Patents

Literature

63results about How to "Improve dispersion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-ion power battery positive electrode material slurry preparation method

The present invention discloses a lithium-ion power battery positive electrode material slurry preparation method, which comprises mixing various components of a positive electrode material slurry, wherein the mixing specifically comprises: 1, using a three-shaft stirrer to carry out dry mixing on a positive electrode active substance, an electric conduction agent and a binder, 2, adding partial solvent to the three-shaft stirrer, and carrying out primary dispersion, and 3, transferring the dispersed slurry to a planetary stirrer, adding the remaining solvent, and carrying out secondary dispersion. According to the present invention, the dry mixing process is used, the solvent is gradually added to the solid powder, and the high solid content of the system is utilized to improve the dispersion effect; and the three-shaft stirrer and the planetary stirrer are combined so as to achieve the good mixing effect.

Owner:WANXIANG 123 CO LTD

Method for dispersing complex conducting agent in electrode slurry for lithium ion capacitor

ActiveCN104658757AImprove dispersion effectThe process steps are simpleHybrid capacitor electrodesElectrolytic capacitorsCvd grapheneLithium-ion capacitor

The invention discloses a method for dispersing a complex conducting agent in an electrode slurry for a lithium ion capacitor. The method comprises the following steps: (1) material weighing: weighing 0.5-14.5% of graphene, 5.5-14.5% of a carbon nano tube and the balance of conducting carbon black, weighing N-methylpyrrolidone which is 4-9 times of the mass of the complex conducting agent, and weighing a surfactant which accounts for 5-15% of the mass of the complex conducting agent, wherein the grapheme, the carbon nano tube and the conducting carbon black constitute the complex conducting agent, and all the materials are weighed for standby application; (2) step-by-step material adding for dispersion: mixing the complex conducting agent with N-methyl-pyrrolidone and the surfactant for ultrasonic dispersion firstly, adding the carbon nano tube for first high-speed dispersion secondly, and adding the grapheme for second high-speed dispersion finally. The method is simple in process sequence, high in operability, and suitable for industrialized production, and has the advantages that the complex conducting agent can uniformly disperse to form a three-dimensional conducting network structure, and the power performance can be obviously improved when the relatively high energy density of capacitance is retained.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

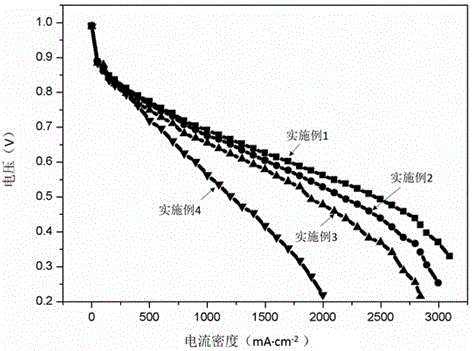

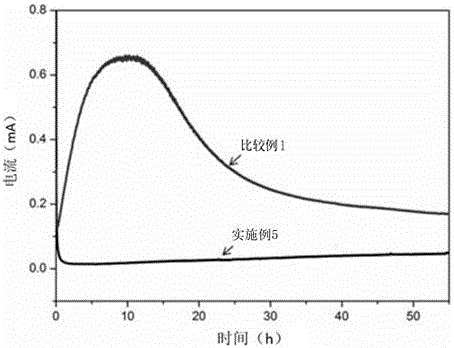

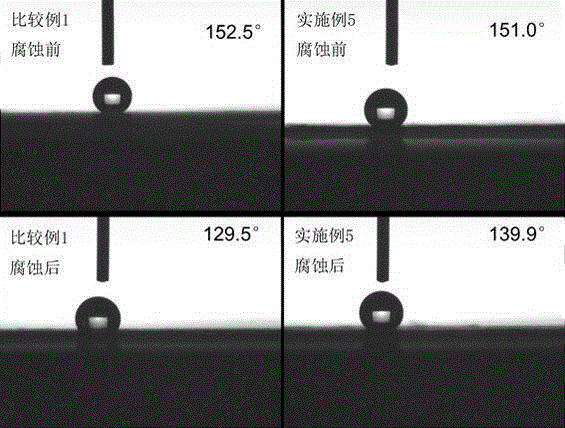

Preparing method for corrosion-resistant gas diffusion layer of fuel cell

InactiveCN105119007AImprove dispersion effectOvercome reunionCell electrodesSolid electrolyte fuel cellsCorrosion resistantEmulsion

The invention discloses a preparing method for a corrosion-resistant gas diffusion layer of a fuel cell. The gas diffusion layer is composed of a micropore layer and a supporting layer. The preparing method includes the following steps: metallic oxide nano-powder is added into a dispersing-agent-containing aqueous solution, and stirring and ultrasonic dispersion are carried out till even suspension liquid is formed; then water repellent emulsion is added, and stirring is carried out till micropore layer slurry is formed; one side of the supporting layer is evenly coated with the micropore layer slurry, and low-concentration water repellent emulsion is sprayed to the other side of the supporting layer; the object is dried and placed into a nitrogen-charged dryer to be sintered, and the gas diffusion layer is obtained. By means of the gas diffusion layer obtained with the preparing method, it is effectively guaranteed that conductive materials and hydrophobic materials in the micropore layer slurry are evenly dispersed, the gas diffusion layer has the proper hydrophilic performance and the proper hydrophobic performance accordingly, the corrosion resistance and the stability of the gas diffusion layer are improved, and cost is reduced.

Owner:HUANGHE S & T COLLEGE

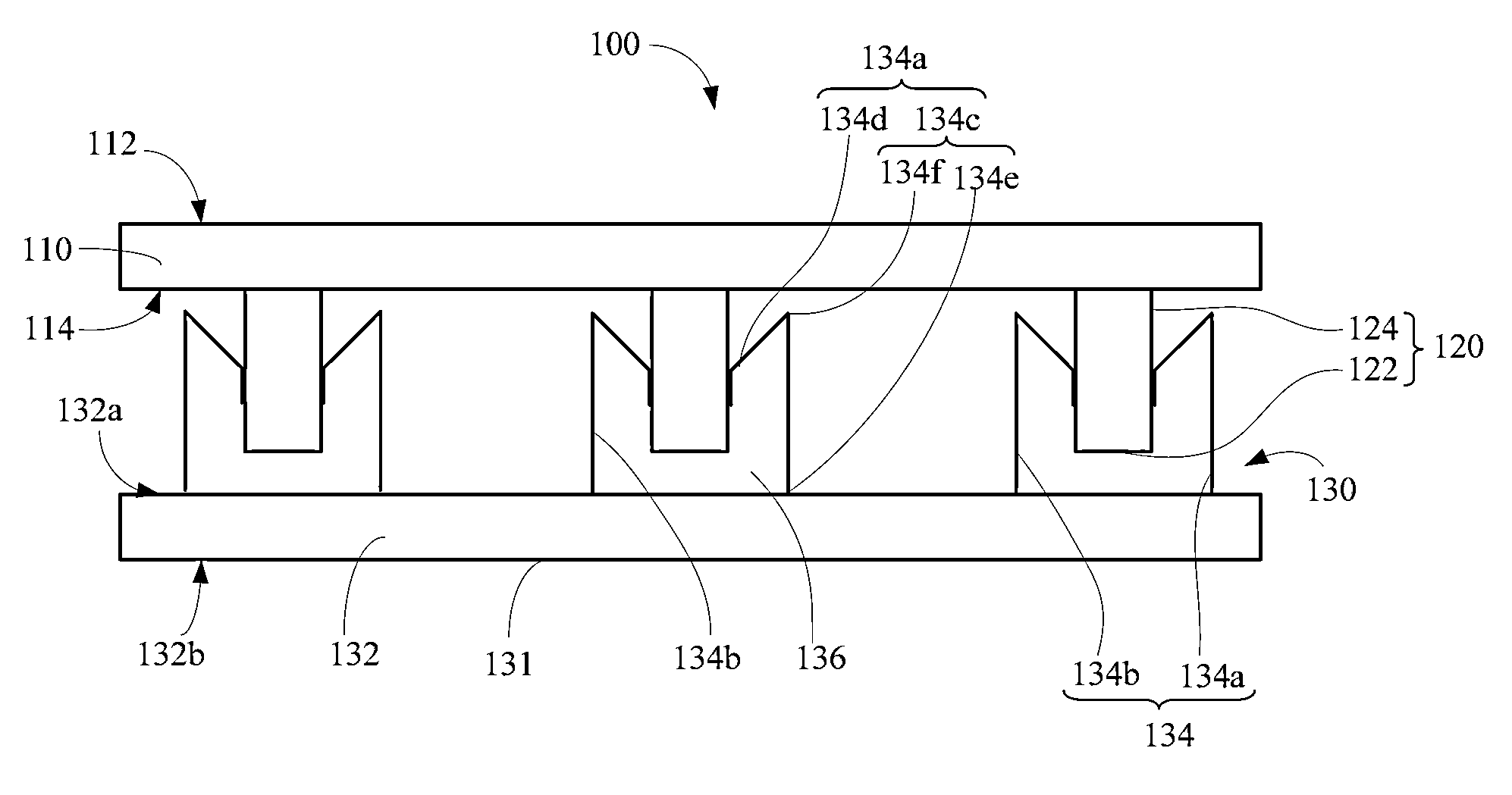

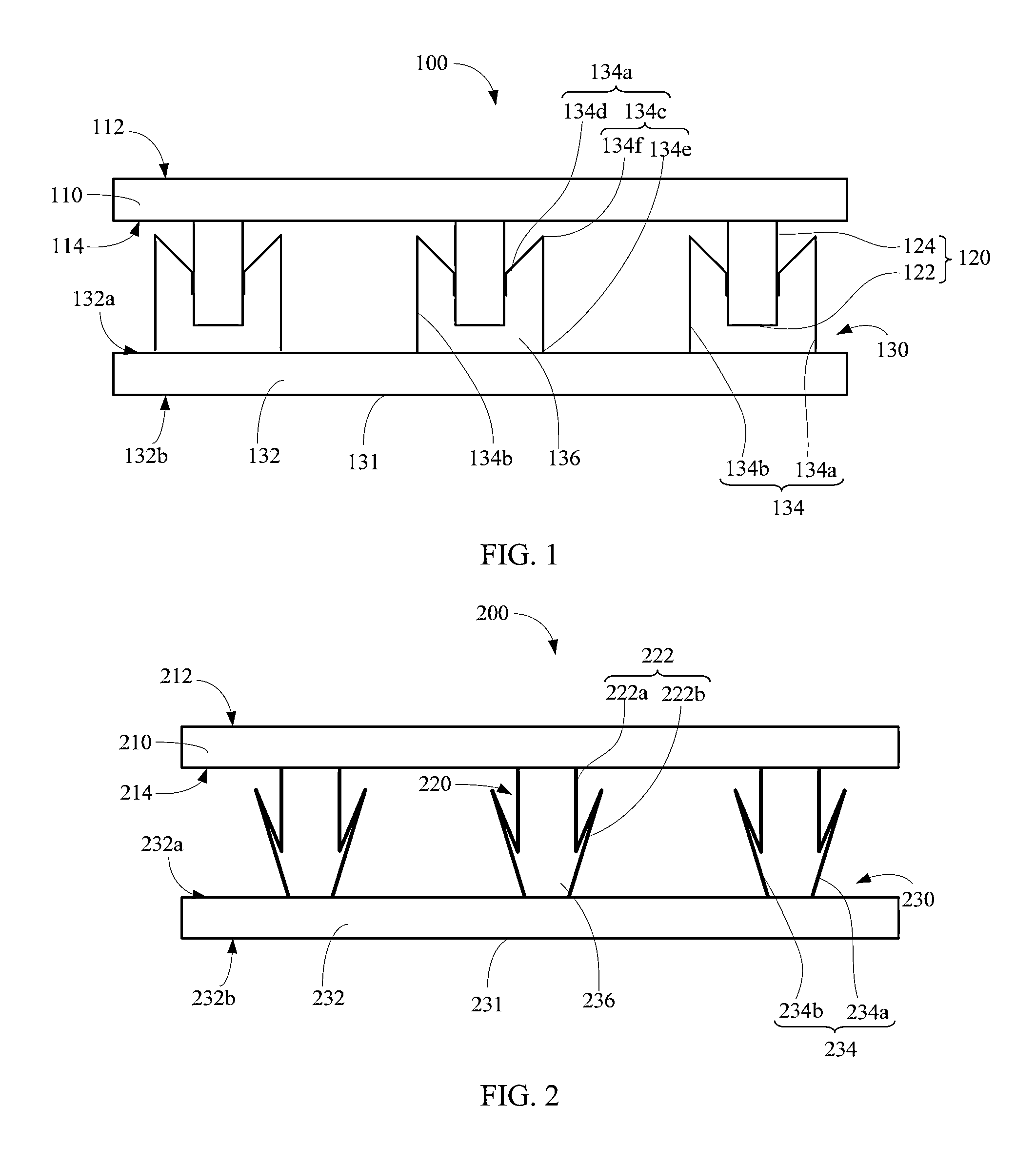

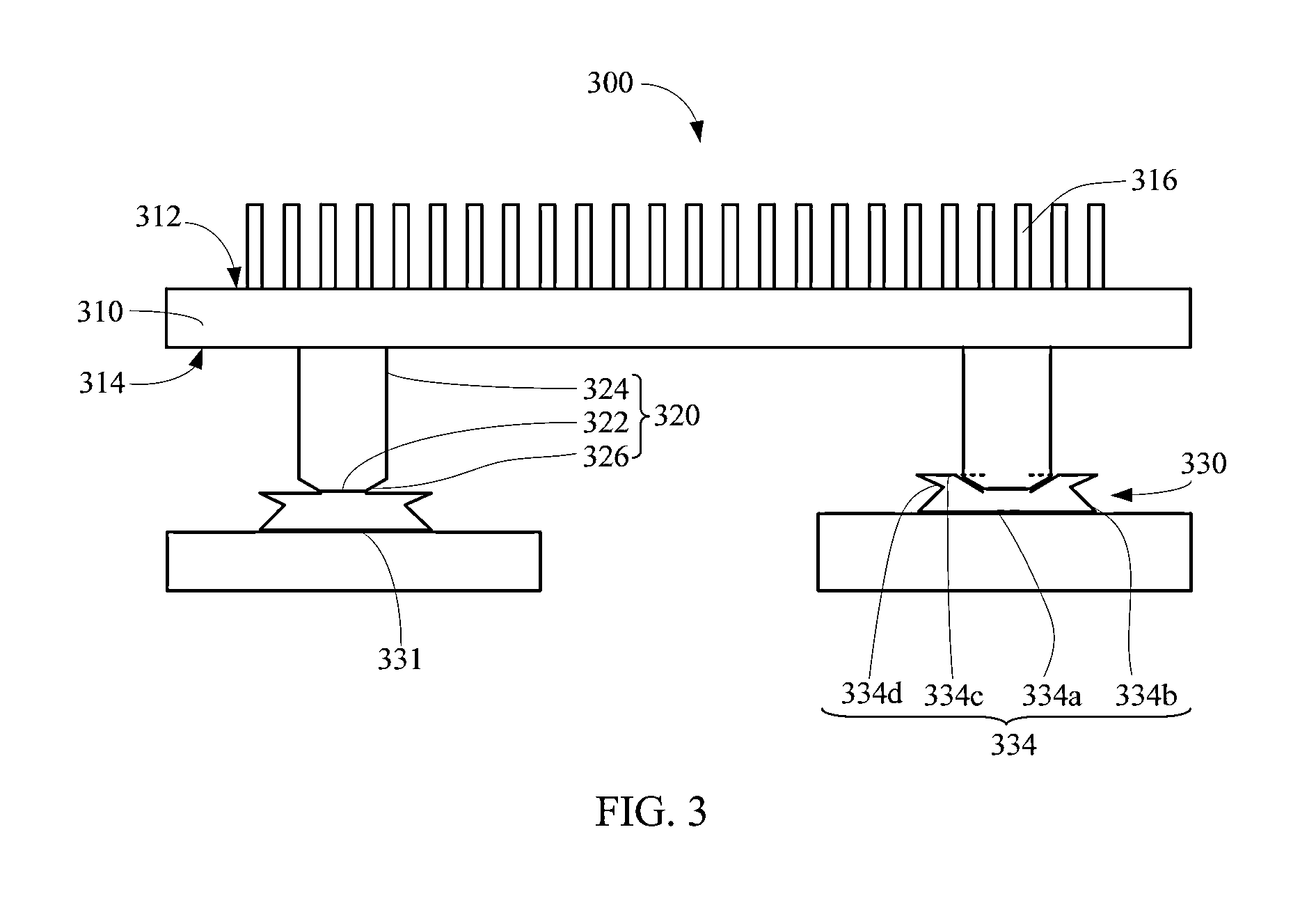

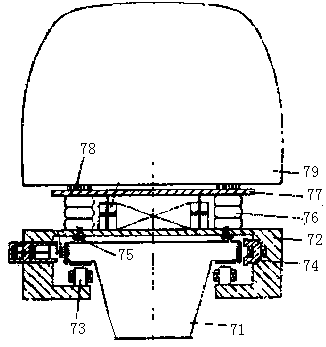

Heat conducting device and electronic device applying the same

InactiveUS20130235529A1Efficient conduction of heatImprove dispersion effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat conducting

A heat conducting device, comprising a first heat conducting board and a heat conducting structure, the first heat conducting board comprising an upper heat conducting arm provided on one surface of the first heat conducting board, the heat conducting structure slidably abutting against the upper heat conducting arm of the first heat conducting board to form a contact surface through which heat transfer is realized, the heat conducting structure comprising a heat conducting surface, wherein the heat conducting structure is used to keep the relative position between the first heat conducting board and the heat conducting surface, allow the varying of the distance between the first heat conducting board and the heat conducting surface of the heat conducting structure through relative sliding between the upper heat conducting arm and the heat conducting structure.

Owner:HUAWEI TECH CO LTD

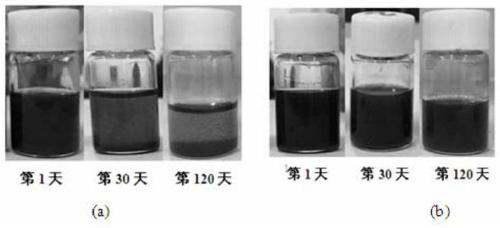

Preparing method of perfluoroalkylpolyether oil-based magnetofluid

InactiveCN103337329AImprove dispersion effectNot easy to ageMagnetic liquidsOrganic/organic-metallic materials magnetismMutual solubilityActive agent

The invention discloses a preparing method of perfluoroalkylpolyether oil-based magnetofluid and belongs to the technical field of materials and material preparation. According to the preparing method of the perfluoroalkylpolyether oil-based magnetofluid, nanometer ferroferric oxide magnetic particles are synthesized with the method of precipitation, modification is carried out with fluorine ether surface-active agents during the synthesis, cleaning is carried out with water and ethyl alcohol alternately, the magnetic particles obtained can be dispersed in transition liquid, the surface-active agents used for assisting the dispersion, carrier liquid and the magnetic particles are dissolved mutually by means of the transition liquid, the transition liquid is eliminated in the heating process, and then the perfluoroalkylpolyether oil-based magnetofluid with a good dispersing effect is obtained. The perfluoroalkylpolyether oil-based magnetofluid manufactured with the method is suitable for vacuum dynamic packing, capable of meeting the demanding requirements for a super-quiet and high-temperature environment, good in waterproof property, good in oil-proof property, and good in acid and alkali resistance.

Owner:江苏海纳精密装备有限公司

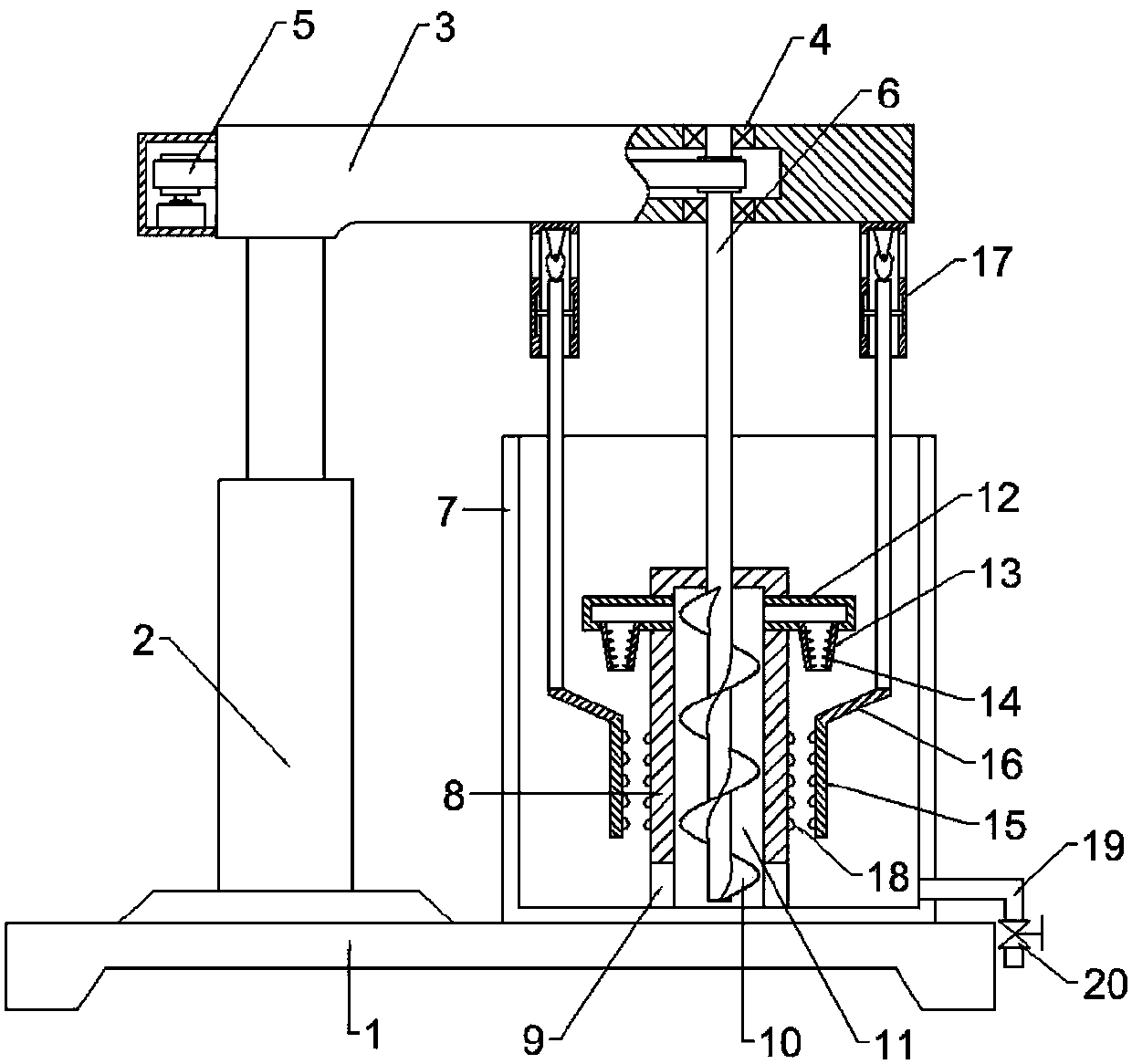

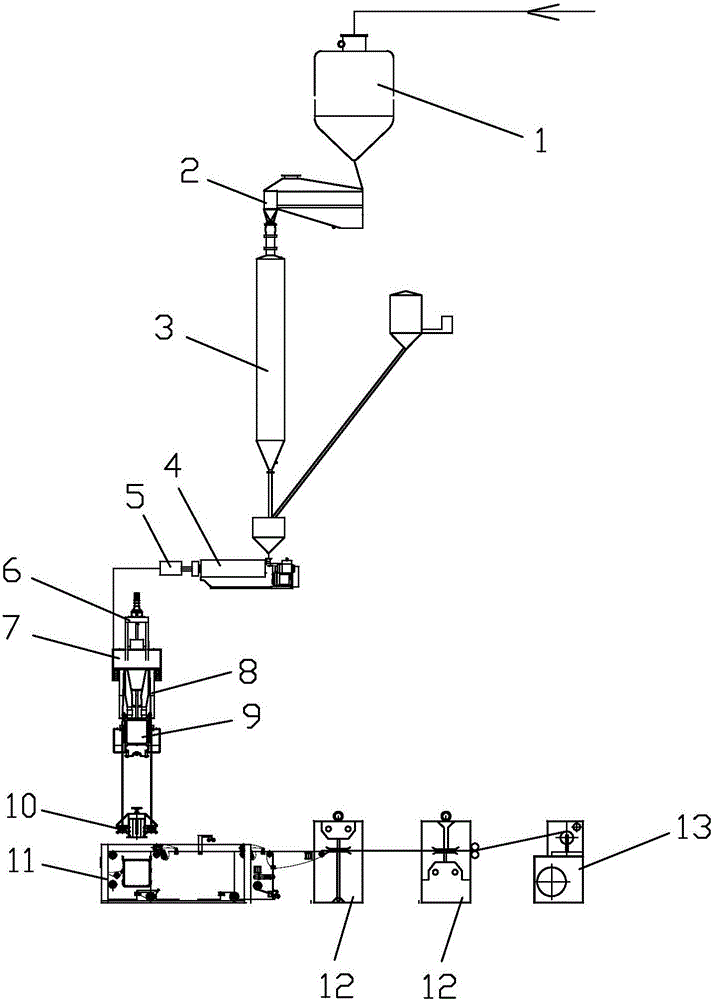

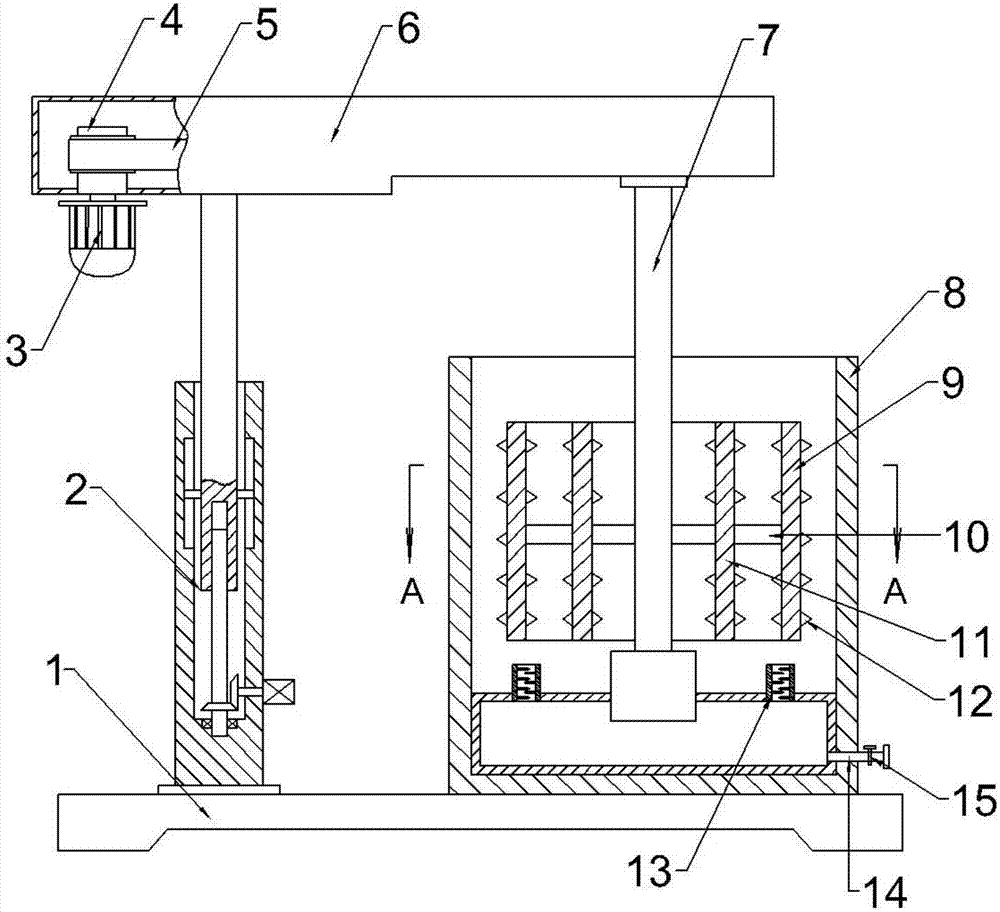

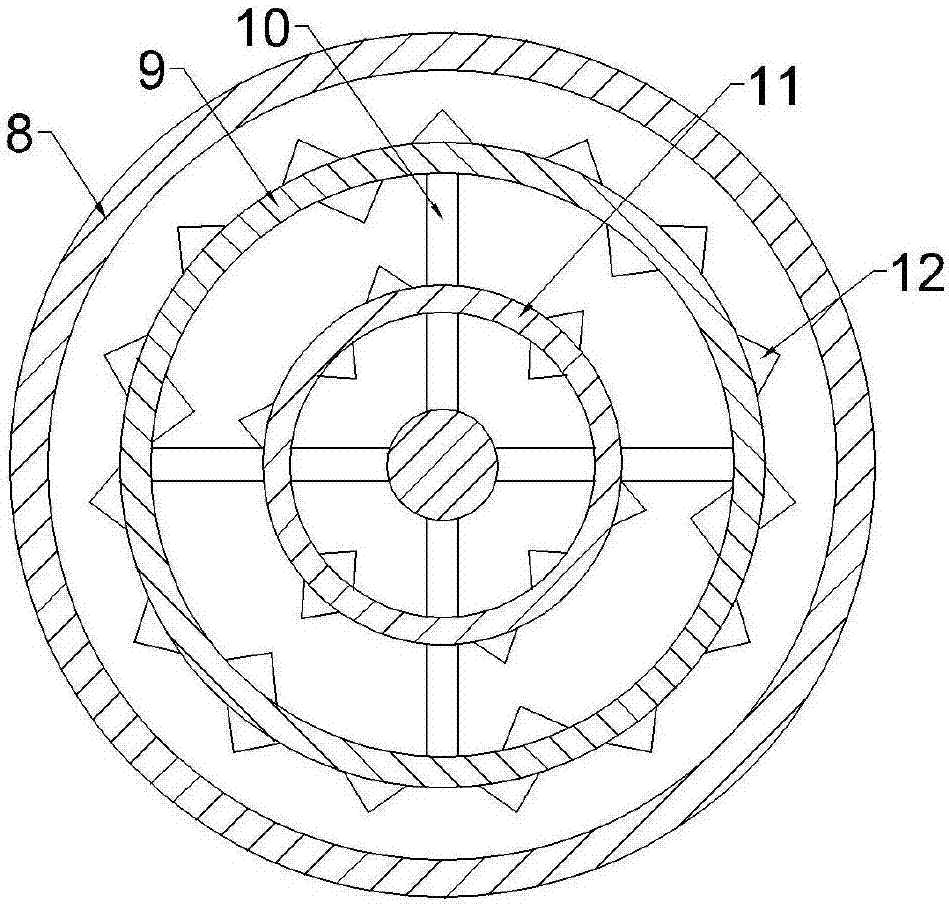

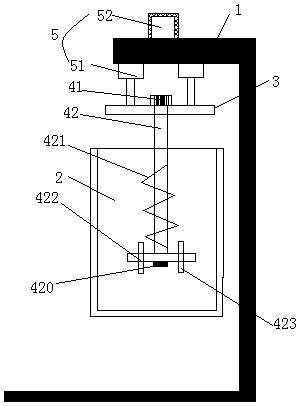

An extrusion type building coating production device based on cam driving

InactiveCN107890787AIncrease impactImprove dispersion effectFlow mixersTransportation and packagingPower unitEngineering

An extrusion type building coating production device based on cam driving is disclosed. The device includes a pedestal. The pedestal is provided with a hydraulic prop. The top of the hydraulic prop isprovided with a cantilever beam. The cantilever beam is provided with a power unit. The right end of the cantilever beam is provided with a pair of bearings. A first rotating shaft is mounted in thebearings and is connected to the power unit. The lower part of the first rotating shaft is disposed in a dispersing barrel. The dispersing barrel is on the pedestal. A mounting column is fixedly connected at the inner middle of the dispersing barrel. The inside of the mounting column is provided with a cavity. The bottom of the mounting column is provided with a material feeding through hole. Thefirst rotating shaft is in the cavity, and is provided with a spiral conveyer. Beneficial effects of the device are that the inside diameters of ejecting round tables decrease gradually so that the flow velocity of coating gradually increases, thus increasing the impact force, and effectively improving dispersing effects; and dispersing raised parts inside the ejecting round tables can achieve certain dispersing effects on the coating.

Owner:丰桢敏

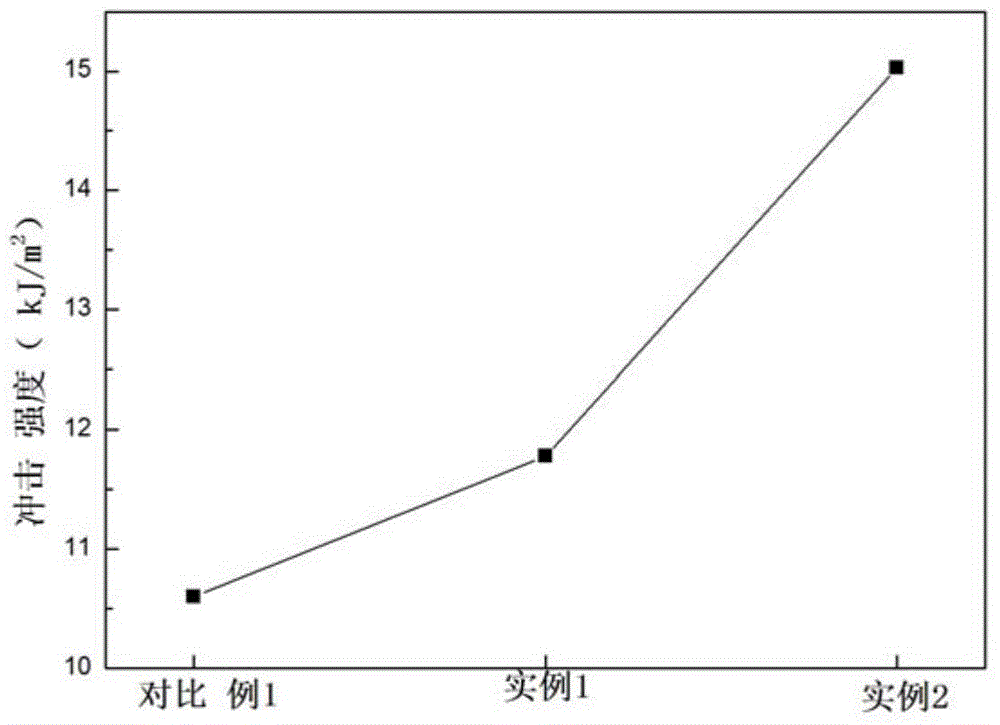

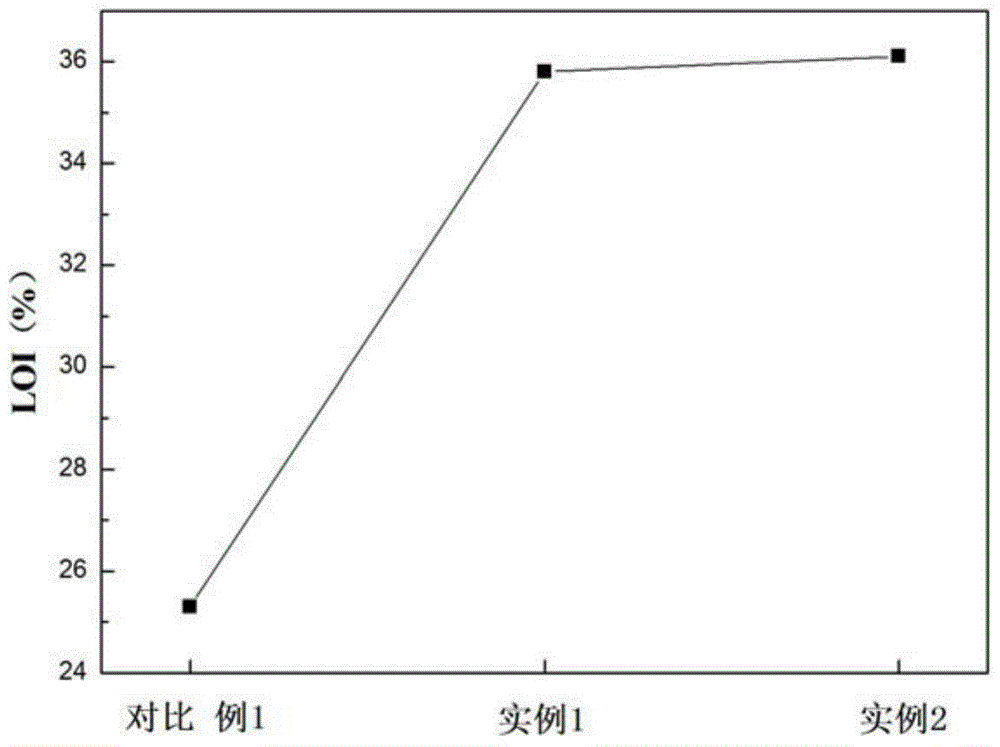

Flame-retardant bismaleimide resin composition and preparation method thereof

The invention discloses a flame-retardant bismaleimide resin and a preparation method thereof, and belongs to the field of polymer composite materials. The flame-retardant bismaleimide resin comprises the following raw materials by weight: 50 to 60 parts of a bismaleimide resin, 40 to 50 parts of an allylic compound, 1 to 10 parts of a flame retardant, and 0.5 to 1.5 parts of carbon nano-tubes. The bismaleimide resin prepared according to the preparation method is excellent in flame retardant property, so that the problem of low flame-retardant grade of the conventional bismaleimide resin is greatly solved; moreover, the flame-retardant bismaleimide resin is outstanding in heat resistance and excellent in mechanical property, so as to serve as a high-performance resin matrix, an adhesive, an insulating paint and the like in the high-tech fields such as the aerospace field, the electronic apparatus field, and the transportation and communication field, and be wide in application range. The preparation method is simple to operate, environmental-friendly and high in feasibility.

Owner:EAST CHINA UNIV OF SCI & TECH

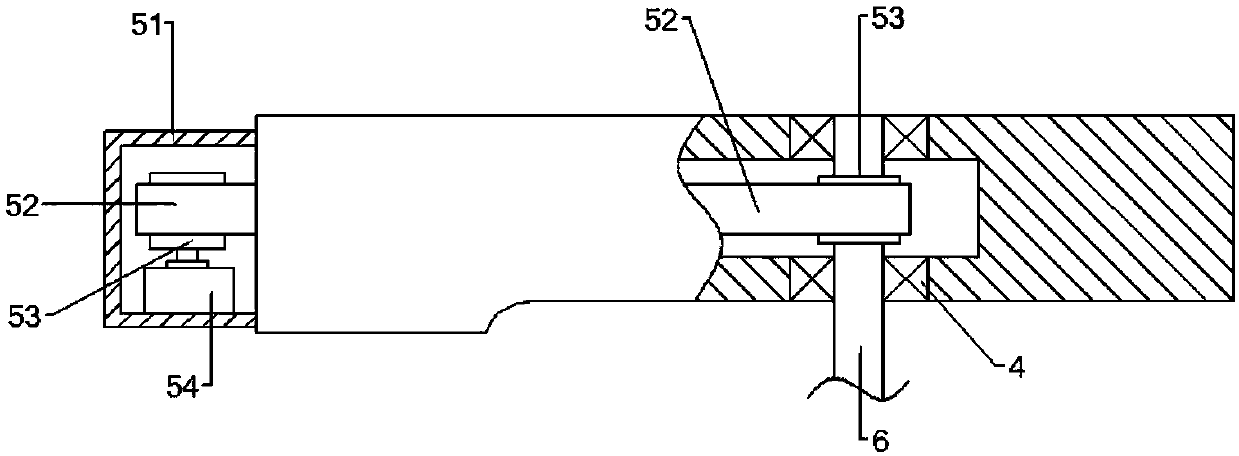

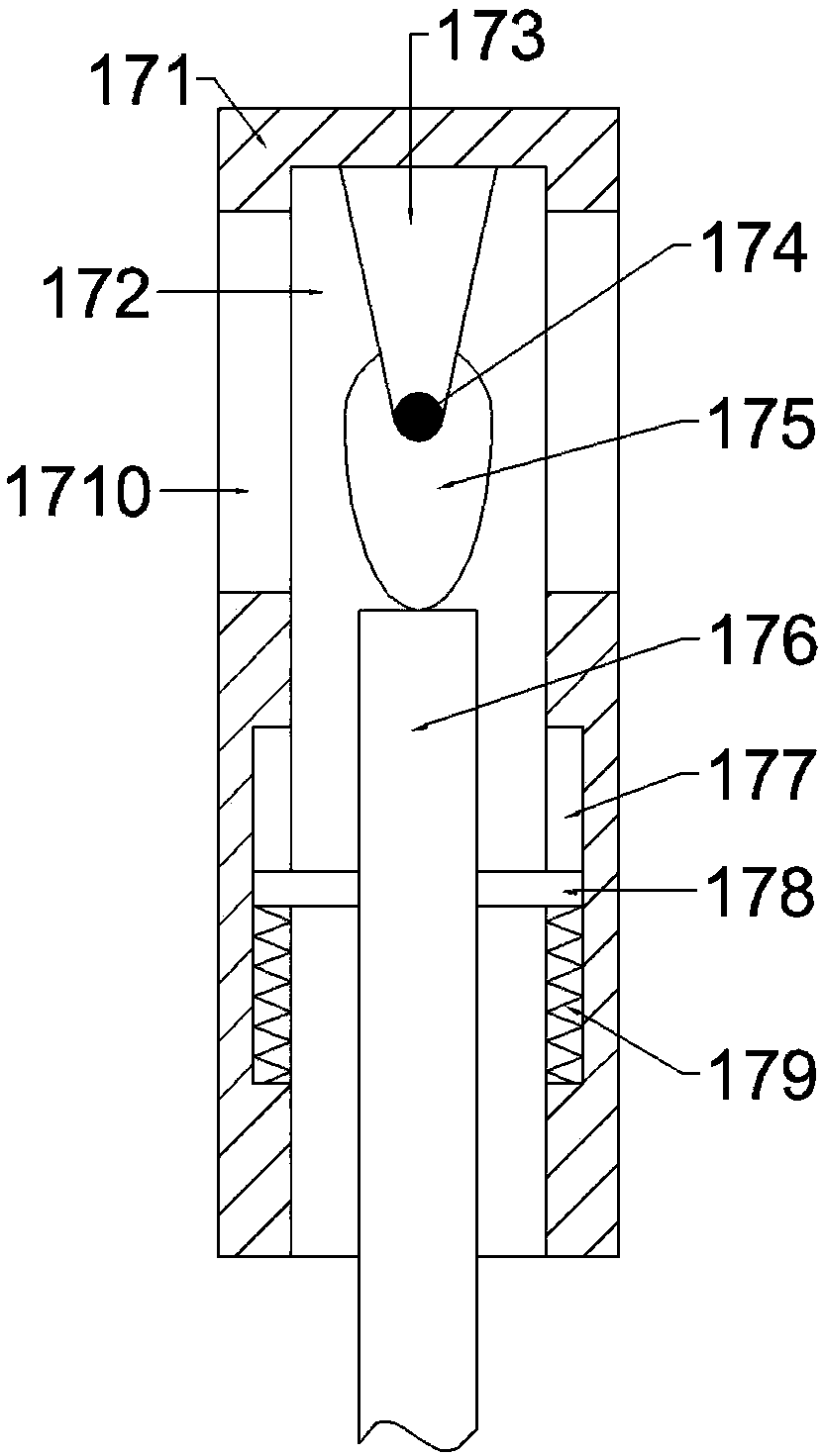

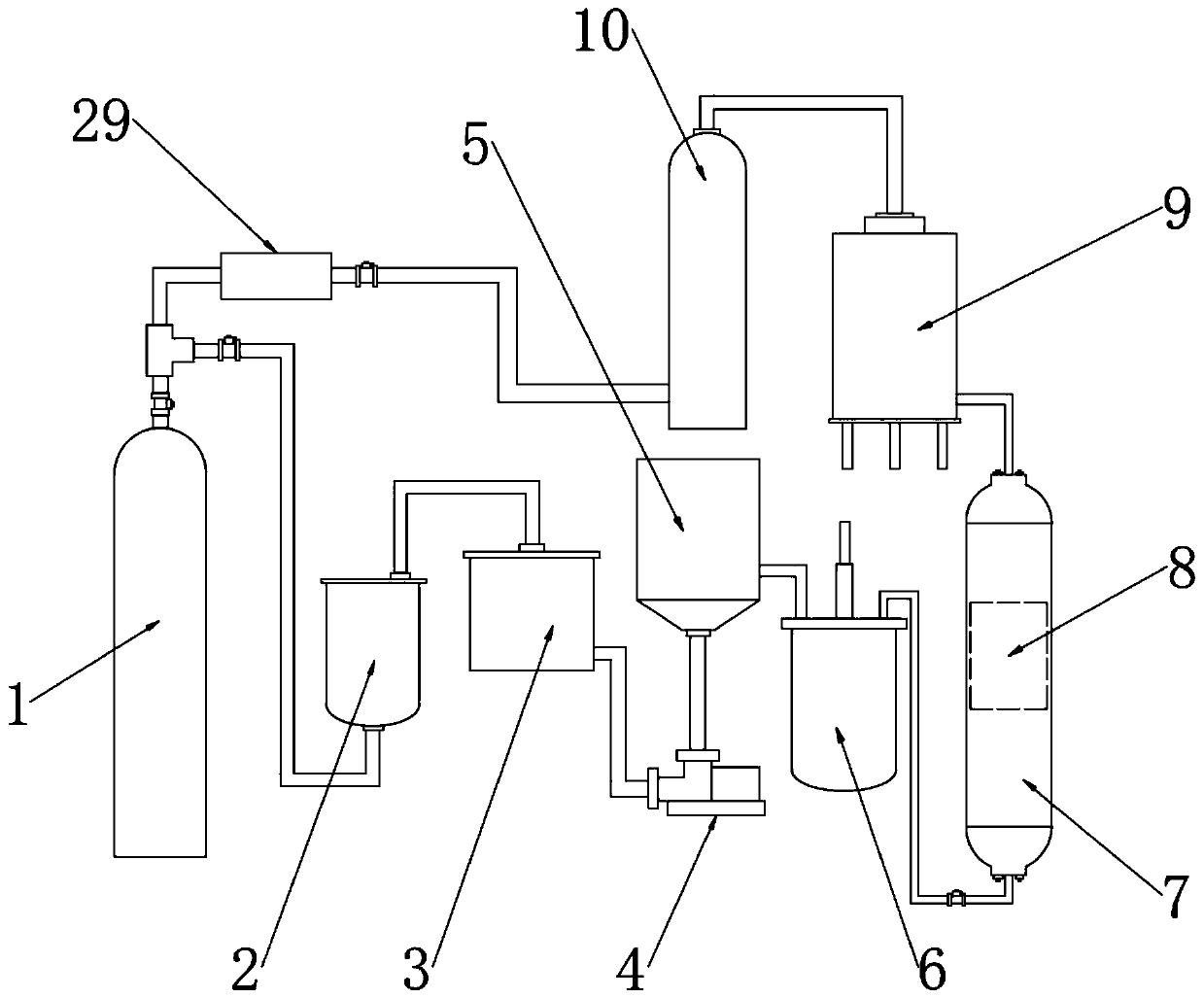

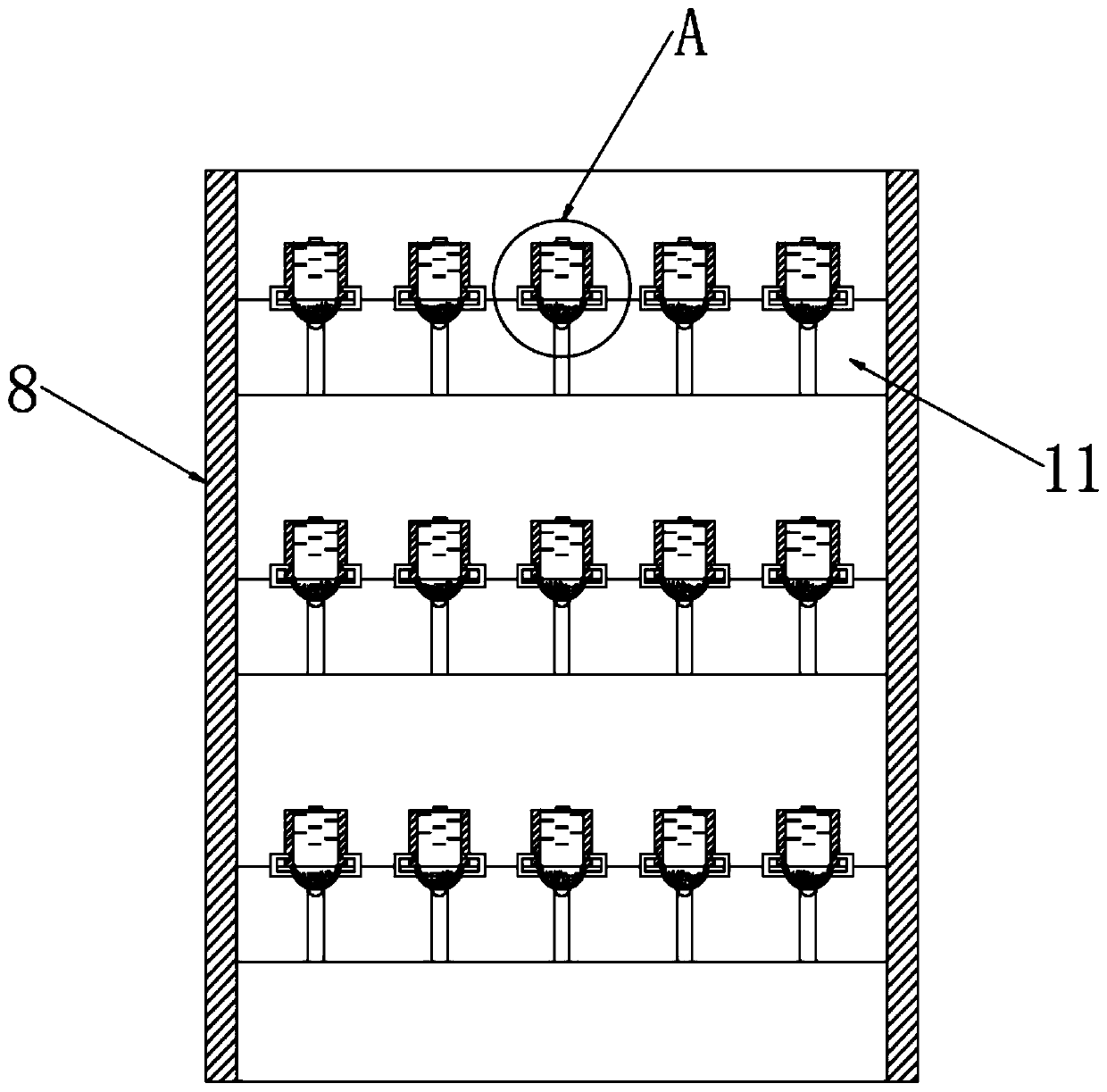

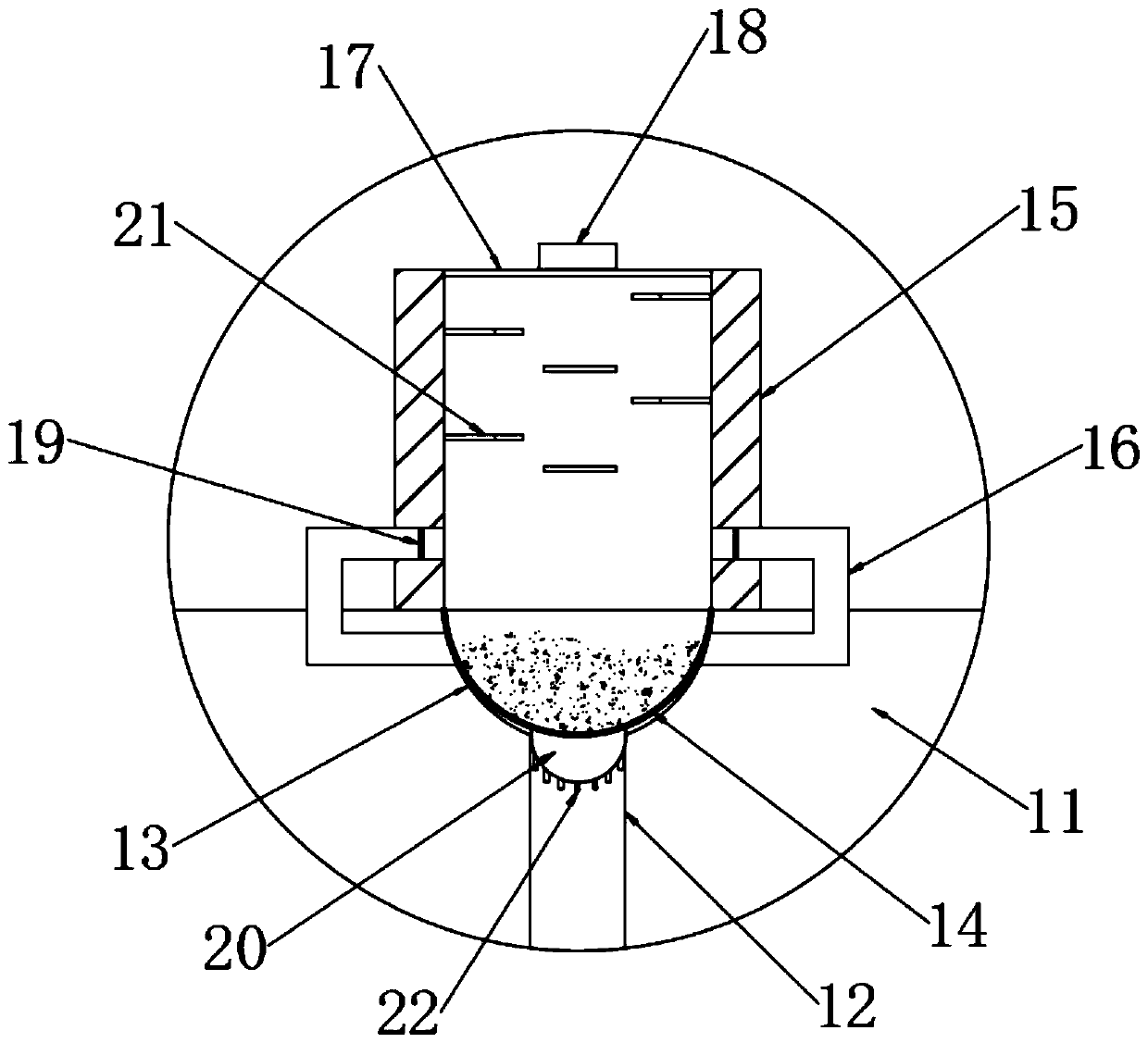

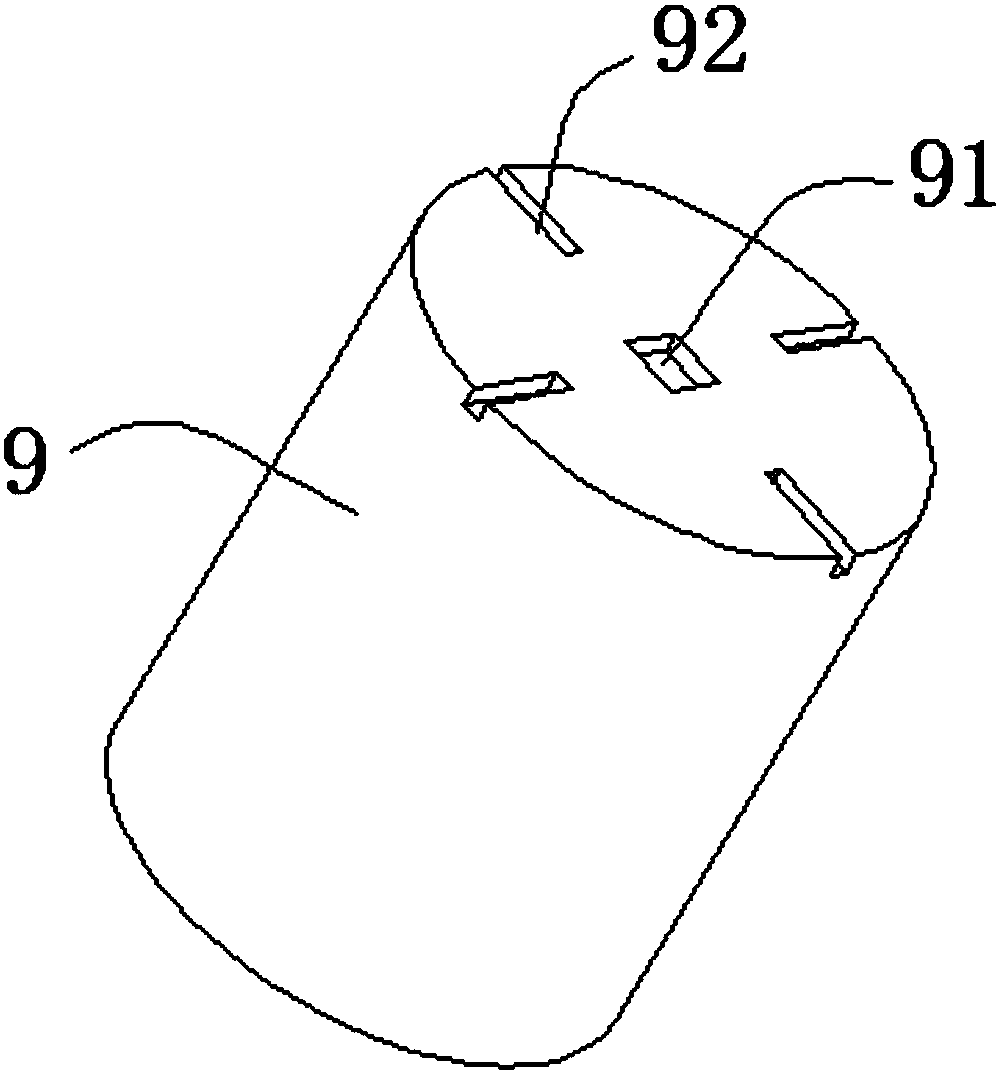

Suspension point contact type supercritical extraction device

PendingCN111282309AImprove extraction rateImprove dispersion effectSolid solvent extractionComposite materialSupercritical fluid

The invention discloses a suspension point contact type supercritical extraction device. The invention belongs to the technical field of supercritical extraction. A hanging basket static extraction mode in a traditional extraction kettle can be abandoned; the deformation characteristic of an empty throwing material receiving film is utilized; contained materials are shaken and thrown in the air; apowdery material is promoted to keep a dispersed suspended state; then, supercritical fluid sequentially passes through a limited space to be in full contact with the materials; the extraction rate of effective substances is obviously improved; through the characteristics of the empty throwing material receiving film and the assisting action of an assisting hanging piece, on one hand, the material dispersion effect is improved, meanwhile, the posture can be changed by overturning, the material is in contact with the supercritical fluid, the materials are fully extracted, and extraction dead corners are not prone to occurring; on the other hand, the situation that the extraction effect is affected due to the static adhesion phenomenon of the powdery materials can be avoided; the one-way extraction rate of the materials can be greatly increased, and the extraction efficiency is greatly improved.

Owner:NANTONG HUAAN SUPER CRITICAL EXTRACTION

Preparation method of ultraviolet aging resistant polyester spunbonded needle-punched geotextile

InactiveCN106087255AImprove dispersion effectImproves UV aging resistanceSpinning solution de-aeratingGeotextilesGeotextilePolyester

The invention discloses a preparation method of an ultraviolet aging resistant polyester spunbonded needle-punched geotextile. The preparation method includes steps of preparation of ultraviolet aging resistant masterbatch and preparation of a spunbonded needle-punched geotextile. Specifically, the step of preparation of the ultraviolet aging resistant masterbatch includes: preparation of polyester chips and functional auxiliaries, high-speed mixing, twin-screw extrusion, pulling, water cooling, pelletizing and drying, wherein the functional auxiliaries include a light stabilizer; the step of preparation of the spunbonded needle-punched geotextile includes: polyester chip feeding, pre-crystallizing, drying, mixing with the ultraviolet aging resistant masterbatch, screw extrusion, prefiltering, melt spinning, cross air blowing, air drawing, yarn swaying for net forming, needling for reinforcement and winding for cloth forming. By mixing of various ultraviolet aging resistant auxiliaries, synergistic effects are achieved, and ultraviolet aging resistance is improved; in addition, by the method, a dispersion effect of the ultraviolet aging resistant auxiliaries in fibers is effectively improved, and accordingly ultraviolet aging resistance of a product is improved, service life of the product is prolonged greatly, and utilization requirements are met.

Owner:FOSHAN S L P SPECIAL MATERIALS

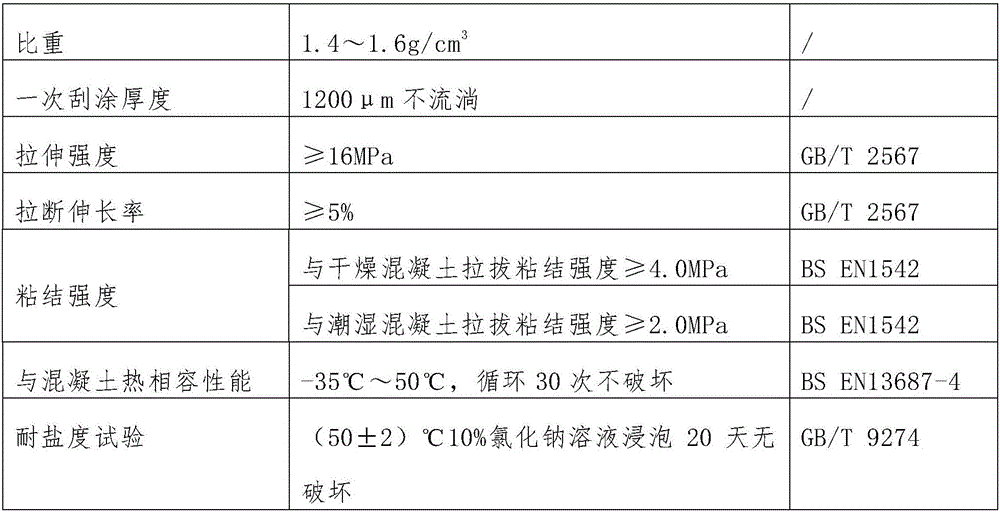

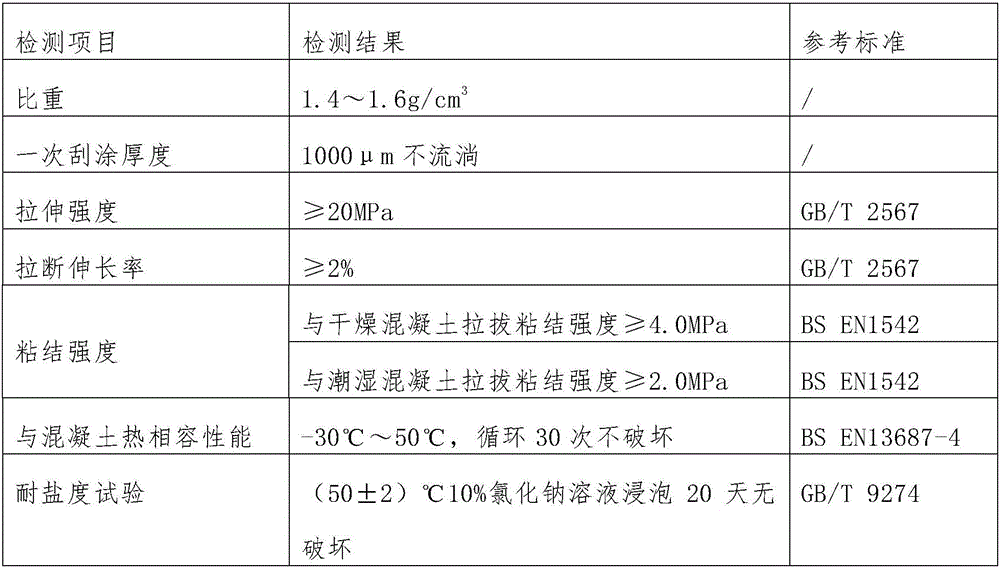

Low-temperature-resistant solvent-free and thick-film type epoxy anticorrosive paint

ActiveCN106433397AImprove dispersion effectEnhanced thixotropic stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsSolventChemistry

The invention discloses low-temperature-resistant solvent-free and thick-film type epoxy anticorrosive paint. The paint is formed by evenly mixing a component A and a component B in a weight ratio being (2-4):1, wherein the component A comprises ingredients in parts by weight as follows: 100 parts of compound toughened epoxy resin, 10-50 parts of anti-flowing gel, 100-150 parts of pigment and filler A and 5-10 parts of an aid; the component B comprises ingredients in parts by weight as follows: 100 parts of a compound curing agent, 0-10 parts of benzyl alcohol and 80-120 parts of pigment and filler. The epoxy anticorrosive paint is free of solvents, contains no harmful substances, can be applied to inner walls of drinking water delivery concrete pipelines and sewage storage tanks, has higher low-temperature toughness and high / low-temperature thermal compatibility with concrete and has high environment adaptability, the concrete surface can be blade-coated with a coating of 1,000 mu m-1,500 mu m thick, flowing and sagging can be avoided, and the construction efficiency is greatly improved.

Owner:蓝色海洋(天津)工程技术有限公司

Immobilized ionic liquid catalyst used for preparing 5-hydroxymethylfurfural and preparation of immobilized ionic liquid catalyst

InactiveCN106475145AImprove dispersion effectHigh catalytic efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventIon

The invention belongs to the technical fields of catalyst preparation method and efficient-conversion of biomass and discloses immobilized ionic liquid catalyst used for preparing 5-hydroxymethylfurfural and preparation of the immobilized ionic liquid catalyst. The catalyst is obtained by immobilizing acidic functional ionic liquid on a carrier, wherein load of the ionic liquid on the carrier is 5%-30%; the catalyst is used for preparing 5-hydroxymethylfurfural. By the arrangement, mild conditions are achieved, operation cost is low, catalytic effect of the catalyst is good, problems about loss of the catalyst and solvent loss and the like during reaction can be effectively solved, regeneration of the catalyst is facilitated, and recycling effect is good.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing aluminum foam material

ActiveCN103898348AImprove surface propertiesImprove dispersion effectFiber structureComposite material

The invention relates to a method for preparing an aluminum foam material. The method comprises the following steps: 1) pretreatment activation of attapulgite; and 2) preparation of nano attapulgite / aluminum foam composite material. Compared with the prior art, the method has the advantages that 1) activation treatment is carried out on the attapulgite, so that the surface performance of the attapulgite powder can be improved and the disperse effect of the attapulgite powder is improved; 2) the attapulgite has a special fiber structure, can play the enhancement and toughening effects in the aluminum foam, and improves the mechanical property and the durability of the aluminum foam material; and 3) the attapulgite mineral soil is abundant and low in price. Thus, the application field is further expanded.

Owner:SUZHOU YUXI NEW MATERIAL TECH

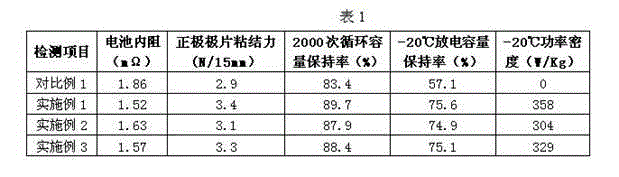

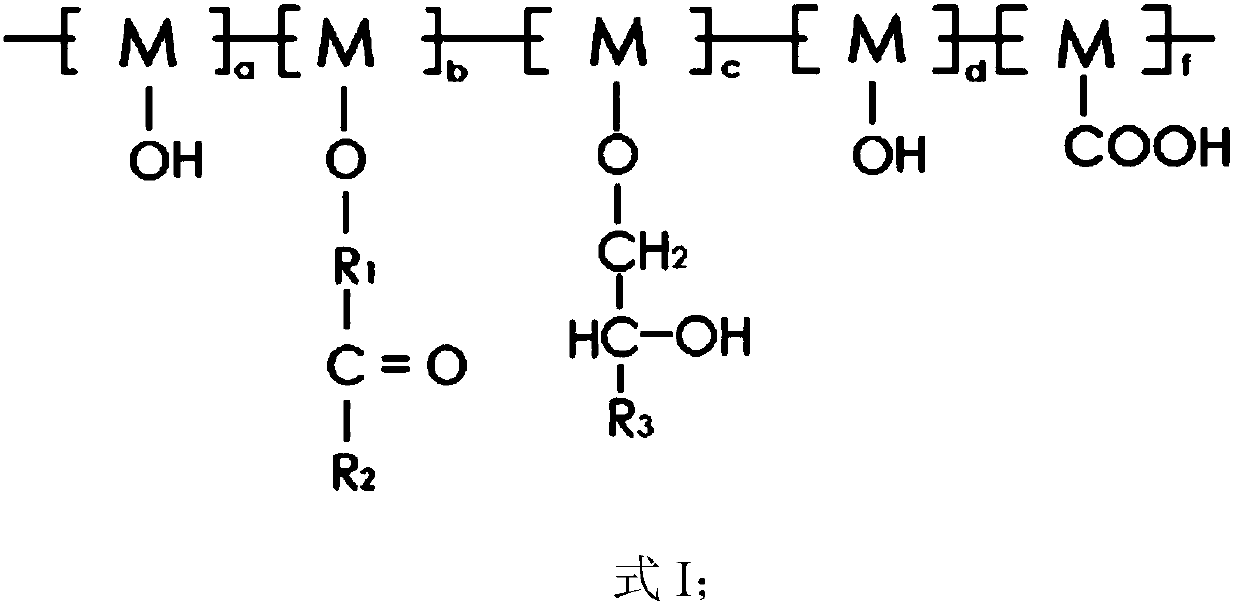

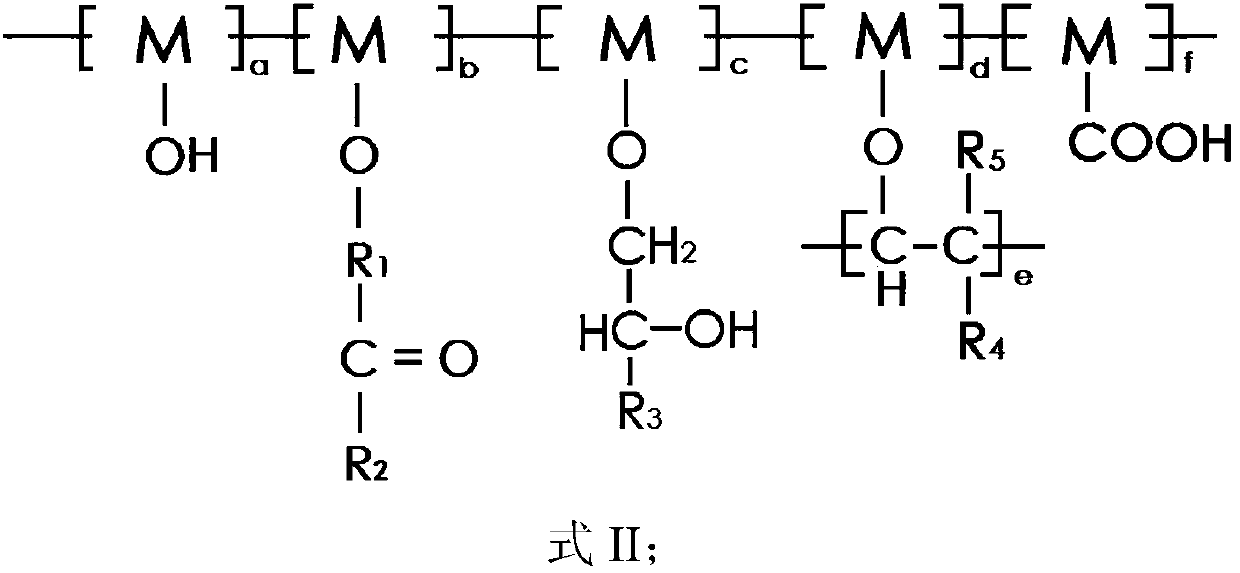

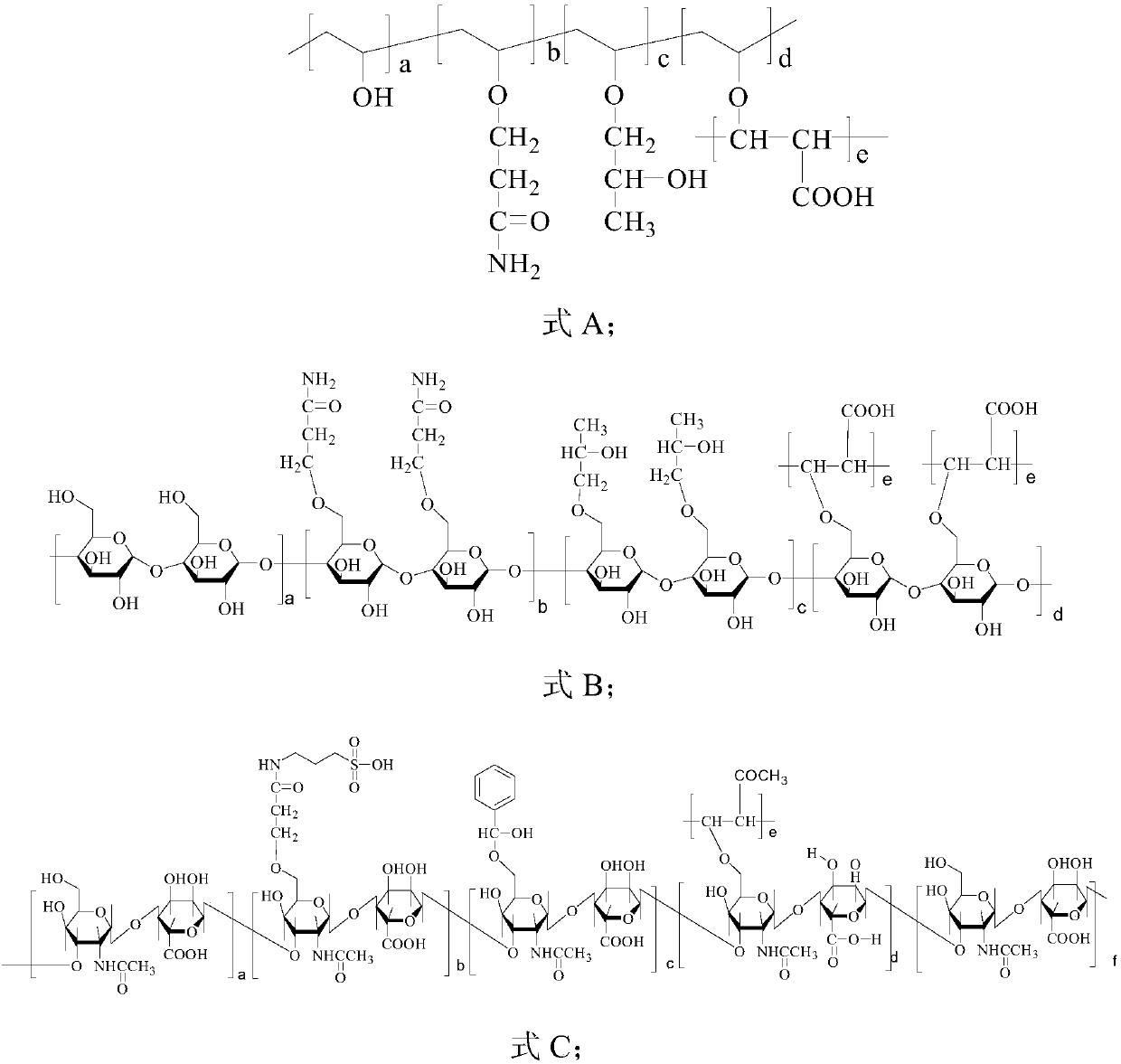

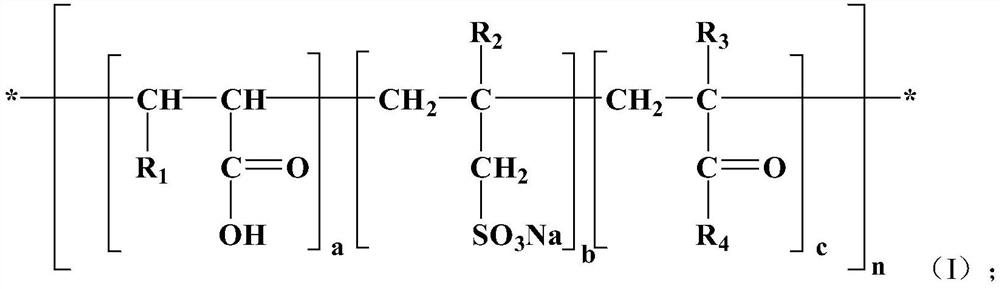

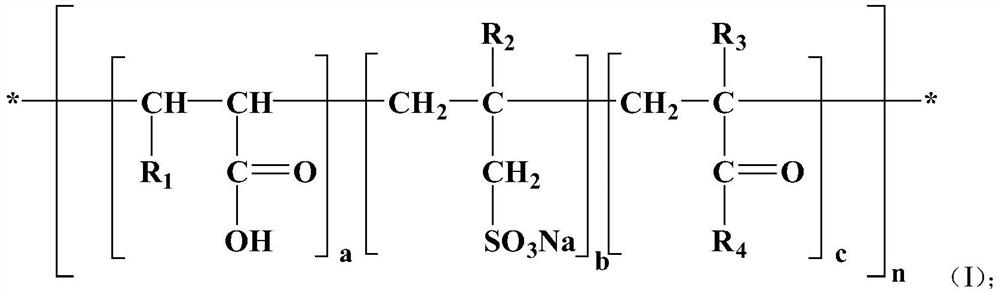

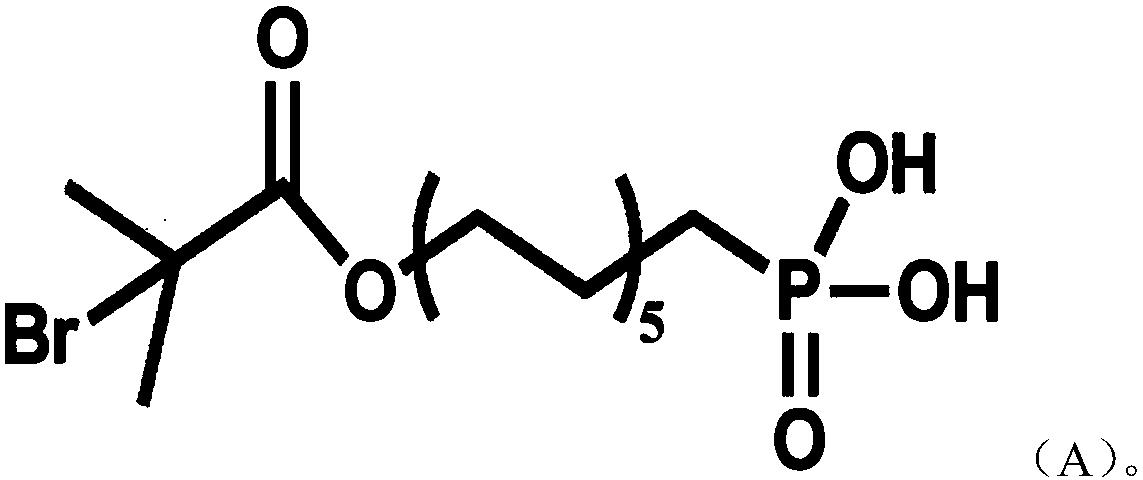

Conductive aqueous binder applied to lithium ion battery and preparation method and application thereof

ActiveCN110690451AIncreased ability to inhibit swellingImprove dispersion effectCell electrodesSecondary cellsWater soluble polymersElectrically conductive

The invention provides a conductive aqueous binder applied to a lithium ion battery and a preparation method and application thereof. The binder is in a three-dimensional grid structure formed by polymerizing conductive particles, water-soluble monomers, and water-soluble polymers. The binder provided by the invention comprises a water-soluble monomer. The water-soluble monomer can provide water solubility and adhesion and forms the three-dimensional grid structure with conductive particles and water-soluble polymers. The conductivity, water solubility, and mechanical properties of the binderprovided by the invention are further enhanced. The binder provided by the invention is safe, environmentally friendly, and low in cost, and is suitable for manufacturing positive and negative electrode pieces of the lithium ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

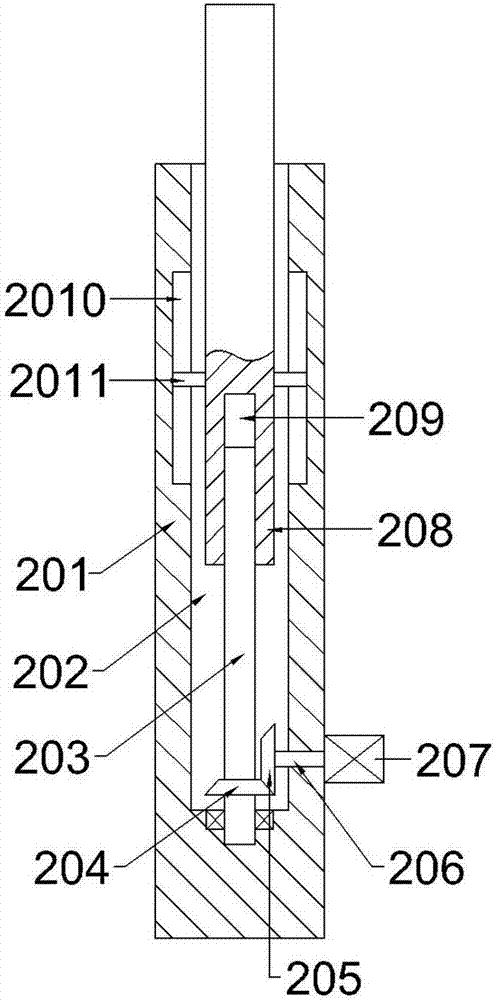

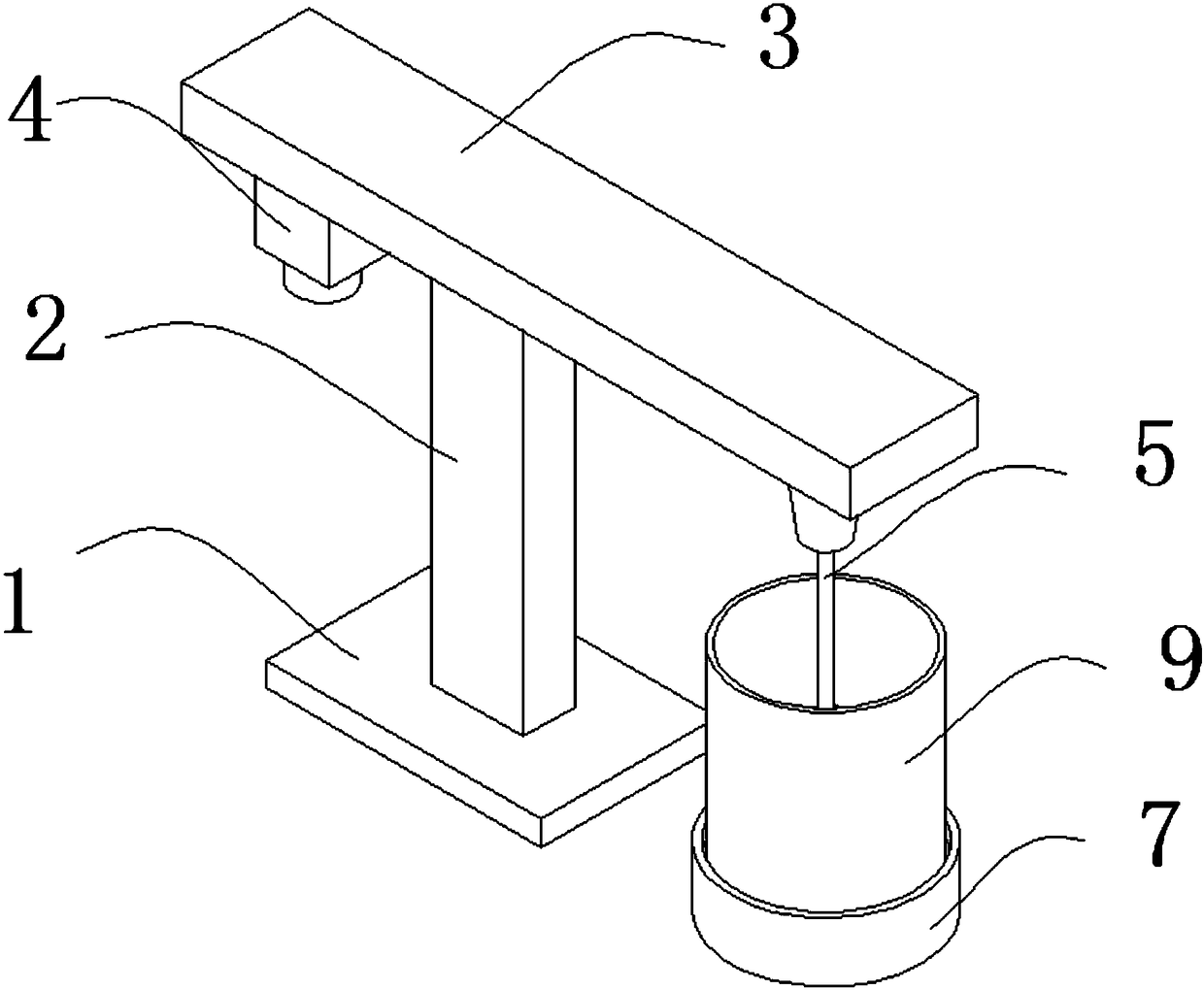

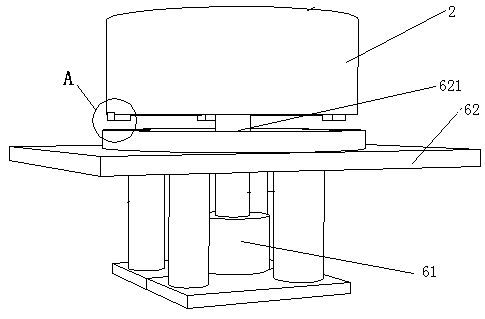

Paint dispersing equipment with spraying dispersion function

InactiveCN107469692AImprove dispersion effectGood dispersion effectShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCantilever

The invention provides paint dispersing equipment with a spraying dispersion function. The equipment comprises a base, a height adjusting device is arranged on the left side of the base, a cantilever beam is arranged at the top end of the height adjusting device, a first motor, a conveyor belt and a pair of belt wheels are arranged in the cantilever beam, one end of the conveyor belt is connected with the first motor through the belt wheels, a main rotary shaft is connected to the other end of the conveyor belt through the belt wheels, the main rotary shaft is located in a dispersing barrel, and the dispersing barrel is located on the base; an inner sleeve cylinder is arranged outside the main rotary shaft in a sleeving mode, and the inner sleeve cylinder is fixedly connected with the main rotary shaft through multiple supporting rods. The paint dispersing equipment has the advantages that when the main rotary shaft moves downward, liquid in a liquid storage shell is extruded by an extruding block, so that the liquid in the liquid storage shell sprays outward through a spraying sleeve cylinder with a certain flow speed, and in the spraying process, dispersing treatment is conducted on paint in the liquid by means of blades, so that the dispersing effect of the paint is improved.

Owner:李云

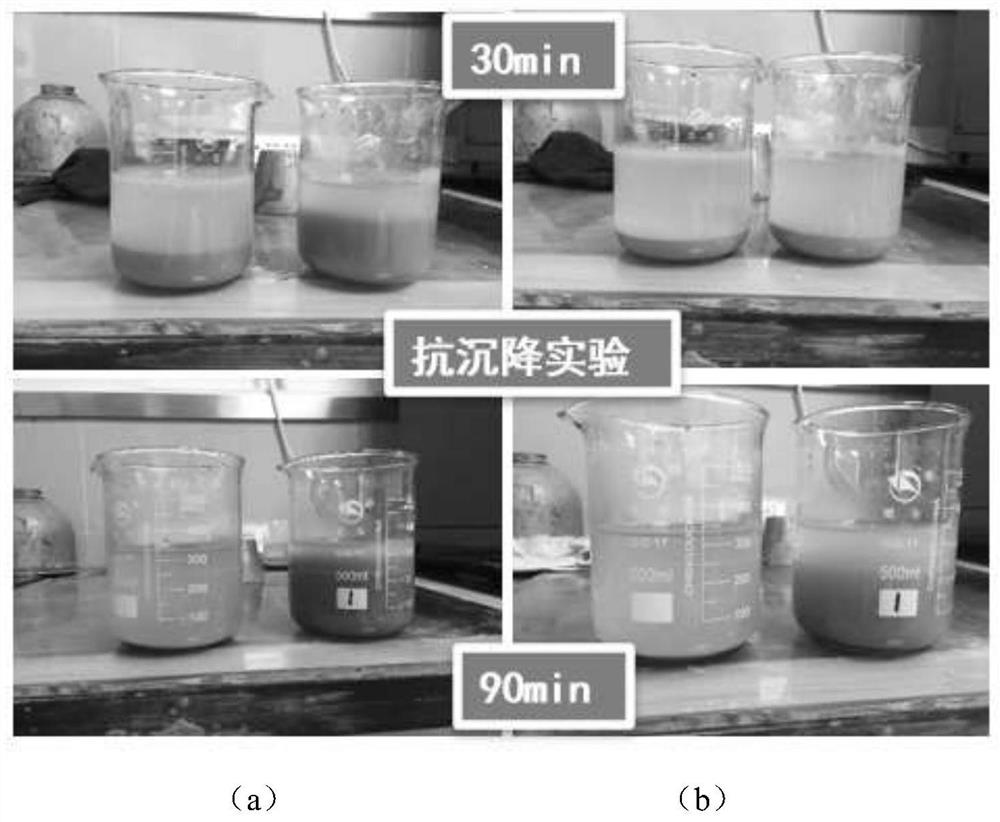

Homogenizing agent for mixing station waste slurry water

ActiveCN112430002AStrong repulsionInhibition dispersionScale removal and water softeningLiquid stateWastewater

The invention belongs to the technical field of concrete functional additives, and particularly relates to a homogenizing agent for mixing station waste slurry water, which is prepared by taking a dispersing component, a workability adjusting component, a mud inhibiting component, a pH value adjusting component and water as main raw materials. The homogenizing agent for the waste slurry water is in a liquid state at normal temperature, is good in homogeneity, meets related standards of admixtures for concrete, can effectively improve the workability, compressive strength and impermeability grade of the obtained concrete, reduces the bleeding rate of the concrete, realizes recycling of wastewater of a mixing station, and has important economic and environmental benefits.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

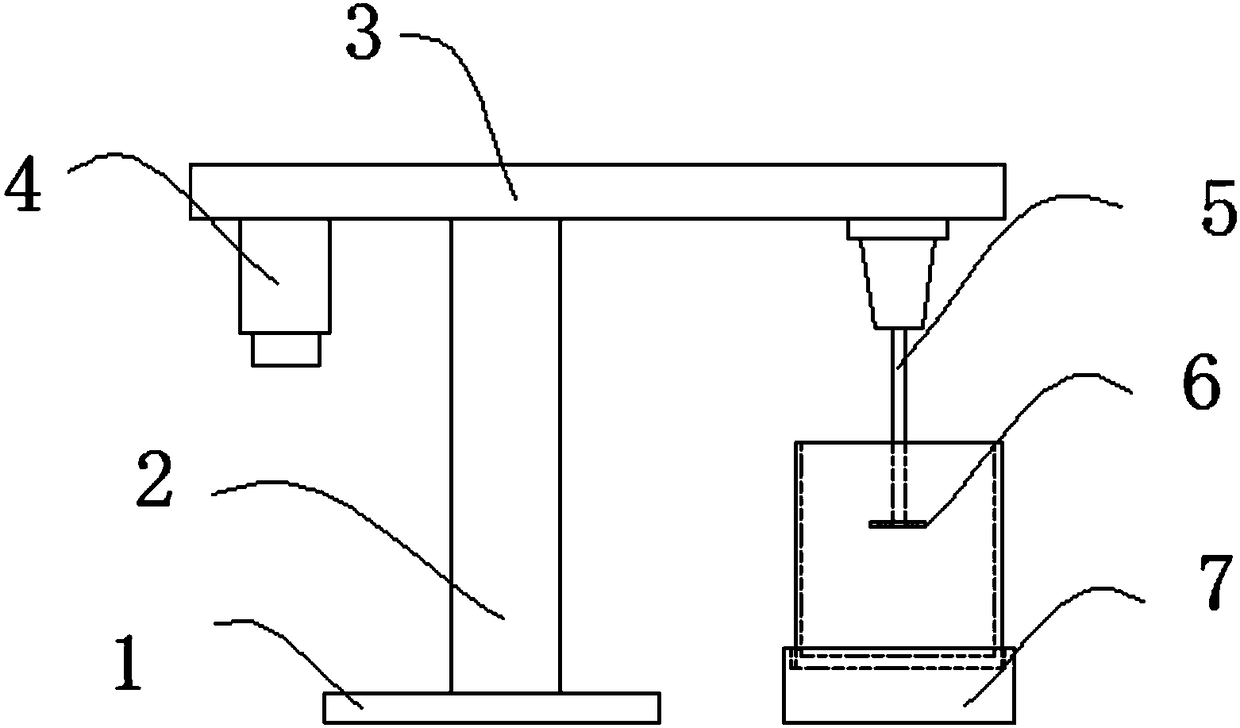

High-efficiency and high-speed dispersing machine

PendingCN108543478AImprove dispersion effectGood dispersionRotating receptacle mixersTransportation and packagingEngineeringCoating

The invention provides a high-efficiency and high-speed dispersing machine and relates to the field of coating production equipment. The high-efficiency and high-speed dispersing machine is characterized by comprising a base, a supporting column, a cross frame, a first motor, a rotating shaft, a dispersing disk and a belt transmission mechanism as well as also comprising a pedestal, a second motor, a round fixed disk and a cylinder body, wherein the pedestal is arranged below the dispersing disk; the second motor is arranged in the pedestal; the fixed disk is arranged above the pedestal; the bottom of the fixed disk is in transmission connection with the top of the second motor; the fixed disk is driven by the second motor to rotate; and the bottom of the cylinder body is detachably connected with the fixed disk. The high-efficiency and high-speed dispersing machine is reasonable in structural design and can greatly improve the dispersing effect of the coating.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

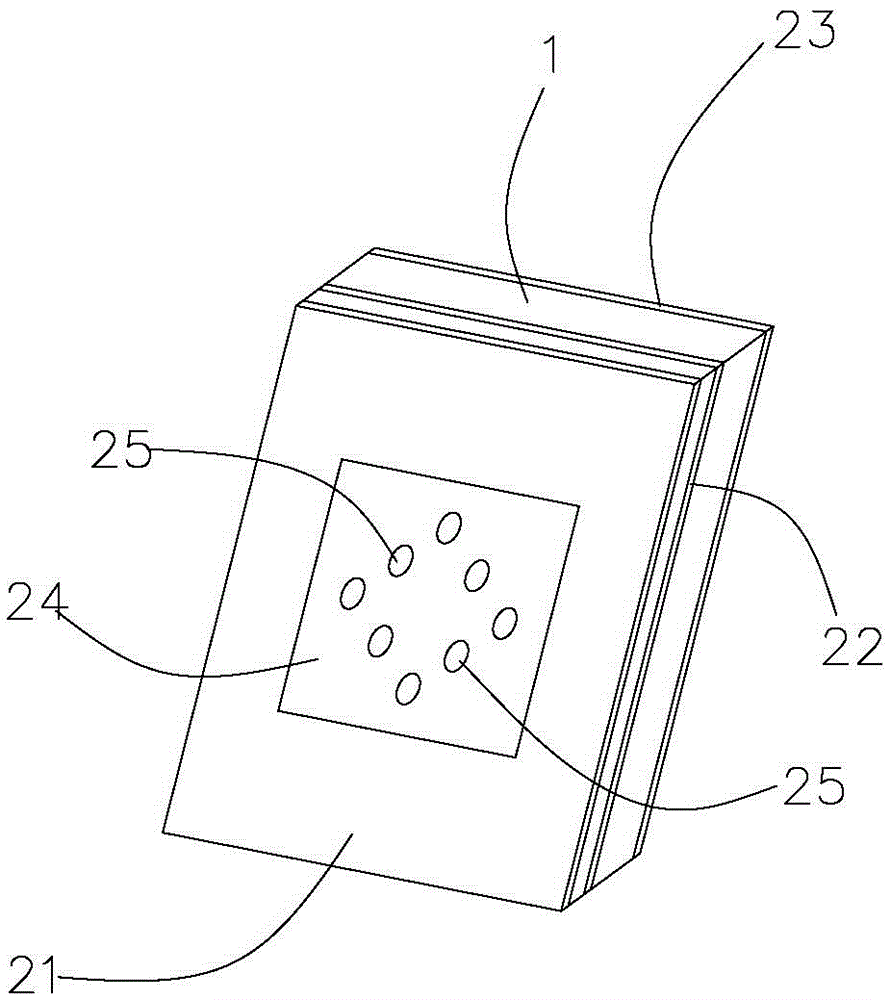

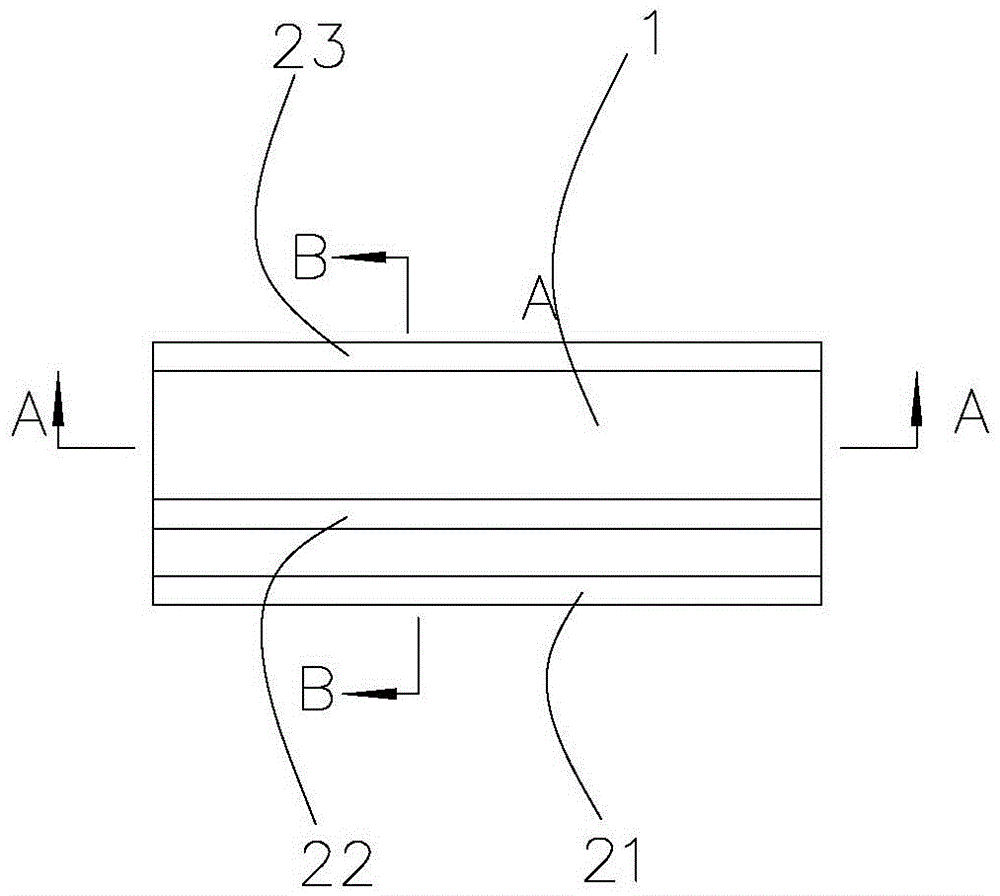

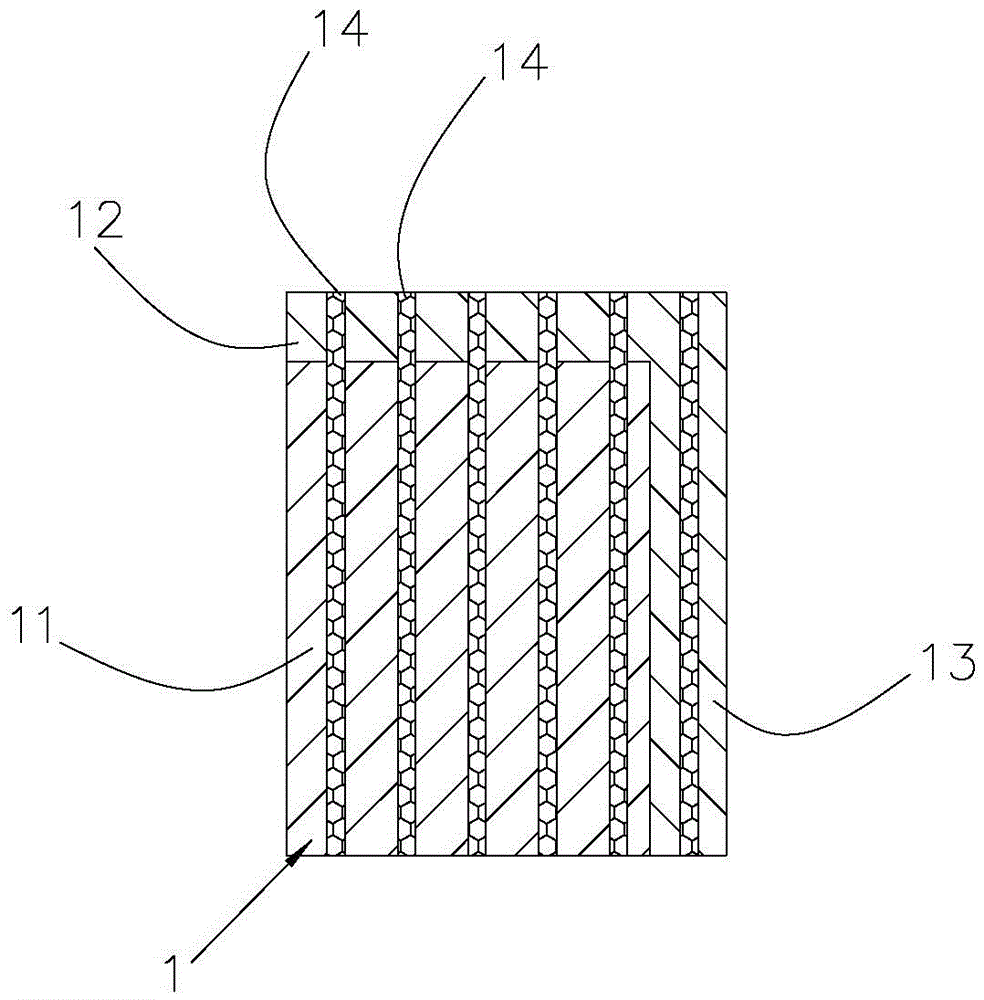

Improved concrete prefabricated slab

ActiveCN105906288AImprove dispersion effectGood dispersionBuilding componentsWater-setting substance layered productBuilding materialFiber

The invention relates to the technical field of building materials and particularly discloses an improved concrete prefabricated slab. The improved concrete prefabricated slab comprises a slab body. The slab body comprises a common concrete part, a first fiber concrete part and a second fiber concrete part, wherein the first fiber concrete part and the second fiber concrete part are connected with the common concrete part and arranged in a crossed mode, and penetrate through the common concrete part. Concrete is prepared from cement paste or cement mortar or other cement base materials. According to the improved concrete prefabricated slab, the first fiber concrete part and the second fiber concrete part are additionally arranged, so that the deformation capability of the prefabricate slab is improved through the high stretchability of fibers, the prefabricated slab is prevented from cracking, and meanwhile connecting parts of the prefabricated slab and other structures are prevented from cracking; the fiber concrete parts and the common concrete part are used in a matched mode, and thus the manufacturing cost of the prefabricated slab can be reduced.

Owner:DONGGUAN UNIV OF TECH

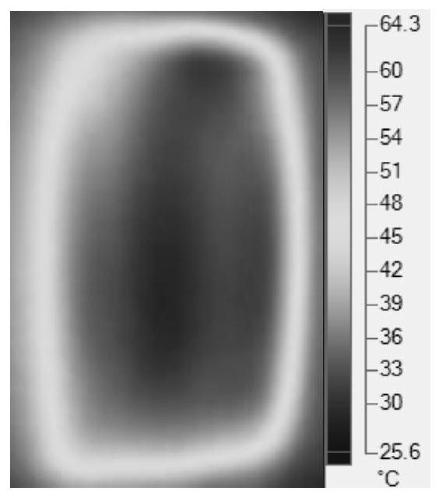

Nanocellulose electrothermal film and preparation method thereof

ActiveCN111073059AImprove agglomerationImprove dispersion effectHeating element materialsAdhesiveHot pressing

The invention provides a nanocellulose electrothermal film and a preparation method thereof. The electrothermal film is a composite film prepared by mixing nanocellulose, carbon nanotubes, graphene and a high-molecular conductive polymer. The electrodes are coated on the edges of the two sides of a composite film by using conductive silver adhesive, and then the composite film is subjected to dipping, cold prepressing and hot-pressing packaging by using packaging resin containing a thermochromic material to obtain the flexible nanocellulose electrothermal film. The electrothermal film providedby the invention has good electrothermal stability, uniformity, insulativity and waterproofness, has relatively low system resistance so as to realize low-voltage supply, also has a thermochromic function, can indicate temperature, and plays a role in early warning and prompting under a high-temperature condition.

Owner:GUANGXI UNIV

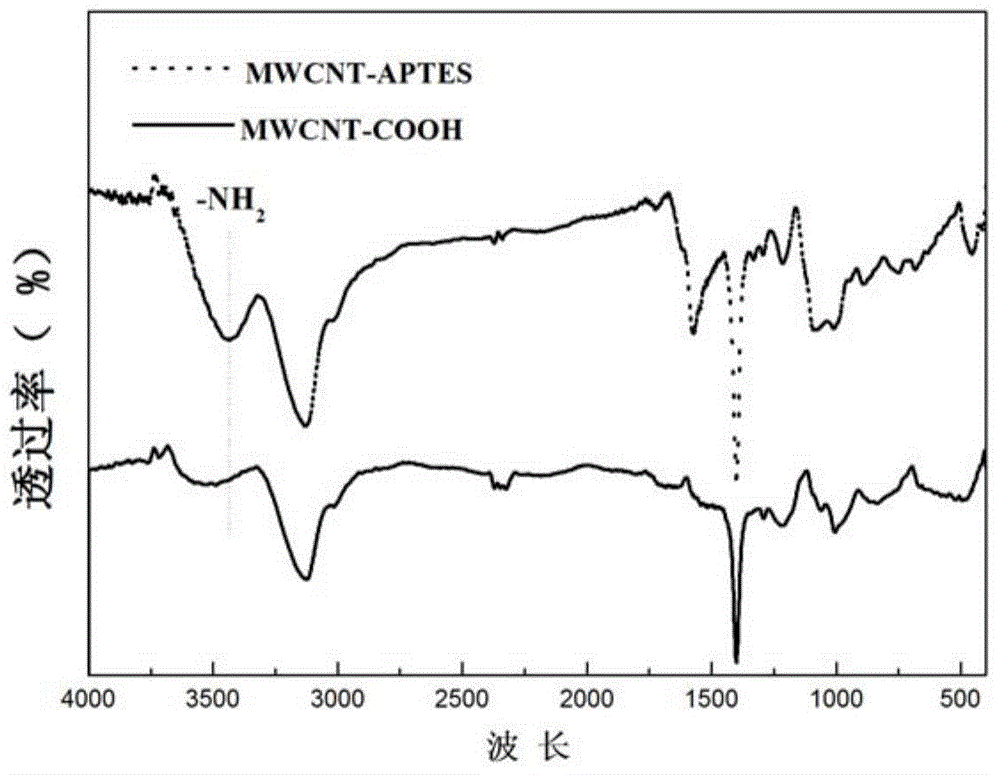

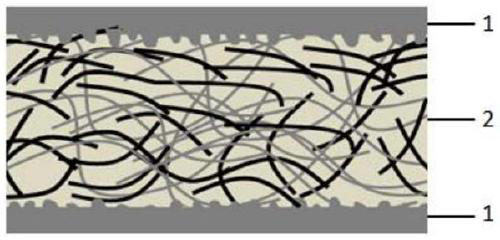

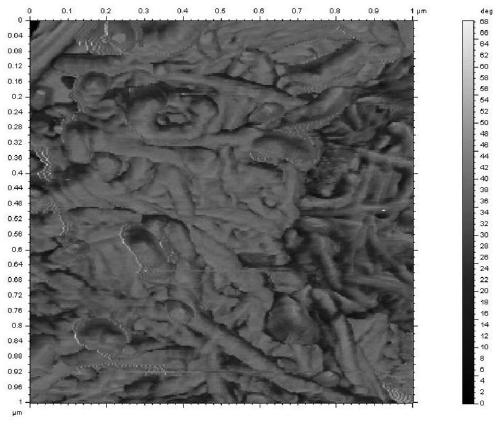

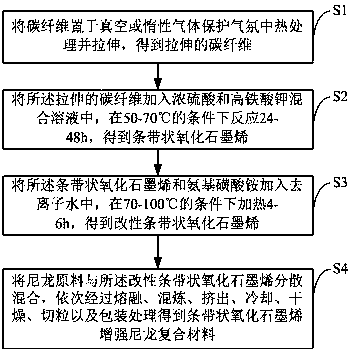

Preparation method of banded graphene oxide reinforced nylon composite material

InactiveCN107629446AImprove mechanical propertiesImprove dispersion effectCvd grapheneGraphite oxide

The invention discloses a preparation method of a banded graphene oxide reinforced nylon composite material; a carbon fiber is used for preparation of banded graphene oxide, then the banded graphene oxide is modified by ammonium sulfamate, the modified banded graphene oxide is prepared, the modified banded graphene oxide is added into a nylon raw material, and the nylon composite material is prepared by a conventional melt blending method. The modified banded graphene oxide can significantly enhance mechanical properties of the nylon material under conditions without changing of the processingperformance; at the same time, graphene oxide has extremely strong barrier effect, oxygen is prevented from entering a substrate and combustible gas is prevented from overflowing after the substrateis heated, and the flame retardant performance of nylon can be significantly improved with cooperation of ammonium sulfamate.

Owner:深圳市八六三新材料技术有限责任公司 +1

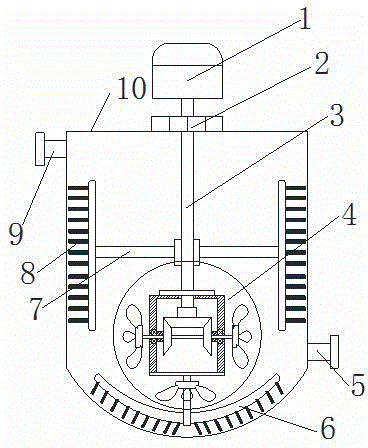

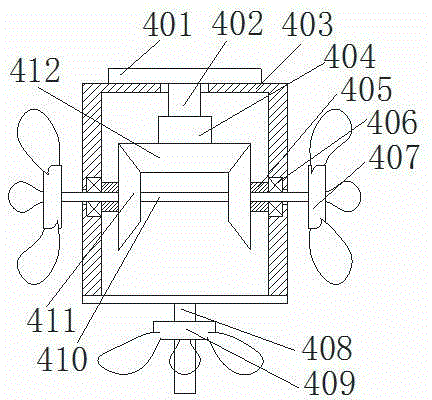

Multifunctional reaction kettle

InactiveCN106311113AImprove dispersion effectImprove efficiencyChemical/physical/physico-chemical stationary reactorsGas generation devicesElectric machineryGear transmission

A multifunctional reaction kettle includes a kettle body. A rotary shaft is arranged therein and is connected to a speed reducer on the top of the kettle body. The speed reducer is connected to a motor. A stirring apparatus is connected to the lower part of the rotary shaft and comprises a positioning disk that passes through and is fixedly connected to the rotary shaft. A gear box body is connected to the positioning disk. A large bevel gear is mounted in the gear box body and is connected to a hydraulic motor. The hydraulic motor is connected to a first rotary shaft that is fixedly connected to the gear box body. An anti-deposit hairbrush is connected to the end of a second rotary shaft. The reaction kettle has the following advantages: with the gear transmission, when a first impeller revolves around the central line of the gear box body, the first impeller also auto-rotates around the axis of the bevel gear, thereby improving dispersion effect. In addition, by means of a side-wall cleaning hairbrush and the anti-deposit hairbrush, agglomerated substances on the bottom and the side wall of the kettle body can be broken fully, thus improving reaction efficiency.

Owner:汪超

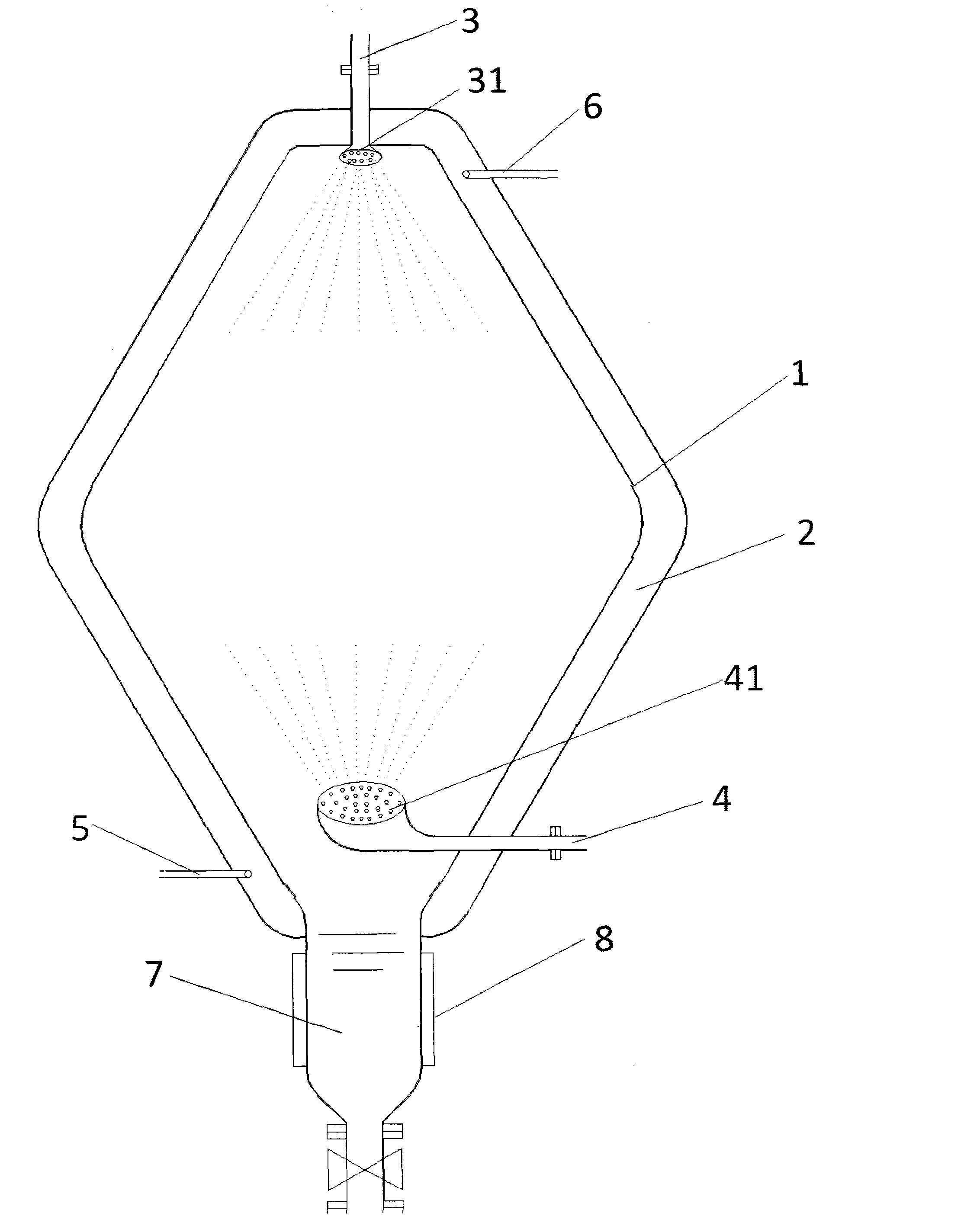

Double-cone atomization gas-liquid reactor

InactiveCN103055794AImprove dispersion effectIncrease the gas-liquid exchange areaChemical/physical/physico-chemical nozzle-type rreactorsLiquid-gas reaction processesEngineeringBy-product

The invention provides a double-cone atomization gas-liquid reactor, which belongs to the technical field of chemical equipment. A shell of the reactor is of a top-bottom double-cone structure; a jacket is arranged out of the shell of the reactor; a liquid phase inlet pipe is arranged at the top of the shell of the reactor, and an inlet end of the liquid phase inlet pipe is provided with a solid cone-shaped nozzle; the lower part of the shell of the reactor is provided with a gas phase inlet pipe, and an inlet end of the gas phase inlet pipe is provided with a disc-like gas phase distributor; and a liquidometer is arranged out of an outlet pipe at the bottom of the shell of the reactor. With the double-cone atomization gas-liquid reactor provided by the invention, a dispersing effect of a gas-liquid material in the reactor is improved, liquid is completely atomized by using the nozzle, a gas-liquid exchange area is increased, a conversion rate of gas-liquid reaction is improved, generation of reaction by-products is reduced, reaction time is shortened, polymerization of thermosensitive substances is effectively prevented, operation is easy and convenient, and reaction security is substantially improved.

Owner:山东瑞博龙化工科技股份有限公司

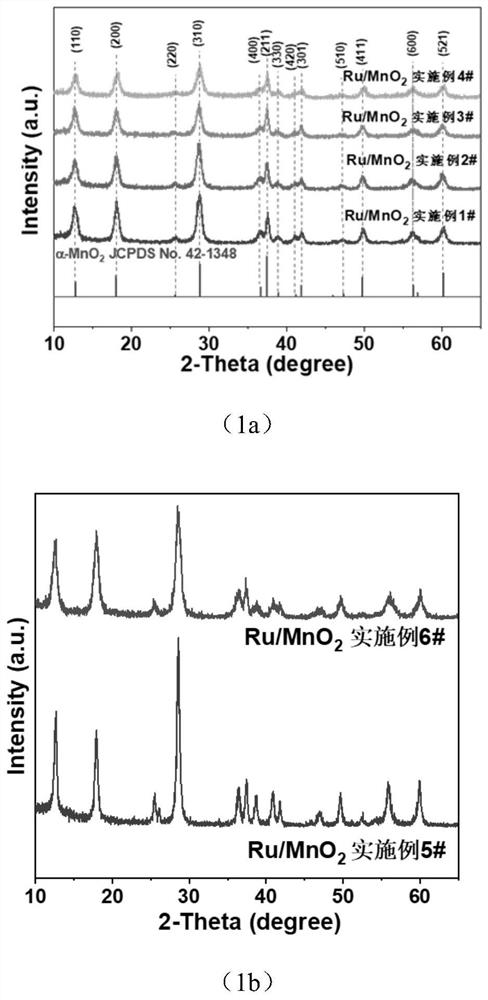

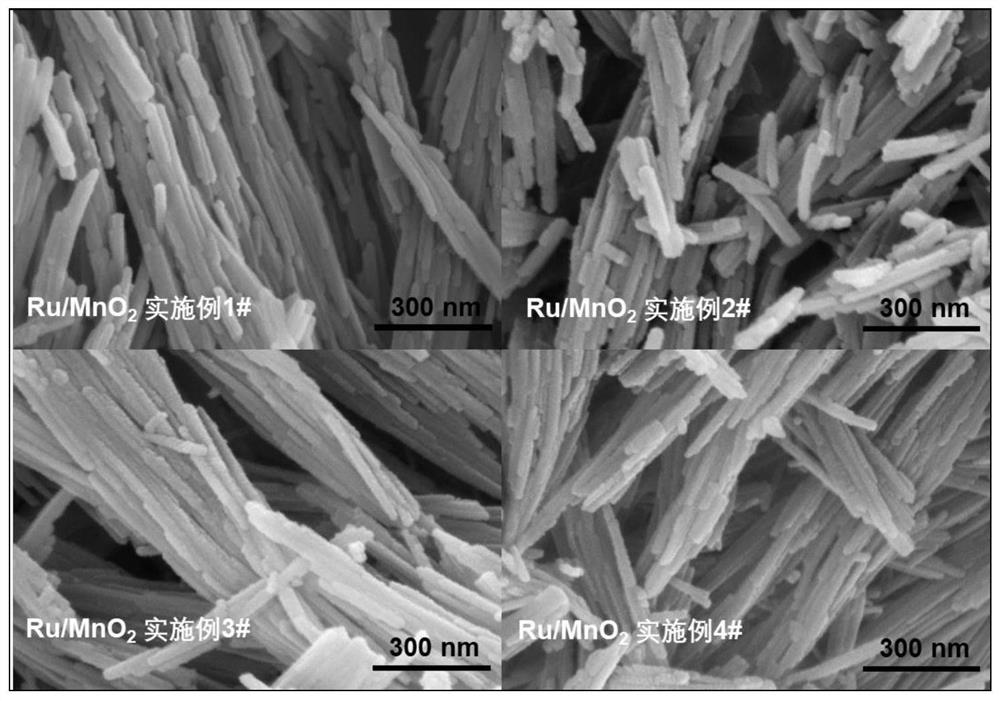

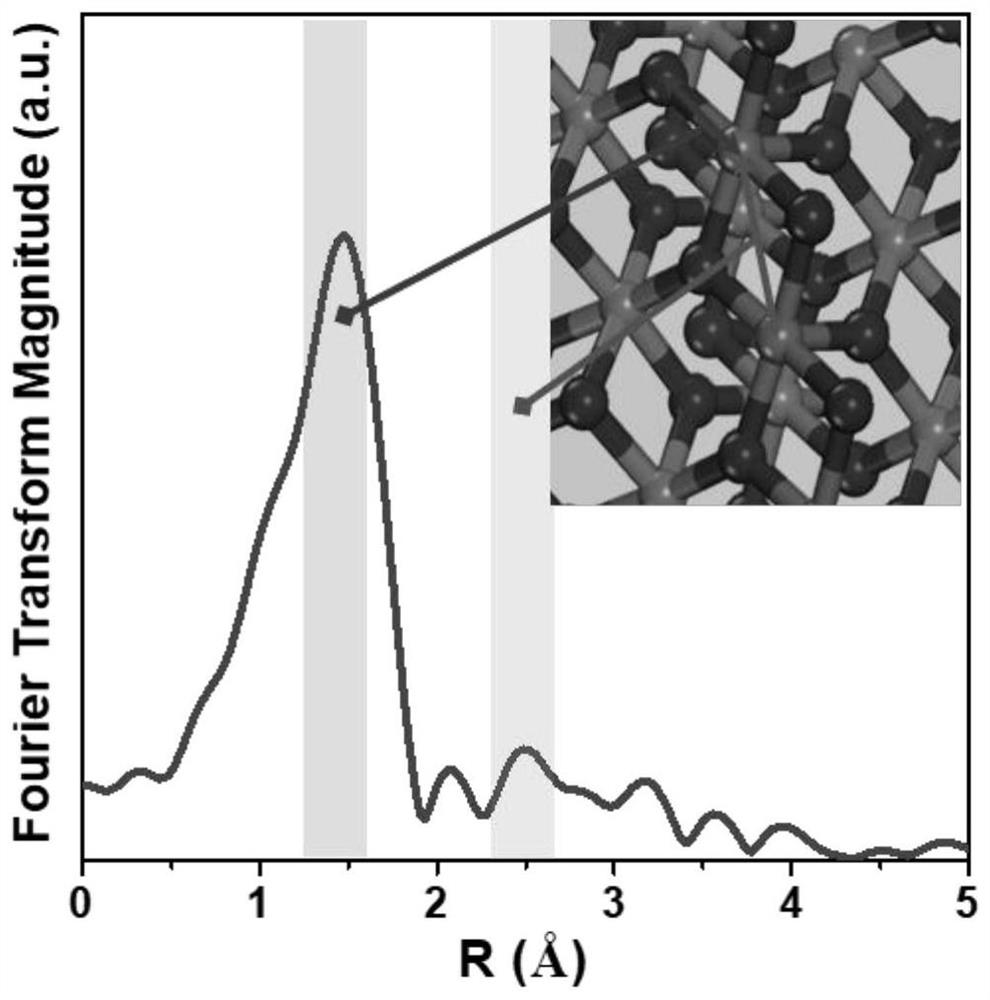

Ruthenium atomic-scale loaded manganese oxide catalyst as well as preparation method and application thereof

ActiveCN113026032AImprove dispersion effectOptimize charge distribution structureElectrodesEnergy inputHydrogen productionOxidizing agent

The invention provides a ruthenium atom-scale loaded manganese oxide catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: 1) carrying out hydrothermal reaction on a mixed solution, filtering, washing and drying to obtain a solid product; wherein the mixed solution comprises manganese salt, an oxidizing agent, a pore filling agent and water; and 2) reacting the solid product and ruthenium salt in solvent water, filtering, washing, drying, roasting and cooling to obtain the catalyst. According to the ruthenium atomic-scale loaded manganese oxide catalyst obtained by the preparation method, the ruthenium element component uniformly dispersed in an atomic scale is anchored on the outer surface of the manganese oxide nanowire with a stable acid medium, so that the dispersion effect of ruthenium metal active sites is effectively improved, the charge distribution structure of the active sites is optimized, and the intrinsic activity and stability of the active sites are improved; and as an anode material of an electrolytic tank for hydrogen production by electrolysis of water under the acidic electrolyte condition, the anode material is applied to the electrolytic tank for hydrogen production by electrolysis of water under the acidic condition, and has excellent acidic oxygen evolution reaction catalytic activity and stability.

Owner:DONGHUA UNIV

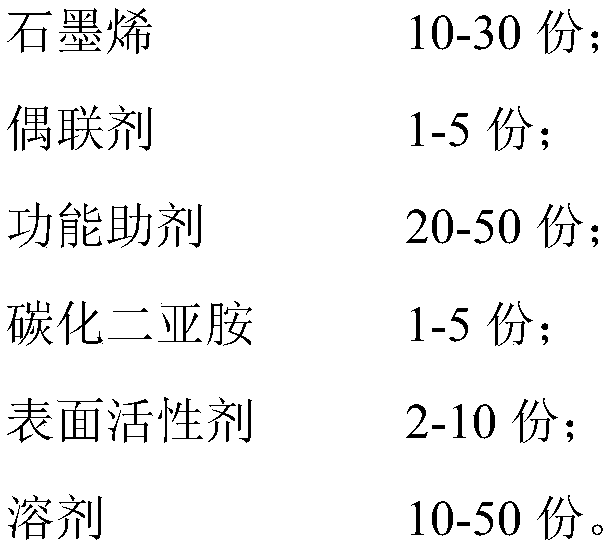

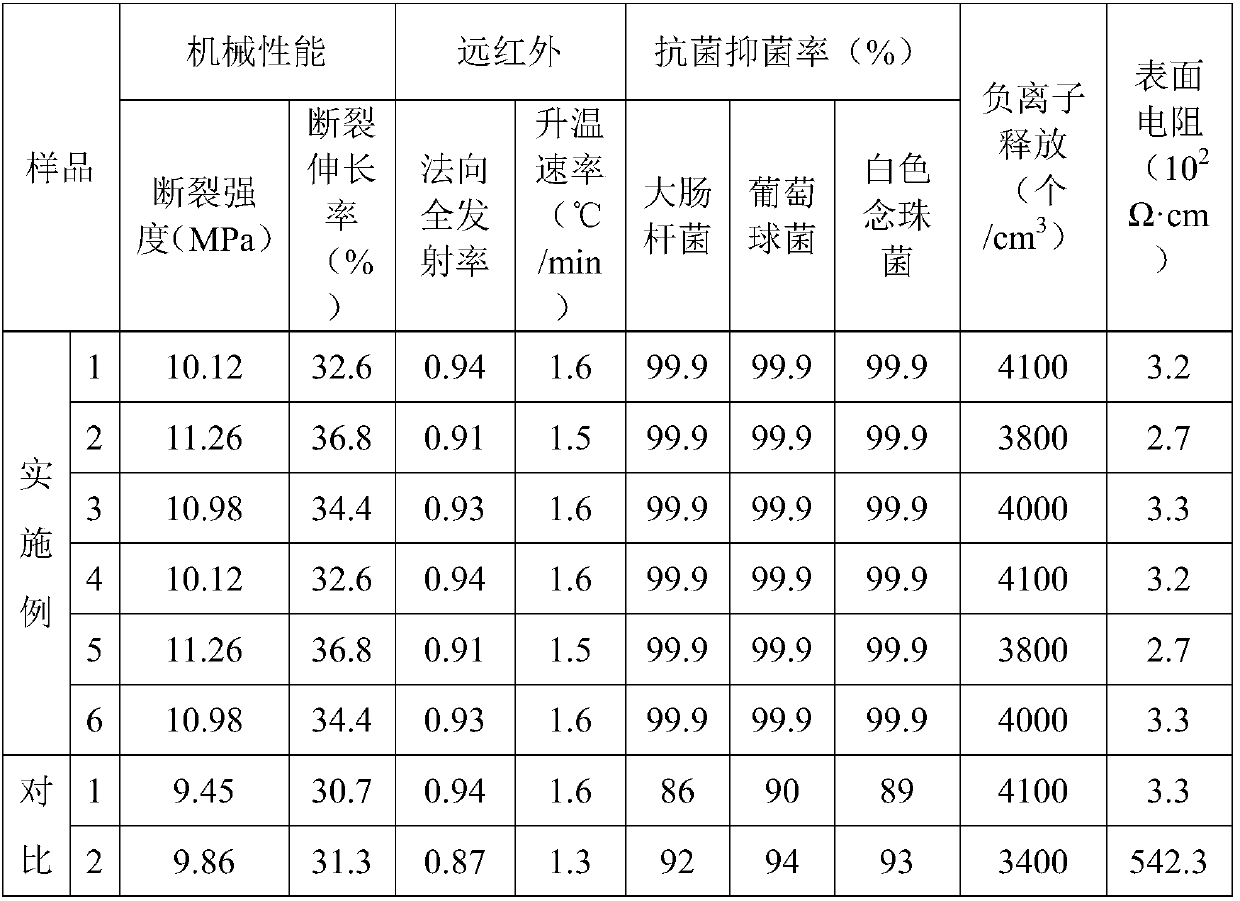

Process for preparing polyamide graphene composite material

InactiveCN109594143AImprove dispersion effectReduce dosageElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentSolventPolyamide

The invention belongs to the technical field of polyamide composite materials and relates to a process for preparing a polyamide graphene composite material. The method comprises the following steps:(1) carrying out pretreatment, namely carrying out surface treatment on graphene and functional aids by using a coupling agent respectively; (2) premixing, namely mixing the graphene treated in the step (1) with the functional aids, further adding carbodiimide, a surfactant and a solvent, and carrying out ultrasonic treatment for 30-60 minutes so as to obtain a modified mixed liquid; and 3) carrying out melt intercalation polymerization, namely mixing a polyamide monomer with the modified mixed liquid obtained in the step (2) to react for 8-10 hours, and carrying out extrusion pelletizing, thereby obtaining a graphene / polyamide composite material. By adopting the process, the functional aids are uniformly dispersed into a polyamide material, the addition amount of the functional aids is greatly reduced, and the material has excellent mechanical properties, antibacterial properties, negative oxygen ion release properties and far-infrared release properties, and has a beneficial effect on human skin health.

Owner:洪春

Plugging filtrate reducer elastic graphite for drilling fluid

ActiveCN111778003AImprove dispersion effectHigh expansion ratioProductsReagentsPotassium manganateDrilling fluid

The invention discloses plugging filtrate reducer elastic graphite for drilling fluid. The plugging filtrate reducer elastic graphite is prepared from the following raw materials: fine flake graphiteparticles, a mixed acid solution, potassium permanganate, ferric trichloride, inorganic hydroxide, a silane coupling agent, a reaction solvent, a dispersant and a modifier. Due to the addition of theinorganic hydroxide, the expansion ratio of the pre-modified graphite in the high-temperature expansion process can be further improved; a good flame-retardant effect is achieved; basic graphite is modified; grafting polyacrylate between layers and on the layers of the basic graphite; the elastic graphite has better mechanical property and wear-resisting property; the crystalline flake graphite issubjected to high-temperature acidification; graphite particles are hollow, can deform after being subjected to external pressure, can restore to the original form after losing pressure, are high inelasticity, good in toughness and resistant to the high temperature of 500 DEG C or above, are suitable for an oil-based or water-based drilling fluid system, can be directly added into a drilling fluid slurry system, are high in compatibility, and have the properties of collapse prevention, plugging, filtrate loss reduction and the like.

Owner:ANHUI LUHAI PETROLEUM AUX TECH

Manufacturing method of winter shirt fabric

ActiveCN105970678AImprove dispersion effectGood antibacterial propertiesDyeing processYarnPolyesterAntibacterial effect

The invention provides a manufacturing method of winter shirt fabric. Polyester fiber and kapok fiber are blended to achieve excellent heat-preserving and antibacterial effect and excellent drapability, the kapok fiber is processed in an environment-friendly mode, so that the kapok fiber is high in heat-preserving property, no chemical agents are needed except a food-grade glycerol and the method is a novel environment-friendly fiber preparing method.

Owner:徐州荣盛纺织整理有限公司

Multifunctional photocatalytic high-dispersion titanium dioxide and preparation method thereof

ActiveCN108404964AImprove dispersion effectBroaden the field of applicationPhysical/chemical process catalystsWater/sewage treatment by irradiationYb elementEuropium

The invention relates to multifunctional photocatalytic high-dispersion titanium dioxide and a preparation method thereof. The titanium dioxide is prepared through codoping modified nitrogen-europium-ytterbium with nano titanium dioxide. The preparation method comprises the following steps: (1) preparation of a solution A: weighing butyl titanate, and adding the weighed butyl titanate into anhydrous ethanol; (2) preparation of a solution B: adding triethylamine, distilled water, concentrated nitric acid, Yb(NO3)3.5H2O and Eu(NO3)3.6H2O into anhydrous ethanol; (3) dropwise adding the solution Ainto the solution B, so as to obtain nitrogen-europium-ytterbium codoped nano titanium dioxide; (4) adding the nitrogen-europium-ytterbium codoped nano titanium dioxide obtained in the step (3) intoa modifier for modifying treatment, thereby obtaining modified nitrogen-europium-ytterbium codoped nano titanium dioxide. The titanium dioxide disclosed by the invention has very high photocatalytic efficiency and dispersion effect, and the prepared titanium dioxide has a broad field of application.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

Preparation method of ATO thermal insulation coating

ActiveCN105602427AImprove dispersion effectStable performancePolyurea/polyurethane coatingsIonThermal insulation

The invention relates to the processing field of thermal insulation coatings, in particular to a preparation method of an ATO thermal insulation coating. The preparation method includes the steps that deionized water is added into nanometer ATO powder, the mixture is stirred evenly, and slurry is prepared; the evenly stirred slurry is perpendicularly jetted to the surface of a roller rotating at high speed through a jetting nozzle from top to bottom; the roller tosses the slurry to an atomizing chamber on one side to form slurry liquid drops; high-pressure inert gas is injected into the atomizing chamber from bottom to top to impact the slurry liquid drops; the inert gas is recycled from the upper side of the atomizing chamber, and the ATO slurry is collected from the lower side of the atomizing chamber; waterborne polyurethane emulsion is added into the collected ATO slurry, the mixture is stirred evenly and then stands, and the ATO thermal insulation coating is obtained. The jetted ATO slurry is crashed under the centrifugal force of the rotating roller and impacted by the high-speed inert gas, clustering of ATO particles in the slurry is broken, in this way, the dispersion effect of the ATO slurry is improved, and then the prepared ATO thermal insulation coating is stable in performance and good in thermal insulation effect.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

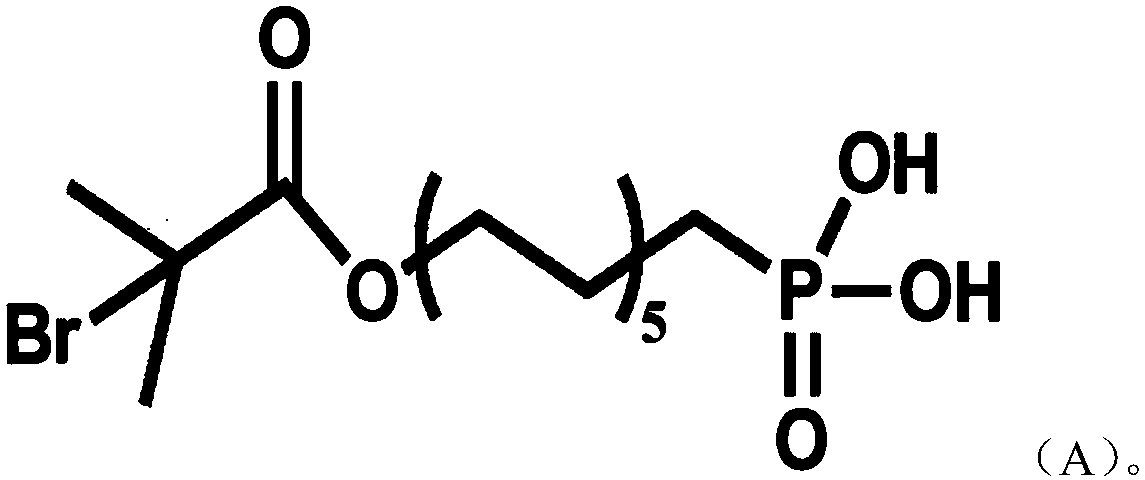

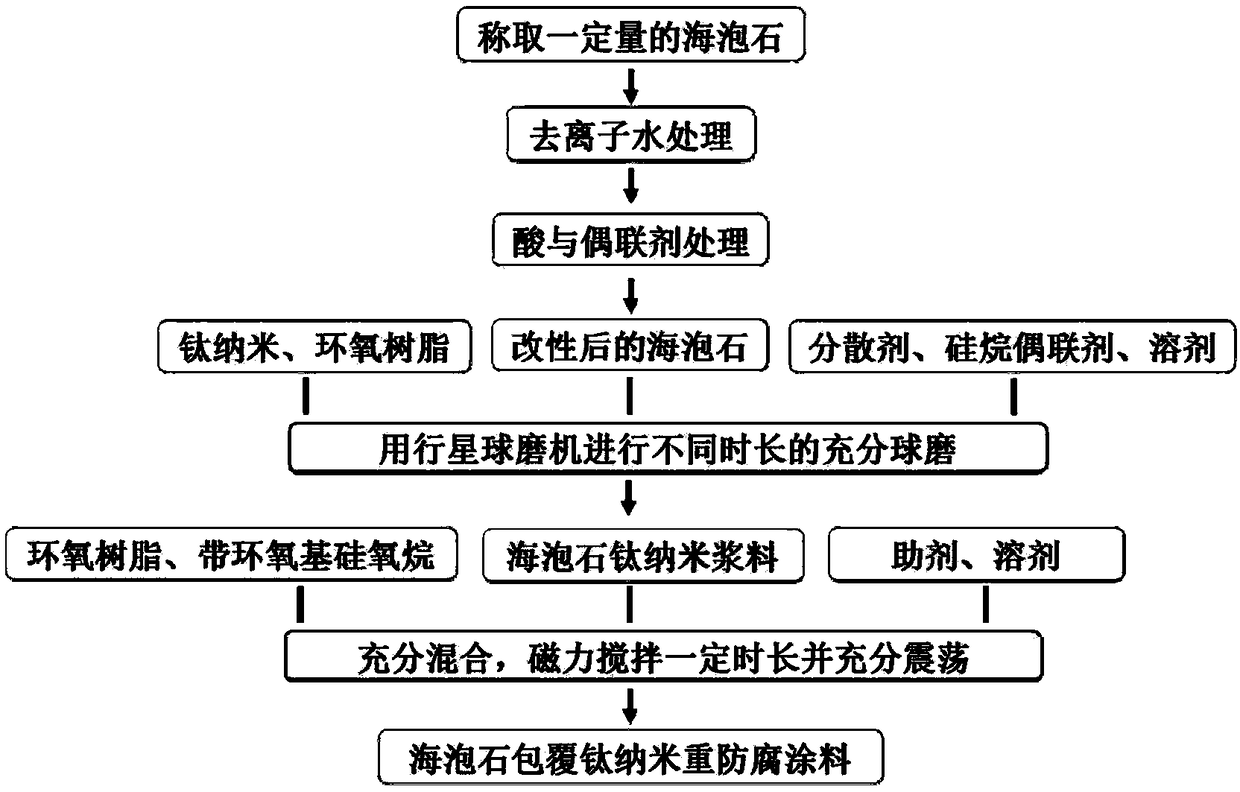

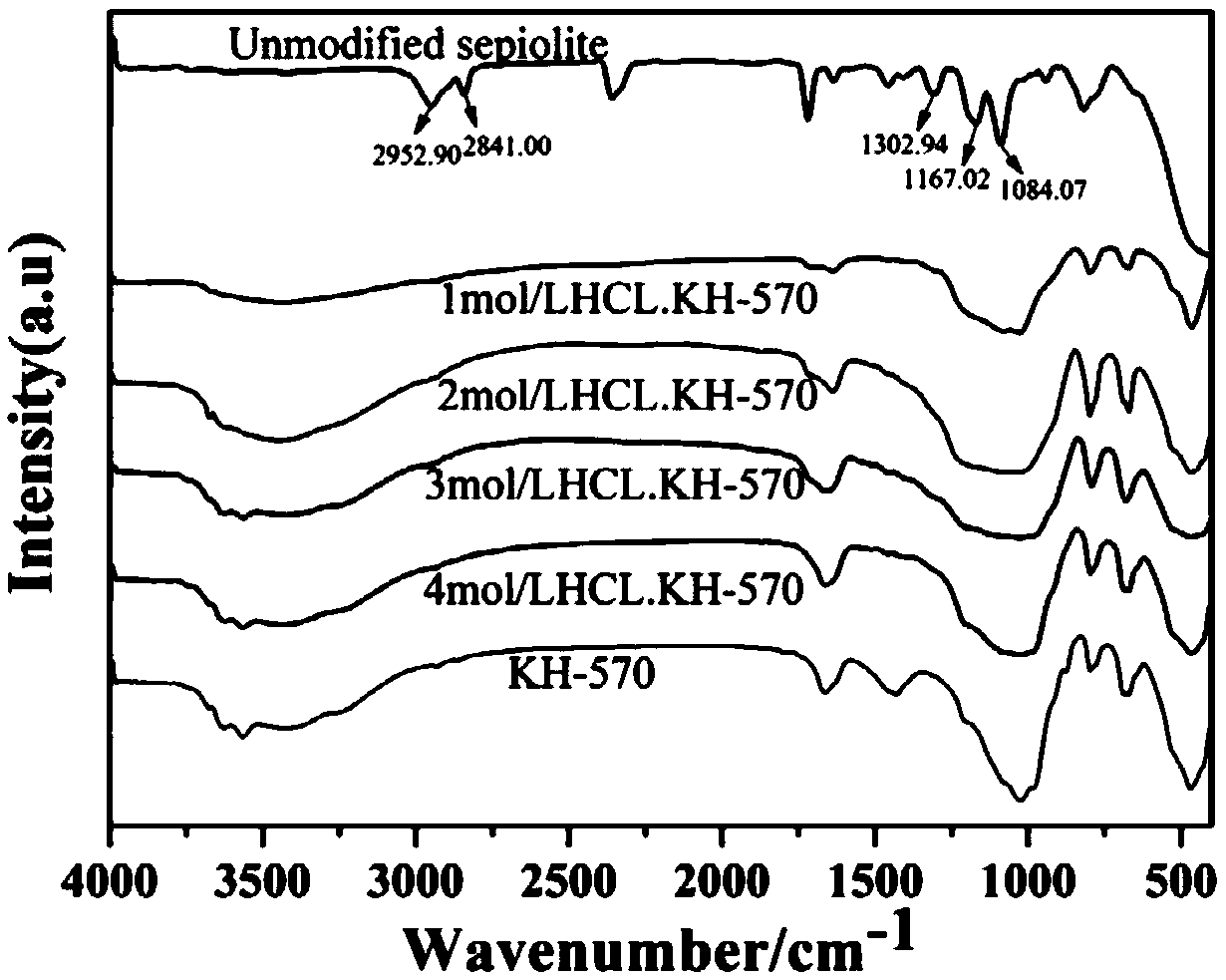

Modified sepiolite coated titanium nano heavy anticorrosive coating and preparation method thereof

ActiveCN109251635AImprove dispersion effectExcellent performanceAnti-corrosive paintsEpoxy resin coatingsSolventSilane coupling

The invention discloses a modified sepiolite coated titanium nano heavy anticorrosive coating and a preparation method thereof. The heavy anticorrosive coating comprises epoxy resin, epoxy-based siloxane, modified sepiolite titanium nano-slurry, a solvent and an auxiliary agent; first sepiolite is subjected to modification treatment; modified sepiolite and titanium powder are mixed to obtain a mixed powder material, the epoxy resin, the dispersing medium, the epoxy-based siloxane and the solvent are added into the mixed powder material for full ball-milling to obtain the nano-scale sepiolite titanium nano-slurry; and the nano-scale sepiolite titanium nano-slurry is mixed the epoxy resin, a silane coupling agent, the solvent and the auxiliary agent for stirring and sufficiently vibrating toobtain the modified sepiolite coated titanium nano heavy anticorrosive coating. A coated layer prepared by the coating disclosed by the invention is excellent in adhesive force, good in wear resistance, high in impact strength, good in flexibility and high in corrosion resistance, and the raw material sepiolite is cheap and easy to obtain, the amount of the titanium powder is effectively reducedby adding of the sepiolite, the coating cost is greatly reduced, and the development of the heavy anti-corrosion coating industry is facilitated.

Owner:XIANGTAN UNIV +1

Coating dispersion machine with cooling function

InactiveCN107875928AImprove dispersion effectIncrease the scope of applicationRotating receptacle mixersRotary stirring mixersInductorEngineering

The invention discloses a coating dispersion machine with a cooling function. The coating dispersion machine comprises a support, a dispersion barrel, a top plate and a stirring mechanism fixed on thetop plate, wherein the stirring mechanism comprises a first motor and a stirring shaft, a lifting mechanism is also fixed on the top plate and comprises hydraulic cylinders fixed on the top plate anda controller for controlling the hydraulic cylinders to move, and the hydraulic cylinders and the controller are fixed on the support; a pressure inductor is arranged at the tail end of the stirringshaft and electrically connected with the controller; a turning mechanism is arranged at the bottom of the dispersion barrel. The dispersion barrel rotates to be matched with the stirring mechanism, the dispersion efficiency is improved, meanwhile, a ball drives the dispersion barrel to rotate, and loss of the dispersion barrel can also be reduced; a water storage cavity is formed, and the technical problems that coating raw materials produce heat during dispersion and stirring and can influence the production quality of a coating are solved.

Owner:百世杉集团有限公司

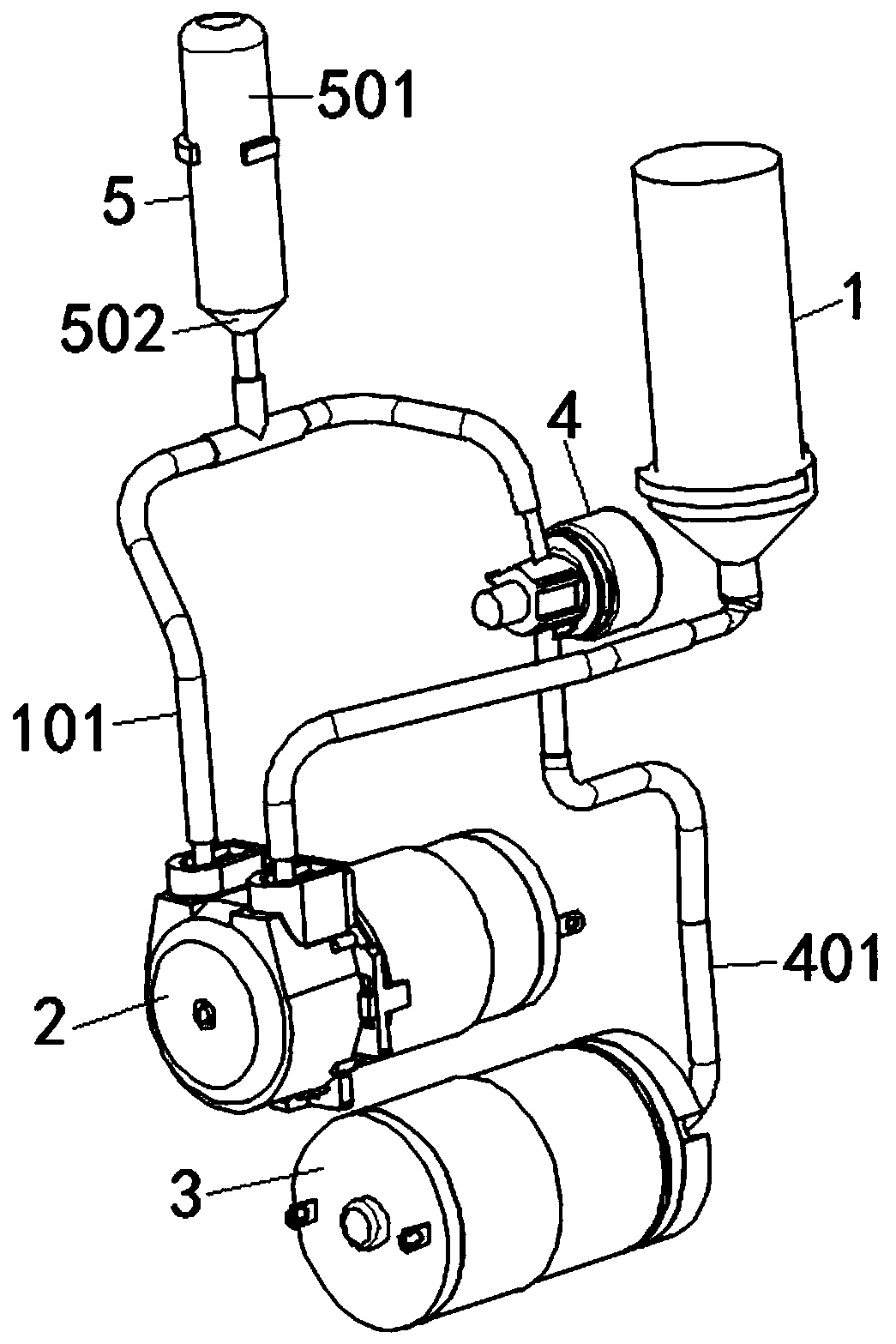

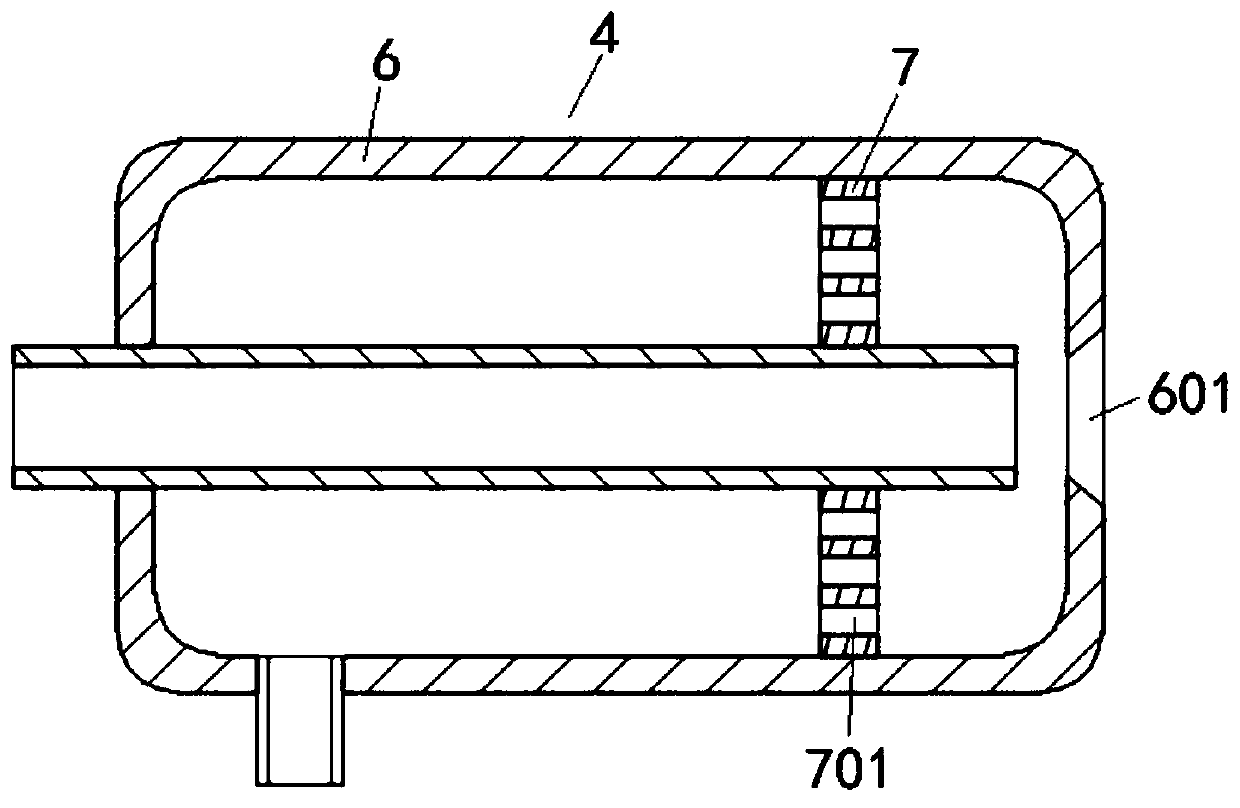

Atomization system based on flow focusing technology

PendingCN110464927AImprove dispersion effectGood for absorption efficiencyMedical atomisersSmall dropletPeristaltic pump

The invention discloses an atomization system based on a flow focusing technology, and relates to the technical field of atomization. The atomization system includes a liquid storage tank, a peristaltic pump, an air pump and a two-fluid spray head device; the bottom of the liquid storage tank communicates with one end of a first connecting pipe; and the other end of the first connecting pipe penetrates through the peristaltic pump and communicates with an liquid inlet pipe of the two-fluid spray head device. According to the atomization system based on the flow focusing technology, spray liquid in the liquid storage tank is delivered to the two-fluid spray head device by the peristaltic pump, while the air pump delivers gas to the two-fluid spray head device, the spray liquid flowing fromthe two-fluid spray head device is driven by the high-speed flowing gas, and a micro jet is formed at the top of the cone, the micro jet is broken into monodisperse micro drops at a certain distance outside a small hole, and thus atomized droplets on the micro nanometer scale are formed; the process can be applied to all kinds of liquid with different viscosity and fluidity, the dispersion effectof the spray liquid is effectively improved, the absorption efficiency of animals and plants for small droplets is facilitated, and the action effect of the liquid is enhanced.

Owner:合肥中科力一科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com