Patents

Literature

89 results about "Langmuir" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The langmuir (symbol: L) is a unit of exposure (or dosage) to a surface (e.g. of a crystal) and is used in ultra-high vacuum (UHV) surface physics to study the adsorption of gases. It is a practical unit, and is not dimensionally homogeneous, and so is only used in this one field. It is named after American physicist Irving Langmuir.

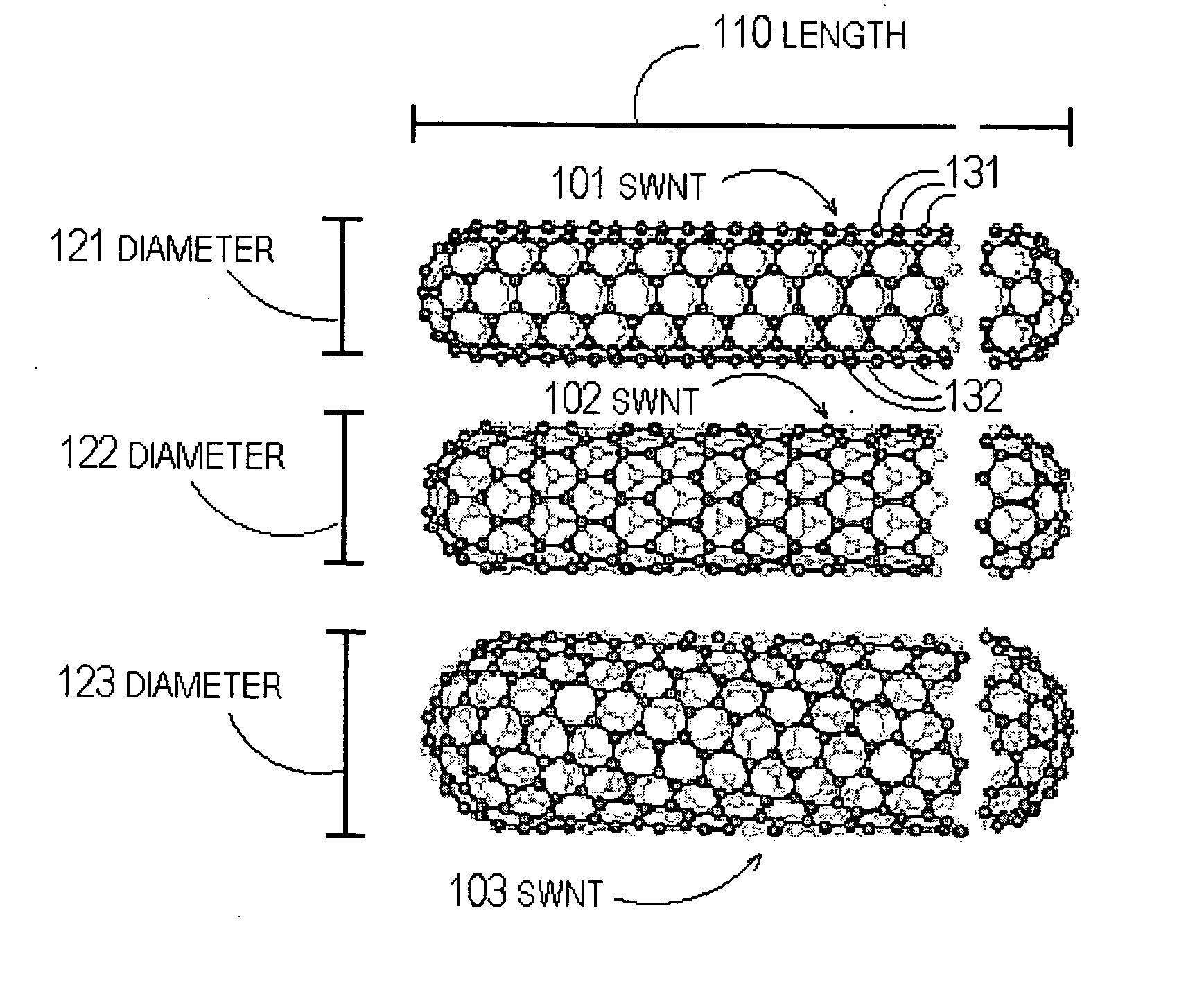

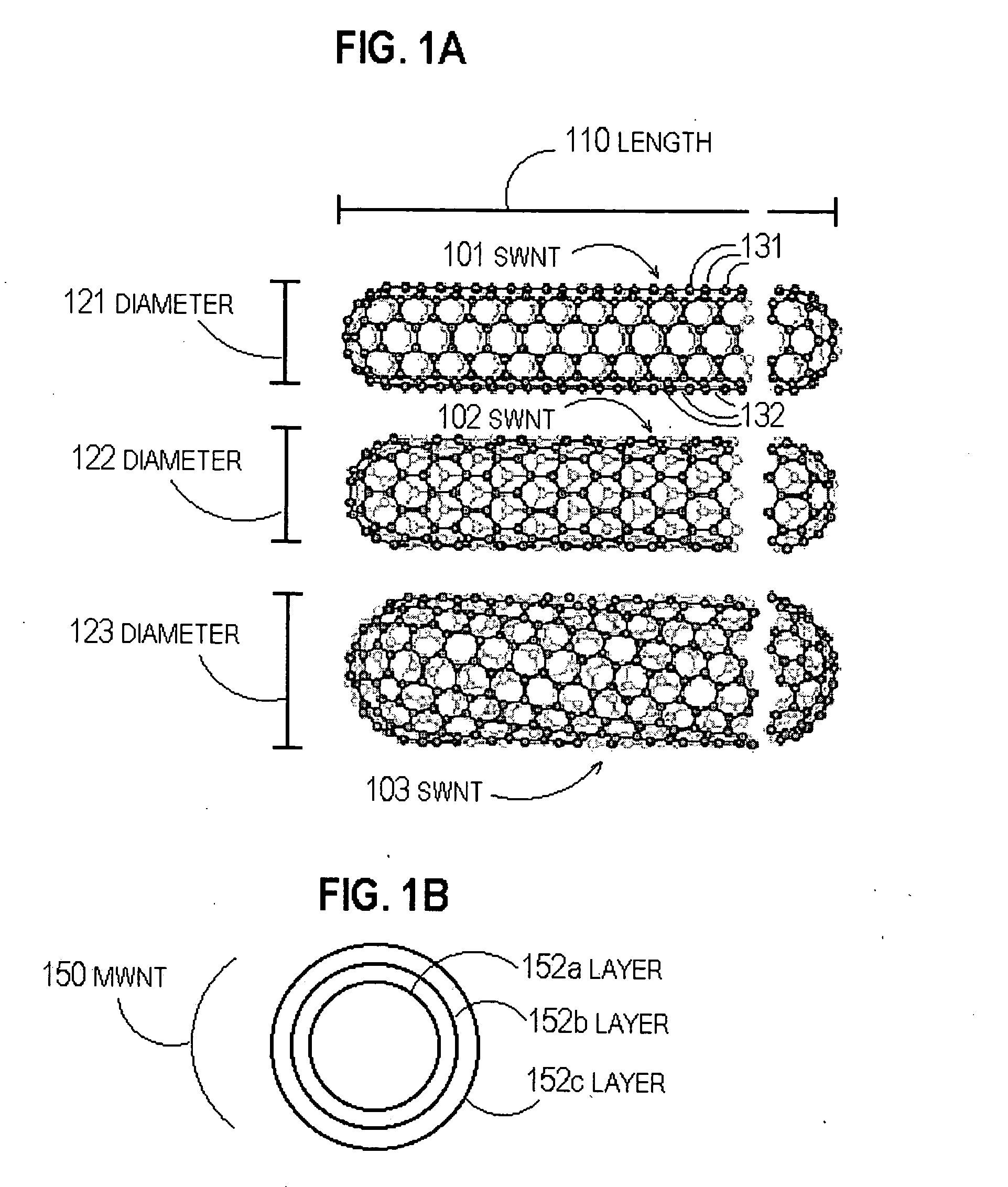

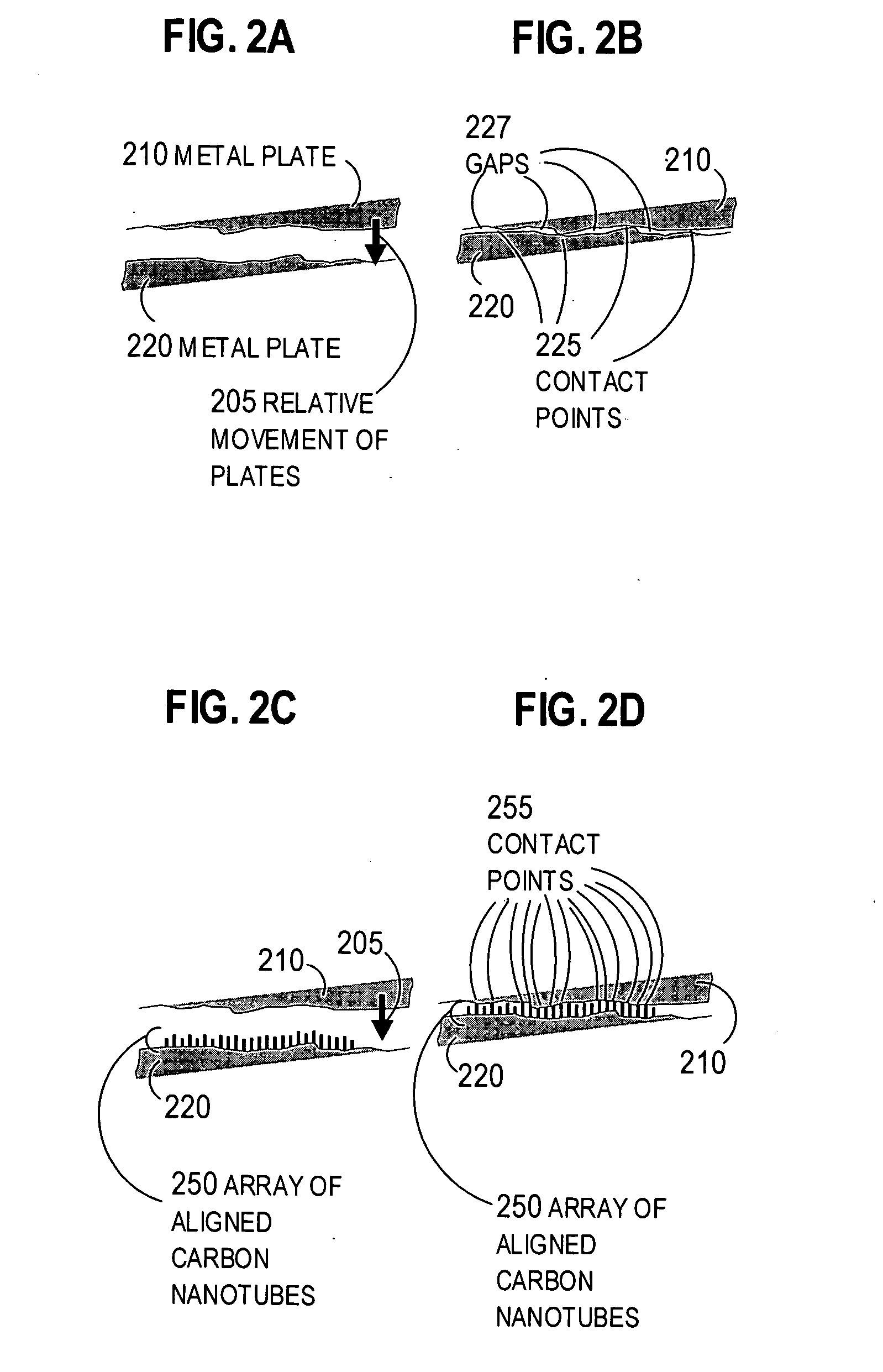

Method of making carbon nanotube arrays, and thermal interfaces using same

Thermal interfaces and methods include an array of carbon nanotubes aligned substantively perpendicularly from a substrate. One method includes arranging metal catalyst particles with a particular ligand on a fluid surface of a Langmuir-Blodgett trough. This forms uniformly spaced particles with spacing based on the particular ligand. The uniformly spaced metal catalyst particles are deposited on a substrate and carbon nanotubes are grown on the particles using chemical vapor deposition. A highly efficient thermal interface can be produced with a carbon nanotube packing ratio greater than fifty percent and used in a thermal switch or other device. In some methods, commercially available nanotubes are condensed on a substrate using carbon nanotubes with terminal carboxylic acids in solution and an amine monolayer on the substrate. Pretreatment of the nanotubes in a switch by applying heavy pressure between two surfaces results in good thermal conductivity between those surfaces at smaller operating pressures.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

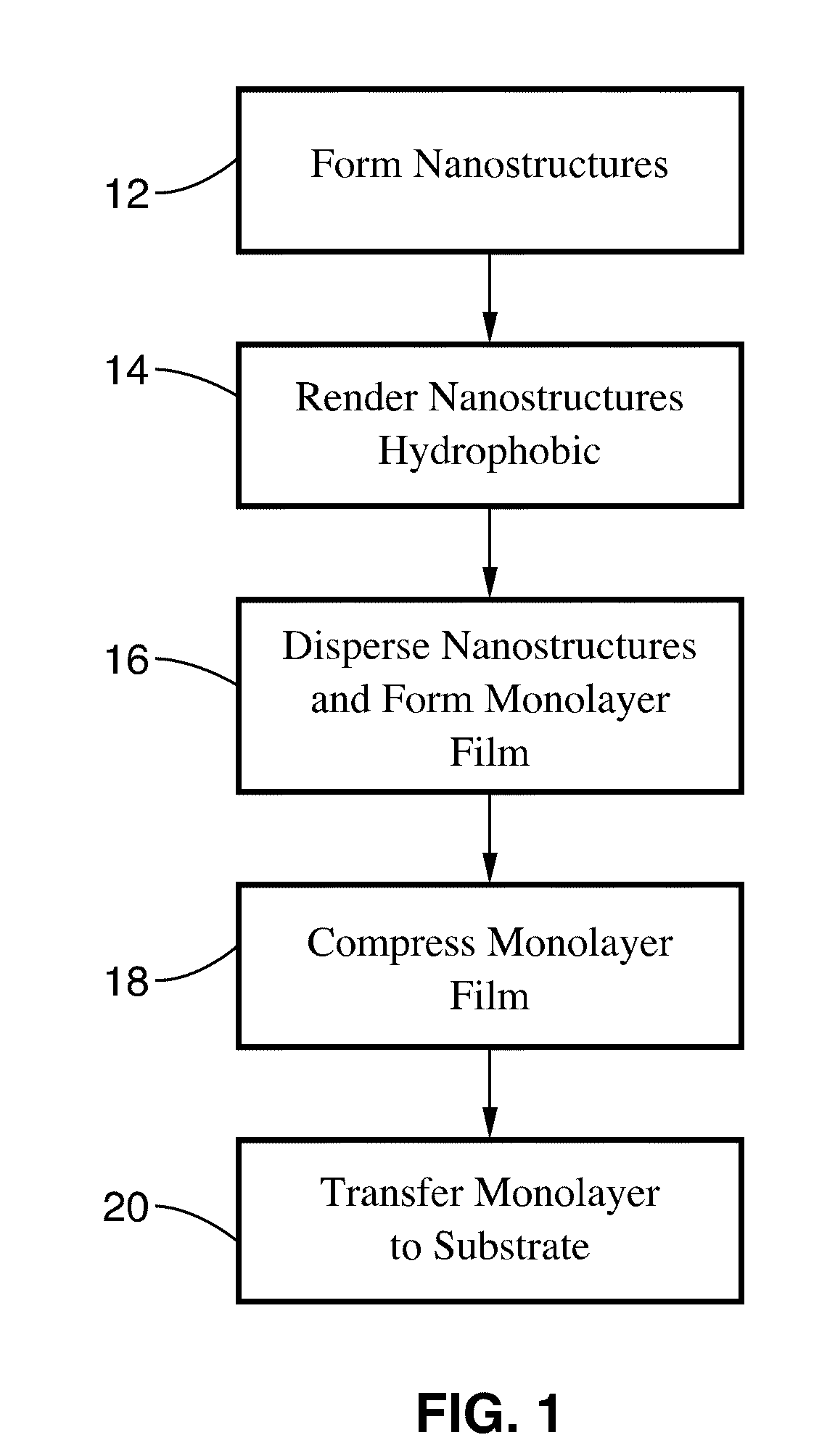

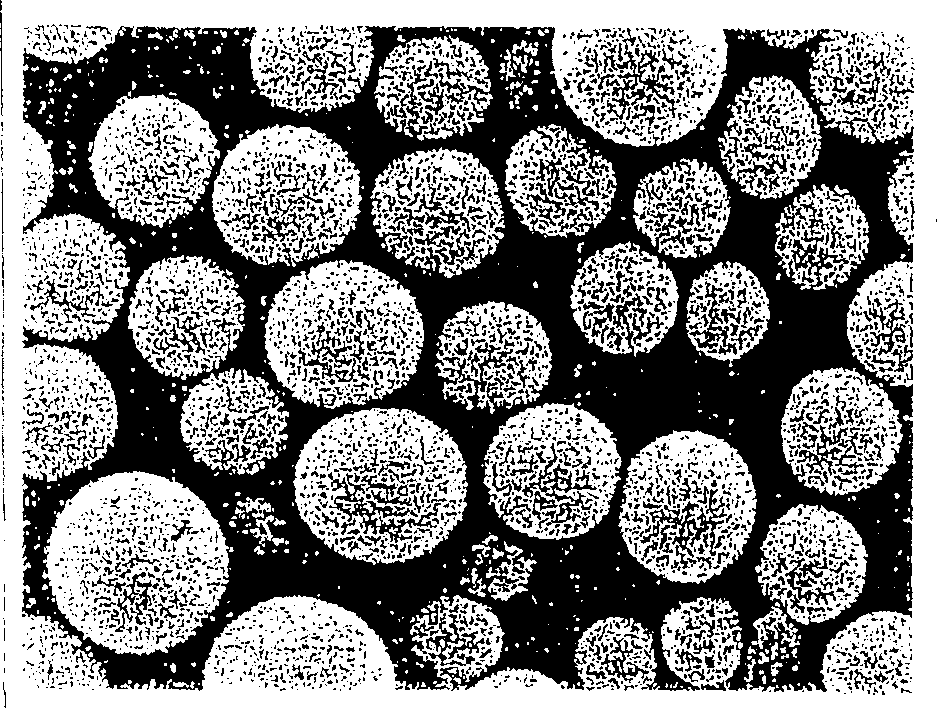

Langmuir-blodgett nanostructure monolayers

InactiveUS20090169807A1Easy to useLarge field enhancementLiquid surface applicatorsNanostructure manufactureNanoparticleEngineering

Methods for assembly of monolayers of nanoparticles using the Langmuir-Blodgett technique, as well as monolayers, assemblies, and devices are described. The surface properties of these monolayers are highly reproducible and well-defined as compared to other systems. These monolayers can readily be used for molecular detection in either an air-borne or a solution environment, and sensors using the monolayer could have significant implications in chemical and biological warfare detection, national and global security, as well as in medical detection applications.

Owner:RGT UNIV OF CALIFORNIA

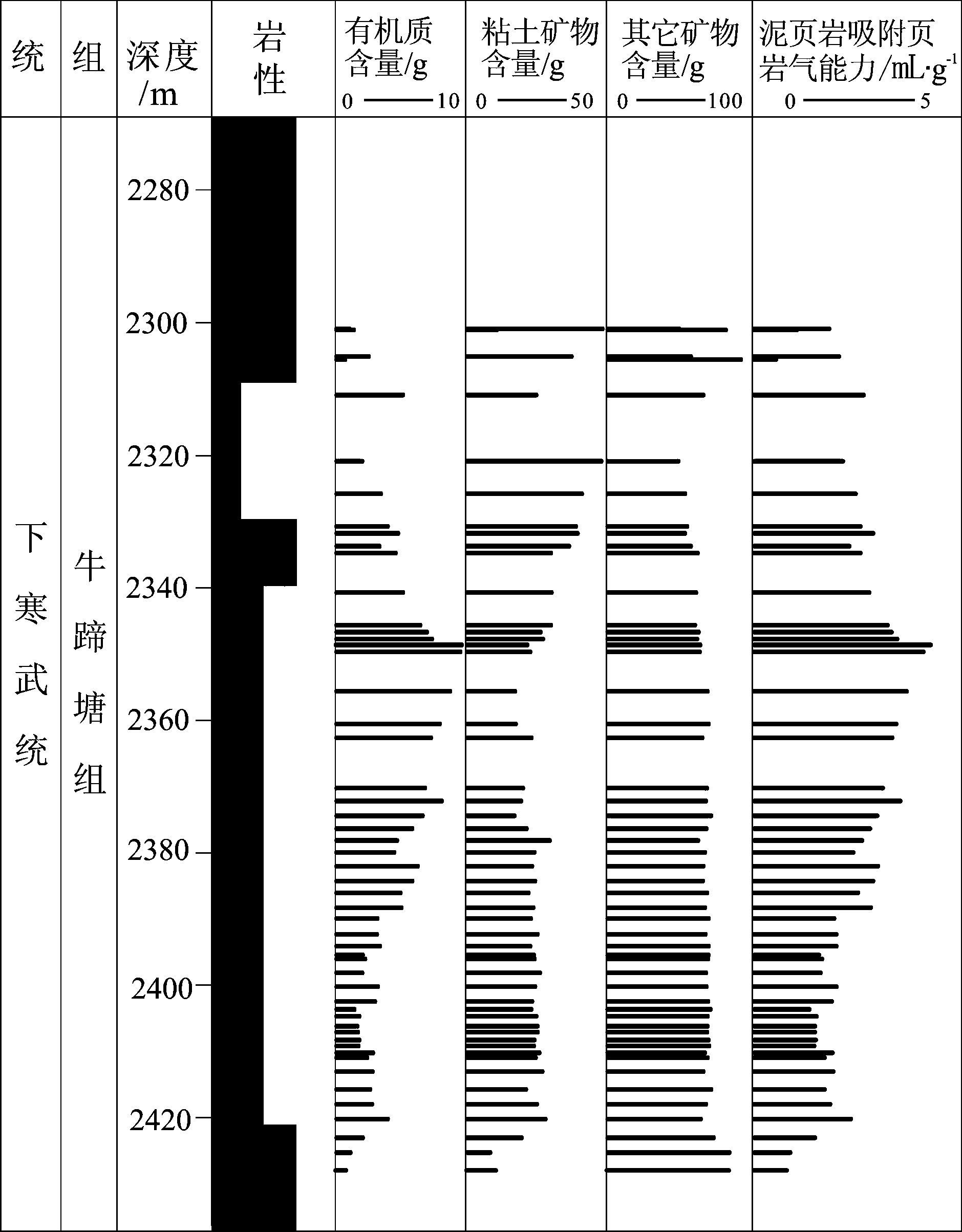

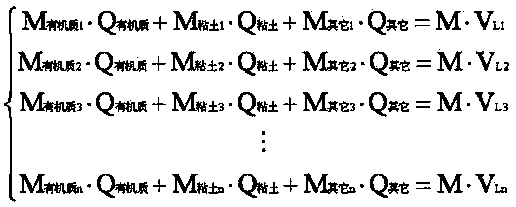

Method used for evaluating shale gas adsorption capacity of shale

InactiveCN103411848ARealize quantitative evaluationEasy to operateMaterial analysisClay mineralsRock core

The invention discloses a method used for evaluating shale gas adsorption capacity of shale, and belongs to the field of petroleum, geological and mining exploration and development technologies. The method is capable of calculating the shale gas adsorption capacity of shale reservoirs under the formation temperature, and solving a problem that the cost of existing on-site core analysis technology and adsorption isothermal experiment is high. The method comprises following steps: the contents of organic matter, clay mineral and other minerals of samples collected from different depth of a same shale reservoir are determined; adsorption isothermal experiments of the samples are performed so as to determine the Langmuir volumes of the samples under the formation temperature; an equation set is established based on the contents and the Langmuir volumes of the organic matter, the clay mineral and the other minerals of the shale samples so as to determine the shale gas adsorption capacities of the organic matter, the clay mineral and the other minerals under the formation temperature; and the Langmuir volume of a related depth point is calculated based on the contents of the organic matter, the clay mineral and the other minerals of other depth points.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of compound nano film

InactiveCN103396573AImprove conductivityImprove electrochemical activityConductive polymerThin membrane

The invention discloses a preparation method of a compound nano film, and belongs to the field of electronic film materials. The method comprises the steps as follows: GOQDs (graphene oxide quantum dots) are assembled in a substrate with an LB (Langmuir blodgett) film method, and then conducting polymers are deposited on the GOQDs in a spin-coating manner, so that the compound nano film with the GOQDs tightly wrapped with the conducting polymers is formed. According to the preparation technique of the GOQDs / conducting polymer compound nano film, the defects in the prior art are overcome, large-area film formation can be implemented easily, the preparation method is reasonable, simple and easy to operate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

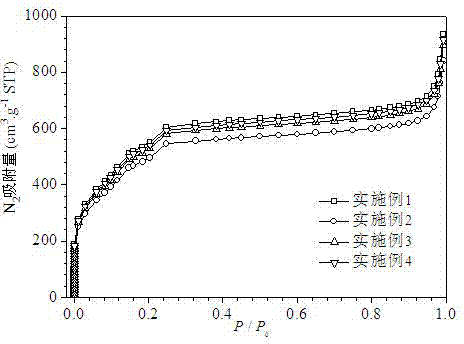

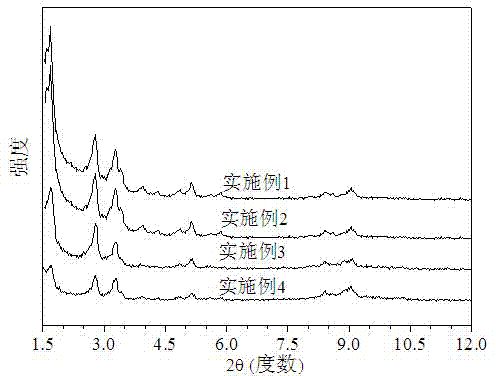

Preparation method of hydrophobic MIL-101 chromium organometallic skeleton material

ActiveCN102408447ALangmuir high surface areaLarge adsorption capacityOther chemical processesDispersed particle separationChromium nitrateMaterials science

The invention discloses a preparation method of a hydrophobic MIL-101 chromium organometallic skeleton material. The method comprises the following steps: dissolving chromium nitrate and 1,4-naphthalenedicarboxylic acid in water, adding hydrofluoric acid and acetic acid to stir evenly, performing a hydrothermal reaction at 210-220 DEG C, washing the obtained product with deionized water, dimethylformamide and ethanol in turn, centrifuging, filtering, and drying to prepare the hydrophobic MIL-101 chromium organometallic skeleton material. The hydrophobic MIL-101 chromium organometallic skeleton material has high Langmuir surface area and also has the high specific surface area and micro-mesoporous skeleton of a traditional MIL-101 material; and as a benzene ring is grafted on the organic connector in the skeleton, the material has higher hydrophobicity and the adsorption capacity of the material to nonpolar organic volatile substances can be increased.

Owner:SOUTH CHINA UNIV OF TECH

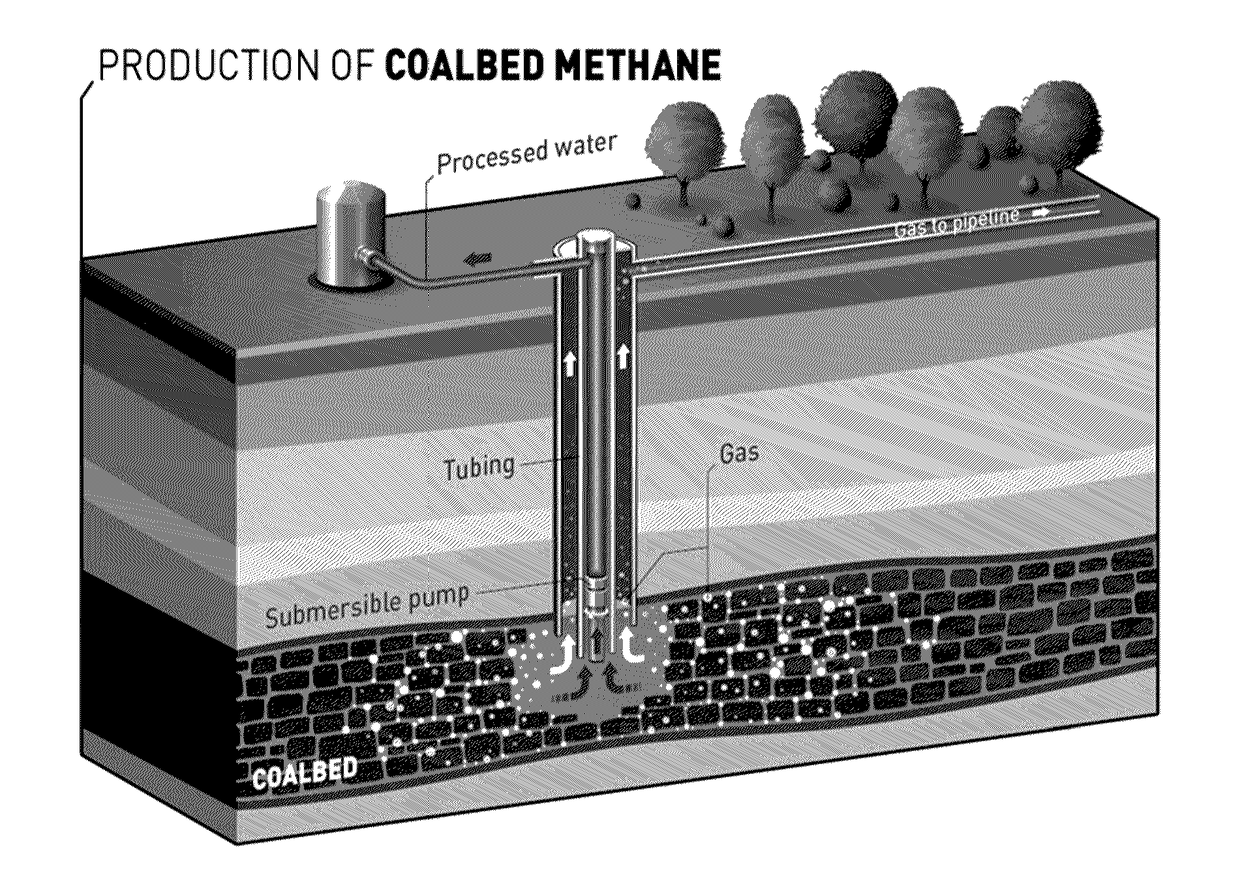

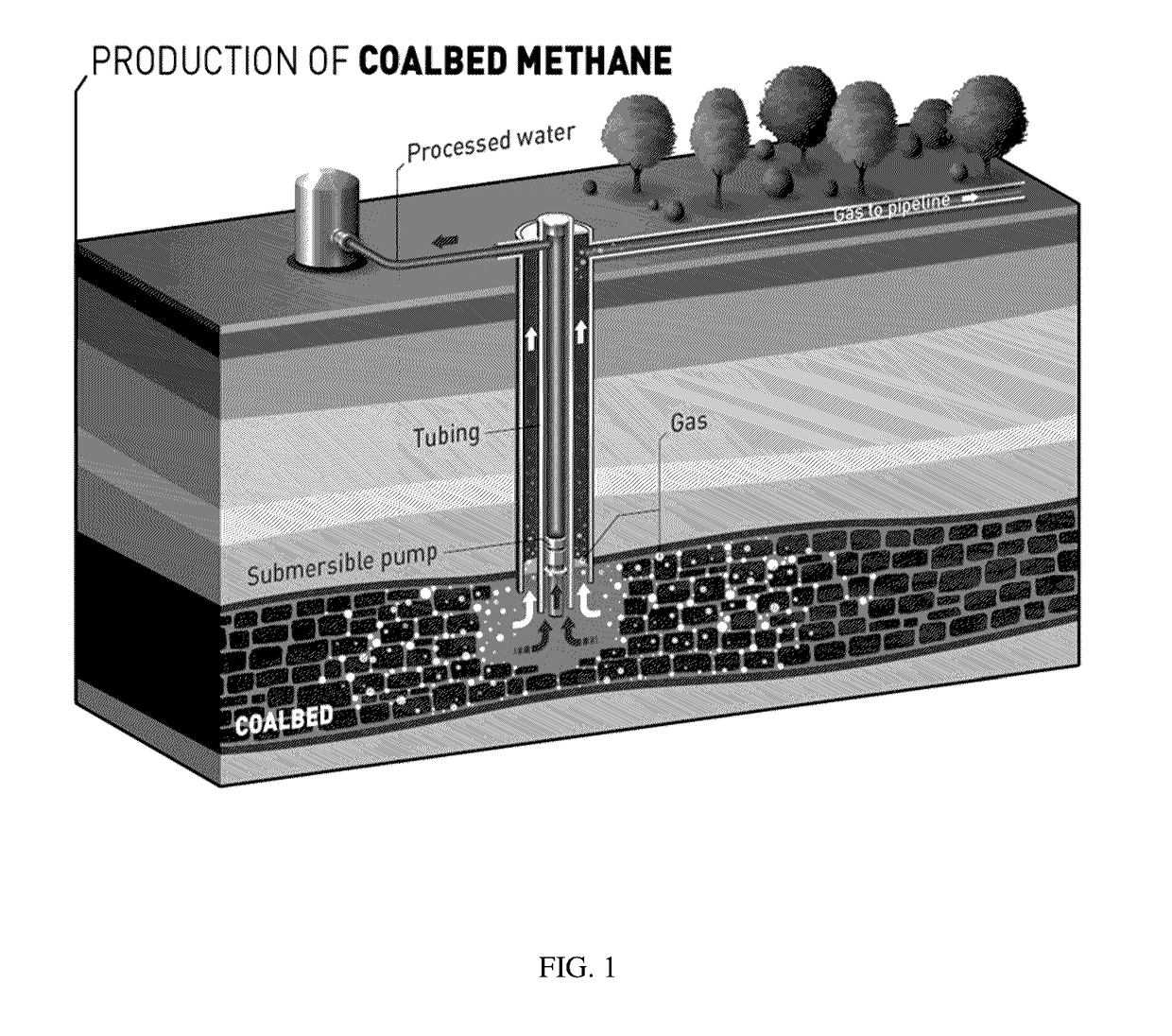

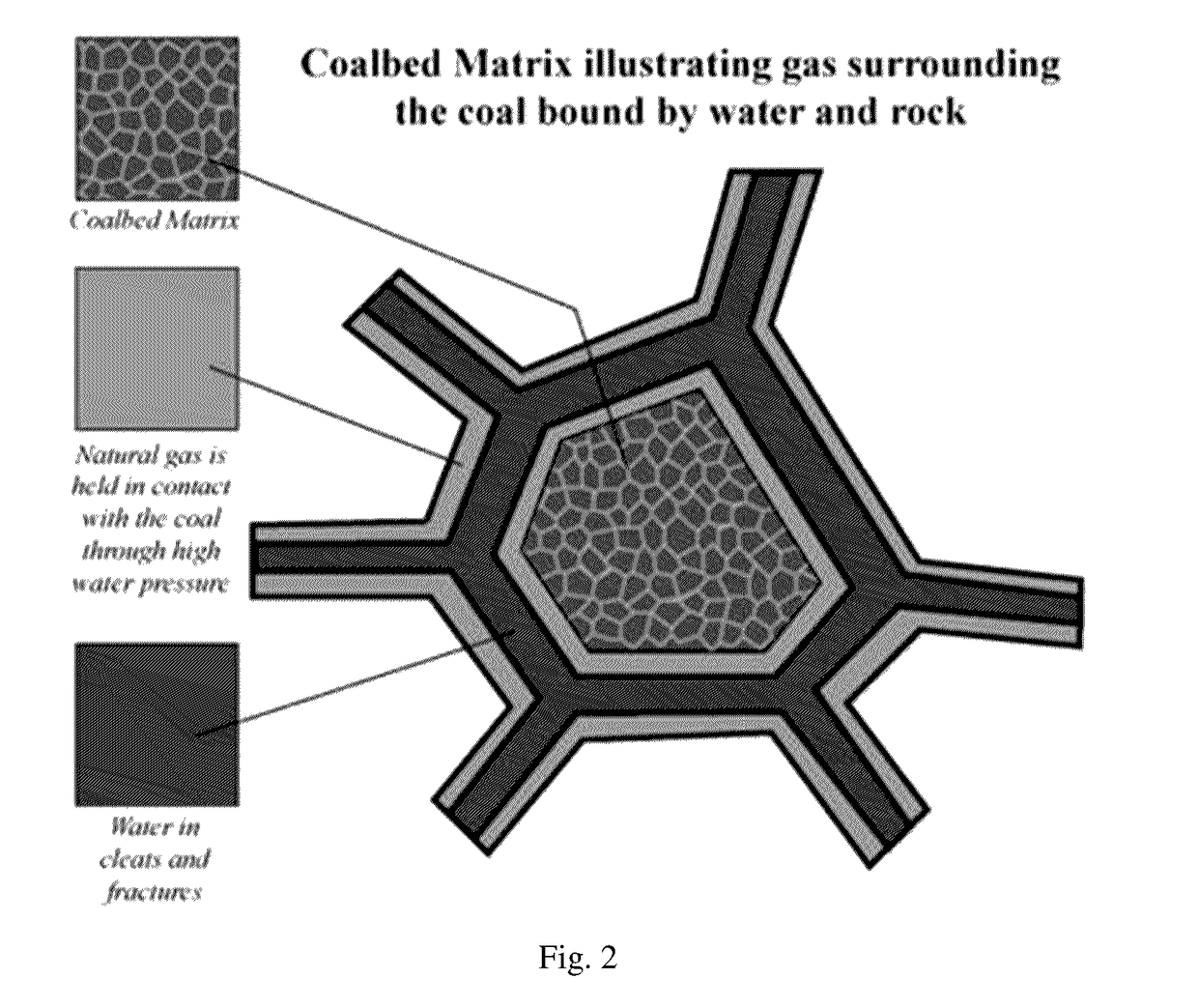

Modeling method for gas production of cbm reservoir rocks

ActiveUS20180306009A1Low reliabilityIncrease the number ofFluid removalDesign optimisation/simulationModel methodTime changes

The present invention includes (a) dividing the reservoir in a coalbed methane (CBM) development area through computer modeling and thereby forming a three-dimensional grids having a plurality of cell, (b) actually forming drilling holes in the development area and thereby obtaining core samples for each depth, (c) modeling the amounts of ash, water, and gas in each of the cells, (d) modeling the pressure change over time in each of the cells under a premise in which a production well is formed in the grids, and (e) performing a Langmuir experiment for the core samples, determining a Langmuir function for a maximum amount of gas adsorption with pressure and amounts of ash and water as variables, and applying the Langmuir function to each of the cells to calculate an amount of gas detected due to pressure change over time.

Owner:KOREA GAS CORPORATION

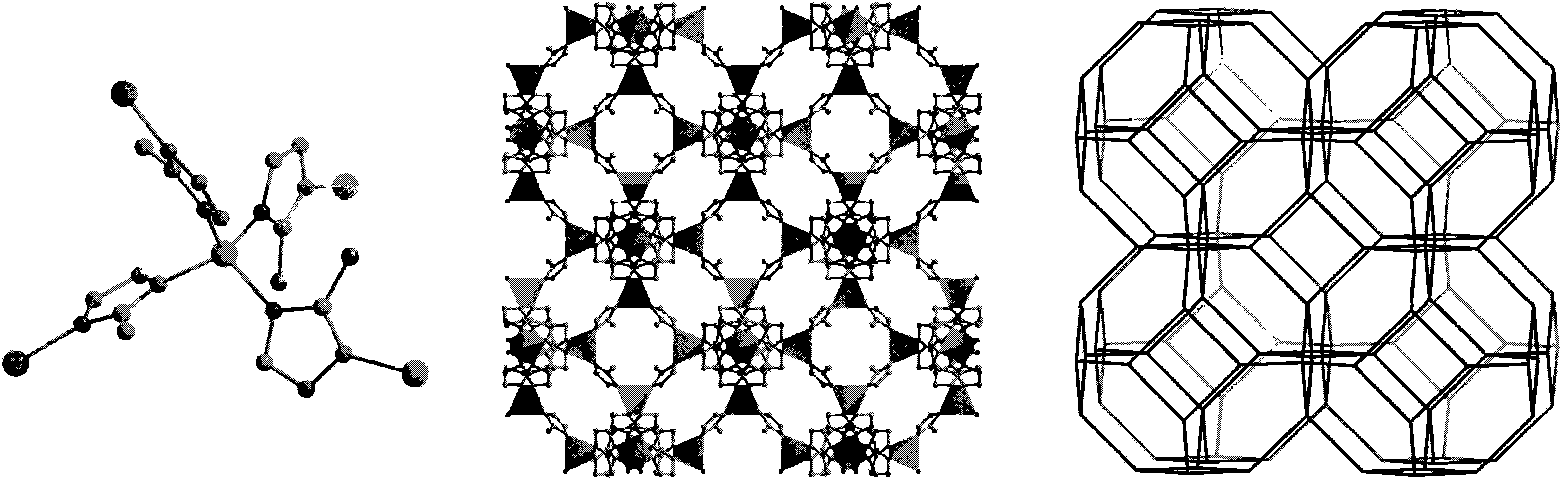

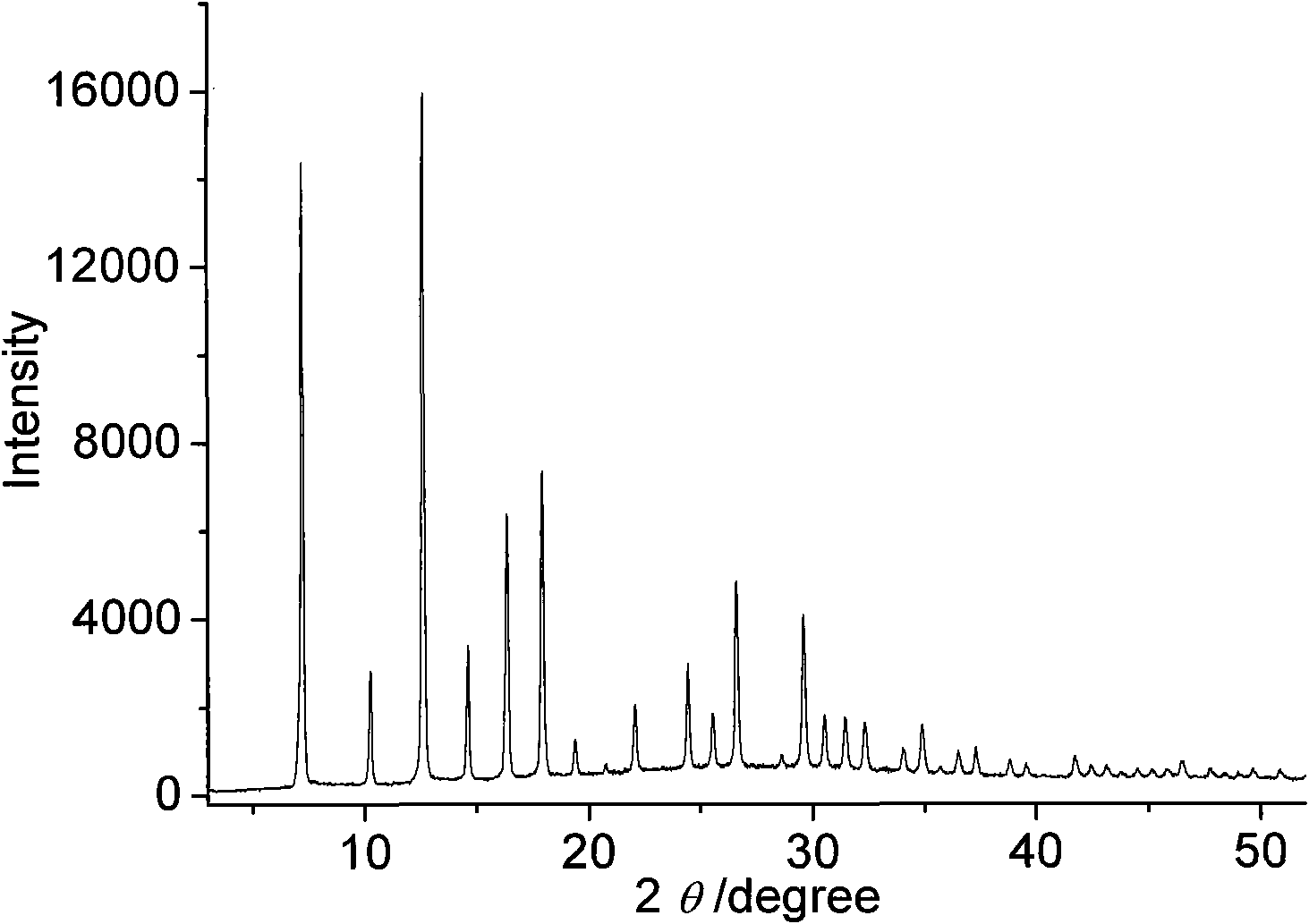

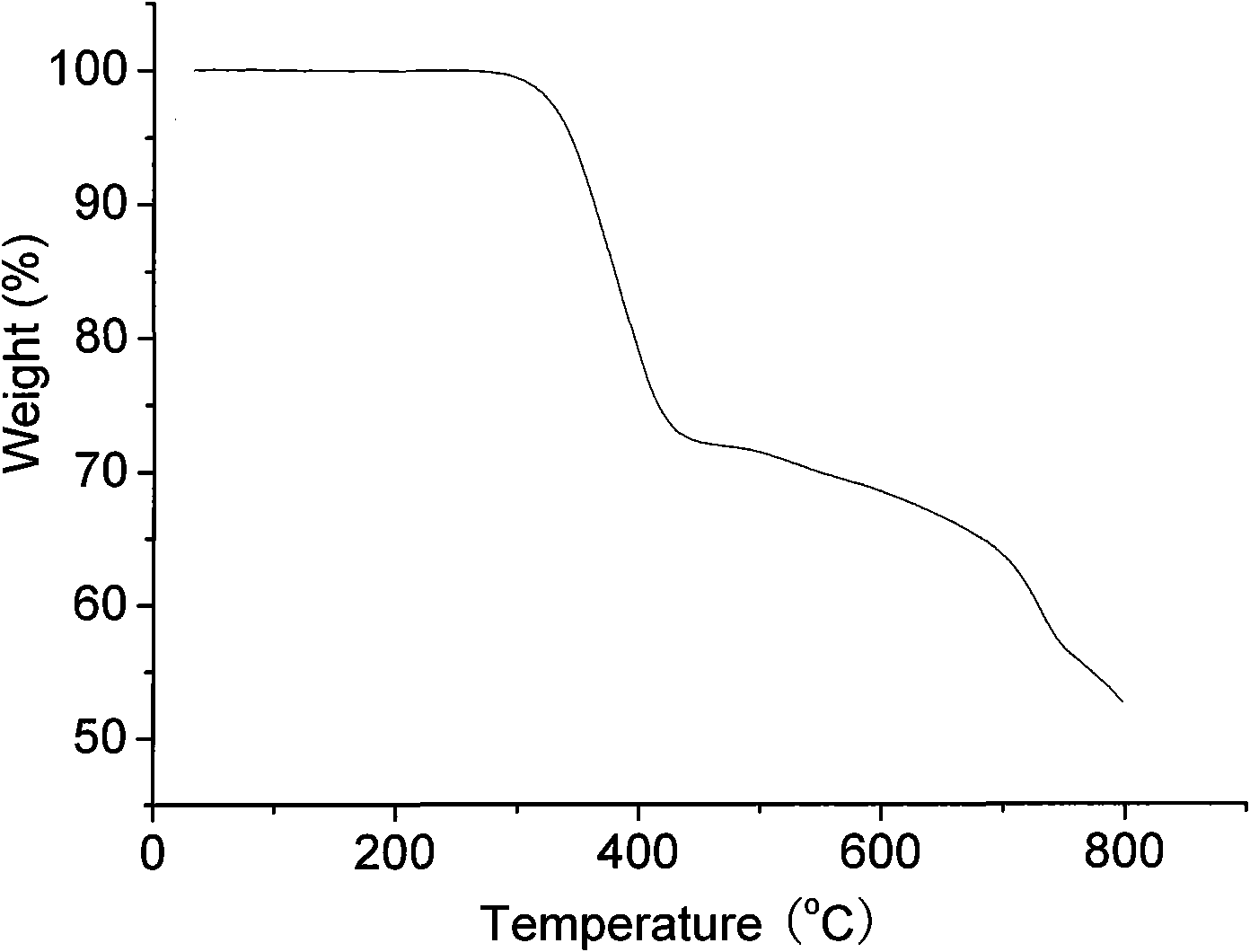

Sodalite porous coordination polymer material as well as preparation method and application thereof

InactiveCN101830857ALarger than surfaceHigh void ratioOther chemical processesDispersed particle separationSpace groupMethyl group

The invention discloses a sodalite porous coordination polymer material as well as a preparation method and application thereof. The sodalite porous coordination polymer material has a chemical formula of [Zn(mtz)2-x(mim)x] infinity (0<=x<2), wherein mtz is a deprotoned 3-methyl-1,2,4-triazole anion, and mim is a deprotoned 2-methylimidazole anion. The polymer material is crystallized in a cubic system and in an I-43m space group, the length of an alpha axis is 1.70 nm, the divalent zinc ion is quadridentate, mim is bidentate, and mtz is bidentate; and a nitrogen atom is not coordinated. The sodalite porous coordination polymer material has a sodalite three-dimensional coordination network structure and a cesium chloride three-dimensional pore canal with a pore ratio of 50%, and has good thermal stability and chemical stability; and the Langmuir specific surface is greater than 1800 m<2> / g, and various gases and vapor can be absorbed effectively. The sodalite porous coordination polymer material can be used for storing, separating, catalyzing and sensing materials, performing molecular recognition and heat exchange, and the like on materials by absorbing guest molecules.

Owner:SUN YAT SEN UNIV

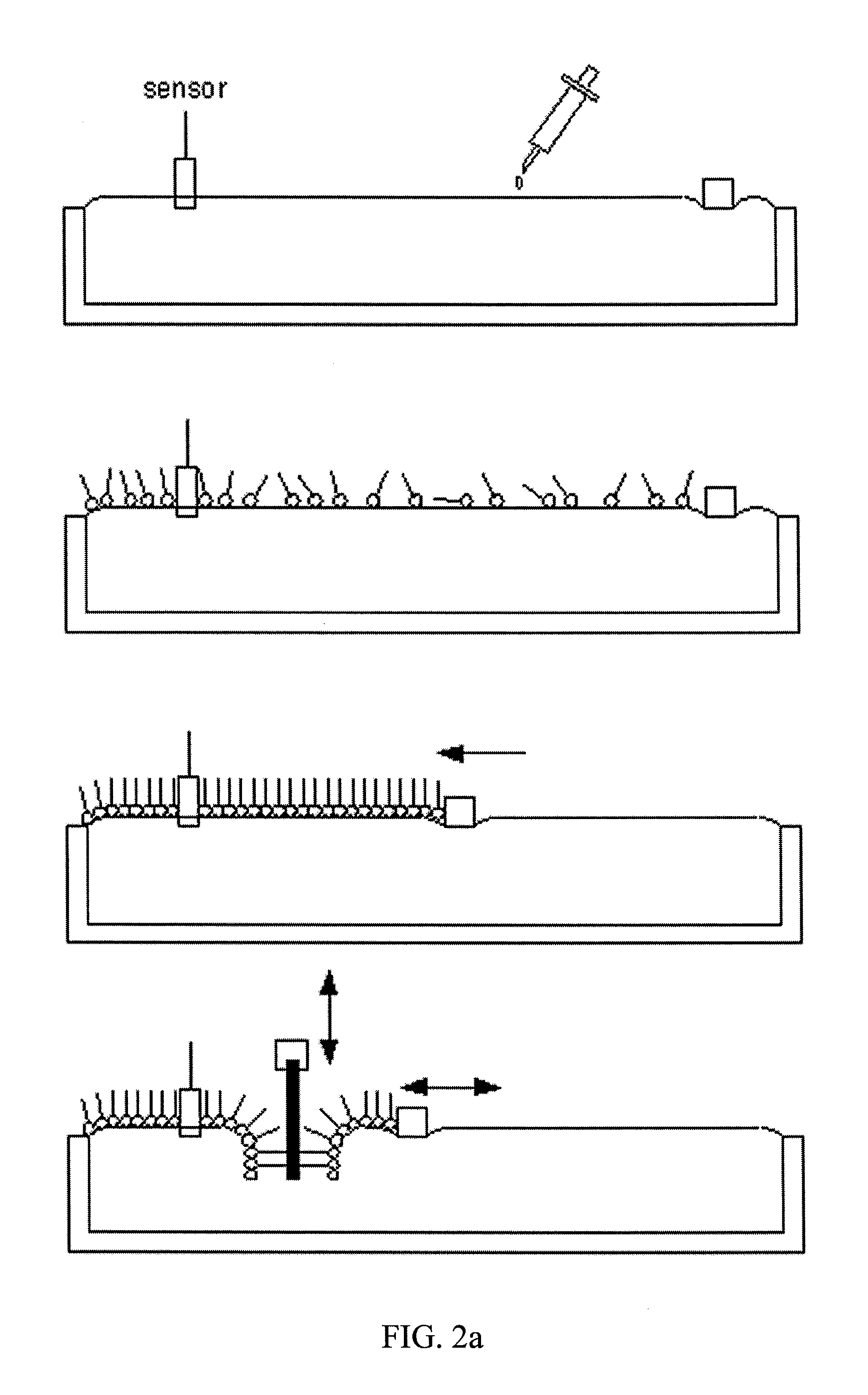

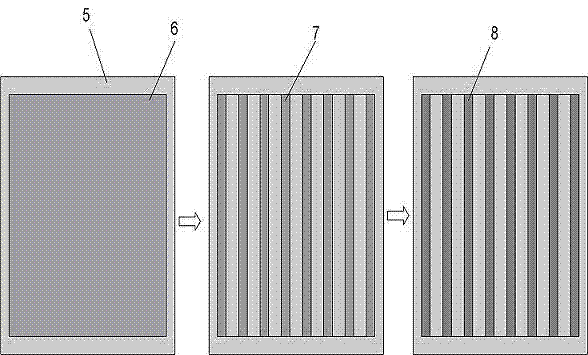

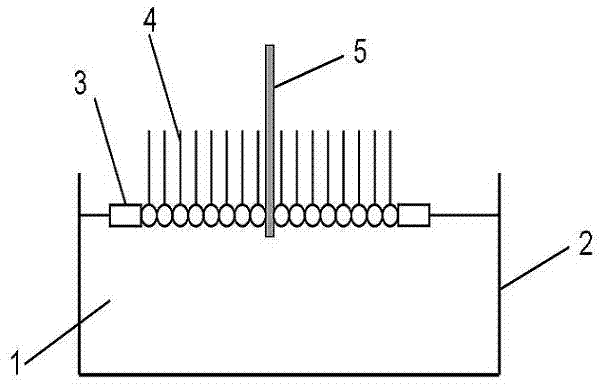

Method for ordered arrangement of nano particles on solid base surface

The present invention relates to nano technology field. The process of arranging nano particles on the surface of solid base includes the specific steps of: dissolving chain organics molecule with hydrophilic or hydrophobic group into non-aqueous volatile solvent; dispersing nano particles in the said solution; spreading the non-aqueous solution on water as base liquid inside Langmuir tank and controlling the film pressure on the single-molecule film of the nano particles on the surface of water; transferring the film via vertical pulling process to treated surface of solid base to form Y-type LB film; and high temperature annealing or high-energy light beam irradiating the nano particle film to dissociate and evaporate organics molecule while leaving the nano particles on the base. The said process is simple, practical and effective and may be used widely.

Owner:SHANGHAI JIAO TONG UNIV

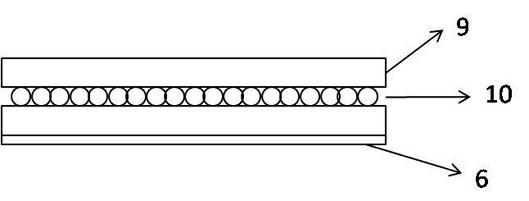

Method for preparing nanocomposite dielectric film

InactiveCN102632675AImprove conductivityExcellent dielectric propertiesFixed capacitor dielectricSynthetic resin layered productsPolymer scienceComposite film

The invention discloses a method for preparing a nanocomposite dielectric film. The method comprises the following steps of: firstly obtaining a polymer dielectric film by a Langmuir-Blodgett (LB) film method; secondly preparing a high-dielectric inorganic / organic composite nanoparticle film on the polymer dielectric film by the LB film method; and finally preparing a polymer dielectric film on the composite nanoparticle film by the LB film method, thereby forming a high-dielectric composite film material with nanoparticles dispersed in a polymer. The polymer-nanoparticle composite dielectric film material prepared by the method overcomes the shortcomings of the prior art, and the preparation method is reasonable and simple, and easy to operate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

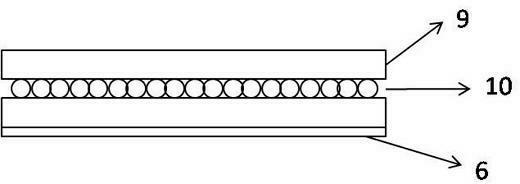

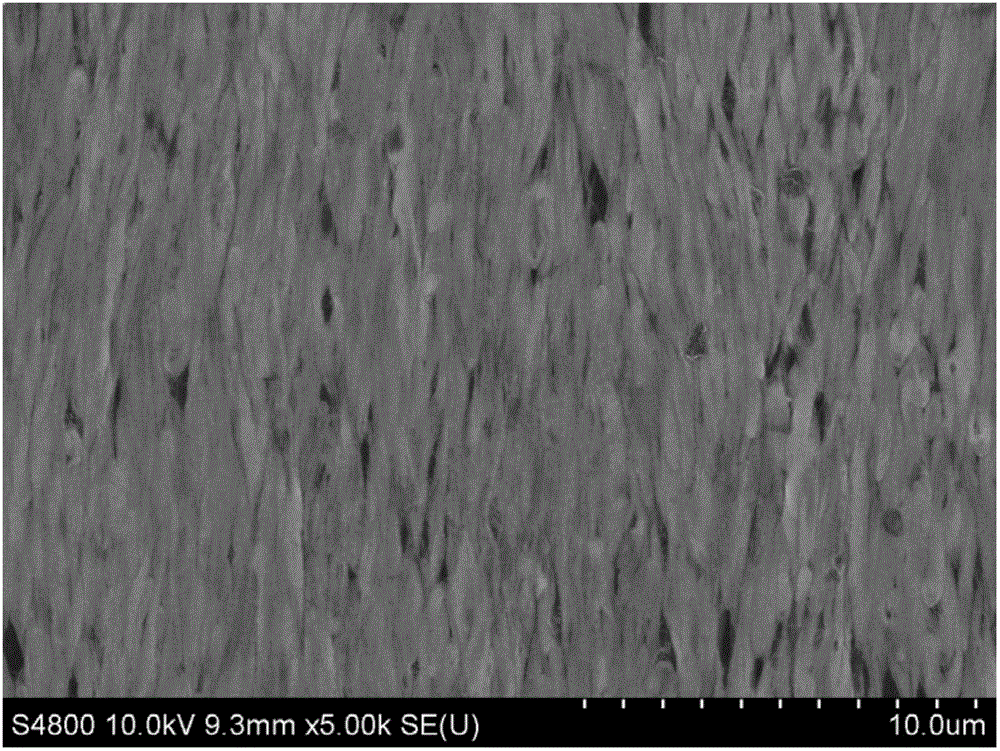

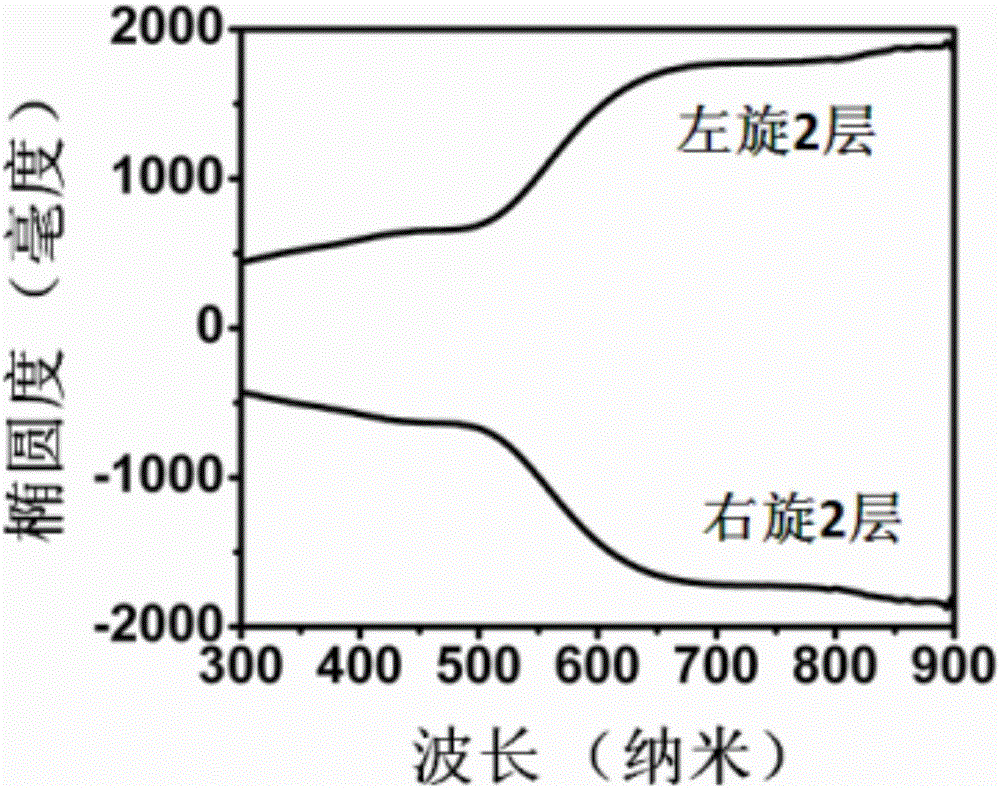

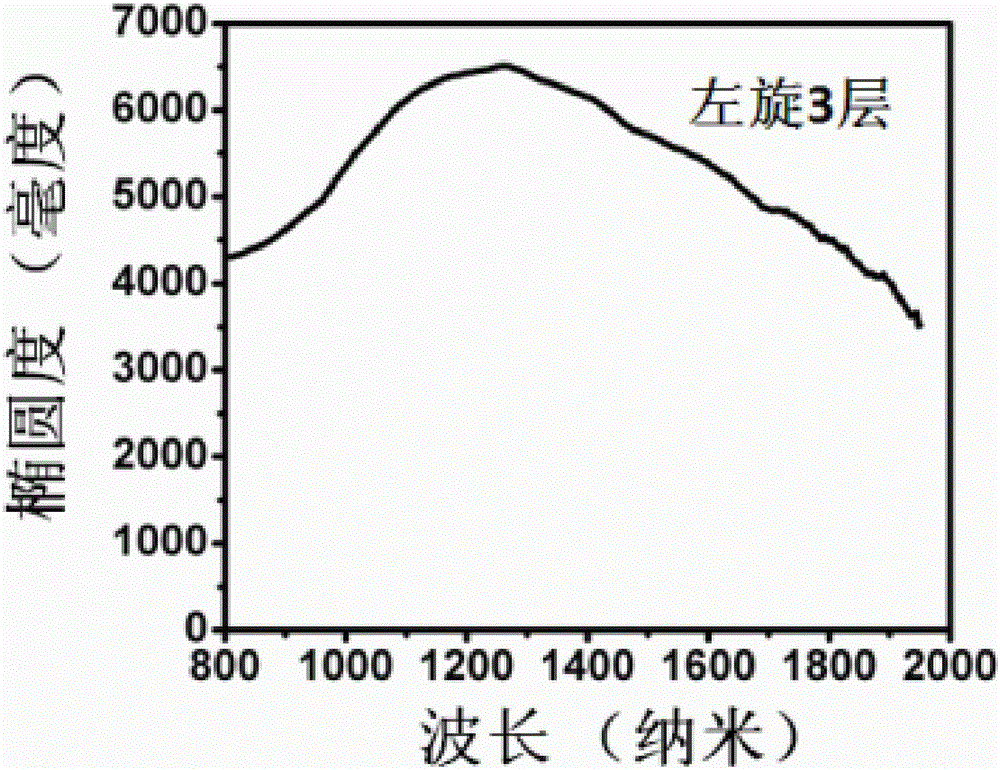

Chiral nano film and preparation method and application thereof

InactiveCN106829854ALong-range orderOptically activeSpecific nanostructure formationMaterial nanotechnologyColloidSolvent

The invention provides a chiral nano film and a preparation method and application thereof. The preparation method of the chiral nano film comprises the steps that a one-dimensional nanomaterial solution is spread on a lower phase in a Langmuir-Blodgett groove, a slide barrier located on the surface of the lower phase pushes a one-dimensional nanomaterial to move on the surface of the lower phase after the solvent is completely volatilized, the area of the one-dimensional nanomaterial is compressed to obtain a one-dimensional nanomaterial assembly film consistent in orientation; a Langmui-Schaeffer transfer method is adopted to transfer the assembly film to a substrate, and the chiral film provided with at least two layers of assembly films is obtained, wherein the assembly films are sequentially staggered clockwise or anticlockwise. The chiral film has ultra-high optical activity, an anisotropy factor is as high as 0.3, the optical activity is highest compared with chiral materials obtained by adopting an existing assembly means, and the preparation method is simple and has universality and wide application prospect.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA +1

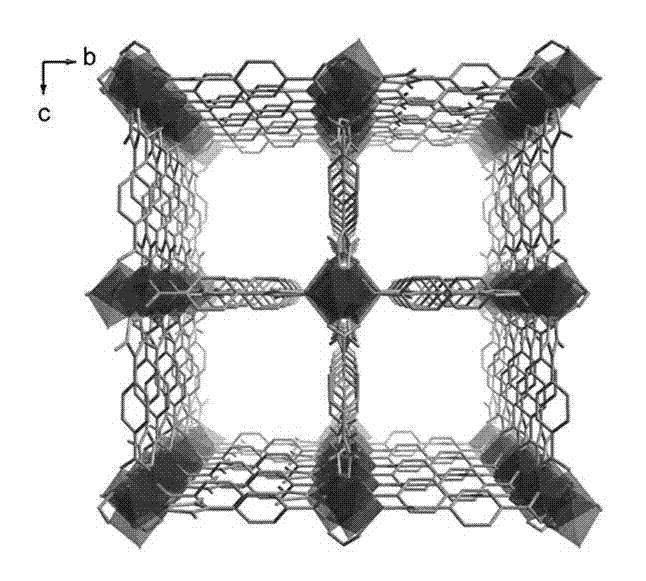

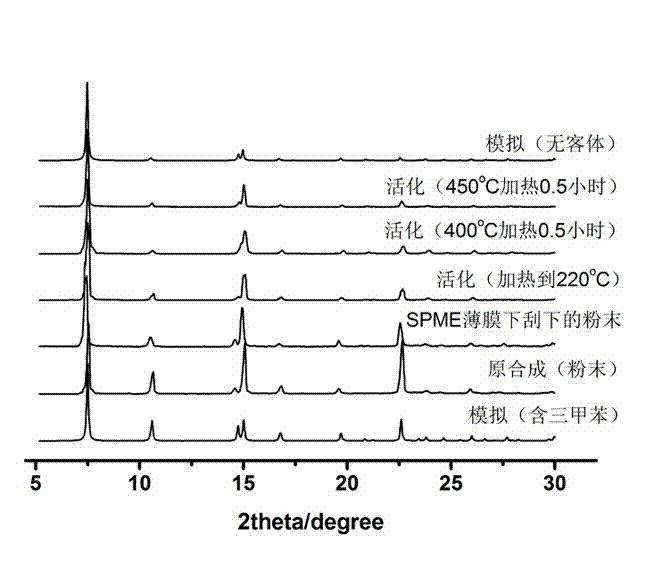

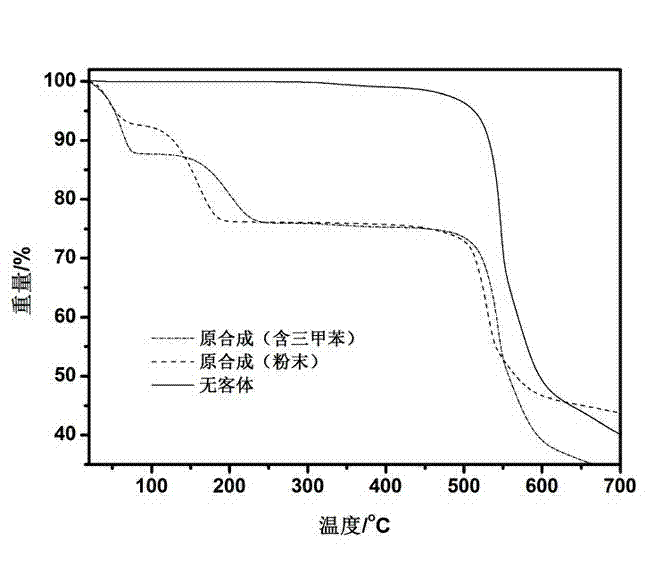

Coordination polymer porous material MAF-X8 and preparing method and application thereof

InactiveCN102775430AImprove thermal stabilityWon't breakOther chemical processesZinc organic compoundsBenzoic acidSpace group

The invention discloses a coordination polymer porous material MAF-X8 and a preparing method and an application thereof. The chemical formula of the coordination polymer porous material MAF-X8 is [Zn (mpba)], wherein the [Zn (mpba)] represents negative ions obtained by removing protons of an organic ligand 2-(3,5-Dimethyl-1H-pyrazol-4-yl) benzoic acid (H2mbpa). MAF-X8 crystals are in an orthorhombic system, an Ibca space group, and in a three-dimensional frame structure with a single-dimensional pore passage formed through the bridging of mbpa2-ligands and quadridentate Zn2+ ions and with a pore rate of 50%, the Langmuir specific surface is larger than 1300m2 / g, and good ghermal stability and chemical stability are provided. Particularly, the coordination polymer porous material MAF-X8 can be conveniently manufactured into thin films to be applied in solid phase micro extraction (SPME), and shows high accumulation ability and adsorption selectivity to non-polar benzene series, and has short adsorption and desorption time, low detection limit, wide linear range and the like simultaneously.

Owner:SUN YAT SEN UNIV

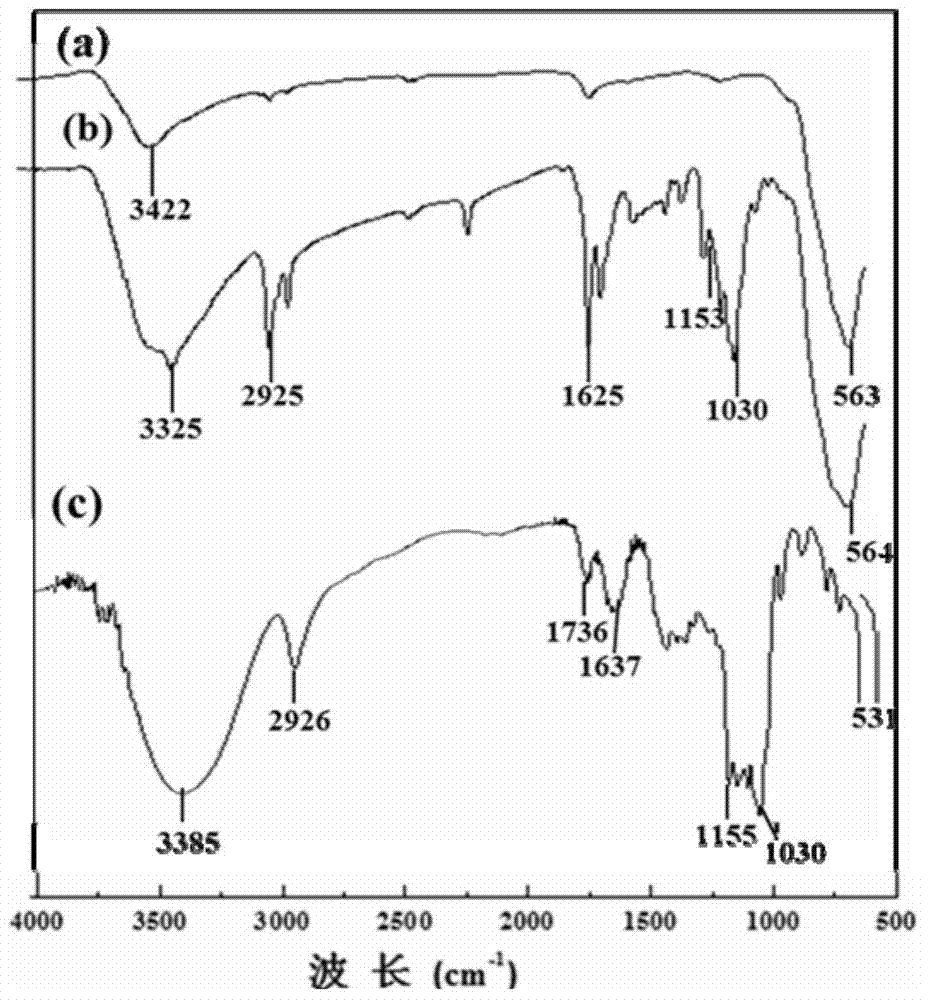

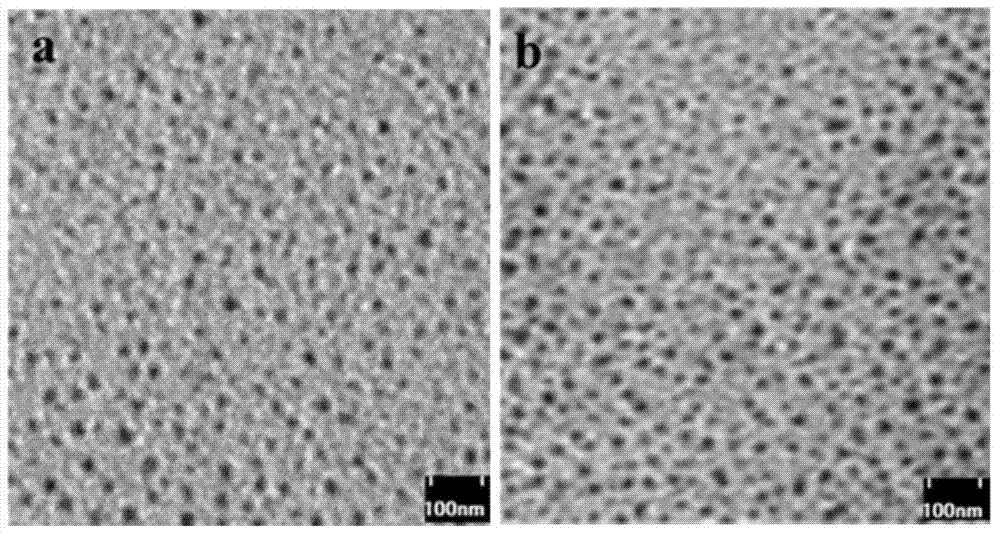

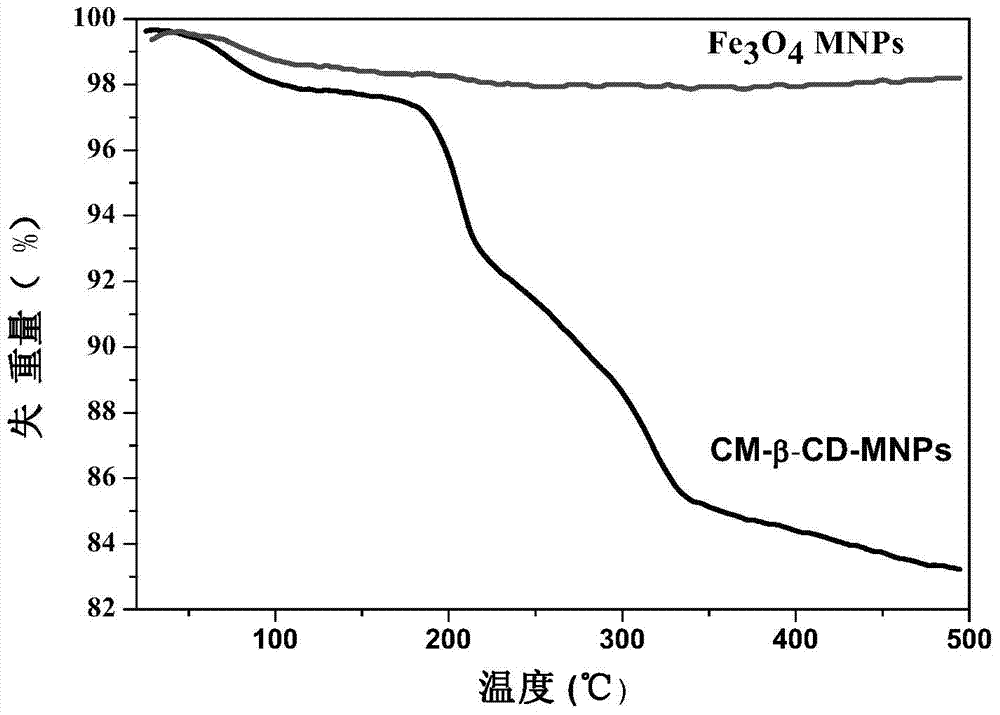

Preparation method of nano pesticide carboxymethyl-beta-cyclodextrin-Fe3O4-magnetic nano-diuron

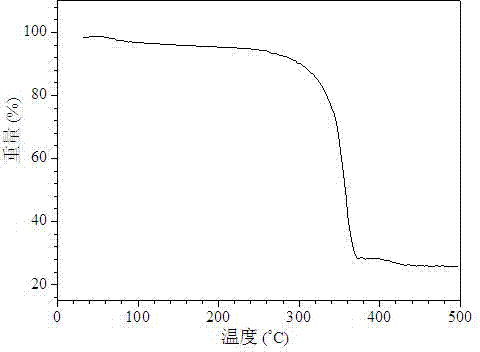

ActiveCN103704232AReduce decompositionReduce churnBiocideAnimal repellantsSolubilityBiocompatibility Testing

The invention discloses a preparation method of nano pesticide carboxymethyl-beta-cyclodextrin-Fe3O4-magnetic nano-diuron, the nano pesticide is a clathrate compound prepared from carboxymethyl-beta-cyclodextrin-Fe3O4-magnetic nanoparticles as a subject and object diuron by Van der Waals force, electrostatic attraction and the like. Fourier transform infrared spectroscopy (FTIR) and thermogravimetric analysis (TGA) show that carboxymethyl-beta-cyclodextrin is successfully grafted onto the surface of the Fe3O4 magnetic nanoparticles. Transmission electron microscopy analysis shows that the average particle size of the nano pesticide is 25 nm. The adsorption of the carboxymethyl-beta-cyclodextrin-Fe3O4-magnetic nanoparticles on the diuron is in line with the Langmuir isothermal adsorption curve. The new pesticide is good in water solubility and good in biocompatibility, has a slow release function, improves the pesticide utilization rate, extends pesticide efficacy preserving period, reduces the application amount and frequency, can be recycled, and reduces the harm of the pesticide on the environment.

Owner:UNIV OF SCI & TECH BEIJING

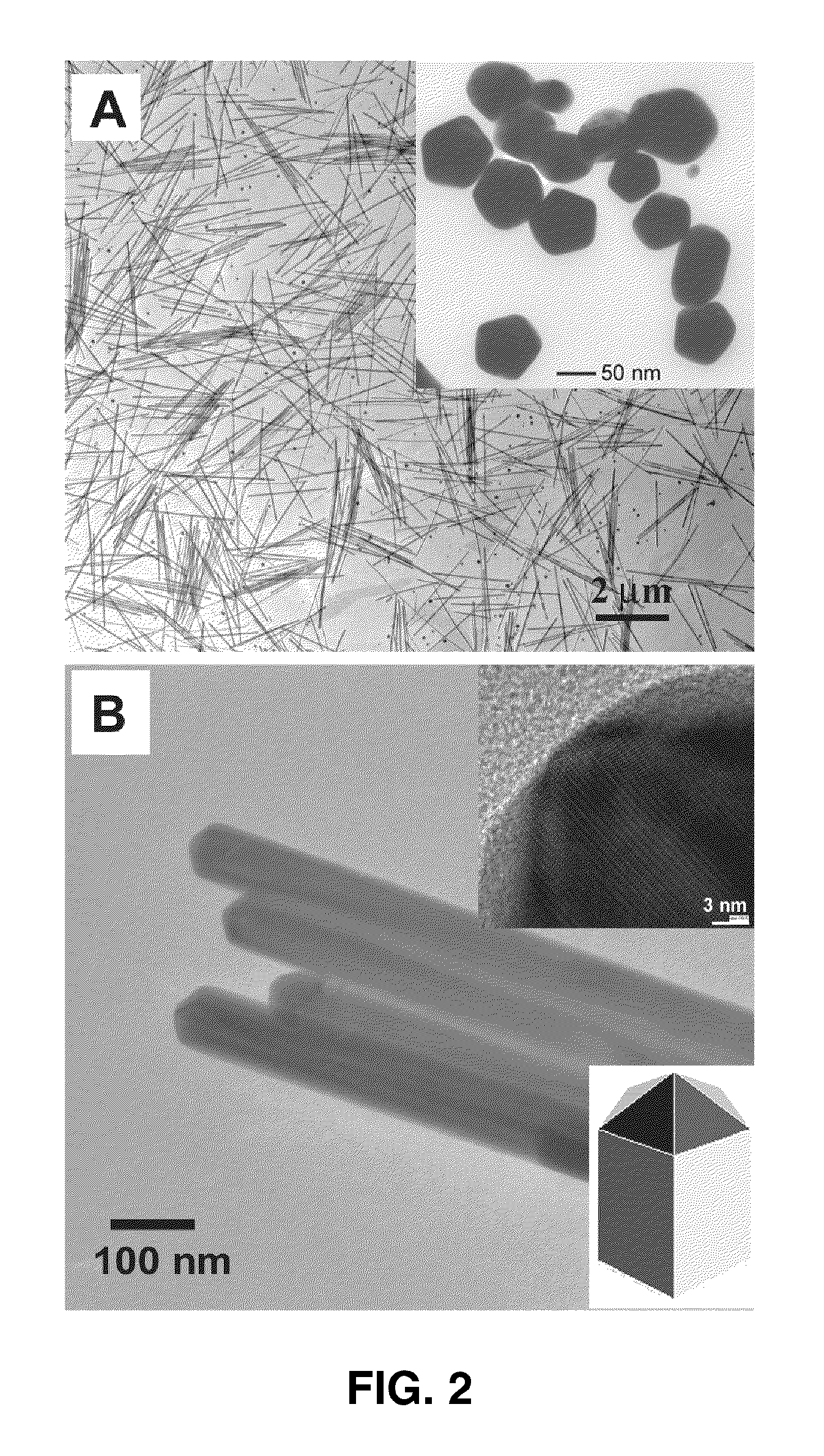

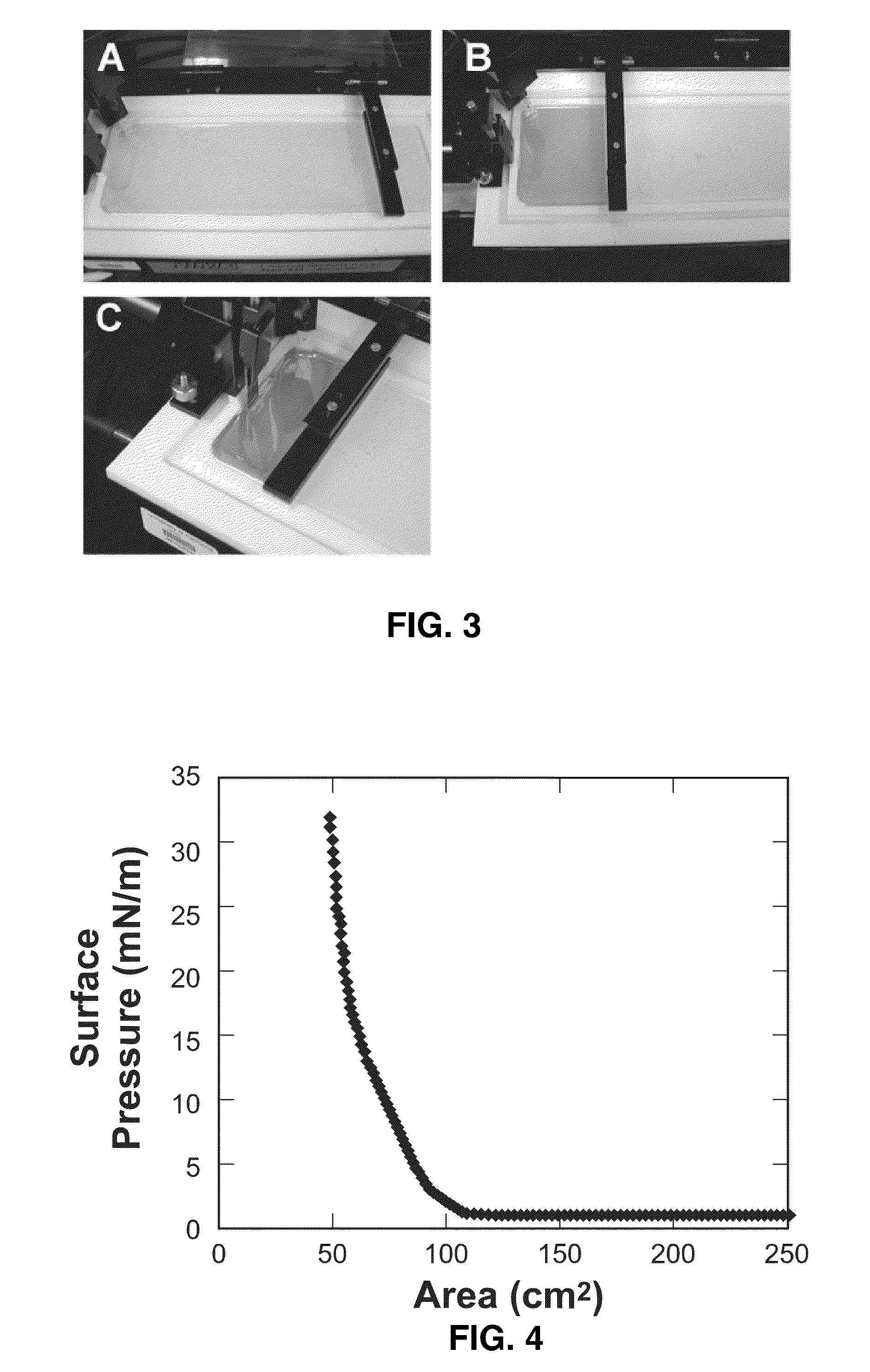

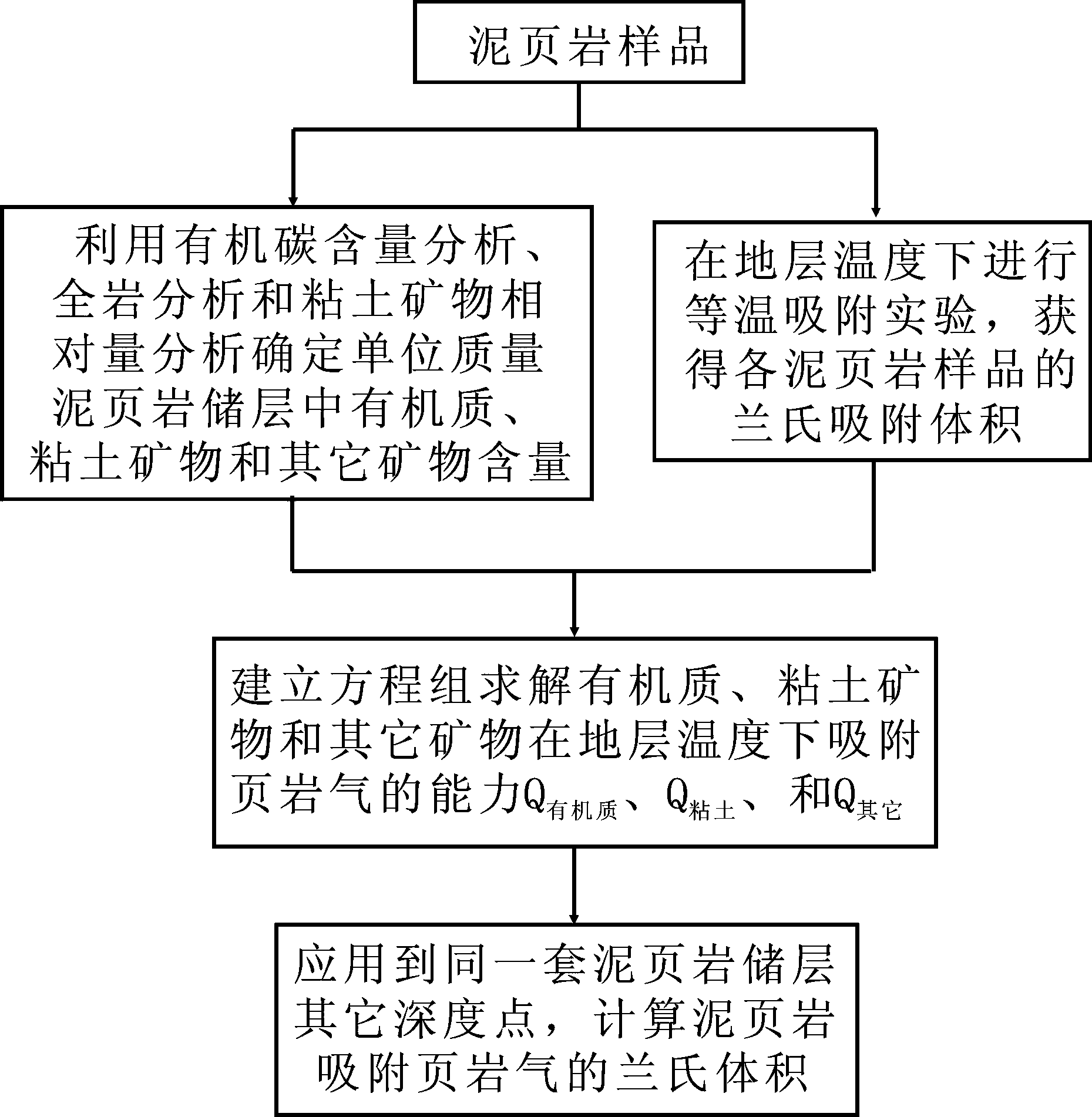

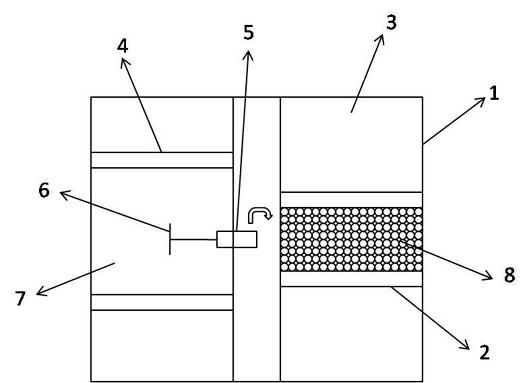

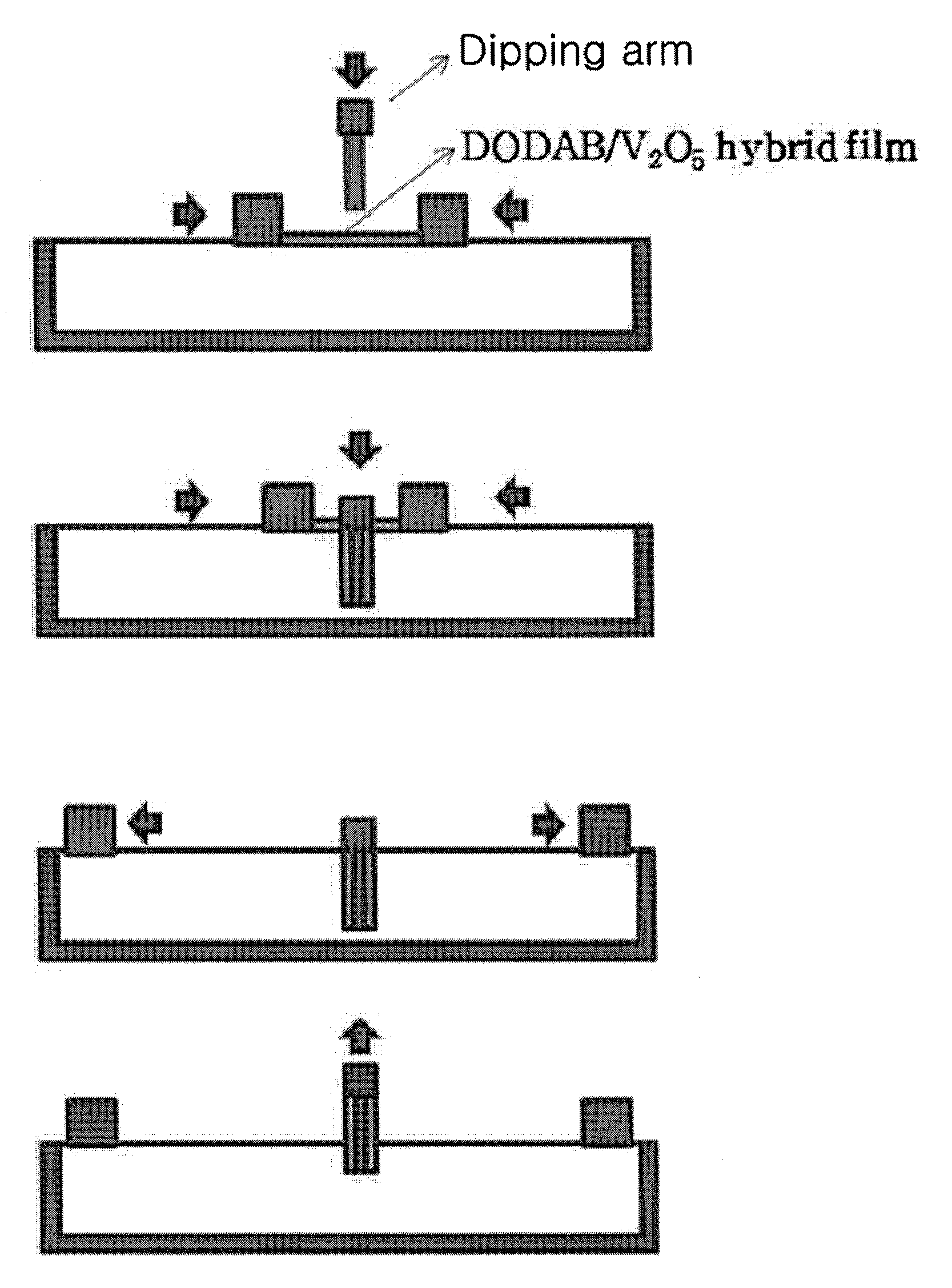

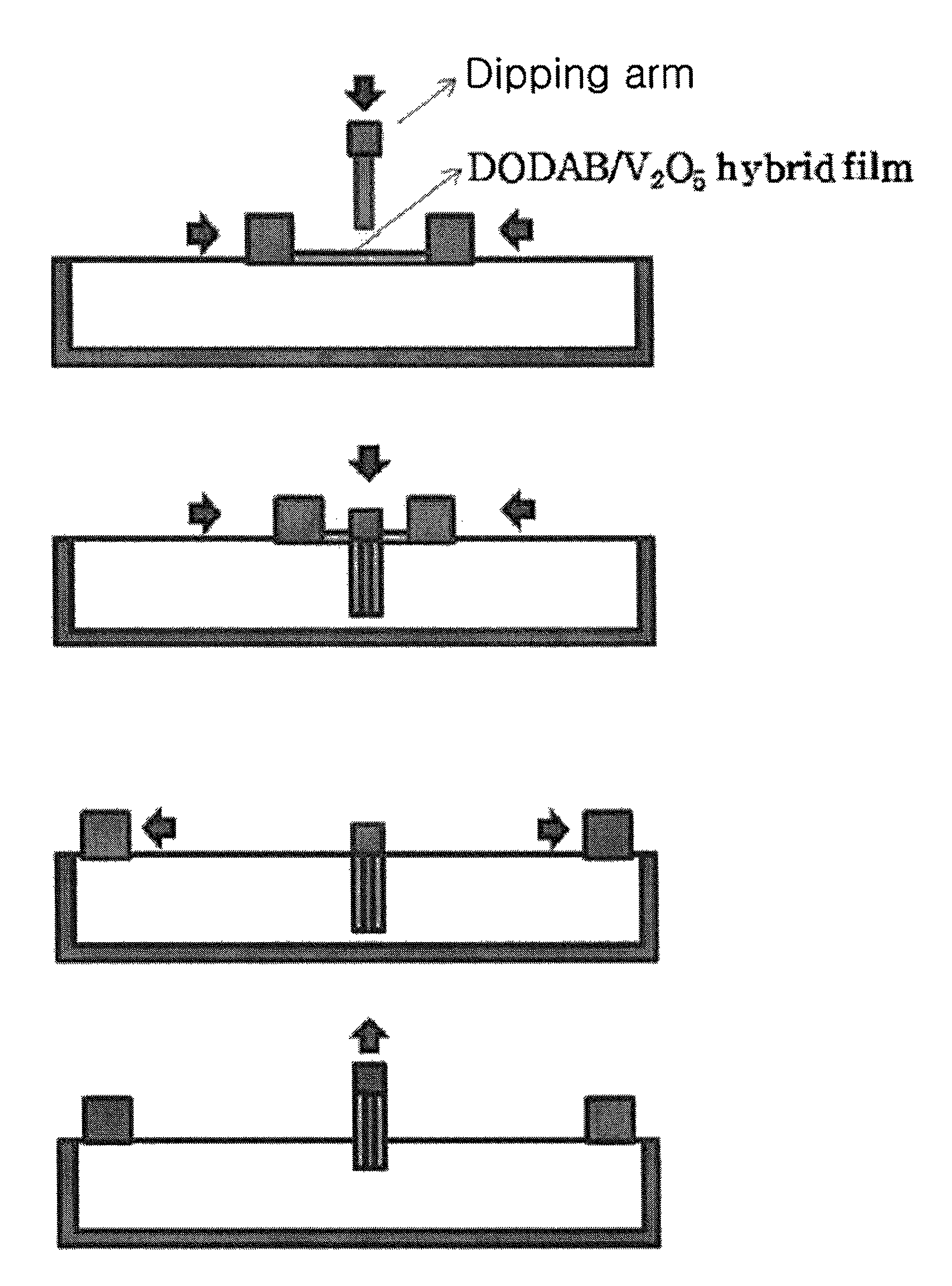

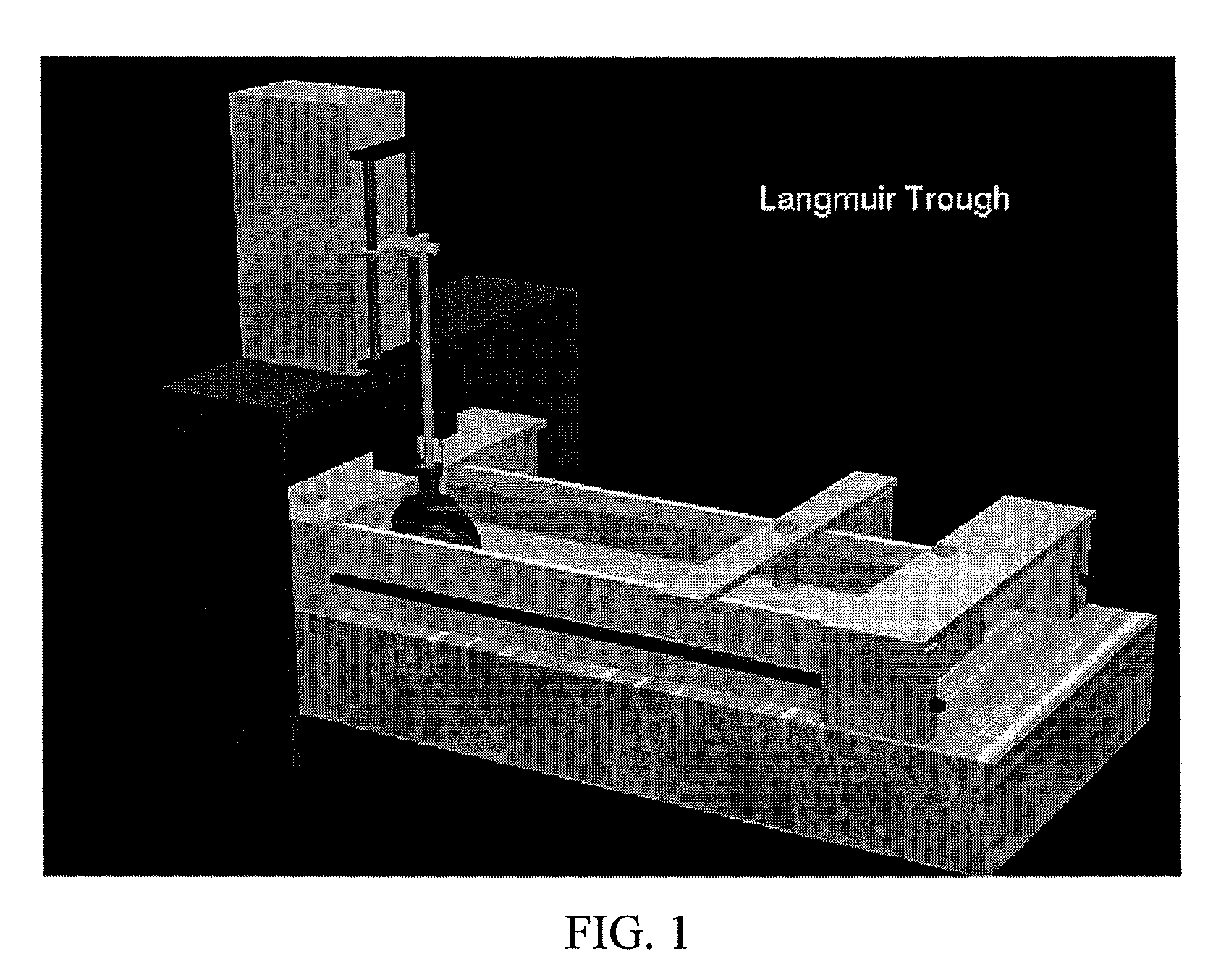

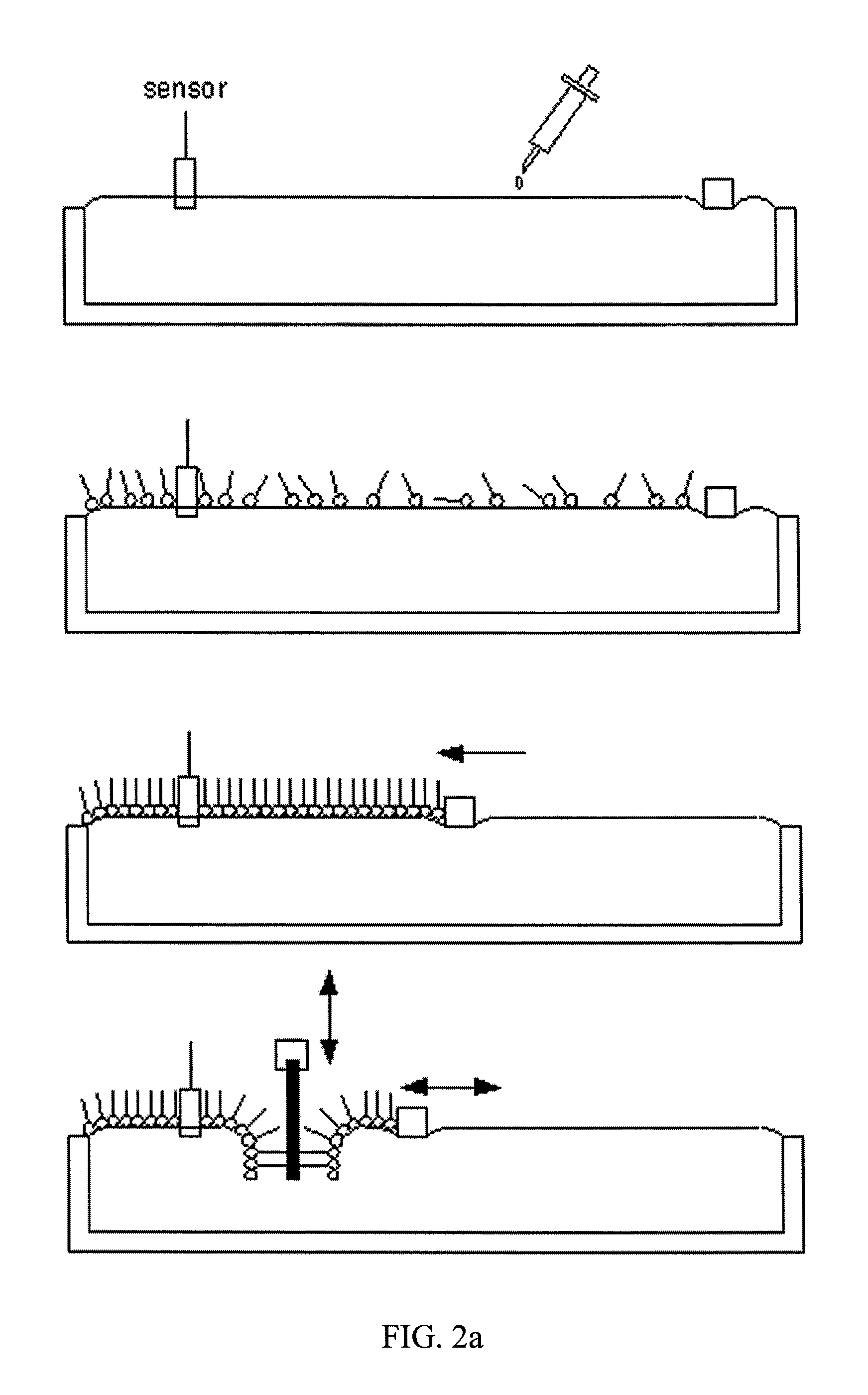

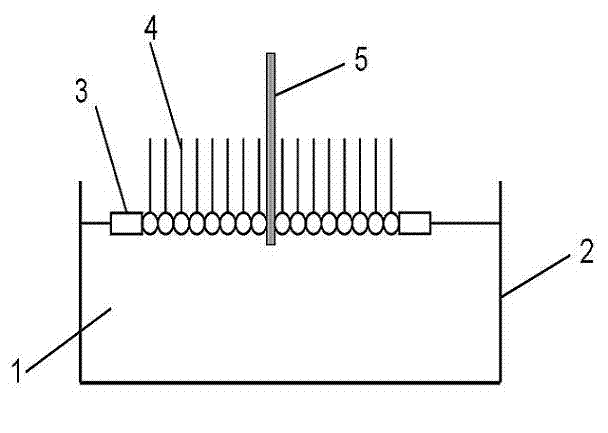

Method for producing film of vanadium pentoxide nanowires having improved alignment and vanadium pentoxide nanowire film produced thereby

ActiveUS20090162272A1Simple processSimple wayMaterial nanotechnologyNanostructure manufactureNanowireOrganic solvent

A method for producing a film of vanadium pentoxide nanowires having improved alignment is provided. The method comprises the steps of a) preparing a solution of vanadium pentoxide (V2O5) nanowires by a sol-gel method; b) diluting the solution of vanadium pentoxide nanowires with water and feeding the dilute aqueous solution into a Langmuir-Blodgett trough; c) adding a dispersant to the dilute aqueous solution of vanadium pentoxide nanowires; d) diluting a solution of a dioctadecyldimethylammonium halide with an organic solvent, applying the dioctadecyldimethylammonium halide solution to the surface of the dilute aqueous solution of vanadium pentoxide nanowires in the Langmuir-Blodgett trough, and allowing the solutions to stand to disperse the dioctadecyldimethylammonium halide solution in the Langmuir-Blodgett trough; e) controlling the surface pressure of the dioctadecyldimethylammonium halide solution using barriers mounted on the Langmuir-Blodgett trough; f) affixing a substrate to a dipping arm of the Langmuir-Blodgett trough and bringing the substrate into contact with the surface of the dioctadecyldimethylammonium halide solution; and g) separating the substrate from the dipping arm. According to the method, the alignment of the nanowires can be markedly improved by sol-gel synthesis, the need for subsequent washing can be eliminated, which contributes to the simplification of the production process, and the nanowires can be cut to desired lengths in a simple manner, thereby ensuring the reproducibility of a device using the nanowire film and achieving improved characteristics of the device. Further provided are a vanadium pentoxide nanowire film produced by the method and a nanowire device comprising the nanowire film. The nanowire device can find application in various fields, including field effect transistors and a variety of sensors, due to its excellent characteristics and reproducibility.

Owner:HANBAT NAT UNIV IND ACADEMIC COOPERATION FOUND

Adsorbents for oral administration, remedies or preventives for kidney diseases and remedies or preventives for liver diseases

An adsorbent for oral administration, characterized by comprising a spherical activated carbon prepared from a thermosetting resin as a carbon source, wherein a diameter is 0.01 to 1 mm, and a specific surface area determined by Langmuir's adsorption equation is 1000 m<2> / g or more; and an adsorbent for oral administration, characterized by comprising a surface-modified spherical activated carbon prepared from a thermosetting resin as a carbon source, wherein a diameter is 0.01 to 1 mm, a specific surface area determined by Langmuir's adsorption equation is 1000 m<2> / g or more, a total amount of acidic groups is 0.40 to 1.00 meq / g, and a total amount of basic groups is 0.40 to 1.10 meq / g. The adsorbents for oral administration exhibit a useful selective adsorbability, that is, a less adsorbability of useful substances in a body, and a greater adsorbability of toxic substances.

Owner:KUREHA KAGAKU KOGYO KK

Method for producing film of vanadium pentoxide nanowires having improved alignment and vanadium pentoxide nanowire film produced thereby

ActiveUS7875320B2Simple processSimple wayMaterial nanotechnologyNanostructure manufactureNanowireOrganic solvent

Owner:HANBAT NAT UNIV IND ACADEMIC COOPERATION FOUND

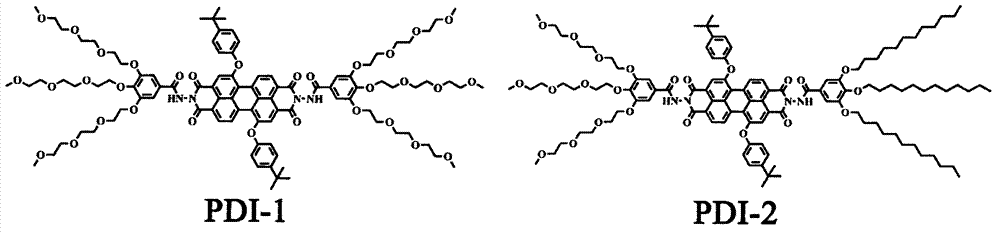

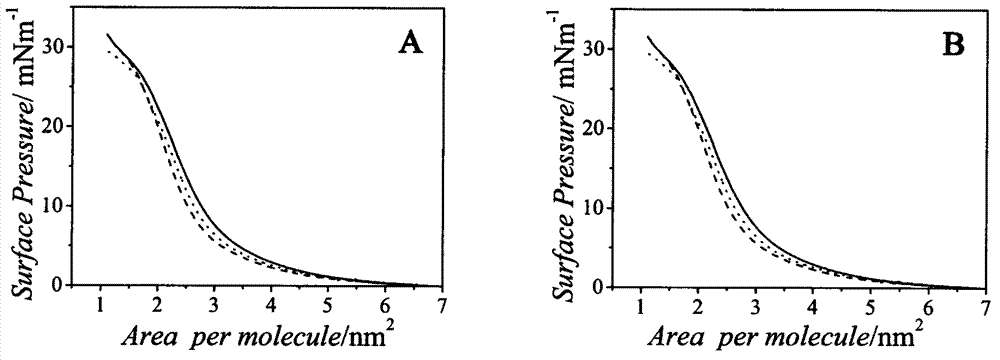

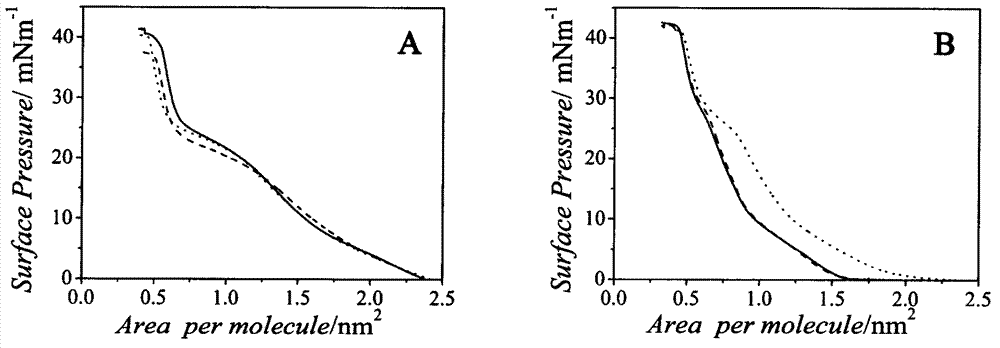

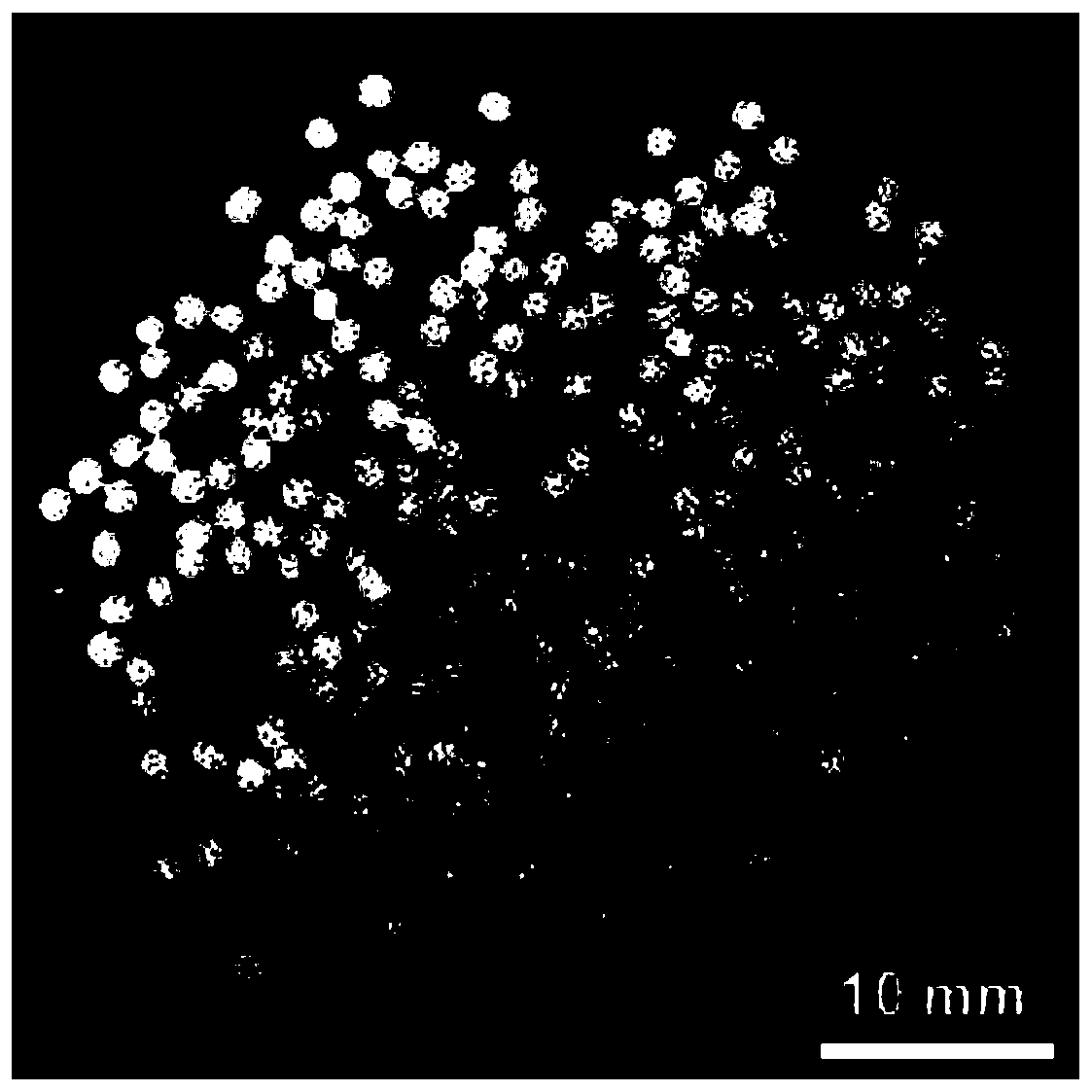

Method for preparing flower-like nano cadmium sulfide by using perylene bisimide derivatives as template

InactiveCN102765746AEasy to controlGood size controlMaterial nanotechnologyCadmium sulfidesFlower likePerylene

The invention relates to a method for preparing flower-like nano cadmium sulfide by using perylene bisimide derivatives as a template. By controlling different reaction time lengths between the system and the H2S gas, a Langmuir film formed by two amphiphilic perylene diimide compounds (PDI-1 and PDI-2) in novel structures on a CdCl2 subphase surface is used as a template for the first time to successfully prepare CdS nanoparticles with different flower-like shapes, of which the particle sizes are respectively 20nm, 30nm, 40nm, 60nm and 80nm. Various means are utilized to comprehensively characterize the microstructure and shape. The method is simple to operate, and the reaction process is easy to control and is carried out in a water phase at room temperature; and thus, the invention has the advantages of mild preparation conditions and low cost, and is easy to implement.

Owner:UNIV OF JINAN

Preparation method of chiral methyl phenyl sulfoixde

InactiveCN104017836AEfficient asymmetric oxidation reactionLow priceMicroorganism based processesFermentationBiotechnologyMicrobiology

The invention discloses a preparation method of chiral methyl phenyl sulfoixde. The preparation method comprises the steps of marking PseudomonasmonteiliiZMU-T05 with the preservation number of CCTCC NO:M2013683 on an LB (Langmuir-Blodgett) culture medium flat board which carries out sterilization for 20 min at the temperature of 121 DEG C, standing to be cultured for 12h at the temperature of 28 DEG C, selecting single colonies as seeds, marking on an M9 culture medium flat board, inducing by virtue of toluene, standing to be cultured, and preserving for standby at the temperature of 4 DEG C after growing for 24h; culturing conventional cells; and carrying out conventional biotransformation. With the adoption of the preparation method, an obtained product is high in the optical purity, is low in the cost and is safe and environmental friendly.

Owner:ZUNYI MEDICAL UNIVERSITY

Method for preparing ordered micron/nano structure array of conducting polymer

InactiveCN102412016AQuick migrationImprove adsorption capacityCable/conductor manufactureIn situ polymerizationConductive polymer

The invention discloses a method for preparing an ordered micron / nano structure array of a conducting polymer, which comprises the following steps of: acquiring an ordered membrane of the conducting polymer monomer through an LB (Langmuir-Blodgett) membrane method, acquiring an ordered array structure of the polymer monomer on the monomer membrane through an etching method, and acquiring an ordered micron / nano structure array of the conducting array through a chemical in-situ polymerization method. The micron / nano structure array of the polymer prepared by the method in the invention can overcome the defects of the prior art, and the preparation method is reasonable and simple and easy to operate.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Hydrous zirconium oxide/strontium alginate composite gel bead, and preparation method application thereof

ActiveCN109847718ABig gapWill not cause churnOther chemical processesCombustible gas purificationWater qualityFluoride

The invention relates to a strontium alginate gel bead product coated with hydrous zirconium oxide and an adsorption application of the strontium alginate gel bead product. A hydrous zirconium oxide dispersion liquid is mixed with a sodium alginate water solution according to a certain volume ratio, then the obtained mixture is dropwise added into a strontium salt solution, stirring is carried outto form gel beads, and water washing is carried out to remove excess strontium ions, so that the hydrous zirconium oxide / strontium alginate composite gel beads with a particle size of 0.1-5 mm are obtained. The gel beads can be used for adsorbing and removing anionic pollutants in water. The Langmuir saturated adsorption capacities of the composite gel beads to phosphate micro-polluted water, fluoride micro-polluted water and arsenite micro-polluted water can respectively reach 53 mg / g, 36 mg / g and 61 mg / g. According to the invention, the separation problem of hydrous zirconium oxide can be solved while high adsorption activity of the hydrous zirconium oxide is ensured, and a certain potential application value is achieved in the field of water purification.

Owner:JINAN UNIVERSITY

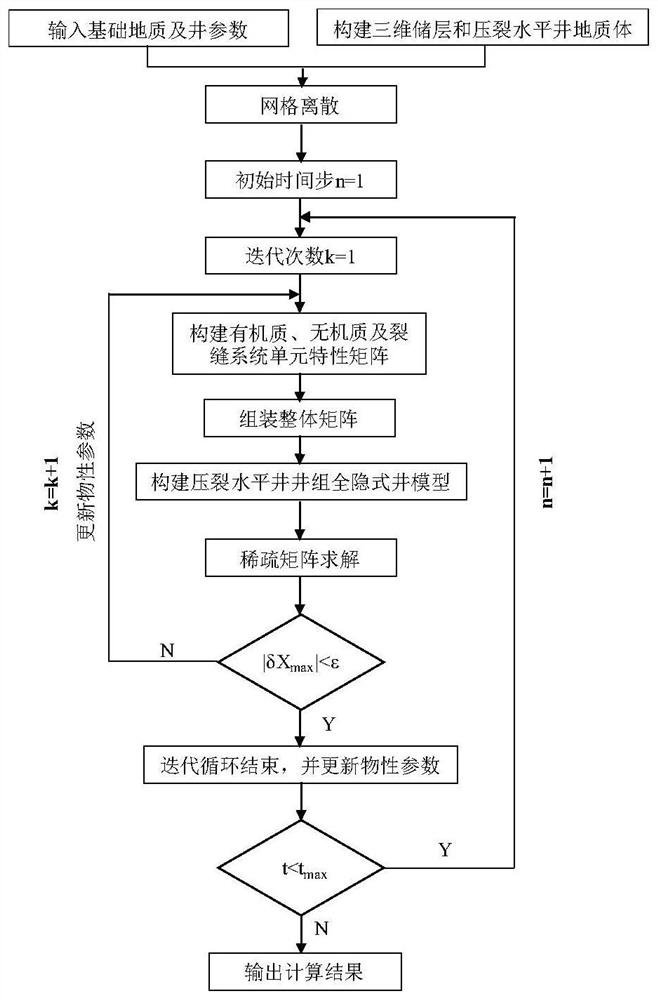

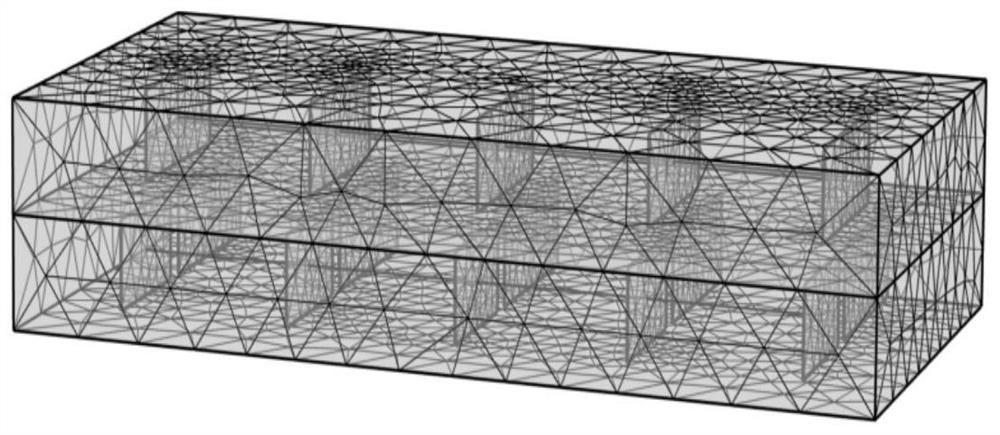

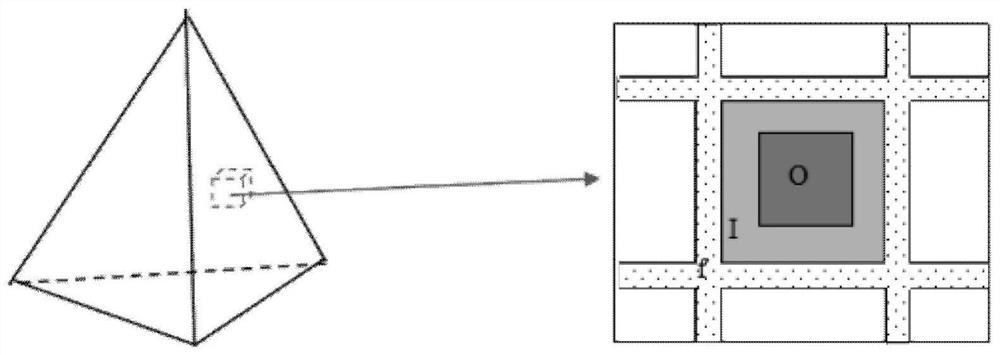

Shale gas reservoir fracturing well group production dynamic numerical simulation method

ActiveCN112031756ASimulation is accurateAccurate predictionFluid removalDesign optimisation/simulationMathematical modelHorizontal wells

The invention discloses a shale gas reservoir fracturing well group production dynamic numerical simulation method. The method comprises the following steps of generating a shale reservoir and a fracturing horizontal well three-dimensional geologic body and performing unstructured tetrahedral mesh discretization; establishing a shale gas reservoir multi-stage fracturing horizontal well comprehensive seepage mathematical model; constructing a fully implicit numerical model of the comprehensive seepage mathematical model based on a control volume finite element method; establishing a fully implicit multi-stage fracturing horizontal well numerical well model based on tetrahedral mesh discretization, embedding the fully implicit numerical model, and constructing a complete multi-system synchronous simultaneous solution matrix; and performing iterative solution on the multi-system synchronous simultaneous solution matrix, and analyzing the influence of Langmuir volume and the like on the production dynamic of the shale gas reservoir fracturing well group. According to the method, the defects of an existing shale gas reservoir two-dimensional simulator are overcome, the physical interlayer heterogeneity of the shale reservoir and the longitudinal extension expansion characteristics of the hydraulic fracturing fracture are comprehensively considered, and accurate simulation and prediction of the production dynamic of the three-dimensional development fracturing well group in the three-dimensional deep shale reservoir are realized.

Owner:SOUTHWEST PETROLEUM UNIV

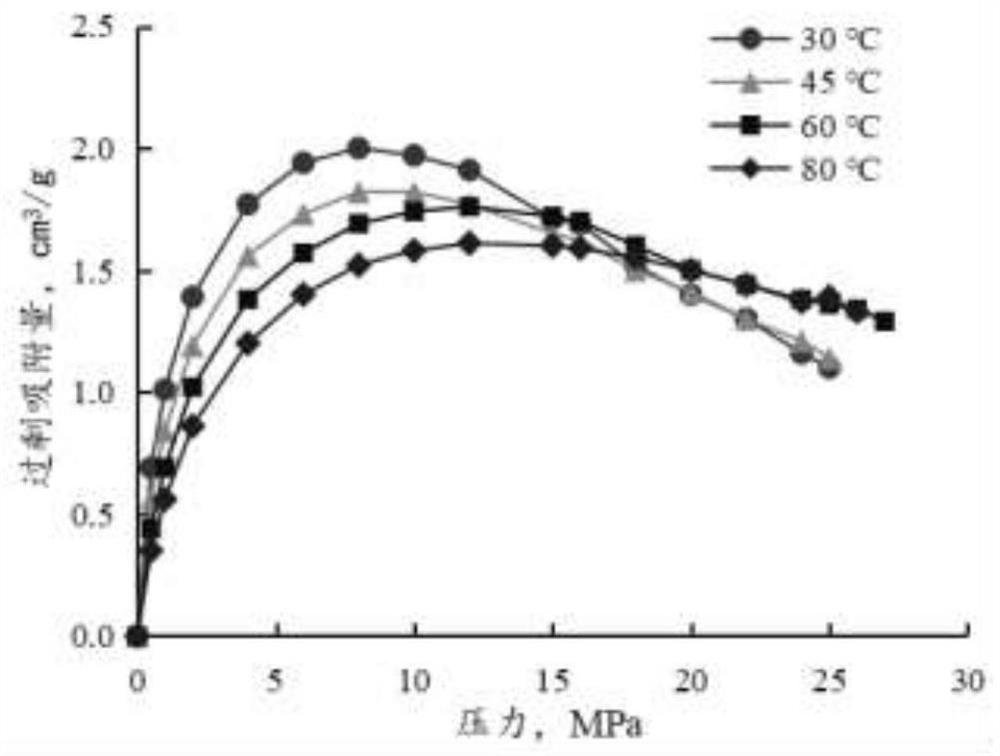

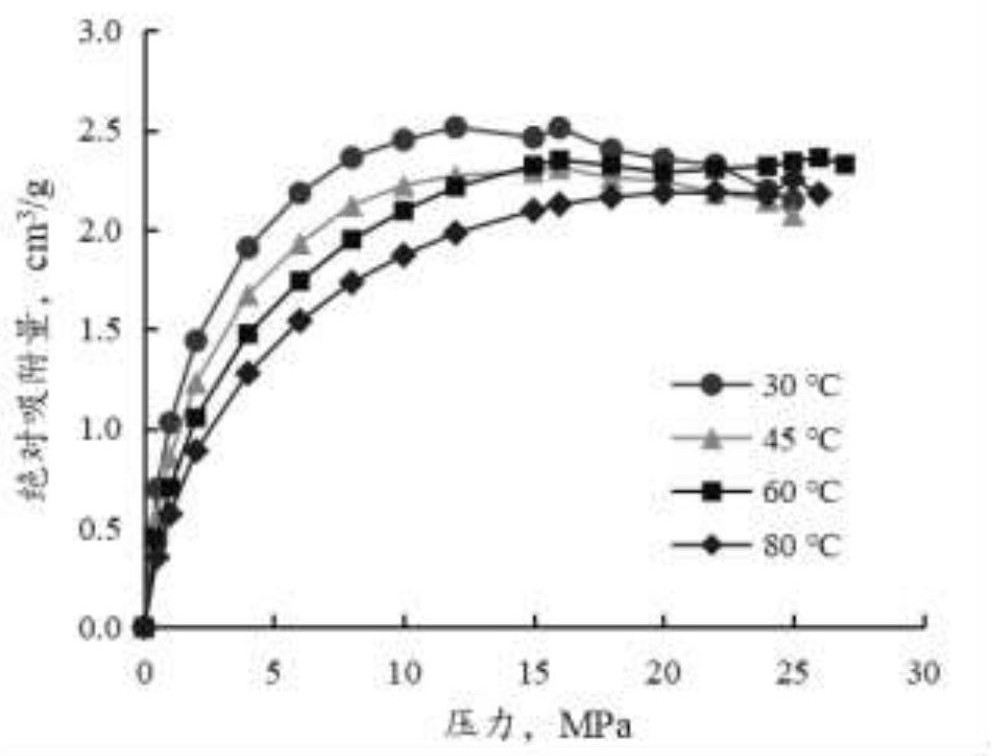

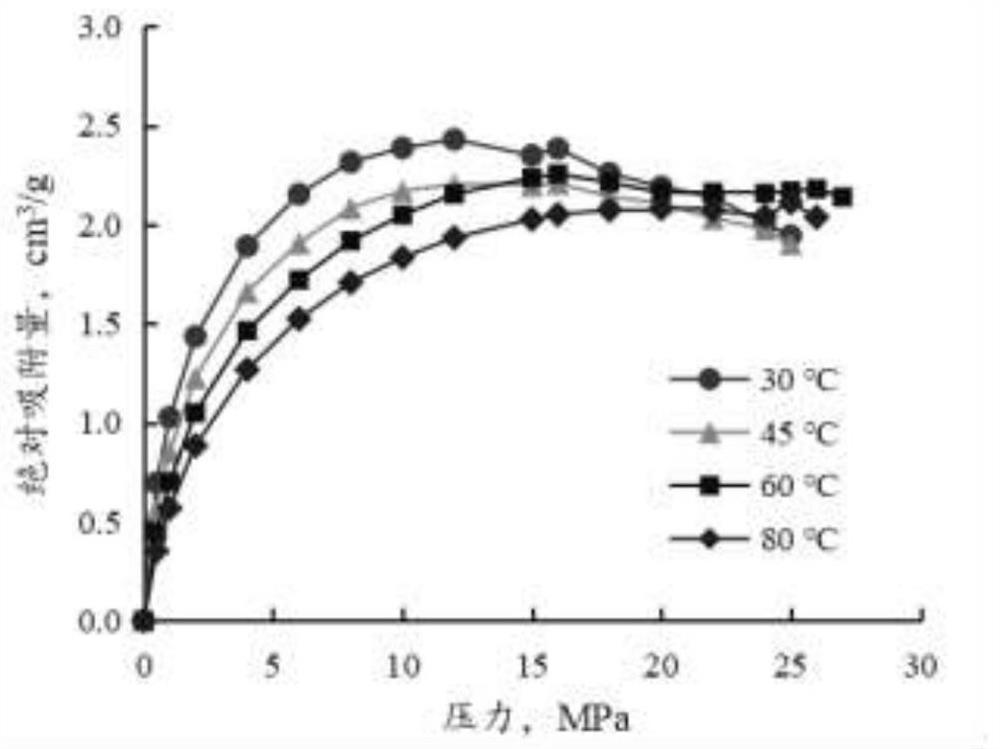

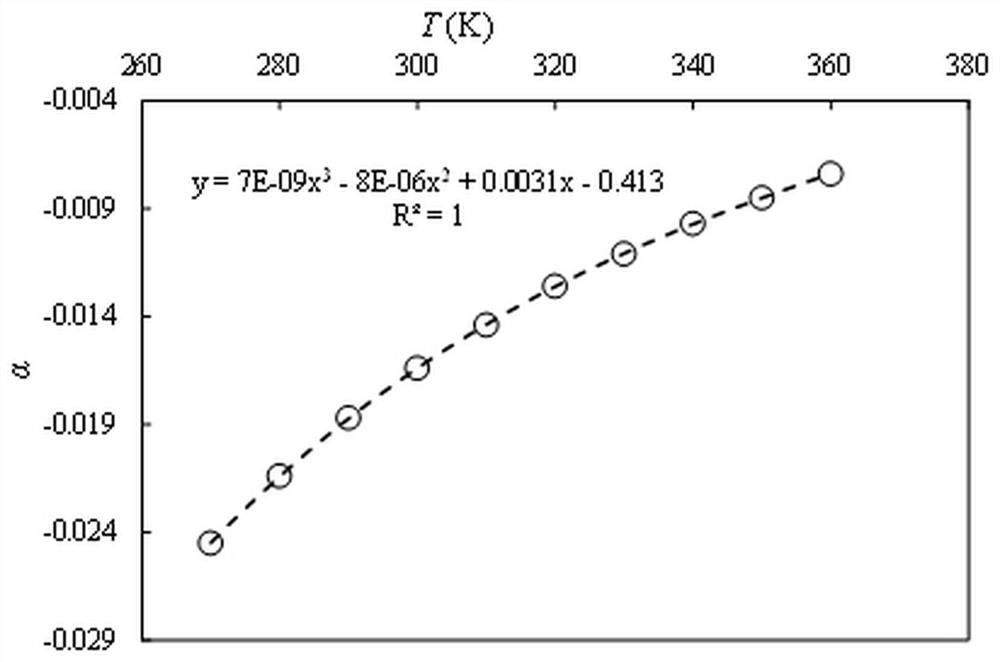

Method for calculating real adsorption capacity of methane in shale based on adsorption potential theory

ActiveCN111896421AReasonable and reliable resultsClear physical backgroundMaterial analysisActivated carbonSorbent

The invention discloses a method for calculating the real adsorption capacity of methane in shale based on an adsorption potential theory. The method, based on a modified D-A isothermal adsorption model, by combining supercritical isothermal adsorption experiment test data, solves model parameters and adsorbed phase methane density at each temperature by adopting loop iteration and an optimal thought, so that the defects of a common Langmuir isothermal adsorption model are overcome; and the obtained model parameters and the adsorption phase methane density can enable the adsorption potential and the adsorption phase volume under each temperature and pressure to be on the same adsorption characteristic curve, the obtained adsorption phase density and the real adsorption capacity can well meet the adsorption potential theory and the optimization theory, and the obtained result is more reasonable and reliable. The method is used for calculating the real adsorption capacity of methane in shale, can also be popularized and used for calculating the real adsorption capacity of methane in adsorbents such as coal and activated carbon, and has wide application value.

Owner:SOUTHWEST PETROLEUM UNIV

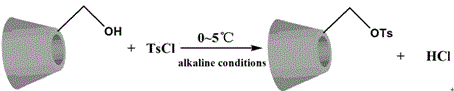

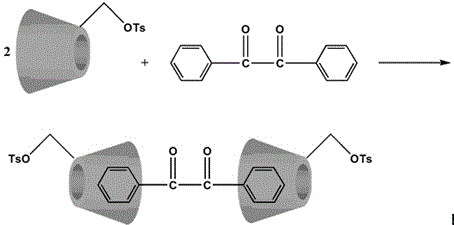

Method for adsorbing thorium by utilizing fiber-bridged beta-cyclodextrin derivative

InactiveCN105664873AHigh adsorption rateImprove adsorption capacityOther chemical processesWater contaminantsFiberPhysical chemistry

The invention relates to a method for adsorbing thorium by utilizing a fiber-bridged beta-cyclodextrin derivative. According to the method provided by the invention, 6-p-toluenesulfonyl ester-beta-cyclodextrin is synthesized, and then reacts with dipheylethanedione to synthesize a 6-p-toluenesulfonyl ester-beta-cyclodextrin fiber-bridged dipheylethanedione (BB beta-CD) adsorbent; and C=O with a chelating effect on metal ions is introduced so that the thorium can be adsorbed very well. All the raw materials are low in price and easy to purchase. A result shows that when the pH value is equal to 3.0 and the adsorption time is 20 minutes, the adsorption on Th<4+> by the BB beta-CD adsorbent is balanced, and the maximum value of an adsorption amount reaches 52.2mg / g; and meanwhile, an adsorption process is described by using a Langmuir adsorption isothermal line and a secondary adsorption dynamic speed equation. Mg<2+>, Pb<2+>, Zn<2+>, Fe<3+> and Cd<2+> are taken as interference ions and nearly do not have influences on the adsorption amount on the Th<4+>.

Owner:NANHUA UNIV

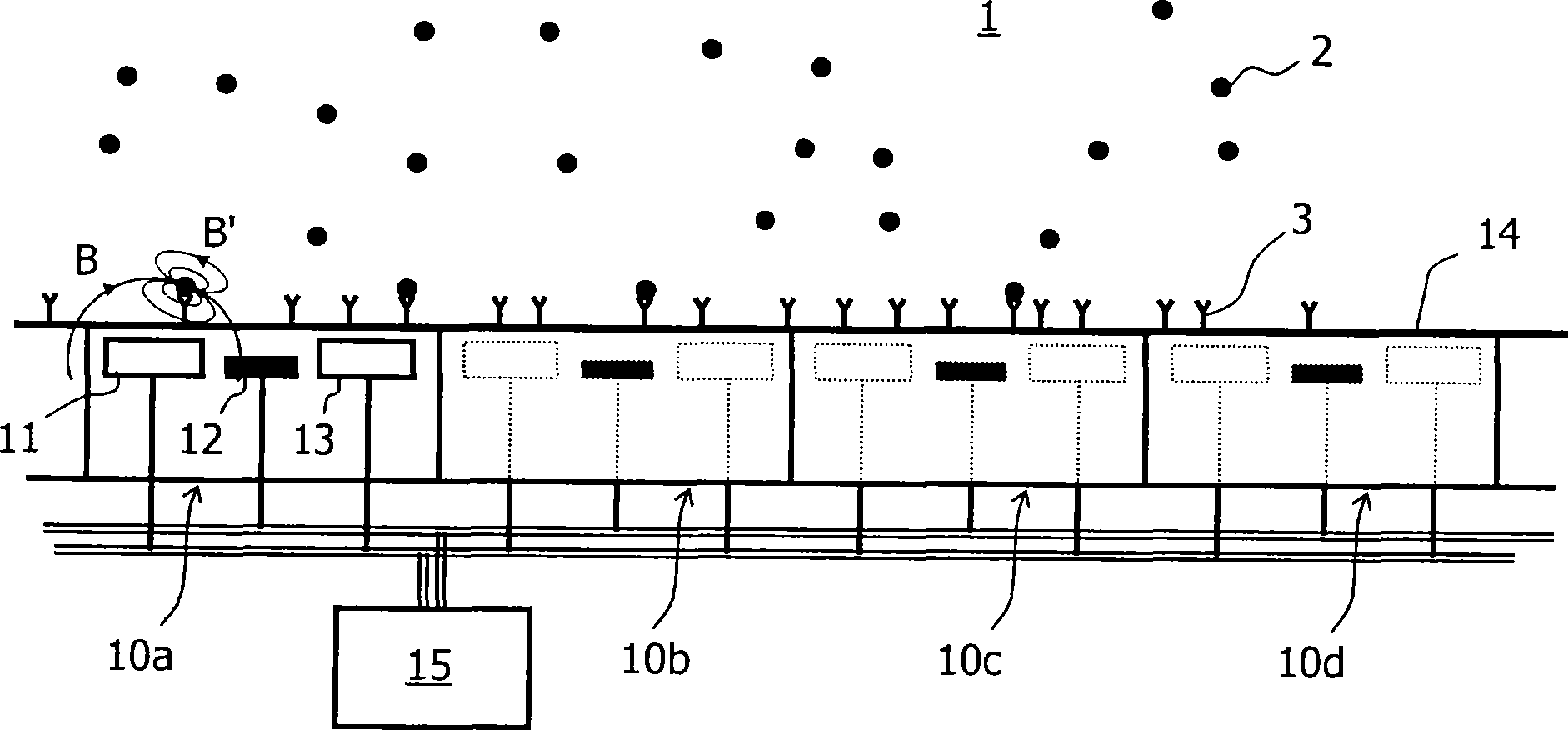

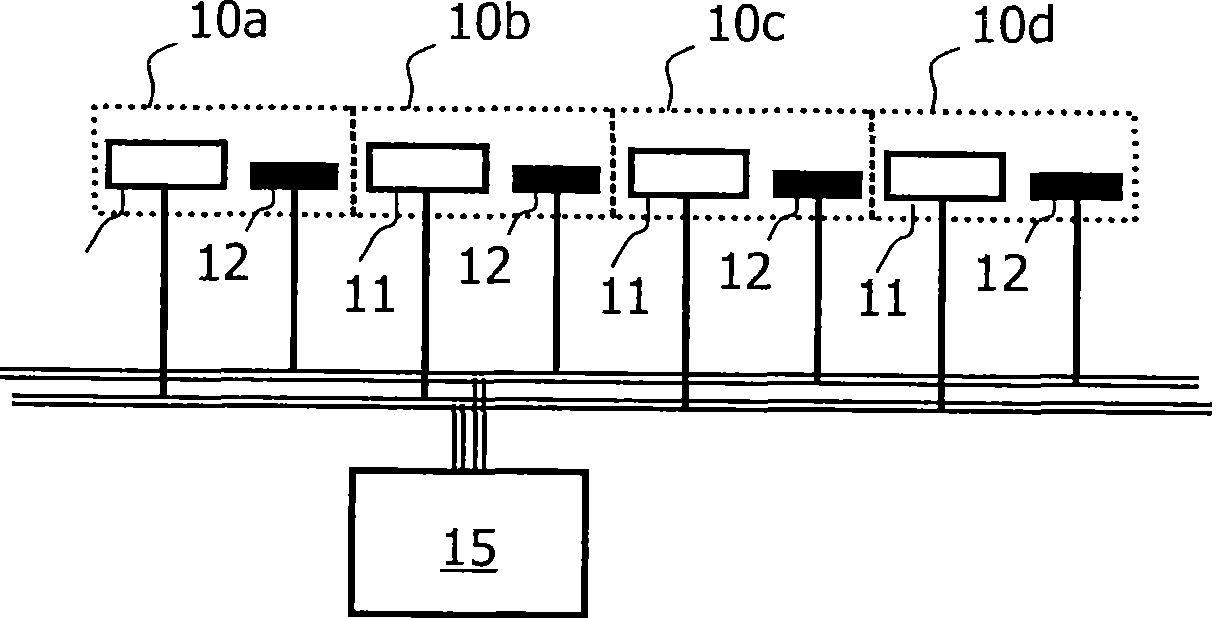

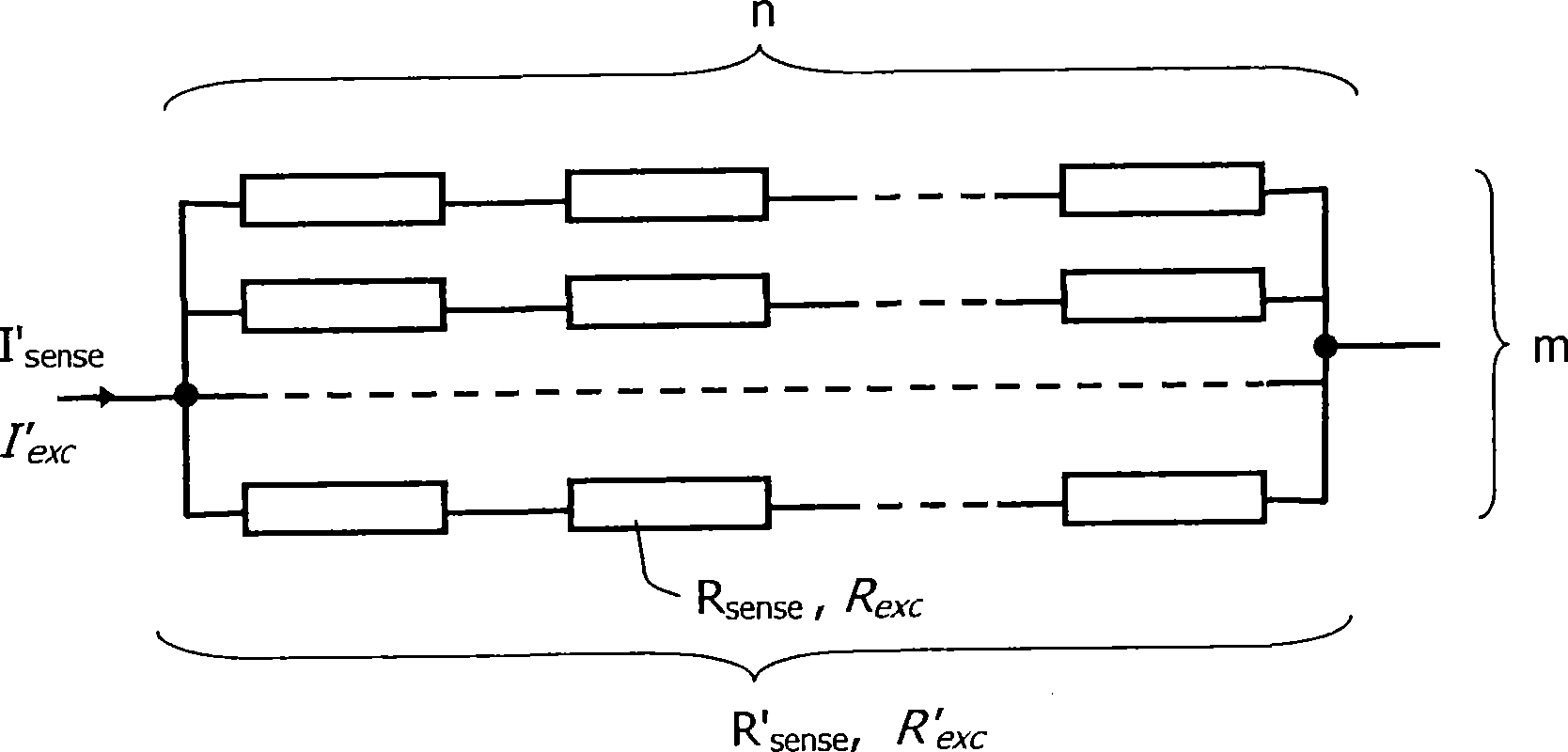

Microelectronic sensor device for concentration measurements

InactiveCN101438159AHigh precisionNanomagnetismMaterial analysis by electric/magnetic meansSignal-to-noise ratio (imaging)Binding site

The invention relates to a method and a magnetic sensor device for the determination of the concentration of target particles (2) in a sample fluid, wherein the amount of the target particles (2) in a sensitive region (14) is observed by sampling measurement signals with associated sensor units (10a-10d). The target particles (2) may optionally be bound to binding sites (3) in the sensitive region, and a parametric binding curve, e.g. a Langmuir isotherm, may be fitted to the sampled measurement signals to determine the desired particle concentration in the sample. Moreover, parameters like the sampling rate and the size of the sensitive region (14) can be dynamically fitted during the ongoing sampling process to improve the signal-to-noise ratio. In another embodiment of the invention, single events corresponding to the movement of target particles into, out of, or within the sensitive region are detected and counted.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for preparing nanocomposite dielectric film

InactiveCN102632675BImprove conductivityExcellent dielectric propertiesFixed capacitor dielectricSynthetic resin layered productsPolymer scienceComposite film

The invention discloses a method for preparing a nanocomposite dielectric film. First, a polymer dielectric film is obtained by a Langmuir-Blodgett (LB) film method, and then a high dielectric inorganic / The organic composite nanoparticle film is finally prepared on the composite nanoparticle film by the LB film method to prepare a polymer dielectric film, thereby forming a high dielectric composite film material in which nanoparticles are dispersed in the polymer. The polymer-nano particle composite dielectric film material prepared by the method overcomes the defects in the prior art, and the preparation method is reasonable and simple, and is easy to operate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

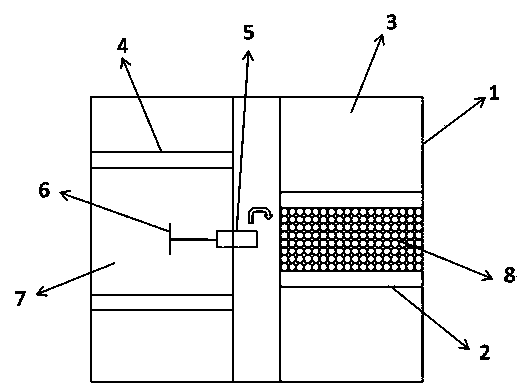

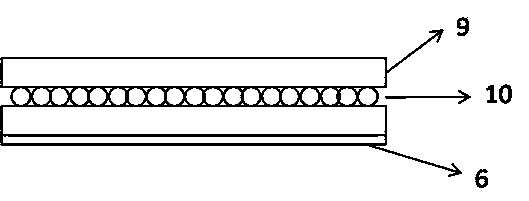

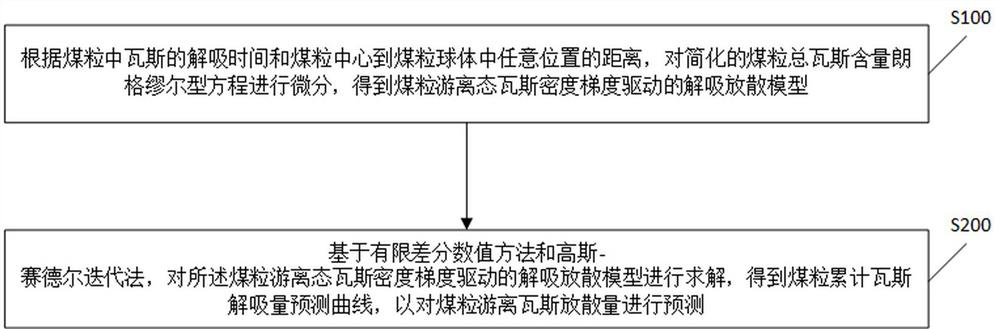

Coal particle gas emission amount prediction system and method based on real gas state

ActiveCN113654945AImprove matchOvercome the amount of desorptionForecastingChemical processes analysis/designDesorptionEngineering

The invention belongs to the technical field of testing or analyzing materials by means of measuring chemical or physical properties of materials, and provides a coal particle gas emission amount prediction system and method based on a real gas state, and the method comprises the following steps: correcting an ideal gas state equation by a compression factor to obtain a real free gas state equation; taking the free gas density as an independent variable, correcting a conventional Langmuir monomolecular layer adsorption isothermal equation taking the pressure as an independent variable, and calculating the gas content in an adsorption state; combining the gas content with the free-state gas content to obtain a simplified Langmuir equation of the coal particle total gas content; differentiating the simplified equation to obtain a desorption and diffusion model driven by the coal particle free state gas density gradient; and based on a finite difference numerical method and a Gaussian-Seidel iteration method, solving the desorption and diffusion model driven by the coal particle state gas density gradient to obtain a prediction curve of the accumulated gas desorption amount of the coal particles so as to predict the gas diffusion amount of the coal particles.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

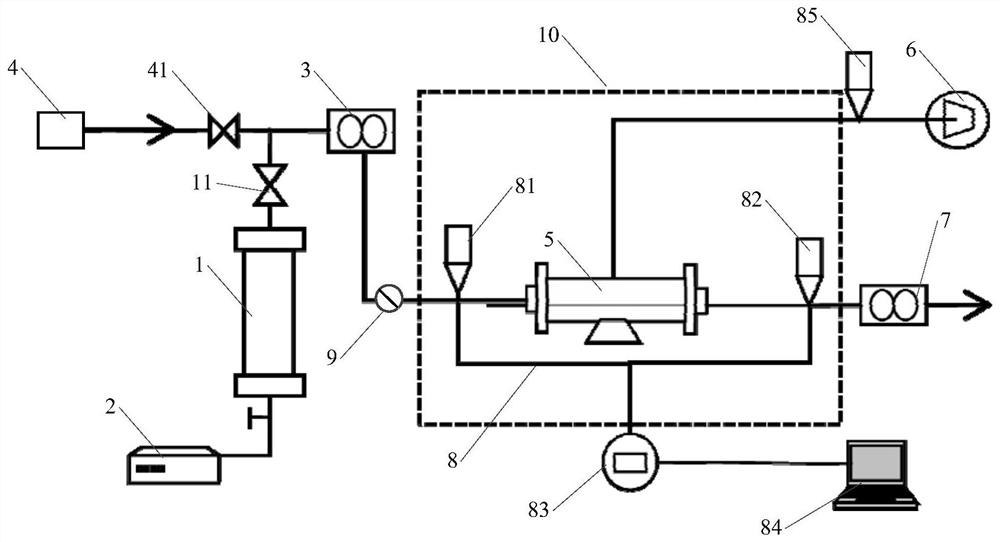

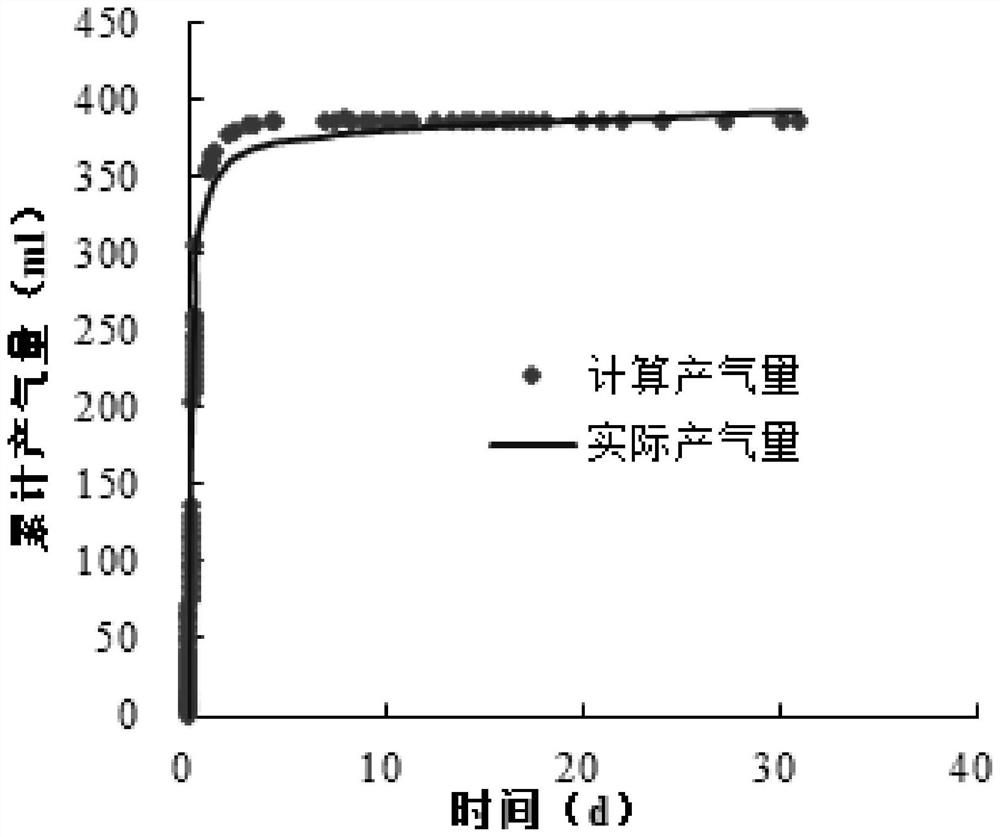

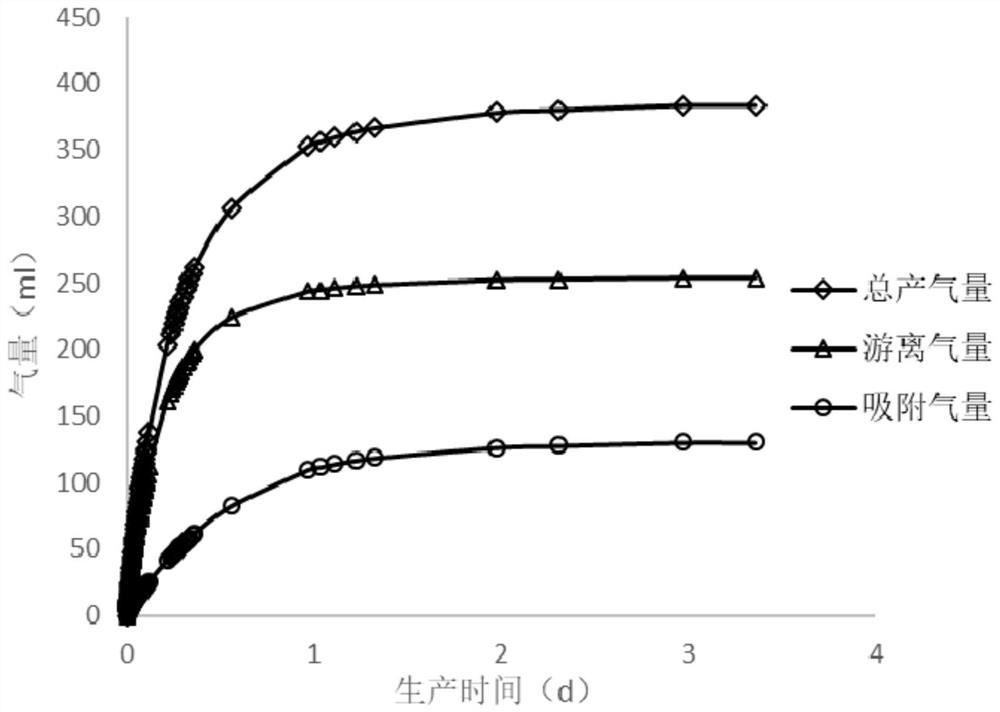

Method for measuring shale adsorption gas quantity and free gas quantity

The invention discloses a method for measuring adsorption gas quantity and free gas quantity of shale. The method comprises the following steps: 1), selecting a shale core sample, and measuring basicphysical property parameters; 2), carrying out a depletion development experiment, and drawing a relation curve of production time and total experiment gas yield; 3), setting an initial numerical value of a correction coefficient according to the corrected free gas amount calculation formula and the corrected Langmuir adsorption formula, and drawing a relation curve of the production time and thecalculated total gas production amount; 4), judging whether the relation curves obtained in the step (2) and the step (3) meet preset conditions or not, if not, adjusting the correction coefficient, repeating the step (3) until the preset conditions are met, and entering the step (5); and 5), drawing a relation curve between the calculated total gas production rate, the calculated free gas production rate and the production time, and calculating the adsorption gas amount and the production time to obtain the real-time adsorption gas amount, the real-time free gas amount and the real-time totalgas production rate. According to the invention, the amounts of adsorbed gas and free gas in the production time can be calculated in real time.

Owner:PETROCHINA CO LTD

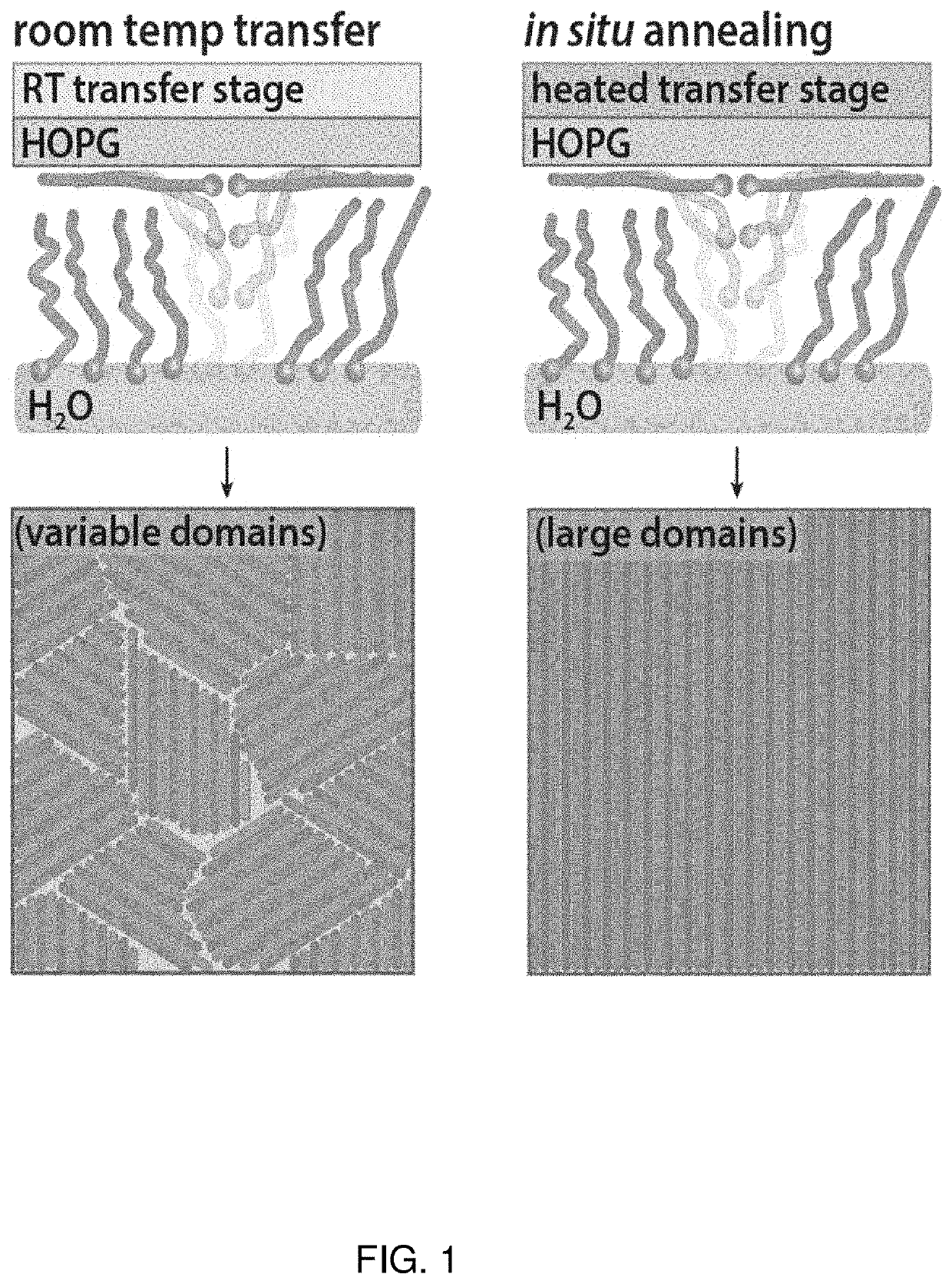

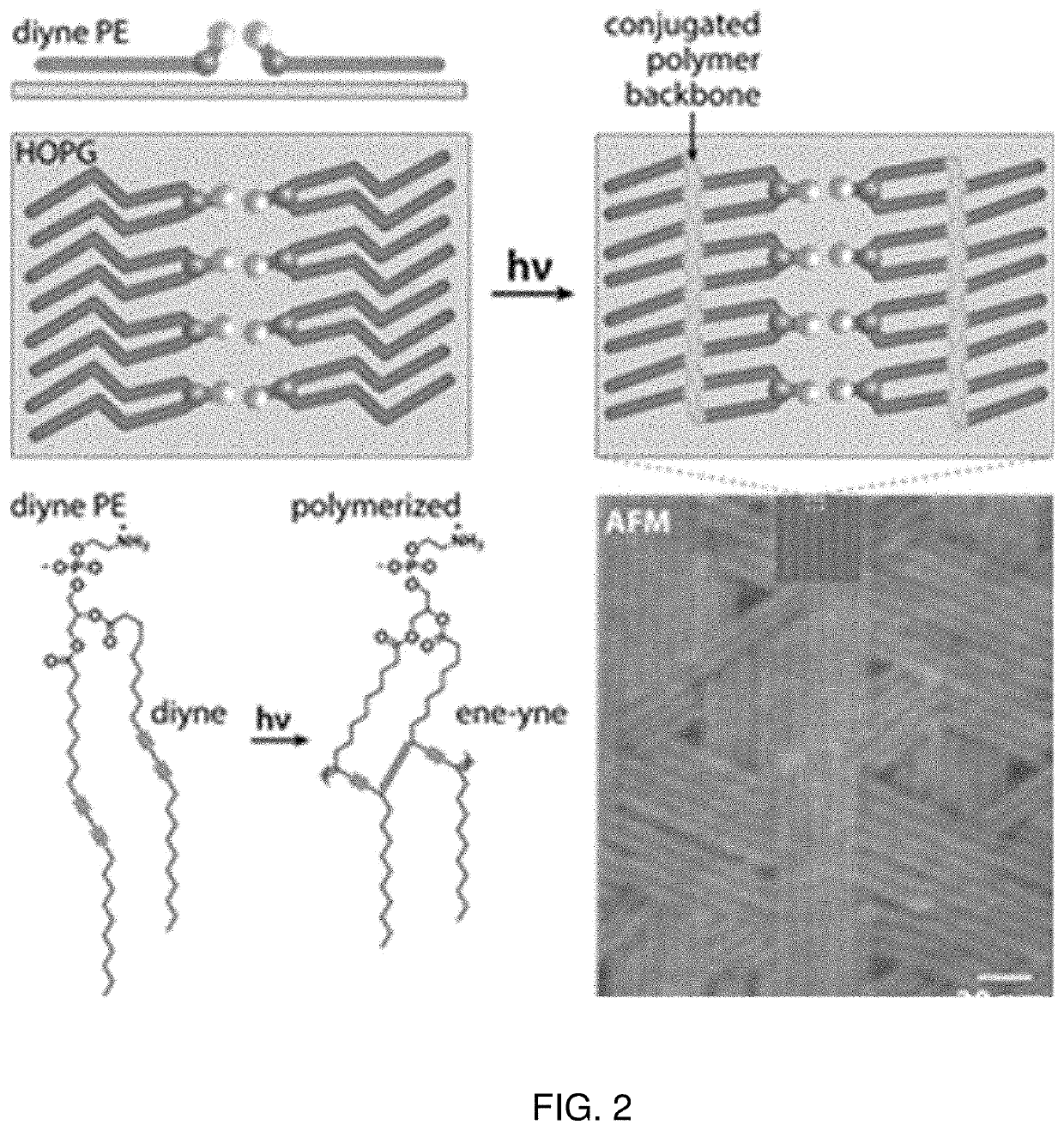

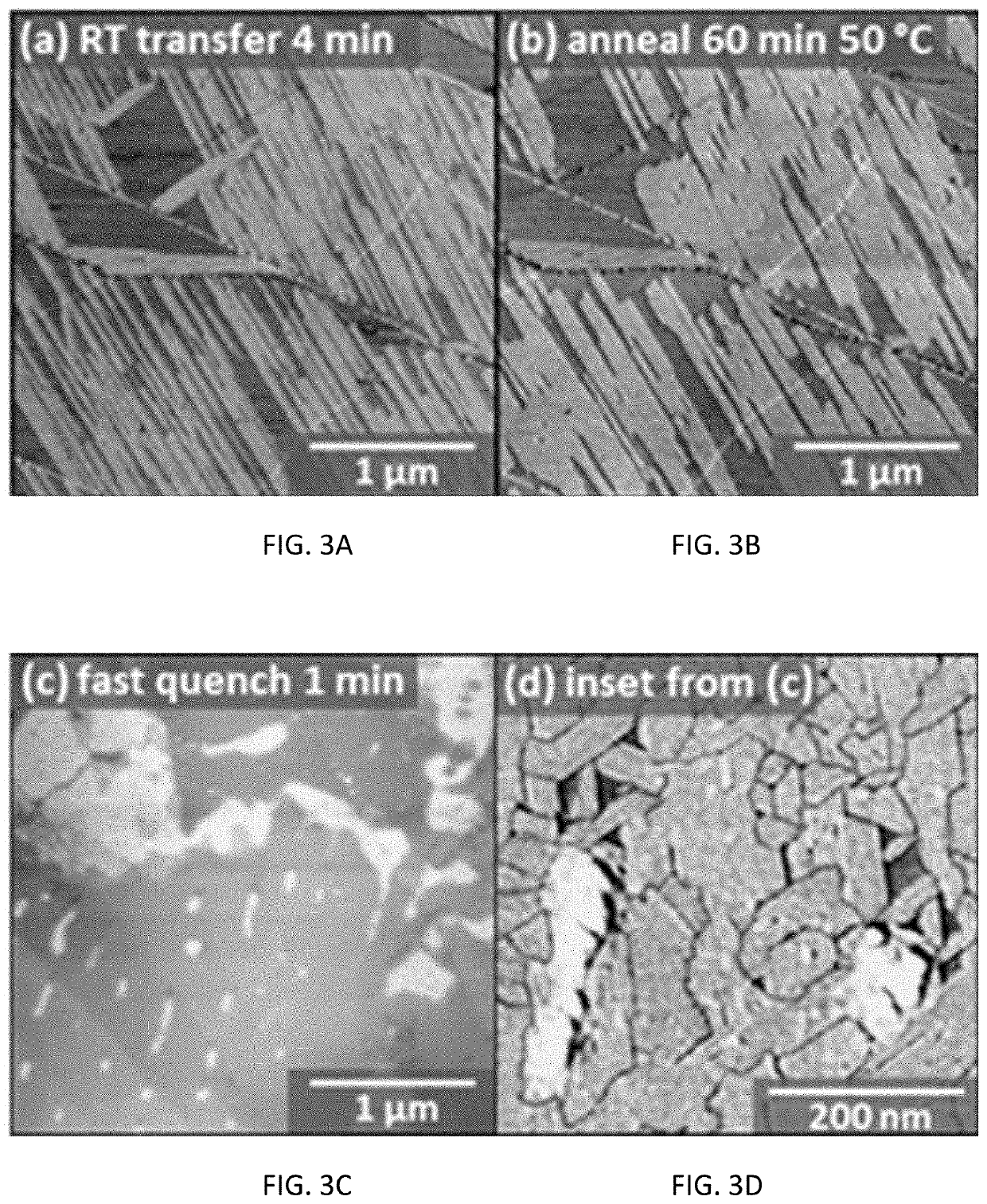

In situ thermal control of langmuir-schaefer transfer

Owner:PURDUE RES FOUND INC

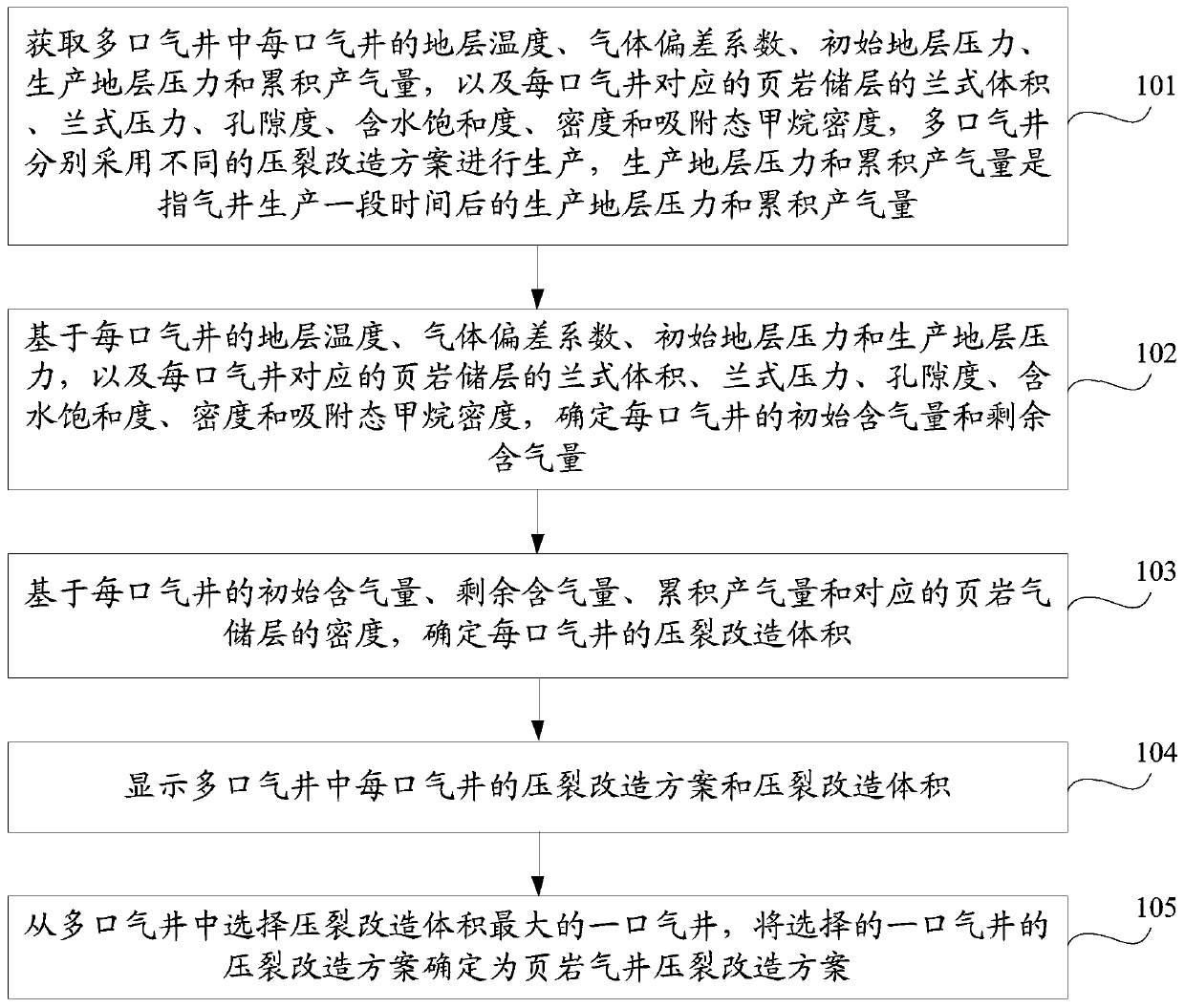

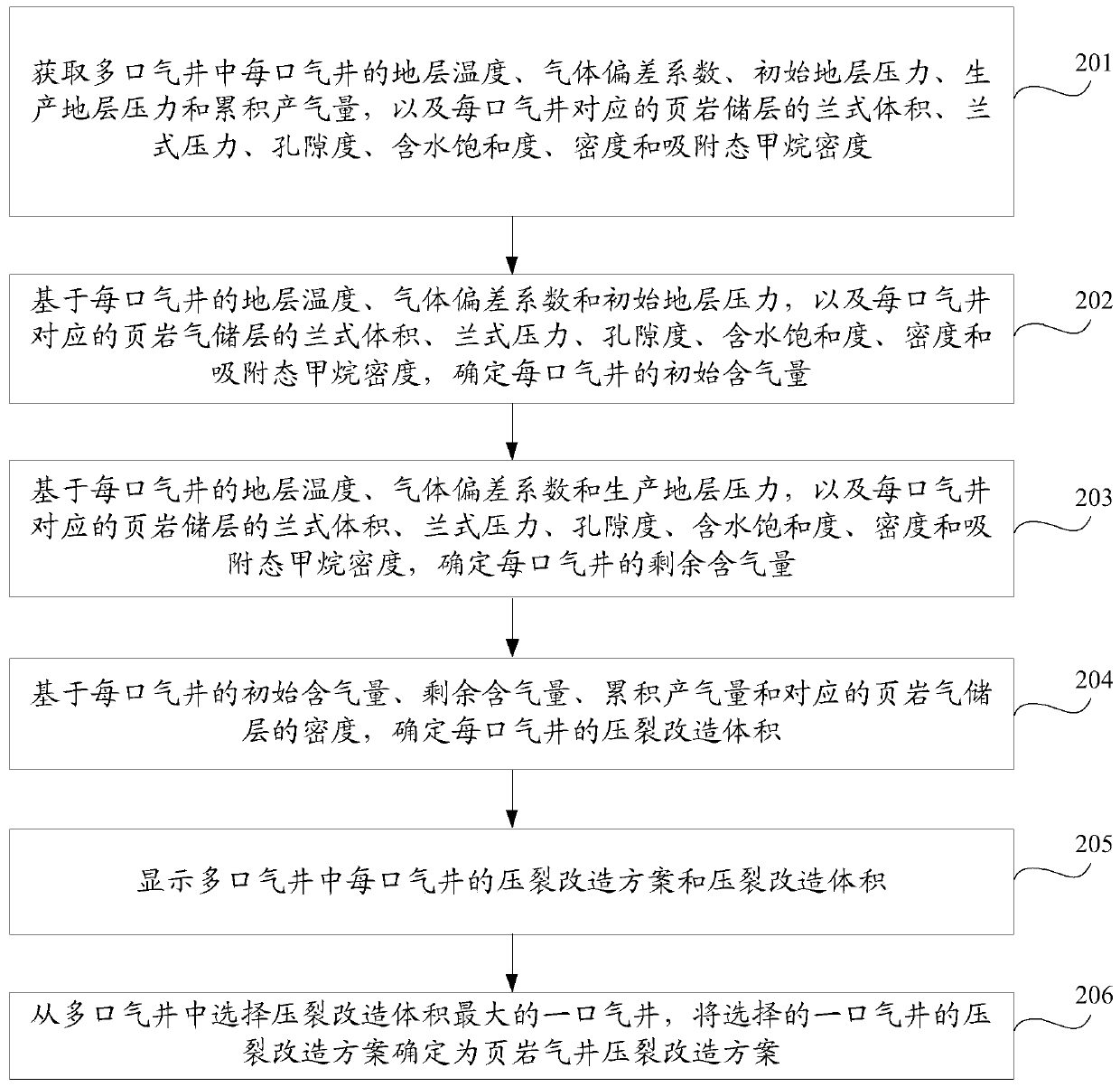

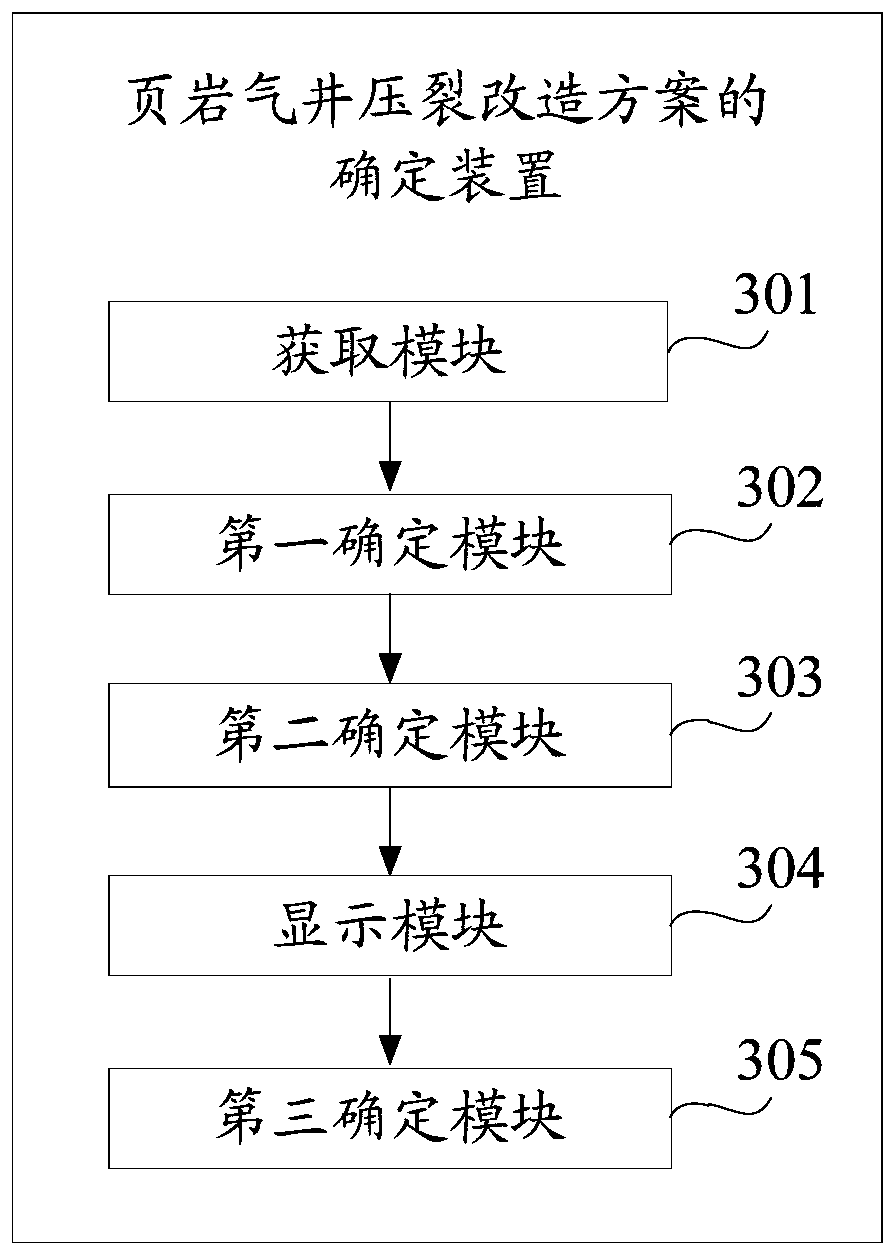

Determination method and device for shale gas well fracturing reformation scheme and storage medium

ActiveCN111396013AOptimizing the Fracturing Rehabilitation ProgramAccurate comparisonSurveyData processing applicationsThermodynamicsShale gas

The invention discloses a determination method and device for the shale gas well fracturing reformation scheme and a storage medium, and belongs to the technical field of oil and gas exploitation. Themethod comprises the steps that the formation temperature, the gas deviation factor, the initial formation pressure, the production formation pressure and the cumulative gas production of each gas well in multiple gas wells are acquired, and the Langmuir volume, the Langmuir pressure, the porosity, the water saturation, the density and the adsorbed-state methane density of the shale reservoir corresponding to each gas well are acquired; the initial gas content and the residual gas content of each gas well are determined; the fracturing reformation volume of each gas well is determined; and the gas well with the maximum fracturing reformation volume is selected from the multiple gas wells, and the fracturing reformation scheme of the selected gas well is determined as the shale gas well fracturing reformation scheme. By means of the method, the fracturing reformation volume, determined by actual production data, of each gas well is quite accurate and objective data, and therefore the more optimized shale gas well fracturing reformation scheme can be determined.

Owner:PETROCHINA CO LTD

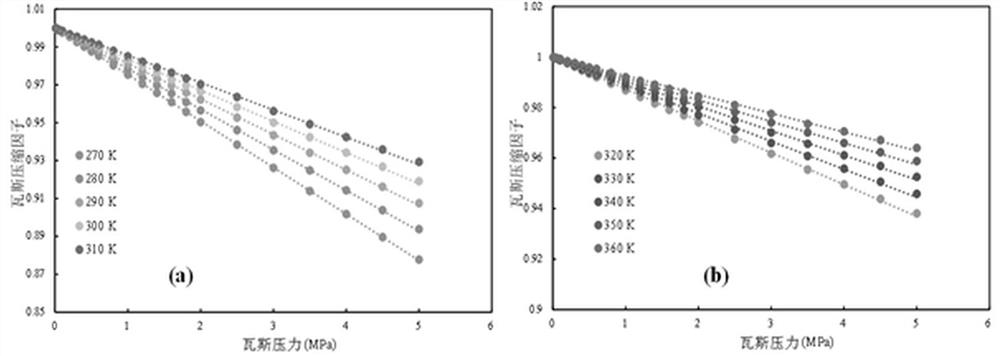

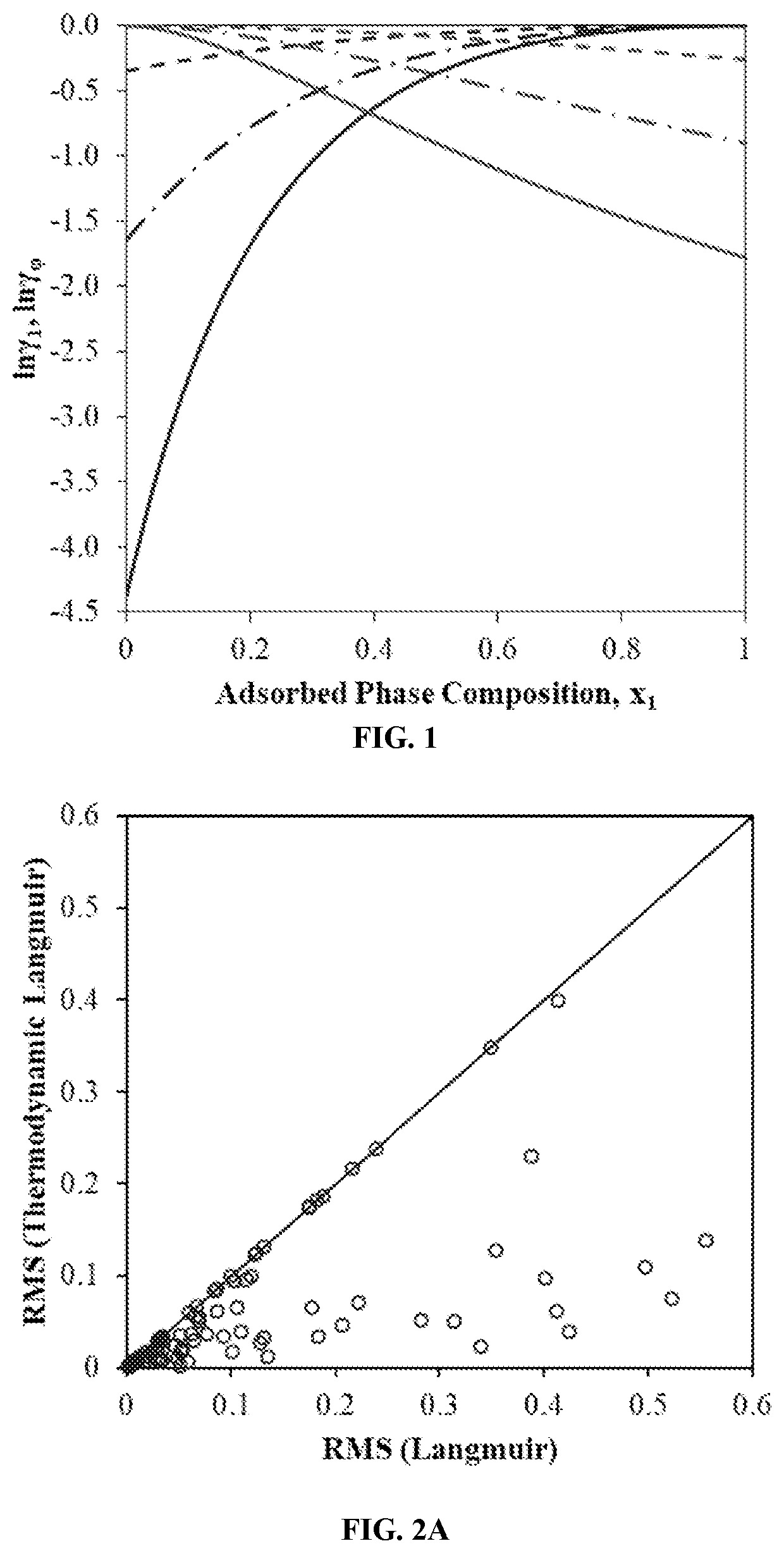

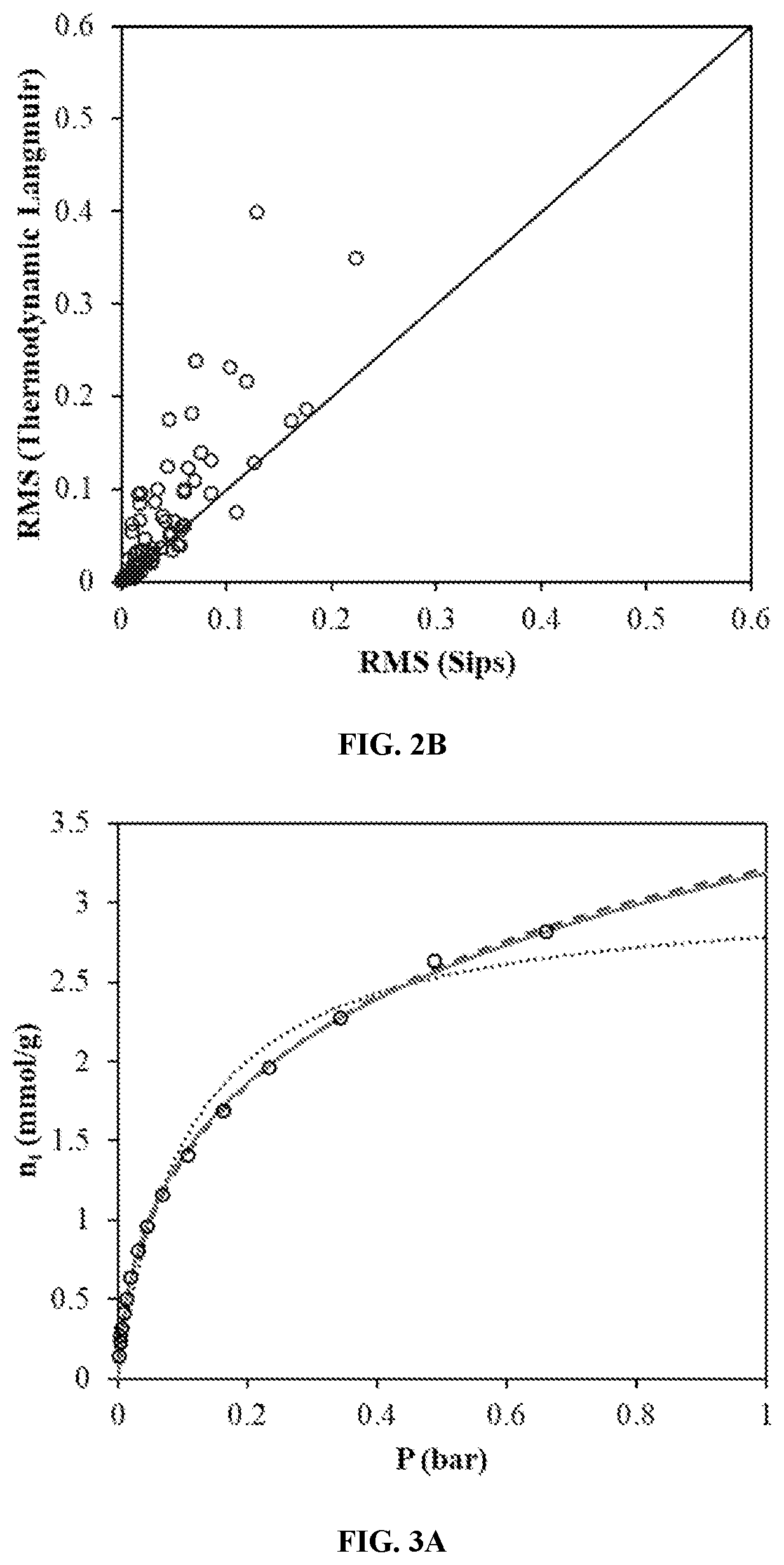

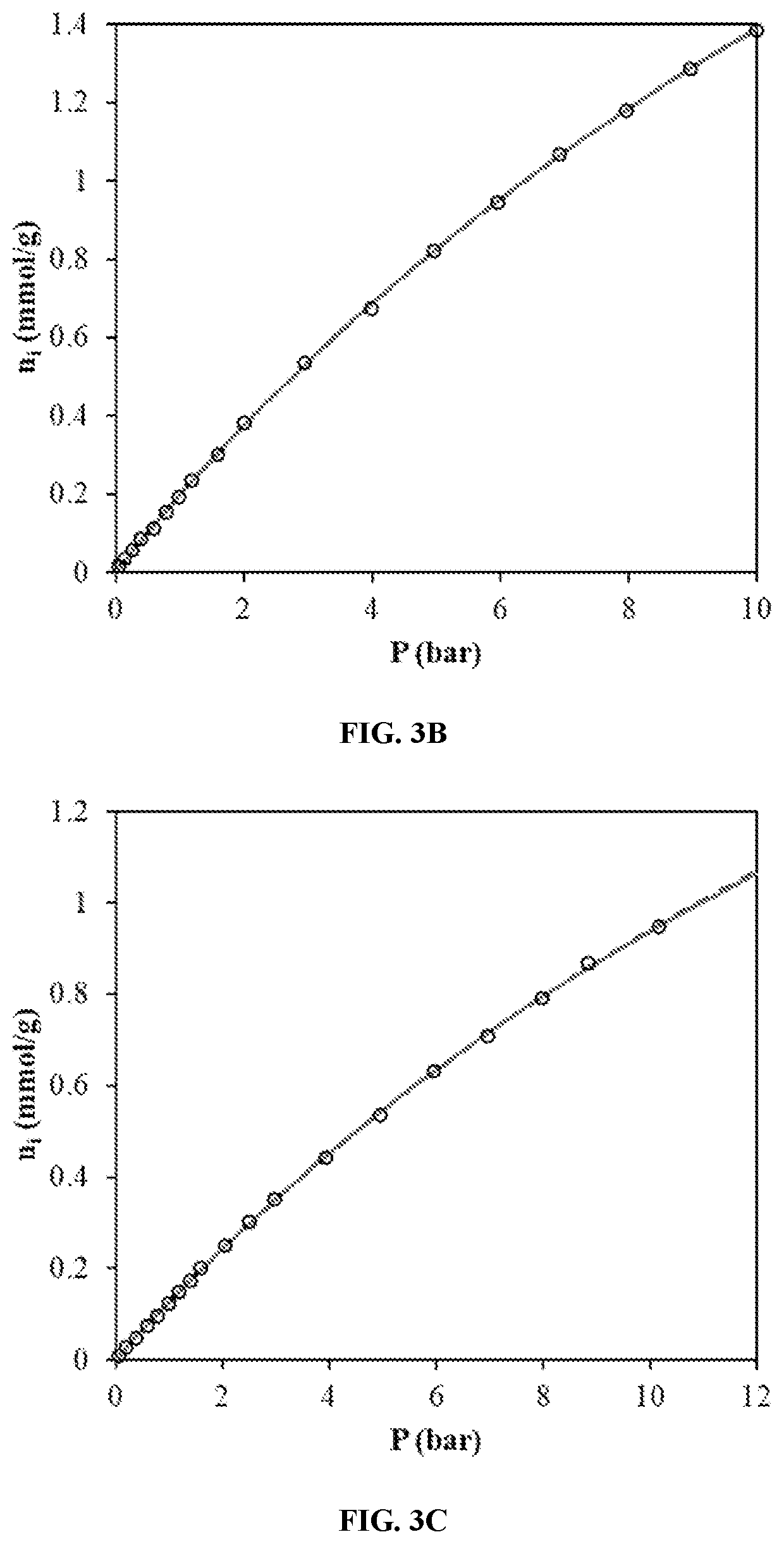

Thermodynamic Formulation for Langmuir Adsorption Isotherms

PendingUS20220341861A1Material heat developmentChemical processes analysis/designChemical physicsAdsorption equilibrium

The present invention includes a method for thermodynamic formulation of a Langmuir isotherm comprising: (1), (1′) (1), (1′) where ni is the adsorption amount of gas component i; (1′) is the adsorption maximum amount; P is the gas vapor pressure, and K is the apparent adsorption equilibrium constant in which adsorption and desorption rates are proportional to a concentrations of vacant sites and occupied sites; and substituting the concentration of both a vacant site and an occupied site with site activities, wherein a reference state for the vacant sites is at zero surface coverage while the reference state for the occupied sites is at full surface coverage.(1′)ni=ni0KP1+KP(1)

Owner:TEXAS TECH UNIV SYST

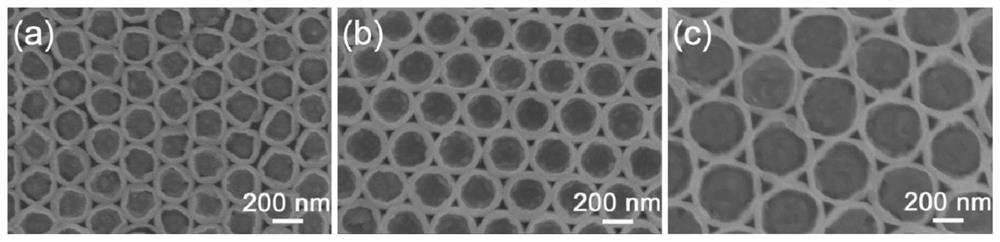

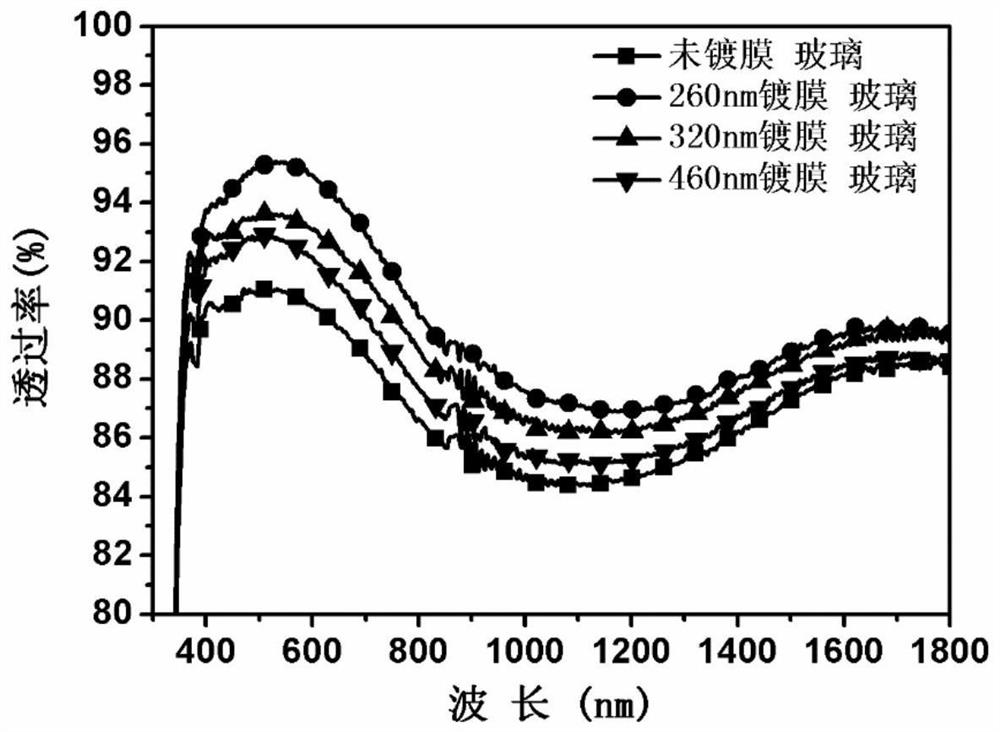

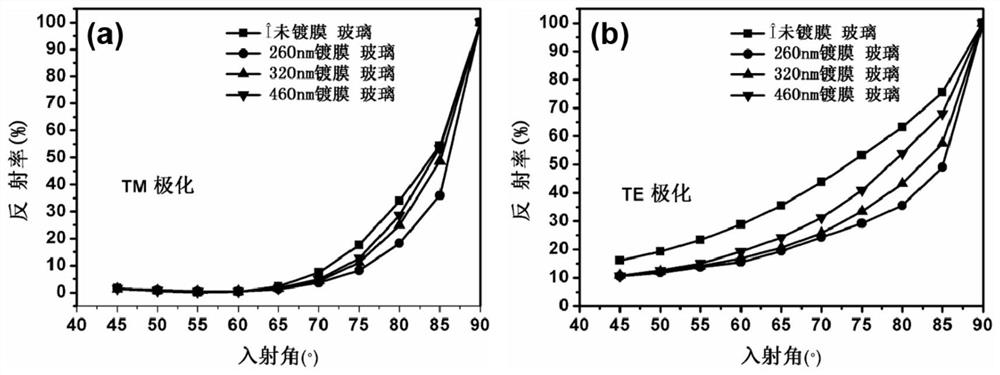

A Two-Dimensional Ordered Porous Nano-Silicon Oxide Anti-reflection Film with Hydrophobic Effect

ActiveCN108178521BAchieve omni-directional anti-reflection effectRealize anti-reflection effectCoatingsNano siliconMicrosphere

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com