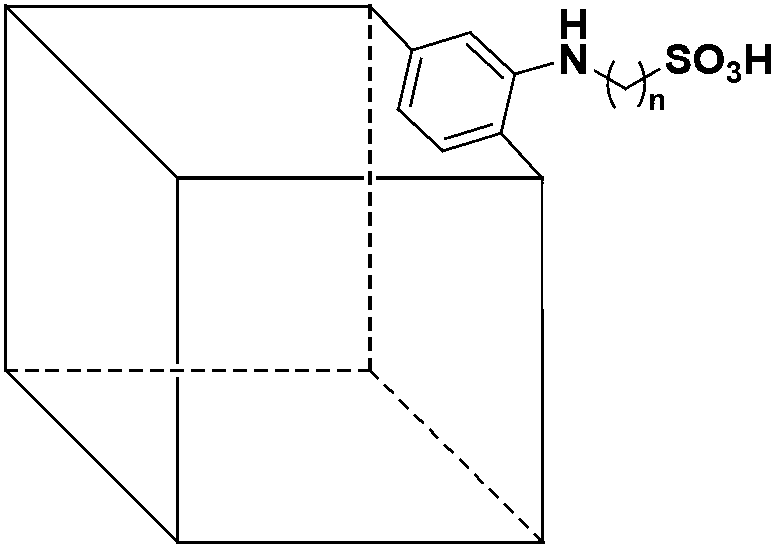

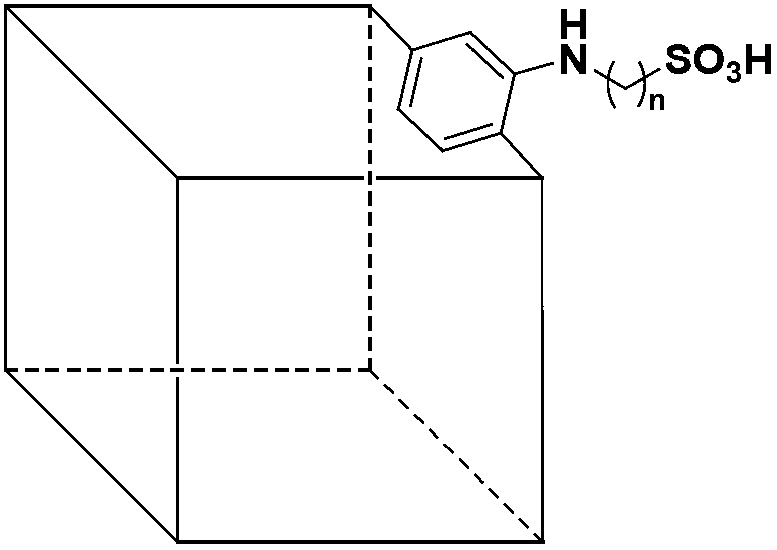

Method for catalytic esterification of -SO3H-containing metal-organic framework compound

A metal-organic framework, -SO3H technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve problems such as difficult product separation, harsh reaction conditions, and large losses , to achieve the effect of strong controllability, simple separation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: 10 mmol of n-butanol, 10 mmol of glacial acetic acid and 16 mg of IRMOF-3a were added to a 25 ml one-necked flask with a stirring bar and a reflux condenser. The reaction was vigorously stirred at 110°C for 45 minutes, cooled to room temperature and filtered. The filtrate was detected by gas chromatography with a conversion rate of 98%, a selectivity of 100%, and a yield of 98%. The filter residue was vacuum-dried at 120°C for 8 hours to remove water and then recycled.

Embodiment 2

[0016] Example 2: 10 mmol of n-octanol, 15 mmol of glacial acetic acid and 16 mg of IRMOF-3a were respectively added to a 25 ml one-necked flask equipped with a stirring bar and a reflux condenser. The reaction was vigorously stirred at 110°C for 60 minutes, cooled to room temperature and filtered. The filtrate was detected by gas chromatography with a conversion rate of 94%, a selectivity of 100%, and a yield of 94%. The filter residue was vacuum-dried at 120°C for 8 hours to remove water and then recycled.

Embodiment 3

[0017] Example 3: 20mol ethanol, 10mmol oxalic acid and 36mg IRMOF-3b were respectively added into a 25ml single-necked bottle with a stirring bar and a reflux condenser. The reaction was vigorously stirred at 110°C for 60 minutes, cooled to room temperature and filtered. The filtrate was detected by gas chromatography with a conversion rate of 92%, a selectivity of 100%, and a yield of 92%. The filter residue was vacuum-dried at 120°C for 8 hours to remove water and then recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com