Catalyst for preparing light aromatics and light paraffins using hydrocarbons as raw materials

A technology for light aromatic hydrocarbons and light alkanes, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc. The effect of smooth, high degree of dealkylation and high acid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

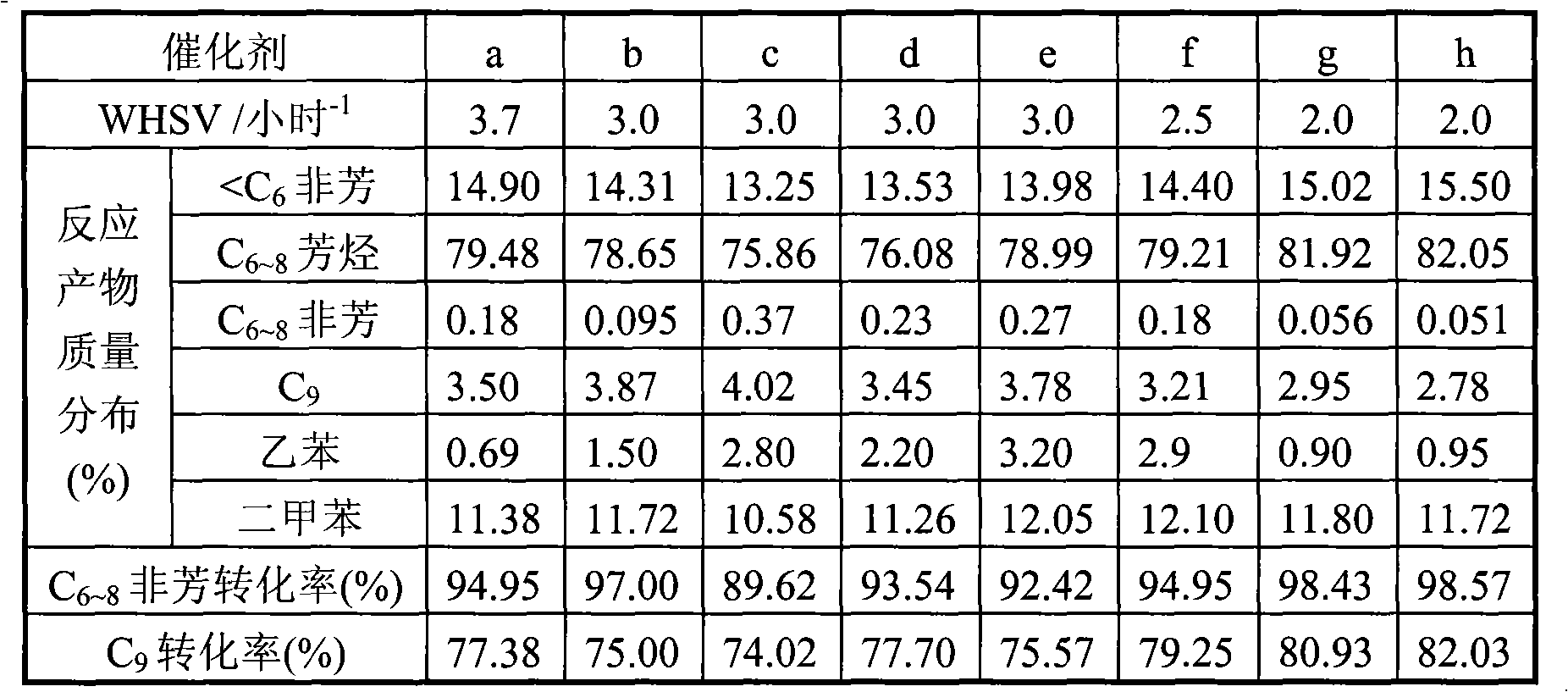

Examples

Embodiment 1

[0014] Use tetrapropylammonium hydroxide (TPAOH) solution, tetraethylorthosilicate (TEOS) and water according to (TPA) 2 O: 5.5TEOS: 90H 2 The molar ratio of O was mixed and stirred evenly, aged and refluxed at 80° C. for three days to obtain the ZSM-5 seed crystal directing agent. Take by weighing 180 grams of white carbon black, 10 grams of squash powder, aqueous solution containing 19.7 grams of sodium aluminate and 40 grams of ZSM-5 seed directing agent, then add 230 grams of silica sol (40% by weight) and an appropriate amount of water to carry out After kneading and forming, drying is carried out to obtain a cylindrical precursor. A mixture of 35 grams of ethylenediamine and 5 grams of distilled water was added to the reaction kettle in advance, and 150 grams of the above-prepared cylindrical precursor was placed in the reaction kettle above the porous stainless steel mesh and sealed at 160 ° C for 5 days. . The product was washed and dried with distilled water, and t...

Embodiment 2

[0016] Take by weighing 100 grams of white carbon black and 20 grams of ultra-stable Y zeolite zeolite (SiO 2 / Al 2 o 3 Molar ratio is 16) the ZSM-5 seed crystal directing agent of 20 grams among the mixed embodiment 1, adds the Al containing 26 grams 2 (SO 4 ) 3 18H 2 The O aqueous solution adjusted the silicon-aluminum ratio of the mixture, and then added 150 grams of silica sol (40% by mass) for kneading and shaping, and then dried to obtain a cylindrical precursor. A mixture of 34 grams of ethylamine and distilled water was added to the reaction kettle in advance, and 100 grams of the above-prepared cylindrical precursor was placed in the reaction kettle above the porous stainless steel mesh and sealed, and gas-solid phase treatment was performed at 180° C. for 5 days. After the product was taken out, it was washed with distilled water, dried in the air, and then calcined at 550° C. in an air atmosphere to obtain a binder-free ZSM-5 / USY zeolite. Then carry out ion ex...

Embodiment 3

[0018] Take by weighing 180 grams of white carbon black and 140 grams of beta type zeolite (SiO 2 / Al 2 o 3 The mol ratio is 20) the ZSM-5 seed crystal directing agent of 40 grams among the mixed embodiment 1, adds and contains 110 grams of Al 2 (SO 4 ) 3 18H 2O aqueous solution was used to adjust the silicon-aluminum ratio of the mixture, and then 220 grams of silica sol (40% by mass) was added for kneading and shaping, followed by drying to obtain a cylindrical precursor. A mixture of 40 grams of ethylamine and distilled water was pre-added into the reaction kettle, and 100 grams of the above-prepared cylindrical precursor was placed in the reaction kettle above the porous stainless steel mesh and sealed, and then gas-solid phase treatment was performed at 150 ° C for 7 days. After the product was taken out, it was washed with distilled water, dried in the air, and then calcined at 550° C. in an air atmosphere to obtain a binder-free ZSM-5 / beta zeolite. Then carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com