Autotrophic deep bed filter using novel composite filler

A composite filler, autotrophic technology, applied in special compound water treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as high cost and organic pollution, reduce sludge production, The effect of reducing energy consumption and avoiding secondary pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A self-supporting deep bed filter using a new type of composite filler.

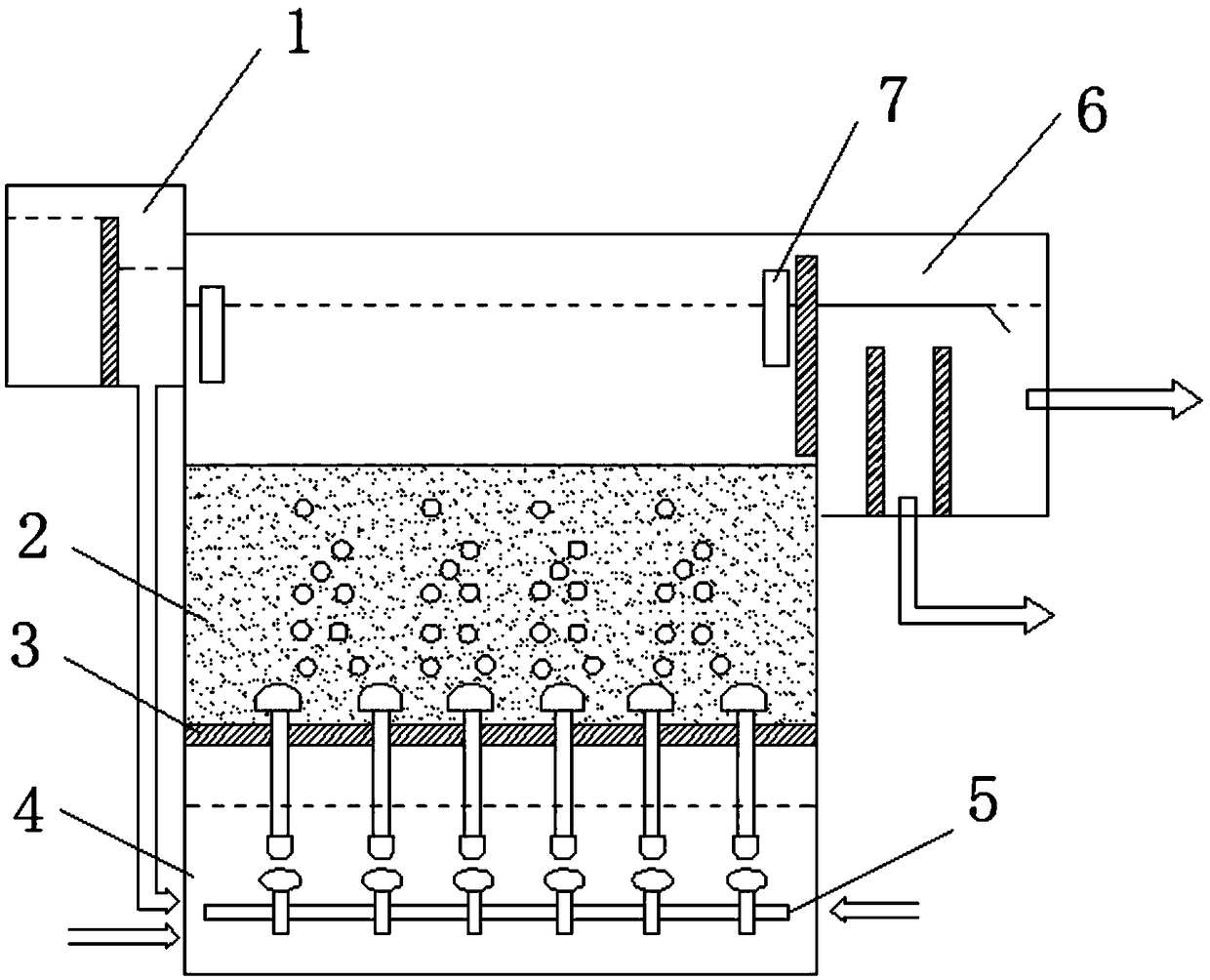

[0024] refer to figure 1 , the upper part of the filter is a water inlet and a backwash outlet respectively, wherein the water inlet is equipped with a water distribution channel 1, and the backwash outlet is equipped with a backwash outlet 6. Between the water distribution channel 1 and the filter tank, and between the backwash outlet channel 6 and the filter tank, a filter material intercepting device 7 is arranged to prevent the loss of the filter material during backwashing. A water inlet pipeline is arranged below the water distribution channel 1, and a backwash water inlet pipeline is arranged at the same time; a backwash outlet pipeline is arranged at the bottom of the backwash outlet channel 7, and an outlet pipeline is arranged on the right side of the backwash outlet channel 7.

[0025] The water distribution canal 1 of this embodiment adopts the water distribution of sub-unit channels....

Embodiment 2

[0038] Comparative Test.

[0039] Compared with the traditional heterotrophic deep bed filter:

[0040] The traditional deep bed filter uses gravel as the filter material, and realizes the denitrification treatment of sewage by adding carbon source. Compared with the more common heterotrophic deep bed filter with external carbon source, the deep bed denitrification filter using new sulfur-iron composite mineral filter material as filler does not need to add organic carbon source, which can effectively avoid the secondary pollution of COD. At the same time, the mud production is greatly reduced, which can reduce the frequency of backwashing and reduce energy consumption. At the same time, in terms of cost, the slow-release sulfur-iron composite filter material is cheaper than organic carbon sources, and it is easy to transport and store.

[0041] The main technical parameters:

[0042] Denitrification volume load: 600-900g / m 3 / d;

[0043] Sludge yield: 0.1g SS / g N;

[00...

Embodiment 3

[0050] Comparative Test.

[0051] Compared with the existing denitrification filter using sulfur ore or iron ore as filler.

[0052] The test structure is shown in Table 1 below.

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com