Method for preparing formic acid through electrochemical catalytic reduction of carbon dioxide

A carbon dioxide, electrochemical technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of slow cathode reaction, accelerated hydrogen evolution reaction, reduced electrocatalytic activity, etc., and achieve improved electrocatalytic activity. , The effect of long-term stability improvement and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

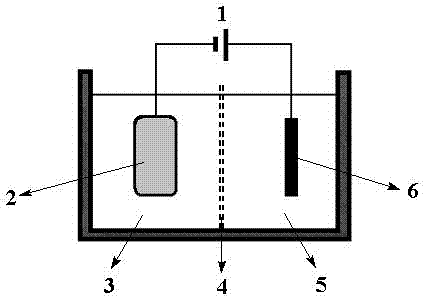

[0028] Embodiment 1: as attached figure 1 As shown, the electrolytic cell is divided into a cathode chamber and an anode chamber by a perfluorosulfonic acid type proton exchange membrane, an In electrode is used as a cathode, a graphite electrode is used as an anode, and carbon dioxide is converted into formic acid through an electroreduction reaction. The specific process is as follows:

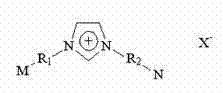

[0029] Step 1. Dissolve 1-butyl-3-methylimidazolium trifluoromethanesulfonic acid ionic liquid in dihydrogen disulfide with a water content of 15% (mass percentage) at room temperature at a liquid / dose volume ratio of 1:4. In methyl sulfoxide, an organic solvent / ionic liquid / water mixed solution is obtained. The mixed solution is transported to the gas absorption tower for dissolving and absorbing carbon dioxide until the concentration of carbon dioxide reaches 0.05 mol / L, injecting the above solution dissolved in carbon dioxide into the cathode chamber as the cathode chamber electrolyte; a...

Embodiment 2

[0032] Embodiment 2: as attached figure 1 As shown, the electrolytic cell is divided into a cathode chamber and an anode chamber by a perfluorosulfonic acid proton exchange membrane, a Pb electrode is used as a cathode, a glassy carbon electrode is used as an anode, and carbon dioxide is converted into formic acid through an electroreduction reaction. The specific process is as follows:

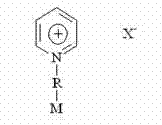

[0033] Step 1: Dissolve 1-butylpyridine trifluoromethanesulfonate ionic liquid in methanol with a water content of 10% (mass percentage) at a liquid / dose volume ratio of 1:6 at room temperature to obtain an organic solvent / ionic liquid / water mixed solution, and then transport the mixed solution to the gas absorption tower, dissolve and absorb carbon dioxide until the carbon dioxide concentration reaches 0.083 mol / L, inject the above solution dissolved in carbon dioxide into the cathode chamber, and use it as the cathode chamber Electrolyte; At the same time, inject 2mol / L sodium bisulfate a...

Embodiment 3

[0036] Embodiment 3: as attached figure 1 As shown, the electrolytic cell is divided into a cathode chamber and an anode chamber by a perfluorosulfonic acid proton exchange membrane, a Sn electrode is used as a cathode, and an IrO 2 ·Ta 2 o 5 The coated titanium electrode serves as the anode, which converts carbon dioxide into formic acid through an electroreduction reaction. The specific process is as follows:

[0037] Step 1, at room temperature, according to the liquid / dose volume ratio of 1:1, 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide ionic liquid is dissolved in water content rate 5% (mass percentage ) in a mixed organic solvent of dimethyl sulfoxide / propylene carbonate (the volume ratio of dimethyl sulfoxide to propylene carbonate is 1:1) to obtain a mixed solution of organic solvent / ionic liquid / water, which is sent to the gas In the absorption tower, after dissolving and absorbing carbon dioxide until the concentration of carbon dioxide reaches 0.69 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com