Process method and device for advanced treatment of nitrate nitrogen in water

A technology of advanced treatment and process method, applied in the field of water treatment, can solve the problems of huge consumption of reducing agent, large consumption of regeneration liquid, application limitation, etc., to reduce the loss of self-active denitrification filter material, reduce the amount of treated water, save energy Effects of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

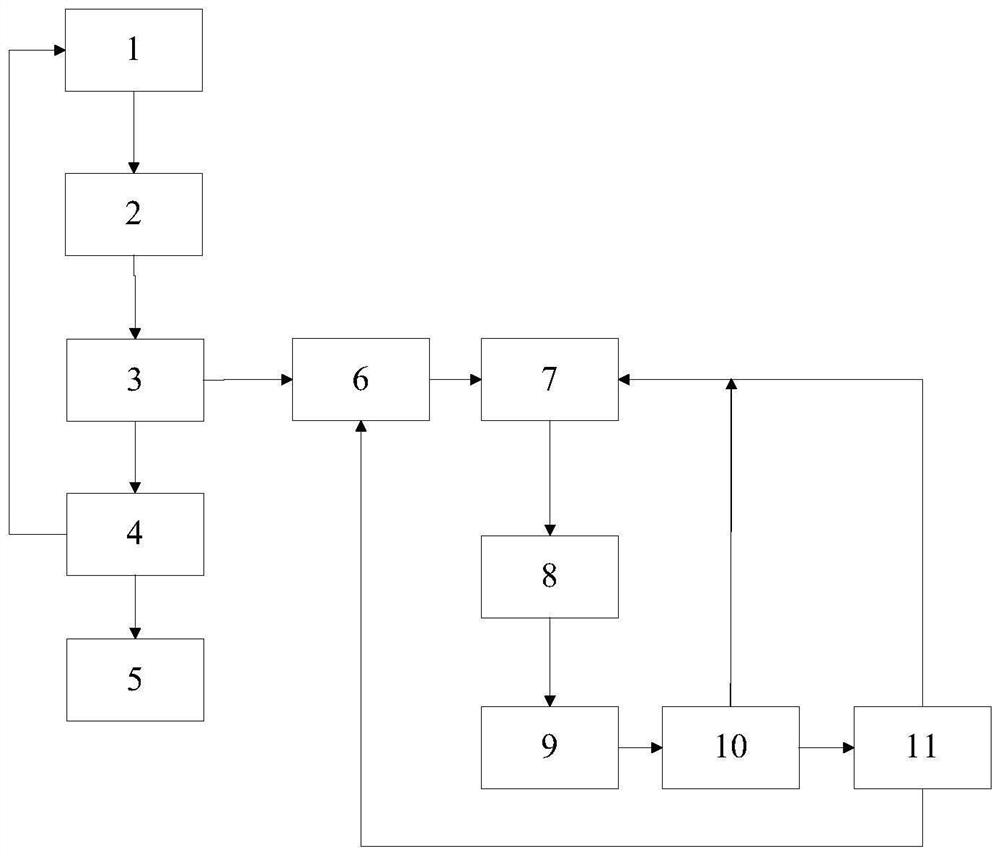

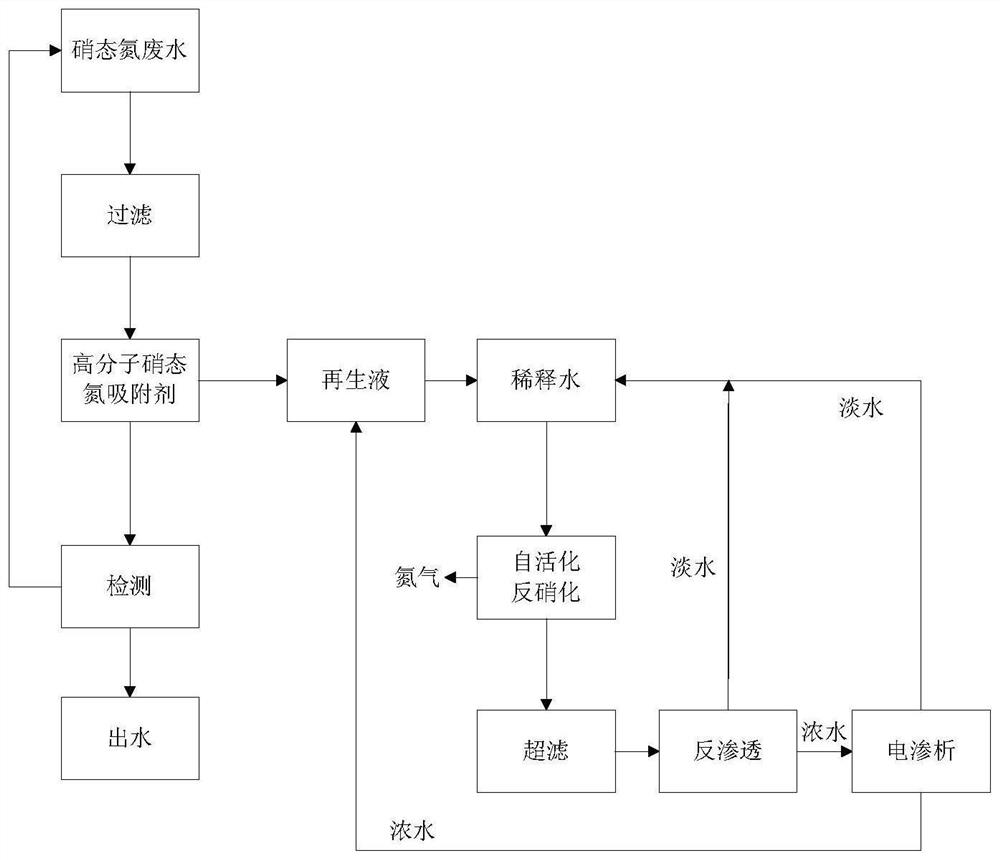

[0054] A device for advanced treatment of nitrate nitrogen in water, the schematic diagram of which is shown in figure 1 , including treatment process equipment and regeneration process equipment;

[0055] Treatment process equipment includes nitrate nitrogen wastewater storage tank 1, ion exchange security filter 2, ion exchange tank 3, nitrate nitrogen online monitoring equipment 4, effluent pool 5; regeneration process equipment includes regeneration liquid storage tank 6, dilution tank 7, Self-active denitrification filter 8, ultrafiltration system 9, reverse osmosis system 10 and electric drive ion membrane 11;

[0056] Wherein, the ion exchange tank 3 is provided with a water inlet, a water outlet, a regenerated liquid inlet and a regenerated liquid outlet, and the ion exchange tank 3 is provided with a polymer phenolic synthetic material with an exchange capacity of 15-30 mg / g. An inlet valve is also arranged above the ion exchange tank 3 for balancing the air pressure...

Embodiment 2

[0072] A device for advanced treatment of nitrate nitrogen in water is the same as that in Embodiment 1, except that a security filter is provided between the ultrafiltration system and the reverse osmosis system.

[0073] A process for advanced treatment of nitrate nitrogen in water, comprising the following steps:

[0074] Step 1: Adsorption

[0075] The mass concentration of nitrate nitrogen in the nitrate nitrogen wastewater in the nitrate nitrogen wastewater storage tank is 10-500mg / L;

[0076] Pass the nitrate nitrogen wastewater in the nitrate nitrogen wastewater storage tank through the ion exchange security filter to remove the sludge suspended matter produced by the front-end conventional nitrification treatment of the sewage, enter the ion exchange tank, and use the polymer nitrate nitrogen adsorbent for adsorption , after adsorption, the effluent from which nitrate radicals have been removed will be discharged to the effluent pool after being tested by the nitrate...

Embodiment 3

[0086] A device for advanced treatment of nitrate nitrogen in water, same as embodiment 1.

[0087] A process for advanced treatment of nitrate nitrogen in water, comprising the following steps:

[0088] Step 1: Adsorption

[0089] The mass concentration of nitrate nitrogen in the nitrate nitrogen wastewater in the nitrate nitrogen wastewater storage tank is 10-500mg / L;

[0090]Pass the nitrate nitrogen wastewater in the nitrate nitrogen wastewater storage tank through the ion exchange security filter to remove the sludge suspended matter produced by the front-end conventional nitrification treatment of the sewage, enter the ion exchange tank, and use the polymer nitrate nitrogen adsorbent for adsorption , after adsorption, the effluent from which nitrate radicals have been removed will be discharged to the effluent pool after being tested by the nitrate nitrogen online monitoring equipment. ;

[0091] Step 2: Regeneration

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com