Patents

Literature

201results about How to "Improve oxygen storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-thermal-stability cerium-based oxygen storage material

InactiveCN101690890AWeaken the interaction forceGood dispersion effectDispersed particle separationCatalyst activation/preparationIndustrial scaleComposite oxide

The invention relates to a method for preparing a high-thermal-stability cerium-based oxygen storage material, which is characterized in that the cerium-based oxygen storage material comprises cerium dioxide, zirconium dioxide, aluminum oxide in a small amount and at least one rare-earth crystal stabilizer selected from lanthanum oxide, praseodymium oxide, yttrium oxide and terbium oxide. The method comprises the following steps in the preparation process: adding a proper amount of surfactant, to obtain a cerium-based composite oxide material having the characteristics of single crystalline phase, high oxygen storage performance and high specific surface area; and ageing the cerium-based composite oxide material at a high temperature (1,050 DEG C) for 5h until the specific surface area thereof is higher than 35m<2> / g and the oxygen storage capacity thereof is higher than 400 mu mol / g. According to the phase results, the cerium-based oxygen storage material has a uniform-phase structure, moreover, a uniform solid solution with a cubic fluorite structure can be prepared from zirconium dioxide, aluminum oxide, stabilizer and cerium dioxide. The preparation process of the oxygen storage material has the characteristics of simple process, lower production cost, easy industrial scale-up, etc.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Nano Cerium-zirconium base compound oxide and preparation process thereof

InactiveCN1449863AAvoid reunionSmall grainDispersed particle separationCatalyst activation/preparationRare-earth elementCerium

The present invention discloses a nano cerium zirconium based compound oxide and its preparation method. Said invented cerium zirconium based compound oxide includes (wt%) 10-90% of CeO2 and 10-90% of ZrO2, and its crystal grain size is greater than or equal to 4 nm or less than or equal to 80 nm. Its preparation method includes the following steps: dissolving nitrates of Ce, Zr and one or more than one metal elements B (B is Ca or Sr or Ba or Mn or Al or Si or any one of rare earth elements except for Ce) in water to prepare solution (I); using hydrogen peroxide and ammonia water and dissolving them in the water to obtain solution (II); adding solution (I) and solution (II) into ammonia water solution, reacting, ageing, suction filtering, drying and roasting at 500-1000 deg.C so as to obtain the invented product with higher chemical activity and thermal stability.

Owner:EAST CHINA UNIV OF SCI & TECH

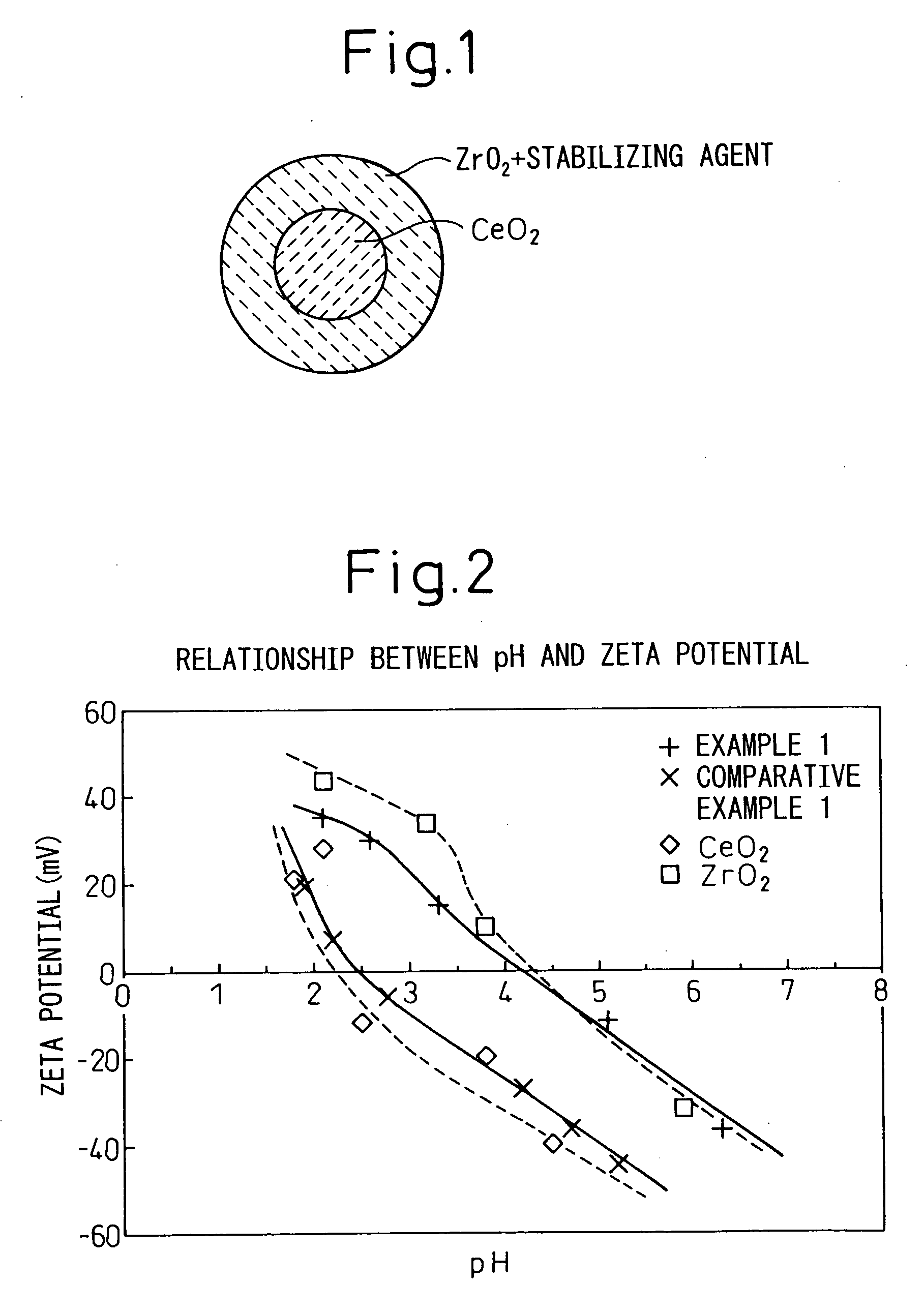

Cerium-zirconium composite metal oxide

ActiveUS20050059547A1Increased durabilityImprove oxygen storage capacityGas treatmentInternal combustion piston enginesMischmetalCerium

A cerium-zirconium composite metal oxide having improved durability at high temperature and a stable oxygen storage capacity is provided. The cerium-zirconium composite metal oxide is characterized in that the total mole number of Ce and Zr is at least 85% based on the total mole number of metal in the composite metal oxide, a molar ratio Ce / Zr is within a range from 1 / 9 to 9 / 1, and an isoelectric point of the composite metal oxide is more than 3.5. Preferably, the molar ratio Ce / Zr is within a range from 3 / 7 to 7 / 3 and the isoelectric point is within a range from 3.8 to 5.0, and the cerium-zirconium composite metal oxide contains a rare earth metal (excluding Ce) in a concentration of less than 15% by mole based on the total mole number of metal in the composite metal oxide. Also the present invention provides a cerium-zirconium composite metal oxide, characterized in that CeO2 forms a core surrounded by ZrO2.

Owner:TOYOTA JIDOSHA KK

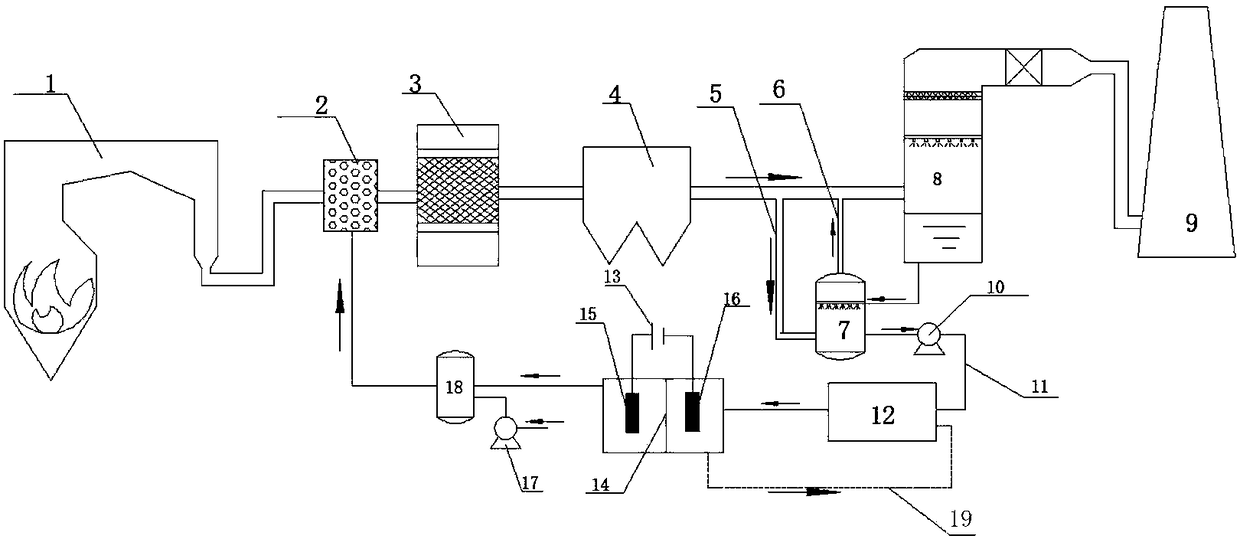

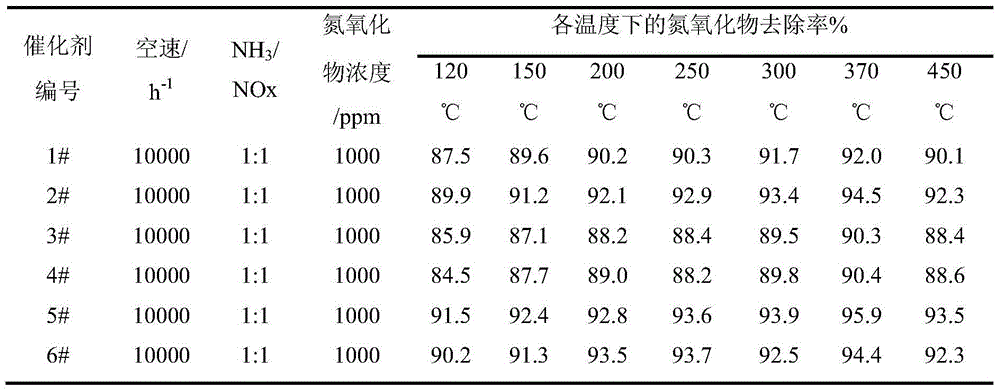

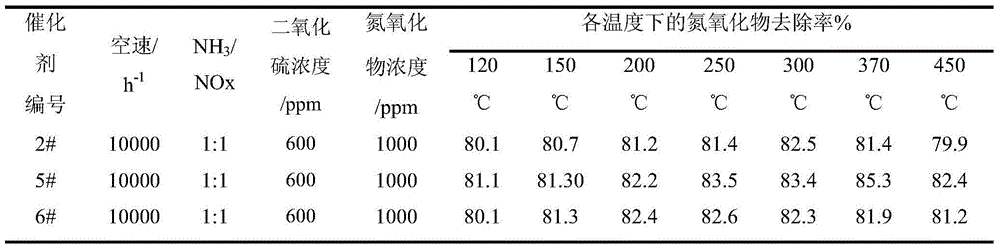

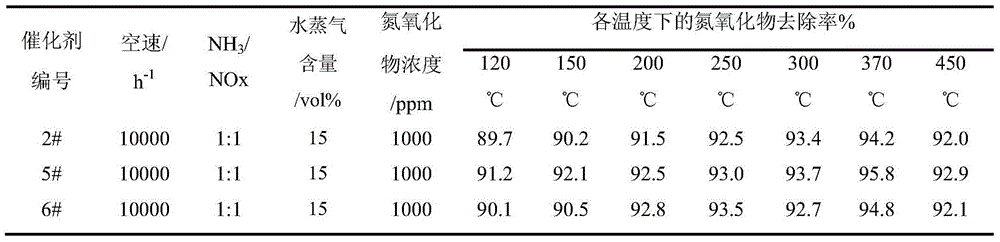

Honeycombed catalyst for low-temperature synergic denitrification, dioxin removal and mercury removal and preparation method thereof

ActiveCN107952449ALow investment costLow running costGas treatmentHeterogenous catalyst chemical elementsRare earthPalygorskite

The invention discloses a honeycombed catalyst for low-temperature synergic denitrification, dioxin removal and mercury removal and a preparation method thereof. The honeycombed catalyst employs metatitanic acid and sulfated palygorskite as carriers, copper oxides, manganese oxides and vanadium oxides as active ingredients and rare-earth metal oxides as active aids. The honeycombed catalyst hereincan provide synergic denitrification, dioxin removal and mercury removal at the low temperature of 80-300 DEG C; under the action of the honeycombed catalyst, NOx and dioxin are selectively catalytically reduced into N2, HCl, CO2 and CO; the produced HCl is suitable for serving as a mercury removal aid; elemental mercury, CO, hydrocarbons and alkenes are thoroughly oxidized into mercury oxide andCO2; the honeycombed catalyst has denitrification rate of 95% and above and dioxin removal rate and mercury removal rate of 90% and above.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

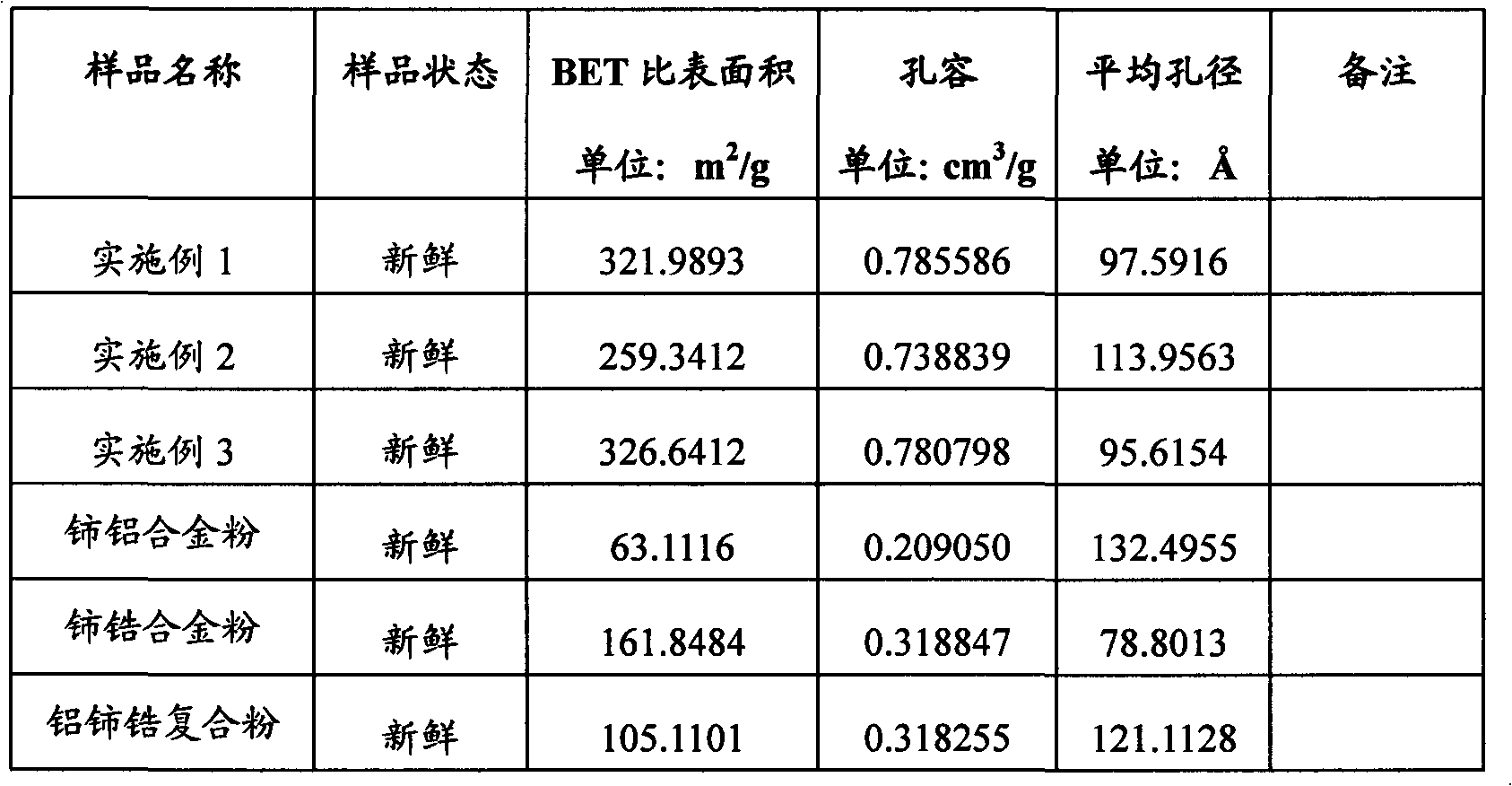

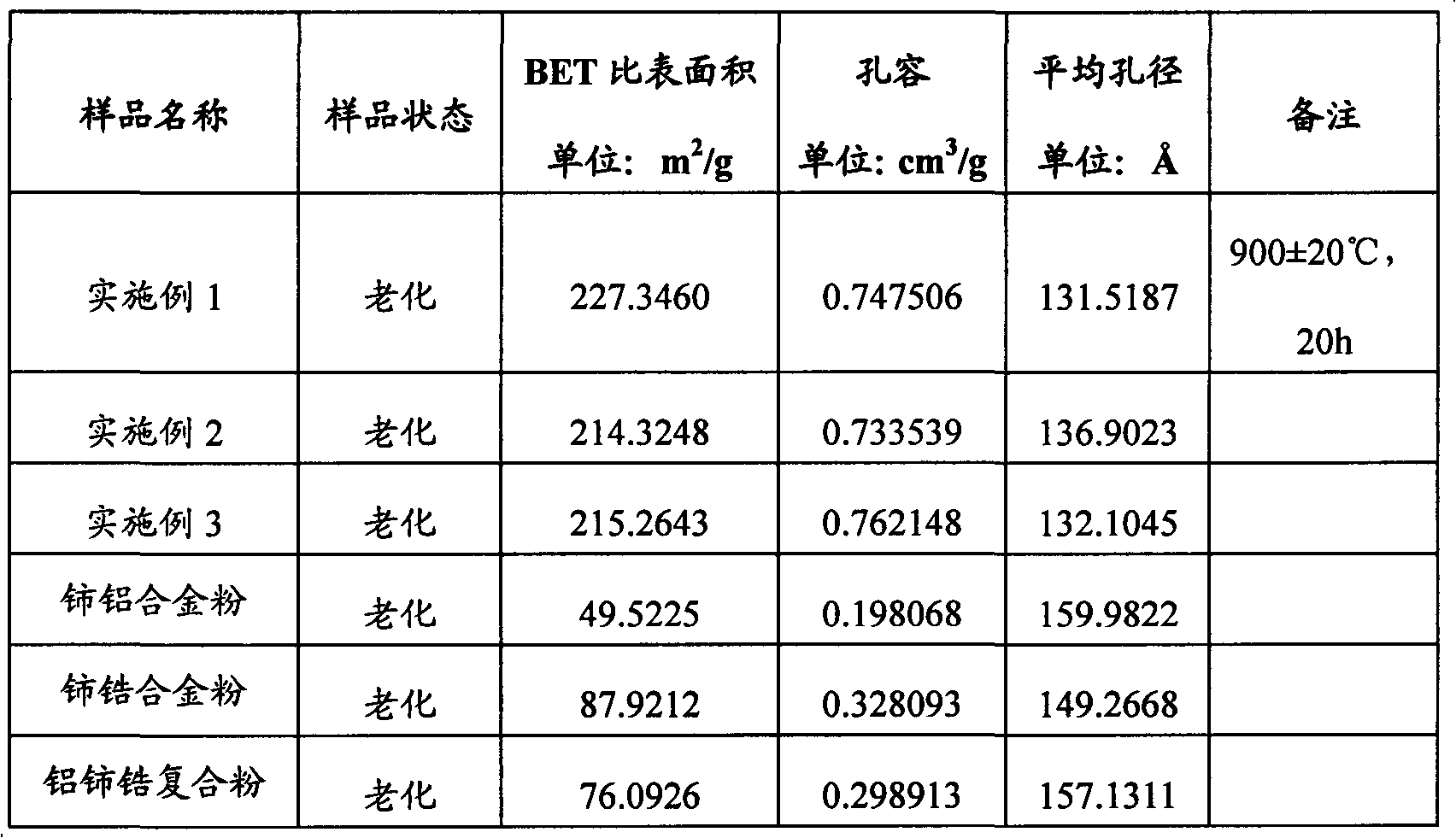

Cerium oxide-zirconium oxide based composite rare-earth oxide with high specific surface area and high oxygen storage capacity and preparation method thereof

ActiveCN103191711ATotal pore volumeFresh specific surface area is highDispersed particle separationCatalyst activation/preparationZirconium hydrideSlurry

The invention discloses a method for preparing a cerium oxide-zirconium oxide based composite rare-earth oxide. The method comprises the following steps of: (1) heating a zirconium salt solution at room temperature, slowly adding sulfate ions, controlling the temperature rise rate so that the temperature is increased in the range of 90-95 DEG C when the sulfate ions are added completely, and then preserving heat for 20-100 minutes, thereby forming a zirconium basic sulfate composite salt precursor; (2) adding a cerium salt and a rare-earth metal salt to the precursor solution and stirring evenly, thereby obtaining a slurry; (3) settling the slurry by using basic carbonate and / or a basic oxalate solution, thereby obtaining a precipitate; and (4) filtering and washing the precipitate obtained in the step (3), removing purities, and calcining the washed precipitate. The cerium oxide-zirconium oxide based composite rare-earth oxide prepared by the method by controlling raw materials and process conditions has the characteristics of being high in total fine pore volume, high in fresh specific surface area, high in oxygen storage capacity and the like.

Owner:CHAOZHOU THREE CIRCLE GRP

Nanometer ceria-zirconium solid solution and preparation method thereof

ActiveCN102580719ALarge apertureLarge hole volumeDispersed particle separationIncinerator apparatusRare earthPore diameter

The invention aims to disclose a nanometer ceria-zirconium solid solution and a preparation method thereof. The nanometer ceria-zirconia solid solution comprises the following components according to weight percent: 15 to 65% of cerium oxide, 12 to 70% of zirconia and 10 to 30% of compound oxide composed of other tombarthite oxide except for ceria and zirconium. Compared with the conventional products, the nanometer ceria-zirconium solid solution obtains larger pore diameter and pore volume through modification of a structural directing agent and a dispersing agent, has a favorable capability of resisting high temperature and ageing, and has the advantages of high oxygen storage capability and high speed in oxygen storage and discharge, so that the purposes of the invention are achieved.

Owner:方复(上海)新材料科技有限公司

Cerium zirconium aluminum composite oxides sosoloid with a mesopore structure and method for preparing the same

InactiveCN101112683AHigh surface areaMesopore narrowFinal product manufactureSolid electrolyte fuel cellsCeriumPore diameter

The invention relates to a preparation method for the cerium-zirconium-aluminum composite oxide solid solution material with mesopore structure. The mesopore Ce1-x-yZrxAlyO2 (x is equal to 0.10-0.45; y is equal to 0.10-0.45) solid solution with high specific surface (200m2 / g through 250m2 / g) is prepared for one step by adopting the simple surface active agent (CTMACI) method, the hole diameter ranges from 2.5 nm to 3.4 nm, the worm-shaped channel structure with narrow distribution of hole diameter, and the invention can be used for high activity catalyst or catalyst carrier. In the preparation process, the operation is simple, the raw material is easy to be obtained and the invention is suitable for the industrial enlarged production.

Owner:山东齐鲁华信实业股份有限公司

Composite aluminium, cerium and zirconium oxide catalytic material and method for producing same

ActiveCN102824904AEnhanced interactionGuaranteed uniformityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPore diameterTemperature resistance

The invention aims to disclose a composite aluminium, cerium and zirconium oxide catalytic material and a method for producing the same. The composite aluminium, cerium and zirconium oxide catalytic material is a composite oxide which consists of 15-30% of cerium oxide, 5-20% of zirconium oxide, 50-75% of aluminium oxide and 0-5% of other rear earth oxides expect cerium by weight. Compared with the prior art, the aluminium oxide is subjected to surface treatment, on one hand, the interaction of the aluminium oxide and the cerium and zirconium-base composite oxides is enhanced; and on the other hand, the uniformity of the aluminium oxide and the cerium and zirconium-base composite oxides is fully ensured; through the modification of a structural directing agent and a dispersing agent, the pore diameter and pore volume of the composite aluminium, cerium and zirconium oxide catalytic material are further improved, and good temperature resistance and aging resistance are obtained; and moreover, the composite aluminium, cerium and zirconium oxide catalytic material has the advantages of high oxygen storage capability and high oxygen storage and release velocities, so the purpose of the invention is realized.

Owner:上海华明高纳稀土新材料有限公司

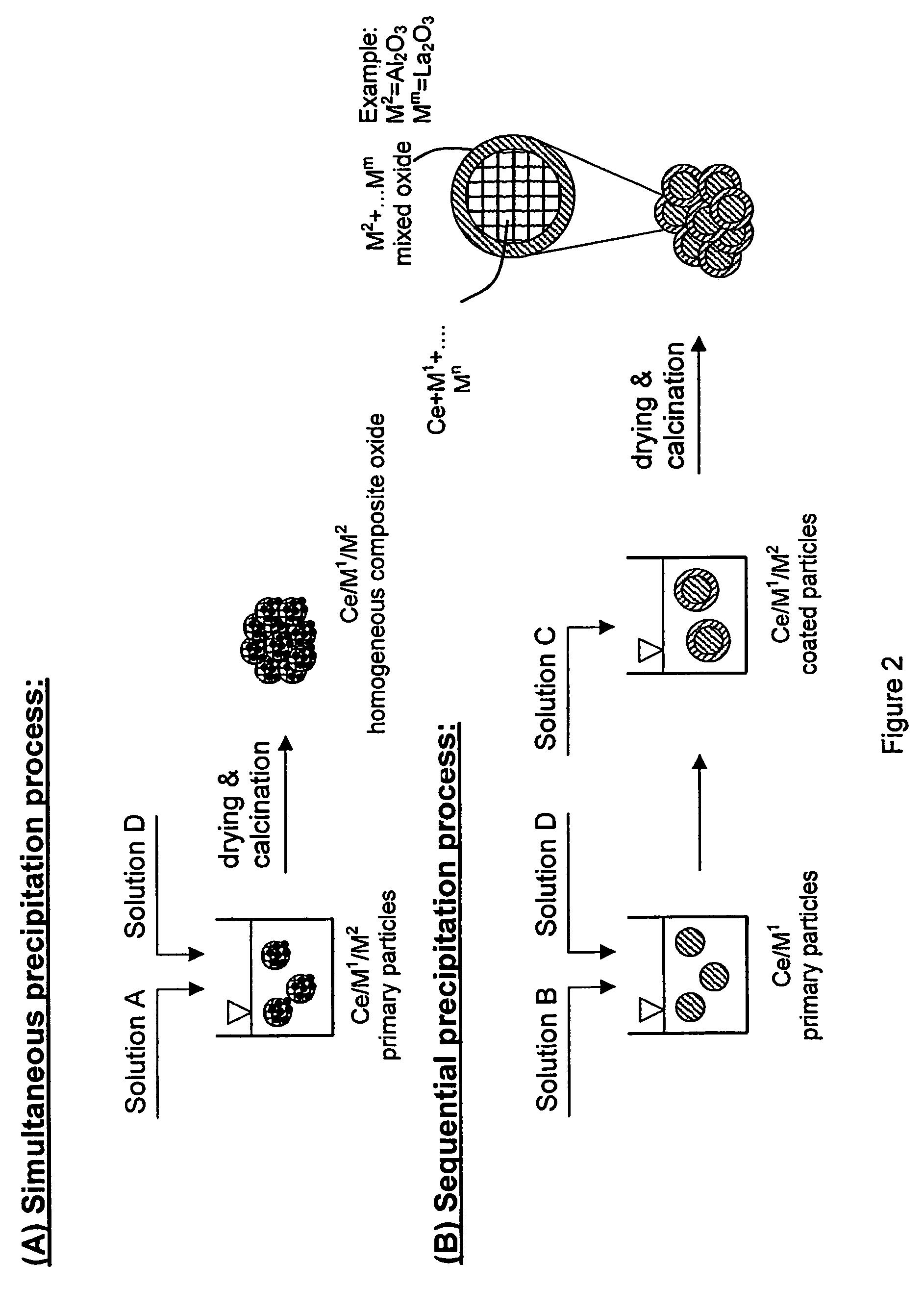

Oxygen storage material, process for its preparation and its application in a catalyst

InactiveUS7202194B2Improve oxygen storage capacityImprove dynamic performanceMaterial nanotechnologyOxygen/ozone/oxide/hydroxideMixed oxideSolid solution

An oxygen storage material comprising cerium oxide and at least one second oxide of a metal M1 is disclosed as well as a process for manufacturing the material and the use of this material in an exhaust gas cleaning catalyst. In a preferred embodiment the oxygen storage material comprises particles from a Ce / M1 mixed oxide solid solution coated with an oxide of another metal M2. Metal M1 e.g. can be calcium or zirconium while metal M2 most preferably is aluminum.

Owner:UMICORE AG & CO KG

Ceria-zirconia composite oxide-loaded perovskite type catalyst with sulfur resistance and preparation method of catalyst

InactiveCN105289602AFacilitate the catalytic cycleOxygen storage capacity is beneficial toIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsComposite oxideOxide

The invention discloses a ceria-zirconia composite oxide-loaded perovskite type catalyst with sulfur resistance. The catalyst comprises an active component, a noble metal promoter and a carrier, wherein the active component is perovskite La1-xSrxMnO3 which accounts for 4 to 14wt% of the catalyst, and x is equal to 0-0.5; the noble metal promoter accounts for 0.01 to 1wt% of the catalyst; the carrier is a Ce1-yZryO2 composite oxide which accounts for 85 to 95% of the catalyst, and y is equal to 0.1-0.5. A preparation process comprises two times of loading: firstly, loading perovskite to the Ce1-yZryO2 composite oxide, and then loading the noble metal promoter to the Ce1-yZryO2 composite oxide. The catalyst provided by the invention reaches relatively high catalyst reactivity during a catalytic combustion process of VOCs, and has relatively high anti-sulfur-poisoning property.

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH

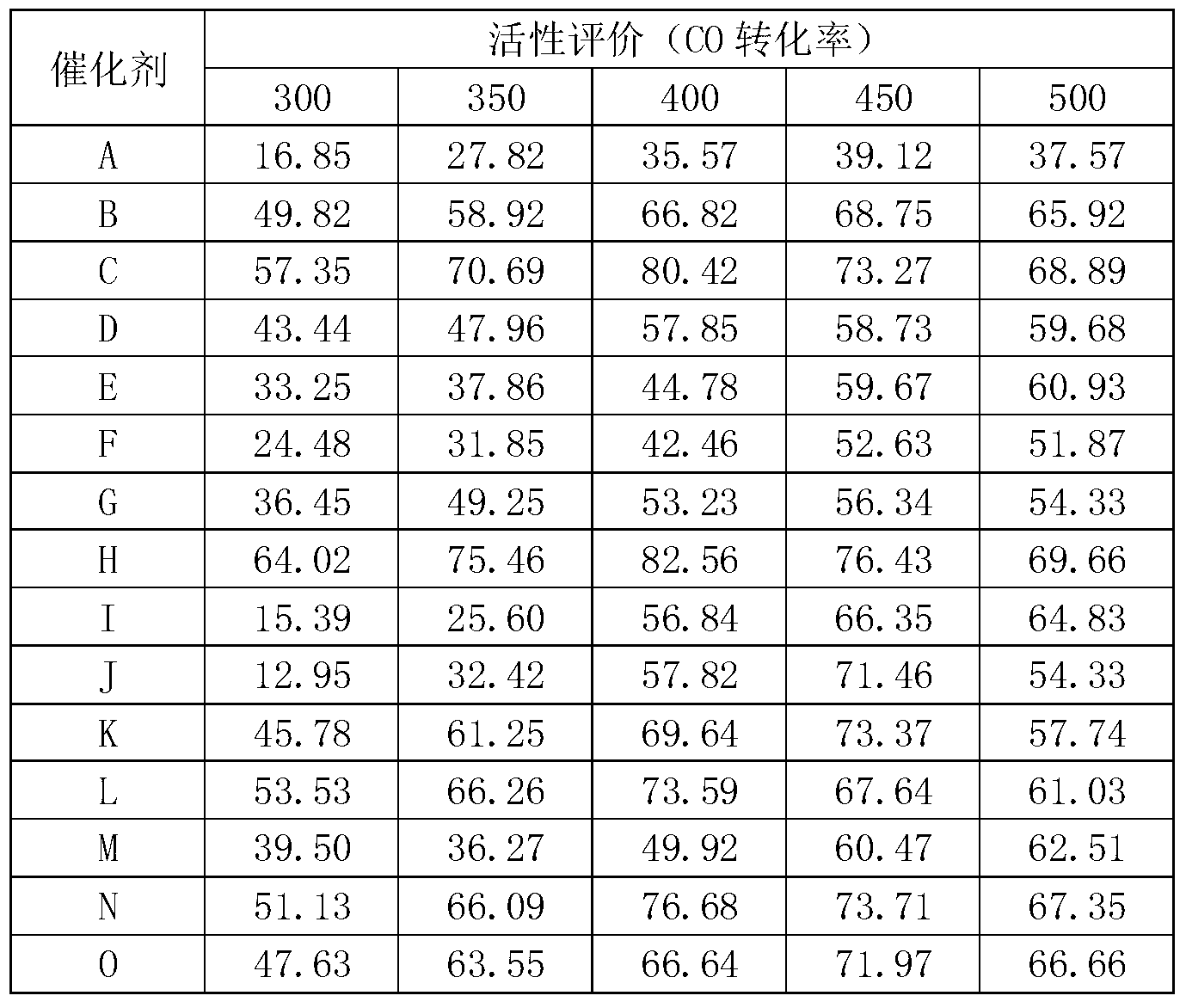

Low-temperature vanadium-titanium-based SCR denitrification catalyst and preparation method thereof

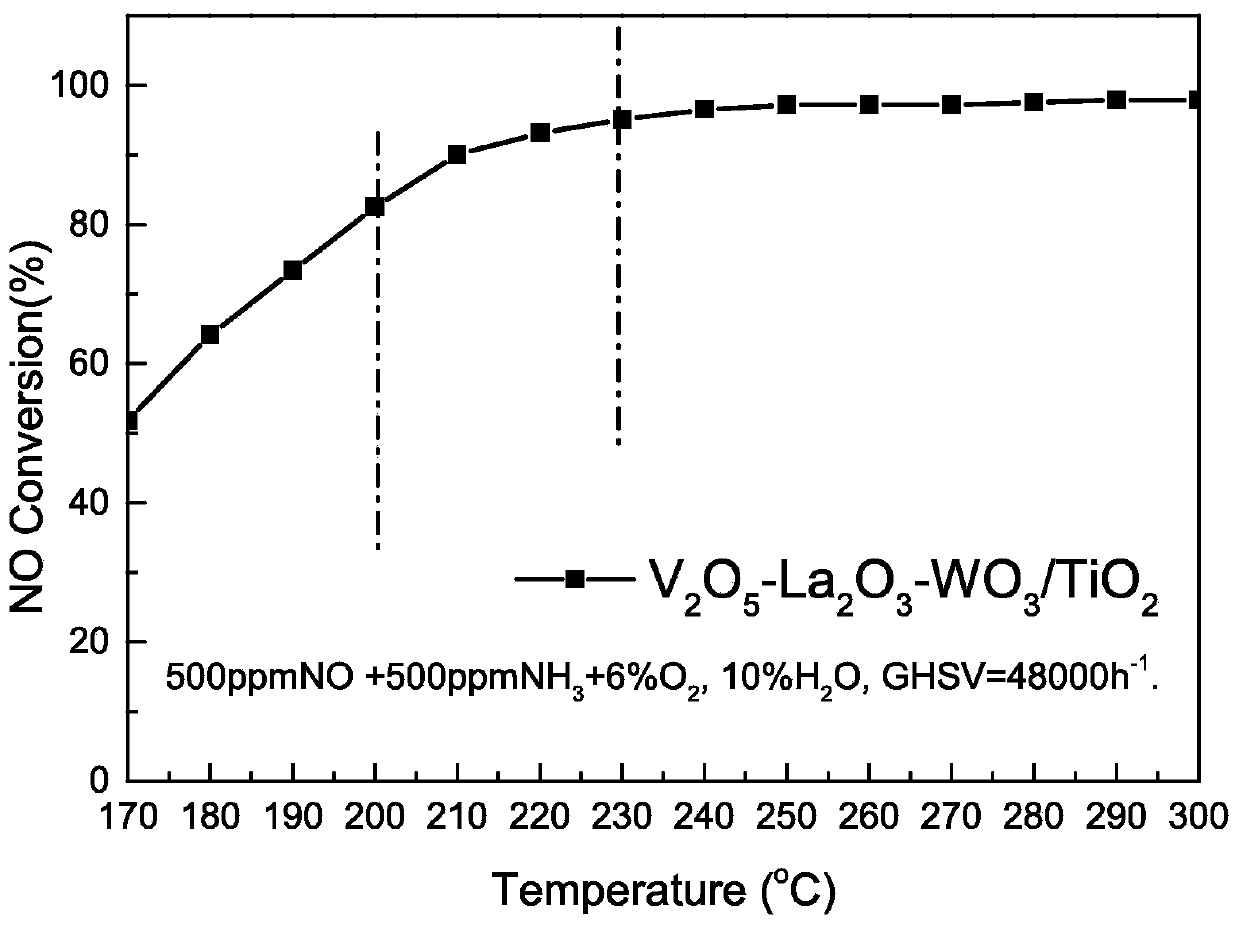

PendingCN110508273AImprove oxygen storage capacityHigh catalytic activityGas treatmentHeterogenous catalyst chemical elementsActive componentRare earth

The invention discloses a low-temperature vanadium-titanium-based SCR denitrification catalyst and a preparation method thereof. According to the present invention, a vanadium oxide V2O5 and a rare earth oxide are used as active components so as to provide the synergistic effect between the V and the rare earth metal, wherein V2O5 provides more acid sites and inhibits the adsorption of SO2 and H2Oon metal active sites, and the rare earth oxide effectively improves the oxygen storage capacity and the catalytic activity of the catalyst in a low-temperature region; and the catalyst has good denitrification effect within a range of 170-280 DEG C, and has good SO2 resistance and good H2O resistance.

Owner:HUAQIAO UNIVERSITY

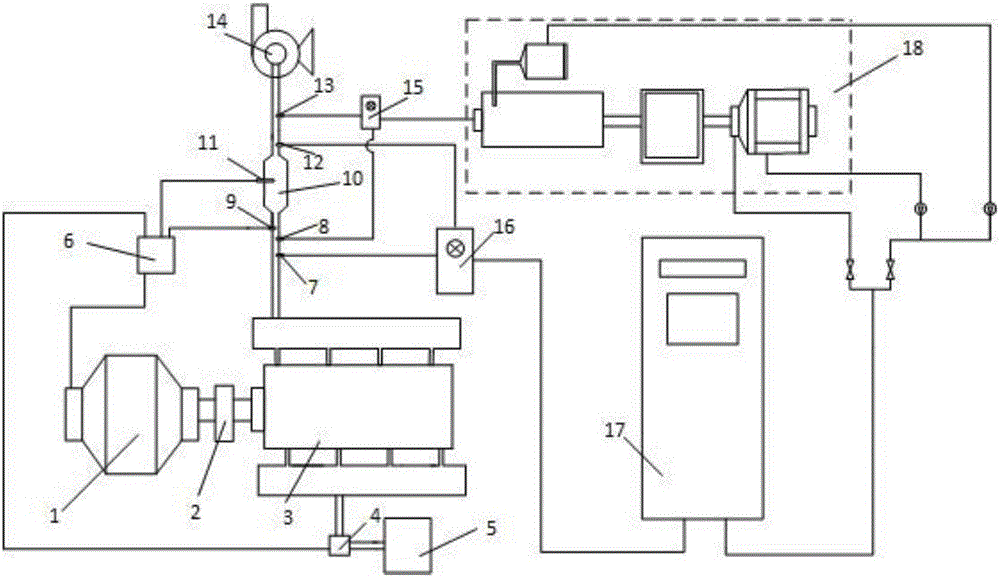

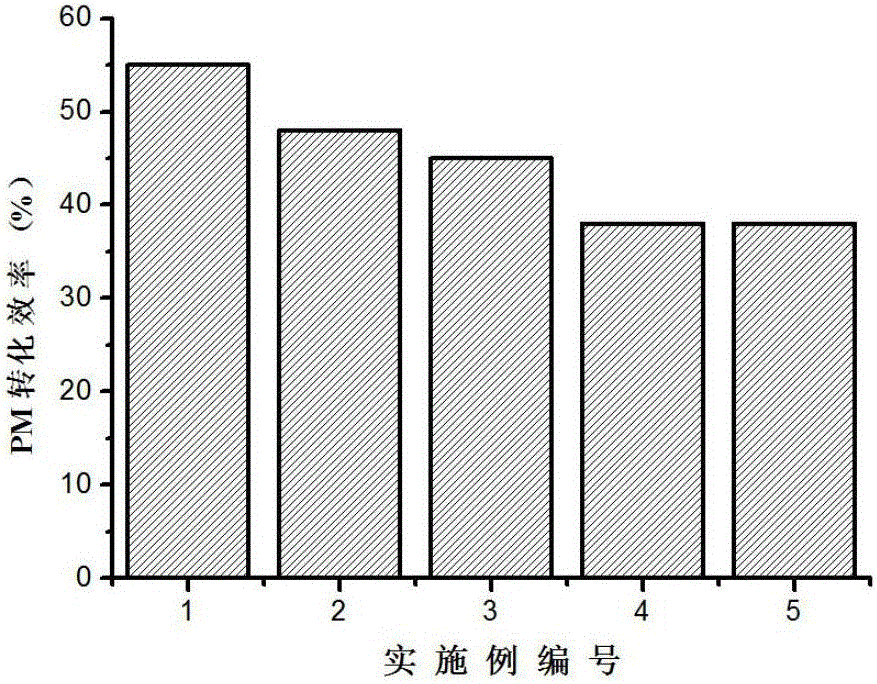

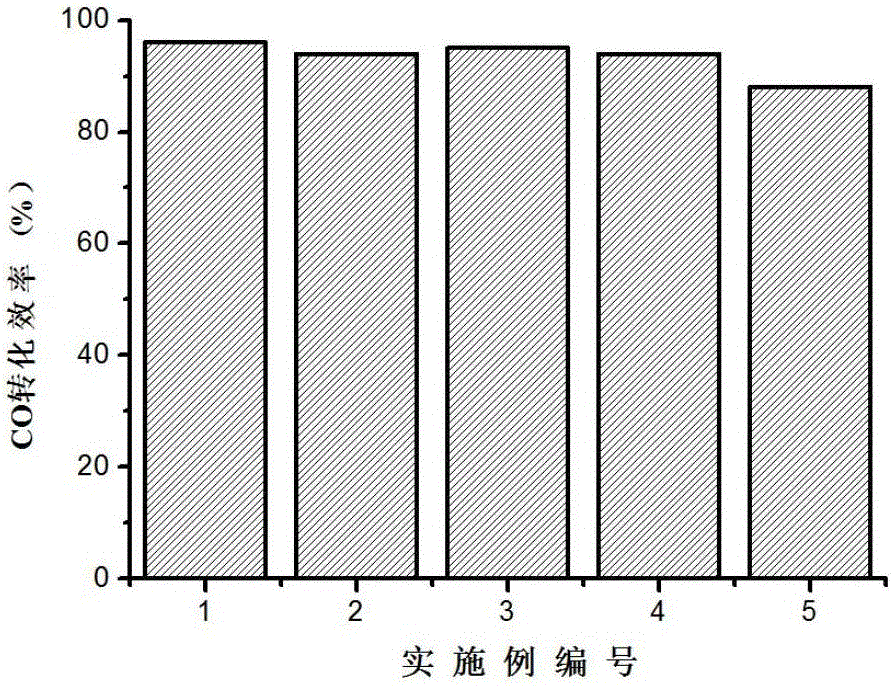

Cuprous modified zeolite diesel engine emission pollutant oxidation and purification catalyst

ActiveCN106669843AReduce manufacturing costImprove sulfur resistanceGas treatmentExhaust apparatusSlurryCordierites

The invention discloses a cuprous modified zeolite diesel engine emission pollutant oxidation and purification catalyst. According to the catalyst, a cuprous modified ZSM-5 molecular sieve and La2O3 form a main catalyst, a CeO2-ZrO2 solid solution is taken as a cocatalyst, SiO2, TiO2 and gamma-Al2O3 form a coating base material and 400-mesh cordierite honeycomb ceramic is taken as a catalyst carrier. The preparation technology comprises the steps of preparation and determination of the raw material amount of a load catalyst, preparation of the cuprous modified ZSM-5 molecular sieve and preparation and coating of coating slurry. The catalyst is used for purifying HC, CO and PM pollutants in diesel engine exhaust by being packaged in a diesel engine oxidation catalyst. a noble metal main catalyst in a traditional diesel engine oxidation catalyst is replaced with the catalyst, so that the production cost is significantly reduced, the sulfur resistance and the heat inactivation resistance of the catalyst are improved, and the catalytic activity of the catalyst in low-temperature oxidation reaction is effectively improved.

Owner:TIANJIN UNIV

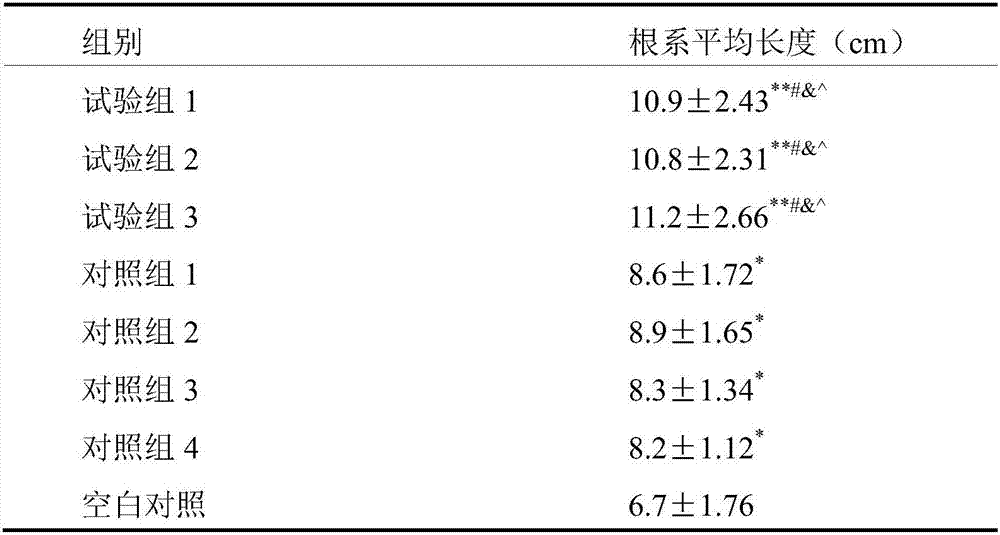

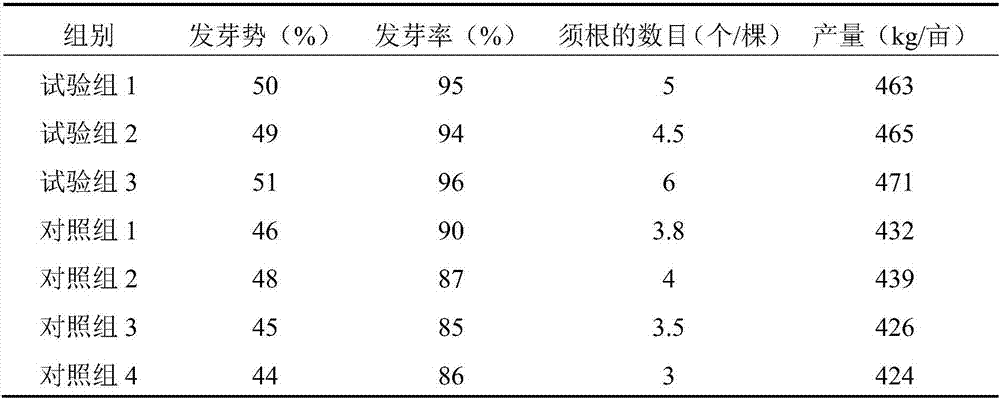

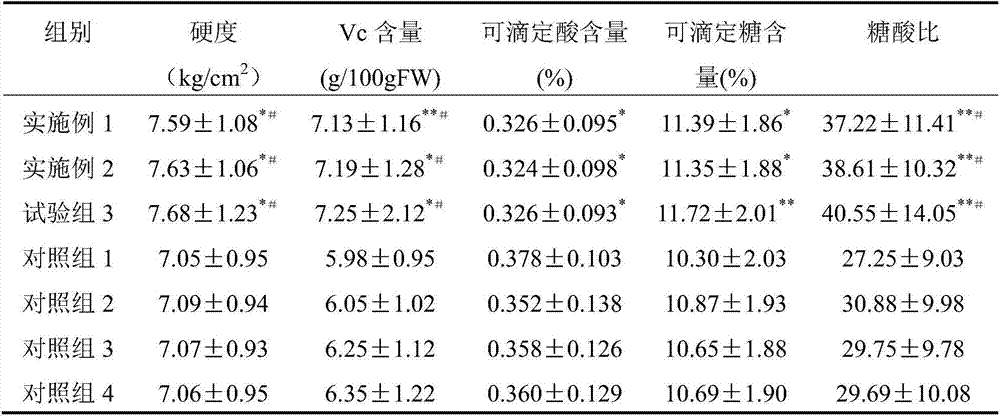

Modifier for promoting plant rooting and sprouting, preparation method thereof and application

The invention discloses a modifier for promoting plant rooting and sprouting and a preparation method thereof and belongs to the technical field of crop growth modifiers. The modifier comprises 3-8 parts of rhamnolipid surfactant and 5-15 parts of sucrose ester surfactant. Preferably, the modifier comprises 5 parts of rhamnolipid surfactant and 10 parts of sucrose ester surfactant. The modifier is prepared from, by weight parts, 3-8 parts of rhamnolipid surfactant, 5-15 parts of sucrose ester surfactant, 2-10 parts of compound bacteria powder, 30-60 parts of thoroughly-decomposed livestock excrement, 35-45 parts of fermented bean dregs, 30-50 parts of thoroughly-decomposed straw, 5-10 parts of potassium fulvic acid, 3-10 parts of dicalcium phosphate and 2-6 parts of zinc gluconate. The modifier can promote rooting and sprouting, enables branches and leaves to flourish, improves yield and is low in production cost, simple in preparation process and suitable for industrial production.

Owner:山东本源生态农业科技有限公司

Honeycomb-like cerium-zirconium-titanium-based denitration catalyst and preparation method thereof

InactiveCN105435769AHigh activityImprove pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasFiltration

The present invention provides a honeycomb-like cerium-zirconium-titanium-based denitration catalyst and a preparation method thereof, and the honeycomb-like cerium-zirconium-titanium-based denitration catalyst is prepared by the steps of preparation of a mud material, filtration and pre-squeezing, preparation of a denitration mud blank, and calcination. The honeycomb-like cerium-zirconium-titanium-based denitration catalyst is non-toxic and environmentally friendly, the boiler flue gas NOx removal rate can reach 90% in a 150-420 DEG C temperature window.

Owner:SHANGHAI LANGT AUTOCATALYST +1

Cerium/aluminum-based composite oxide with high specific surface area and its preparation method

InactiveCN102847559AInhibit growthHigh specific surface areaCatalyst carriersDispersed particle separationRare-earth elementCerium

The invention provides a cerium / aluminum-based composite oxide with high specific surface area and its preparation method. The composite oxide has chemical formula of AlzCexRyO2, wherein R is rare earth element, x (10-50%), y (1-8%) and z (1-x-y) are molar ratios of Al, Ce and R. The composite oxide is used in three-way catalyst for exhaust gas purification of automobile, has large specific surface area, high thermal stability, and strong oxygen storage ability.

Owner:南京辉虎环保科技有限公司

Flat-plate type sulfur-resistant low-temperature SCR denitration catalyst and preparation method thereof

ActiveCN105289644AStrong mechanical propertiesExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The invention specifically relates to a flat-plate type sulfur-resistant low-temperature SCR denitration catalyst and a preparation method thereof, belonging to the fields of environmental protection and environmental catalysis. The method comprises the following steps: with nanometer composite oxide Ce-ZrO2 as a carrier, manganese oxide as an active component and iron oxide and molybdenum oxide as cocatalysts, carrying out equivalent-volume impregnation, drying, roasting and crushing so as to prepare a powdery catalyst; and subjecting the prepared powdery catalyst to acidification by sulfuric acid and then carrying out mixing, rolling coating, fold pressing, shearing, drying and roasting so as to obtain the flat-plate type sulfur-resistant low-temperature SCR denitration catalyst. The prepared catalyst has denitration activity of 85 to 98% in a temperature range of 80 to 150 DEG C and has excellent resistance to sulfur dioxide poisoning.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

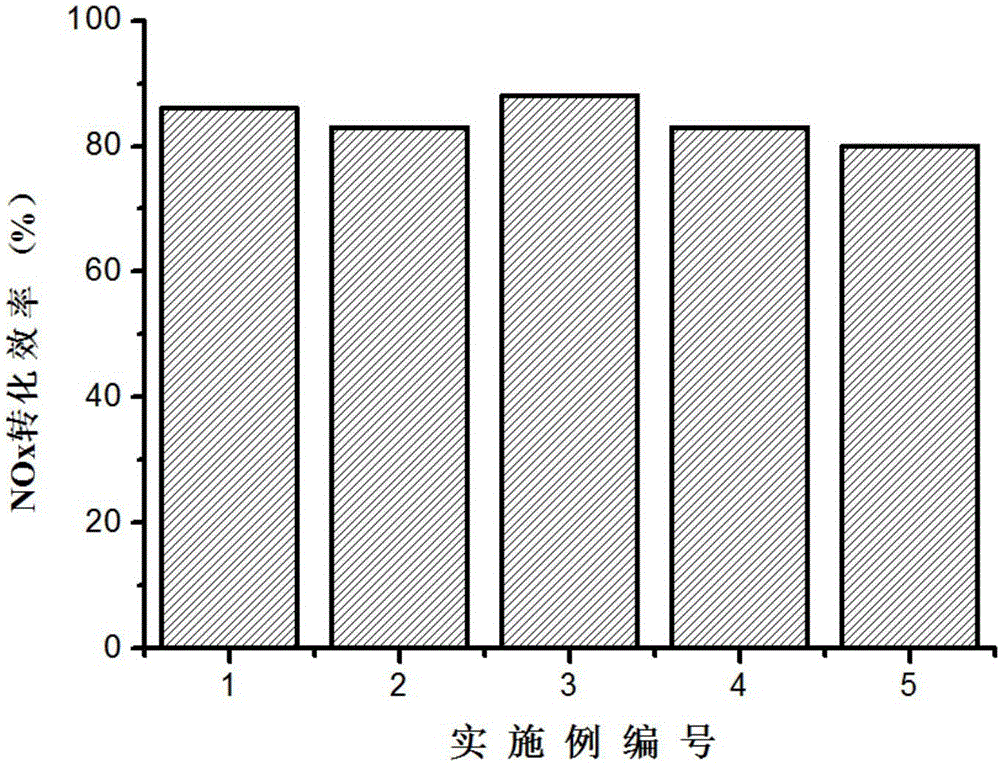

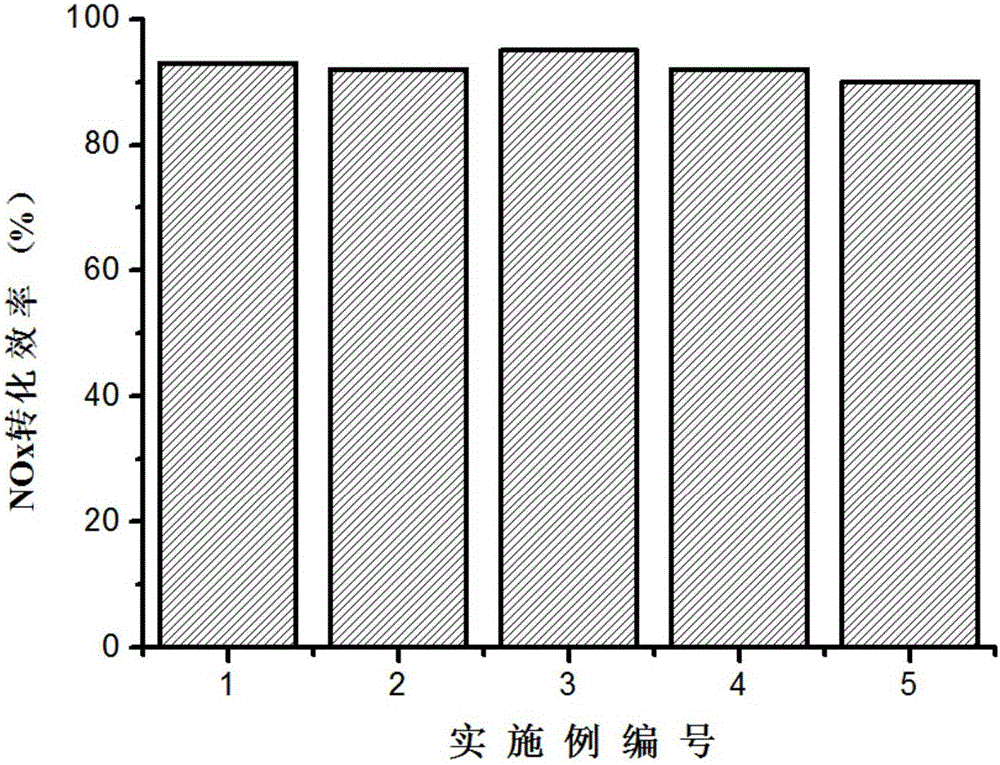

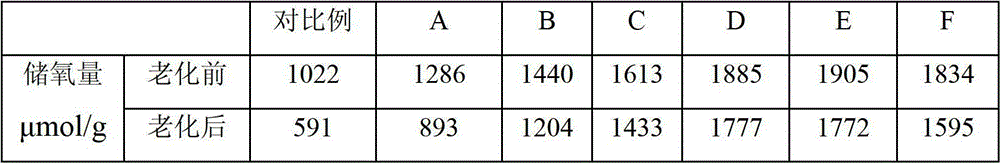

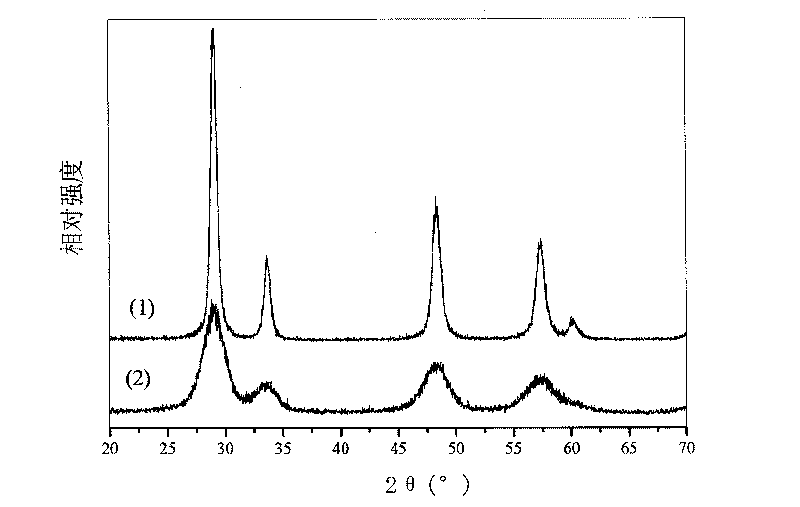

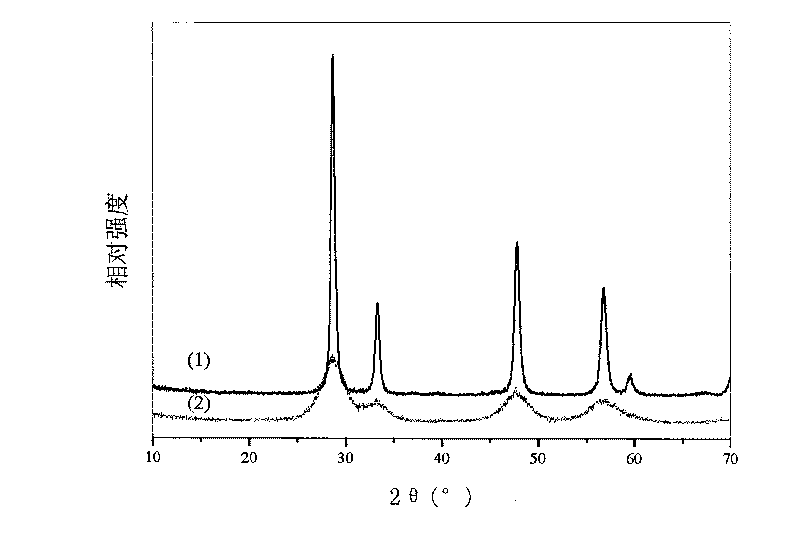

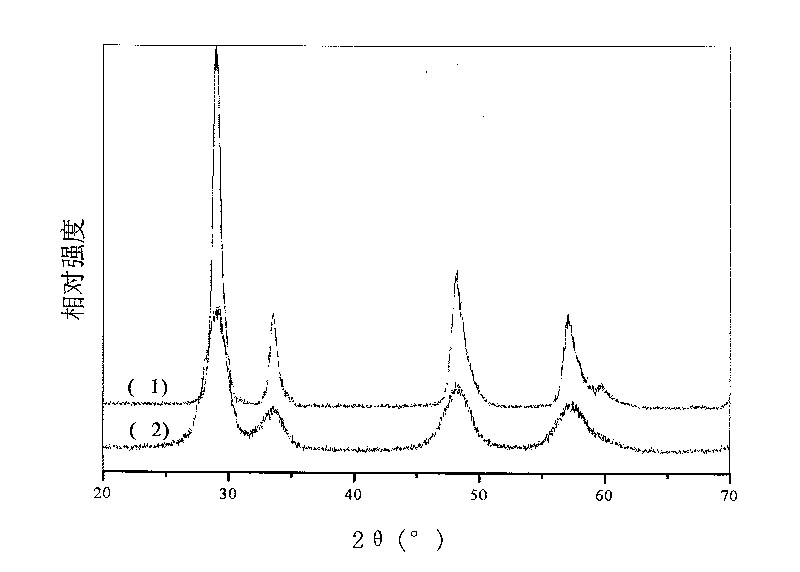

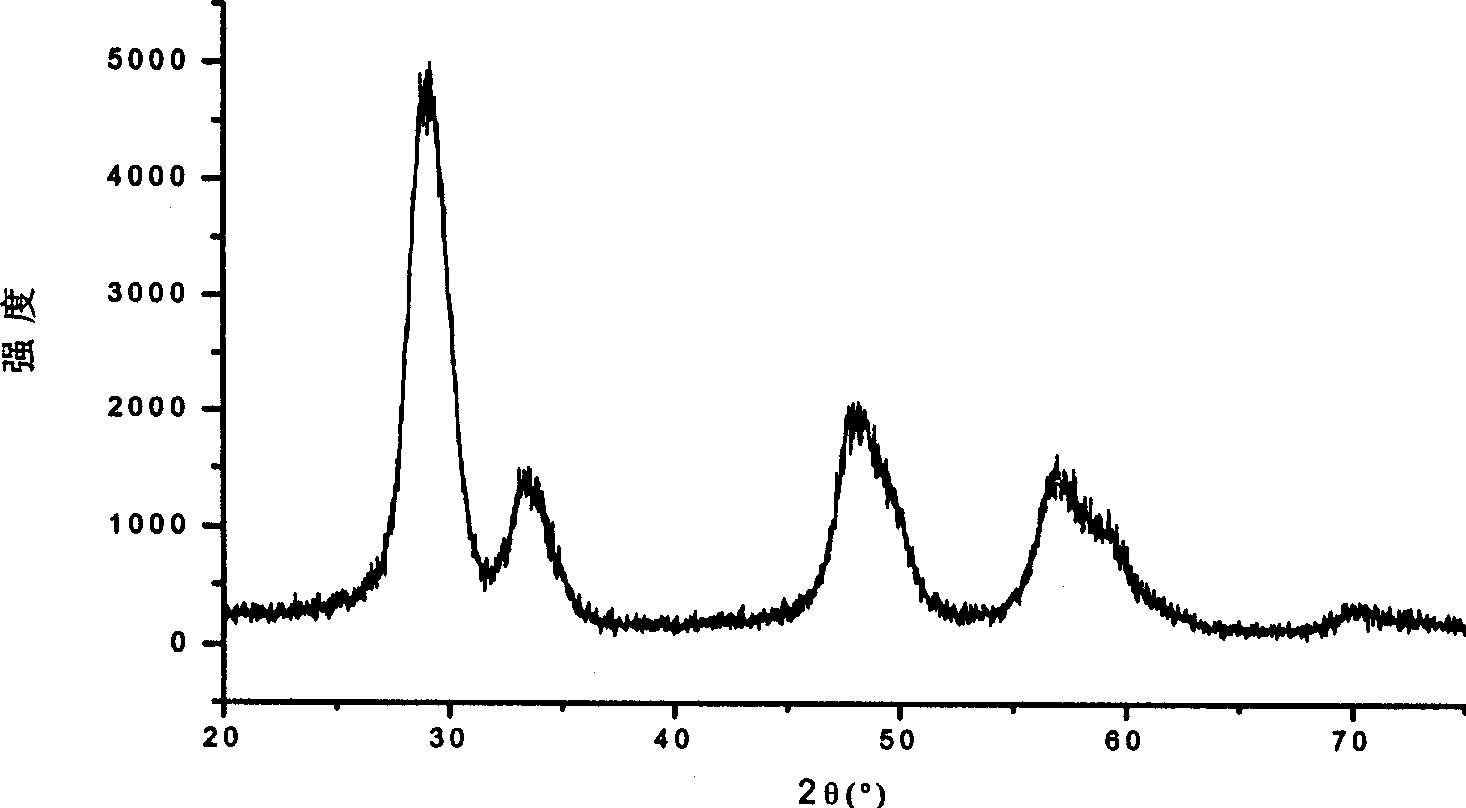

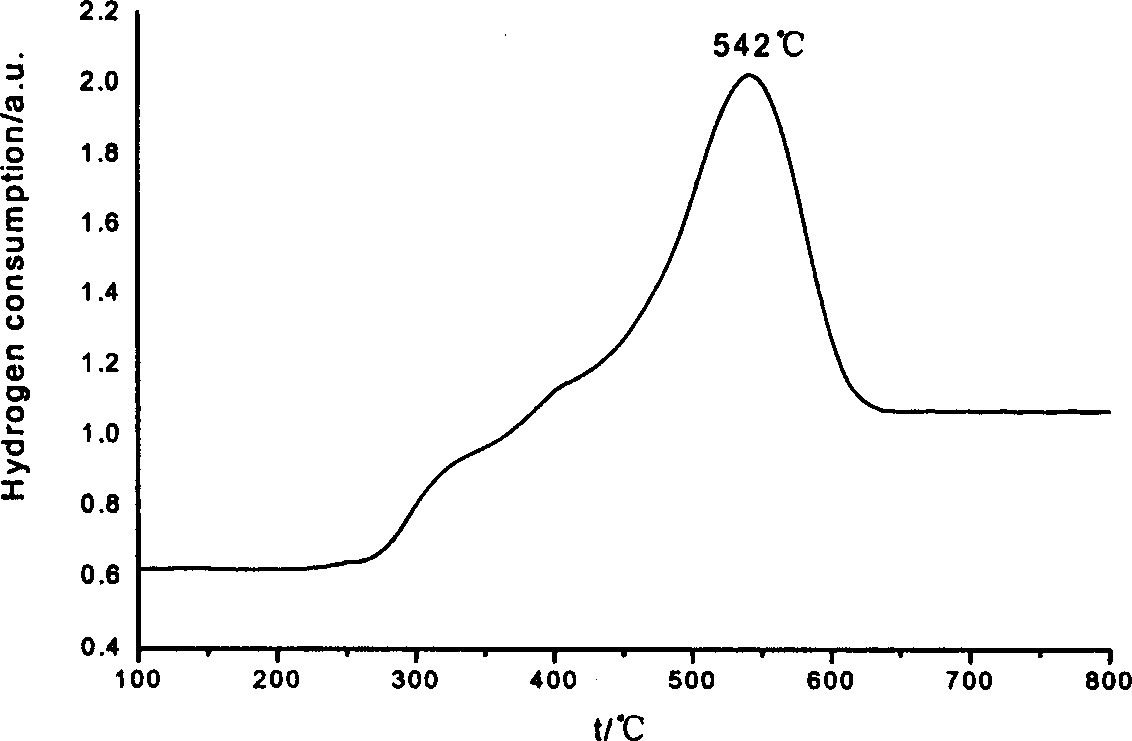

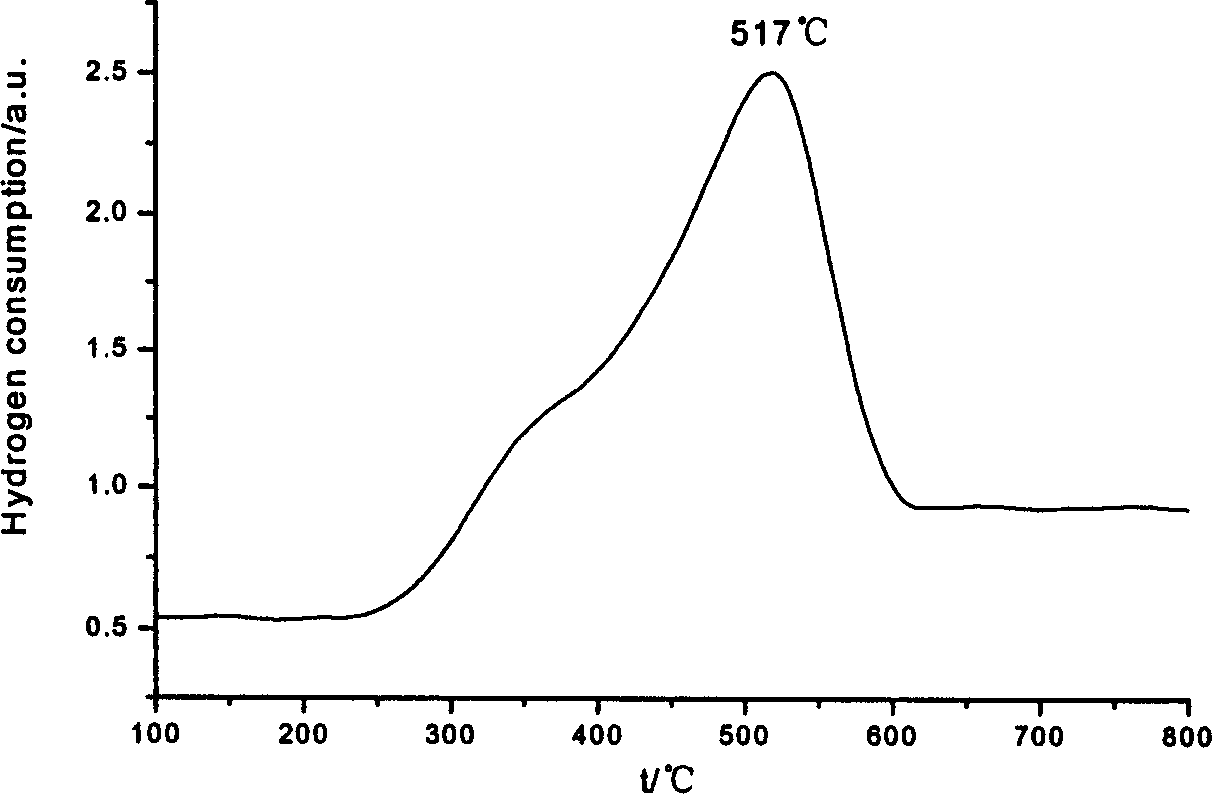

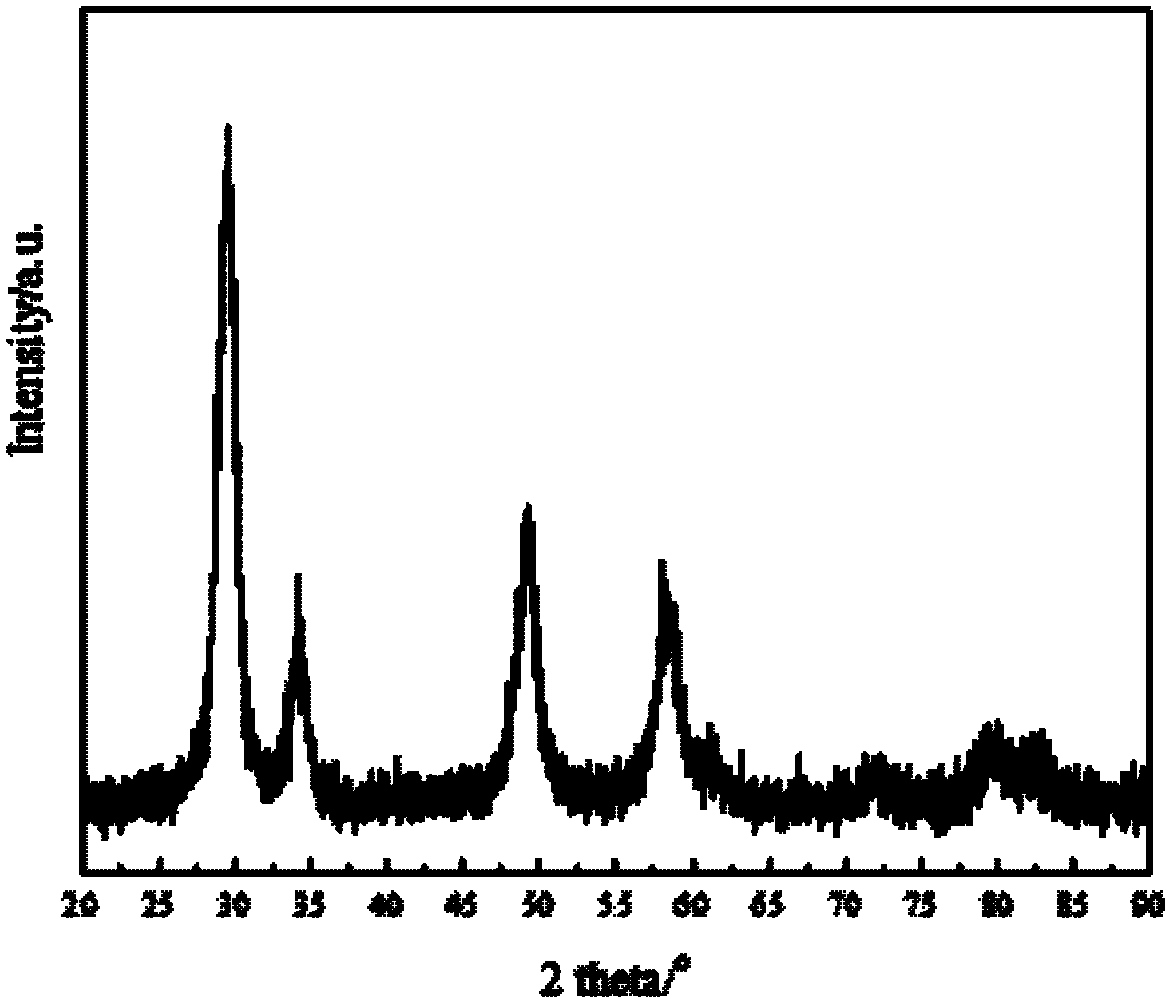

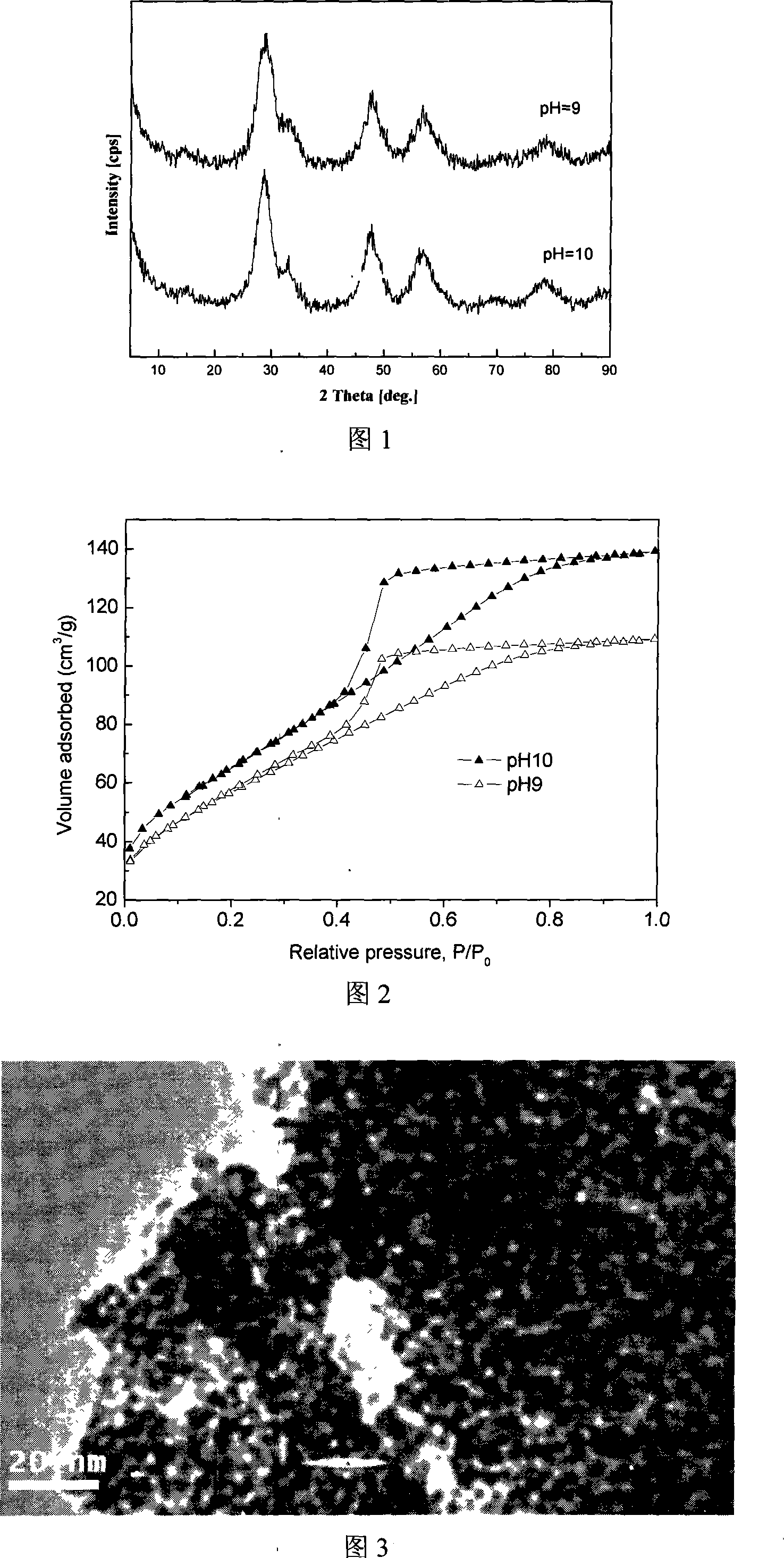

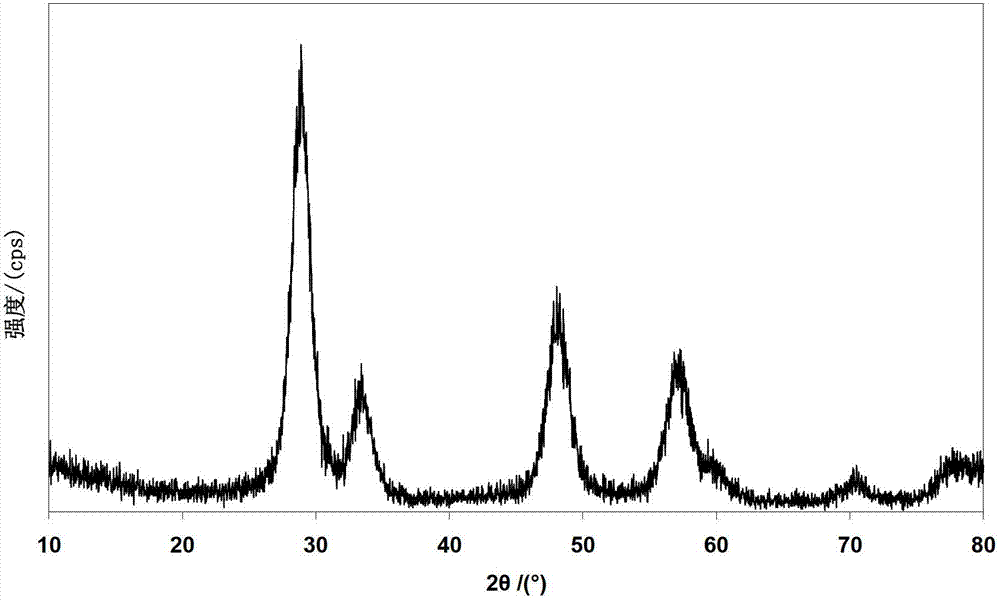

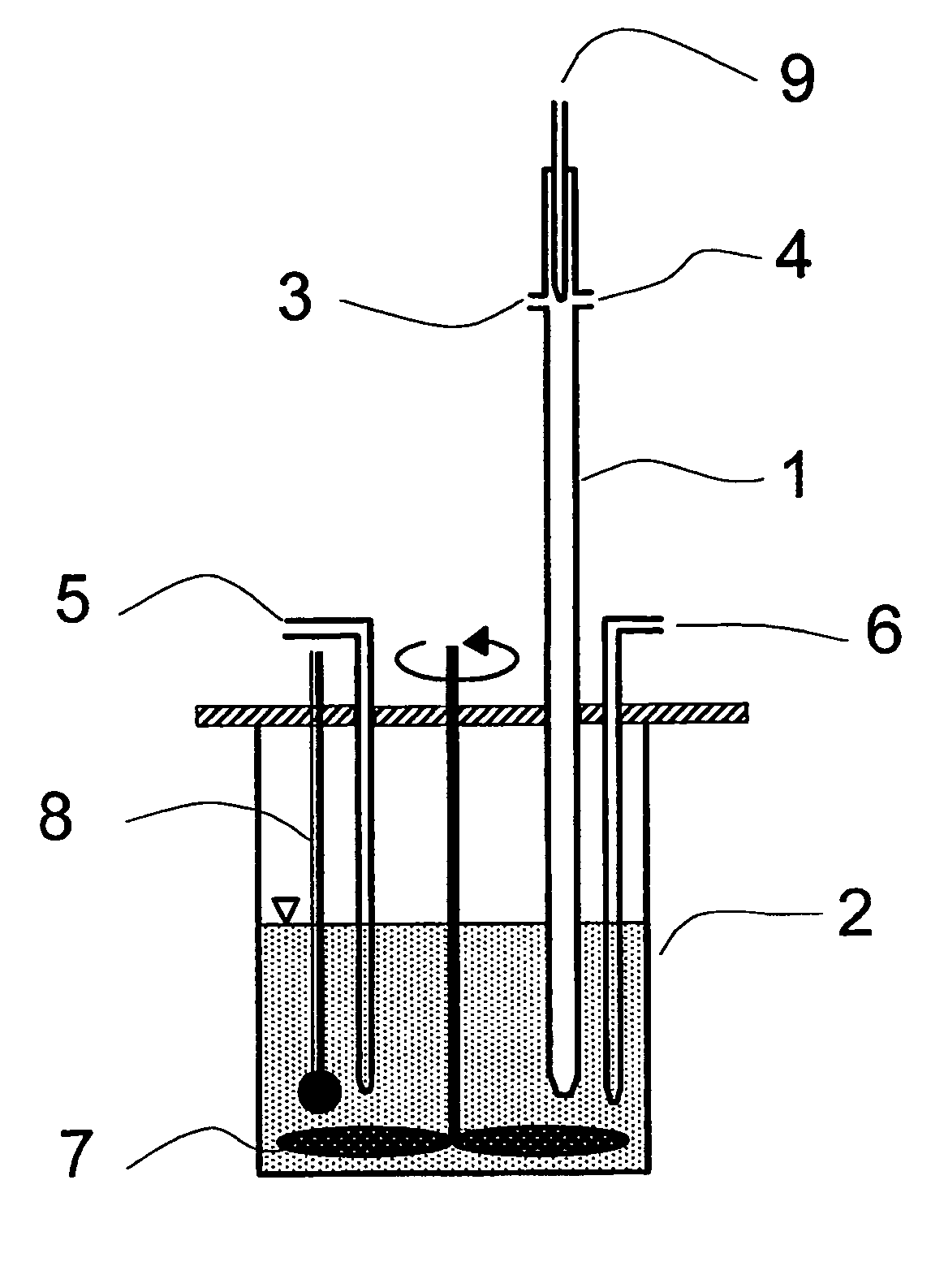

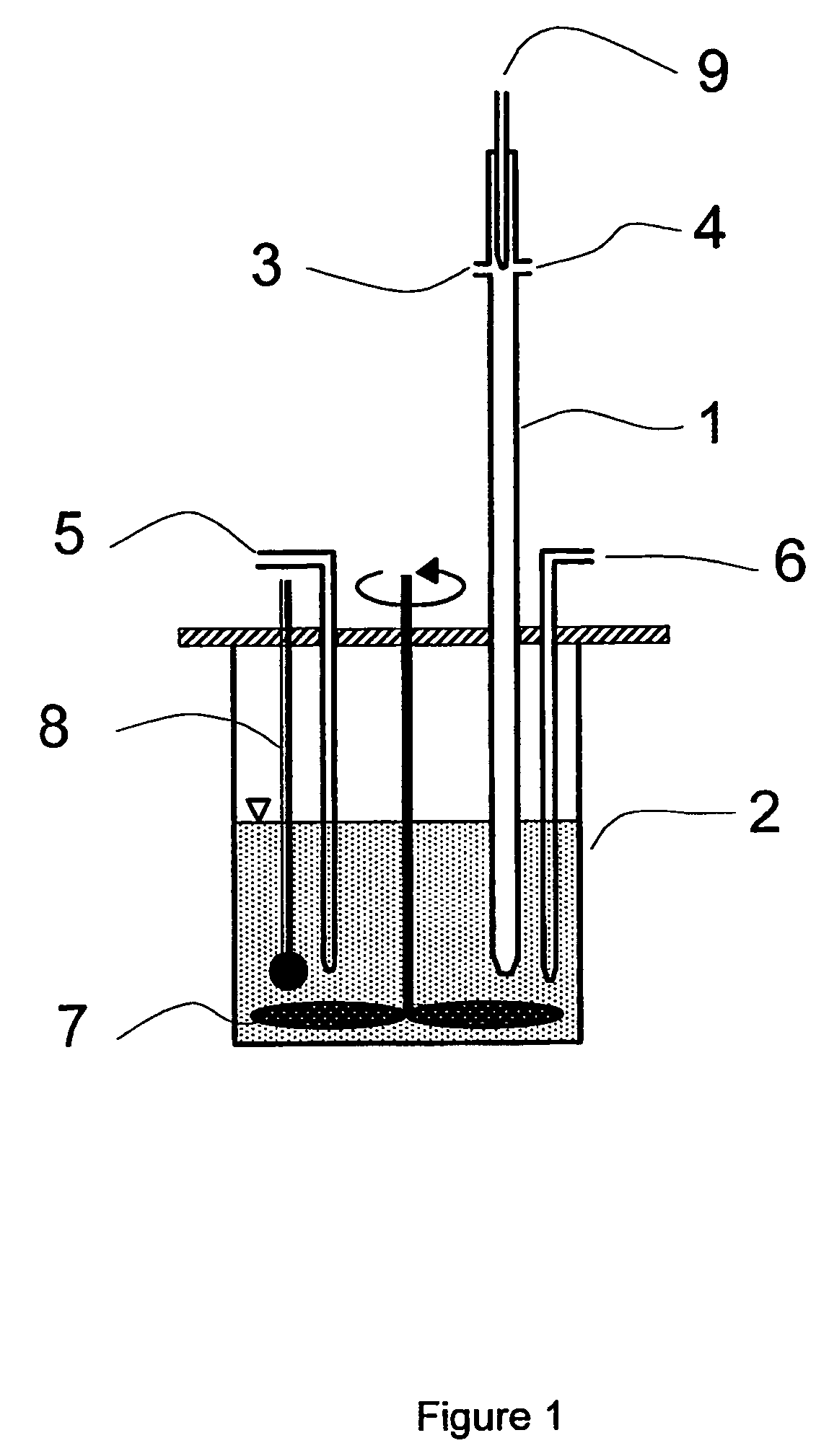

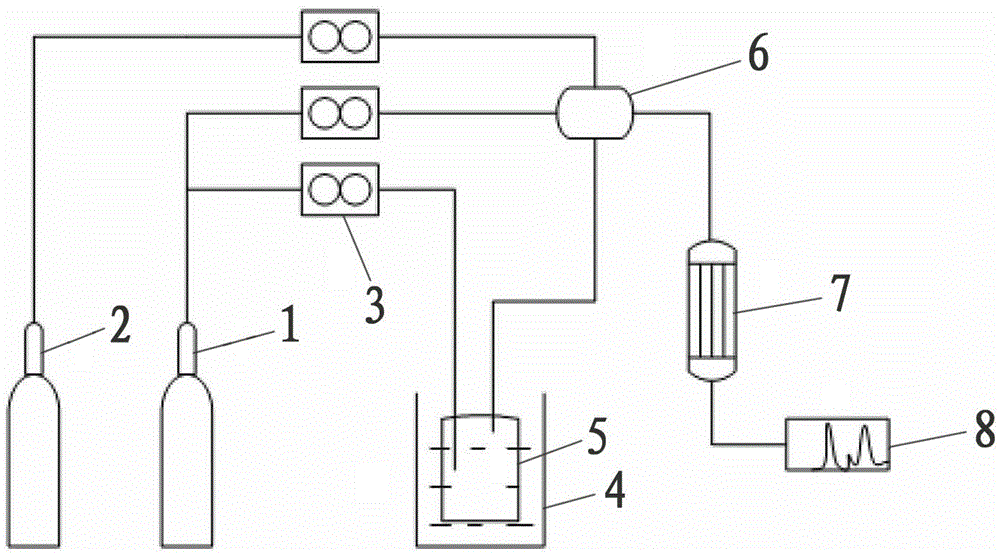

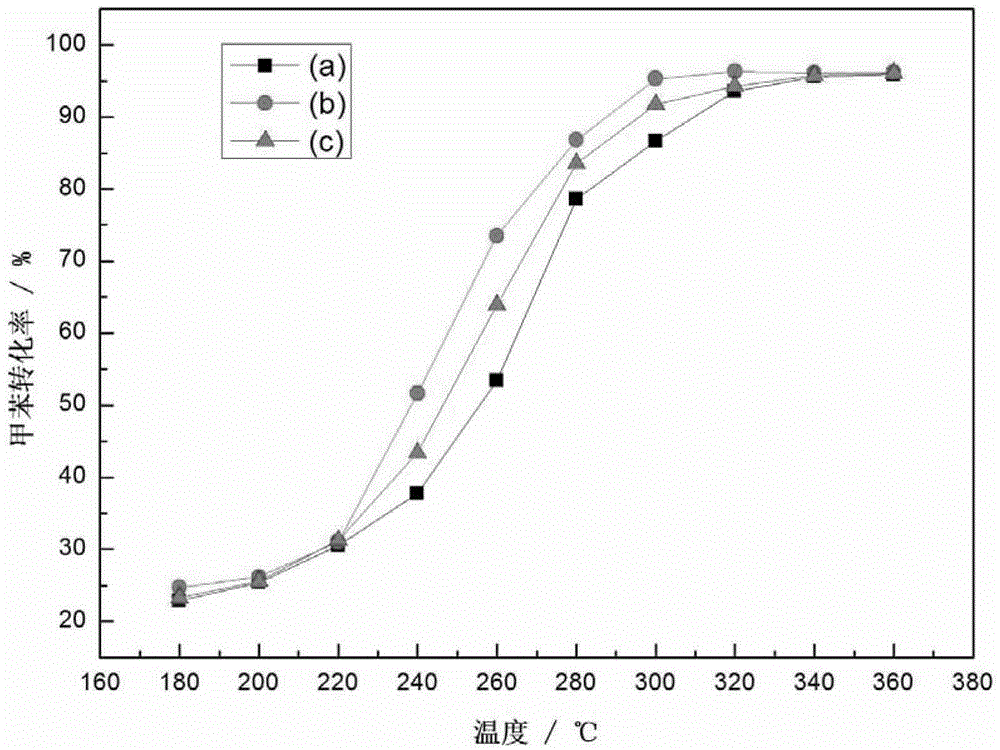

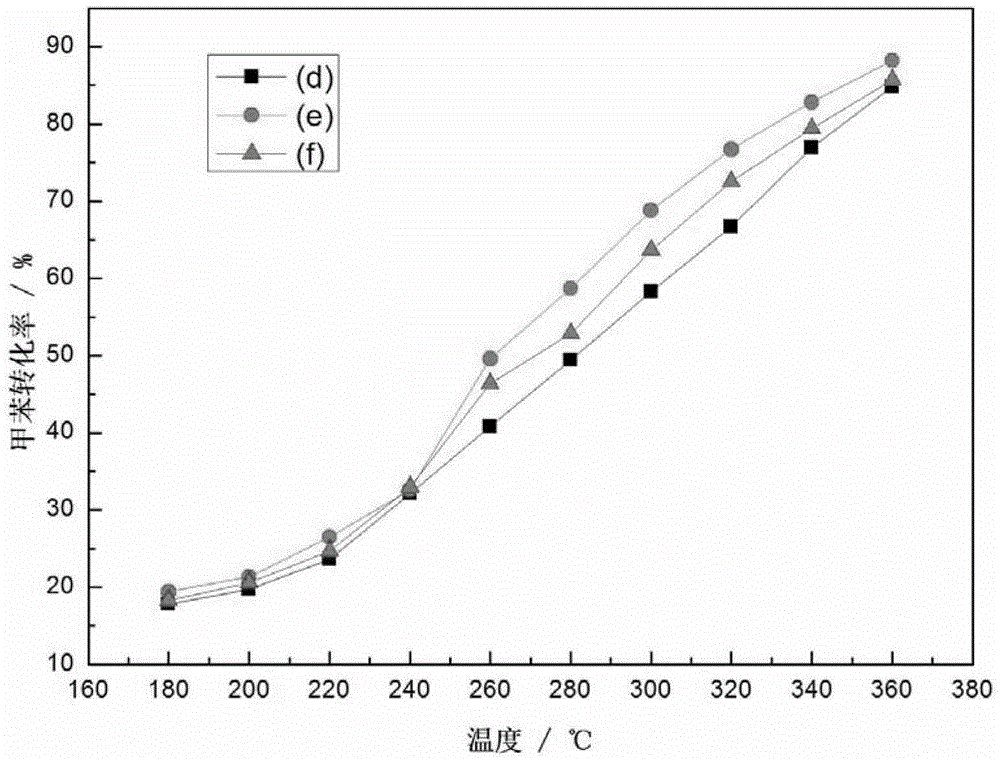

Metal doped modified layered [delta]-MnO2, preparation and applications thereof

ActiveCN110102287AIncreased toxicityImprove catalytic oxidation efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationVolatile organic compound

The invention relates to metal doped modified layered [delta]-MnO2, preparation and applications thereof. According to the present invention, the metal doped modified layered [delta]-MnO2 is preparedby adding a settling agent through a hydrothermal method, wherein the specific surface area is increased by 5 times compared with the undoped layered [delta]-MnO2, and the pore channels are dense, such that the metal doped layered [delta]-MnO2 has high catalytic oxidation activity and high chlorine resistance, and has efficient catalytic degradation performance on refractory volatile organic compounds in organic waste gas; and the preparation method is simple, and has industrial application value.

Owner:BEIJING UNIV OF CHEM TECH

Oxygen storage material for the catalytic purification of car exhaust gas

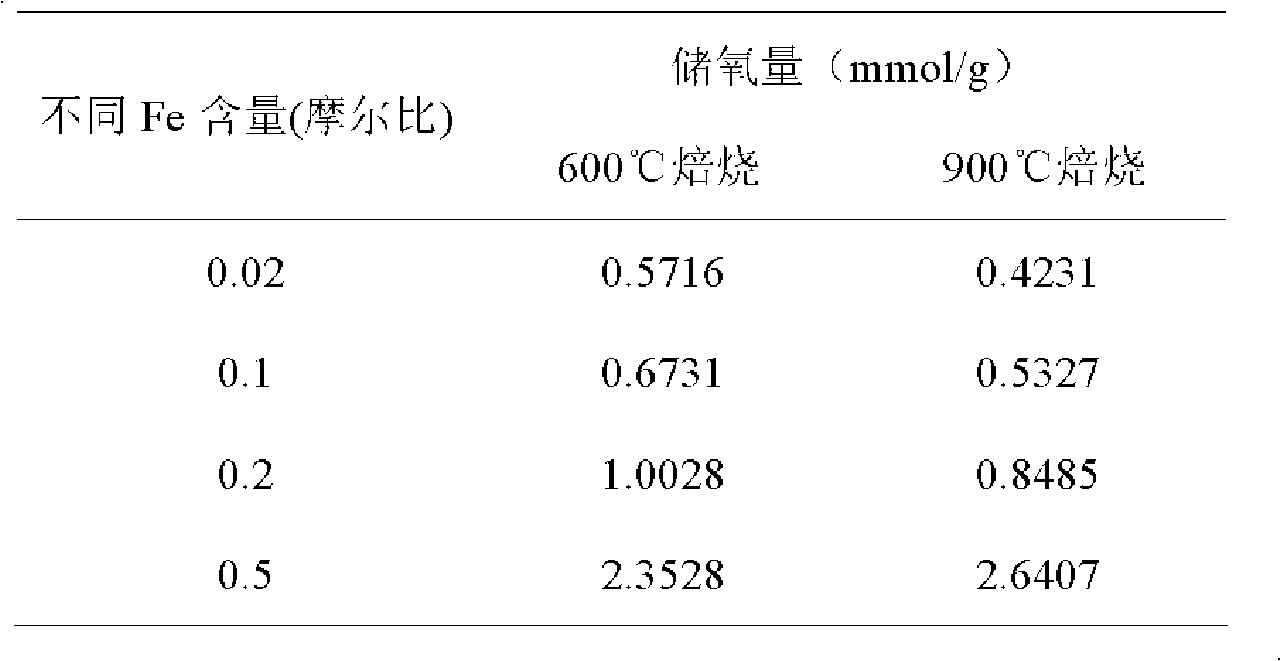

InactiveCN101549256ASimple preparation processImprove oxygen storage capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCelsius Degree

The invention discloses an oxygen storage material for the catalytic purification of car exhaust gas, belongs to pollution control technology field, relates to an oxygen storage material for the catalytic purification of car exhaust gas, especially relates to an oxygen storage material which can remains the oxygen storage property at the elevated temperature of 900 Celsius system. The material is prepared with the colloidal sols jelly glue method which is indicated taking cerium nitrate, zirconium nitrate and ferric nitrate as raw charge, adding moderate citric acid as agglomerating agent, and preparing the powder of cerium ferro-zirconium composite oxides with taking de-ionized water as dissolvent and absolute ethyl alcohol as additive. The effect and benefit of this invention is indicated that the provided preparing technology for oxygen storage material is simple, which has stronger oxygen storage property of cerium zirconium composite oxides oxygen storage material, and especially the oxygen storage property does not fall after high temperature roasted.

Owner:DALIAN UNIV OF TECH

Catalyst for synthesis of methanol and formaldehyde through selective oxidation of methane, and preparation method and application thereof

ActiveCN103785375AGood dispersionHigh selectivityPreparation by oxidation reactionsOrganic compound preparationPtru catalystPhysical chemistry

The invention discloses a catalyst for synthesis of methanol and formaldehyde through selective oxidation of methane. According to the invention, SiO2 modified by Nb and Ce is used as a carrier, and Mo and Sb are used as active components; in terms of the weight of the finished catalyst, Mo accounts for 5 to 11%, Sb accounts for 7 to 20%, Nb accounts for 1 to 3.5%, and Ce accounts for 1 to 3.5%, with the balance being SiO2. A preparation method for the catalyst used for synthesis of methanol and formaldehyde through selective oxidation of methane comprises the following steps: loading Nb and Ce by using an impregnation method so as to prepare SiO2 modified by Nb and Ce; then loading the active components--Sb and Mo; and finally, carrying out molding and screening so as to prepare the finished catalyst. The catalyst can be used for a selective oxidation reaction of methane for preparation of methanol and formaldehyde at a low pressure and has the advantages of a high methane conversion rate, high methanol and formaldehyde selectivity, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxygen storage capacity substance and method of oxygen storage capacity in three-way catalyst for purifying automotive exhaust gas

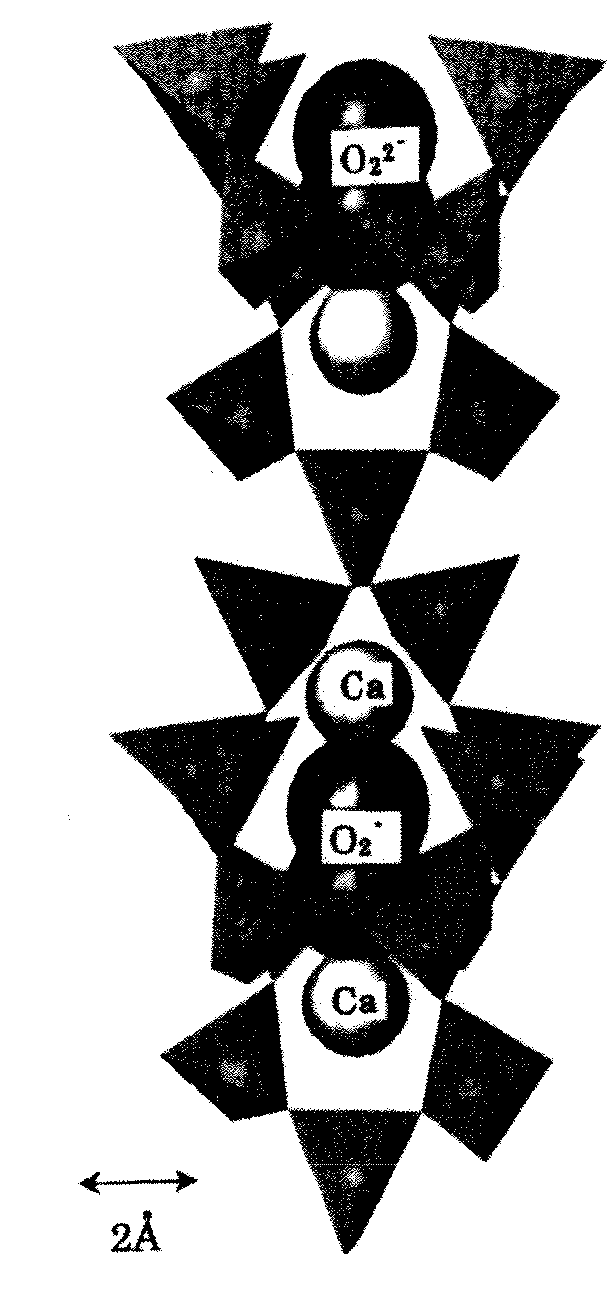

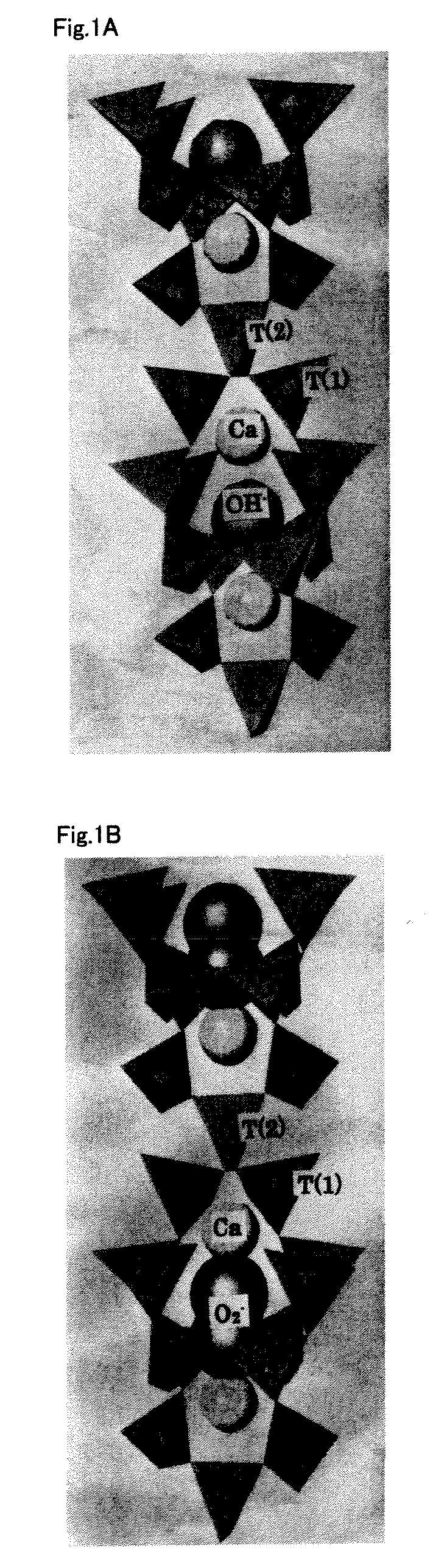

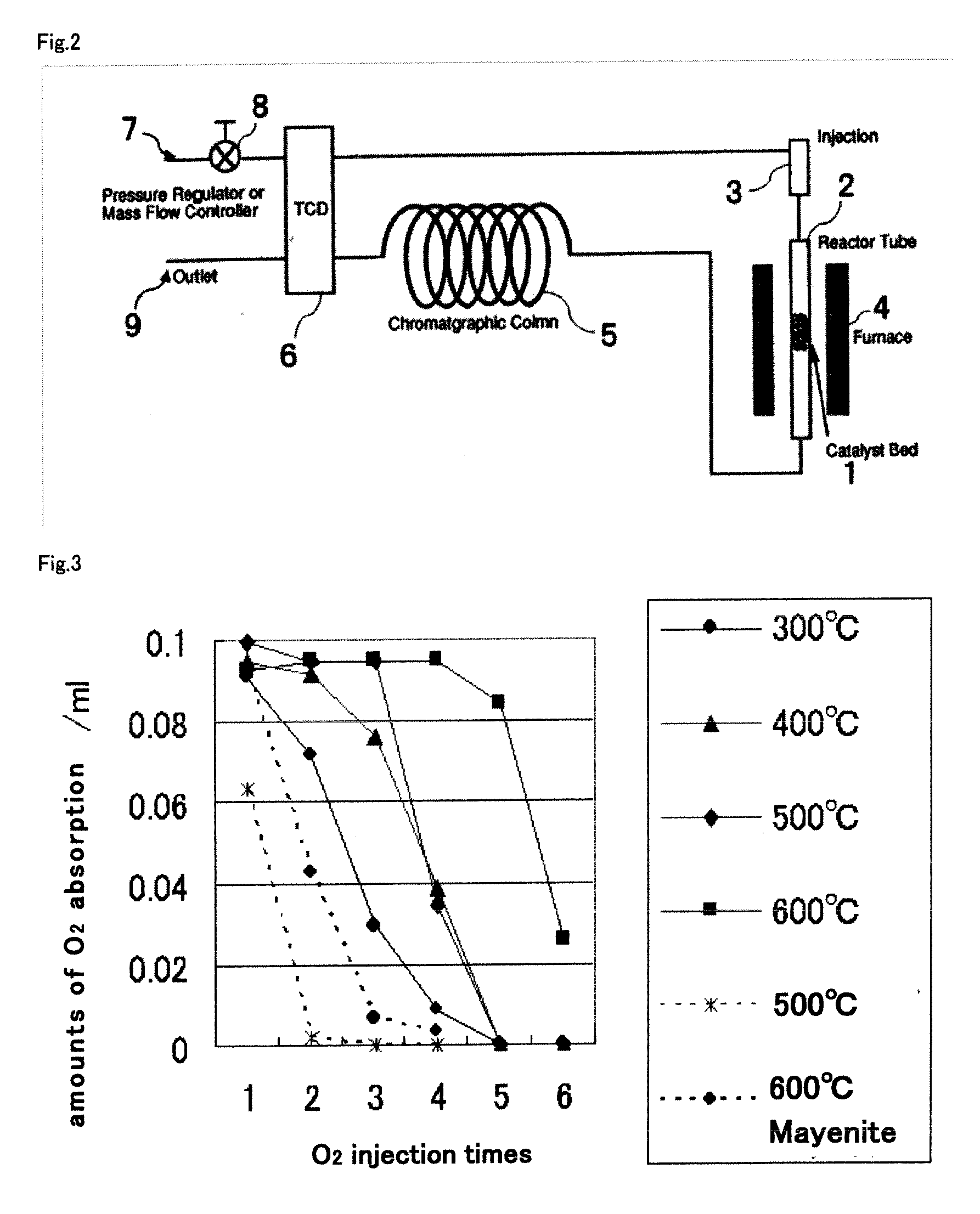

InactiveUS20090148369A1Low priceLarge capacityOxygen/ozone/oxide/hydroxideNitrogen compoundsSilicon dioxideTetrahedron

[PROBLEMS] To provide an oxygen storage substance which has higher oxygen storage capacity than conventional substances and is inexpensive. [MEANS FOR SOLVING PROBLEMS] The oxygen storage substance is a calcium aluminosilicate (mayenite), i.e., a substance of a crystal structure which is synthesized by hydrothermally treating a mixture of calcium oxide, alumina (sol), and amorphous silica, has a three-dimensional network composed of AlO4 tetrahedrons and (Al,Si)O4 tetrahedrons in which part of the aluminum atoms have been replaced with silicon atoms, with vertex oxygen atoms being shared, and has oxide ions (O2−) occluded in microspaces in the structure. Part of the calcium atoms may be replaced with atoms of a transition metal, e.g., copper.

Owner:HIROSAKI UNIVERSITY

Ternary catalyst for automobile tail gas treatment

InactiveCN106268970AImprove catalytic performanceImprove oxygen storage capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention relates to a ternary catalyst for automobile tail gas treatment. The ternary catalyst comprises a honeycomb substrate, and is characterized in that a lower Pd coating is adhered to the honeycomb substrate, a middle Pd coating is adhered to the lower Pd coating, and an upper Rh coating is adhered to the middle Pd coating; the lower Pd coating comprises a Pd-loaded cerium-zirconium solid solution and La2O3-doped aluminum oxide (La2O3-Al2O3); the middle Pd coating comprises Pd-loaded La2O3-Al2O3 and a bonding agent; the upper Rh coating comprises an Rh-loaded cerium-zirconium solid solution and La2O3-Al2O3. Since the middle Pd coating contains no CeO2 ingredient, and Pd is loaded on La2O3-Al2O3, so that the catalytic capability of the ternary catalyst is improved, and the oxygen storage capability of the ternary catalyst is improved; compared with a traditional Pd / Rh dual-coating ternary catalyst, the ternary catalyst provided by the invention has relatively high hydrocarbon compound, carbonic oxide and oxynitride treatment capacity, and especially has relatively high oxynitride conversion capacity.

Owner:桐城市宇洁机动车尾气检测有限公司

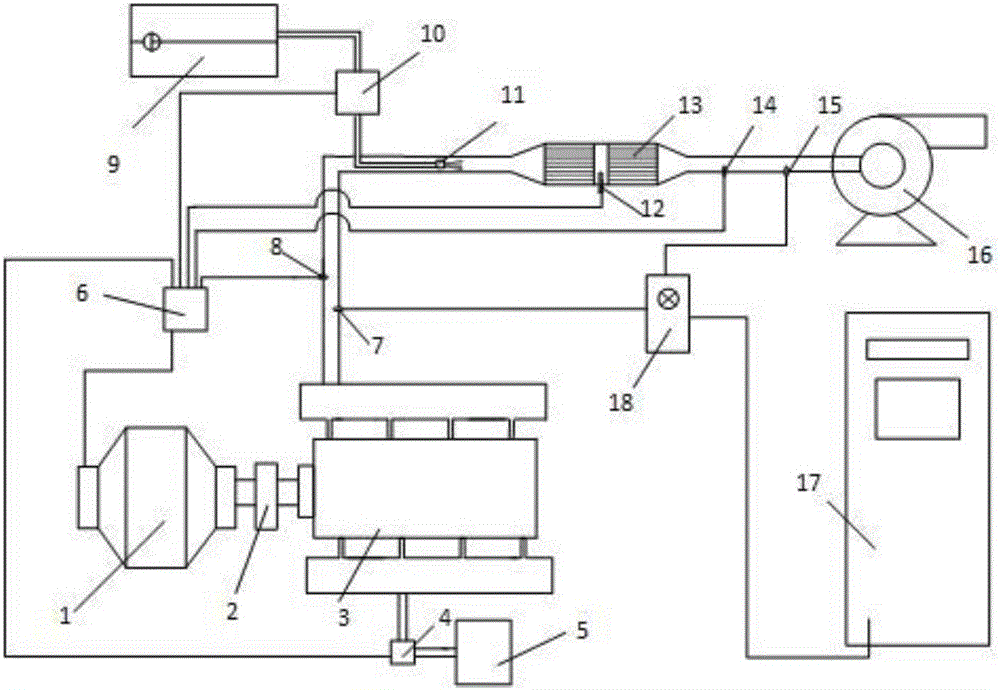

System and method for carrying out electrolysis treatment on high-chlorine desulfurization wastewater and coupling denitration and mercury removal

ActiveCN108371879AImprove denitrification efficiencySpeed up SCR responseNitrous oxide captureGas treatmentHigh concentrationElectrolysis

The invention discloses a method and system for carrying out zero-emission treatment on high-chlorine desulfurization wastewater and promoting flue gas to be subjected to denitration and mercury removal. The method comprises the following steps: firstly, carrying out reverse refluxing concentration on the desulfurization wastewater and part of the flue gas; after pre-treating the wastewater, pumping the wastewater into a cathode chamber of an electrolysis system, so as to obtain alkaline slurry containing high-concentration chlorine ions; refluxing the alkaline slurry into a pre-treatment coagulation precipitation tank; enabling the high-concentration chlorine ions to penetrate though an anion exchange membrane to enter an anode chamber; electrolyzing in the anode chamber to generate chlorine gas and oxygen gas; after mixing the chlorine gas, the oxygen gas, anode electrolyte and air, conveying a mixture into a prepositioned SCO system to participate in oxidization of Hg<0> and part ofNO. According to the method disclosed by the invention, high-chlorine desulfurization wastewater treatment and the denitration and mercury removal of the flue gas are subjected to ectopic coupling, so that the zero-emission aim of the desulfurization wastewater is realized, the problem of Hg<0> pollution also can be solved through simultaneous oxidation and the content of NO2 in the flue gas is improved; denitration reaction of rapid SCR (Selective Catalytic Reduction) is promoted and simultaneous denitration and mercury removal of the flue gas are realized.

Owner:WUHAN UNIV

Metallic composite oxides material with three hiberarchy and manufacture method thereof

ActiveCN101249438AImprove oxygen storage capacityImprove conversion rateInternal combustion piston enginesDispersed particle separationCeriumCe element

The invention discloses metal composite oxides material with three-layer structure for automobile tail gas clean-up catalyst coating and a preparation method thereof. The metal composite oxide material with three-layered structure is characterized in that the material has a three-layer structure including an alumina inner layer, and an intermediate layer and an outermost layer made from cerium-zirconium oxide and doped with ceria-removed rare earth oxide; when the atom ratio of Ce / Zr of cerium-zirconium oxide of the outermost layer is higher than or equal to 1, the atom ratio of Ce / Zr of cerium-zirconium oxide of the ntermediate layer is lower than or equal to 1 / 3; and when the atom ratio of Ce / Zr of cerium-zirconium oxide of the outermost layer is lower than or equal to 1 / 3, the atom ratio of Ce / Zr of cerium-zirconium oxide of the ntermediate layer is higher than or equal to 1. The material has good high temperature stability and high pollutant treatment capacity.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

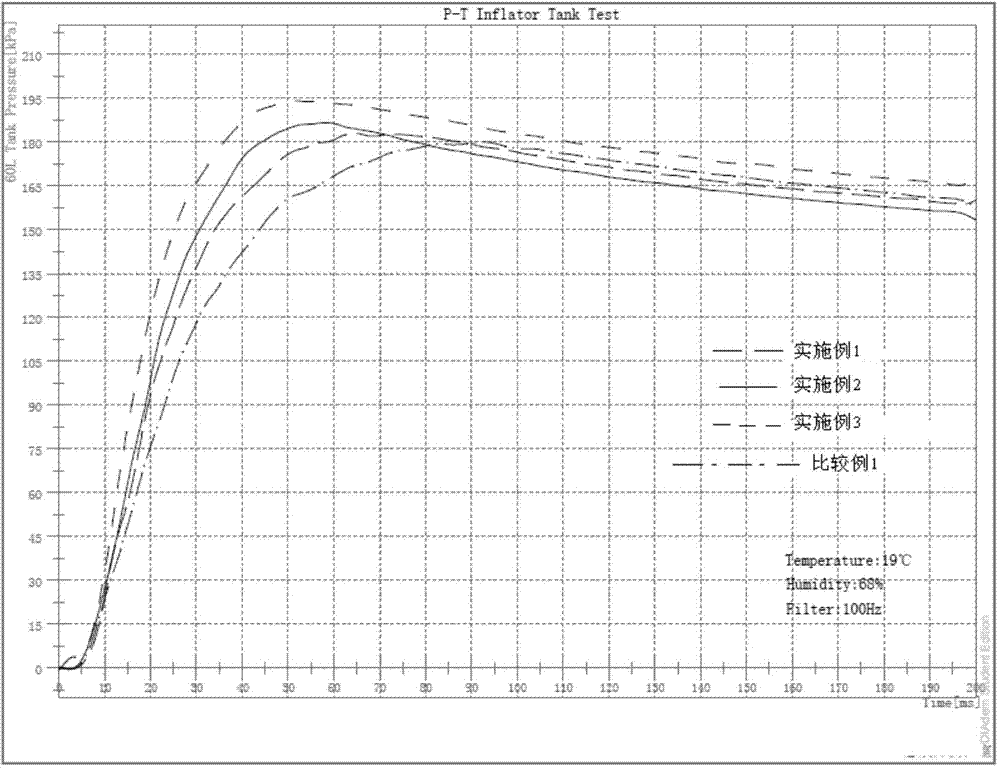

Gas generating agent composition and preparation method thereof

ActiveCN104744185AThe decomposition temperature is advancedPromote decompositionPressure gas generationProduction rateCombustion

The invention relates to a gas generating agent composition. The gas generating agent composition comprises fuel, an oxidizing agent, a rare earth metal organic salt and an azotetrazolate nonmetal salt which are used as raw material components. By adding the rare earth metal organic salt and the azotetrazolate nonmetal salt to the fuel and the oxidizing agent, the decomposition temperature of the fuel is ahead of time, the fuel decomposition is promoted, and the combustion rate and the gas production rate are increased; and lots of gases are generated after reaction of the azotetrazolate nonmetal salt with oxides, thus enhancing the ignitability, increasing the combustion rate and reducing the combustion temperature. The gas generating agent composition is capable of effectively improving the ignitability and reducing the combustion temperature, meanwhile does not generate residues and is high in gas generation efficiency, large in gas production rate and fast in combustion rate.

Owner:BYD CO LTD

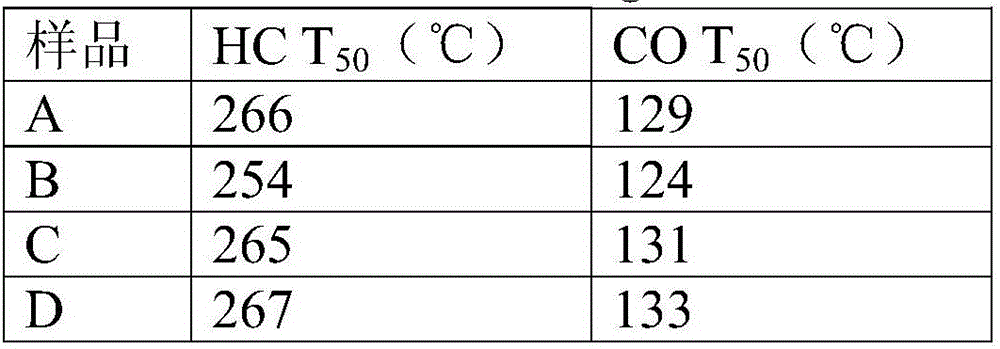

Pt-Pd bimetallic catalyst for NO oxidation and preparation method of Pt-Pd bimetallic catalyst

InactiveCN106807432AExcellent NO oxidation abilityGood NO oxidation abilityGas treatmentMolecular sieve catalystsMolecular sieveManganese

The invention relates to a Pt-Pd bimetallic catalyst for NO oxidation. The Pt-Pd bimetallic catalyst comprises a carrier, the carrier is coated with a coating loading precious metal Pt and precious metal Pd, the coating comprises a manganese-aluminum composite oxide and a molecular sieve, the weight ratio of manganese to aluminum oxide in the manganese-aluminum composite oxide is 1:9-99, the coating amount of the coating is 80-180 g / L, the coating amount of the precious metal Pt and the precious metal Pd is 0.5-4.5 g / L, and the weight ratio of the precious metal Pt and the precious metal Pd is (15-1):1. According to a preparation method of the Pt-Pd bimetallic catalyst, firstly, the manganese-aluminum composite oxide is prepared in an equivalent-volume impregnation and high-temperature activation manner; secondly, slurry is prepared, and the precious metal Pt and the precious metal Pd are added; finally, the carrier is soaked into the slurry, dried and sintered to prepare into the catalyst. The preparation method of the catalyst is simple and easy to operate, the prepared catalyst has remarkable oxidizing capacity for NO in tail gas of a diesel vehicle, the conversion ratio of produced NO2 is high, a conversion temperature window of the NO2 is wide, the heat stability of the catalyst is good, and the catalyst has high HC and CO oxidizing capacity.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

Cuo/CexZr1-xO2-M high-temperature water gas conversion catalyst in IGCC (Integrated Gasification Combined Cycle) system, and preparation method thereof

InactiveCN103263929AEasy to prepareLarge specific surface areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementMass ratio

The invention discloses a Cuo / CexZr1-xO2-M high temperature water gas conversion catalyst in IGCC system, and a preparation method thereof and belongs to the technical field of water gas conversion catalysts. For the catalyst provided by the invention, the copper oxide is used as the active component, the zirconium oxide-cerium oxide composite oxide is used as the carrier, and different types of auxiliaries are also added. The catalyst is characterized in that the content of the active component copper oxide, counted by metal elements, is 10-40wt%; the mass ratio of the cerium oxide to the zirconium oxide is (1:4)-(4:1), the auxiliaries include rare earth elements, such as Y and La, and transition metals, such as Fe, Co and Ni; and the auxiliaries content M is 1-4wt%. The preparation method of the catalyst is a reverse adding coprecipitation method, and such method can be used for improving the specific area and metal dispersity of the catalyst. The Cuo / CexZr1-xO2-M high temperature water gas conversion catalyst has better high-temperature catalytic activity and thermostability, in a 400-500 DEG C reaction temperature region, the Co conversion rate approaches to the balanced conversion rate, and the defect of poor thermostability of the copper-based catalyst is solved. Moreover, the preparation process is relatively simple, so that the catalyst has high practical utilization value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

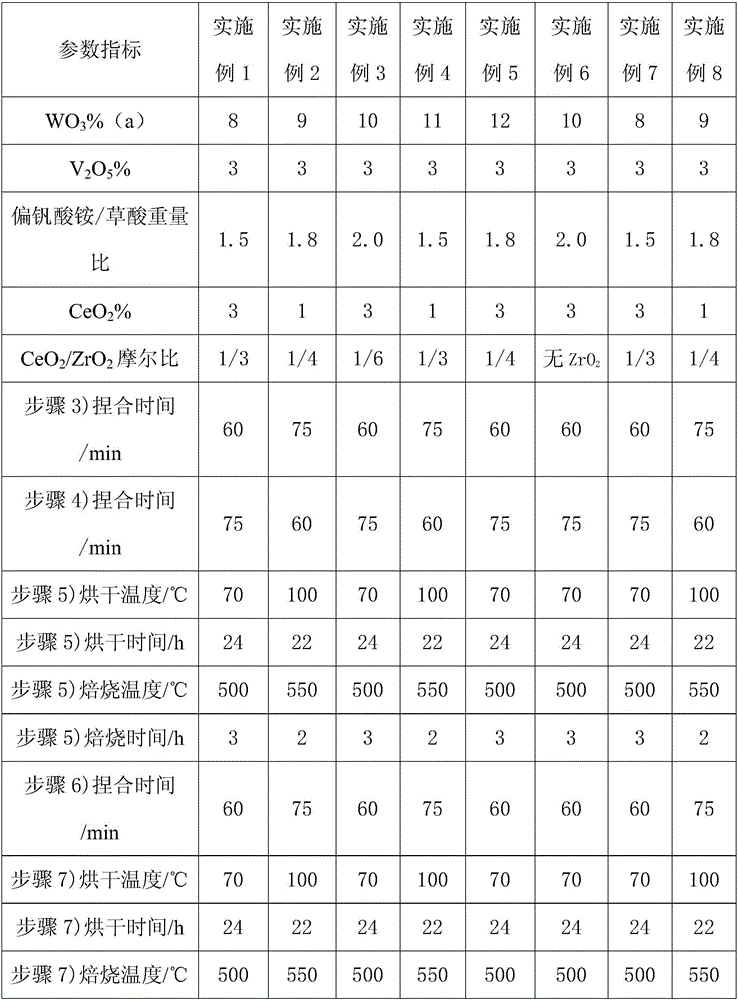

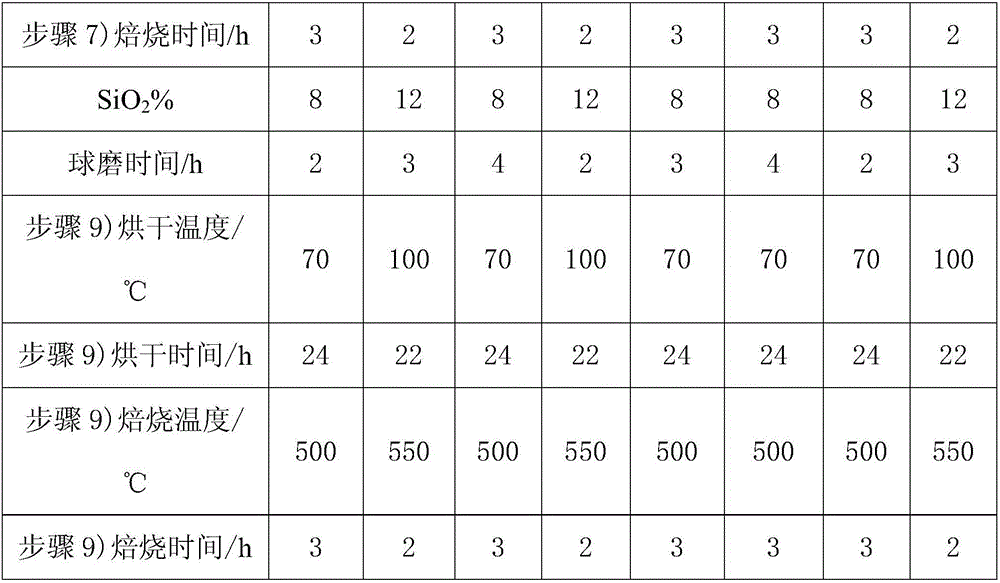

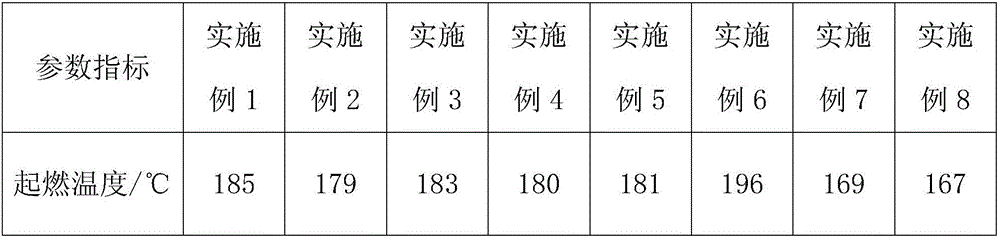

Preparation method for low-temperature V-W-TiO2 based selective reduction catalyst

InactiveCN106582615AGood dispersionImprove oxygen storage capacityGas treatmentInternal combustion piston enginesIonChemistry

The invention discloses a preparation method for a low-temperature V-W-TiO2 based selective reduction catalyst. The method comprises the following steps of weighing ammonium metatungstate, ammonium metavanadate, cerous nitrate, oxalic acid powder, zirconium acetate and de-ionized water; performing kneading, drying, grinding and roasting to obtain V-Ce-Zr-W-TiO2 powder; mixing the V-Ce-Zr-W-TiO2 powder, silica sol and the de-ionized water; performing ball-milling, dipping and drying; and finally performing roasting to obtain the catalyst. According to the method, the addition of the cerous nitrate facilitates the dispersion of WO3 and improves the oxygen storage capacity of the catalyst; the addition of the zirconium acetate improves the effect of CeO2; and the synergistic effect of CeO2-ZrO2 and WO3 can facilitate the dispersity of V2O5 on the surface of TiO2, so that the prepared V-W-TiO2 based selective reduction catalyst has the advantages that the low-temperature activity is good, the initiation temperature is lower than 190 DEG C, and the like, and is especially suitable for purification of NOx in diesel exhaust gas.

Owner:凯龙蓝烽新材料科技有限公司

Ferrous modified molecular sieve type diesel engine selective catalytic reduction catalyst

ActiveCN106622348AImprove the catalytic activity of low temperature SCR reactionSuppress generationGas treatmentMolecular sieve catalystsCordieriteSlurry

The invention discloses a ferrous modified molecular sieve type diesel engine selective catalytic reduction catalyst. The catalyst is composed of a main catalyst, an auxiliary catalyst, a coating base material and a catalyst carrier, wherein a ferrous-La bimetallic modified ZSM-5 molecular sieve serves as the main catalyst; a CeO2-ZrO2 solid solution serves as the auxiliary catalyst; the coating base material is composed of SiO2, TiO2 and gamma-Al2O3; and a 400-mesh cordierite honeycomb ceramic serves as the catalyst carrier. A preparation process comprises the following steps: preparing and confirming the dosage of the supported catalyst raw materials; preparing the main catalyst, namely, the ferrous-La bimetallic modified ZSM-5 molecular sieve; and preparing the coating slurry and coating. The catalyst is packaged in a diesel engine SCR catalytic converter and is used for catalyzing the SCR reaction of the reducing agent and NOx, so as to realize the purification of NOx pollutants in the exhaust gas of the diesel engine. According to the invention, the environmental harm of the traditional catalyst is reduced, the generation of the secondary pollutants, such as SO3 derivatives, is restrained, and the low-temperature SCR reaction catalytic activity of the catalyst is obviously improved.

Owner:TIANJIN UNIV

Oxygen storage material for catalytic purification of automobile exhaust and preparation method of oxygen storage matrial

InactiveCN102744074AImprove oxygen storage capacitySimple methodDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationPolyethylene glycol

The invention relates to an oxygen storage material for the catalytic purification of automobile exhaust and a preparation method of the oxygen storage material. The oxygen storage material has a structure formula of CexZr(0.93-x)FeyLa(0.07-y)O2, wherein x is equal to 0.2-0.8 and y is equal to 0-0.01. The preparation method comprises the steps of weighing cerium salt, zircon salt, lanthanum salt and ferric salt according to the stoichiometric proportion in the structure formula and adding the salts in deionized water to prepare mixed solution; adding polyethylene glycol with a molecular weight of 2000-6000 into the mixed solution and adding a precipitator under stirring condition for reaction; after the reaction, carrying out ageing and filtration; and carrying out washing, drying and roasting on filtered matters. The oxygen storage material provided by the invention has good oxygen storage property, after being aged at a high temperature of 1000 DEG C for 5h, the oxygen storage material still has higher oxygen storage property, so that the oxygen storage material has high-temperature ageing resistance which is better than that of cerium-zircon composite oxide oxygen storage materials; and the oxygen storage material is simple in preparation method, easy to operate and suitable for industrial production.

Owner:JIANGSU GAOCHUN CERAMICS +1

Preparation method for nanogold particle loading CeO2-TiO2 composite catalyst

InactiveCN104941642AIncrease the areaEnhanced interactionMetal/metal-oxides/metal-hydroxide catalystsNanoparticleReagent

A preparation method for a nanogold particle loading CeO2-TiO2 composite catalyst comprises the following steps: (1) preparing a CeO2-TiO2 carrier by adopting a sol-gel method; (2) loading nanogold particles on the CeO2-TiO2 carrier. The nanoparticles prepared according to the preparation method are uniform in distribution and high in loading capacity, the preparation process is simple, the condition is mild, the environment is friendly, and no chemical reagent residual is generated. The nanogold particle loading CeO2-TiO2 composite catalyst product has an efficient catalysis effect, and can be applied to fields such as catalytic wet oxidation, motor vehicle exhaust catalytic purification, atmospheric pollutant catalytic degradation and sulfur dioxide catalytic elimination.

Owner:曾旭 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Metal doped modified layered [delta]-MnO2, preparation and applications thereof Metal doped modified layered [delta]-MnO2, preparation and applications thereof](https://images-eureka.patsnap.com/patent_img/19f06261-5c00-4304-aaae-11ec20617632/HDA0001566735880000011.png)

![Metal doped modified layered [delta]-MnO2, preparation and applications thereof Metal doped modified layered [delta]-MnO2, preparation and applications thereof](https://images-eureka.patsnap.com/patent_img/19f06261-5c00-4304-aaae-11ec20617632/HDA0001566735880000021.png)

![Metal doped modified layered [delta]-MnO2, preparation and applications thereof Metal doped modified layered [delta]-MnO2, preparation and applications thereof](https://images-eureka.patsnap.com/patent_img/19f06261-5c00-4304-aaae-11ec20617632/HDA0001566735880000022.png)