Washing machine pulsator and washing machine thereof

A washing machine and pulsator technology, which is applied to washing machines with containers, washing devices, textiles, and paper making, etc., can solve the problems of large pulsator space occupied by stirring blades, weak friction between water flow and clothes, and small space for clothes to turn over. Achieving good dehydration effect, improved washing and/or drying effect, easy dispersal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

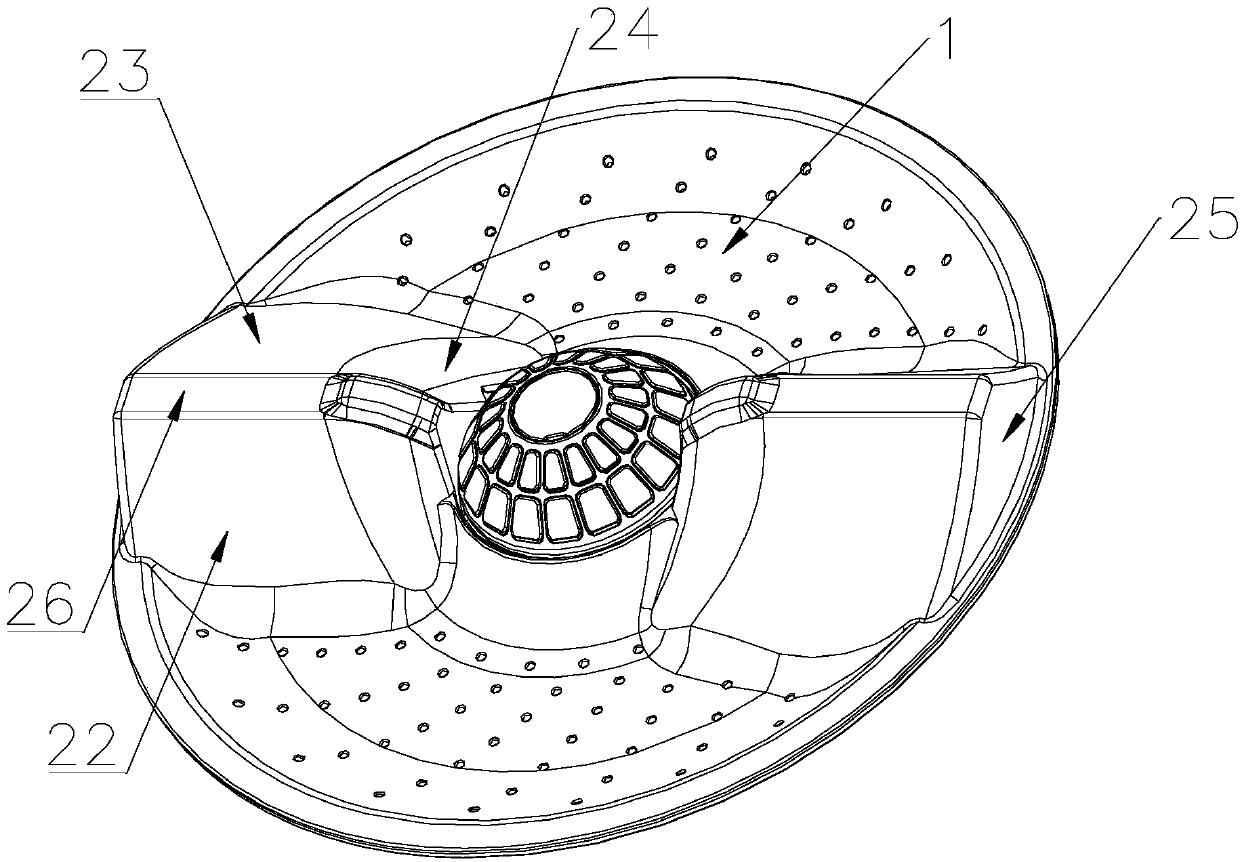

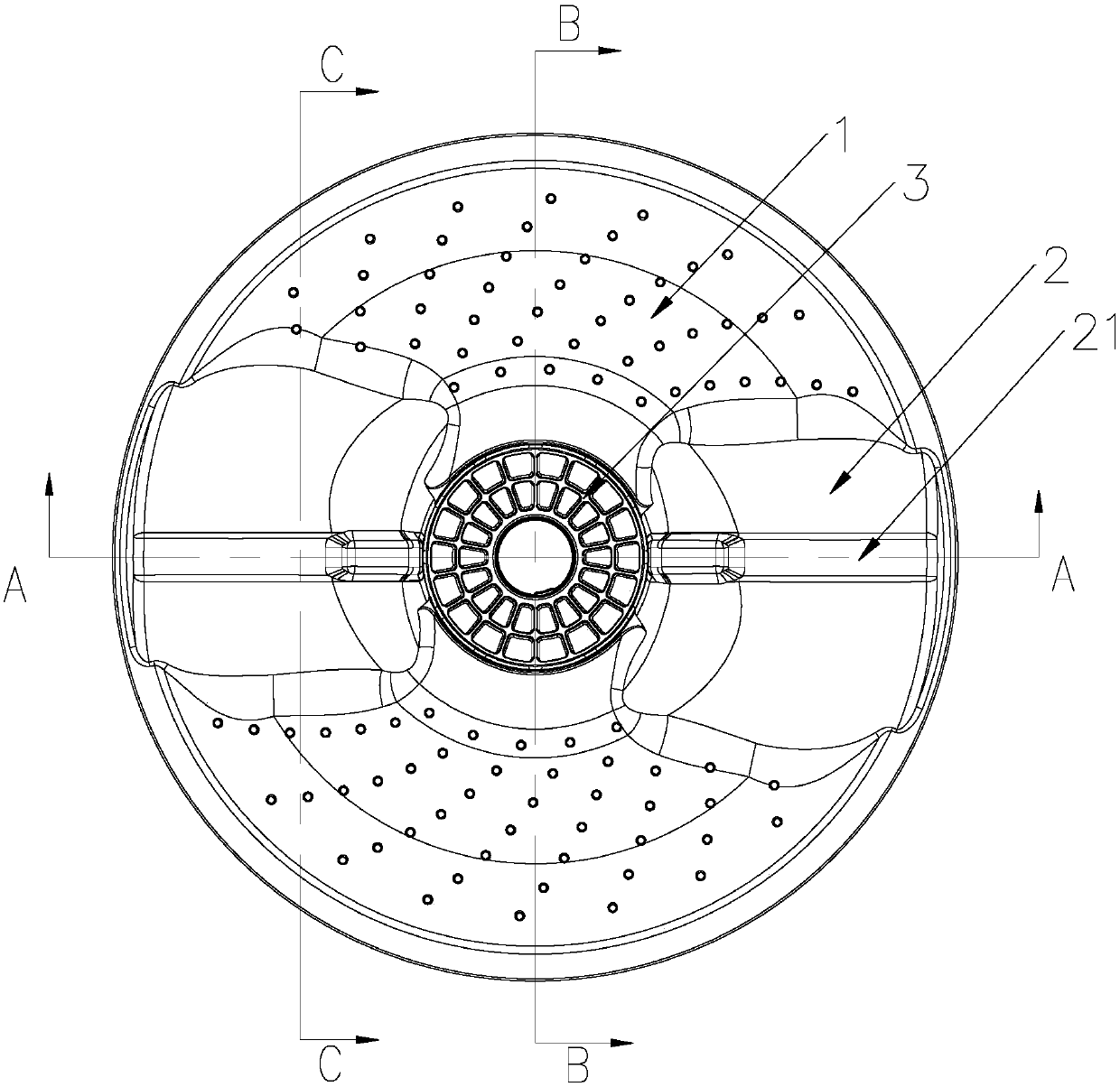

[0064] Such as Figure 1 to Figure 5 As shown, this embodiment provides a pulsator for a washing machine, including a pulsator body 1, on which two raised stirring blades 2 extend from the center along the radial direction of the pulsator body 1, two The stirring blades 2 extend radially on the same diameter.

[0065] The stirring blade 2 is wide at the bottom and gradually narrows toward the top. The stirring blade 2 includes a first side 22 and a second side 23 extending from the top 21 to the impeller chassis 11. The first side 22 and the second side are The side surfaces 23 are located on both radial sides of the stirring blade 2 , and the curves where the first side 22 and the second side 23 intersect with the impeller body 1 are substantially parallel to the radial direction of the stirring blade 2 .

[0066] The deviation angle between the curve of the first side 22 and the second side 23 intersecting the impeller body 1 and the radial direction of the impeller is less...

Embodiment 2

[0077] This embodiment provides a washing machine pulsator, including a pulsator body, on which two raised stirring blades extending from the center along the radial direction of the pulsator body are arranged, and the two stirring blades extend radially on the same diameter.

[0078] This embodiment is a further limitation of Embodiment 1. Compared with Embodiment 1, the difference is that the center of the impeller body is provided with a raised central part, and the inner edge of the stirring blade at least partially wraps around the central part and starts from the central part. extend.

[0079] The length of the inner edge of the stirring blade surrounding the center is greater than 20% of the length of the outer edge of the stirring blade, and the length of the inner edge of the stirring blade is less than or equal to the length of the outer edge of the stirring blade.

[0080] The central part is arranged in a hemispherical structure, and the surface is provided with a n...

Embodiment 3

[0082] Such as Figure 1-6 As shown, this embodiment provides a pulsator for a washing machine, including a pulsator body 1, on which two raised stirring blades 2 extend from the center along the radial direction of the pulsator body 1, two The stirring blades 2 extend radially on the same diameter.

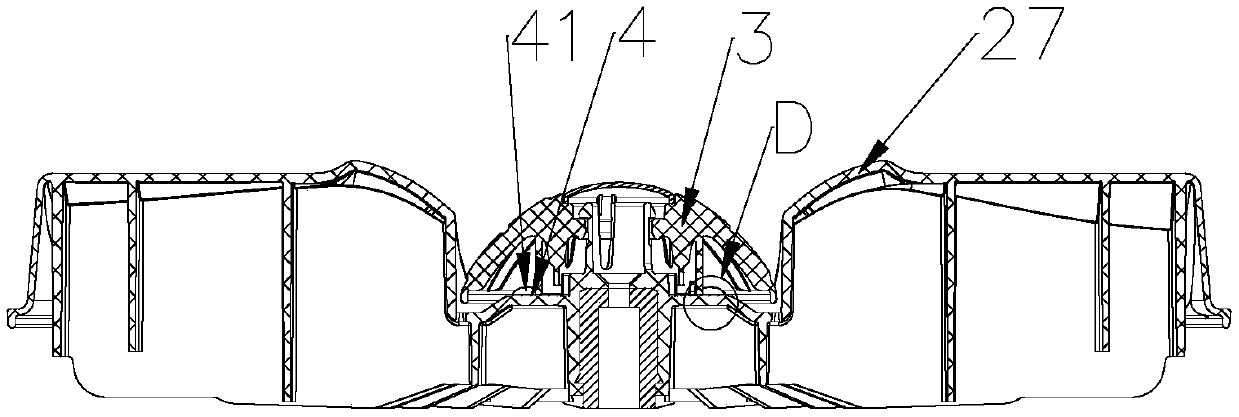

[0083] This embodiment is a further limitation of the first embodiment. The center of the pulsator body 1 is provided with a freely rotatable center wheel 3 and a friction structure arranged under the center wheel 3 .

[0084] The friction structure is a metal washer 4 , which is connected to the pulsator body 1 by screws 41 , and the center runner 3 is rotatably arranged above the metal washer 4 . The diameter of the outer edge of the metal gasket 4 is greater than or equal to the outer diameter of the bottom of the center runner 3 .

[0085] The central runner 3 has a hemispherical structure, and several bumps 31 are arranged on the surface of the central runner 3 . Preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com