Tobacco product for heating and preparation method thereof

A technology of tobacco products and tobacco, which is applied in the field of tobacco and can solve problems such as unfavorable insertion and removal, pollution of the heating chamber, unfavorable chamber cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

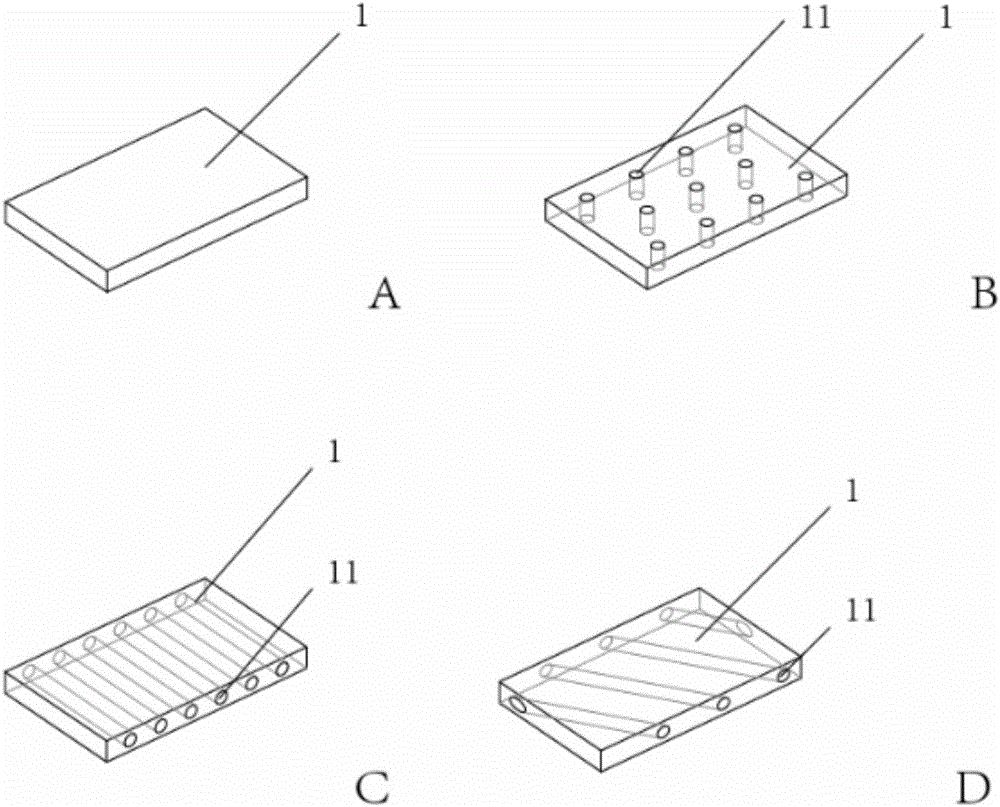

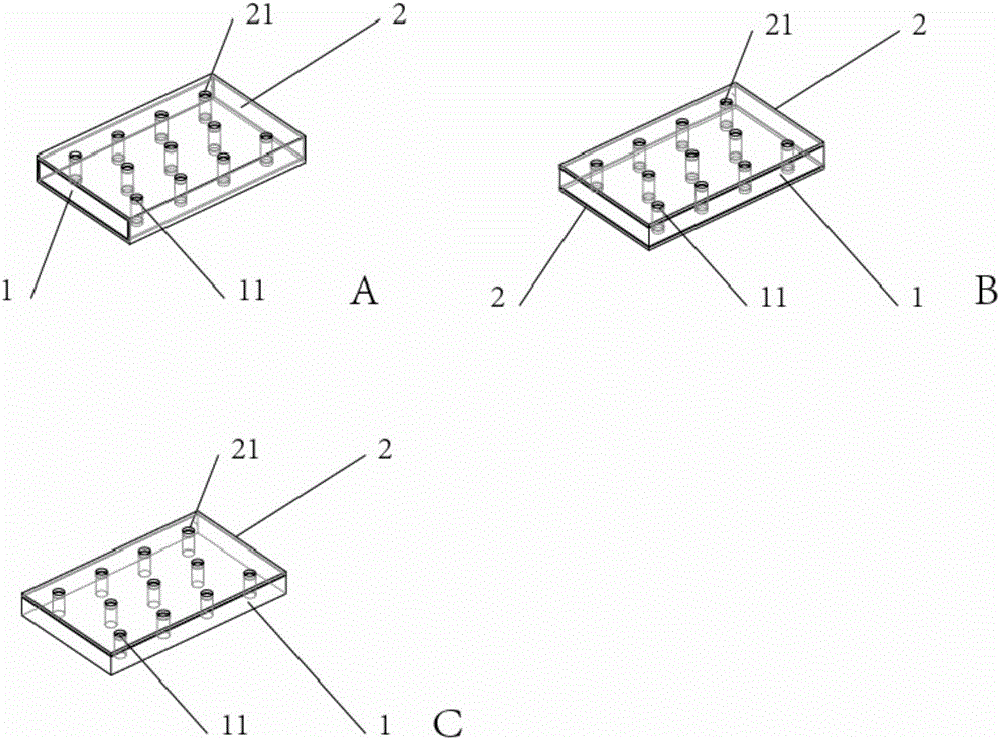

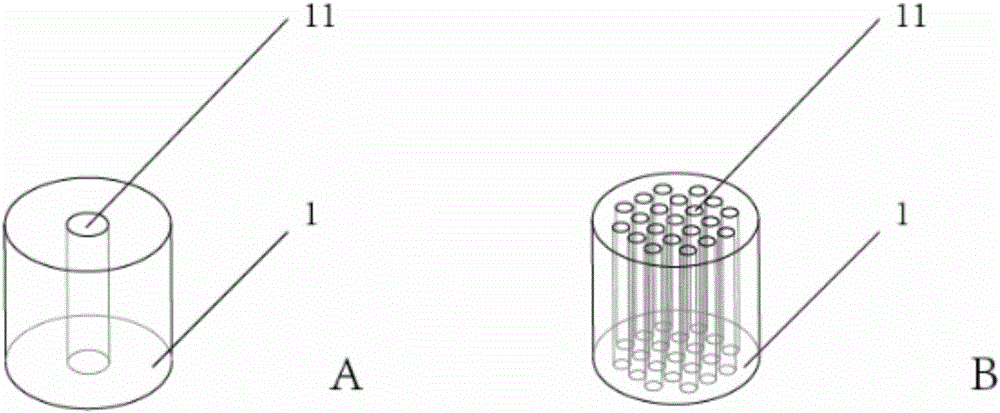

Method used

Image

Examples

Embodiment 1

[0106]Take 1000g of flue-cured tobacco and grind it with 860 type whole grain milling machine, and the particle size of tobacco powder obtained after grinding is ≤250 μm. Get 200g glycerin and 10g tobacco essence (sandalwood) by proportioning, mix with tobacco powder. Among them, the mass ratio of flue-cured tobacco to glycerin is 5:1, and the mass ratio of tobacco essence to flue-cured tobacco is 1:100. When mixing, use a YXDJ-200 heating type mixing mixer, the mixing time is 15min, and the mixing speed is 60r / min. Then the mixture was placed in a stainless steel storage tank in a room with a constant temperature and humidity for alcoholization treatment. The alcoholization temperature was 30° C., the alcoholization relative humidity was 70%, and the alcoholization time was 6 hours. Then, the alcoholized mixture is extruded with a SJ90 screw extruder with a cutting device, and then dried with a DH-SD842A tunnel type fast dryer at a drying temperature of 100 °C for a drying t...

Embodiment 2

[0109] Take 1000g of oriental tobacco and grind it with a 860-type whole grain mill, and the particle size of the tobacco powder obtained after grinding is ≤250 μm. Get 200g glycerin and 50g natural essence (peppermint fragrance) by proportioning, mix with tobacco powder. Among them, the mass ratio of oriental tobacco to glycerin is 5:1, and the mass ratio of natural essence to oriental tobacco is 1:20. When mixing, use a YXDJ-200 heating type mixing mixer, the mixing time is 15min, and the mixing speed is 100r / min. Then the mixture was placed in a stainless steel storage tank in a room with a constant temperature and humidity for alcoholization treatment. The alcoholization temperature was 30° C., the alcoholization relative humidity was 70%, and the alcoholization time was 6 hours. Then, the alcoholized mixture is extruded with a SJ90 screw extruder with a cutting device, and then dried with a DH-SD842A tunnel type fast dryer at a drying temperature of 100 °C for a drying t...

Embodiment 3

[0112] Take 1000g of tobacco flakes and grind them with a 860-type whole grain mill, and the particle size of the tobacco powder obtained after grinding is ≤250 μm. Get 300g glycerin and 30g natural essence (eucalyptus oil) by proportioning, mix with tobacco powder. Among them, the mass ratio of tobacco flakes to glycerin is 10:3, and the mass ratio of natural essence to tobacco flakes is 3:100. When mixing, use a YXDJ-200 heating type mixing mixer, the mixing time is 15min, and the mixing speed is 300r / min. Then the mixture was placed in a stainless steel storage tank in a room with a constant temperature and humidity for alcoholization treatment. The alcoholization temperature was 30° C., the alcoholization relative humidity was 70%, and the alcoholization time was 6 hours. Then, the alcoholized mixture is extruded with a SJ90 screw extruder with a cutting device, and then dried with a DH-SD842A tunnel type fast dryer at a drying temperature of 100 °C for a drying time of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com