Preparation of activated carbon-based catalyst used for selective reduction desulphurization of flue gas

A catalyst and selective technology, applied in the field of flue gas removal of SO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

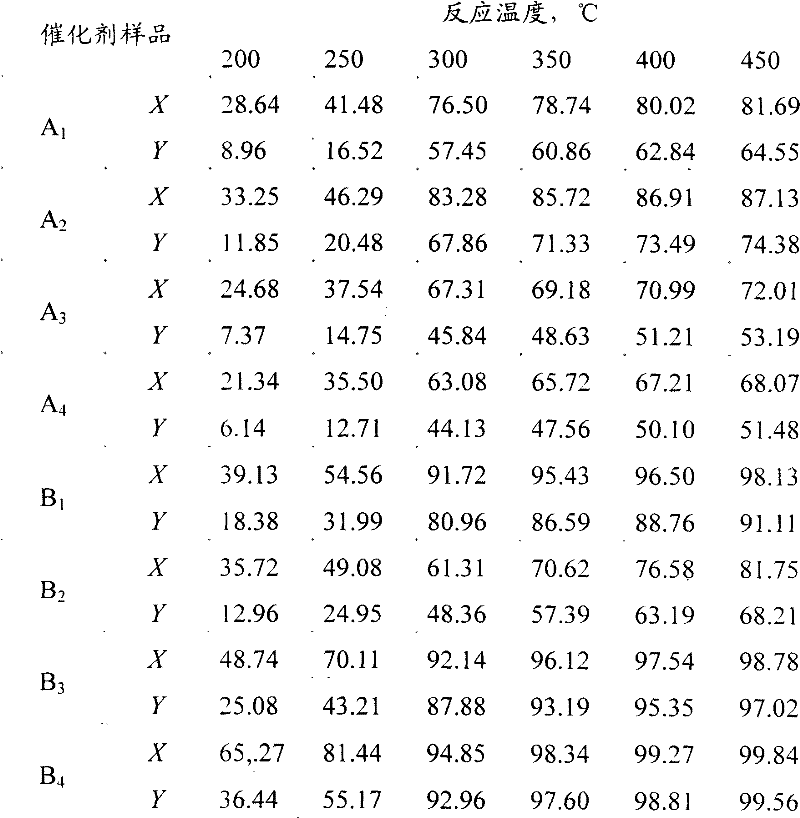

Examples

Embodiment 1

[0017] Modification of activated carbon carrier: Soak coconut shell activated carbon with a particle size of 40-60 mesh in deionized water for 24 hours, then wash with deionized water several times, and then dry at 110°C for 12 hours. Activated carbon after drying with 2.5w% HNO 3 Carrier 1 was obtained by oxidizing at 90°C for 6 hours and drying at 110°C for 12 hours. The specific surface area of the obtained carrier is 1900m 2 / g.

[0018] Preparation of the catalyst: 101 g of ferric nitrate was dissolved in 210 mL of water to obtain an impregnation solution 1. Using equal-volume impregnation, impregnate 100 g of the above-mentioned carrier with 210 mL of the impregnation solution for 2 h, and dry at a constant temperature of 110 ° C for 12 h, and then the obtained catalyst precursor N 2 Calcined at 500°C for 5h under atmosphere to obtain catalyst sample A 1 .

Embodiment 2

[0020] Modification of activated carbon carrier: Soak coconut shell activated carbon with a particle size of 40-60 mesh in deionized water for 24 hours, then wash with deionized water several times, and then dry at 110°C for 12 hours. Activated carbon after drying with 5w% HNO 3 Carrier 2 was obtained by oxidizing at 90°C for 6 hours and drying at 110°C for 12 hours. The specific surface area of the obtained carrier is 2045m 2 / g.

[0021] Catalyst preparation: 210 mL of impregnation solution 1 was prepared according to the same method as in Example 1. Using equal-volume impregnation, impregnate 100 g of the above-mentioned carrier with 210 mL of the impregnation solution for 2 h, and dry at a constant temperature of 110 ° C for 12 h, and then the obtained catalyst precursor N 2 Calcined at 500°C for 5h under atmosphere to obtain catalyst sample A 2 .

Embodiment 3

[0023] Dissolve 77.86g of nickel nitrate in 210mL of water to obtain immersion solution 2. Using the method of equal volume impregnation, 100 g of the carrier 2 obtained in Example 2 was impregnated with 210 mL of the impregnation solution for 2 h, and dried at a constant temperature of 110 ° C for 12 h, and then the obtained catalyst precursor N 2 Calcined at 500°C for 5h under atmosphere to obtain catalyst sample A 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com