Controllable sol-gel method for preparing polyethylene glycol phase-change heat-conducting composite material and application

A sol-gel method and polyethylene glycol technology, which is applied in the field of polyethylene glycol phase-change heat-conducting composite materials and its preparation, can solve problems such as insufficient structural coating performance, imperfect gelation degree, and easy leakage. Achieve low cost, promote thermal conductivity, and enhance thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare a polyethylene glycol phase-change thermally conductive composite material according to the following steps:

[0032] (1) Preparation of Polyethylene Glycol and Tetraethyl Silicate Dispersion: Dissolve 0.0075 molar parts of polyethylene glycol in 2.5 molar parts of ethanol solution, stir at 80°C for 30 min, and then add 3.0 molar parts of deionized Dilute with water, then add 0.075 mole parts of tetraethyl silicate solution, then adjust the pH to 1 with 2 mol / L hydrochloric acid, and obtain the dispersion after ultrasonication for 2 hours;

[0033] (2) Solification process: at room temperature, add 0.06 mole parts of calcium hydroxide solution dropwise to the stirred dispersion within 30 minutes. Afterwards, the temperature was raised to 40° C., and the stirring was continued for 24 hours to obtain a sol-formed silica polyethylene glycol sol.

[0034] (3) Gelation process: the above sol was taken out, stirred with a glass rod, and 0.005 molar parts of ammonium ...

Embodiment 2

[0036] Prepare a polyethylene glycol phase-change thermally conductive composite material according to the following steps:

[0037] (1) Preparation of Polyethylene Glycol and Tetraethyl Silicate Dispersion: Dissolve 0.0075 molar parts of polyethylene glycol in 2.5 molar parts of ethanol solution, stir at 80°C for 60 min, and then add 3.0 molar parts of deionized Dilute with water, then add 0.075 mole parts of tetraethyl silicate solution, then adjust the pH to 1 with 2 mol / L hydrochloric acid, and obtain the dispersion after ultrasonication for 2 hours;

[0038] (2) Solification process: at room temperature, add 0.04 mole parts of magnesium hydroxide solution dropwise to the stirred dispersion within 30 minutes. Afterwards, the temperature was raised to 40° C., and the stirring was continued for 36 hours to obtain a sol-formed silica polyethylene glycol sol.

[0039] (3) Gelation process: the above sol was taken out, stirred with a glass rod, and 0.005 molar parts of ammoniu...

Embodiment 3

[0041] Prepare a polyethylene glycol phase-change thermally conductive composite material according to the following steps:

[0042] (1) Preparation of Polyethylene Glycol and Tetraethyl Silicate Dispersion: Dissolve 0.0075 molar parts of polyethylene glycol in 2.5 molar parts of ethanol solution, stir at 80°C for 30 min, and then add 3.0 molar parts of deionized Dilute with water, then add 0.075 molar parts of tetraethyl silicate solution, then adjust the pH to 1 with 2 mol / L hydrochloric acid, and obtain the dispersion after ultrasonication for 4 hours;

[0043] (2) Solification process: at room temperature, add 0.04 mol parts of aluminum hydroxide solution dropwise to the stirred dispersion within 30 minutes. Afterwards, the temperature was raised to 50° C., and the stirring was continued for 24 hours to obtain a sol-formed silica polyethylene glycol sol.

[0044](3) Gelation process: the above sol was taken out, stirred with a glass rod, and 0.05 molar parts of ammonium c...

PUM

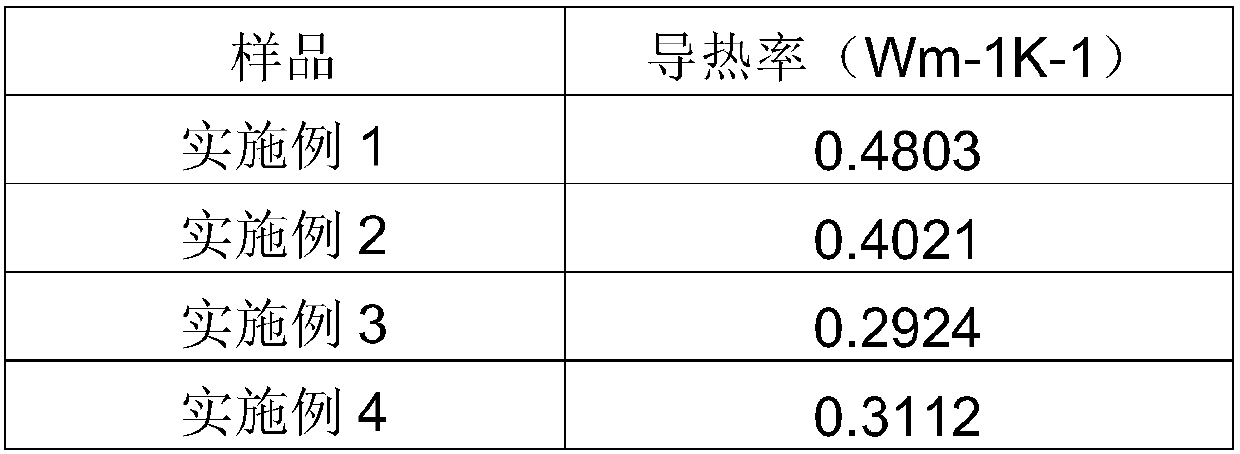

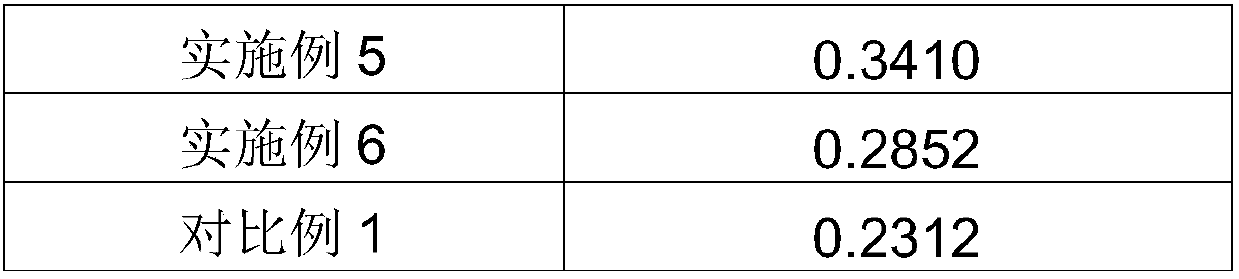

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com