Double-cone atomization gas-liquid reactor

A technology of atomizing gas and reactors, which is applied in chemical/physical/physicochemical nozzle reactors, chemical instruments and methods, and chemical methods for reacting liquid and gaseous media, etc., which can solve the problem of many by-products and production costs high, low conversion rate of gas-liquid reaction, etc., to achieve the effect of easy operation, prevention of polymerization, and improvement of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

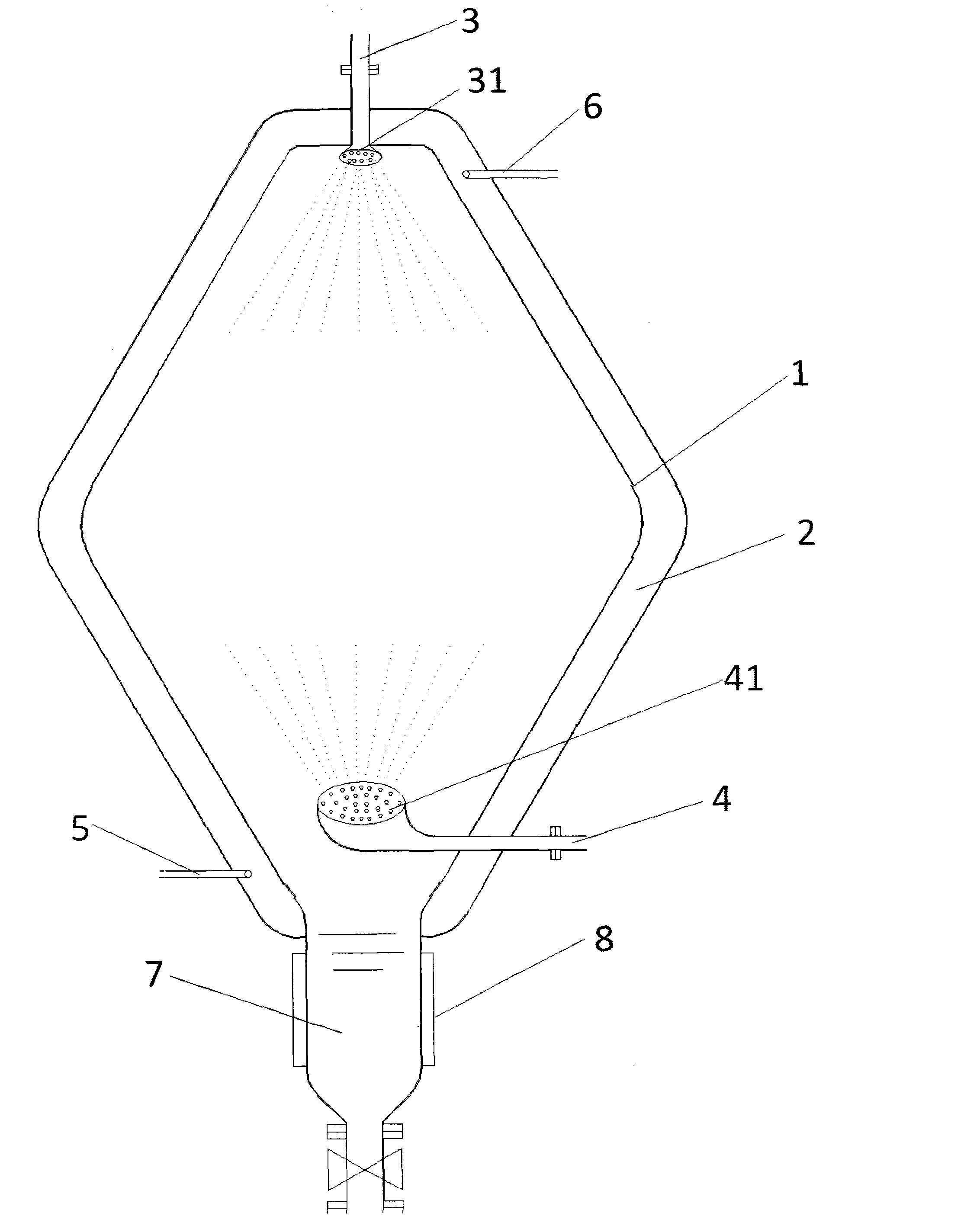

[0012] A double-cone atomization gas-liquid reactor, the reactor shell 1 is a double-cone structure up and down, the reactor shell 1 is provided with a jacket 2, and the jacket 2 has the same upper and lower double-cone structure as the reactor shell 1 The upper part of the jacket 2 is provided with a jacket outlet pipe 6, the lower part of the jacket 2 is provided with a jacket inlet pipe 5, the top of the reactor shell 1 is provided with a liquid phase inlet pipe 3, and the inlet end of the liquid phase inlet pipe 3 is provided with a solid cone Nozzle 31, a gas phase inlet pipe 4 is arranged at the lower part of the reactor shell 1, and a disk type gas phase distributor 41 is arranged at the inlet end of the gas phase inlet pipe 4, and a glass plate liquid level gauge 8 is arranged outside the outlet pipe 7 at the bottom of the reactor shell 1.

[0013] When the device of the present invention is in use, the liquid phase material with a certain pressure passes through the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com