Roll roller extruding machine for producing waterproof rolls with feeding mechanism

A feeding mechanism and waterproof membrane technology, which is applied in the directions of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of increasing complexity and inability to improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

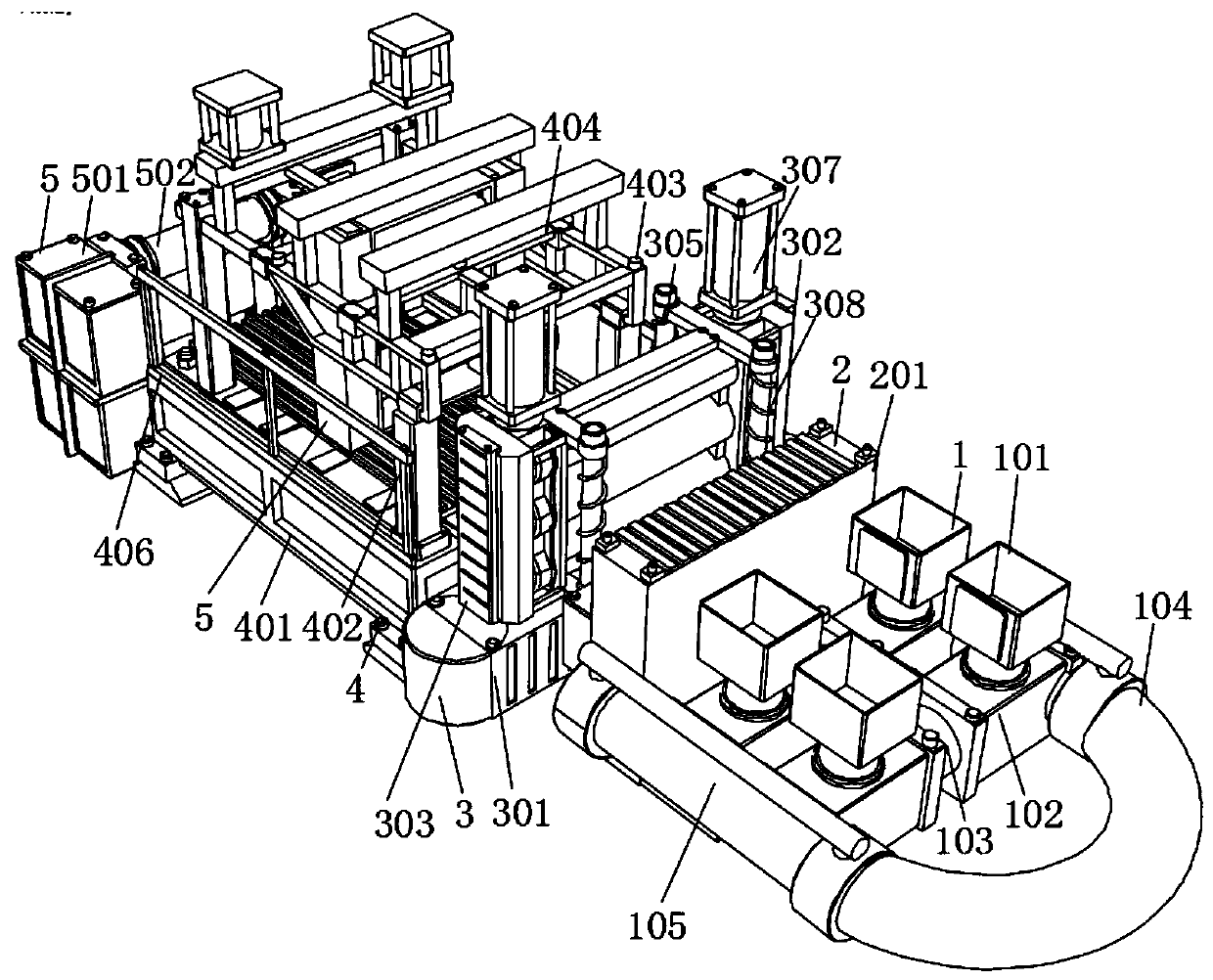

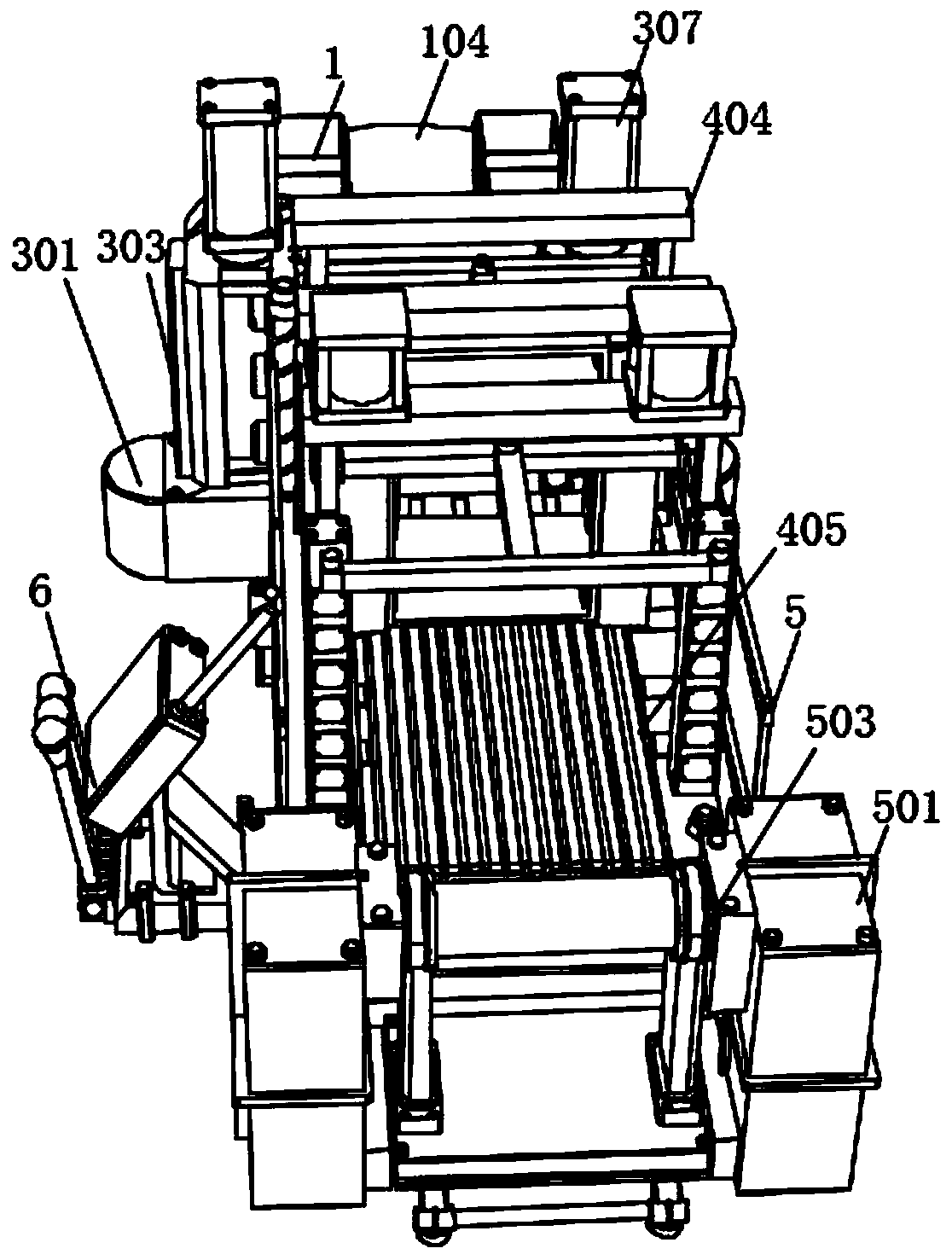

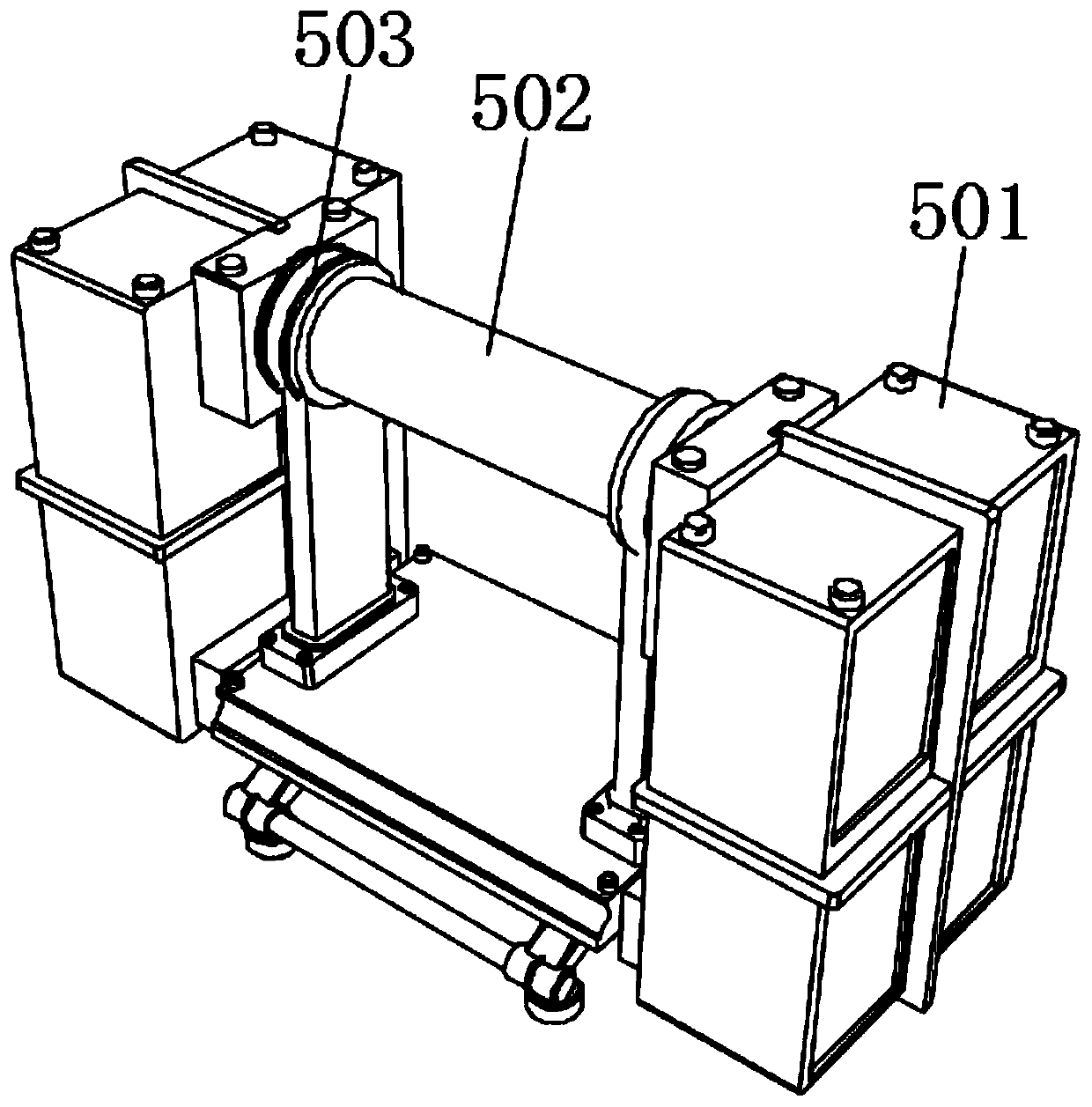

[0028] see Figure 1-5 , the present invention provides the following technical solutions: including a feeding mechanism 1, a shaping hot-pressing mechanism 2 is fixedly installed at the end of the feeding mechanism 1, and a roller extruder is fixedly installed on the side wall surface of the shaping hot-pressing mechanism 2 3. A transport mechanism 4 is fixedly installed on the back of the side wall of the roller extruder 3 , and a winding mechanism 5 is fixedly installed at the end of the transport mechanism 4 .

[0029] In this embodiment, the feeding mechanism 1 includes several injection funnels 101 for storing raw materials. The bottom ends of the several injection funnels 101 are connected with a heat-pressed pump, and the outer cover of the heat-pressure pump is connected with a protective box 102. The side walls of the protective box 102 are fixedly connected with feeding conduits 103, and the ends of several feeding conduits 103 are connected with the discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com