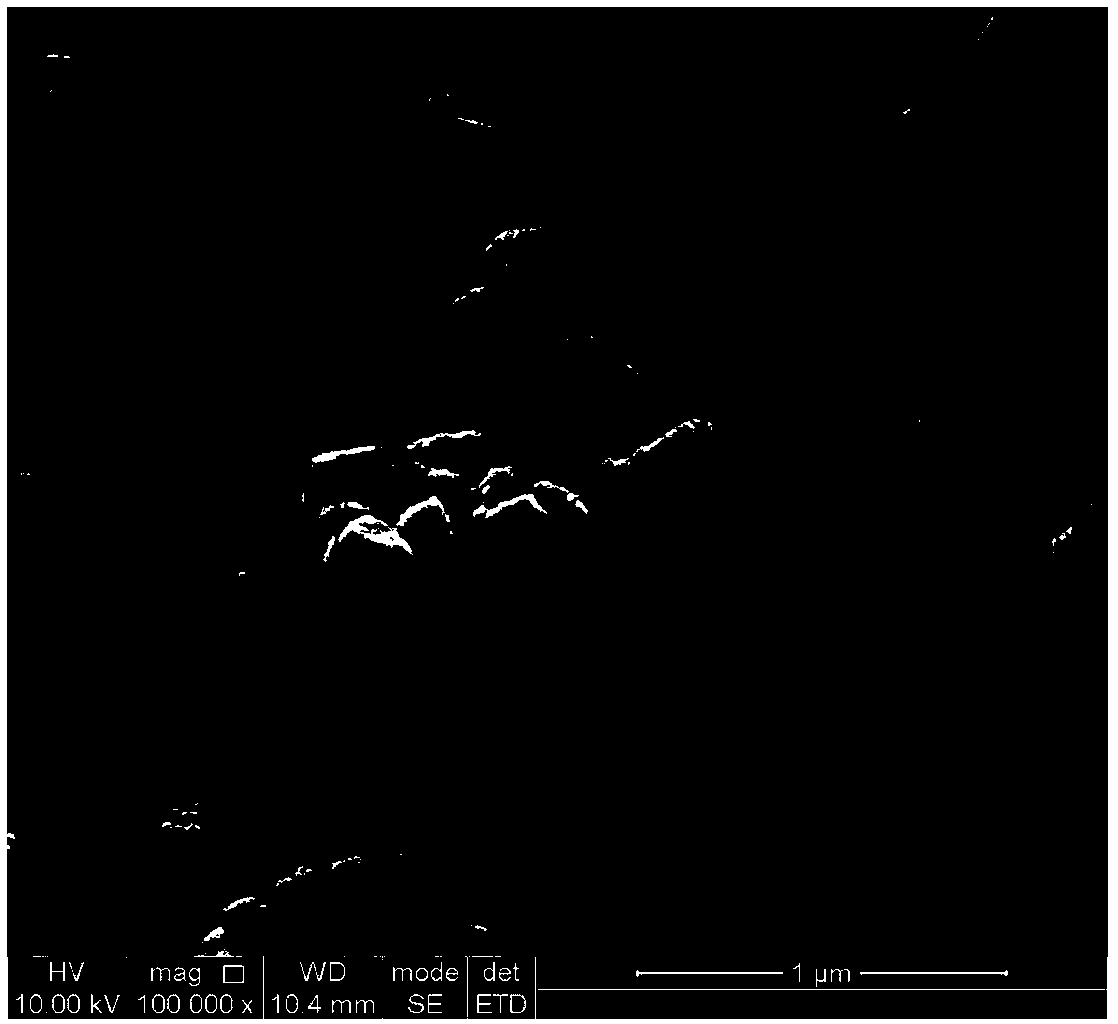

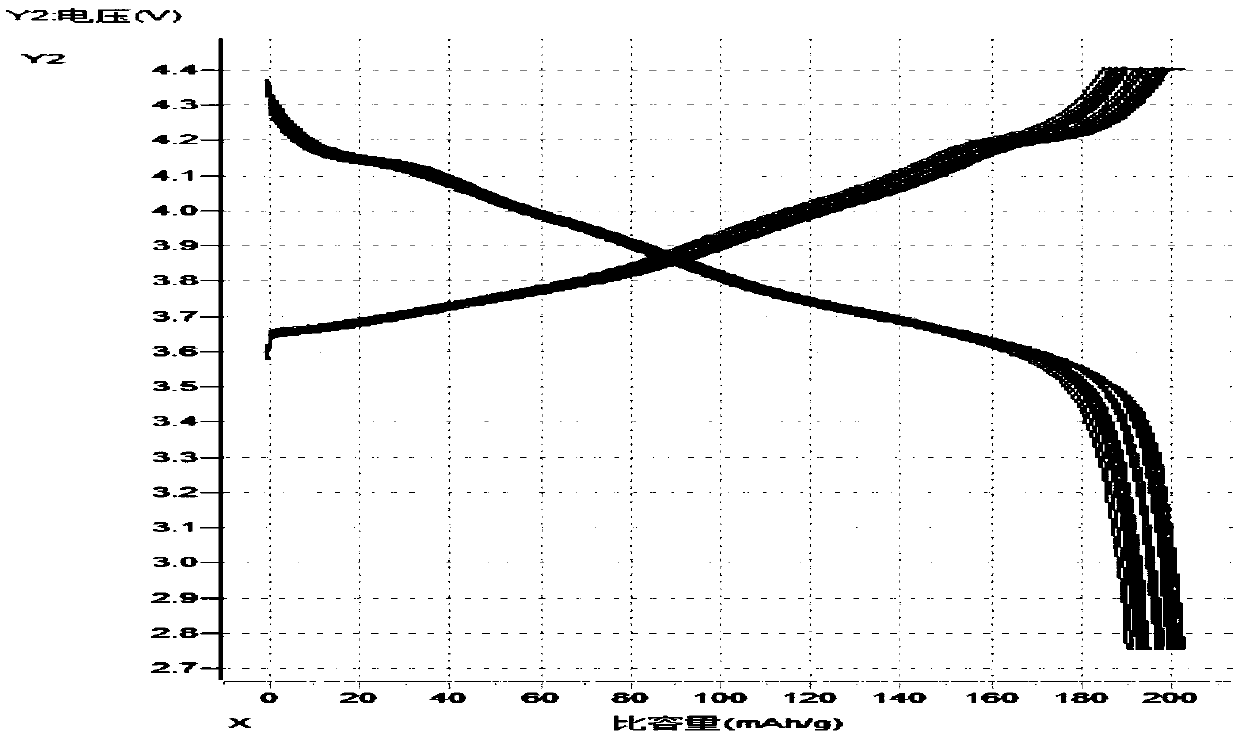

Cobalt-free lithium-rich ternary anode material NMA and preparation method thereof

A cathode material, lithium-rich technology, applied in the field of lithium-ion battery material preparation, can solve the problems of hindering Li ion extraction and intercalation activity, reducing the cycle stability of cathode materials, capacity and cycle stability, etc., to reduce heavy metal ion pollution , Improve capacity and stability, the effect of small density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing cobalt-free lithium-rich ternary positive electrode material NMA as claimed in claim 1, comprising the steps of:

[0038] 1) The soluble nickel salt, manganese salt, aluminum salt, cerium salt, titanium salt, zirconium salt, magnesium salt, the corresponding stoichiometry of the required components determined according to the precursor chemical formula of the cobalt-free lithium-rich ternary positive electrode material NMA Proportional mixing; adding deionized water to obtain a metal salt solution; that is, according to the chemical formula of the cobalt-free lithium-rich ternary cathode material NMA is Li 1+P Ni 1-x-y-z mn x al y m z o 2 , the chemical formula of the precursor is Ni 1-x-y-z mn x al y m z (OH) 2 , where: 0.033+ 、Ti 4+ 、Zr 4+ , Mg 2+ One or more than two kinds of specific target precursors that need to be produced and prepared are selected, and the specific values of X, Y, and Z are determined. Ce 3+ 、Ti 4+ 、Zr 4+ ...

Embodiment 1

[0053] Take 462.6g of battery-grade nickel sulfate hexahydrate, 30.4g of battery-grade manganese sulfate monohydrate, 20g of battery-grade aluminum sulfate octadecahydrate, 1.1g of analytically pure zirconium sulfate, add deionized water, and prepare a 1L solution, which is converted into nickel sulfate , manganese sulfate, aluminum sulfate mixed aqueous solution, the total metal ion concentration is 2mol / l, this is solution A; get analytically pure sodium hydroxide 161.6g, add deionized water, be mixed with the solution of 1L, convert to the concentration of sodium hydroxide is 4mol / l, this is solution B. Use 3L reactor to get bottom water (deionized water) 450ml, A, B solution are pumped into 3L reactor simultaneously and carry out co-precipitation reaction, reaction conditions are: Stirring intensity: Medium, feed time 30min, reaction time 2h, aging The reaction time is 60min, and the reaction temperature is 60°C. Vacuum filter while hot, take out the filter cake, add 1L o...

Embodiment 2

[0055] Take 461.6g of battery-grade nickel sulfate hexahydrate, 30.1g of battery-grade manganese sulfate monohydrate, 20g of battery-grade aluminum sulfate octadecahydrate, 0.7g of analytically pure zirconium sulfate, 1.0g of analytically pure titanium sulfate, add deionized water, and prepare 1L The solution, converted to the total metal ion concentration in the mixed aqueous solution of nickel sulfate, manganese sulfate, aluminum sulfate, and zirconium sulfate, is 2mol / l, which is solution A; take 161.6g of analytically pure sodium hydroxide, add deionized water, and prepare 1L solution, converted to a sodium hydroxide concentration of 4mol / l, this is solution B. The solutions A and B are simultaneously pumped into a 3L reactor for co-precipitation reaction. The reaction conditions are: stirring intensity: medium, feeding time 30min, reaction time 2h, aging time 60min, reaction temperature 60°C. Vacuum filter while hot, take out the filter cake, add 1L of deionized water, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com