Oxygen storage material for catalytic purification of automobile exhaust and preparation method of oxygen storage matrial

A technology for catalytic purification and automobile exhaust, which is applied in the fields of pollution control and methods, can solve problems such as the decline of oxygen storage performance, and achieve the effects of simple method, easy operation and high oxygen storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

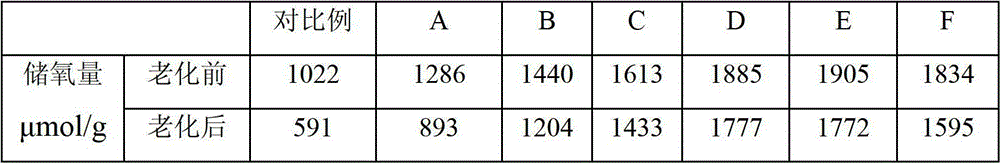

Examples

Embodiment 1

[0027] Get 217.1g cerium nitrate, 99.4g zirconium oxynitrate, 30.3g lanthanum nitrate, add deionized water to prepare mixed metal salt solution 1L, then add 30g polyethylene glycol 2000 and stir to dissolve, then under stirring condition, the mass fraction of ammonia is 5%, the mass fraction of ammonium carbonate is 10% ammonia water-ammonium carbonate buffer solution is added to the mixed metal salt solution to keep the pH value of the mixed solution at 8.0, react at room temperature for 1h and age for 2h, filter, wash with water, and finally at 100 °C for 3 h, and the dried product was calcined at 500 °C for 4 h to obtain a solid solution oxygen storage material Ce 0.5 Zr 0.43 La 0.07 o 2 .

[0028] The product is marked A.

Embodiment 2

[0030] Get 130.3g of cerium nitrate, 145.7g of zirconium oxynitrate, 29.9g of lanthanum nitrate and 0.40g of ferric nitrate, add deionized water to prepare 1L of mixed metal salt solution, then add 30g of polyethylene glycol 2000 and stir to dissolve, then dissolve under stirring The mass fraction of ammonia is 5%, the mass fraction of ammonium carbonate is 10% ammonia water-ammonium carbonate buffer solution, add mixed metal salt solution to keep the pH value of the mixed solution at 8.0, react at room temperature for 1h and age for 2h, filter, washed with water, and finally dried at 100°C for 3h, and the dried product was calcined at 500°C for 4h to obtain the solid solution oxygen storage material Ce of the present invention 0.3 Zr 0.63 Fe 0.001 La 0.069 o 2 .

[0031] The product is labeled B.

Embodiment 3

[0033] Take 173.7g of cerium nitrate, 179.8g of zirconium nitrate, 29.0g of lanthanum nitrate and 1.2g of ferric nitrate, add deionized water to prepare 1L of mixed metal salt solution, then add 30g of polyethylene glycol 4000 and stir to dissolve, then dissolve ammonia under stirring conditions The mass fraction of ammonium carbonate is 10%, and the mass fraction of ammonium carbonate is 10%. The ammonia water-ammonium carbonate buffer solution is added to the mixed metal salt solution to keep the pH value of the mixed solution at 8.5, react at room temperature for 2h and age for 1h, filter, wash with water , and finally dried at 120°C for 2h, and the dried product was calcined at 600°C for 3h to obtain the solid solution oxygen storage material Ce of the present invention 0.4 Zr 0.53 Fe 0.003 La 0.067 o 2 .

[0034] The product is marked C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com