Technological method for purifying 1,4-butanediol and co-producing tetrahydrofuran

A technology of tetrahydrofuran and butanediol, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as increasing difficulty and complex reactor structure, and achieve suppression of side reactions, reduction of manufacturing costs and Operating cost, effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

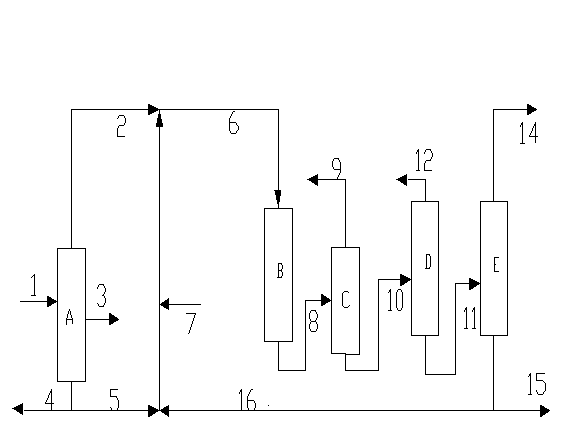

[0035] The crude 1,4-butanediol stream containing 0.36% 2-(4-hydroxybutoxy)tetrahydrofuran, 0.75% gamma-butyrolactone content, 98.89% 1,4-butanediol enters via line 1 Rectification tower A, the rectification tower adopts the conventional packing tower, operates under reduced pressure, controls tower top pressure 1.0kPa, reflux ratio 5.0, tower top reflux temperature 80 ℃, under this condition enters the stream of rectification tower A to pass separation, the side line 1,4-butanediol with a purity of 99.83% enters the product tank area through pipeline 3, and the overhead stream is composed of: 2-(4-hydroxybutoxy)tetrahydrofuran content 0.56%, γ-butyrolactone content 0.99%, The content of 4'-hydroxybutyl 4-hydroxybutyrate is 0.12%, and the content of 1,4-butanediol is 98.33%. Bottom stream composition: 2-(4-hydroxybutoxy)tetrahydrofuran content 0.02%, γ-butyrolactone content 0.01%, 4-hydroxybutyric acid 4'-hydroxybutyl ester content 0.24%, 1,4-butanedi The alcohol content is 9...

Embodiment 2

[0037] The crude 1,4-butanediol stream containing 0.5% 2-(4-hydroxybutoxy)tetrahydrofuran enters the rectification tower A through pipeline 1. The rectification tower adopts a conventional packed tower and is operated under reduced pressure to control the top pressure of 3.0 kPa, reflux ratio 15.0, the stream entering rectification tower A is separated, and 1,4-butanediol with a purity of 99.83% is obtained from the side line and enters the product tank area through line 3, and the bottom stream is all passed through line 5 and the tower from line 2 After mixing the 1,4-butanediol stream containing 0.94% 2-(4-hydroxybutoxy)tetrahydrofuran and the hot hydrogen coming from line 7, the hydrogen / butanediol molar ratio is controlled to be 8, and enter through line 6 In tetrahydrofuran reactor B, control the liquid hourly space velocity of 1,4-butanediol to 3.0h -1 , Carry out dehydration cyclization reaction under 110 ℃ of reaction temperature, reaction pressure 0.2MPa condition, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com