Method for increase production of BTX (benzene, toluene and xylol) aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

A technology of BTX aromatics and hydrocracking, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of low added value of heavy aromatics and high cost of trimethylbenzene monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

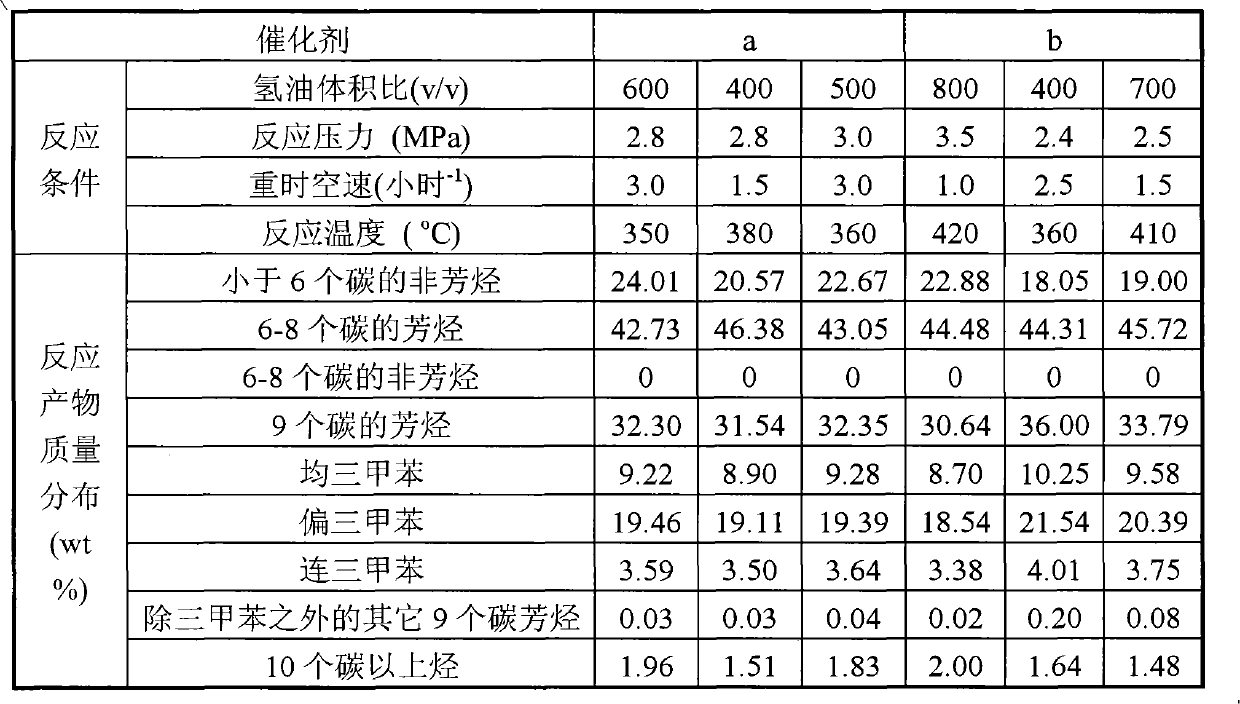

Embodiment 1~2

[0015] Binder-free ZSM-5 zeolite (SiO 2 / Al 2 o 3The molar ratio is 60) prepared with reference to Chinese patent CN100384735C, the prepared binderless ZSM-5 zeolite crushing strength is greater than 75N / particle, the weight content of ZSM-5 zeolite is 98.5%, the product is ion-exchanged with ammonium nitrate solution, and after exchange Carry out roasting and transform into hydrogen-type zeolite. On the hydrogen-type binderless ZSM-5 zeolite, impregnate 0.05% Pt and 0.25% Zn by weight, and calcinate at 450°C for 4 hours to obtain catalyst a; on the hydrogen-type binderless ZSM-5 zeolite Catalyst b was obtained by impregnating 0.3% of Pd and 0.05% of Pb in weight ratio, and calcining at 450° C. for 4 hours. Reduction-activated a and b catalysts were used for reaction evaluation, and the composition of the heavy aromatics reaction raw materials used was aromatics with 6-8 carbons in weight percent: 1.79%; mesitylene: 12.15%; trimitylene: 38.35%; Pythylene: 3.95%; other 9 ca...

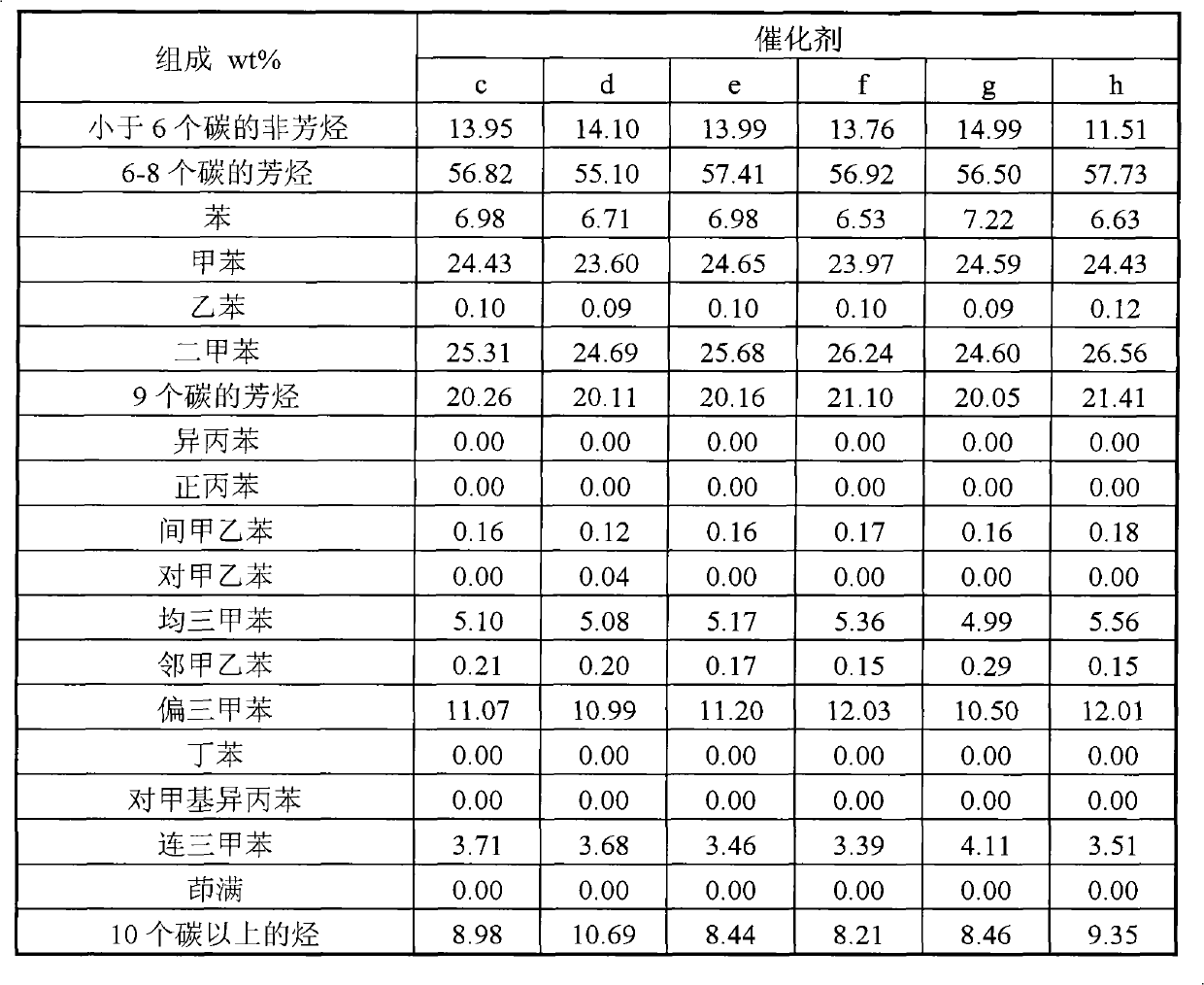

Embodiment 3~5

[0017] Binder-free ZSM-5 zeolite (SiO 2 / Al 2 o 3 The molar ratio is 20) prepared with reference to Chinese patent CN100384735C, the prepared binderless ZSM-5 zeolite has a crushing strength greater than 65N / particle, and the weight content of ZSM-5 zeolite is 99.6%. The product is ion-exchanged with ammonium nitrate solution, and after the exchange Carry out roasting and transform into hydrogen-type zeolite. On the hydrogen-type binderless ZSM-5 zeolite, impregnate 0.005% of Pt and 0.01% of Sn by weight, and calcined at 450°C for 4 hours to obtain catalyst c; on the hydrogen-type binderless ZSM-5 zeolite Impregnate 0.5% of Pd, 0.01% of Zn and 1.0% of La by weight, and calcinate at 450°C for 4 hours to obtain catalyst d; impregnate 0.03% by weight of hydrogen-type binder-free ZSM-5 zeolite Pt, 0.02% Bi and 0.2% Sn were calcined at 450° C. for 4 hours to obtain catalyst e. Reduction-activated c, d, e catalysts were used for reaction evaluation, and reduction-activated c-e c...

Embodiment 6~7

[0019] Binder-free ZSM-11 zeolite (SiO 2 / Al 2 o 3 The molar ratio is 45) prepared with reference to Chinese patent CN101348261A, the prepared binderless ZSM-11 zeolite crushing strength is greater than 80N / particle, the weight content of ZSM-11 zeolite is 97.9%, the product is ion-exchanged with ammonium nitrate solution, after exchange Carry out roasting and transform into hydrogen-type zeolite. On the hydrogen-type binderless ZSM-11 zeolite, impregnate 0.06% of Pt and 0.2% of Zn by weight, and calcinate at 450°C for 4 hours to obtain catalyst f; on the hydrogen-type binderless ZSM-11 zeolite Catalyst g was obtained by impregnating 0.2% Pt and 0.20% Bi by weight and calcining at 450° C. for 4 hours. Use reduction-activated f, g catalyst to carry out reaction assessment, the heavy aromatics reaction raw material composition and reaction conditions that adopt are the same as embodiment 3, reaction conditions and reaction result are listed in table 2, can find out from table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com