Method for producing lubricating oil basic oil

A technology for lubricating base oil and distillate oil, which is applied in the directions of lubricating compositions, base materials, petroleum industry, etc., can solve the problems of high investment and operating costs, complex technological processes, affecting economic benefits, etc., and achieves good reaction effects and satisfying Index requirements, the effect of extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

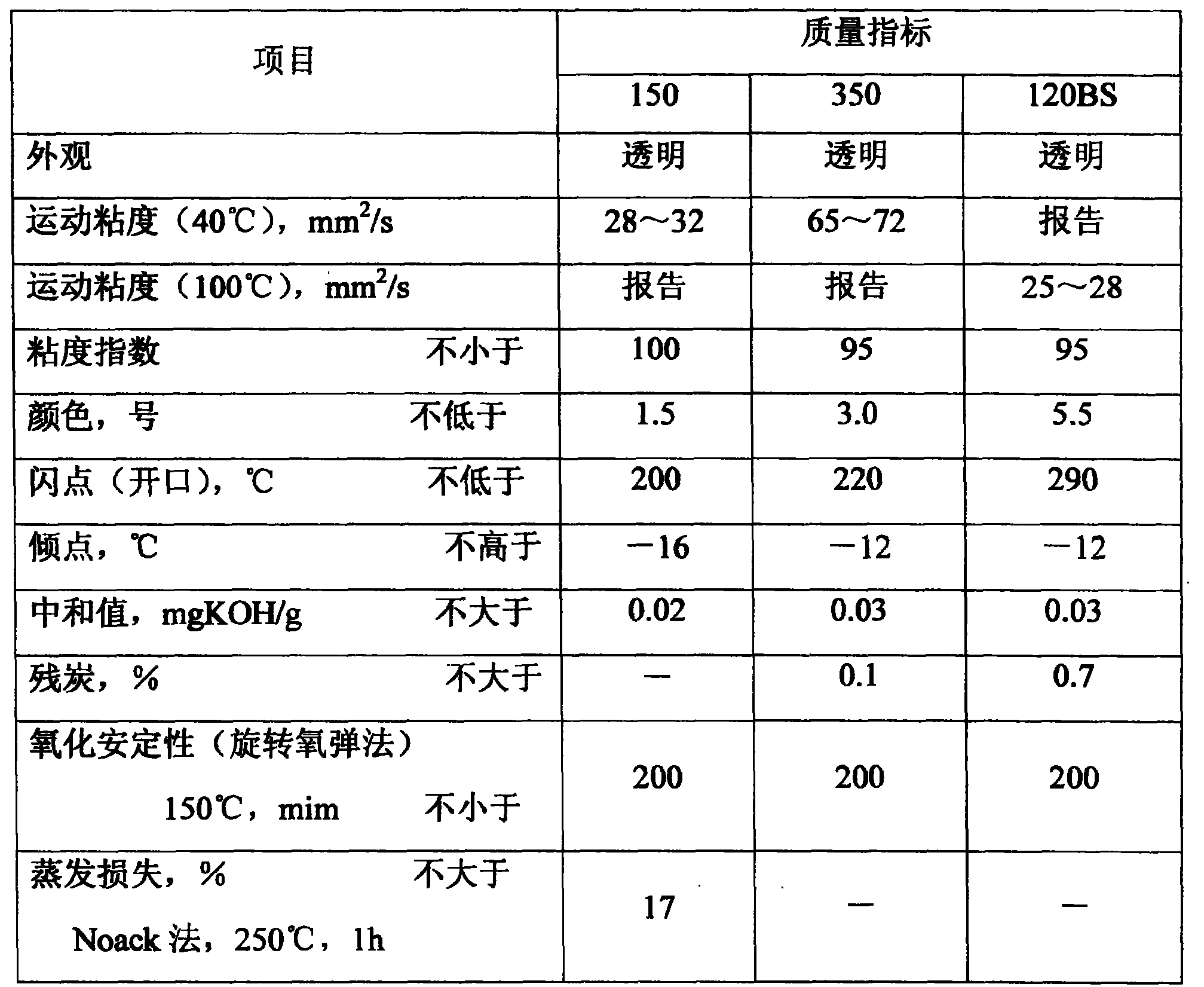

[0014] The method for producing food-grade white oil of the present invention adopts a low-pressure hydroisomerization-adsorption treatment process, including the following steps: After the raw material oil and hydrogen are mixed, they first enter the hydroisomerization reactor, and in the presence of hydrogen and a hydroisomerization catalyst Under the isomerization reaction, the reaction product enters the gas-liquid separator, and the liquid phase enters the fractionation tower to cut out the lubricating oil fraction. The lubricating oil fraction is subjected to adsorption treatment, and the effluent of the adsorption treatment is the lubricating oil base oil product.

[0015] Since the unstable components in the oil produced by hydroisomerization are precipitated under light conditions and affect the performance of the product, the product of the hydroisomerization reaction needs to undergo an adsorption process to remove the unstable components to improve the color of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com