Method for improving acidity of MCM-22 molecular sieve based catalyst

A technology of MCM-22 and molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low acid density, weak acid strength, limitations, etc., and achieve increased acid density and high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

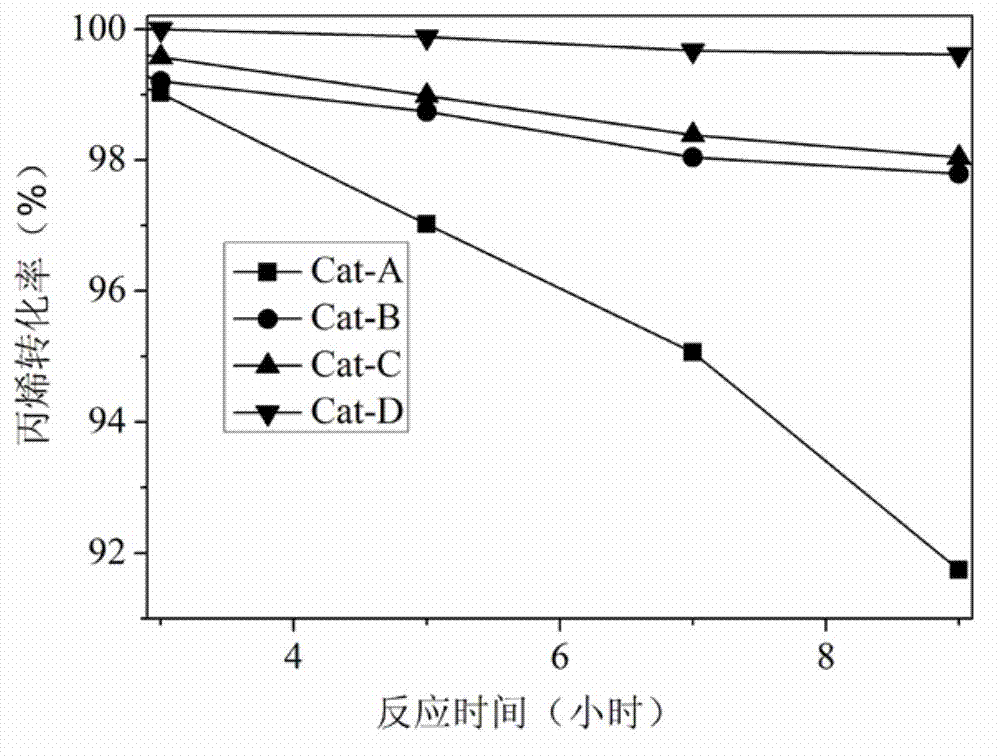

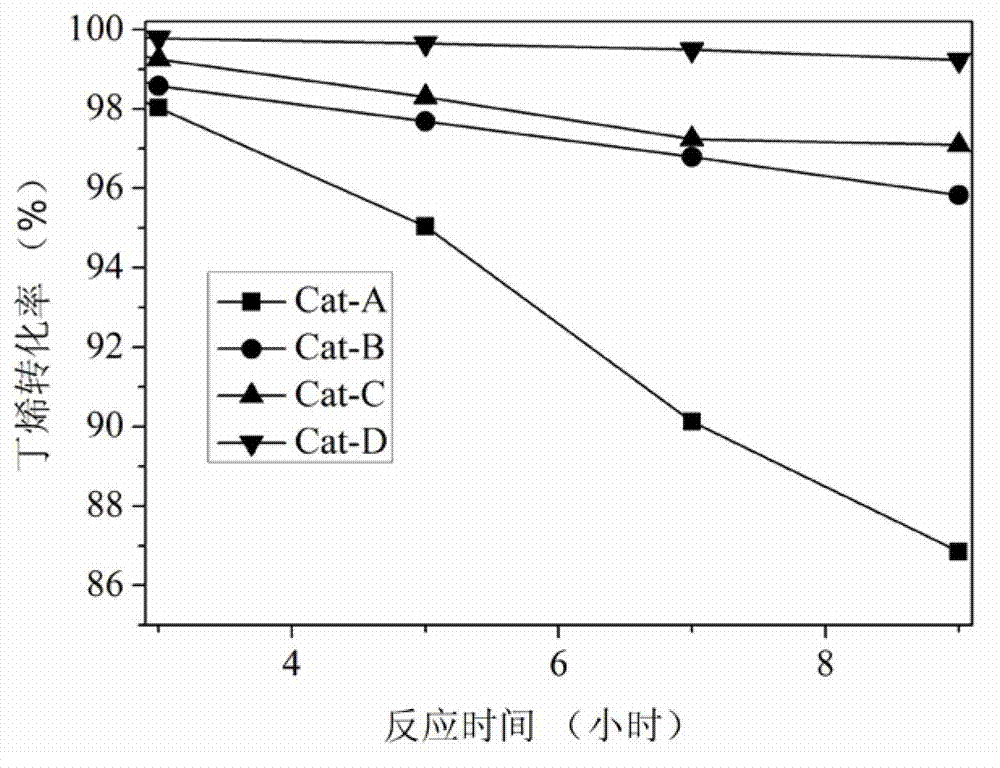

[0019] Get 20g roasting and remove the Na-type MCM-22 molecular sieve of template agent, be 0.05 mol / liter Al(NO 3 ) 3 The solution was treated in a stainless steel reactor at 175 degrees Celsius for 72 hours, filtered, washed and dried; the product was exchanged in 400 ml of ammonium nitrate solution with a concentration of 0.8 mol / liter at 80 degrees Celsius for 2 hours, twice in a row, filtered and washed After drying, it is calcined at 540°C to obtain hydrogen-type molecular sieves. The molecular sieves were pressed into tablets and crushed into 20-40 mesh particles, which were designated as Cat-B. The change of propylene and butene conversion with time on the obtained catalyst sample is shown in figure 1 with figure 2 .

Embodiment 2

[0021] Get 20g roasting and remove the Na-type MCM-22 molecular sieve of template agent, be 0.1 mol / liter Al(NO 3 ) 3 The solution was treated in a stainless steel reactor at 175 degrees Celsius for 72 hours, filtered, washed and dried; the product was exchanged in 400 ml of ammonium nitrate solution with a concentration of 0.8 mol / liter at 80 degrees Celsius for 2 hours, twice in a row, filtered and washed After drying, it is calcined at 540°C to obtain hydrogen-type molecular sieves. The molecular sieves were pressed into tablets and crushed into 20-40 mesh particles, which were designated as Cat-C. The change of propylene and butene conversion with time on the obtained catalyst sample is shown in figure 1 with figure 2 .

Embodiment 3

[0023] Get 20g roasting and remove the Na-type MCM-22 molecular sieve of template agent, be 0.2 mol / liter Al(NO 3 ) 3 The solution was treated in a stainless steel reactor at 175 degrees Celsius for 72 hours, filtered, washed and dried; the product was exchanged in 400 ml of ammonium nitrate solution with a concentration of 0.8 mol / liter at 80 degrees Celsius for 2 hours, twice in a row, filtered and washed After drying, it is calcined at 540°C to obtain hydrogen-type molecular sieves. The molecular sieve is pressed into tablets and crushed into 20-40 mesh particles, which are designated as Cat-D. The change of propylene and butene conversion with time on the obtained catalyst sample is shown in figure 1 with figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com