Patents

Literature

81results about How to "Good dispersion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-thermal-stability cerium-based oxygen storage material

InactiveCN101690890AWeaken the interaction forceGood dispersion effectDispersed particle separationCatalyst activation/preparationIndustrial scaleComposite oxide

The invention relates to a method for preparing a high-thermal-stability cerium-based oxygen storage material, which is characterized in that the cerium-based oxygen storage material comprises cerium dioxide, zirconium dioxide, aluminum oxide in a small amount and at least one rare-earth crystal stabilizer selected from lanthanum oxide, praseodymium oxide, yttrium oxide and terbium oxide. The method comprises the following steps in the preparation process: adding a proper amount of surfactant, to obtain a cerium-based composite oxide material having the characteristics of single crystalline phase, high oxygen storage performance and high specific surface area; and ageing the cerium-based composite oxide material at a high temperature (1,050 DEG C) for 5h until the specific surface area thereof is higher than 35m<2> / g and the oxygen storage capacity thereof is higher than 400 mu mol / g. According to the phase results, the cerium-based oxygen storage material has a uniform-phase structure, moreover, a uniform solid solution with a cubic fluorite structure can be prepared from zirconium dioxide, aluminum oxide, stabilizer and cerium dioxide. The preparation process of the oxygen storage material has the characteristics of simple process, lower production cost, easy industrial scale-up, etc.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of hybrid collector for oxide ore flotation

InactiveCN101181700AGood homogenization effectGood dispersion effectFlotationRevolutions per minuteSolvent

The invention relates to a preparation method of oxide ore flotation mixed collectors. The preparation method is characterized in that the preparation process comprises the steps that: (1) saponifier which is weighted in proportion is fully dissolved in hot water; (2) the weighted collecting flotation agent is stirred and mixed homogeneously at the speed of more than 600 revolutions per minute; (3) the prepared original mixture of the collecting flotation agent is added in the hot solvent which is dissolved with the saponifier, and the mixed solvent is stirred for 30 to 120 minutes until the solvent is homogeneous at the temperature of 50 DEG C to 90 DEG C and the speed of 10 to 200 revolutions per minute. The invention has the advantages that: agents are modified by controlling feeding order, preparation temperature, stirring speed and stirring time of agents, thus homogenization effect is good; agents do not agglomerate at comparatively low temperature, and dispersant effect is good; aging of the agents is long.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

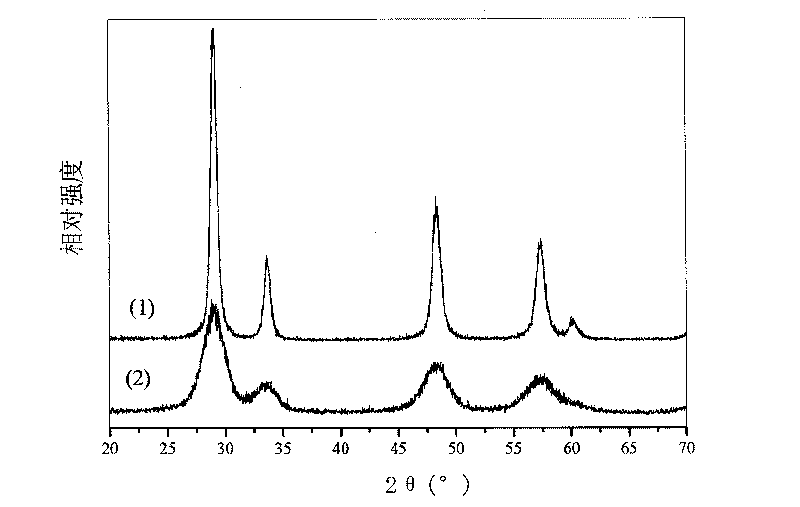

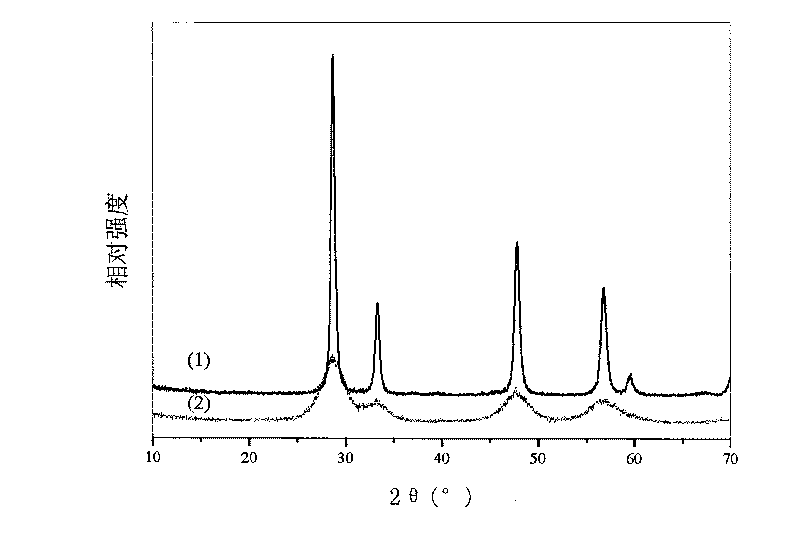

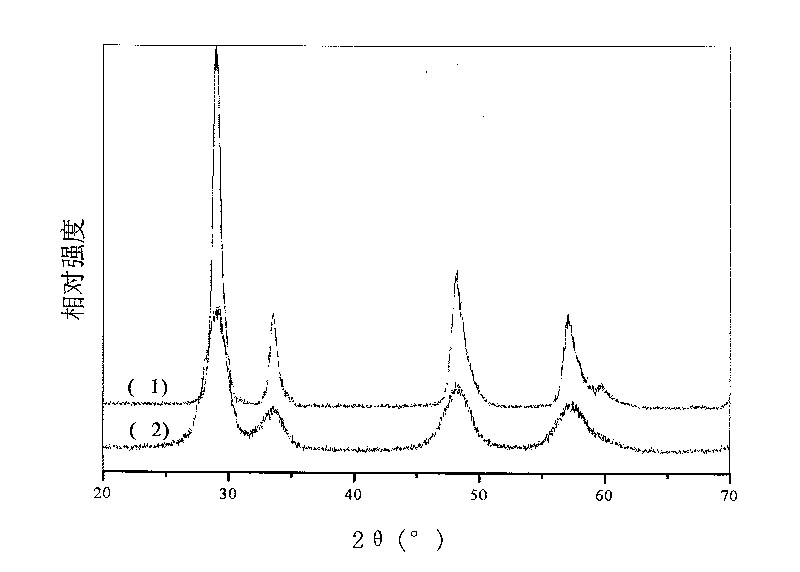

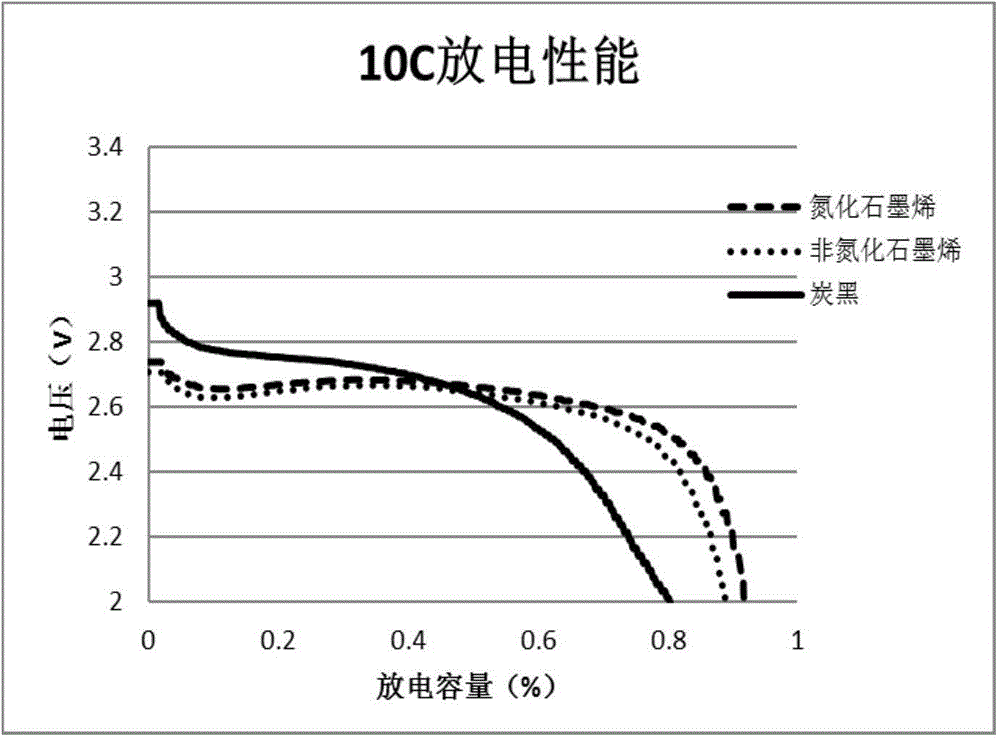

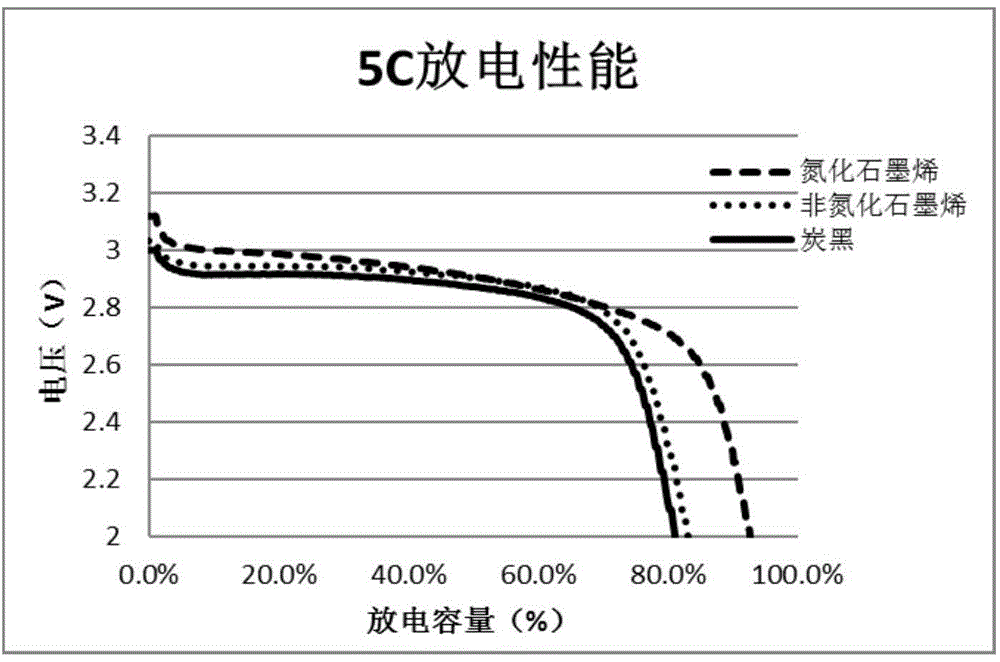

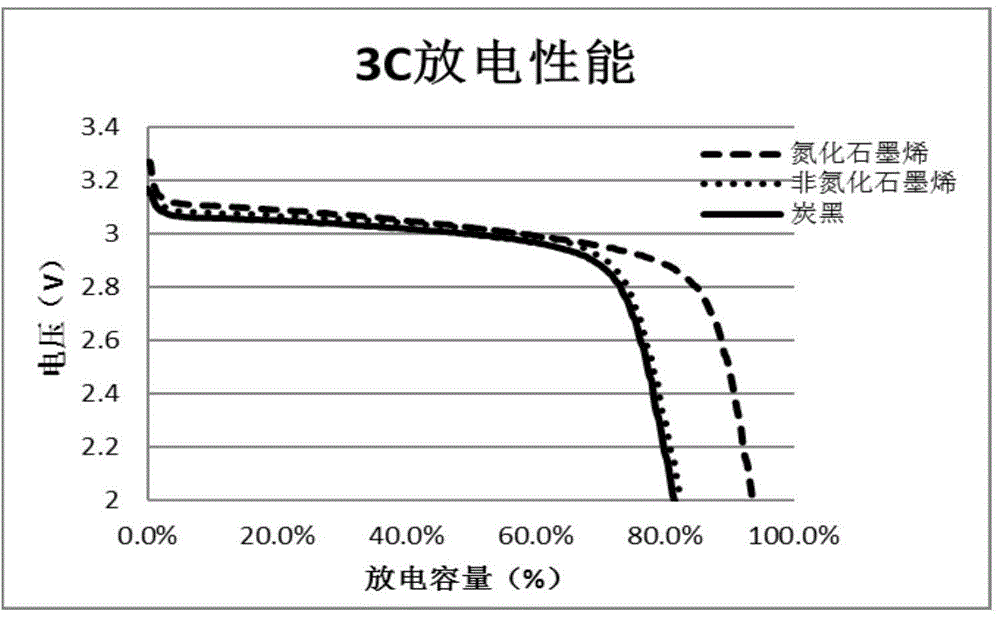

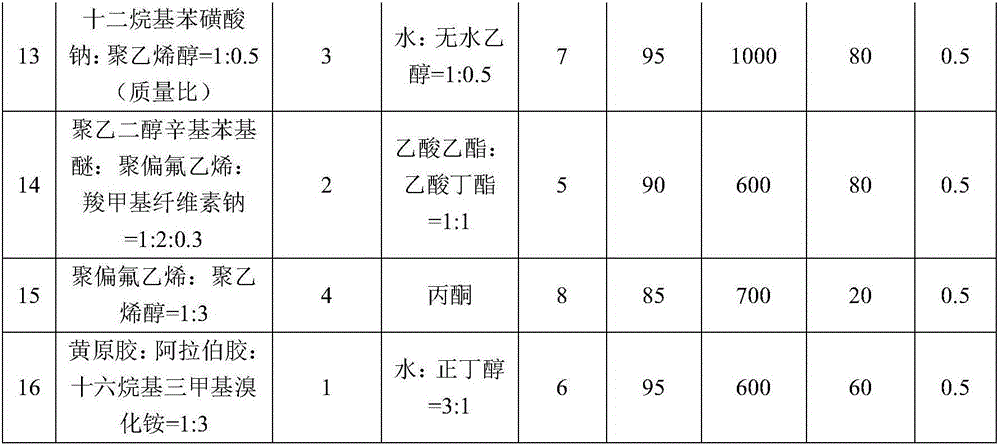

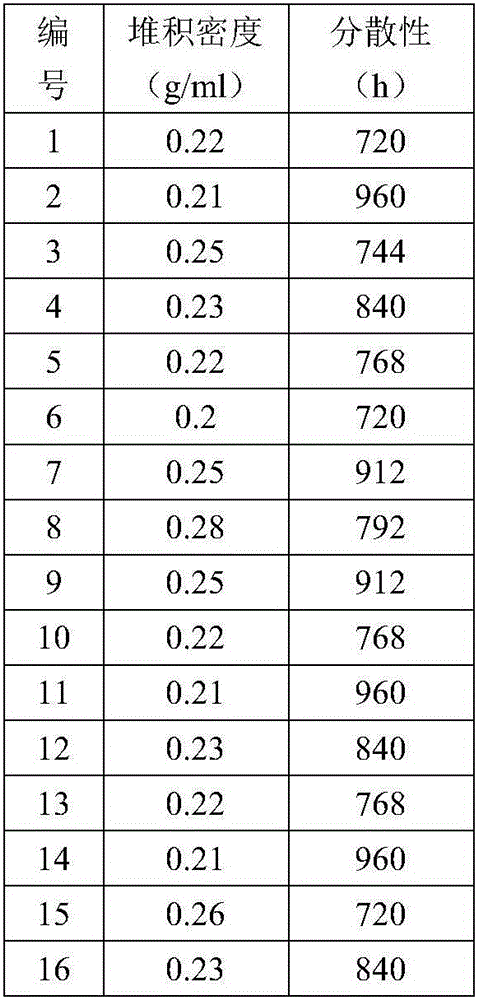

Preparation method of azotized graphene lithium ion power battery slurry

The invention relates to a preparation method of azotized graphene lithium ion power battery slurry. The preparation method mainly comprises the preparation of azotized expanded graphite and azotized graphene lithium ion power battery slurry. The preparation method comprises the steps of firstly, introducing a nitrogen increasing agent in the expandable graphite and expanded graphite preparation process, and azotizing to obtain azotized expanded graphite; and secondly, preparing azotized graphene by taking the azotized expanded graphite as the raw material, and introducing substances such as a dispersing agent, a conductive agent, active materials and a binder in the preparation process so as to obtain the azotized graphene lithium ion power battery slurry. According to the preparation method, azotized graphene or the compound of azotized graphene and other conductive additives is adopted as the conductive additive of the lithium ion power battery slurry, the high-temperature cycle performance, high-temperature storage performance and high-rate discharge performance are further improved; on the other hand, the preparation of azotized graphene and the dispersion of the lithium ion power battery slurry are implemented simultaneously, and the problem that graphene cannot be dispersed easily in the application process can be solved.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Anionic asphalt temperature mixed agent and preparation method thereof

ActiveCN104419209AGood dispersion effectGood stabilityClimate change adaptationBuilding insulationsChemistryAsphalt

The invention discloses an anionic asphalt temperature mixed agent and a preparation method thereof, The anionic asphalt temperature mixed agent comprises the following components by weight percentage: 0.1-5wt% of carboxylic acid high-molecular component, 0.1-5wt% of sulfuric ester high-molecular component, 0.1-5wt% of sulfonic acid high-molecular component, 0.1-20wt% of low molecular component, 1-15wt% of inorganic micro powder and 50-98.6wt% of water, The preparation method comprises the following steps: adding water in a container, respectively adding the carboxylic acid high-molecular component, the sulfuric ester high-molecular component and sulfonic acid high-molecular component, stirring for 1-2 hours under 40-60 DEG C, then adding the low molecular component and the inorganic micro powder, heating to 60-80 DEG C, continuously performing isothermal stirring for 0.5-1 hour to obtain the anionic asphalt temperature mixed agent. The anionic asphalt temperature mixed agent can effectively reduce the high temperature viscosity of asphalt, and has the advantages of good dispersion, stable performance, easy acquisition of raw materials, low production cost, simple preparation method and wide application scope.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nanometer core-shell rubber particle toughening epoxy resin compound and preparation method of nanometer core-shell rubber particle toughening epoxy resin compound

ActiveCN105176003AGood dispersion effectGood storage stabilitySynthetic resin layered productsMetal layered productsPliabilityChemistry

The invention provides a nanometer core-shell rubber particle toughening epoxy resin compound and a preparation method of the nanometer core-shell rubber particle toughening epoxy resin compound. The compound comprises epoxy resin, nanometer core-shell rubber particles, a silane coupling agent and an optional diluting agent, wherein the epoxy resin accounts for 39 percent to 84 percent of the weight of the compound; the content of the nanometer core-shell rubber particles accounts for 8.4 percent to 23.4 percent of the weight of the epoxy resin; the silane coupling agent is added into the compound in a form of being coated onto the surfaces of the nanometer core-shell rubber particles; the content of the silane coupling agent accounts for 1 percent to 10 percent of the weight of the nanometer core-shell rubber particles. The nanometer core-shell rubber particle toughening epoxy resin compound has the advantages that the dispersing effect is good; in addition, the storage stability is good; when the compound is used as a toughening agent to be added into an epoxy resin composition for preparing copper cladded plates, the toughness of epoxy resin curing materials can be improved, so that the copper cladded plates with excellent toughness and flexibility can be prepared.

Owner:GOODE EIS SUZHOU CORP LTD

Method for improving external quantum efficiency of semiconductor LED

InactiveCN1838439AGood light transmissionImprove external quantum efficiencySemiconductor devicesQuantum efficiencyRefractive index

This invention relates to a method for improving semiconductor light emitting diode outer quantum efficient, which coats at least one layer of film on the LED's surfacing. The refractivity of film is between LED semiconductor light medium and packaging resin or packaging air, wherein the three mediums' refractivity as follows:etasemiconductor>etax>etapackaging, then packaging with high molecule resin. Because the former, present and back film refractivity' relationship as follows: etax2=etax-1 .etax+1, so their order as follows: etax+1>etax>etax-1,wherein X=1,2,3,4,5,7 or 9. Because the film has high translucent and better color radiation, so it improves LED chip's outer quantum efficient, radiation efficient and luminous flux.

Owner:FUJIAN NORMAL UNIV

Warm mix asphalt and preparation method thereof

ActiveCN104559245AGood dispersion effectGood stabilityClimate change adaptationBuilding insulationsStearic acidAsphalt

The invention discloses warm mix asphalt and a preparation method thereof. The warm mix asphalt comprises the following raw materials in percentage by weight: 0.1-10 percent of stearic acid, 0.1-10 percent of cocoanut oil fatty acid diethanolamide, and 80-99.8 percent of matrix asphalt. The preparation method for the warm mix asphalt comprises the following steps: respectively adding the stearic acid and cocoanut oil fatty acid diethanolamide in a reaction vessel according to a ratio, uniformly mixing, adding the mixture in the matrix asphalt according to a ratio, and uniformly mixing to prepare the warm mix asphalt. The warm mix asphalt is environment-friendly, and has a good application prospect in mix asphalt mixing.

Owner:CHINA PETROLEUM & CHEM CORP +1

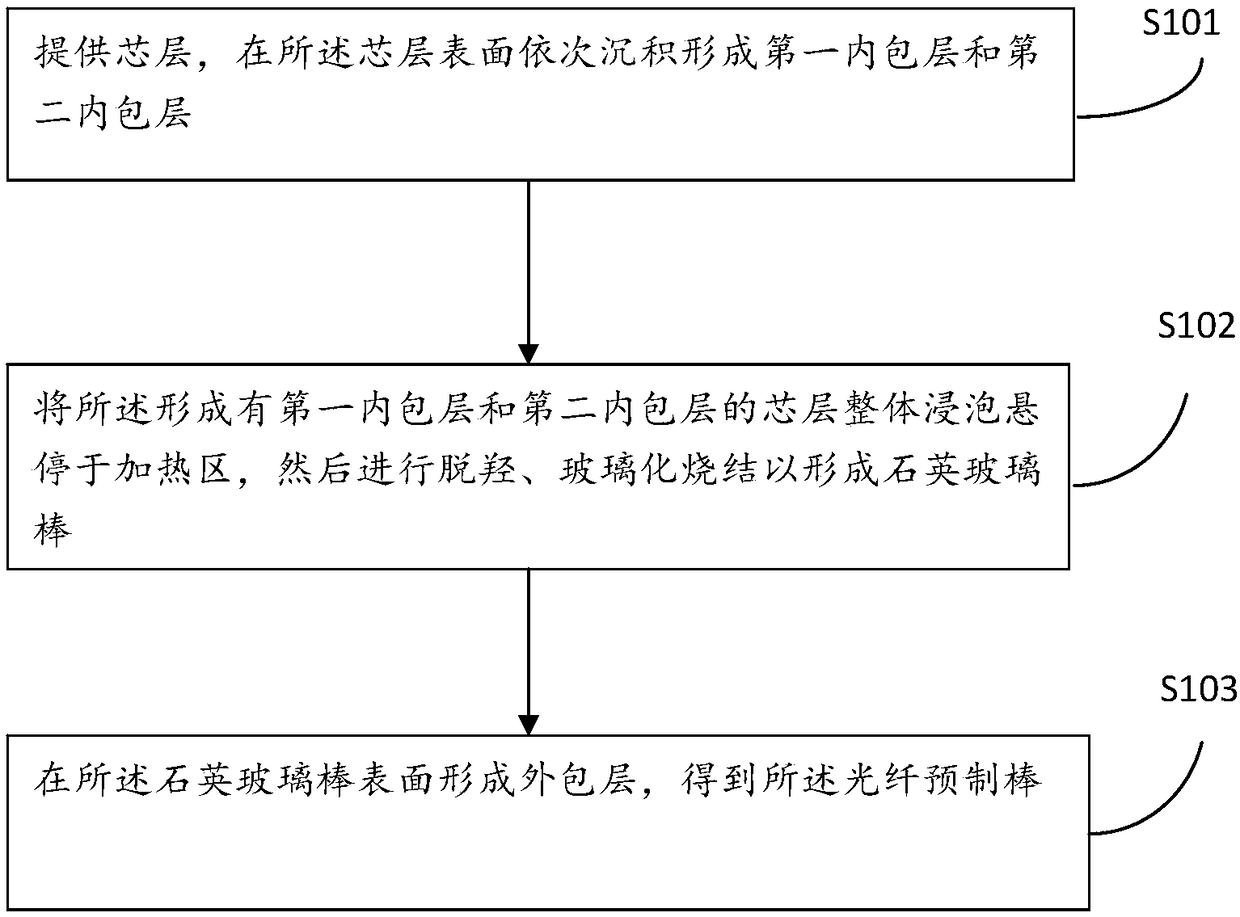

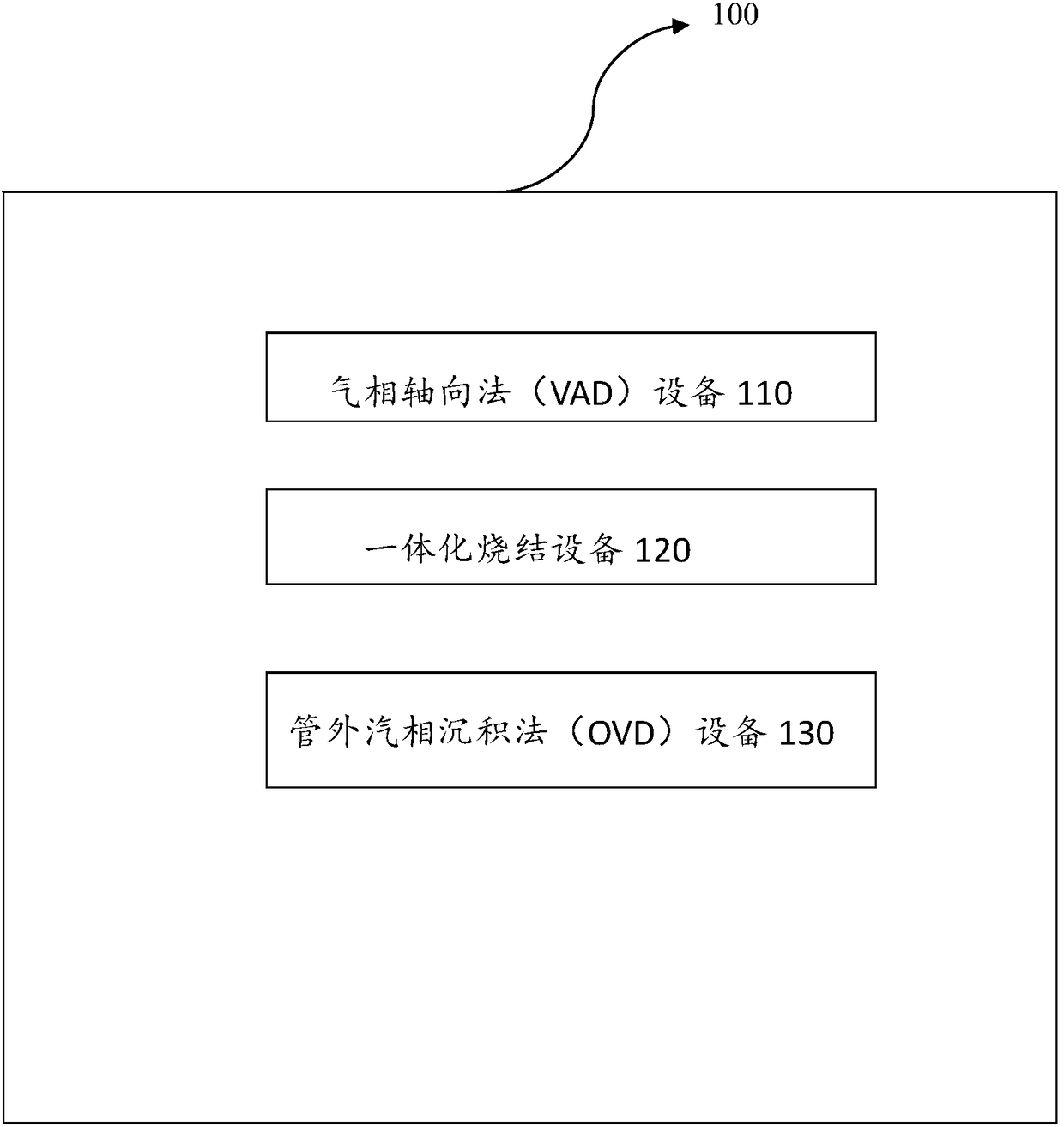

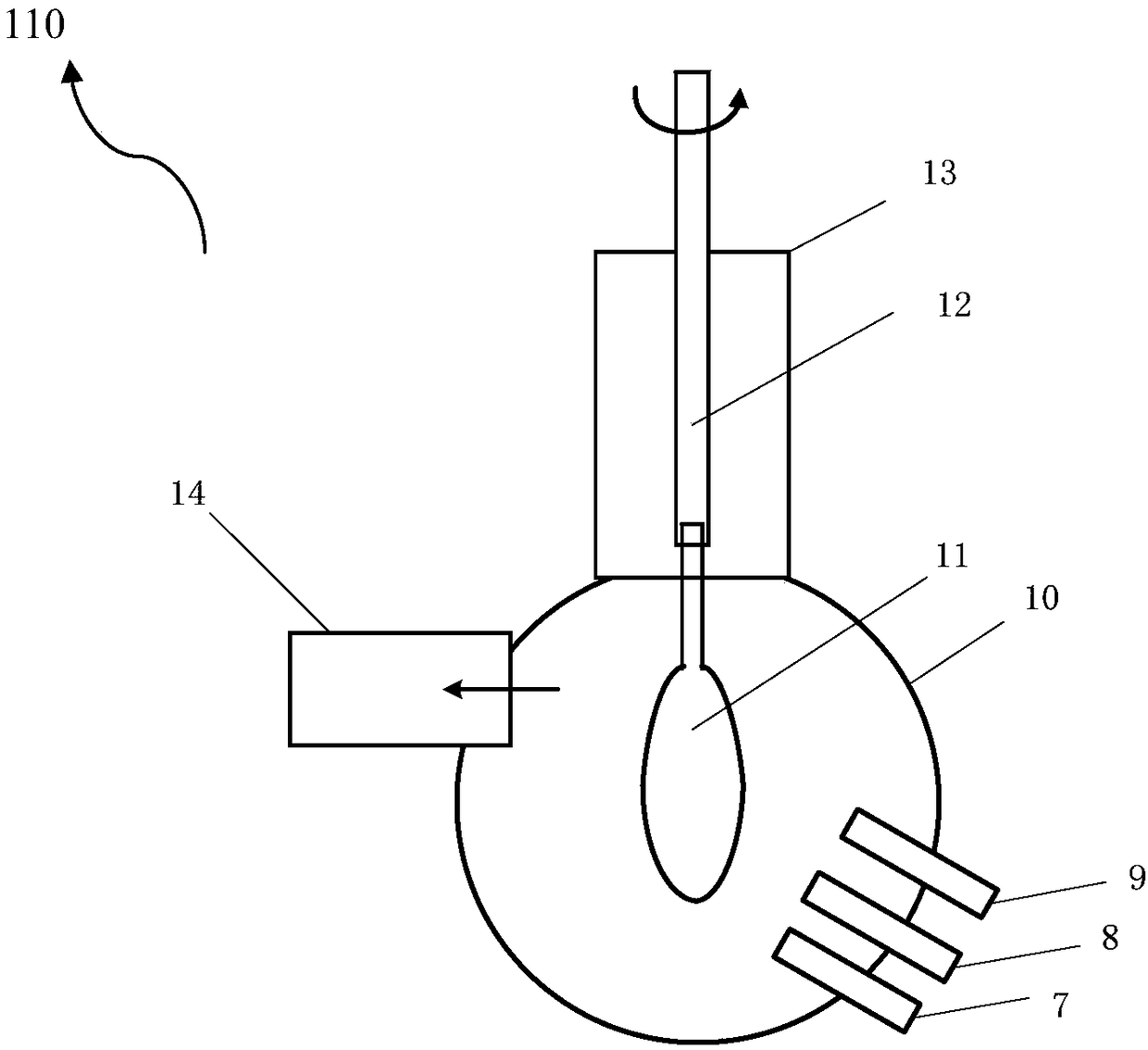

Optical fiber preform and manufacture method thereof

PendingCN109081575ALow hydroxyl contentPrecise control of fluorine dopingGlass making apparatusFiberZero-dispersion wavelength

The invention provides a manufacture method of an optical fiber preform, comprising the steps: providing a core layer, and precipitating a first inner coating layer and a second inner coating layer sequentially on the surface of the core layer; soaking the core layer with the first and second inner coating layers in a heating zone in suspended manner, and carrying out dehydroxylation and vitrification sintering to form a quartz glass rod; forming an outer coating layer on the surface of the quartz glass rod to obtain the optical fiber preform. The optical fiber preform herein has large size and good fluorine-doping control precision for a recessed layer, has bending performance under small radius R of < / =5 mm, has low fiber attenuation and good color dispersion, has zero-color-dispersion wavelength of < / =1320 nm and low hydroxy content, and meets the indicator of ITU-TG657B3 and higher.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

Efficient aqueous pigment dispersant

InactiveCN102974267AGood dispersion effectLittle environmental hazardTransportation and packagingInksFatty alcoholPOLYOXYETHYLENE ETHER

The invention relates to an auxiliary agent for a pigment, which is particularly suitable for dispersing the pigment, has good dispersion performance and high stability, and belongs to the field of application of a fine chemistry industry. A dispersant is prepared from fatty alcohol-polyoxyethylene ether, fatty alcohol-polyoxyethylene ether monoester, fatty alcohol-polyoxyethylene ether diester, carboxylated fatty alcohol-polyoxyethylene ether, carboxylated fatty alcohol-polyoxyethylene ether monoester and carboxylated fatty alcohol-polyoxyethylene ether diester. The dispersant is easily and biologically degraded and meets ecological and green and environment-friendly requirements; and a unique molecular chain structure can better disperse the pigment and can keep the pigment stable.

Owner:JIANGNAN UNIV

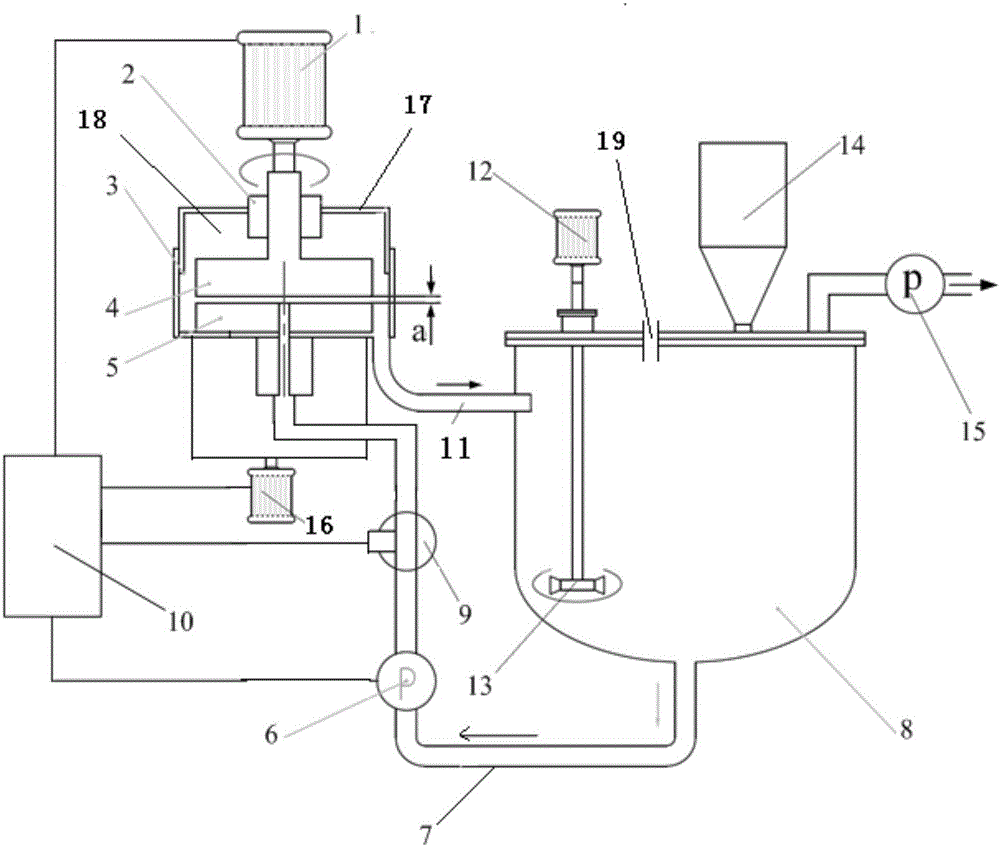

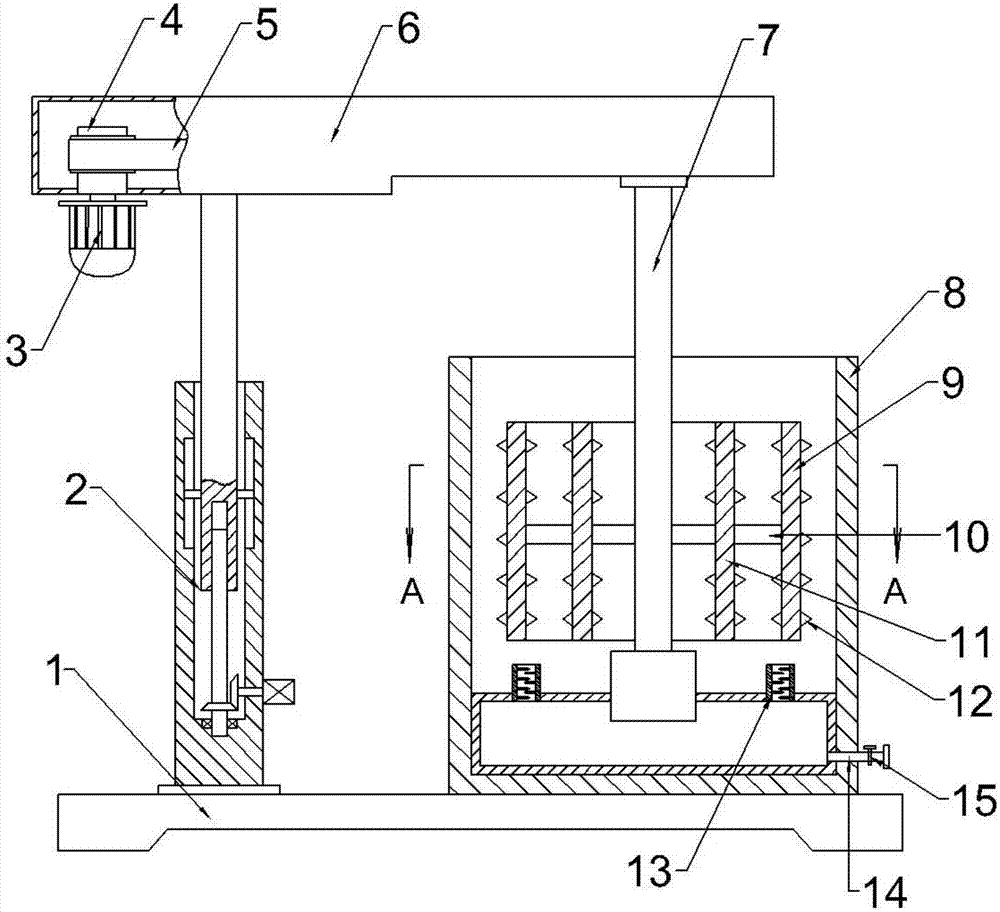

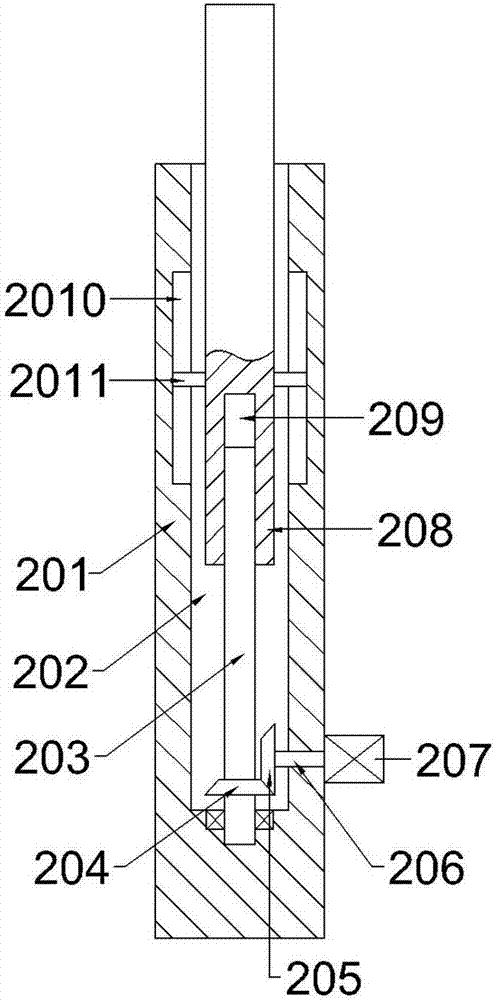

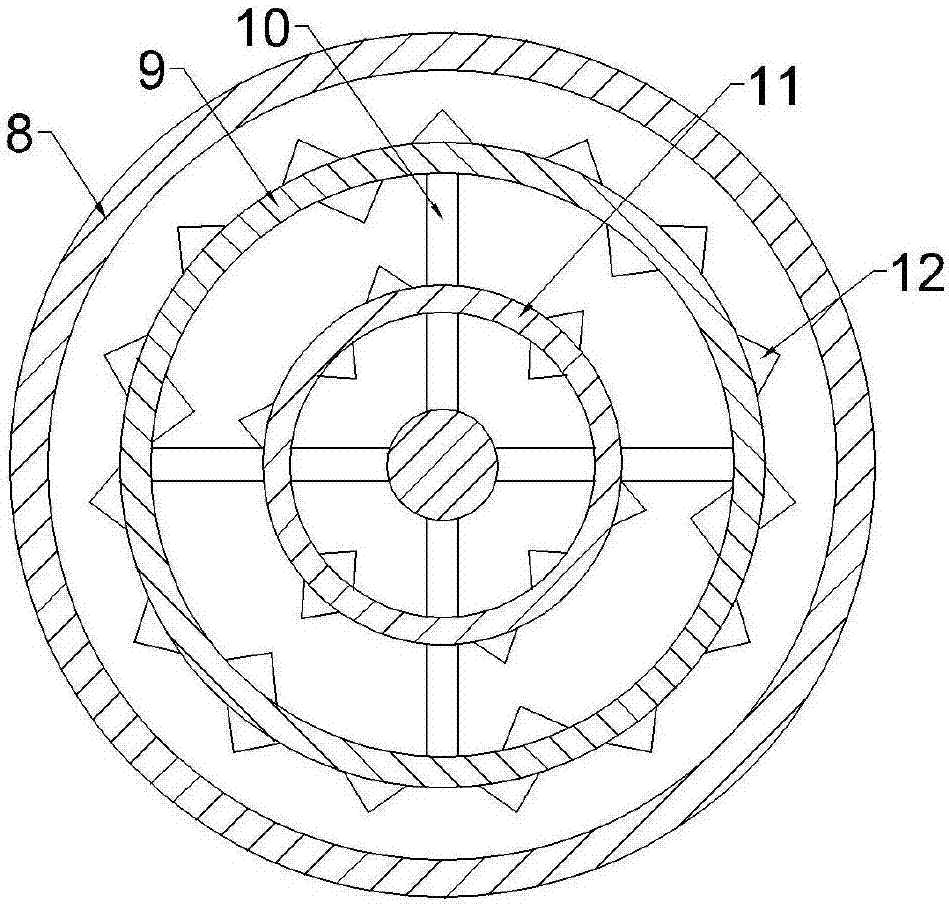

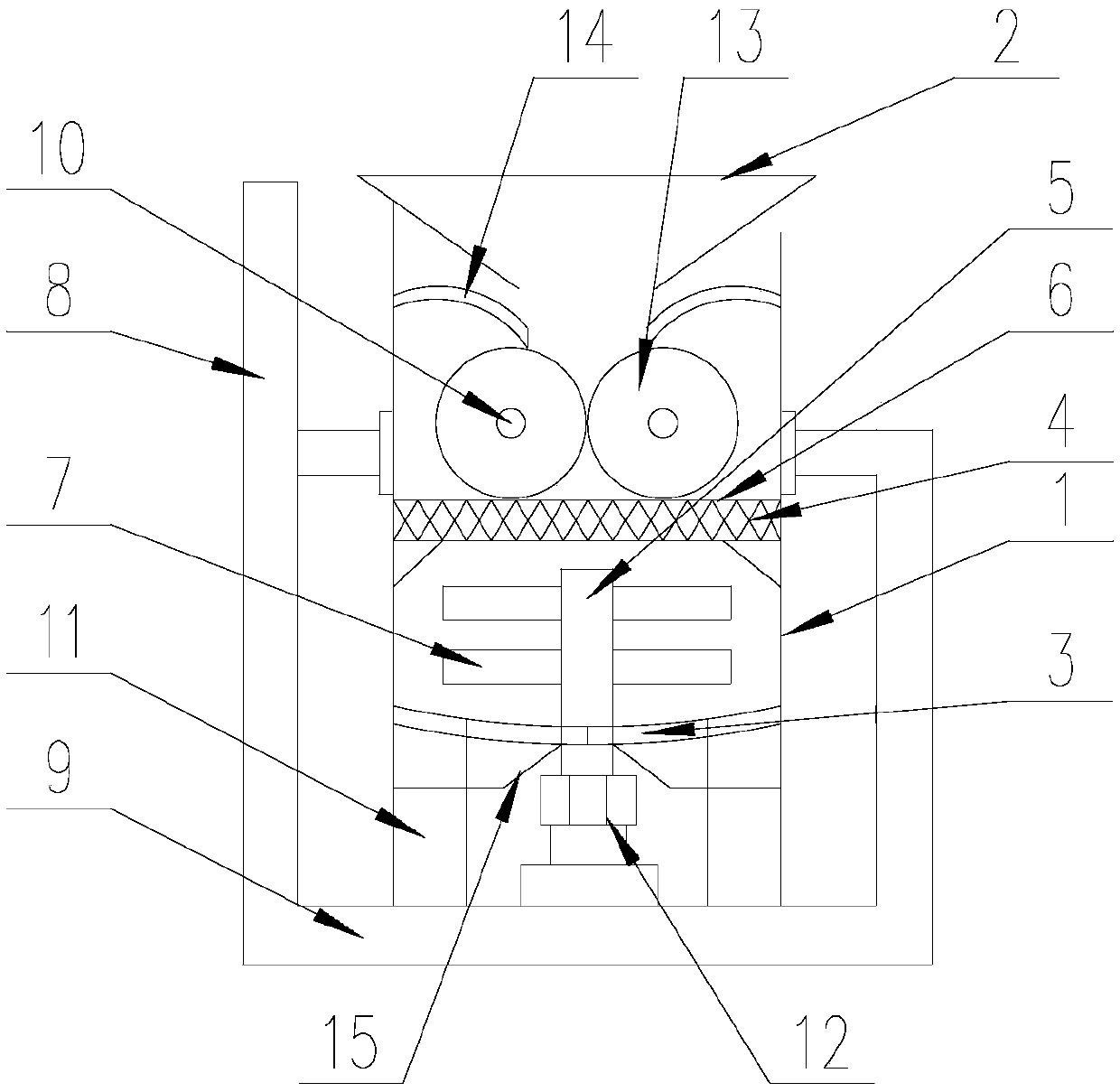

High-speed centrifugal film dispersion machine

InactiveCN105833939AGood dispersion effectPlay the role of dispersing materialsCocoaGrain treatmentsEngineeringCirculating pump

The invention discloses a thin film dispersing machine, which comprises a grinding chamber (18), wherein a movable grinding disc (4) and a static grinding disc (5) are arranged in the grinding cavity (18), and a material hole is arranged in the middle of the static grinding disc (5) , the material hole communicates with the bottom of the storage tank (8) through the first circulation pipe (7), the first circulation pipe (7) is provided with a circulation pump (6), and the grinding chamber (18) passes through The second circulation pipe (11) communicates with the upper part of the storage tank (8). The invention has good dispersion effect.

Owner:无锡新光粉体科技有限公司

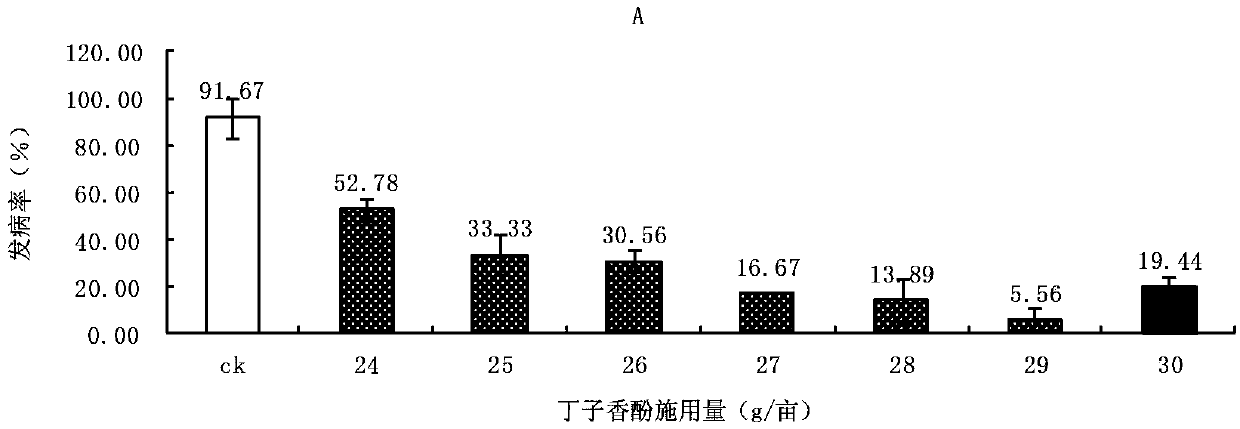

Trichoderma preparation for controlling pepper phytophthora blight and field tank mix pesticide containing the same

The invention discloses a trichoderma preparation for controlling pepper phytophthora blight and a field tank mix pesticide containing the same. The trichoderma preparation comprises, by weight: 28-32% of Trichoderma conidia, 10-15% of a dispersant, 4-6% of a wetting agent, 1-2% of a protective agent, and 50-55% of a carrier, wherein the trichoderma is Trichoderma. asperellum CGMCC No.6422. The field tank mix pesticide is prepared by mixing the trichoderma preparation and a bactericide and dissolving the mixture in water during application. The bactericide is eugenol or mandipropamid. The trichoderma preparation provided in the invention has the advantages of good dispersing effect, long storage period, and good pepper phytophthora blight control effect. In addition, the field tank mix pesticide developed in the invention can achieve a good control effect with a reduced number of times of pesticide delivery to phytophthora capsici, the control cost can be lowered, and pollution of reagents to the environment is reduced.

Owner:ZHEJIANG UNIV

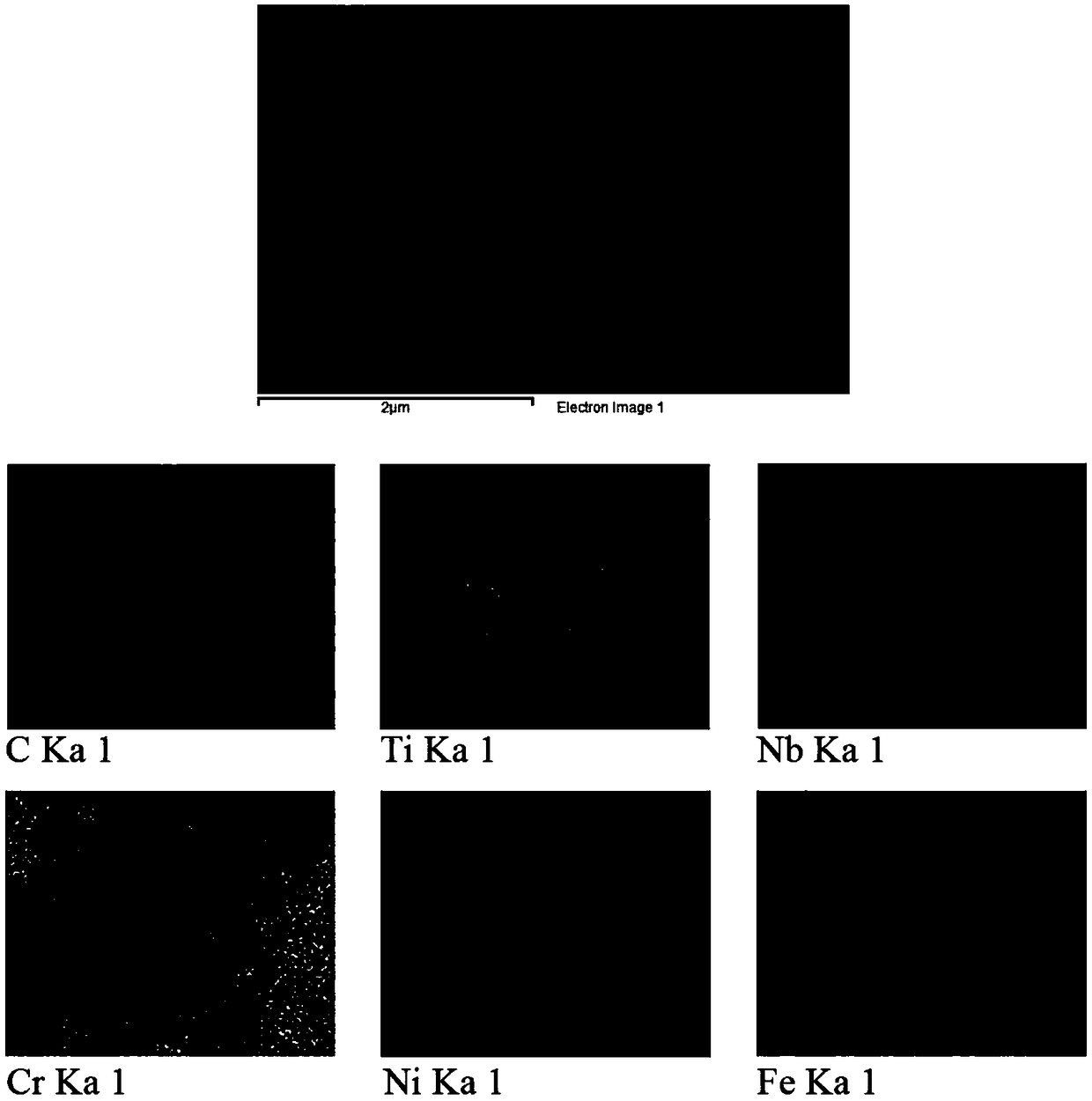

Laser cladding in-situ synthesized complex carbide (Ti, Nb) C strengthened Ni-based coatings and preparation

ActiveCN108866538AUniform particle distributionGood dispersion effectMetallic material coating processesSurface finishingBall mill

The invention discloses laser cladding in-situ synthesized complex carbide (Ti, Nb) C strengthened Ni-based coatings and preparation, and belongs to the technical field of surface treatment. The preparation steps include that firstly, the surface of Cr12MoV automobile die steel is cleaned by means of an angle grinder and acetone; and secondly, alloy powder used for laser cladding is prepared according to chemical components and placed into a ball mill to be subjected to mixing for two hours, a coaxial power feeding mode is adopted for preparing four four-layer abrasion resistant coatings on the surface of a base material, the coatings are compact in structure, uniform in in-situ strengthening phase distribution, good in dispersion effect, free of pollution on interface, and good in metallurgical bonding with the base material. The microhardness is around 700 HV, and the mechanical performance of the surface of the die steel is remarkably improved.

Owner:BEIJING UNIV OF TECH

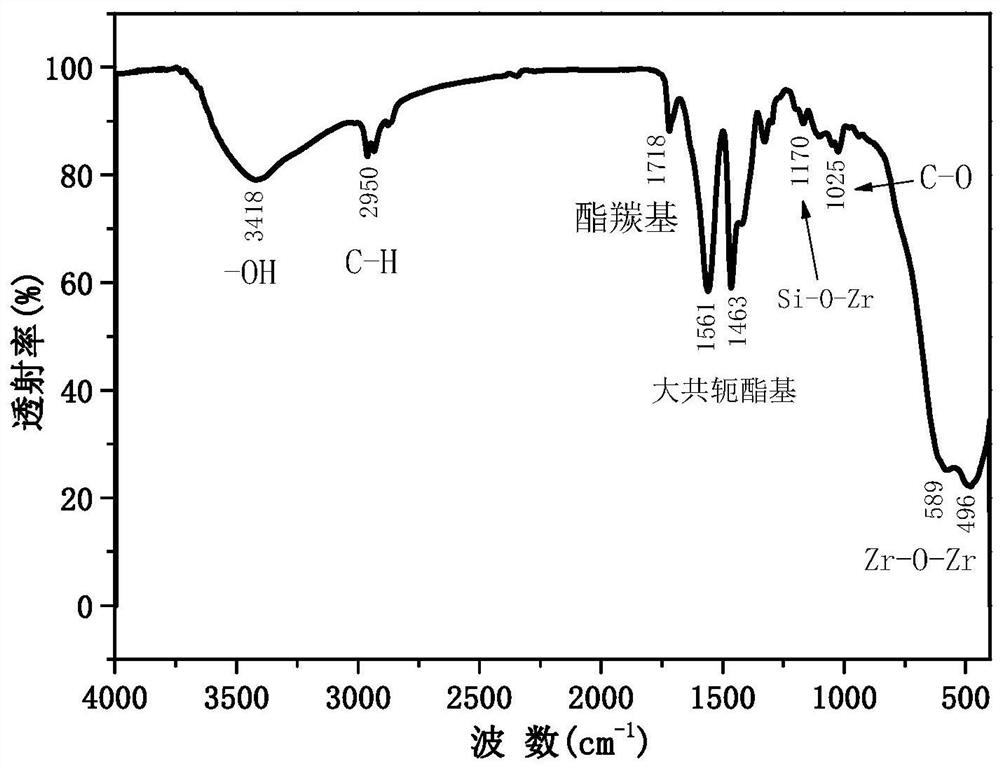

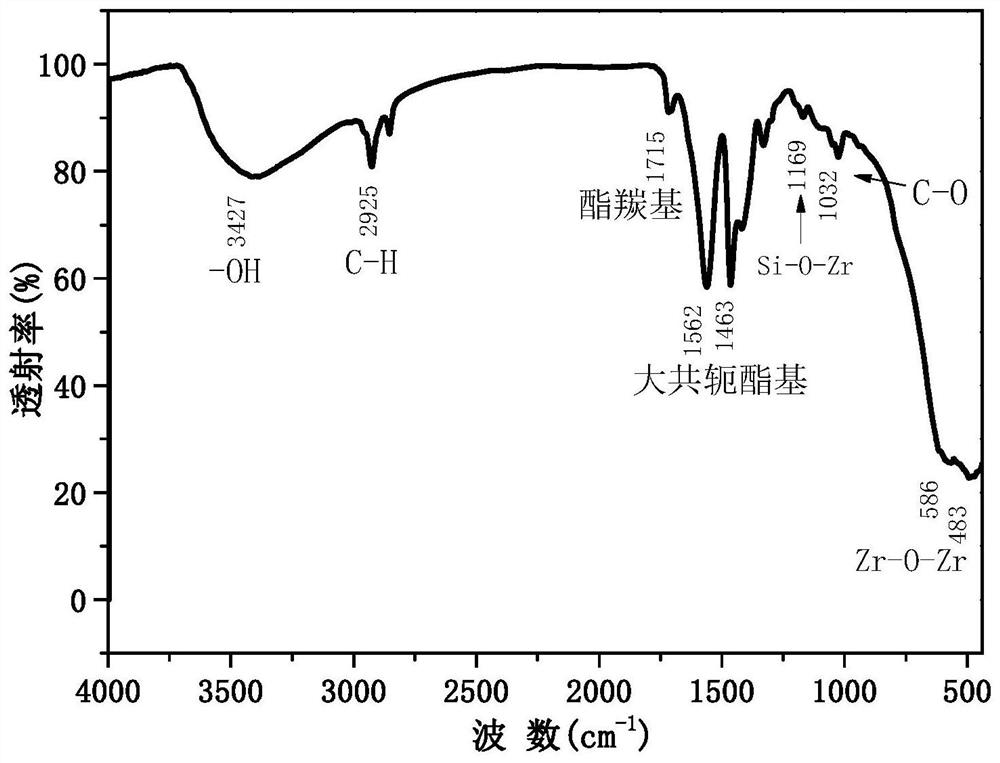

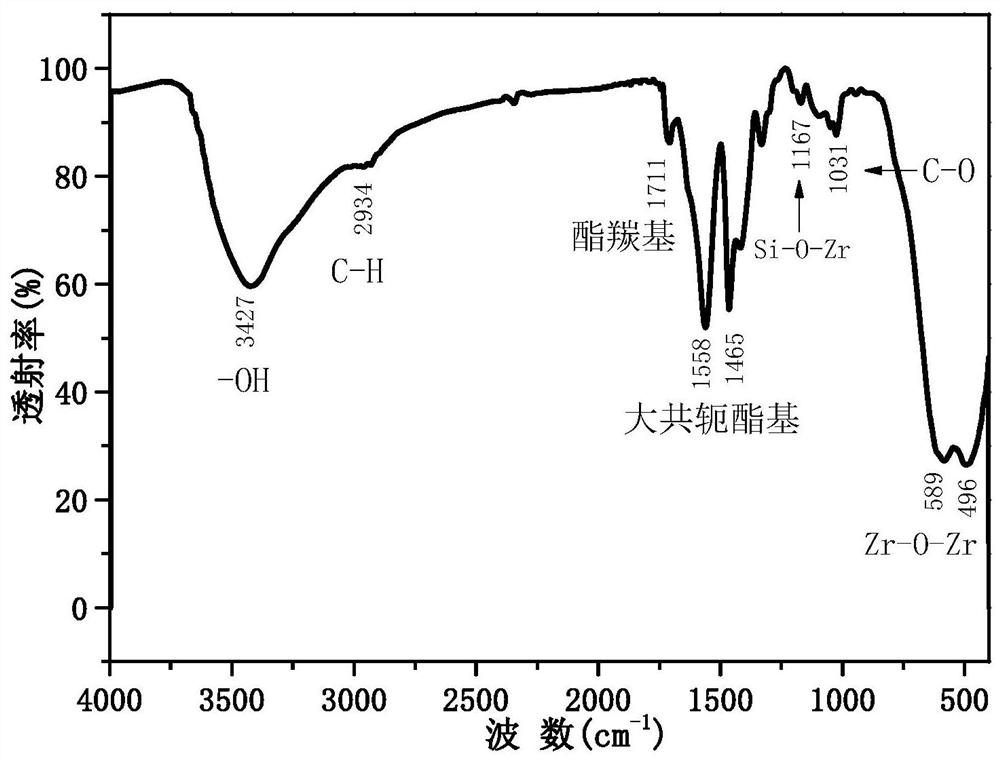

Nano-zirconia dispersion liquid, preparation method thereof, monomer dispersion liquid obtained based on nano-zirconia dispersion liquid and optical film

InactiveCN113773691AEasy to operateGood dispersion effectCoatingsOptical elementsCarbonyl groupEther

The invention provides a nano-zirconia dispersion liquid, a preparation method thereof, a monomer dispersion liquid obtained based on the nano-zirconia dispersion liquid and an optical film, and belongs to the field of fine chemical engineering. The amount of nano-zirconia particles contained in the nano-zirconia dispersion liquid provided by the invention is 45 to 75 weight percent; through infrared spectrum characterization, it is found that functional groups in the following peak intervals are grafted on the surfaces of the nano zirconium oxide particles: a hydroxyl group with the peak interval of 3200 cm <-1 > to 3600 cm <-1 >, a Zr-O-Zr group with the peak interval of 480 cm <-1 > to 850 cm <-1 >, a saturated carbon-hydrogen bond with the peak interval of 2850 cm <-1 > to 2960 cm <-1 >, an ester carbonyl group with the peak interval of 1700 cm <-1 > to 1750 cm <-1 >, a delocalized conjugated ester group with the peak interval of 1460 cm <-1 > to 1580 cm <-1 >, a Si-O-Zr group with the peak interval of 800 cm <-1 > to 1200 cm <-1 > and a C-O ether bond with the peak interval of 1000 cm <-1 > to 1200 cm <-1 > the nano-zirconia dispersion liquid provided by the invention has high dispersion content, and the refractive index can reach 1.420-1.565; the dispersion content of the nano-zirconia monomer dispersion liquid obtained based on the nano-zirconia dispersion liquid can reach 55-85wt%, and the refractive index can reach 1.620-1.720; and the refractive index of a high-refractive coating can be greatly improved in subsequent preparation of a brightness enhancement film or an anti-reflection film, and therefore, the performance of the film is improved.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

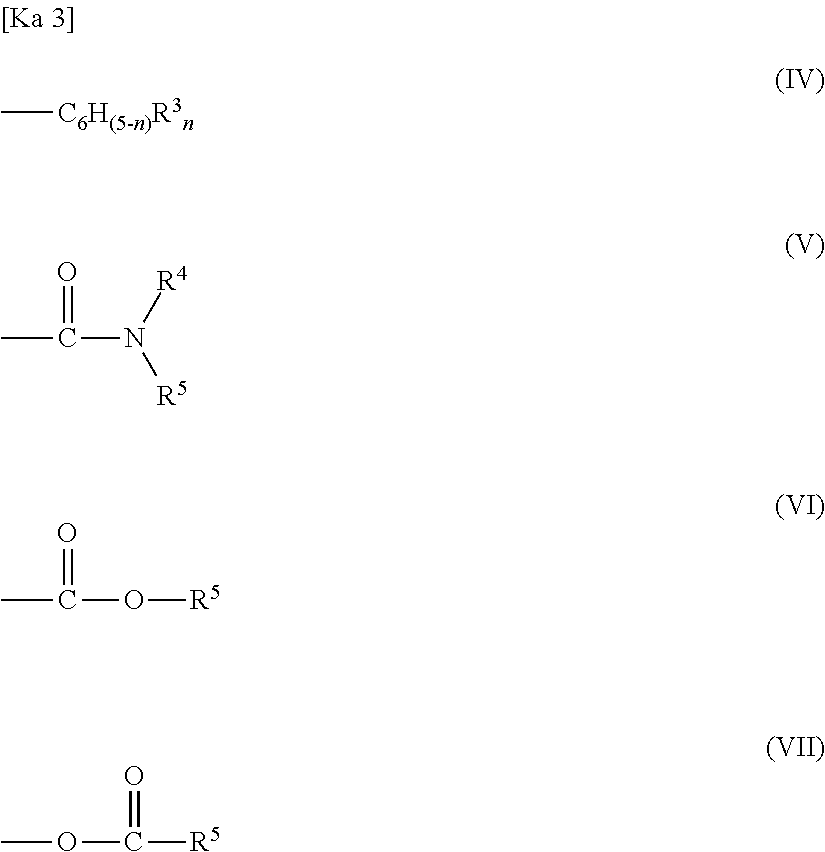

Engineering plastic resin composition containing graft copolymer

InactiveUS20110021703A1High compatible abilityGood dispersion effectMixingWeight distributionSide chain

Provided is a resin composition containing a resin component prepared by blending a graft copolymer with an engineering plastic, wherein the above graft copolymer is a graft copolymer satisfying (a) to (e) shown below:(a) a graft rate is 1 to 150% by mass,(b) a weight average molecular weight measured by GPC is 500 to 400000,(c) a molecular weight distribution (Mw / Mn) is 1.5 to 4,(d) a main chain is a polymerization chain containing 1 to 100% by mass of a monomer unit having a functional group interacting with the engineering plastic and(e) a side chain is a homopolymerization chain of a single kind selected from α-olefins having 3 to 28 carbon atoms or a copolymerization chain of two or more kinds selected therefrom or a copolymerization chain comprising an α-olefin unit having 3 to 28 carbon atoms and an ethylene unit which accounts for 50% by mass or less, and a mesopentad ratio [mmmm] of the polymerization chain is 30 to 80 mole %.

Owner:IDEMITSU KOSAN CO LTD

Paint dispersing equipment with spraying dispersion function

InactiveCN107469692AImprove dispersion effectGood dispersion effectShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCantilever

The invention provides paint dispersing equipment with a spraying dispersion function. The equipment comprises a base, a height adjusting device is arranged on the left side of the base, a cantilever beam is arranged at the top end of the height adjusting device, a first motor, a conveyor belt and a pair of belt wheels are arranged in the cantilever beam, one end of the conveyor belt is connected with the first motor through the belt wheels, a main rotary shaft is connected to the other end of the conveyor belt through the belt wheels, the main rotary shaft is located in a dispersing barrel, and the dispersing barrel is located on the base; an inner sleeve cylinder is arranged outside the main rotary shaft in a sleeving mode, and the inner sleeve cylinder is fixedly connected with the main rotary shaft through multiple supporting rods. The paint dispersing equipment has the advantages that when the main rotary shaft moves downward, liquid in a liquid storage shell is extruded by an extruding block, so that the liquid in the liquid storage shell sprays outward through a spraying sleeve cylinder with a certain flow speed, and in the spraying process, dispersing treatment is conducted on paint in the liquid by means of blades, so that the dispersing effect of the paint is improved.

Owner:李云

Fire-resistant anti-corrosion coating and method for preparing same

InactiveCN104387921ASimple production processGood dispersion effectFireproof paintsAnti-corrosive paintsSilicone resinQuinoline

The invention discloses a fire-resistant anti-corrosion coating. The fire-resistant anti-corrosion coating is characterized by being prepared from the following raw materials in parts by weight: 2-4 parts of bentonite, 1-3 parts of quartz sand, 2-3 parts of chromium diboride, 2-3 parts of smoked sheet rubber, 23-26 parts of phenolic resin, 3-4 parts of aluminum phosphate, 24-28 parts of acrylic-acid modified epoxy resin, 2-3 parts of 8-hydroxyquinoline, 2-3 parts of carboxylic glyceride, 4-6 parts of acetone, 4-6 parts of sintered bauxite, 1-2 parts of an antioxidant (RD), 1-2 parts of an antioxidant (DSTP), 1-3 parts of beeswax, 10-14 parts of organic silicone resin, 5-7 parts of talc, 4-5 parts of eleostearic acid, 1-3 parts of isopropyl tri(dioctyl pyrophosphate acyloxy)titanate, 12-15 parts of butyl acetate, 8-12 parts of xylene and 4-7 parts of assistants. The coating disclosed by the invention has the advantages of resisting fire, weathering and corrosion and shielding electromagnetic waves, further has the advantages of environmental friendliness, energy conservation, simple production process, good dispersion effect, low cost, stable performance and long service life, and has good economic and social benefits.

Owner:WUHU BAOYI AMUSEMENT EQUIP

UV (Ultraviolet) curing nanosilver wire sizing agent for touch screen and preparation method thereof

ActiveCN106833353AGood dispersion effectSimple processNon-conductive material with dispersed conductive materialPolyurea/polyurethane coatingsSolventPrepolymer

The invention discloses an UV (Ultraviolet) curing nanosilver wire sizing agent for a touch screen and a preparation method thereof. The preparation method is characterized by adopting a photo-active prepolymer as a growth template of a nanosilver wire and polyol as a reducing agent in a silver nitrate / polyol system, carrying out centrifugal separation on the system after completing a reaction, and removing supernatant of the polyol, thus preparing a compound of a nanosilver wire / photo-active prepolymer. A photo-initiation monomer, a photo-initiator, a solvent and relevant adjuvants are added in the compound, and the UV curing nanosilver wire sizing agent can be prepared into photo-initiated and cured products of conducting printing ink or conducting adhesive and the like according to needs. According to a nanosilver wire compound prepared by the invention, the nanosilver wire has good dispersity in the system by utilizing adsorbing and coating of the prepolymer on the nanosilver wire, and the uniformity is good; meanwhile, the UV curing nanosilver wire sizing agent can be directly used for blending products, the process is simple, and a good industrial prospect is obtained.

Owner:SOUTH CHINA UNIV OF TECH +1

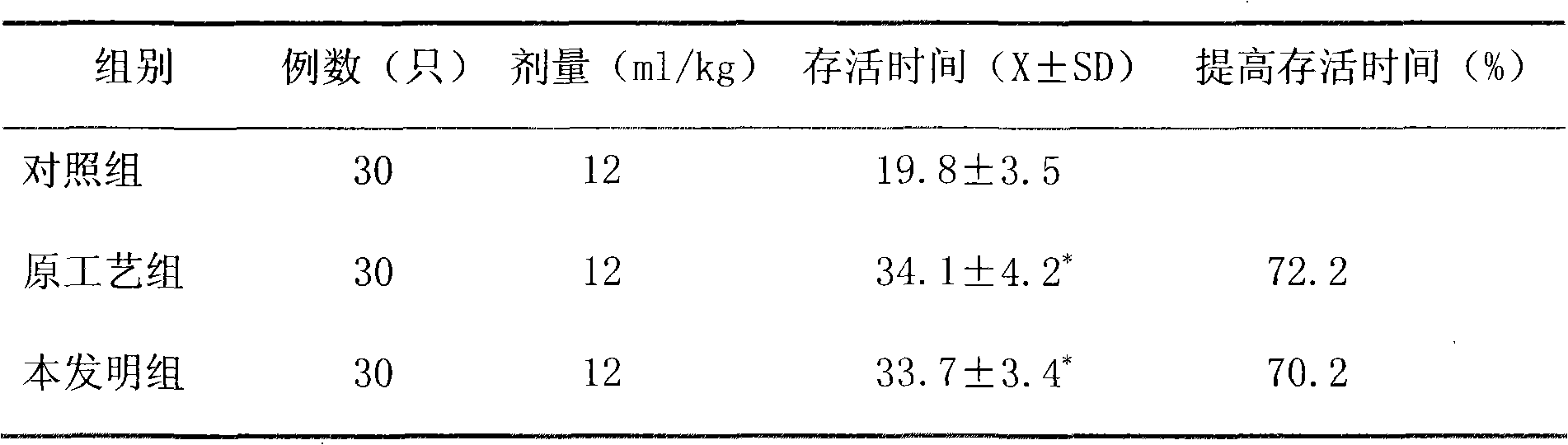

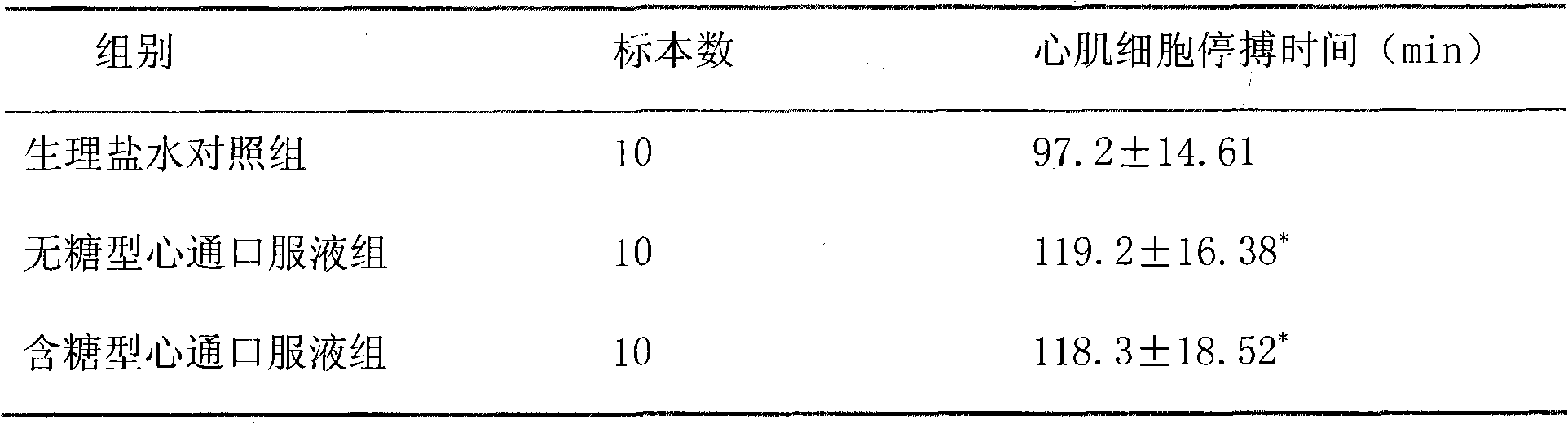

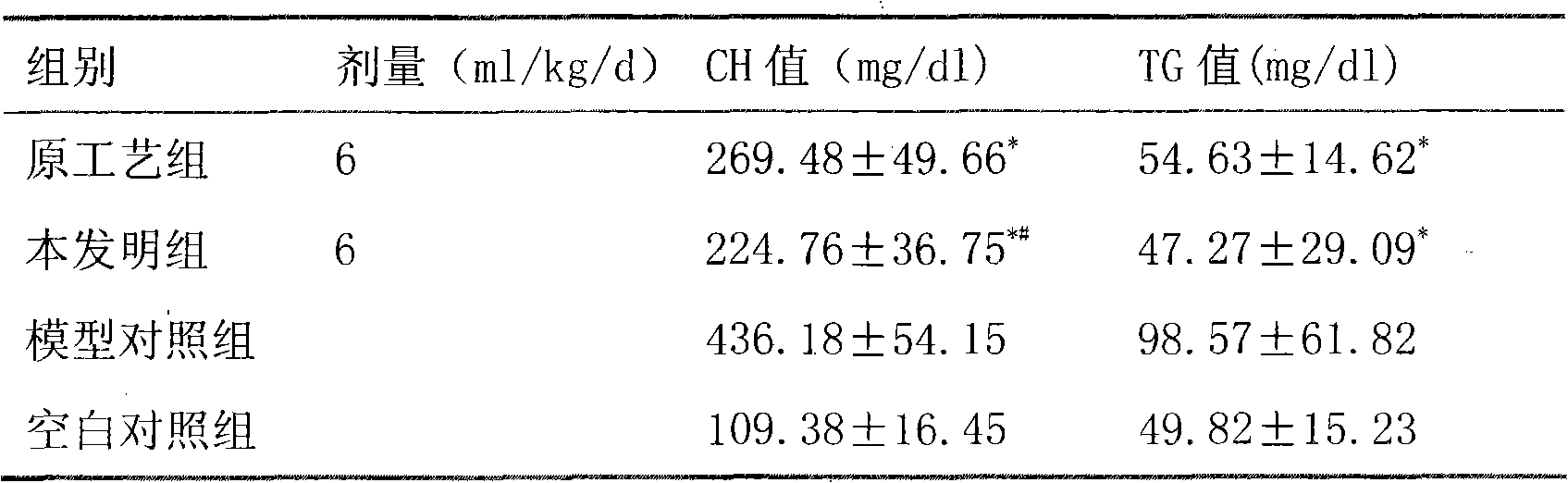

Preparation method of sugar-free traditional Chinese medicine oral liquid for treating angina pectoris

ActiveCN101780212AGood dispersion effectEasy to absorbPharmaceutical delivery mechanismCardiovascular disorderWater solubleSolubility

The invention discloses a preparation method of sugar-free traditional Chinese medicine oral liquid for treating angina pectoris. In order to overcome the defects of the traditional taste modifying process for preparing the sugar-free oral liquid, the invention adopts the beta-cyclodextrin inclusion technique to modify taste, develops a sugar-free oral liquid specification, realizes the industrialization of the production process of the Chinese medicine oral liquid to which the inclusion technique is applied, improves the taste of the preparation, improves the medicine use compliance of patients, ensures the clinical efficacy of the product, and simultaneously, increases the water-solubility of low-polarity active components by the formation of an inclusion compound, and improves the quality stability of the preparation.

Owner:LUNAN HOPE PHARM CO LTD

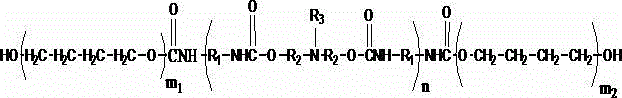

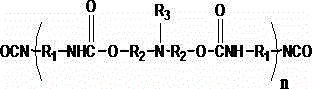

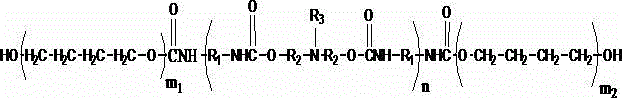

Preparing method of hyperdispersant and non-dyed polyurethane elastic fiber

ActiveCN104878463AGood dispersion effectReduce procurement costsMonocomponent polyurethanes artificial filamentPigment addition to spinning solutionPrepolymerChemistry

The invention relates to a preparing method of hyperdispersant and non-dyed polyurethane elastic fiber. According to the method, a diisocyanate compound and polytetramethylene ether glycol are added into a N,N-dimethylacetamide or N,N-dimethylformamide solvent according to the mole ratio being (1.6-2.2):1, and a prepolymer solution is prepared; the temperature is lowered to 8 DEG C to 10 DEG C while the stirring is carried out; a mixed amine solution is added, and a spinning stock solution with the viscosity being 3800 to 4500 poises and the solid content being 30 percent to 40 percent is obtained; the spinning stock solution is injected into color paste to prepare a premixed stock solution; the premixed stock solution and the spinning stock solution are subjected to multiage tackifying blending; then, flatting agents, lubrication debonding agents and yellowing-proof agents are added; the mixture is fully stirred, and a colored stock solution is prepared; the non-dyed polyurethane elastic fiber with the fiber number being 40D to 300D is prepared by a conventional method. The preparing method has the advantages that the hyperdispersant is prepared by the self, the uniformity and the stable dispersion of the color paste in the spinning stock solution are ensured, and the coloring process of multiage tackifying blending is adopted, so that the color paste can be uniformly, fast and stably dispersed in the spinning stock solution.

Owner:LIANYUNGANG DUZHONG NEW AOSHEN SPANDEX

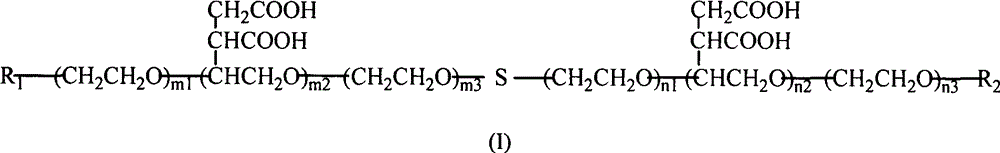

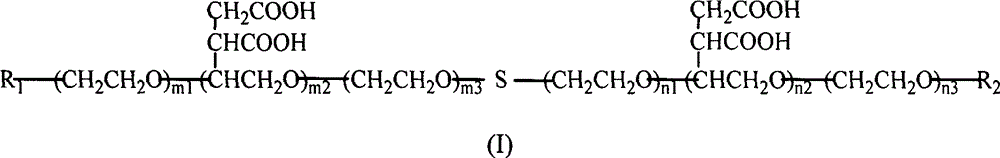

Polyether and carboxylic acid double-modified polyethyleneimine aqueous dispersant, and preparation method and application thereof

ActiveCN108816152AGood dispersion effectIncrease anchorageCarbon compoundsTransportation and packagingDouble bondSide chain

The invention discloses a polyether and carboxylic acid double-modified polyethyleneimine aqueous dispersant, and a preparation method and an application thereof. The polyethyleneimine molecular chainof the dispersant has a polyether side chain and a carboxylate side group, and the dispersant is prepared through a Michael addition reaction of a primary amino group and a secondary amino group contained in the polyethyleneimine and double bonds contained in alpha, beta-unsaturated acid salts and alpha, beta-unsaturated acid esters of polyether, wherein the polyethyleneimine makes the dispersanthave a good anchoring effect on inorganic powder; the polyether is a solvation chain and makes the dispersant have a steric hindrance effect; carboxylic acid is an ionic group and makes the dispersant have an electrostatic repulsion effect; and the polyether and the carboxylic acid commonly inhibit and prevent the agglomeration of dispersed particles, and the polyethyleneimine, the polyether andthe carboxylic acid are combined to obtain an excellent dispersion performance. The aqueous dispersant has an excellent dispersion performance when applied to water dispersion systems of an inorganicpigment, silicon-carbon powder, graphene and other inorganic powders.

Owner:SUN YAT SEN UNIV +1

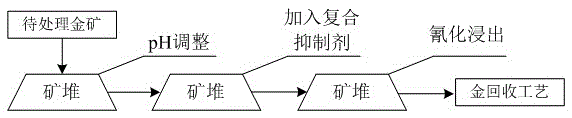

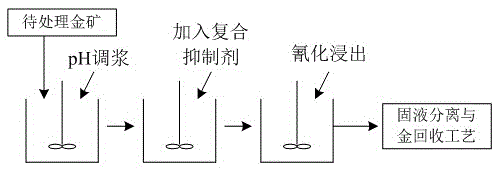

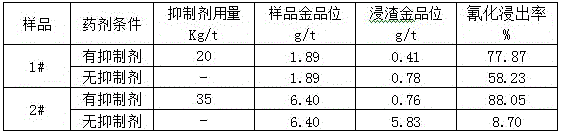

Carbonaceous gold ore inhibitor and using method thereof

The invention discloses a carbonaceous gold ore inhibitor and a using method thereof. The carbonaceous gold ore inhibitor aims at solving the problem that preg-robbing carbon (being mainly of organic carbon) in carbonaceous gold ores adsorbs gold cyanogen complex ions. The carbonaceous gold ore inhibitor comprises the following three materials in percent by mass: 10%-30% of sodium dodecyl benzene sulfonate, 10%-30% of sodium lauryl sulfate and 50%-70% of polyoxyethylene sorbitan laurate. The composite inhibitor is a surface active agent, reduces the adsorption loss of the gold cyanogen complex ions through the adsorption effect on preg-robbing carbon / iron-sulfur-arsenic oxidation bacteria residue bodies and remarkably increases the cyanidation leaching rate of gold. The inhibitor has the advantages of strong adaptability, good water solubility, good dispersion effect, small influence on environments, simple operation and the like. The popularization and application of the composite inhibitor and the using method thereof can remarkably increase the cyanidation recovery rate of gold in the carbonaceous gold ores and increases the comprehensive utilization ratio of resources and the economic income of enterprises.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

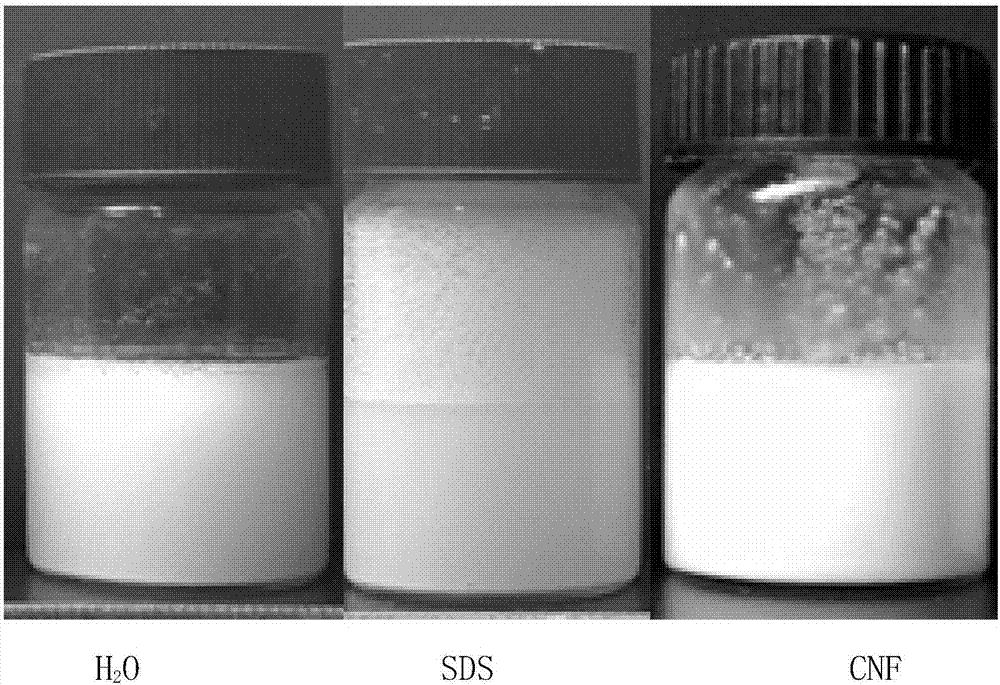

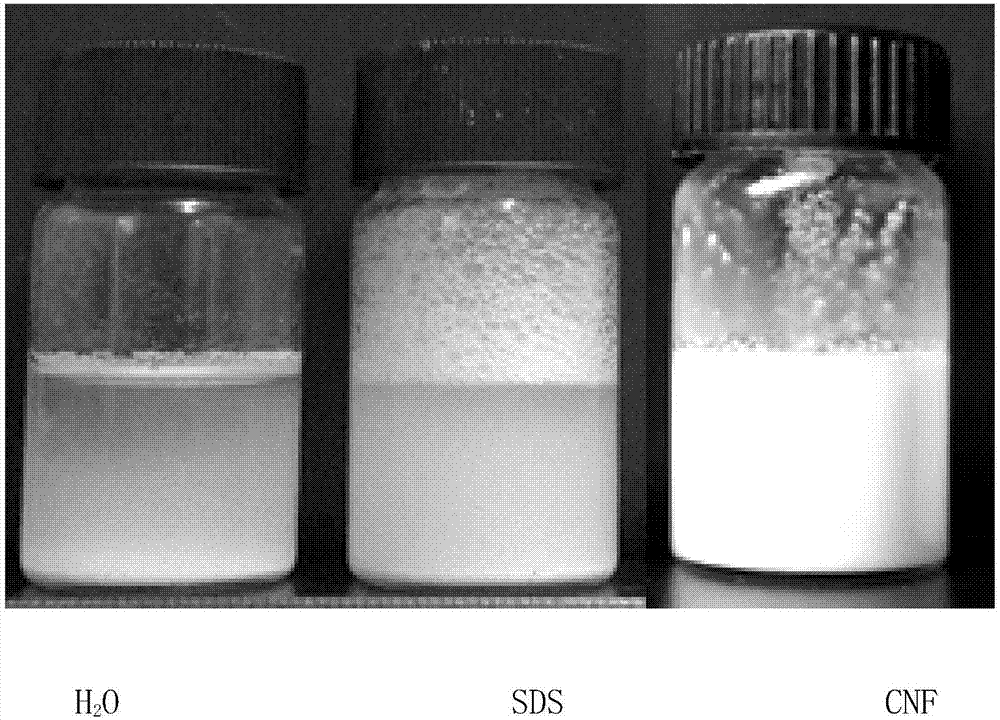

Method for stably dispersing metal oxide nanoparticles in aqueous phase

InactiveCN107324286AGood dispersion effectImprove stabilityOxide/hydroxide preparationNanometreNanofiber

The invention belongs to applications of nanomaterials in fields of chemical engineering and food, and particularly relates to a method for stably dispersing metal oxide nanoparticles in an aqueous phase. CNF (cellulose nanofiber) is taken as a dispersion aid for dispersing the metal oxide nanoparticles. The method is simple and convenient to operate, low in cost, green and pollution-free, a dispersion solution of the metal oxide nanoparticles prepared with the method has good dispersibility and high stability, subsequent use and long-term storage of the dispersion solution are facilitated, usage efficiency of the metal oxide nanoparticles is improved, and application fields of the metal oxide nanoparticles are further broadened.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

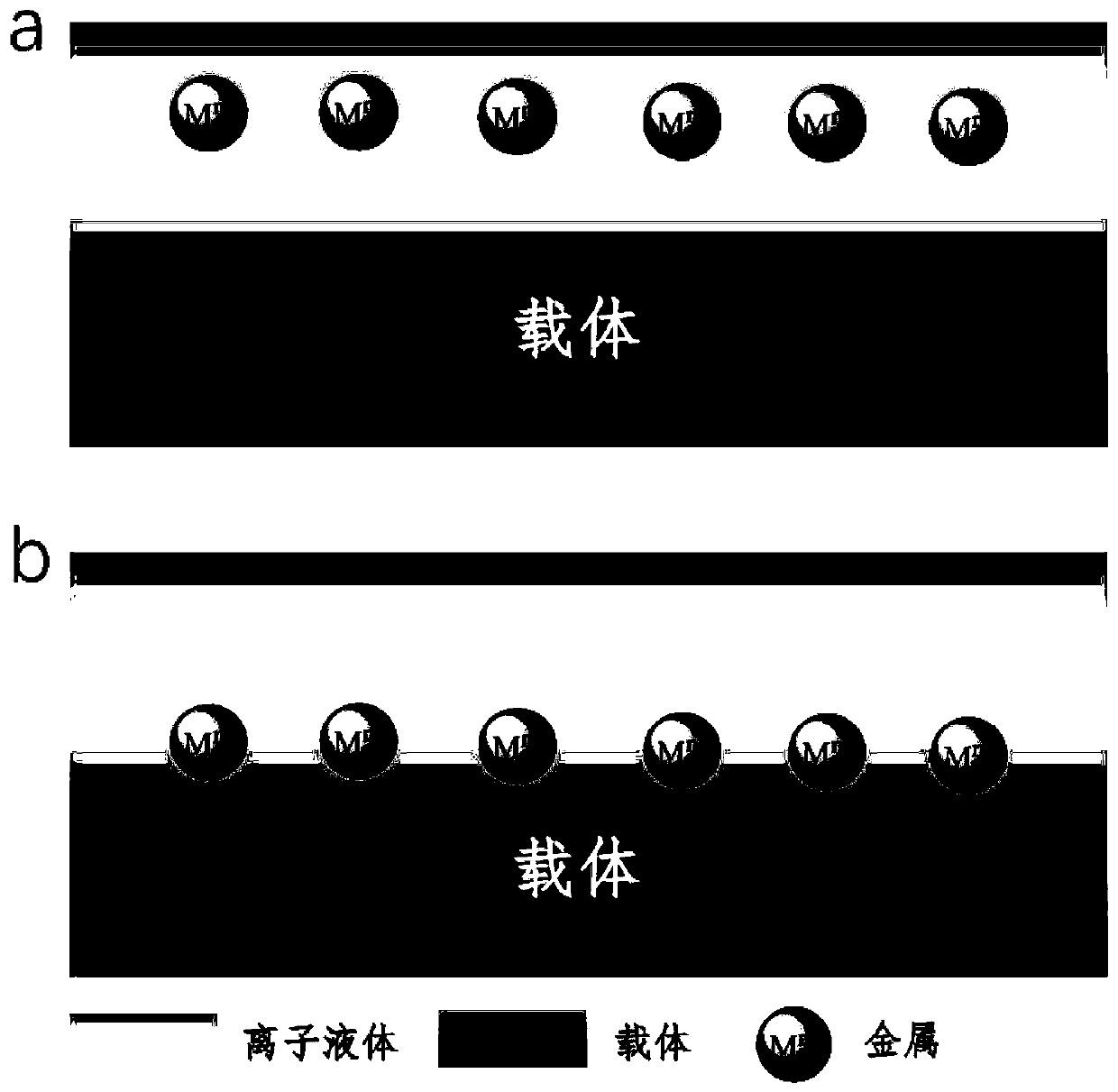

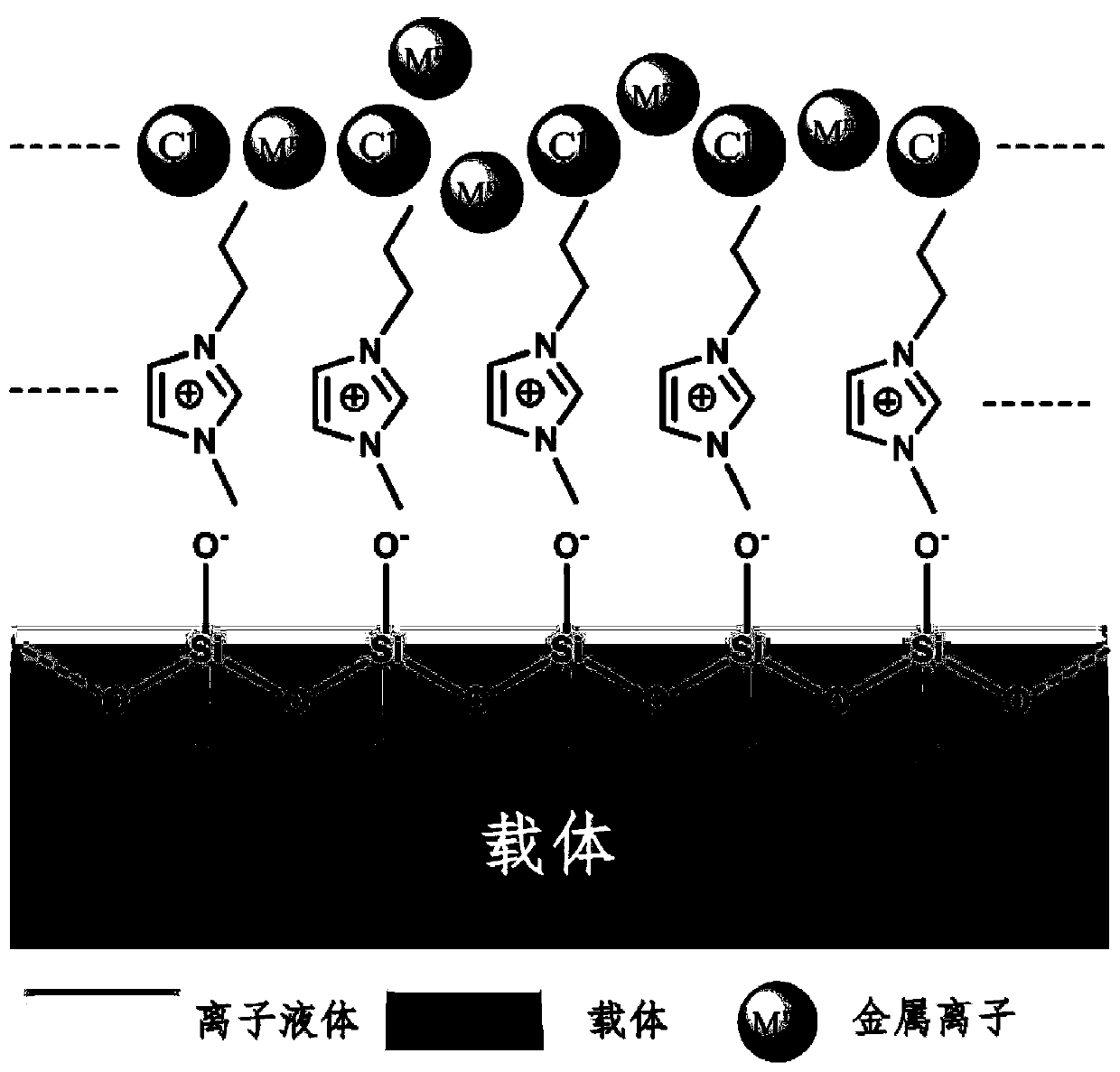

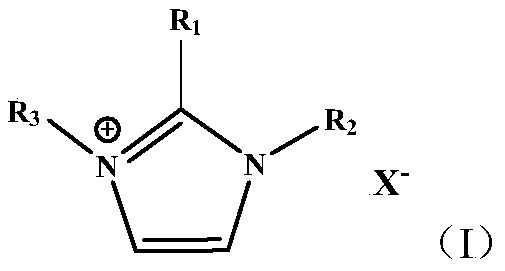

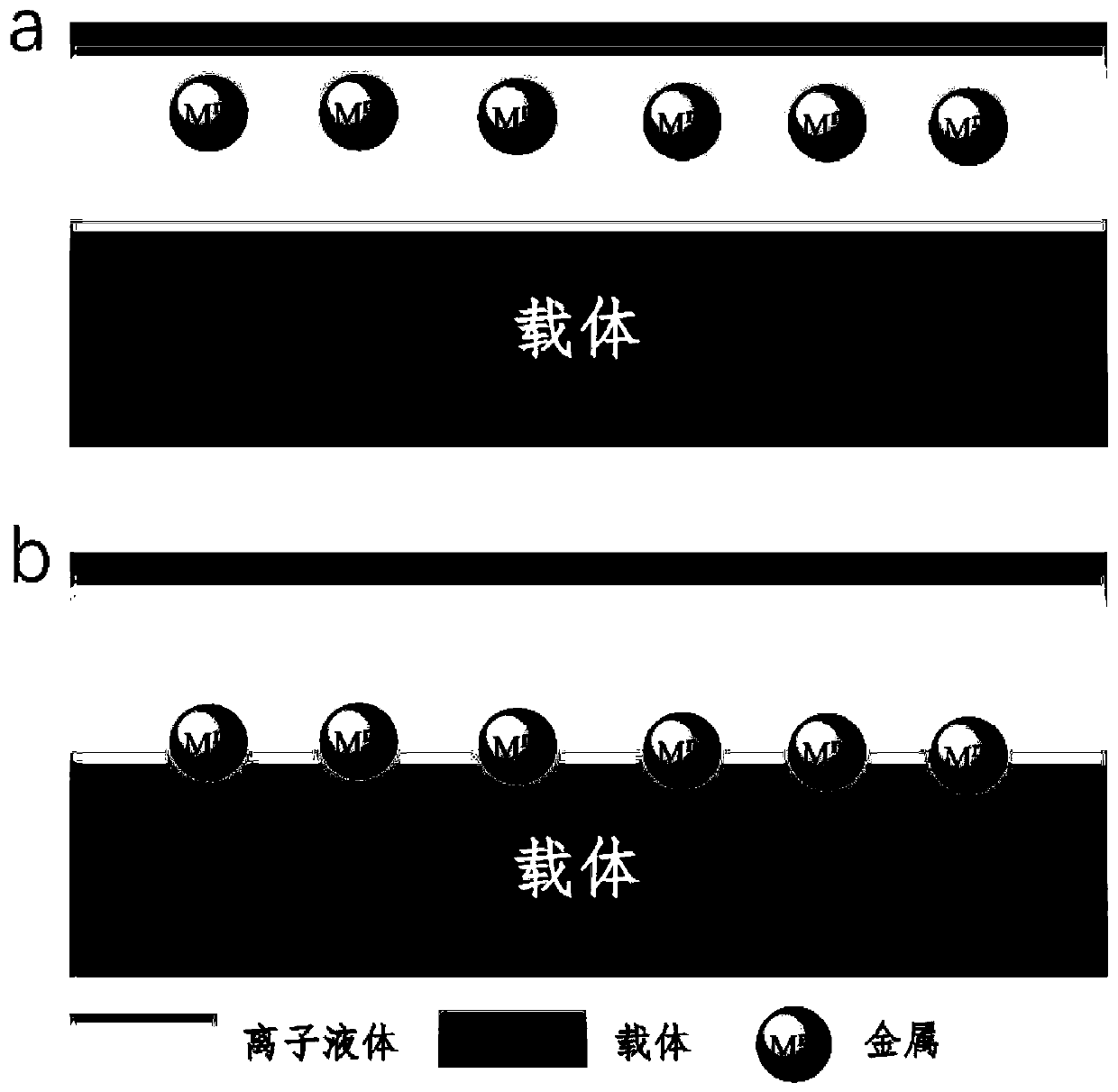

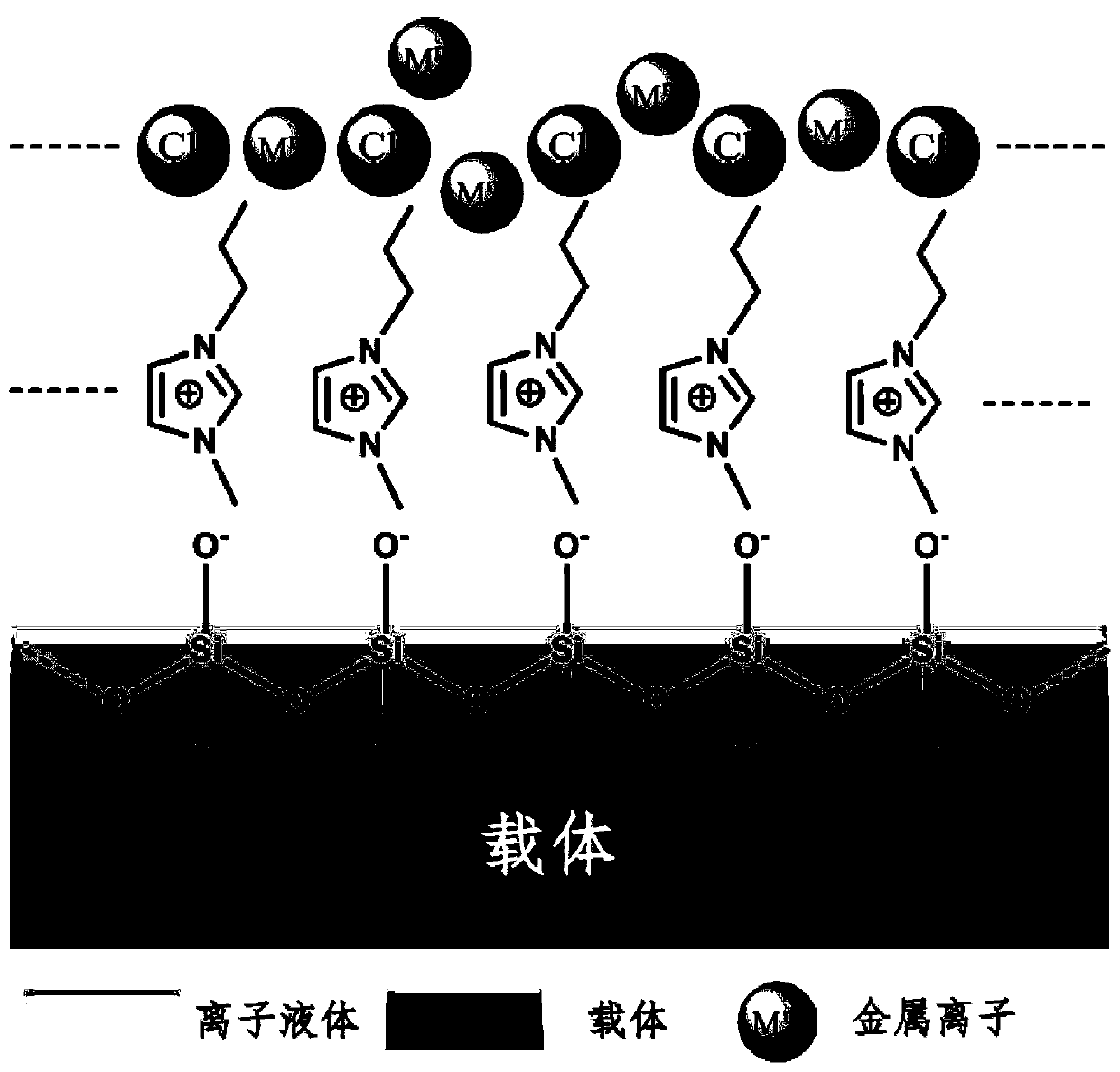

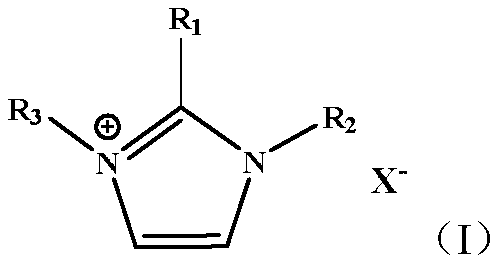

Catalyst loaded with ionic liquid and preparation method and application of catalyst

ActiveCN110743619AGood dispersion effectHigh catalytic activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsMaterials sciencePtru catalyst

The invention provided a catalyst loaded with ionic liquid and a preparation method and application of the catalyst. According to the catalyst, the dispersion effect of metal in a carbide carrier is better, the catalytic activity is higher, the stability is better, ionic liquid is stabilized on the surface of the carrier through silicon hydroxyl, and is not prone to being loosen from the surface of the carrier, the metal is stabilized on the outer surface layer of the catalyst through the form of coordination with the ionic liquid, the influence of mass transfer is reduced, meanwhile the dispersion of the metal is increased, an external static electric filed is introduced into the preparation of the metal-based catalyst loaded with the ionic liquid for the first time, the enrichment of a metal active center on the surface layer of the ionic liquid is promoted, because the metal active center of the catalyst is distributed on the surface layer of the ionic liquid, the influence of substrate diffusion is reduced, and under the evaluated reaction conditions, the induction period of the catalyst is eliminated.

Owner:ZHEJIANG UNIV OF TECH

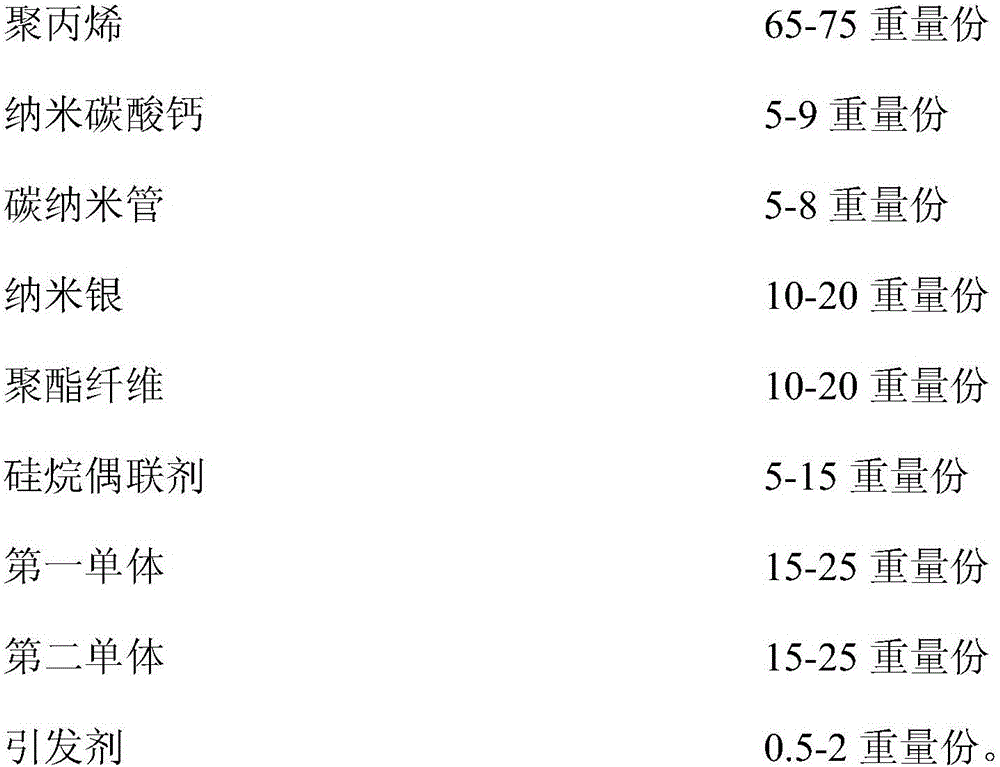

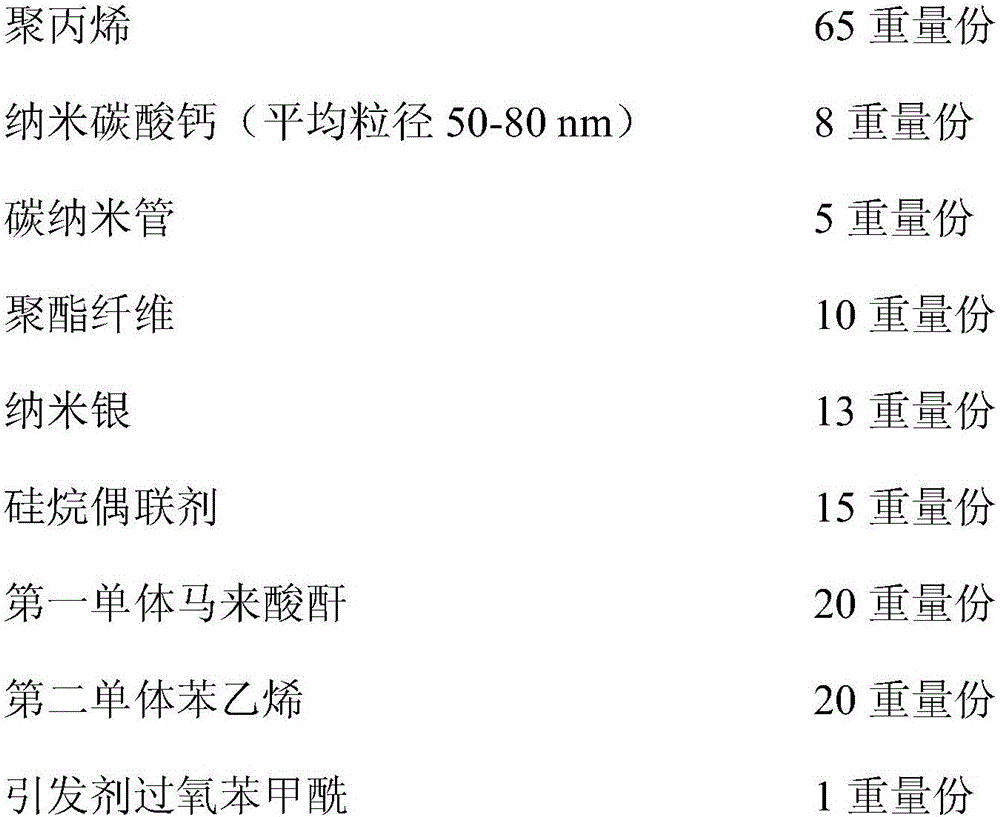

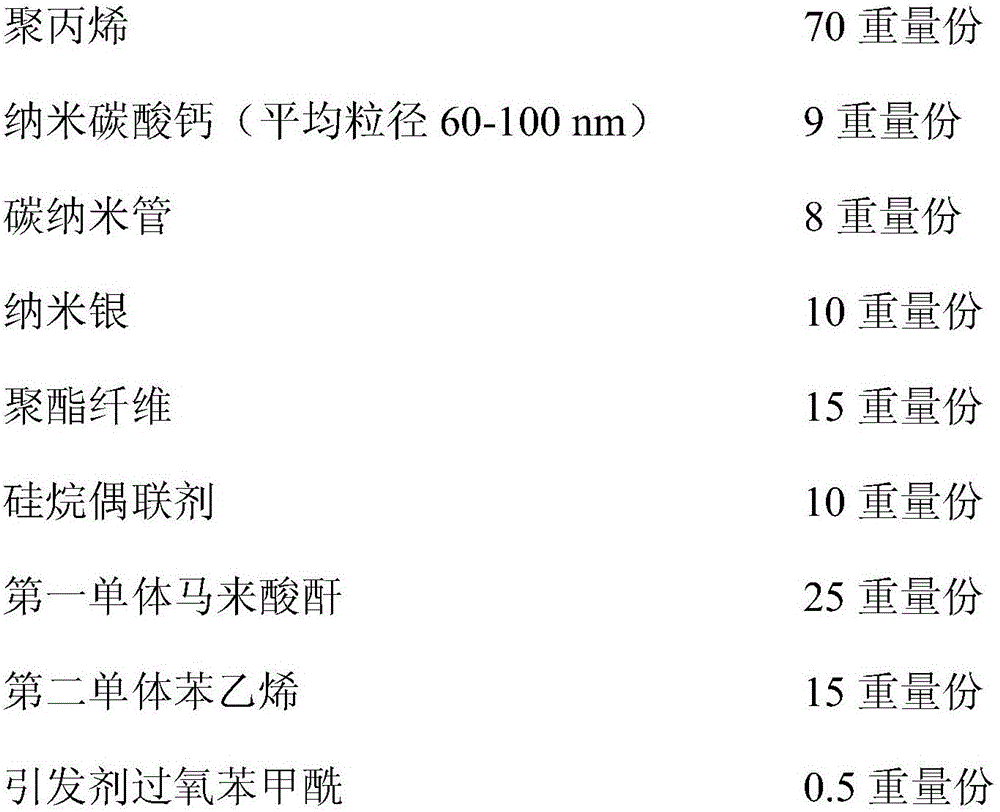

Nanocomposite and preparation method and application thereof

The invention provides a nanocomposite and a preparation method and application thereof. According to the nanocomposite, polyethylene, nano-calcium carbonate, ceramic nano-particles, nano-silver, a silane coupling agent, a first monomer, a second monomer and an initiator are adopted for preparing a nano-modified master batch. Due to the fact that nano-calcium carbonate and the ceramic nano-particles are dispersed in the nano-modified master batch, the nano-modified master batch has good mechanical properties. Besides, the silane coupling agent can enhance the compatibility between nano-calcium carbonate, the ceramic nano-particles and the polyethylene material, so that the nanocomposite has a better dispersion effect. The in-situ graft intercalation technology is utilized for obtaining the nanocomposite with an intercalation, nano-compositing of polyethylene and inorganic matter is realized, and therefore the mechanical properties, heat resistance, aging resistance and the like of polyethylene plastics are effectively improved.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Graphdiyne-based composite material catalyst and preparation method and application thereof

ActiveCN110743617AGood dispersion effectHigh catalytic activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsComposite materialGraphyne

The invention provides a graphdiyne-based composite material catalyst and a preparation method and application thereof. The dispersing effect of metal in the graphdiyne-based composite material catalyst is better, the catalytic activity is higher, the stability is better, and the metal is stabilized on the outer surface layer of the catalyst through the form of coordination with ionic liquid, so that the influence of mass transfer is reduced, and the dispersity of the metal is improved meanwhile. According to the graphdiyne-based composite material catalyst and the preparation method and application thereof, an external static electric field is introduced into the preparation of the ionic-liquid-loaded metal-based catalyst for the first time, the enrichment of metal active centers on the surface layer of the ionic liquid is promoted, since the metal active centers of the catalyst are distributed on the surface layer of the ionic liquid, the influence of substrate diffusion is reduced,and under the evaluated reaction condition, the induction period of the catalyst disappears.

Owner:ZHEJIANG UNIV OF TECH

Grinding mixer for concentrated feed for young sheep

InactiveCN109092194AGood dispersion effectStir wellFeeding-stuffTransportation and packagingEngineeringYoung sheep

The invention discloses a grinding mixer for concentrated feed for young sheep and solves the problem of poor crushing and refining effects of existing sheep feed mixing devices on feed. The grindingmixer comprises a body, a charging bin on the upper side, a roll device in the middle and a stirring device on the lower side. Roll barrels rotating in opposite directions are used for grinding feed,the feed falls into a filter net plate, penetrates through the filter net plate to fall into a stirring area to be stirred and discharged. The grinding mixer has the advantages of good grinding and mixing effects on the feed and good stirring and dispersion effects of different types of feed.

Owner:宜宾县成乐肉羊养殖专业合作社

Electric-conductive super-hydrophobic paint and preparation method thereof

ActiveCN109486354AGood dispersion effectIncrease the degree of cross-linkingPolyurea/polyurethane coatingsEpoxy resin coatingsSolventEmulsion

The invention relates to electric-conductive super-hydrophobic paint. The electric-conductive super-hydrophobic paint is obtained by mixing a component A and a component B according to a weight ratioof 10:(1-5), wherein the component A comprises the following preparation raw materials: epoxy resin E44, polyurethane emulsion, polytetrafluoroethylene emulsion, sulfonated graphene oxide, cyclodextrin modified polyester coated nano yttrium oxide, a cyclodextrin modified polyester coated carbon nano tube and a solvent C; and the component B comprises the following preparation raw materials: polyether amine grafted with hyaluronic acid, 1-methyl-4-aminoimidazole, hexamethylenediamine and a solvent D. The invention further relates to a preparation method for the electric-conductive super-hydrophobic paint. The electric-conductive super-hydrophobic paint is good in cleaning property, anti-pollution and good in conductivity, and has good market prospect.

Owner:湖北彩砼新材料有限公司

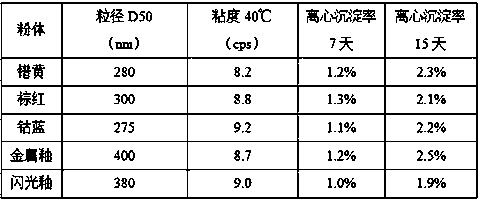

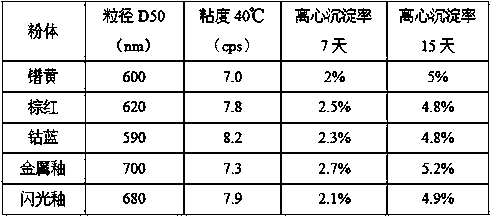

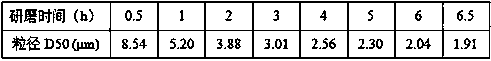

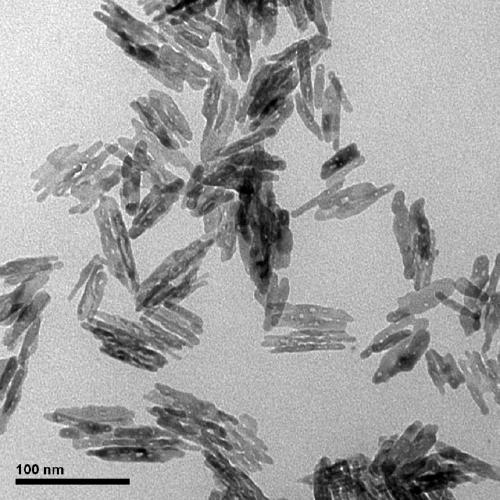

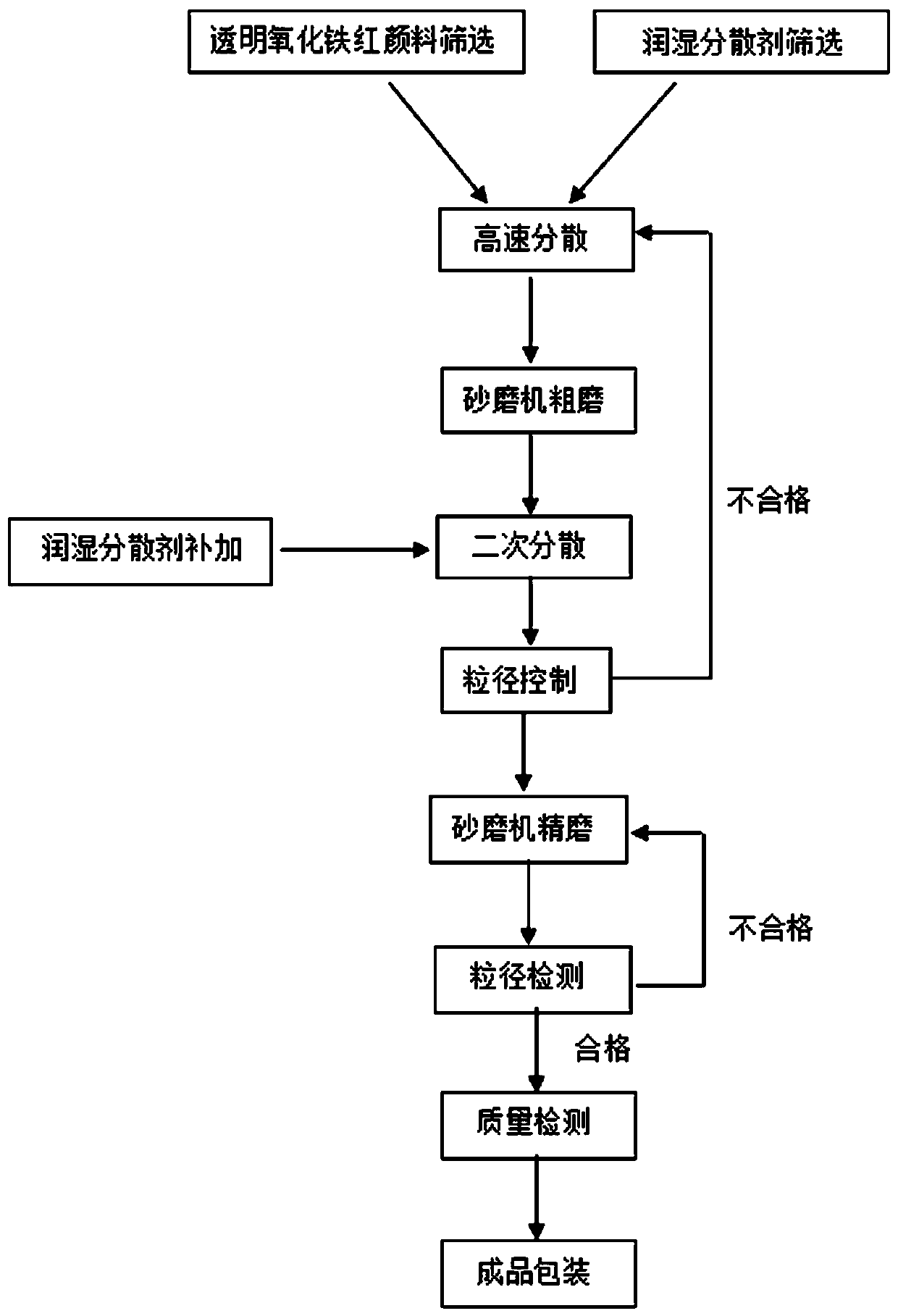

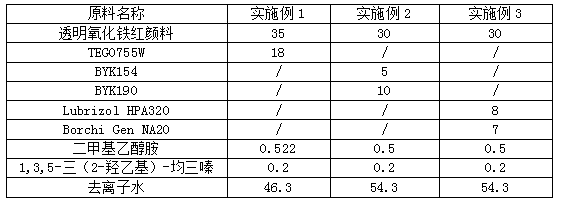

Transparent nano-ferric oxide ink-jet color paste and preparation method thereof

The invention relates to transparent nano-ferric oxide ink-jet color paste. The transparent nano-ferric oxide ink-jet color paste contains the following components in parts by weight: 30-35 parts of ferric oxide, 15-20 parts of a dispersing agent, 0.4-0.6 part of a pH adjuster, 0.2-0.4 part of a sterilizing agent and 45-55 parts of water. By utilizing a brand new processing process and equipment and a preferable color paste formula, the particle size of the color paste can reach the nanoscale, and the storage stability is good; and the color past is of a resin-free system, does not contain a solvent component, is environment-friendly and can be widely applied to various types of ink-jet coatings.

Owner:ZHEJIANG NAMEI MATERIAL TECH

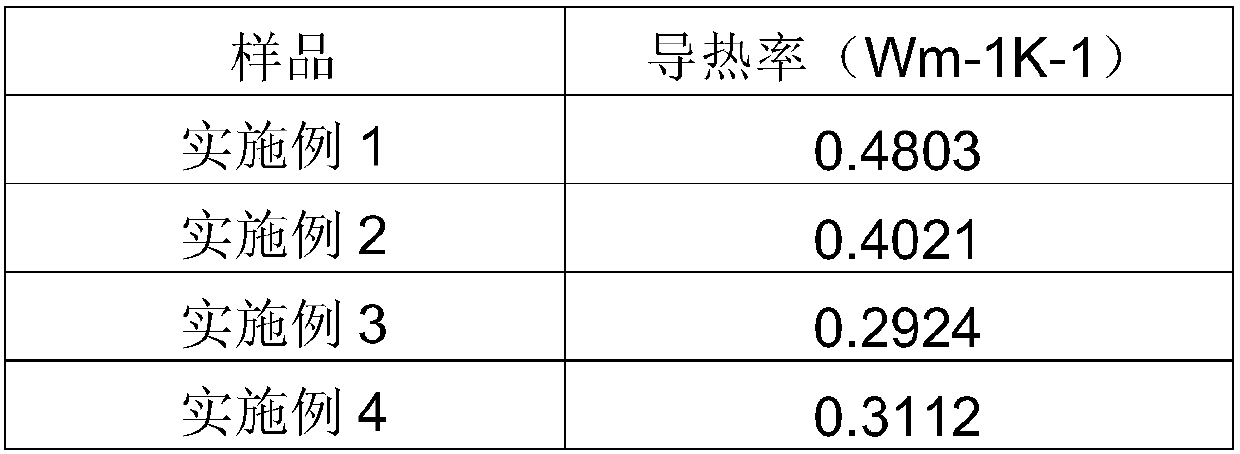

Controllable sol-gel method for preparing polyethylene glycol phase-change heat-conducting composite material and application

The invention discloses a controllable sol-gel method for preparing polyethylene glycol phase-change heat-conducting composite material and an application. The method comprises the following steps: dispersing polyethylene glycol in tetraethyl silicate, and then adding metal hydroxide to a solution to form sol. Polyethylene glycol is dispersed in tetraethyl silicate, the cost is low, and the dispersion effect is good. Compared with an existing sol-gel method, the controllable sol-gel method has the advantages that metal hydroxide is introduced and a two-step gelation process is formed; the degree of gelation can be controlled according to the type of metal hydroxide, gelation temperature and gelation time; finally, the gel is directly formed by counter-ion ammonia ions. The composite material with controllable gelation degree can be obtained by adjusting and controlling the conditions, and thermal stability of the composite material is enhanced while heat conductivity is improved.

Owner:NANXIONG MATERIAL PRODION BASE OF CHINESE ACADEMY OF SCI GUANGZHOU CHEM +2

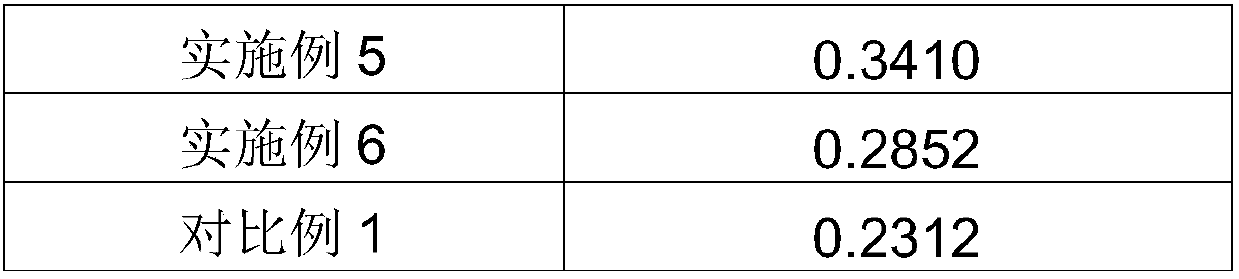

PP (Polypropylene)/carbon nano-tube conductive master batch

The invention discloses PP (Polypropylene) / carbon nano-tube conductive master batch. The PP / carbon nano-tube conductive master batch contains the following raw materials in parts by weight: 70-95 parts of PP polymer matrix material and 0.01-30 parts of active carbon nano-tubes, wherein the active carbon nano-tubes are obtained through carrying out high-speed stirring on carbon nano-tubes, meanwhile, dissolving a dispersant in liquid, and spraying the solution into carbon nano-tube powder with stirring in a spraying manner so as to activate surfaces of the carbon nano-tubes. According to the PP / carbon nano-tube conductive master batch, the carbon nano-tubes are subjected to pretreating modification and then are added into a PP material matrix as conductive filler, and thus the PP / carbon nano-tube conductive master batch is prepared. The PP / carbon nano-tube conductive master batch can be applied to the preparation of anti-electrostatic products and are excellent in anti-electrostatic property.

Owner:嘉兴高正新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com