Fischer-Tropsch synthesis catalyst, its preparation method and application thereof

A Fischer-Tropsch synthesis and catalyst technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve problems not involved in catalyst applications, etc., and achieve improved activity stability, increased selectivity, The effect of improving the selectivity of light olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

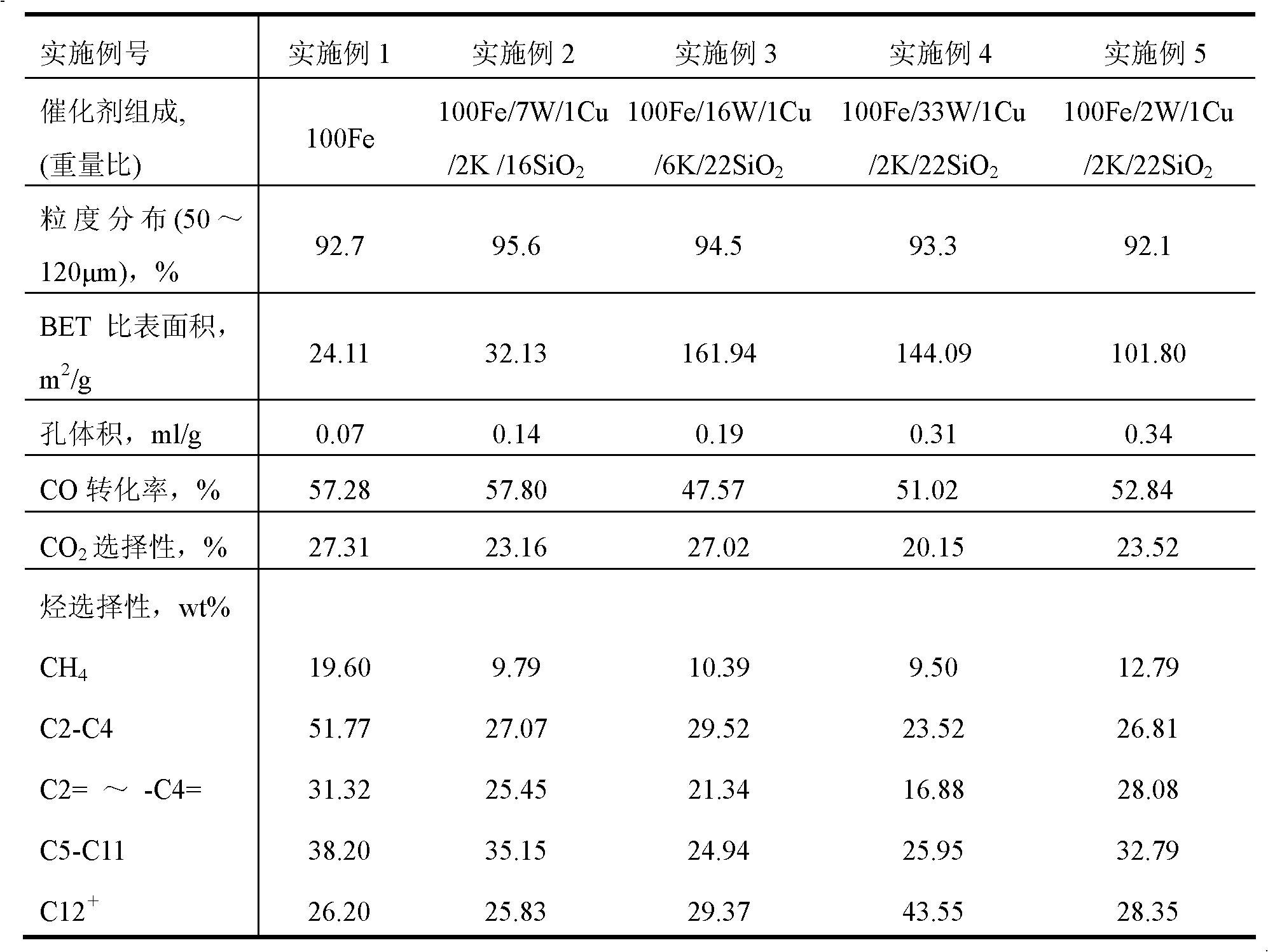

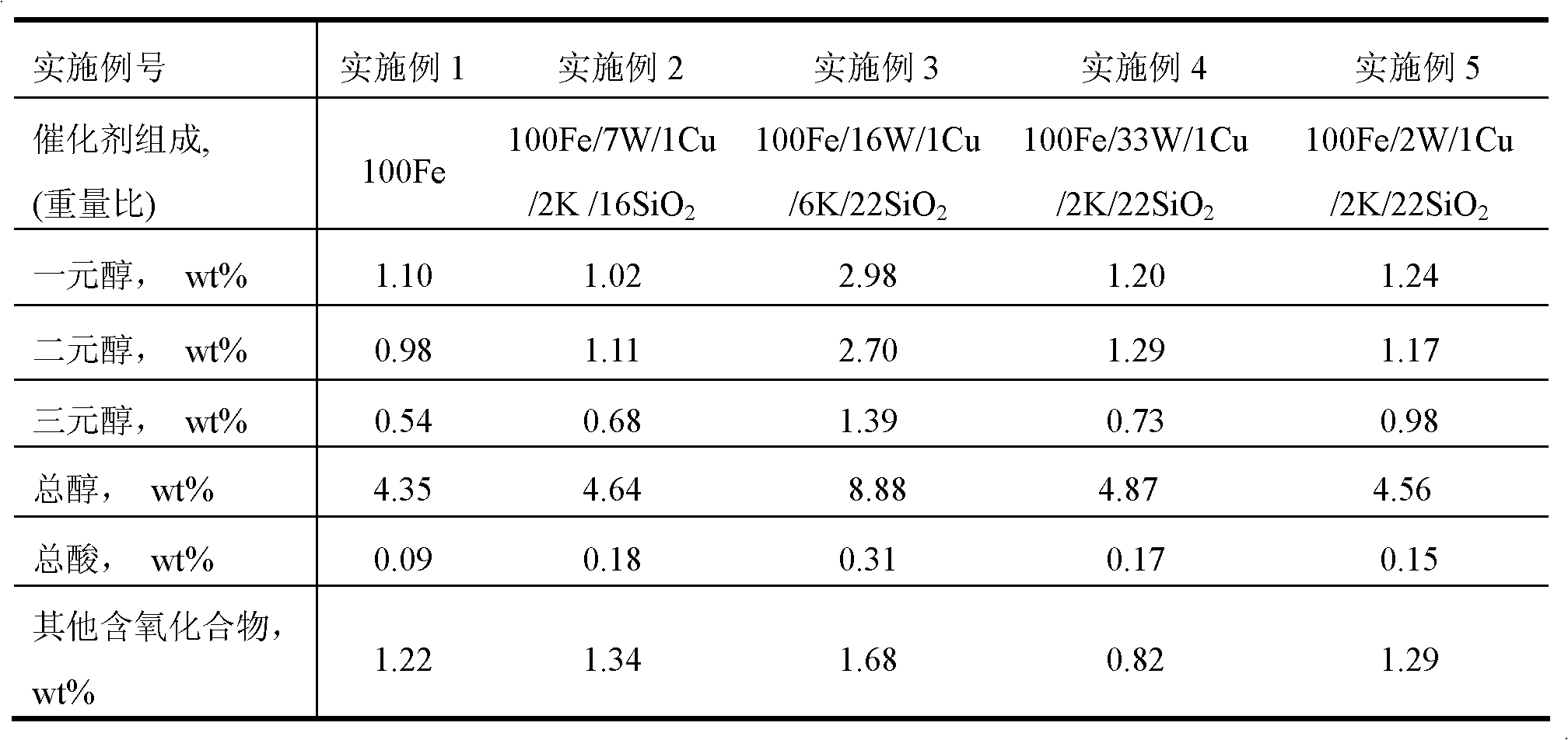

Examples

Embodiment 1

[0062] Take 1000 ml of 1M ferric nitrate solution (56 g of iron) and preheat to 80°C. Take a sufficient amount of 3M ammonia solution and preheat it to 60°C in an alkali-resistant tank. Add the nitrate solution into the continuously stirring precipitation tank and keep the temperature at 80°C, the pH value is 7.0±0.5, take a sufficient amount of 3M ammonia solution dropwise into the solution until precipitation occurs, stop adding ammonia solution and continue stirring After 3 hours, a catalyst precipitated slurry of 100 Fe was obtained. The precipitated slurry is left to stand for aging, washed, and suction filtered to obtain a precipitated filter cake. Dry the filter cake in an oven at 120°C for 24 hours, send the catalyst particles into a muffle furnace and bake at 300°C for 8 hours to obtain a shaped catalyst.

[0063] The obtained catalyst was subjected to a reaction pressure of 0.5MPa, a reaction temperature of 350°C, and a space velocity of 3000h -1 , H of syngas 2 ...

Embodiment 2

[0066] Take 1000ml of 1M ferric nitrate solution (56g iron) and 10ml of 1M copper nitrate solution (0.64g copper) and mix and preheat to 80°C. Take a sufficient amount of 3M ammonia solution and preheat it to 60°C in an alkali-resistant tank. Mix nitrate and 20ml of 1M ammonium metatungstate (3.68g tungsten) into the continuously stirring precipitation tank and keep the temperature at 80°C and the pH value of 7.0±0.5, add the ammonia solution dropwise to the stirring In the solution, until precipitation occurs, stop adding ammonia water dropwise, and continue to stir for 3 hours. The precipitated slurry is left to stand for aging, washed, and suction filtered to obtain a precipitated filter cake. The weight ratio of deionized water / filter cake is 1 / 1 deionized water, and the mass ratio is 100Fe / 16SiO 2 30wt% silica sol solution and 0.2M K with a mass ratio of 100Fe / 2K 2 CO 3 The solution is added to the filter cake, fully stirred and beaten to obtain a mass ratio of 100Fe / ...

Embodiment 3

[0070] Take 1000 ml of 1M ferric nitrate solution (56 g of iron) and preheat to 80°C. Take a sufficient amount of 3M ammonia solution and preheat it to 60°C in an alkali-resistant tank. Mix the nitrate solution and 50ml of 1M ammonium metatungstate (9.19g tungsten) into the continuously stirring precipitation tank, keep the temperature at 80°C, and the pH value is 7.0±0.5, add the ammonia solution drop by drop until Precipitation occurs, the dropwise addition of ammonia water is stopped, and stirring is continued for 3 hours to obtain a catalyst precipitation slurry having a tungsten / iron mass ratio of 16.4W / 100Fe. The precipitated slurry is left to stand for aging, washed, and suction filtered to obtain a precipitated filter cake. Deionized water with a weight ratio of deionized water / filter cake of 1 / 1, a 0.2M potassium silicate solution with a mass ratio of 5.6K / 100Fe and a mass ratio of 16.1SiO 2 The 30Wt% silica sol solution of / 100Fe is added to the filter cake, fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com