Patents

Literature

80results about How to "High acid density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing light aromatics and light paraffins using hydrocarbons as raw materials

ActiveCN101347742AHigh acid densityUnobstructed orificeOrganic chemistryMolecular sieve catalystsAbsorption capacityPARAFFIN HYDROCARBONS

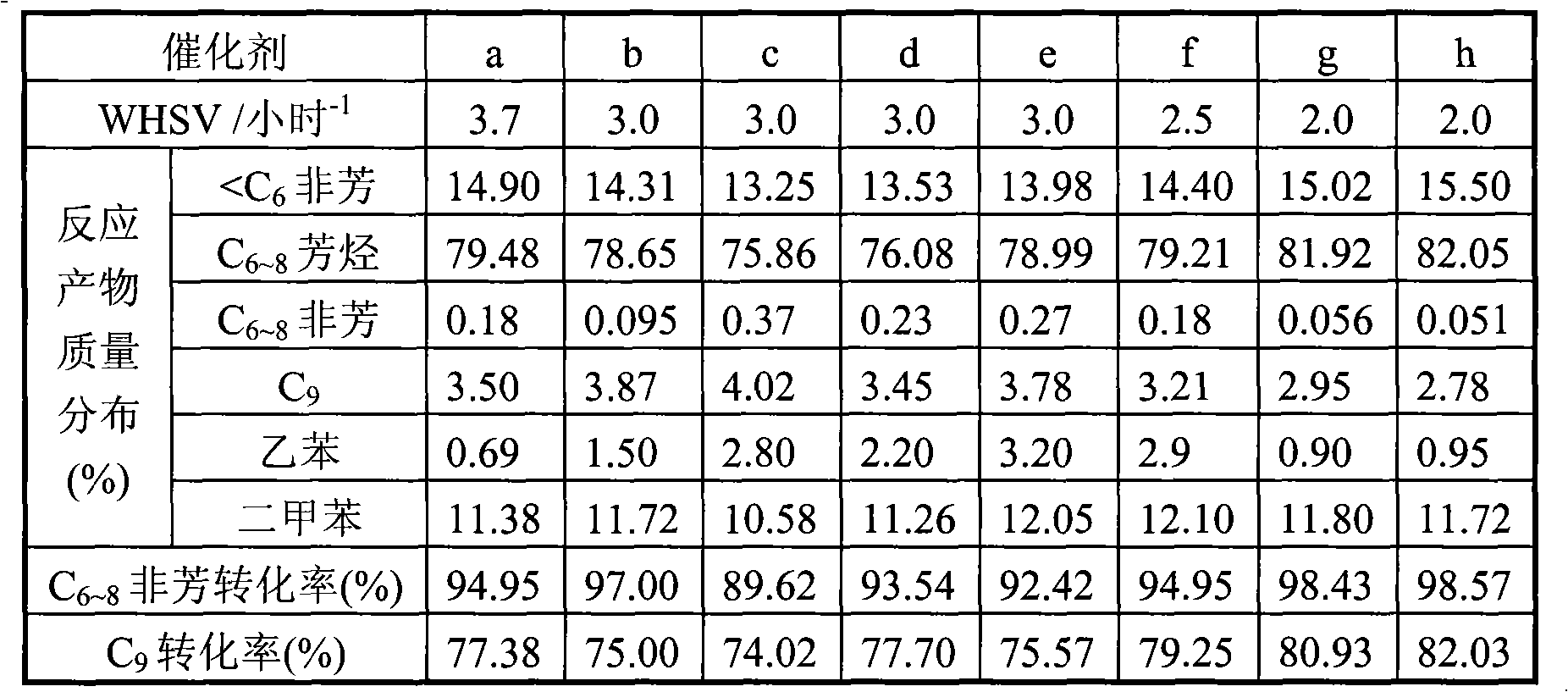

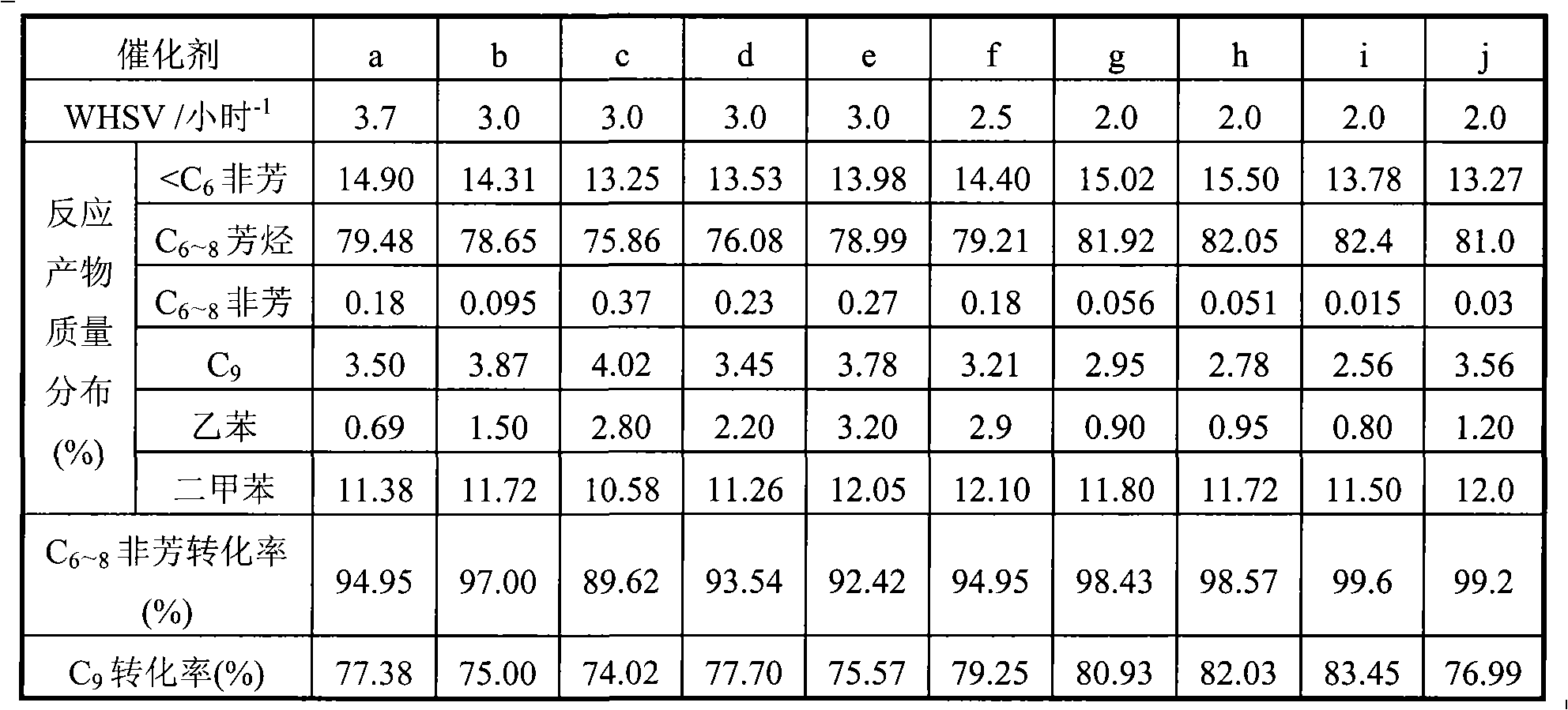

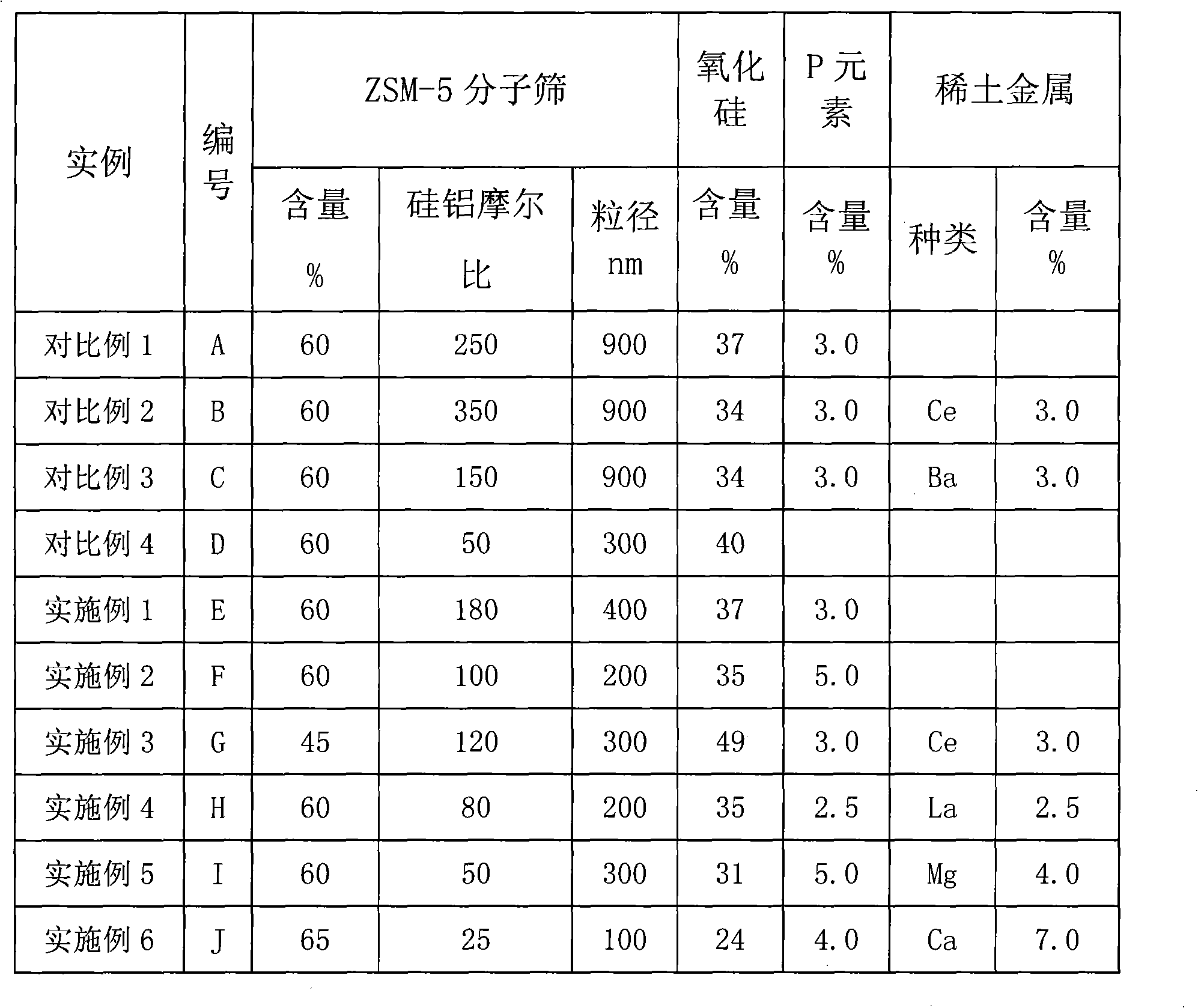

The invention relates to a catalyst for preparing light aromatic hydrocarbons and light paraffin hydrocarbons by using hydrocarbon raw materials, and the catalyst is mainly used for solving the technical problems that a binding agent in a bifunctional catalyst which is prepared by using a zeolite carrier containing the binding agent of the prior art can reduce the content of effective components, cause the decrease of the absorption capacity, reduce the effective surface area and further cause lower activity and poorer stability. The catalyst comprises the following components counted by the percentage by weight: a) 0.01 to 0.8 percent of at least one of Pt or Pd; b) and the rest of at least one of binding agent-free mordenite, Beta zeolite, Y zeolite, ZSM-5 or ZSM-11, thereby preparing the bifunctional catalyst; therefore, the technical proposal can better solve the problems and can be used in the industrial production for the preparation of the light aromatic hydrocarbons and the light paraffin hydrocarbons by using the hydrocarbon raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

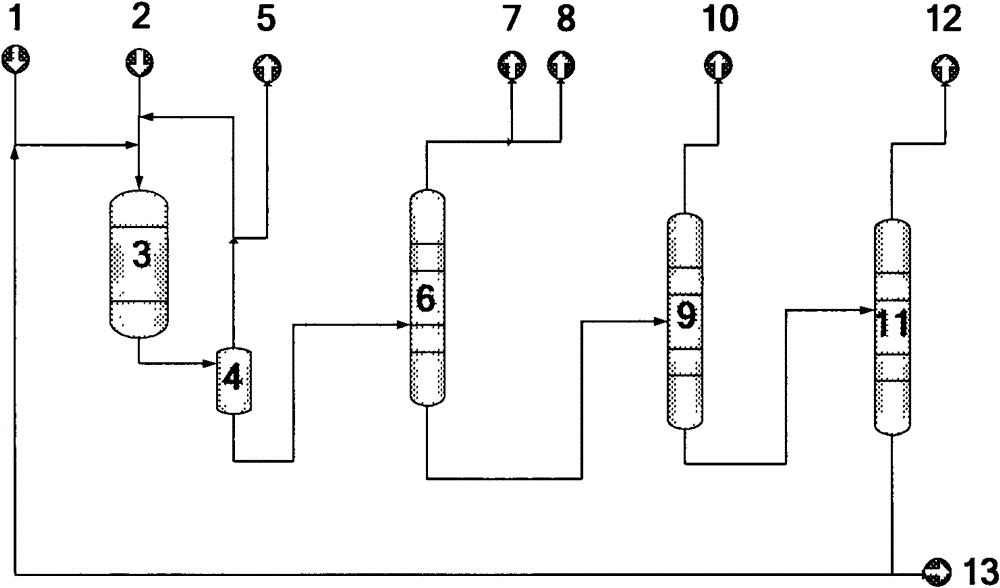

Method for producing light arene and light alkane from hydrocarbon raw material

ActiveCN101348733AHigh acid densityUnobstructed orificeTreatment with hydrotreatment processesSolventBoiling point

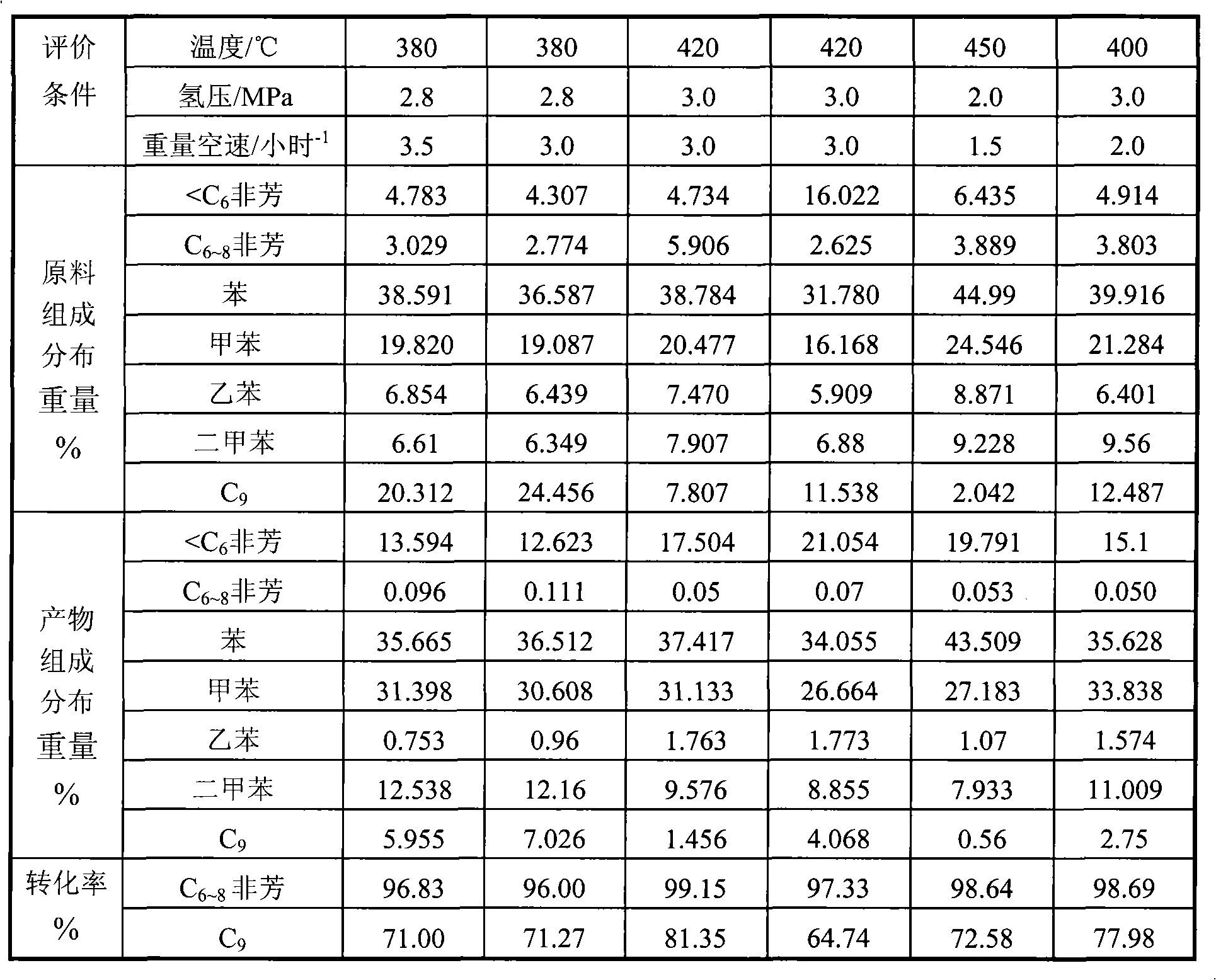

The invention relates to a method for producing lightweight arene and lightweight alkane by utilizing a hydrocarbon material, which mainly solves the technical problems that the hydrocarbon material needs a solvent for extraction in the prior separation process and has the complex process and high cost; and heavyweight arene and the separated non-arene have low utilization value. The method comprises the following technical proposal: in the presence of a zeolite catalyst containing Pt or Pd, the hydrocarbon material with a boiling point of between 30 and 250 DEG C is adopted; the heavyweight arene in the hydrocarbon material has transalkylation reaction with the lightweight arene by hydrodealkylation groups; the lightweight arene is subjected to isomerization reaction and transformed into a component abundantly containing BTX(B is benzene, T is toluene and X is xylene) lightweight arene; non-arene has hydrocracking reaction to generate lightweight alkane ; in a distillation tower, according to different boiling points, liquid phase products can be respectively separated into benzene, toluene, xylene and C9<+> arene; and the lightweight arene can be separated from gas phase products, thereby well solving the problems and being used in the industrial production of the lightweight arene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing light arene and light alkane from hydrocarbon raw material

ActiveCN101348405AHigh acid densityUnobstructed orificeMolecular sieve catalystsHydrocarbon oil crackingSolventTransalkylation

The invention relates to a method for preparing light arene and light alkane by hydrocarbon raw materials, mainly solving the technical problems in the prior art that heavy arene and non-aromatic hydrocarbons have low utilization value and solvent extraction needs to be carried out for separating BTX (B is benzene, T is toluene and X is xylene) arene. Through taking reformate, cracked gasoline, a mixture containing C9<+> (C9 and more than C9) arene, naphtha and a mixture of the substances as raw materials and carrying out hydrogenation lightening treatment, the method ensures that heavy arene undergoes dealkylation reaction and transalkylation reaction and light arene undergoes isomerization reaction, and the like so as to be converted into a composition rich in BTX light arene; moreover, an adopted catalyst comprises at least one of Pt or Pd and at least one of mordenite, Beta-zeolite, Y zeolite, ZSM-5 zeolite or ZSM-11 zeolite, and the technical proposal solves the technical problems better, and can be used in the industrial production for arene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746092AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionHydrogenBoiling point

The invention relates to a method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low added value of the heavy aromatic hydrocarbons, and complex flow, low product purity, low yield and the like in separation of 1,3,5-trimethylbenzene monomers from the heavy aromatic hydrocarbons. According to the method, hydrogen type binder-free ten-membered ring zeolite loading 0.005-0.5% by mass of Pt or Pd is adopted as a catalyst, hydrogen and the heavy aromatic hydrocarbons which are raw materials undergo hydrocracking treatment, and 1,2,4-trimethylbenzene and heavy aromatic hydrocarbons having boiling points greater than the boiling point of the 1,2,4-trimethylbenzene in products are returned to a reactor, so BTX aromatic hydrocarbon yield increase and 1,3,5-trimethylbenzene separation production are realized. The method well solves the problems, and can be used for the industrial production for yield increases of the BTX (benzene, toluene and xylol) aromatic hydrocarbon and the 1,3,5-trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon desulfurizer

InactiveCN1261218CHigh acid densityUniform and weak acid strengthCatalytic crackingMolecular sieve catalystsRare earthSilicon

A kind of hydrocarbon-oil desulfuration agent contains, on the catalyst-weight basis, 15-60% phosphorus-modified and rare-earth-contained Y type zeolite, 10-60% inorganic oxide, and 0-75% clay; and phosphorus-modified and rare-earth-contained Y type zeolite contains, in weight percent, 0.5-8% phosphorus in presence as P2O5 and 18-35% rare-earth in presence as RE2O3, Moreover, the proportion of silicon and aluminium in zeolite is lower than 6.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for increase production of BTX (benzene, toluene and xylol) aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746093AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionBenzeneHydrogen

The invention relates to a method for the increase production of BTX aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low heavy aromatic hydrocarbon added value and high cost for separating and producing trimethylbenzene monomers in the heavy aromatic hydrocarbons containing methylethylbenzene, propylbenzene and butylbenzene. The method comprises a step that the heavy aromatic hydrocarbons are subjected to a hydrocracking reaction through adopting Pt / Pd-loaded hydrogen type binder-free ten-membered ring zeolite as a catalyst under reaction conditions comprising that the reaction temperature is 320-450DEG C, the reaction pressure is 2.0-4.0Mpa, the hydrocarbons raw material weight hourly space velocity is 1.0-4.0h<-1> and the hydrogen / hydrocarbon raw material ratio by mole is 3-10:1. The method well solves the problems through above technical scheme, and can be applied to the industrial production of the BTX aromatic hydrocarbons and the trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

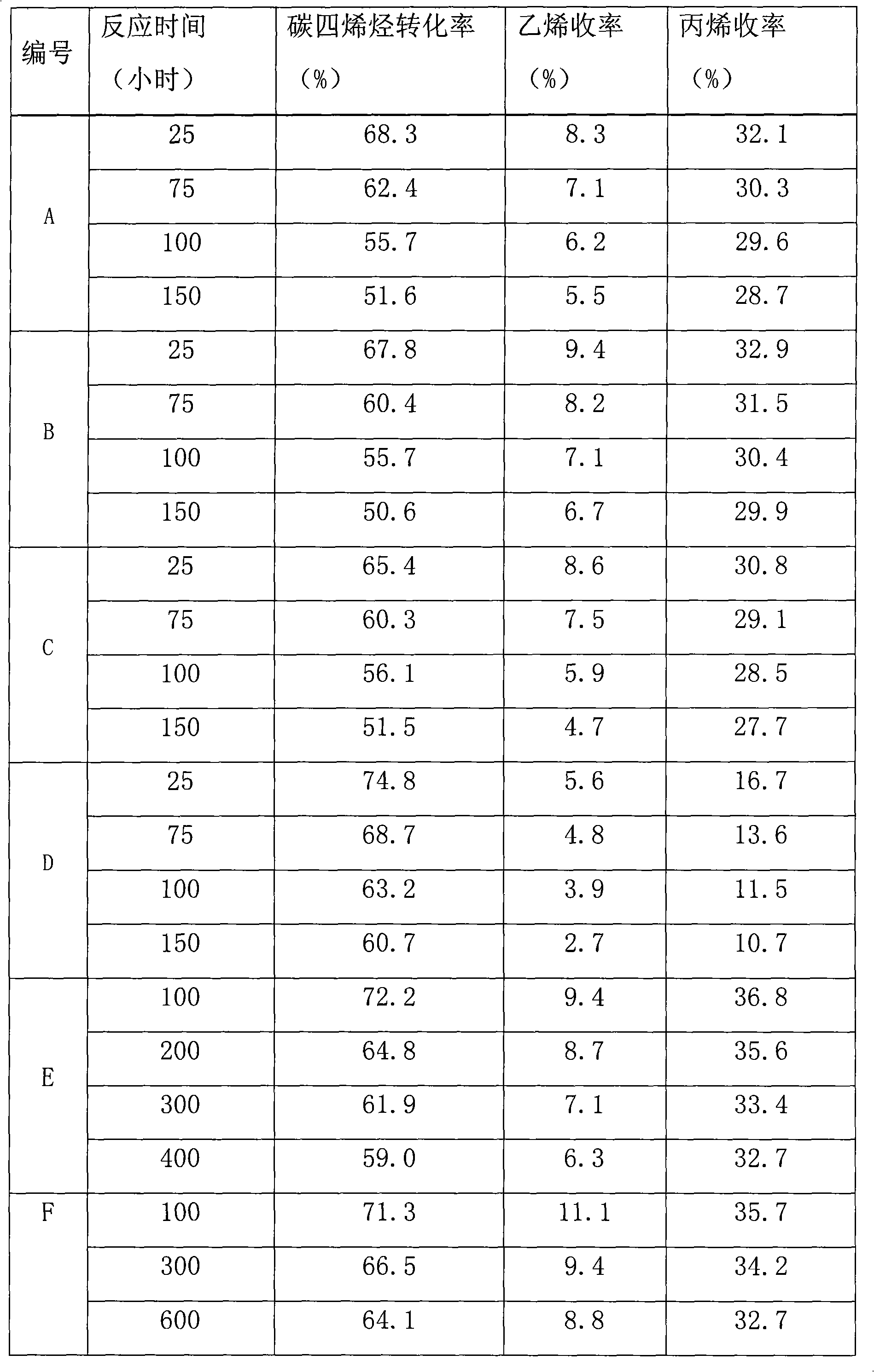

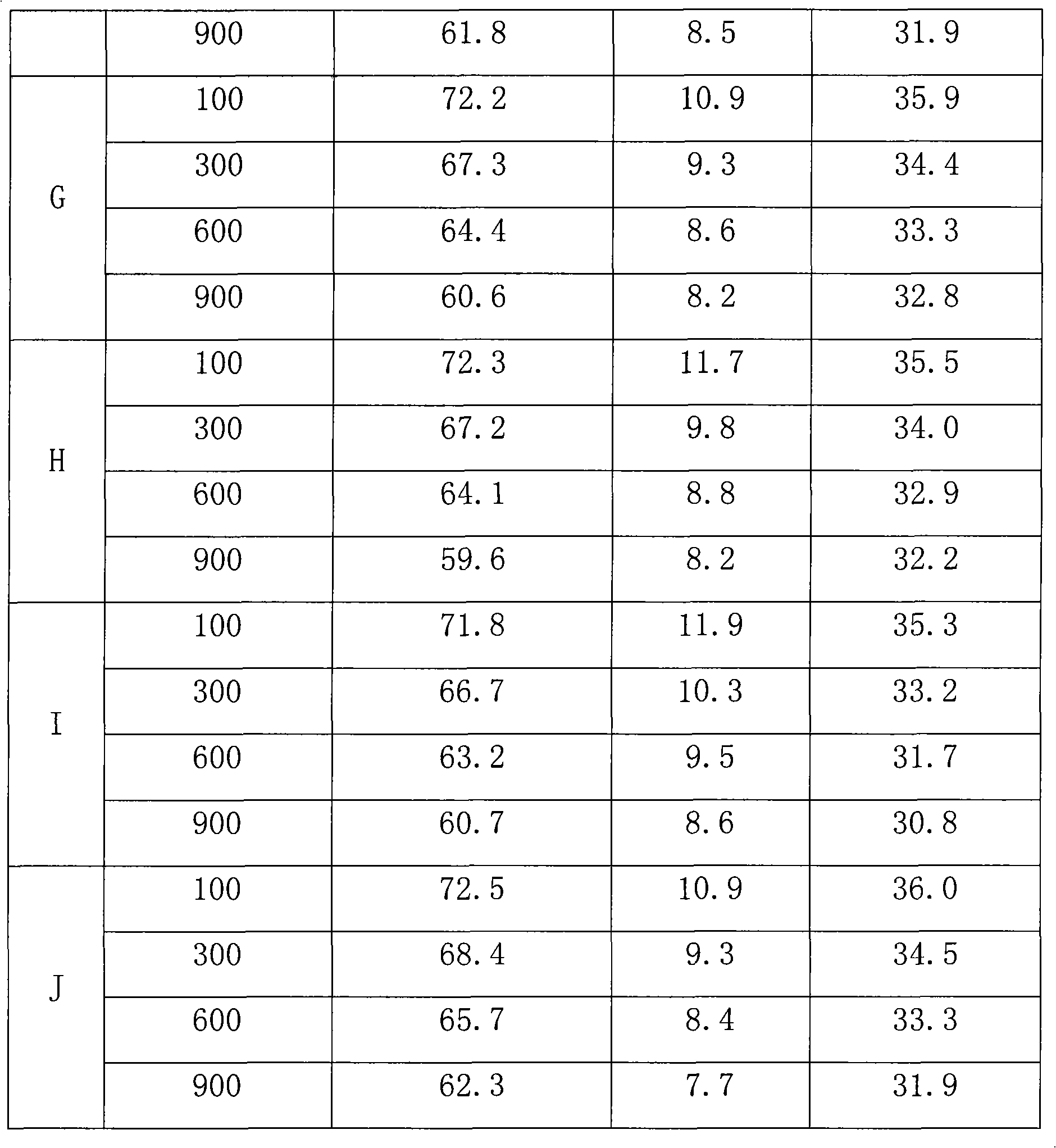

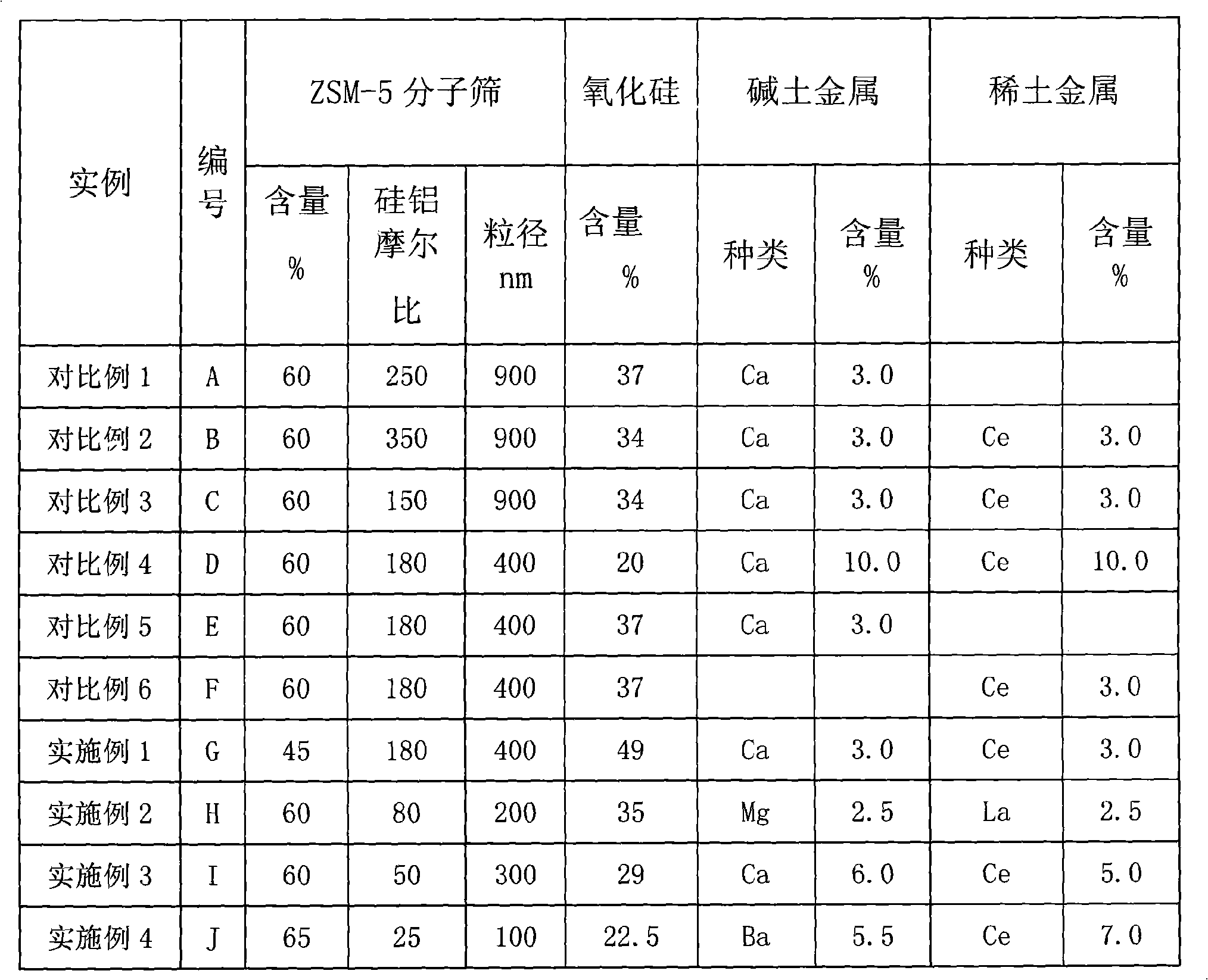

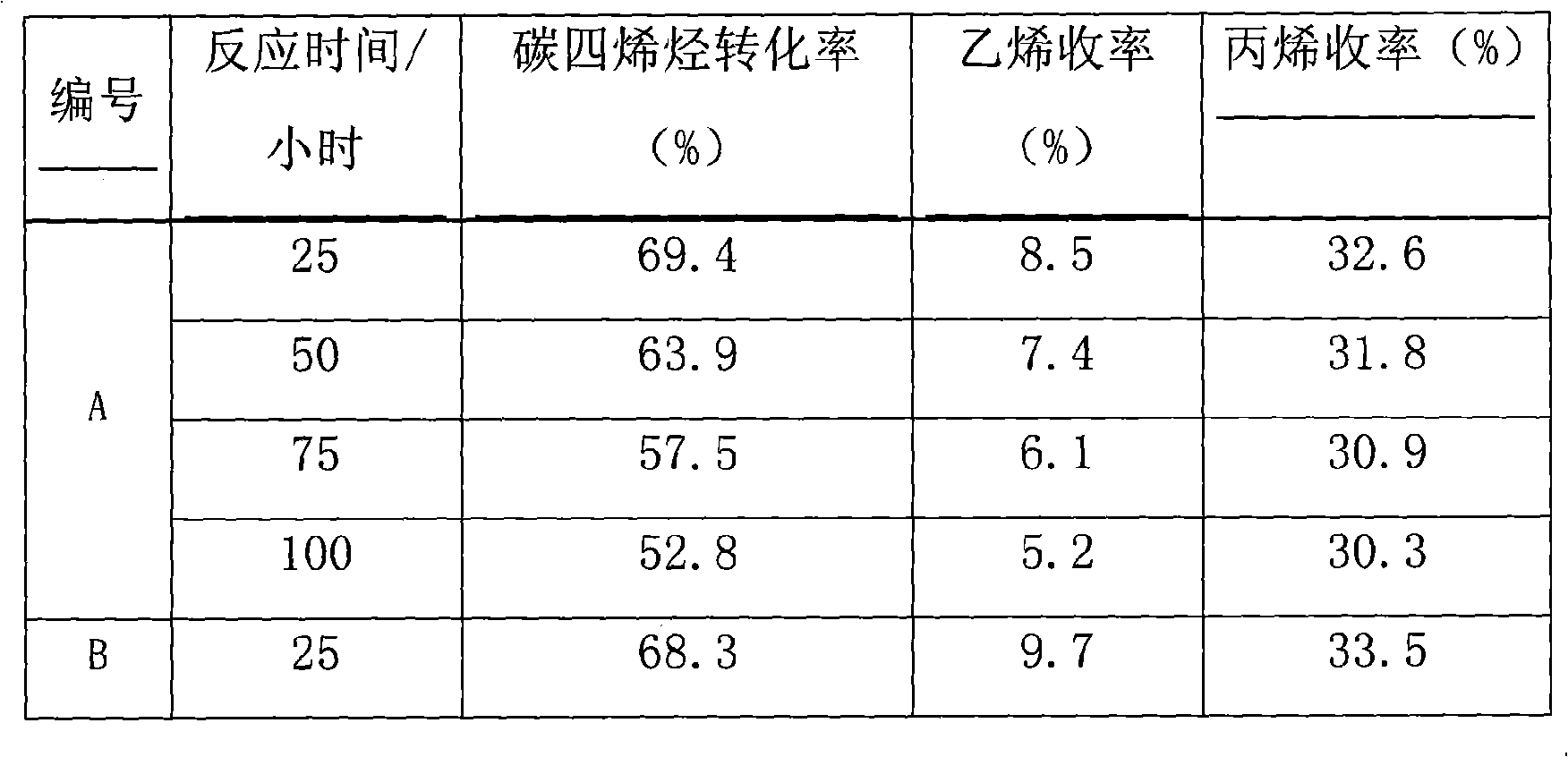

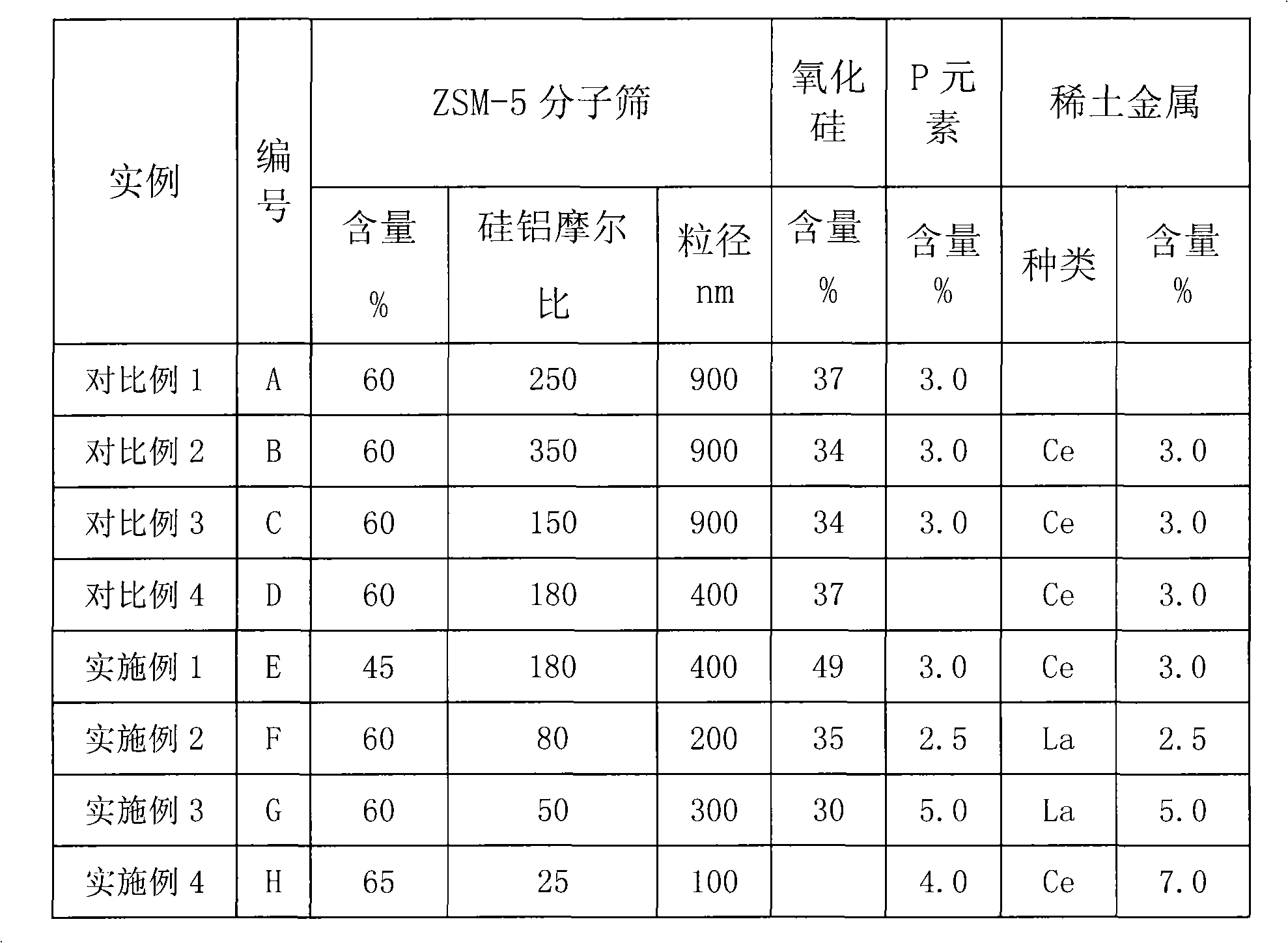

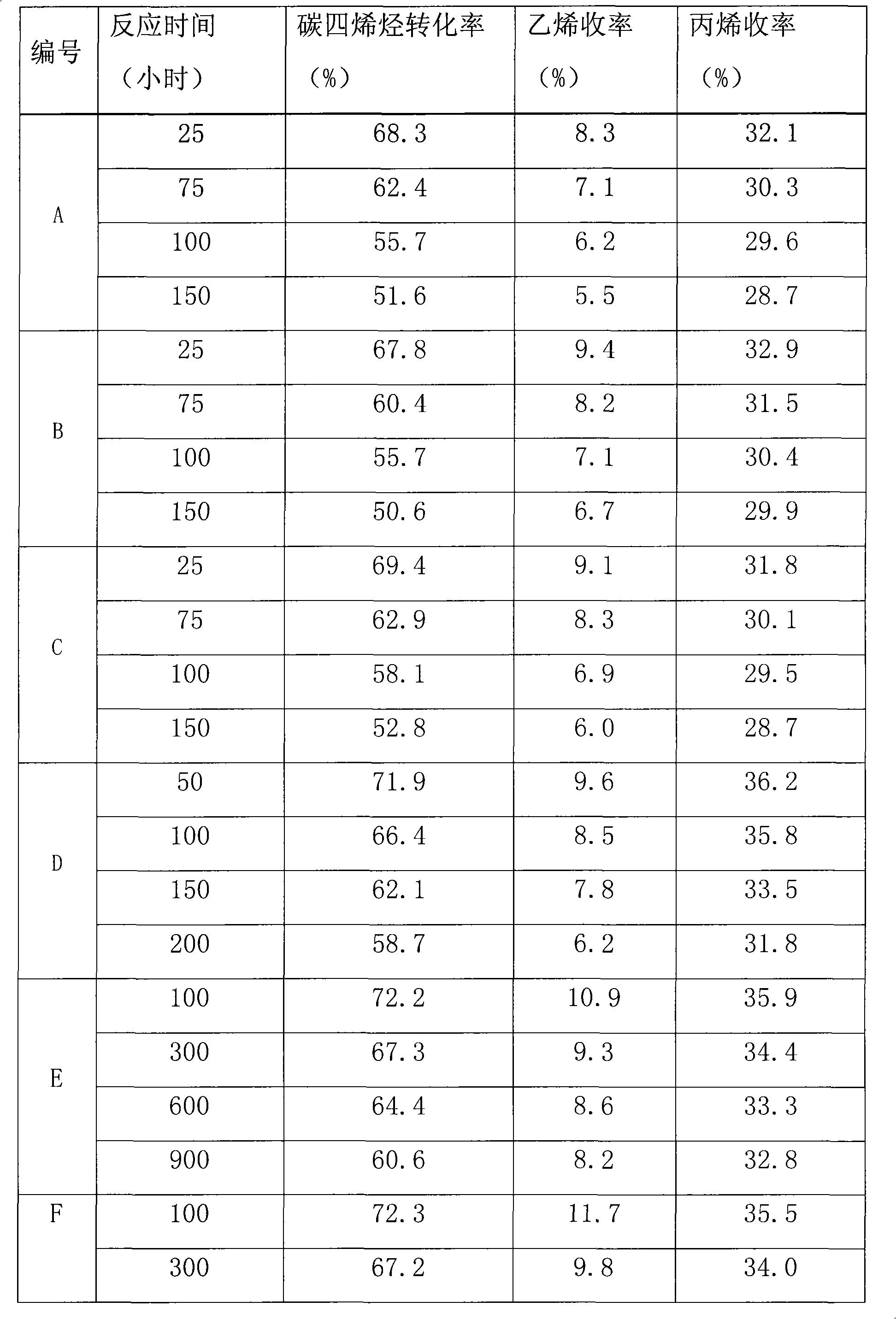

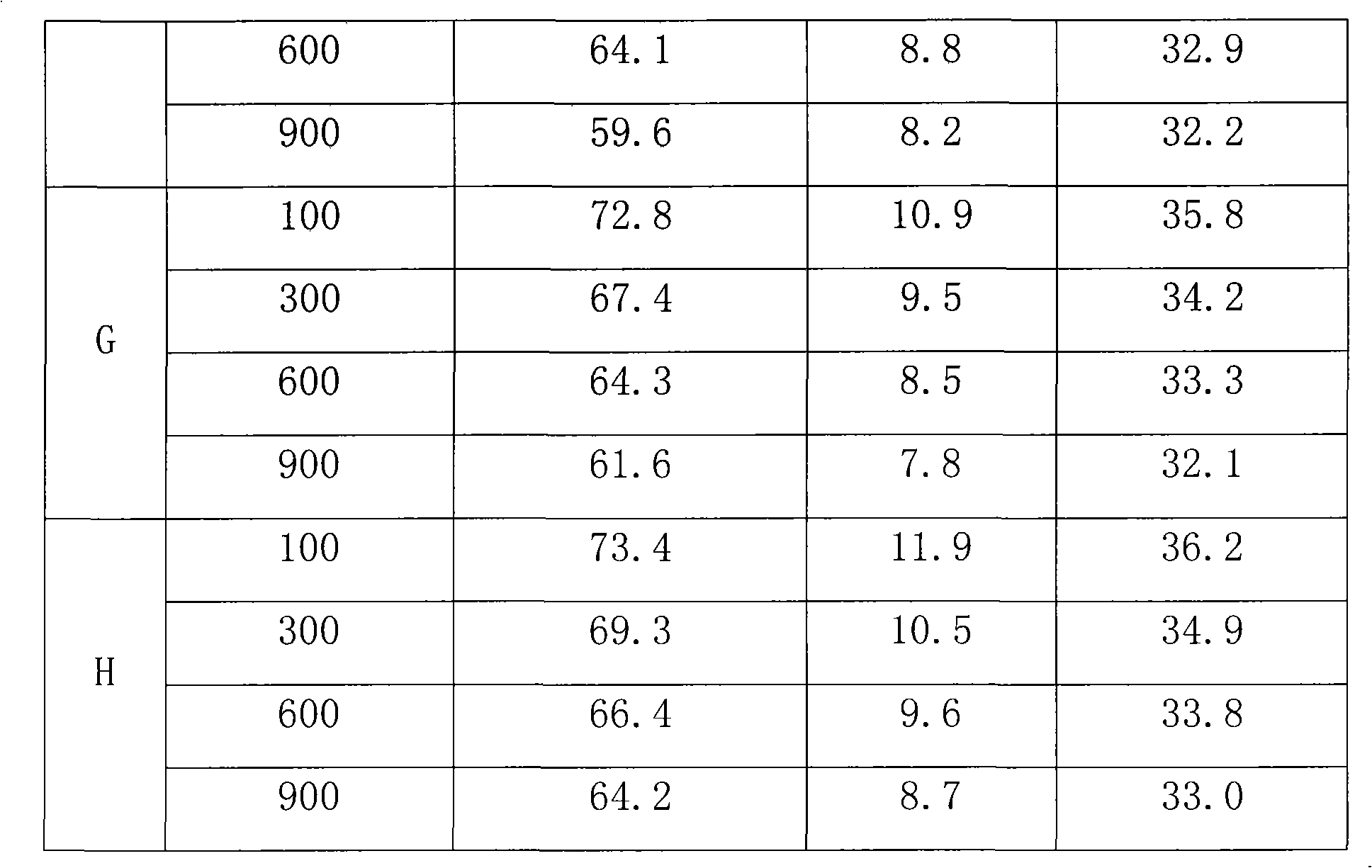

Method for producing propylene and ethylene through catalytic cracking of olefins

InactiveCN101684059AExtended service lifeMeet industrial productionCatalytic crackingMolecular sieve catalystsAdhesiveAlkane synthesis

The invention provides a novel method for producing propylene and ethylene through catalytic cracking of olefins, which comprises the steps of: taking C4-C12 olefins as raw materials; and performing acatalytic cracking reaction of the olefins on the raw materials through a catalyst bed to generate the propylene and the ethylene under the conditions that the reaction temperature is between 450 and650 DEG C, the reaction pressure is between 0 and 0.3MPa, the weight space velocity of the olefins is between 1 and 14 h<-1>, and the weight ratio of water to the olefins is 0.1-10, wherein a catalyst comprises a ZSM-5 molecular sieve, an adhesive and a phosphorus element supported on the catalyst, the silicon-aluminum molar ratio SiO2 / Al2O3 of the ZSM-5 molecular sieve is 10-300, and the grain diameter of crystal grains of the ZSM-5 molecular sieve is between 10 and 800nm. The method has longer reaction operation time while maintaining the high yield of the propylene and the ethylene, and can be used for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for olefin catalytic cracking to produce propylene and ethylene and application thereof

ActiveCN101584991AApplicable operating processMole lowMolecular sieve catalystsBulk chemical productionAlkaline earth metalReaction temperature

The invention discloses a catalyst for olefin catalytic cracking to produce propylene and ethylene and an application method thereof. The catalyst comprises a ZSM-5 molecular sieve of which the silicon aluminum molar ratio of SiO2 / Al2O3 is 10 to 300 and the crystal grain diameter is 10 to 800 nanometers, and rare earth and alkaline-earth metal elements loaded thereon. The catalyst is applied to a process for performing olefin catalytic cracking reaction through a catalyst bed to produce the propylene and the ethylene by using C4-C12 olefin as a raw material under the conditions of reaction temperature of 450 to 650 DEG C, reaction pressure of 0 to 0.3 MPa, the weight space velocity of hydrocarbon materials of 1 to 14 h and the weight ratio of water / hydrocarbon materials of 0.1 to 10. The catalyst provided by the invention can keep high propylene and ethylene yield, has longer reaction operation time at the same time, and can be used for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

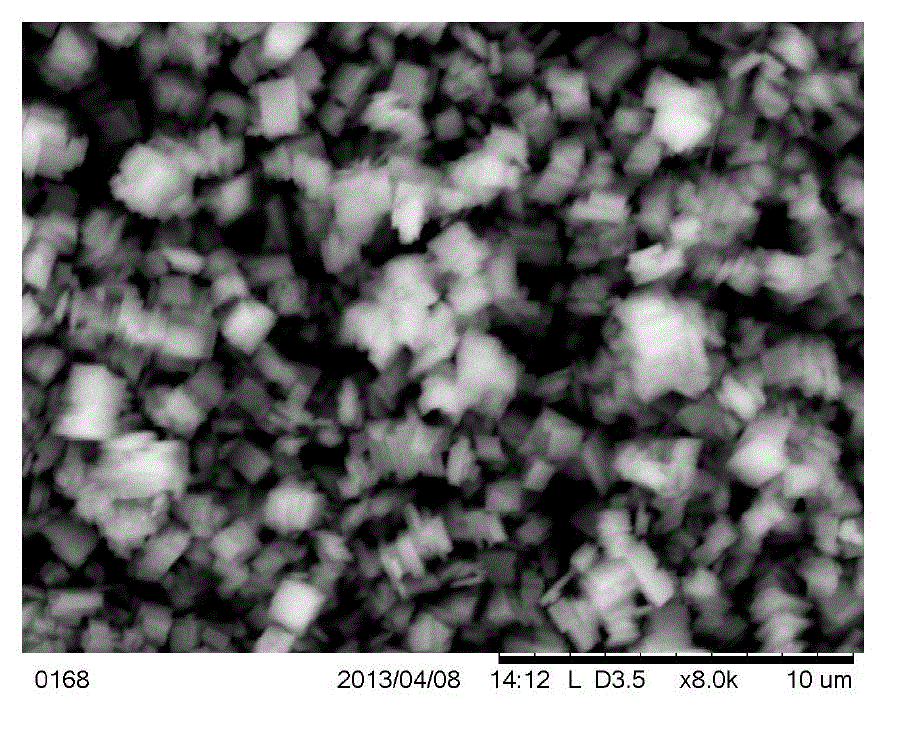

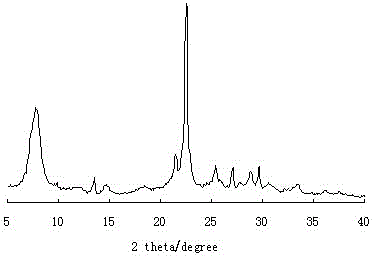

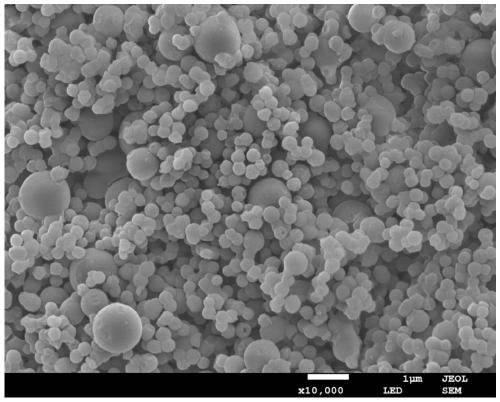

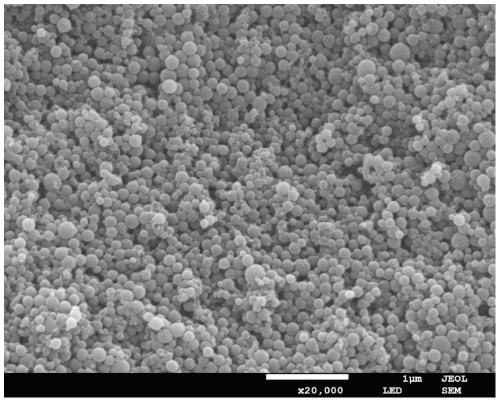

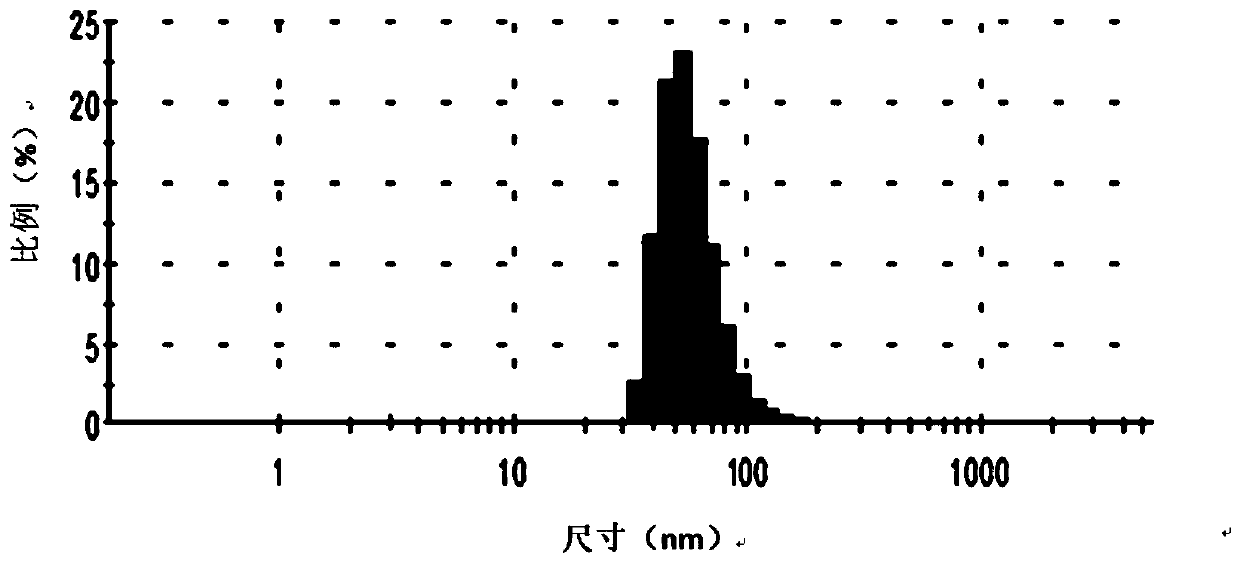

Preparation method of small-crystal-grain SAPO-34 molecular sieve

InactiveCN103332702ALarge specific surface areaSmall grain sizeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveRoom temperature

The invention relates to a preparation method of a small-crystal-grain SAPO-34 molecular sieve. A gel formed by an aluminum source, a phosphorus source, a silicon source, a solvent and a template is subjected to aging before crystallization, wherein the aging temperature is 1-14 DEG C, and the aging time is 30 minutes to 50 hours. The SAPO-34 molecular sieve prepared by aging has the characteristics of higher specific area, small grain size and uniform dispersion, and the average grain size is less than 2 mu m. The acid density of the product obtained by the special aging step is higher than that of the product which is not subjected to aging or subjected to room-temperature aging. The molecular sieve has excellent catalytic effect relative to the unaged product in MTO catalytic reaction.

Owner:天津众智科技有限公司

Catalyst for olefin catalytic cracking to produce propylene and ethylene and application thereof

InactiveCN101590421AApplicable operating processMole lowMolecular sieve catalystsBulk chemical productionRare earthReaction temperature

The invention provides a novel catalyst for olefin catalytic cracking to produce propylene and ethylene and a use method thereof. The catalyst comprises ZSM-5 molecular sieve in which the silicon aluminium mole ratio SiO2 / Al2O3 is 10-300 and the grain size is 10-800nm, and phosphorus element and rare earth metal elements which are loaded on the molecular sieve; wherein, C4-C12 olefin is used as raw materials, the reaction temperature is 450-650 DEG C, the reaction pressure is 0-0.3Mpa, the weight hourly space velocity of olefin is 1-14h, the weight ratio of water to the olefin is 0.1-10; the raw materials are sent to catalyst bed to perform olefin catalytic cracking reaction to produce propylene and ethylene. By applying the catalyst provided by the invention, the high yield of propylene and ethylene can be maintained, while the reaction operating time can be longer, thus being applicable to the industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

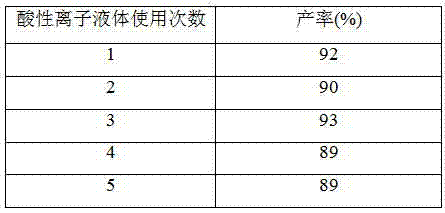

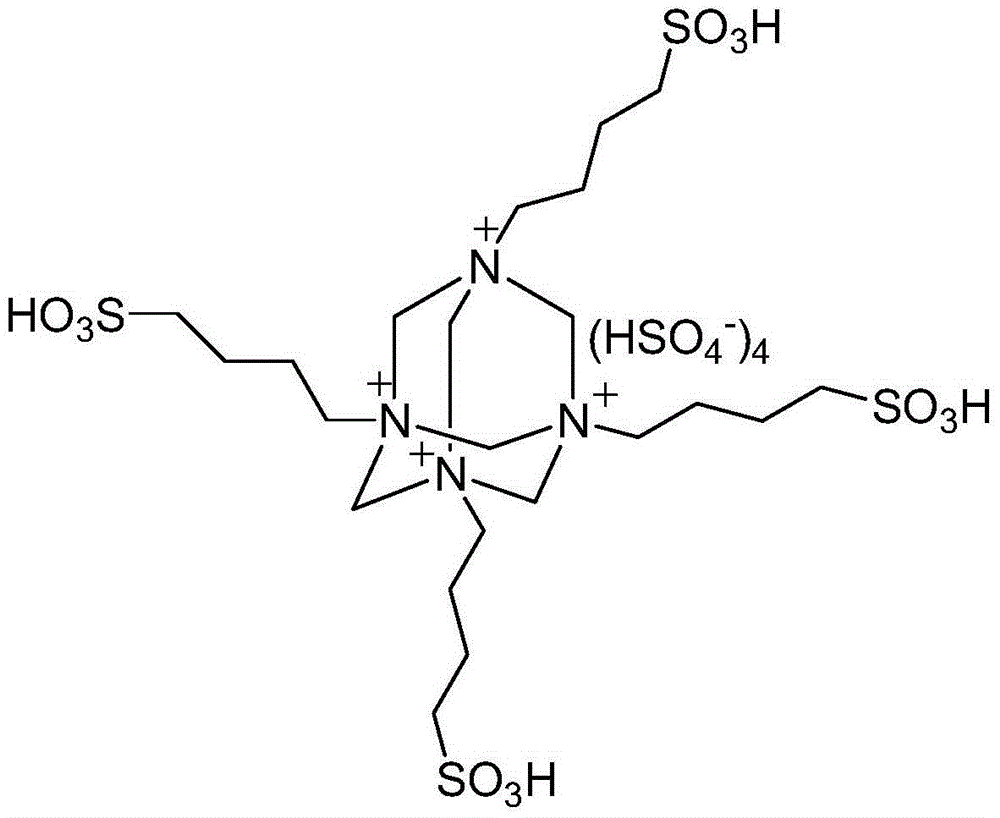

Method for preparing xanthene amerantrone derivative via catalysis of acidic ionic liquid

InactiveCN103193753AHigh acid densityHigh catalytic activityOrganic chemistryChemical recyclingSolventKetone

The invention provides a method for preparing a xanthene amerantrone derivative via the catalysis of an acidic ionic liquid, and belongs to the technical field of organic chemosynthesis. The method comprises the following steps: performing a condensation reaction, wherein the molar ratio of aromatic aldehyde to a 1,3 hexanedione derivative is 1:2, the molar weight of an acidic ionic liquid catalyst accounts for 5% to 10% of the adopted aromatic aldehyde and the adding amount of absolute ethyl alcohol serving as a reaction solvent accounts for 70% to 90% of the total weight of materials; performing a reflux reaction for 2 to 5 hours under the action of one atmospheric pressure as the reaction pressure; after reacting, cooling by using ice water and filtering; and recrystallizing filter residues by using 95% of ethanol, thereby obtaining the pure xanthene amerantrone derivative. Compared with the traditional preparation method taking acid, alkali and other acidic ionic liquids as the catalysts, the method provided by the invention has the characteristics of being high in catalytic activity and less in catalyst adding amount, realizing catalyst recycling and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Composite solid acid catalyst, preparing process and application in the alkylation

ActiveUS20110100876A1High activity and selectivityHigh acid densityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlkyl transferInorganic acids

The present invention provides a composite solid acid catalyst consisting of from 50%-80% by weight of a porous inorganic support, from 15% to 48% by weight of a heteropoly compound loaded thereon, and from 2% to 6% by weight of an inorganic acid. The present invention further provides a process for preparing said composite solid acid catalyst and a process for conducting an alkylation reaction by using such catalyst. The composite solid acid catalyst of the present invention has the acid sites type of Brönsted acid and has an acid sites density of not less than 1.4×10−3 mol H+ / g. Moreover, said composite solid acid catalyst has the homogeneous acid strength distribution, and is a solid acid catalyst having excellent performances.

Owner:CHINA PETROCHEMICAL CORP +1

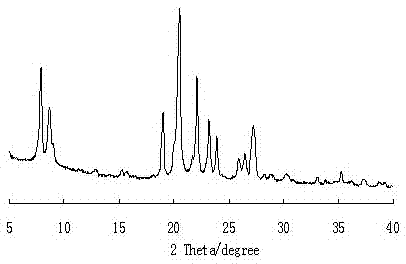

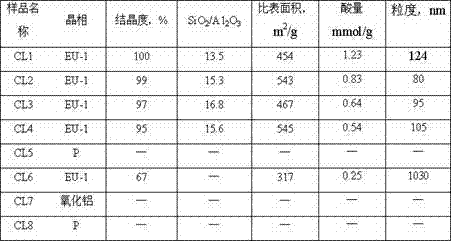

EU-1 molecular sieve and synthesis method thereof

ActiveCN106946267AHigh crystallinityHigh acid densityCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The invention discloses an EU-1 molecular sieve and a synthesis method thereof, wherein the crystal structure of the EU-1 molecular sieve is a typical EUO structure. The synthesis method comprises: mixing an inorganic alkali, an aluminum source, a silicon source, a templating agent and water, stirring to obtain a silicon-aluminum gel, and crystallizing for a certain time; and adding water, a second templating agent and alumina, uniformly stirring, and carrying out hydrothermal crystallization to obtain the EU-1 molecular sieve. According to the present invention, the EU-1 composite molecular sieve synthesized by the method is the low silica-alumina ratio zeolite, and has the high crystallinity; and with the synthesis method, the generation of the impurity crystal can be avoided, and the operation is simple and easy to perform.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon desulfurizer

InactiveCN1583966AHigh acid densityUniform and weak acid strengthHydrocarbon oils refiningRare earthSilicon

A kind of hydrocarbon-oil desulfuration agent contains, on the catalyst-weight basis, 15-60% phosphorus-modified and rare-earth-contained Y type zeolite, 10-60% inorganic oxide, and 0-75% clay; and phosphorus-modified and rare-earth-contained Y type zeolite contains, in weight percent, 0.5-8% phosphorus in presence as P2O5 and 18-35% rare-earth in presence as RE2O3, Moreover, the proportion of silicon and aluminium in zeolite is lower than 6.

Owner:CHINA PETROLEUM & CHEM CORP +1

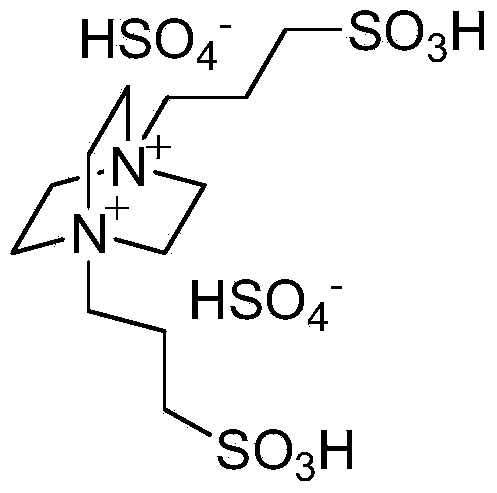

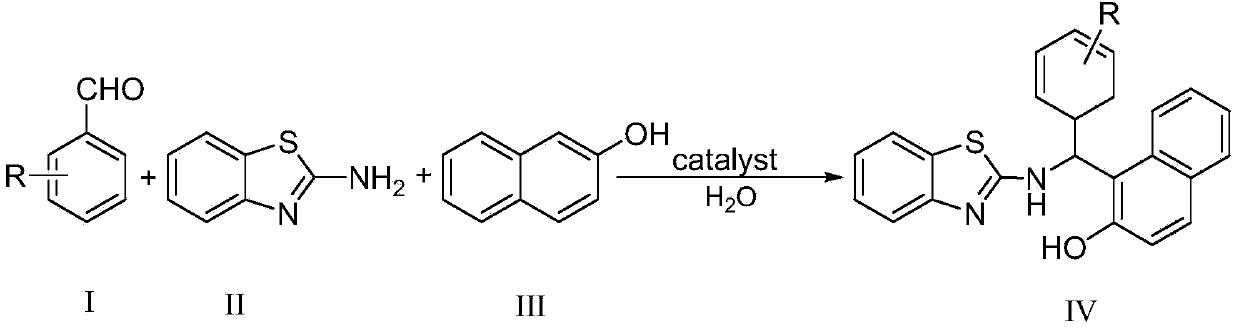

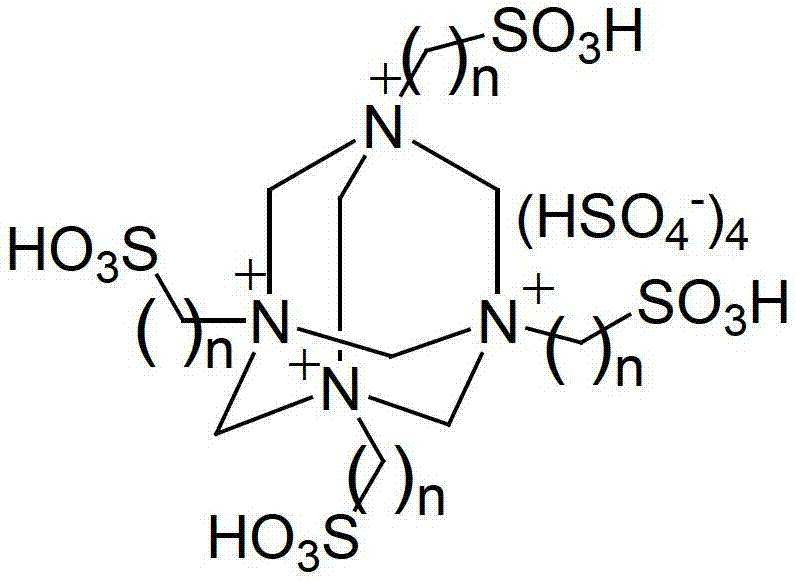

Green method for catalytically synthesizing 2'-aminobenzothiazolyl-arylmethyl-2-naphthol

InactiveCN103360339AHigh acid densityHigh catalytic activityOrganic chemistryChemical recyclingChemical synthesisRecyclable catalyst

The invention provides a green method for catalytically synthesizing 2'-aminobenzothiazolyl-arylmethyl-2-naphthol, belonging to the field of organic chemical synthesis. The method comprises the following steps: carrying out synthetic reaction, wherein the aromatic aldehyde:2-aminobenzothiazole:beta-naphthol mol ratio is 1:1:1, the bissulfonate acidic ion liquid catalyst accounts for 5-8 mol% of the aromatic aldehyde, the reaction temperature is 80-95 DEG C, the reaction time is 3-10 minutes, and the volume (ml) of the reaction solvent water is 3-5 times of the molar weight (mmol) of the aromatic aldehyde; and after the reaction is finished, cooling to room temperature, carrying out vacuum filtration, recrystallizing the filter residue with 95% ethanol, and carrying out vacuum drying to obtain the 2'-aminobenzothiazolyl-arylmethyl-2-naphthol.Compared with other synthesis methods, the invention has the characteristics of high catalytic activity, low catalyst consumption, recyclable catalyst, low environmental pollution in the whole process, simple and convenient after-treatment and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

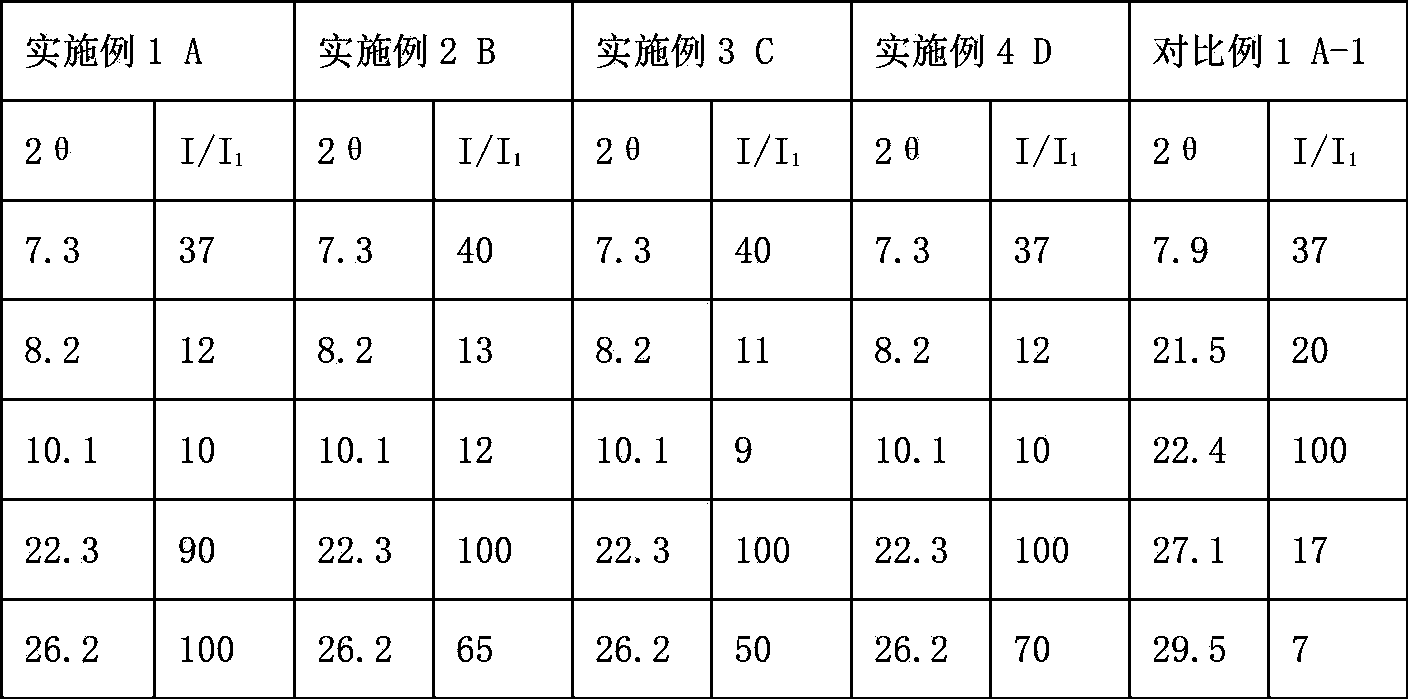

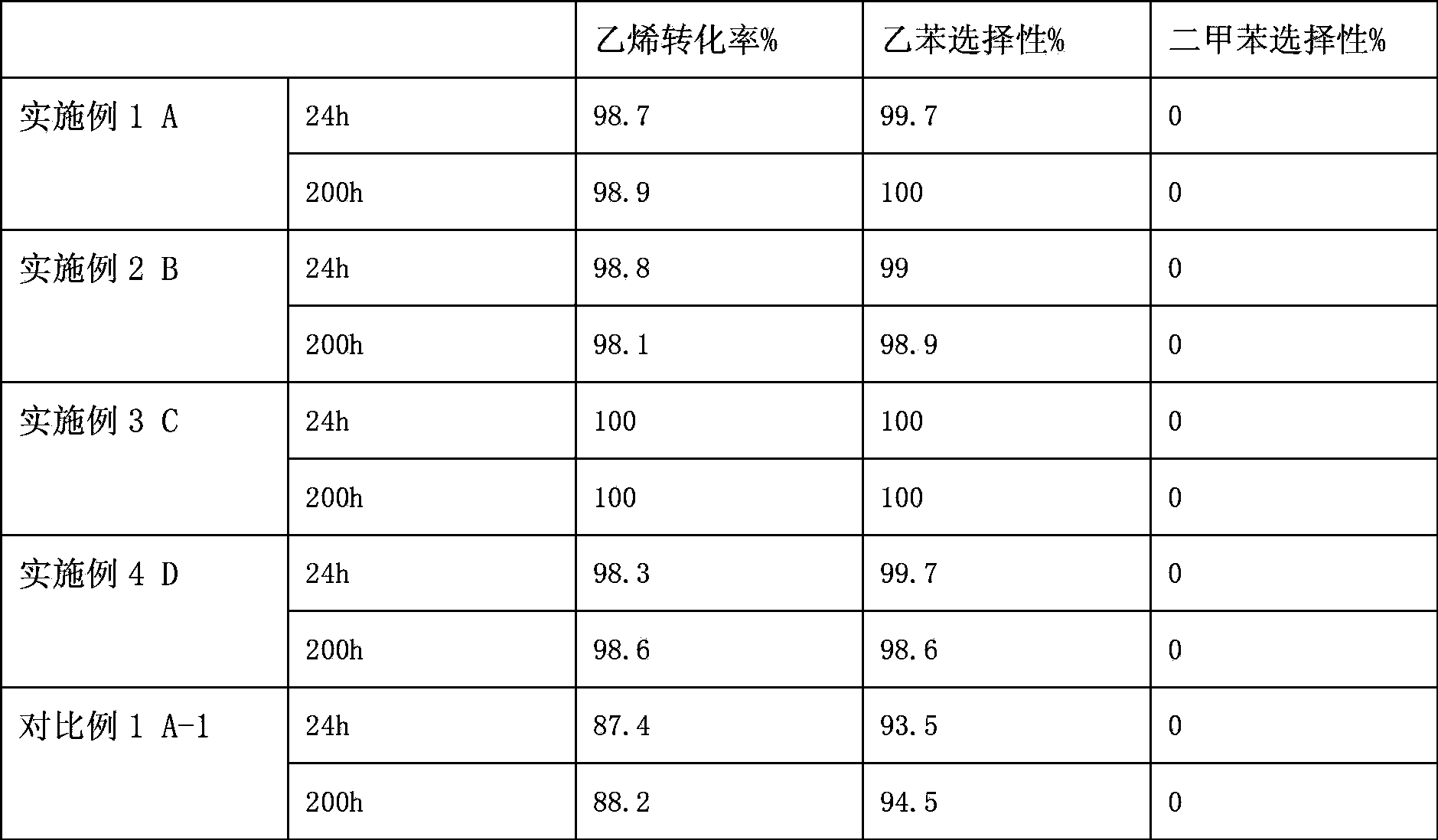

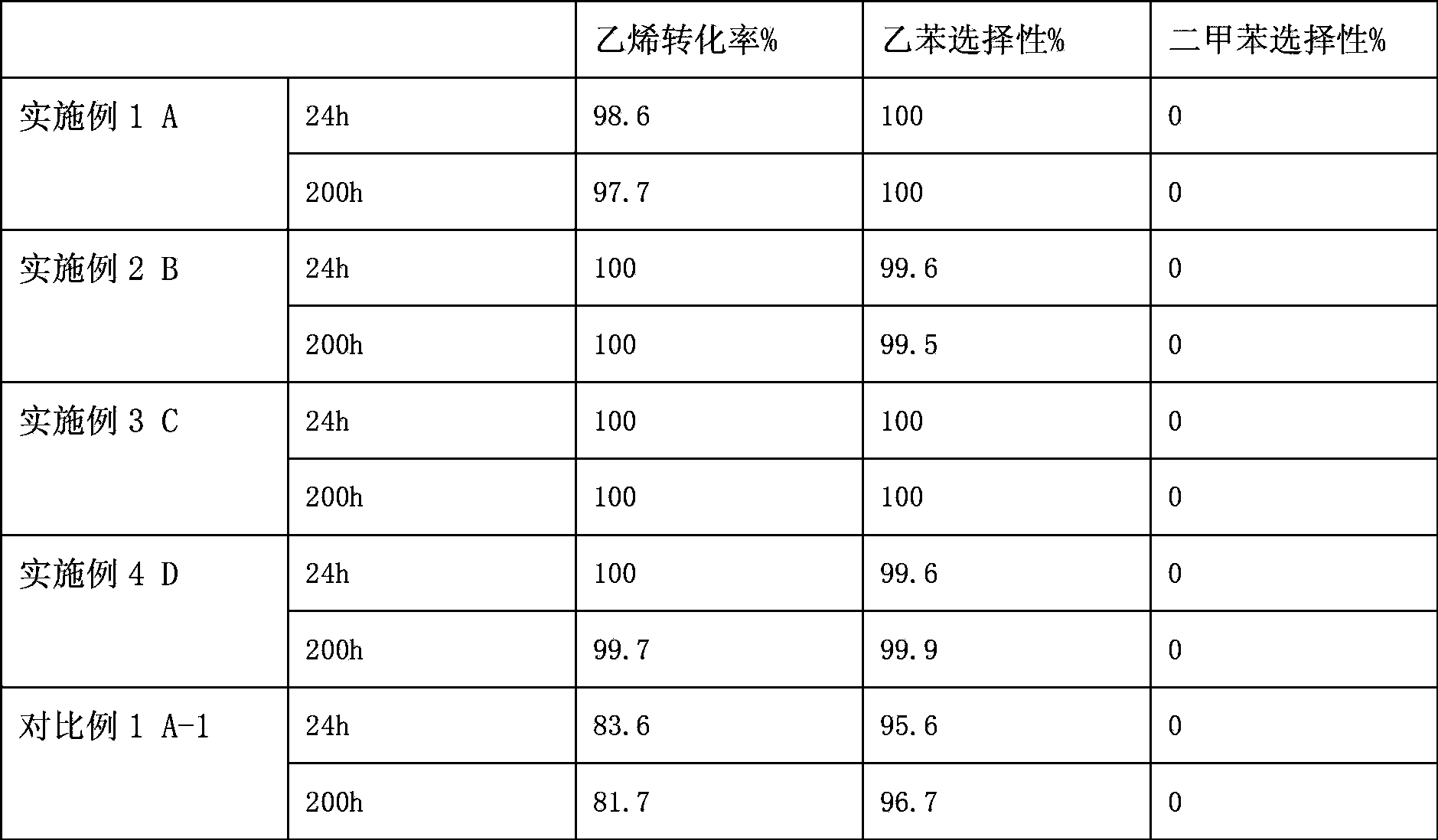

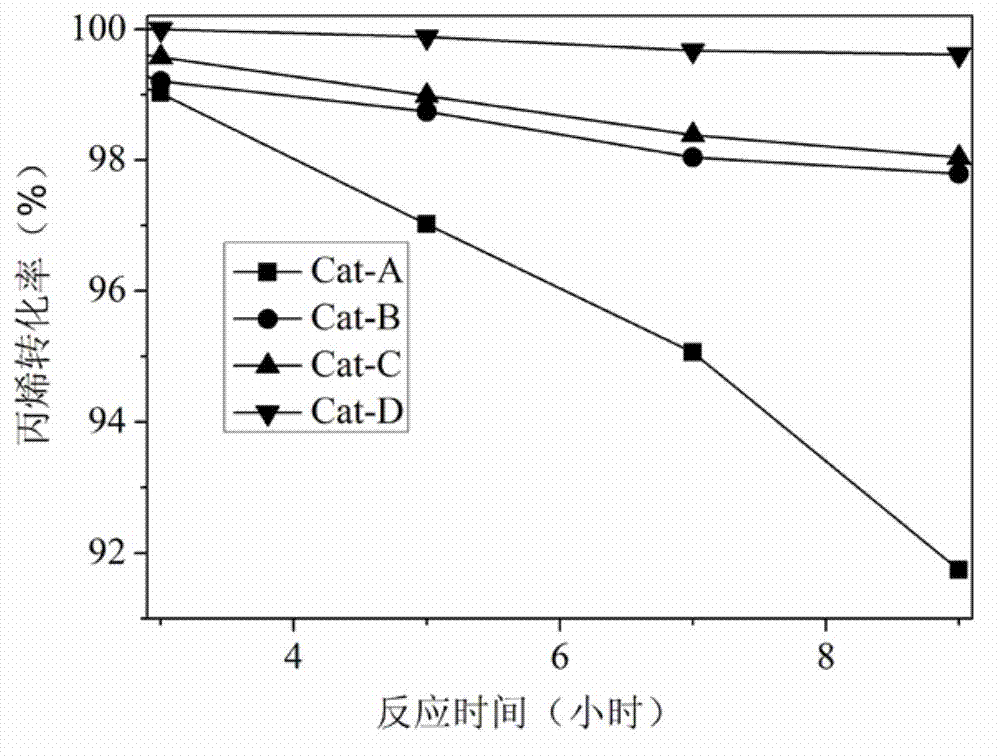

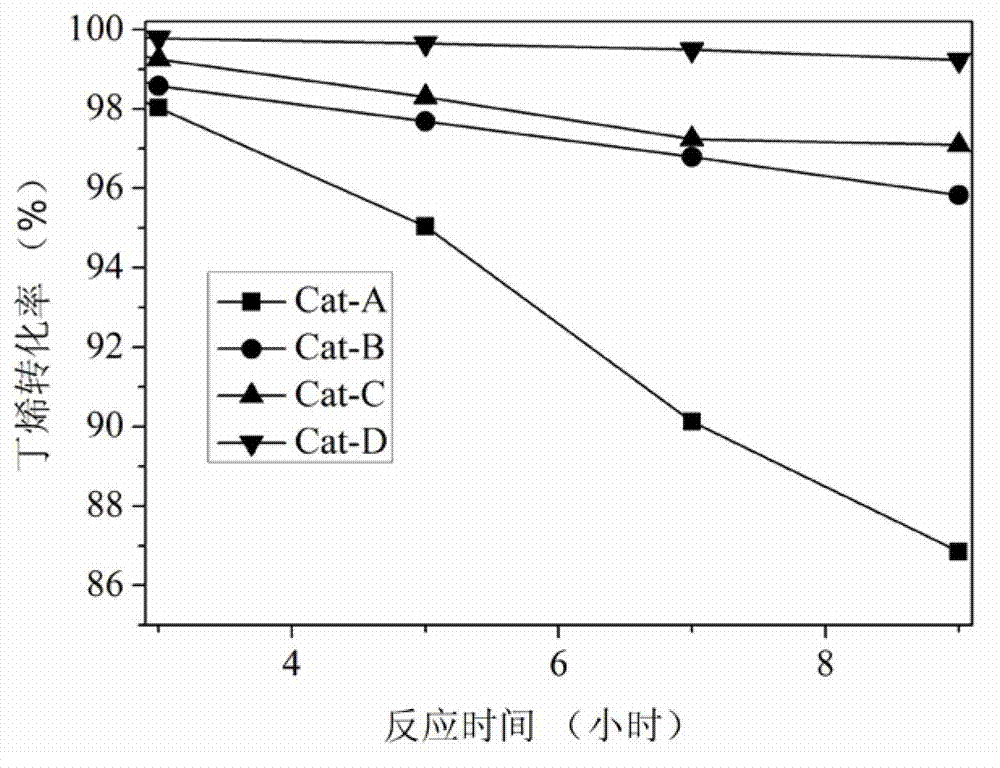

Catalyst for synthesizing ethylbenzene through ethylene and benzene liquid phase method and preparation and application of catalyst

ActiveCN103831129AHigh catalytic activityHigh catalytic efficiencyMolecular sieve catalystsHydrocarbonsTetramethylammonium bromidePolymer science

The invention relates to a catalyst for synthesizing ethylbenzene through an ethylene and benzene liquid phase method and preparation and application of catalyst. The preparation method comprises the following steps: uniformly mixing and stirring an MCM-49 molecular sieve, sodium hydroxide, water, tetraethylammonium bromide and silica sol in a gelatinizing kettle at the temperature of 20-60 DEG C, forming uniform sol-gel, and continuously stirring for 5-10 minutes; crystallizing in a crystallization kettle at the temperature of 140-150 DEG C for 48-96 hours; and filtering the obtained product, washing to pH of 10 by using distilled water, drying at the temperature of 110 DEG C for 12 hours, roasting at the temperature of 560-580 DEG C for 4 hours, performing ion exchange on the obtained MCM-49-beta molecular sieve in a ammonium nitrate solution with the concentration of 10-20 percent, drying at the temperature of 110 DEG C for 12 hours, and roasting at the temperature of 560-580 DEG C for 4 hours. According to the catalyst, the ethylene conversion rate is above 98 percent in the process of preparing the ethylbenzene through ethylene and benzene, the selectivity of the ethylbenzene is above 99 percent, and the product does not contain dimethylbenzene.

Owner:PETROCHINA CO LTD

Environmentally-friendly synthesis method of bisphenol fluorene

ActiveCN108250049AHigh acid densityGood catalyticOrganic chemistryOrganic compound preparationWater bathsSynthesis methods

The invention discloses an environmentally-friendly synthesis method of bisphenol fluorine. The method comprises the following steps: adding phenol, 9-fluorenone, 3-thiohydracrylic acid and an immobilized ionic liquid catalyst into an ultrasonic reaction kettle at 150 to 400 w, and placing the reaction kettle into a water bath at 25 to 50 DEG C for reaction for 1 to 3 h; collecting the immobilizedionic liquid catalyst through a magnetic field, and washing and drying the collected immobilized ionic liquid catalyst for repeated use; washing the residual reaction liquid without the immobilized ionic liquid catalyst with boiled water to separate out crystals, performing suction filtration and vacuum drying on the crystals to obtain a bisphenol fluorine coarse product, and recrystalizing the bisphenol fluorine coarse product to obtain white bisphenol fluorine crystals. Compared with a conventional preparation catalyst of the bisphenol fluorine, the catalyst disclosed by the invention has the advantages of high reaction cavity and high selectivity; furthermore, reaction conditions are mild, and the reaction efficiency is high; and in addition, the quality of the bisphenol fluorine is obviously improved.

Owner:MEIWA PLASTIC SHANGHAI

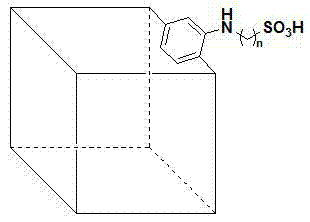

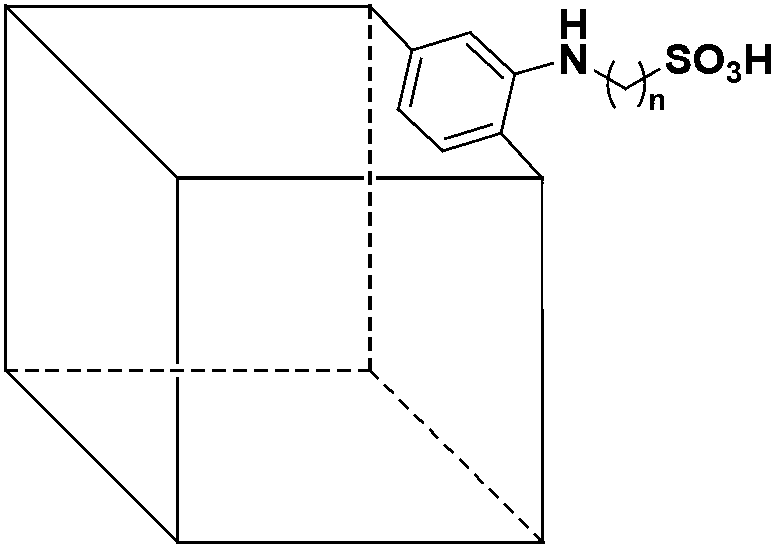

Method for preparing acetal or ketal under catalytic action of metal-organic frameworks

InactiveCN103113347AImprove conversion rateHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisFiltration

The invention provides a method for preparing acetal or ketal under the catalytic action of metal-organic frameworks, belonging to the technical field of organic chemistry synthesis. In the acetal or ketal reaction, the mol ratio of aldehyde or ketone to alcohol is 1:(1-6), the molar weight of the metal-organic frameworks calculated on the basis of -SO3H is 10% of the aldehyde or ketone, the reaction temperature is 80-100 DEG C, the reaction time is 1-3 hours, and the reaction pressure is one atmosphere; the temperature is reduced to room temperature after the reaction; and the metal-organic framework catalyst obtained by filtration can be recycled after being subjected to vacuum dehydration at 120 DEG C. The method provided by the invention is environment-friendly; and the catalyst has the advantages of high conversion rate and high selectivity, and can be recycled many times while the catalytic activity is not obviously lowered.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

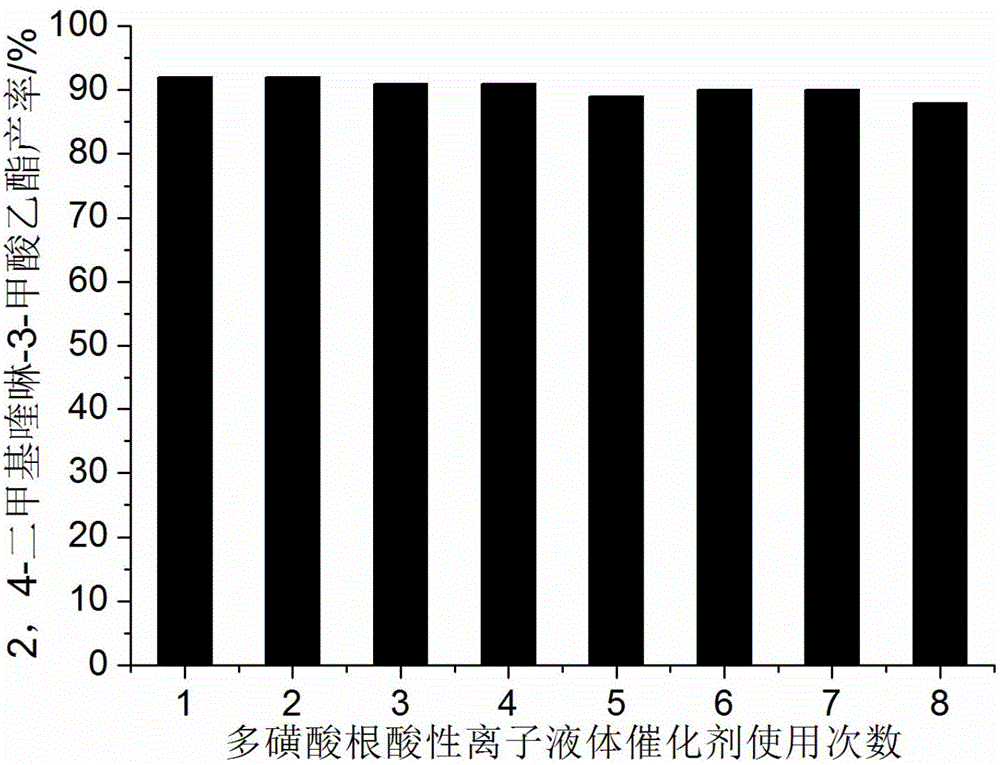

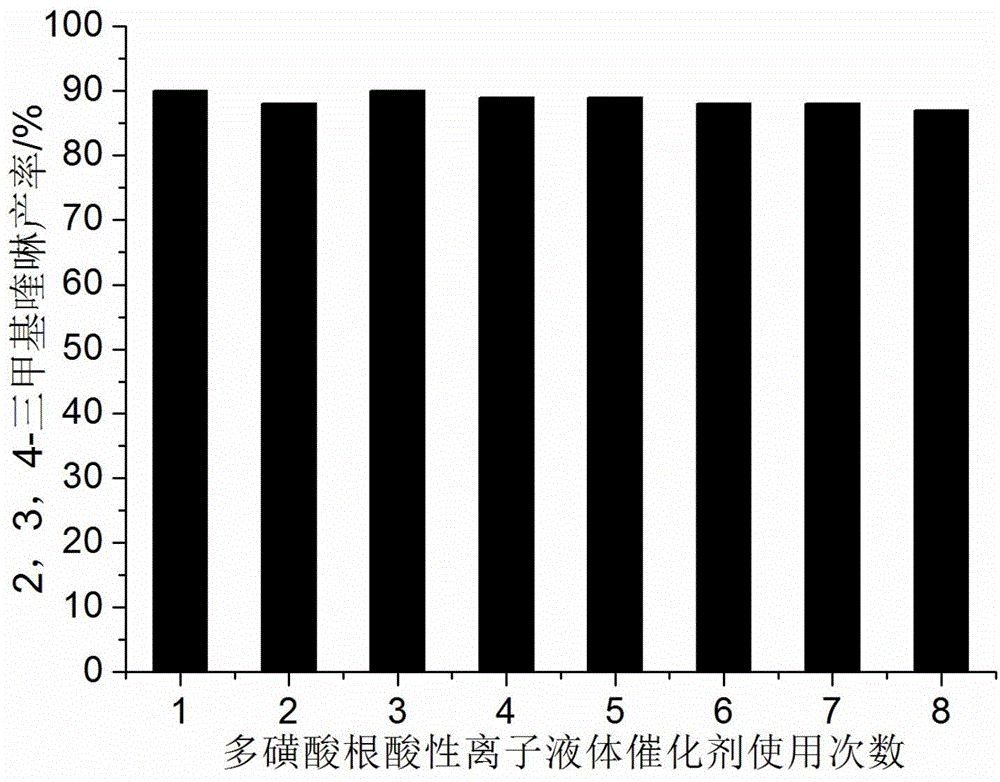

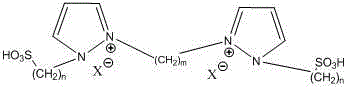

Quinoline derivative efficient catalytic synthesis method

ActiveCN104311484AHigh acid densityHigh catalytic activityOrganic chemistryM-aminoacetophenoneSynthesis methods

The invention discloses a quinoline derivative efficient catalytic synthesis method belonging to the technical field of organic synthesis. The molar ratio of an active alpha-methyl or methylene carbonyl compound and 2-amino acetophenone is 1: 1, the molar amount of a multi sulfonic acid r adical acidic ionic liquid catalyst is 7-10% of the use amount of the 2-amino acetophenone, the reaction solvent 75% ethanol aqueous solution volume (ml) is 3-5 times of the molar amount (mmol) of the 2-amino acetophenone, the reflux reaction time is 5-25min, a filter residue is obtained by cooling to room temperature after the reaction and filtering, and the obtained filter residue is dried under vacuum to obtain a pure quinoline derivative. Compared with a synthesis method using other acidic ionic liquid as a catalyst, the catalyst has high catalytic activity, less use amount and less loss quantity during the circulation use, and the whole synthetic process has the advantages of being simple, convenient, economic and the like, and is convenient for industrialized mass production.

Owner:南京苏亦欣医药科技有限公司

Method for catalytic esterification of -SO3H-containing metal-organic framework compound

InactiveCN103073420AHigh acid densityHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisOrganic synthesis

The invention provides a method for catalytic esterification of a -SO3H-containing metal-organic framework compound, and belongs to the technical field of organic synthesis chemistry. In esterification reaction, a molar ratio of alcohol to acid is 1:(1-2); based on -SO3H, the molar weight of the -SO3H-containing metal-organic framework compound is 8 percent of the alcohol; the reaction temperature is 110DEG C, the reaction time is 30 to 60 minutes, and the reaction pressure is one atmosphere; after reaction, the temperature is reduced to room temperature; and after filtration, the obtained -SO3H-containing metal-organic framework compound catalyst is subjected to vacuum drying at 120DEG C to be recycled. Compared with the traditional reaction process using protonic acid, Lewis acid and acidic ionic liquid as a catalyst, the method has the advantages that the catalytic activity is high, the using amount of the catalyst is small, the catalyst is easily separated from a reaction system, the catalyst can be recycled and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

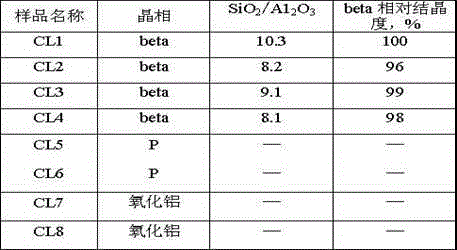

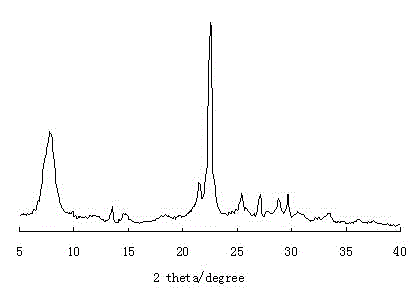

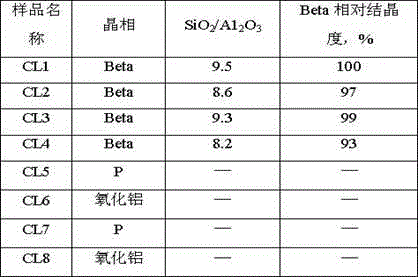

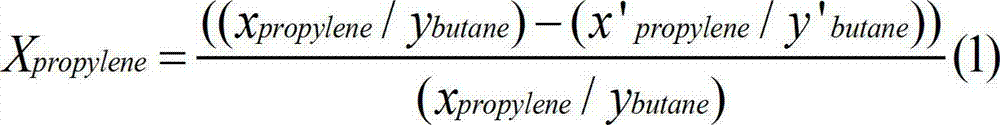

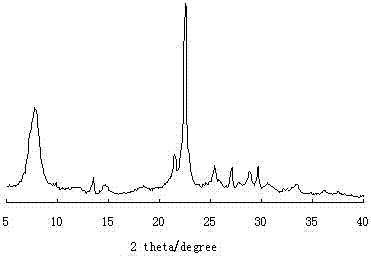

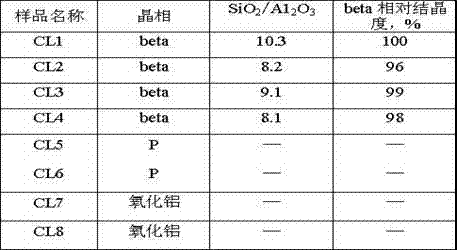

Aluminum-rich Beta Zeolite synthesis method

ActiveCN105540605AHigh purityReduce releaseCrystalline aluminosilicate zeolitesSynthesis methodsCrystallinity

The present invention discloses an aluminum-rich Beta zeolite synthesis method, which comprises: placing aluminum nitrate in a high temperature furnace, and calcining to synthesize alumina; mixing an inorganic base, an aluminum source, a silicon source and water, and stirring to obtain a silicon aluminum gel; adding the obtained alumina, and drying until the water is completely evaporated; and finally loading the dried gel into the upper portion of the reactor, adding a fixed amount of ammonia water to the bottom portion of the reactor, and carrying out crystallization synthesis to obtain the Beta zeolite. According to the present invention, the synthesized Beta zeolite is low silica-alumina ratio zeolite, and has high crystallinity, and the generation of miscellaneous crystals is effectively avoided and the operation is simple and easy to perform.

Owner:CHINA PETROLEUM & CHEM CORP +1

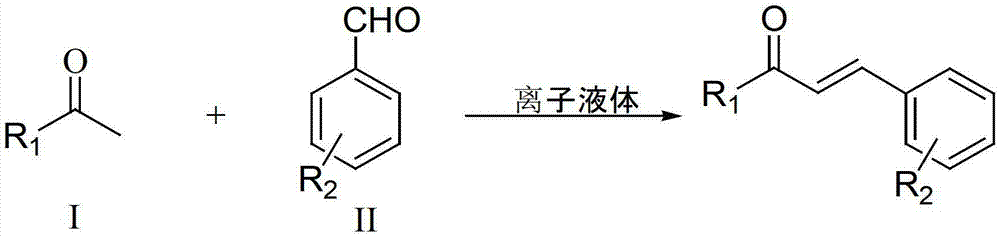

Method for preparing chalcone and directive through multi-sulfonate ion liquid catalysis

InactiveCN103193607AHigh acid densityHigh catalytic activityOrganic compound preparationCarbonyl compound preparationChemical synthesisReaction temperature

The invention provides a method for preparing chalcone and a directive through multi-sulfonate ion liquid catalysis, and belongs to the technical field of organic chemistry synthesis. In the condensation reaction of the method, the mole ratio of raw material aldehyde to ketone is 1:1, the molar weight of a multi-sulfonic acid group ion liquid catalyst is 8%-10% of the used ketone or aldehyde, the reaction temperature is 120-140 DEG C, the reaction time is 8-20 hours, the reaction pressure is 1 atmospheric pressure, an upper layer product separated through standing layering after the reaction is recrystallized to obtain products, namely the chalcone and the derivative; and a separated lower layer which contains the multi-sulfonate ion liquid catalyst can be subjected to vacuum drying treatment at 110 DEG C for 2 hours and then can be recycled. Compared with the traditional preparation method which takes bronsted acid, Lewis acid and other acidic ion liquids as catalysts, the method provided by the invention has the advantages that catalytic activity is high, catalyst usage amount is small, the separation of the catalyst and the products is simple and convenient, the catalyst is recycled, and the catalytic activity of the catalyst is not obviously reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Synthetic method of Beta zeolite

ActiveCN105621439APromote growthReduce releaseMolecular sieve catalystsOther chemical processesAluminium nitrateCrystallinity

The invention discloses a synthetic method of Beta zeolite. The synthetic method of Beta zeolite comprises the following steps: firstly placing aluminium nitrate into a high temperature furnace, and roasting to prepare special aluminium oxide; mixing inorganic base, an aluminium source, a silicon source, a template and water, and stirring to obtain silica-alumina gel; adding the above prepared aluminium oxide into silica-alumina gel; and finally carrying out hydrothermal crystallization to obtain Beta zeolite. The Beta zeolite synthesized by the method is low aluminium-silicon ratio zeolite, and has high degree of crystallinity. By the synthetic method, generation of foreign crystals is effectively avoided. In addition, the synthetic method is simple to operate and feasible.

Owner:CHINA PETROLEUM & CHEM CORP +1

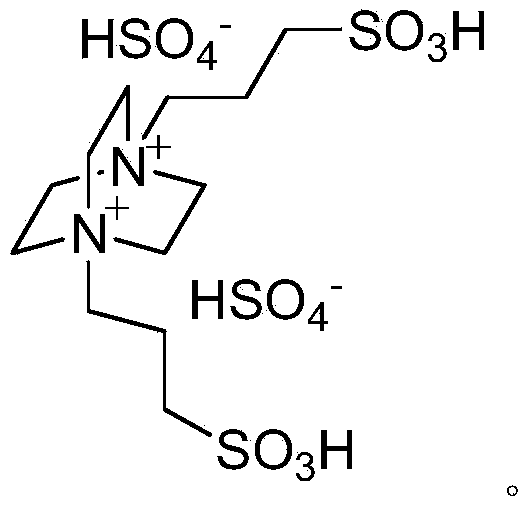

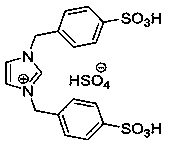

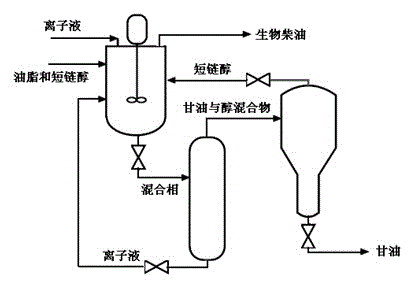

Pyrazole strongly acidic ionic liquid catalyst and application thereof

InactiveCN102614912AImprove thermal stabilityAvoid partial lossFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselVolumetric Mass Density

The invention discloses a pyrazole strongly acidic ionic liquid catalyst. The catalyst is pyrazole dication strongly acidic ionic liquid. The ionic liquid catalyst has the advantages of high acid density, high catalytic activity, high stability, short catalytic reaction time, mild reaction condition, simple process, recyclability, small loss during use and the like. The catalyst can be applied to preparation of biodiesel; the preparation reaction speed is high; the reaction time is greatly shortened; and the reaction condition is mild.

Owner:KUNMING UNIV OF SCI & TECH

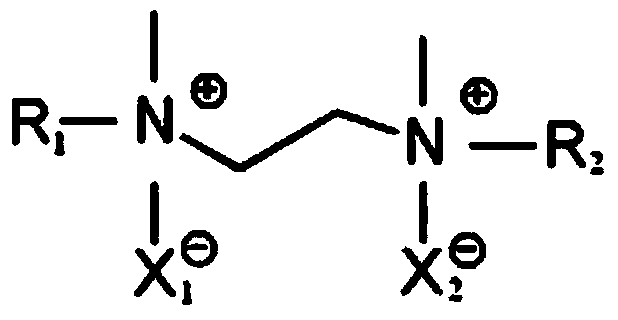

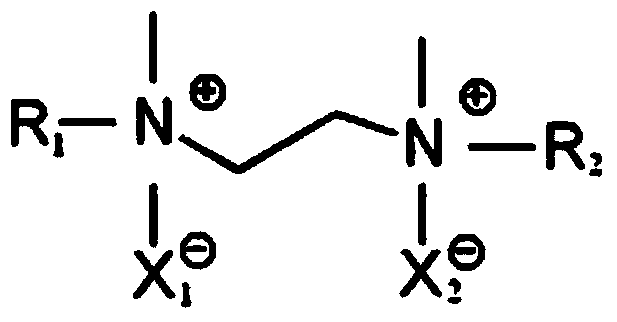

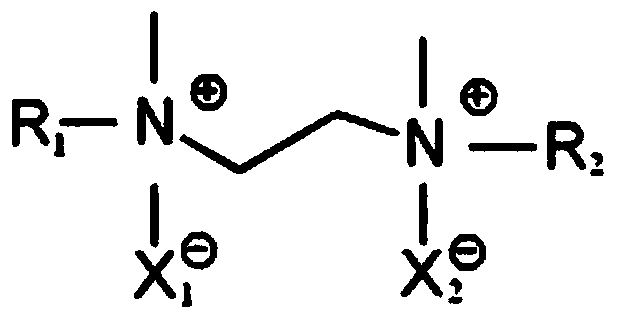

Ionic liquid catalyst for C5/C6 alkane isomerization and preparation and using method of catalyst

InactiveCN103934023AHigh acid densityReduce dosageHydrocarbon by isomerisationOrganic compound preparationAlkaneIsomerization

The invention provides an ionic liquid catalyst for C5 / C6 alkane isomerization. The chemical structural formula of the catalyst is as shown in the specification, wherein R1 and R2 are respectively any one of C2-C9 straight chain alkyl; X1 and X2 are respectively any one of AlCl4<-> and Al2Cl7<->, or X1 and X2 are respectively any one of AlCl3Br<-> and Al2Cl6Br<->. When the ionic liquid catalyst provided by the invention is applied to isomerization reaction, a reaction system is of liquid-liquid phase, and the reaction is stable and easy to control. After the reaction is accomplished and a product is cooled to be the room temperature, the ionic liquid catalyst is coagulated to be solid again, and thus being conveniently separated from a liquid phase product.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for improving acidity of MCM-22 molecular sieve based catalyst

InactiveCN102962094AHigh acid densityHigh catalytic activityMolecular sieve catalystsHydrocarbonsIonMolecular sieve

The invention provides a method for improving acidity of an MCM-22 molecular sieve based catalyst. The method comprises the following specific steps of: processing a roasted Na-type MCM-22 molecular sieve for 5-180 hours at a temperature of 50 to 250 DEG C by 0.01-1.0 mol / L Al(NO3)3 solution; and washing and drying the obtained products and exchanging the obtained products with ammonium nitrate solution; and filtering the obtained products, washing the obtained products by deionized water, drying the obtained products, and then roasting the obtained products to obtain the H-type catalyst. According to the method, in the process of preparing the catalyst by modifying the MCM-22 molecular sieve by the Al(NO3)3 solution, the acid density and the acid strength of the molecular sieve can be effectively improved; and compared with those of the unprocessed MCM-22 molecular sieve based catalyst, the activity and the stability for catalyzing transformation of propylene and butane of the catalyst provided by the invention are obviously improved in the process of catalyzing alkylation reaction of benzene and liquefied gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A method for synthesizing aluminum-rich beta zeolite

ActiveCN105540605BHigh purityReduce releaseCrystalline aluminosilicate zeolitesSynthesis methodsCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano spherical carbon-based solid acid taking lignin as raw material as well as preparation method and application thereof

PendingCN110479309AIncrease contact pointsFavorable to replaceSugar derivativesOrganic compound preparationFiltrationSolid acid

The invention belongs to the field of nanometer material catalysis, and particularly discloses a method for preparing nanometer spherical carbon-based solid acid by taking lignin as a raw material. The method comprises the following steps: dissolving the modified or unmodified lignin in an organic solvent, and adding water, so that the lignin is self-assembled to obtain lignin nano colloidal spheres; drying the lignin nano colloidal spheres, then dispersing the dried lignin nano colloidal spheres into a certain volume of water, filling a polytetrafluoroethylene tank with the mixture, carryingout hydrothermal carbonization, and carrying out suction filtration, washing and drying on the carbonized product; and putting the dried lignin nano carbon spheres and a certain volume of concentratedsulfuric acid into a polytetrafluoroethylene tank for sulfonation, and carrying out suction filtration, washing and drying on the sulfonated product to obtain the lignin nano spherical carbon-based solid acid. The carbon-based solid acid can replace sulfuric acid for application in an acid catalytic reaction, and has the advantages of being green, regenerable and low in corrosion to equipment andthe like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

A method for removing nitrogen compounds in oil products

ActiveCN107699274BHigh acid densitySmall oil ratioOrganic chemistryHydrocarbon oils refiningProtonationPolypyrrole

The invention discloses a method for removing nitride in an oil product by utilizing multi-sulfonate ionic liquid. The method comprises the following steps: adding the multi-sulfonate ionic liquid into the oil product to carry out protonation removal on non-alkaline nitride in the oil product and carry out sulfonation removal on alkaline nitride in the oil product. Specifically, the method comprises the following steps: mixing the multi-sulfonate ionic liquid with the oil product according to the mass / volume ratio of 1g / 450mL; stirring under a room-temperature condition for 20min to 30min to enable pyrrole in the oil product to be subjected to protonation reaction, so as to generate polypyrrole; carrying out sulfonation transformation on isoquinoline to generate 5-isoquinoline sulfonic acid to remove the isoquinoline. According to the method disclosed by the invention, the non-alkaline nitride which takes the pyrrole as a representative can be protonated by the strong acidity in the ionic liquid and further reacts to generate the polypyrrole, so as to remove the non-alkaline nitride; on the other hand, the alkaline nitride which takes the isoquinoline as a representative can be subjected to the sulfonation transformation to generate the 5-isoquinoline sulfonic acid to remove the alkaline nitride; a thiophene type sulfur-containing compound in the oil product and an olefin typecompound can be subjected to alkylation, so that disturbance, caused by the sulfur-containing compound, on a denitrification process is greatly reduced.

Owner:QINGDAO YONGQUAN PETROLEUM CO LTD

Composite solid acid catalyst, preparing process and application in the alkylation

ActiveUS8309486B2High acid densityHigh activityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlkyl transferSolid acid

The present invention provides a composite solid acid catalyst consisting of from 50%-80% by weight of a porous inorganic support, from 15% to 48% by weight of a heteropoly compound loaded thereon, and from 2% to 6% by weight of an inorganic acid. The present invention further provides a process for preparing said composite solid acid catalyst and a process for conducting an alkylation reaction by using such catalyst. The composite solid acid catalyst of the present invention has the acid sites type of Brönsted acid and has an acid sites density of not less than 1.4×10−3 mol H+ / g. Moreover, said composite solid acid catalyst has the homogeneous acid strength distribution, and is a solid acid catalyst having excellent performances.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com