Tin-containing L zeolite and preparation method thereof

A technology of molecular sieve and mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

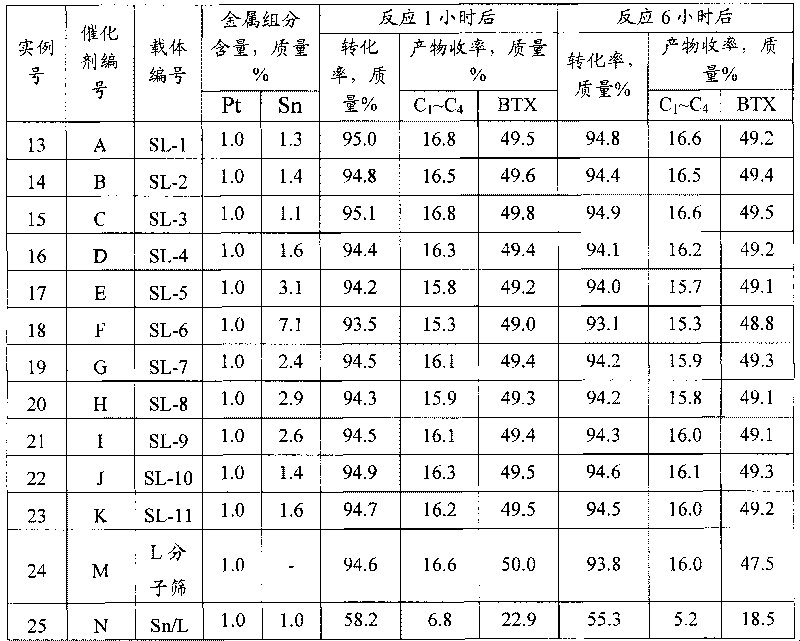

[0015] The preparation method of the molecular sieve provided by the present invention comprises that the molar ratio of tin source, aluminum source, silicon source, inorganic base and water is (0.01~0.8) SnO 2 :Al 2 o 3 :(5~20)SiO 2 : (0.5 ~ 4.0) Inorganic base: (60 ~ 300) H 2 The ratio of O is fully mixed to form a reaction mixture gel, and after hydrothermal crystallization at 100-200° C., the solid is washed and dried. In the reaction mixture gel, the tin contained in the tin source compound is represented by SnO 2 Calculated, the aluminum contained in the aluminum source compound is expressed as Al 2 o 3 Calculated, the silicon contained in the silicon source compound is expressed as SiO 2 count.

[0016] The molar ratio of each substance contained in the above-mentioned reaction mixture gel is preferably (0.05~0.5)SnO 2 :Al 2 o 3 : (7~15)SiO 2 : (1 ~ 3.0) Inorganic base: (100 ~ 200) H 2 O.

[0017] In the method of the present invention, there is no special ...

example 1

[0027] Directing agents used in the present invention were prepared.

[0028] According to the molar composition of the feeding mixture, it is 8K 2 O·Al 2 o 3 14SiO2 2 ·320H 2 For the formula of O, 4.35g Al(OH) 3 (produced by Aluminum Corporation of China, brand H-WF-10, the same below), was added to 106ml of a solution containing 30gKOH (purity 82%, the same below), heated and dissolved to obtain aluminum sol. Add aluminum sol to 65mL silica sol (containing 30% SiO 2, the pH value is 9, the same below), stirred for 0.5 hours to form a white gel, and aged the white gel at 30°C for 72 hours to obtain a translucent sol, which is a crystallization directing agent.

example 2

[0030] Prepare the tin-containing L molecular sieve of the present invention.

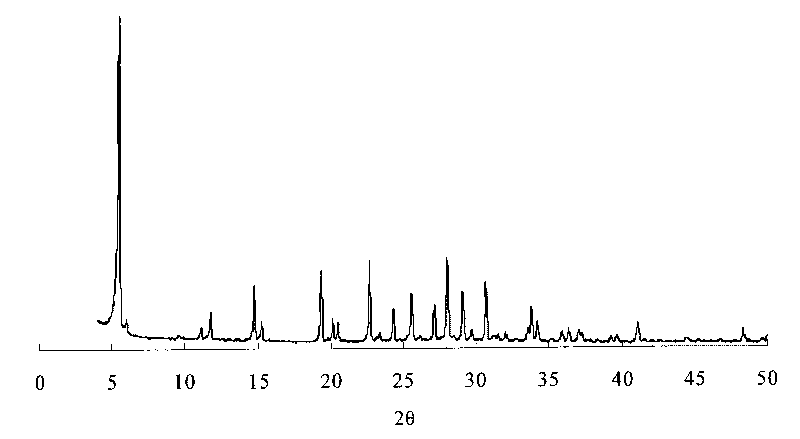

[0031] 4.35gAl(OH) 3 Add to 50mL solution containing 12.9gKOH, heat and dissolve to obtain aluminum sol, 1.94gSnCl 4 ·5H 2 O was dissolved in 20mL of distilled water, and then mixed with aluminum sol to form a mixed solution. The mixed solution was added to 78.3mL of silica sol under stirring, and stirred for 0.5 hours to form a white gel. The molar composition was: 0.1SnO 2 1.7K 2 O·Al 2 o 3 8.47SiO2 2 136H 2 O. Move the above white gel into the reaction kettle for crystallization at 150°C for 3 days, then rapidly cool to 40°C, the product is centrifuged and washed until the pH value of the liquid phase is 10-11, and the obtained solid is dried at 120°C for 10 hours to obtain Tin L molecular sieve raw powder SL-1, its X-ray powder diffraction analysis spectrum is shown in figure 1 , the relative crystallinity is 112%, and the anhydrous chemical composition (based on oxide molar ratio) is:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com