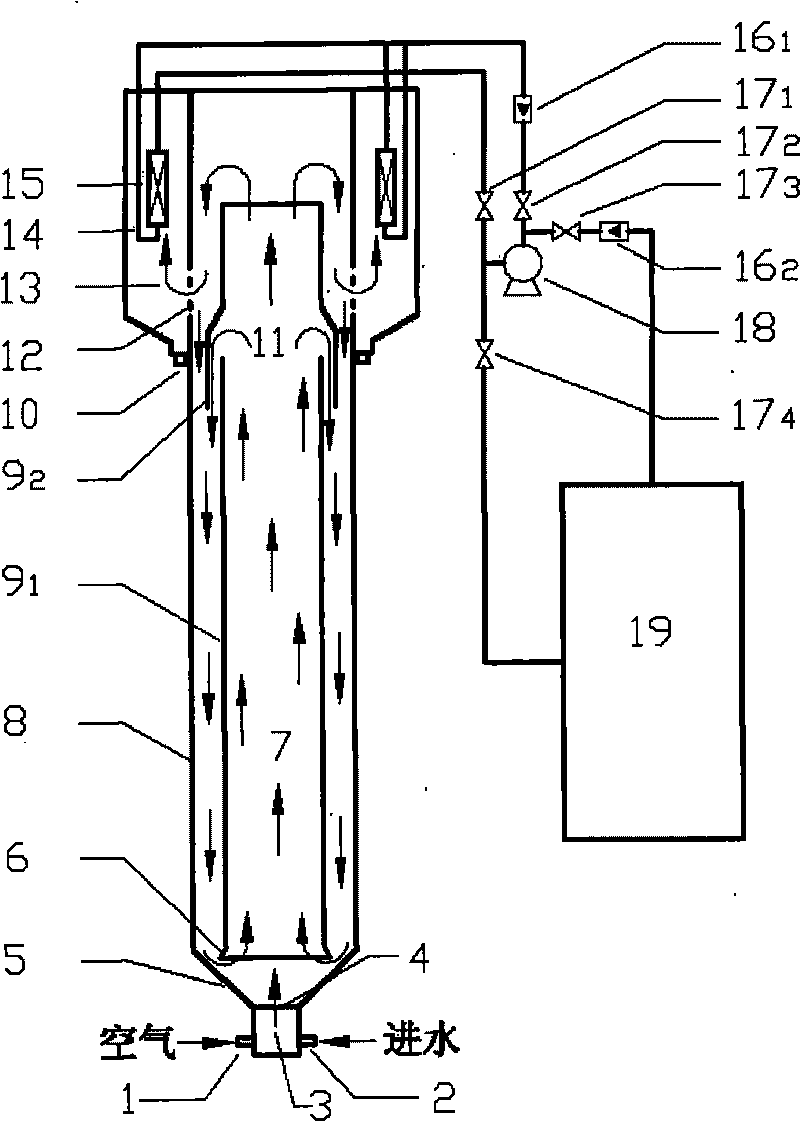

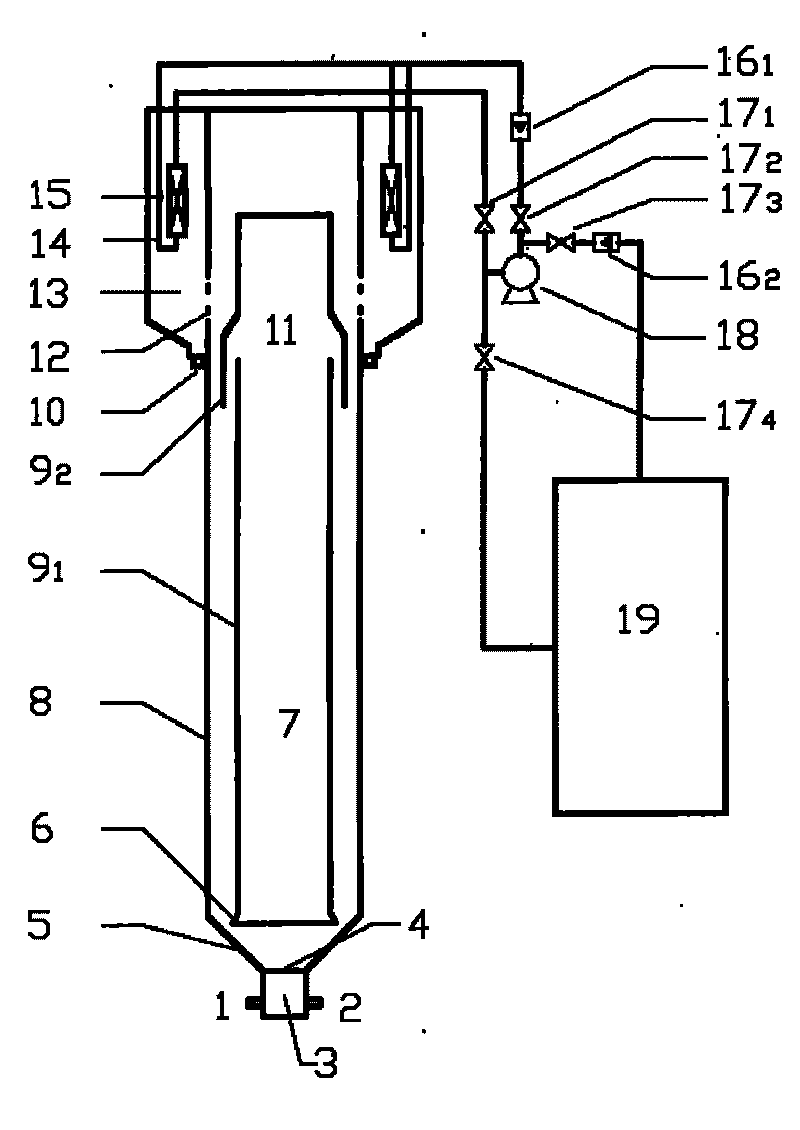

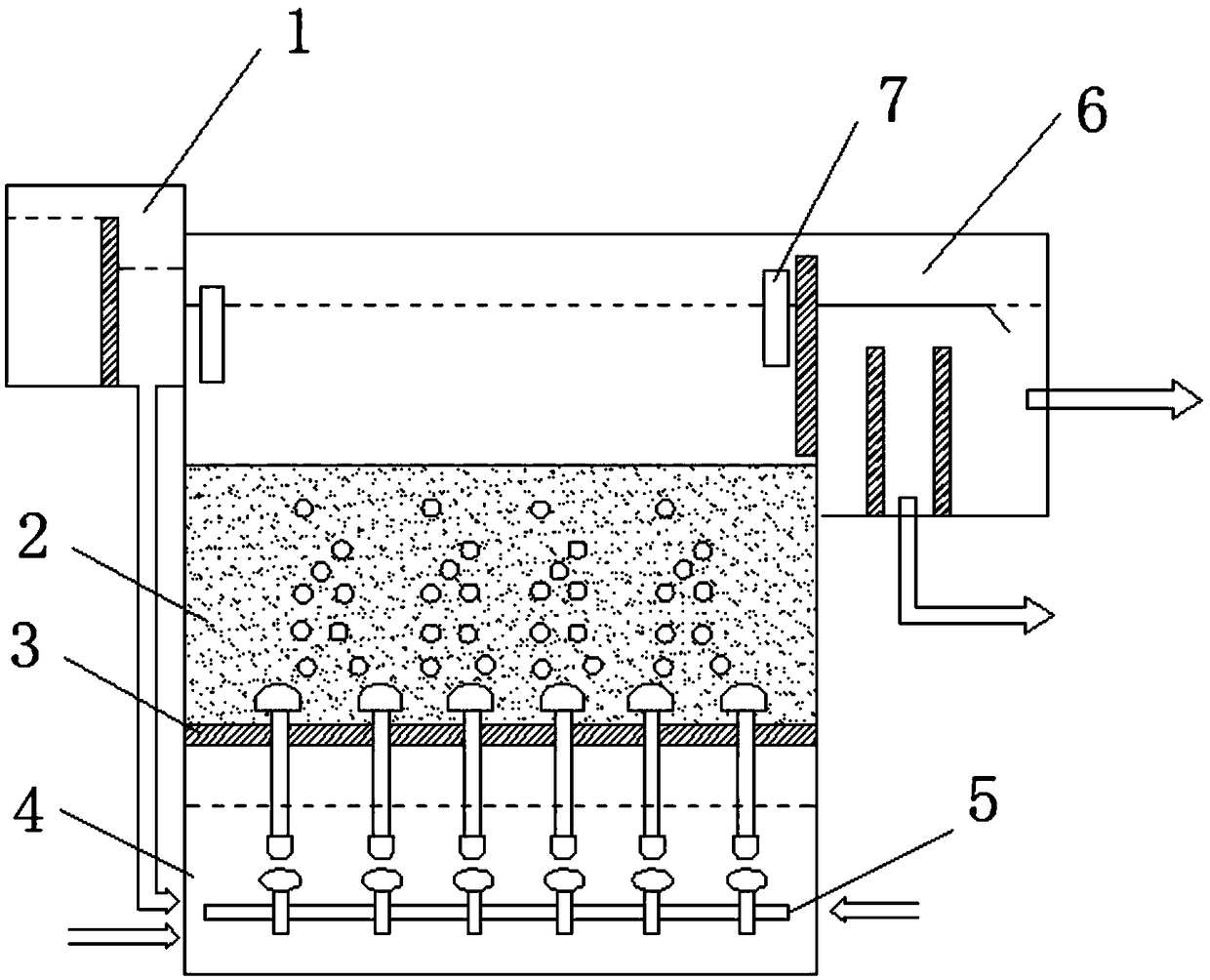

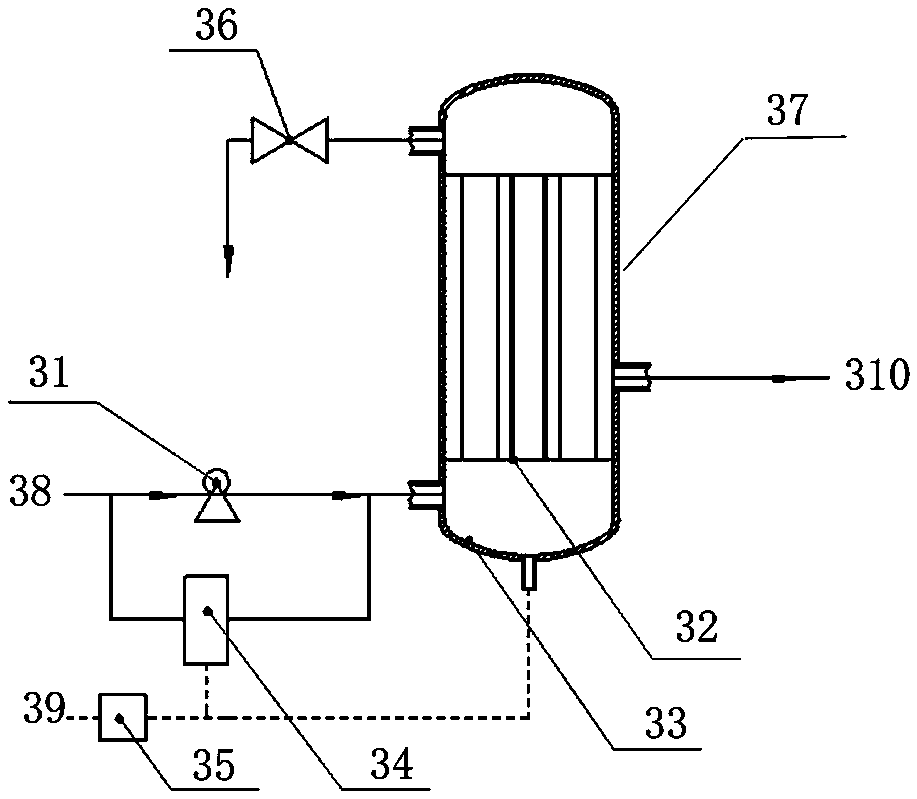

Three-phase fluidized-bed reactor

InactiveCN101733046AImprove the mixing effectEasy constructionTreatment using aerobic processesSustainable biological treatmentIndustrial effluentFluidized bed

The invention discloses a three-phase fluidized-bed reactor. The three-phase fluidized-bed reactor solves the technical problems of poor gas-water mixing, difficult operation, undesirable solid-liquid separating effect and high effluent turbidity of an internal circulating three-phase fluidized-bed reactor. The three-phase fluidized-bed reactor comprises a gas-water mixing area, a reacting area, separating area and a filtrating area; the gas-water mixing area is, through a micro-porous gas distributor, communicated with the reacting area which is formed by an outer barrel and an inner barrel; a precipitating area and the filtrating area are formed outside the separating area on the top and communicated with each other through a perforated plate; the filtrating area is provided with a filtering component; and the filtrating component is connected with a water outlet and back wash system which comprises a water pump, a plurality of valves, a plurality of flowmeters and the like. The three-phase fluidized-bed reactor is characterized in that: the gas-water mixing area is shaped as a column; and the filtering component is a film component. The three-phase fluidized-bed reactor is used for treating the domestic sewage and the industrial effluent, so the municipal sewage is recycled to meet the municipal non-drinking water quality standards.

Owner:NANJING UNIV OF SCI & TECH

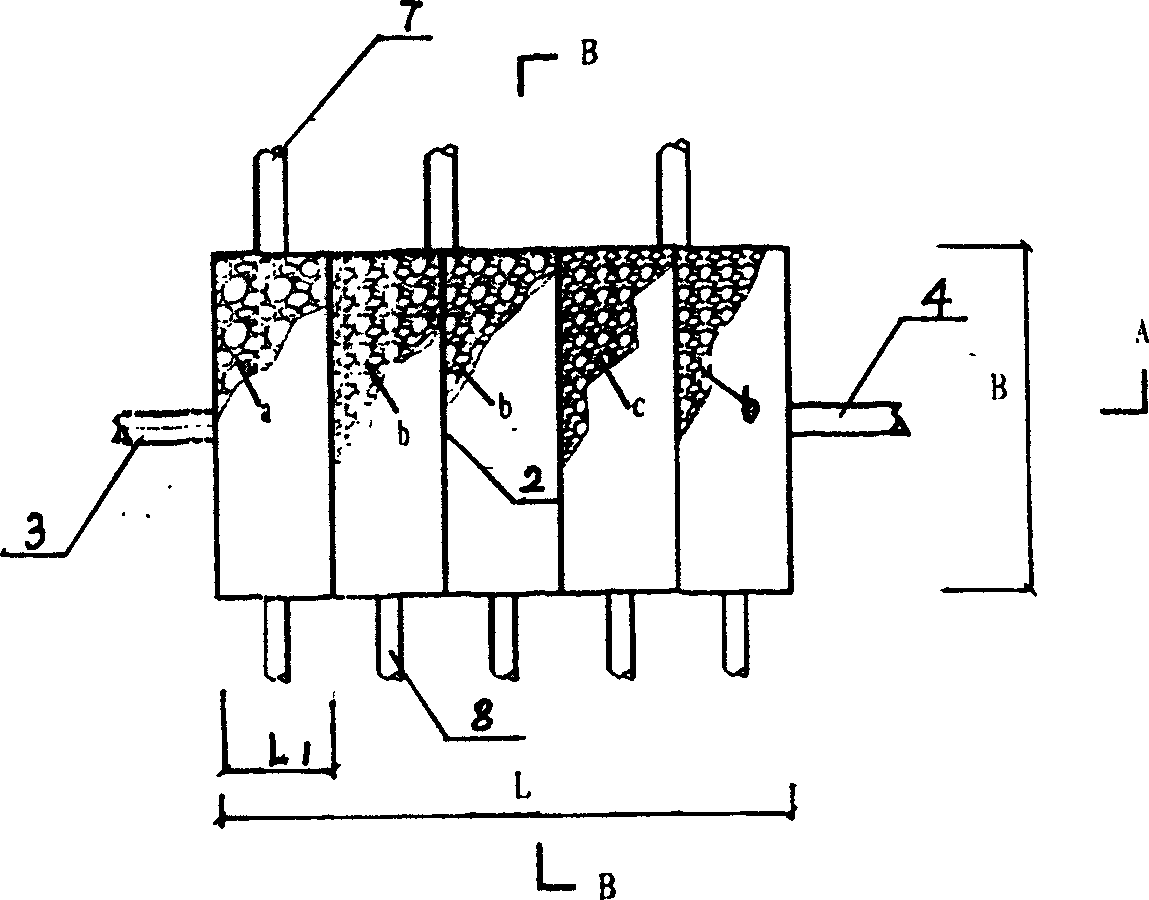

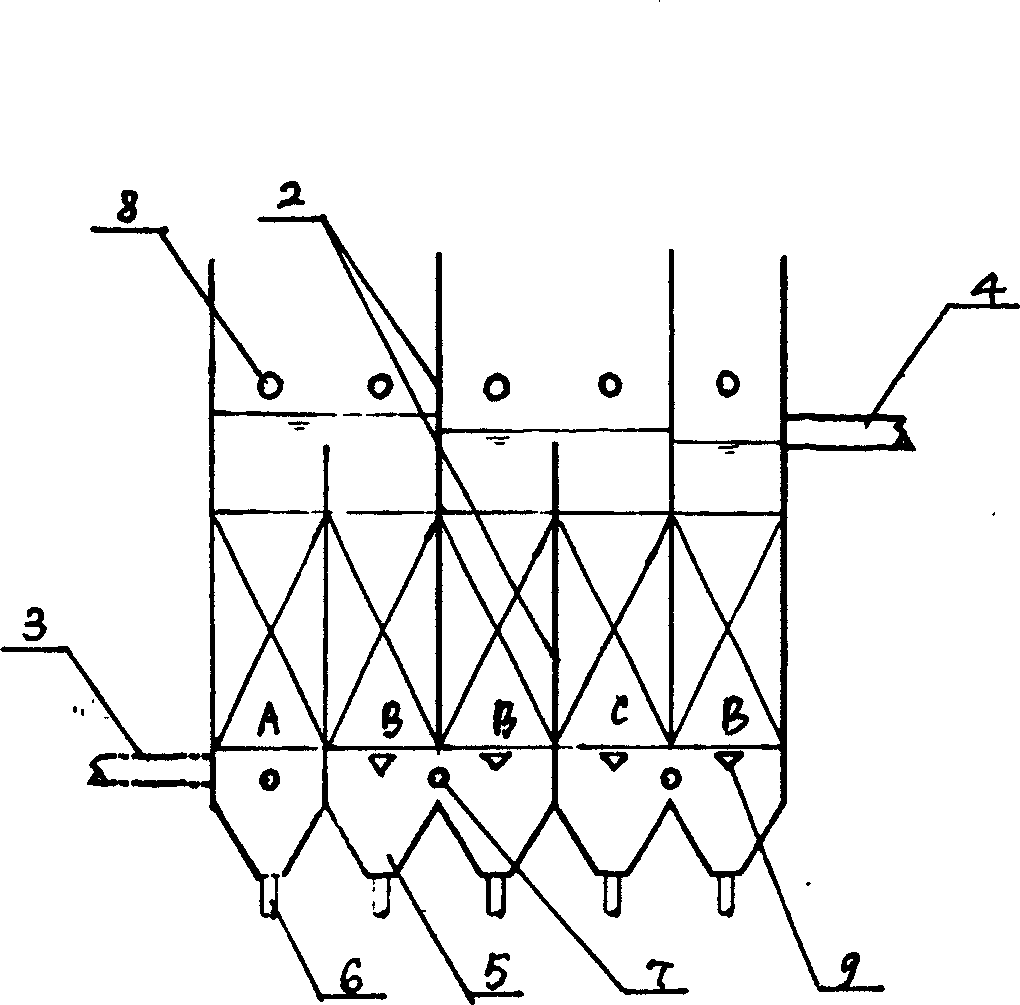

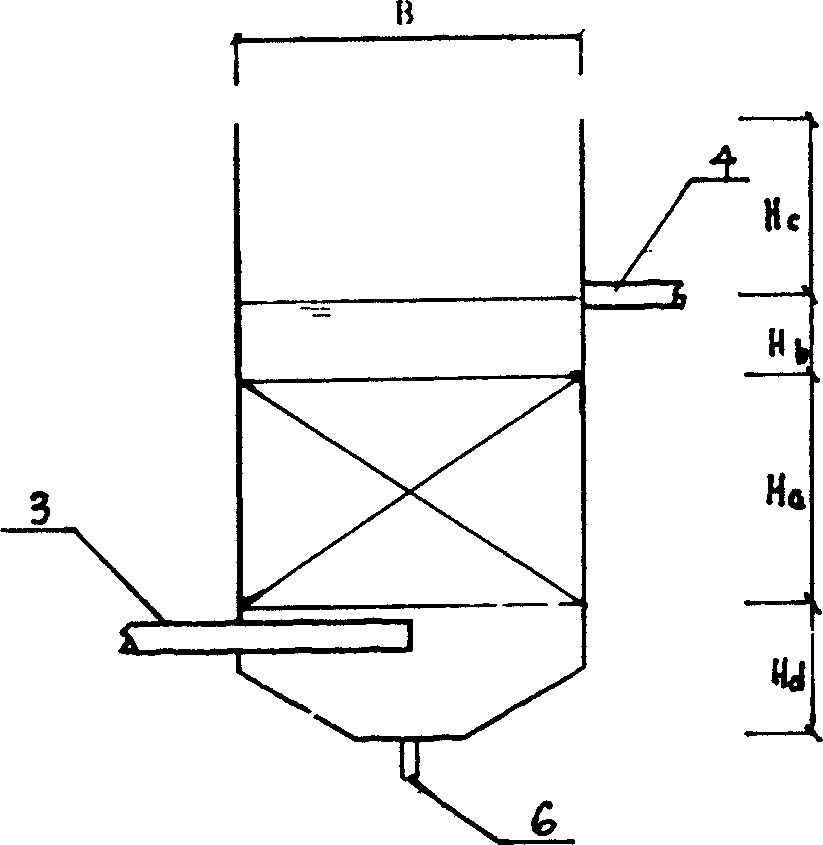

Vertical deflector combined Filtration type dephosphorization and nitrogen rejection facility

InactiveCN1562802AGuaranteed thicknessGuaranteed process lengthSustainable biological treatmentBiological water/sewage treatmentFiltrationNitrogen

The device contains at least two single filter tanks connected each other, water entrance pipe connected with first single filter tank and water exit pipe connected with last single filter tank, devision plates are used to separate the single filter tanks up and down crisscrossed, sewage up and down baffling passageway is preset. Bottom of single filter tank are mud collector, mud sludging pipe and filling layer is the middle part, the fillings are anaerobic filling, aerobic filling and high-grad iron filling, at least two of them are combined to put into the filter tanks, each fillings combination is put to one filter tank to form different function area. The design of sewage up and down baffling passageway is to ensure obtaining length of flow path required by process, the combination of mutiple fillings is suited for requirements of different water quality.

Owner:CHONGQING UNIV

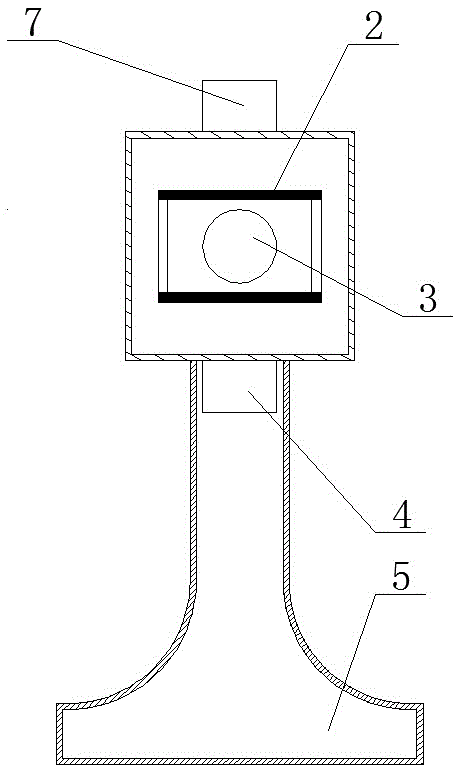

Energy-saving and environment-friendly chemical sewage treatment system

InactiveCN111362363AImprove permeabilityImprove processing efficiencySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater flowSewage

The invention discloses an energy-saving and environment-friendly chemical sewage treatment system, which comprises a seat plate, and a supporting plate is fixedly connected to the top surface of theseat plate. Through a filter device, under a constant water pressure, a filter element can move towards the water flowing direction along with the reduction of the permeability of a microporous filterscreen; the lower the permeability of the microporous filter screen is; the larger the moving distance of the filter element towards the water flow direction is; through a linkage device, the displacement change of the filter element can be reflected to a strain device; through cooperation among the linkage device, the strain device, an electric connection device, a track limiting device and a contact, the backwashing time point is determined, and backwashing is automatically carried out. The backwashing time point does not need to be manually set; the backwashing time point can be changed along with the change of the content of impurities in sewage, the high permeability of the microporous filter screen can be kept, the backwashing frequency can be greatly reduced, the sewage treatment efficiency is improved, and the practicability of the energy-saving and environment-friendly chemical sewage treatment system is improved.

Owner:安徽净工坊环保科技有限公司

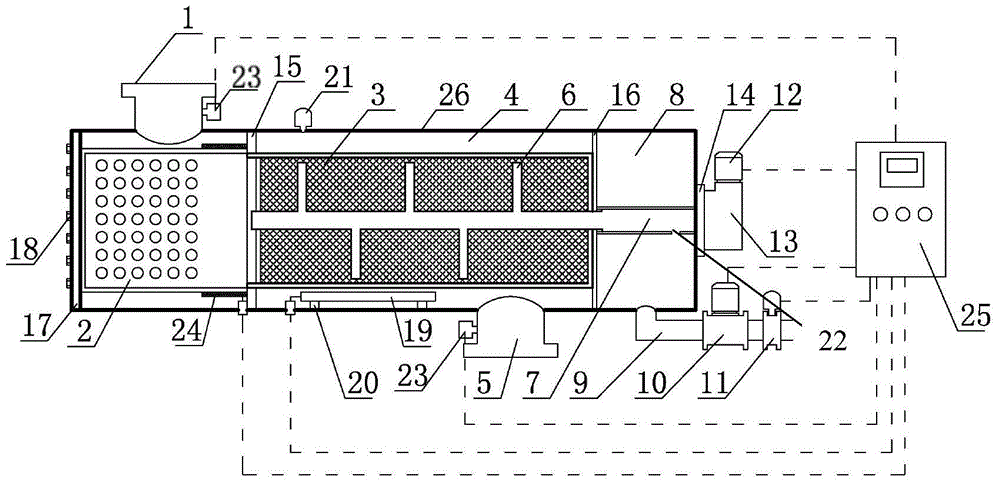

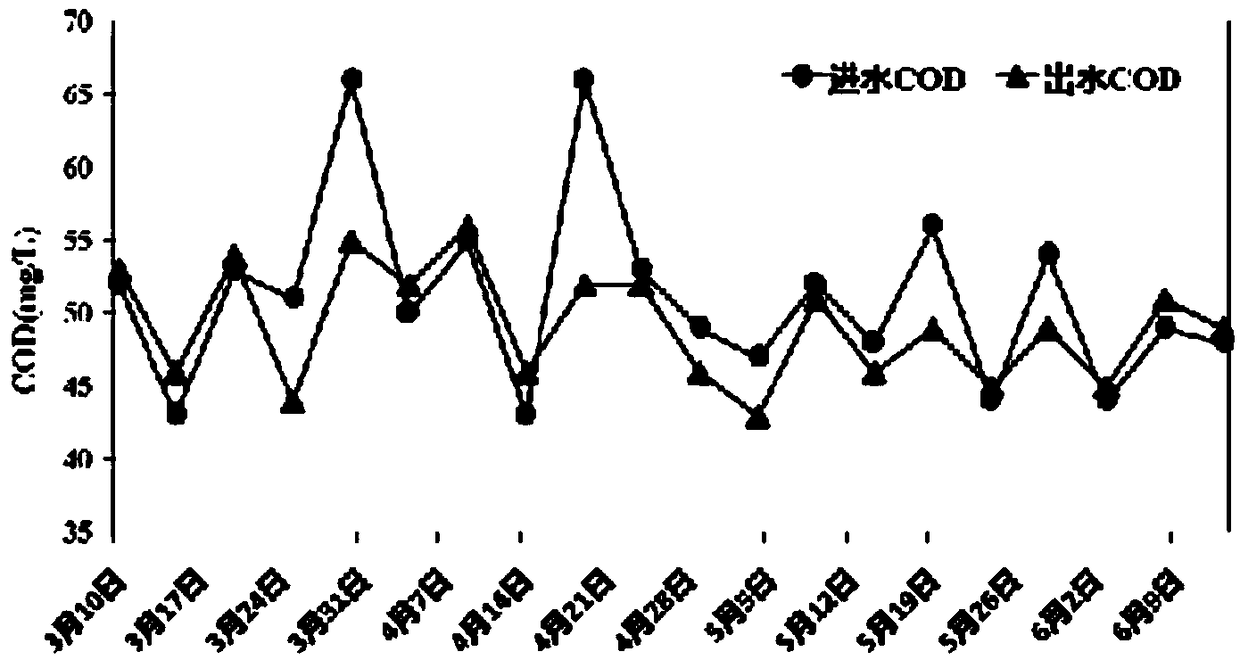

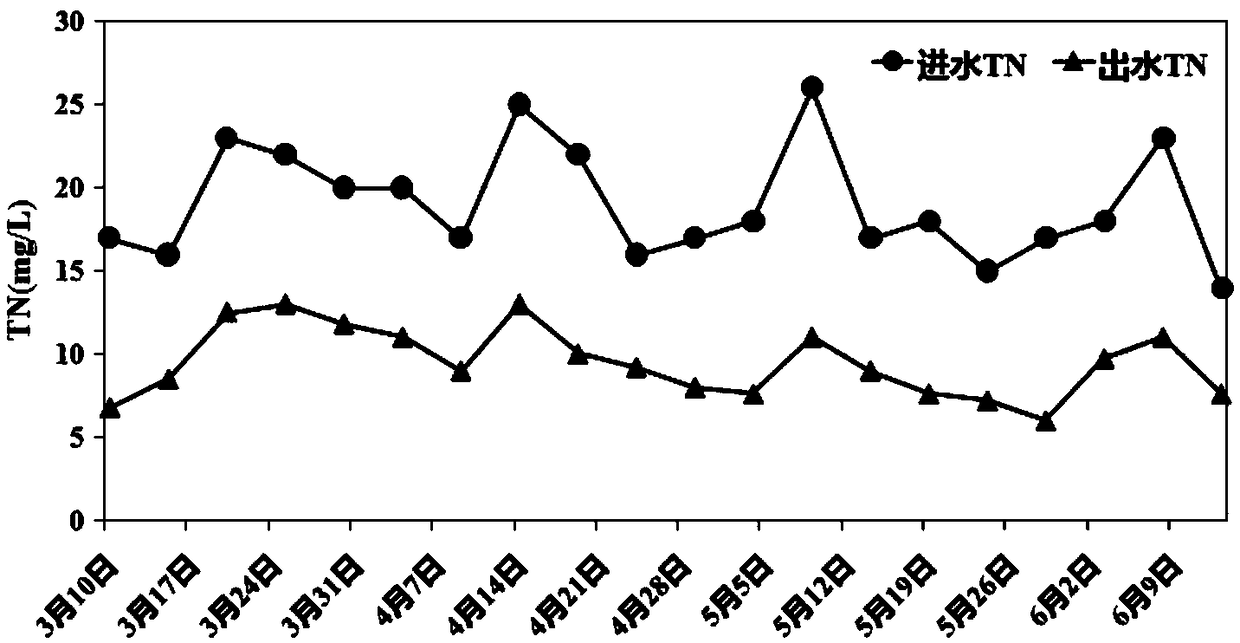

Porous packing coated membrane bioreactor (MBR) device and sewage treatment method

ActiveCN107986433AMembrane fouling mitigationReduce processing costsBiological treatment apparatusSustainable biological treatmentCoated membraneWater quality

The invention discloses a porous packing coated membrane bioreactor (MBR) device and a sewage treatment method. According to the porous packing coated MBR device, porous sponge packing sleeves the exterior of a ceramic membrane module and can rotate around the ceramic membrane module, and the ceramic membrane module is cleaned by means of physical friction of the porous polyurethane sponge packing, so that the membrane fouling problem of an MBR is alleviated, the backwashing frequency is reduced, an MBR system can still operate normally in a surface friction cleaning process, and the effluenteffect is not influenced. The porous polyurethane sponge packing enriches a biofilm and almost produces no residual sludge; the packing can be replaced and can also be reused after being washed with an alkaline solution. An MBR biochemical reaction pool is combined with a moving bed reactor, so that the biomass is increased, and the quality of effluent is ensured.

Owner:SHANDONG JIANZHU UNIV

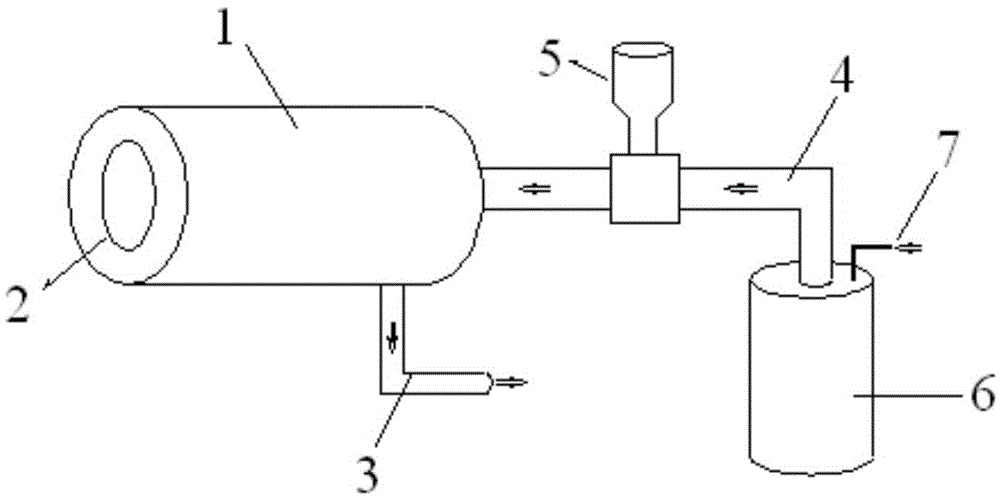

Anti-scale method and device of filter used in ship ballast water management system

ActiveCN104973719AReduce backwash frequencyReduce dosageMultistage water/sewage treatmentStationary filtering element filtersControl systemWater filter

The invention discloses an anti-scale method and device of a filter used in a ship ballast water management system. The device comprises a coarse filter screen, a fine filter screen, a back-washing unit, a sewage discharge unit, and a control system; the coarse filter screen, a first partition plate, the fine filter screen, another partition plate, and the sewage discharge unit are horizontally arranged in the filter cavity; a control unit is part of main control equipment; the first partition plate between the fine filter screen and the coarse filter screen and the filter cavity form a filtering cavity, a water inlet is arranged on the filter shell, is above the coarse filter screen, and is communicated with the filter cavity; and a water outlet is arranged in the filter shell and is communicated with the filtering cavity. The device also comprises a variable-frequency processing unit, which is composed of a signal generator controlled by the control system and electromagnetic coils, and the electromagnetic coils are winded around the coarse filter screen. The provided anti-scale method and device solve the problem that conventional ship ballast water filter is easily obstructed during the application process, and the anti-scale device has the advantages of high integration level, small volume, and high intelligentization degree, and can meet the application requirements of a ship ballast water management system.

Owner:SUNRUI MARINE ENVIRONMENT ENG

High-concentration ammonia-nitrogen wastewater treatment process

ActiveCN103936192ASolve the problem of incomplete precipitationSmall footprintWater contaminantsMultistage water/sewage treatmentHigh concentrationFiltration membrane

The invention relates to a high-concentration ammonia-nitrogen wastewater treatment process which comprises the following steps: (1) adding magnesium salt and phosphate into wastewater to be treated according to the ammonia-nitrogen concentration of the wastewater, wherein the molar ratio of NH<3->N:Mg<2+>: PO4<3-> in the wastewater is controlled at 1:(2-3.5):(1.5-3.0); and adjusting the pH value of the wastewater by a sodium hydroxide solution to 8.5-9, and stirring for 3-5 minutes; (2) after full reaction, filtering the wastewater by a micro-filtration membrane, wherein effluent generated after filtering by the micro-filtration membrane is the wastewater without ammonia-nitrogen; and dehydrating concentrated solution (separated out after filtration of the micro-filtration membrane) by a plate-and-frame filter press; and (3) after dehydration by the plate-and-frame filter press, refluxing the obtained filtrate and mixing with the wastewater to be treated, wherein the main component of the filter residue is struvite which is directly recovered as an agricultural fertilizer or is regenerated to be recycled. The process provided by the invention is low in cost, and not only can treat ammonia-nitrogen in the wastewater to reach the discharge standard, but also can recycle useful components from the wastewater.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

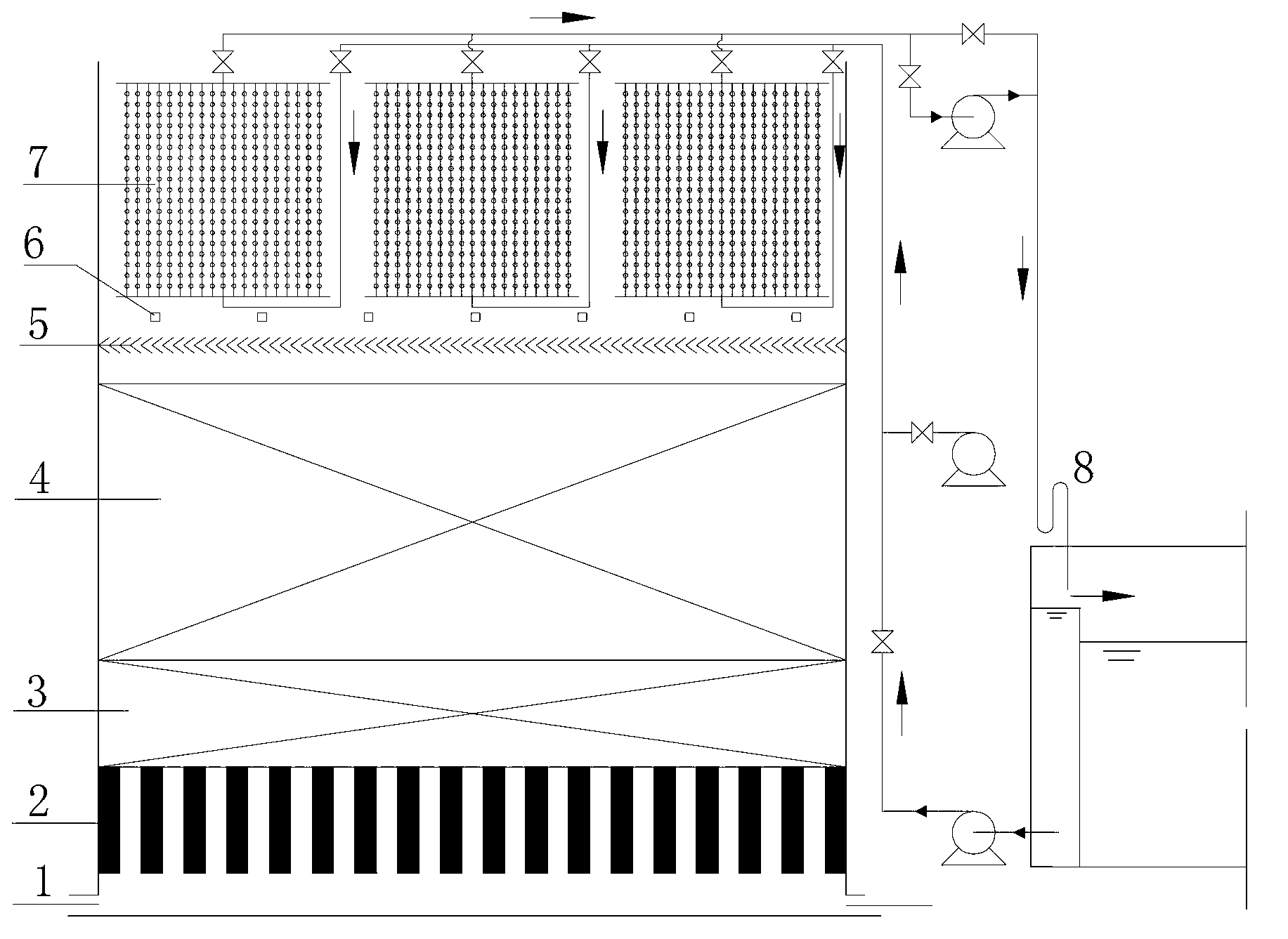

Autotrophic deep bed filter using novel composite filler

PendingCN109368769AAvoid secondary pollutionLow mud productionWater treatment compoundsBiological treatment apparatusBrickDistribution system

The invention discloses an autotrophic deep bed filter using a novel composite filler. A water inlet end and a back washing water outlet end are formed in the upper part of the autotrophic deep bed filter using the novel composite filler, wherein a water distribution ditch is mounted at the water inlet end; a back washing water outlet ditch is mounted at the back washing water outlet end; a filtering material layer, a bearing layer and a filtering brick layer are arranged in the filter in sequence from top to bottom; a gas distribution and water distribution system is connected to the filtering brick layer; filtering material intercepting devices are arranged between the water distribution ditch and the filter and between the back washing water outlet ditch and the filter; and the filler of the filtering material layer is an electronic slow release type filler formed by processing sulphur-iron composite ores. The autotrophic deep bed filter using the novel composite filler, disclosed by the invention, has the advantages that an organic carbon source does not need to be added because a deep-bed denitrifying filter with the novel sulphur-iron composite ore filtering material as the filler is adopted, and a problem of COD secondary pollution can be effectively solved.

Owner:BEIJING MECHANICAL BIOLOGICAL ENG

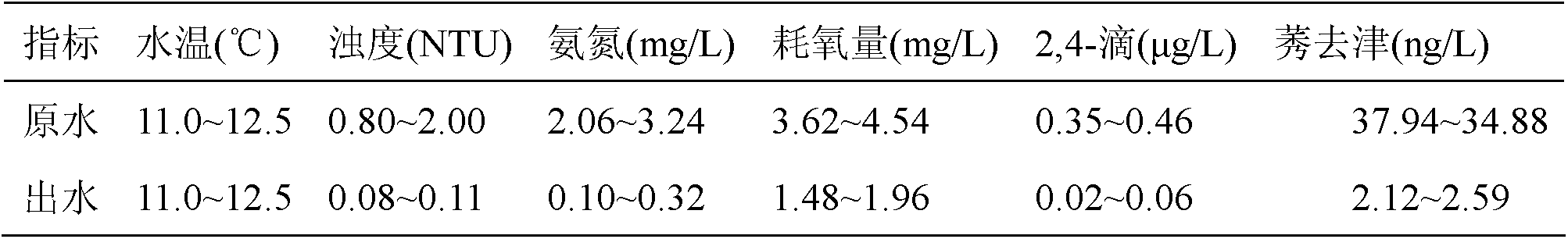

Strengthening method for removing ammonia nitrogen and organic matters in rear activated carbon filter for ultrafiltration

InactiveCN103539279AReduce cloggingSolve the problem of insufficient dissolved oxygenWater contaminantsWater/sewage treatment bu osmosis/dialysisActivated carbonUltrafiltration

The invention discloses a strengthening method for removing ammonia nitrogen and organic matters in a rear activated carbon filter for ultrafiltration, particularly discloses a strengthening method for removing ammonia nitrogen and organic matters in the rear activated carbon filter for ultrafiltration in drinking water treatment, and aims to solve the problem that the capacity of the activated carbon filter for removing the ammonia nitrogen and the organic matters is limited. The strengthening method comprises the steps of firstly, arranging a coagulation sedimentation unit in front of an activated carbon filter, and arranging an ultrafiltration unit at the rear of the activated carbon filter; then, adopting different strengthening measures according to different concentrations of ammonia nitrogen and organic matters in inlet water of the activated carbon filter. The method comprises the following concrete steps: (1) when the concentration of the ammonia nitrogen is less than 1.5mg / L and the index of potassium permanganate is less than 3mg / L, changing the activated carbon filter to be in an upward flowing way; (2) when the index of the potassium permanganate is greater than 3mg / L, additionally arranging an ozone unit in front of the activated carbon filter in the step (1); (3) when the concentration of the ammonia nitrogen is greater than 1.5mg / L, aerating at the bottom of the activated carbon filter in the step (1); (4) when the concentration of the ammonia nitrogen is greater than 1.5mg / L and the concentration of the permanganate is greater than 3mg / L, combining the step (2) and the step (3).

Owner:HARBIN INST OF TECH

Upward-flowing fluidization biofilter coupled with negative pressure membrane

ActiveCN103253760ARealize purificationAvoid wear and tearBiological water/sewage treatmentSuspended particlesParticulates

The invention relates to a biofilter and discloses an upward-flowing fluidization biofilter coupled with a negative pressure membrane, for solving the technical problems of an existing biofilter, such as poor filtering effect on suspended particles, planktons, benthonic animals and microorganism residues in water bodies, as well as high turbidity of treated water. The upward-flowing fluidization biofilter comprises a water inlet, a water distribution layer, a supporting layer, a filling layer, an anti-interference cantboard, an air floatation releaser and a negative pressure membrane assembly. According to a water treatment process, inlet water passes through the upward-flowing biofilter, is filtered by the negative pressure membrane in an upper clear water area and is naturally siphoned by using a siphon tube to discharge water, and thus a water treatment process is finished. The method can be used for effectively removing organic pollutants, natural organic matters, ammonia nitrogen and other pollutants out of water, the loss of biological matters is reduced, a wear damage effect of particles, such as filler, on membranes is avoided, and the plugging effect of biological metabolites and biological cells on the membranes is also avoided.

Owner:HARBIN INST OF TECH

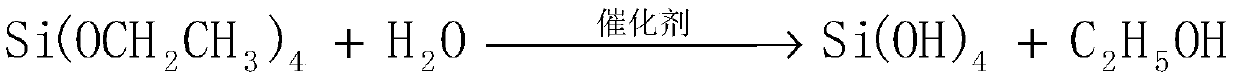

Method for preparing anti-pollution membrane by utilizing silicon dioxide nano material

InactiveCN111068529AEnhanced Pollution Control LevelReduce the frequency of flushingSemi-permeable membranesSustainable biological treatmentMembrane foulingEnvironmental engineering

The invention provides a method for preparing an anti-pollution membrane by utilizing a silicon dioxide nano material. The method comprises the following steps: S1, obtaining silicon dioxide nano particles with various load mesopores; S2, loading anti-membrane-pollution components into loading mesopores of the silicon dioxide nanoparticles to obtain the silicon dioxide nanoparticles loaded with the anti-membrane-pollution components, and taking the silicon dioxide nanoparticles as an additive for membrane preparation; and S3, adding the additive obtained in the step S2 into a membrane materialin the membrane preparation process of a membrane module to prepare the anti-pollution membrane. After the easily-prepared multi-load low-price silicon dioxide nanoparticles are used as the carrier of the anti-membrane-pollution component, the stability of the anti-membrane-pollution component can be greatly enhanced, the membrane pollution control level is enhanced, the membrane washing frequency is reduced, the service life of the membrane is prolonged, and the efficiency of a membrane bioreactor is improved.

Owner:沃克福德环境科技(深圳)有限责任公司

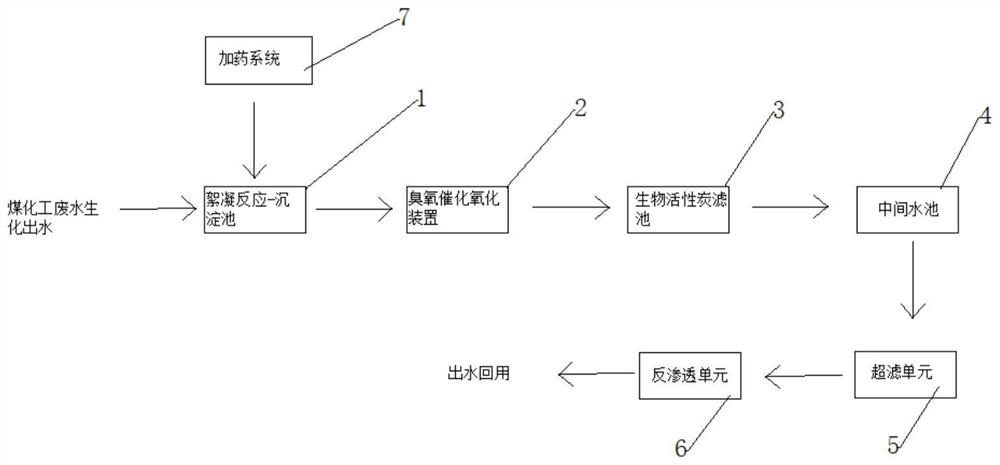

Coal chemical wastewater treatment device and process

PendingCN113716806AReduce backwash frequencyReduce utilityWater treatment parameter controlWater/sewage treatment bu osmosis/dialysisReverse osmosisCatalytic oxidation

The invention relates to a coal chemical wastewater treatment device and process, belonging to the technical field of wastewater treatment. The device is sequentially provided with a flocculation reaction-sedimentation tank, a catalytic ozonation device, a biological activated carbon filter tank, an ultrafiltration unit and a reverse osmosis unit which communicate with each other along a water inlet direction, wherein the flocculation reaction-sedimentation tank adopts an integrated structure and is coupled with a dosing system connected with the flocculation reaction-sedimentation tank; the ozone catalytic oxidation device is coupled with the biological activated carbon filter tank; and the flocculation reaction-sedimentation tank is provided with image recognition equipment, and the image recognition equipment is used for recognizing and comparing floc in the flocculation reaction-sedimentation tank and feeding a result back to a chemical adding system to control a chemical adding amount. The device and the process in the invention solves the technical problem of blockage of a biological membrane in a membrane element caused by membrane element pollution due to inaccurate chemical dosage during flocculation and precipitation reaction in traditional devices and processes, reduce the dosage of ozone and bactericide, and prolong the service life of activated carbon.

Owner:CISDI RES & DEV CO LTD

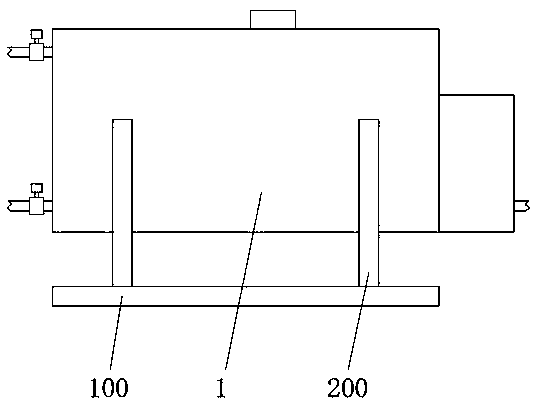

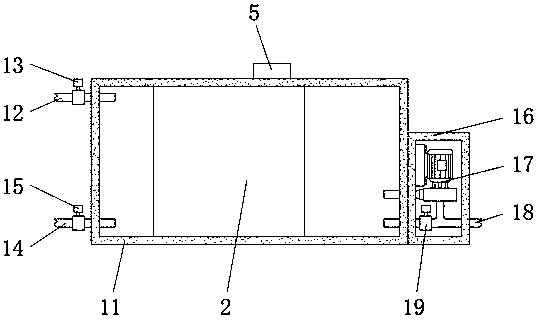

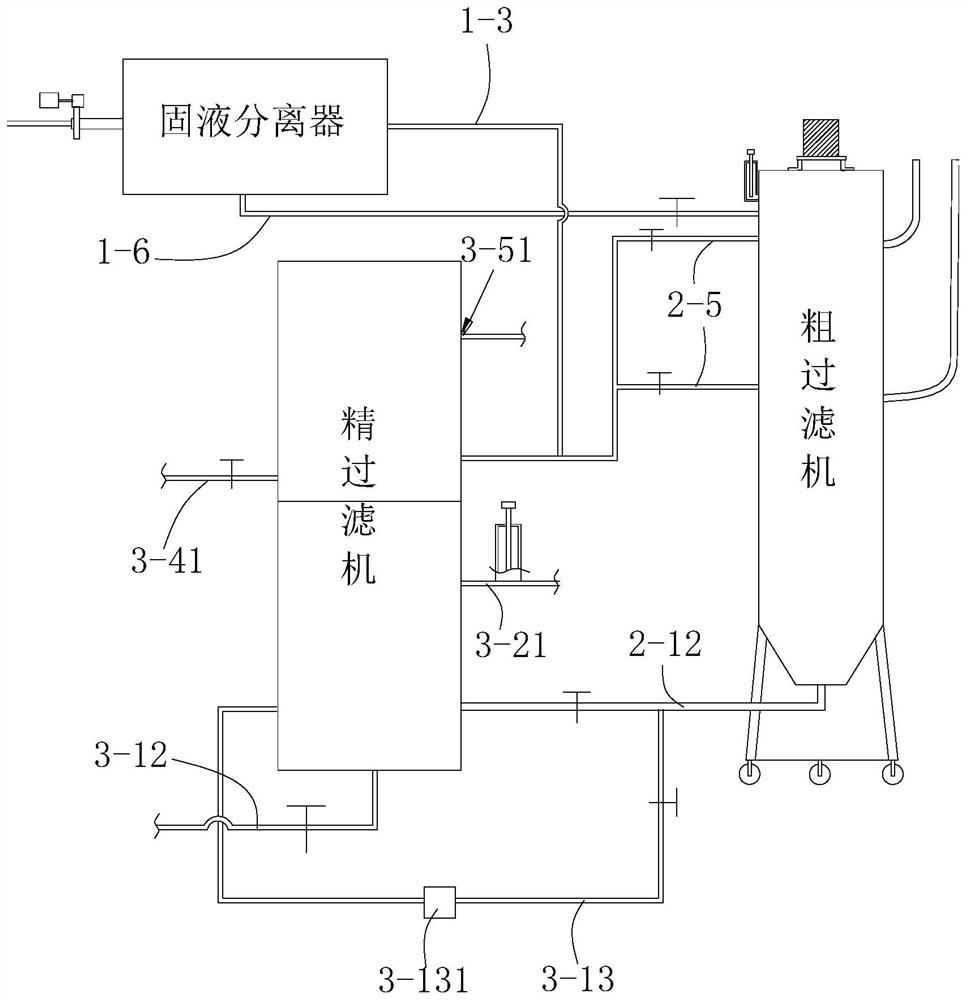

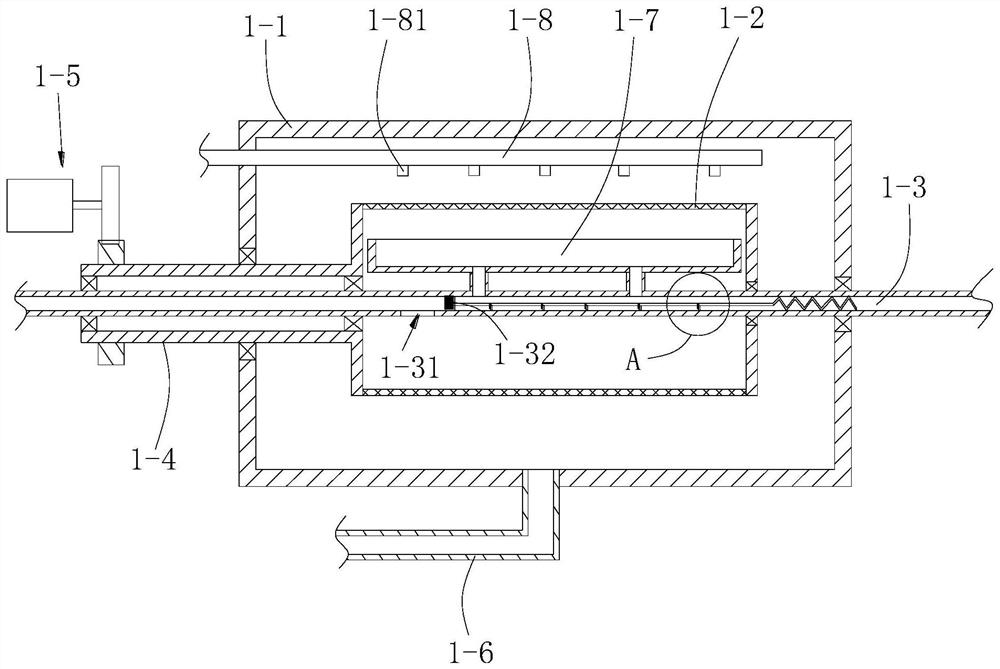

Sewage filtering machine

ActiveCN113599908AReduce filter pressureReduce backwash frequencyWater/sewage treatmentMultistage water/sewage treatmentWater resourcesProcess engineering

The invention discloses a sewage filtering machine, and belongs to the field of sewage treatment equipment, wherein the sewage filtering machine comprises a solid-liquid separator, a coarse filtering machine and a fine filtering machine; the solid-liquid separator, the coarse filtering machine and the fine filtering machine are sequentially communicated, and sewage carrying floc is sequentially filtered by the solid-liquid separator, the coarse filtering machine and the fine filtering machine; and impurities in liquid filtered for multiple times are obviously reduced, the solid-liquid separator, the coarse filtering machine and the fine filtering machine are reasonable in structure and assist with one another, backwashing operation of the coarse filtering machine is achieved, an additionally input water body is reduced as much as possible, water recycling is achieved, and water resources are saved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

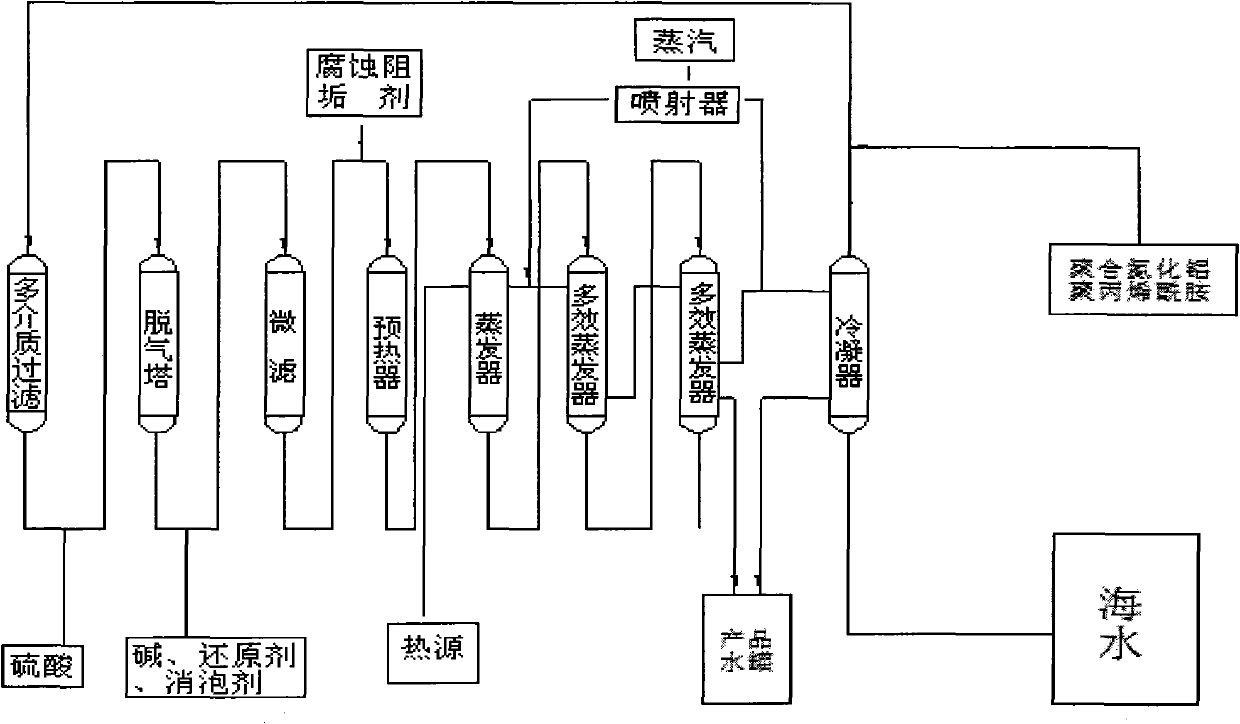

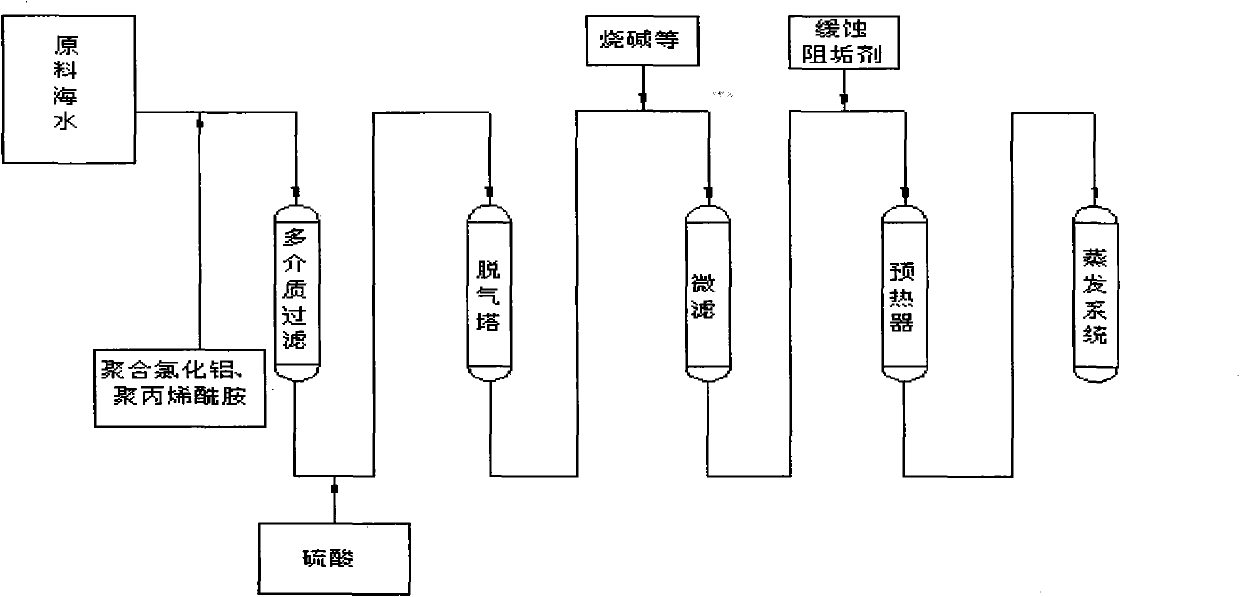

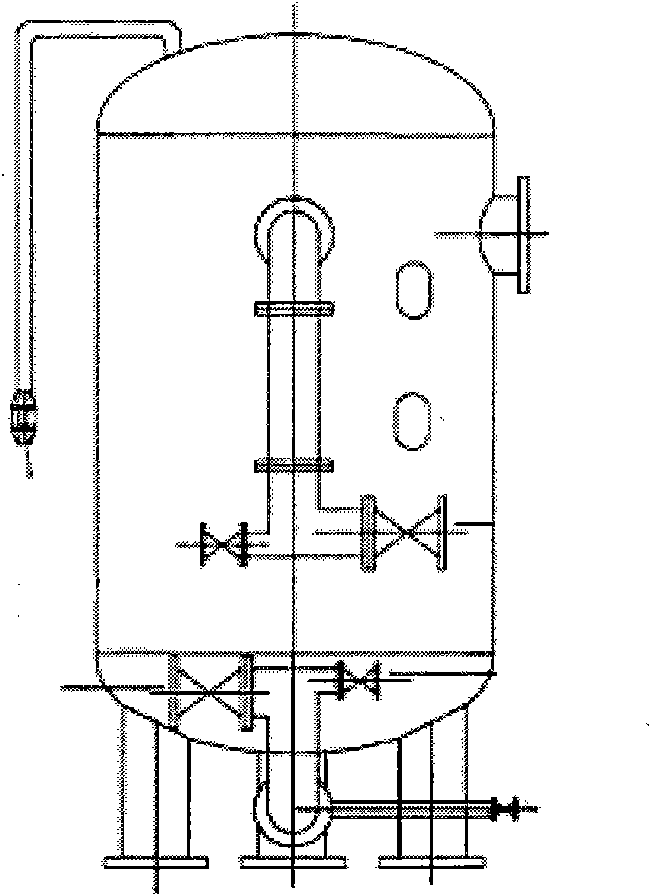

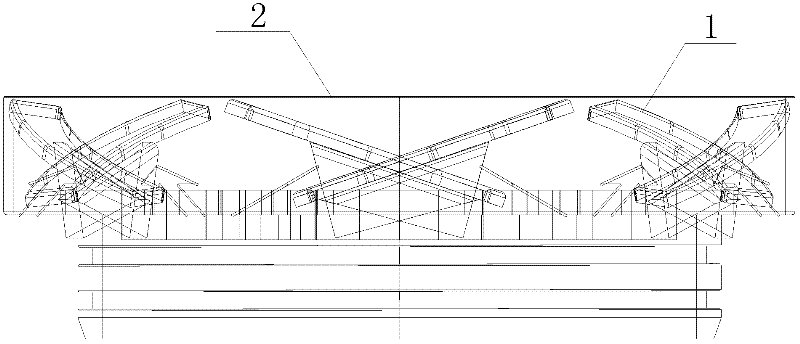

Process method and device for desalting seawater at low temperature

ActiveCN102531256BLow costReduce and inhibit growthSeawater treatmentMultistage water/sewage treatmentAluminium chlorideSulfite salt

The invention relates to a process method and a device for desalting seawater at low temperature. The process method comprises the following steps that: adding aluminum polychlorid and polyacrylamide into the seawater, and feeding into a multi-media filter; preheating the seawater to 43 DEG C, regulating the pH value to be 4.3, adding acid and feeding into a degassing tower to remove carbon dioxide and dissolved oxygen from the seawater; adding sodium hydroxide, a reducer sodium sulfite and an organosilicon defoaming agent into the seawater, and feeding into a microstrainer to remove small molecular organic matter; adding an organophosphorus corrosion and scale inhibitor into the seawater, feeding into the tube side of a preheater and heating to 72.4 DEG C, and feeding into an evaporator for evaporation; allowing the seawater at an outlet of the evaporator to flow into a first multi-effect evaporation tower to ensure that the seawater is concentrated; and allowing the seawater to flow into a second multi-effect evaporation tower so as to further finish the concentration of the seawater, obtaining freshwater at an outlet of the sixth-effect shell side of the second multi-effect evaporation tower, condensing by using a condenser, and feeding into a product water tank. Desalted water for boilers can be obtained by the process method, the content of oxygen is less than 3ppb, the content of carbon dioxide is less than 3ppm, and the possibility of dirt growth is also reduced or inhibited in the preheating and evaporation process.

Owner:PETROCHINA CO LTD +1

High-concentration ammonia-nitrogen wastewater treatment process

ActiveCN103936192BCompliance with emission standardsSolve the problem of incomplete precipitationWater contaminantsMultistage water/sewage treatmentHigh concentrationFiltration membrane

The invention relates to a high-concentration ammonia-nitrogen wastewater treatment process which comprises the following steps: (1) adding magnesium salt and phosphate into wastewater to be treated according to the ammonia-nitrogen concentration of the wastewater, wherein the molar ratio of NH<3->N:Mg<2+>: PO4<3-> in the wastewater is controlled at 1:(2-3.5):(1.5-3.0); and adjusting the pH value of the wastewater by a sodium hydroxide solution to 8.5-9, and stirring for 3-5 minutes; (2) after full reaction, filtering the wastewater by a micro-filtration membrane, wherein effluent generated after filtering by the micro-filtration membrane is the wastewater without ammonia-nitrogen; and dehydrating concentrated solution (separated out after filtration of the micro-filtration membrane) by a plate-and-frame filter press; and (3) after dehydration by the plate-and-frame filter press, refluxing the obtained filtrate and mixing with the wastewater to be treated, wherein the main component of the filter residue is struvite which is directly recovered as an agricultural fertilizer or is regenerated to be recycled. The process provided by the invention is low in cost, and not only can treat ammonia-nitrogen in the wastewater to reach the discharge standard, but also can recycle useful components from the wastewater.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

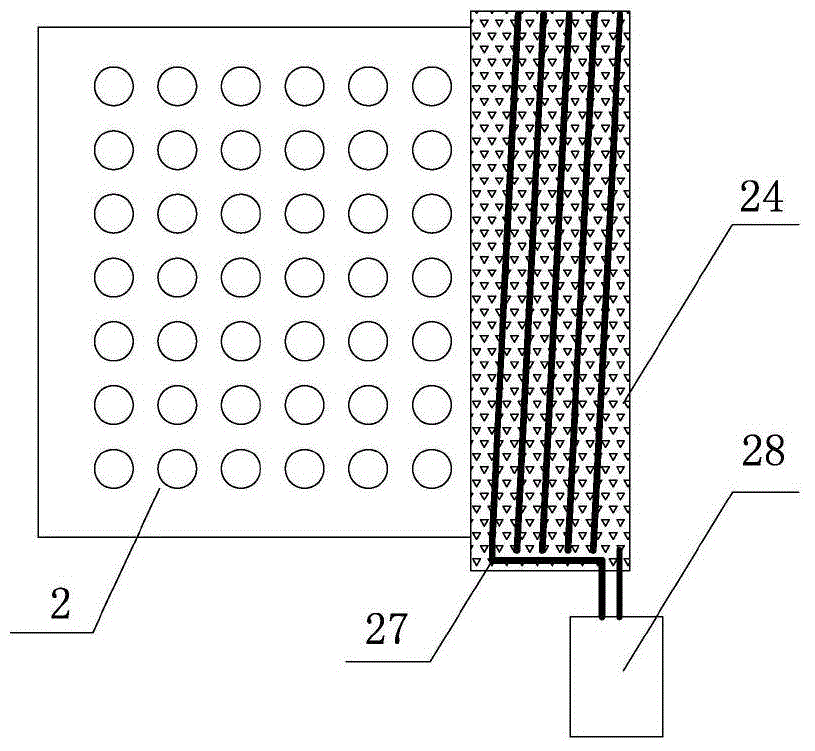

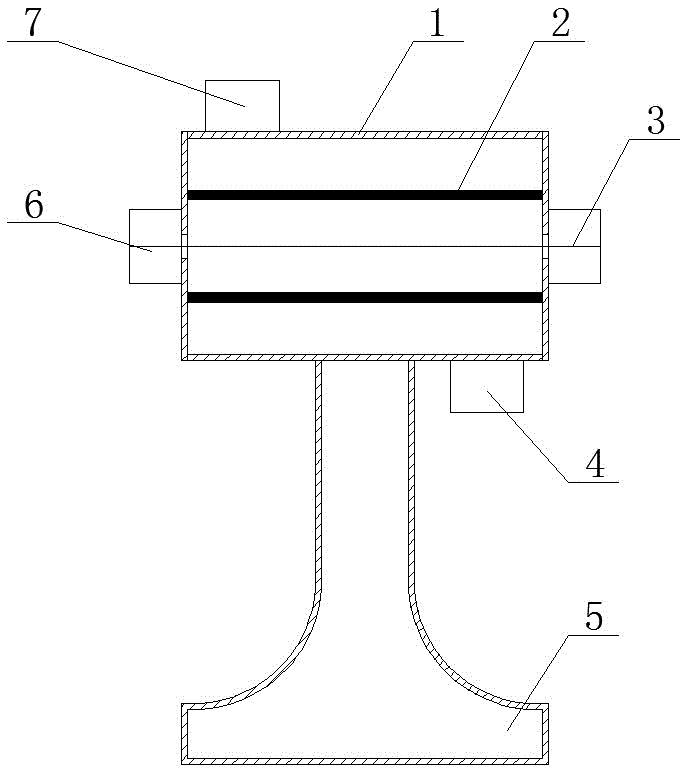

Laminated filtering centrifugal diversion base

InactiveCN102416276AReduce cleaning frequencyReduce backwash frequencyFiltration circuitsStationary filtering element filtersWater savingWater quality

The invention discloses a laminated filtering centrifugal diversion base, which comprises a centrifugal diversion base body and a laminating group, wherein diversion blades are uniformly arranged between the outer wall of the centrifugal diversion base body and the laminating group, and have arc-shaped structures; and one end of each diversion blade is higher than the other end. Due to the adoption of the diversion blades in the centrifugal diversion base, water current is centrifuged under the action of diversion blades while flowing through the diversion base, particles in water get far away from the laminating group, move toward the top end along the outer wall of the centrifugal diversion base and are finally concentrated on the top of a filter unit, only a small quantity of impurities are attached to the surface of the laminating group, the cleaning frequency of the laminating group is greatly lowered, filtering is more effective, the water-saving effect is more remarkable, the back flushing frequency is lowered, the filtering efficiency is increased by 30 percent and the back flushing efficiency is lowered by 20 percent under the condition of the same water quality, and a centrifugal sand-stone separator used in the conventional configuration can be saved.

Owner:乌鲁木齐瑞拓环保设备制造有限公司

Automatic sand flushing device for upper electric field water discs

InactiveCN104987880AExcellent self-lubricating performanceReduce depositionDewatering/demulsification with electric/magnetic meansRefining by electric/magnetic meansSpray nozzleElectric field

The invention relates to an automatic sand flushing device for upper electric field water discs. The automatic sand flushing device for the upper electric field water discs comprises automatic sand removing plates, a back flushing inlet pipe, multiple back flushing water pipes, multiple spray nozzles and downpipes, the automatic sand removing plates are arranged on the upper sides of the bottom faces of the corresponding water discs, the water discs are each in a V shape, and correspondingly, a water groove is formed in the bottom of each water disc; the back flushing water pipes are arranged above the automatic sand removing plates, the spray nozzles are evenly distributed on the back flushing water pipes, the back flushing inlet pipe is communicated with the back flushing water pipes to supply water to the back flushing water pipes, and the downpipes are communicated with the water grooves in the bottoms of the water discs. By means of the automatic sand flushing device for the upper electric field water discs, the defect that sediments and mechanical impurities cannot be removed automatically through original double-oil-taking and double-electric-field electric desalting and dewatering equipment in the crude oil desalting and dewatering process of upper electric fields is overcome.

Owner:JIANGSU GOLDEN GATE ENERGY & EQUIP CO LTD +1

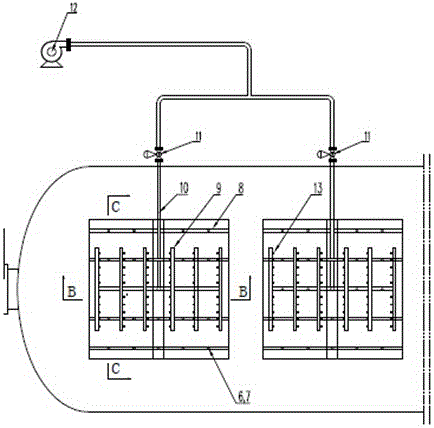

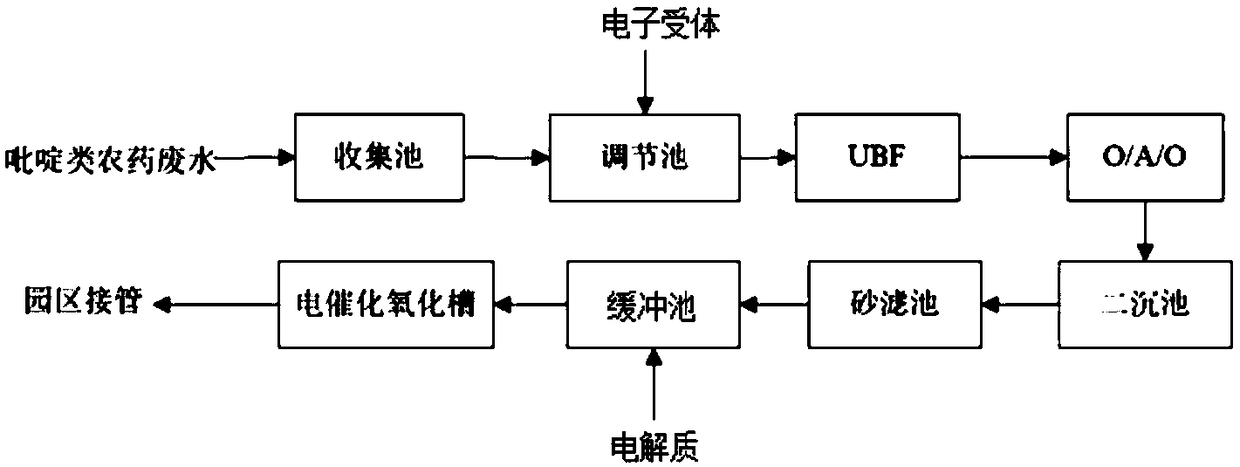

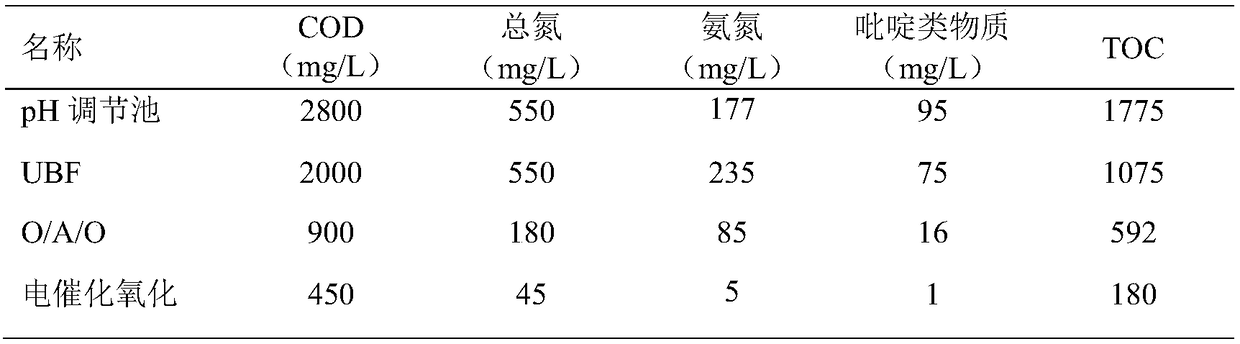

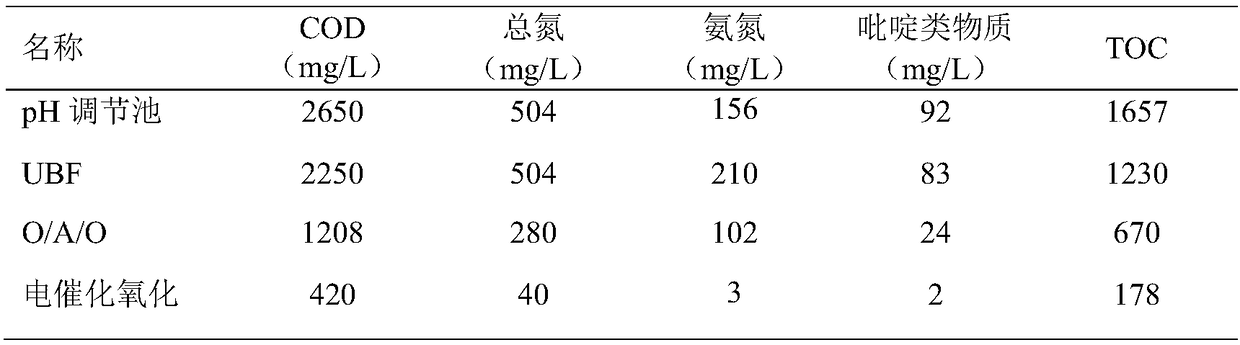

Method for treating pyridine pesticide wastewater by aid of biological-electrochemical coupling technologies

ActiveCN108892321AMeet the process requirementsAvoid water CODWater contaminantsTreatment involving filtrationChemical oxygen demandCatalytic oxidation

The invention discloses a method for treating pyridine pesticide wastewater by the aid of biological-electrochemical coupling technologies, and belongs to the technical field of pesticide wastewater treatment. The method includes carrying out UBF+O / A / O microbial enhanced treatment on the pyridine pesticide wastewater; carrying out sand filter on biochemical effluent and then treating the biochemical effluent by the aid of electro-catalytic oxidation technologies. The method has the advantages that exogenous electron receptors are provided, accordingly, anaerobic and anoxia biodegradation effects can be enhanced, and ring-opening degradation of pyridine substances can be promoted; the biochemical effluent is efficiently electro-catalytically oxidized to treat the wastewater, accordingly, the high-COD (chemical oxygen demand), high-ammonia and high-nitrogen pyridine wastewater which is difficult to biochemically degrade can be efficiently and stably treated by the aid of the method, andpyridine pesticide wastewater discharge can reach standards; the method is easy and convenient to operate, high in efficiency and stability and free of secondary pollution, maintenance can be facilitated, and the like.

Owner:江苏南大华兴环保科技股份公司

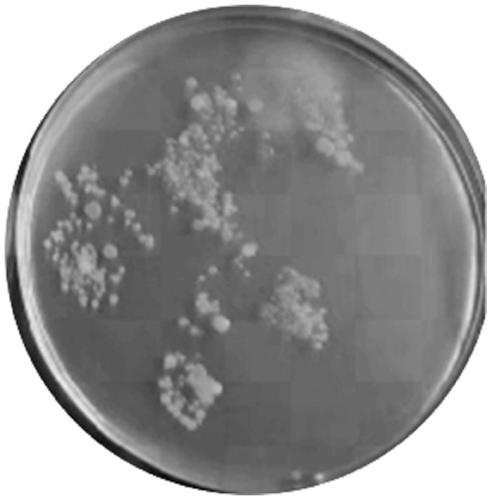

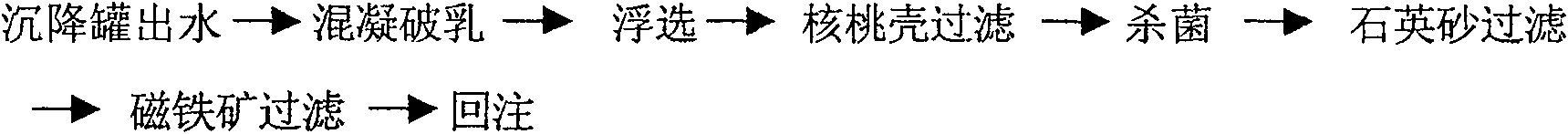

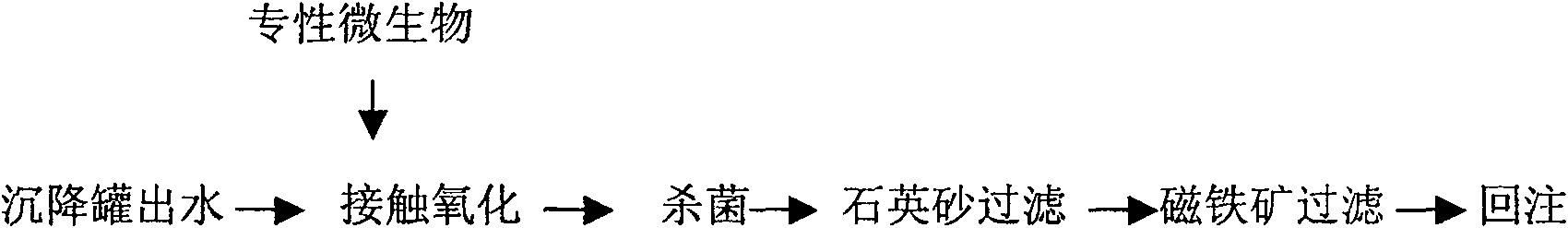

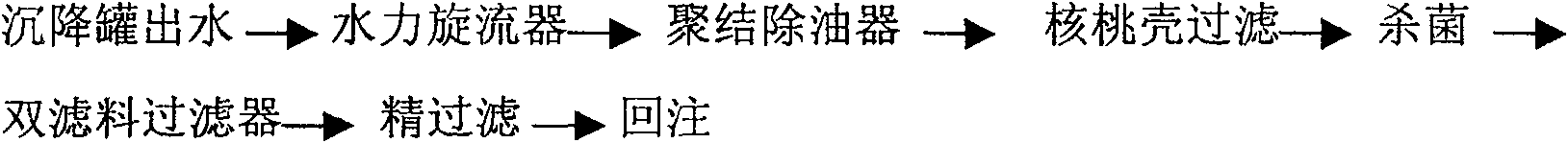

Oil field re-injection water microbiological treatment

ActiveCN100572524CImprove salt toleranceEasy to handleTreatment using aerobic processesBacteriaWater qualityOil field

The improved process of treating oil field effluent for reinjection features aerobic biochemical treatment and subsequent filtering. The microbes for the aerobic biochemical treatment include Bacillus cereus, Corynebacterium, Bacillus subtilis and Pseudomonas alcaligenes, and the inflow water has pH value controlled in 6-9. The process can reach oil field water injection standard, including oil not more than 2 mg / l, SS not more than 1 mg / l and grain size mid value not greater than 1 micron. The present invention has the advantages of simple technological process, low cost, stable treating effect, no secondary pollution, etc., and is especially suitable for use in oil field.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

Novel membrane filtration method and device adopting same

InactiveCN105461018AReduced impurity adhesion rateLow costSemi-permeable membranesMembranesFiltration membraneWater discharge

The invention provides a novel membrane filtration method and a device adopting the same and belongs to the field of sewage treatment. The method includes the steps of 1 coarse filtration, 2 fine filtration and 3 ceramic filtration, wherein the ceramic filtration is that tiny impurities are filtered out by using a filtering membrane under the effect of vibration waves; the vibration waves are provided by a vibration device which can be a vibration machine or an ultrasonic generator. The pore size of the filtering membrane is 0.1 to 100 um. The membrane filtration device by adopting the method comprises a shell (1) and the filtering membranes (2), wherein the shell (1) is fixedly provided with a sewage port I (3), a sewage port II (4), a clear water port I (6) and a clear water port II (7) which are used for sewage feeding, sewage discharging, clear water feeding and clear water discharging respectively. The inner cavity of the shell (1) is divided into a sewage cavity and a clear water cavity by the filtering membrane (2), and the sewage cavity and the clear water cavity are respectively communicated with the sewage ports and the clear water ports. The device is further provided with the vibration device for providing vibration waves for the filtering membrane (2). The impurity attaching rate of the filtering membrane is remarkably reduced, the service life of the filtering membrane is remarkably prolonged, the back flushing frequency is reduced, maintenance workload is reduced, and the efficiency is improved.

Owner:石勇

System capable of improving recycled waste emulsion ultrafiltration efficiency by use of pH regulation

InactiveCN104609528AReduce pollutionExtended service lifeWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by neutralisationHigh concentrationLiquid waste

The invention relates to a system capable of improving recycled waste emulsion ultrafiltration efficiency by use of pH regulation. The system comprises a waste emulsion holding tank, an ultrafiltration membrane component connected with the waste emulsion holding tank by use of a pipeline, and also a pH value regulating device connected with the waste emulsion holding tank; the pH value regulating device is used for regulating the pH value of a solution in the waste emulsion so that the solution can be weakly alkaline. Compared with the prior art, the system is characterized in that NaOH or dilute sulfuric acid is added to the waste emulsion to regulate the pH to the range of 9-10 so that the waste liquid can be weakly alkaline, next, the waste liquid is fed into the ultrafiltration membrane component by use of a high-pressure pump for ultrafiltration, and then clean water is discharged, while the high-concentration waste liquid is discharged from the other side; as a result, the ultrafiltration effect is greatly improved, and more importantly, the pollution on the membrane due to impurities in the filtration process is reduced, and moreover, the frequency of back washing is reduced and the service life of the membrane is prolonged.

Owner:SHANGHAI DAZHONG XIANGYUAN POWER SUPPLY

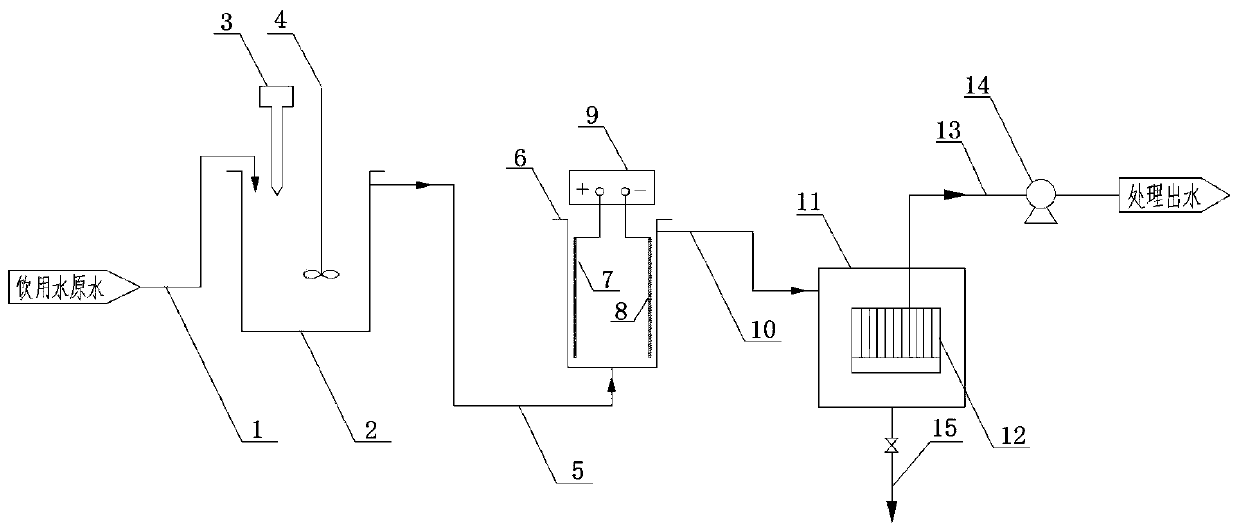

Water treatment system and method for removing humic acid in drinking water

PendingCN109879496ASmall operating pressure lossReduce backwash frequencyWater contaminantsMultistage water/sewage treatmentFlocculationWater treatment system

The invention discloses a water treatment system and method for removing humic acid in drinking water. The water treatment system for removing the humic acid in the drinking water comprises a chemicalcoagulation device, an electric flocculation device and an ultrafiltration membrane separation device, wherein the chemical coagulation device communicates with the electric flocculation device, andthe electric flocculation device communicates with the ultrafiltration membrane separation device. According to the water treatment system and method for removing the humic acid in the drinking water,a chemical coagulation-electric flocculation coupling-ultrafiltration membrane separation technology is adopted to remove the humic acid in drinking water raw water, and the treated yield water can meet the requirement of Chinese (hygienic standard for drinking water) (GB5749-2006); and the technical structure is simple, the yield water quality is stable, the operating pressure loss of the ultrafiltration membrane separation device is small, the decay speed of membrane flux is low, and the membrane module backflushing frequency is low.

Owner:WUHAN POLYTECHNIC UNIVERSITY

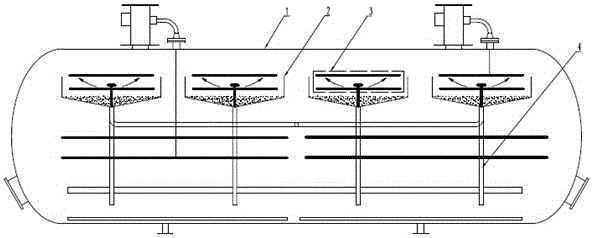

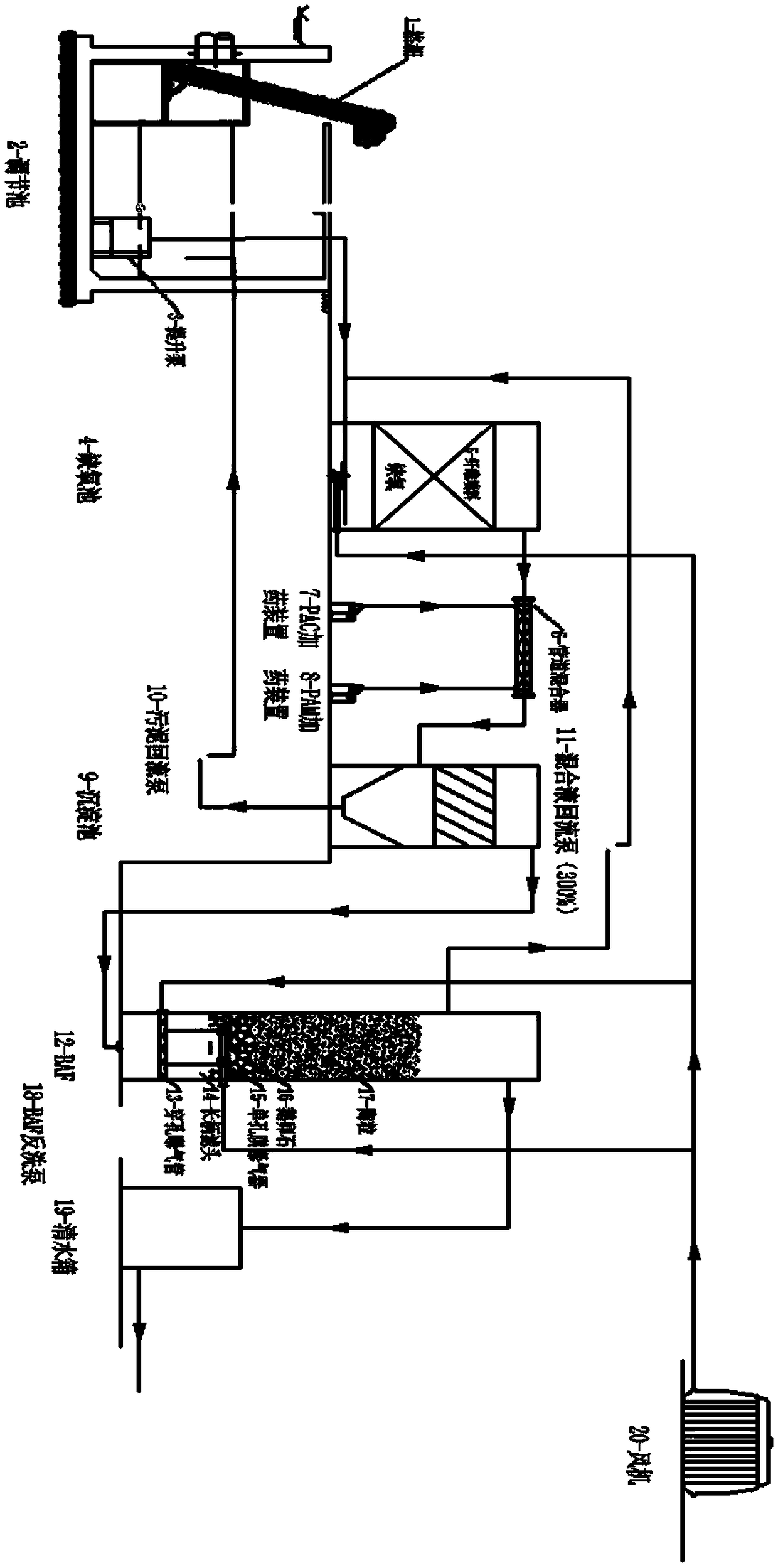

Integrated and efficient sewage treatment equipment for treating urban domestic sewage

PendingCN109264934AUniform air distributionNot easy to blockSpecific water treatment objectivesTreatment involving filtrationSewageEnergy consumption

The invention belongs to the technical field of sewage treatment equipment, and particularly relates to integrated and efficient sewage treatment equipment for treating urban domestic sewage. The efficient sewage treatment equipment mainly comprises a grid, a regulating tank, a lifting pump, a front high-density filler anoxic tank, a pipeline mixer, a sedimentation tank, a BAF biological aerated filter (BAF) and a clean water tank which are sequentially connected. The integrated and efficient sewage treatment equipment can solve the problem that the aerated biological filter tank has high requirements for the concentration of suspended matter of inflow water, and reduce the backwashing frequency and energy consumption; the quality of outflow water is greatly improved, and the outflow waterreaches level-A standards.

Owner:鹏凯环境科技股份有限公司

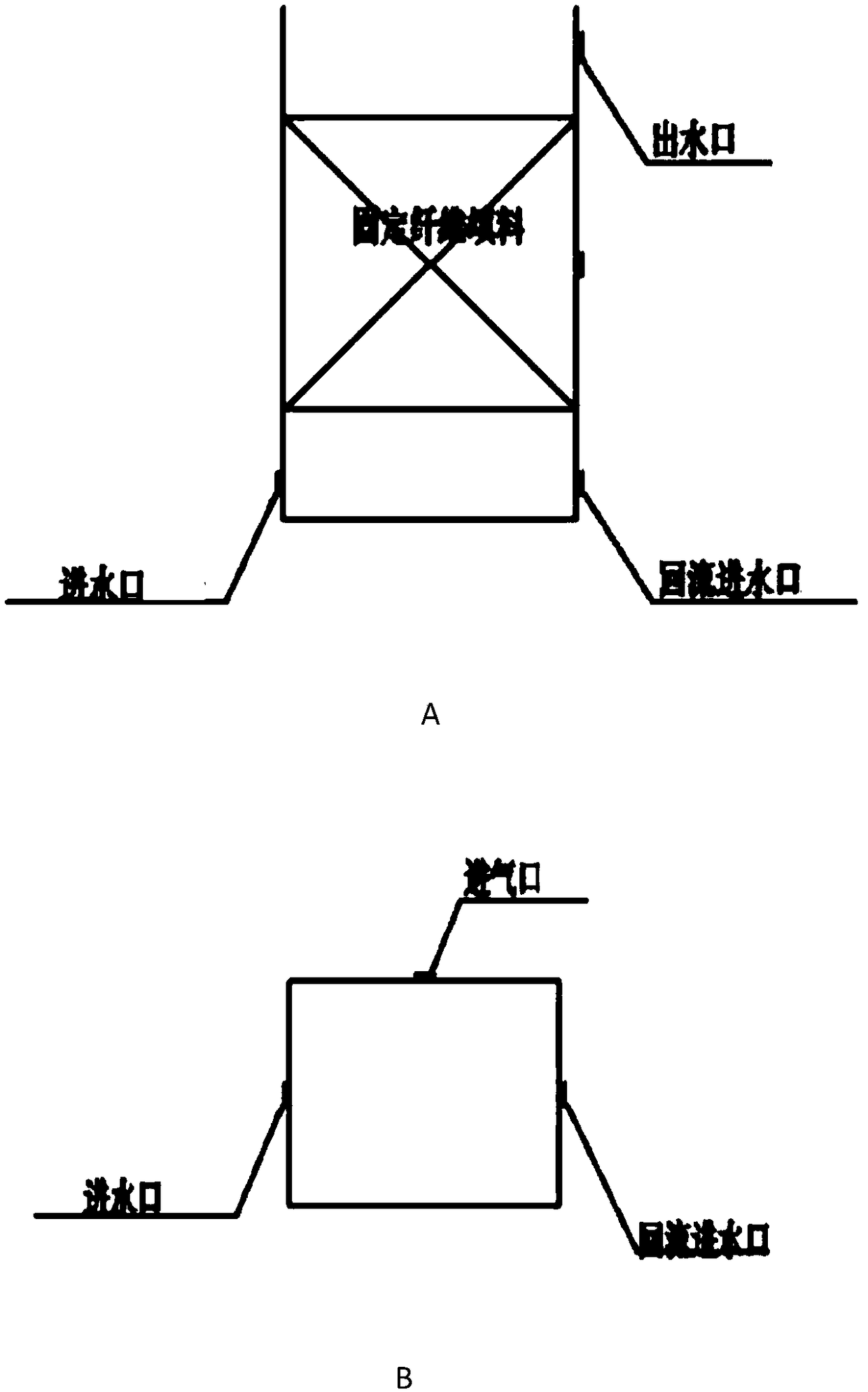

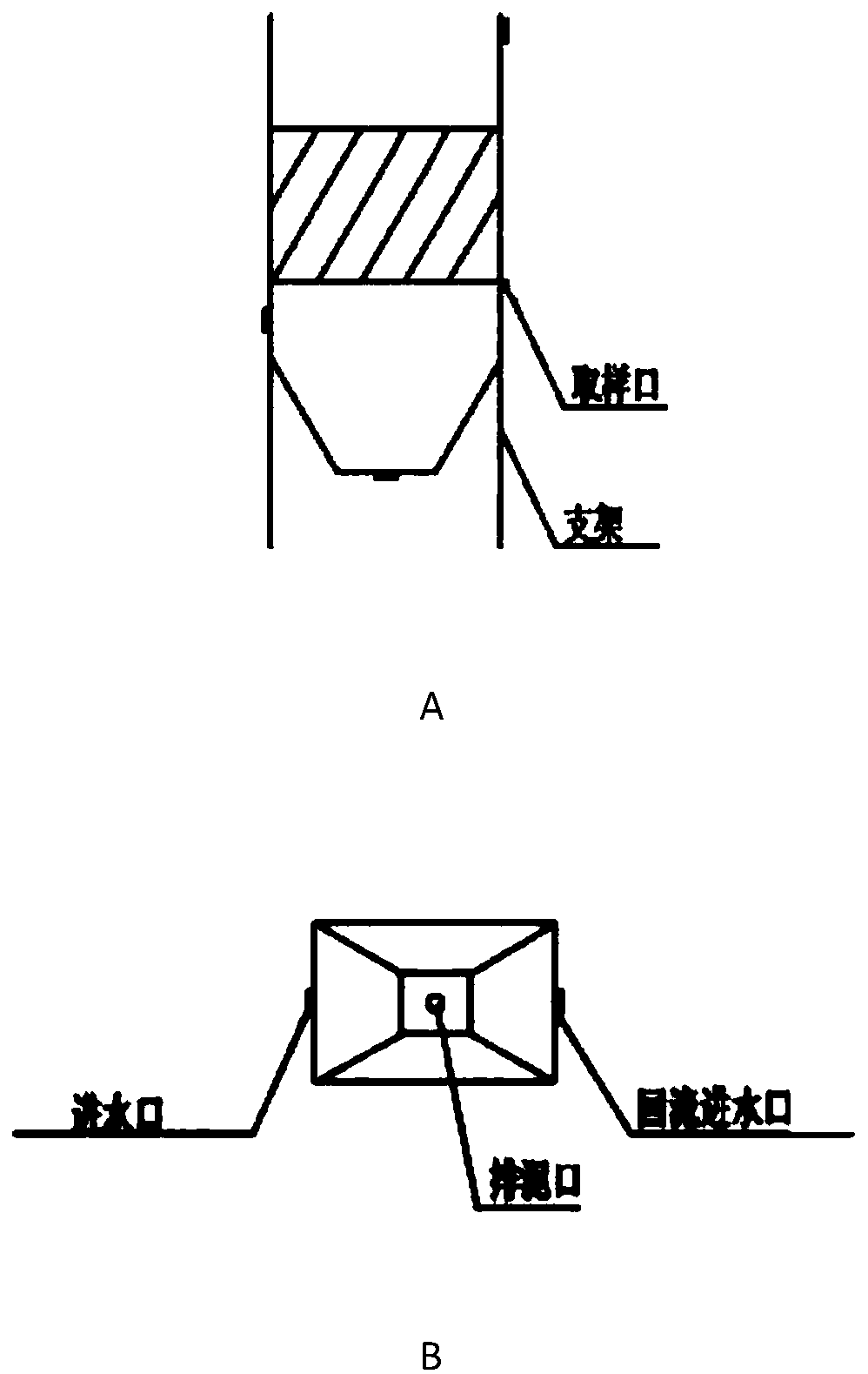

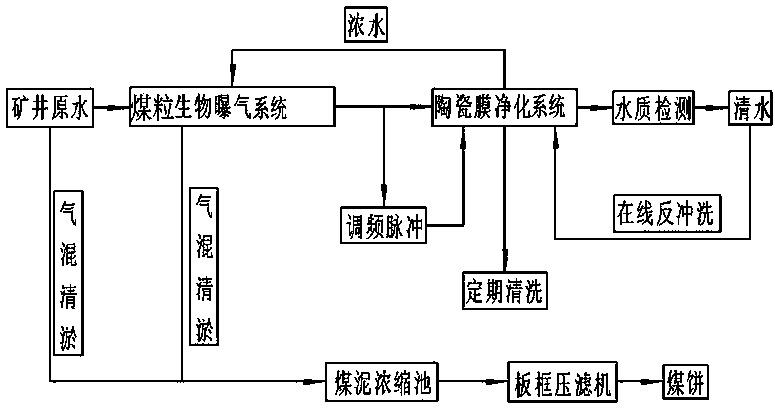

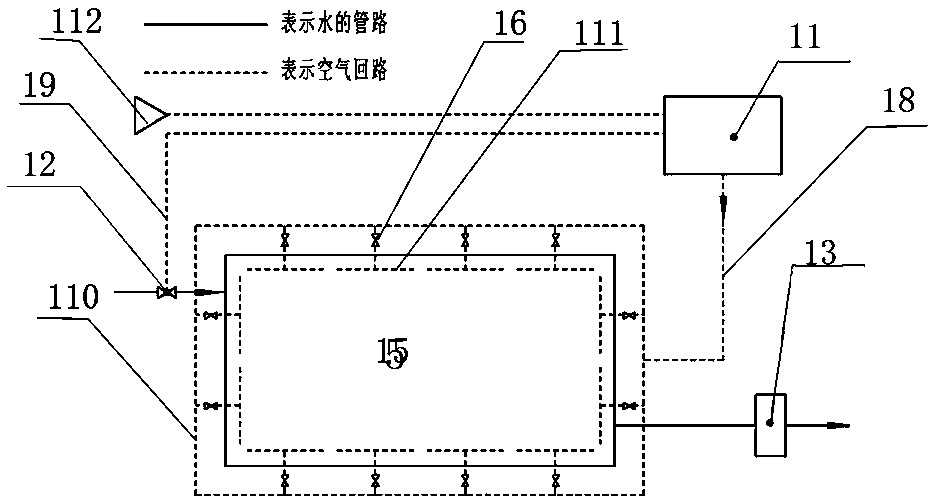

Novel comprehensive treatment device for coal mine water

PendingCN108503148AImprove running stabilityReduce backwash frequencyWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningAeration systemEnvironmental engineering

The invention provides a novel comprehensive treatment device for coal mine water. The device comprises a coal particle biological aeration system, a ceramic membrane purification system, coal slurrygas mixing and dredging systems and a slurry pressing system; after raw mine water enters the coal slurry aeration system for treatment and sedimentation, supernatant liquid enters the ceramic membrane purification system for purification, concentrated water purified by the ceramic membrane purification system is discharged and enters the coal particle biological aeration system again, then clearwater purified by the ceramic membrane purification system is discharged and enters a clear water pool; coal slurry treated by the coal particle aeration system is settled and mixed with gas in the gas mixing and dredging system of an aeration pool and then enters the slurry pressing system. The device is simple in process and machinery, convenient to maintain, safe and practical, and the use of coagulating agents and the environmental risk brought by chemical agents are avoided.

Owner:HENAN JINYUAN ENVIRONMENTAL PROTECTION TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com