Patents

Literature

31results about How to "Squeeze well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

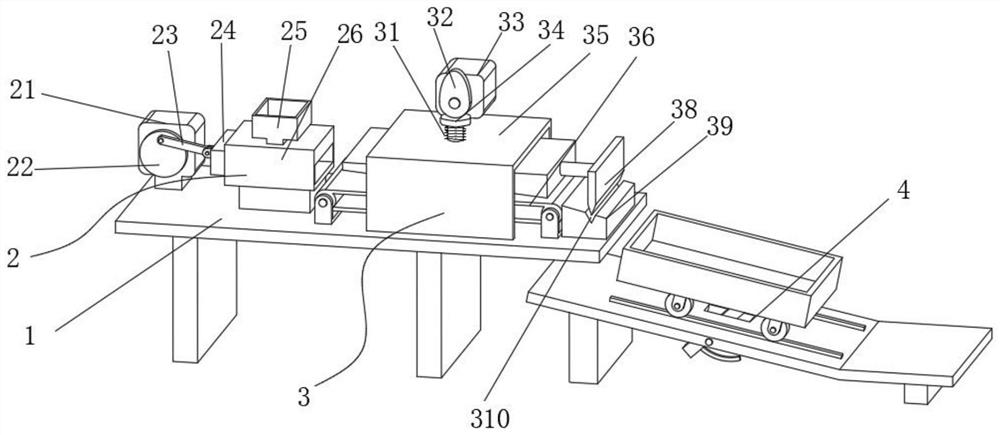

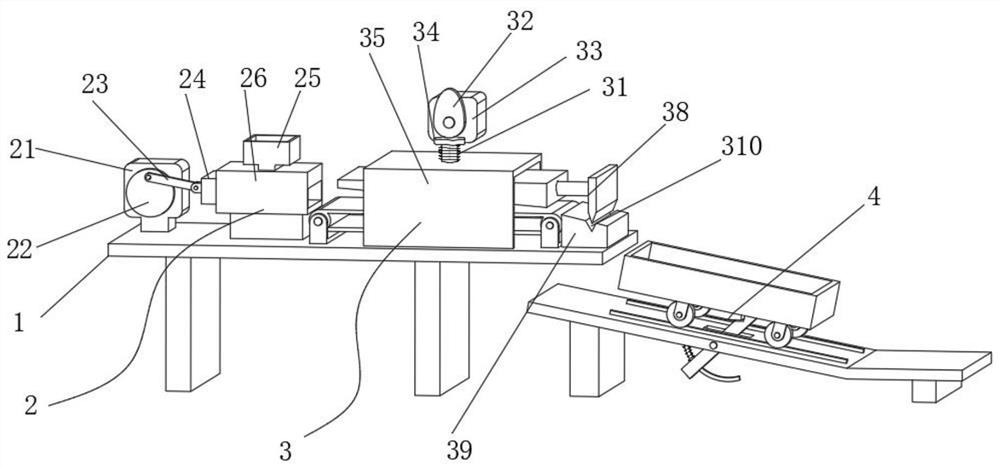

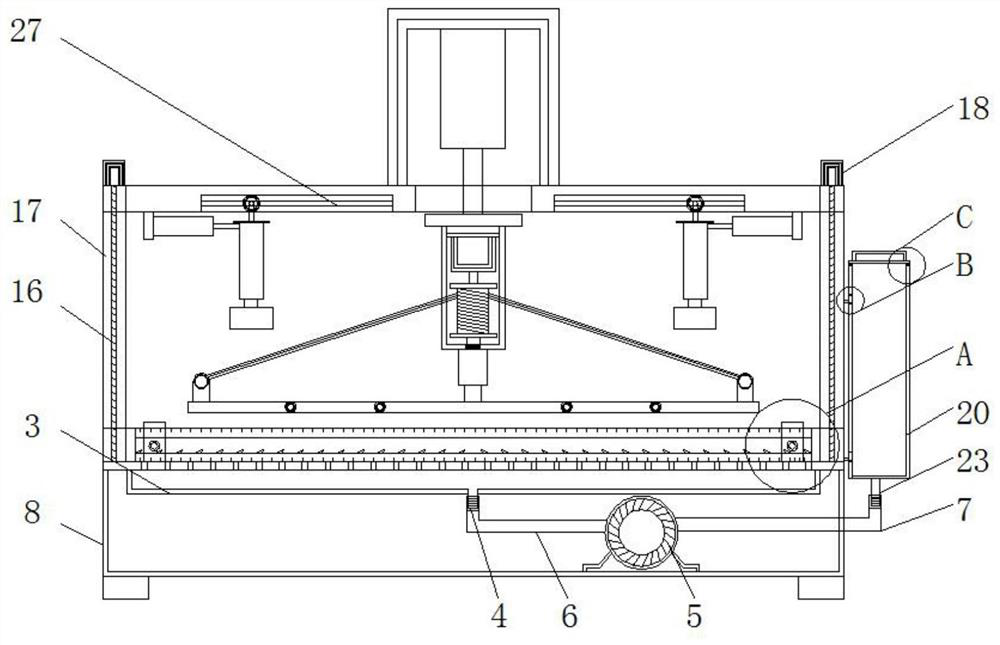

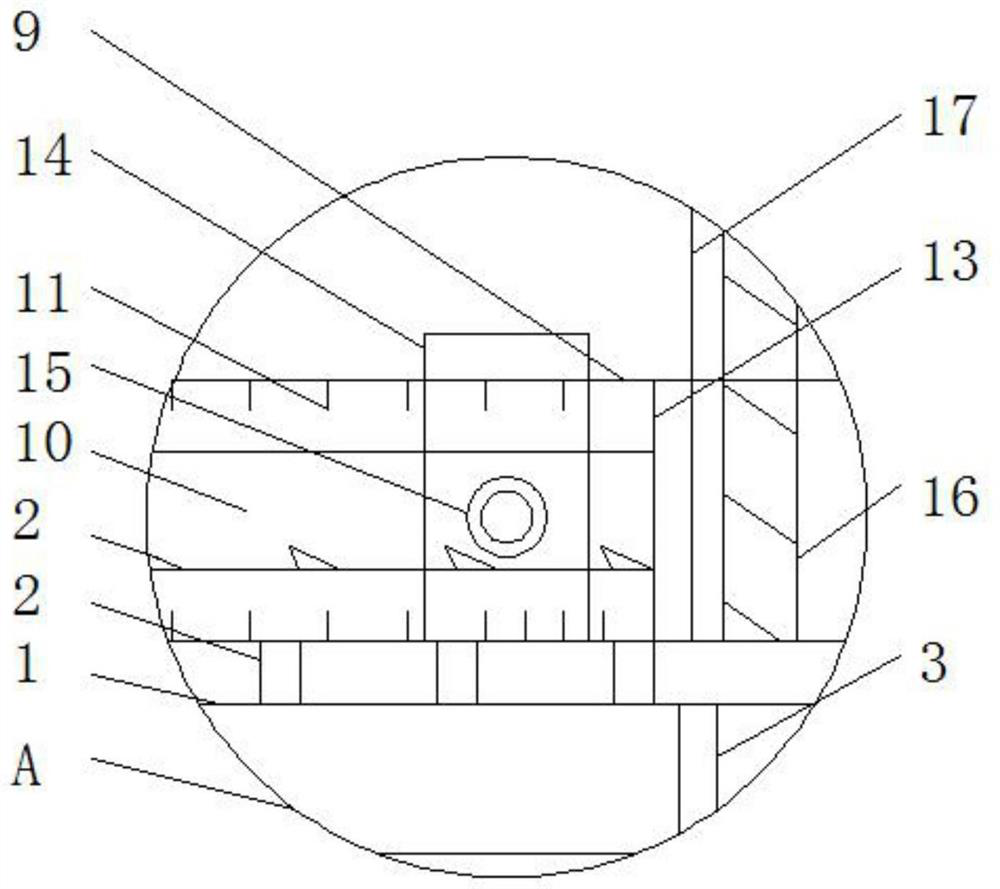

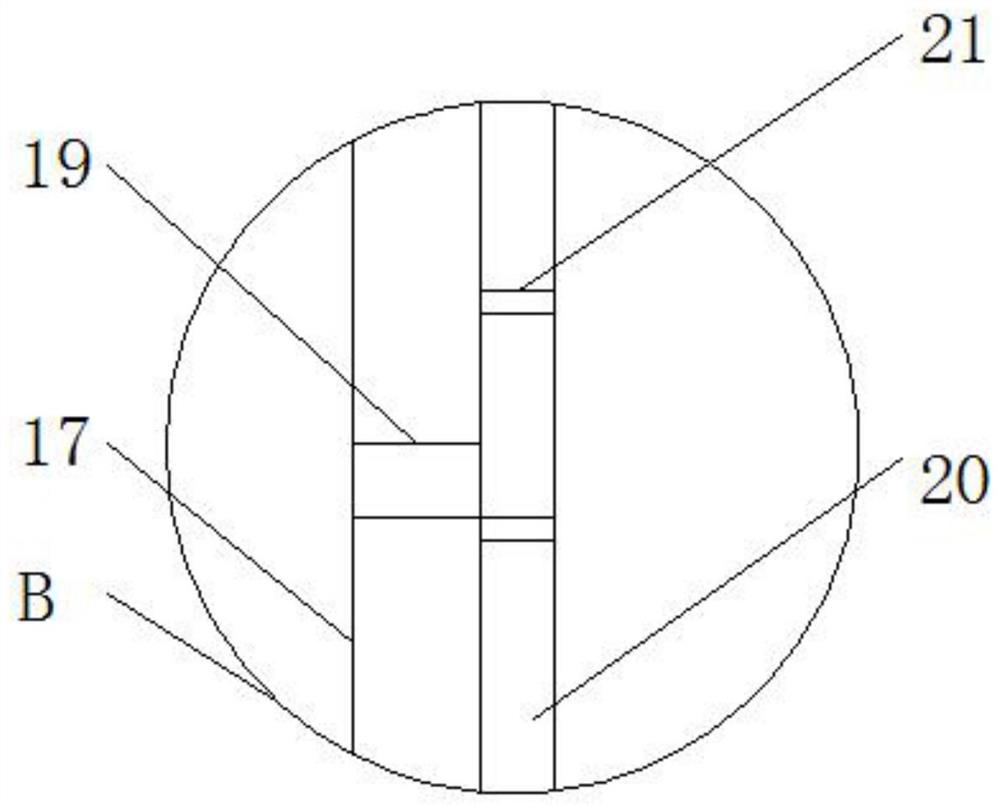

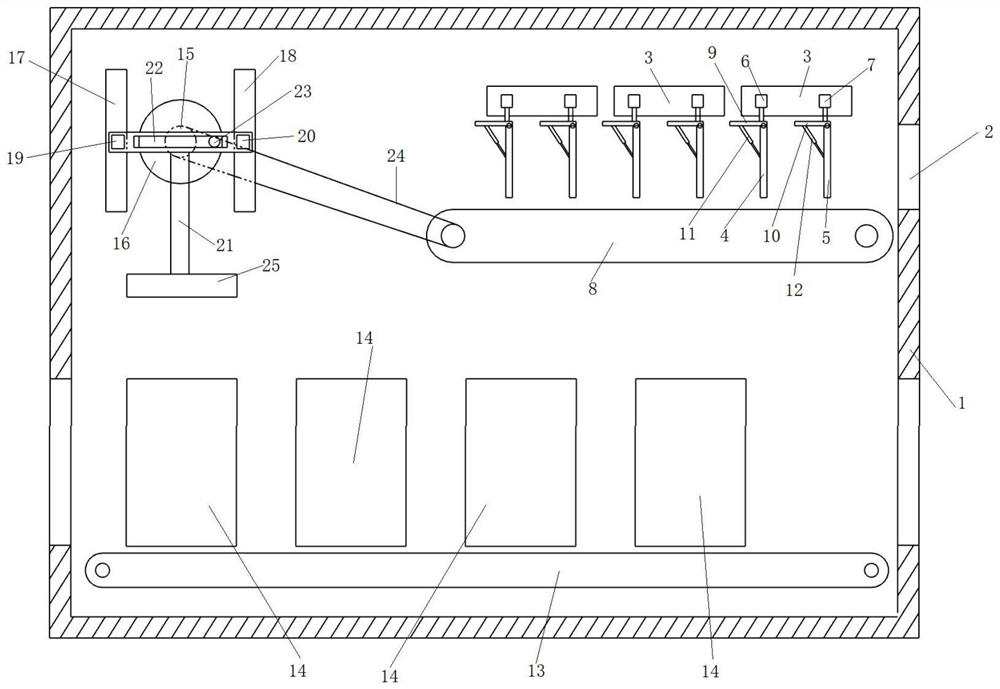

Control wire winding device with function of preventing wire coil from loosening

InactiveCN107444977ASqueeze wellIncrease the binding speedFilament handlingPackagingEngineeringConductor Coil

The invention discloses a control wire winding device with a function of preventing a wire coil from loosening. The control wire winding device comprises a bottom plate, wherein two first supporting legs and a second supporting leg are arranged on the left side and the right side of the upper surface of the bottom plate respectively; a first bearing is clamped on the left side surface of the second supporting leg; a first rotating shaft is connected into the first bearing in a sleeving manner; one end of the first rotating shaft is fixedly connected with the right side surface of a first wire winding wheel; two clamp slots are formed in the left side surface of the first wire winding wheel. According to the control wire winding device with the function of preventing the wire coil from loosening, the first wire winding wheel, a second wire winding wheel, sliding chutes, a motor, a slide bar, electric push rods, telescopic devices and an extrusion roll are arranged, so that when the device is used for bundling and fixing a control wire, the control wire can be prevented from loosening; meanwhile, the control wire after being bundled and fixed can be taken down from the first wire winding wheel and the second wire winding wheel, therefore, the bundling and fixing speed of a worker for the control wire is increased, the bundling and fixing efficiency of the control wire is improved, and production efficiency of the control wire is guaranteed.

Owner:JIANGYIN YONGCHANG TRAFFIC MACHINERY PARTS

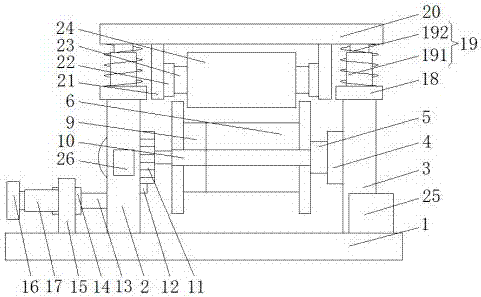

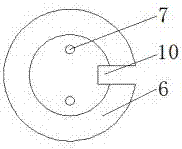

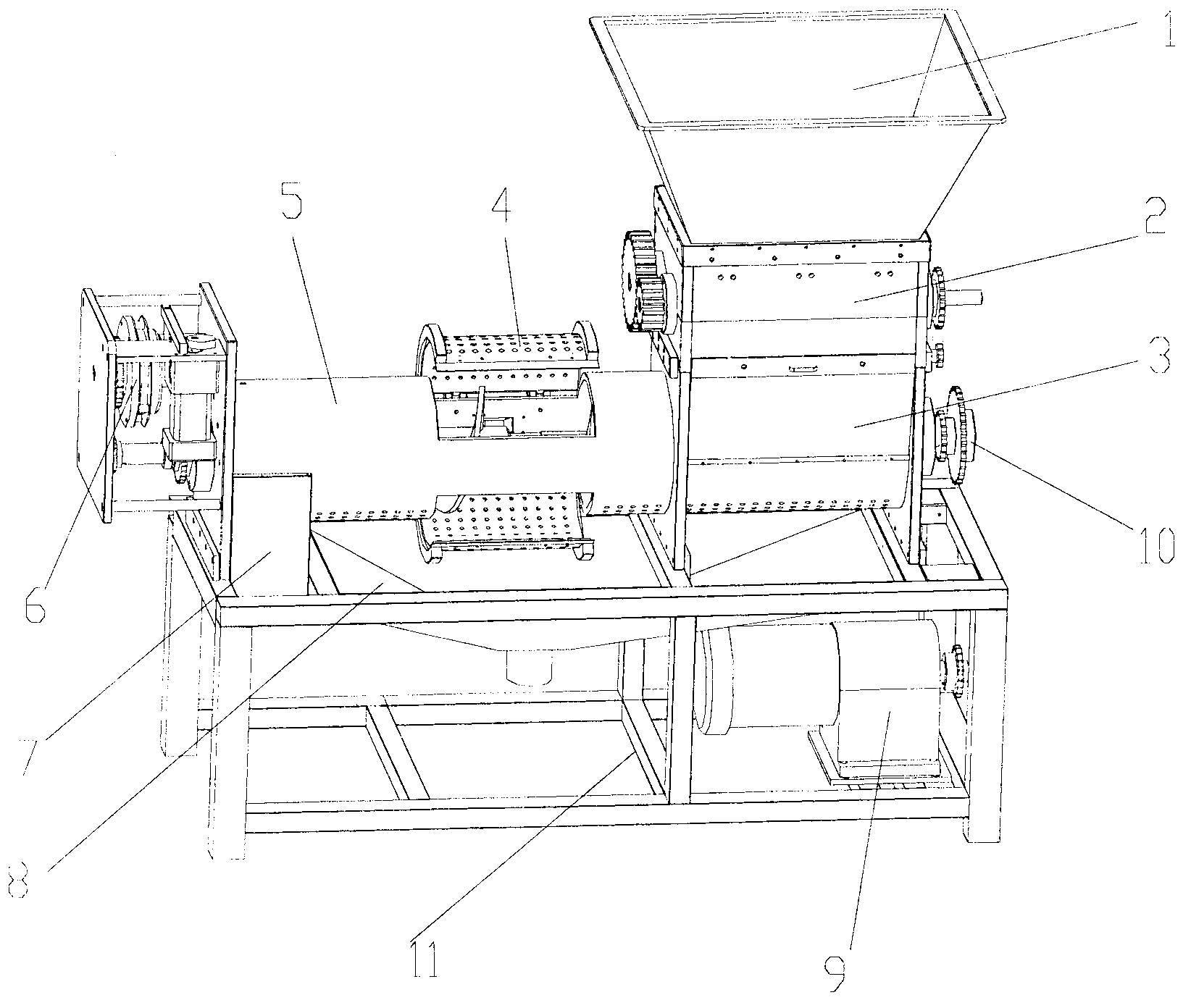

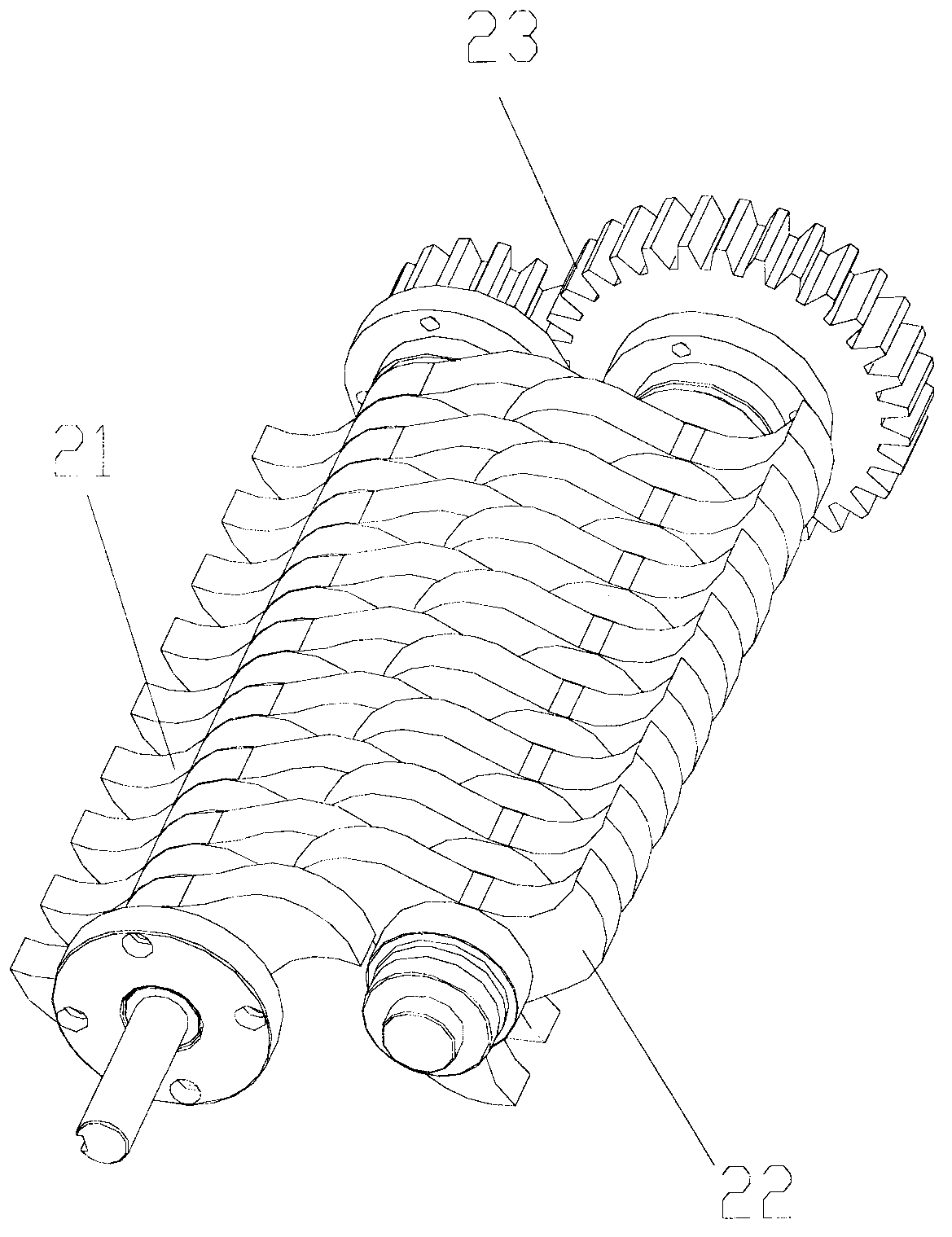

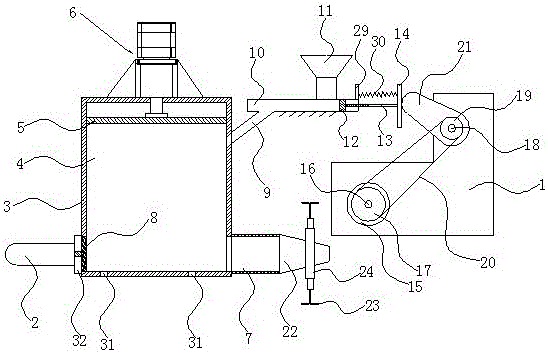

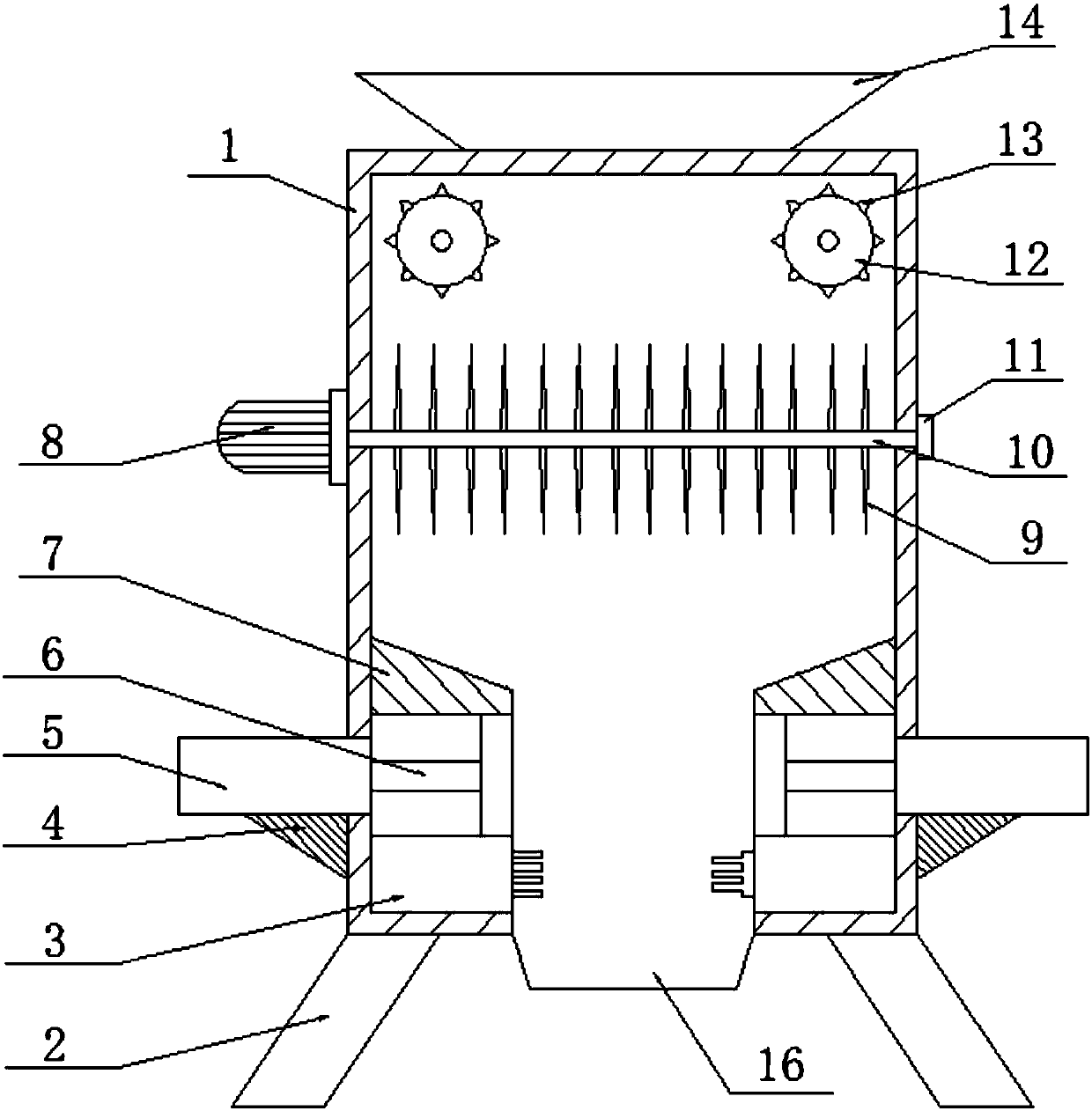

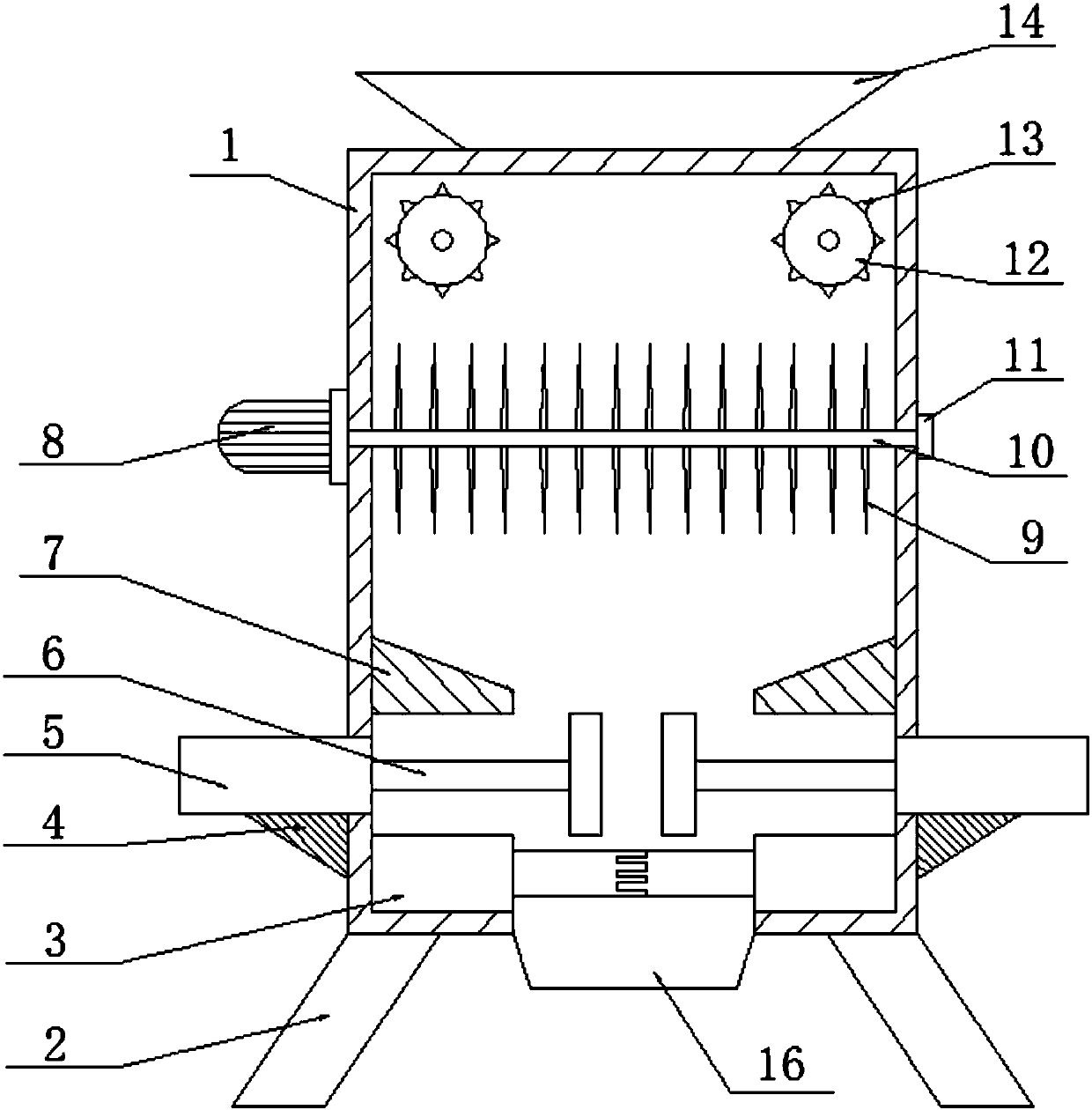

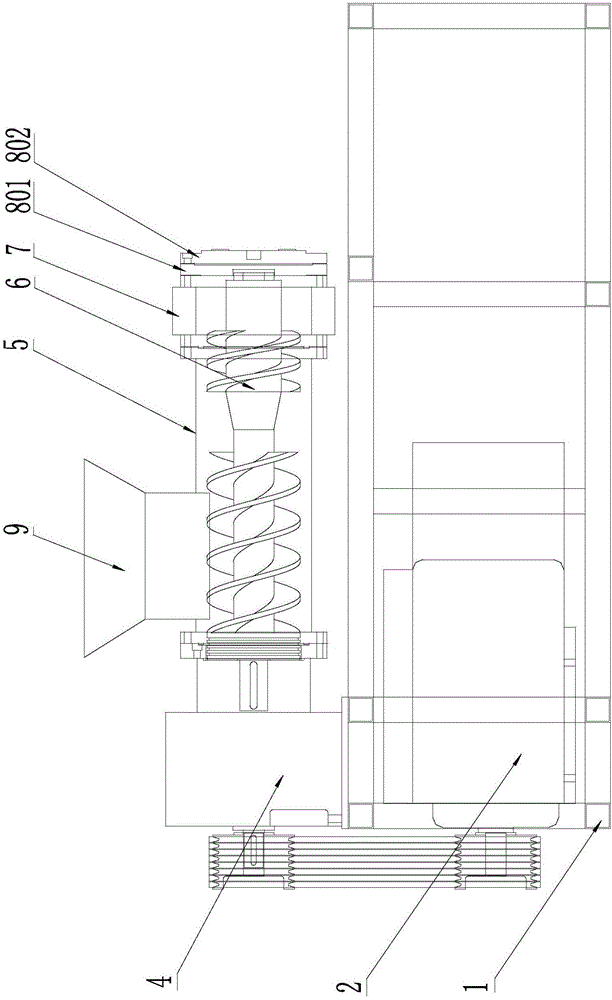

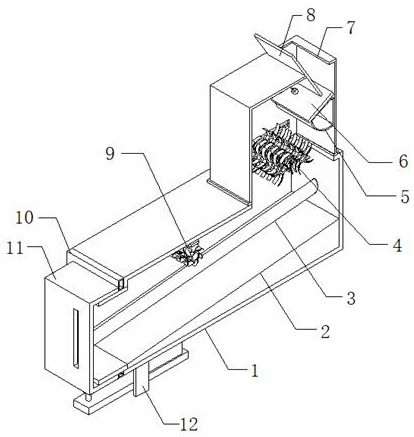

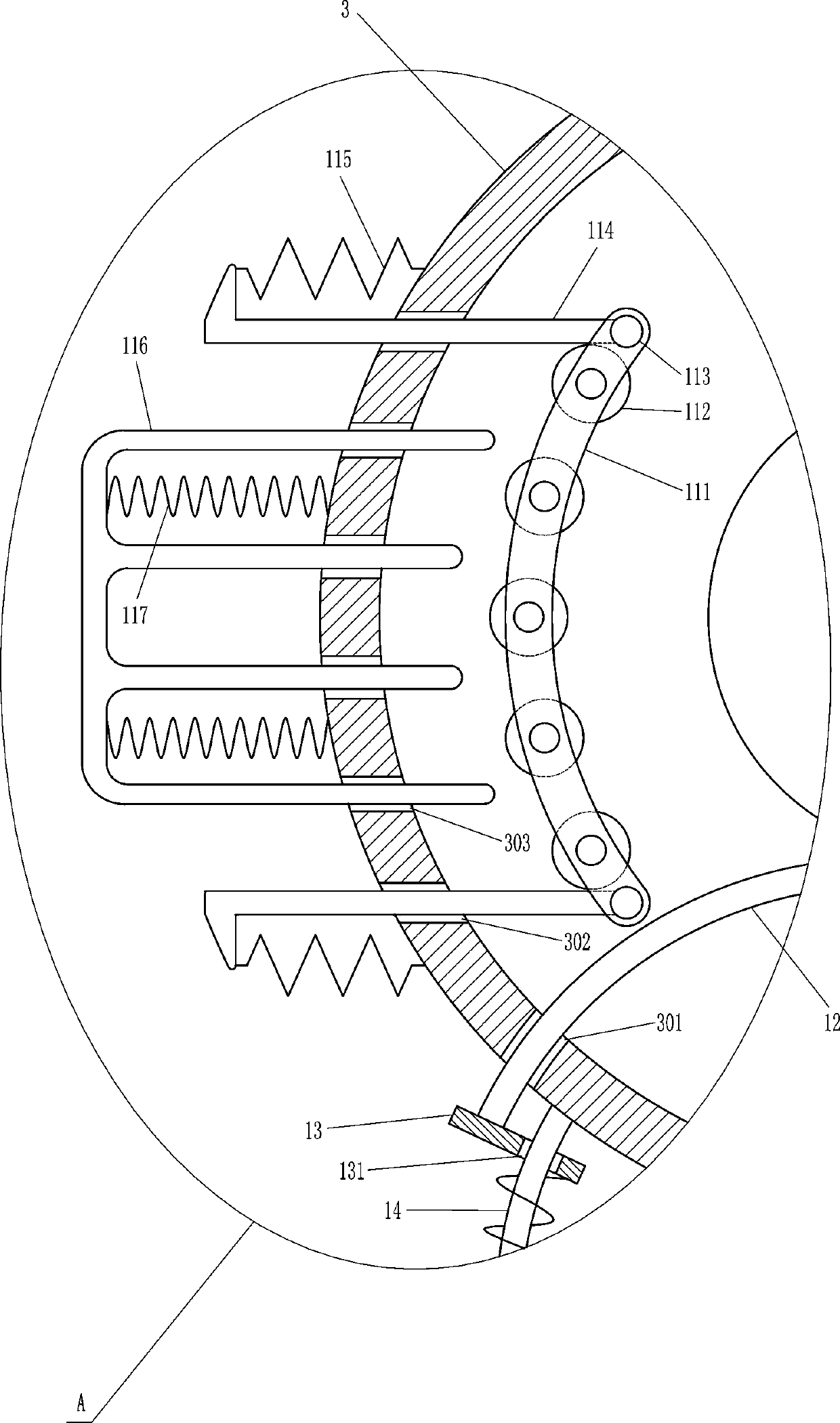

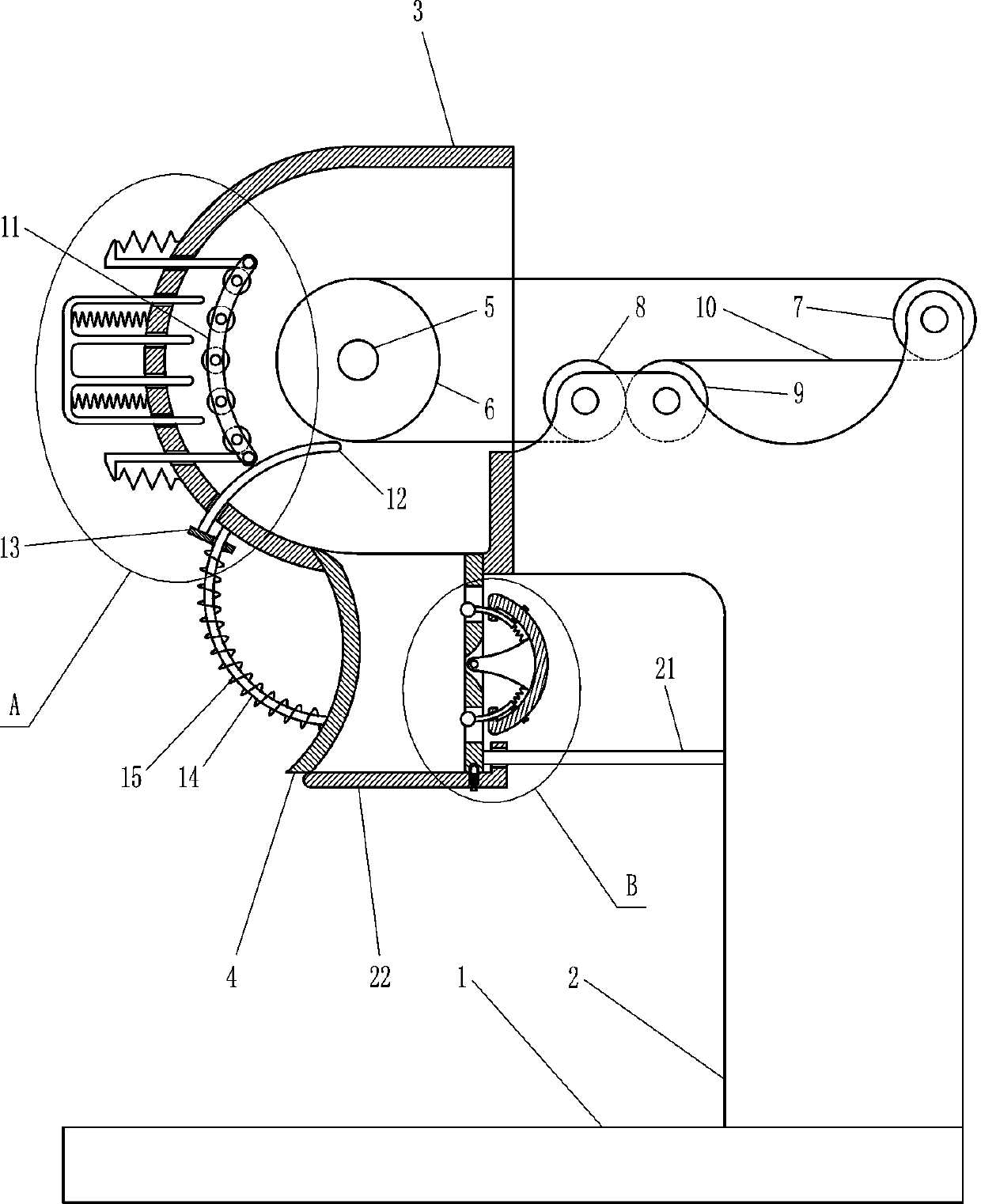

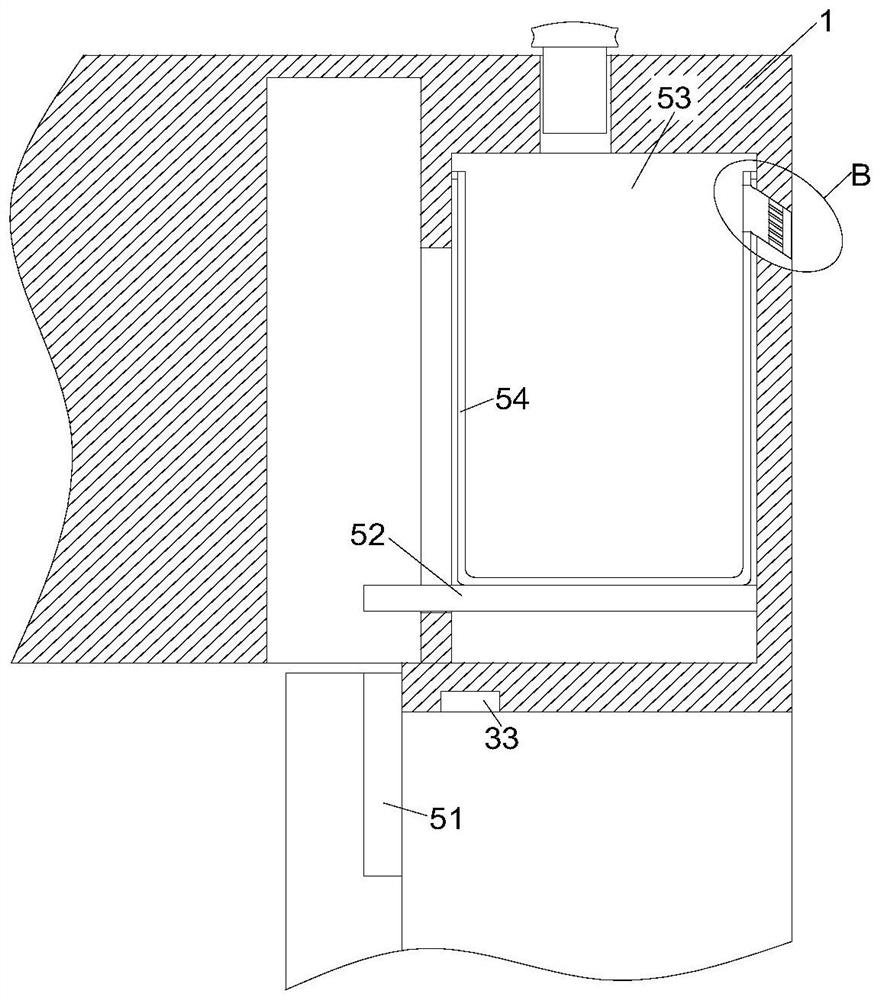

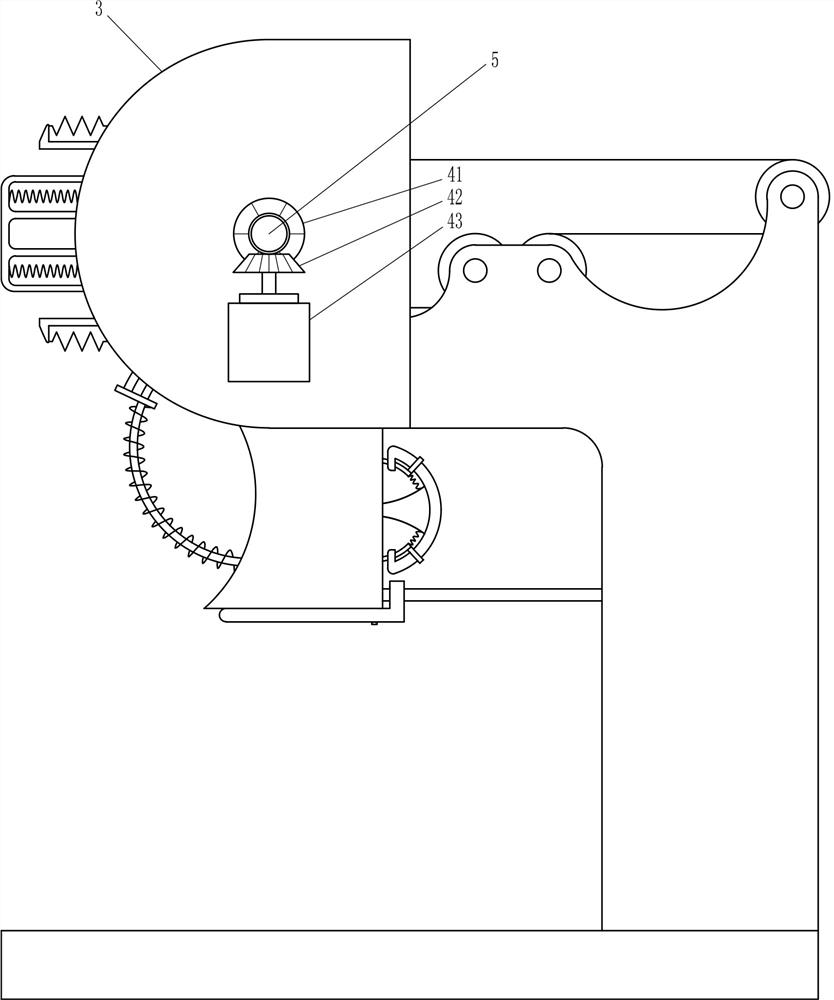

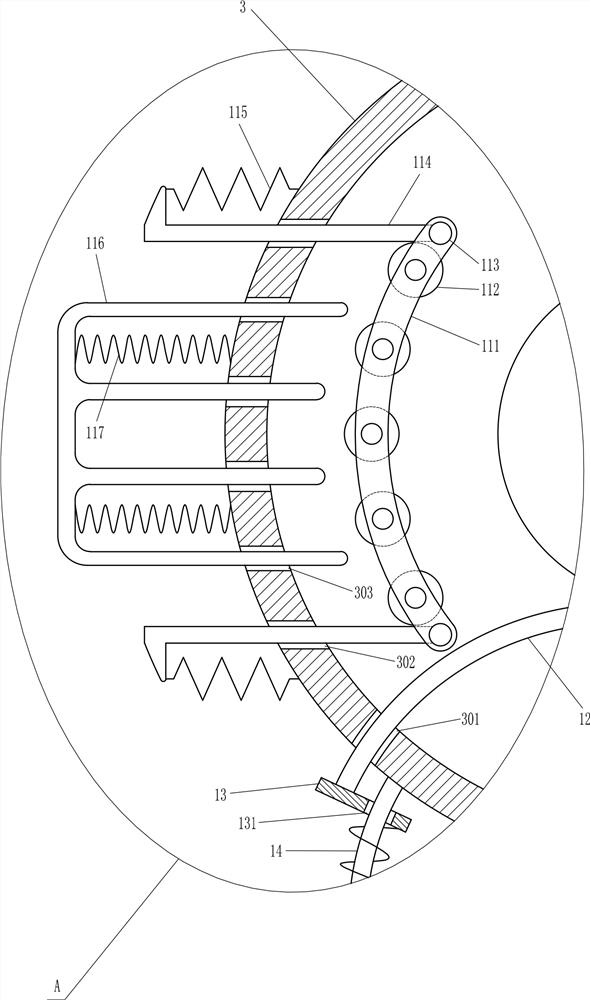

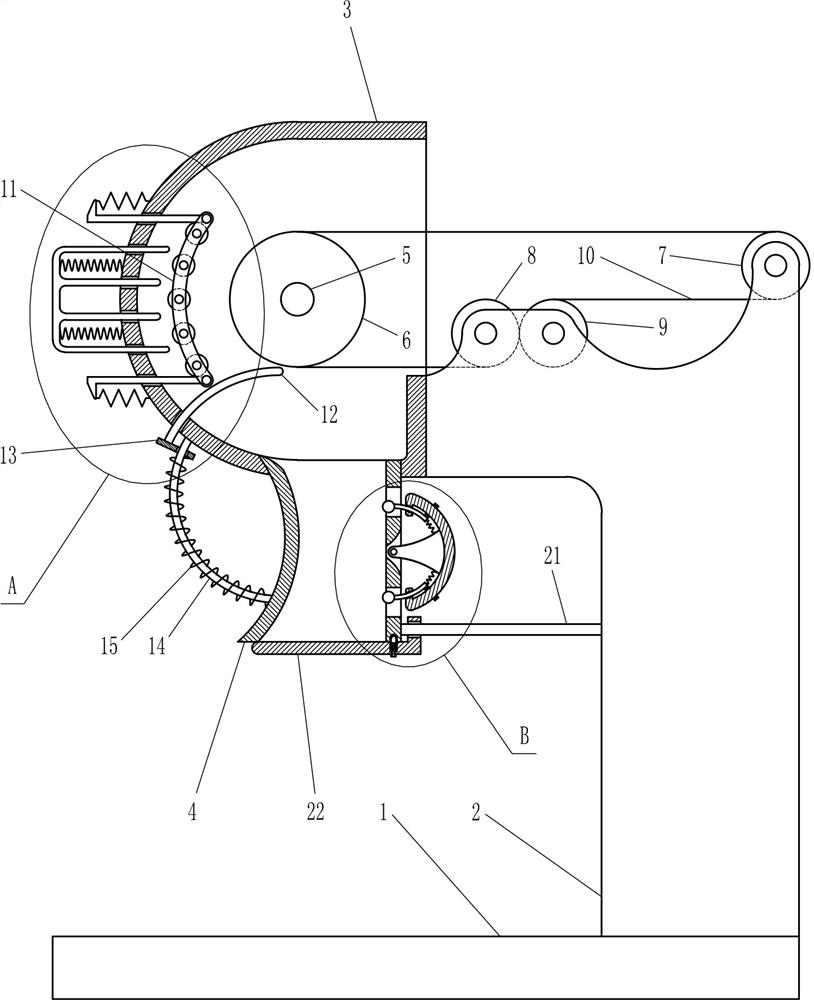

Automatic organic material crushing and dewatering machine and crushing and dewatering method

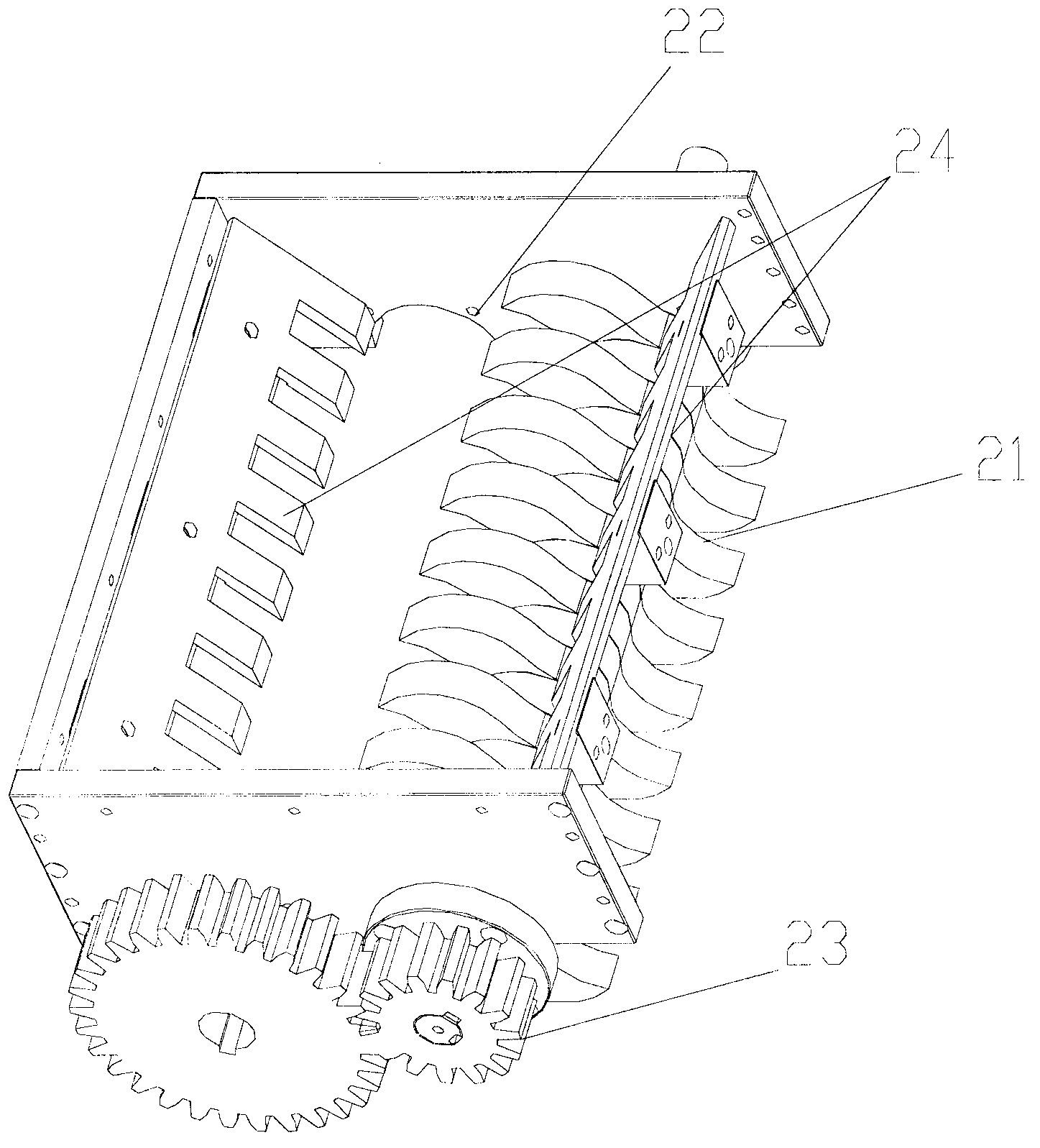

The invention discloses an automatic organic material crushing and dewatering machine which comprises a base frame, a feeding bucket, a hob crushing device, a driving chain wheel, a spiral feeding bin, an extruding dewatering bin, a spiral discharge bin, a discharge variable speed link group, a discharge port and a main motor, wherein the driving chain wheel, the spiral feeding bin, the extruding dewatering bin, the spiral discharge bin and the discharge variable speed link group are connected in sequence by screw rods; a water collecting bucket is arranged below the extruding dewatering bin; the hob crushing device is composed of a set of special crossed hobs with double blades and three blades and driven to operate by a pair of variable gears connected with the hobs; and screw rod structures are arranged in the spiral feeding bin and the spiral discharge bin, and spiral blade structures are arranged on screw rods to continuously push materials. The invention further discloses a crushing and dewatering method which uses the automatic organic material crushing and dewatering machine; different organic materials can be crushed and dewatered; the defects of the existing equipment available on the market are overcome; the automatic organic material crushing and dewatering machine has the advantages of simplicity and convenience in operation and maintenance; the service efficiency and the working efficiency of the equipment are improved; additionally, the operating environment is improved; and the wear of the equipment is reduced.

Owner:深圳市三盛环保科技有限公司

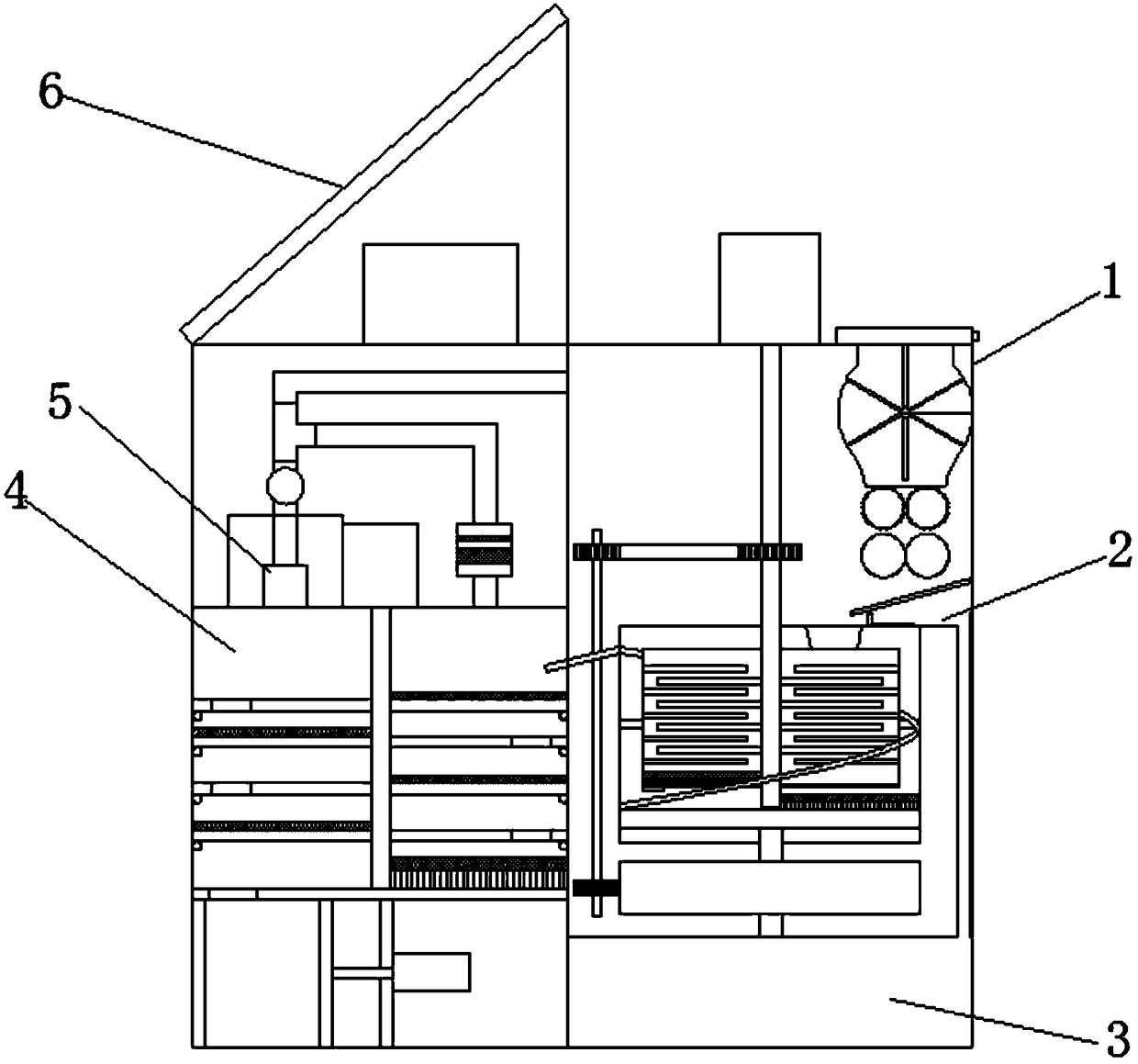

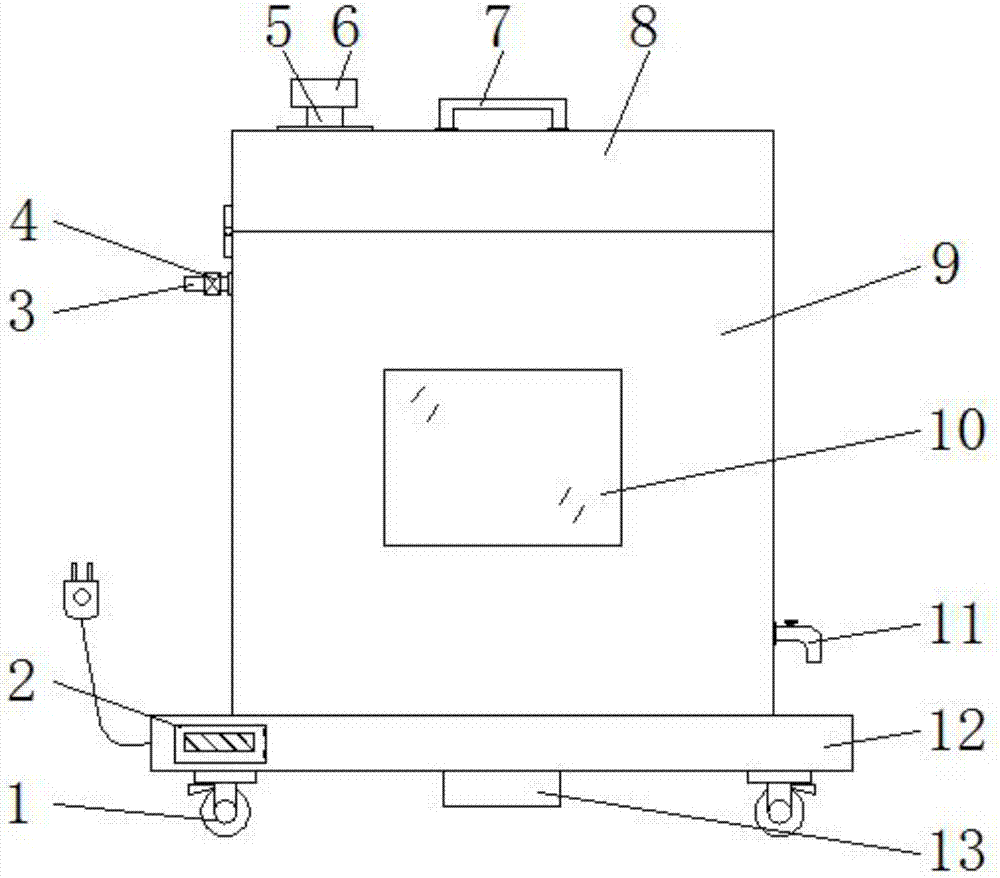

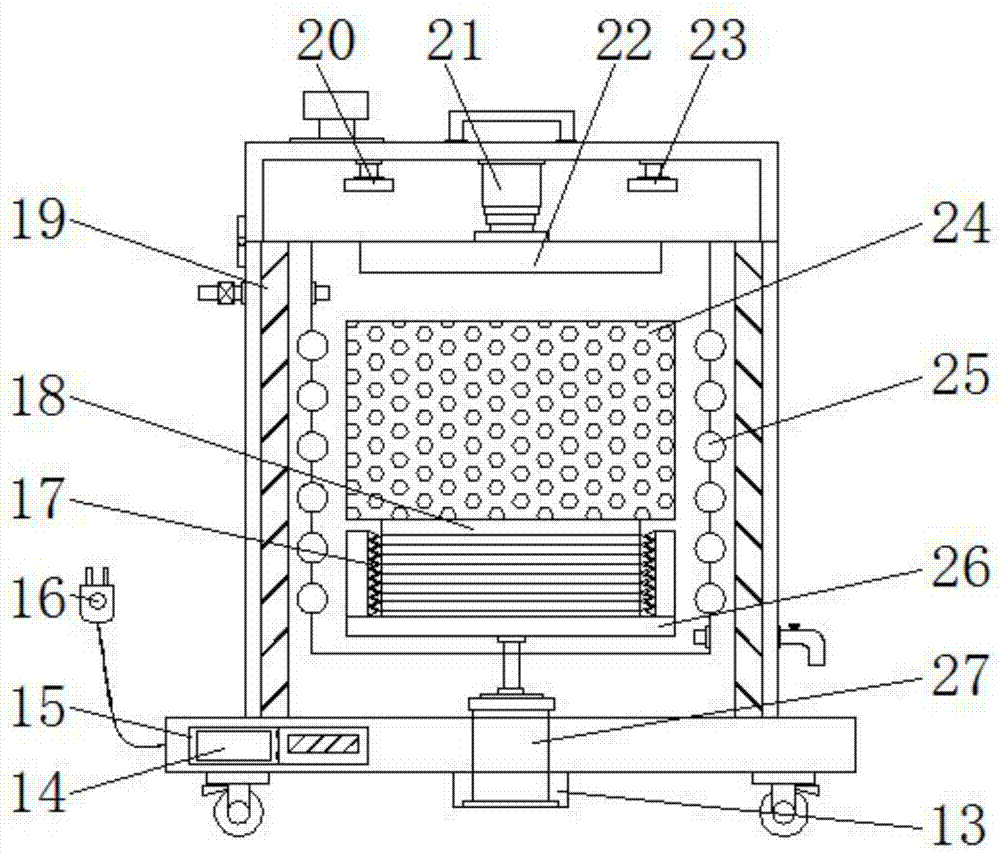

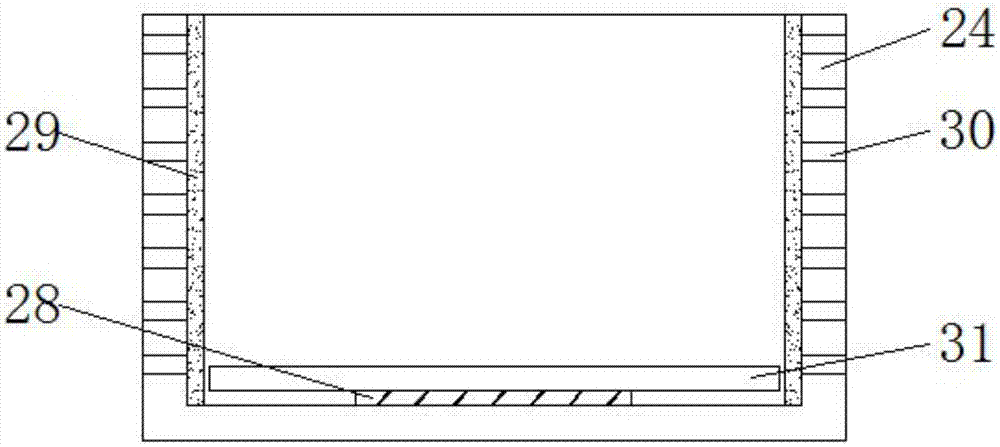

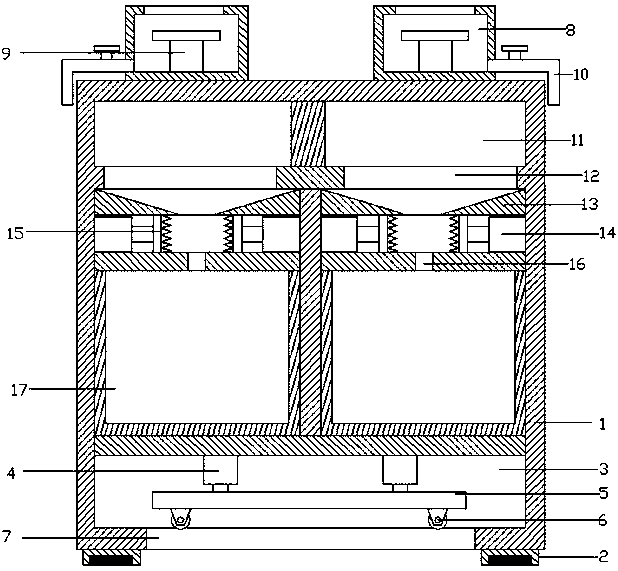

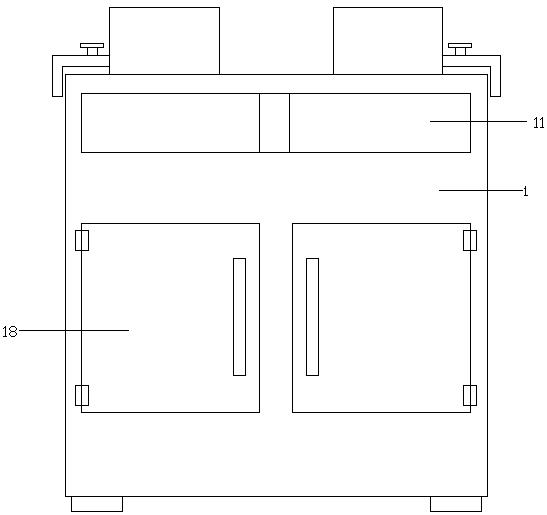

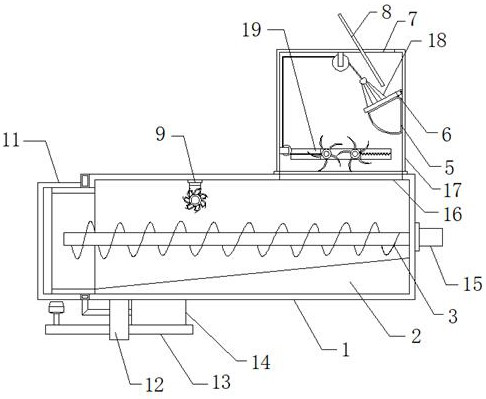

Environment-friendly garbage treatment device

ActiveCN108580522AReasonable structural designEasy for primary crushingWaste processingSolid waste disposalCompression deviceUltraviolet

The invention provides a specific technical scheme of an environment-friendly garbage treatment device. The environment-friendly garbage treatment device is characterized by comprising a crushing device, a liquid collecting tank, a liquid collecting box, a disinfecting compression device and a deodorizing device. The environment-friendly garbage treatment device provided by the invention is reasonable in structural design. The deodorizing device and an odor-resisting device are combined, so that the environment problem that garbage is piled up to ferment is solved effectively. A first crushingdevice and a second crushing device are combined in a first box body, so that the crushing effect is improved and the garbage crushing efficiency is improved by crushing step by step; a plurality ofdrying discs and a plurality of ultraviolet lamps are arranged in the second box body for ultraviolet sterilization and drying sterilization while drying, so that the condition that the garbage is moist to breed infectious microbes is avoided; a compression device is arranged on the lower part of the second box body, so that the dried garbage is compressed and recovered; a solar assembly is also arranged on the second box body of the device, so that operation of the whole device is driven by solar power generation, and the device is energy-saving and environment-friendly.

Owner:天津鼎拓恒远知识产权服务有限公司

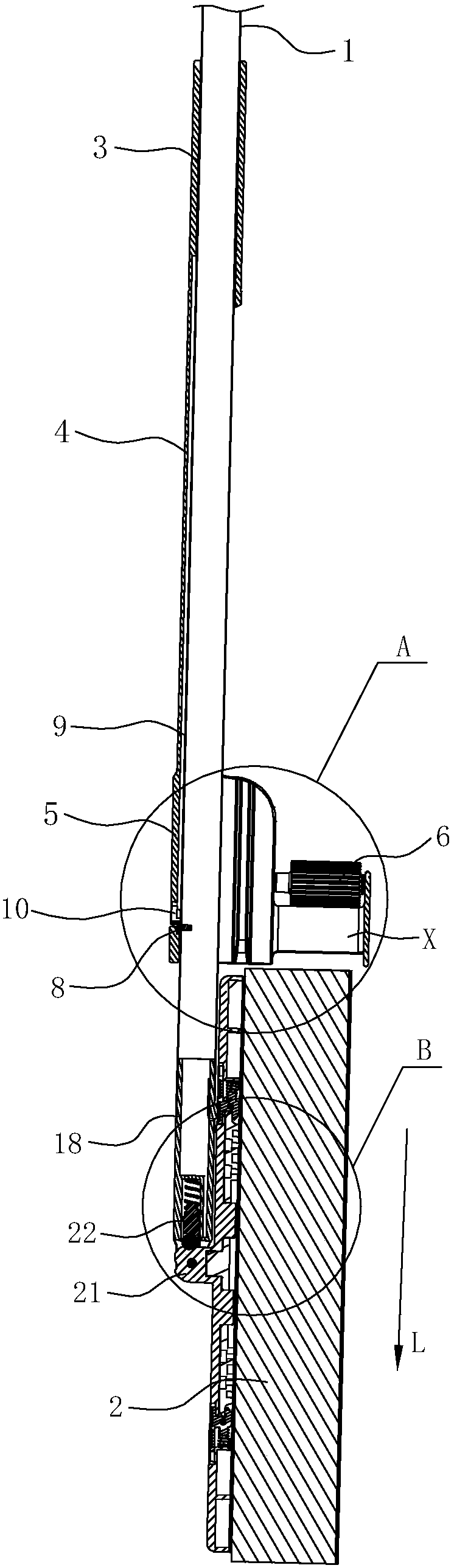

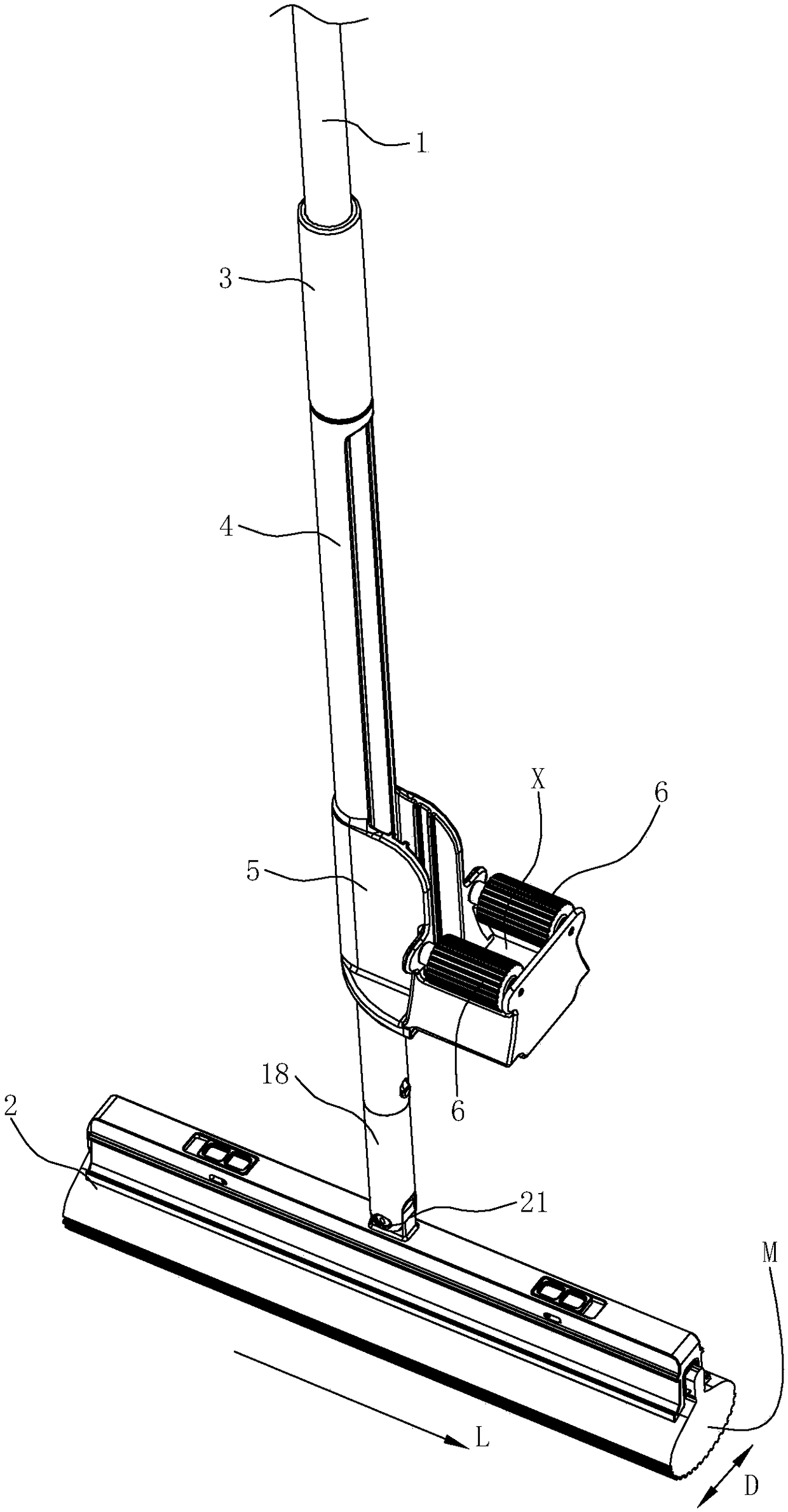

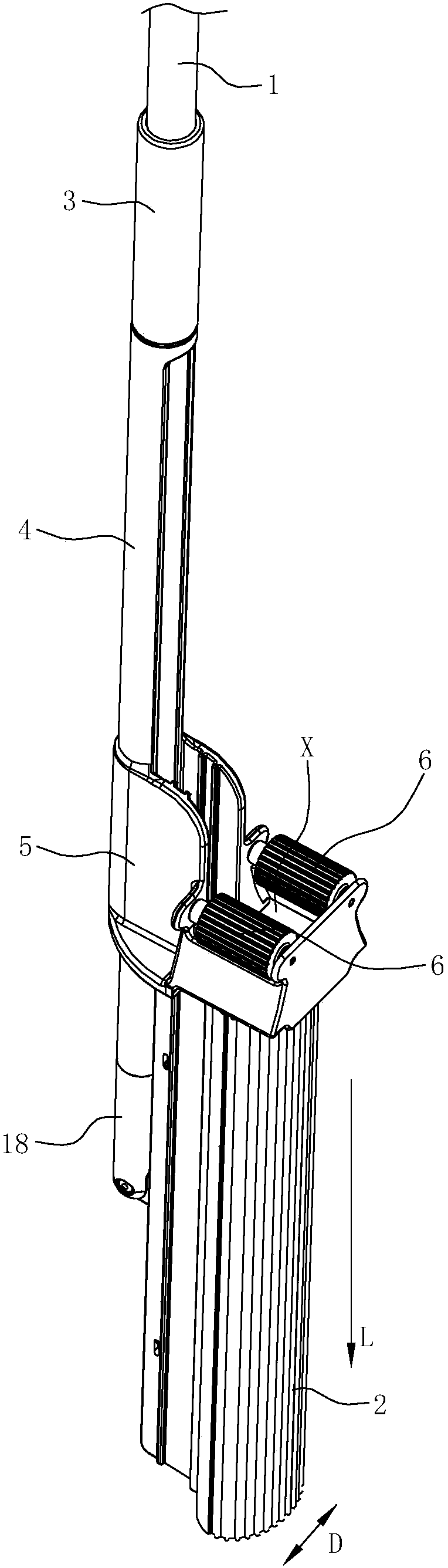

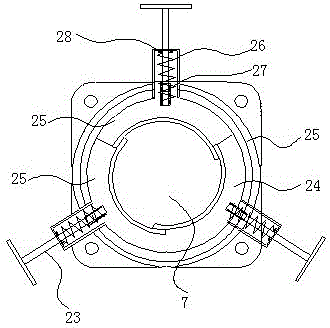

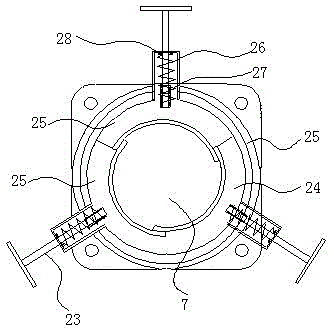

Mop provided with self-water-squeezing foamed cotton head

ActiveCN108338758ASqueeze stroke is longShort contact distanceCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention relates to a mop provided with a self-water-squeezing foamed cotton head. The mop comprises a mop rod and the foamed cotton head, and is characterized in that the foamed cotton head is rotatably connected to the lower end of the mop rod, a water squeezing handle is arranged on the mop rod, the water squeezing handle and the mop rod can slide vertically relatively, the water squeezinghandle is connected with a water squeezing head through a connecting rod, the water squeezing head is provided with a penetrating opening with the appearance being matched with that of the cross section of the foamed cotton head, the foamed cotton head can be rotated to be parallel to the mop rod and opposite to the penetrating opening, and a squeezing part for squeezing water of the foamed cotton head which passes through the penetrating opening is arranged in the penetrating opening. For the mop provided with the self-water-squeezing foamed cotton head, the water squeezing method of the traditional collodion mop is changed, the foamed cotton head can be enabled to rotate freely relative to the mop rod, and meanwhile, a good water squeezing effect is guaranteed.

Owner:NINGBO DERUNTANG INTELLIGENT TECH CO LTD

Extrusion device for plastic bottles

The invention discloses an extruding device for plastic bottles, which comprises a frame, a cylinder, a box body, an extruding plate, a pushing device, a discharge pipe, and a first pushing plate. The piston rod of the cylinder is connected with the first pushing plate. A feed pipe is installed on the top side wall of the box, and a hollow pipe is connected to the feed pipe, and a feed hopper is connected to the hollow pipe. A second push plate that can move left and right relative to it is arranged inside the hollow pipe. A push rod is fixedly connected to the board, a flat plate is fixedly connected to the push rod, a first motor is installed on the frame, a first rotating shaft is connected to the output shaft of the first motor, and a first sprocket is installed on the first rotating shaft. A second rotating shaft is rotatably installed on the frame, and a second sprocket is installed on the second rotating shaft. The first sprocket and the second sprocket are connected by transmission chain transmission, and a cam is installed on the second rotating shaft. The invention can significantly reduce the labor intensity of operators and effectively ensure that waste plastic bottles are better squeezed.

Owner:谢森涛

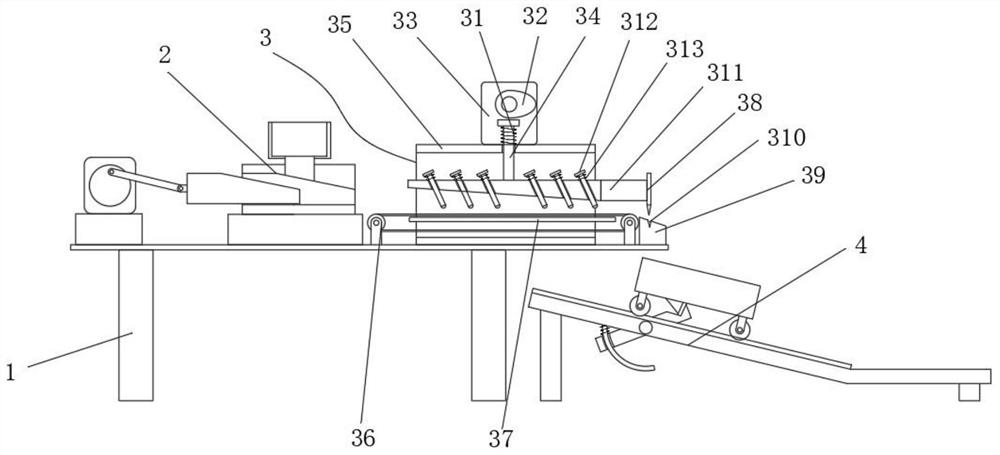

Waste recovery mechanism of plate cutting device

ActiveCN112170922APrevent splashEnsure safetyShearing machinesMetal working apparatusElectric machineryProcess engineering

The invention discloses a waste recovery mechanism of a plate cutting device. The waste recovery mechanism comprises a supporting frame, a separating-pushing structure, an extruding-slitting assemblyand a transferring structure, wherein the separating-pushing structure is arranged at one end of the top side of the supporting frame; the extruding-slitting assembly is arranged at the other end of the top side of the supporting frame; and the transferring structure is arranged on one side of the supporting frame. Through arrangement of the extruding-slitting assembly, blanked waste operates in acam motor and drives a cam to rotate, so that pushing and pressing of a vibration rod and sinking of an extruding plate can be achieved; the bottom side of the extruding plate is an inclined face, and an included angle between the inclined face and a supporting plate is gradually reduced, so that the volume of the waste can be gradually reduced; reset springs operate in cooperation with pushing rods, so that materials are stable during extrusion, and a better extrusion effect can be achieved; a cutter sinks, and waste can be cut under cooperation of a cutting base, so that the waste is further cut, the size of the waste is reduced, occupied space is reduced, and waste recovery can be achieved through better cooperation.

Owner:安徽金贺财建筑工程有限公司

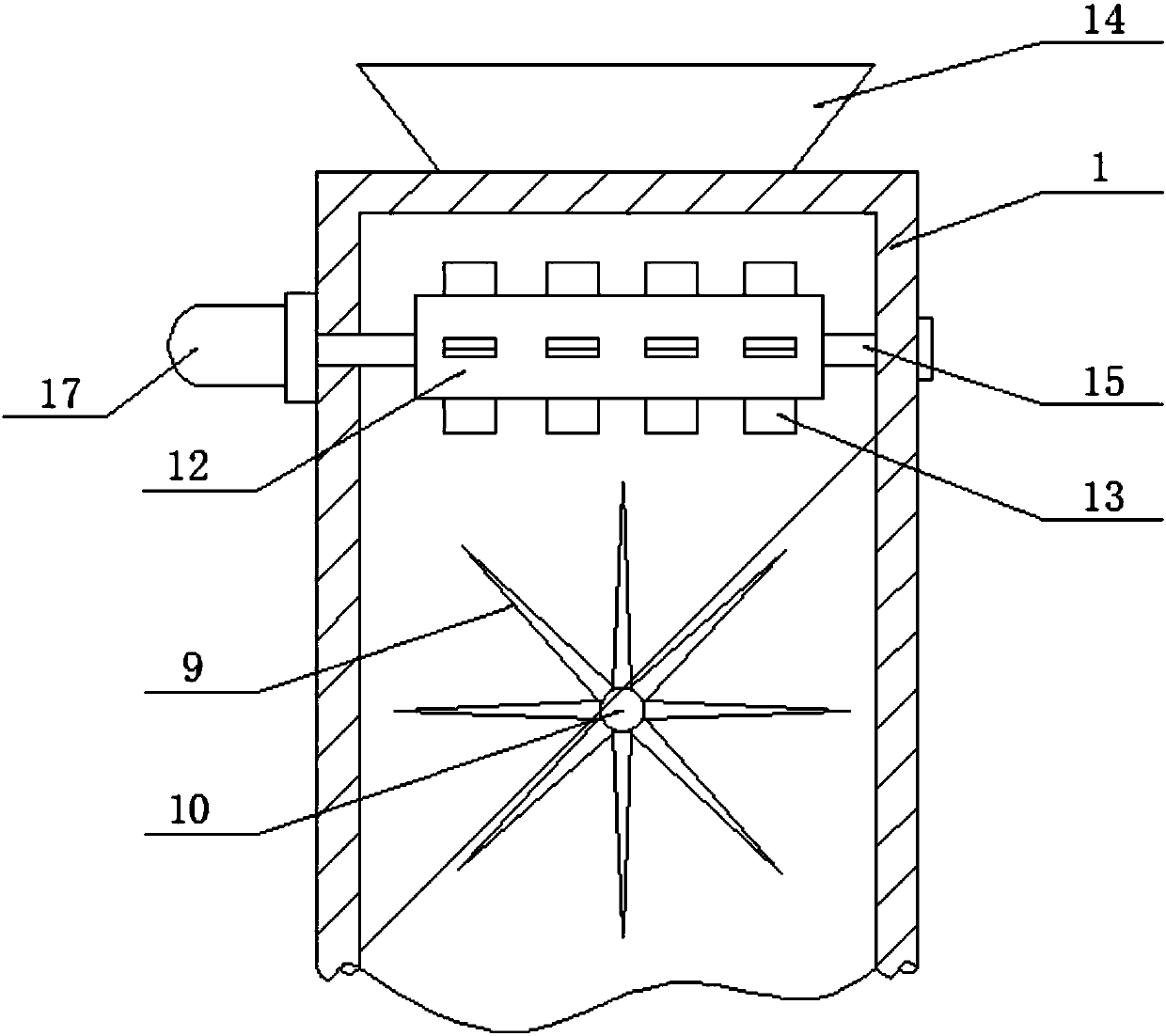

Building material foam recovery processing device

InactiveCN107756678AGuarantee the effect of extrusion treatmentImprove processing efficiencyPlastic recyclingGrain treatmentsHydraulic cylinderExtrusion

The invention relates to the technical field of environmental protection, in particular to a building material foam recovery processing device. The building material foam recovery processing device comprises a processing box, an extrusion plate, a crushing blade and a roller, wherein the upper end surface of the processing box is fixedly provided with a discharging valve, the outer end surface ofthe processing box is fixedly provided with a mounting seat, the upper end surface of the mounting seat is fixedly provided with a hydraulic cylinder, the outer end surface of a first rotating shaft is fixedly provided with the crushing blade, the outer end surface of a second rotating shaft is fixedly provided with the roller, building material foams can be prevented from always staying on the upper part of the crushing blade by virtue of the roller arranged on the upper part of the crushing blade, and the building material foams can be extruded by utilizing a triangular plate into the crushing blade to be crushed, so that the processing efficiency of the building material foam recovery processing device is increased; the crushing blade is arranged on the upper part of the extrusion plate, the building material foams can be crushed into small foams, so that the next extrusion treatment is facilitated; and the building material foam recovery processing device is scientific in structure, reasonable in design, good in recovery effect, high in compression rate and high in practicability.

Owner:WUXI AOTU AUTOMATION TECH CO LTD

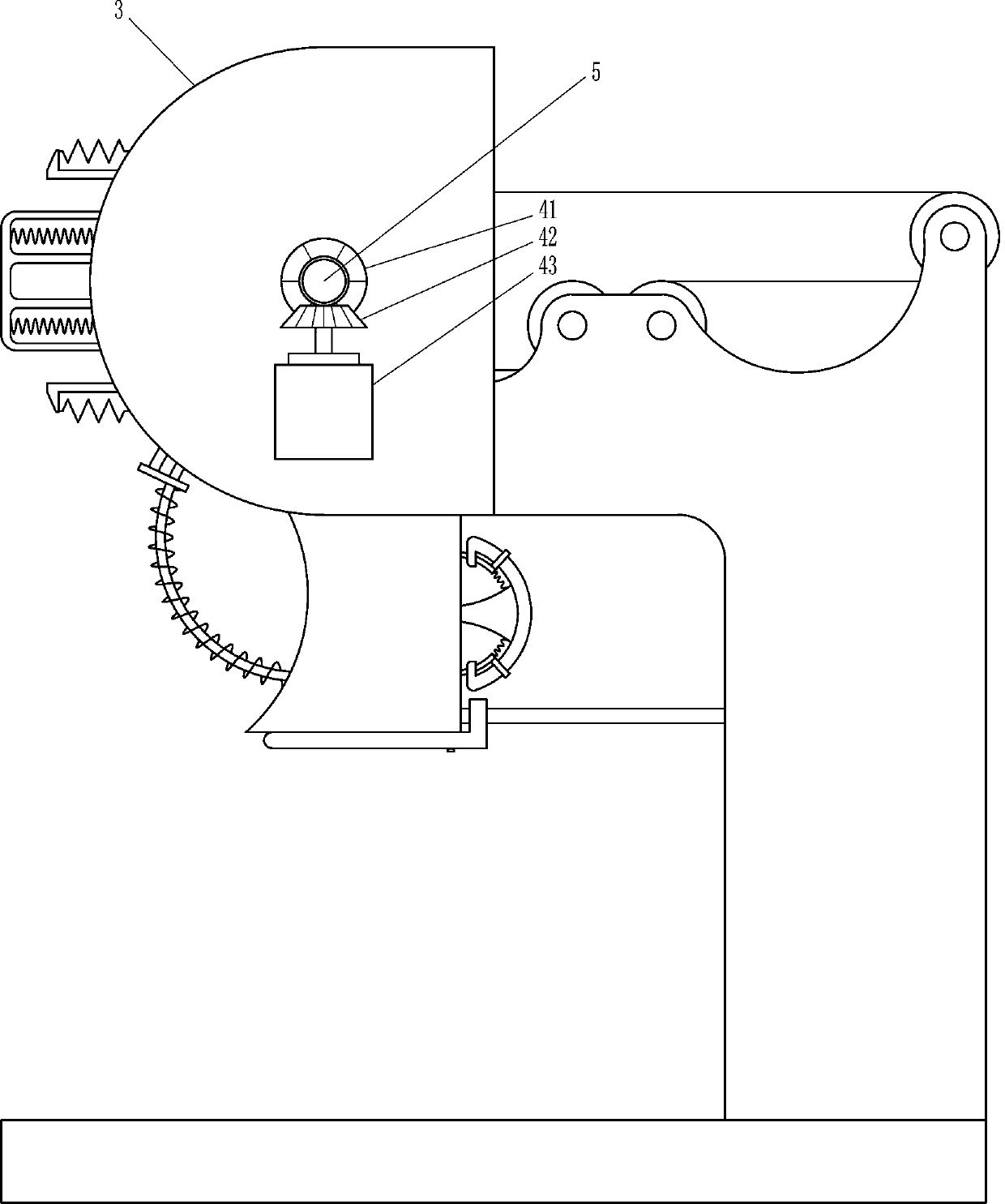

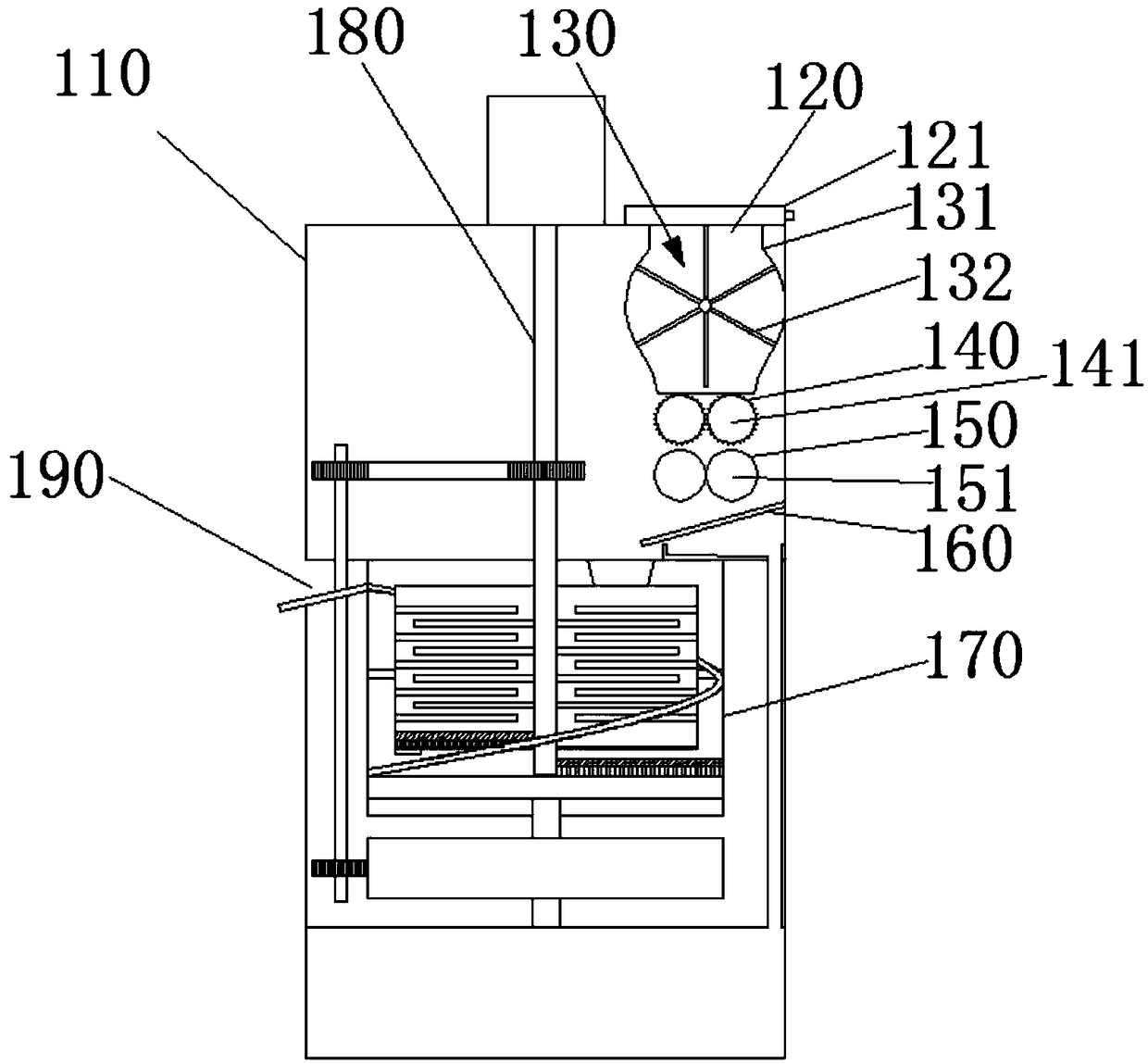

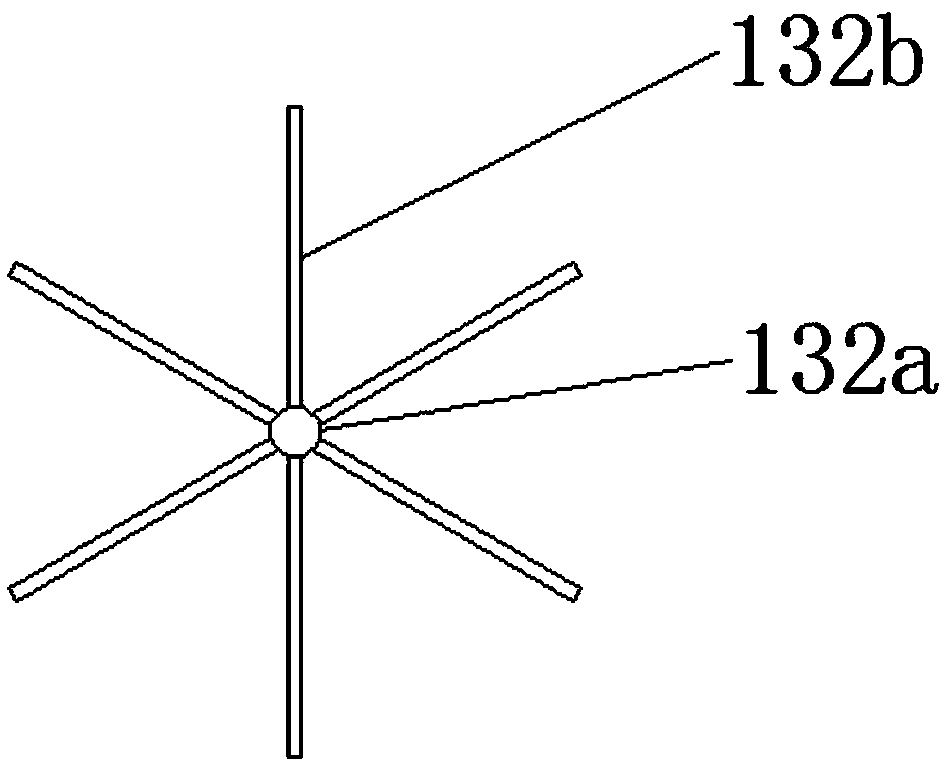

Automatic decocting equipment for paederia scandens with effects of relieving pain and detoxicating

InactiveCN107374966ASqueeze wellEasy to cleanPharmaceutical product form changeDomestic articlesEngineeringPressure sensor

The invention relates to an automatic decocting equipment for analgesic and detoxifying traditional Chinese medicine chicken wilting rattan, which comprises a base, a box body and a sealed upper cover. A device box is provided at the center of the device box, and a rotating motor is installed inside the device box through bolts, and the output shaft of the rotating motor extends to the inside of the box, and is fixedly connected with a rotating seat, and the center position at the top of the rotating seat There is a cavity, and a filter cartridge is detachably installed on the rotating seat. The bottom of the filter cartridge is provided with a connecting column that matches the cavity. The side wall of the filter cartridge is evenly provided with filter holes. The inner wall of the filter cartridge A filter cloth is provided on the top, and a support plate is provided at the bottom of the inside of the filter cartridge, and a pressure sensor is provided at the bottom of the support plate. The filter cartridge of the present invention is detachably connected with the rotating seat through the connecting column through threads, so that the decocted medicine dregs are easy to clean, easy to use, and have good practicability.

Owner:高卫东

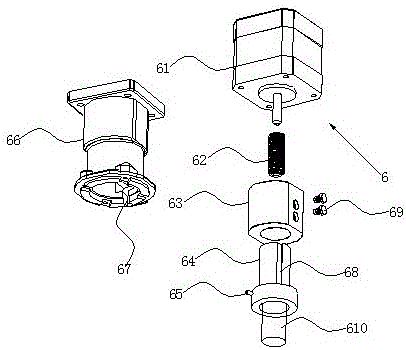

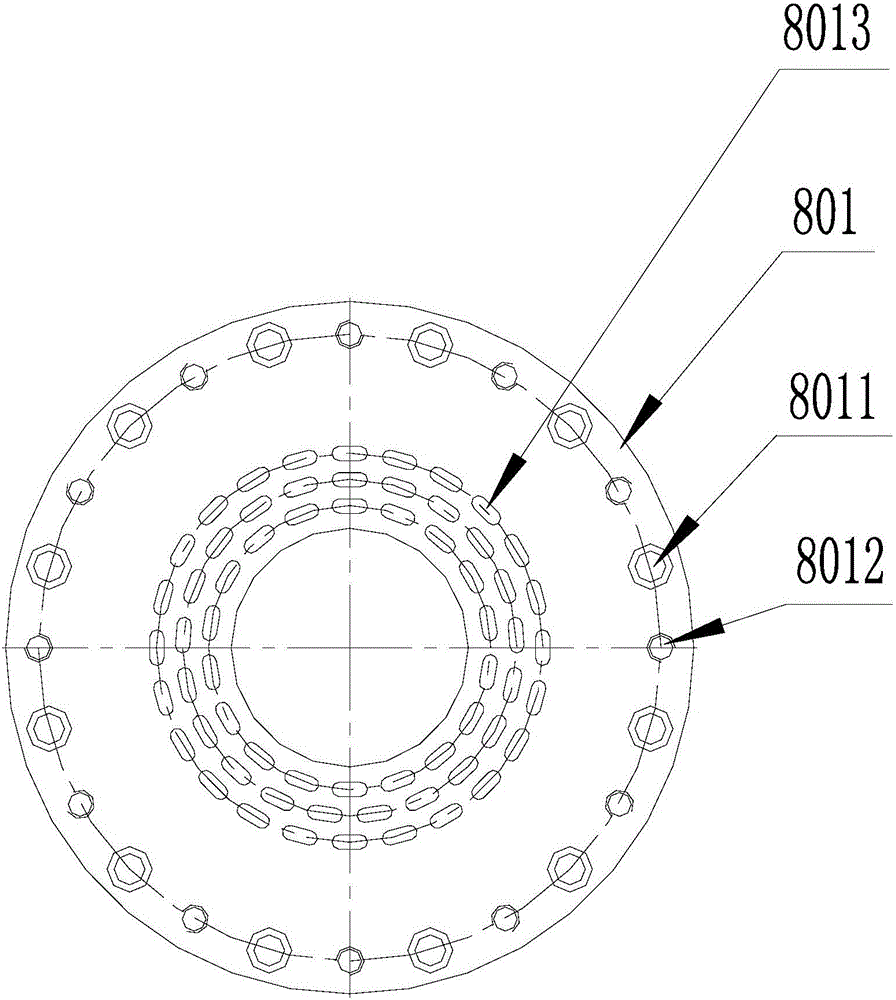

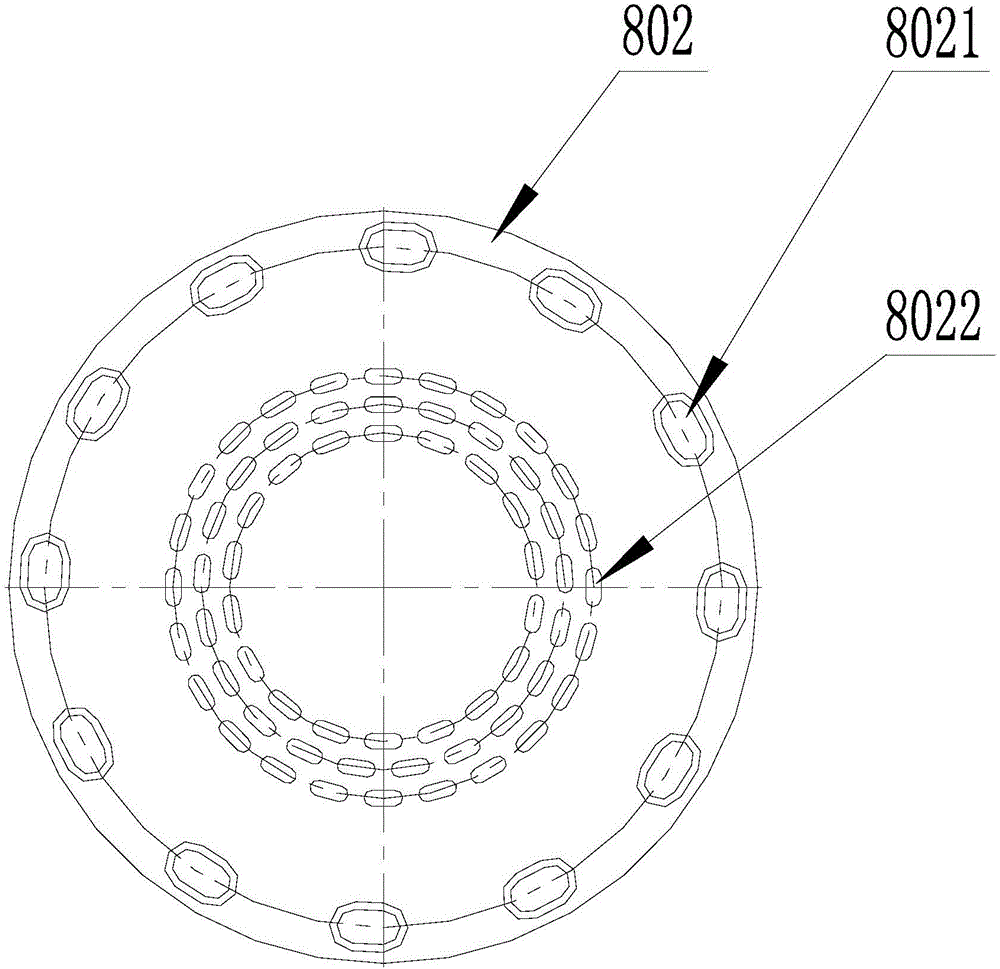

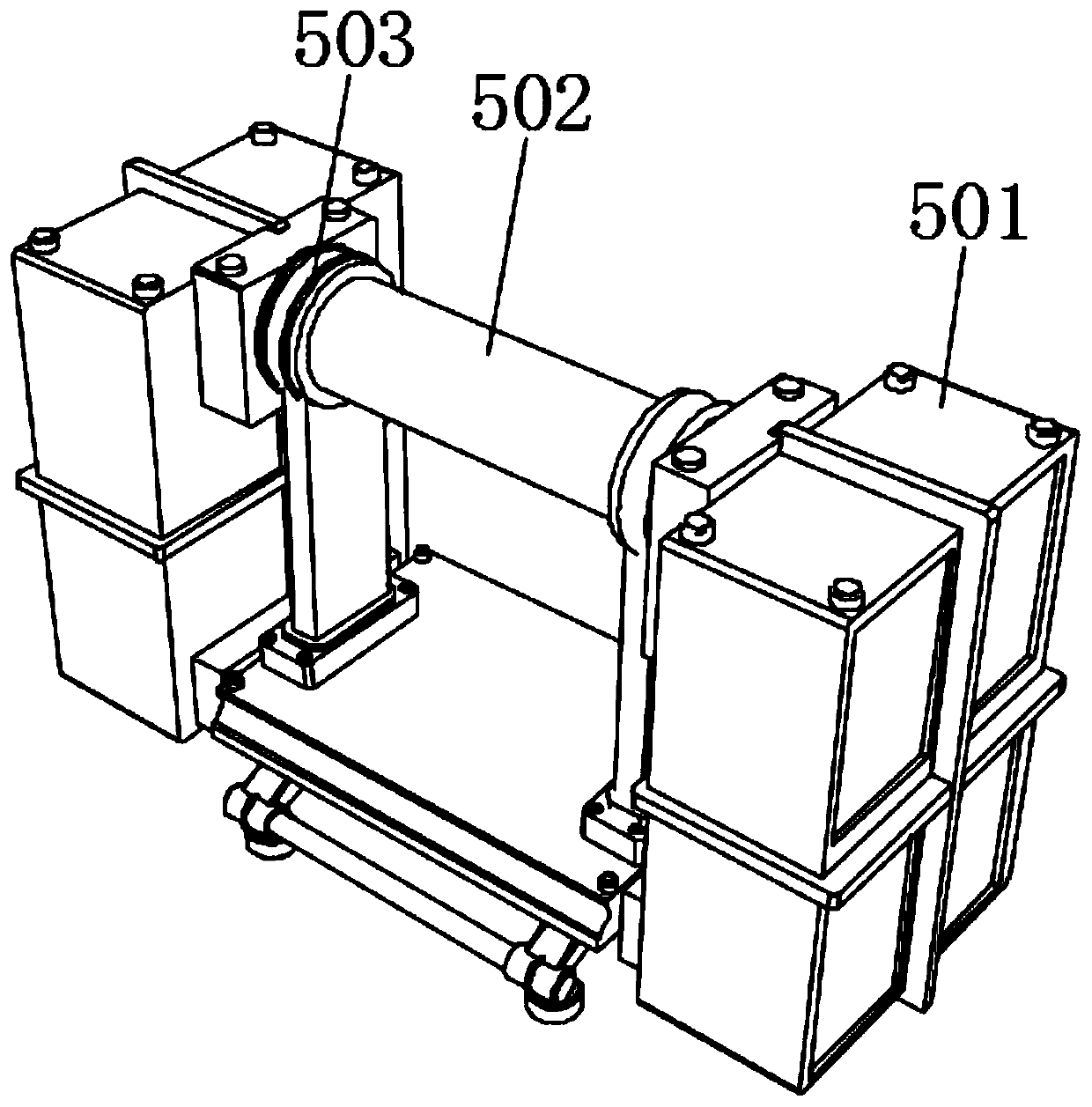

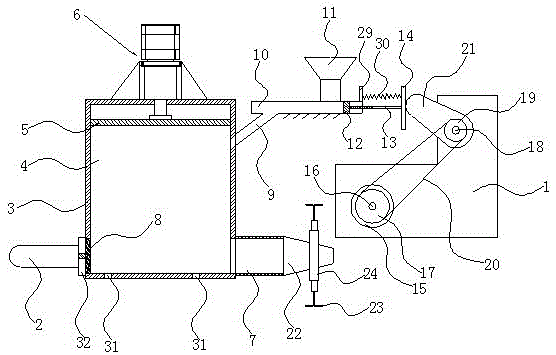

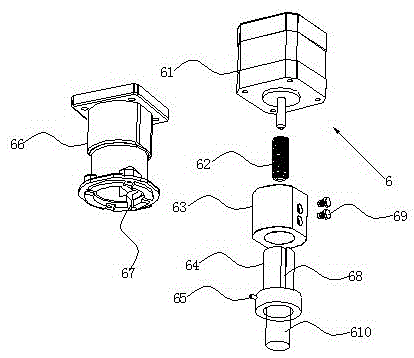

Squeezing drying granulating machine and adjustable mouth mold device thereof

The invention relates to a squeezing drying granulating machine. The squeezing drying granulating machine comprises a rack, a motor, a speed reduction box, a machine barrel, a threaded rod, a heating device, a feeding port, a first mouth mold connected with the tail end of the machine barrel and a second mouth mold connected with the first mouth mold. An adjustable mouth mold device of the squeezing drying granulating machine comprises the first mouth mold and the second mouth mold connected with the first mouth mold; the first mouth mold is provided with N counter bores; the first mouth mold is provided with N threaded holes, and the threaded holes and the counter bores are arranged at intervals; the first mouth mold is provided with N first discharging holes; the second mouth mold is provided with N adjusting holes, and the positions of the adjusting holes correspond to those of the threaded holes; and the second mouth mold is provided with N second discharging holes. By adjusting the positions of the first discharging holes of the first mouth mold and the positions of the second discharging holes of the second mouth mold and changing the pressure in the machine barrel, the squeezing drying granulating machine can achieve an ideal squeezing drying effect on plastics with various characteristics, the function that one machine is multipurpose is achieved, various squeezing drying requirements are met, and the using cost is saved for customers.

Owner:ZHANG JIAGANG BAIXIONG KLIMENS MACHINERY

Efficient sludge harmless treatment equipment

PendingCN112811771AEasy to separateEasy dischargeSludge treatment by de-watering/drying/thickeningSludgeWater filter

The invention discloses efficient sludge innocent treatment equipment which comprises a stand column, a flow dividing box is arranged at the top of the stand column, a water filtering net is obliquely arranged in the flow dividing box, and the bottom end of the water filtering net communicates with a sludge treatment assembly.According to the efficient sludge innocent treatment equipment, through the water filtering net on the flow dividing box, sludge and muddy water can be conveniently separated; sewage is conveniently discharged to a sand filtering box through a water conveying pipe at the bottom of a flow dividing box, residual silt in muddy water is conveniently separated through a sand filtering net, separated sludge is conveniently conveyed into a stirring tank through an inclined plate to be stirred, sludge caking is prevented, the sludge is conveniently extruded through an extrusion ring, residual moisture is conveniently discharged, meanwhile, centralized collection treatment is carried out, and the separated muddy water and sludge are treated again while mud-water separation is carried out on the sludge through the whole sludge treatment assembly, so that the sludge is subjected to classified treatment, and time and labor are saved.

Owner:广东丰和环保科技有限公司

Garbage can for municipal construction

The invention discloses a garbage can for municipal construction, which comprises a can body, wherein supporting bases are arranged at four corners of the lower side of the can body, a connecting chamber is formed in the lower end of the can body, first electric telescopic rods are arranged on the top end in the connecting chamber, a connecting plate is arranged at the lower sides of the first electric telescopic rods, rollers are arranged at four corners of the lower side of the connecting plate, cigarette ash covers are arranged at the left end and the right end of the upper side of the canbody, projections are arranged inside the cigarette ash covers, drain tubes are arranged at the lower ends of the outer sides of the cigarette ash covers, garbage inlets are formed in the left end, the right end, the front end and the rear end of the upper end of the can body, second openings are formed under the garbage inlets, guide channels are formed in the lower sides of the second openings,second electric telescopic rods are arranged at the left end and the right end of the lower side of each guide channel, pressing plates are arranged between the second electric telescopic rods, a discharge outlet is formed under a space between the pressing plates, internal cans are arranged on the lower sides of the discharge outlets, and closing doors are arranged on the front sides of the internal cans. The garbage can can effectively facilitate garbage storage for equipment, the storing capability of the garbage can is increased, and the garbage can can be conveniently used by sanitation workers.

Owner:李翠仙

Extrusion device used for producing wood-plastic floor and capable of conveniently replacing die head

The invention discloses an extrusion device used for producing wood-plastic floors and capable of conveniently replacing a die head. The extrusion device comprises a box body, wherein a discharging pipe is arranged on the outer wall of one side of the box body; a die head is fixed on the outer wall of the discharging pipe; the inner wall of one side of the box body is rotatably connected with a conveying auger through a bearing; a motor is fixed on the outer wall of one side of the conveying auger; the motor is fixedly connected with the box body; a through opening is formed in one side of the outer wall of the top of the box body; a feeding pipe is fixed on the inner wall of the through opening; a feeding opening is formed in one side of the outer wall of the top of the feeding pipe; and a feeding plate is fixed on the inner wall of one side of the feeding opening. According to the extrusion device, the raw material dispersing effect can be improved; the situation that the extrusion of the raw materials is influenced due to the fact that the inside of the device is blocked by accumulation of the raw materials can be avoided; the raw material stirring effect can be improved; the die head can be conveniently taken out of the device; and the damage of the die head caused by great force when disassembling the die head can be avoided.

Owner:安徽爱瑞德新材料有限公司

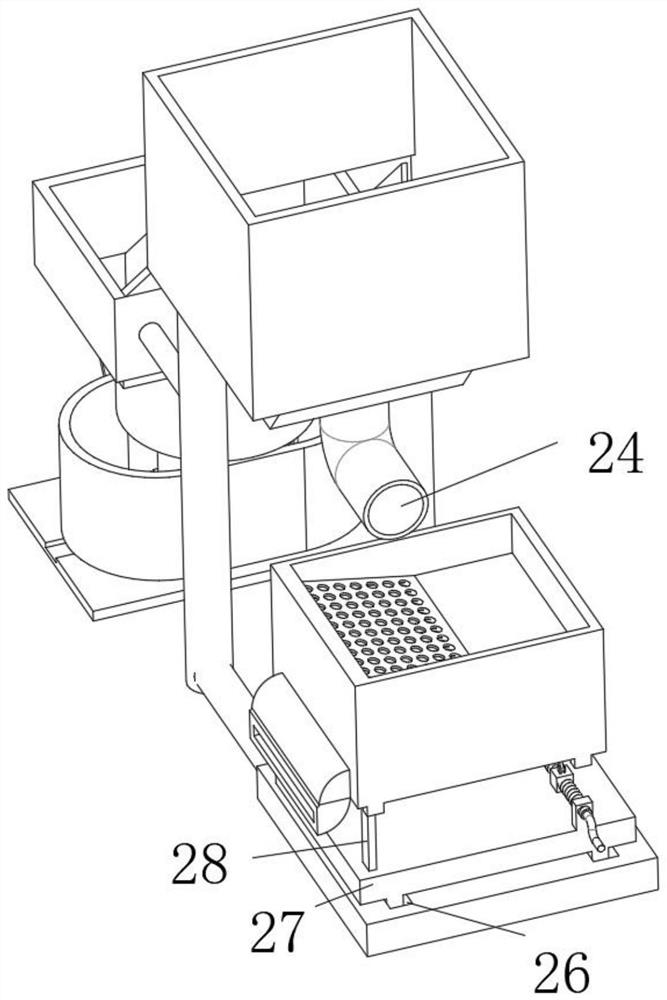

Bagged compound fertilizer agglomeration treatment device

The invention relates to agglomeration treatment devices, in particular to a bagged compound fertilizer agglomeration treatment device which can relieve the burden of working staff and save time and labor. The bagged compound fertilizer agglomeration treatment device provided by the invention comprises a base, two racks, a barrel, a discharge hopper and the like. The two racks are fixedly connected to the top of the base. The left ends of the two racks are fixedly connected with the lower portion of the right side face of the barrel. The bottom of the barrel is connected with the discharge hopper in an embedded mode. A big rotary shaft is rotatably connected with the middle portion of the barrel and is fixedly sleeved with a big rotary roller. The big rotary roller is located in the barrel. According to the bagged compound fertilizer agglomeration treatment device, a first belt roller is located on the right side of the barrel and is rotatably connected with the right ends of the uppersides of the racks; a third belt roller is located on the right side of a second belt roller; there is no need to manually turn over bagged compound fertilizer; and the burden of the working staff isrelieved, and time and labor are saved.

Owner:山西凯美佳肥业有限公司

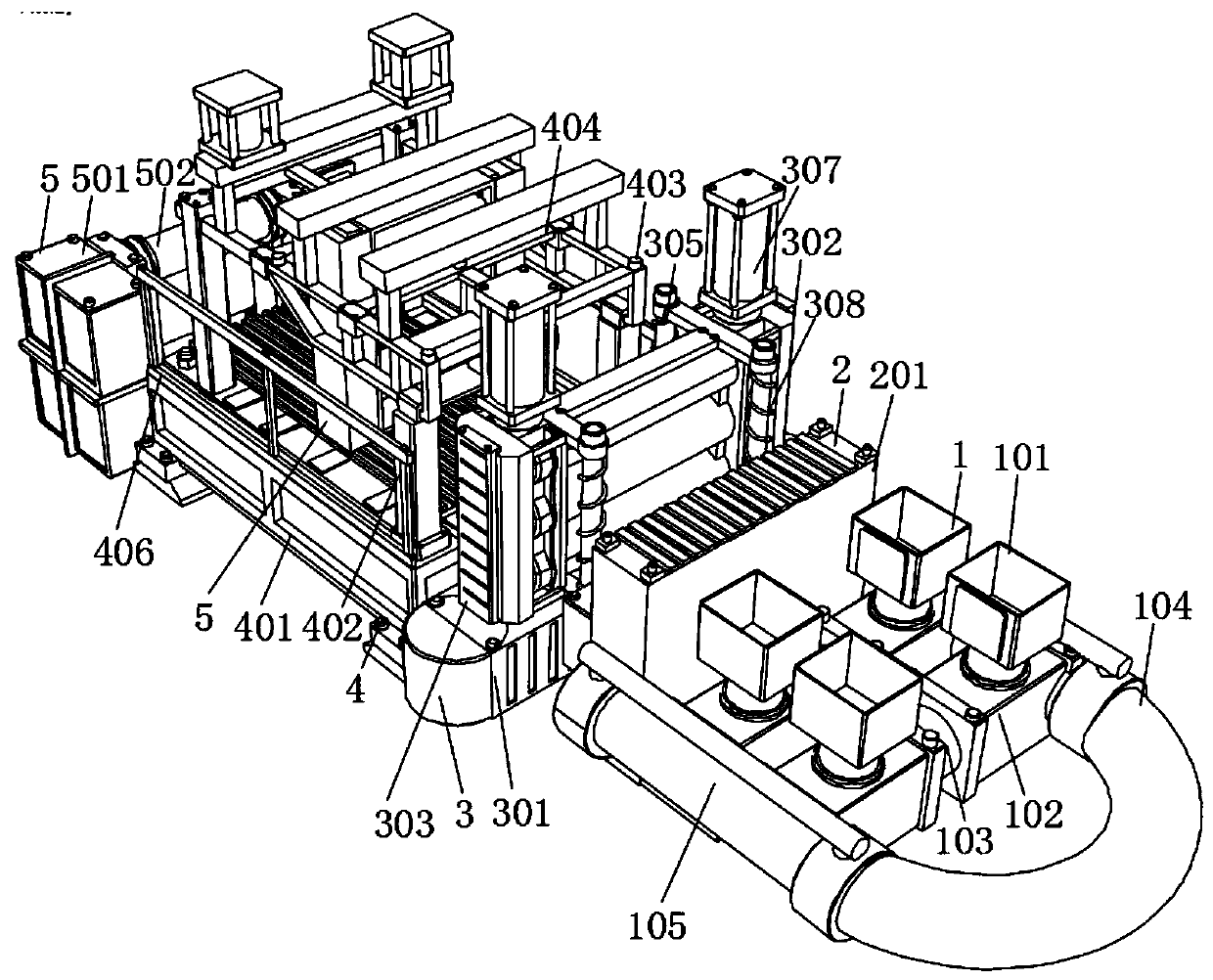

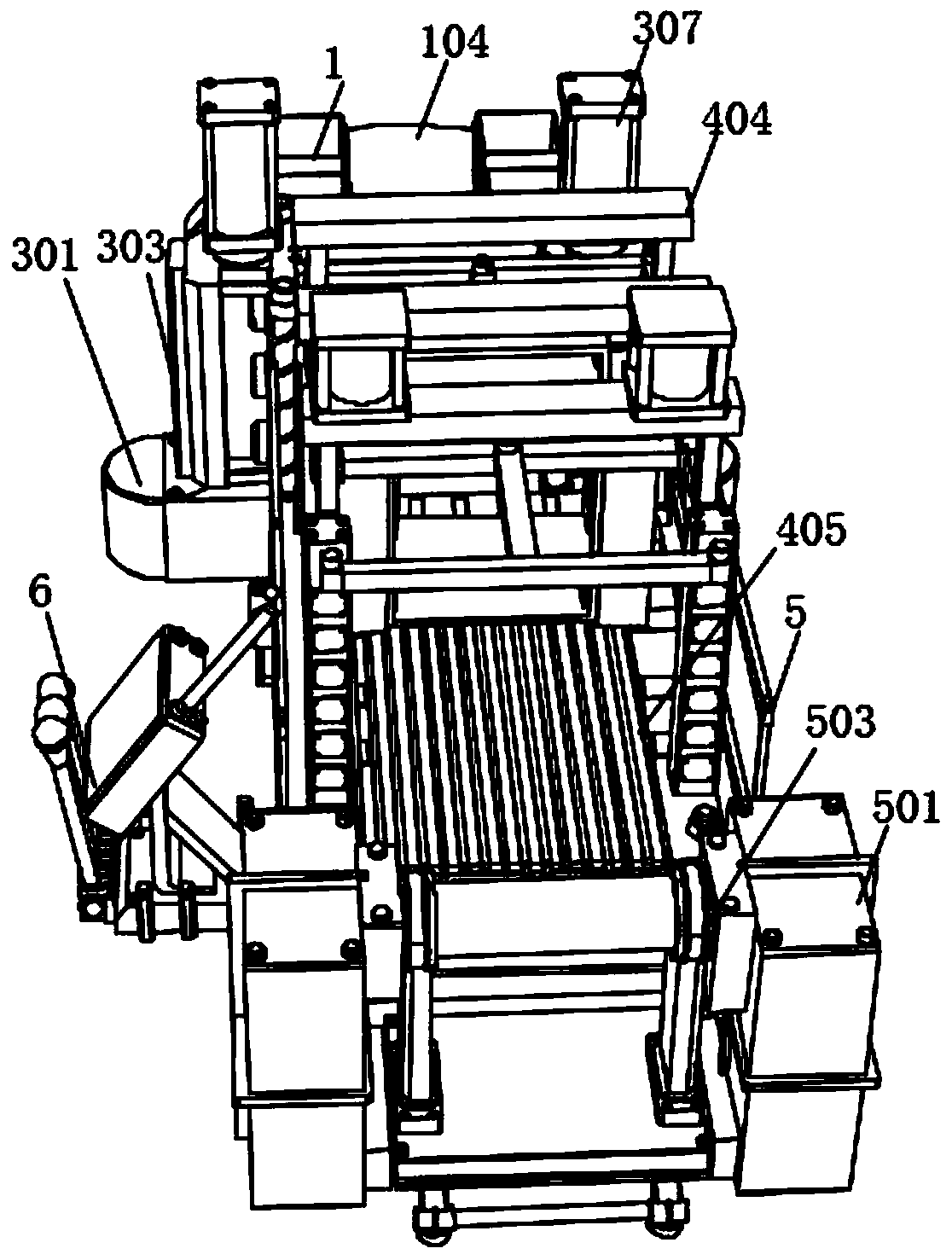

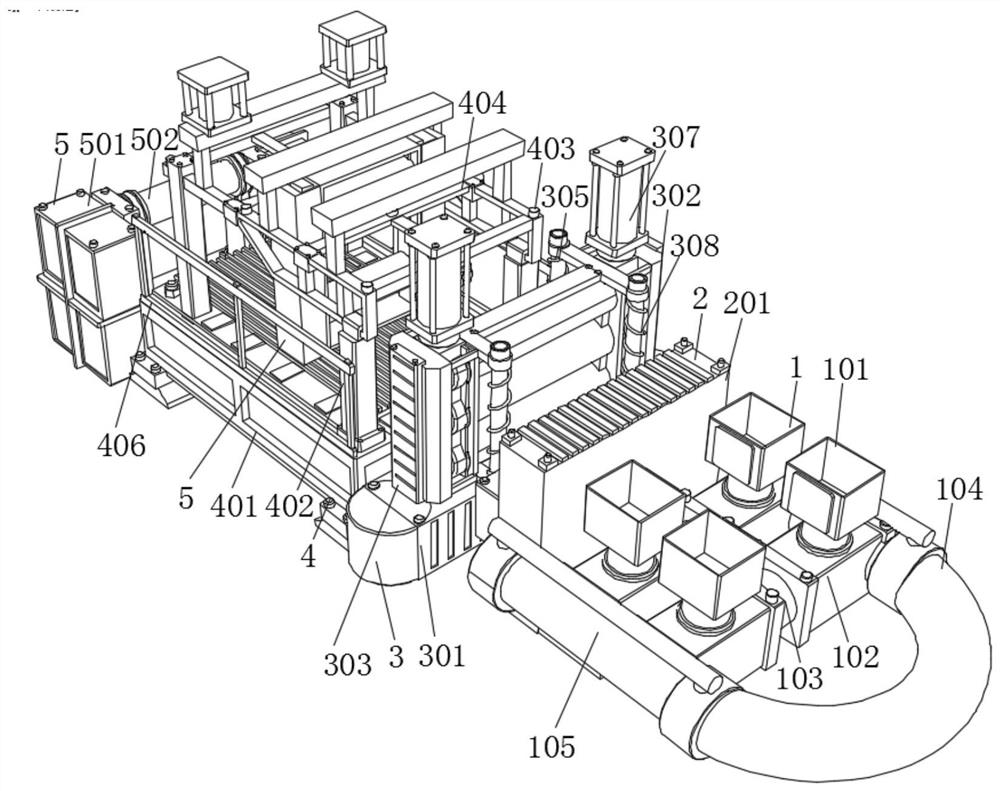

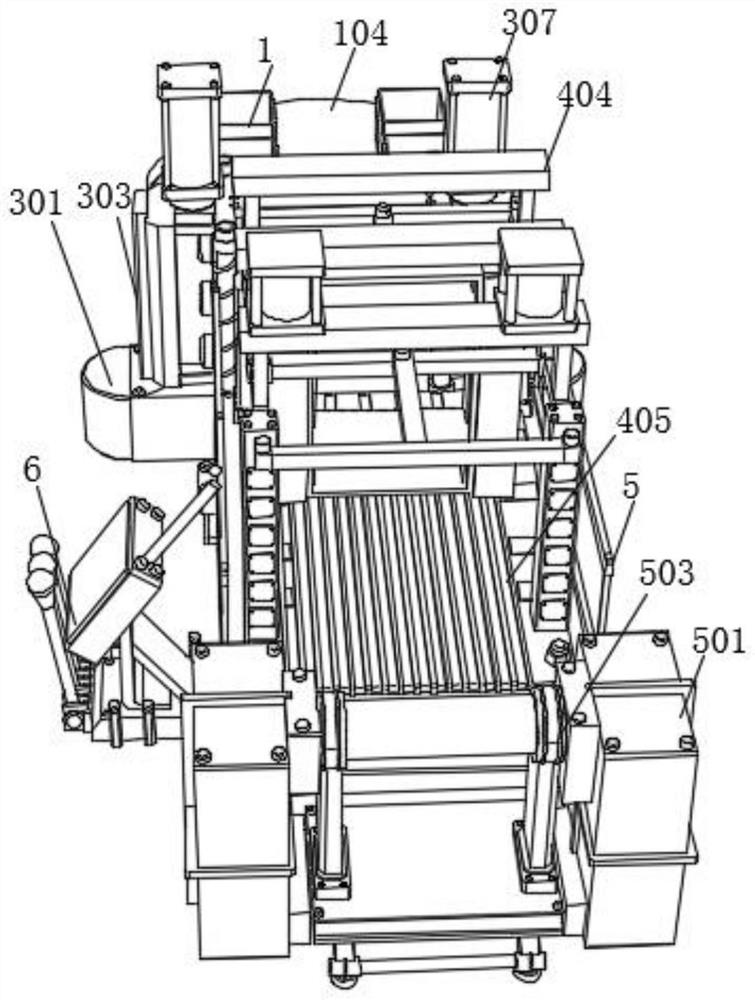

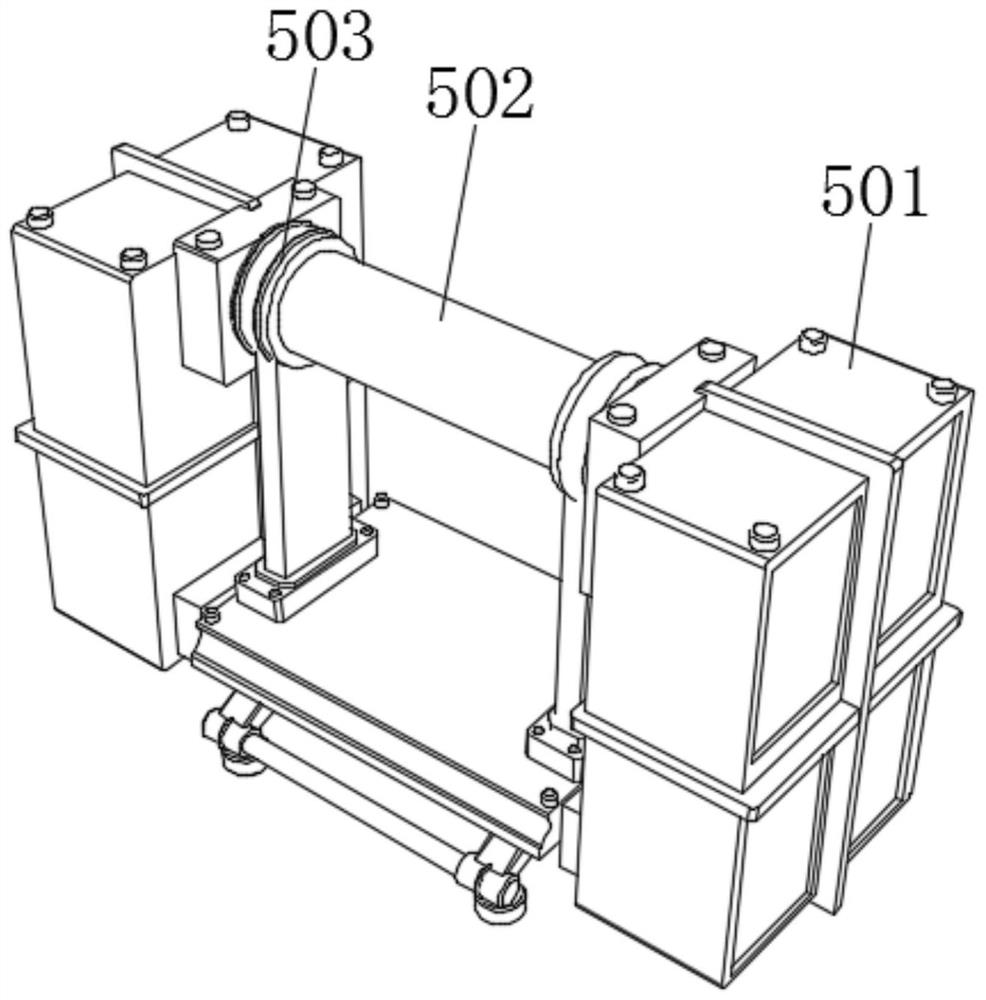

Roll roller extruding machine for producing waterproof rolls with feeding mechanism

The invention provides a roll roller extruding machine for producing waterproof rolls with a feeding mechanism, and belongs to the technical field of waterproof roll production. The roll roller extruding machine comprises the feeding mechanism, a shaping hot-pressing mechanism is fixedly installed at the end head of the feeding mechanism, the roller extruding machine is fixedly installed on the surface of the side wall of the shaping hot-pressing mechanism, a transportation mechanism is fixedly installed on the back surface of the side wall of the roller extruding machine, a winding mechanismis fixedly installed at the end head of the transportation mechanism, the feeding mechanism comprises a plurality of material injection funnels used for storing raw materials, a hot-pressing pump is arranged at the bottom ends of the multiple material injection funnels in a communication mode, and a protective box is connected to the exterior of the hot-pressing pump in a covering mode. By arranging the feeding mechanism, the material injection funnels, the protective box and a material-conveying guide pipe, the raw materials for producing the waterproof rolls are conveniently subjected to hot-melting treatment after being input, a high-pressure pump of asphalt is taken out and guided out through the heating of the hot-pressing pump in the heating process, and particle raw materials are conveniently subjected to heating and hot-melting treatment under the electrifying action of the hot-pressing pump arranged in the protective box.

Owner:沈永成

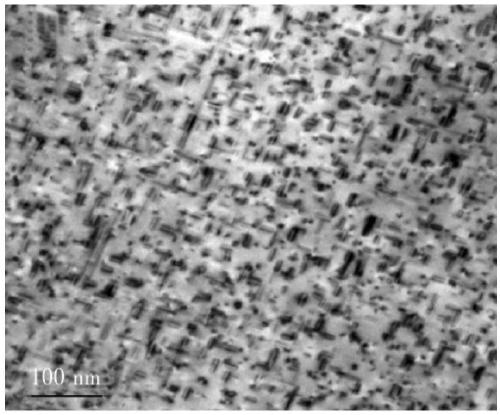

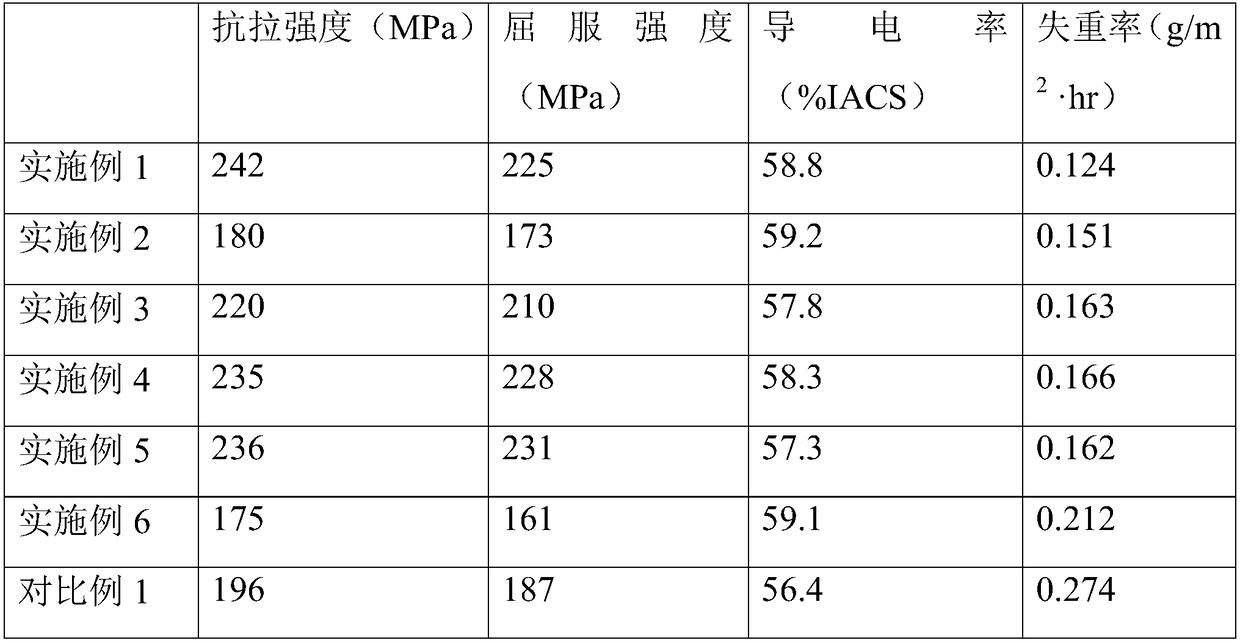

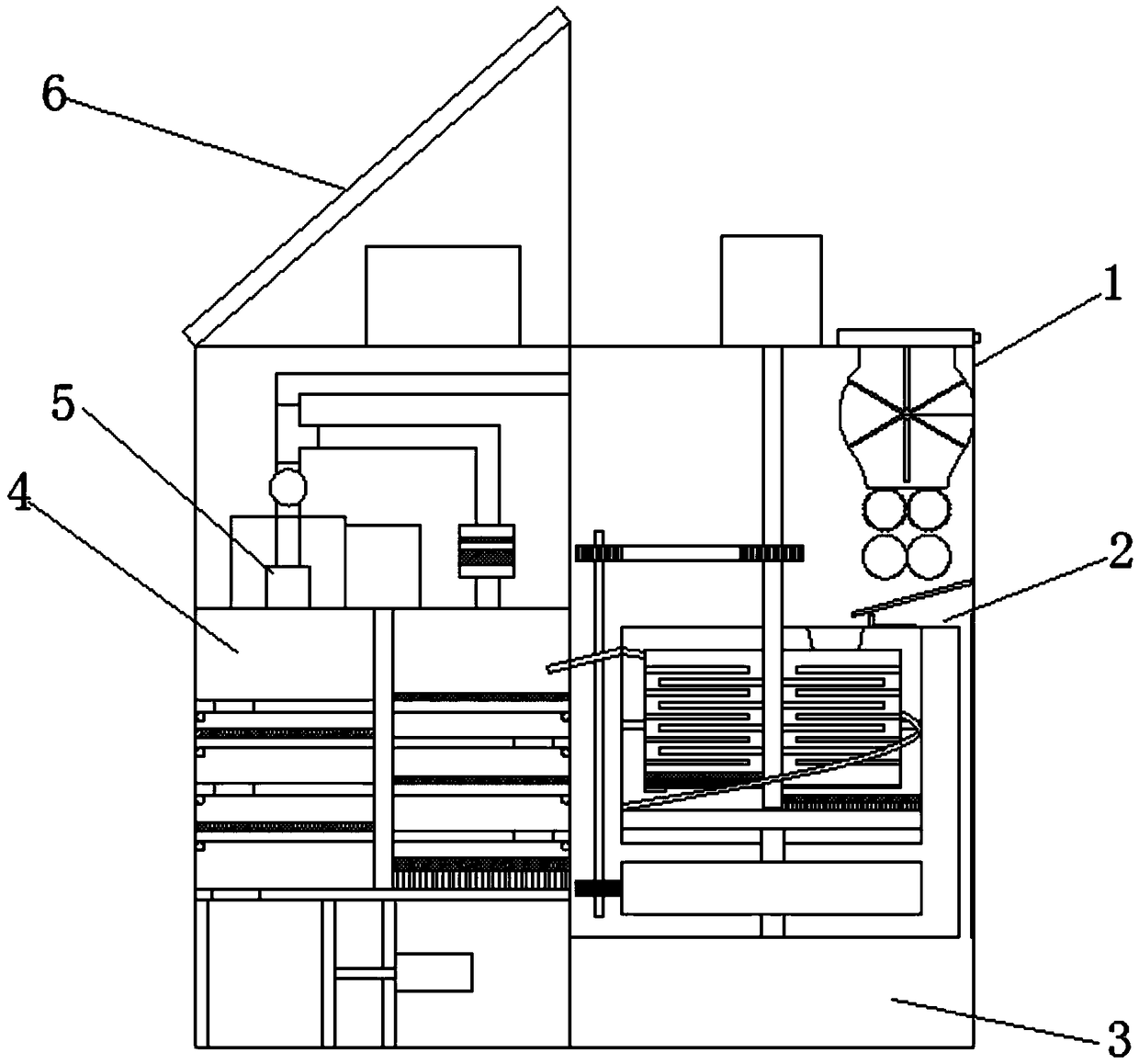

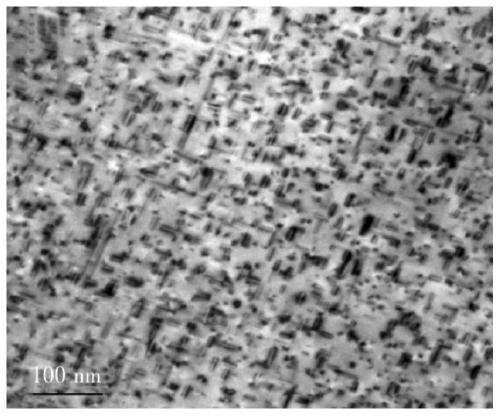

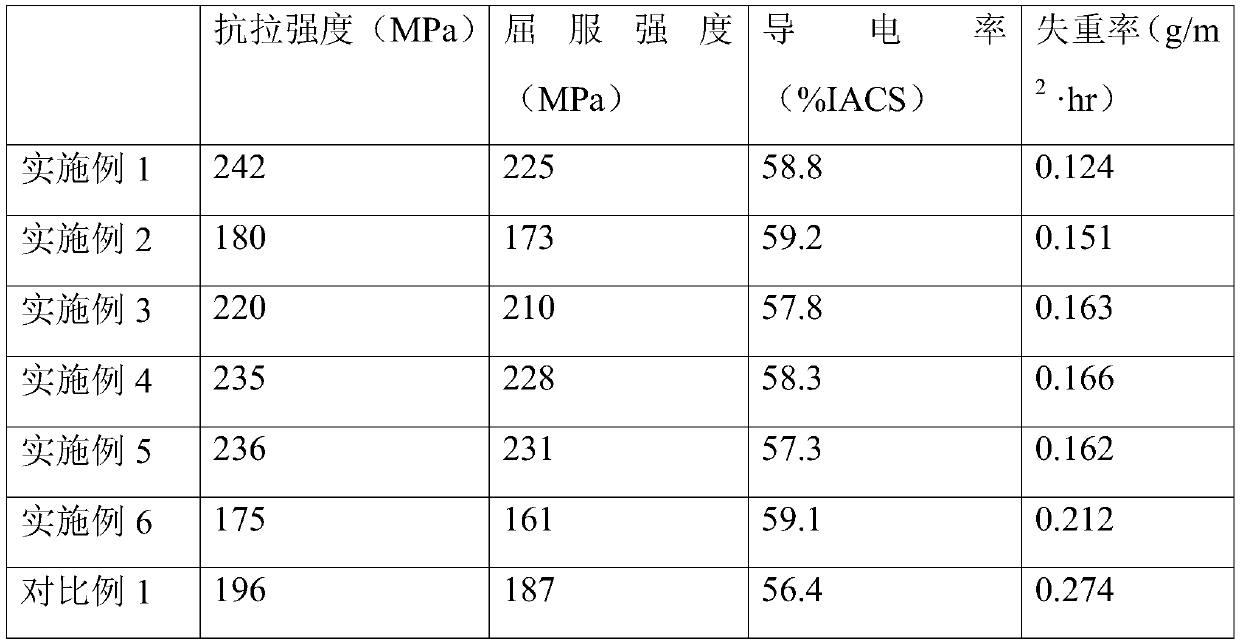

High-conductivity corrosion-resistant aluminum alloy and preparation method thereof

ActiveCN109161738AHigh conductivity and corrosion resistanceEnhanced interfacial strain energyHigh conductivityImpurity

The invention relates to the technical field of aluminum alloys, and particularly relates to a high-conductivity corrosion-resistant aluminum alloy and a preparation method thereof. The aluminum alloycomprises the following elements by weight percentage: 0.3-0.6% of Si, 0.6-0.9% of Mg, 0.01-0.04% of B, 0.01-0.02% of Ti, 0.005-0.01% of Sr, 0.001-0.005% of Pr, 0.02-0.1% of Er, 0.2-0.4% of Fe, 0.01-0.02% of Mn, 0.01-0.02% of Cr, 0.005-0.015% of Zr, 0.02-0.05% of Cu, 0.03-0.07% of Zn and the balance of aluminum and unavoidable impurities. The aluminum alloy is relatively high in tensile strength(240 MPa or more than 240 MPa), yield strength, electric conductivity (58% or more than 58%) and corrosion resistance.

Owner:东莞市东兴铝业有限公司

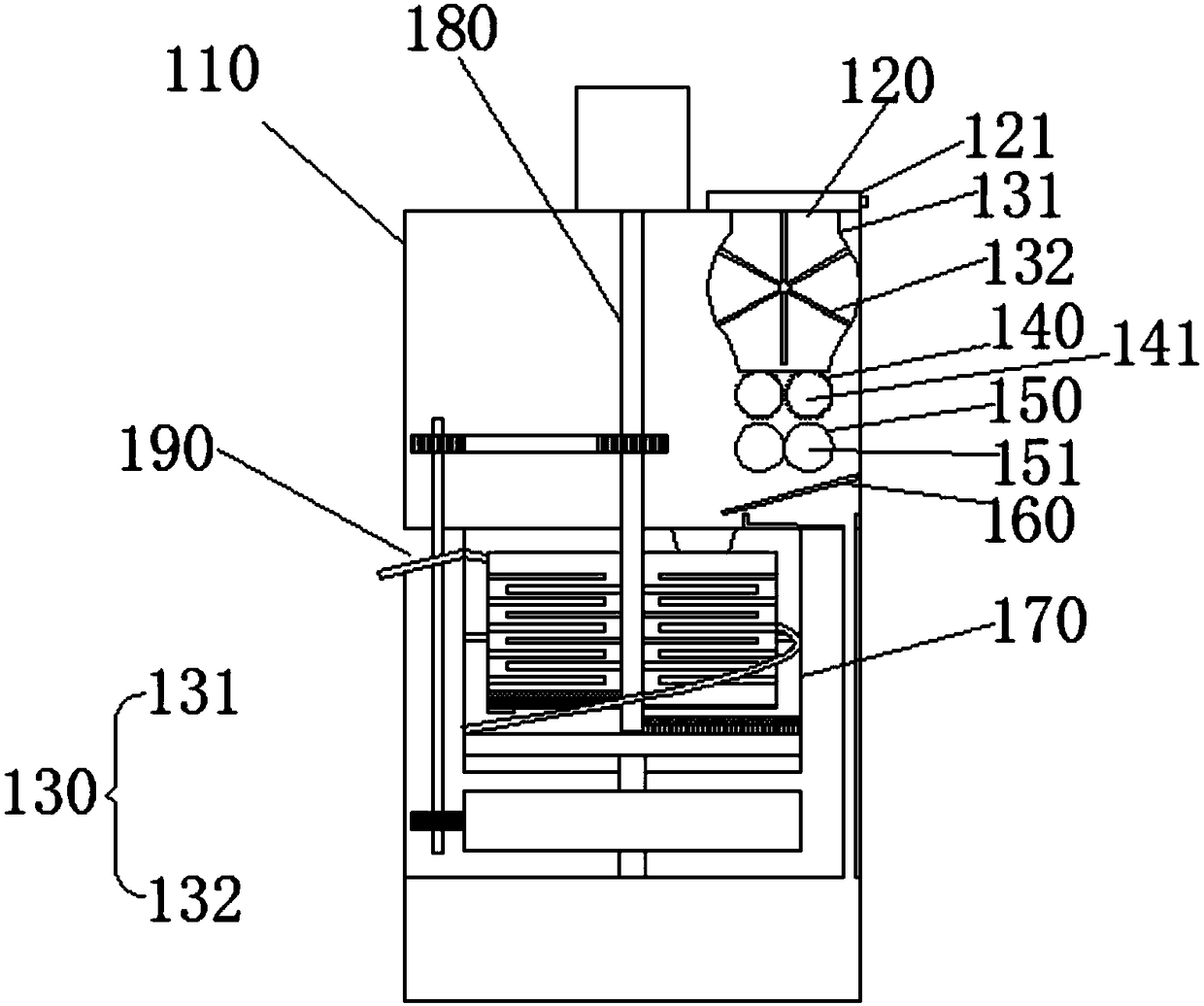

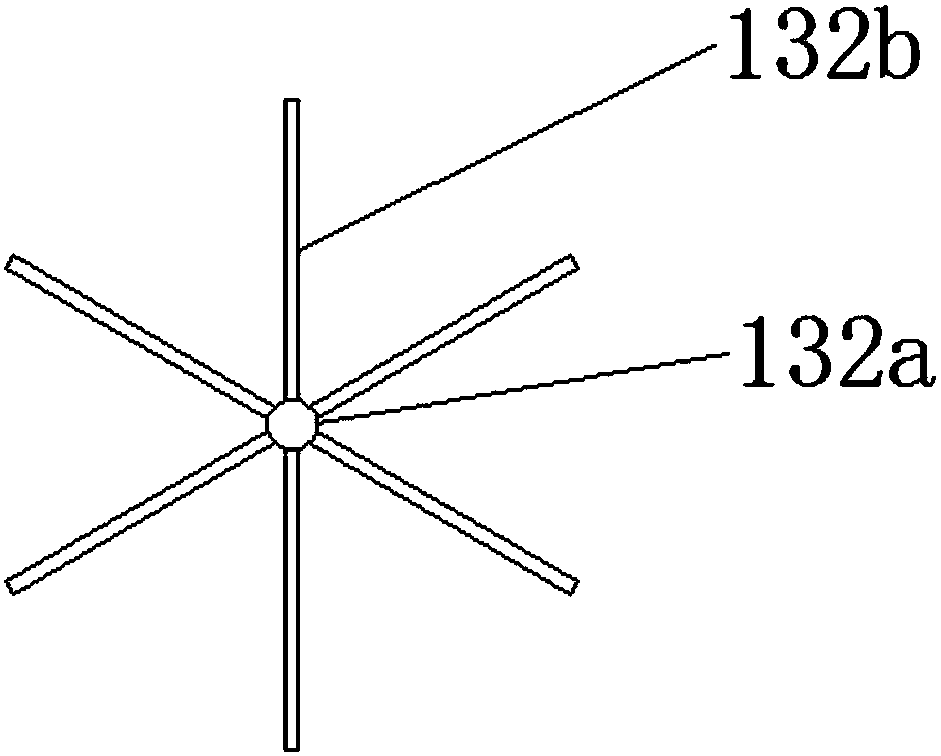

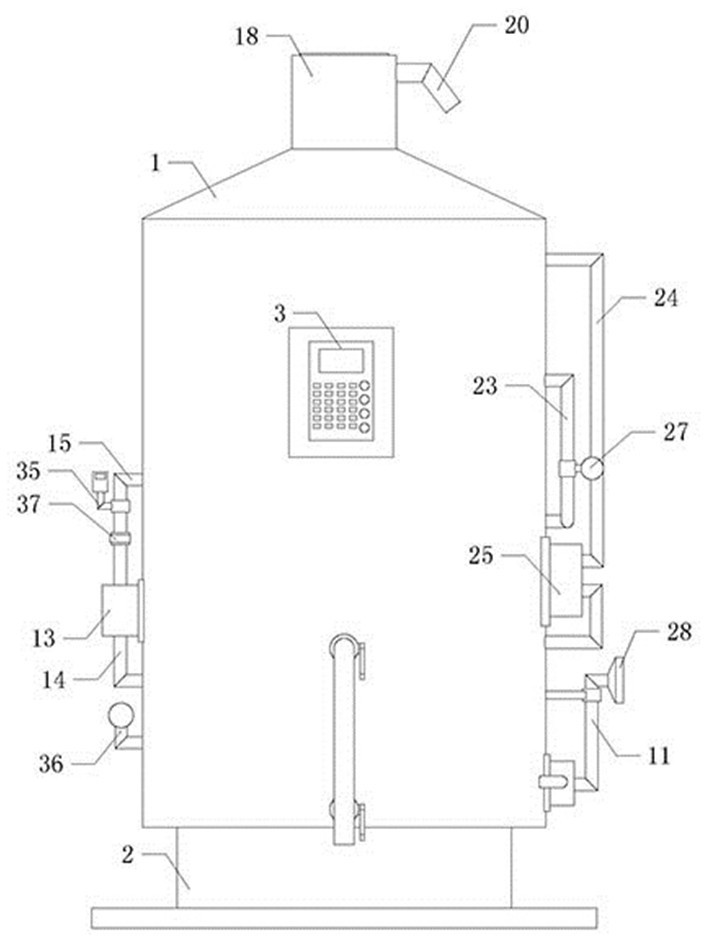

An environmentally friendly garbage disposal device

ActiveCN108580522BReasonable structural designEasy for primary crushingWaste processingSolid waste disposalDeodorantCompression device

The present application provides a specific technical solution of an environment-friendly garbage disposal device, which is characterized in that it includes a crushing device, a liquid collection tank, a liquid collection tank, a disinfection compression device and a deodorization device. An environment-friendly garbage disposal device of the present application has a reasonable structural design, and the combination of the deodorization device and the deodorization device can effectively avoid environmental problems caused by garbage piled up and fermented; the first crushing device and the second crushing device in the first box are combined The step-by-step crushing not only improves the crushing effect, but also improves the garbage crushing efficiency; the second box is equipped with multiple drying plates and multiple ultraviolet lamps, which can perform ultraviolet sterilization while drying, and dry sterilization, which avoids the breeding of miscellaneous waste in wet garbage. The lower part of the second box is equipped with a compression device to facilitate the compression and recovery of dry garbage; the second box of the device is also equipped with a solar module, and the operation of the whole device is driven by solar power generation, which is energy-saving and environmentally friendly.

Owner:天津鼎拓恒远知识产权服务有限公司

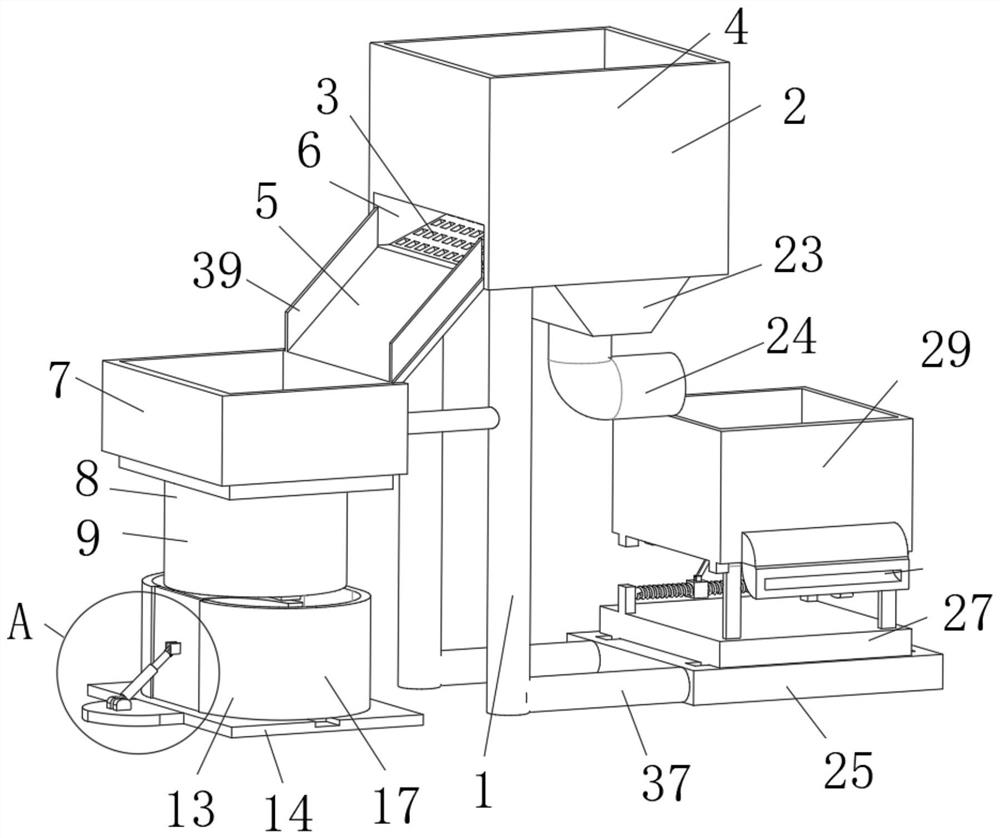

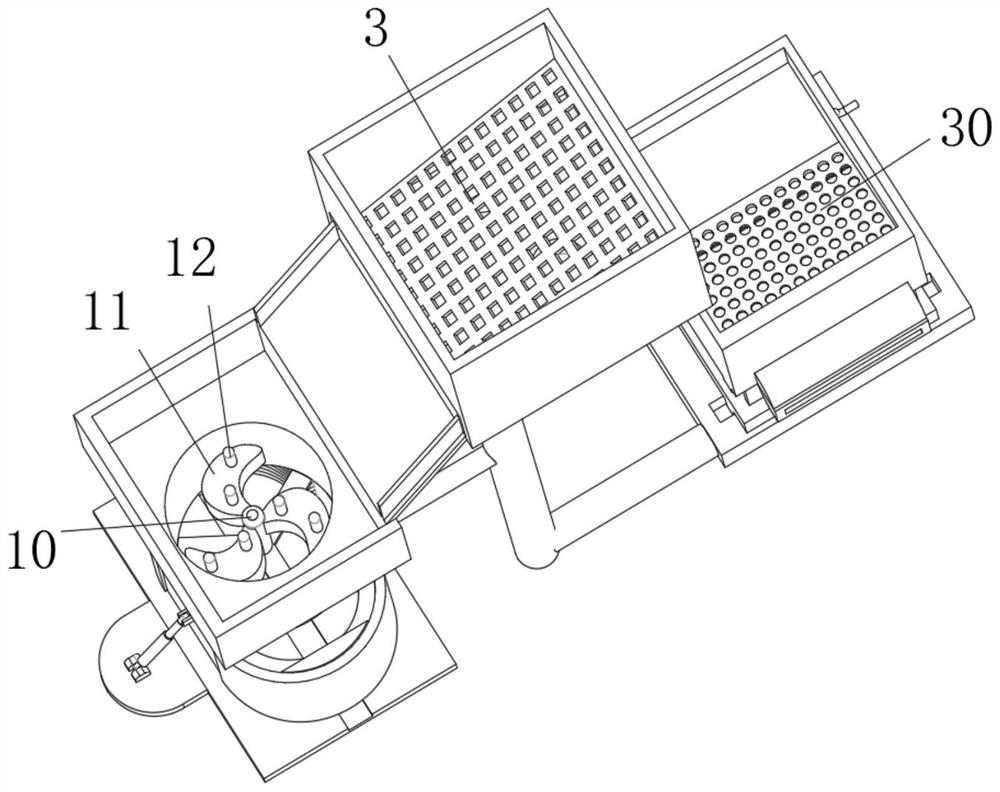

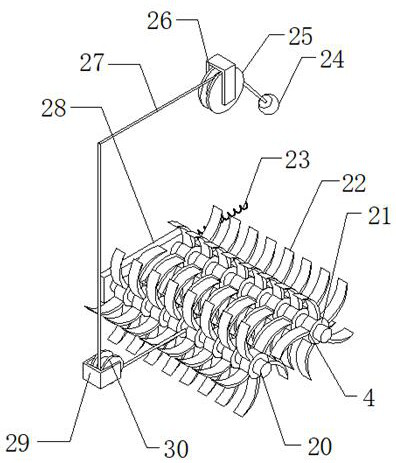

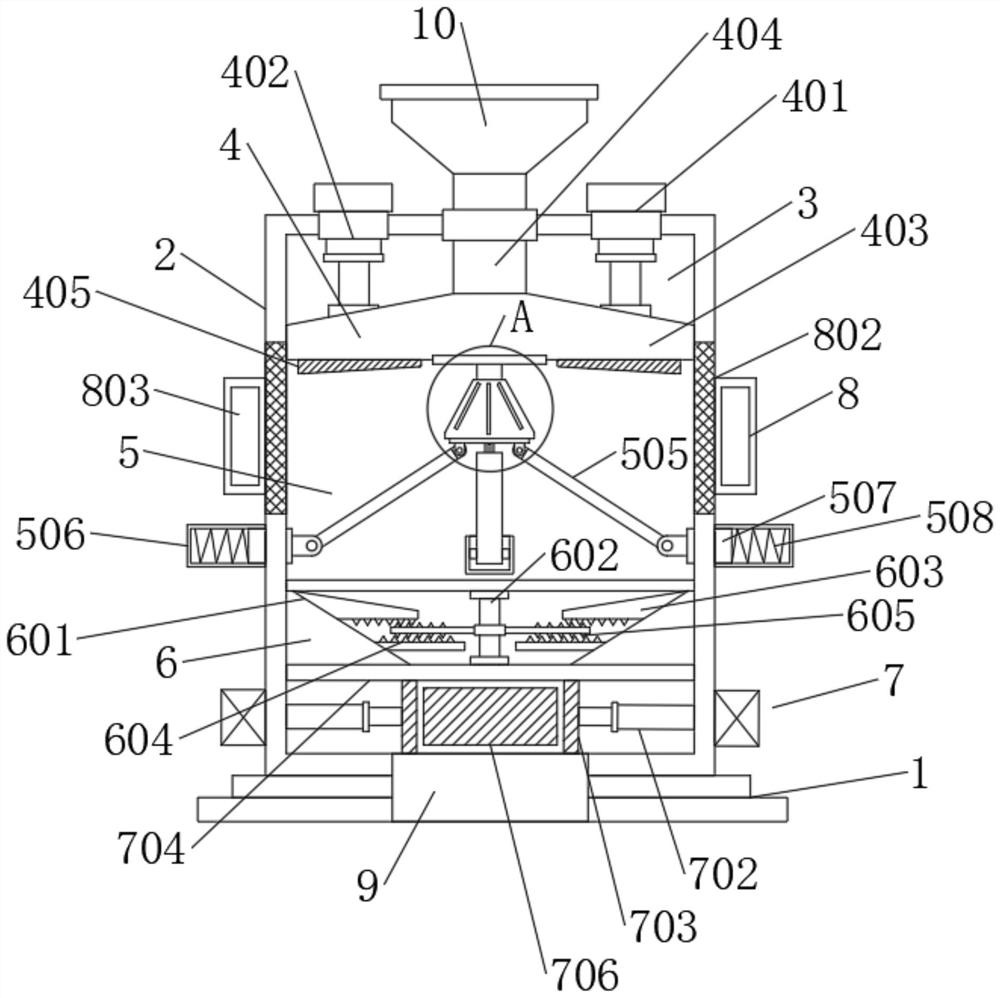

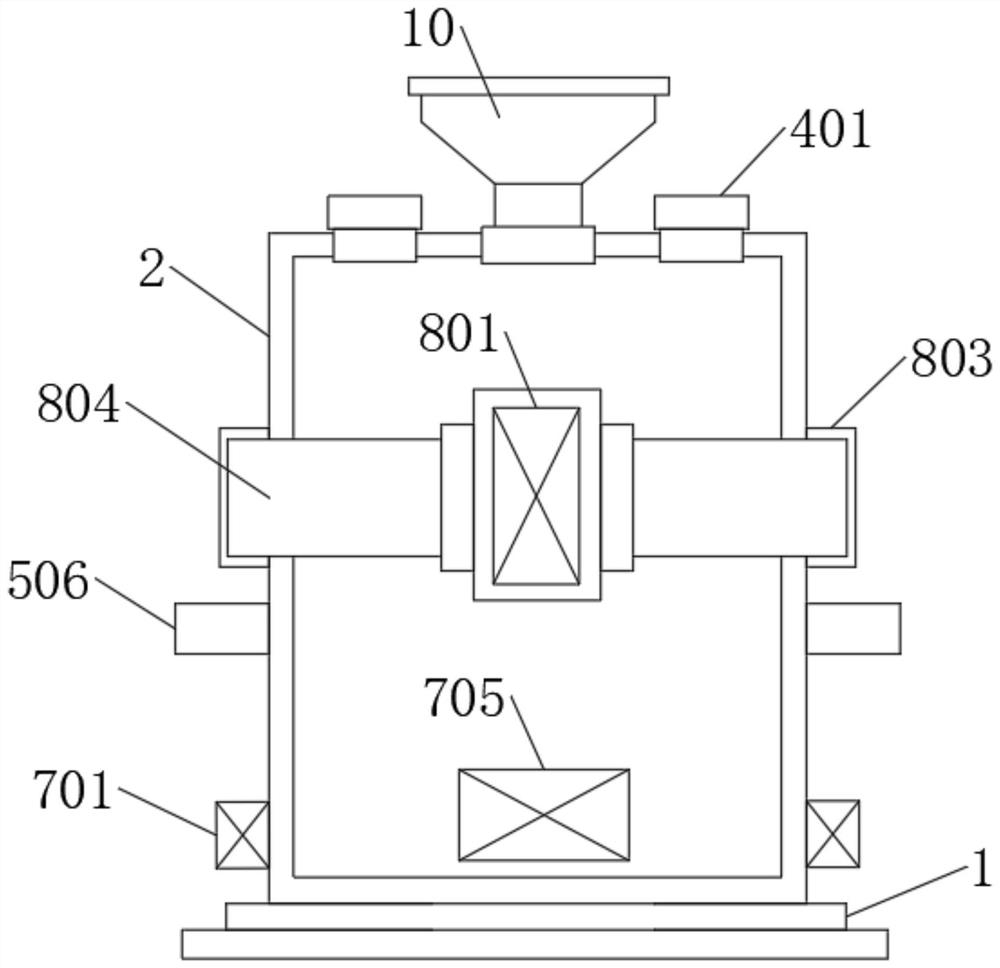

A construction waste crushing and recycling equipment

ActiveCN113680792BImprove crushing effectSqueeze wellConstruction waste recoverySolid waste disposalProcess engineeringBriquette

The invention discloses a construction waste pulverizing and reusing equipment. The construction waste pulverizing and reusing equipment comprises: a stable seat; a box body located outside the stable seat; a feeding hopper, wherein the feeding hopper is arranged outside the box body; A pulverizing device, the first pulverizing device is arranged inside the box; a second pulverizing device, the second pulverizing device is connected with the first pulverizing device; wherein, the first pulverizing device includes: a pressing material pulverizing device, the The pressing material crushing device is arranged inside the box and is used for material crushing by downward pressure; the material guiding component is connected with the pressing material crushing device and is used for the top pressure material guiding treatment of the material. The material is pressed inside the device. The crushing device cooperates with the material guide assembly to repeatedly crush the material, and then cooperates with the second crushing device at the bottom to further improve the garbage crushing effect, which is beneficial to the extrusion treatment of the bottom briquetting assembly, reduces the forming volume of the briquette, and facilitates subsequent use again.

Owner:刘秀梅

Waste recovery mechanism of a cutting device for plates

ActiveCN112170922BPrevent splashEnsure safetyShearing machinesMetal working apparatusElectric machineryProcess engineering

The invention discloses a waste material recovery mechanism for a cutting device for plates, which comprises: a support frame, a separation and pushing structure, an extrusion and cutting assembly and a transfer structure. A separation and pushing structure is installed on one end of the top side of the support frame. An extruding and cutting assembly is installed on the other end of the top side of the supporting frame, and the transfer structure is installed on one side of the supporting frame. By setting the extruding and cutting assembly, the punched waste works on the cam motor to drive the cam to rotate , can push the vibrating rod, the extrusion plate sinks, the bottom side of the extrusion plate is a slope, the angle between the slope and the support plate is gradually reduced, and the volume of the waste can be gradually compressed, and the return spring cooperates with the push rod The lower operation ensures that the material is stable during extrusion and can achieve a better extrusion effect. The cutting knife sinks, and with the cooperation of the cutting seat, the waste can be divided, the waste can be further divided, the volume of the waste can be reduced, and the waste can be reduced. The occupation of space can be better coordinated to realize the recycling of waste.

Owner:安徽金贺财建筑工程有限公司

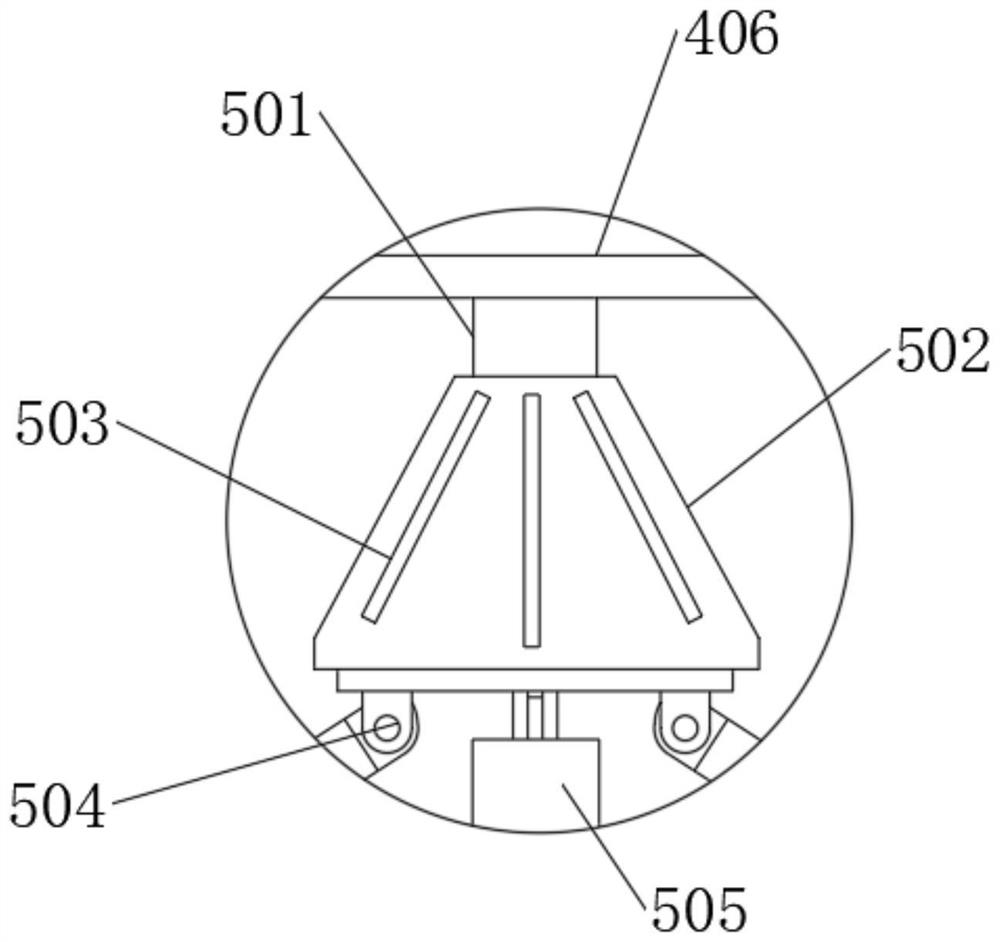

A kind of extrusion molding device for coconut palm mattress

ActiveCN113319972BChange the relative distance positionEasy to placeFlat articlesDomestic articlesStructural engineeringMechanical engineering

The invention discloses an extrusion molding device for coconut palm mattresses, which includes a force plate, a wrapping cover, a fan, a first installation frame, an adjustment plate, a first screw rod, an output motor, a collection box, a cover plate and Adjust the counterweight device, the top of the force plate is penetrated with a through hole, the bottom of the wrapping cover is inlaid and fixed with a first pipe connector, the left side of the fan is inlaid and fixed with a suction pipe, and the front of the first installation frame runs through There is a first chute, the inside of the first chute is fixed with locking teeth, wire blocks are fixed on both sides of the first installation frame, and handles are fixed on both sides of the adjustment plate, which is used for coconut palm mattresses The extrusion molding device is provided with locking teeth, which can limit the adjusted grip bar through the locking teeth, thereby avoiding the rolling connection between the adjusted grip bar and the first chute, and changing the distance between the adjustment plates at the same time. The relative distance, in turn, causes the need to manually adjust the process again, which not only troubles but also reduces work efficiency.

Owner:盐城酷艺家居有限公司

A kind of aluminum alloy with high conductivity and corrosion resistance and preparation method thereof

ActiveCN109161738BHigh conductivity and corrosion resistanceEnhanced interfacial strain energyUltimate tensile strengthHigh conductivity

Owner:东莞市东兴铝业有限公司

A double-sided adhesive die-cutting waste discharge mechanism for a die-cutting machine and its working method

ActiveCN113352390BHigh speedSpeed up die cuttingMetal working apparatusArticle deliveryHydraulic cylinderElectric machinery

Owner:深圳市兴龙宝实业有限公司

Squeezing type garbage can

ActiveCN114435805APrevent overflowAvoid enteringWaste collection and transferRefuse receptaclesEngineeringStructural engineering

The extrusion type garbage can comprises a can body, a garbage opening is formed in the right side of the can body, an extrusion structure is arranged in the can body, and a disinfection assembly is arranged on the extrusion structure; the extrusion structure comprises an extrusion plate, supporting grooves, a connecting block, a transmission block, a triangular plate and a cover plate, the extrusion plate is slidably connected into the barrel body, a plurality of supporting grooves are formed in the inner wall of the barrel body, the cover plate moves upwards, at the moment, the disinfection assembly works, a cavity C in the cover plate moving upwards synchronously moves upwards, and the connecting plate is extruded; alcohol disinfectant is placed in the disinfection groove, the connecting plate is squeezed to move upwards, the disinfectant in the isolation sleeve is forced to be sprayed out from the liquid outlet and sprayed to the holding rod so as to disinfect the hand, and after the hand leaves the holding rod, a small amount of the alcohol disinfectant flows down along the outer wall of the barrel body and finally drips on the isolation film wrapping the outer side of the holding rod. Therefore, the safety of the isolating membrane is enhanced.

Owner:ZHEJIANG HOSPITAL

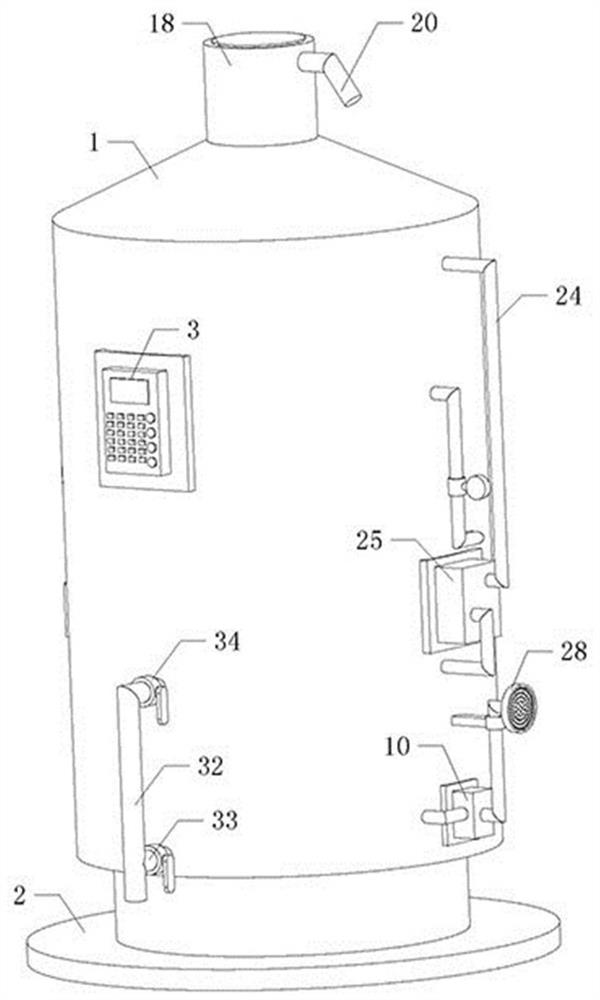

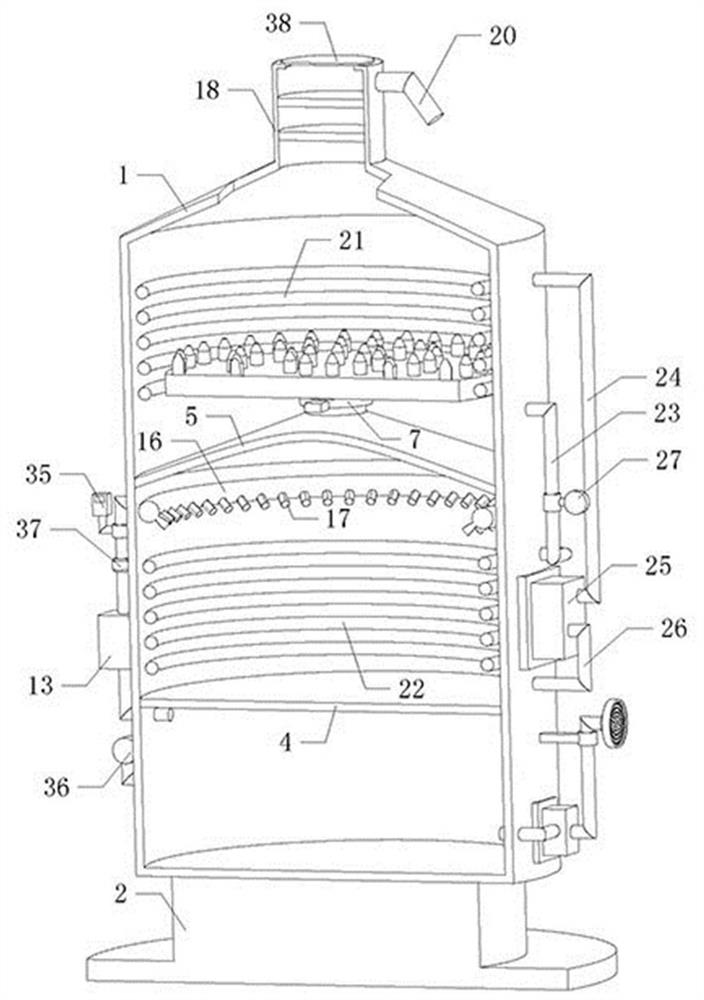

A breeding waste gas treatment device

ActiveCN111957172BEasy to monitor in real timeAir pressure real-time monitoringGas treatmentDispersed particle separationAnimal scienceDomestic bird

The invention relates to the technical field of purification equipment, in particular to a breeding waste gas treatment device which can effectively improve the air quality in a poultry breeding room,improve the living environment of poultry, prevent waste gas from being directly discharged into outside air and damaging the environment, prevent a human body from inhaling the waste gas and injuring the human body and improve the practicability and reliability by purifying the waste gas. The device comprises a purification bin, a base, a central control box, a first partition plate, a second partition plate and an air guide channel. The top of the purification bin is conical, the base is installed at the bottom of the purification bin, the central control box is installed on the upper frontside of the purification bin, and the first partition plate is installed on the lower side of the inner wall of the purification bin.

Owner:SHANDONG HENGIN AGRI & ANIMAL HUSBANDRY MACHINERY

A hardening treatment device for bagged compound fertilizer

ActiveCN110385167BSqueeze wellSolve compactionGrain treatmentsRotational axisAgricultural engineering

The invention relates to a hardening treatment device, in particular to a hardening treatment device for bagged compound fertilizers. The technical problem to be solved is to provide a hardening treatment device for bagged compound fertilizers which can reduce the burden of workers and save time and effort. Provides such a hardening treatment device for bagged compound fertilizers, including a base, a frame, a cylinder, a discharge hopper, etc.; two frames are fixedly connected to the top of the base, and the left ends of the two frames are connected to the cylinder. The lower part of the right side of the body is fixedly connected, the bottom of the barrel is embedded with a discharge hopper, the large rotating shaft is rotationally connected with the middle part of the barrel, the large rotating roller is fixedly sleeved on the large rotating shaft, and the large rotating roller is located in the barrel. In the present invention, the first belt roller is located on the right side of the cylinder body, the first belt roller is rotatably connected to the right end on the upper side of the frame, and the third belt roller is located on the right side of the second belt roller, and there is no need to manually adjust the bagged compound fertilizer. Flipping reduces the burden on the staff and saves time and effort.

Owner:山西凯美佳肥业有限公司

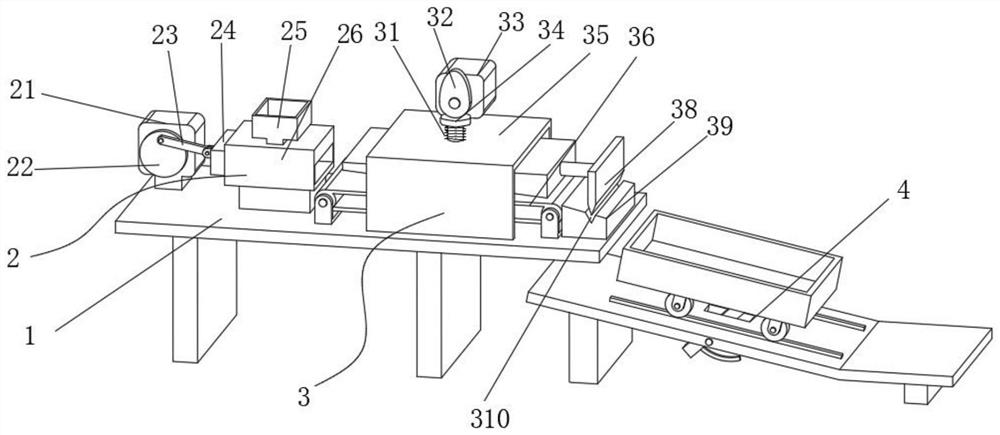

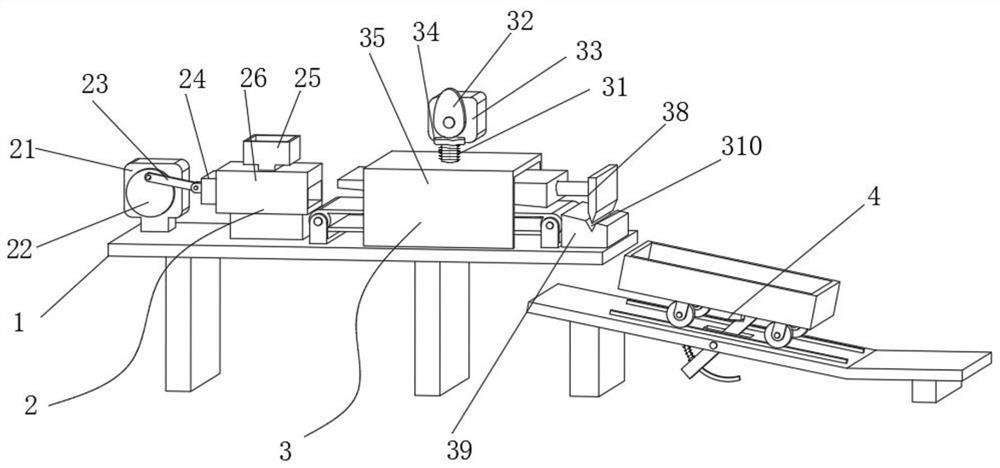

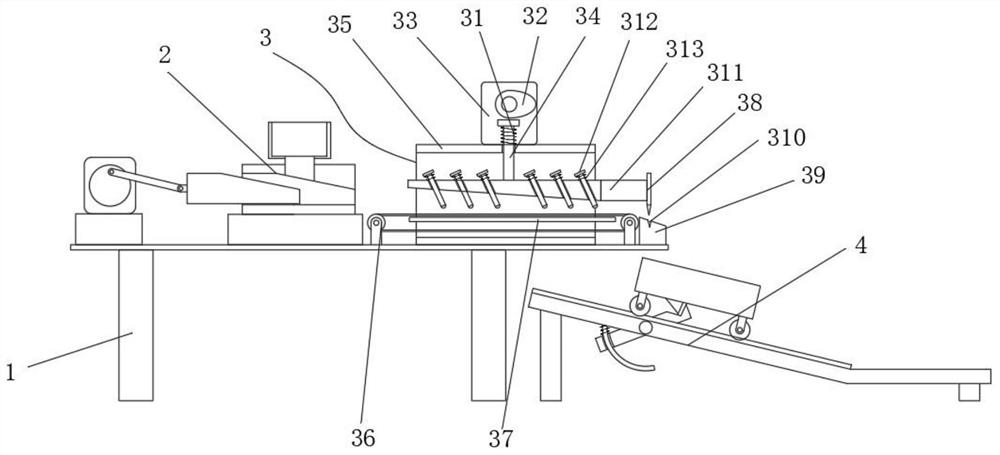

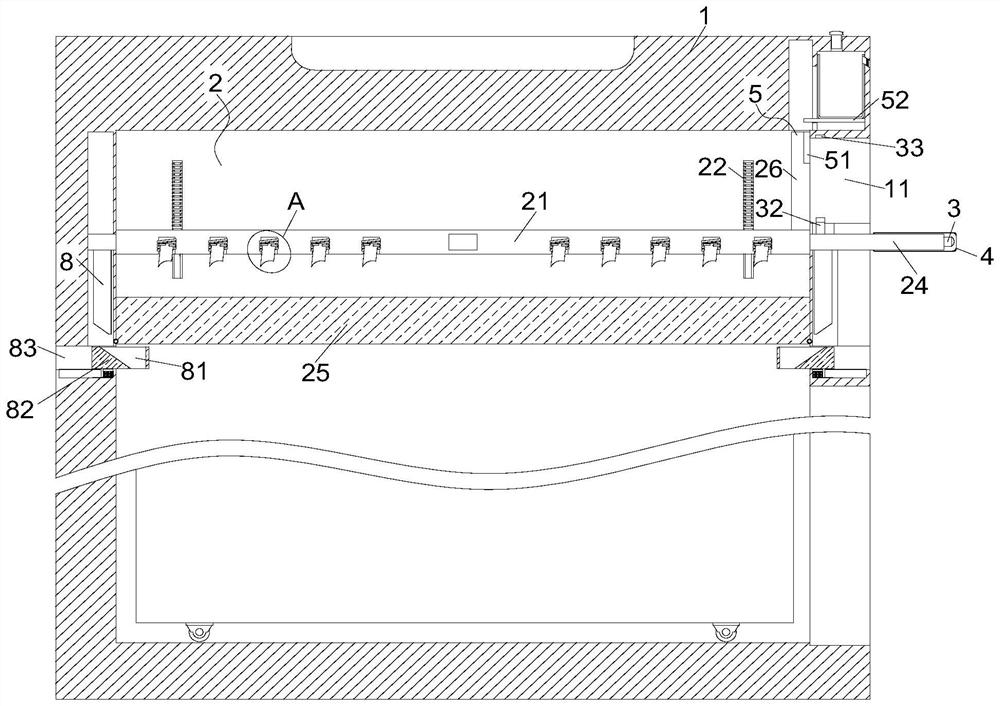

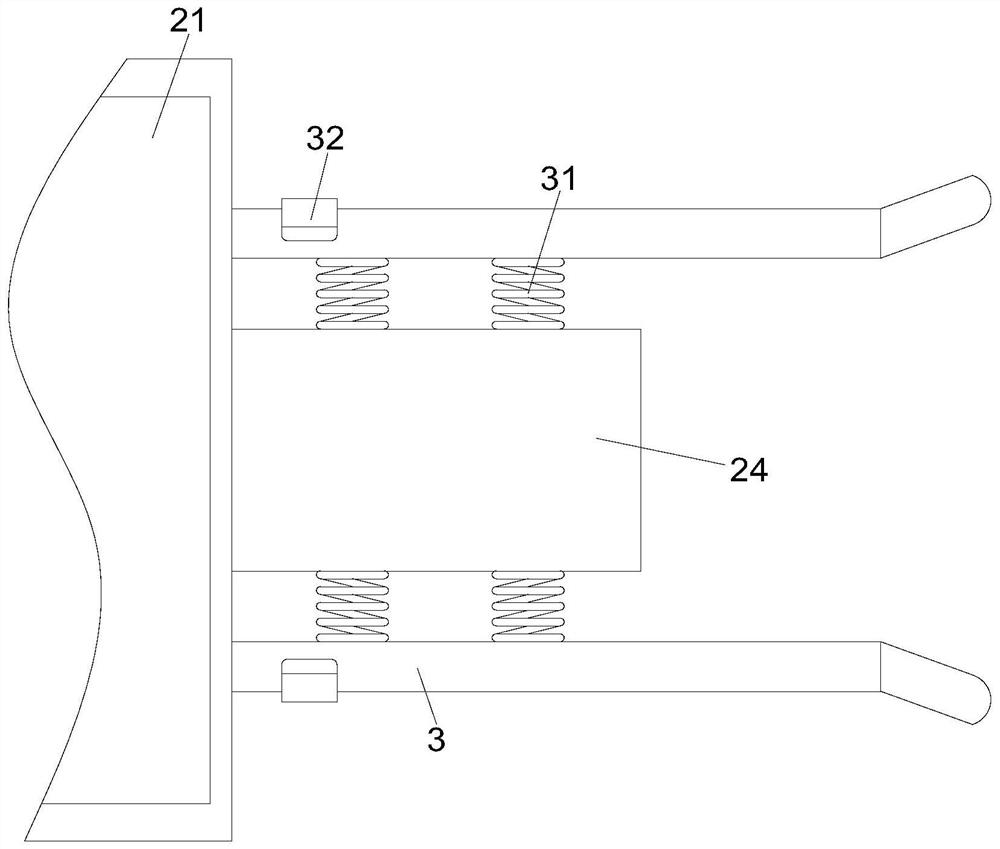

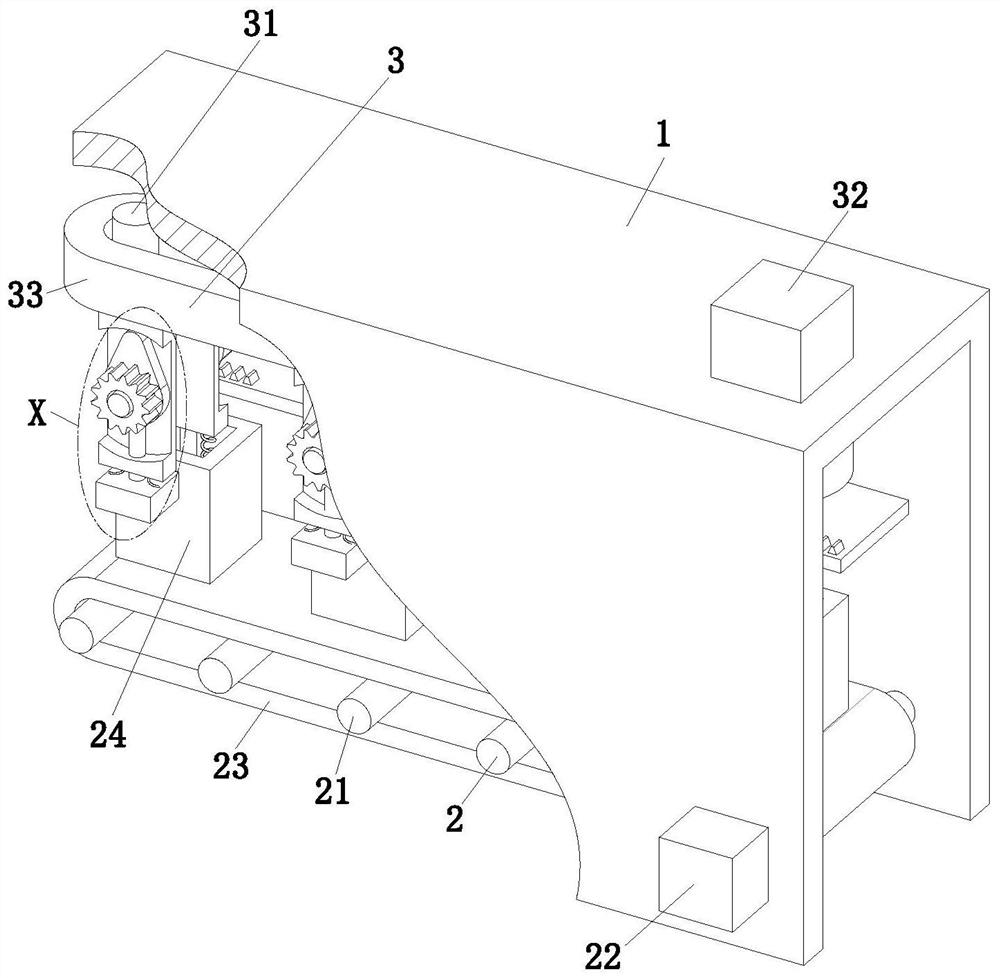

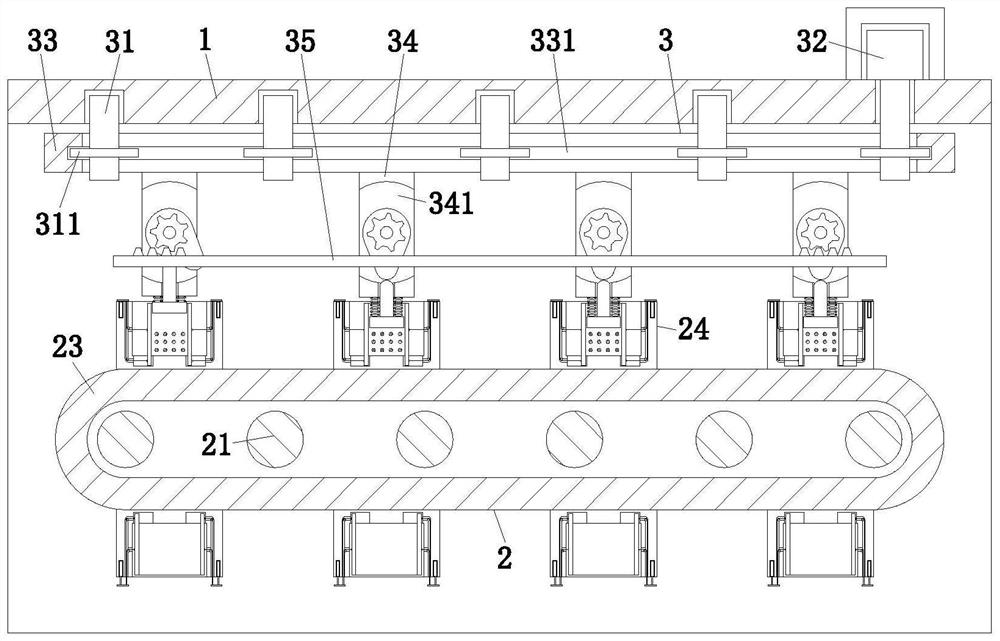

Transporter of corn cutting and bundling machine

ActiveCN111837658AEasy to move in reverseEasy to increase occupancyConveyorsBalingAgricultural engineeringStructural engineering

The invention discloses a transporter of a corn cutting and bundling machine. The transporter comprises a shell, wherein a feeding port is formed in the right side of the shell, a first conveying beltis arranged in the shell, multiple extruding assemblies are arranged above the first conveying belt, each extruding assembly comprises a first slide groove formed in the inner side wall of the shell,and a first slider and a second slider are arranged in the first slide groove in a sliding manner; first fixed plates connected with the first sliders are arranged above the first conveying belt, a first left conveying plate is hinged with the right side of each first fixed plate, second fixed plates connected with the second sliders are arranged above the first conveying belt, a first right conveying plate is hinged with the right side of each second fixed plate, the first slide grooves are provided with driving parts, and the driving parts drive the first slider and the second sliders to move relatively or oppositely. According to the transporter of the corn cutting and bundling machine, gaps between corn stalks are reduced conveniently, and therefore, existential space is increased.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

A coil roll extruder with a feeding mechanism for waterproof coil production

The invention provides a coil roll extruder with a feeding mechanism for waterproof coil production, which belongs to the technical field of waterproof coil production and includes a feeding mechanism. The pressing mechanism, the side wall surface of the shaping hot pressing mechanism is fixedly equipped with a roller extruder, the back of the side wall of the roller extruder is fixedly installed with a transport mechanism, and the end of the transport mechanism is fixedly installed with a winding mechanism, for The feeding mechanism includes several feeding funnels for storing raw materials. The bottom ends of the several feeding funnels are connected with a heat-pressed pump, and the outer cover of the heat-pressed pump is connected with a protective box. In the present invention, through the provided feeding mechanism, feeding funnel, protective box and feeding conduit, it is convenient to put the raw materials for producing the waterproof coiled material into the hot-melt treatment, and realize the heating and heating process through the heating of the hot pressure pump. The high-pressure pump of asphalt is taken out, and the heat-pressure pump installed inside the protective box is energized to heat and melt the granular raw materials.

Owner:沈永成

Novel extrusion device for plastic bottles

The invention discloses a novel extrusion device for plastic bottles, which comprises a frame, a cylinder, a box body, an extrusion plate, a pushing device, a discharge pipe, and a first push plate, and the piston rod of the cylinder is connected with the first push plate , a feed pipe is installed on the top side wall of the box, a hollow pipe is connected to the feed pipe, a feed hopper is connected to the hollow pipe, and a second push plate that can move left and right relative to it is arranged inside the hollow pipe. A push rod is fixedly connected to the push plate, a plane plate is fixedly connected to the push rod, a first motor is installed on the frame, a first rotating shaft is connected to the output shaft of the first motor, and a first sprocket is installed on the first rotating shaft A second rotating shaft is rotatably installed on the frame, a second sprocket is installed on the second rotating shaft, the first sprocket and the second sprocket are connected through a transmission chain, and a cam is installed on the second rotating shaft. The invention can significantly reduce the labor intensity of operators and effectively ensure that waste plastic bottles are better squeezed.

Owner:谢森涛

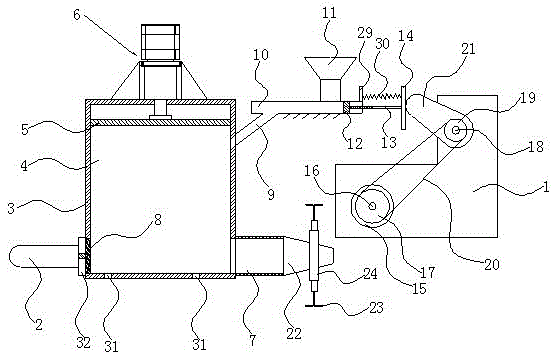

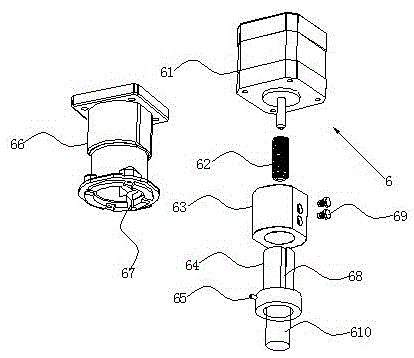

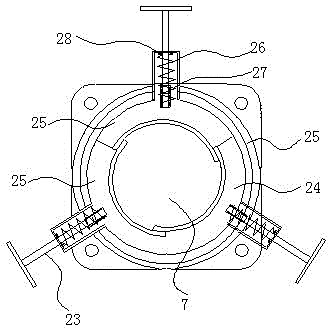

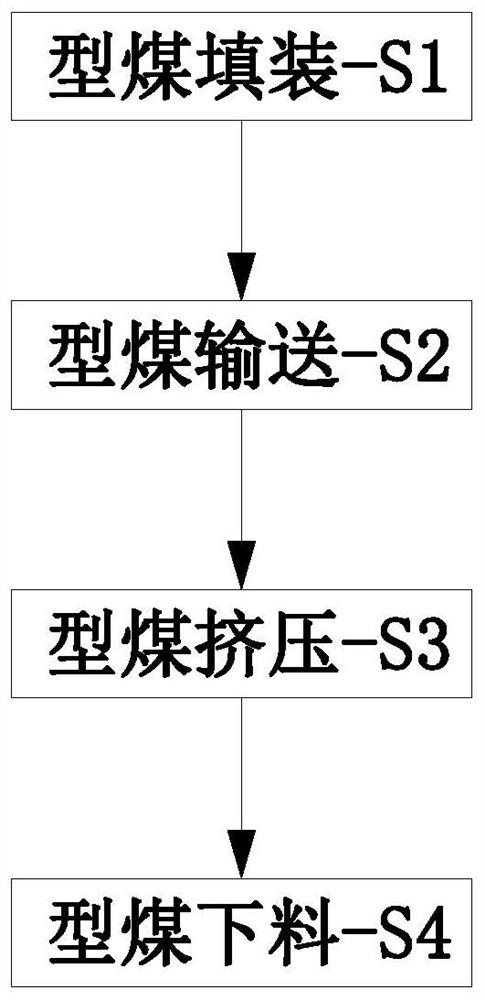

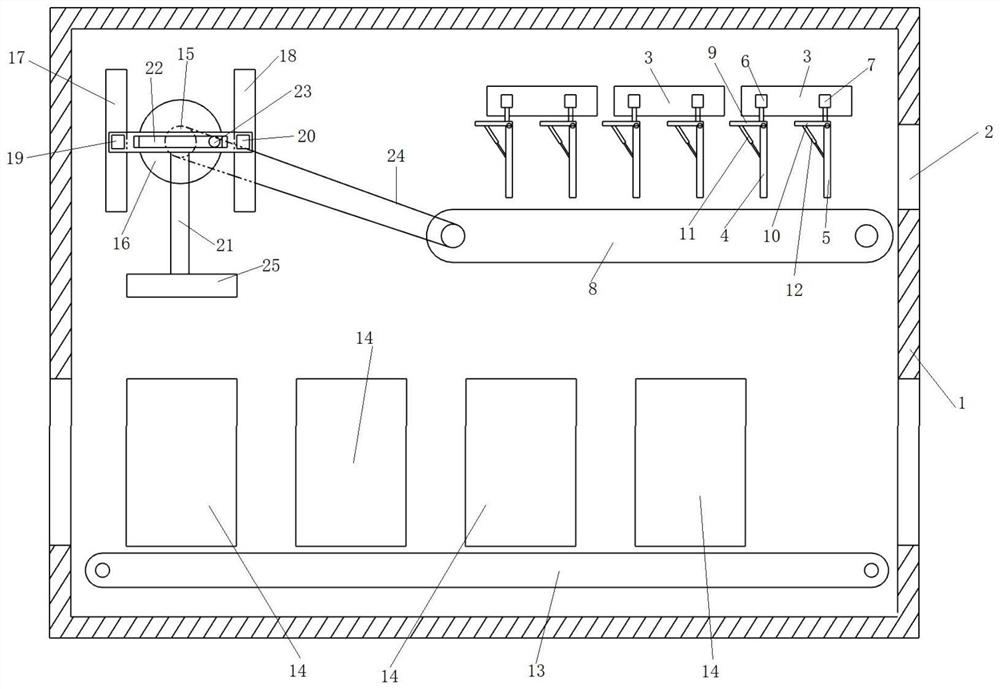

Extrusion forming production and processing method for biomass briquette

ActiveCN113211850AEasy to processAvoid shortageWaste based fuelWorking-up peatProcess engineeringMaterials science

The invention provides an extrusion forming production and processing method for biomass briquette. An extrusion forming production and processing method for the biomass briquette is adopted by the extrusion forming production and processing method for the biomass briquette as follows: the extrusion forming production and processing device for the biomass briquette comprises a C-shaped plate, a conveying unit and an extrusion unit, wherein an opening of the C-shaped plate is arranged downwards; the conveying unit is installed on the inner wall of the lower side of the C-shaped plate; and the extrusion unit is arranged on the inner wall of the upper end of the C-shaped plate. According to the extrusion forming production and processing method for the biomass briquette, the problem that when the briquette is produced and processed at present, a double-roller extrusion device is mostly adopted to extrude and shape the briquette, but the device cannot ensure the filling rate of the briquette during extrusion processing, so that material shortage of the briquette is easily caused and later use is influenced can be solved; and the problem that when common briquette is produced and processed, the briquette is mostly subjected to double-roller extrusion treatment, and the extrusion mode cannot be used for performing pressure maintaining and shaping on the briquette, so that the extrusion effect is reduced, and cracking, slag falling and the like of the briquette are easily caused can be solved.

Owner:武安市佳耐达洁净型煤有限公司

A transportation device for corn cutting and bundling machine

ActiveCN111837658BEasy to move in reverseEasy to increase occupancyConveyorsBalingAgricultural engineeringStructural engineering

The invention discloses a transportation device for a corn cutting and bundling machine, which comprises a casing, a material inlet is opened on the right side of the casing, a first conveyor belt is arranged inside the casing, and a plurality of extruding components are arranged above the first conveyor belt. The pressing assembly includes a first chute opened on the inner side wall of the casing, a first slider and a second slider are slidably arranged in the first chute, and a first fixed block connected with the first slider is arranged above the first conveyor belt. The right side of the first fixed plate is hinged with the first left conveying plate, the second fixed plate connected with the second slider is arranged above the first conveyor belt, the right side of the second fixed plate is hinged with the first right conveying plate, the first The chute is provided with a driving part, and the driving part drives the first slide block and the second slide block to move towards each other or oppositely. The invention facilitates reducing the gaps between the corn stalks, thereby increasing the existing space.

Owner:知运保(亳州)技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com