Method for producing propylene and ethylene through catalytic cracking of olefins

A catalytic cracking, propylene technology, applied in chemical instruments and methods, catalytic cracking, bulk chemical production, etc., can solve problems such as long-term operation, and achieve the effect of satisfying industrial production and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

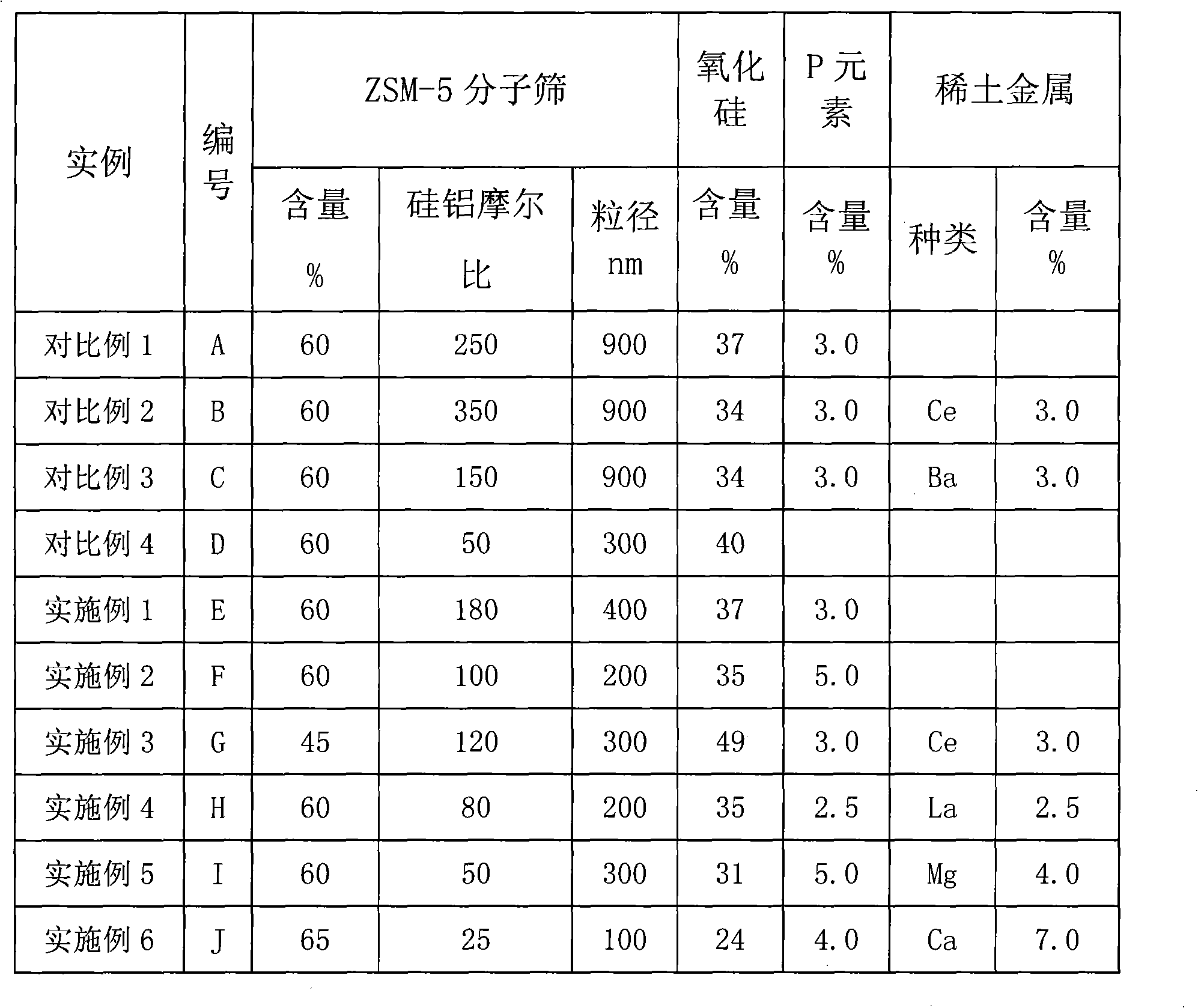

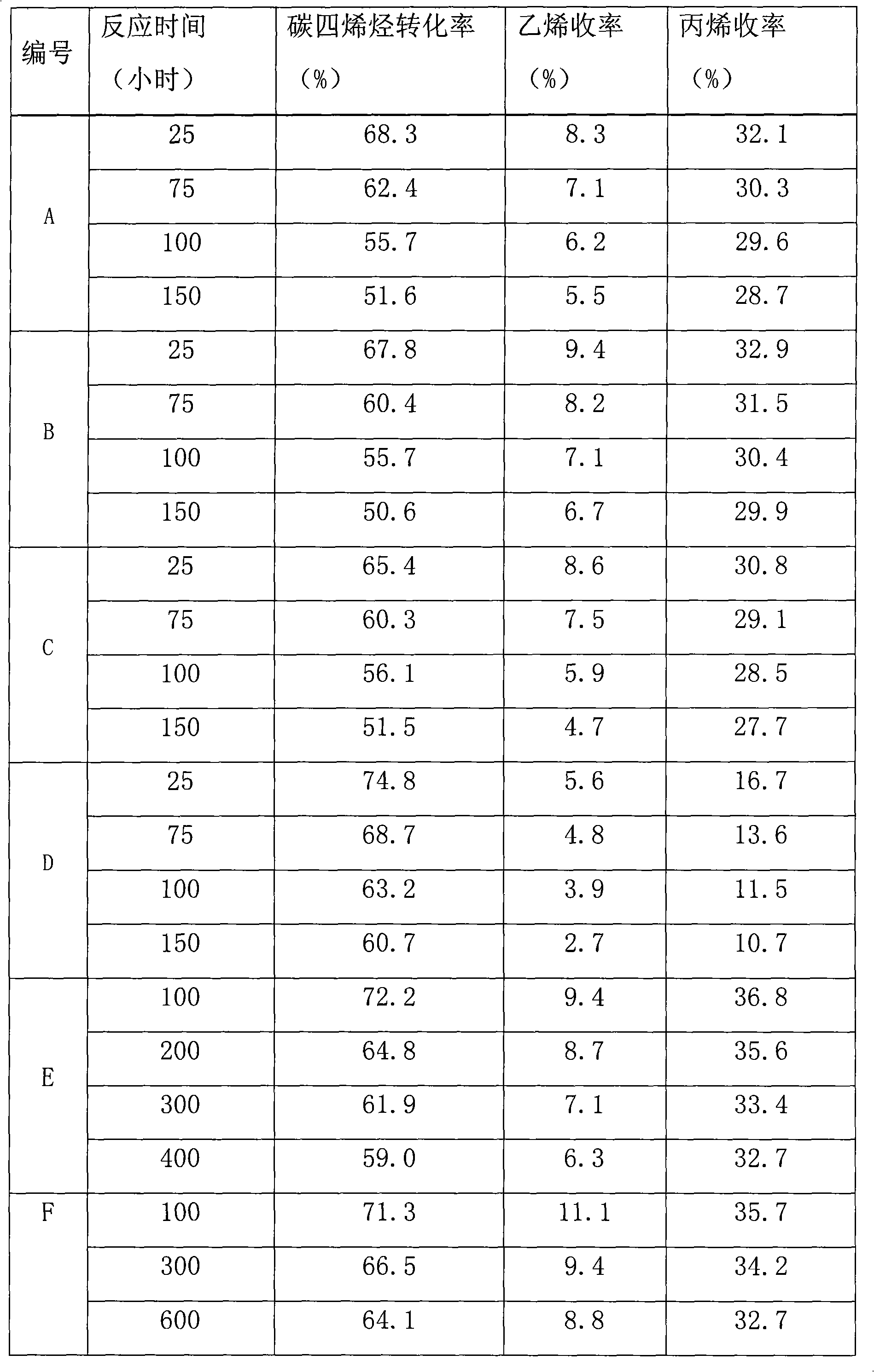

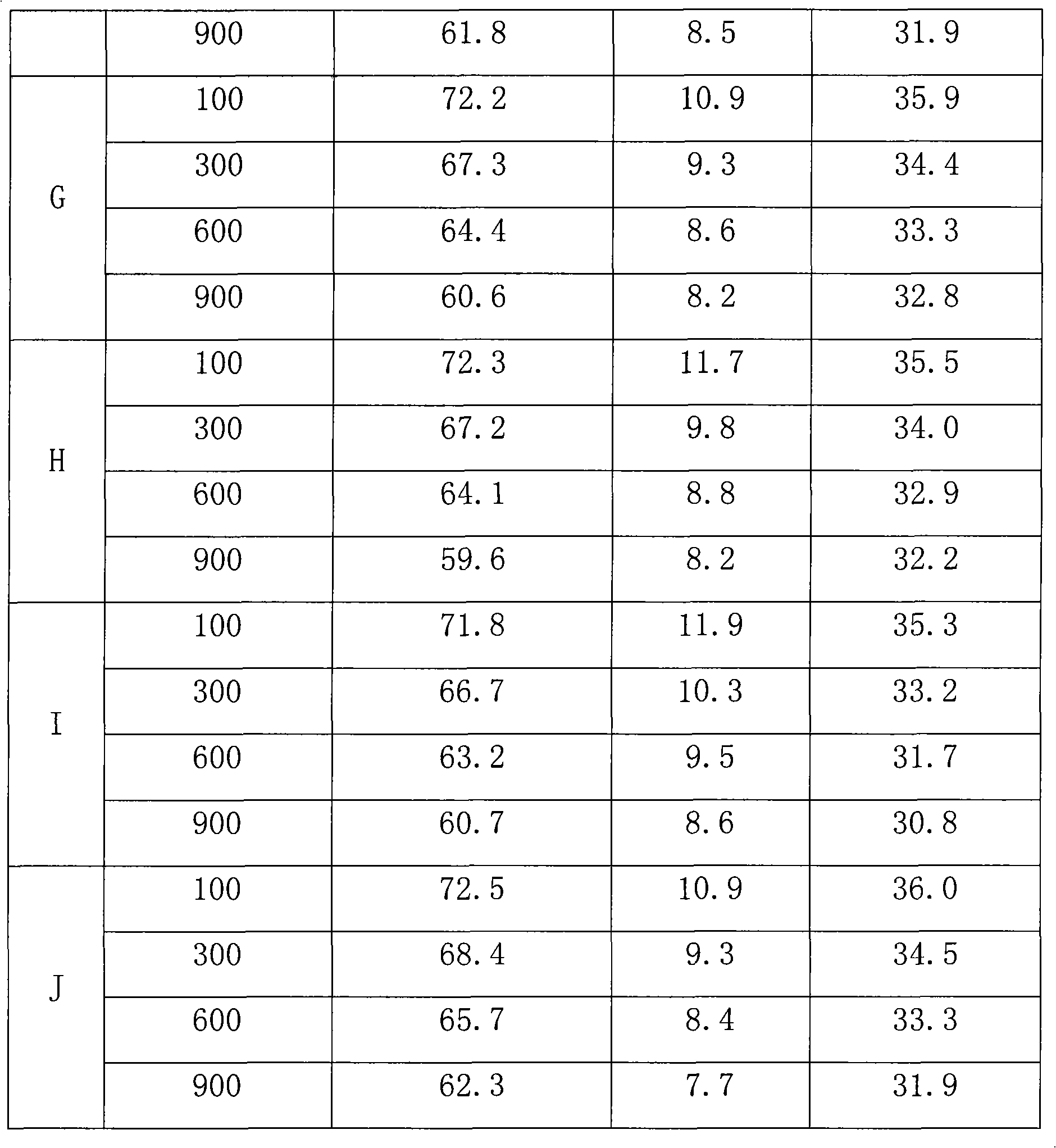

Examples

preparation example Construction

[0046] The preparation method of H-type ZSM-5 molecular sieve:

[0047] After the ZSM-5 molecular sieve raw powder with the required silicon-aluminum ratio and particle size was roasted at 550°C to remove the template agent, the ratio of molecular sieve (g) to exchange solution (ml) was 1:10, and NH 4 NO 3 The solution (0.8mol / L) was exchanged in a 90°C water bath for 5 hours, and filtered; the filter cake was exchanged twice with the same amount of exchange liquid as before, filtered, and washed with distilled water until there was no NO in the filtrate. 3 - Existence, drying at 110°C, and calcining at 550°C to obtain HZSM-5 molecular sieve.

Embodiment 1

[0058] The raw powder of ZSM-5 molecular sieve (mole ratio of silicon to aluminum is 180, particle size is 400nm) is processed according to the above preparation method to obtain HZSM-5 molecular sieve. Mix the HZSM-5 molecular sieve with silicon oxide and cinnamon powder in proportion, add an appropriate amount of dilute nitric acid after mixing, extrude into a cylindrical shape with a diameter of 3mm, dry at 120°C and roast at 550°C to obtain ZSM-5 Rods of molecular sieve and silica. Take a certain amount of cylindrical particles, impregnate the particles with a solution containing phosphoric acid at room temperature, filter and separate, dry at 120°C and roast at 550°C. The L citric acid solution was treated in a water bath at 90°C for 3 hours, and after solid-liquid separation, it was calcined at 600°C for 4 hours to obtain the desired catalyst E.

Embodiment 2

[0060] The raw powder of ZSM-5 molecular sieve (mole ratio of silicon to aluminum is 100, particle size is 200nm) is processed according to the above preparation method to obtain HZSM-5 molecular sieve. Mix the HZSM-5 molecular sieve with silicon oxide and cinnamon powder in proportion, add an appropriate amount of dilute nitric acid after mixing, extrude into a cylindrical shape with a diameter of 3mm, dry at 120°C and roast at 550°C to obtain ZSM-5 Rods of molecular sieve and silica. Take a certain amount of cylindrical particles, impregnate the particles with a solution containing phosphoric acid at room temperature, filter and separate, dry at 120°C and roast at 550°C. The desired catalyst F was obtained by treating L citric acid solution in a water bath at 80°C for 5 hours, separating solid and liquid at 600°C for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com