Patents

Literature

33results about How to "Increase the strength of the current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

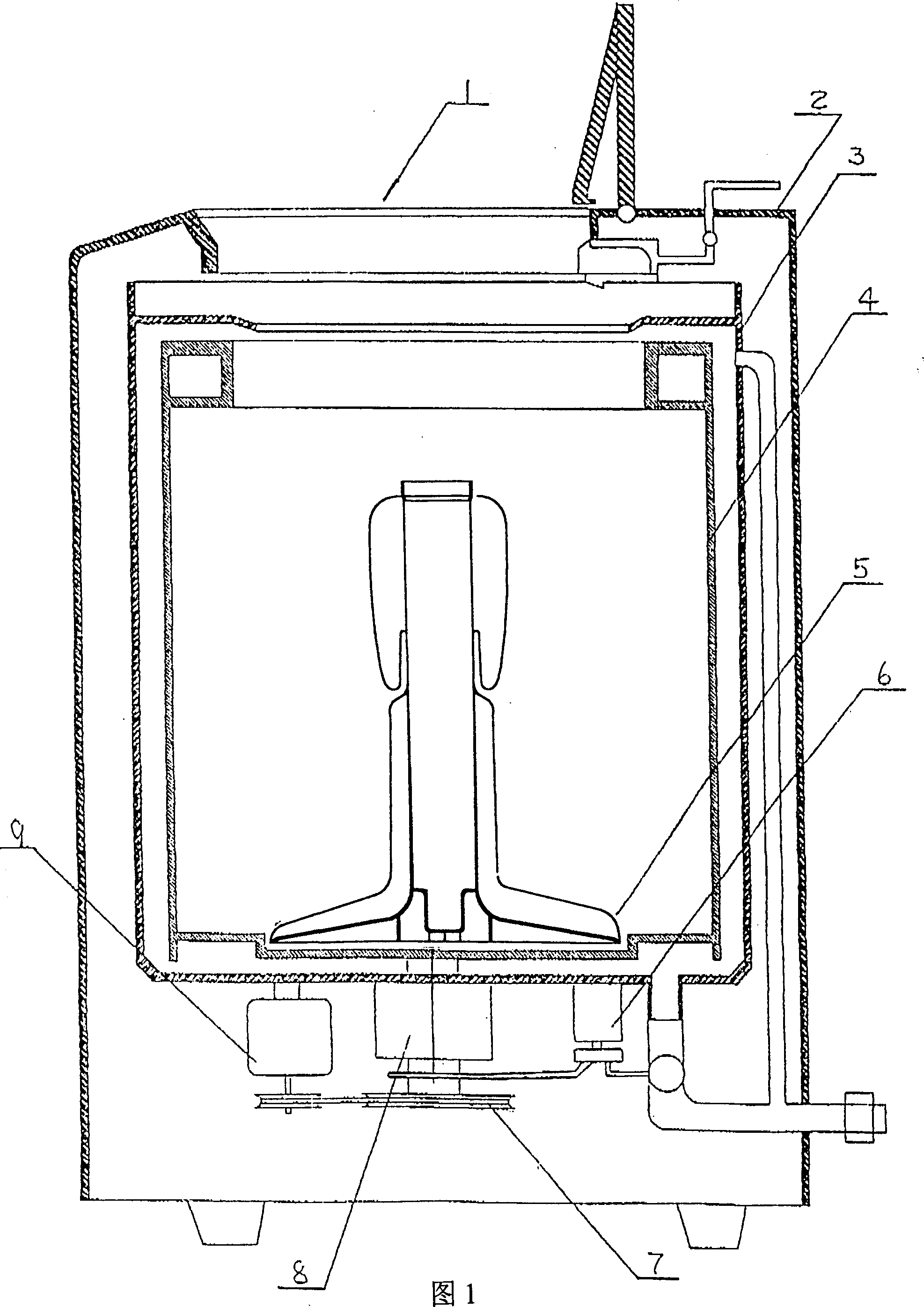

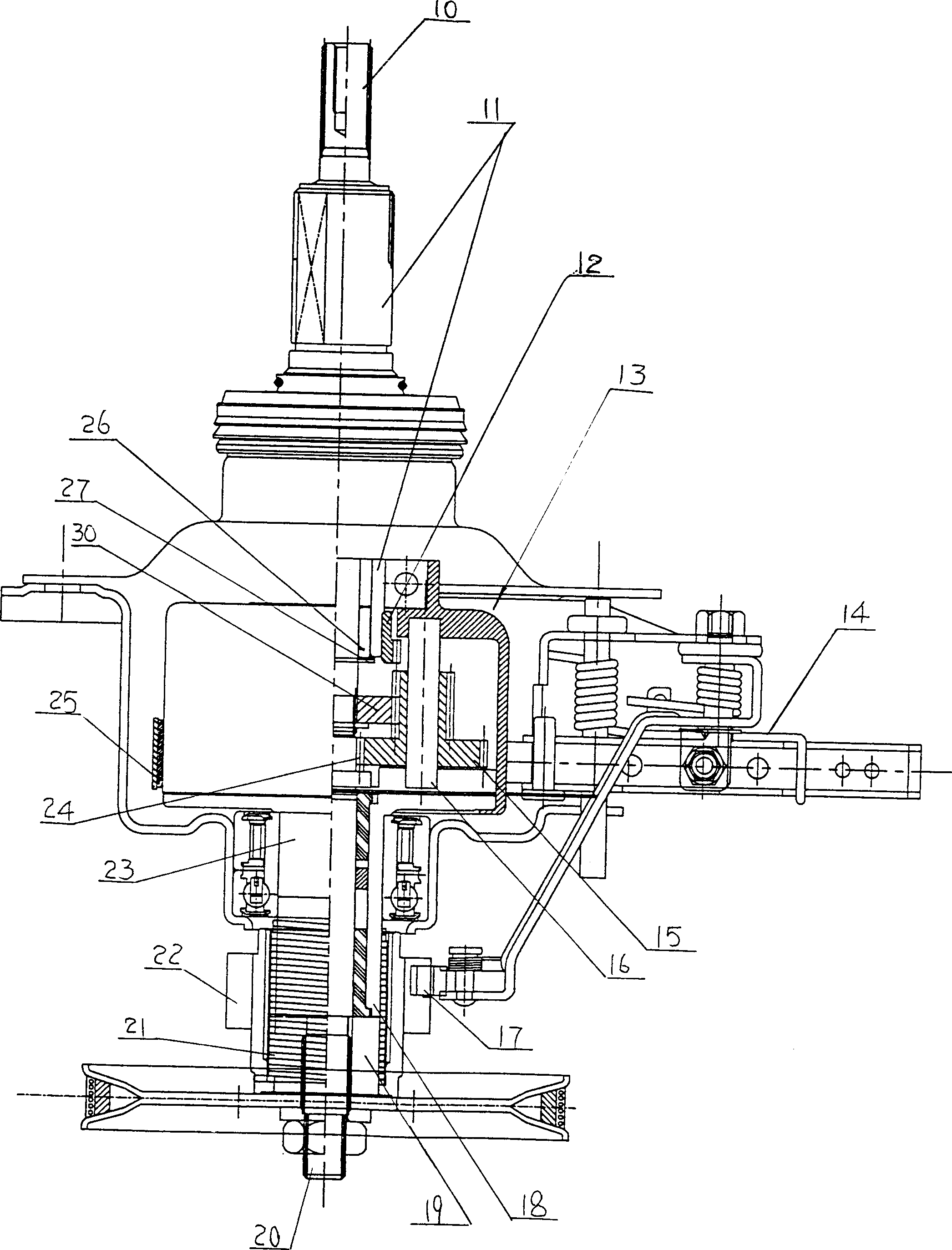

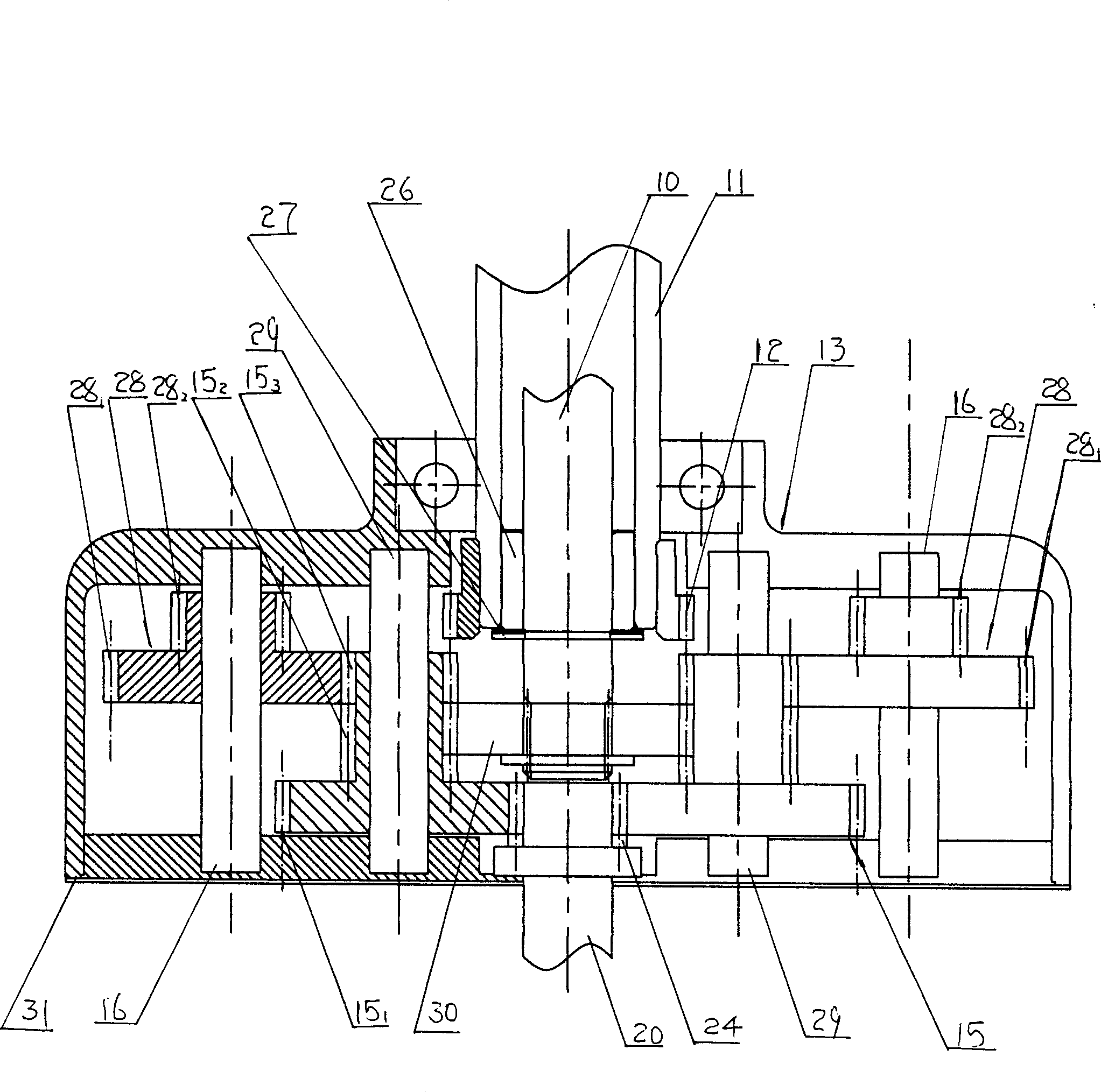

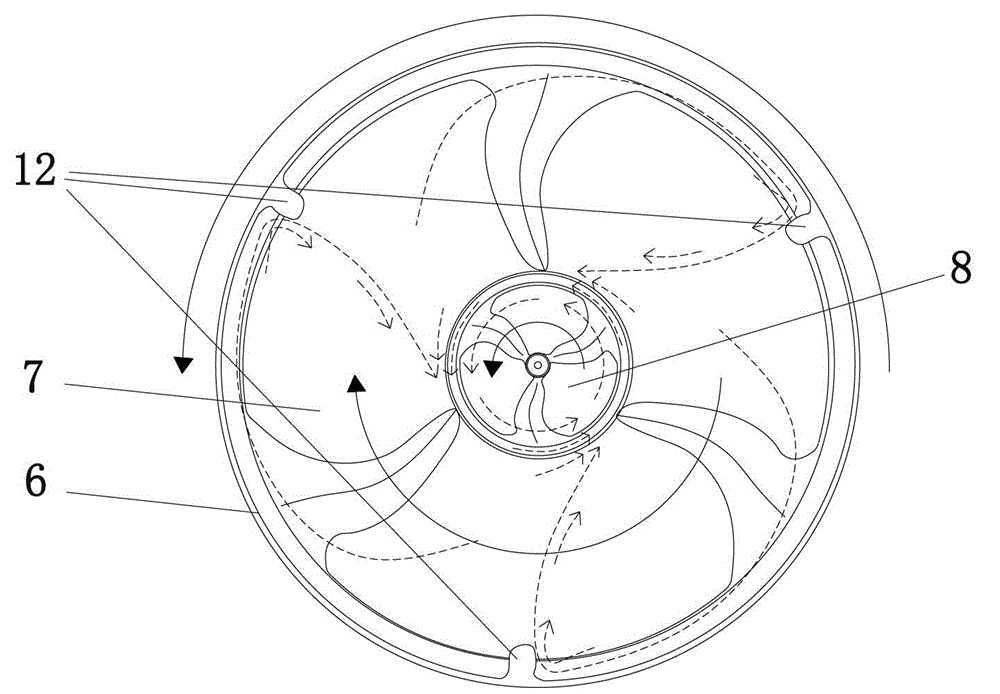

Washing method of agitatory washer and its washer

InactiveCN1381634AReduce entanglementIncrease the strength of the currentOther washing machinesWashing machine with receptaclesWater flowEngineering

Owner:HAIER GRP CORP +1

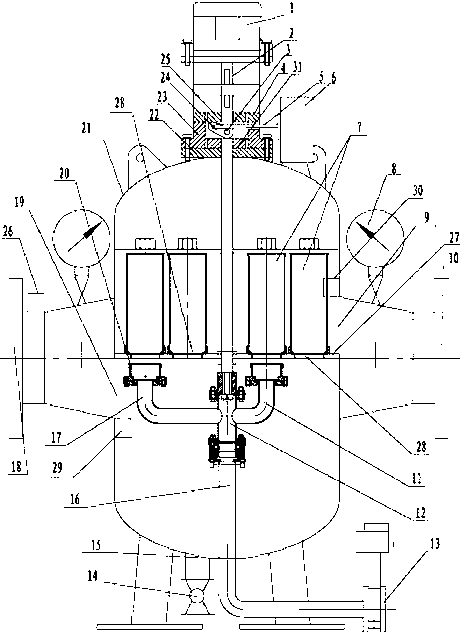

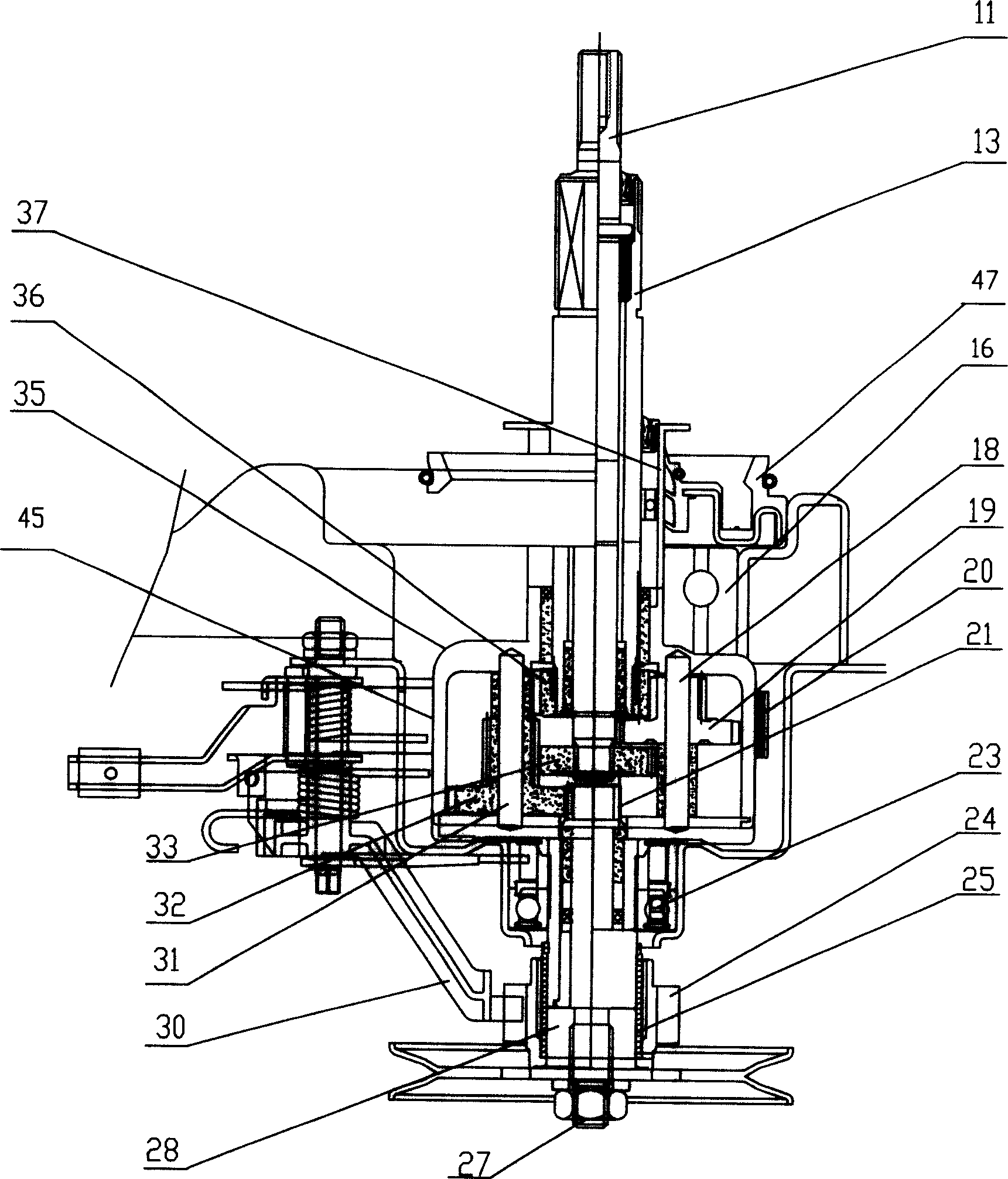

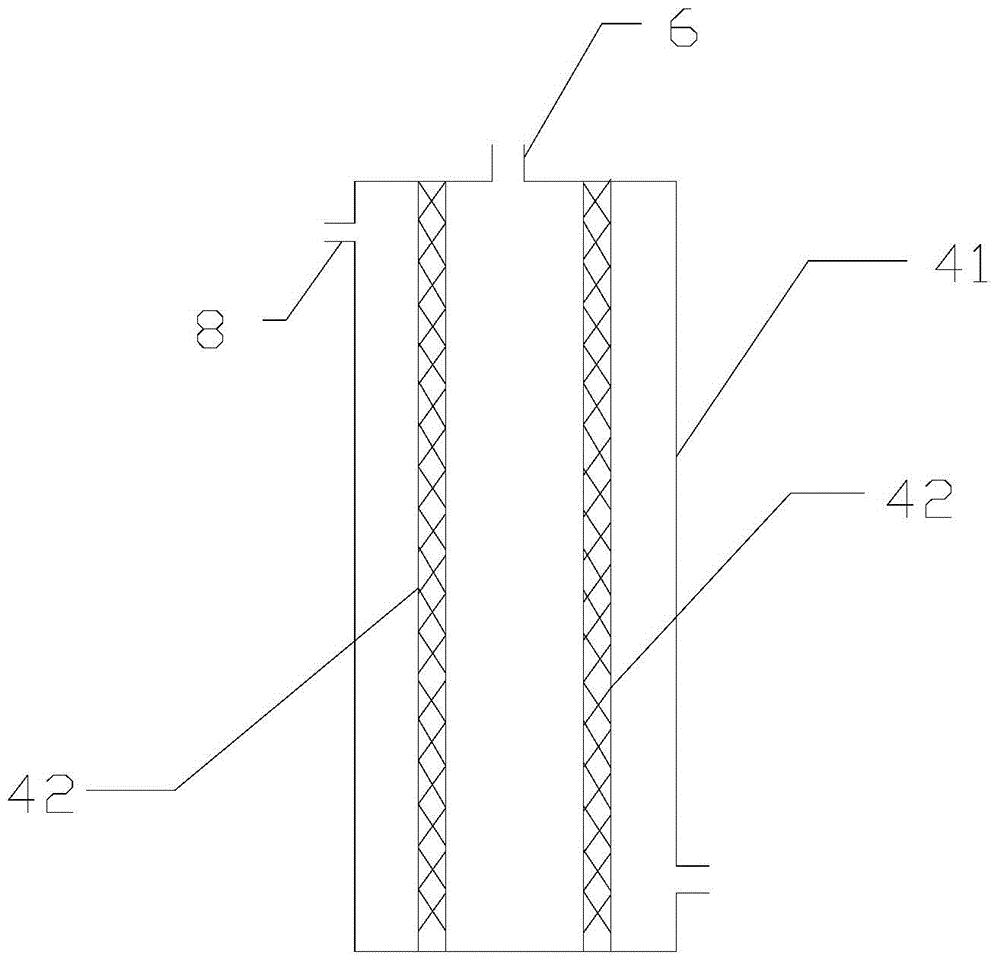

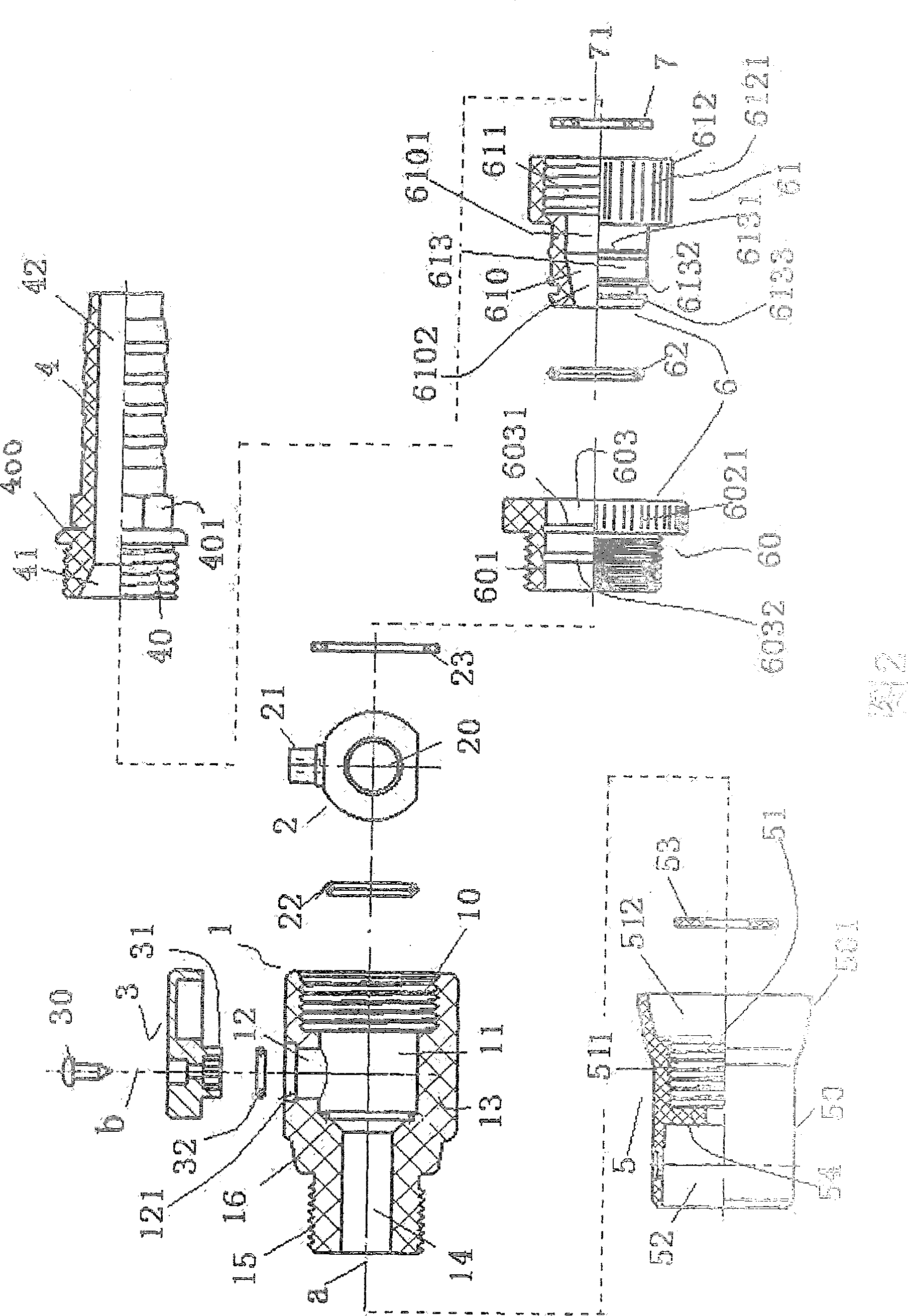

Multi-filter cylinder automatic backwashing filter apparatus

InactiveCN102794044AReduce backwash frequencyMaximum backwash frequencyStationary filtering element filtersElectric machineControl system

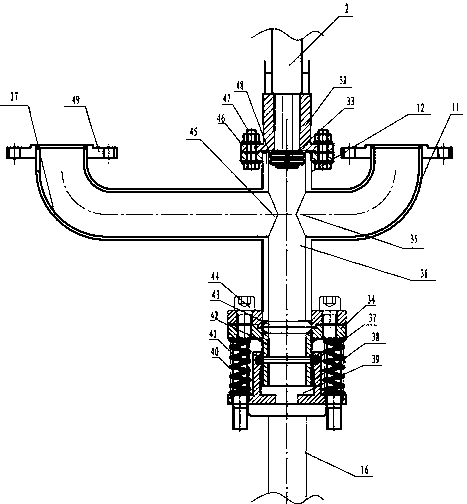

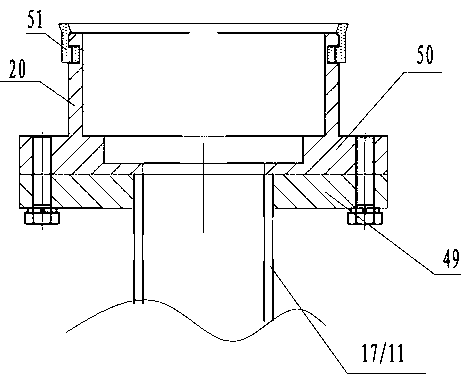

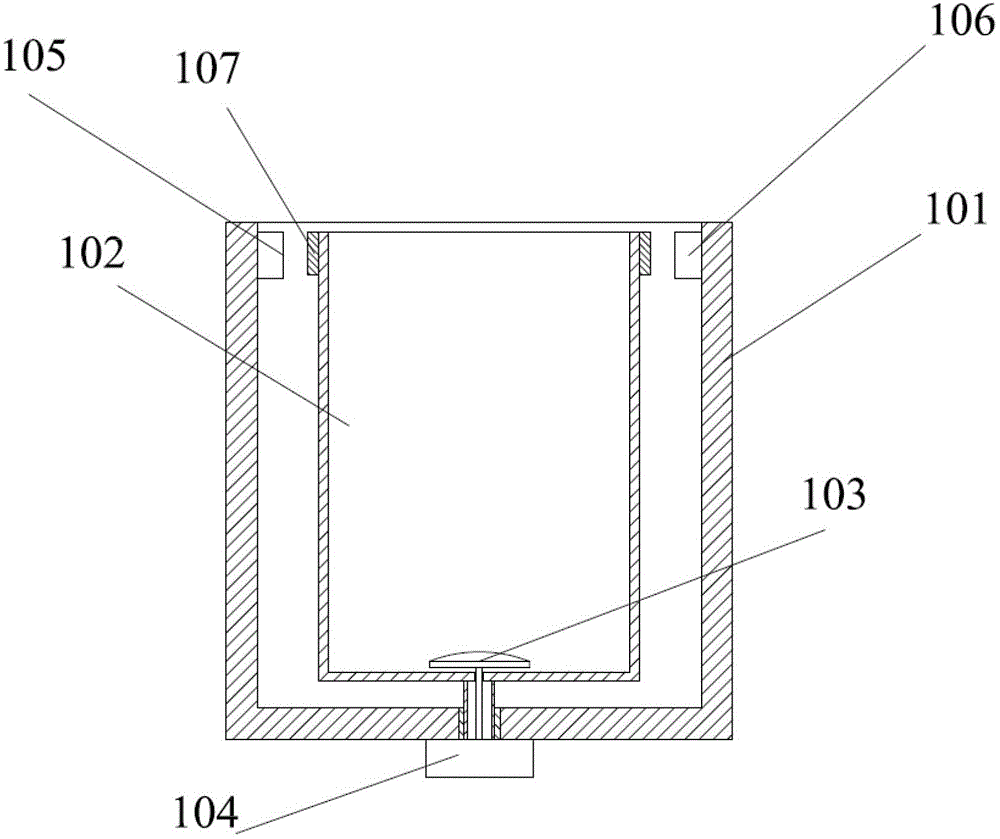

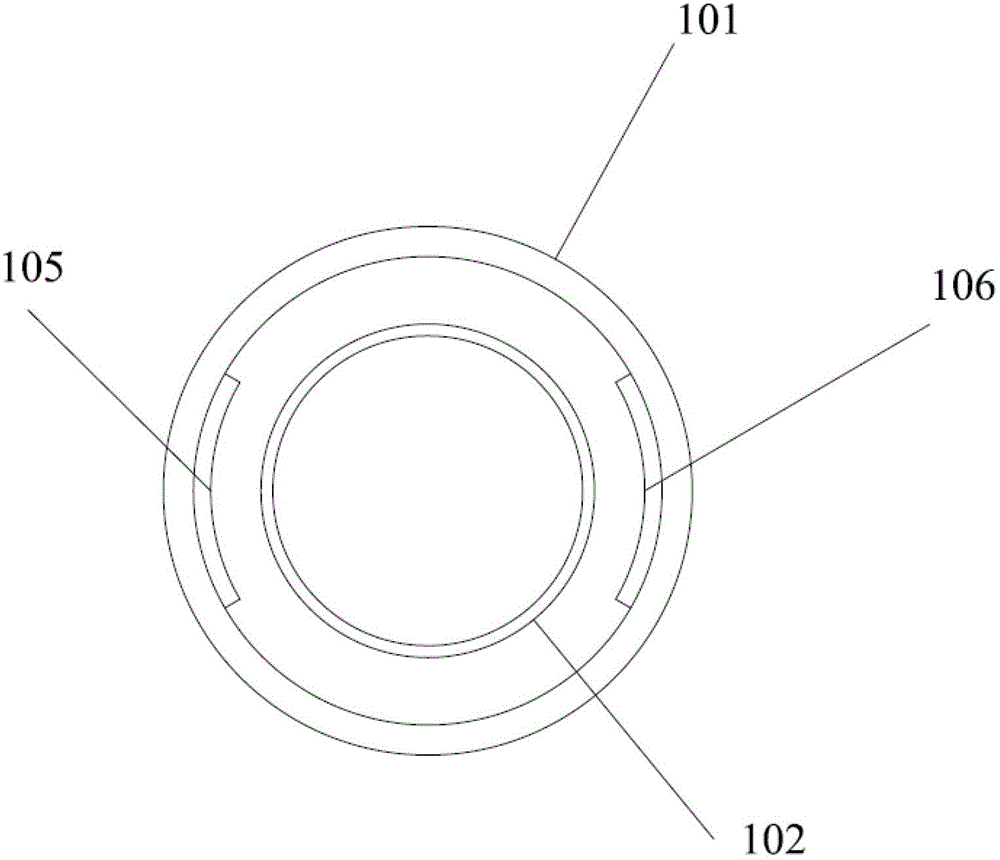

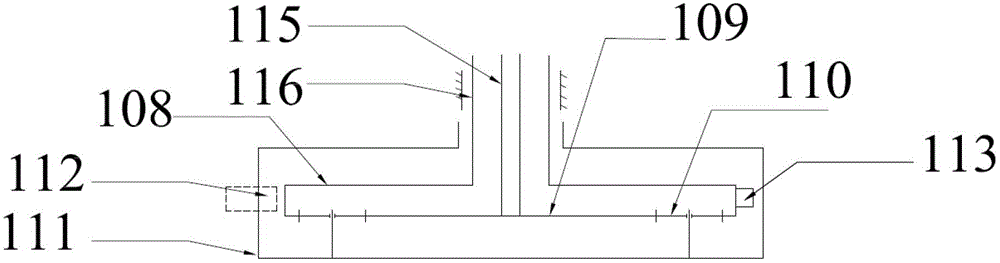

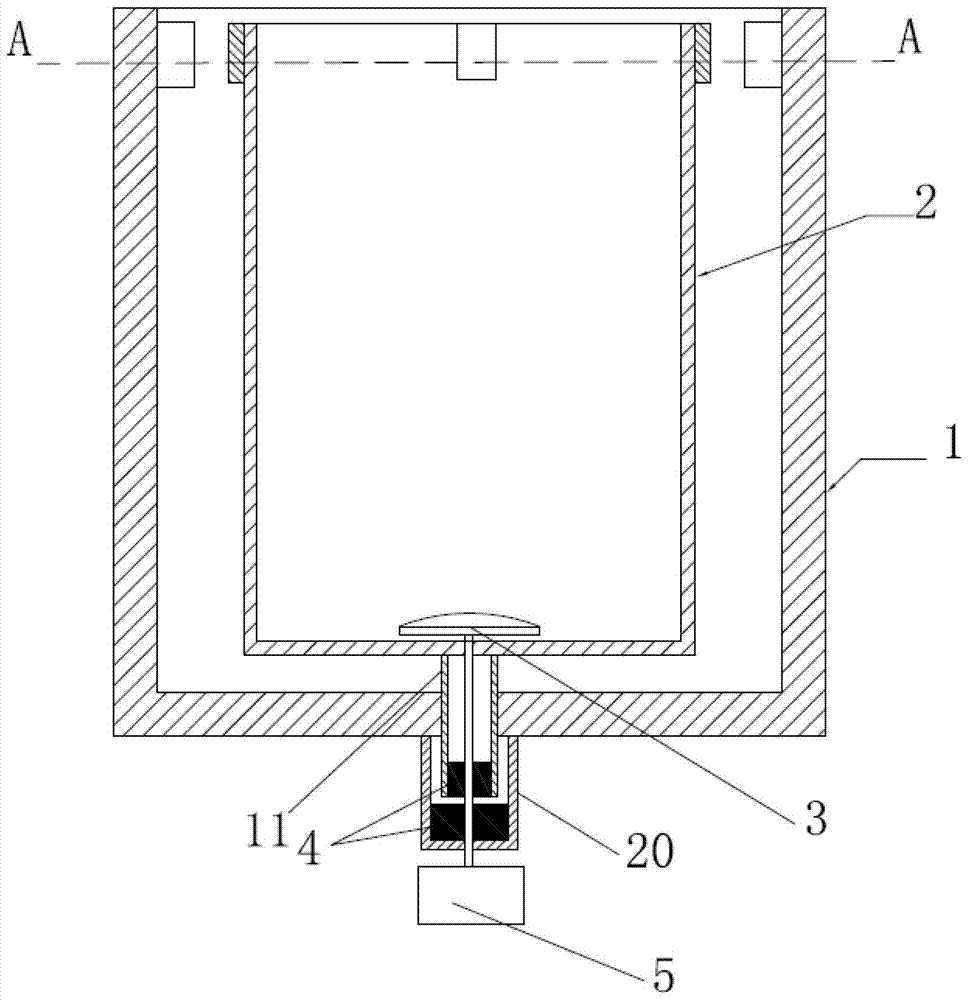

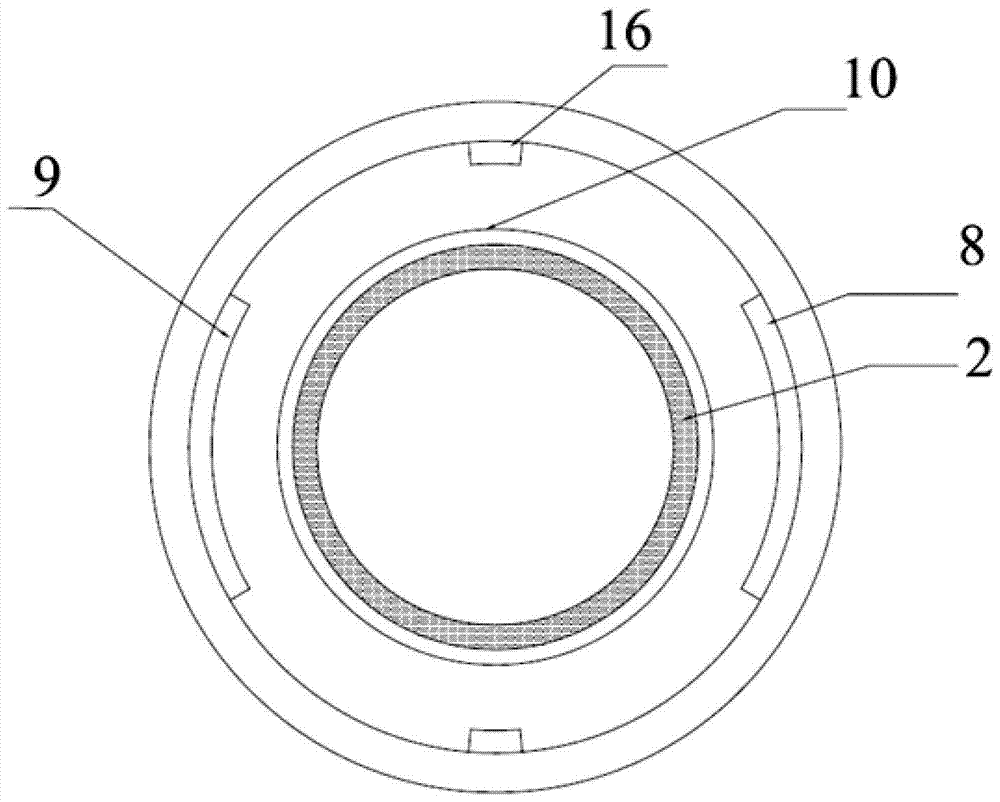

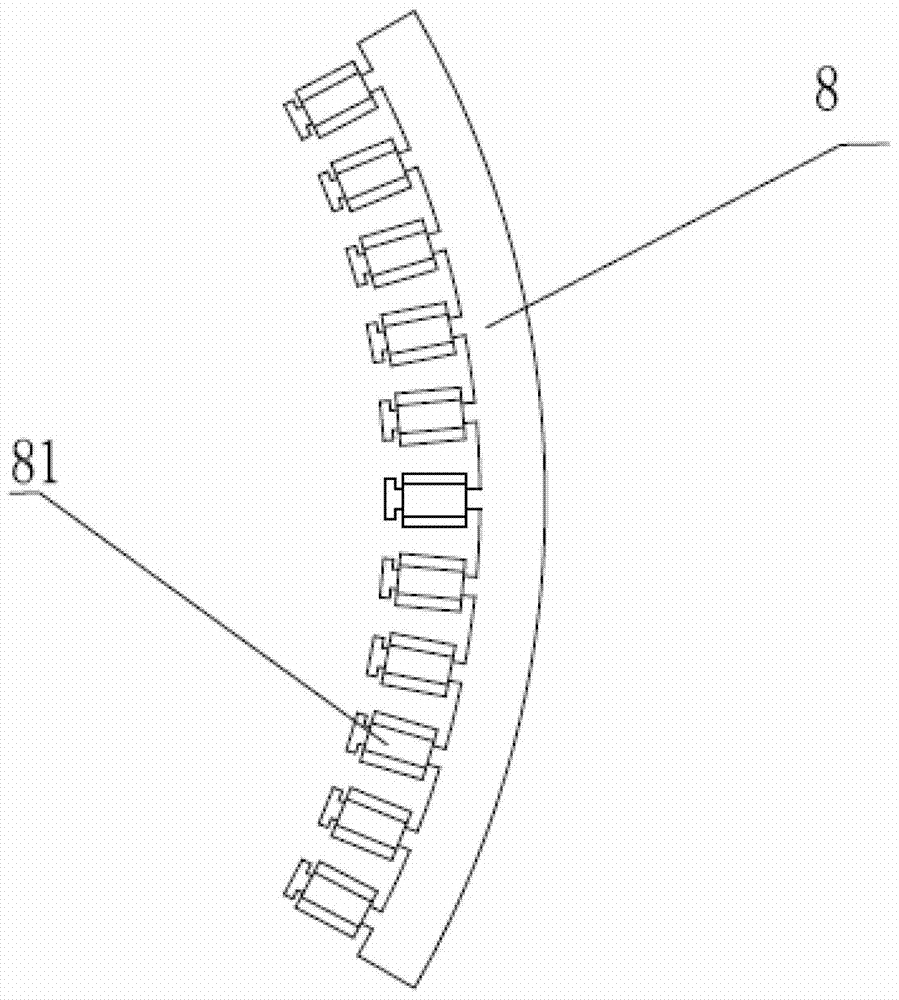

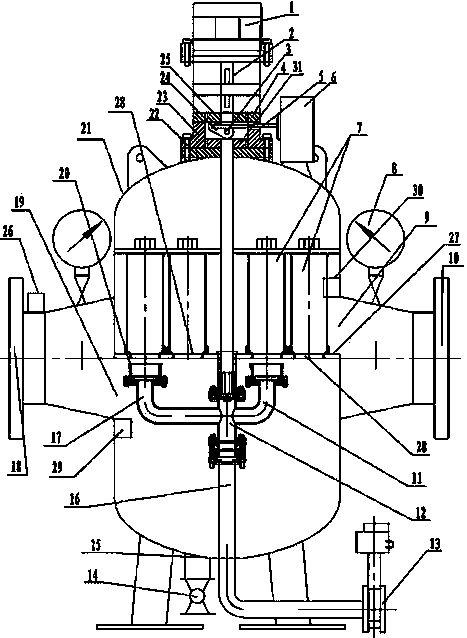

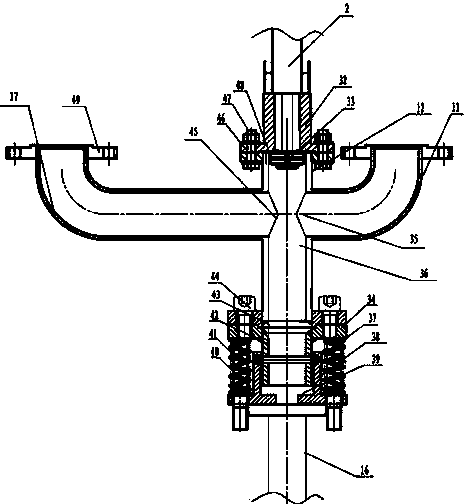

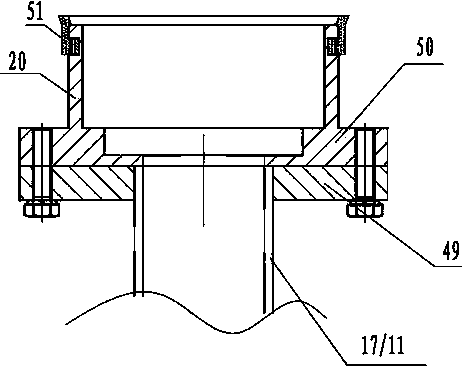

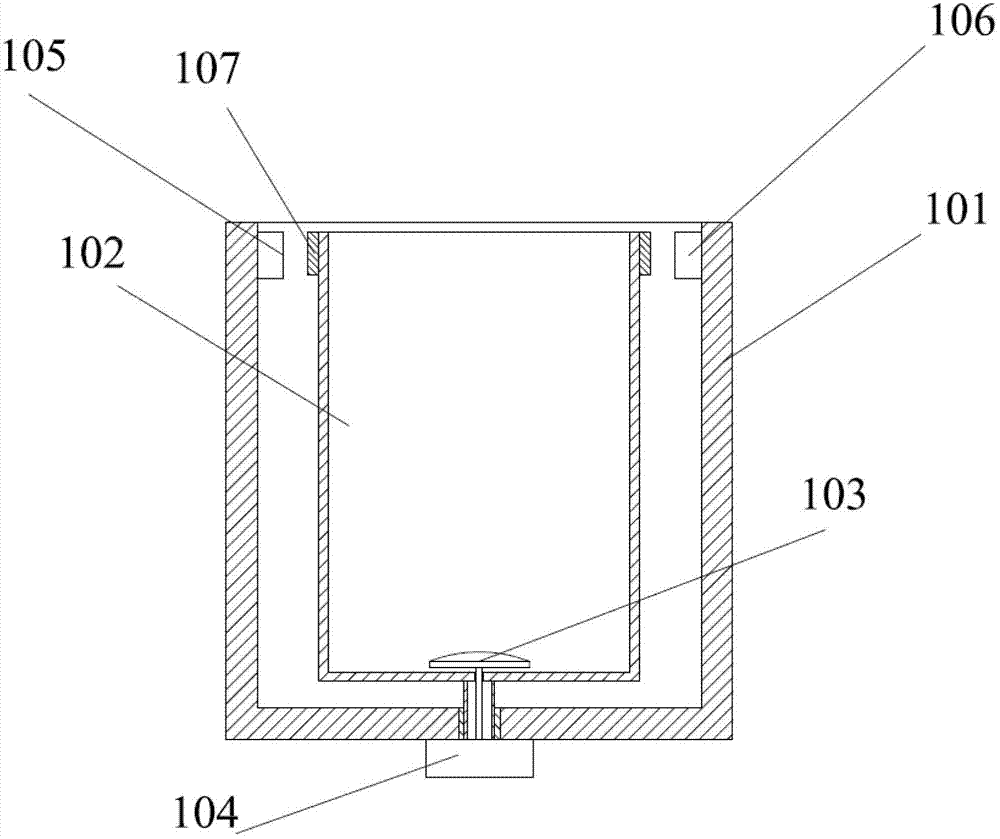

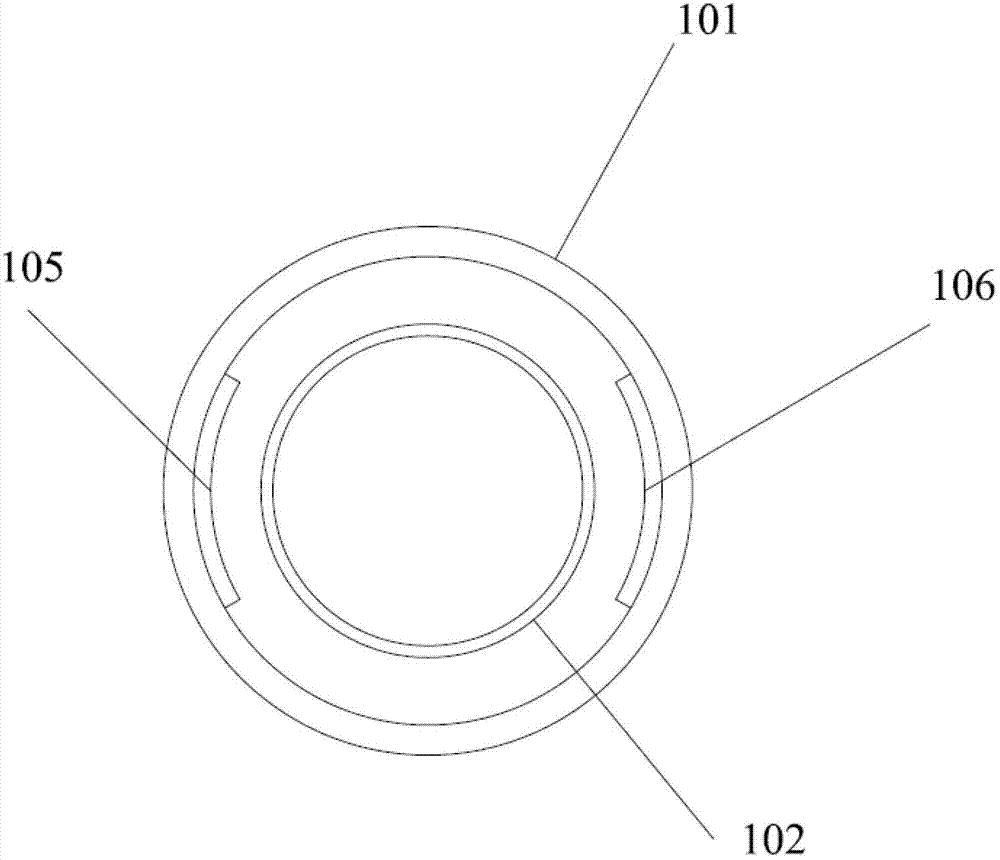

The invention discloses a multi-filter cylinder automatic backwashing filter apparatus. A housing is divided into an upper chamber and a lower chamber by a separation plate. The separation plate is provided with filter cylinders in the manner of one, two, or multiple concentric circles. The sidewall of the housing under the separation plate is provided with a sewage inlet, and the sidewall of the housing above the separation plate is provided with a pure water outlet. A motor of a backwashing mechanism drives a main shaft to rotate. A lifting mechanism drives the main shaft to go up and down. A multi-way connection seat connects the main shaft, rotating arms and a waste pipe together. The main shaft drives the rotating arms to lift and rotate. The waste pipe is fixed. Suction nozzles fixed on the upper end port of the rotating arms can be in sealed connection with water inlets on the separation plate. The end part of the waste pipe is connected with an electric drain valve or a pneumatic drain valve. A control system controls the actions of the motor, the lifting mechanism and the electric drain valve or the pneumatic drain valve. The filter apparatus has the advantages of small size, large amount of water filtration, high production efficiency, good filtration effect of filtered water, good backwashing effect, low frequency of backwashing, long-life apparatus, low maintenance rate, and saving backwash water.

Owner:HEBEI AGRICULTURAL UNIV. +1

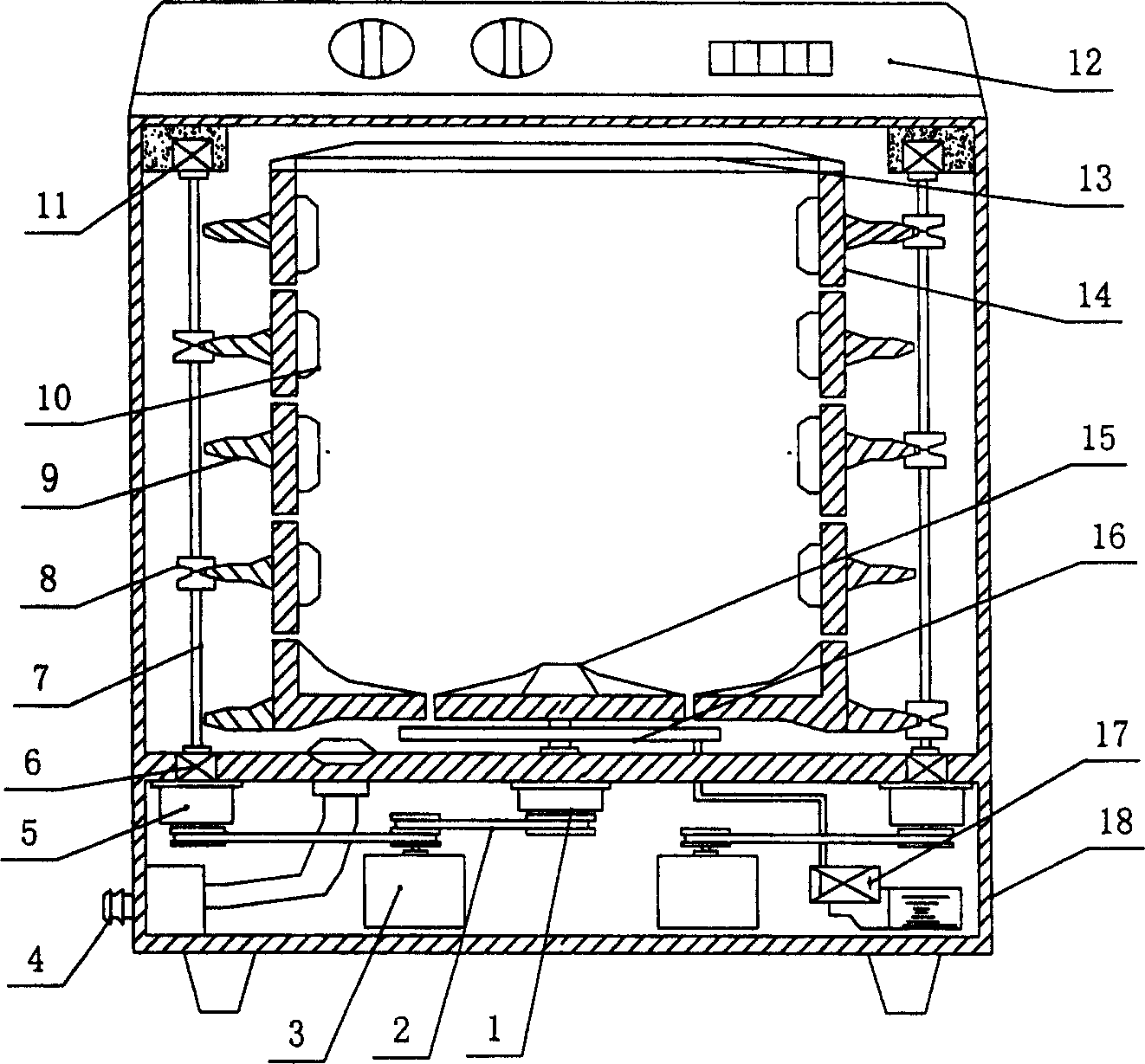

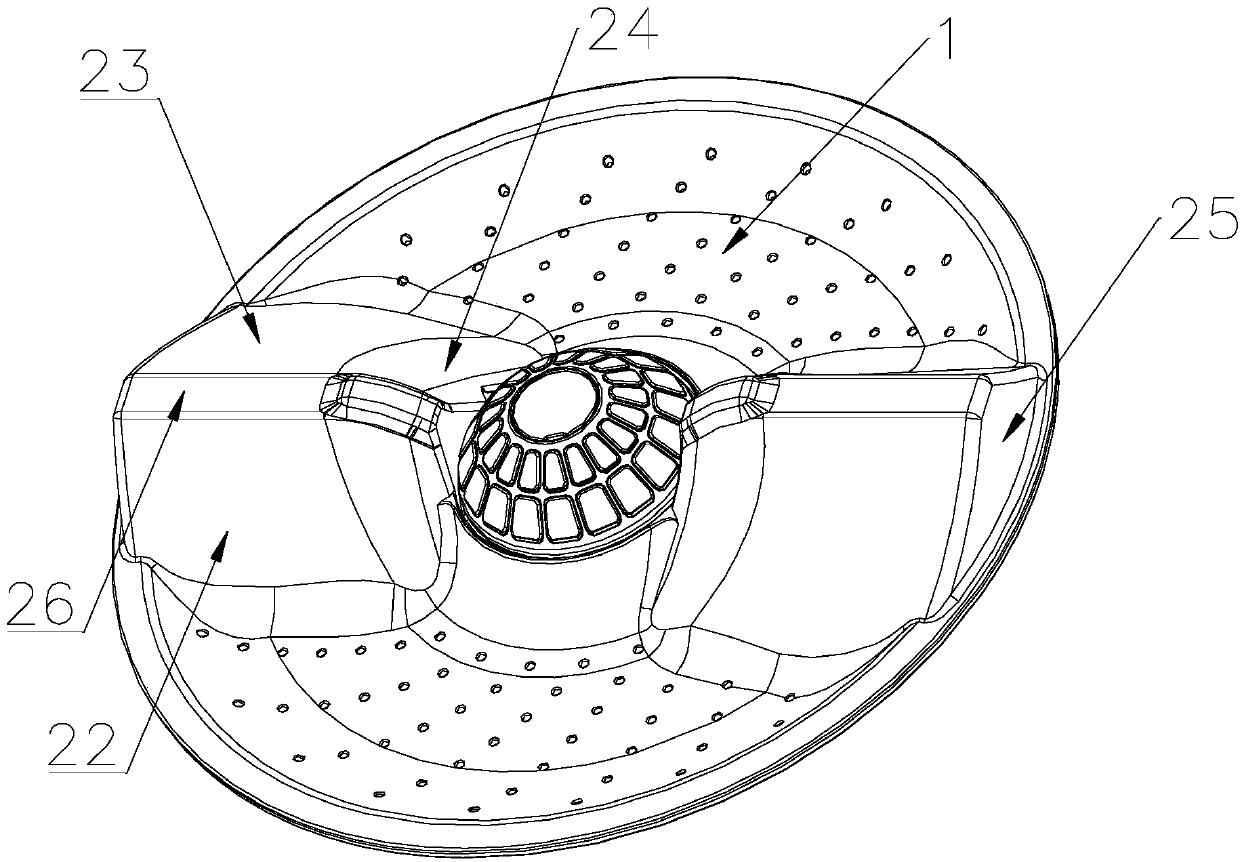

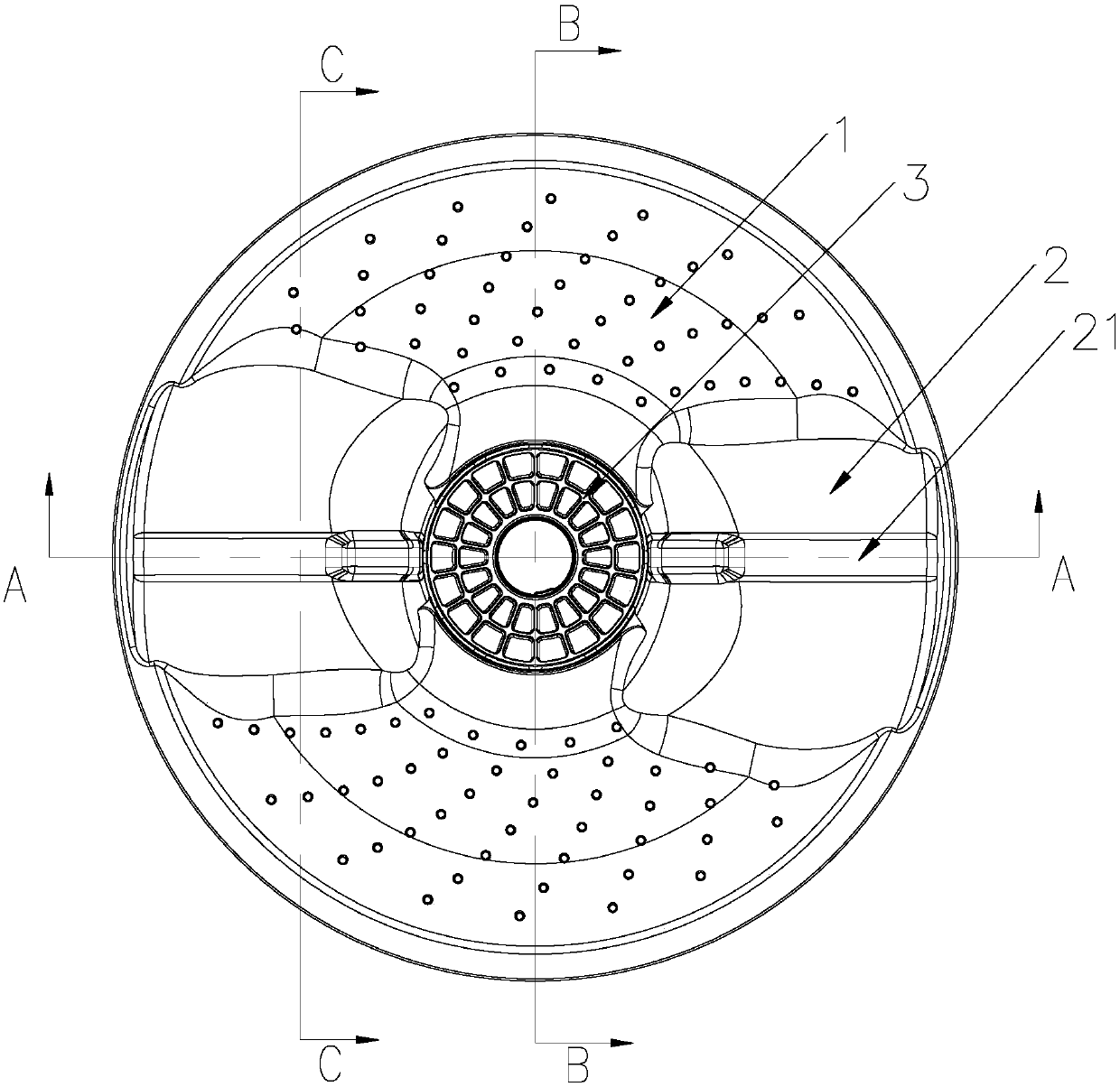

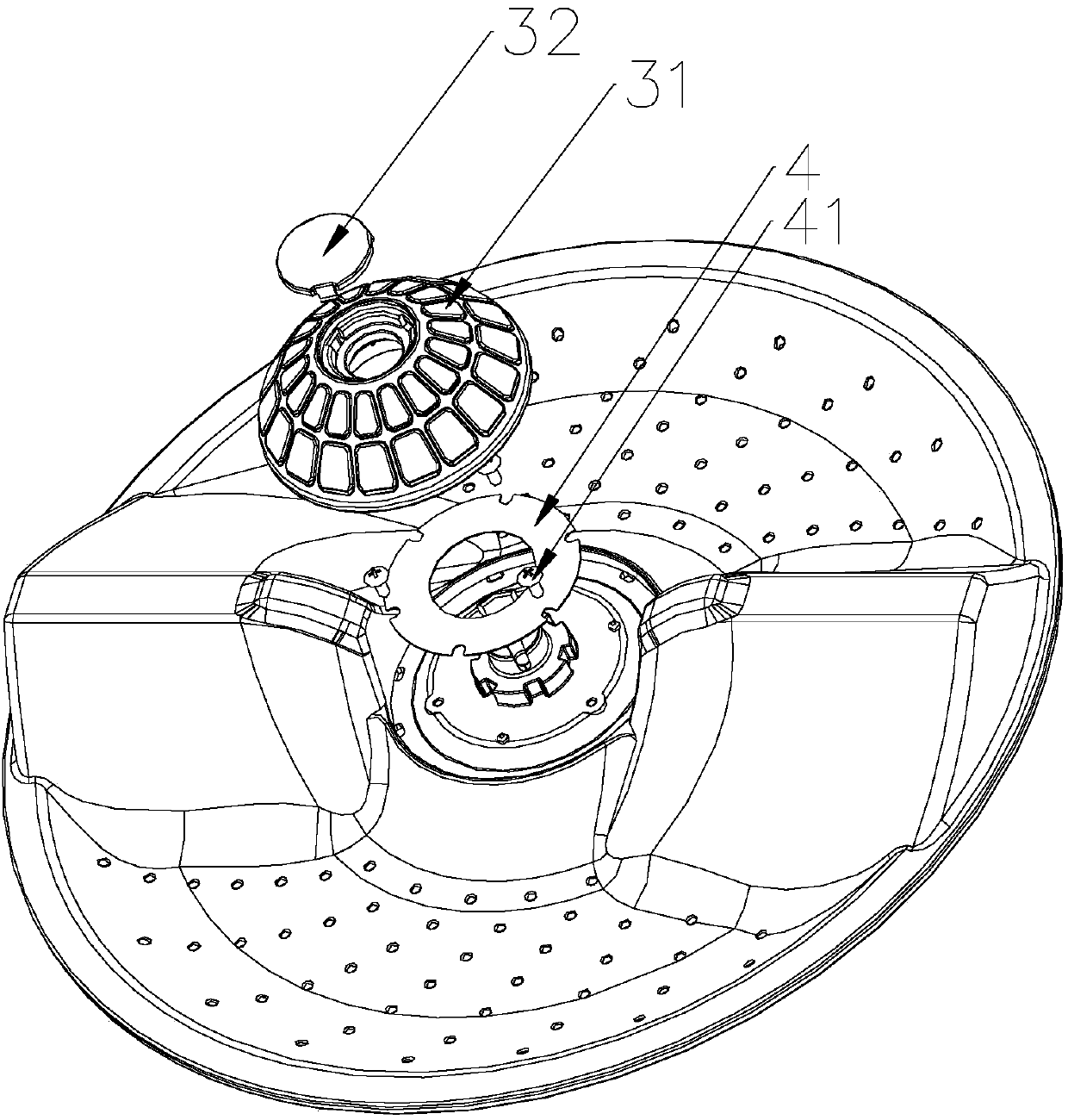

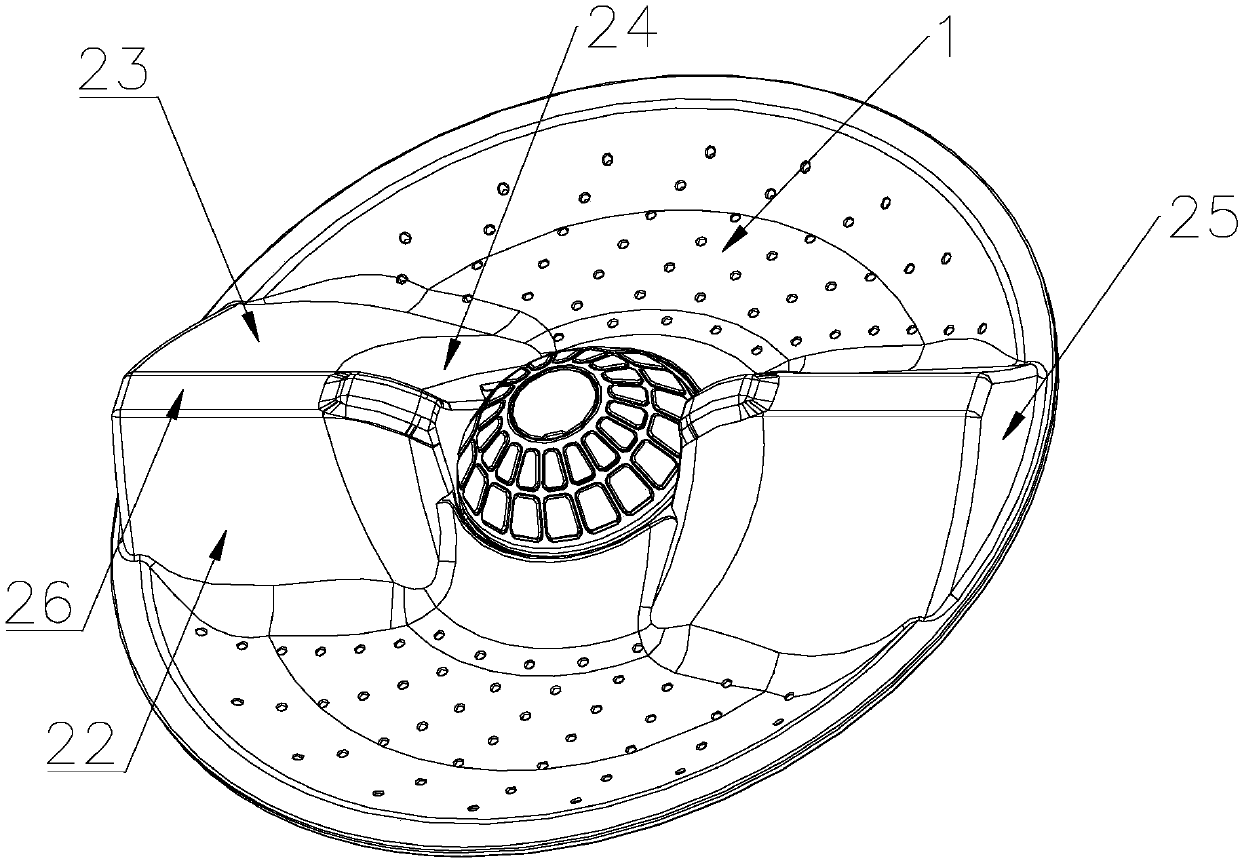

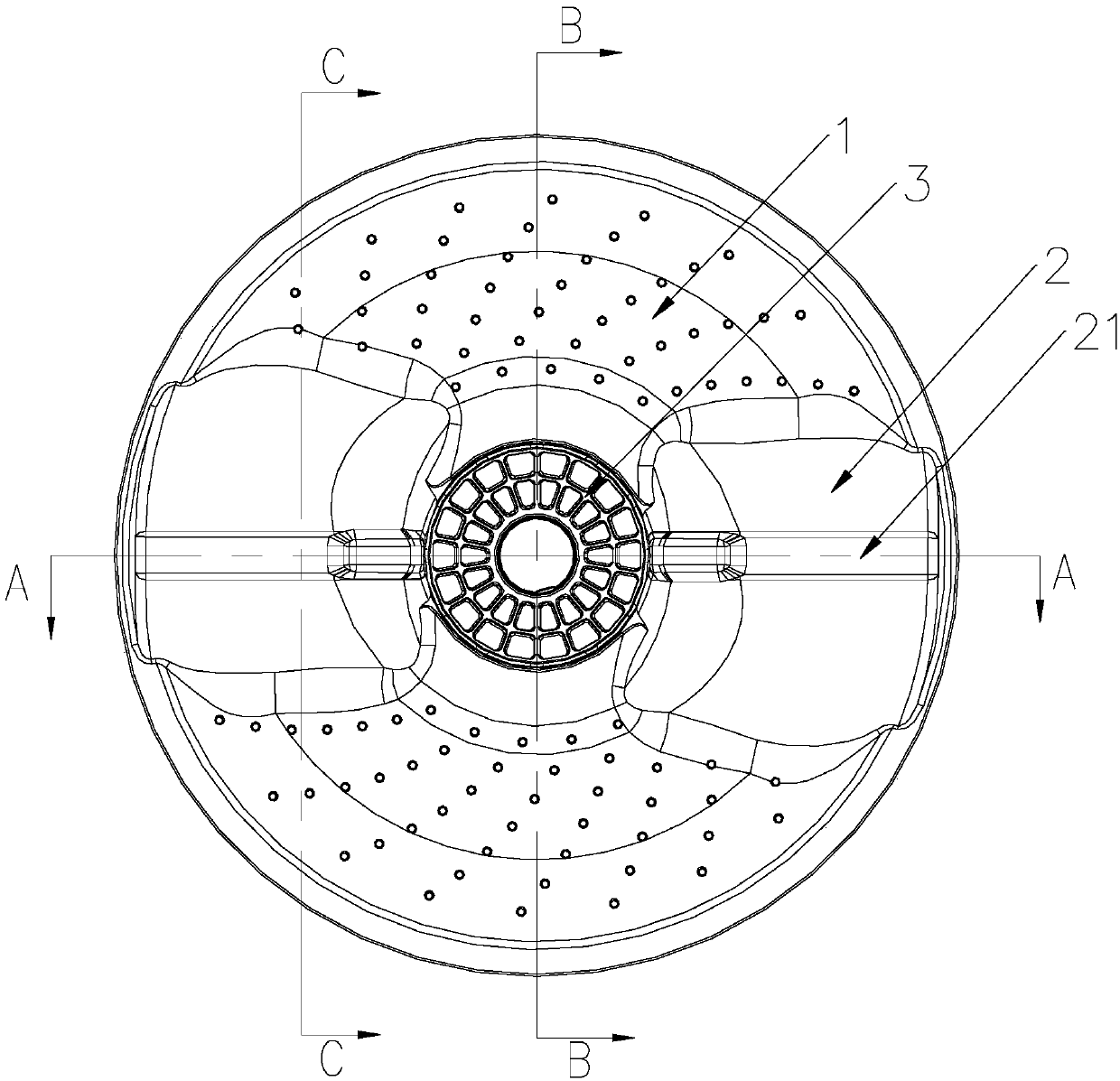

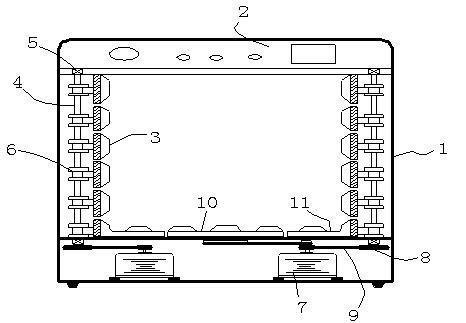

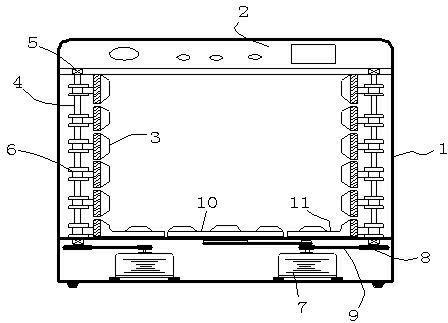

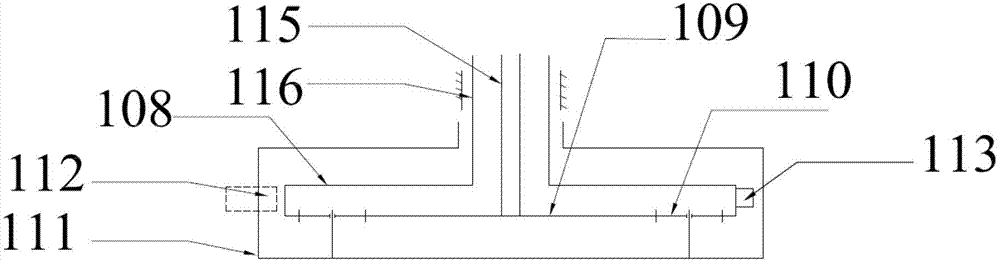

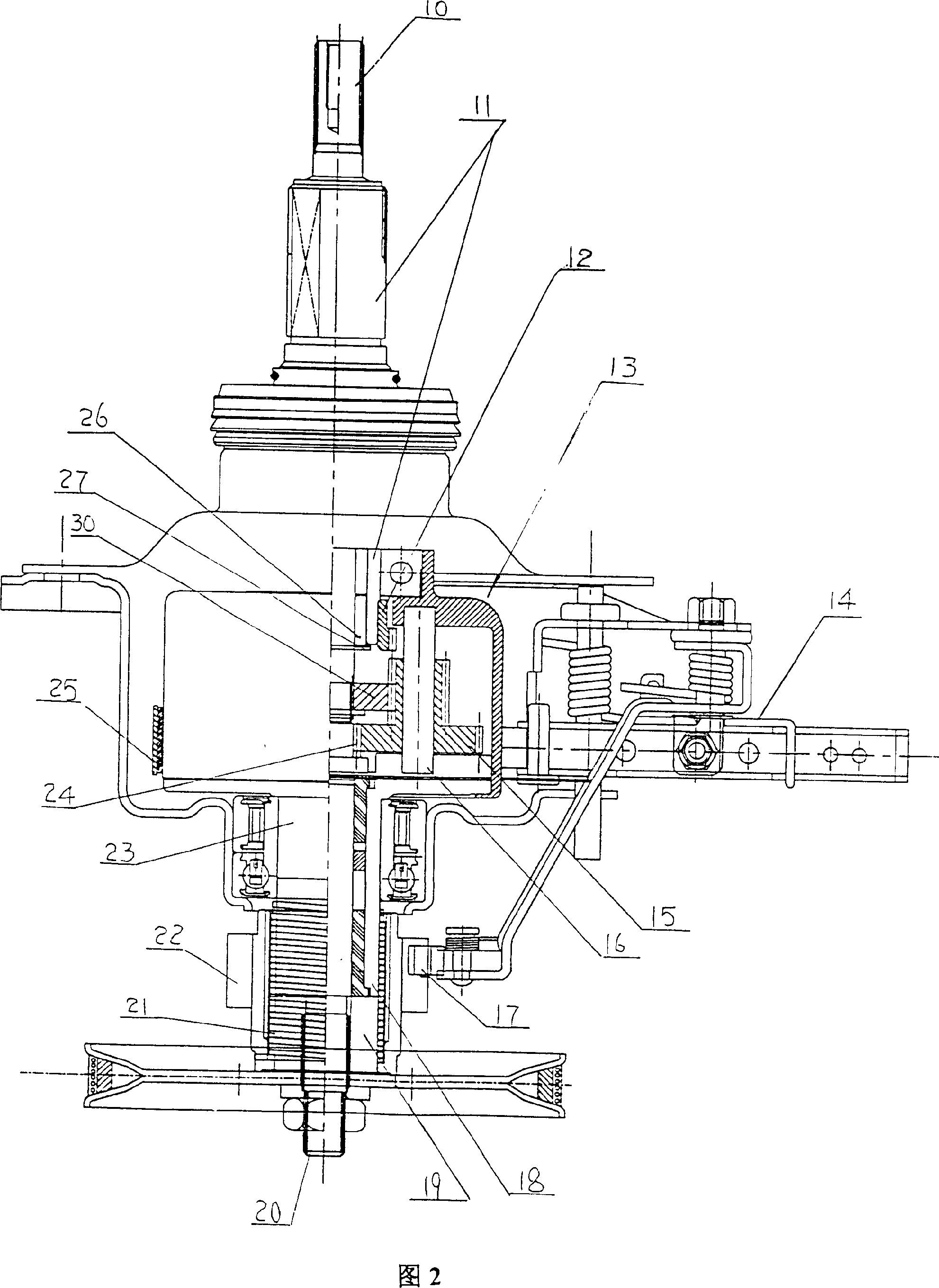

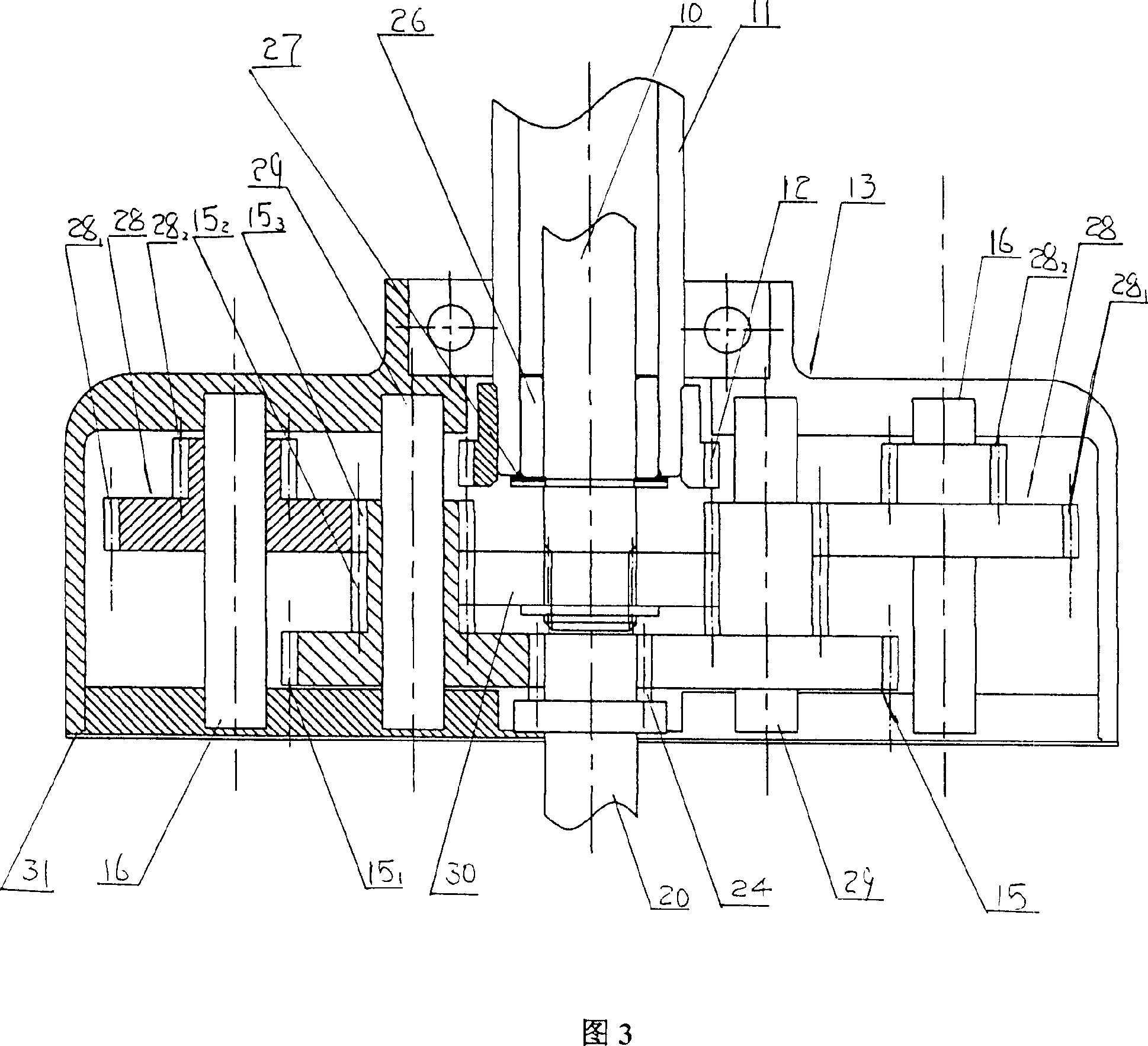

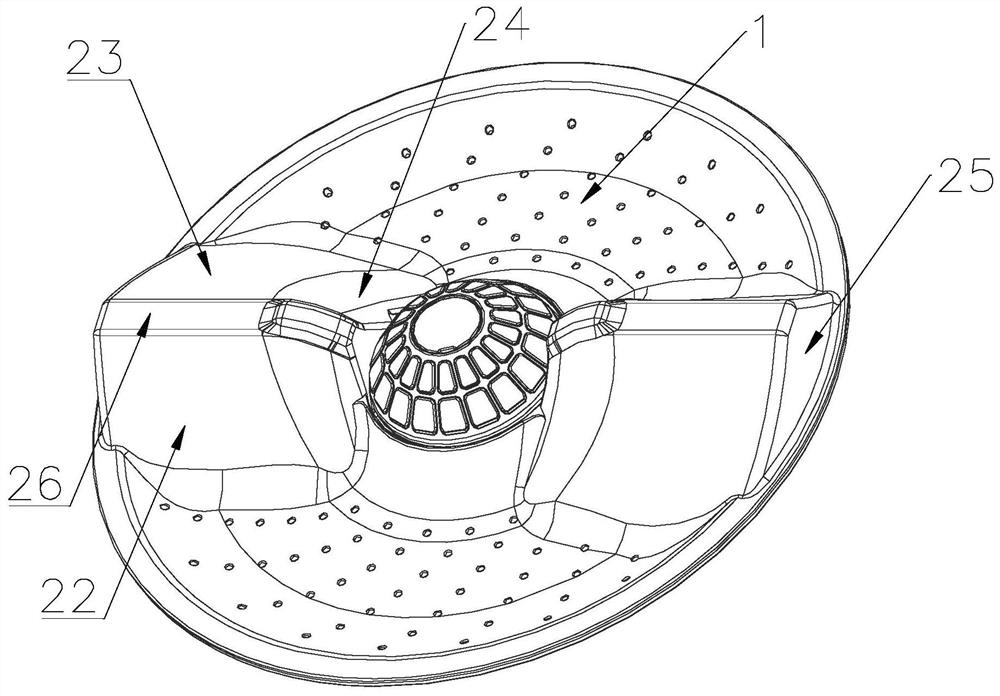

Two-impeller three-power washing machine and control method thereof

ActiveCN102720032ASpeed up kneadingEnhances the effect of tumbled laundryOther washing machinesWashing machine with receptaclesImpellerEngineering

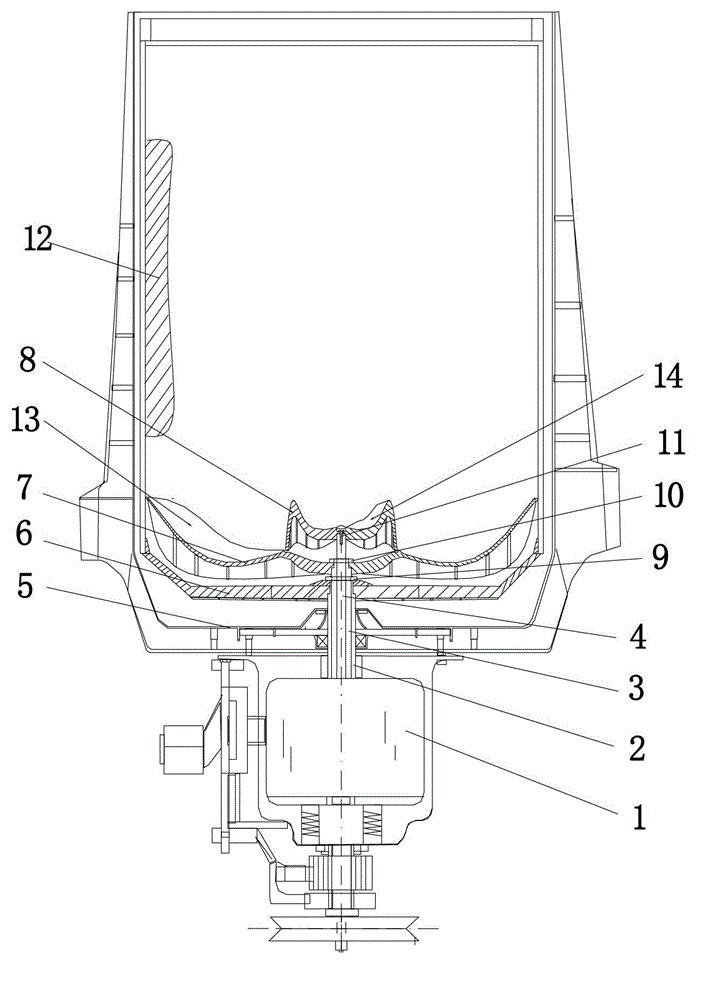

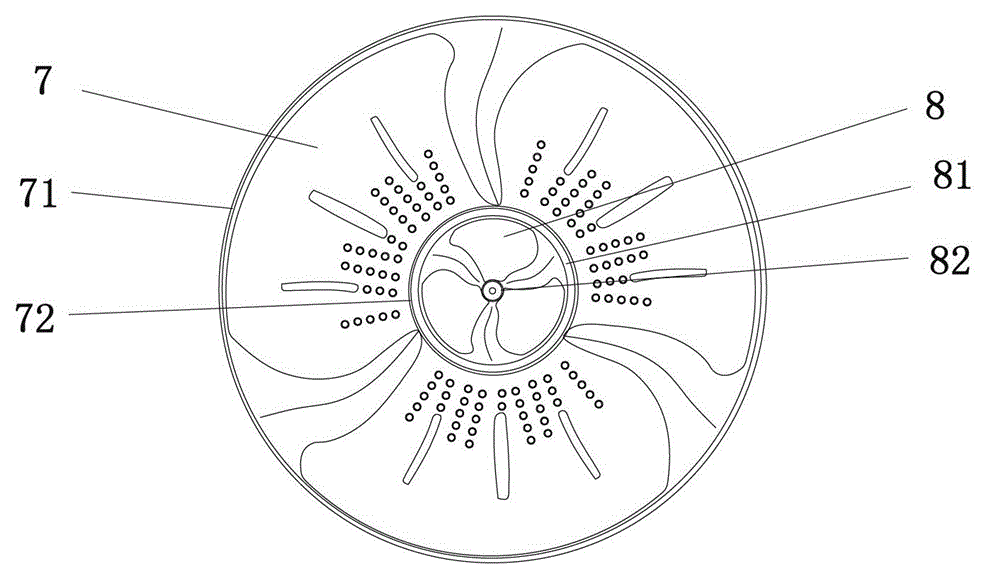

The invention belongs to the field of a washing machine, and particularly relates to a two-impeller three-power washing machine and a control method thereof. The two-impeller three-power washing machine comprises an outer tub, an inner tub, a main impeller, an auxiliary impeller and a three-power speed reducing clutch, wherein the main impeller and the auxiliary impeller are located at the bottom of the inner tub; the auxiliary impeller is located above the center of the main impeller; the inner tub, the main impeller and the auxiliary impeller are concentrically mounted on a power rotation shaft of the three-power speed reducing clutch; the outer edge of the main impeller uplifts along the bottom of the wall of the inner tub; the longitudinal section from any point on the outer edge of the main impeller to the center of the impeller is of an L-shaped structure in arc transition; and the auxiliary impeller is of a basin-shaped structure with an uplifted outer edge. The two-impeller three-power washing machine has the characteristics of high cleaning rate, high washing uniformity and the like.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Wave washing machine

InactiveCN101008143ATo achieve the purpose of not being entangledReduce or save useOther washing machinesPortable liftingPulp and paper industryTransmitter

The invention relates to a washing machine, especially an improvement on prior tub-type washing machine. The invention is characterized in that: the inner tub in washing washes reversely and clockwise via several wave rings, to form wave-type wave wheel. And the invention comprises wave ring, mixing ring, motor, power transmitter, air pump or electrolyze device. The invention has multiply washing functions, with high effect.

Owner:戴文育

Universal dynamical washing machine

InactiveCN1687505AEasy flipImprove cleaning ratioOther washing machinesWashing machine with receptaclesElectricityControl system

The present invention relates to a universal power washing machine, including machine case, outer barrel, inner barrel, pulsator equipped in the inner barrel, power mechanism, gearing and control system. The pulsator includes a horizontal and a vertical pulsator respectively connected with the concentric output axis of horizontal pulsator and output axis of vertical one rotating in opposite directions. The inner barrel of this present invention keeps relative still when washing clothes. The aclinic and vertical pulsators are circumvolving in opposite directions, which can realize universal current lavation to turn clothes more easily and not be enlaced. At the same time, it can increases the flow intensity and improve the clean rate. It can also prolong the life of washing machine, decrease noise and save electricity by the use of new-style clutch.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

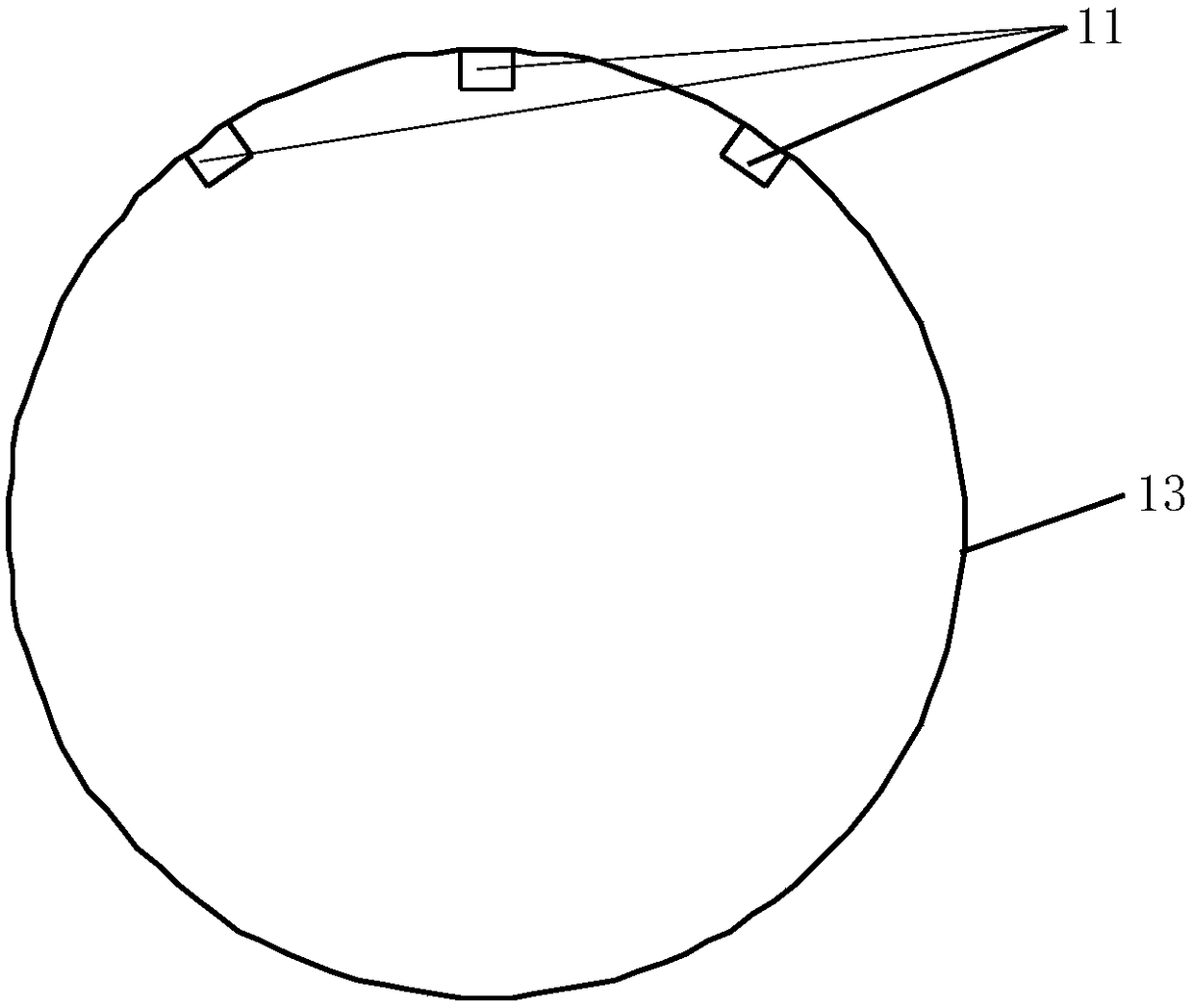

Washing machine pulsator and washing machine thereof

ActiveCN107653622AEasy to wrapNot easy to tangleWashing machine with receptaclesTextiles and paperPulp and paper industry

The invention discloses a washing machine pulsator and a washing machine thereof. The washing machine pulsator comprises a pulsator body, wherein two protruding stirring blades extending from the center in the radial direction of the pulsator body are arranged on the pulsator body, and the two stirring blades radially extend on the same diameter. The washing machine pulsator is large in stirring blade area, movable spaces for clothes exist at a vertical part and a middle part, intertwining is avoided, washing and drying effects are better, and dried clothes are fluffy.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

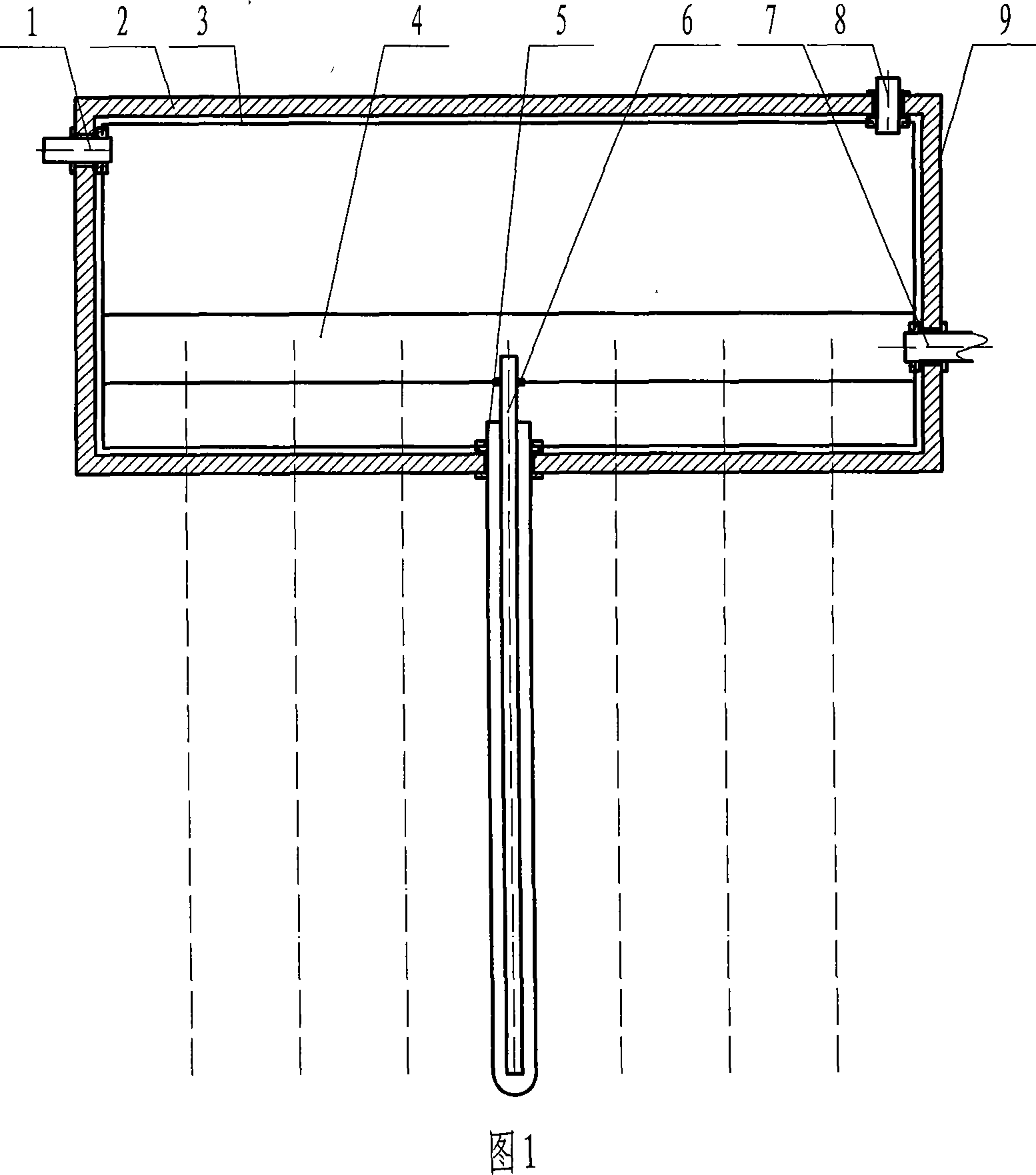

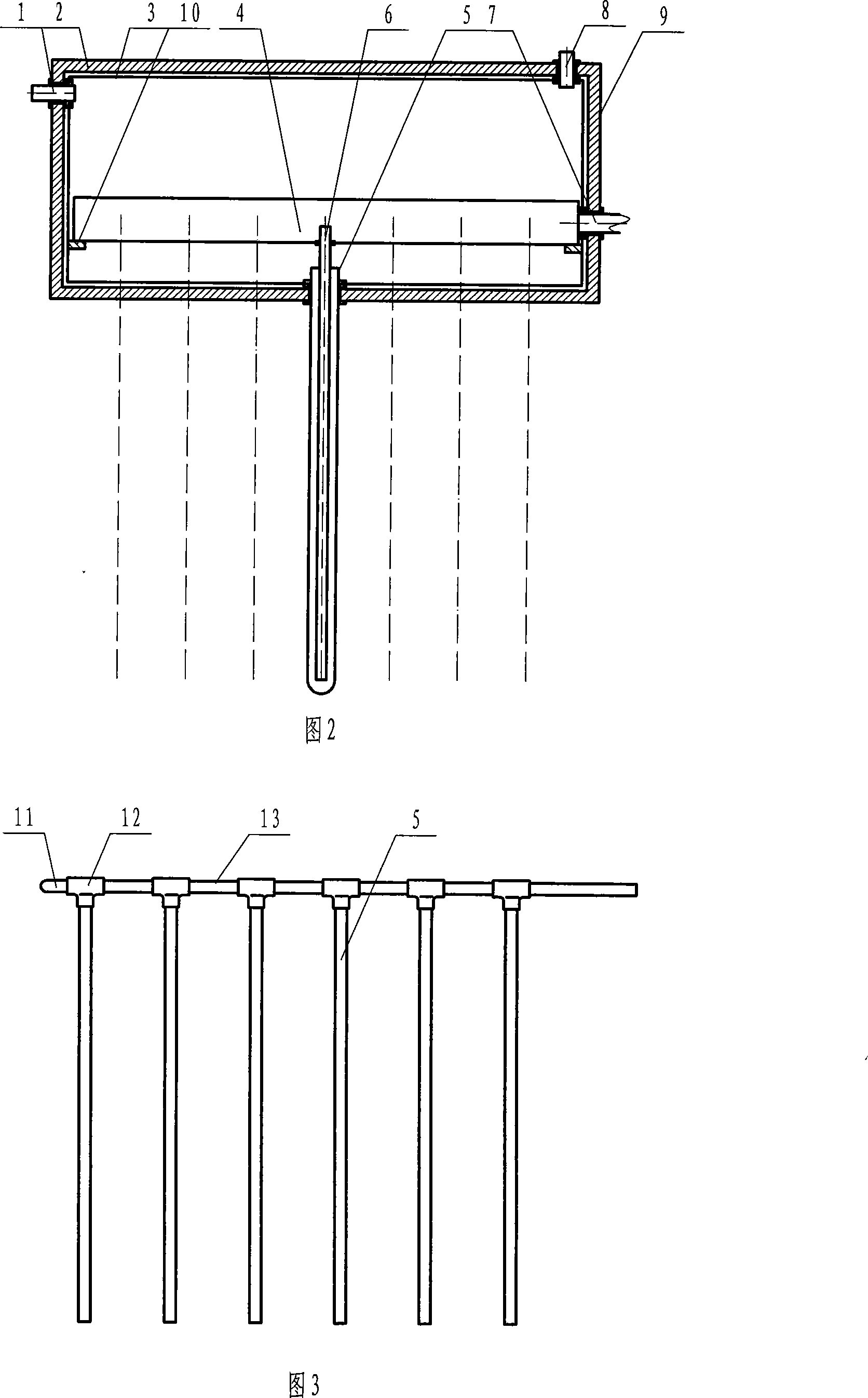

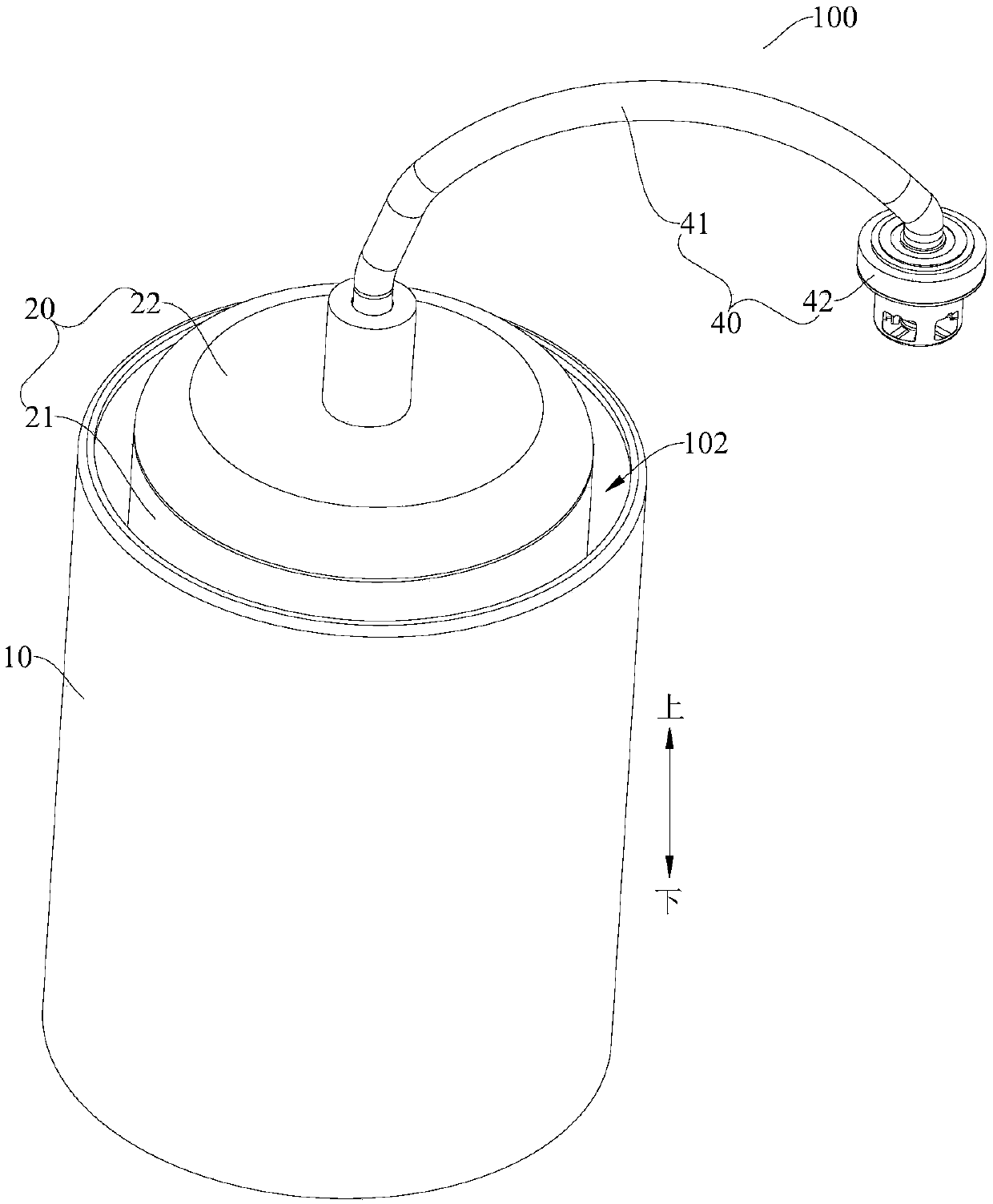

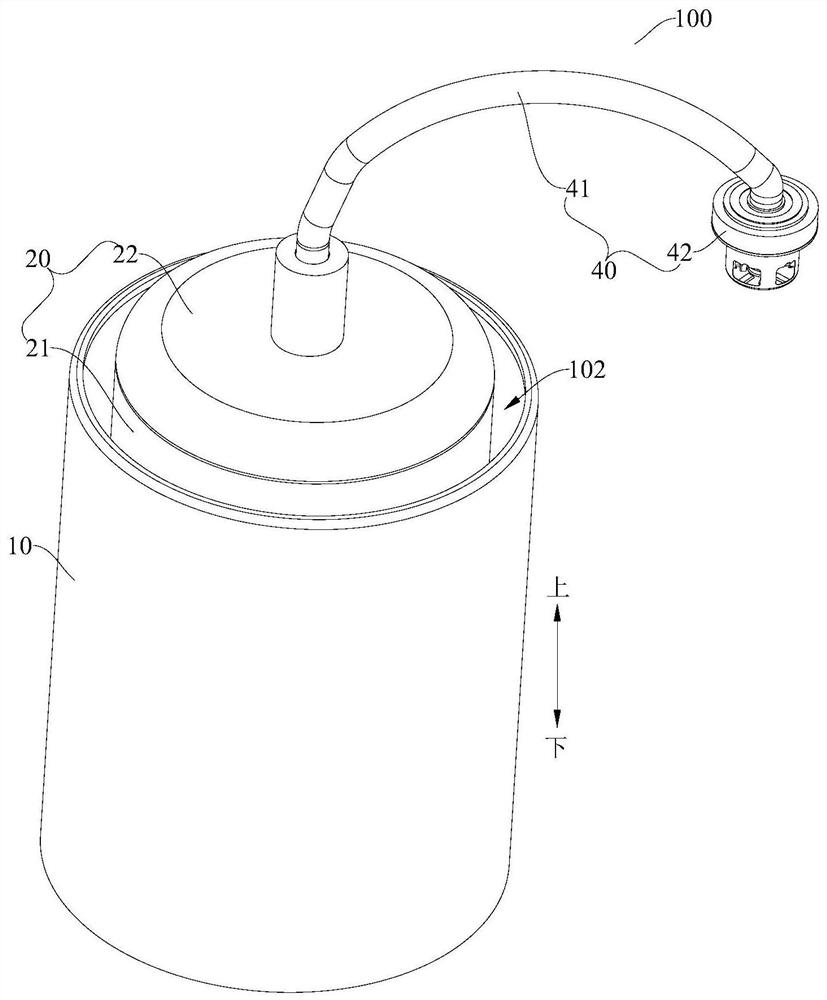

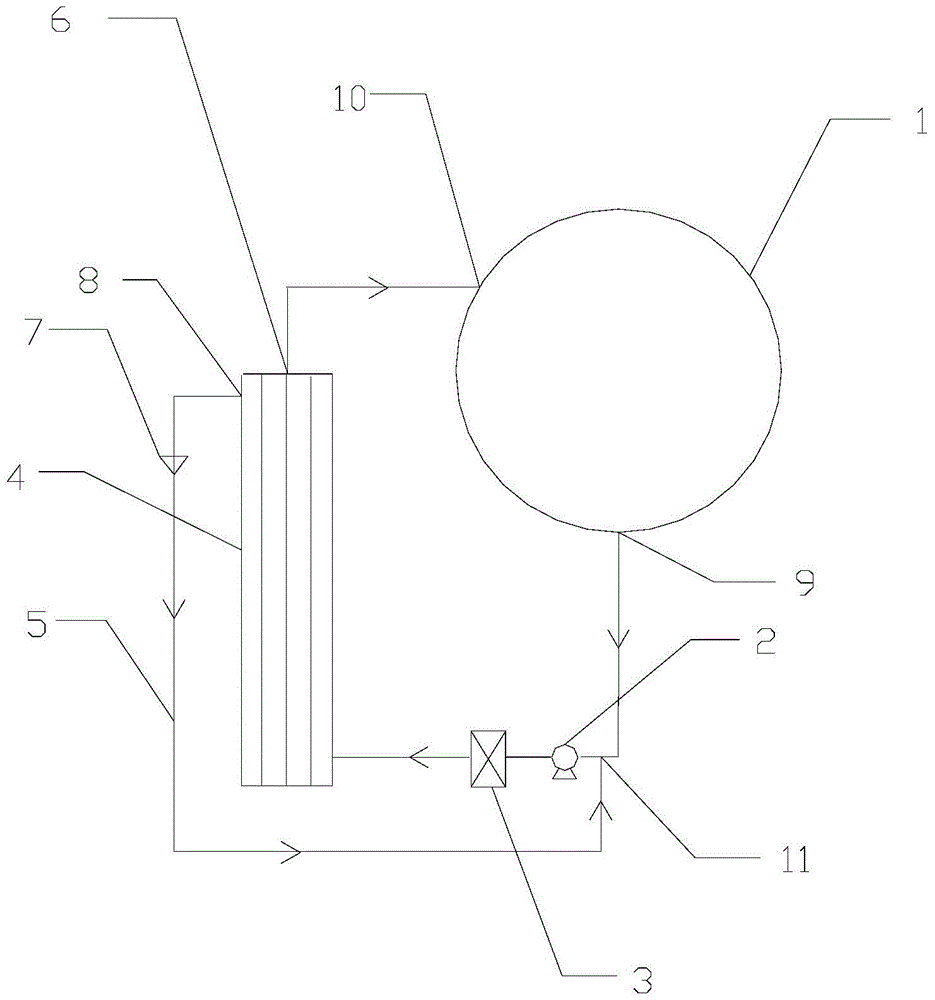

Solar water heater with nursing function

InactiveCN101226002ALarge water capacityNot easy to burstSolar heat devicesSolar thermal energy generationSolar waterWater capacity

The invention provides a solar water heater with nursing function, belonging to the field of heat exchange equipment, in particular to solar energy equipment, which comprises at least a support, a water tank, a plurality of heat-collecting tubes and a plurality of heat-collection plates. The solar water heater is characterized in that: the water tank and the heat-collection plates are fixed on the support; one end of the heat-collecting tube is opened, while the other is closed; the open end is inserted to the water tank from the bottom of the water tank, and the closed end is supported on a tail box on the bottom of the heat-collection plate; the solar water heater also comprises a nursing device which comprises a water tank of the nursing device and a plurality of water inlet and outlet pipes, the water tank of the nursing device is arranged in the bottom area in the solar water tank and is connected with the water inlet and outlet of the solar water heater; one end of the water inlet and outlet pipe is connected with the water tank of the nursing device, while the other end is inserted into the heat-collecting tube. The solar water heater with nursing function has the advantages of less liability to cause cracking of the heat-collecting tube and generate scale and precipitates in the heat-collecting tube, and ability to increase water capacity of the solar water heater.

Owner:陈海泉

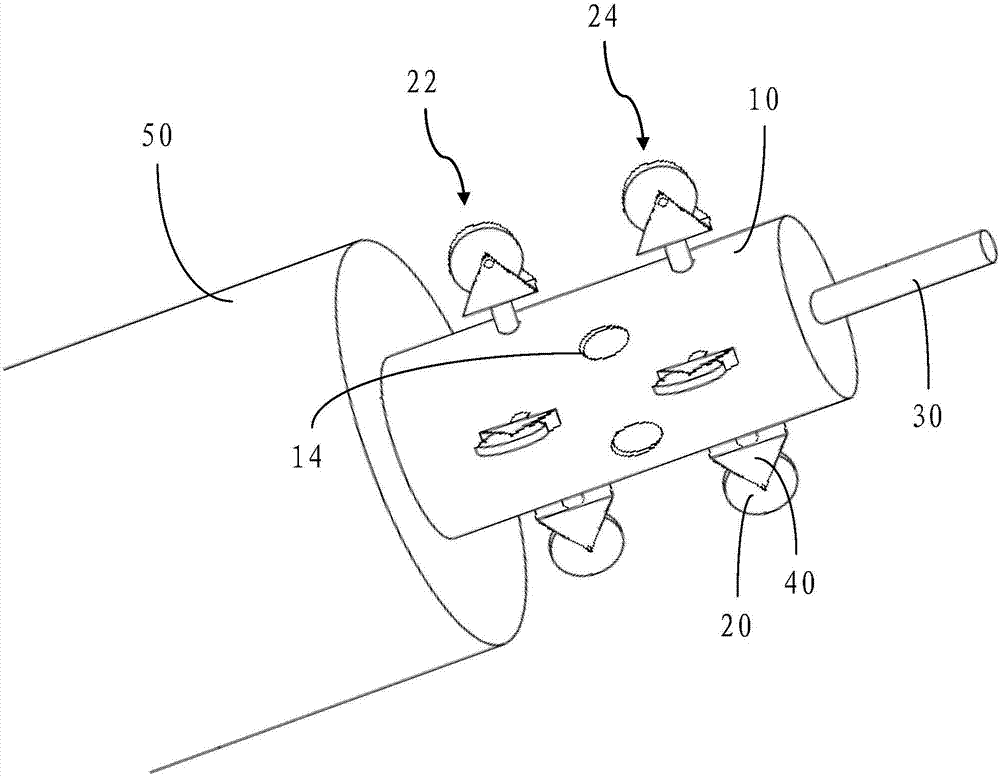

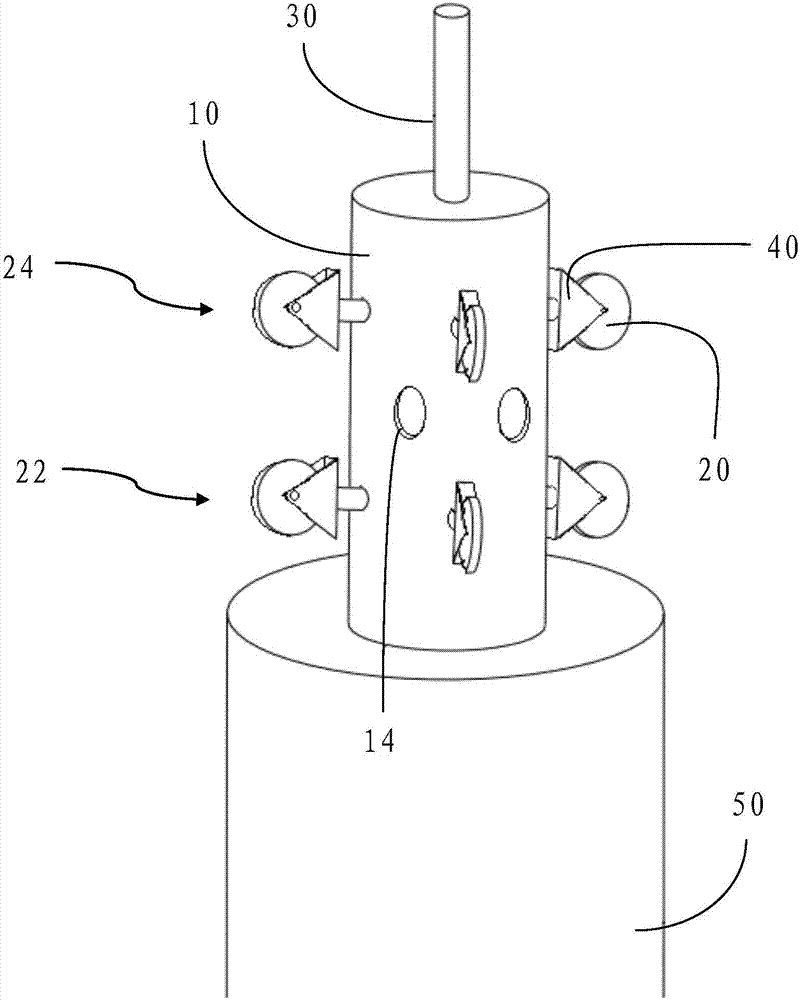

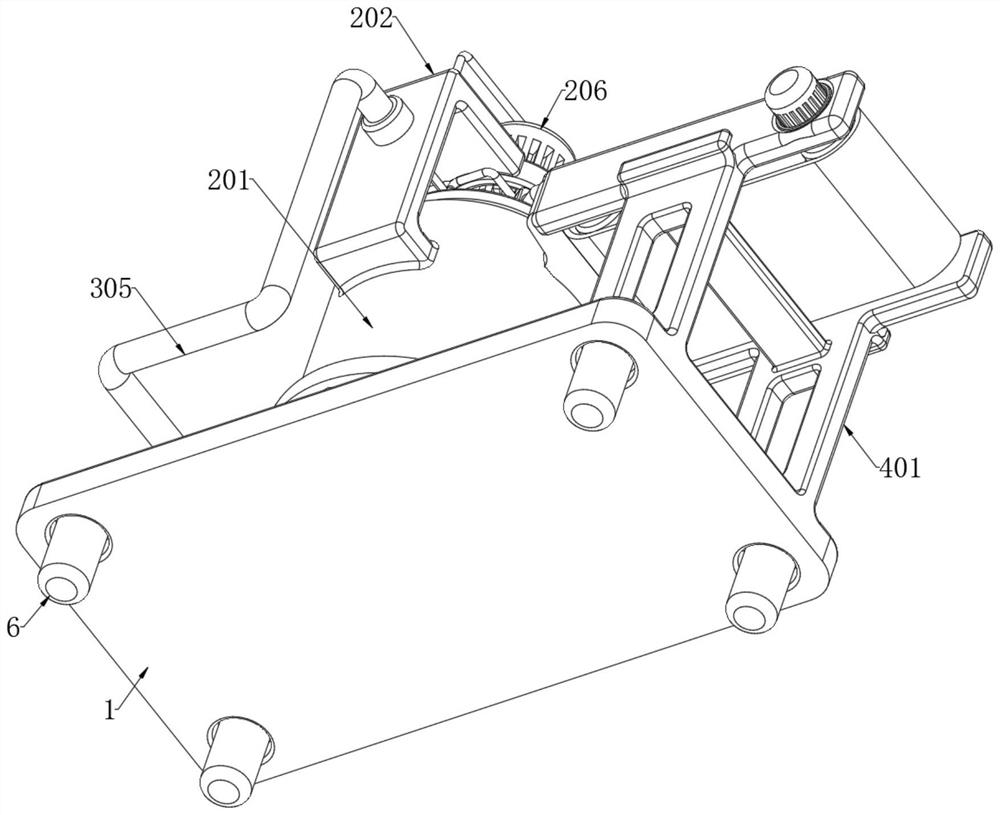

Portable cleaning trolley device for pipeline

The invention discloses a portable cleaning trolley device for a pipeline. The portable cleaning trolley device for the pipeline is a cleaning trolley capable of being assembled on the end part of a water hose (water supply hose) and entering the pipeline to clean the inner wall of the pipeline. The cleaning trolley comprises a trolley body, wherein a water inlet pipe connected with the water hose is arranged at the tail end of the trolley body; a plurality of water outlet holes are formed in the periphery of the trolley body; the water outlet holes are connected with the water inlet pipe; and a plurality of trolley wheels are further arranged on the periphery of trolley body. According to the portable cleaning trolley device for the pipeline, the cleaning trolley device is capable of stably moving along the pipeline through the arrangement of the trolley wheels which are uniformly distributed along the trolley body, so that the purpose of uniformly cleaning the pipeline is achieved; and the front end of the cleaning trolley device is closed, and a water flow pressure is adequately ensured through the configuration that the water inlet pipe 30 is connected with the water outlet holes 14, so that the cleaning effect of the pipeline is ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Washing machine and washing machine driving method

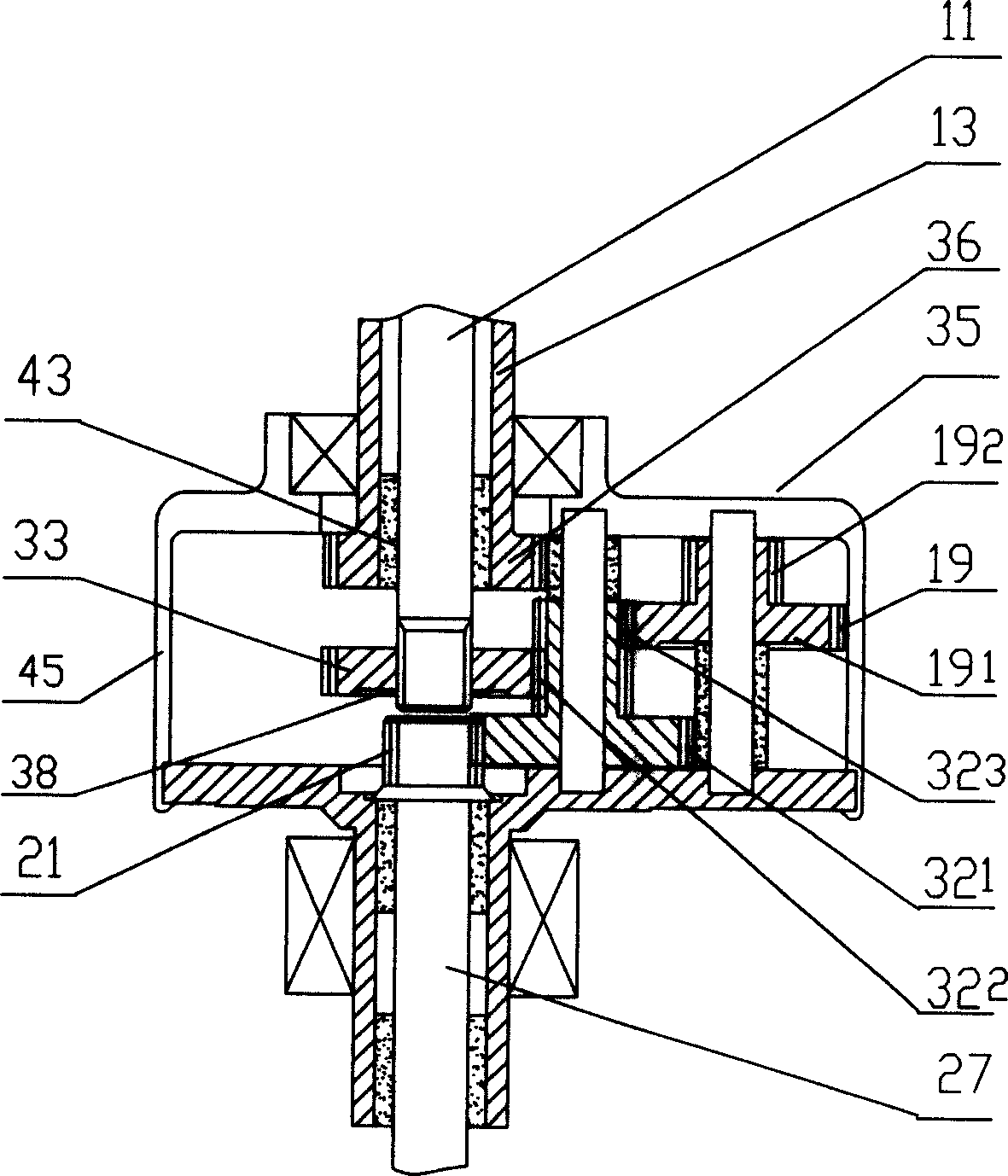

ActiveCN103911816AEasy to wrapIncrease the strength of the currentOther washing machinesTextiles and paperClutch controlWater flow

The invention provides a washing machine and a washing machine driving method. The washing machine comprises an inner drum, an outer drum, a wavy wheel and a clutch. The inner drum is connected with the input end of the clutch, the wavy wheel is connected with the output end of the clutch, and the wavy wheel rotates under the action of the inner drum through the clutch in the same or the opposite direction. The clutch controls the inner drum and the wavy wheel to rotate in the same direction or opposite direction, so that the water flow intensity during the washing process can be effectively enhanced, further the cleanliness can be improved, and the problem of intertwining of clothes can be effectively improved.

Owner:HAIER GROUP TECHN R&D CENT +1

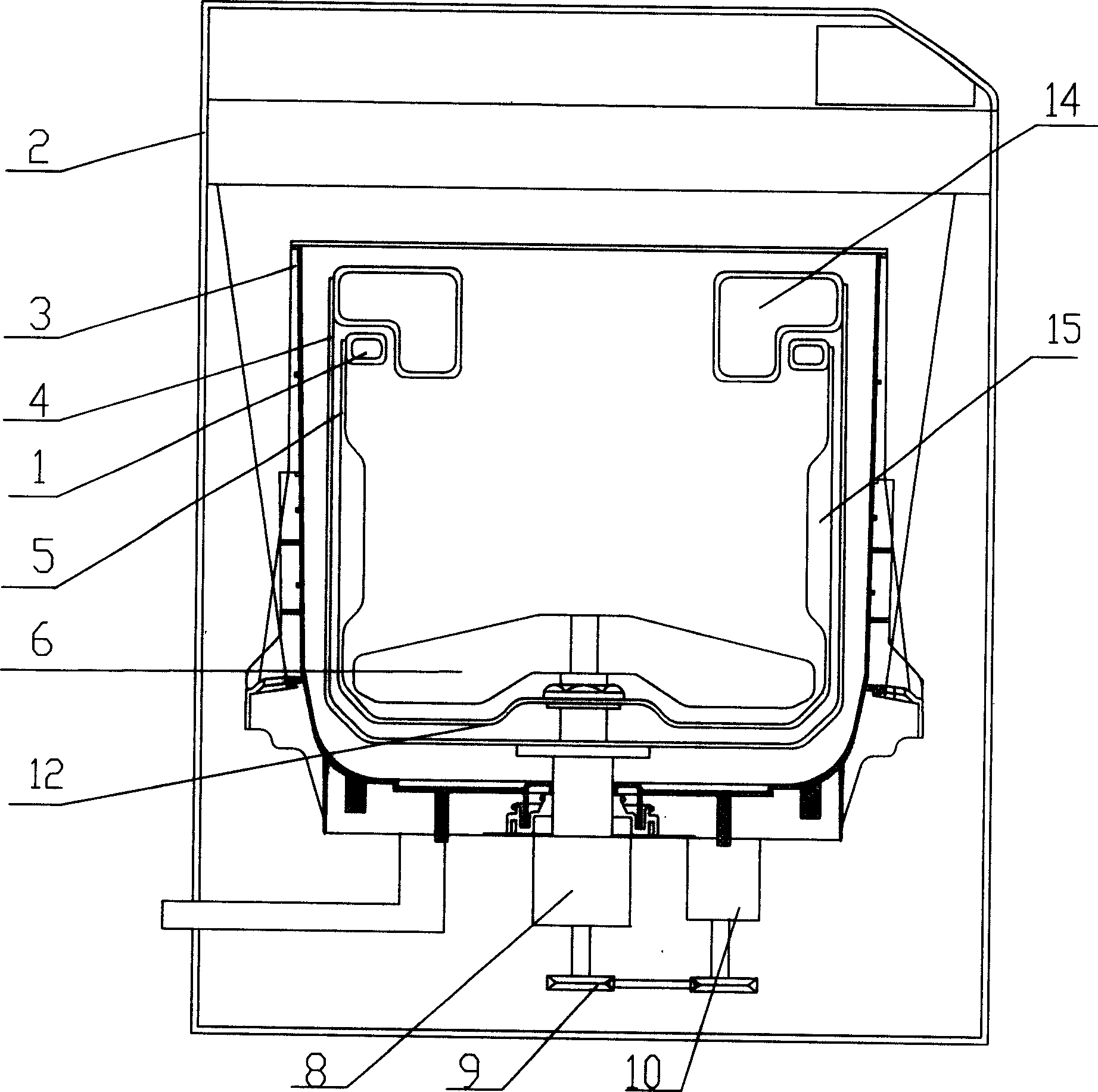

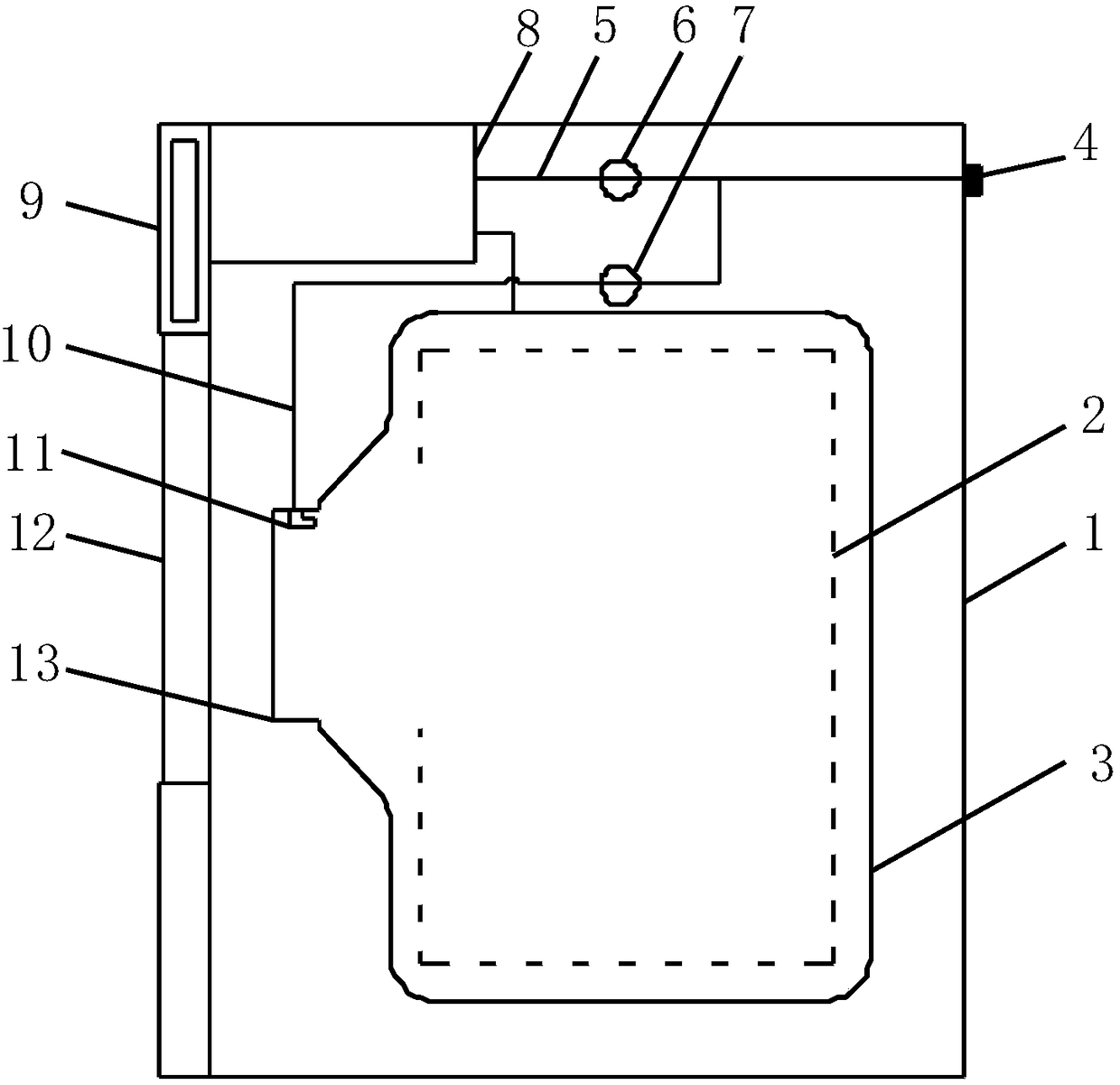

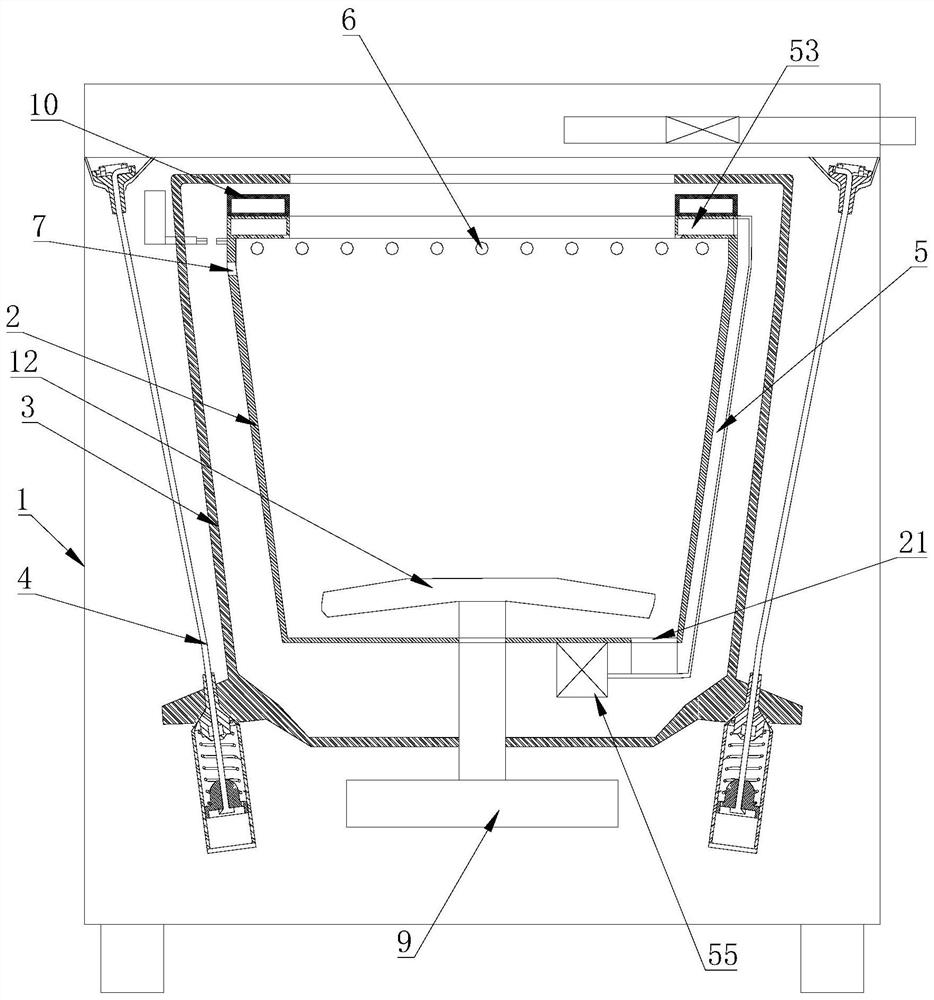

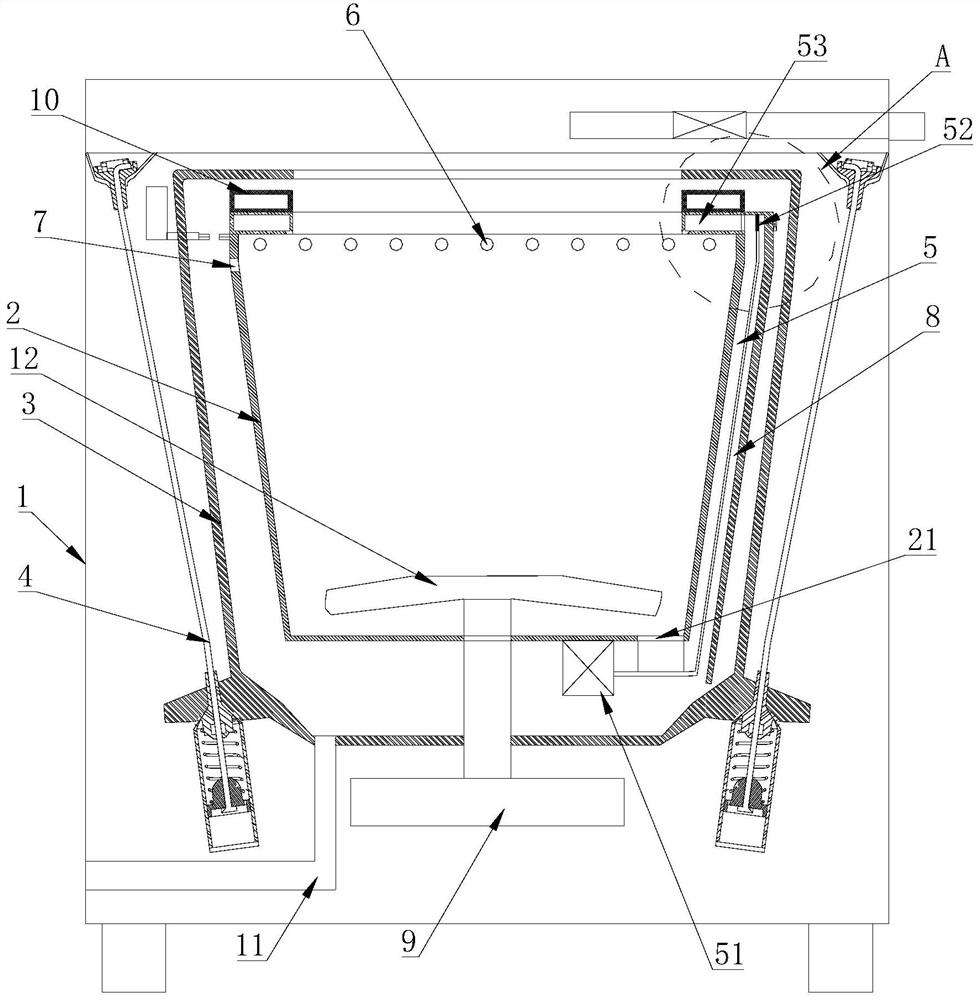

Clothes treating device

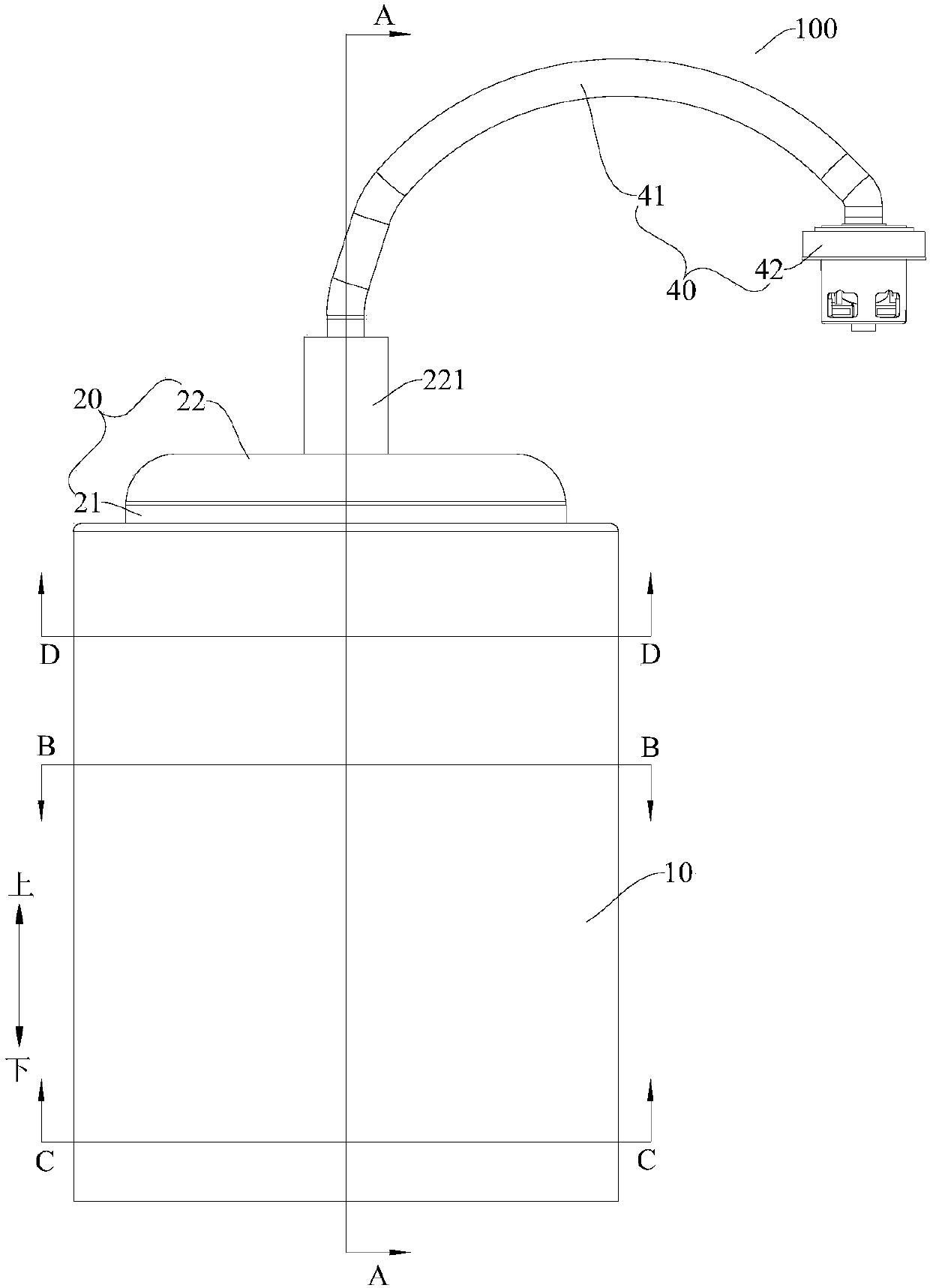

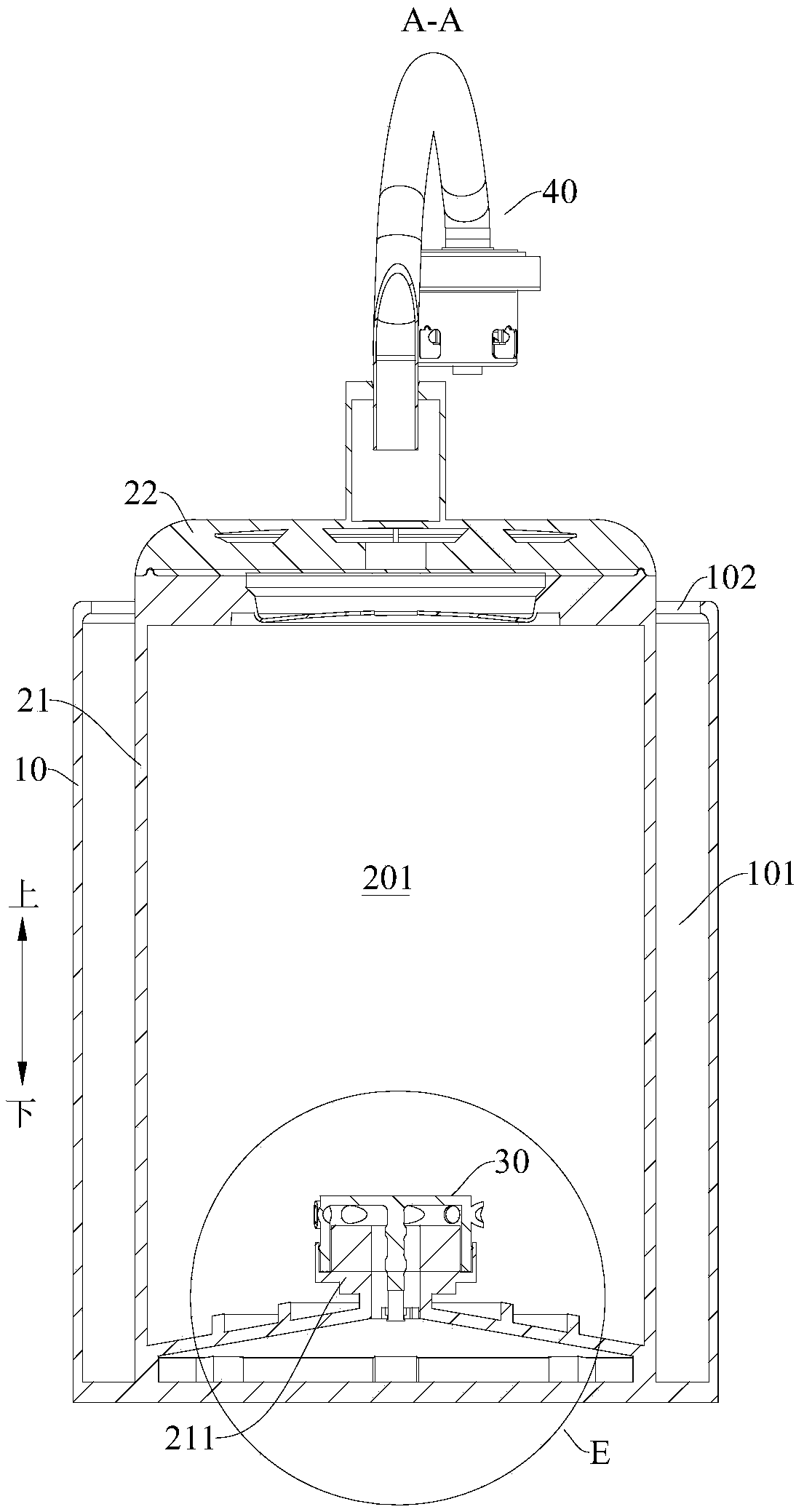

ActiveCN110453454AGood water saving effectIncrease the strength of the currentOther washing machinesTextiles and paperLow stressLow-pressure area

The invention discloses a clothes treating device. The clothes treating device comprises a water container, a washing container, a rotary body and an air exhaust assembly, wherein the washing container is disposed in the water container, a washing chamber used for containing clothes is defined in the washing container, and an air inlet passage communicated with the outside is defined between the washing container and the water container; the rotary body is rotatably arranged in the washing chamber, the rotary body is provided with at least one flow passage, and the flow passages are communicated with the washing chamber and the air inlet passage; the air exhaust assembly is connected to the washing container and used for extracting air in the washing chamber. According to the clothes treating device in the embodiment, kneading type washing water flow moving crosswise is formed in the washing chamber to improve the washing effect; the rotating high-speed water flow forms a moving low-pressure area driving the clothes around the water flow to rotate continuously, so that the good clothes rolling effect is good.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

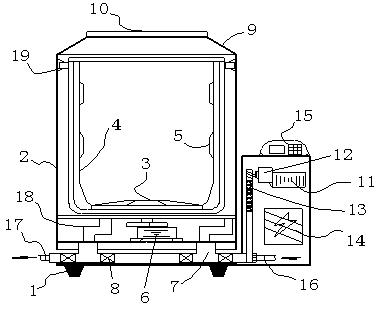

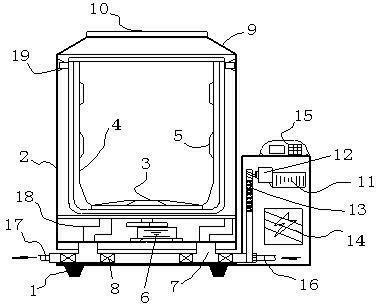

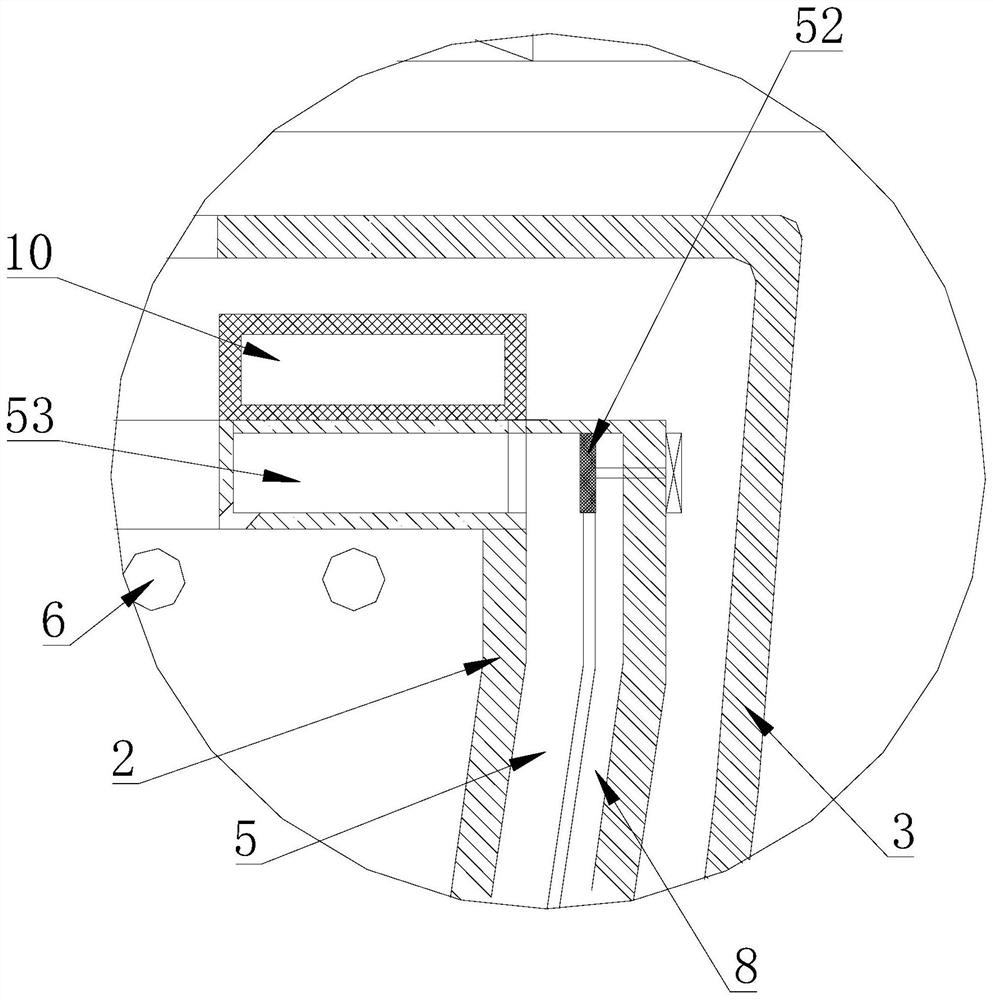

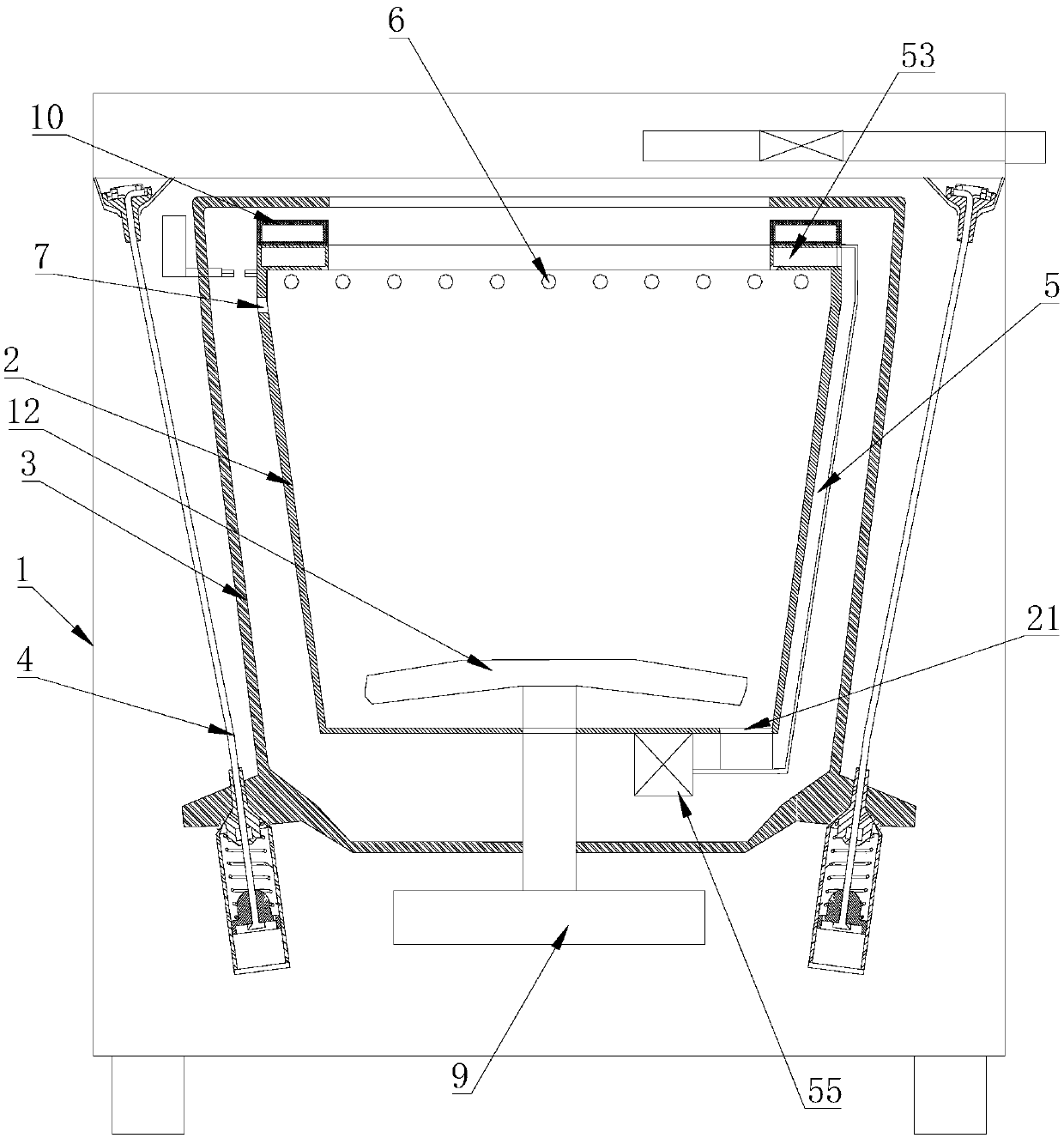

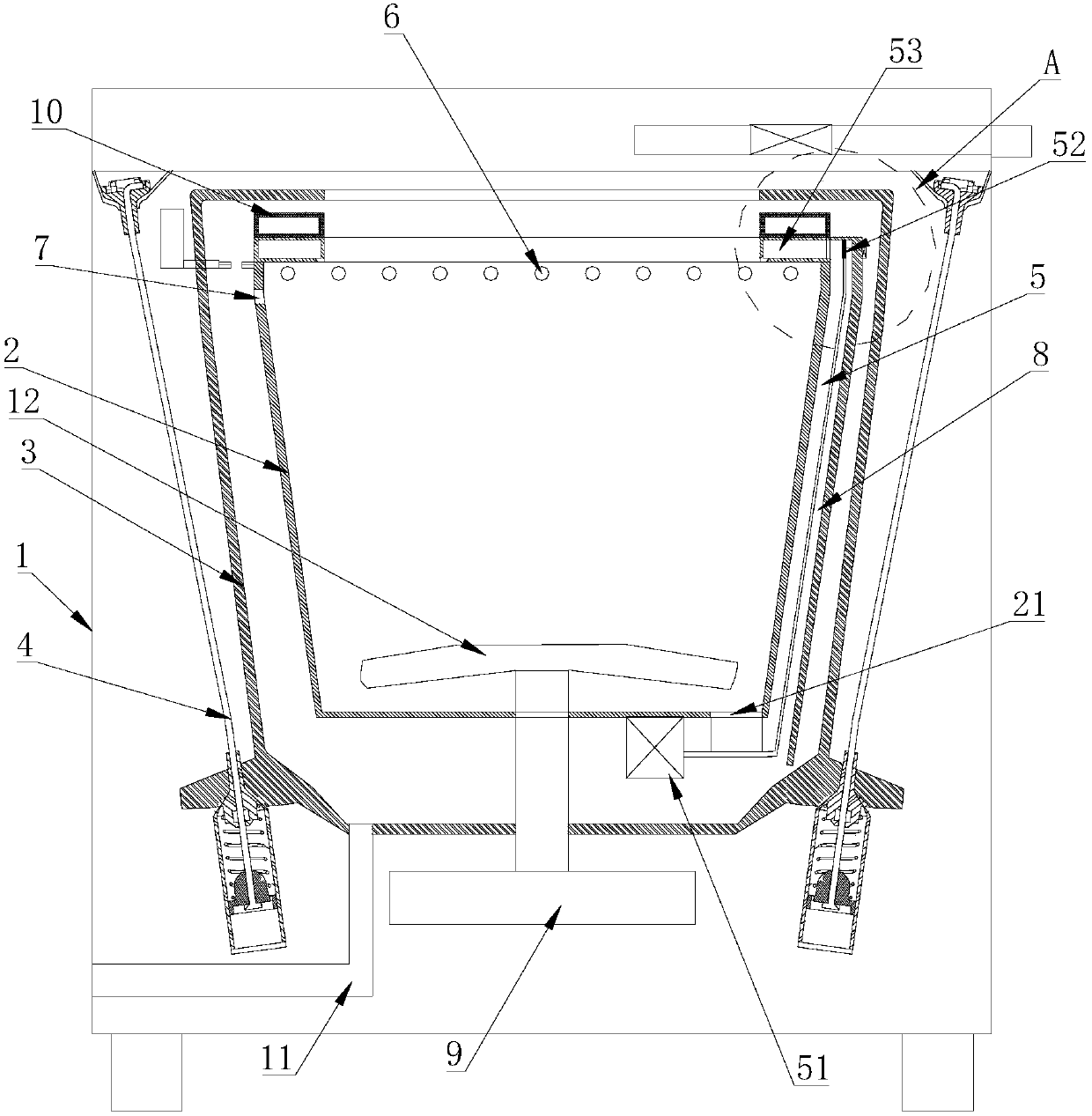

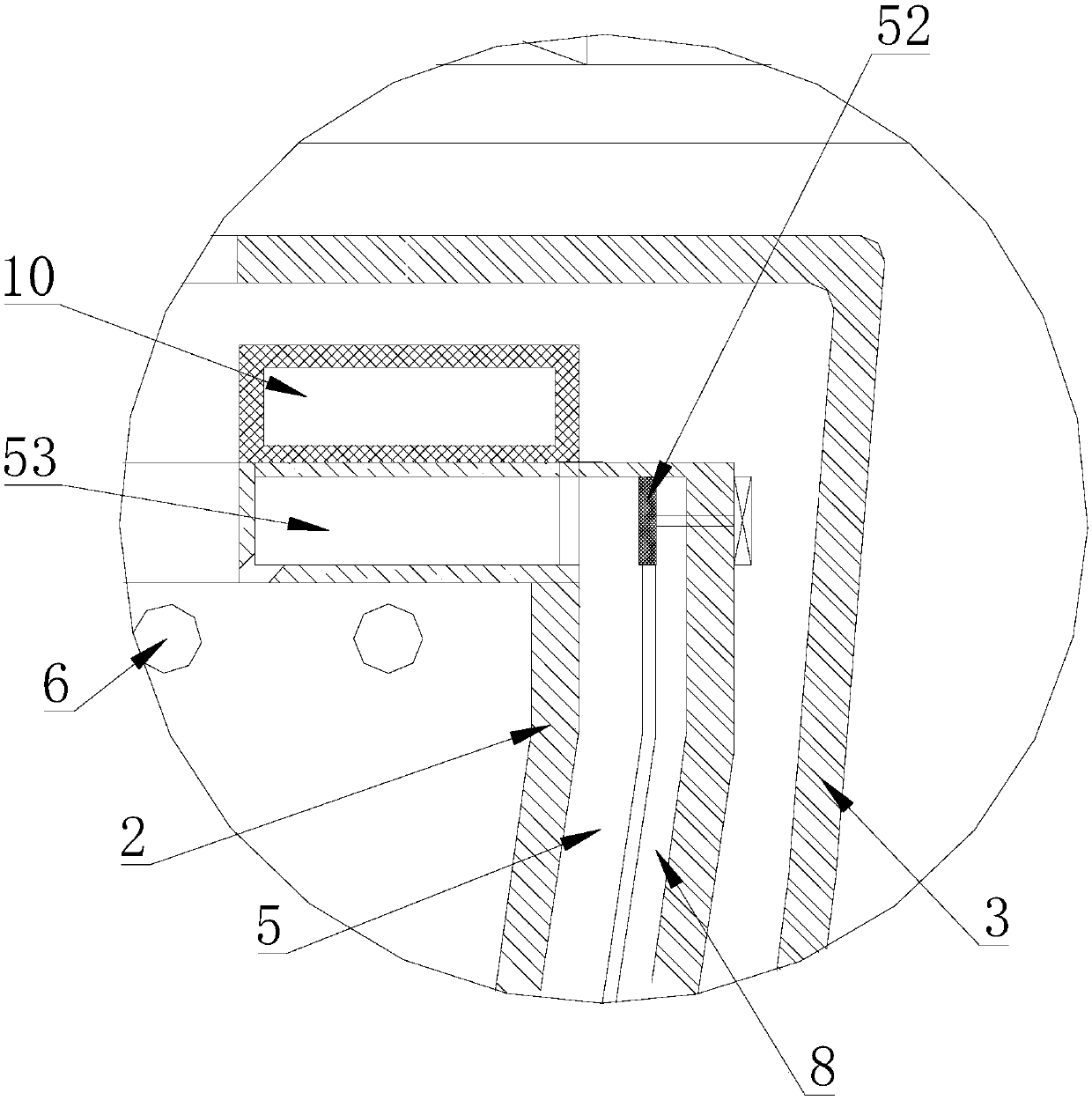

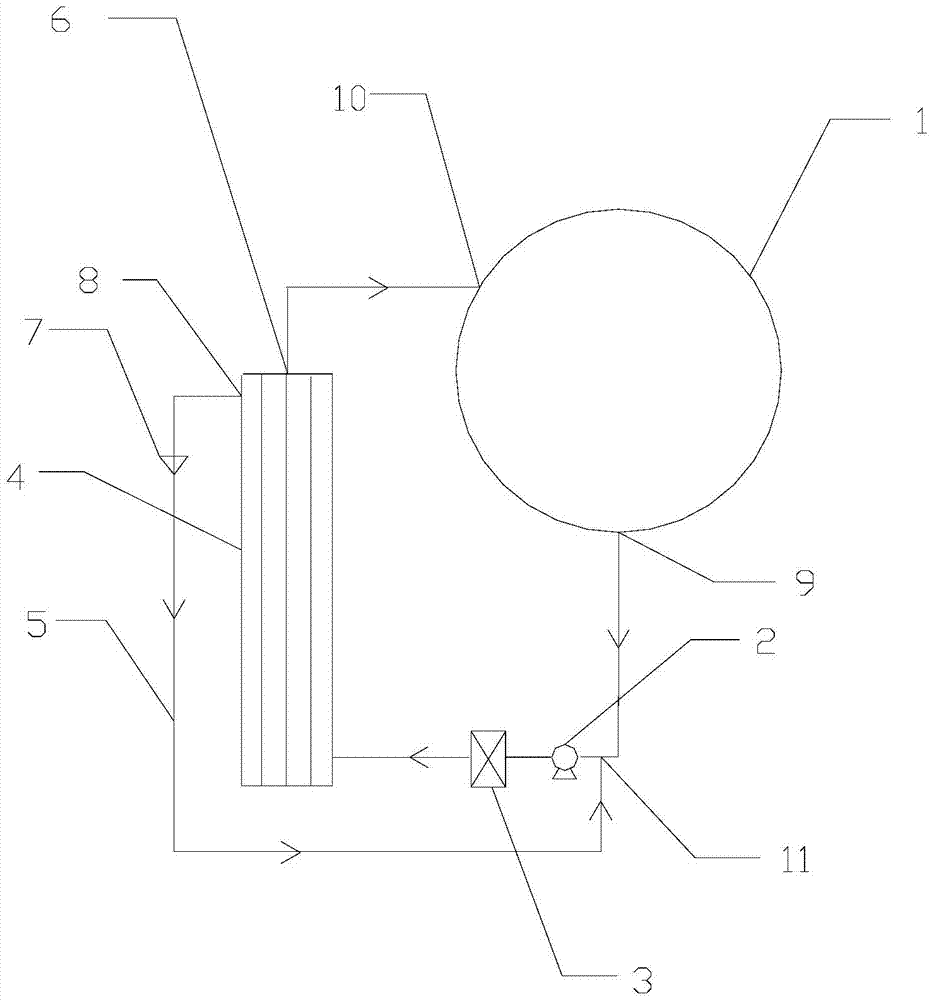

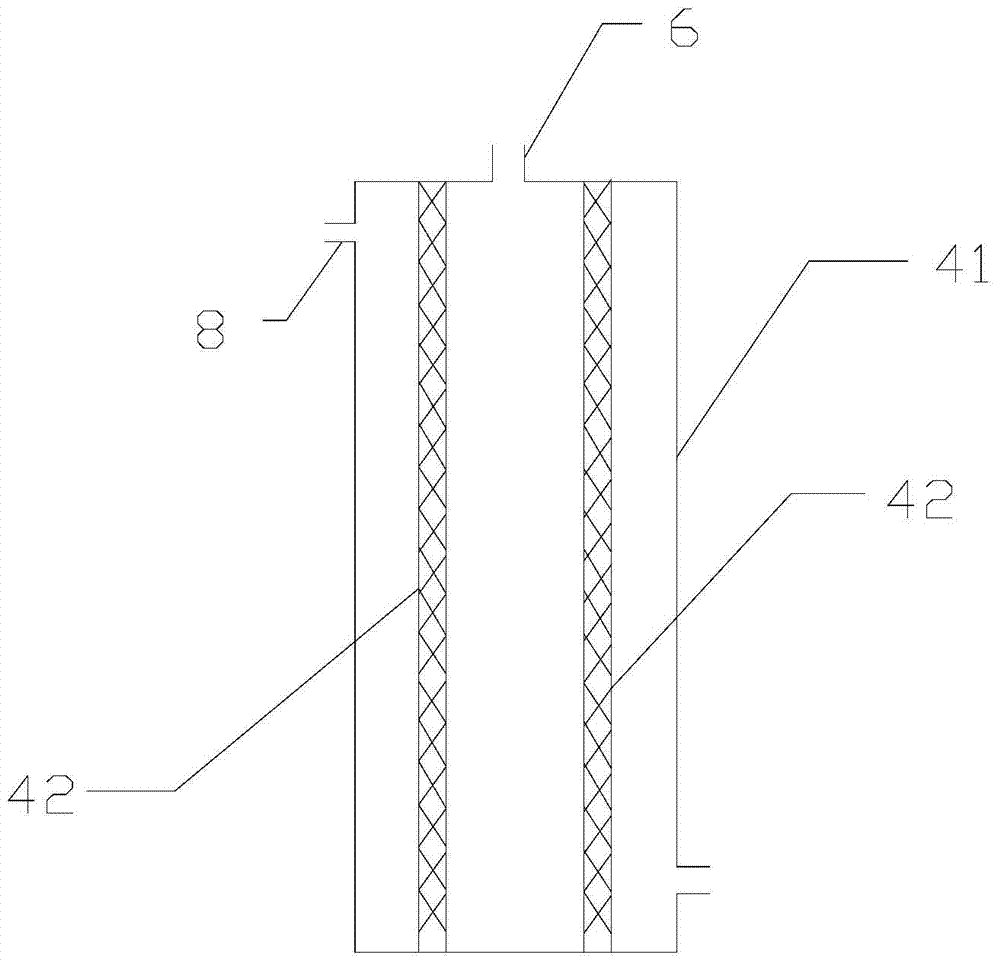

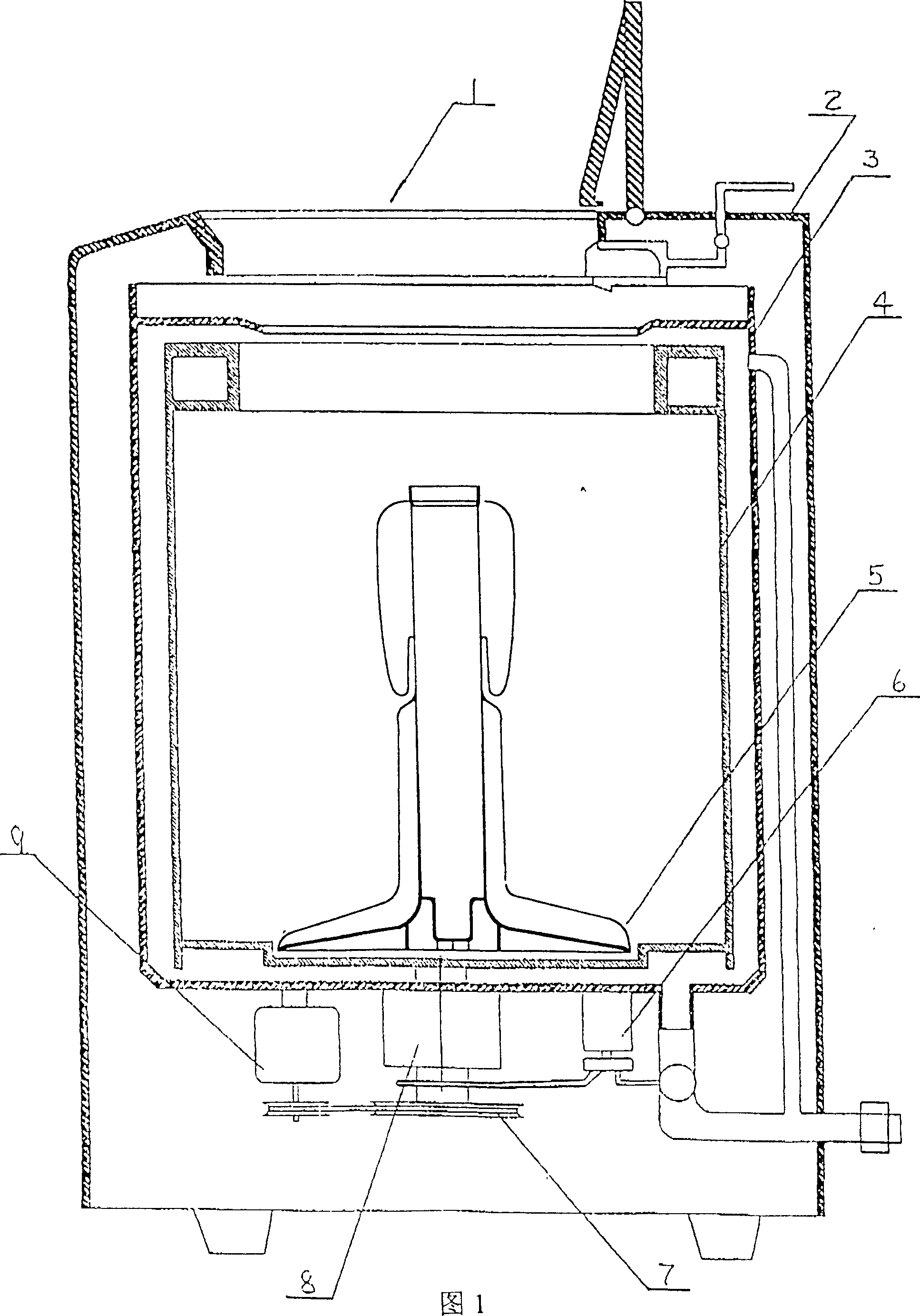

Pneumatic-vacuum combined type washing machine

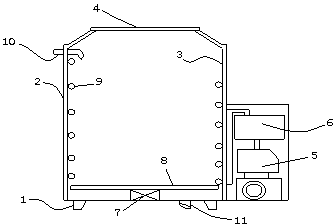

InactiveCN103276558ATo achieve the purpose of not being entangledAvoid wrinklesOther washing machinesWashing machine with receptaclesWater dischargePulp and paper industry

The invention relates to an optimization method of an existing cylinder-type washing machine structure and a washing machine adopting the method, in particular to a pneumatic-vacuum combined type washing machine comprising legs, a shell, an inner cylinder, a seal cover, an air compressor, an air storage tank, a bearing, a rotary plate, spraying nozzles and a vacuum pump. The pneumatic-vacuum combined type washing machine is characterized in that the legs are fixed under the shell; the inner cylinder is arranged in the shell vertically; a cylinder mouth ring is arranged on the top of the inner cylinder; the seal cover is mounted on the cylinder mouth; the rotary plate is arranged at the bottom of the inner cylinder, and is arranged in the bearing; the spraying nozzles arrayed in different directions are distributed on the cylinder wall of the inner cylinder and are connected to the air storage tank through a pipeline; a valve is arranged on the pipeline; the air storage tank is connected to the air compressor through an air pipe; the bottom of the inner cylinder is connected to a drain valve through a water discharging pipe; the drain valve is further connected to the vacuum pump or a water suction pump; and the bottom of the inner cylinder may be further connected to an air drying device.

Owner:戴文育

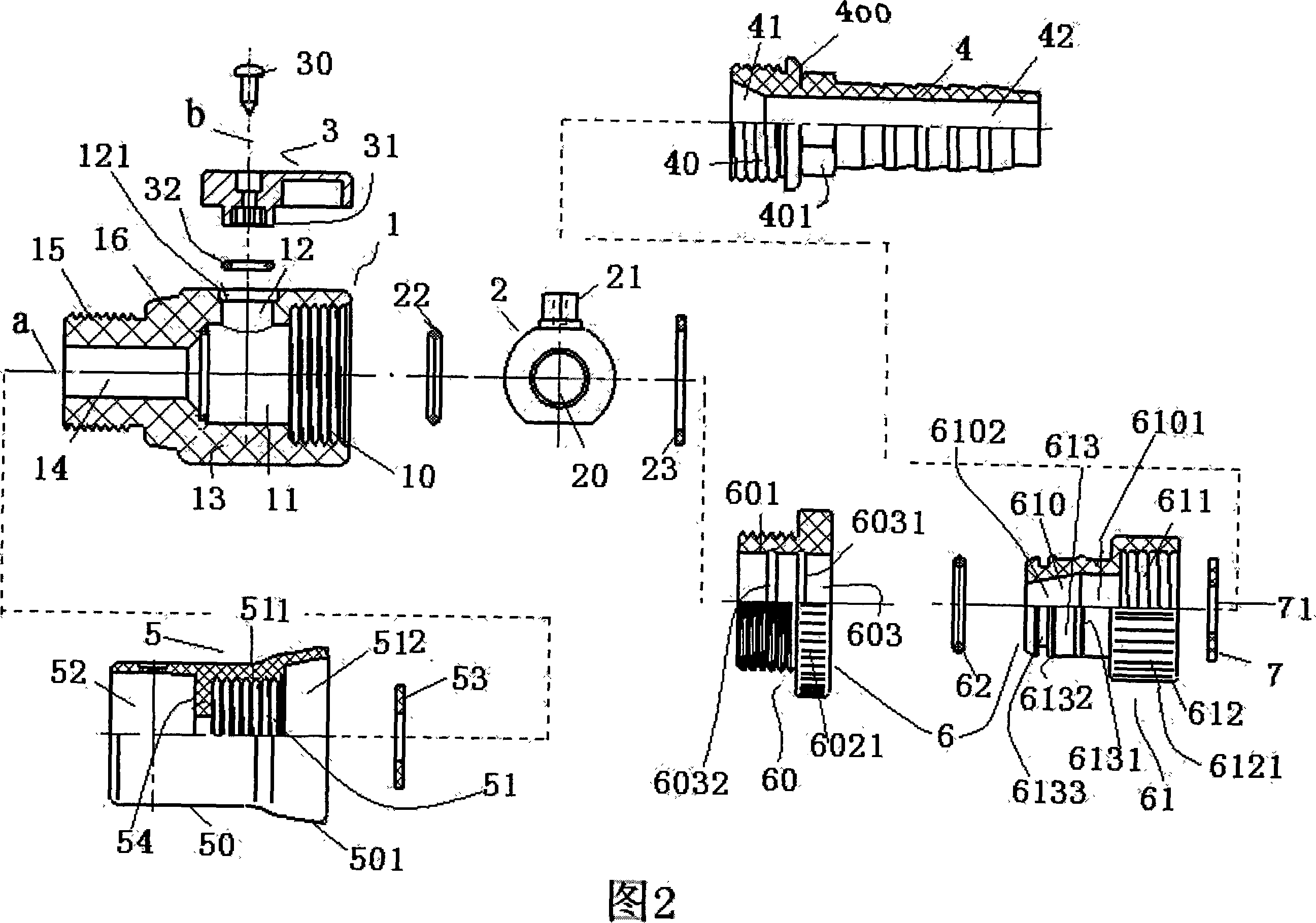

Water flow controller for water spraying tool

InactiveCN101088627AOptimize structural configurationIncrease the strength of the currentSpray nozzlesWater flowSteering control

The present invention is one water flow controller for water spraying tool, especially one water spraying pipe. The water flow controller includes one ball valve to control the water flow passage, one pipe connector connected to one end of the ball valve, and one water tap connector connected to the other end of the ball valve. The water tap connector has one first water accumulating cavity to form water pressure and one second water accumulating cavity in the joint to the water tap. The present invention has raised water flow controlling effect, good sealing effect, low cost and other advantages.

Owner:TIANJIN JINMAO GROUP

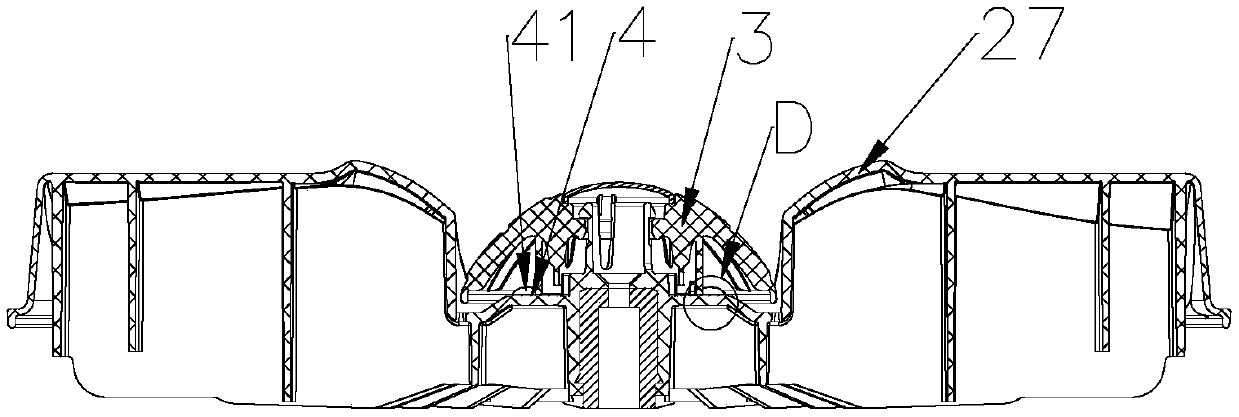

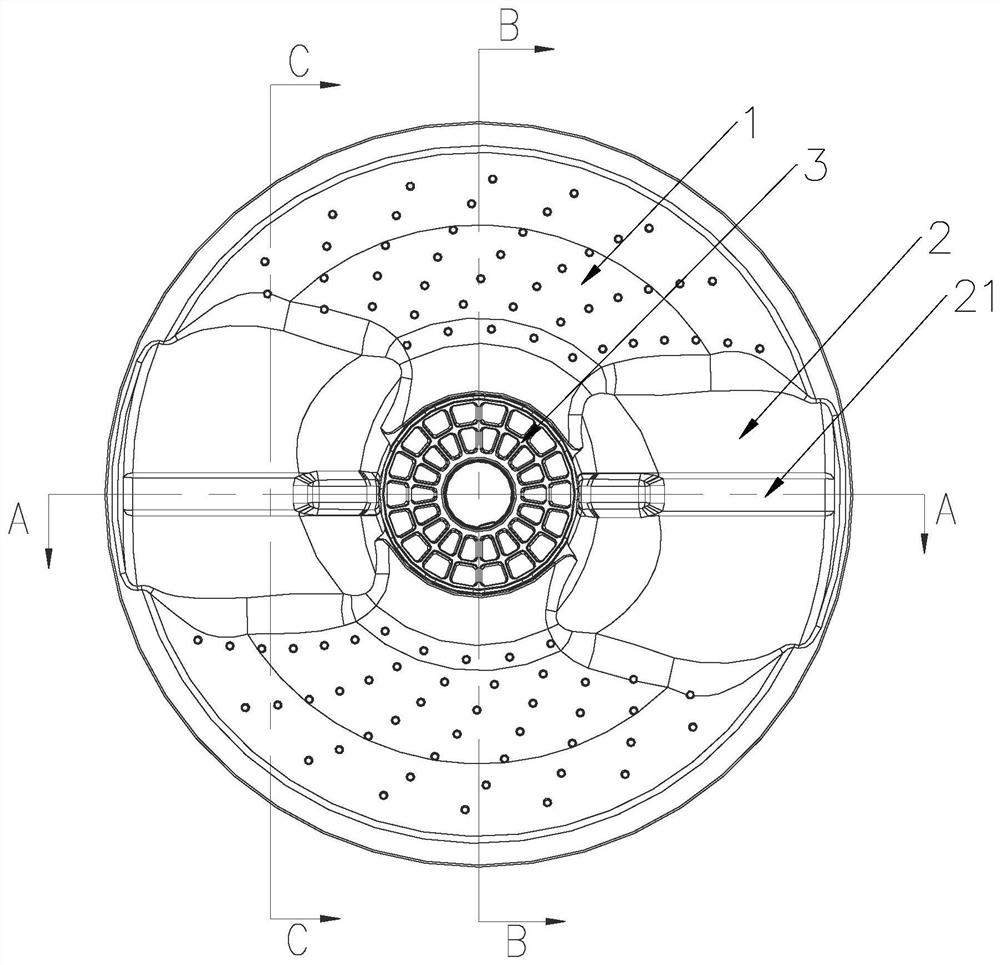

Washing machine impeller and washing machine with the same

ActiveCN107653621AIncrease frictionReduce frictionWashing machine with receptaclesTextiles and paperImpellerEngineering

The invention discloses a washing machine impeller and a washing machine with the same. The washing machine impeller comprises an impeller body; a center rotating wheel capable of rotating freely anda smooth supporting structure are arranged in the center of the impeller body, wherein the smooth supporting structure is arranged under the center rotating wheel so as to reduce the friction betweenthe center rotating wheel and the impeller body. As the impeller is provided with the smooth supporting structure, wear between the center rotating wheel and the impeller body is prevented; as the center rotating wheel is arranged, clothes can be easily scattered and prevented from twining, and accordingly the washing effect is improved; stirring blades have a large area and a steep appearance, space is provided for clothes to move in the upper part, the lower part and the middle part, twining is prevented, the washing and drying effects are good, and the clothes are fluffier after being dried.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Swinging washing machine

InactiveCN102634956ATo achieve the purpose of not being entangledIncrease rubbingOther washing machinesWashing machine with receptaclesImpellerHorizontal axis

A swinging washing machine resolves the technical problems that in the prior art, cleaning ratio is not high, clothes are twined together and the like, aims to realize a further obvious washing effect, and mainly consists of a swinging barrel, a base and a swinging mechanism. The swinging washing machine is characterized in that the lower end of the swinging barrel is connected with the base via a movable joint, the swinging mechanism is disposed between the swinging barrel and the base, and accordingly the swinging barrel obliquely swings back and forth on a horizontal axis relative to a perpendicular axis. During working, both an inner barrel and a stirring ring of the swinging barrel are driven to rotate in reverse directions relatively, water spirally flows inwards or outwards by a bump, clothes rubbing strength and water flow strength are improved, at the moment, the swinging barrel obliquely swings back and forth on the horizontal axis relative to the perpendicular axis, all-directional clothes rubbing and all-directional water flow changing effects can be realized, so that clothes roll during rubbing, twisting of the clothes is avoided, and comprehensive rubbing washing which cannot be realized only by rotation of an impeller or a drum is realized by the swinging washing machine.

Owner:谢永宁

Wave washing machine

InactiveCN102383290AIncrease rubbingIncrease the strength of the currentOther washing machinesTextiles and paperEngineeringAir bubble

Owner:戴文育

Washing machine and washing machine driving method

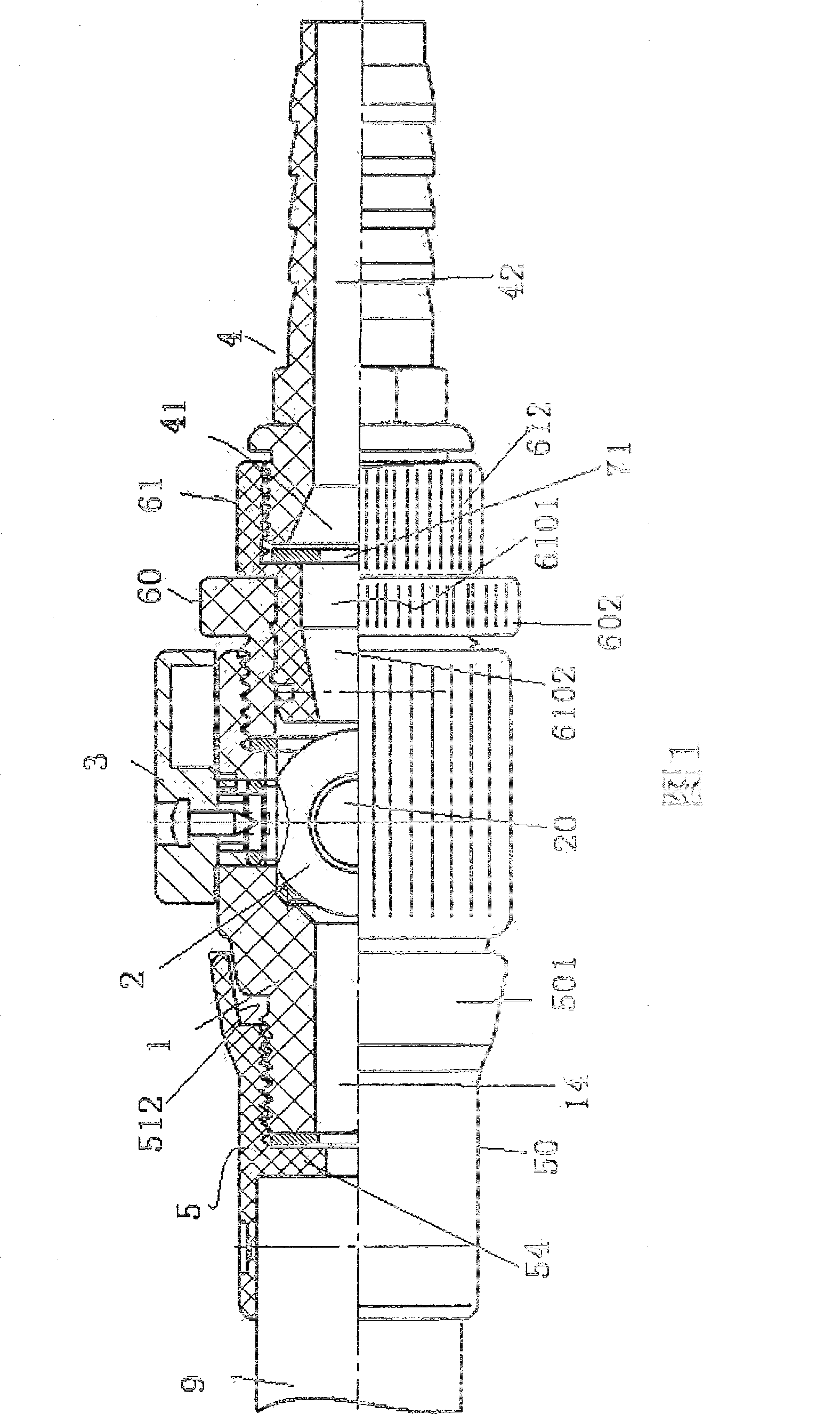

ActiveCN103911795BSave spaceIncrease the strength of the currentOther washing machinesWashing machine with receptaclesMotor driveWater flow

A washing machine and a washing machine driving method provided by the present invention, wherein the washing machine includes: an inner cylinder, an outer cylinder, a pulsator and a pulsator motor, a primary coil is arranged along the circumference of the outer cylinder, and a secondary induction part is correspondingly arranged on the inner cylinder, When the primary coil is energized, it generates magnetic force with the secondary induction part to drive the inner cylinder to rotate. The pulsator motor drives the pulsator to rotate in the same direction or in the opposite direction to the inner cylinder. The outer cylinder of the washing machine is used as the primary of the induction motor, and the inner cylinder is used as the induction motor. The secondary of the motor, when the primary is energized, generates magnetic force with the secondary to drive the inner cylinder to rotate, and the pulsator motor drives the pulsator to rotate to achieve dual power, which can effectively strengthen the water flow intensity and improve the cleanliness. In addition, the inner cylinder and the wave The wheels are controlled separately, no clutch is required, and the space of the whole machine is effectively solved.

Owner:HAIER GROUP TECHN R&D CENT +1

Multi-filter cylinder automatic backwashing filter apparatus

InactiveCN102794044BReduce backwash frequencyMaximum backwash frequencyStationary filtering element filtersControl systemRinse water

The invention discloses an automatic backwash filter device with multiple filter cartridges. The casing is divided into upper and lower chambers by a partition. Filter cartridges are installed on the partition in the form of one or more concentric circles. The casing at the lower end of the partition There is a sewage inlet on the side wall, and a clean water outlet on the side wall of the upper shell; the motor of the backwash mechanism drives the main shaft to rotate, the lifting mechanism drives the shaft to lift, and the multi-way connection seat connects the main shaft, the rotating arm and the sewage pipe Together, the main shaft drives the rotating arm to lift and rotate, the sewage pipe is fixed, the upper port of the rotating arm is fixed with a suction nozzle that can be sealed and connected to the water inlet on the partition, and the end of the sewage pipe is connected to an electric sewage valve or a pneumatic sewage valve. The control system controls the action of the motor, lifting mechanism and electric blowdown valve or pneumatic blowdown valve. The invention has the advantages of small volume, large filtering capacity, high production efficiency, good filtering effect of filtered water, good backwashing effect, low backwashing frequency, long service life of equipment, low maintenance rate and saving backwashing water.

Owner:HEBEI AGRICULTURAL UNIV. +1

Washing machine and washing machine driving method

ActiveCN103911816BEasy to wrapIncrease the strength of the currentOther washing machinesTextiles and paperClutch controlWater flow

The invention provides a washing machine and a washing machine driving method, wherein the washing machine comprises: an inner cylinder, an outer cylinder, a pulsator and a clutch, the inner cylinder is connected to the input end of the clutch, the pulsator is connected to the output end of the clutch, and the pulsator acts on the inner cylinder through the clutch The bottom rotates in the same direction or in the opposite direction, and the clutch controls the inner cylinder and the pulsator to rotate in the same direction or in the opposite direction, which can effectively increase the water flow intensity during the washing process, thereby improving the cleanliness and effectively improving the problem of entanglement of clothes.

Owner:HAIER GROUP TECHN R&D CENT +1

Roller washing machine

InactiveCN108691154AIncrease the strength of the currentImprove cleanlinessOther washing machinesTextiles and paperInlet valveWater flow

The invention provides a roller washing machine. The roller washing machine comprises a box, an outer barrel, an inner barrel, an ordinary inlet system and a strong water flow inlet system, wherein the strong water flow inlet system comprises: a second inlet pipe, a second inlet valve and a nozzle, the first end of the second inlet pipe is connected with the nozzle, and the second end of the second inlet pipe is connected with the inlet, and the second inlet valve is arranged on the second inlet pipe, which is used to control the open and close of the second inlet pipe, the nozzle is installedin the box, and the injection orifice of the nozzle directs toward inside the barrel mouth of the inner barrel. The scheme uses the strong water flow formed by the water pressure of tap water to washclothes in the washing earlier and middle period and cause the surface stain to dissolve, so as to enhance the cleaning effect. Compared with the circulatory system in the existing technology, the technology does not need pumping, the system structure is simpler, the cost is lower, and the flow intensity of washing clothes is large, and the cleaning effect is good.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Clothes treatment device

ActiveCN110453454BImprove rolling effectGood cleaning uniformityOther washing machinesTextiles and paperWash waterWater flow

The invention discloses a clothes treatment device. The clothes treatment device comprises: a water storage container; a washing container, the washing container is arranged in the water storage container and defines a washing chamber for accommodating clothes, and the washing container and the water storage container define The air intake passage communicated with the outside world; the rotating body, the rotating body is rotatably arranged in the washing chamber, the rotating body has at least one flow channel, and the flow passage connects the washing chamber and the air intake passage; the air extraction component , the air extraction component is connected to the washing container for extracting the air in the laundry chamber. According to the clothes treatment device of the embodiment of the present invention, the rubbing washing water flow of interlacing movement is formed in the washing chamber, which improves the washing effect; the rotating high-speed water flow forms a moving low-pressure zone, which drives the clothes around the water flow to rotate continuously, and the clothes tumble effect is good .

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

A spray washing machine

ActiveCN110886065BIncrease the strength of the currentImprove washing efficiencyOther washing machinesTextiles and paperLaundry washing machineWater flow

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Washing machine and washing control method

ActiveCN104674519AReduce pollution rateImprove throughputOther washing machinesControl devices for washing apparatusCross-flow filtrationPollution

The invention relates to a washing machine and a washing control method. A draining port and a water inlet are formed in a washing barrel and are communicated through a circulating pipe, a pre-filtering module and a fine filtering module are connected to the circulating pipe, the fine filtering module is provided with a first water outlet and a second water outlet, filtered liquid in the fine filtering module is drained from the first water outlet, the fine filtering module is connected with the water inlet of the washing barrel, and non-filtered liquid is drained out of the second water outlet and returns to the fine filtering module. The recovered water purifying efficiency can be improved while the layout structure of the washing machine is optimized, drained water of the washing machine can be filtered by the filtering modules in the purifying process by utilizing a high-speed cross flow filtration principle, the pollution speed of a filtering membrane is reduced, flux of the filtering membrane is improved, and the service life of the filtering membrane is prolonged.

Owner:HAIER GROUP TECHN R&D CENT +1

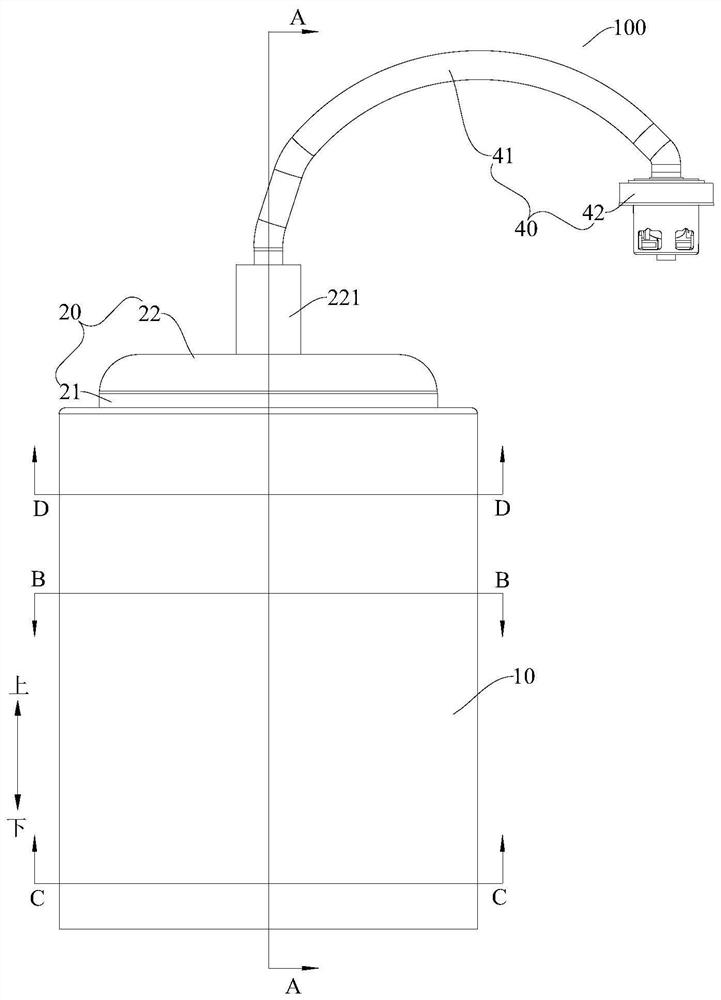

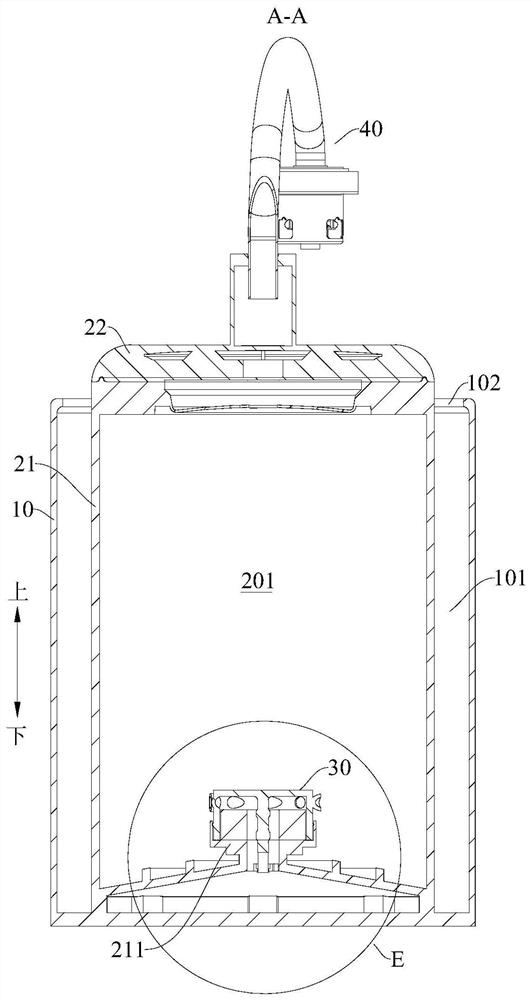

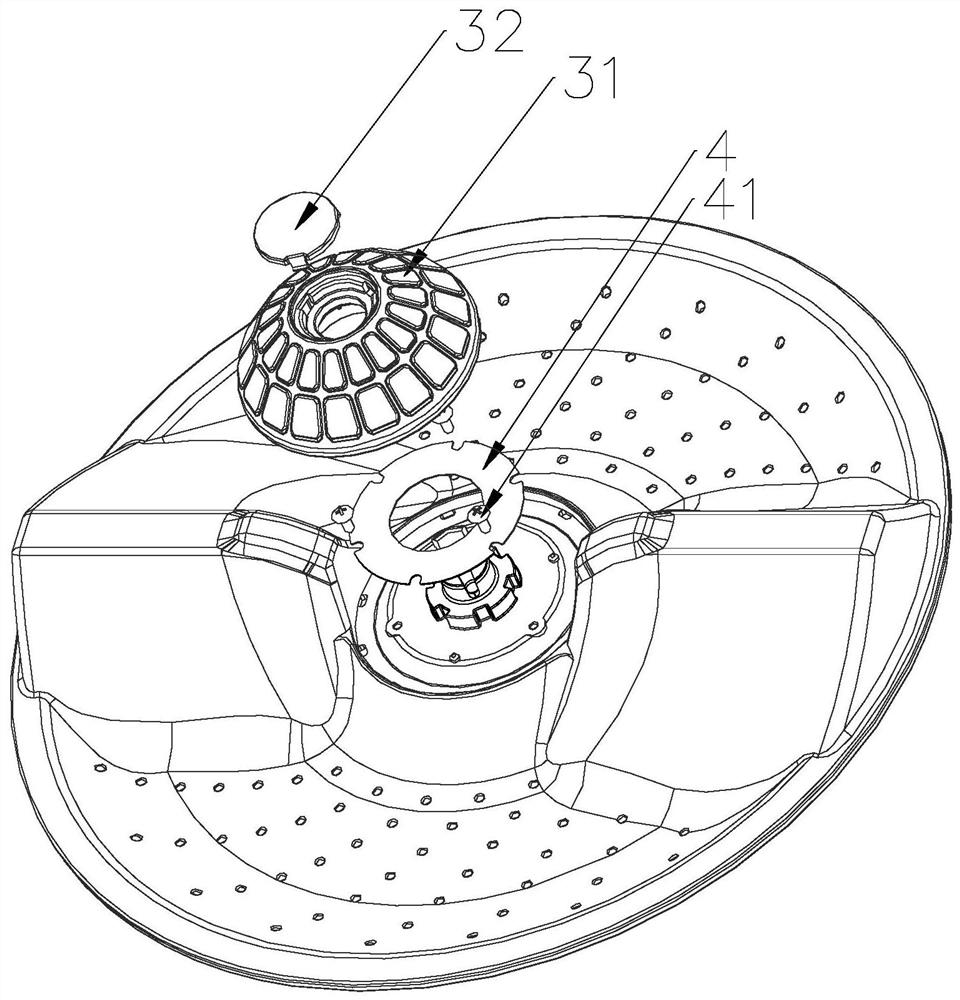

Spray washing machine

ActiveCN110886065AIncrease the strength of the currentImprove washing efficiencyOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses a spray washing machine which comprises a non-porous inner drum. The non-porous inner drum is vertically arranged, a driving motor drives the inner drum to rotate, a cycle runner extends from bottom to top and is formed in the side wall of the non-porous inner drum, the upper end and the lower end of the cycle runner are communicated with the inside of the non-porous innerdrum, a pump is arranged on the cycle runner and drives water flow to flow from bottom to top, the vertical cycle runner is formed in the non-porous inner drum, washing water in the non-porous inner drum can flow from bottom to top along the cycle runner under the action of the pump and is continually cycled from bottom to top, water flow intensity in the non-porous inner drum is improved, water flow diversities are enriched, and the washing efficiency and the washing cleanliness of the washing machine are remarkably improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

A kind of washing machine and laundry control method

ActiveCN104674519BReduce pollution rateImprove throughputOther washing machinesControl devices for washing apparatusCross-flow filtrationEngineering

The invention relates to a washing machine and a washing control method. A draining port and a water inlet are formed in a washing barrel and are communicated through a circulating pipe, a pre-filtering module and a fine filtering module are connected to the circulating pipe, the fine filtering module is provided with a first water outlet and a second water outlet, filtered liquid in the fine filtering module is drained from the first water outlet, the fine filtering module is connected with the water inlet of the washing barrel, and non-filtered liquid is drained out of the second water outlet and returns to the fine filtering module. The recovered water purifying efficiency can be improved while the layout structure of the washing machine is optimized, drained water of the washing machine can be filtered by the filtering modules in the purifying process by utilizing a high-speed cross flow filtration principle, the pollution speed of a filtering membrane is reduced, flux of the filtering membrane is improved, and the service life of the filtering membrane is prolonged.

Owner:HAIER GROUP TECHN R&D CENT +1

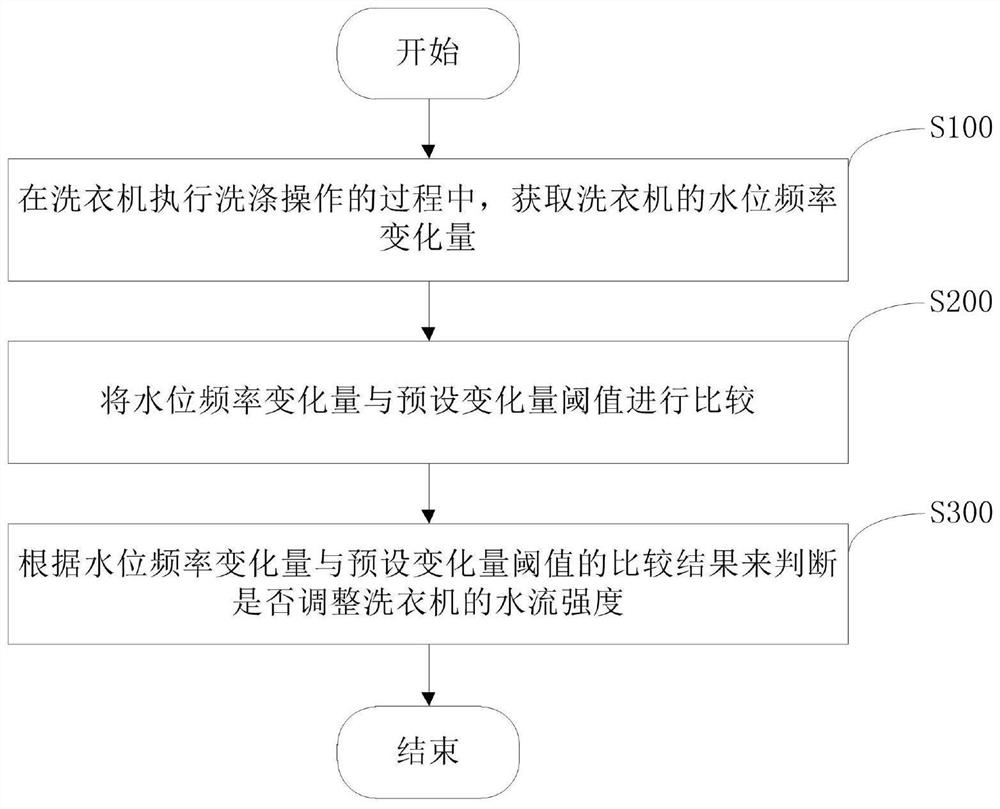

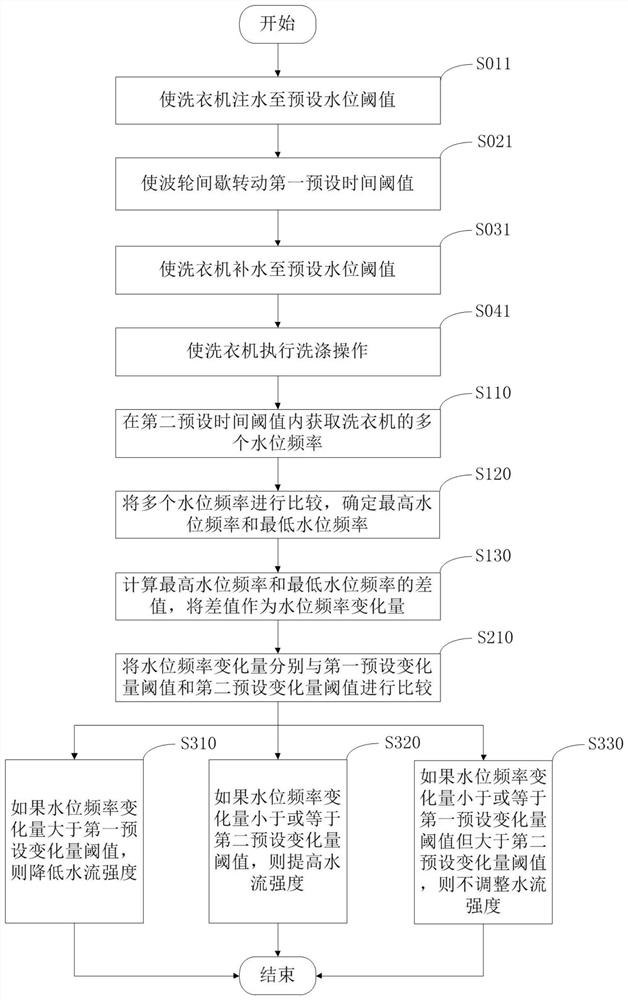

Control method for washing equipment

PendingCN113718468AReasonable current strengthEasy to wearControl devices for washing apparatusTextiles and paperWater flowProcess engineering

The invention relates to the technical field of washing equipment, in particular to a control method for washing equipment, and aims to solve the problem that clothes are seriously damaged or difficult to clean due to the fact that the water flow intensity of existing washing equipment is not matched with the weight of clothes. In order to achieve the purpose, the control method comprises the following steps: in the washing operation executing process of the washing equipment, the water level frequency variation of the washing equipment is obtained; the water level frequency variation is compared with a preset variation threshold; and whether to adjust the water flow intensity of the washing equipment or not is judged according to a comparison result of the water level frequency variation and the preset variation threshold. Whether the water flow intensity of the washing equipment is adjusted or not is judged according to the comparison result of the water level frequency variation and the preset variation threshold, so that the water flow intensity of the washing equipment is matched with the weight of the clothes, the clothes can be cleaned up, wear of the clothes is prevented from being aggravated, and a better washing effect is provided for the clothes.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

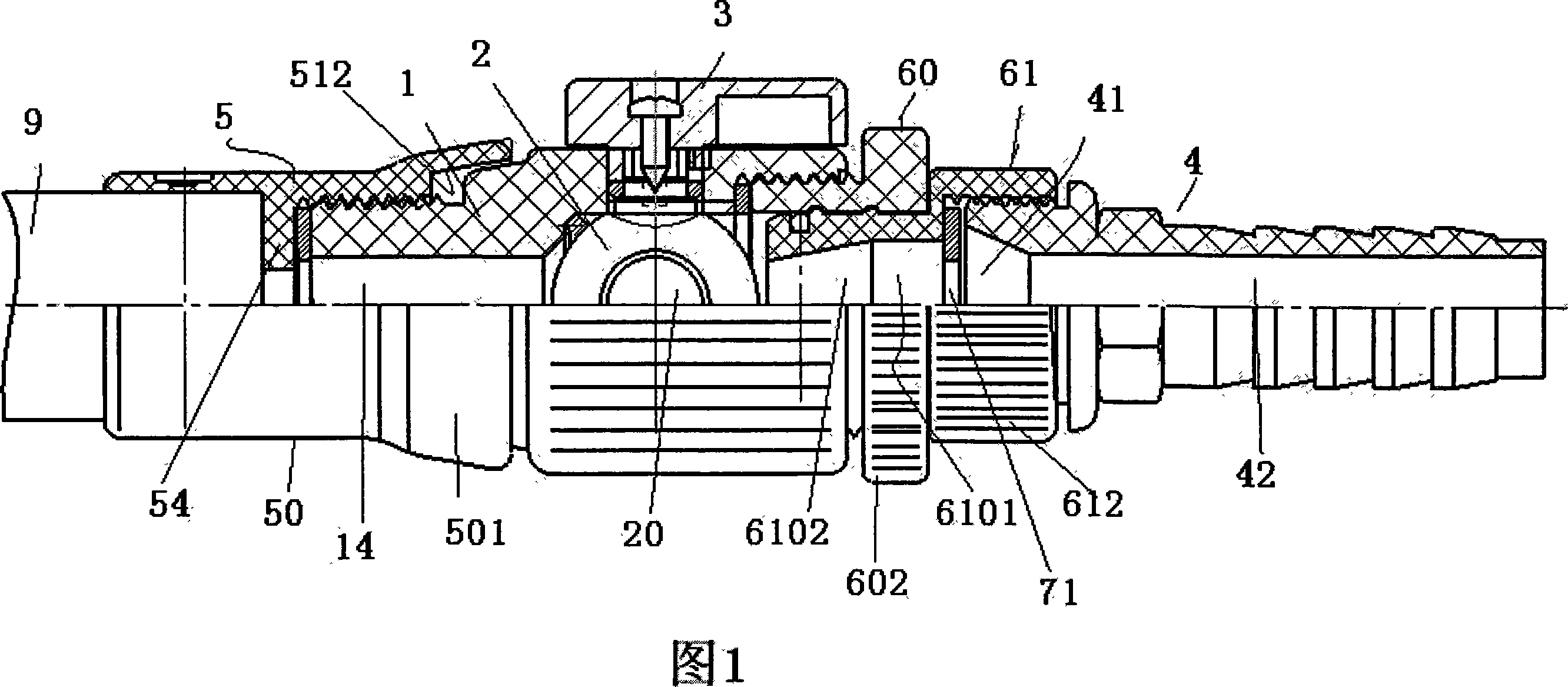

Water flow controller for water spraying tool

InactiveCN100493733CIncrease the strength of the currentImprove wildnessSpray nozzlesWater flowSteering control

The present invention is one water flow controller for water spraying tool, especially one water spraying pipe. The water flow controller includes one ball valve to control the water flow passage, one pipe connector connected to one end of the ball valve, and one water tap connector connected to the other end of the ball valve. The water tap connector has one first water accumulating cavity to form water pressure and one second water accumulating cavity in the joint to the water tap. The present invention has raised water flow controlling effect, good sealing effect, low cost and other advantages.

Owner:TIANJIN JINMAO GROUP

Washing method of agitatory washer and its washer

InactiveCN1316093CReduce entanglementIncrease the strength of the currentOther washing machinesWashing machine with receptaclesWater flowMechanical engineering

A washing method for agitatory washer features that its internal drum and its high-wave wheel (agitator) are respectively driven to rotate in mutually opposite directions for increasing the water stream intensity and its high-wave wheel (agitator) has big height to generate the complex rolling stream from top to bottom for eliminating dead corners.

Owner:HAIER GRP CORP +1

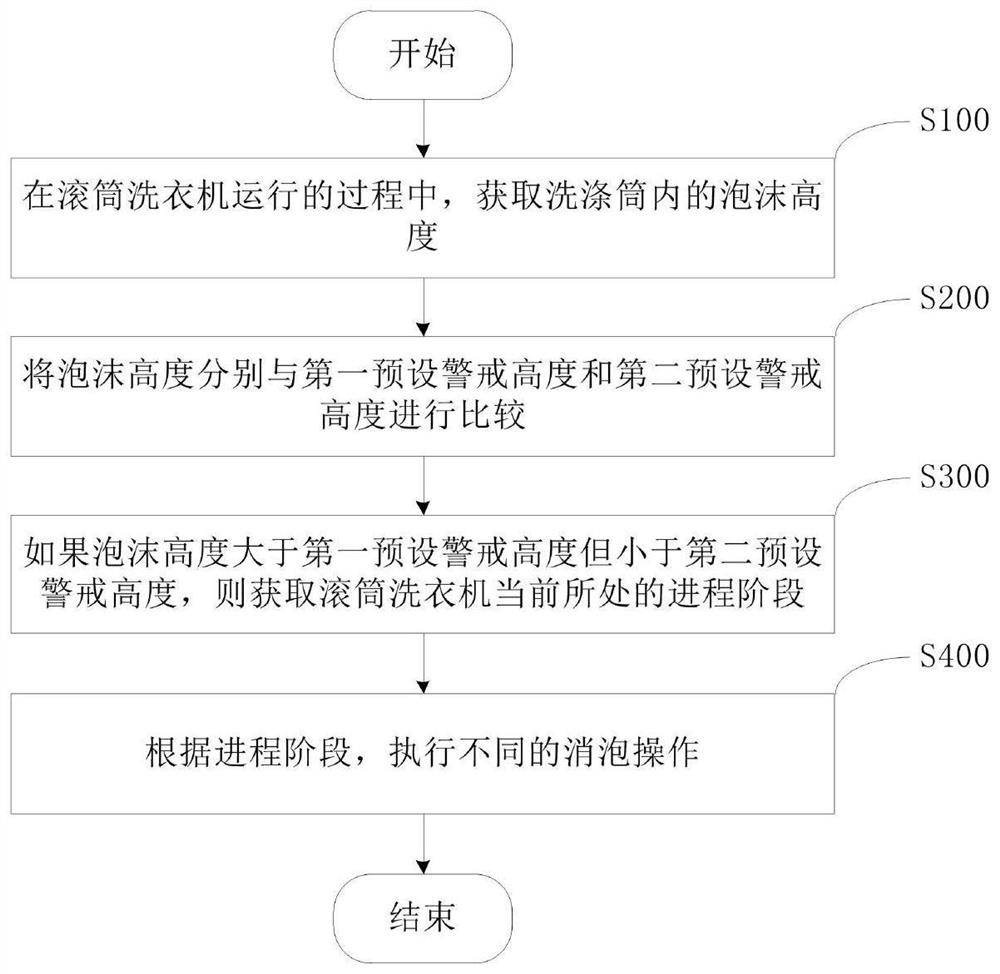

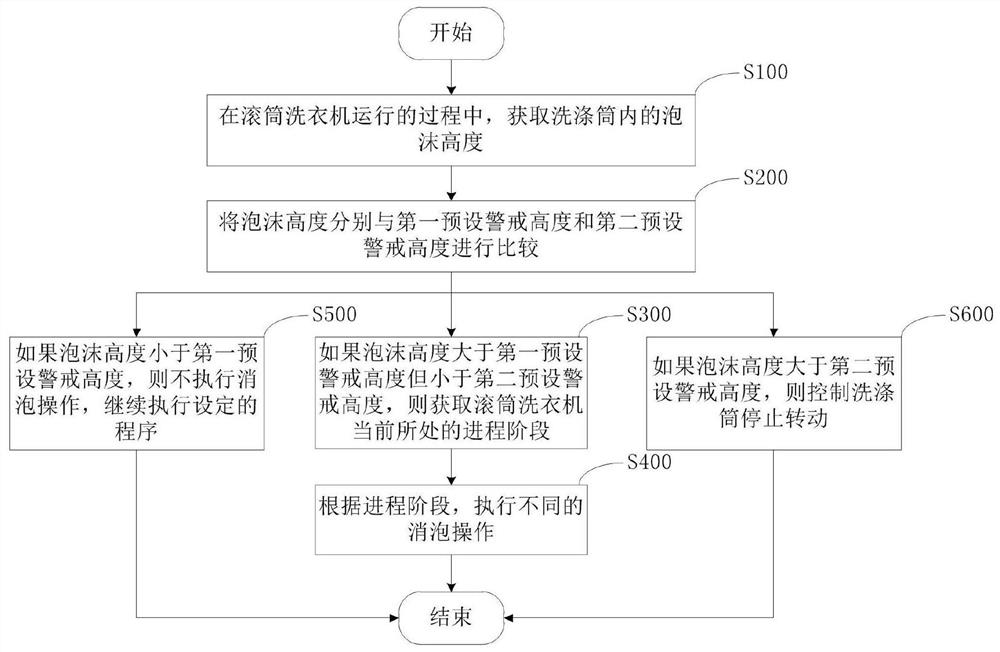

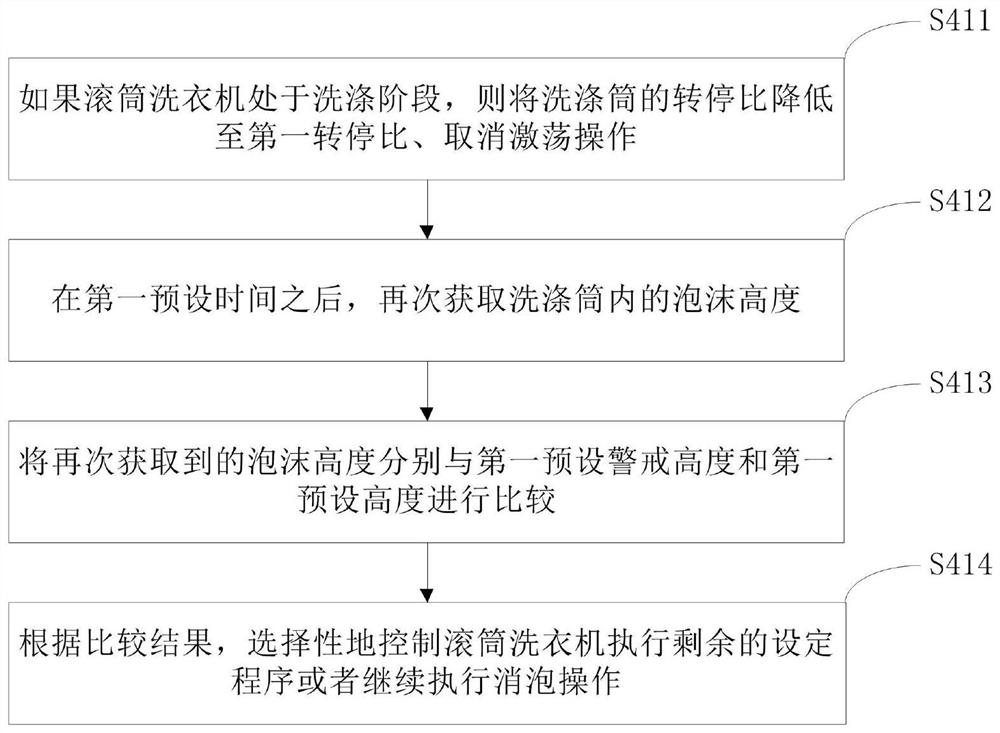

Defoaming method for washing equipment

PendingCN114808390AQuick eliminationEliminate effectiveOther washing machinesControl devices for washing apparatusProcess engineeringIndustrial engineering

The invention relates to the technical field of smart home, particularly provides a defoaming method for washing equipment, and aims to solve the problem that the defoaming effect of existing washing equipment is not ideal. The defoaming method provided by the invention comprises the following steps: in the running process of the washing equipment, obtaining the height of foam in a washing drum; comparing the foam height with a first preset warning height and a second preset warning height respectively; if the foam height is larger than the first preset warning height but smaller than the second preset warning height, the current process stage of the washing equipment is obtained; according to the process stage, different defoaming operations are executed, whether the foam in the washing cylinder needs to be subjected to defoaming treatment or not can be pre-judged in advance, the situation that the ventilation pipe is blocked due to the fact that the washing cylinder is filled with a large amount of foam is avoided, defoaming treatment can be conducted in a targeted mode, the foam in the washing cylinder can be rapidly and effectively eliminated, and the service life of the washing cylinder is prolonged. And the normal operation of the washing equipment is ensured.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

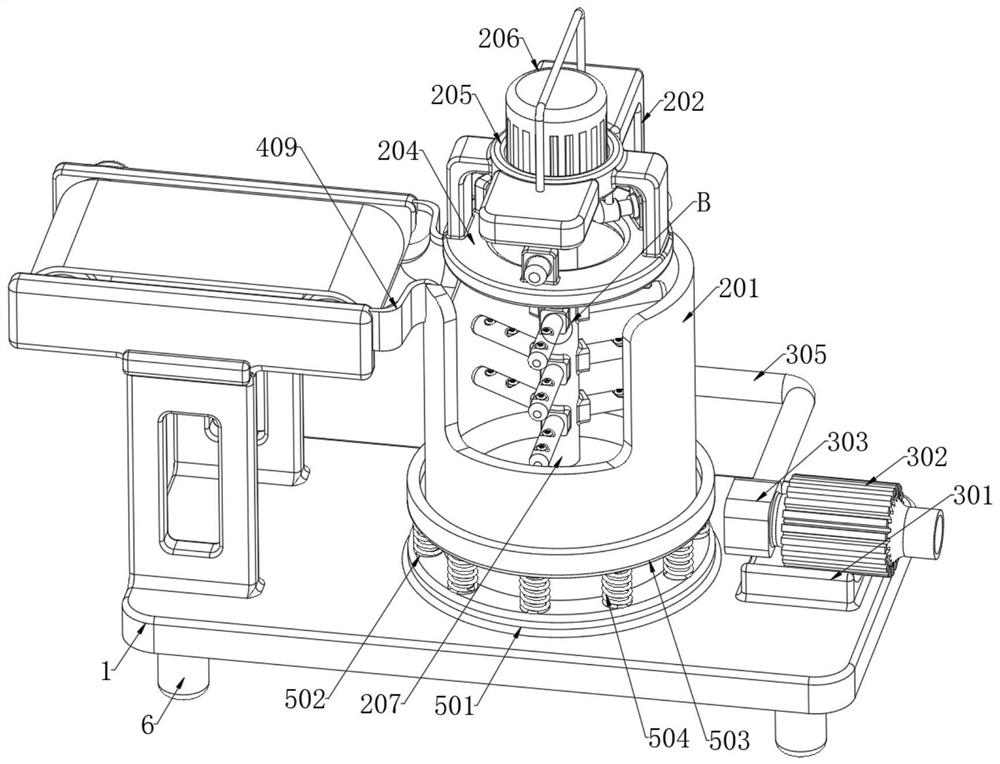

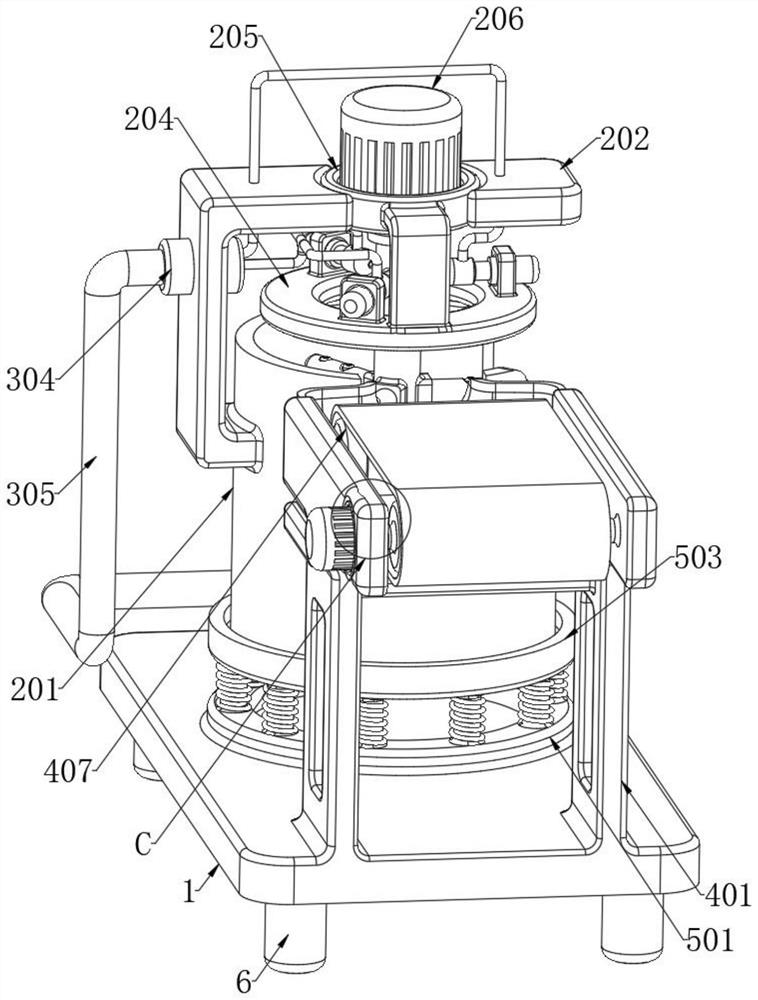

Multi-step concrete stirring device adopting rapid pulping method and processing technology of multi-step concrete stirring device

PendingCN114227922AImprove permeabilityAccelerate incomingCement mixing apparatusVibration suppression adjustmentsWater sourceProcess engineering

The rapid pulping method multi-step concrete stirring device comprises a bottom plate, the top of the bottom plate is fixedly provided with a driving mechanism, a water source carrying mechanism, a material conveying mechanism and a buffering mechanism, the driving mechanism comprises a reaction outer cylinder, and the outer surface wall of the reaction outer cylinder is fixedly provided with a U-shaped frame; a metal ring A is fixedly mounted in the center of the top of the U-shaped frame, water is conveyed into each spray head through an internal water pipe and is doped into materials with different heights, so that a water source can rapidly permeate into the materials, and when the water level rises to the specified height, a water passing joint is separated from the interior of a water inlet, and the water passing joint is separated from the interior of the water inlet; meanwhile, a servo motor A is started to enable a stirring rod on a transmission rod A to rapidly rotate, mixing of the material and a water source is accelerated, the water source can fully permeate into the material by adopting an internal water adding mode, the caking phenomenon of partial areas is prevented, and the final pulping level of the device is improved.

Owner:怀宁县四通混凝土制品有限公司

Washing machine pulsator and washing machine thereof

ActiveCN107653621BIncrease frictionReduce frictionWashing machine with receptaclesTextiles and paperLaundry washing machinePulley

The invention discloses a washing machine pulsator and its washing machine, wherein the washing machine pulsator comprises a pulsator body, a freely rotatable center runner is arranged in the center of the pulsator body, and a lower center runner and a center runner are arranged under the center runner. Smooth support structure for friction between impellers. The pulsator of the present invention is provided with a smooth support structure to prevent wear between the center runner and the pulsator; the center runner is provided so that the clothes are easily scattered and not entangled, and the washing effect is enhanced; the stirring blade has a large area and a steep shape , Clothes have movable space in the upper, lower and middle parts to avoid entanglement, the washing and drying effect is better, and the dried clothes are more fluffy.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com