Patents

Literature

636results about How to "Improve activity stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing formic acid through electrochemical catalytic reduction of carbon dioxide

InactiveCN102190573AGood solubility and absorption propertiesImprove conductivityOrganic compound preparationCarboxylic compound preparationSupporting electrolyteOrganic solvent

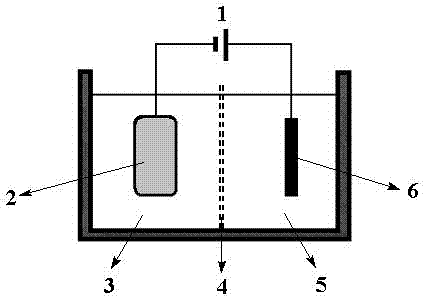

The invention relates to a method for preparing formic acid through electrochemical catalytic reduction of carbon dioxide, and belongs to the technical field of carbon dioxide recycling. In the method, a proton exchange membrane separates an electrolytic tank into a cathode chamber and an anode chamber, organic solvent / ionic liquid / water mixed solution in which a large amount of carbon dioxide is dissolved is injected into the cathode chamber, and aqueous solution containing supporting electrolyte is injected into the anode chamber; and after an electrolysis power supply is connected, the carbon dioxide undergoes electroreduction reaction on the cathode to form the formic acid. By the method, the organic solvent / ionic liquid / water mixed solution with the advantages of good conductivity, low viscosity, high capacity of dissolving the carbon dioxide, wide electrochemical window, and low use cost can be obtained, and when the carbon dioxide is electrically reduced in the mixed solution, the current density in the electroreduction reaction of the carbon dioxide can be improved and the electrocatalytic activity and long-time stability of a cathode material are improved.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing lubricating oil basic oil

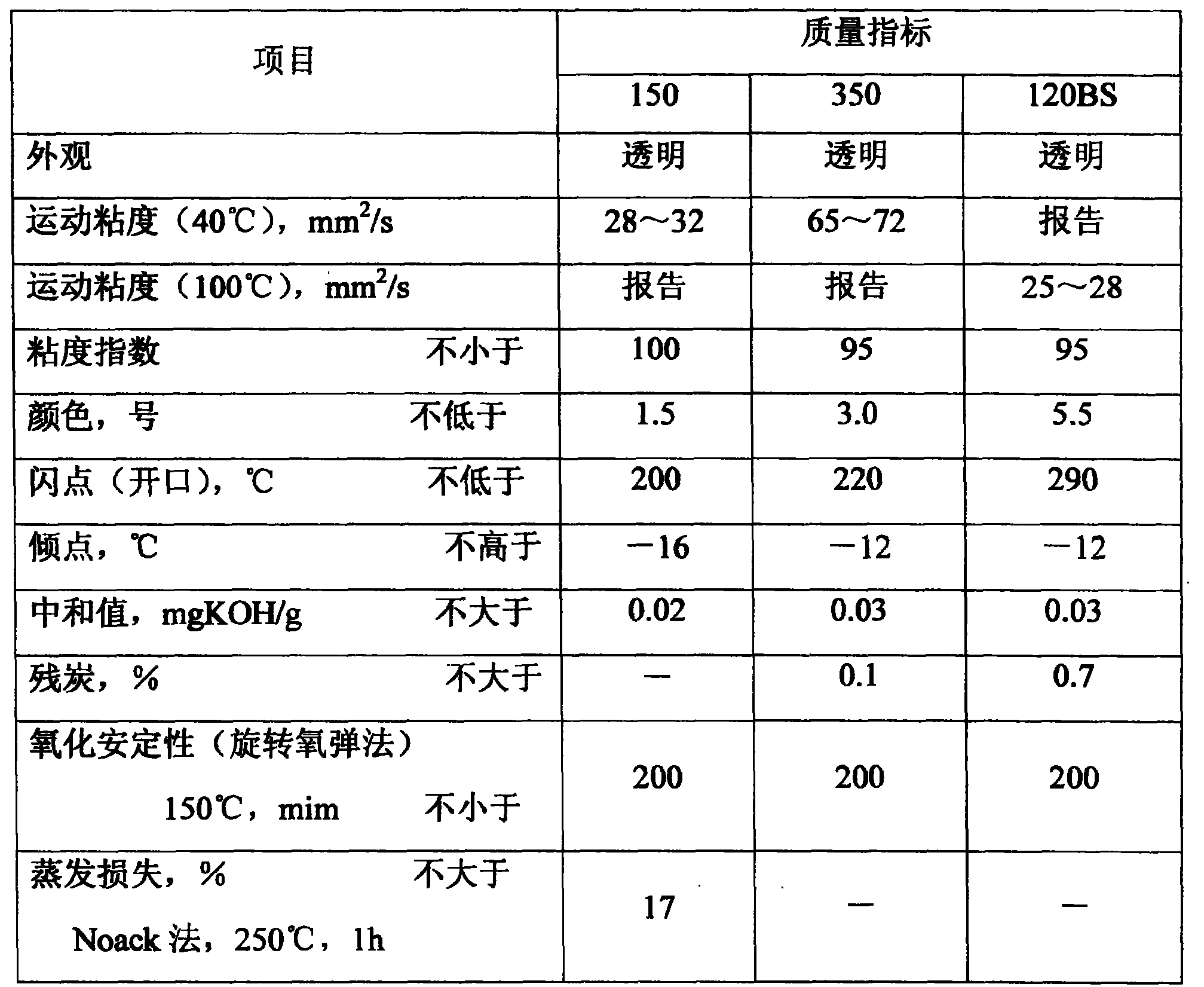

ActiveCN101173191AMeet the indicator requirementsLow pour pointTreatment with hydrotreatment processesBase-materialsBase oilPour point

The invention discloses a method for producing lube base oil, which is characterized in that low-pressure hydroisomerization and adsorption treatment are adopted and organically combined, and the lube base oil meeting the standard of HVIW is obtained; the raw material firstly enters a low-pressure hydroisomerizing reactor, and the pour point is lowered; after gas-liquid separation of the heterogeneous product, adsorption treatment is done to the separated lube fraction for color enhancement and stability improvement. The invention has the advantages that adaptability of the raw oil is strong; operating condition is mild; investment and operating cost is low; and the prepared lube base oil meeting the standard of HVIW can be applied to blinding with various brands of high-grade lube.

Owner:CHINA PETROLEUM & CHEM CORP +1

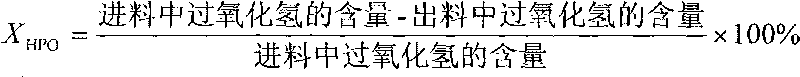

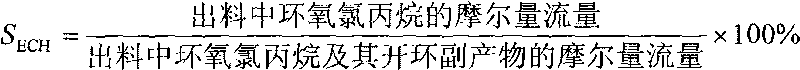

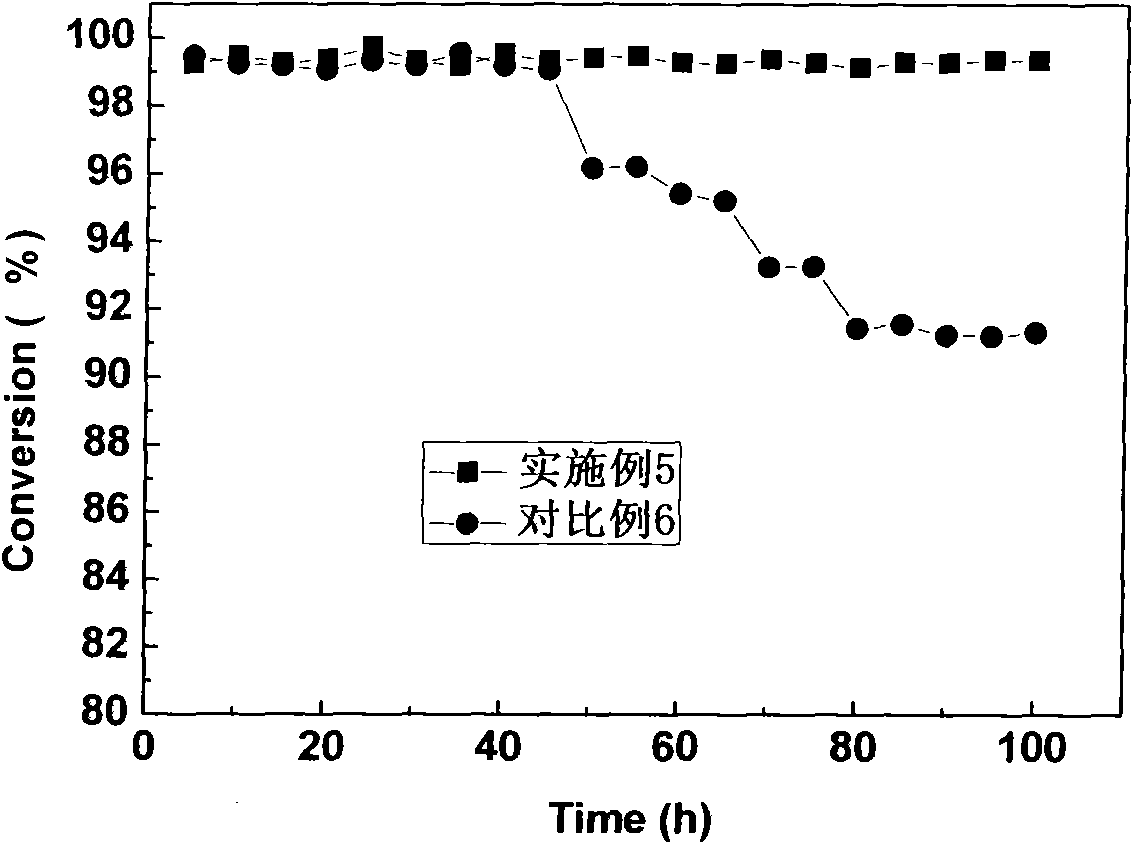

Production method of epoxy chloropropane

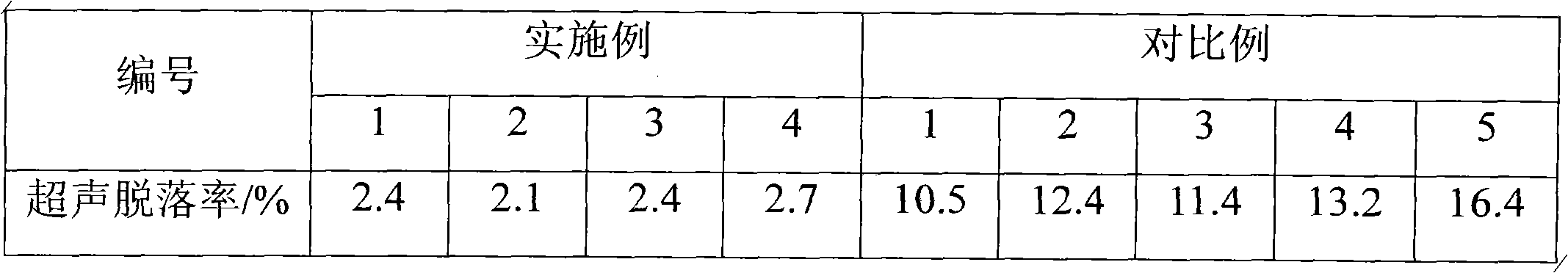

ActiveCN101747296AImprove activity stabilityReduce usage and operating costsOrganic chemistryMolecular sieve catalystsSolventMolecular sieve

The invention relates to a production method of epoxy chloropropane. The method provided in the invention comprises contacting 3-chloropropene with hydrogen peroxide with existence of titanium silicalite molecular sieve catalyst, alkaline additive and solvent, wherein, the temperature of contact between 3-chloropropene and hydrogen peroxide is raised from 10-55 DEG C to 65-100 DEG C, and the temperature raising velocity is 0.02-1 DEG C / h. Compared with the prior art, the method for producing epoxy chloropropane provided in the invention greatly enhances activity stability of catalyst, obviously reduces use cost and operation expenditure of catalyst; the technique process is simple and the implementation is convenient.

Owner:CHINA PETROLEUM & CHEM CORP +1

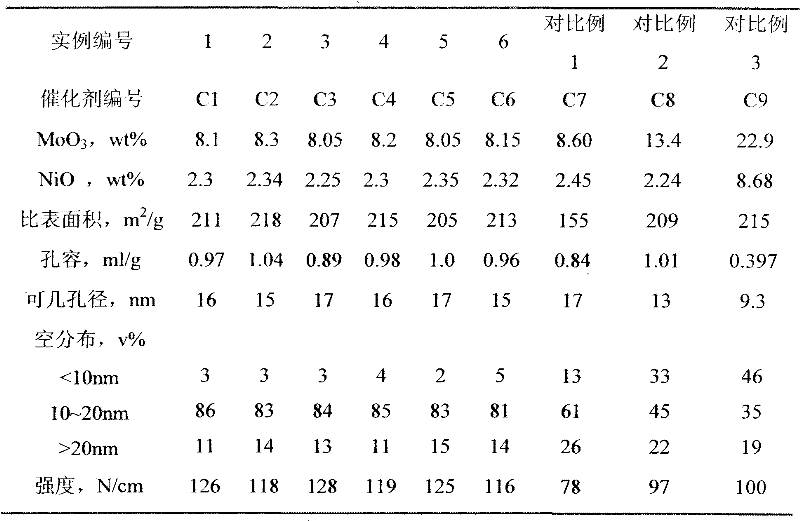

Grading method of catalyst of deep hydrodesulfurization of diesel oil

ActiveCN101591566AHigh activityReduce dosageTreatment with hydrotreatment processesRefining to eliminate hetero atomsLiquid productHydrodesulfurization

The invention discloses a grading method of catalyst of deep hydrodesulfurization of diesel oil, comprising the following steps: base oil and hydrogen are mixed, then the mixture is led into a hydrogenation reactor to carry out hydrogenation reaction; reaction effluent is cooled and separated to obtain hydrogen-rich gas and liquid product; the hydrogenation reactor sequentially comprises four hydrogenation reaction zones, wherein, the first hydrogenation reaction zone is filled with hydrogenation protective agent, the second hydrogenation reaction zone is filled with hyrorefining catalyst (1)containing active metal cobalt-molybdenum, the third hydrogenation reaction zone is filled with the mixture of the hyrorefining catalyst (1) and hyrorefining catalyst (2), and the fourth hydrogenation reaction zone is filled with the hyrorefining catalyst (2) containing active metal nickel-tungsten. The invention carries out reasonable grading on catalyst of different systems, gives full play to the advantages of each catalyst in different desulphurizing states, improves whole catalyst activity by synergy of each catalyst, and can obtain ultra low sulfur diesel oil, sulfur content of which satisfies Euro IV standard under moderate operation condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy arenes lightening catalyst and preparing method thereof

InactiveCN1472181AImprove activity stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsMordeniteCarbon deposit

Owner:CHINA PETROLEUM & CHEM CORP +1

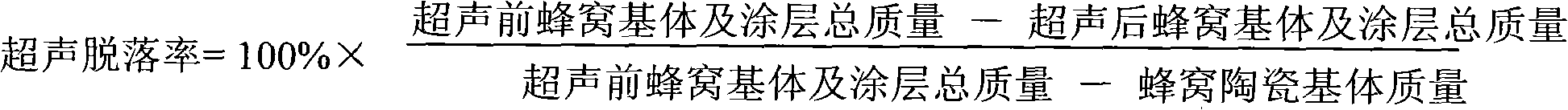

Preparation method of catalytic combustion catalyst

ActiveCN102049312ASimple preparation processEasy to operateDispersed particle separationCatalyst activation/preparationOperational performanceAirflow

The invention discloses a preparation method of a catalytic combustion catalyst. The method comprises the following steps: firstly, performing hydrothermal pretreatment on a honeycomb ceramic matrix; secondly, soaking the honeycomb ceramic matrix with alumina sol; and finally, loading additives and precious metal active components. The catalyst coating obtained by the method of the invention has high bonding degree with the matrix, is difficult to crack and peel off and has less dosage of additives. Thus, the catalyst has good operational performance and activity stability and can maintain higher activity under the scouring of high space velocity airflow and thermal shock, so that the long-term stable operation of the catalyst can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

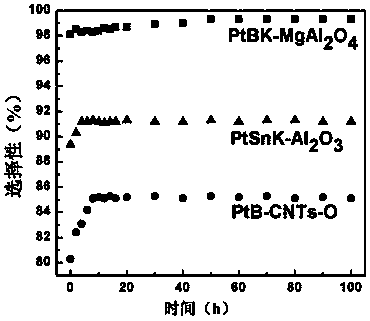

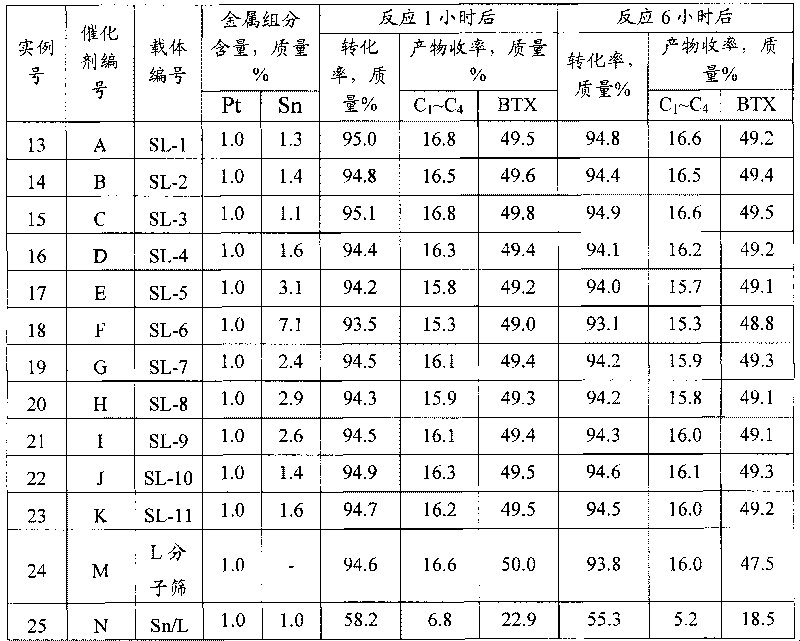

Dehydrogenation catalyst taking Sn-containing alumina as carrier and preparation method thereof

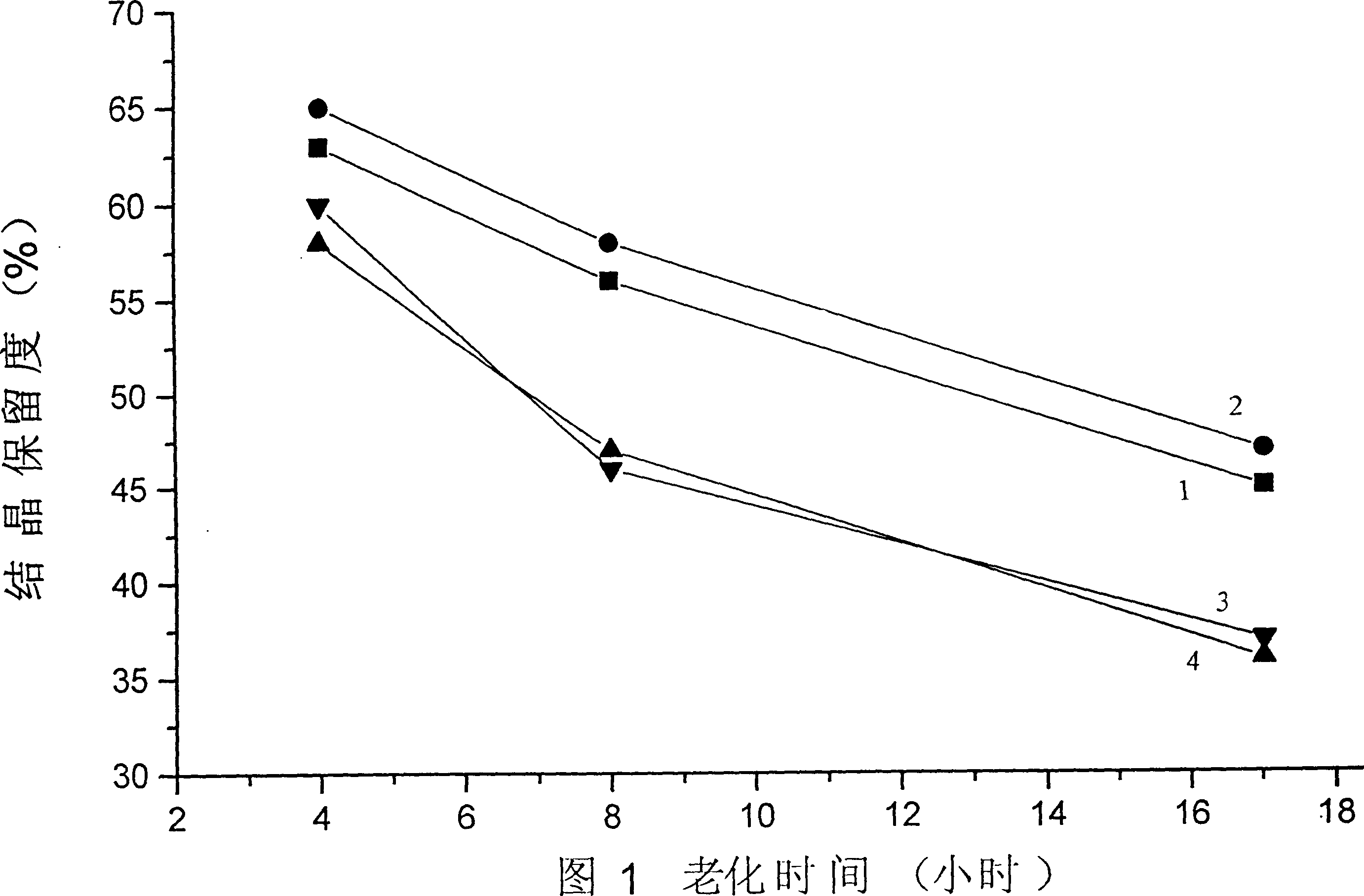

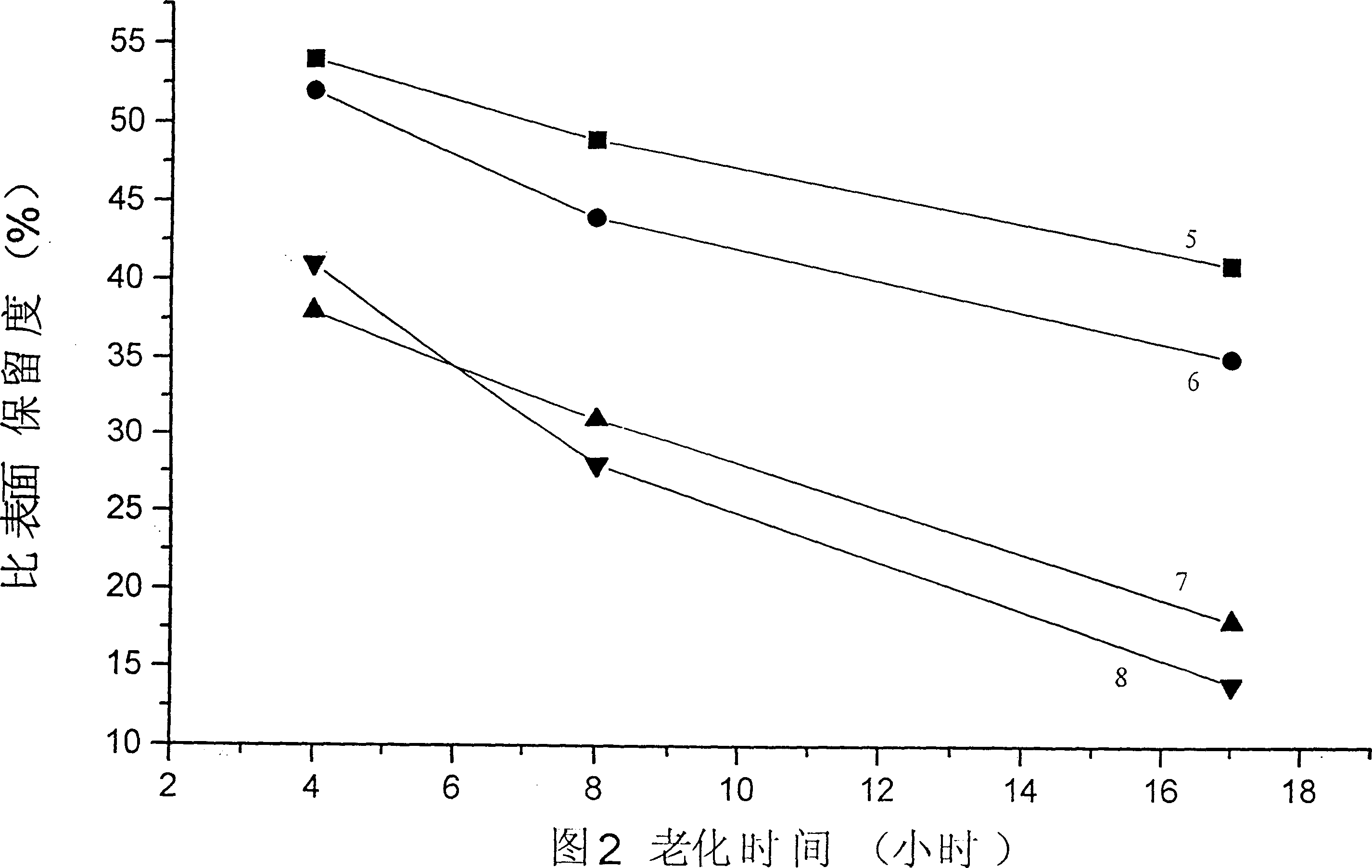

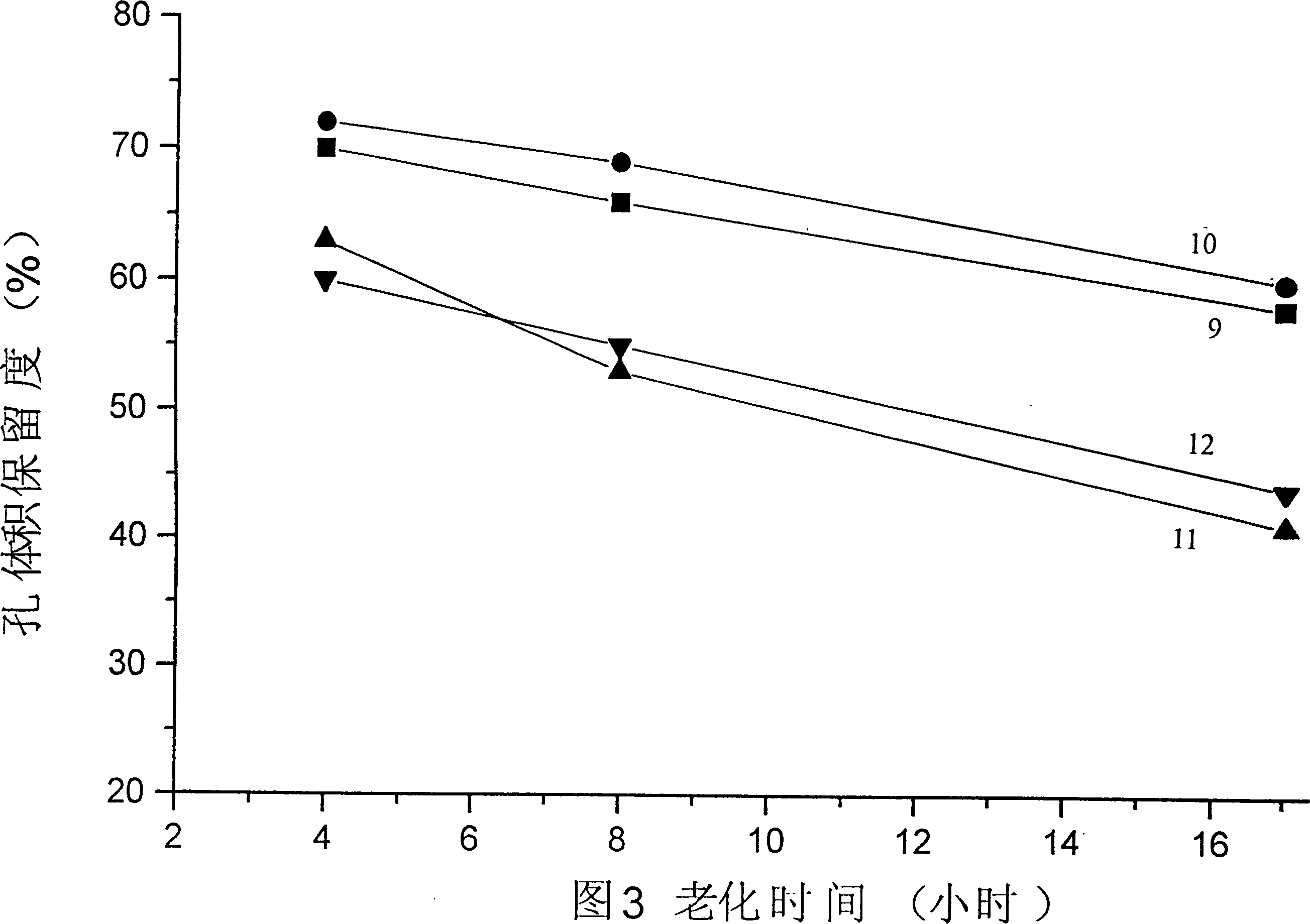

ActiveCN101898131ALarge specific surface areaHigh selectivityCatalyst activation/preparationHydrocarbonsFiberAdditive ingredient

The invention discloses a dehydrogenation catalyst taking Sn-containing alumina as a carrier and a preparation method thereof. The dehydrogenation catalyst takes the Sn-containing alumina as the carrier, nano fibers are carried on the pore surface of the carrier, and dehydrogenation active metal ingredients are carried by an immersion method. The preparation method for the catalyst comprises the following steps of: introducing the carrier to Sn when the alumina is gelled, carrying the carbon nano fibers to the Sn-containing alumina carrier in situ by ethylene cracking, then immersing the dehydrogenation active ingredients, and performing thermal treatment and water vapor treatment to obtain the final dehydrogenation catalyst. When the catalyst is used for a hydrocarbon dehydrogenation reaction process, in particular a propane dehydrogenation process, the catalyst has the advantages of high activity, high selectivity and the like, and particularly greatly improves the stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

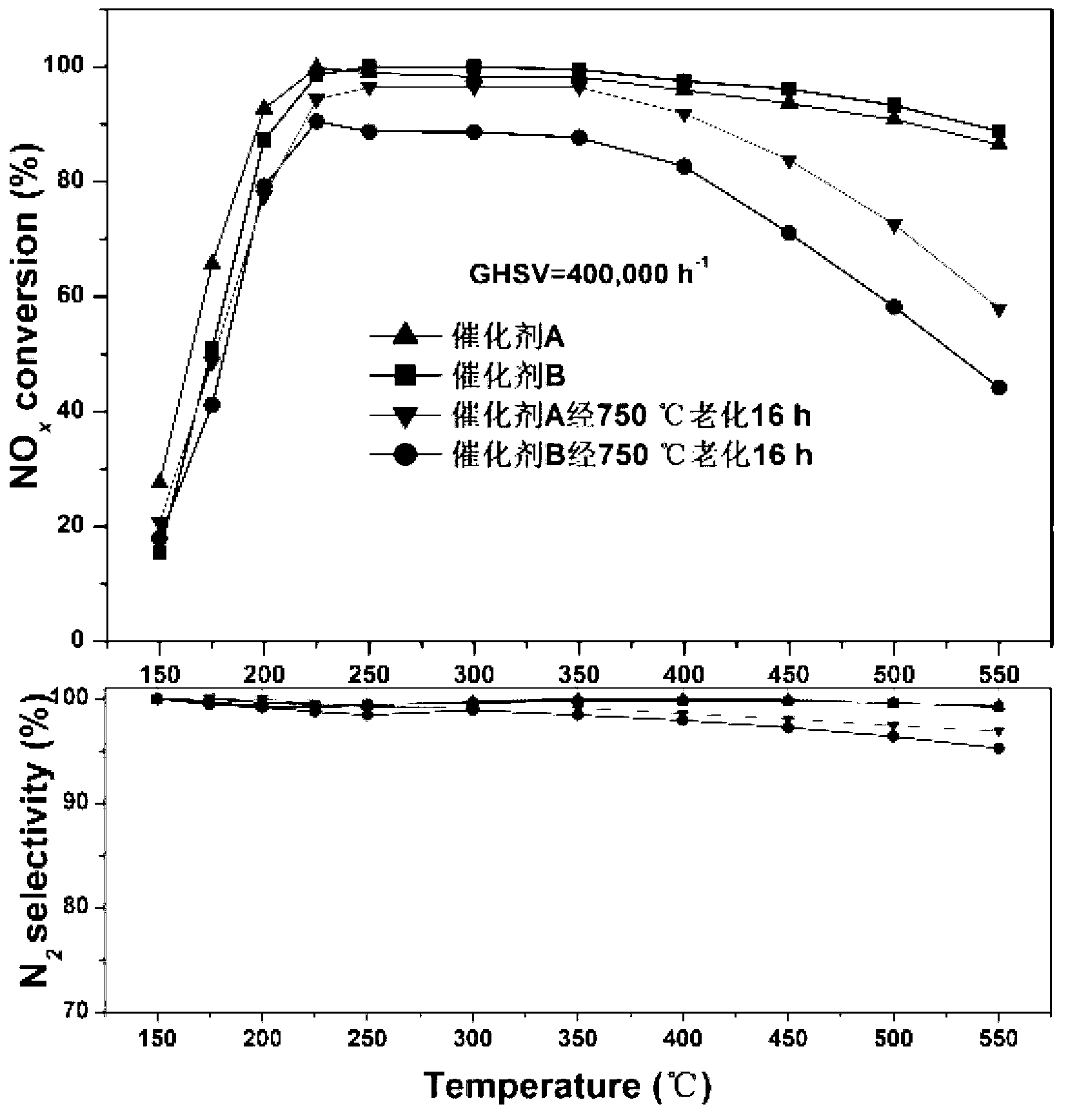

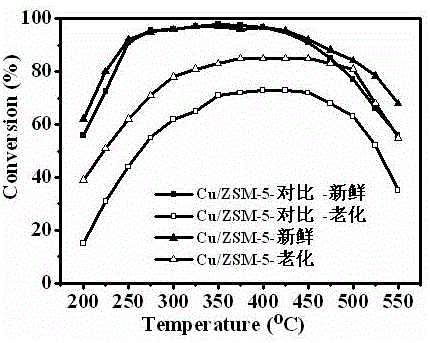

Cu-SSZ-13 catalyst, and preparation method and application thereof

ActiveCN103157505ASolve pollutionImprove activity stabilityMolecular sieve catalystsDispersed particle separationAfter treatmentSynthesis methods

The invention discloses a method for preparing a Cu-SSZ-13 catalyst through an in-situ synthesis method. A Cu-SSZ-13 molecular sieve sample is prepared by taking acid as an exchange reagent and treating through an in-situ synthesis method. Compared with the currently used ammonium nitrate ion exchange method, the after treatment method for the Cu-SSZ-13 molecular sieve prepared through an in-situ synthesis method is more environment-friendly and effective; the activity of the prepared catalyst is higher; and the hydrothermal stability is better. According to the method, the silica-alumina ratio of the molecular sieve structure is increased while the catalyst having high catalytic activity is obtained; and the obtained Cu-SSZ-13 catalyst has excellent hydrothermal stability, wide temperature window and excellent N2 selectivity, and is very applicable to purification of tail gas from diesel cars.

Owner:江西中科鸿虔新材料有限公司

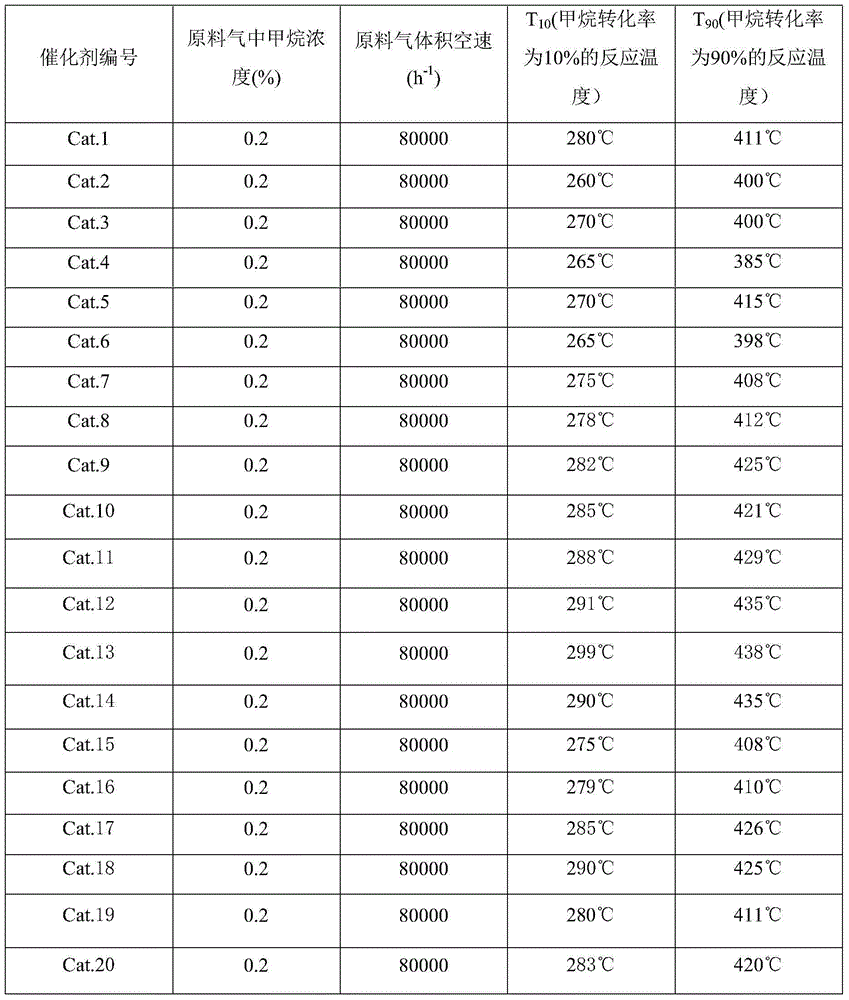

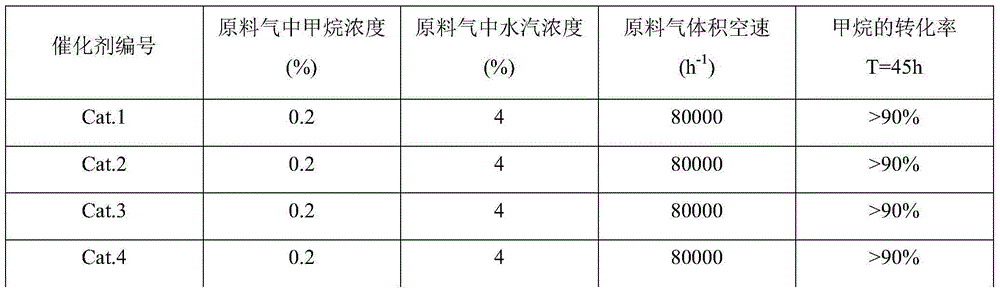

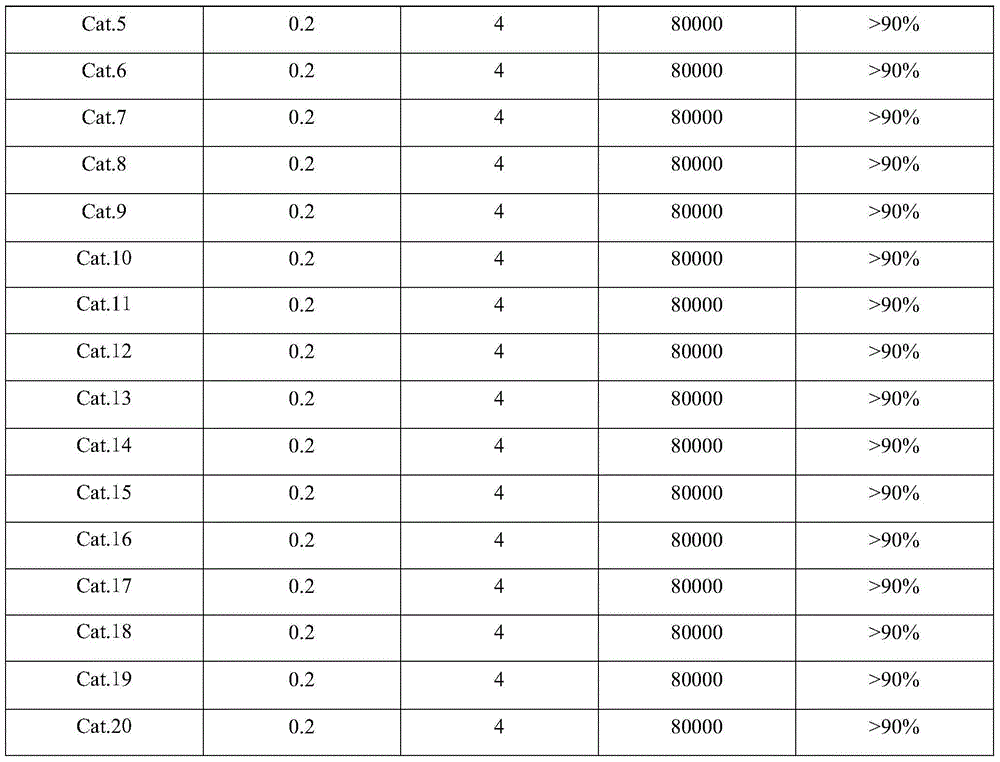

Non-noble metal oxide combustion catalyst, and preparation method and use thereof

InactiveCN105381800AEasy to synthesizeLow costDispersed particle separationCatalyst activation/preparationChemical synthesisCobalt(II,III) oxide

The present invention relates to a non-noble metal oxide combustion catalyst and a preparation method and use thereof, and belongs to the technical field of energy utilization and environment protection. The catalyst is iron oxide, cobaltosic oxide, nickel oxide, cupric oxide, vanadium oxide, chrome oxide, manganese dioxide or cerium dioxide prepared according to the following steps: (1) using hydrothermal chemical synthesis to form a precursor of a catalyst; and (b) washing, filtering, shaping, drying and calcinating the obtained precursor of the catalyst, and finally forming a combustion catalyst or coating the precursor of the catalyst on a carrier to form a combustion catalyst. The catalyst prepared by the method can be used in catalytic combustion of methane and other VOC gas, and has the advantages that the synthesis process is simple, the cost is low, the catalytic activity and hydrothermal stability is high, and the light-off temperature and complete combustion temperature of methane are low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

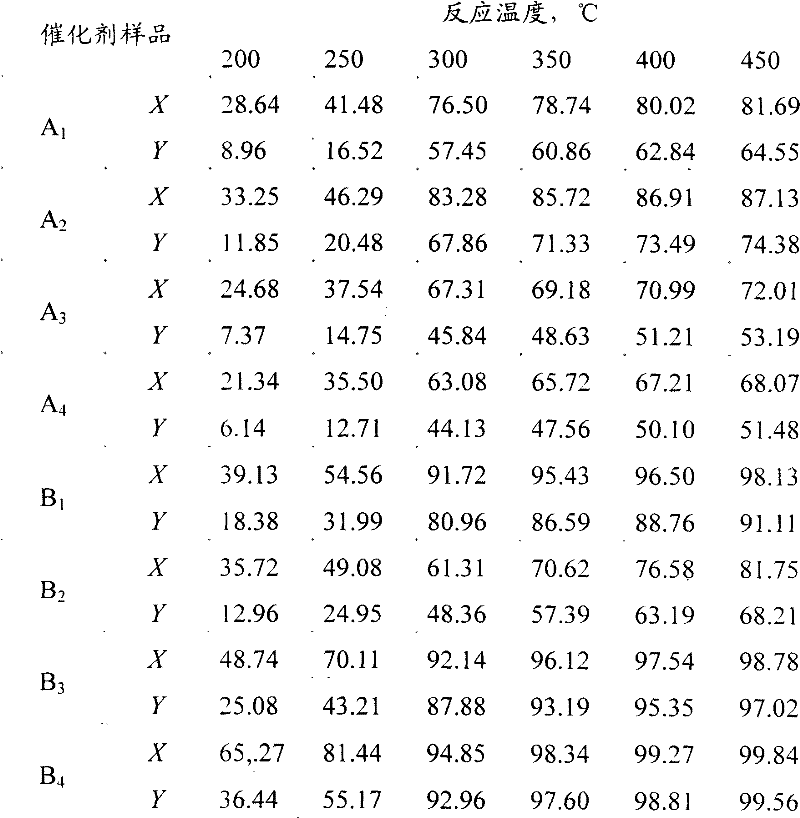

Preparation of activated carbon-based catalyst used for selective reduction desulphurization of flue gas

ActiveCN102357364AImprove activity stabilityGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCoalPollution

Belonging to the technical field of sulfur recovery, the invention relates to a catalyst for selective reduction desulphurization, its preparation method and application. The catalyst is characterized in that: a catalyst active component is loaded on a carrier by means of an isometric immersion method, a multiple immersion method and an immersion precipitation method so as to obtain the catalyst; the catalyst carrier consists of coconut-shell activated carbon, fruit-shell activated carbon and coal-based activated carbon; the oxidation modifier of the catalyst carrier is one or a mixture of any of chloric acid, nitric acid, hydrogen peroxide or concentrated sulfuric acid; the active component of the catalyst is one or a mixture of any of CuO, NiO, Fe2O3, ZnO, Cr2O3, Co2O3, MnO2, and V2O5. The desulfurizer of the invention employs a selective reduction desulphurization technology to convert SO2 in flue gas into elemental sulfur. The preparation technology of the catalyst has the advantages of simplicity, easy control, low cost and long service life. Adoption of the activated carbon-based catalyst prepared in the invention for selective reduction desulphurization not only realizes high efficiency SO2 conversion rate and sulfur selectivity, but also effectively prevents secondary pollution.

Owner:SHANDONG QINGYUAN GROUP CO LTD

Preparation method of surface organic modified titanium carbide nanosheet

PendingCN108557822ALess corrosiveImprove operational safetyTitanium carbideNanotechnologyHeat stabilityHigh surface

The invention relates to a preparation method of a surface organic modified titanium carbide nanosheet, belonging to the technical field of preparation of nano materials. The preparation method comprises the following steps: etching an aluminum atom layer in titanium aluminum carbide by virtue of a mixed solution of lithium fluoride and hydrochloric acid so as to prepare titanium carbide precipitates, re-dispersing the titanium carbide precipitates into water, carrying out ultrasonic treatment and centrifugation so as to remove precipitates, and extracting supernatant liquid, so as to obtain titanium carbide nanosheet suspension liquid; and finally adding a surfactant water solution to react, so as to obtain the surface organic modified titanium carbide nanosheet. Compared with a method for etching titanium aluminum carbide by virtue of hydrofluoric acid, the method for preparing titanium carbide by etching the aluminum atom layer in titanium aluminum carbide by virtue of the mixed solution of lithium fluoride and hydrochloric acid has the advantages that the corrosivity is reduced, and the operation safety is improved; and the surface organic modified titanium carbide nanosheet prepared by virtue of the preparation method has relatively high surface activity and heat stability, has good compatibility with high-molecular materials and can be uniformly dispersed into the high-molecular materials, so that the mechanical properties, flame retardance and thermal properties of the high-molecular materials are improved.

Owner:HEFEI UNIV

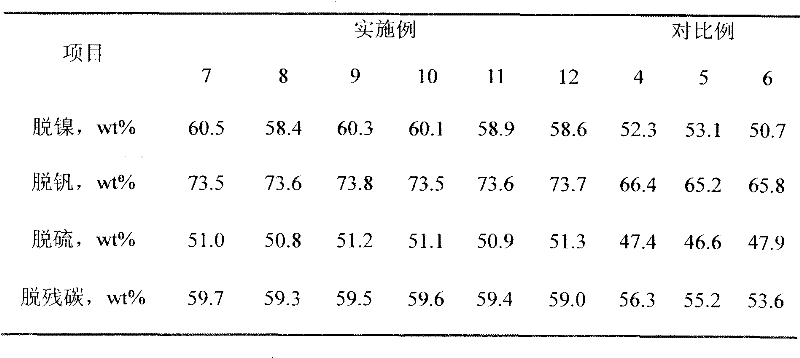

Process for preparing demetalizing and desulfurizing catalyst of heavy oil hydrogenation

InactiveCN1458236AReduce acidityImprove activity stabilityRefining to eliminate hetero atomsChemistryFuel oil

The present invention discloses a preparation process of heavy oil hydrogenating, demetallizing and desulfruizing catalyst. Aluminum containing material in two different forms, including roasted alumina and dry aluminum hydroxide glue powder, is used. Of the assistant alkali metal element and / or alkali earth metal element, part is mixed with dry aluminum hydroxide glue powder and part is loaded onto the carrier via soaking process, so as to result in the inhomogeneous distribution of the assistant on the carrier. The catalyst has high demetalizing activity and desulfurizing activity, and highactivity stability, especially high desulfurizing activity stability. The catalyst may be used in the hydrodemetalizing and hydrodesulfurizing treatment of heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

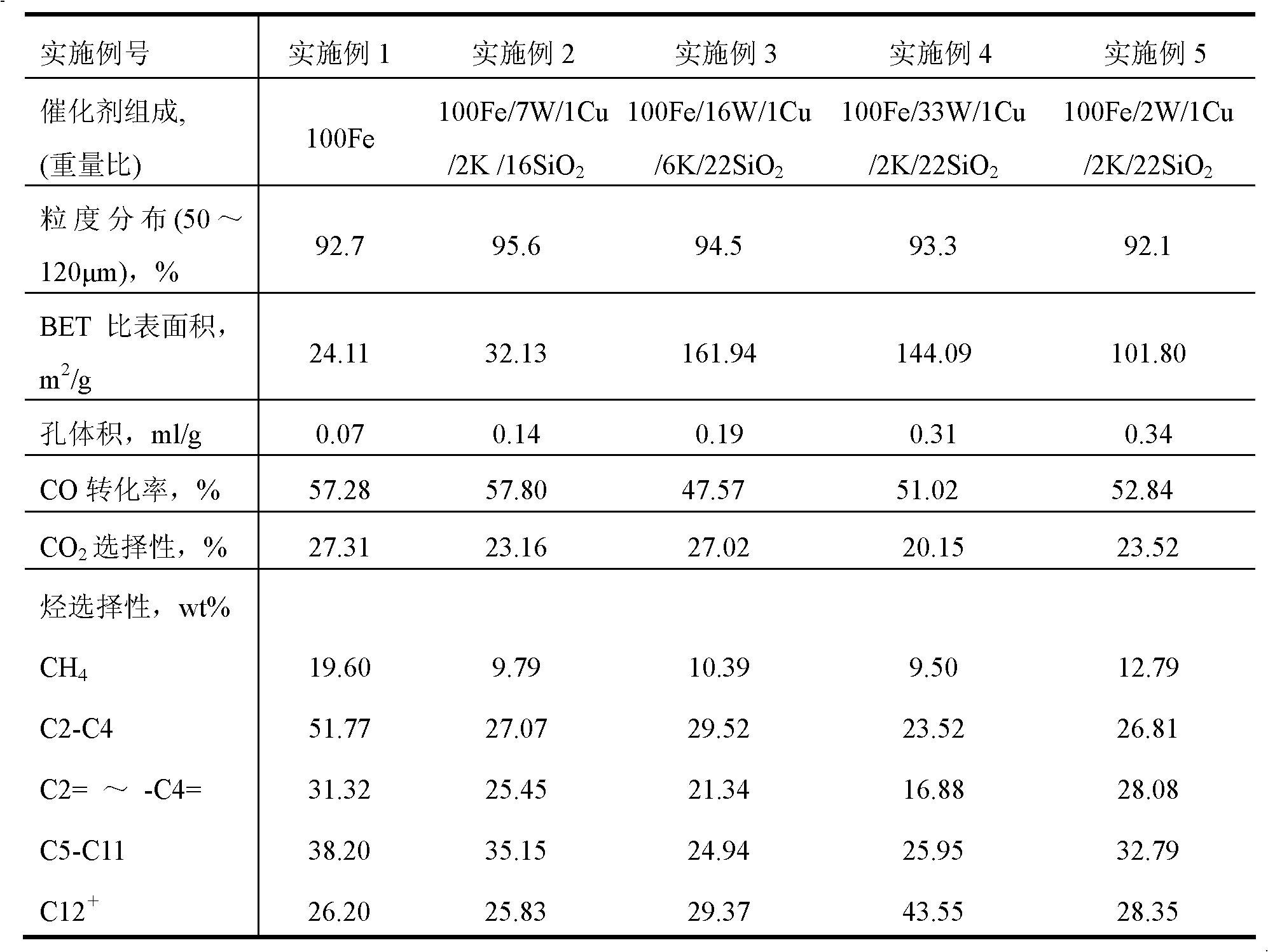

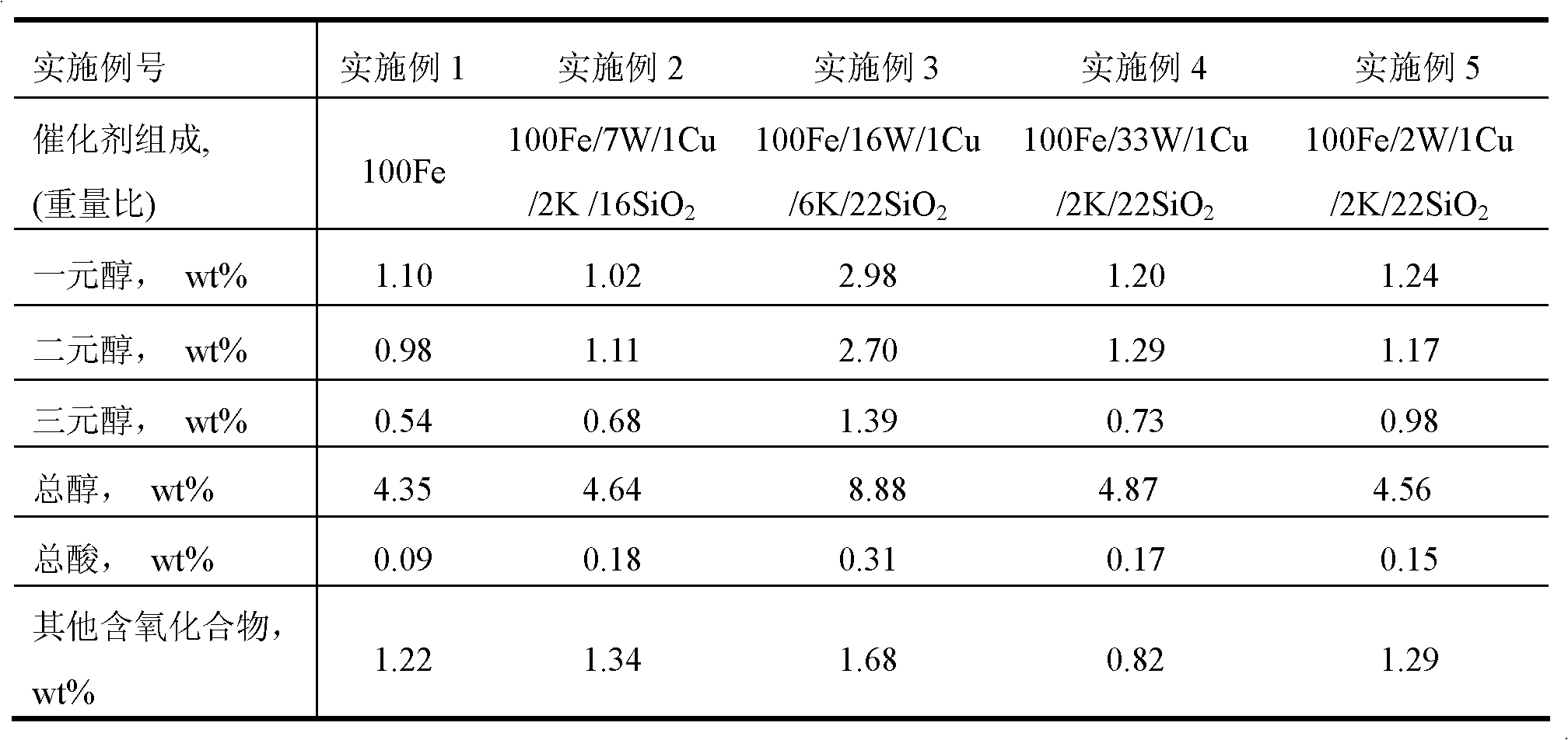

Fischer-Tropsch synthesis catalyst, its preparation method and application thereof

InactiveCN102728379AImproved stability of synthetic activityImprove sulfur resistanceLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsCoprecipitationOxygen

The invention relates to a Fischer-Tropsch synthesis catalyst, its preparation method and an application thereof. The catalyst comprises the following main components: Fe, a metal auxiliary component W, a Cu auxiliary agent, an alkaline auxiliary agent selected from Li, Na, K, Mg, Ca, Rb and Cs, and a structural promoter which contains at least one ingredient or any combination selected from SiO2, active carbon, Al2O3, ZrO2 and TiO2. The specific surface area of the catalyst provided by the invention is usually 50-240 m<2> / g. The catalyst can be prepared by a sol-gel method, a coprecipitation method, an immersion method or any combination of the above preparation methods, but preferably by a parallel flow precipitation method. The catalyst provided by the invention can be used in high selectivity production of hydrocarbons, oxygen-containing compounds and the like through Fischer-Tropsch synthesis of synthetic gas. its reaction activity and stability are obviously improved. And selectivity of light olefins in the Fischer-Tropsch synthesis product hydrocarbon is obviously raised.

Owner:SYNFUELS CHINA TECH CO LTD

Process for preparing demetalizing and desulfurizing catalyst of heavy oil hydrogenation

InactiveCN1205314CAdjust the pore size distributionImprove activity stabilityRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention discloses a preparation method of heavy oil hydrogenation demetallization and desulfurization catalyst, which uses two kinds of aluminum-containing materials in different forms, one is calcined alumina, the other is aluminum hydroxide dry rubber powder, and the alkali metal And / or alkaline earth metal elements are additives, the additives are pre-mixed with aluminum hydroxide dry rubber powder, and part is loaded on the catalyst by impregnation method, so that the additives are unevenly distributed on the catalyst. The catalyst prepared by the method of the invention has high demetallization activity and desulfurization activity at the same time, and the stability of activity, especially the stability of desulfurization activity is good. It can be used in hydrodemetallization and hydrodesulfurization of heavy and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for oil-in-water type soybean isolated protein

InactiveCN101317623AAvoid excessive protein denaturationHigh protein recoveryProtein composition from vegetable seedsFood preparationProteolysisOil in water

The invention discloses a preparation method for emulsion-typed soybean protein isolate, which comprises the steps as follows: pre-crushed low-temperature defatted soybean flour (DSF) is taken as raw material and mixed with deionized water with the water / material ratio of 5-20w / w, is heated to 40-60 DEG C under alkali condition and leached for 20-30min so as to lead the soybean meal to expand by absorbing water; Acalase alkaline protease is added to carry out the enzymolysis; the bottom residue is removed by centrifuging so as to obtain soybean proteolysis supernatant; furthermore, the soybean proteolysis supernatant is homogenized and acidity is adjusted to PH 4.5; the protein in the soybean proteolysis supernatant is deposited and centrifuged for 10-20min; the obtained deposition is mixed with the deionized water by the water / material ratio of 3-5w / w; the mixed solution is adjusted to neutral by adding NaOH and frozen dryly or sprayed dryly so as to obtain the emulsion-typed soybean protein isolate. The process of the invention is simple and reliable, which remarkably improves the emulsion performance of the soybean protein.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing hydro-demetalization catalyst

ActiveCN102441398ALarge hole volumeLarge apertureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionWater vapor

The invention discloses a method for preparing a hydro-demetalization catalyst, which comprises the following steps of: (1) weighing two kinds of pseudoboehmite dry colloidal powder with different natures, evenly mixing, adding an extrusion aid, then, carrying out peptization, forming, drying, and roasting to prepare an alumina carrier; (2) preparing a dipping solution from a VIB metallic compound and / or a VIII metallic compound; and (3) dipping the alumina carrier prepared in the step (1) by using the dipping solution prepared in the step (2), drying an obtained wet catalyst, and then, roasting the catalyst in water-vapor-contained atmosphere to prepare the final catalyst. With the adoption of the method disclosed by the invention, the hydro-demetalization catalyst with a large pore diameter, large pore volume and concentrated pore distribution can be prepared under the condition of not using a pore-expanding agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

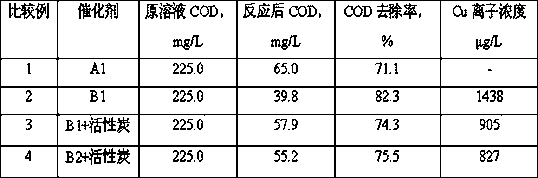

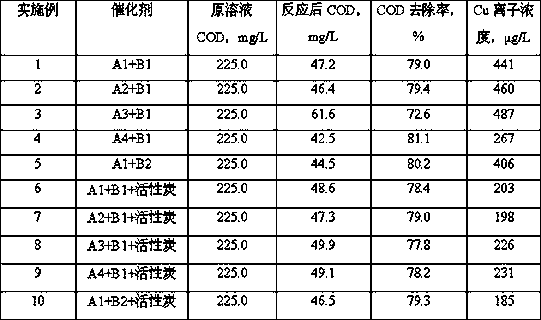

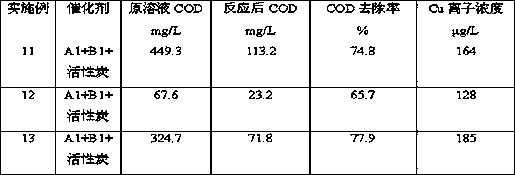

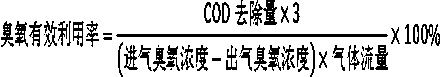

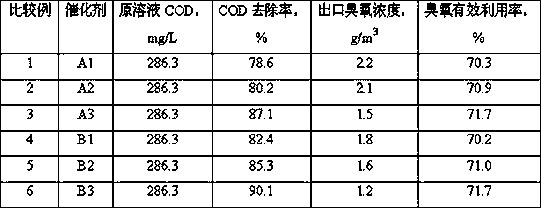

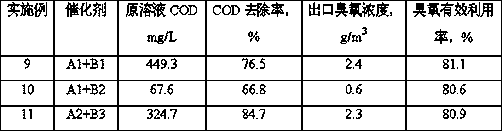

Treatment method of organic wastewater

ActiveCN108069502AEasy to handleGood removal effectWater contaminantsMultistage water/sewage treatmentMetalChemistry

The invention relates to the technical field of wastewater treatment and particularly discloses a treatment method of organic wastewater. The treatment method comprises steps as follows: the organic wastewater and ozone enter a reactor for a reaction, and the reactor is sequentially filled with a catalyst A and a catalyst B according to the contact sequence with the organic wastewater. The methodadopts a simple process, is good in stability and high in COD removal capability and can solve the problem about metal loss.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Process for preparing super-stable Y zeolite containing rare-earth elements

InactiveCN1159101CAchieve the purpose of exchangeLower activation energyCatalytic crackingMolecular sieve catalystsHigh resistanceRare-earth element

A rare-earth contained super-stable Y zeolite is prepared from the super-stable Y zeolite containing sodium oxide (3-5 wt.%), rare-earth compound and water in wt ratio of 1:(0.001-0.5):(1-10) through preparing solution of rare-earth compound, mixing and the said Y zeolite, and grinding with shearing stress of at least 10 kg / cm2 for at least 1 min. Its advantages are higher hydrothermal stability, high stability of activity, and high resistance to sodium and heavy metal pollutions.

Owner:CHINA PETROLEUM & CHEM CORP +1

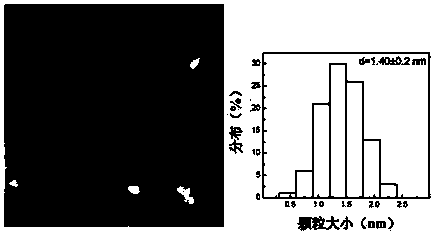

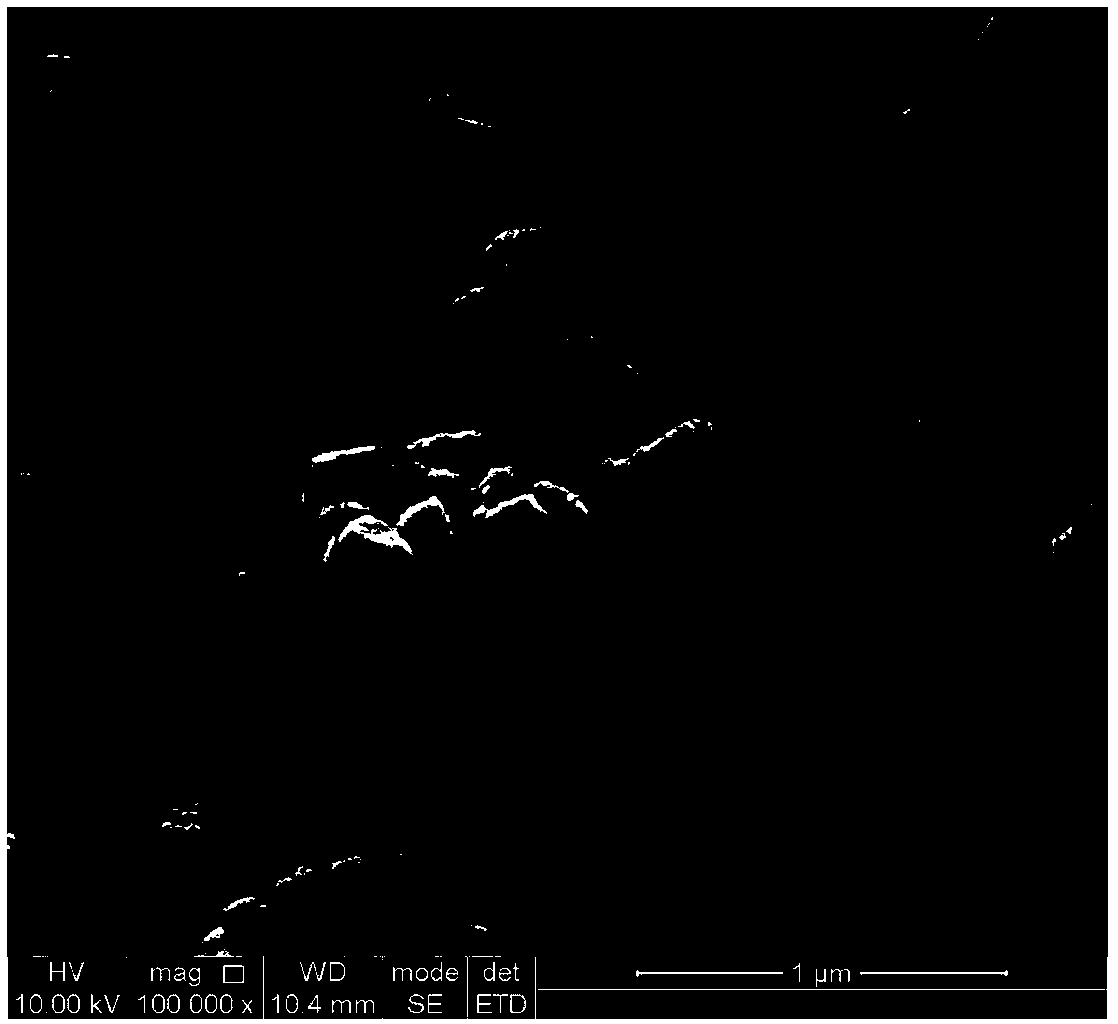

Propane dehydrogenation catalyst and preparation method thereof

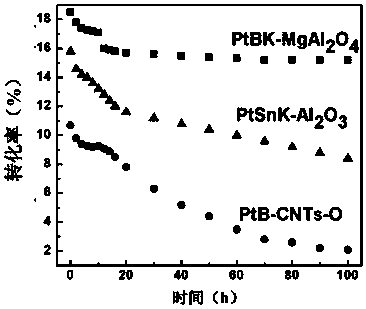

ActiveCN108325523AImprove conversion rateHigh selectivityMaterial nanotechnologyCatalyst carriersMagnesium AluminateChemistry

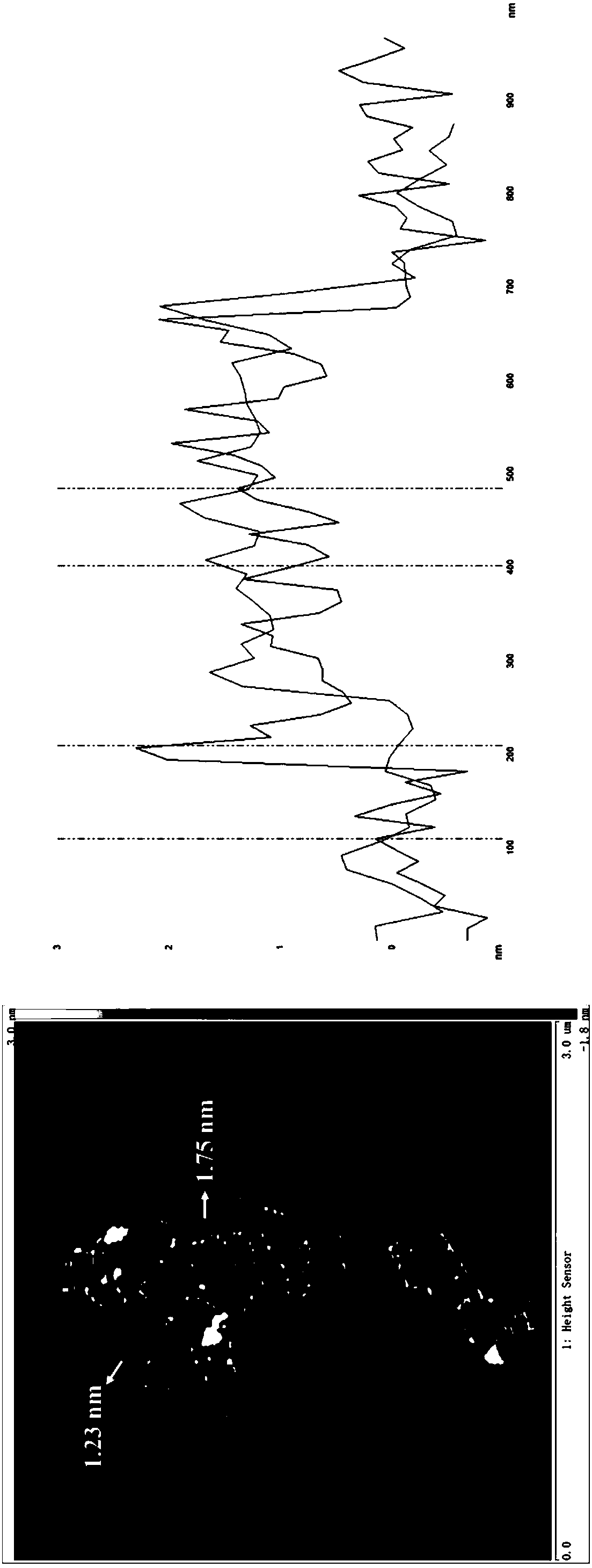

The invention discloses a propane dehydrogenation catalyst, which is obtained by loading metal platinum on magnesium aluminate spinel carriers, wherein the metal platinum of the catalyst is in a one-dimensional or two-dimensional highly dispersed state on the surface of the carrier; platinum atoms exist in a single atom or sub-nanometer cluster form; the particle diameter of the sub-nanometer cluster is smaller than 1nm. The invention also discloses a preparation method of the propane dehydrogenation catalyst. Compared with a catalyst prepared by the existing method, the obtained propane dehydrogenation catalyst has the advantages that the conversion rate and the selectivity are obviously improved; the stability is high; good application prospects are realized.

Owner:贵研工业催化剂(云南)有限公司

Hydrogenating and demetalization catalyst and its prepn

InactiveCN1417300AHigh activityImprove activity stabilityCatalyst activation/preparationHydrocarbon oils refiningPore distributionHigh activity

The hydrogenating and demetalization catalyst contains a alumina carrier and hydrogenating group VIB and group VIII metal component carried on the carrier, where the alumina carrier is gamma-alumina,which has such pore distribution that the pore volume of pores of 10-20 nm diameter accounts for 70-98 % of the total pore volume. The catalyst has high activity and high activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

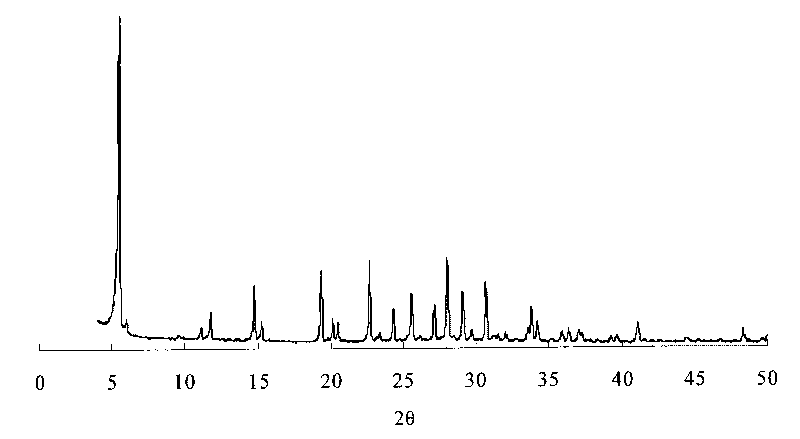

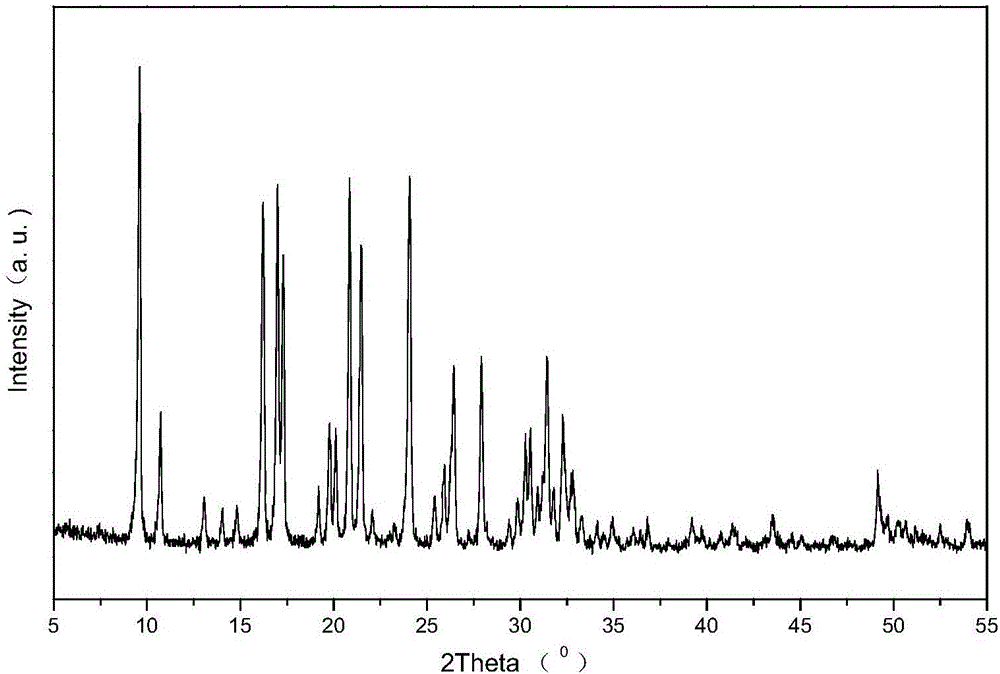

Tin-containing L zeolite and preparation method thereof

ActiveCN101746774AHigh purityHigh crystallinityCrystalline aluminosilicate zeolitesAlkaneMolecular sieve

The invention provides tin-containing L zeolite. The chemical composition of the zeolite is (0.9-1.3)M.(0.01-0.3) SnO2.Al2O3.(5-7) SiO2, wherein M in a formula is K2O or a mixture of K2O and Na2O. The zeolite supporting noble metal is used for alkane aromatization reaction, and has good aromatization activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of inorganic-organic compound-type adsorbent based on clinoptilolite and application for removing Cr(VI) in industrial waste water

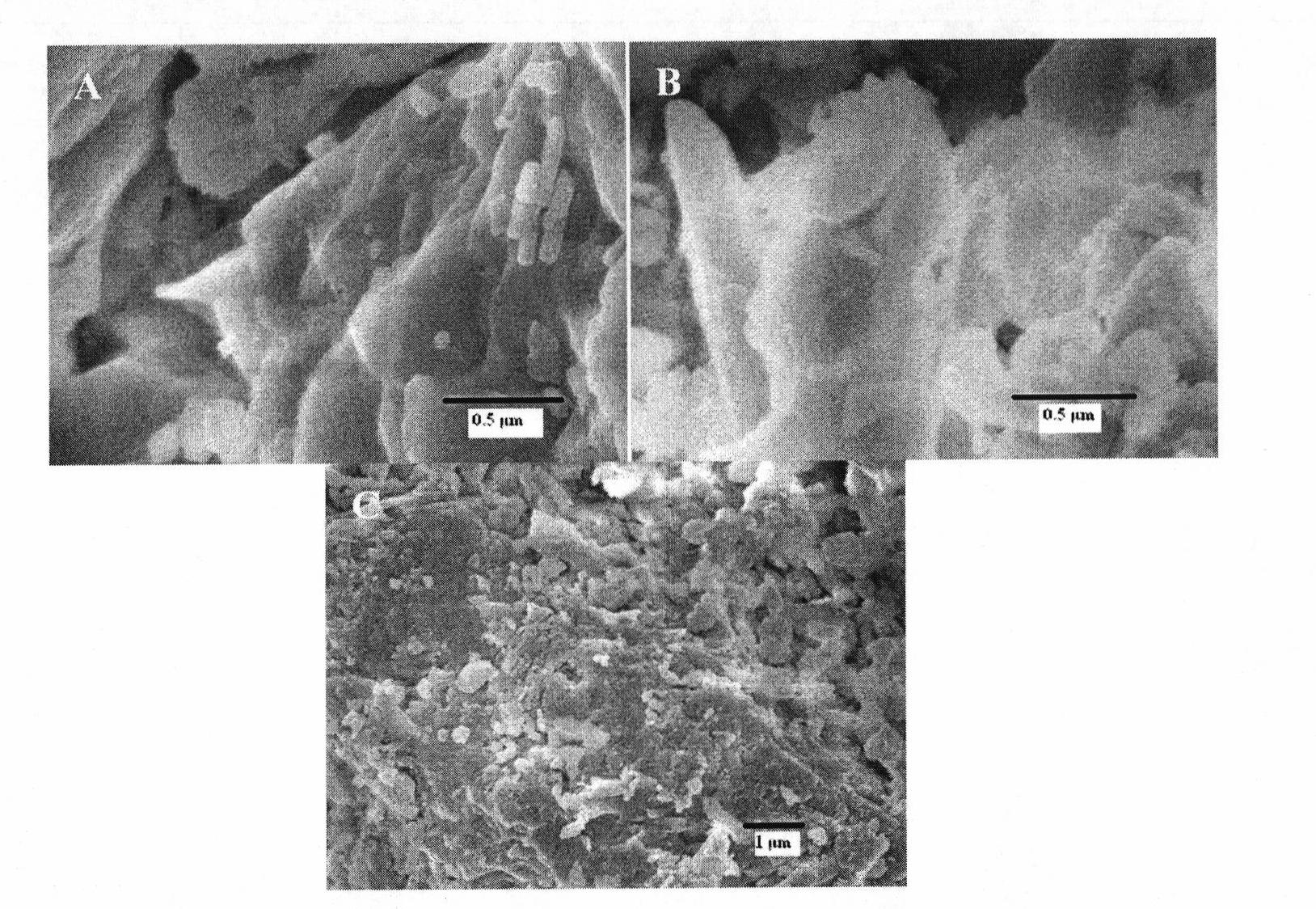

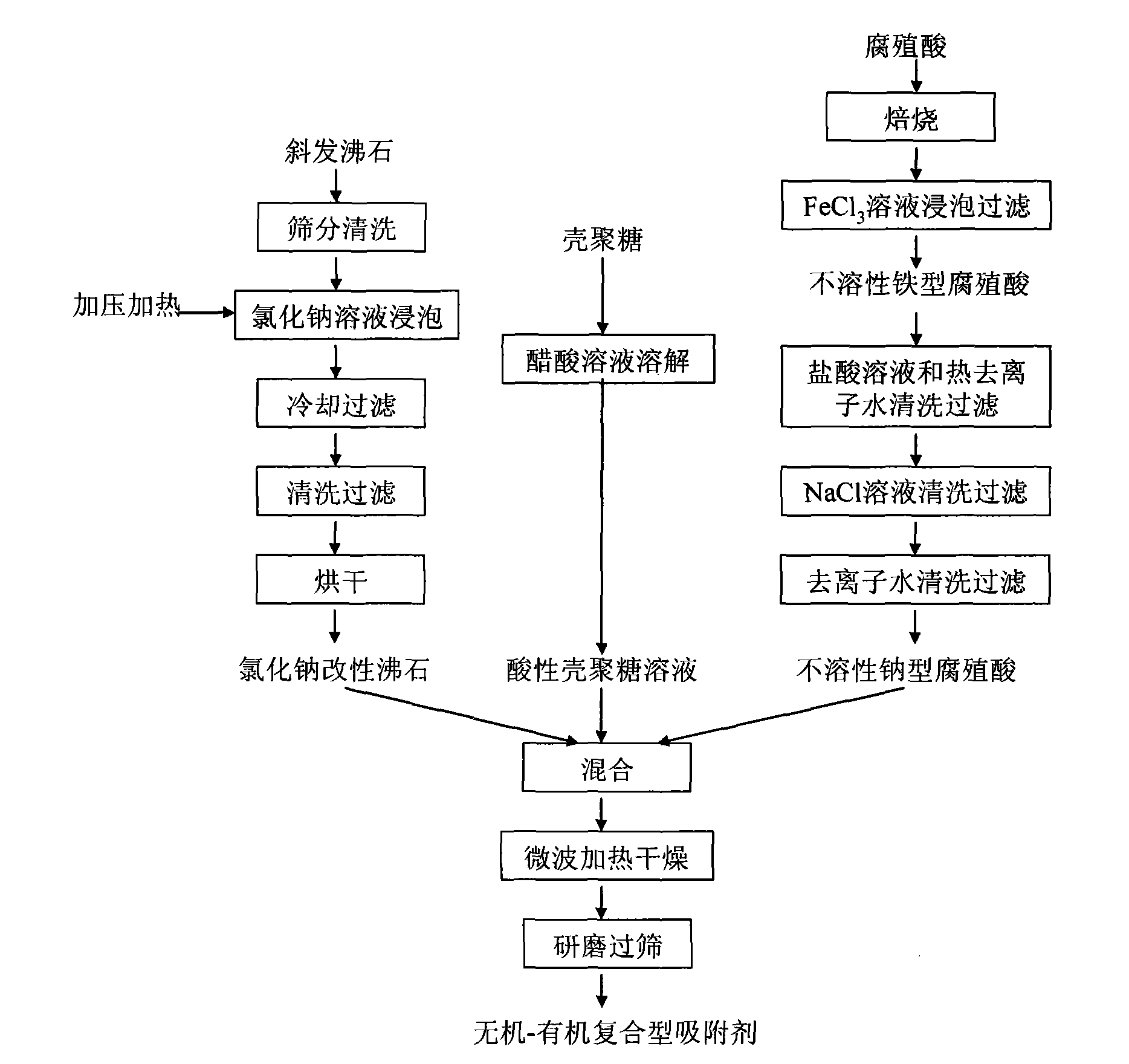

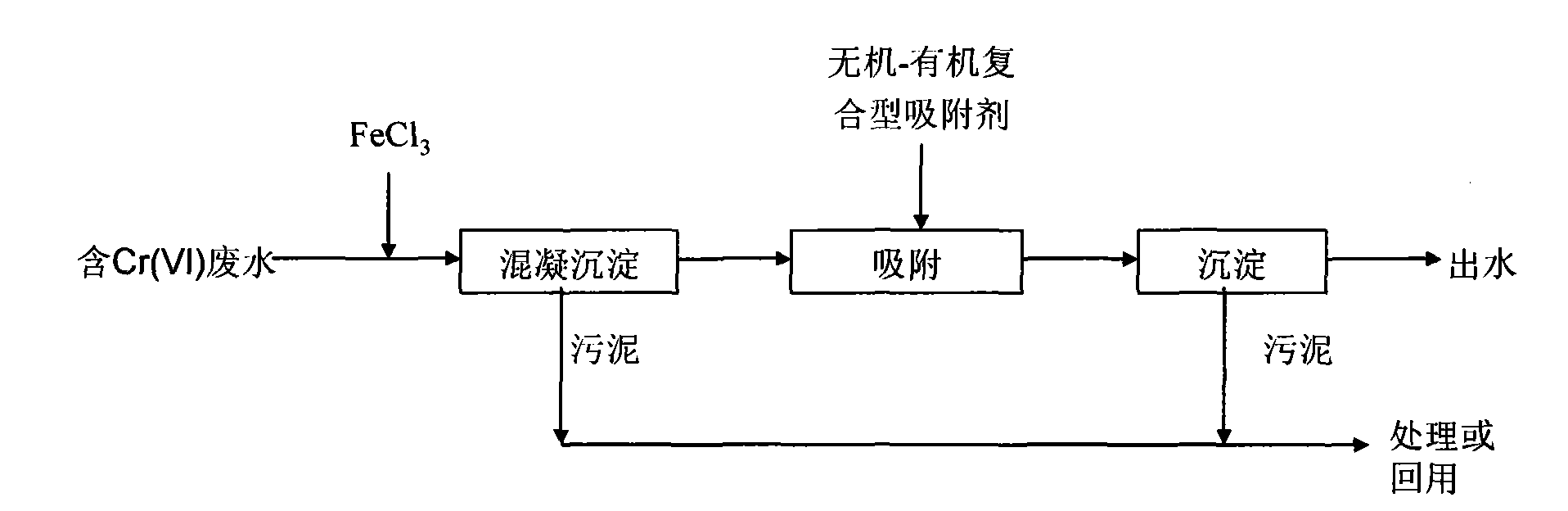

InactiveCN101797496ALarge adsorption capacityWide variety of sourcesOther chemical processesAluminium silicatesIndustrial waste waterSorbent

The invention belongs to the technical field of waste water processing. An inorganic-organic compound-type adsorbent is prepared by compositing three natural materials of natural clinoptilolite, humic acid and chitosan. The method comprises the following specific steps of: performing pre-activation modification on the natural clinoptilolite, performing insolubility processing on humic acid, sufficiently mixing the processed clinoptilolite, insoluble humic acid and acidic chitosan solution according to a certain proportion, heating and drying through microwave, grinding and screening to prepare the inorganic-organic compound-type adsorbent with a loose porous structure, high surface activity and high ion exchanging performance. The prepared adsorbent is used for processing the industrial waste water with the concentration of Cr(VI) lower than 100mg / L, wherein the concentration of effluent Cr(VI) is lower than 0.5mg / L, which meets the requirement of the maximum permissible discharge concentration of the first type of pollutant in the national waste water comprehensive discharge standard. The method has easily obtained materials, simple processing technique and high processing efficiency, and is suitable for large-scale production.

Owner:BEIJING FORESTRY UNIVERSITY

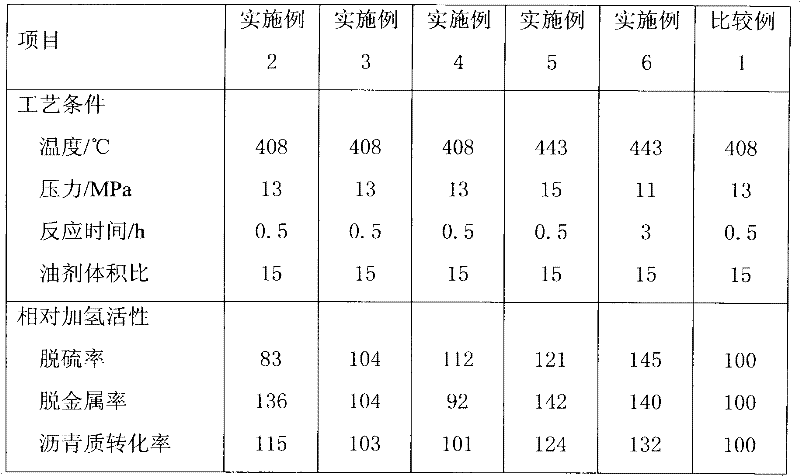

Heavy raw material boiling bed hydrogenation treatment method

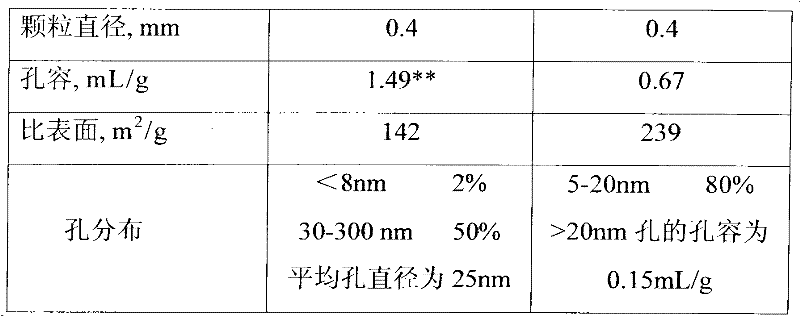

ActiveCN102443414ALarge apertureStrong metal capacityHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenSlag

The invention relates to a heavy raw material boiling bed hydrogenation treatment method. A boiling bed hydrogenation treatment reactor is used, the heavy oil raw material oil and hydrogen gas enter a reactor from the bottom, the reaction is carried out under the heavy raw material oil hydrogenation treatment condition, materials after the reaction are discharged out from the reactor from the top, a mixed catalyst of at least two catalysts is used in the boiling bed hydrogenation treatment reactor, and the mixed volume is 1:(0.1-10). One catalyst has the properties that the specific surface is 80 to 200 mm<2> / g, the several-hole diameter can be 15 to 30nm, and holes with the hole diameter being 30 to 300nm account for 35 percent to 60 percent of the total hole volume. The other catalyst has the properties that the specific surface is 180 to 300 mm<2> / g, and holes with the hole diameters being 5 to 20nm at least account for 70 percent of the total hole volume. The method has the advantages that the operation performance of the boiling bed slag oil hydrogenation treatment process can be effectively improved, and the hydrogenation activity level and the operation flexibility are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

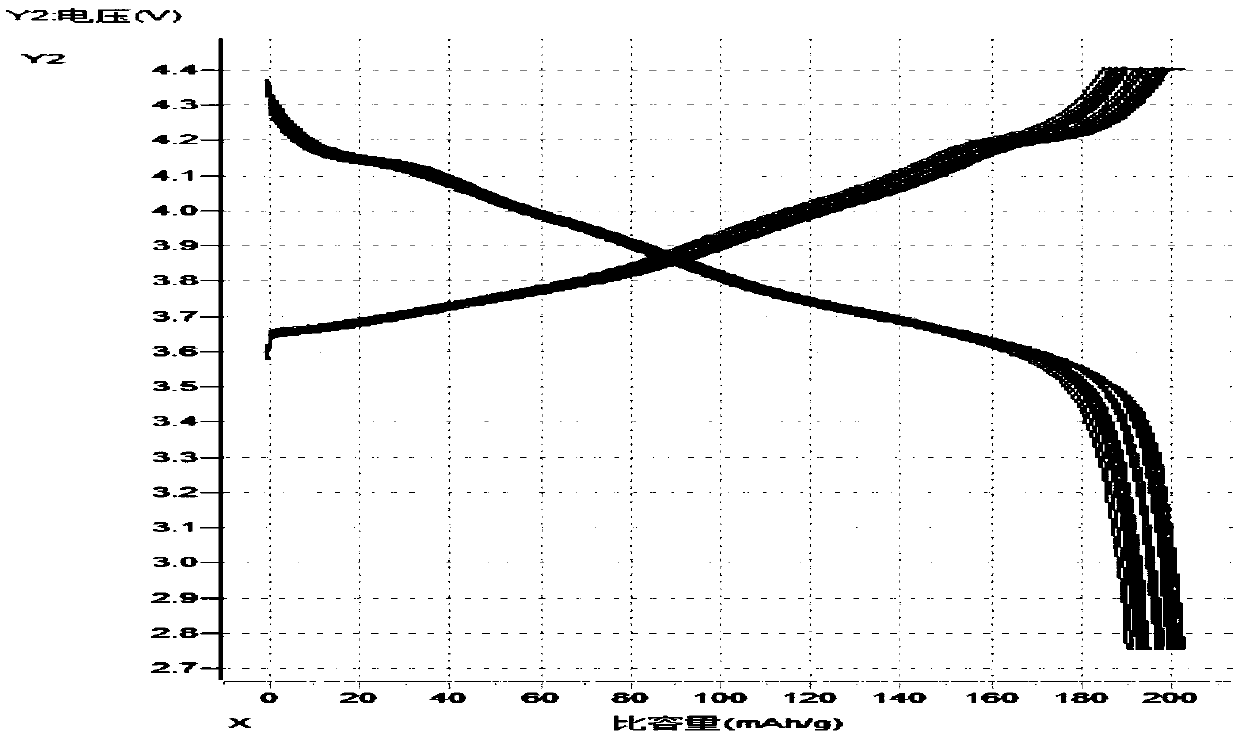

Cobalt-free lithium-rich ternary anode material NMA and preparation method thereof

InactiveCN109686970AIncrease capacityImprove stabilityMaterial nanotechnologySecondary cellsCobaltMaterials science

The invention discloses a cobalt-free lithium-rich ternary anode material NMA and a preparation method thereof. The chemical formula of the material is Li1 + PNi1-x-y-zMnxAlyMzO2, wherein: 0.03 < P <0.3, 0.1 < X <0.6, 0.01 < Y <0.1, 0.01 < Z <0.3, M is one or more of Ce <3+>, Ti <4+>, Zr <4+> and Mg <2+>; the precursor of the material is nano sheet-shaped agglomerated particles, and the thicknessof the nano sheet-shaped precursor is 30-50 nanometers. The material has the main application and advantages that the lithium-rich layered NMA cathode material is prepared by combining layered LiNiO2phase with layered LiMnO2 phase by replacing expensive Co with cheap Mn and adding excessive lithium (rich lithium). Since cobalt is not contained, the preparation cost is reduced by 20-30%, the capacity of the anode material reaches 190-200 mAh / g, and the capacity retention rate of 100 cycles is kept to 90-95%.

Owner:SICHUAN UNION SHINE MECHANICAL EQUIP CO LTD

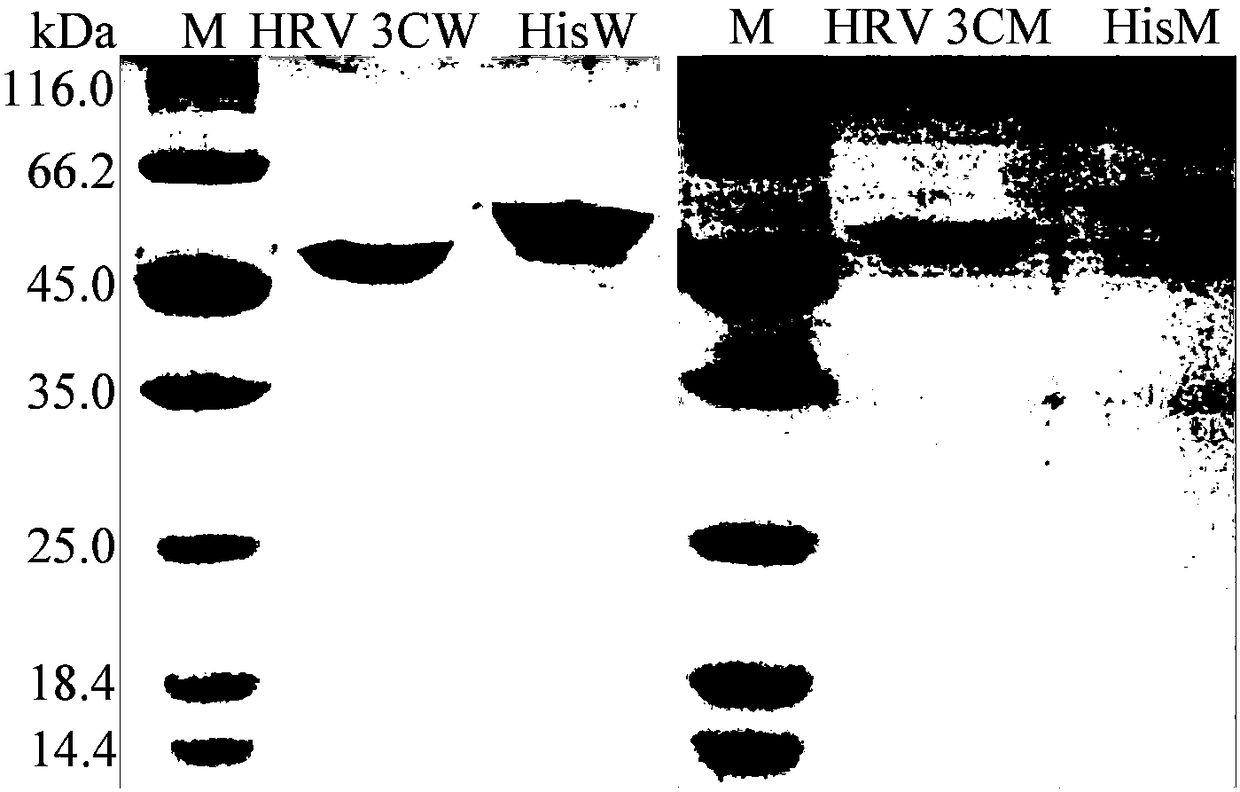

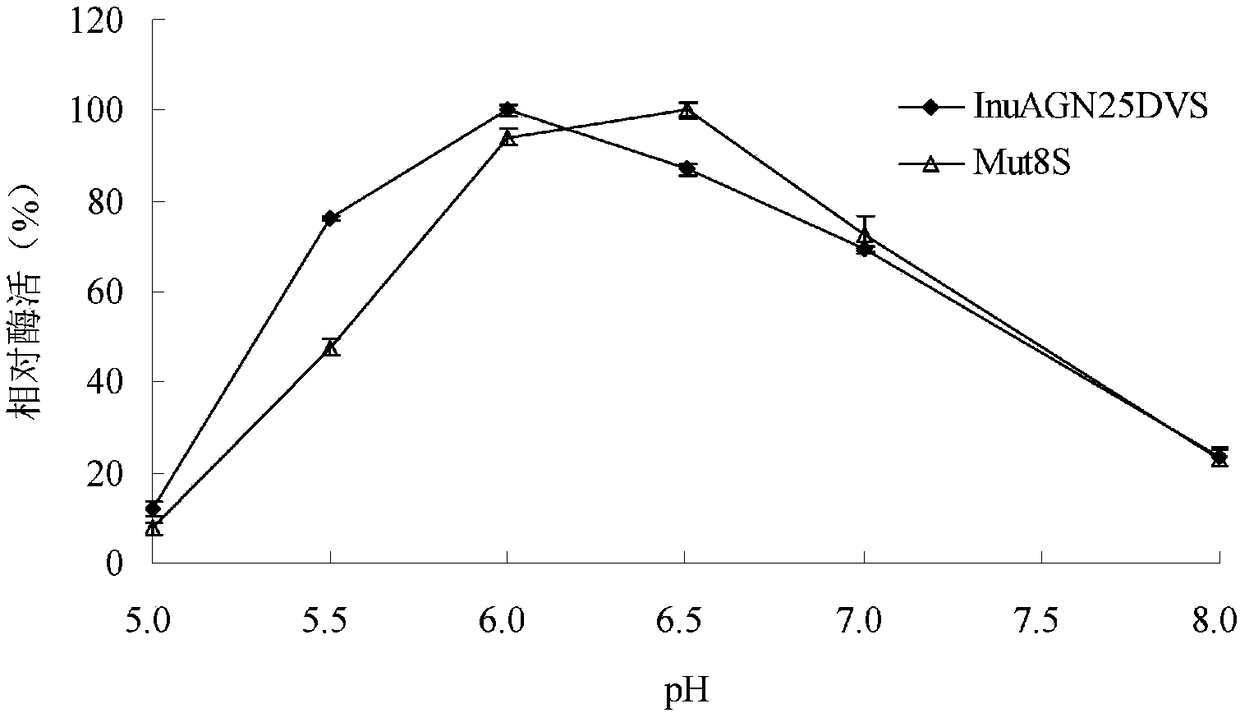

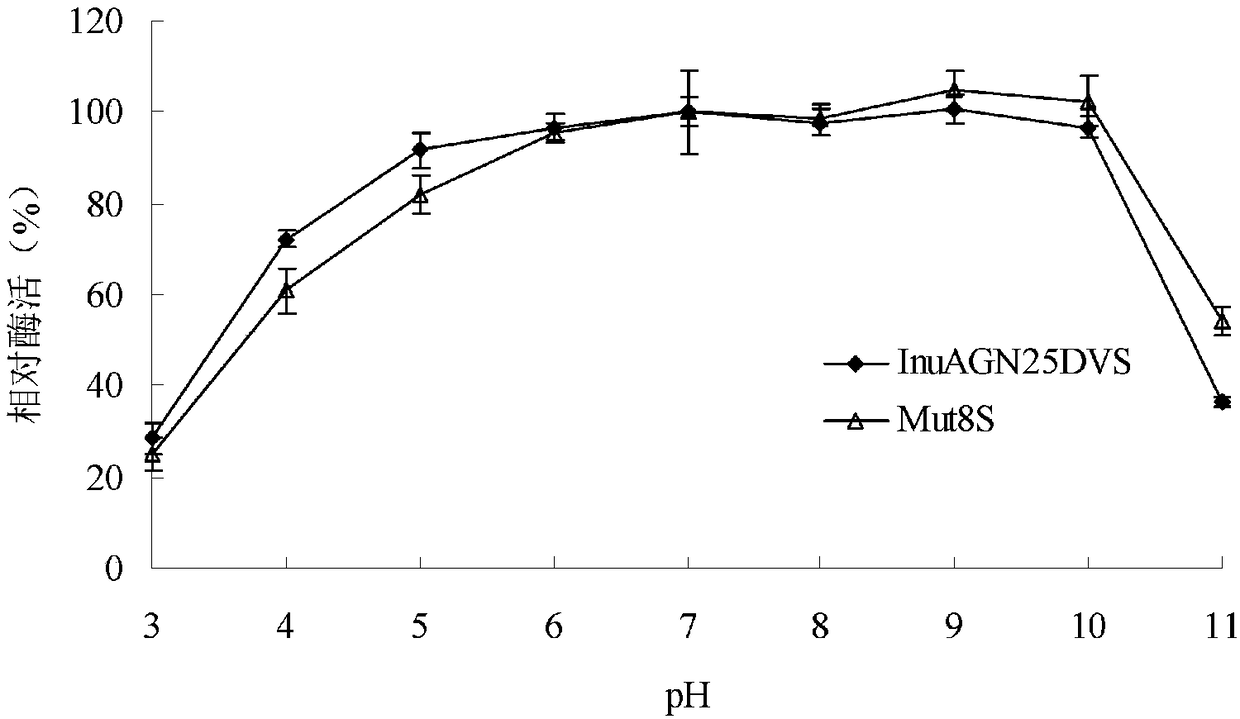

Low-temperature exoinulinase mutant Mut8S with improved heat stability

ActiveCN108504644AChange thermal stabilityIncreased thermal activityFermentationGlycosylasesBiotechnologyGenetically engineered

The invention relates to the technical fields of genetic engineering and protein modification and particularly relates to a low-temperature exoinulinase mutant Mut8S with the improved heat stability.The amino acid sequence of the mutant Mut8S is represented by SEQ ID NO.1. The optimal pH value of the Mut8S is 6.5; the optimal temperature of the Mut8S is 40 DEG C, and the Mut8S respectively has the enzyme activities of 16%, 27%, 51%, 76% and 78% at the temperatures of 0 DEG C, 10 DEG C, 20 DEG C, 30 DEGC and 50 DEG C; and after being processed at 50 DEG C for 60 minutes, the Mut8S still preserves 100% of the enzyme activity; and the enzyme can be used for hydrolyzing inulin so as to generate fructose. The low-temperature exoinulinase mutant Mut8S with the improved heat stability can be applied to the industries of foods, wine brewing, biological energy sources and the like.

Owner:YUNNAN NORMAL UNIV

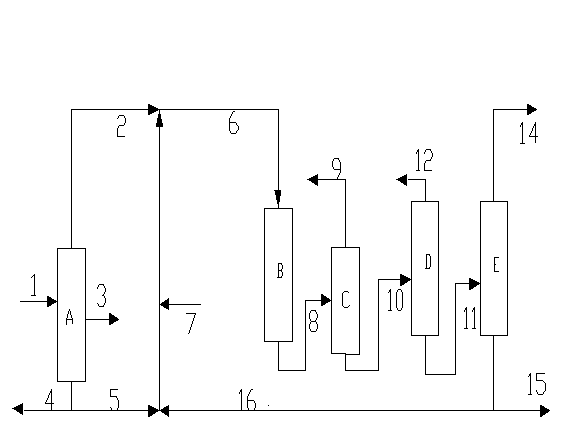

Technological method for purifying 1,4-butanediol and co-producing tetrahydrofuran

ActiveCN103044198AReduce lossesFlexible adjustment of outputOrganic compound preparationHydroxy compound preparationPtru catalystIon exchange

The invention discloses a technological method for purifying 1,4-butanediol and co-producing tetrahydrofuran. The technological method comprises the following steps: a raw 1,4-butanediol material flow containing 2-(4-hydroxyl butoxy) tetrahydrofuran enters a 1,4-butanediol refining tower, and a 1,4-butanediol product is produced at the side line of the refining tower; and material flows rich in the 1,4-butanediol at the top and bottom of the refining tower enter a tetrahydrofuran reactor, dehydration cyclization is continuously carried out for producing the tetrahydrofuran through a palladium carried sulfonating ion exchange resin catalyst in the presence of hydrogen; after reaction, a raw tetrahydrofuran material flow enters a gas-liquid separator, a gas phase flow is reused or is discharged, and a liquid phase enters an azeotropic distillation tower; and azeotrope of tetrahydrofuran and water is obtained at the tower top and is separated to obtain the tetrahydrofuran product, liquid at the tower bottom enters a dehydration tower, and a material flow at the tower bottom returns to the tetrahydrofuran reactor. According to the technological method, the tetrahydrofuran with the high selectivity is produced while the 1,4-butanediol product with the high purity is separated out, the seperation problem of the 2-(4'-hydroxyl butoxy) tetrahydrofuran in the 1,4-butanediol product flow is solved, and the production cost is greatly reduced; and the technological method is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-silica-alumina-ratio SSZ-39 zeolite, and synthesis and application thereof

ActiveCN106745031AHigh crystallinityOvercome problems such as decreased crystallinityMolecular sieve catalystsOther chemical processesDispersityFiltration

The invention discloses a preparation method of a high-crystallinity high-dispersity adjustable-silica-alumina-ratio high-silicon SSZ-39 molecular sieve catalyst. The method comprises the following steps: proportionally adding a sodium source, a silicon source, an aluminum source, fluorine ions, a template, a growth polymerization inhibitor and deionized water into a synthesis kettle, carrying out dynamic or static crystallization in different temperature sections, and carrying out filtration, washing and drying on the product to obtain molecular sieve raw powder; and carrying out high-temperature roasting to remove the template, carrying out ion exchange, and carrying out high-temperature roasting to obtain the high-silica-alumina-ratio SSZ-39 molecular sieve. The high-silica-alumina-ratio SSZ-39 molecular sieve has appropriate acid site, heat stability and pore size. The high-crystallinity high-dispersity controllable-silica-alumina-ratio SSZ-39 molecular sieve can be used for MTO (methanol to olefins) reaction for catalytically converting organic oxides (such as methanol and / or dimethyl ether and the like) into low-carbon olefins, and has the advantages of very high reaction activity and high selectivity for ethylene and propylene.

Owner:中海亚环保材料有限公司

Method for treating wastewater through catalytic wet oxidation of ozone

PendingCN108069499AEasy to handleImprove effective utilizationWater contaminantsHeterogenous catalyst chemical elementsCatalytic oxidationOxidative treatment

The invention relates to the technical field of wastewater treatment and particularly discloses a method for treating wastewater through catalytic wet oxidation of ozone. The method comprises the steps as follows: organic wastewater and ozone enter a reactor to react, and the reactor is sequentially filled with a catalyst A and a catalyst B in the contact sequence with the organic wastewater. Themethod comprises a simple process and has good stability, the COD removal capacity is high, the effective utilization rate of ozone can be increased, and the dosage of ozone can be reduced.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

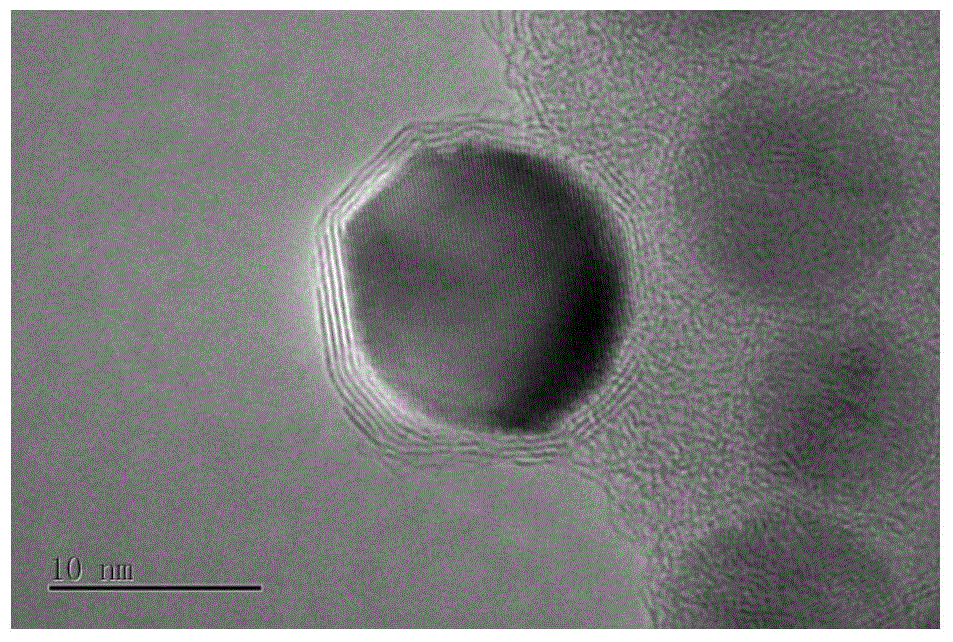

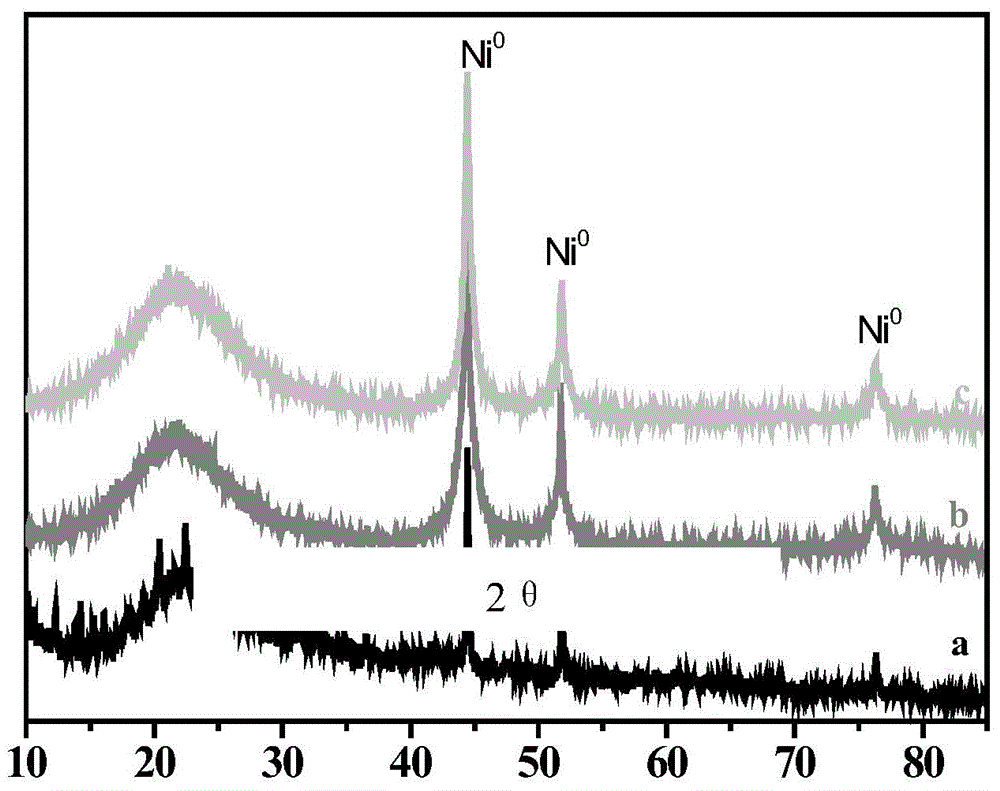

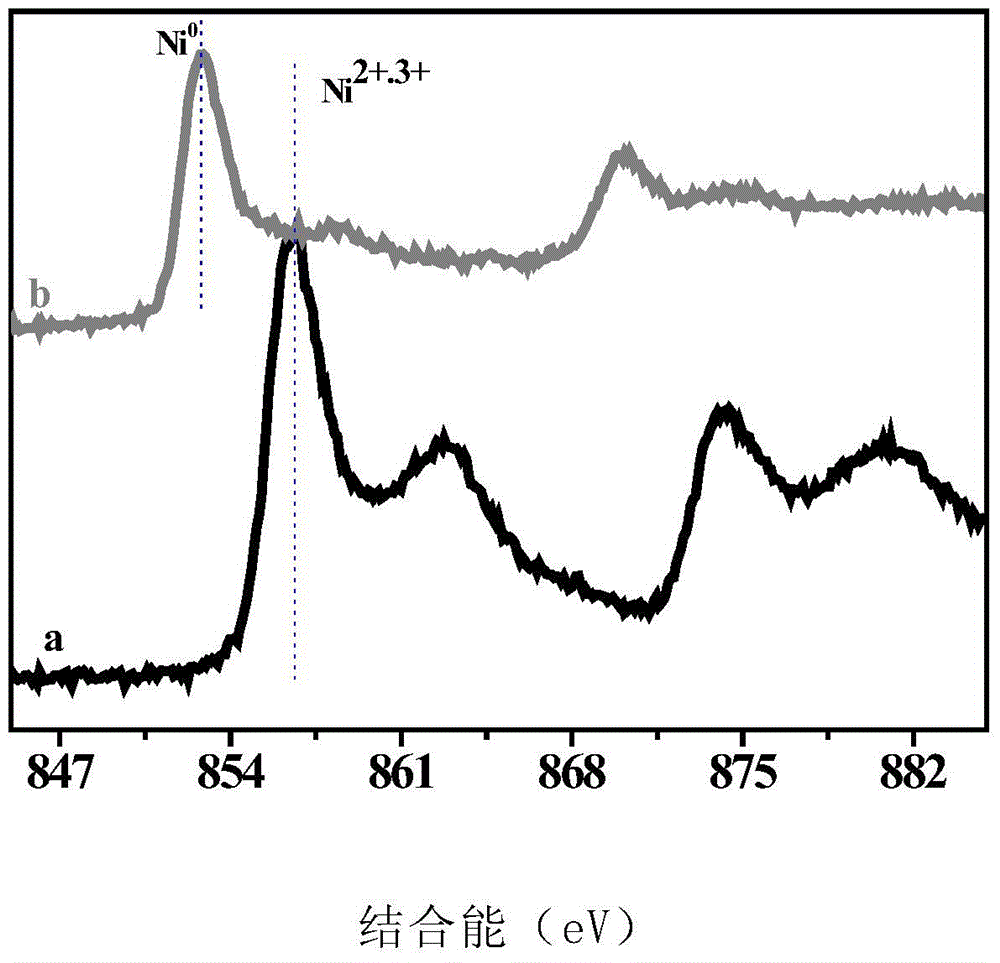

Metal@BN core-shell structure nanometer catalyst for synthesis gas methanation reaction, and preparation method thereof

ActiveCN106179438APrevent sintering and lossAvoid Catalyst DeactivationHydrocarbon from carbon oxidesPhysical/chemical process catalystsNano catalystSyngas

The invention discloses a metal@BN core-shell structure nanometer catalyst for a synthesis gas methanation reaction, and a preparation method thereof. According to the present invention, the composition of the catalyst is 5-30wt.%Mx@(BN)y / SiO2, wherein metal M nanoparticles are loaded on a SiO2 support, the loading mass percentage is 5-30%, an ultrathin boron nitride (BN) layer is covered on the surface, the catalyst has a core-shell structure, and a molar ratio y / x of the BN to the metal nanoparticles is 0.1-10; with the application of the catalyst in the methane preparation reaction through the hydrogenation of the catalytic synthesis gas, the sintering and the loss of the metal nanoparticles can be prevented, and the catalyst deactivation caused by the carbon deposition on the catalyst active site surface can be prevented with the core-shell structure; and the catalyst has high low-temperature activity and high high-temperature stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Copper-based molecular sieve catalyst as well as preparation method and application thereof

ActiveCN105772064AImprove activity stabilityHigh hydrothermal stabilityGas treatmentInternal combustion piston enginesMolecular sieveFreeze-drying

The invention discloses a copper-based molecular sieve catalyst, as well as a preparation method and application of the copper-based molecular sieve catalyst for purifying catalyst oxynitride in a post-treatment Urea-SCR system on a diesel vehicle. The preparation method comprises the following steps: firstly performing ultrasonic impregnating and then performing freeze-drying treatment, so that the catalytic activity and the hydrothermal stability of the copper-based molecular sieve catalyst are effectively improved.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com