Graphdiyne-based composite material catalyst and preparation method and application thereof

A technology of composite materials and graphyne, which is applied in the field of graphyne-based composite catalysts and its preparation and application, can solve the problems of low mass transfer and low dispersion of gas metals, achieve high catalytic activity, promote enrichment, and eliminate induction period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Catalyst preparation:

[0087] 1) Select 10 g of graphdiyne powder, select 0.1 g of melamine and dissolve it in 5 mL of toluene, spray the obtained impregnating solution onto the surface of the aforementioned carrier, and put it into a quartz boat in a tube furnace, in a nitrogen atmosphere at 800 ° C Calcined for 2h, the obtained solid sample was set aside.

[0088] 2) Dissolve 0.08g of triphenylmethylphosphine bistrifluoromethanesulfonimide salt and 0.02g of triphenylethylphosphine bromide in 10mL of toluene, stir well, then add the solid sample obtained in step 1) , impregnated for 2 hours, and dried at 180°C for later use. Wherein the mass loading of ionic liquid is 1%.

[0089] 3) Dissolve 4.23g of copper chloride in 2.12mL of toluene, stir evenly, add the sample obtained in step 2), dip in an external 0.2kV static electric field for 2h, and dry at 180°C for later use. Wherein the mass loading of copper element is 20%.

[0090] 4) 14.43 g of the solid sample ob...

Embodiment 2

[0094] Catalyst preparation:

[0095] 1) Select 10 g of graphdiyne film, select 2.0 g of boric acid and dissolve it in 100 mL of nitrogen-methylpyrrolidone, spray the obtained impregnating solution onto the surface of the aforementioned carrier, and put it into a quartz boat in a tube furnace. Calcined in an argon atmosphere for 10 h, the obtained solid sample was used for future use.

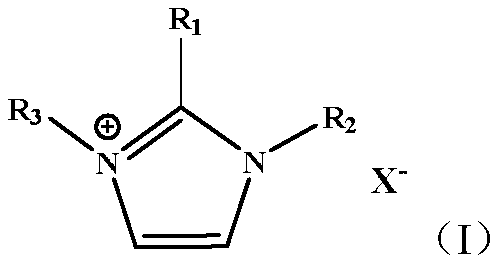

[0096] 2) Take 0.6g of 1-propyl-2,3-dimethylimidazole bistrifluoromethanesulfonimide salt and 1.4g of 1-hexyl-2,3-dimethylimidazole bistrifluoromethanesulfonimide The salt ionic liquid was dissolved in 10 mL of nitrogen methyl pyrrolidone, and after stirring evenly, the solid sample obtained in step 1) was added, soaked for 10 h, and dried at 180°C for use. Wherein the mass loading of ionic liquid is 20%.

[0097] 3) Dissolve 0.2g of rhodium chloride in 1.6mL of nitrogen methylpyrrolidone, stir evenly, add the sample obtained in step 2), dip in an external 4kV static electric field for 3h, an...

Embodiment 3

[0102] Catalyst preparation:

[0103] 1) Select 10 g of copper-based graphyne, select 1.5 g of triphenylphosphine and dissolve it in 50 mL of nitrogen-nitrogen dimethylformamide, spray the obtained impregnating solution onto the surface of the aforementioned carrier, and put it into the quartz crystal in the tube furnace. In the boat, it was calcined in a helium atmosphere at 500°C for 6 hours, and the obtained solid sample was used for future use.

[0104] 2) Dissolve 0.3g of 1-butyl-3-methylimidazolium hexafluorophosphate and 0.7g of nitrogen-methylpyrrolidone hydrochloride in 50mL of nitrogen-nitrogen dimethylformamide, stir well, and add to step 1) The obtained solid samples were soaked for 5 hours and dried at 180°C for use. Wherein the mass loading of ionic liquid is 10%.

[0105] 3) Dissolve 0.103g of ruthenium chloride in 0.5mL of nitrogen-nitrogen dimethylformamide, stir evenly and add the sample obtained in step 2), dipping in an external 2.0kV static electric field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com