Cuo/CexZr1-xO2-M high-temperature water gas conversion catalyst in IGCC (Integrated Gasification Combined Cycle) system, and preparation method thereof

A technology of cexzr1-xo2-m and shift catalyst, which is applied in the field of water gas shift process and catalyst, can solve the problems of high content of copper in active components, increased cost of catalyst, narrow active temperature zone, etc., achieves uniform distribution and overcomes poor thermal stability , improve the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

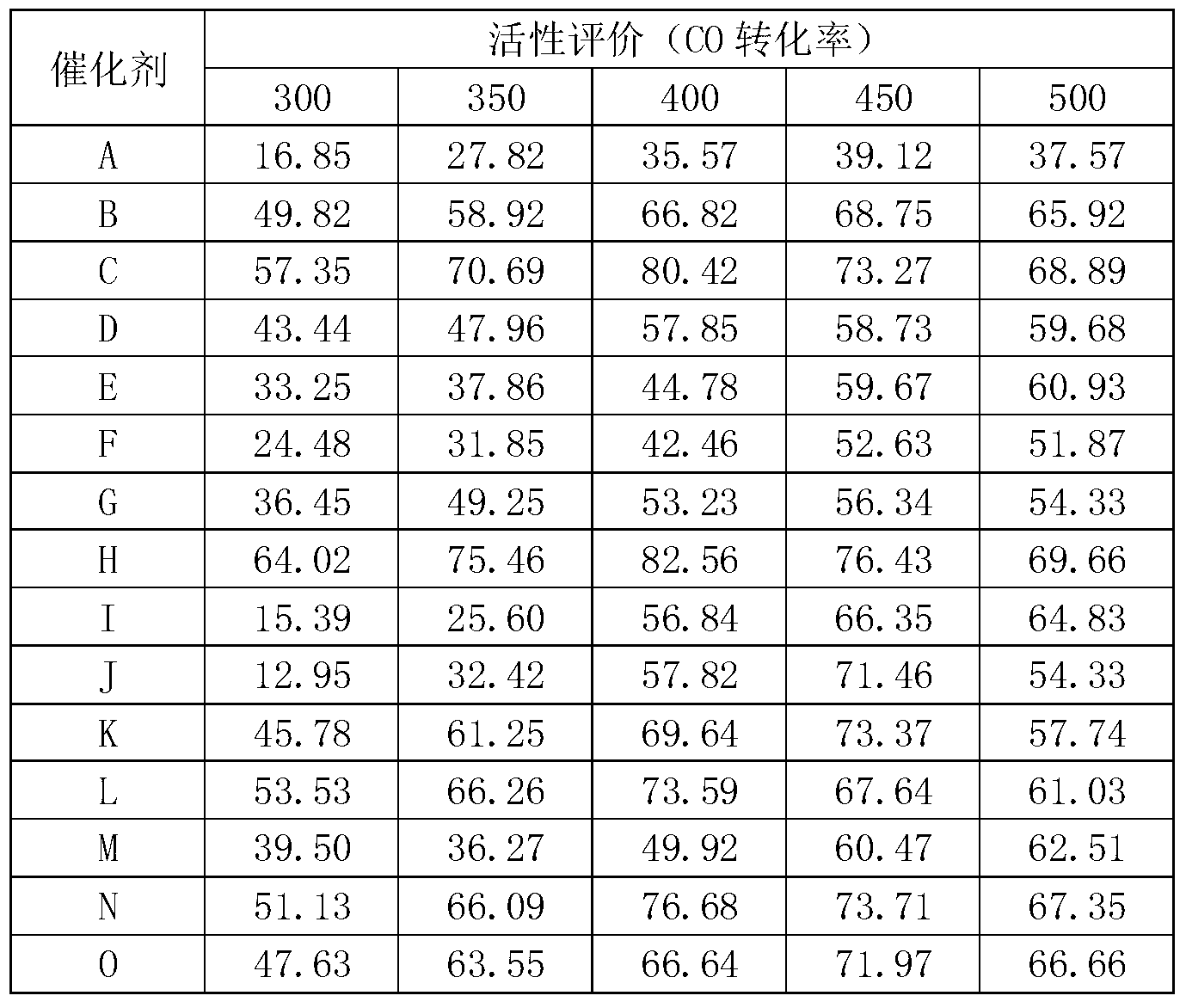

Examples

Embodiment example 1

[0017] At room temperature, 3.80 g of copper nitrate and 12.75 g of ceric ammonium nitrate were weighed and dissolved in 200 ml of deionized water to prepare a mixed salt solution. Prepare a 0.5mol / L KOH solution, add the above mixed salt solution dropwise to the KOH solution under stirring with a polytetrafluoroethylene stirring paddle, control the pH value to 9-11, after the dropwise addition, stir for 3 hours, and let it stand for aging for 18 hours , and then filtered, washed, dried at 120°C for 12 hours, and roasted at 600°C for 4 hours to obtain a copper-based high-temperature water-gas shift reaction catalyst A. The active component, copper oxide, has a content of 20% in terms of metal elements.

Embodiment example 2

[0019] At room temperature, weigh 3.80 g of copper nitrate, 10.20 g of cerium ammonium nitrate, and 1.74 g of zirconyl nitrate, and dissolve them in 200 ml of deionized water to prepare a mixed salt solution. Prepare a 0.5mol / L KOH solution, add the above mixed salt solution dropwise to the KOH solution under stirring with a polytetrafluoroethylene stirring paddle, control the pH value to 9–11, after the dropwise addition, stir for 3 hours, and let it stand for 18 hours , then filtered, washed, dried at 120°C for 12h, and roasted at 600°C for 4h to obtain a copper-based high-temperature water-gas shift reaction catalyst B. The active component copper oxide, calculated as a metal element, has a content of 20%, and cerium oxide and The mass ratio of zirconia is 4:1.

Embodiment example 3

[0021] At room temperature, 3.80 g of copper nitrate, 8.49 g of cerium ammonium nitrate, and 2.90 g of zirconium oxynitrate were weighed and dissolved in 200 ml of deionized water to prepare a mixed salt solution. Prepare a 0.5mol / L KOH solution, add the above mixed salt solution dropwise to the KOH solution under stirring with a polytetrafluoroethylene stirring paddle, control the pH value to 9–11, after the dropwise addition, stir for 3 hours, and let it stand for 18 hours , then filtered, washed, dried at 120°C for 12h, and roasted at 600°C for 4h to obtain a copper-based high-temperature water-gas shift reaction catalyst C. The active component of copper oxide is 20% in terms of metal elements. The mass ratio of zirconia is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com